Patents

Literature

48results about How to "Improve sharpening efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

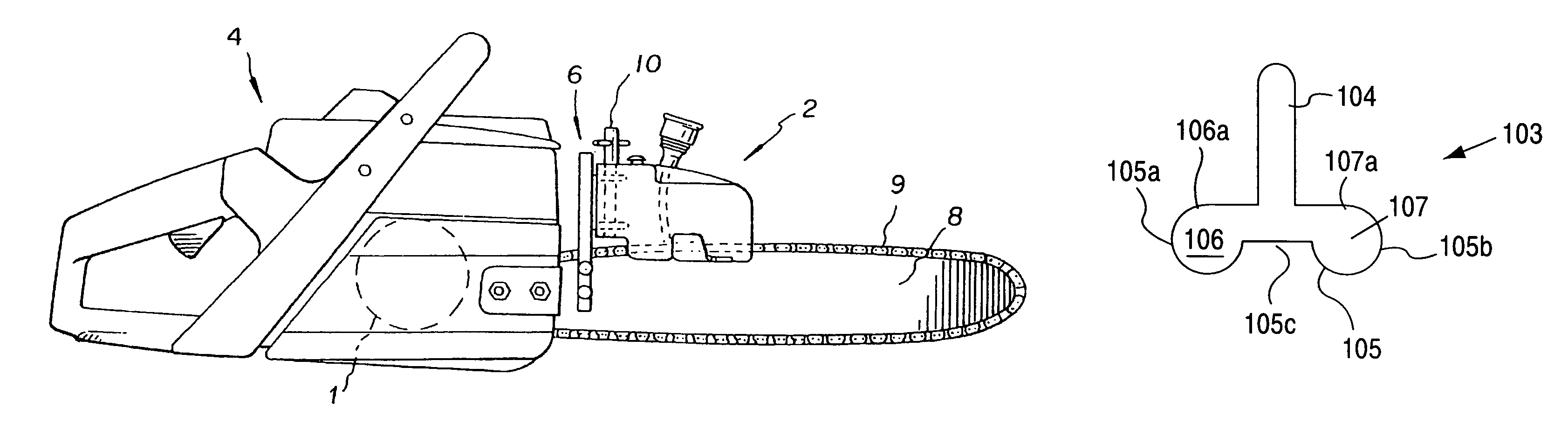

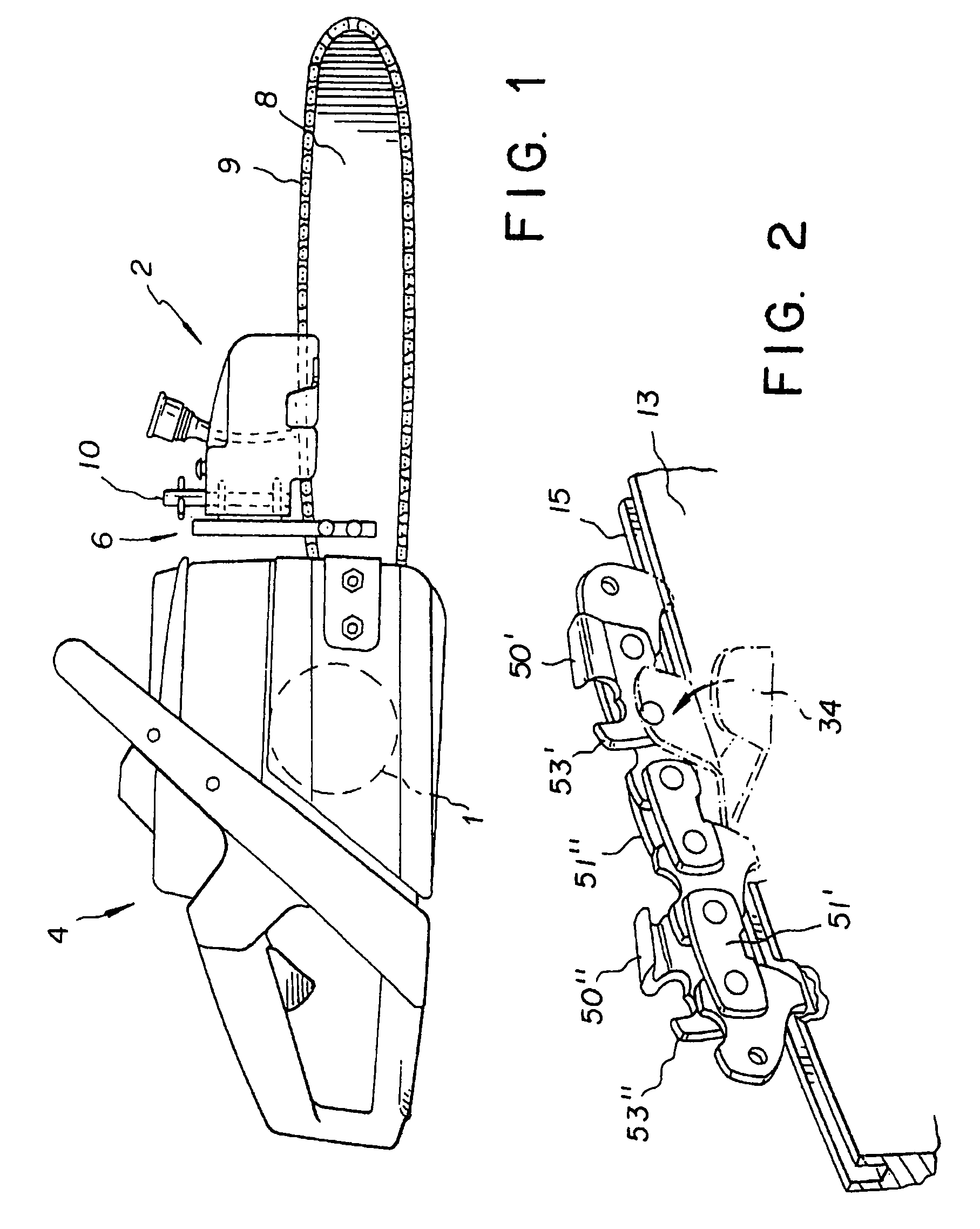

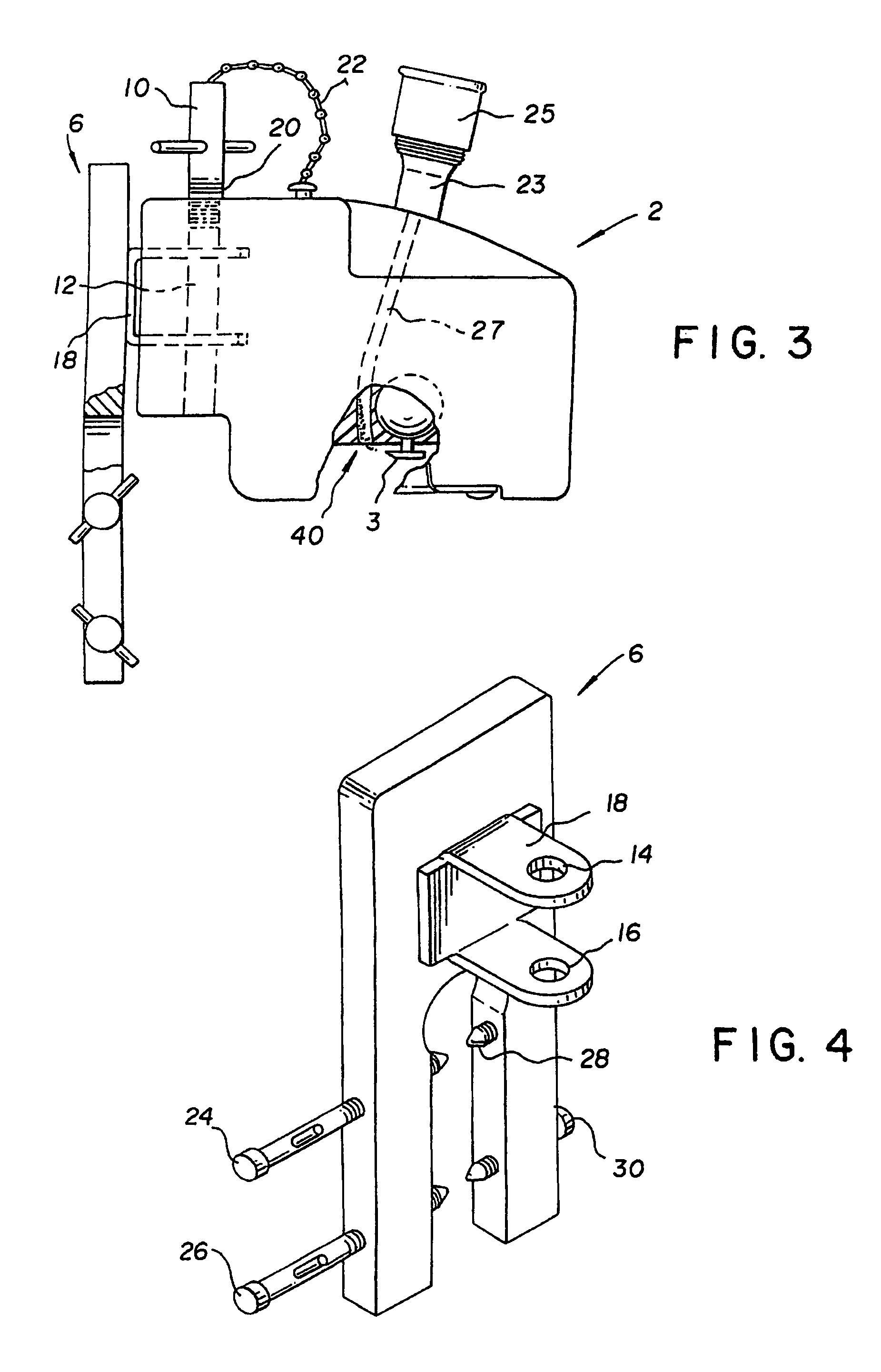

Chain saw sharpener with composite wiskar

InactiveUS7900536B2Light weightQuickly and conveniently attachedMetal sawing devicesCutting toolsEngineeringChain saw

A wiskar for sharpening cutting teeth of a chain provided on a chain bar of a chain saw. A housing is removably attached to the chain bar and includes a recess to receive the wiskar therein. The wiskar includes a first member configured to be operationally engaged by the recess of the housing; and a second member configured to frictionally engage a bottom surface of the cutting teeth. The second member includes a body portion intermediate the opposing ends, wherein opposing ends of the second member each have at least one lobe defined therein. Abrasives are uniformly impregnated throughout the first and second member to sharpen the bottom surface of the cutting teeth. At least the second member is manufactured from a pliable material that erodes due to friction caused by the cutting teeth engaging the lobes of the second member.

