Optical fiber connector integrated with a plurality of rectangular multi-core optical fiber contact pins and integrated connector

A technology of optical fiber connector and multi-core optical fiber, applied in the coupling of optical waveguide, etc., can solve the problems of unfavorable small volume and high density installation, complex structure and processing technology, etc., and achieve the effect of convenient and fast disassembly and accurate centering positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

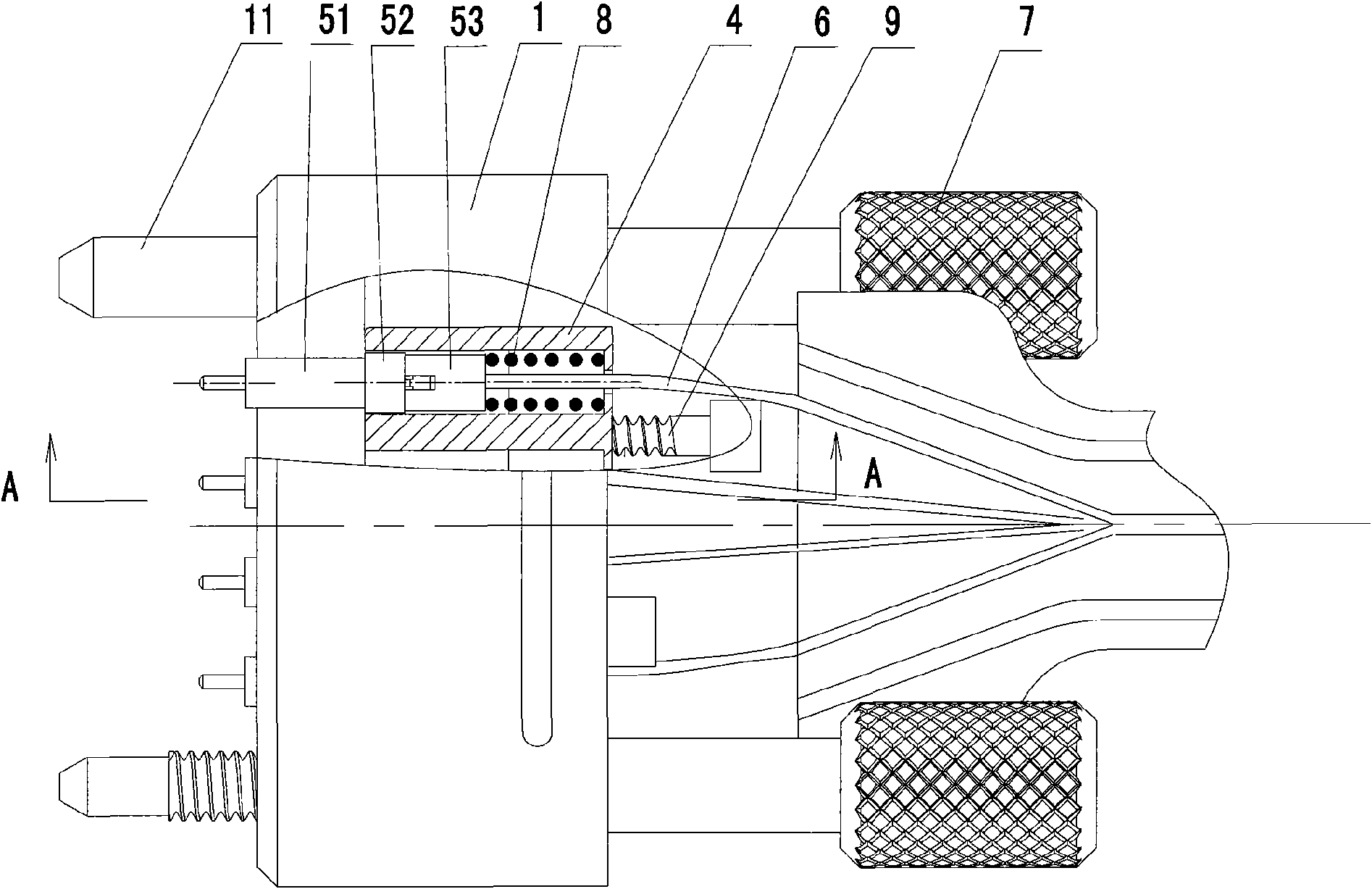

