On-line automatic reshaping machine for palletized goods

A shaping machine and pallet technology, applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of loose goods, out-of-tolerance shapes, and tilting, and achieve high shaping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

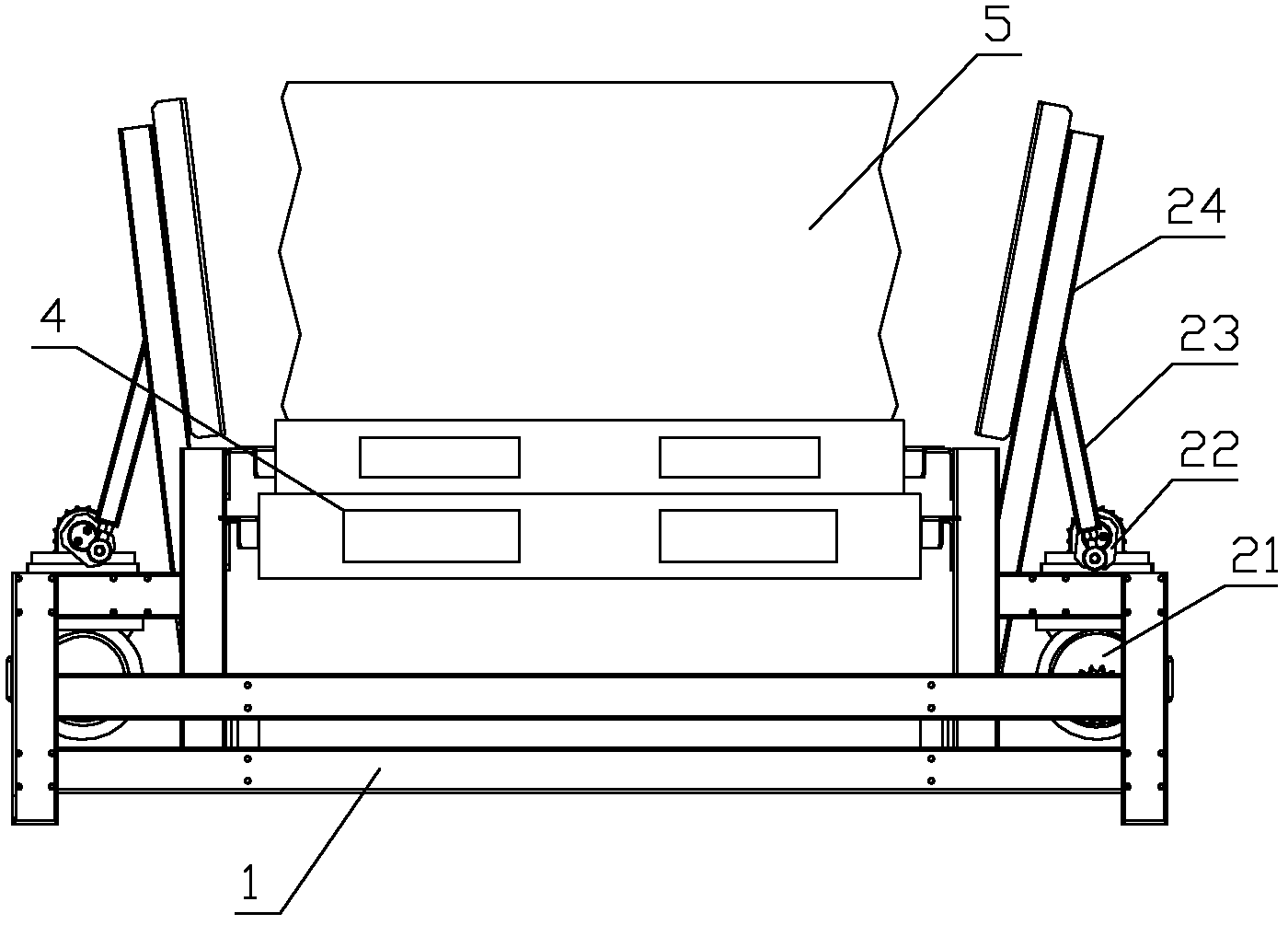

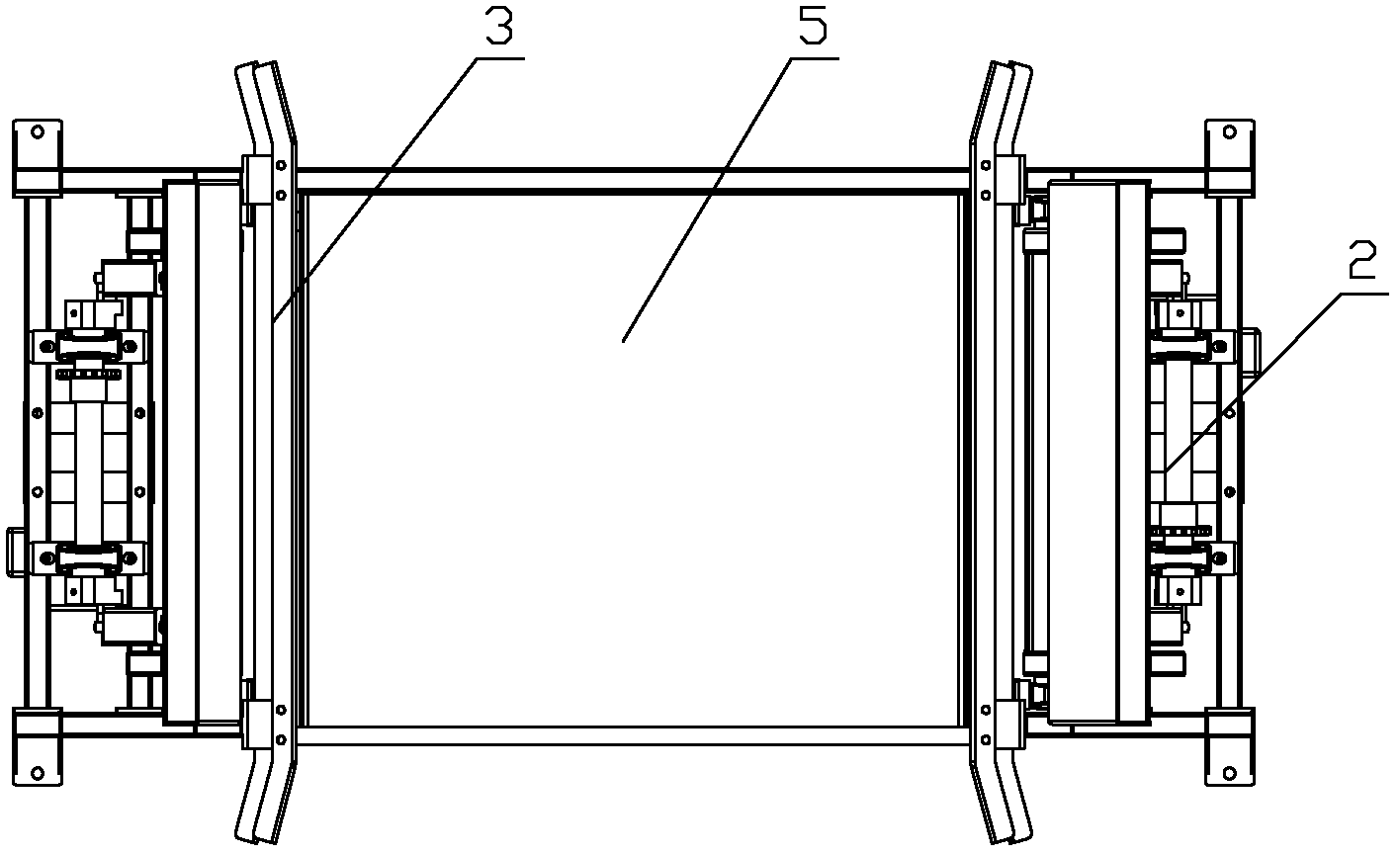

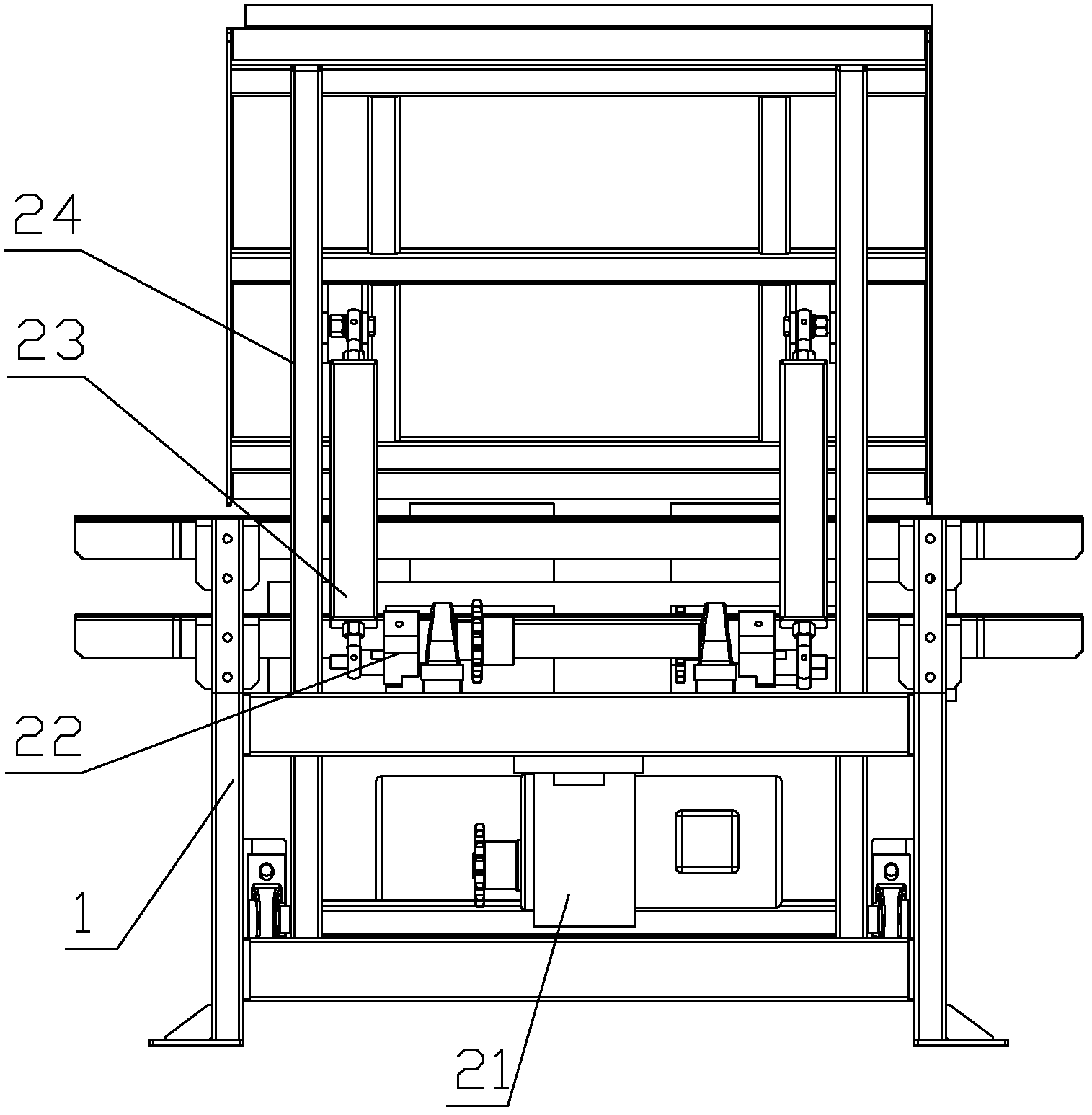

[0016] Combine below Figure 1 to Figure 3 Specifically explain the embodiment of the online automatic shaping machine for palletized goods of the present invention, including a conveyor 1, carrying palletized goods 5 on the conveying plane of the conveyor, and said conveyor is provided with clamping and shaping pallet goods on the left and right sides of the conveying plane Shaping device 2. Described shaping device comprises splint 24 that is located at the left and right sides of conveyor conveying plane, and described splint bottom is rotatably connected on the conveyor frame, and described splint middle part is rotatably connected with at least one support arm 23, and the support arm lower end is connected with The curved arm 22 is rotatably connected, and the curved arm and the support arm are linked to drive the splint to clamp and shape the pallet goods. The frame bottom of the conveyor is provided with a motor 21, and the output shaft of the motor and the crank shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com