Owner:CHAIN MASTERS

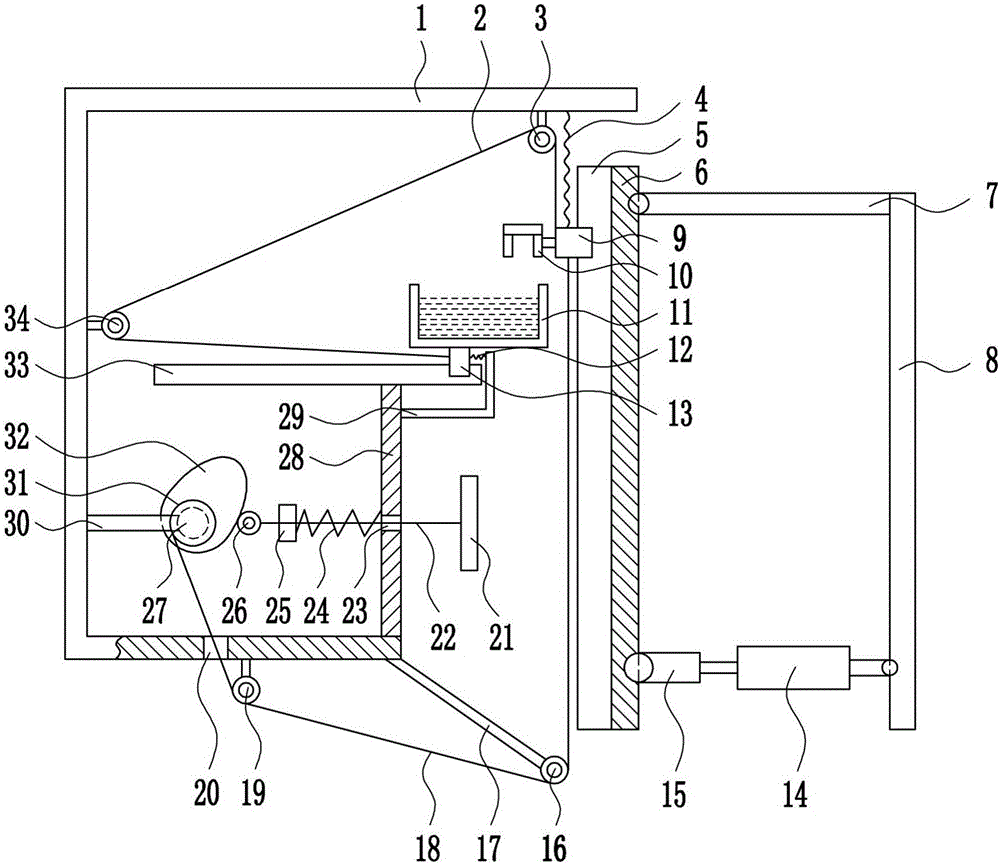

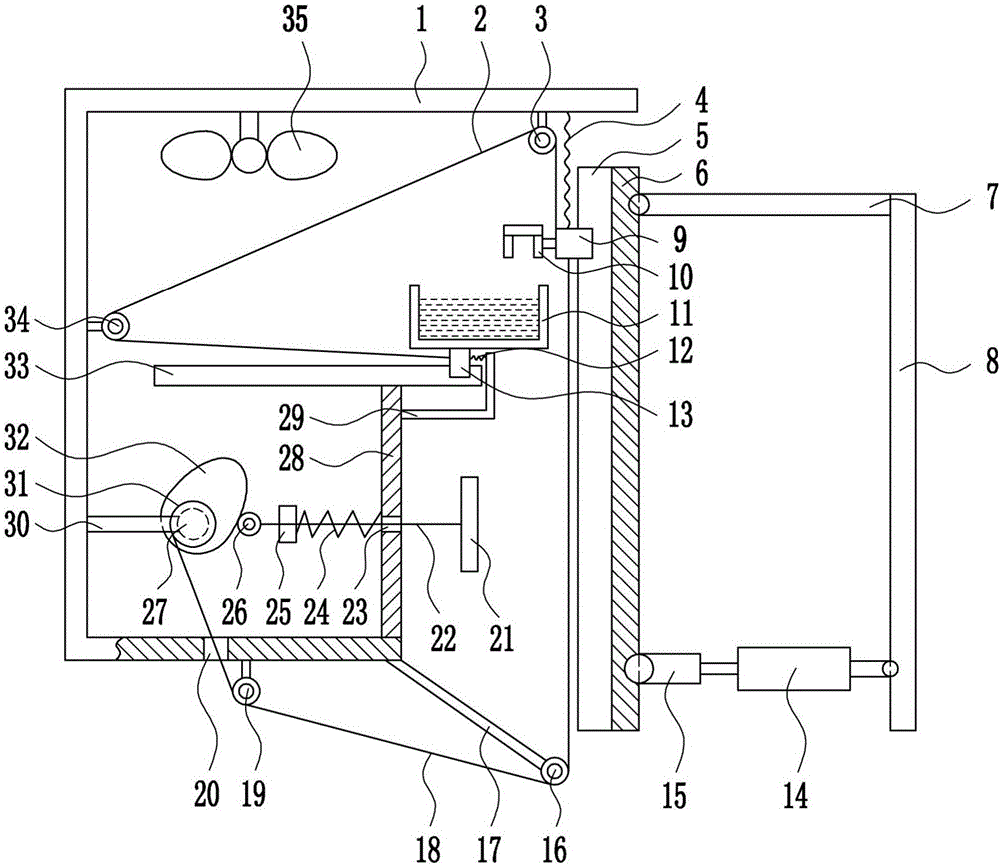

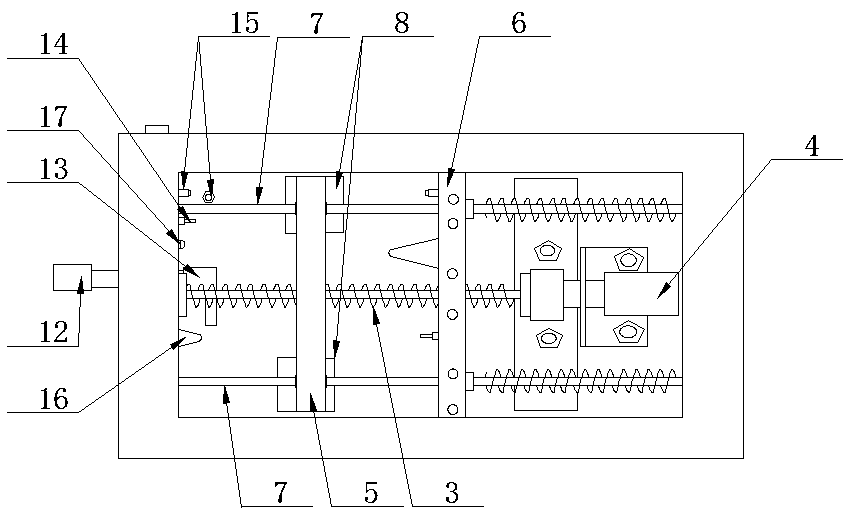

Safe knife grinding device for hardware manufacturing

ActiveCN106141820AFlat surfaceImprove sharpening efficiencyGrinding drivesOther manufacturing equipments/toolsEngineeringPulley

The invention relates to a knife grinding device, in particular to a safe knife grinding device for hardware manufacturing. The technical aim that the safe knife grinding device for hardware manufacturing is good in knife grinding effect is achieved. In order to achieve the technical aim, the safe knife grinding device for hardware manufacturing comprises a second support, a second pull rope, a fourth fixed pulley, a first spring, a first sliding rail, a fixing plate, a second connecting rod, a first support, a first sliding block, a thumb air cylinder and the like. A first connecting rod is connected to the left side of a first air cylinder, the second connecting rod is arranged at the upper end of the left side of the first support, and the fixing plate is hinged to the left end of the second connecting rod. According to the knife grinding device, a motor rotates forwards to drive a grinding tool to move rightwards and drive a knife to move downwards so as to enable the grinding tool to upwards grind the knife; and when the motor rotates backwards, the first spring drives the knife to upwards move so as to enable the grinding tool to downwards grind the knife.

Owner:广东天一刀具有限公司

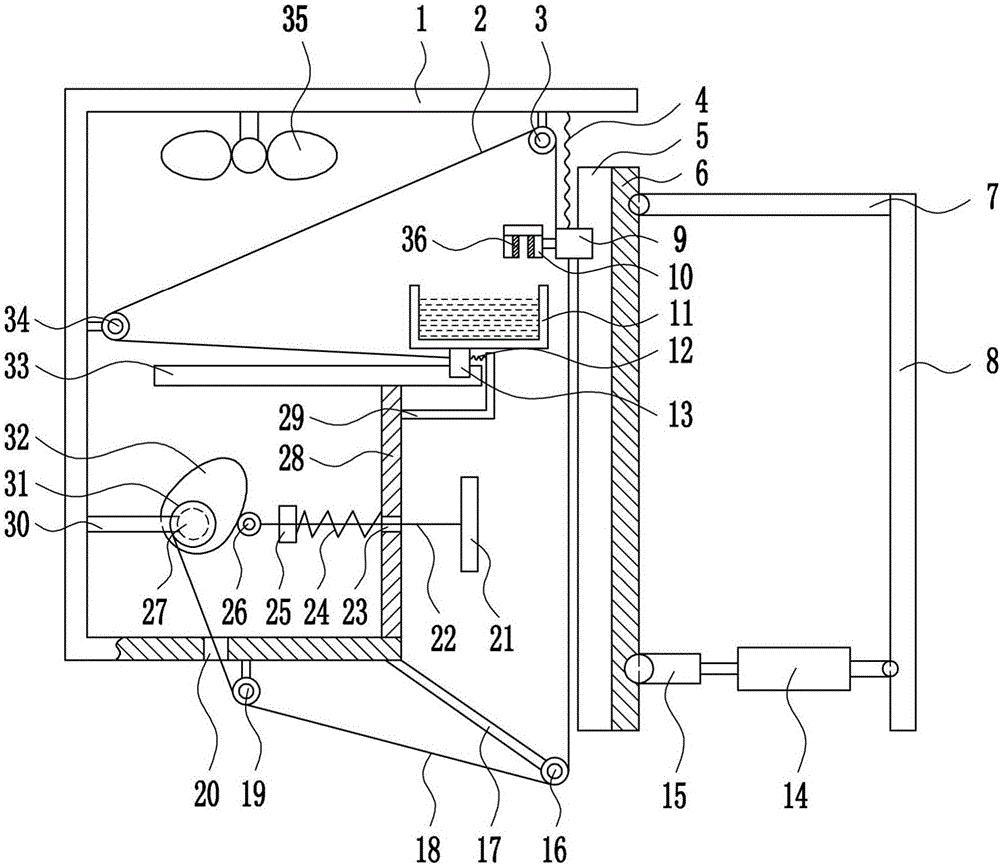

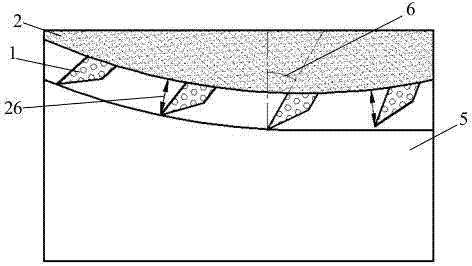

Spiral and orderly arranging fiber tool capable of conducting positive rake angle machining and preparation method thereof

InactiveCN107243848AImprove efficiencyImprove processing efficiencyBonded abrasive wheelsGrinding devicesFiberHelical line

The invention discloses a helically and orderly arranged fiber cutter capable of positive rake angle processing and a preparation method thereof. The fiber cutter includes fiber, carcass and steel matrix; the fiber is tangent to the base circle in the steel matrix, and the fiber can process the workpiece with a positive rake angle during cutting; Arranged in an orderly manner. The preparation method is as follows: the fiber is prepared by wire electric discharge cutting technology; the series of fibers are clamped and sharpened by special clamps; the matrix is prepared on the prefabricated steel base by pressing and sintering technology; A series of small holes arranged in a helical line are processed on the body; epoxy resin is injected into the small holes, the fibers are inserted into the small holes, and the embracing device is used to ensure that the blade height of the fibers is consistent; the fiber cutter is prepared by heating and curing. The helical and orderly arranged fiber cutter prepared by the invention can realize positive rake angle processing, significantly reduce cutting force and cutting temperature, and improve cutting performance.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

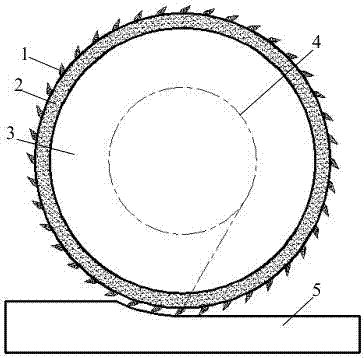

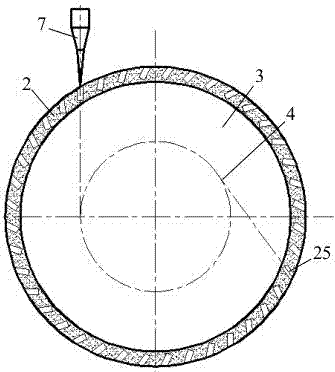

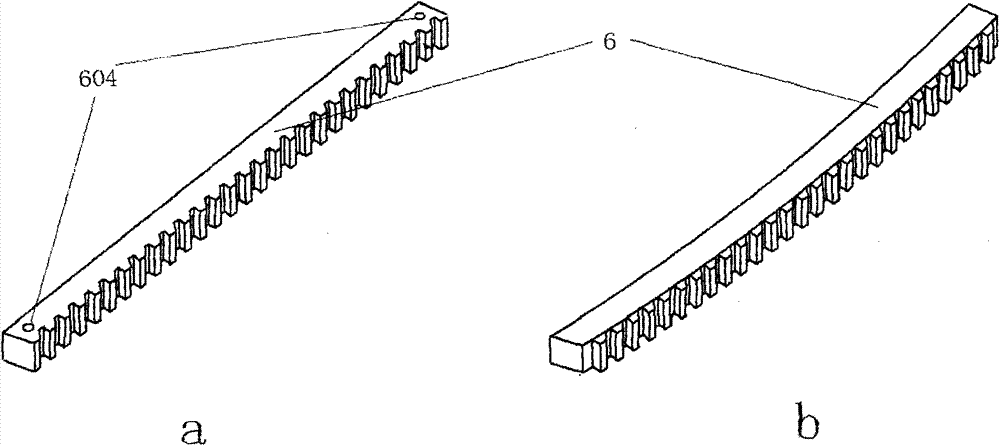

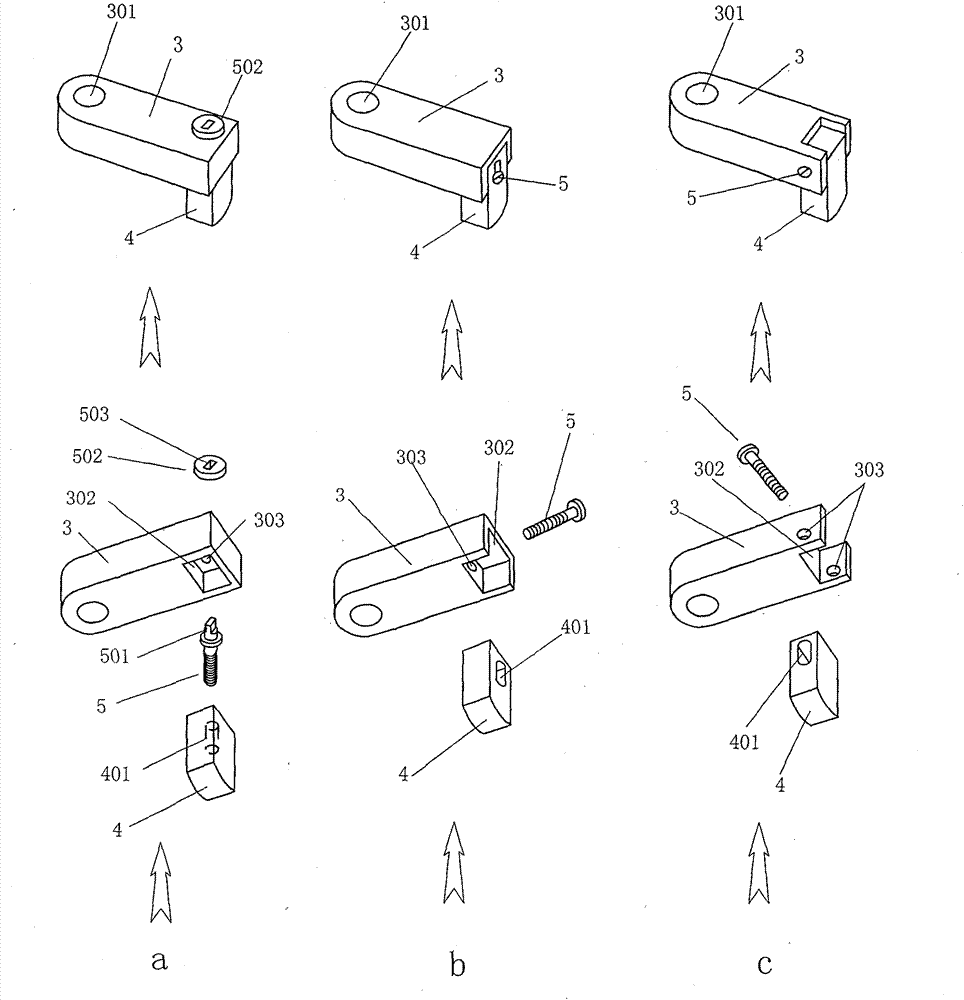

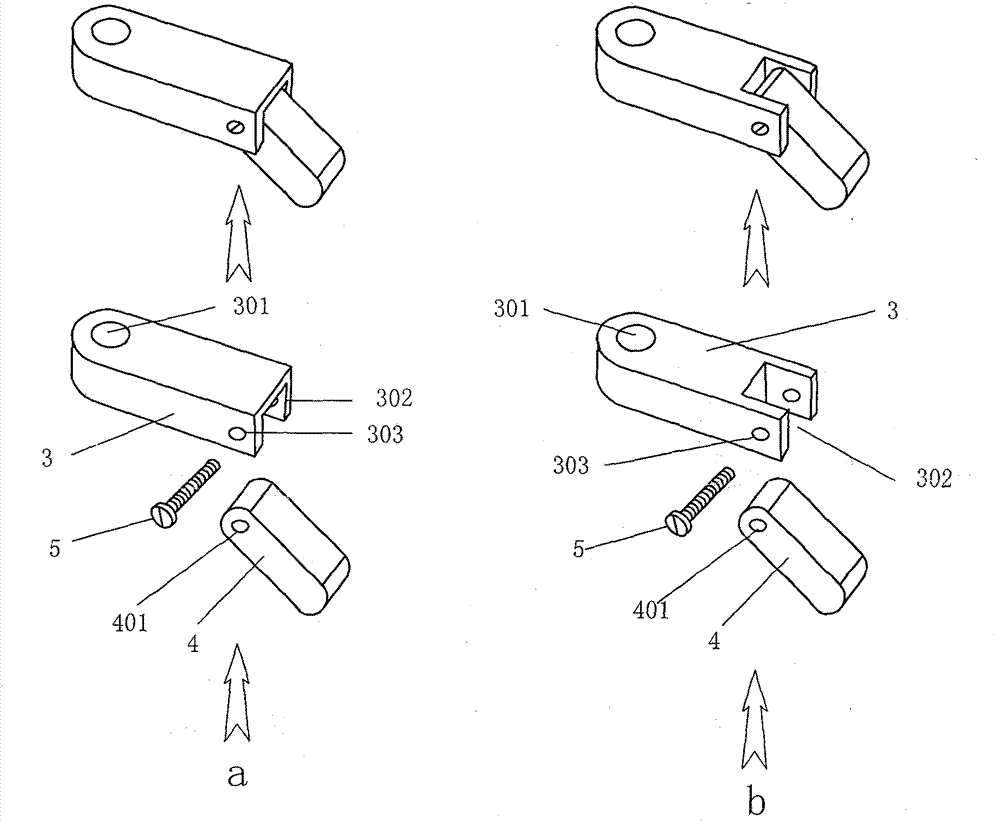

Gear grinding head and guide rail type manual knife sharpener

InactiveCN103659474ASolve the problem of partial wearUniform wearGrinding machine componentsOther manufacturing equipments/toolsLinear motionGear grinding