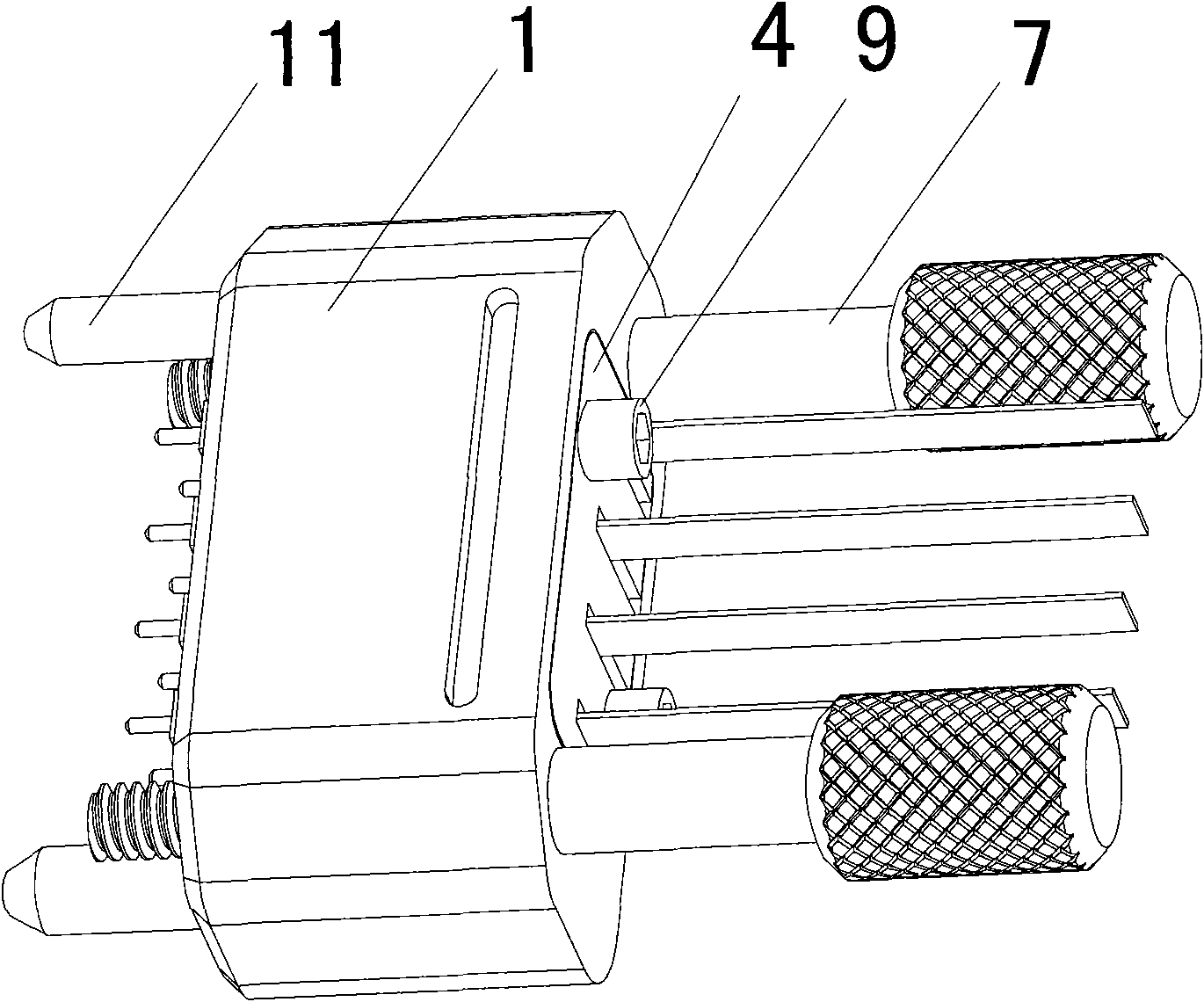

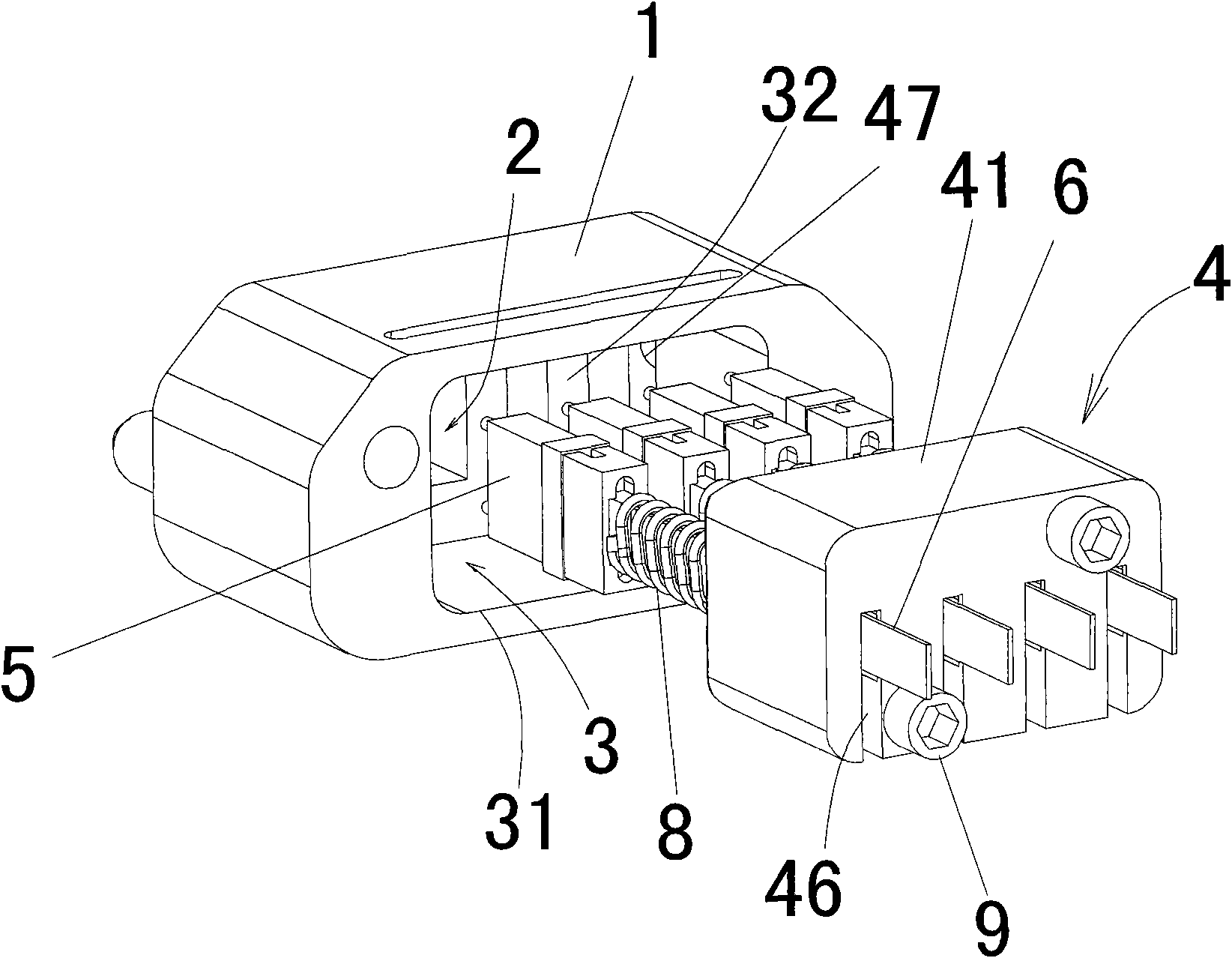

[0032] Such as Figure 1 to Figure 5As shown, the optical fiber connector of the present invention includes a connector housing 1 and a plurality of rectangular multi-core optical fiber ferrules 5 terminating multi-core ribbon optical cables 6 assembled therein, and the rectangular multi-core optical fiber ferrules 5 are MPO ferrules , the pin 5 includes a ferrule 51 at the front end and a pin holder 53 fixedly connected to the tail end of the ferrule 51, the ferrule 51 is provided with a limit shoulder 52, and the front end of the ferrule 51 is provided with a positioning pin or a positioning hole, MPO The ferrule belongs to the prior art, and its structure will not be described in detail here. The ferrule 5 can also choose other types of rectangular multi-core optical fiber ferrules 5, such as MT. The connector housing 1 is fixedly equipped with a pressure plate 4 and a spring 8 pressing between the pressure plate 4 and the pin holder 53 of the pin assembly 5 .

[0033] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com