Cylindrical construction part provided with holed stiffening ribs and filled with steel fiber reinforced concrete

A technology for steel fiber reinforced concrete and concrete-filled steel tubular columns, which is applied to building components, columns, piers, etc., can solve the problems of insufficient structural integrity, self-heavy weight, insufficient adhesion between steel pipes and concrete, and improve the insufficient adhesion. , Light weight, good for anti-seismic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

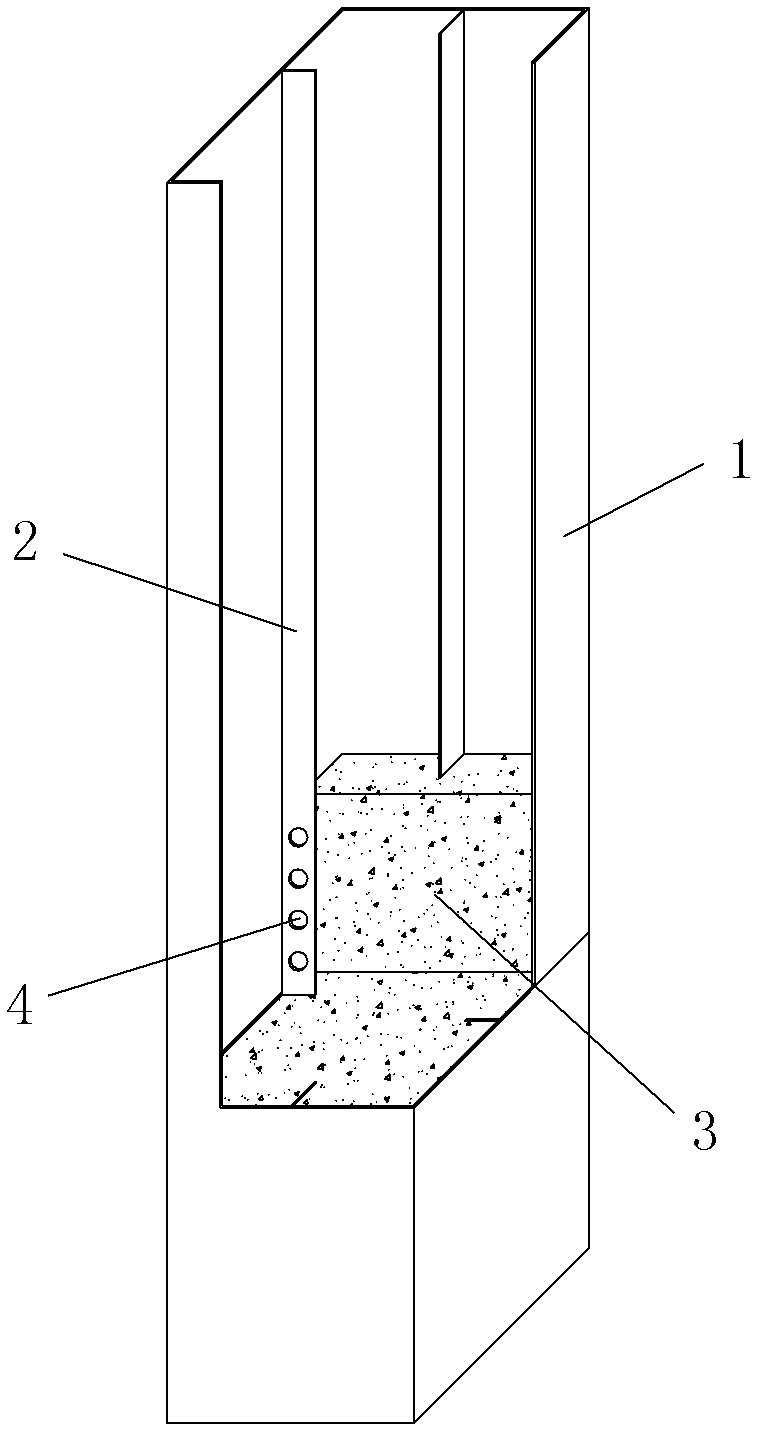

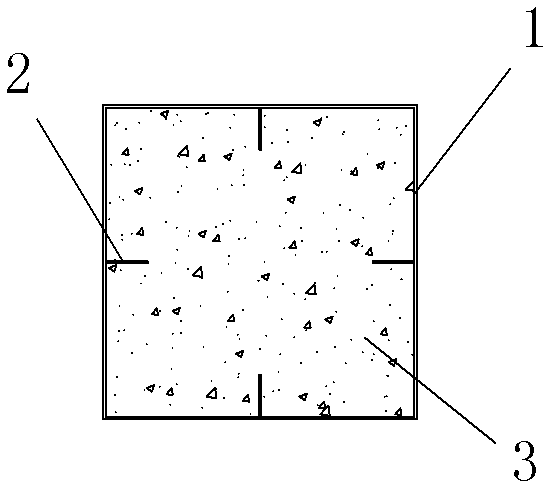

[0028] Such as figure 1 , figure 2 A columnar structure with opening stiffeners and filled with steel fiber concrete is shown, including square steel pipes 1 arranged vertically, and a plurality of vertical stiffeners arranged on the four inner walls of square steel pipes 1 respectively. 2 and a steel fiber concrete column 3 poured from steel fiber concrete filled in the inner lower part of the square steel pipe 1, the steel fiber concrete column 3 fastens and connects the square steel pipe 1 with a plurality of vertical stiffeners 2 as a whole , the structures and dimensions of the plurality of vertical stiffeners 2 are the same, the laying direction of the plurality of vertical stiffeners 2 is consistent with the direction of the central axis of the hollow steel pipe 1 and the laying of the plurality of vertical stiffeners 2 on the same level. The four inner side walls of the square steel pipe 1 include a left side wall and a right side wall symmetrically arranged on the ...

Embodiment 2

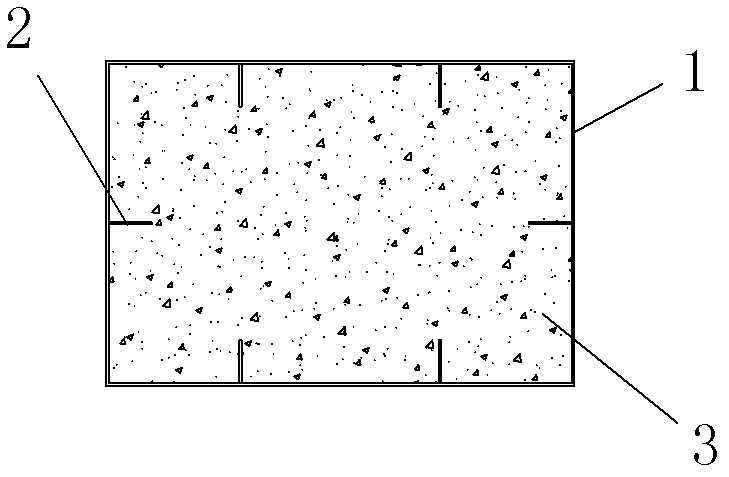

[0040] In this embodiment, the difference from Embodiment 1 is that the cross section of the square steel pipe 1 is rectangular, L1>L2, and the number of the plurality of vertical stiffeners 2 is 4-10.

[0041] Such as image 3 As shown, in this embodiment, the number of multiple vertical stiffeners 2 is 6, wherein N1=2, N2=1, during actual processing and manufacturing, multiple vertical stiffeners can be used according to actual specific needs The number of ribs 2 is adjusted accordingly.

[0042] In this embodiment, the rest of the structures, connections and manufacturing processes are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com