The invention discloses a gear grinding head and a guide rail type manual knife sharpener. The guide rail type manual knife sharpener mainly comprises the gear grinding head which is composed of a grinding body and a stem gear, a grinding head fixing part, a connecting rod, an adjustable tailstock, a tailstock positioning screw rod and a rack type guide rail, wherein the grinding body is a cylinder, one end face of the grinding body is a grinding surface, the other end face of the grinding body is an installation surface, a gear is arranged in the middle of the stem gear, a center positioning pillar is arranged at one end of the stem gear, the end, provided with the center positioning pillar, of the stem gear is bonded with and fixed to the grinding body, the other end of the stem gear is a grinding head shaft which is mounted at one end of the connecting rod, a tailstock installation groove is formed in the other end of the connecting rod, the adjustable tailstock is mounted in the groove, the adjustable tailstock is stretchable or foldable entirely, the rack type guide rail is linear or arc-shaped, a tooth row is arranged on one lateral side of the guide rail and can drive the gear on the gear grinding head in a rubbing mode to enable the gear to rotate proactively and limit the linear motion of the gear grinding head so that the grinding surface of the gear grinding head can be abraded evenly and be prevented from deforming, and meanwhile, the sharpening efficiency is improved remarkably.

Owner:郭广仁

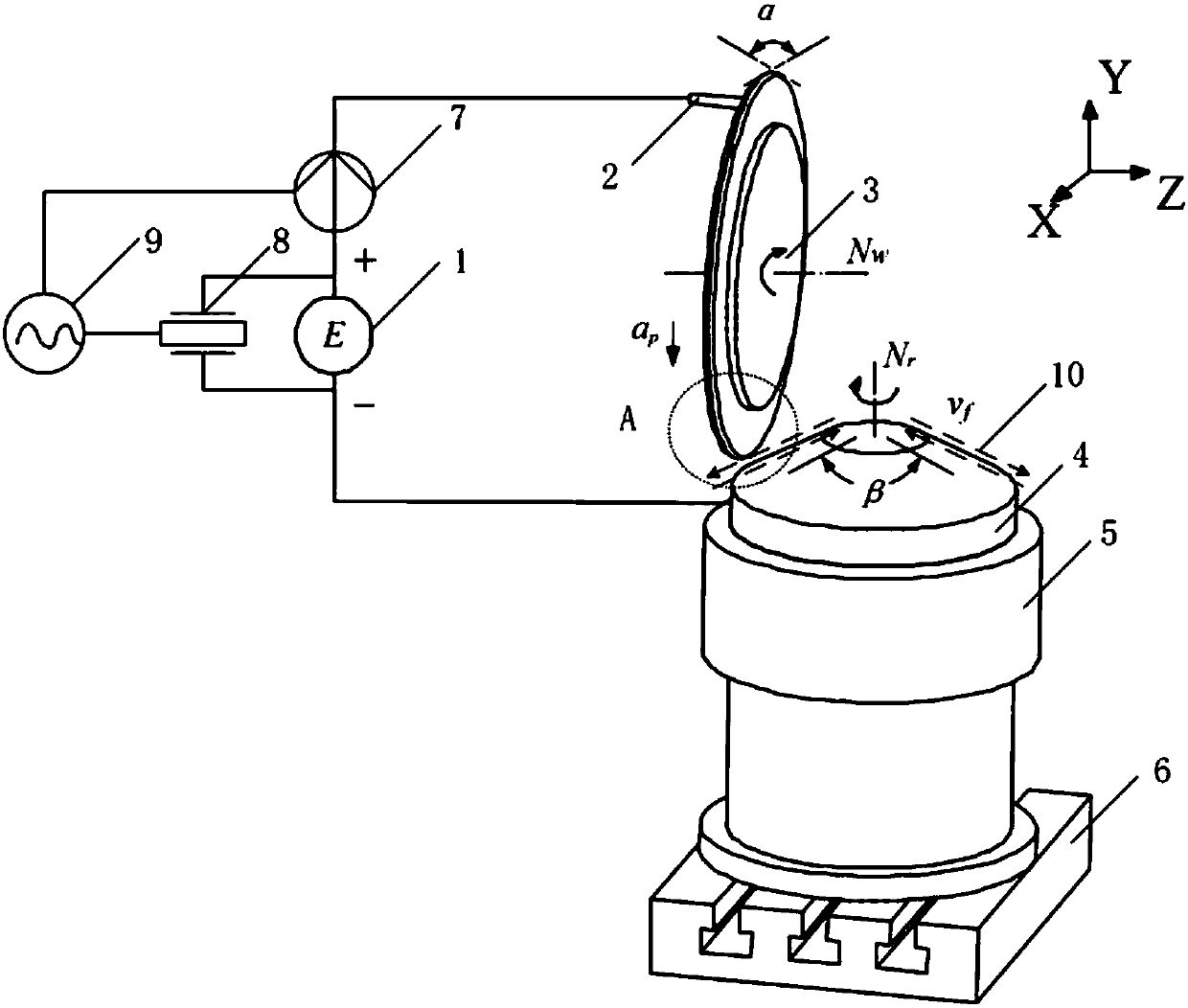

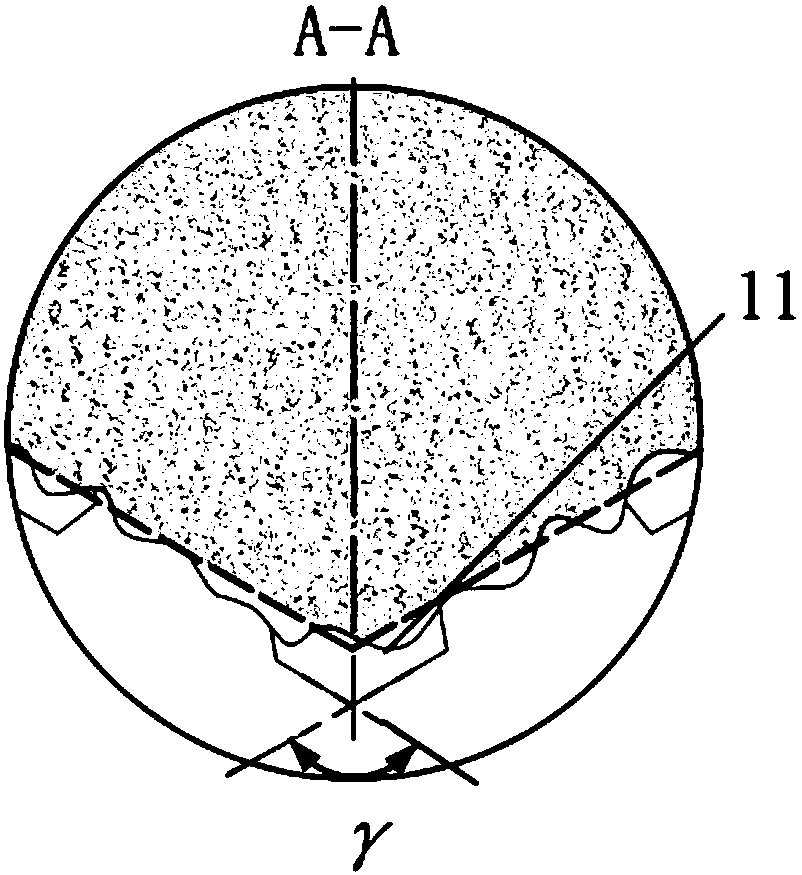

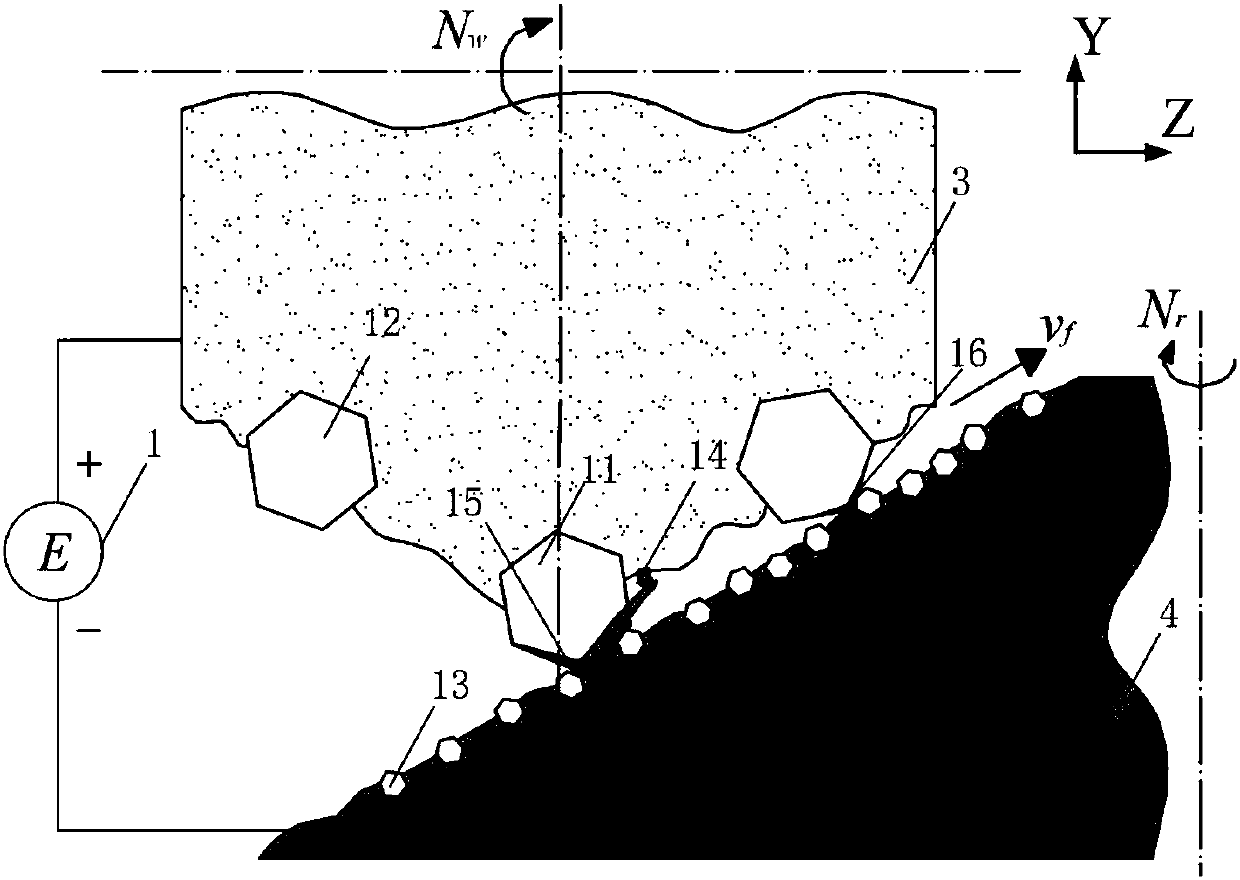

Abrasive wheel micro-point abrasive particle electric heating chemical sharpening device and online control method thereof

PendingCN107598723AImprove sharpening efficiencyAvoid detectionEdge grinding machinesGrinding feed controlNumerical controlMotion parameter

The invention discloses an abrasive wheel micro-point abrasive particle electric heating chemical sharpening device. The abrasive wheel micro-point abrasive particle electric heating chemical sharpening device comprises a power source, a graphite brush, a micro-point abrasive wheel, an opposite-grinding frustum platform, a rotating device, a numerical control grinding machine workbench, a currentsensor, a voltage sensor and an oscilloscope. The rotating device is fixedly arranged on the numerical control grinding machine workbench, and the opposite-grinding frustum platform is fixedly arranged on the rotating device. The micro-point abrasive wheel, the graphite brush, the current sensor, the power source and the opposite-grinding frustum platform are connected in sequence through wires ina positive polarity mode so as to form a discharge circuit. The voltage sensor and the current sensor are connected with the oscilloscope together. The invention further discloses an online control method of the abrasive wheel micro-point abrasive particle electric heating chemical sharpening device. According to the abrasive wheel micro-point abrasive particle electric heating chemical sharpening device and the online control method, workers only need to adjust motion parameters of a numerical control grinding machine to control pulse discharge trimming parameters, and the good sharpening effect of micro-point micro abrasive particles of the abrasive wheel can be achieved. The forming precision of the sharpened point micro abrasive particles is high, the circular arc radius of the pointis small, the point is not prone to abrasion, and precise grinding machining of materials which are not hard or brittle can be achieved.

