Method for representing nano film micro-area deformation area by virtue of combination of photetching technique and transmitted electron microtechnique

A technology of transmission electron microscopy and lithography technology, which is applied in the field of joint characterization of nano-film micro-region deformation by lithography technology and transmission electron microscopy technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

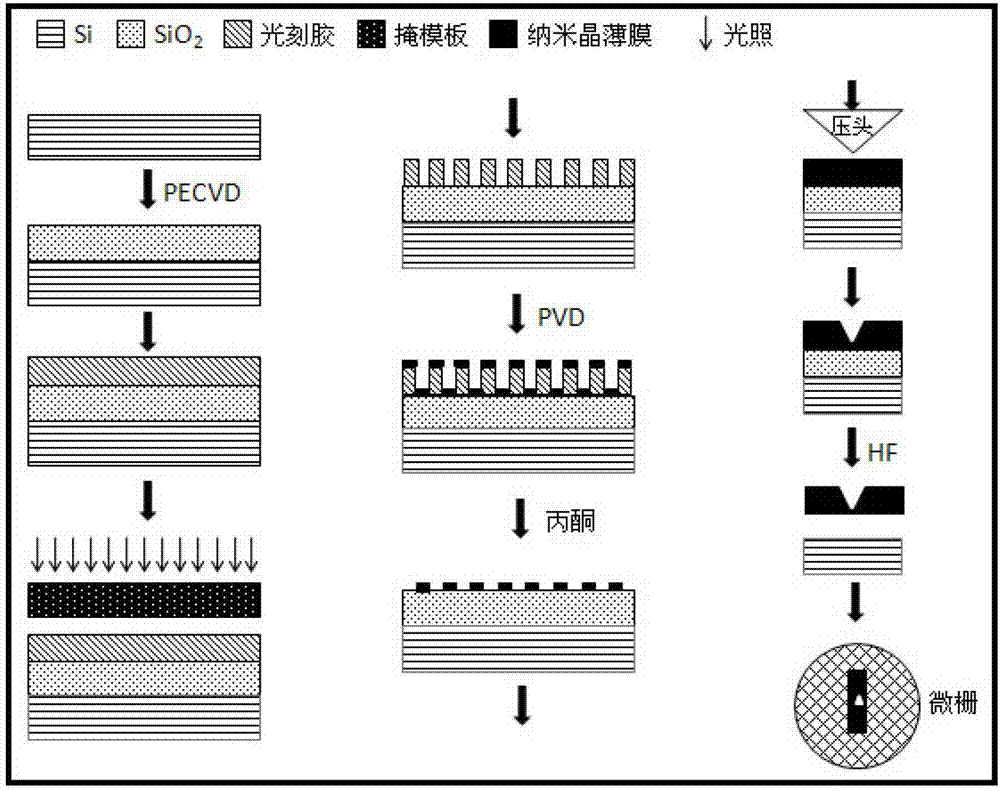

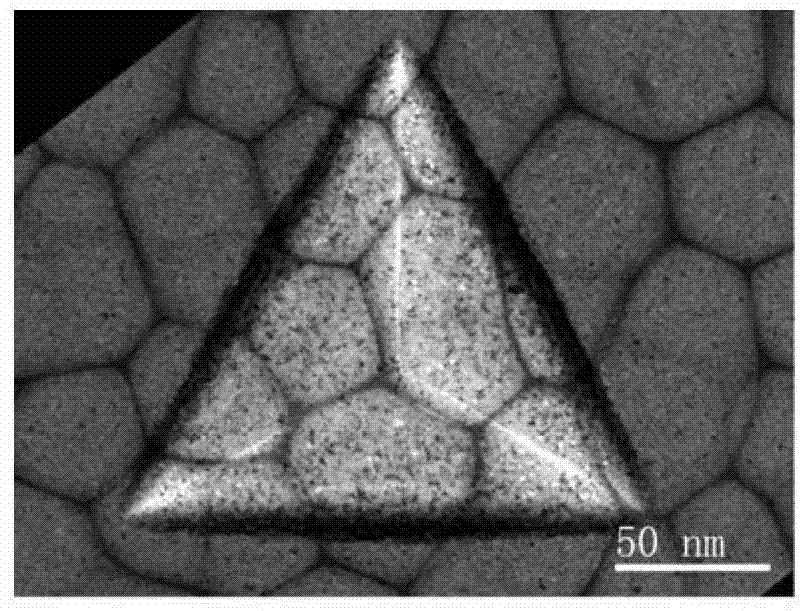

Method used

Image

Examples

Embodiment

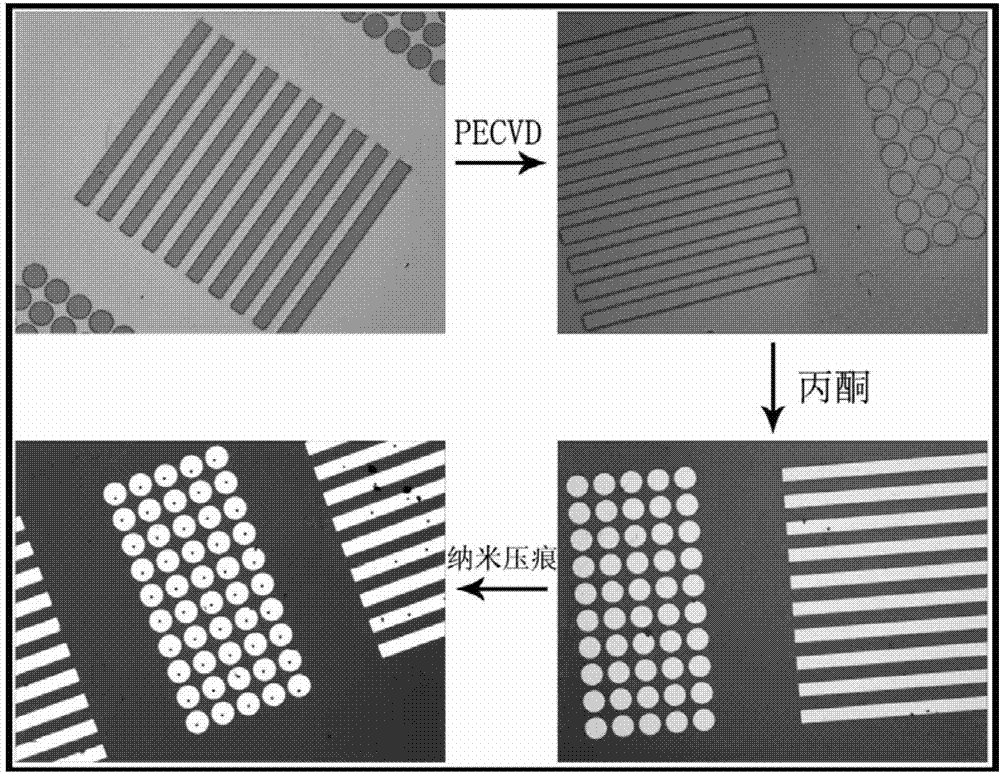

[0035] 1) Make a silicon wafer with a specific pattern

[0036] ① Prepare a circular or rectangular mask for the experiment. The diameter of the circular mask of the mask is 45 microns, and the interval is 10 microns; the width of the square mask is 35 microns, the length is 500 microns, and the interval is 30 microns. All patterns Evenly distributed on the mask plate.

[0037] ② Choose a silicon wafer in the direction, and then use plasma-enhanced chemical vapor deposition (PECVD) to prepare an amorphous silicon dioxide layer with a thickness of 200-300nm on the silicon wafer.

[0038] ③Clean the substrate. Put the substrate into the acetone solution and ultrasonically clean it for 5 minutes, then put the substrate into the alcohol solution and ultrasonically clean it for 5 minutes to remove the residual acetone, finally clean it with deionized water, and dry the sample with nitrogen.

[0039] ④ Throw away the glue on the substrate. In the glue-spinning stage, the speed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com