Synchronous circle shaping device for cylindrical work-piece

A technology for cylindrical parts and supporting cylinders, which is applied in the field of synchronous rounding devices for cylindrical parts, can solve the problems of low shaping efficiency and poor shaping quality, and achieve the effects of high shaping efficiency and good shaping quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

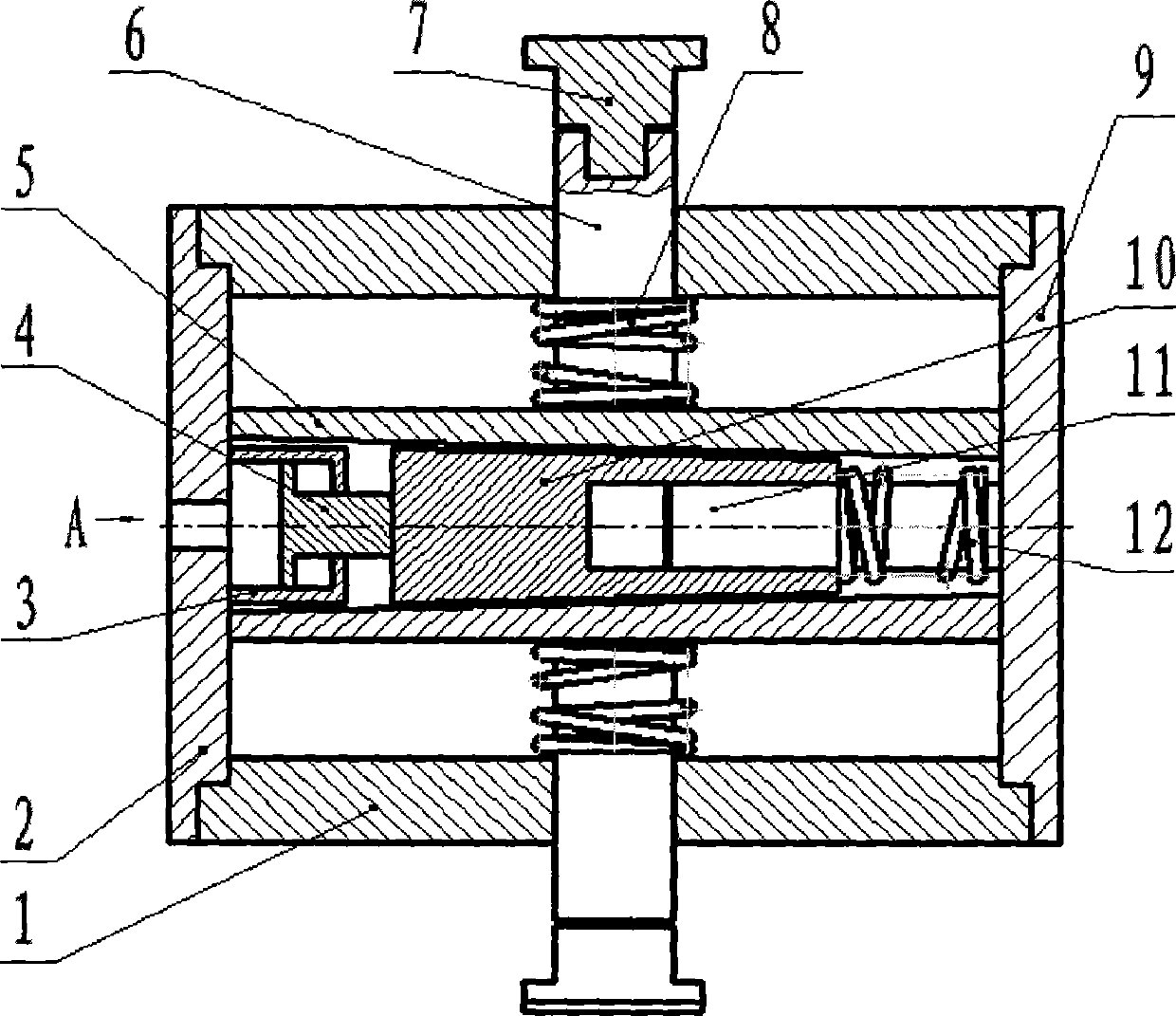

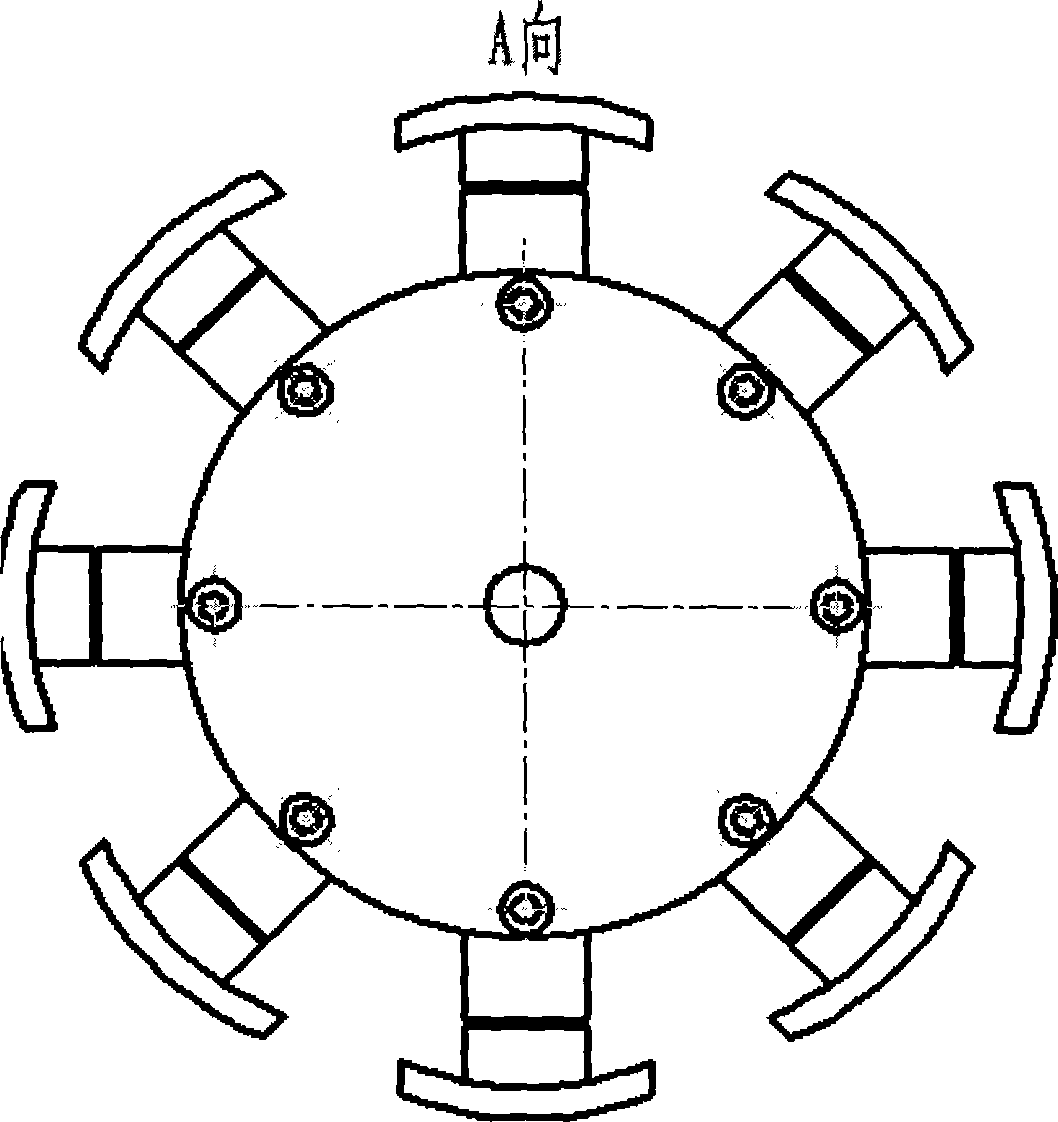

[0025] A synchronous rounding device for cylindrical parts of the present invention, such as figure 1 As shown, it includes a support cylinder 1, a left end cover 2, a cylinder body 3, a piston 4, an expansion body 5, a support rod 6, a support head 7, a radial return spring 8, a right end cover 9, a sliding expansion rod 10, a guide rod 11, Axial return spring 12;

[0026] The left end cover 2 is a circular cover plate with a vent hole in the center;

[0027] The cylinder body 3 is a cylindrical structure with an open end and a bottom at the other end. The cylinder body 3 has a bottom and a center of one end with a piston rod passing hole;

[0028] The outer diameter of the piston at the head of the piston 4 matches the inner diameter of the inner wall of the cylinder body 3; Processing with external thread;

[0029] The shape of the expansion rod 10 is a conical structure that converges from left to right. The center of the left end face of the expansion rod 10 is process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com