Owner:SOUTH CHINA UNIV OF TECH

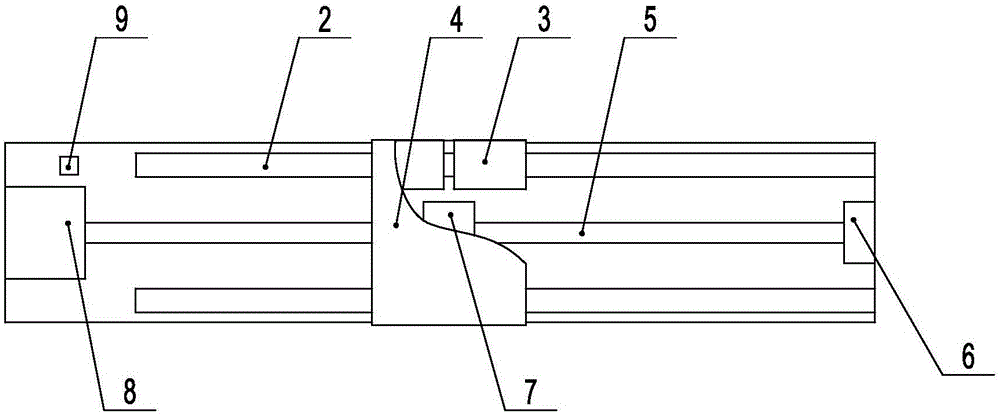

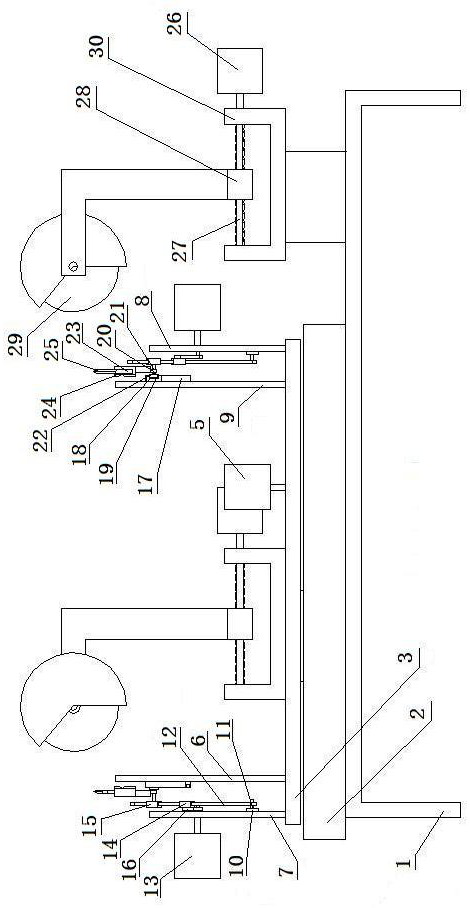

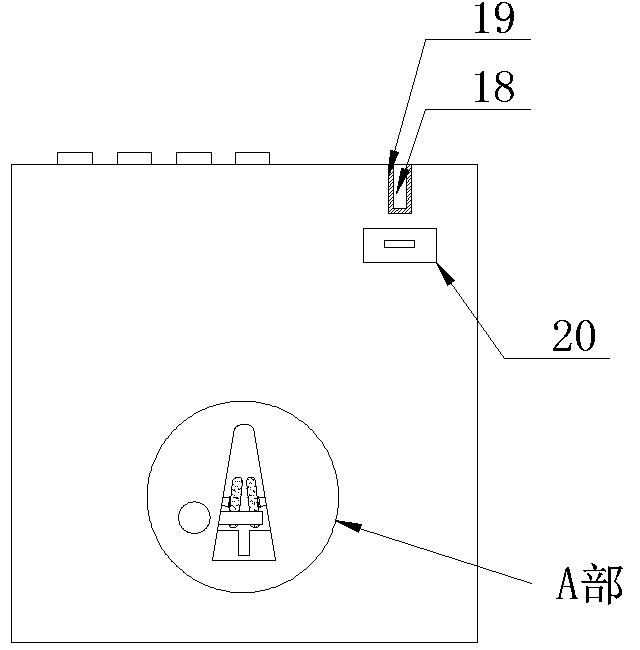

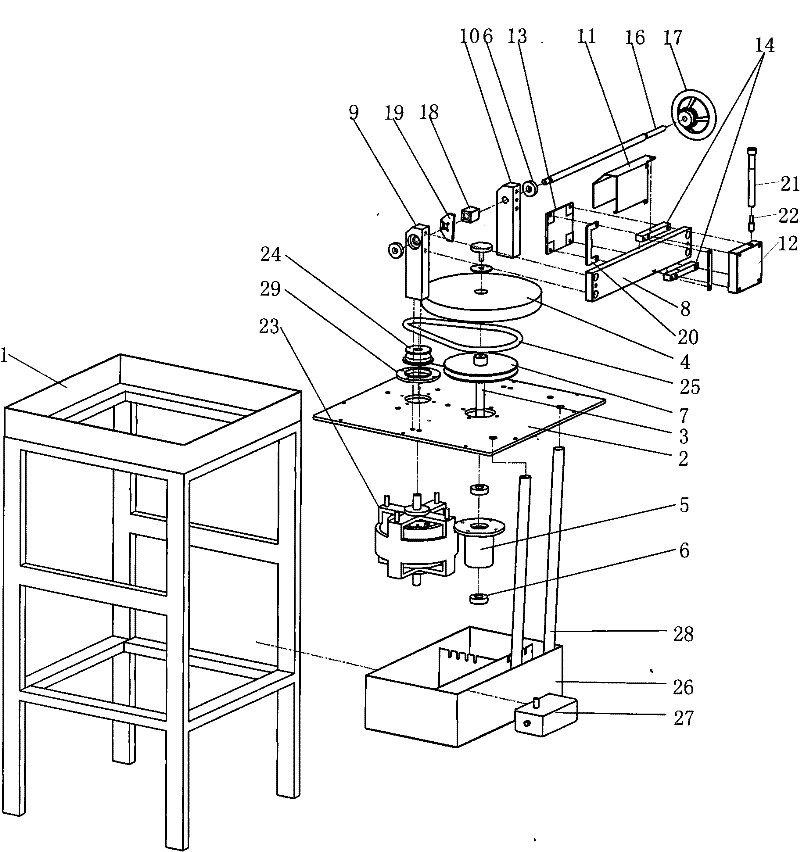

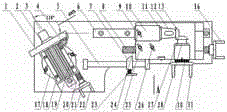

Silage harvester automatic knife sharpening device

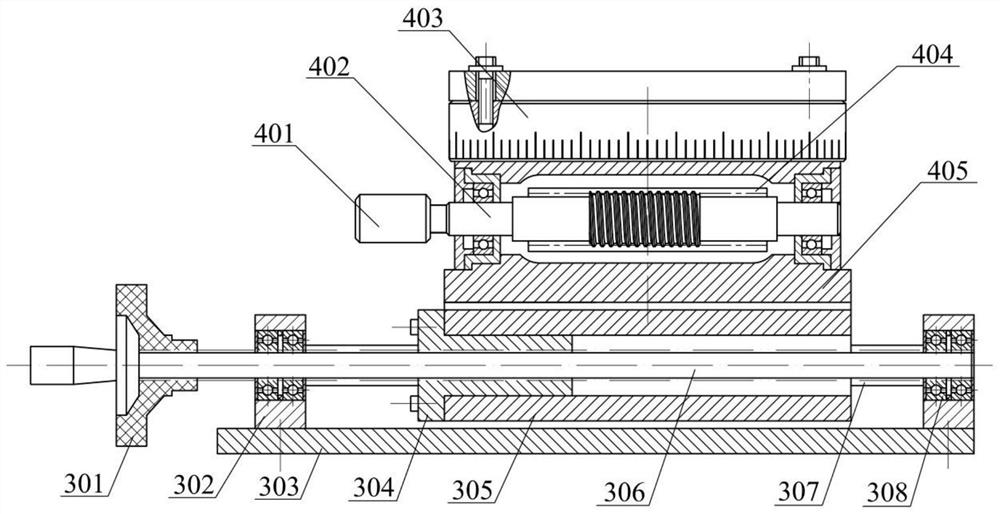

The invention provides a silage harvester automatic knife sharpening device which is characterized by comprising a reciprocating motion mechanism and a knife sharpening feeding mechanism, wherein the reciprocating motion mechanism comprises a guide rail base, two guide rails horizontally installed on the guide rail base, paired sliding blocks installed on the two guide rails respectively, a sliding block plate for fixedly connecting the paired sliding blocks to form a whole body, a lead screw, a lead screw supporting seat, a screw nut, a motor and a pawl; the knife sharpening feeding mechanism comprises a knife sharpening shell, a knife grinder, a worm wheel, a worm gear, a shaft, a feeding sleeve and a ratchet and is connected with the sliding block plate of the reciprocating motion mechanism through the knife sharpening shell; before a knife is sharpened, the knife grinder is in contact with a moving blade of a rotary knife type cutter; and during knife sharpening, the screw nut drives the knife grinder to carry out reciprocating motion under the driving of the motor, and thus a cutting edge of the moving blade on a drum is sharpened again. According to the silage harvester automatic knife sharpening device, the structure design is simple and practical, the manufacturing difficulty and the cost are lowered, operation control is liable, and the working efficiency and the operation quality are improved.

Owner:SHANDONG UNIV OF TECH

Timber pile sharpening device for gardens

PendingCN111438773ASmooth cutGood sharpening qualityProfiling/shaping machinesElectric machineDrive motor

The invention discloses a timber pile sharpening device for gardens. The device comprises a bottom plate, wherein a timber pile cutting assembly and an adjusting assembly are arranged on the bottom plate, the timber pile cutting assembly comprises a supporting block, a cutting motor and a cutterhead, the supporting block is mounted on one side of the bottom plate, the cutting motor is riveted on the supporting block, and the cutterhead is fixedly mounted at the output end of the cutting motor; and the adjusting assembly comprises clamping plates, rotary plates, a groove, a drive motor, screw rods, belts, screws and clamping blocks, the groove is formed in the bottom plate, the screw rods are rotationally arranged in the groove and connected with the output end of the drive motor through the belts, the drive motor is riveted on the bottom plate, the clamping plates are glidingly mounted in the groove and are in threaded connection with the screw rods, second through holes are formed inthe clamping plates, clamping blocks are distributed on the left, right and upper sides of the second through holes and fixedly connected with one ends of the screw rods, the screw rods rotationally penetrate through the clamping plates, the other ends of the screw rods are connected with the rotary plates, the clamping plates drive timber piles to move stably, so that the timber piles are cut more stably by cutters, and the sharpening quality is better.

Owner:于云仙

Laser trimming device and method for superhard abrasive forming grinding wheel

ActiveCN112571282AReduce jumpingImprove sharpening efficiencyAbrasive surface conditioning devicesLaser beam welding apparatusAcoustic emissionLaser scanning

The invention discloses a laser trimming device and method for a superhard abrasive forming grinding wheel. The device is sequentially provided with a reflection lens clamp, a reflection lens base, ahorizontal displacement adjusting table, a vertical displacement adjusting frame and a fixed support along the laser beam emitting direction; and is provided with a constant-angle rotating knob, a displacement lead screw and acoustic emission equipment. The device is a three-degree-of-freedom reflecting lens carrying device which can move in the x direction, the y direction and the z direction androtate around the axis; and a reflecting lens is regulated and controlled to reflect an emergent laser beam at a nearly vertical angle, so that laser energy acts in the horizontal direction and the vertical direction at the same time, and the shaping efficiency is improved by times. A method for coating a laser cross section by the lens clamp is designed, and a modification method for increasingthe laser scanning times in an odd number is provided, so that high modification efficiency and good grinding wheel outline appearance are ensured, and high speed and energy conservation are realized;and a model for sharpening a scanning track of a laser beam on the surface of the grinding wheel is established, and a method for controlling the optimal scanning times and performing layered laser scanning sharpening is provided, so that the effects that abrasive particles are excellent in edging and high in percent of pass are achieved.

