Refracting high-power semiconductor laser array beam shaping device

A laser array and laser beam technology, applied in the field of laser technology applications, can solve the problems of difficult processing, difficult assembly adjustment, low precision, etc., and achieve the effects of low processing difficulty, high shaping efficiency, and reduced focal length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

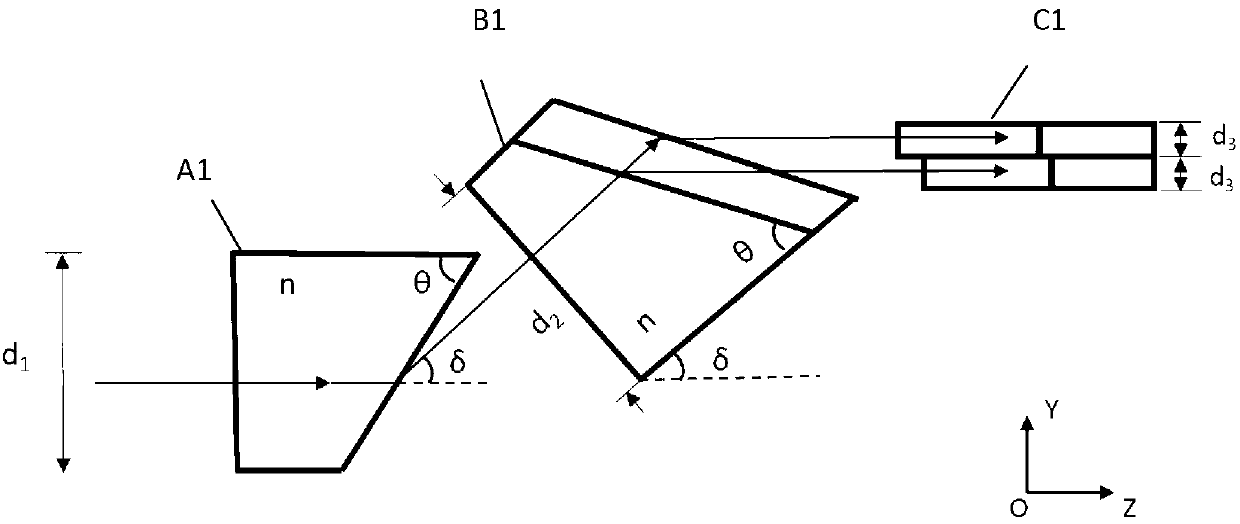

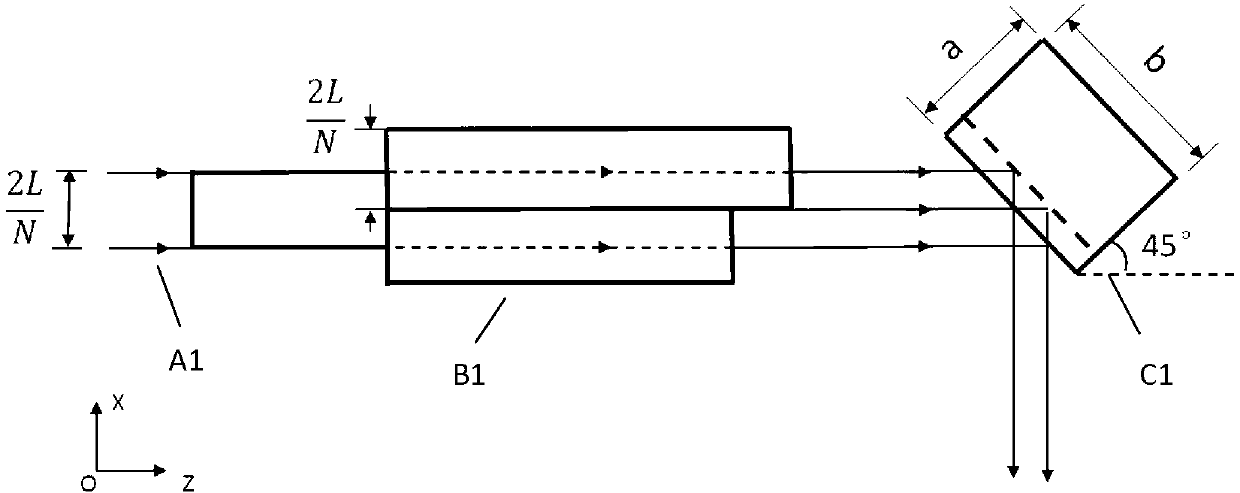

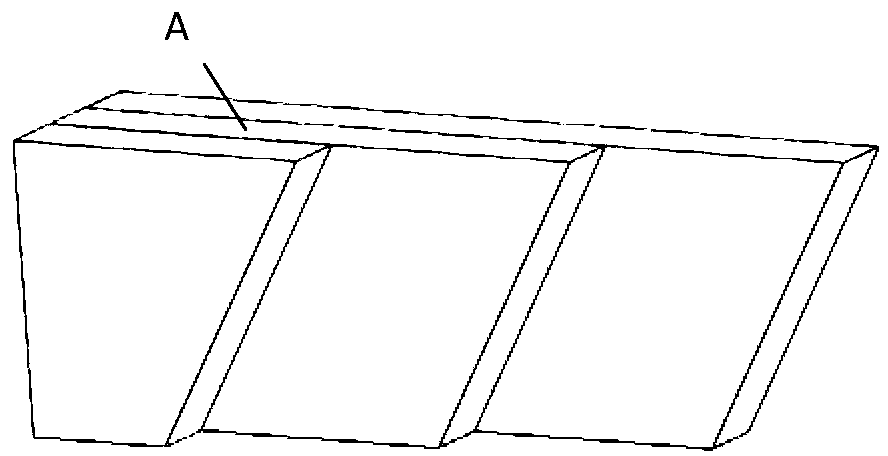

[0049] In this embodiment, the light beam emitted by the one-dimensional array of semiconductor lasers is divided into N equal parts in the direction of the slow axis, where N=2K (K is a natural number), and N is obtained according to the product relationship between the optical parameters of the fast axis and the slow axis, its satisfying relationship BPP in the equation f and BPP S are the fast-axis and slow-axis optical parameter products calculated after the one-dimensional array beam is collimated, respectively. Assuming N=6, see Figure 9 The structure of the shaping system in this embodiment includes a semiconductor laser one-dimensional array light source 1, a fast-axis collimator lens 2, a slow-axis collimator lens 3, the first right-angle transmission trapezoidal glass group A, and the second right-angle transmission trapezoidal glass group B and rectangular reflective glass set C.

[0050] The first right-angled trapezoidal transmission glass group A is compose...

Embodiment 2

[0059] In this embodiment, the light beams emitted by the two-dimensional array of semiconductor lasers are collimated along the fast and slow axes and compressed along the fast axes to form elongated light spots, and then undergo beam shaping by the shaping device. refer to Figure 11 , specifically, the light emitted by the semiconductor laser two-dimensional array 8 passes through the fast-axis collimating cylindrical lens 9 and the slow-axis collimating microlens array 10 in turn, and then passes through the first right-angle trapezoidal glass group A and the second right-angled trapezoidal glass group A. Group B, beam shaping device composed of rectangular glass group C.

[0060] In this embodiment, assuming that the number of cuts of the two-dimensional beam along the slow axis direction is N=6, the beam width H in the fast axis direction after the two-dimensional beam is collimated and compressed in the fast axis direction, the two-dimensional beam in the slow axis dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com