Reshaping mechanism for cylinderical workpiece mounted to pressing machine

A technology for presses and round tubes, which is applied in the field of shaping mechanisms for round tube-shaped workpieces, can solve the problems of being unsuitable for mass production and low shaping efficiency, and achieves the protection of appearance and shaping concave molds, high shaping efficiency, and improved shaping quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

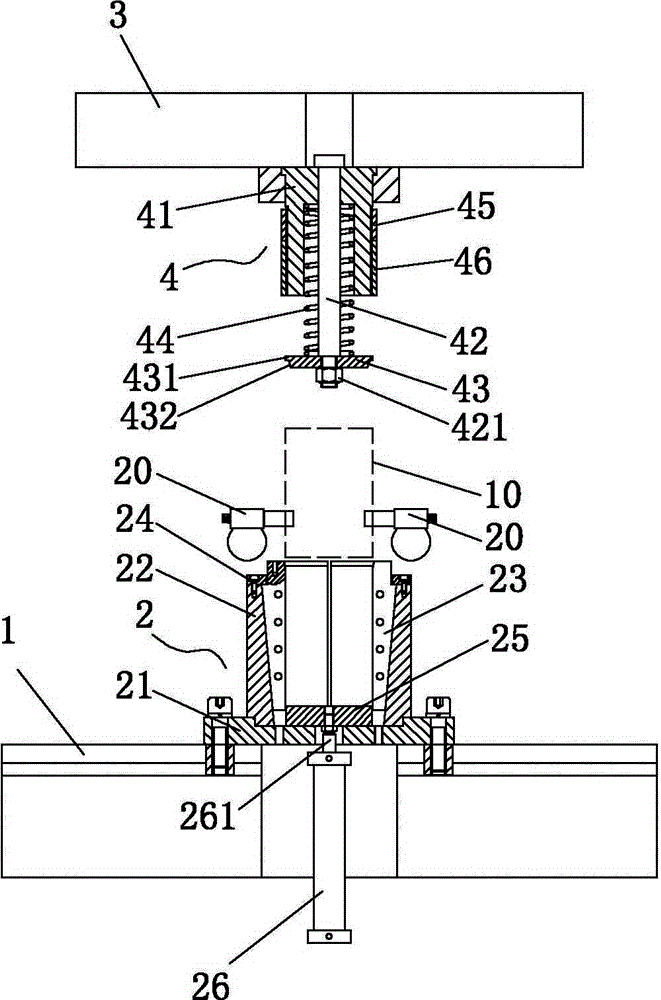

[0022] Figure 1 to Figure 5 As shown, a shaping mechanism for a circular tubular workpiece mounted on a press, comprising a die assembly 2 mounted on a workbench 1 of a press, and a punch assembly 4 mounted on a slider 3 of a press;

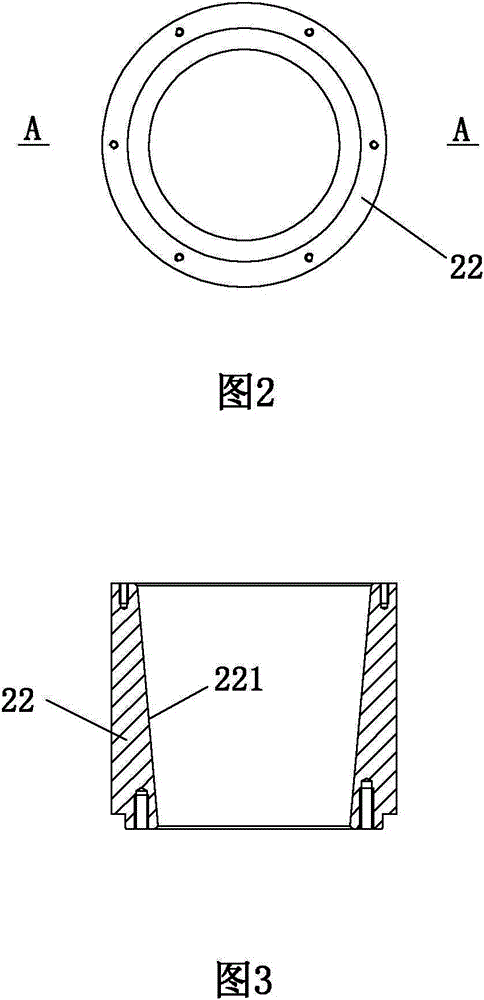

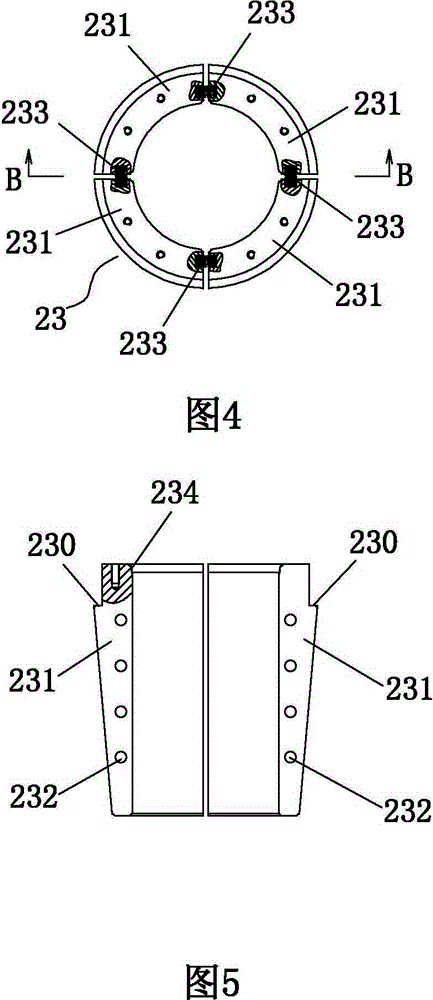

[0023] The die assembly 2 includes a base 21 connected to the press table 1, the upper part of the base 21 is fixed with a jacket 22 perpendicular to the press table 1, and the middle of the jacket 22 is processed with an inverted tapered axial passage. Hole 221, inner sleeve 23 is installed on the inverted tapered axial through hole 221 of outer cover 22, and the outer surface of inner sleeve 23 is inverted tapered and the inverted tapered axial through hole 221 of outer cover 22 matches, and inner sleeve 23 A cylindrical axial through hole is processed in the middle, and a section of cylindrical and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com