Owner:HUNAN UNIV OF SCI & TECH

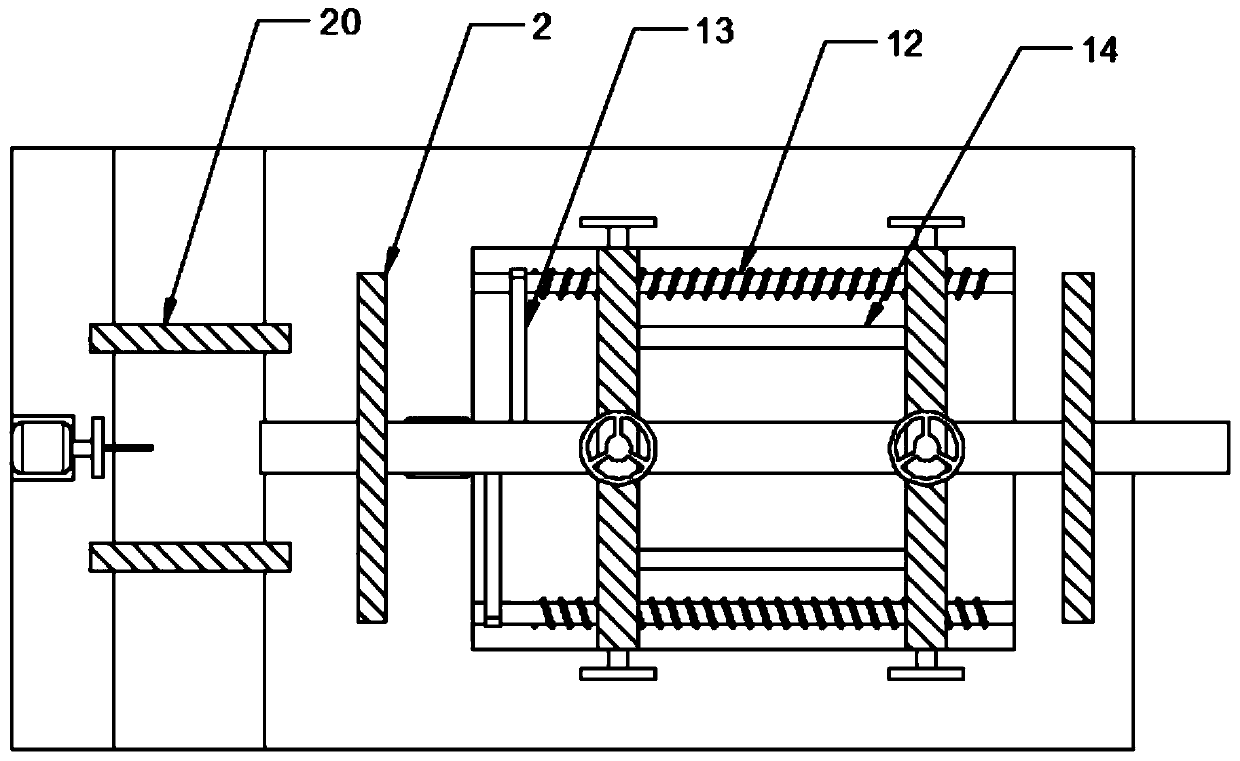

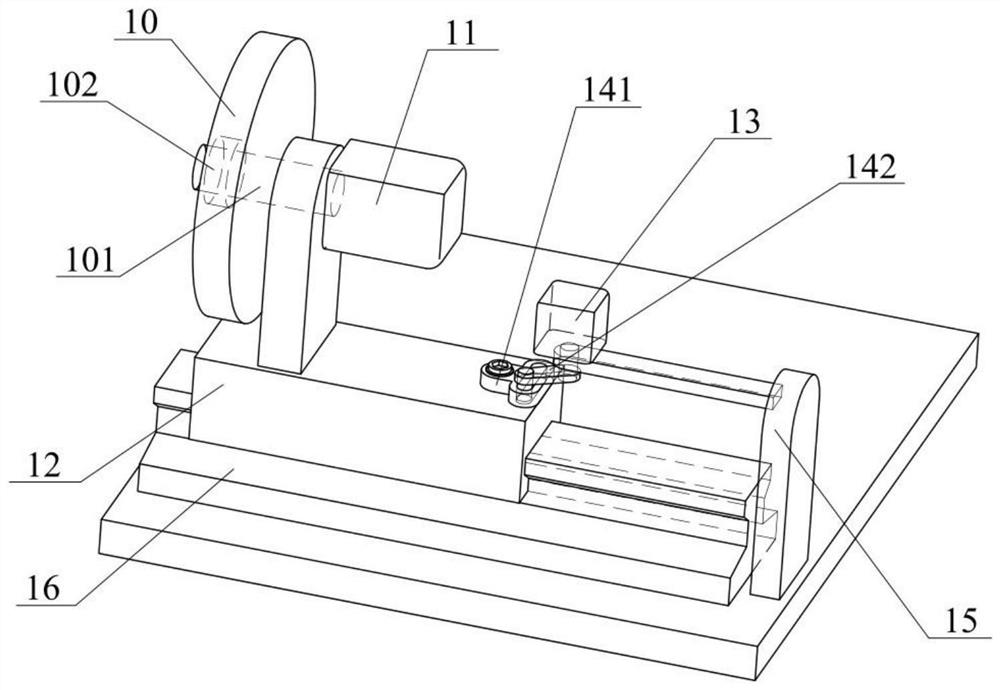

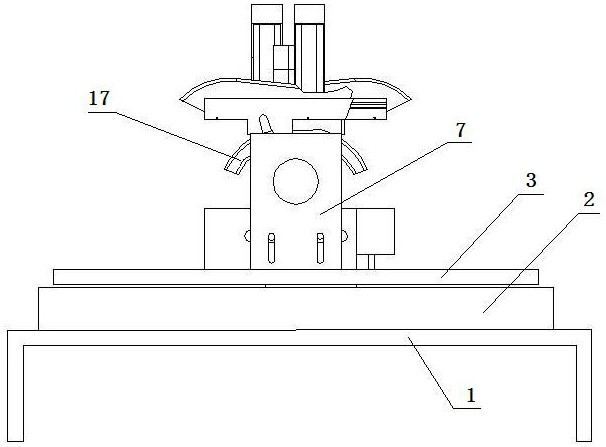

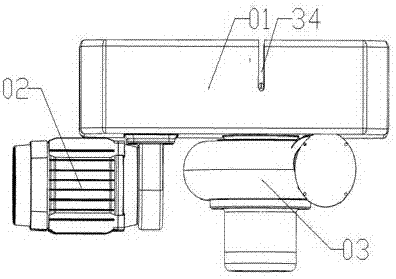

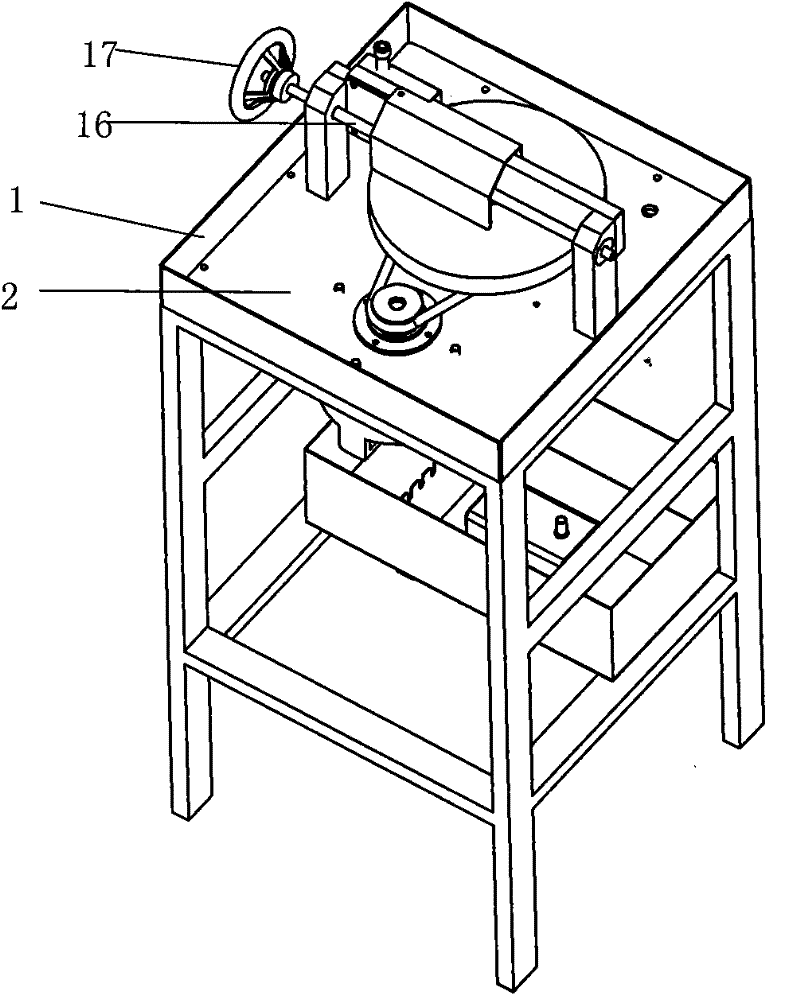

Universal drill sharpening machine

ActiveCN102785132AUnique structureExtended service lifeMilling cuttersOther manufacturing equipments/toolsEngineeringGrinding wheel

The invention relates to a sharpening machine, in particular to a universal drill sharpening machine, which comprises a sharpening machine chassis, wherein a sharpening head is fixedly arranged at one side of the sharpening machine chassis, and a drill matched with the sharpening head is fixedly arranged at the other side of the sharpening machine chassis; the sharpening head comprises a sharpening head moving guide rail, and a grinding wheel, a sharpening head rotating disc, a sharpening head power source, a sharpening head moving screw 20 and a sharpening head moving screw 22 which are sequentially arranged on the sharpening moving guide rail from top to bottom, and the grinding wheel is fixed with a grinding wheel compaction flange, and the sharpening head power source is fixedly arranged on the sharpening head rotating disc; and the sharpening head moving screw 20 is supported by a support, and the sharpening head moving screw 22 is used for controlling the sharpening head moving screw. The sharpening machine has the advantages of unique structure, accuracy, efficiency, practicality, resistance and high sharpening efficiency, various problems caused by artificial grinding of drill are solved, the service life of the drill is prolonged, and the drilling precision is high.

Owner:KOCEL EQUIP

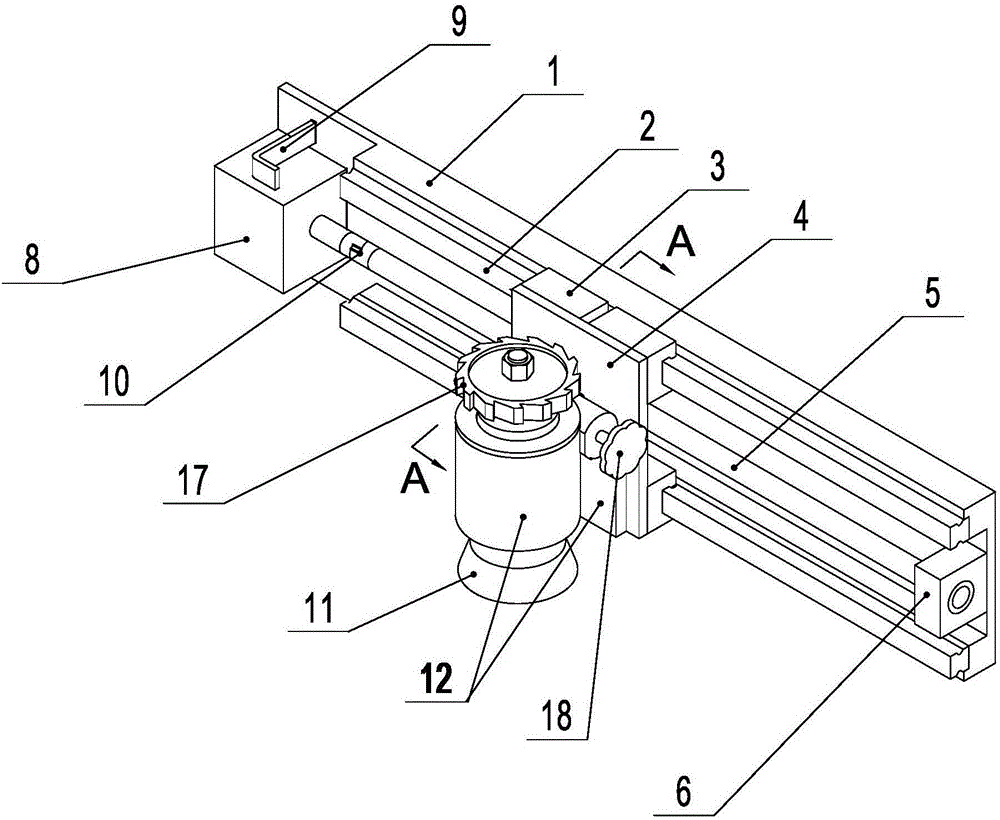

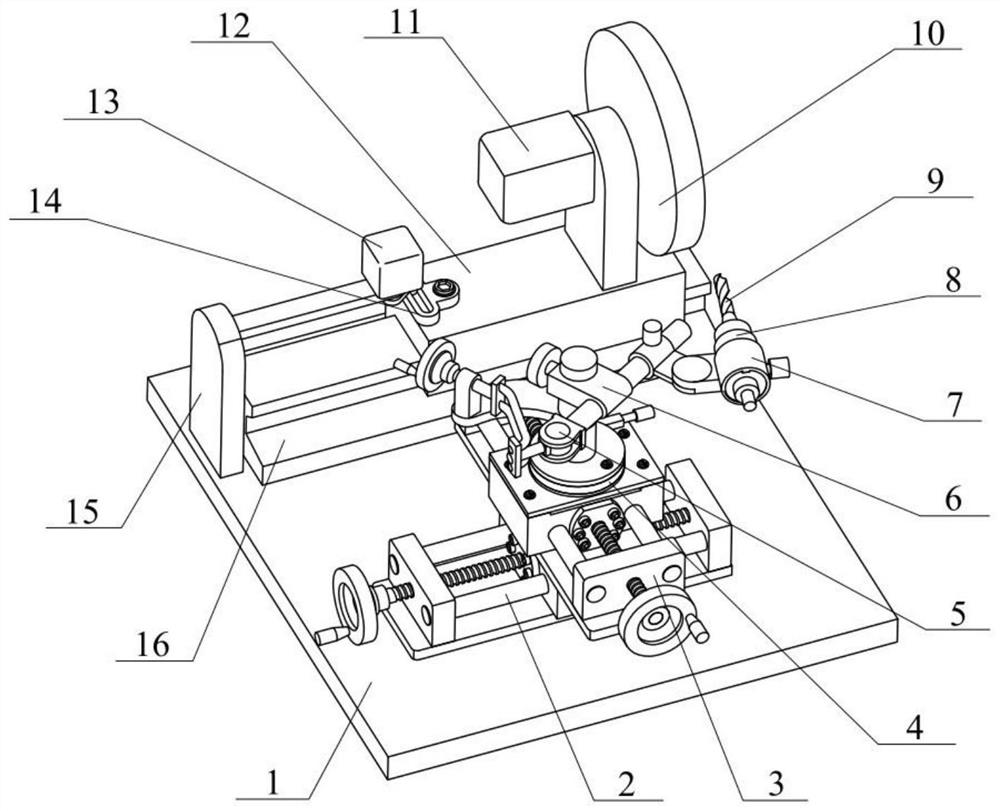

Adjustable twist drill grinding device

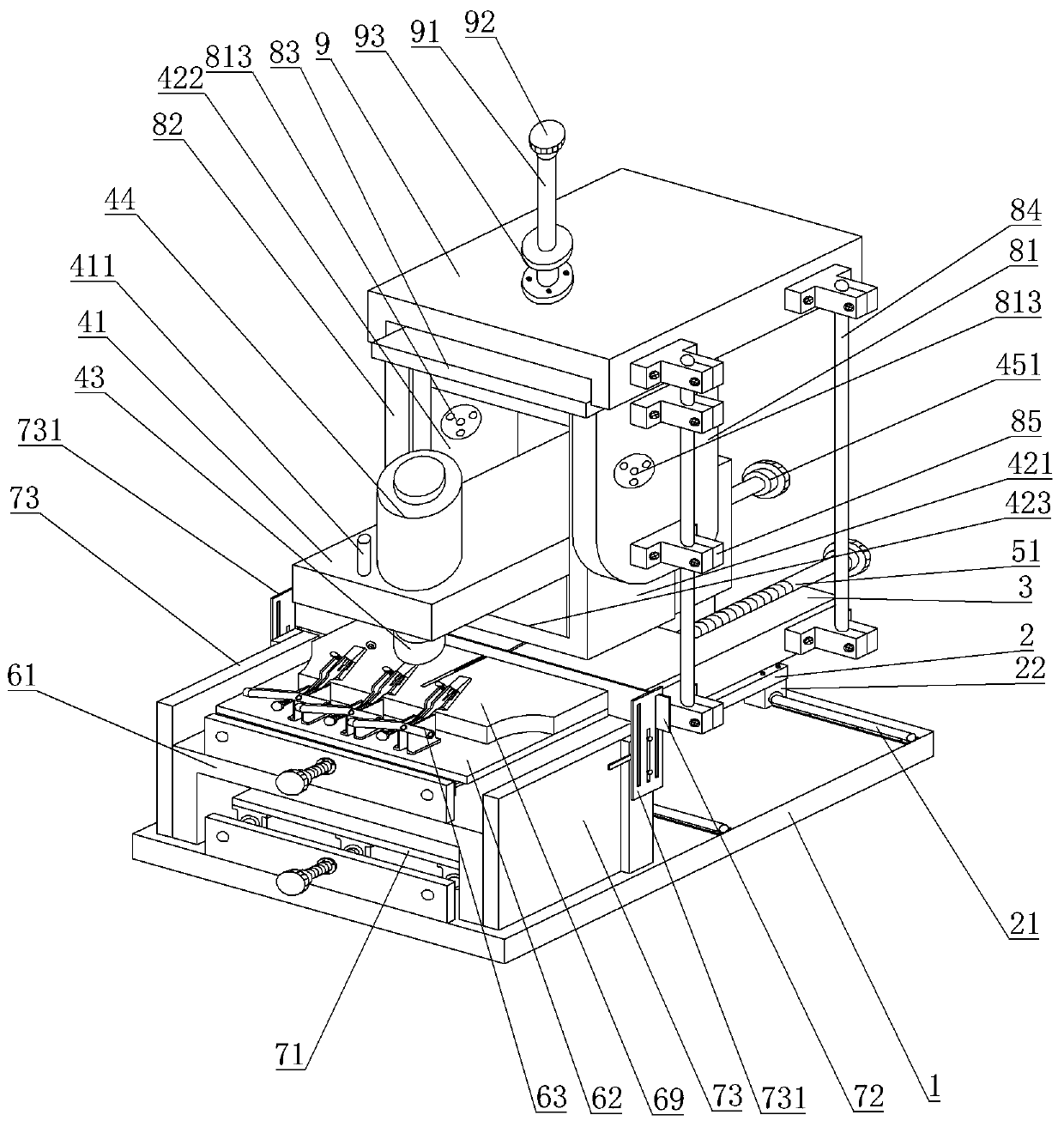

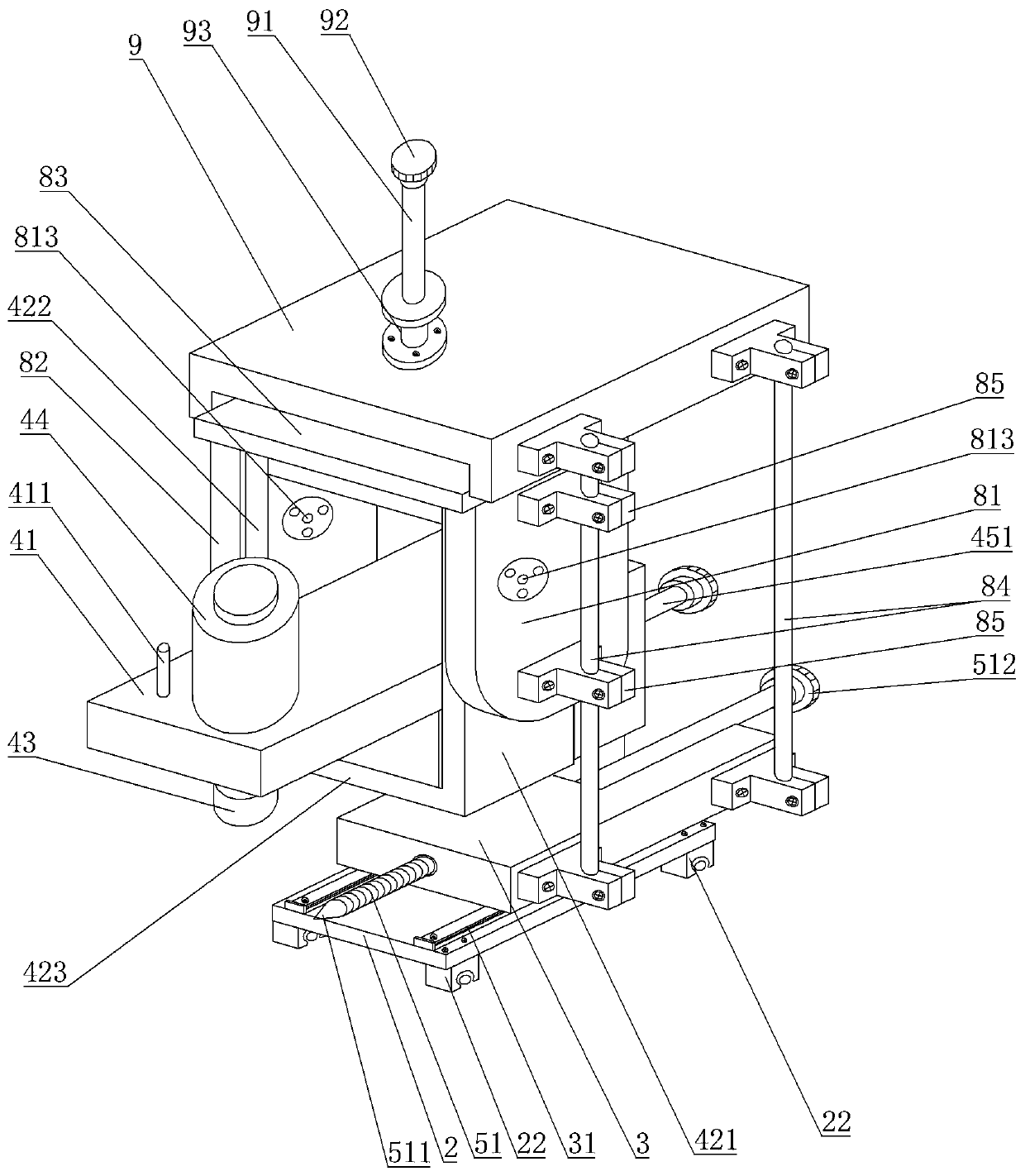

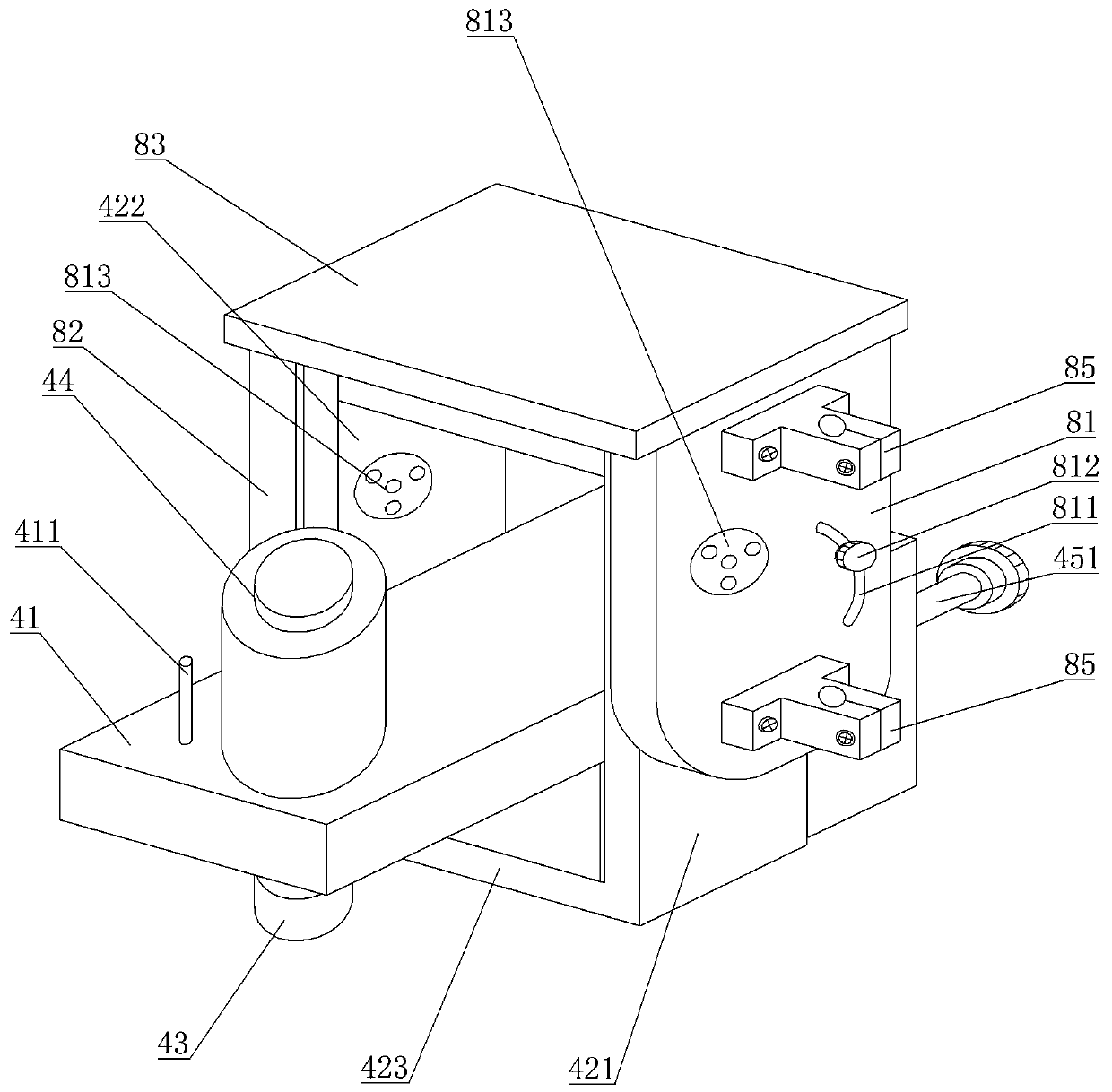

PendingCN111618670AReduce technical requirements for sharpeningSimplify forming motionGrinding carriagesGrinding drivesEngineeringGrinding wheel

The invention discloses an adjustable twist drill grinding device. The adjustable twist drill grinding device comprises a horizontal base, a transverse horizontal sliding guide rail mechanism, a longitudinal horizontal sliding guide rail mechanism, a rotary workbench, a cutter grinding transmission mechanism, a vertical sliding mechanism, a clamping mechanism, a drill chuck, a twist drill and a grinding wheel grinding mechanism, wherein the transverse horizontal sliding guide rail mechanism and the longitudinal horizontal sliding guide rail mechanism are arranged on the horizontal base in a cross-shaped overlaying mode; the rotary workbench is arranged on the longitudinal horizontal sliding guide rail mechanism and used for moving in the longitudinal and transverse directions in the horizontal plane along with the transverse horizontal sliding guide rail mechanism and the longitudinal horizontal sliding guide rail mechanism; the cutter grinding transmission mechanism is arranged on therotary workbench and connected with the clamping mechanism through the vertical sliding mechanism; the clamping mechanism is connected with the drill chuck; the drill chuck is used for mounting the twist drill; and the grinding wheel grinding mechanism is arranged on one side of the horizontal base.

Owner:SHAANXI SCI TECH UNIV

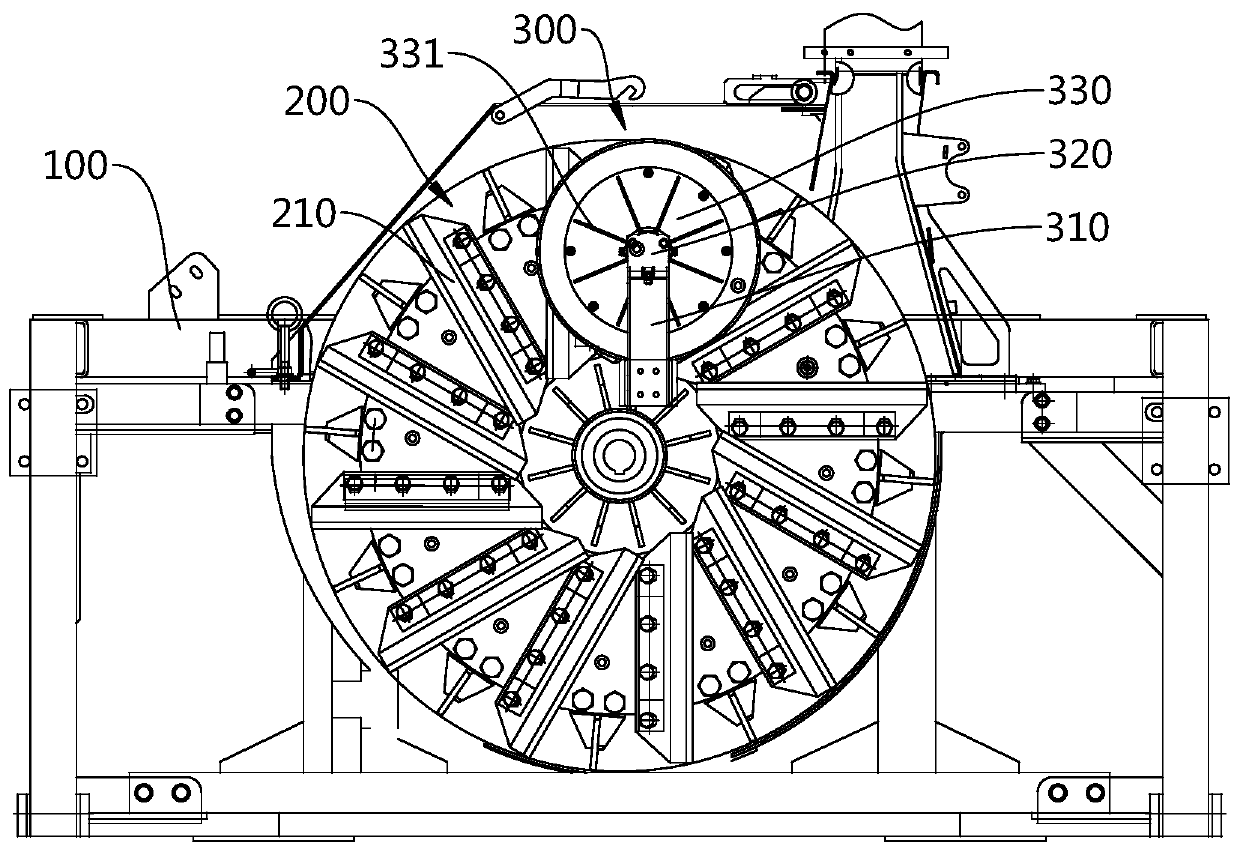

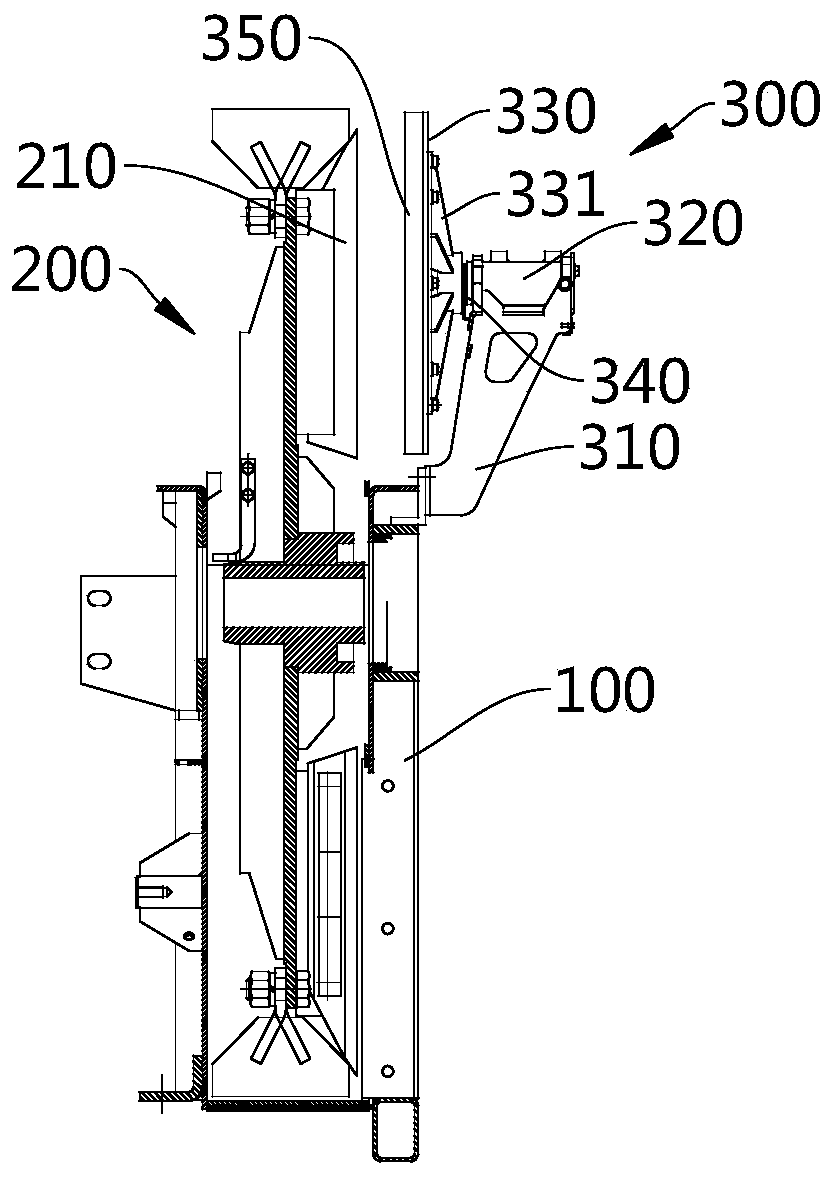

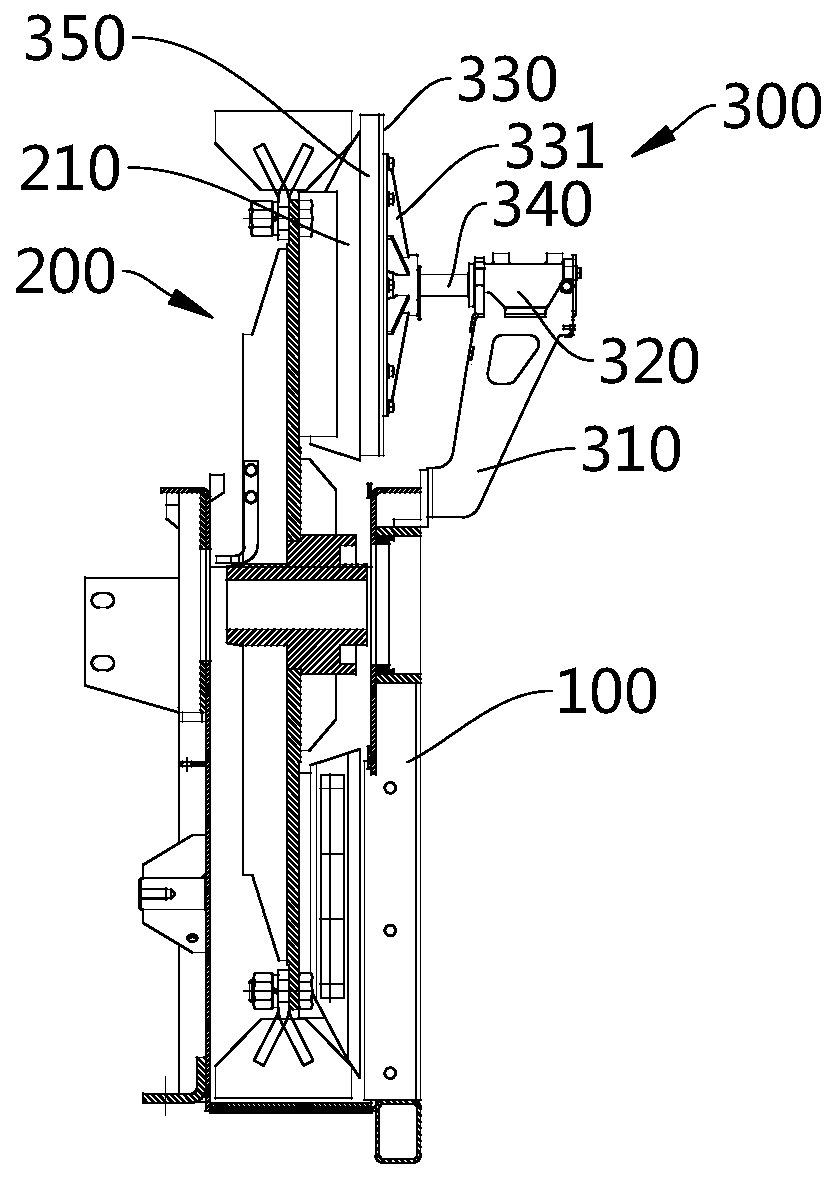

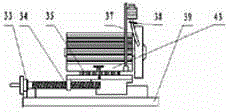

High-stability bamboo stick sharpening machine

InactiveCN109015243AHigh conveying precisionImprove delivery stabilityEdge grinding machinesGrinding drivesEngineeringConveyor belt

The invention discloses a high-stability bamboo stick sharpening machine which comprises a machine base. A rotating wheel is rotationally connected to the middle of the machine base, and a plurality of feeding grooves are evenly distributed on the rotating wheel. A conveyor belt set is arranged at the top of the rotating wheel, and grinding devices are arranged on the two sides of the conveyor belt set. A push rod device and a collecting groove are formed in the two sides of the rotating wheel correspondingly. The feeding grooves comprise arc-shaped grooves, oblique faces are arranged on the positions, between the arc-shaped grooves and the outer wall of the rotating wheel, of one sides of the arc-shaped grooves in the rotating direction of the rotating wheel, and protruding corners are arranged at the junctions of the oblique faces and the arc-shaped grooves. Arc-shaped faces are arranged on the positions, between the arc-shaped grooves and the outer wall of the rotating wheel, of theother sides of the arc-shaped faces in the rotating direction of the rotating wheel. The high-stability bamboo stick sharpening machine has the characteristics of being high in working efficiency andgood in conveying and sharpening stability.

Owner:安吉前程竹木机械有限公司

Knife grinding device for plastic packaging bag shearing knife

PendingCN112276691AImprove sharpening efficiencyReduce labor intensityGrinding drivesOther manufacturing equipments/toolsElectric machineryGrindstone

The invention discloses a knife grinding device for a plastic packaging bag shearing knife. The knife grinding device comprises a bottom plate, a grinding assembly, a moving assembly and a clamping assembly, wherein the grinding assembly, the moving assembly and the clamping assembly are arranged on the bottom plate, the grinding assembly comprises a mounting table and a motor arranged at the topof the mounting table, and a knife grinding stone is arranged on an output shaft of the motor. The clamping assembly is fixed to the moving assembly. According to the knife grinding device for the plastic packaging bag shearing knife, a cutting edge is ground in a semi-automatic mode, the knife grinding efficiency is improved, the labor intensity of workers is reduced, a blade fixing plate with the adjustable inclination angle is arranged, the grinding inclination angle of the knife grinding stone to the cutting edge can be adjusted according to actual needs, and the applicability is good; anadjustable blade locking assembly is arranged, and rectangular blades of different size can be adapted and locked and ground; and the knife grinding device is simple in structure, low in requirement for the installation environment, not prone to breaking down and simple in later maintenance and repair.

Owner:贵州闽乾思源塑料制品有限责任公司

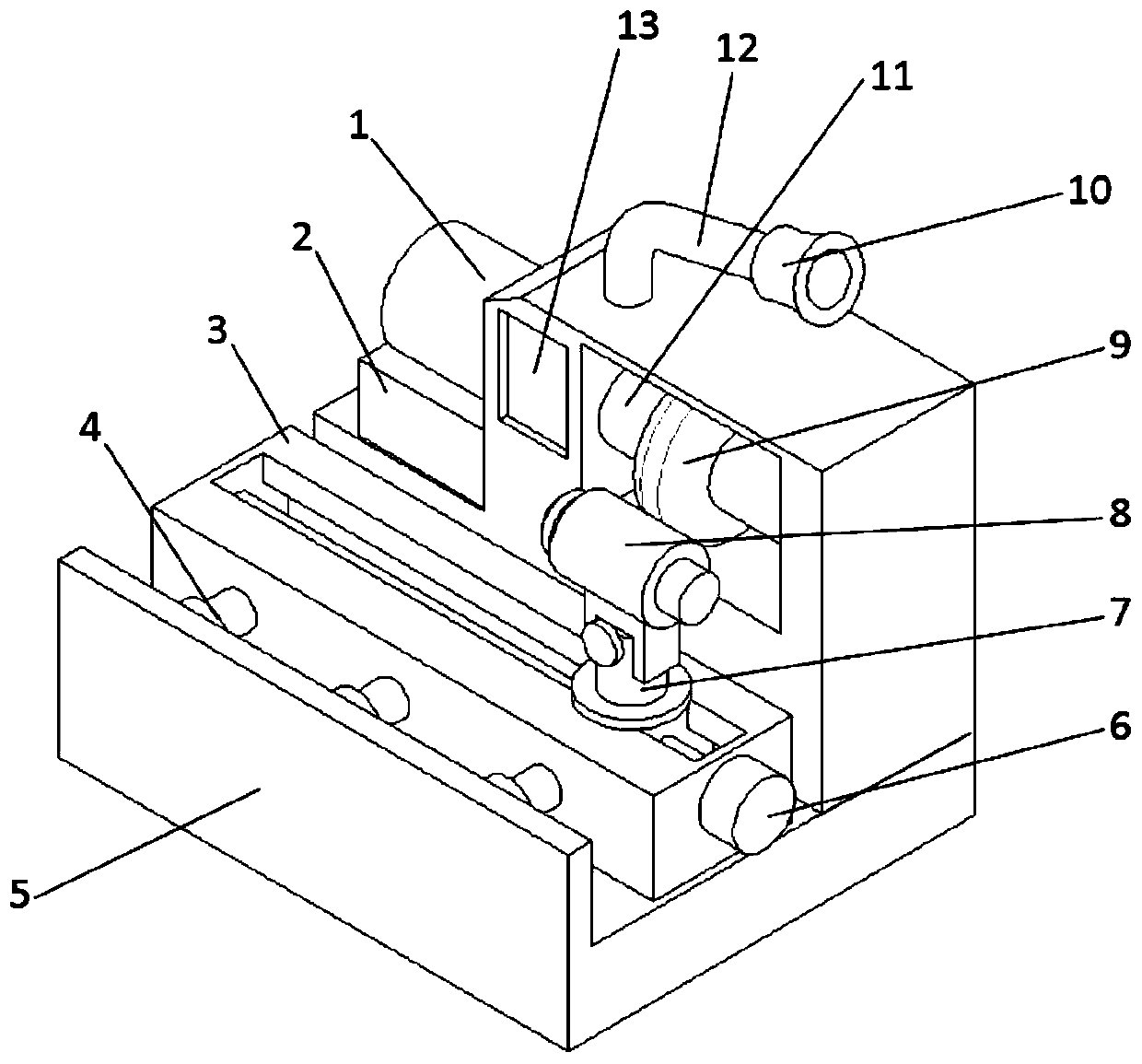

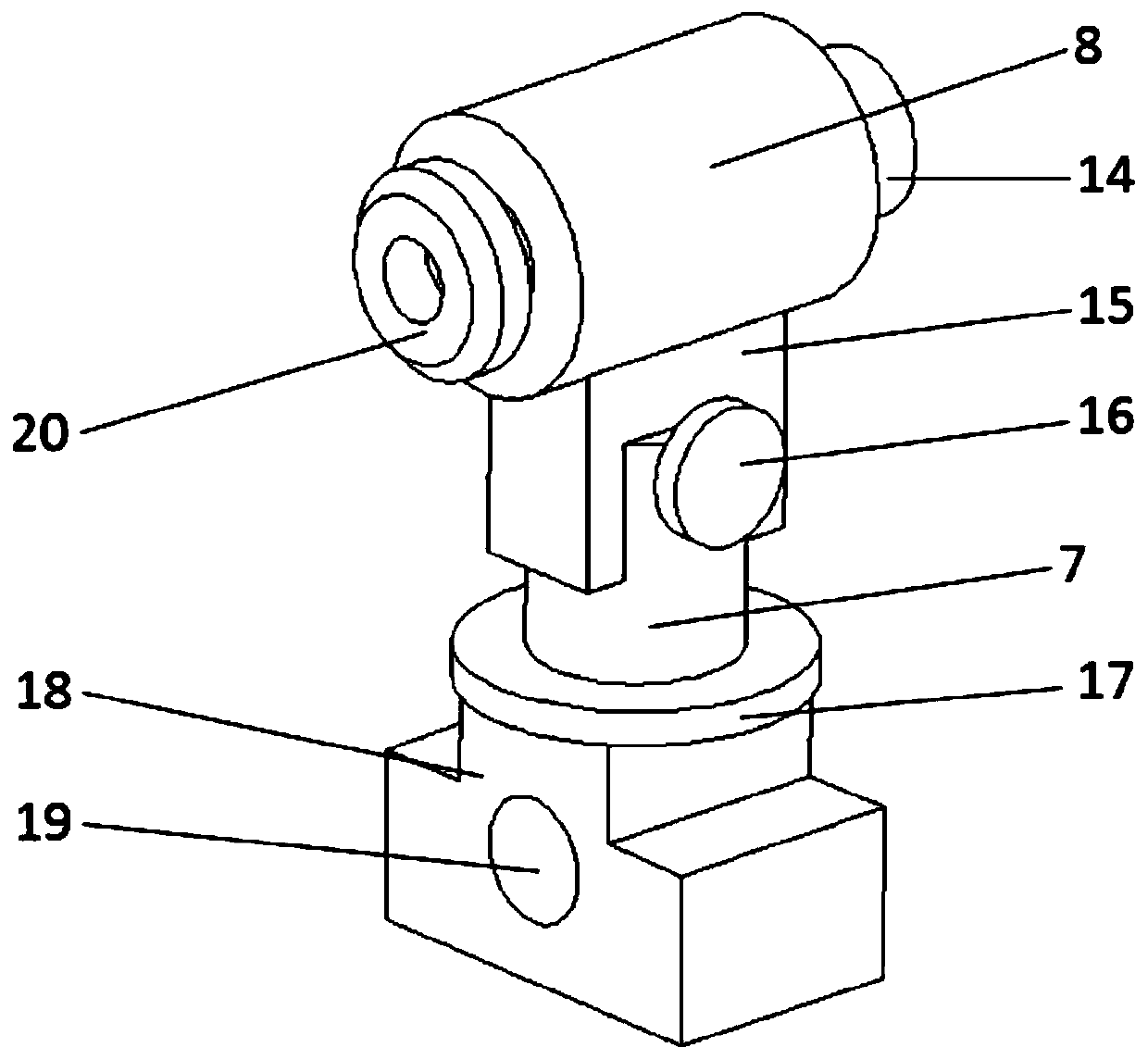

Clamping and cooling device for manual sharpening of external turning tool

InactiveCN109262379AReduce the temperatureReduce annealingPlaning/slotting toolsTurning toolsEngineeringSharpening

The invention provides a clamping and cooling device for manual sharpening of an external turning tool. The clamping and cooling device comprises a clevis, a clamping sleeve, a cavity, a liquid filling port, a liquid storage cavity, a fixed seat and a fixed ring. The lower end of the clevis is in threaded connection with a clamping bolt, a support column is fixedly connected above the clevis, a connecting column is rotatably connected above the support column, and the clamping sleeve is fixedly connected above the connecting column. The cavity and the liquid storage cavity are opened inside the clamping sleeve. The fixed ring is inserted into an opening, and the other end of the cavity is fixedly connected with the fixed seat. The liquid filling port is opened in the upper right side of the liquid storage cavity. The external turning tool is clamped inside the fixed ring and the cavity. The fixed ring includes a clamping block, an elastic layer and a clamping hole. By means of matchingof the fixed ring, the fixed seat and the clamping sleeve, the external turning tool can be inserted into the clamping hole inside the fixed ring, and then the fixed ring and the external turning tool are inserted into the clamping sleeve. The clamping sleeve can be held to sharpen the external turning tool, scalding during the sharpening can be avoided, and the sharpening efficiency is improved.

Owner:刘轩佑

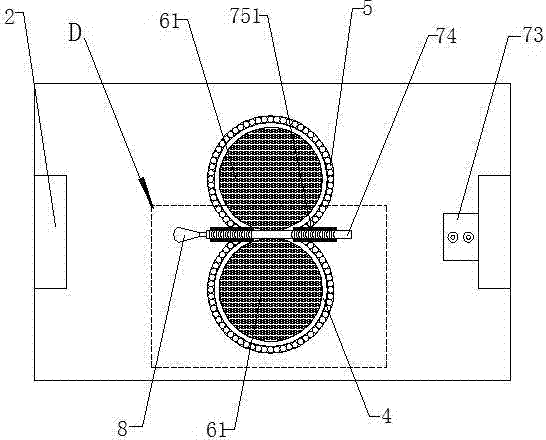

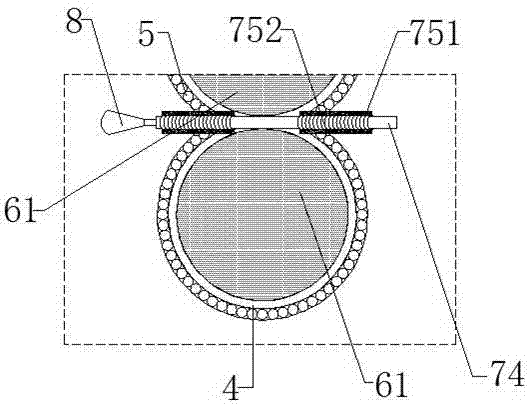

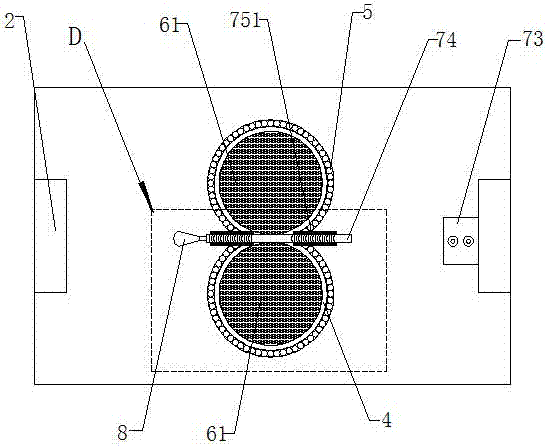

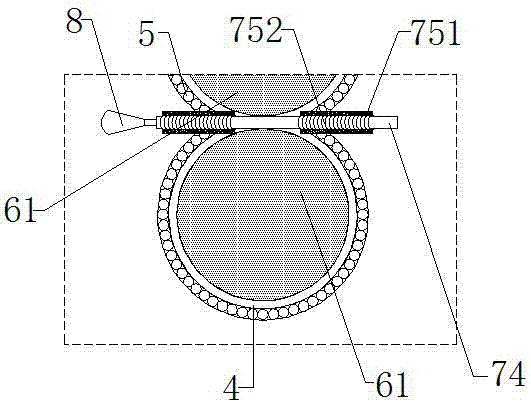

Automatic double-grindstone knife grinding device for processing kitchen knives

ActiveCN104493648APlay a protective effectImprove clamping effectOther manufacturing equipments/toolsGrinding work supportsFailure rateEngineering

The invention discloses an automatic double-grindstone knife grinding device for processing kitchen knives. The automatic double-grindstone knife grinding device for processing kitchen knives comprises an operation table, wherein side brackets are vertically arranged on two sides of the upper end surface of the operation table; a water spraying mechanism is arranged between the two side brackets; a horizontal moving device is arranged between the two side brackets; a rotary driving mechanism is arranged at the bottom of the operation table; a rotation shaft which penetrates through the operation table is arranged atthe upper end of the rotary driving mechanism; double grindstone sets are fixedly arranged on the rotation shaft; a bearing is fixedly arranged on a part at the periphery of the rotation shaft on the operation table; the bearing is embedded into the operation table and sleeves the rotation shaft. The automatic double-grindstone knife grinding device has the benefits that the knife grinding device is capable of simultaneously grinding blades of two sides of knife bodies; the knife grinding efficiency and uniformity of the ground blades of the knife bodies on two sides are improved; the automatic double-grindstone knife grinding device is simple in structure, easy to operate, low in cost, high in knife grinding efficiency, low in failure rate, high in automatic degree and firm to clamp; the time is reduced; the labor is alleviated; the water is conveniently and uniformly sprayed; the knife bodies are convenient to fix and demount.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

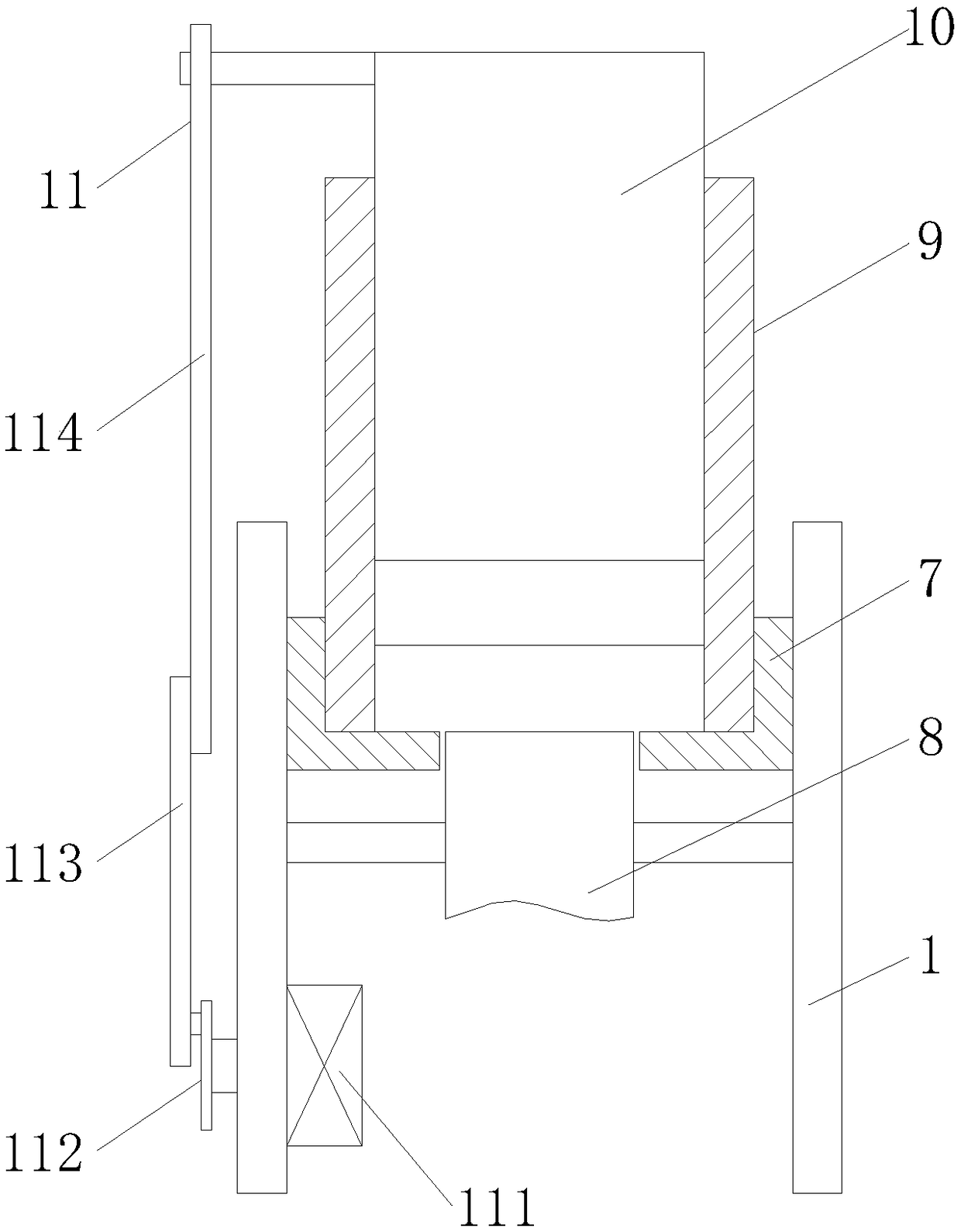

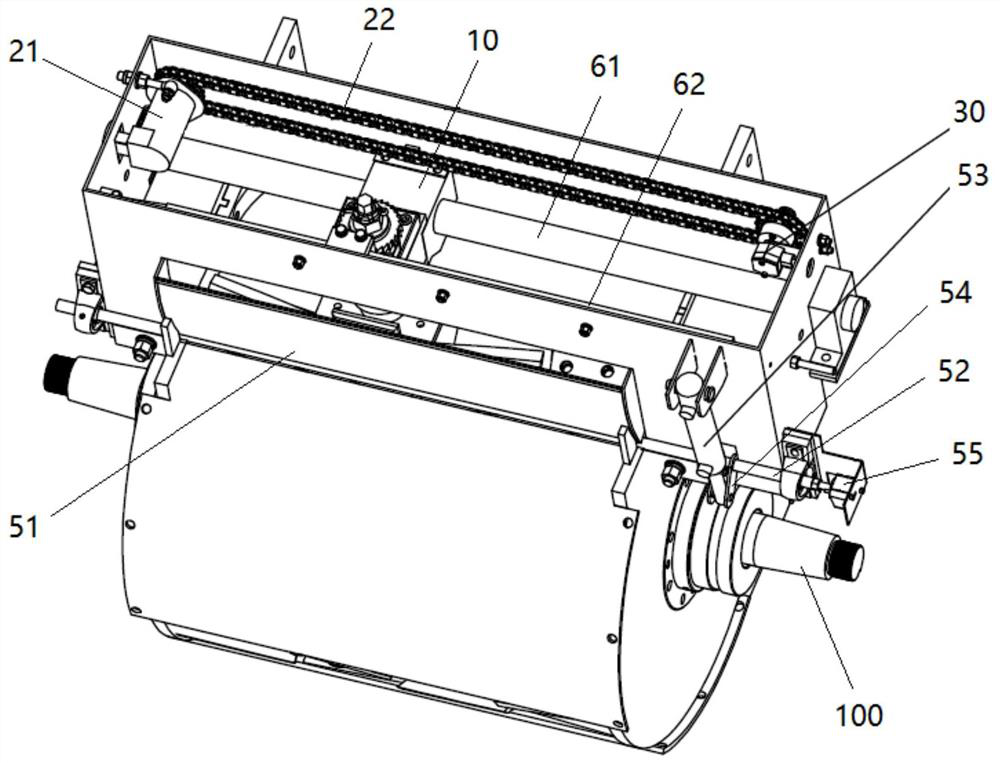

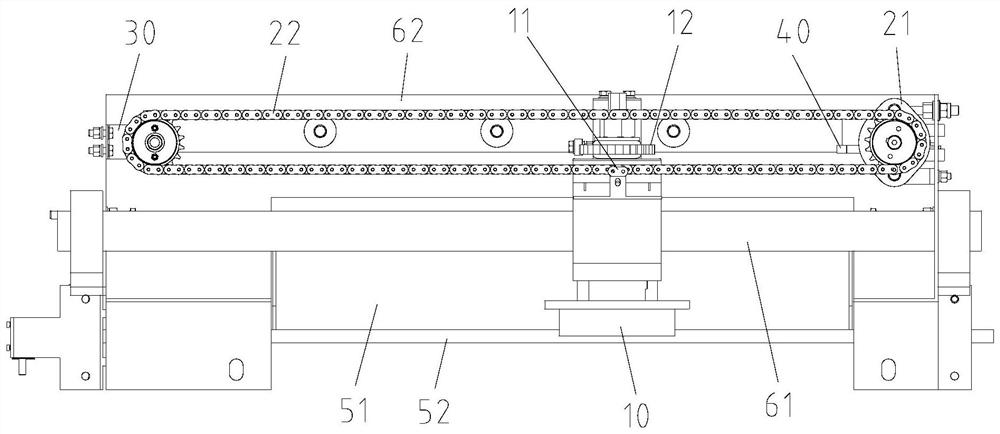

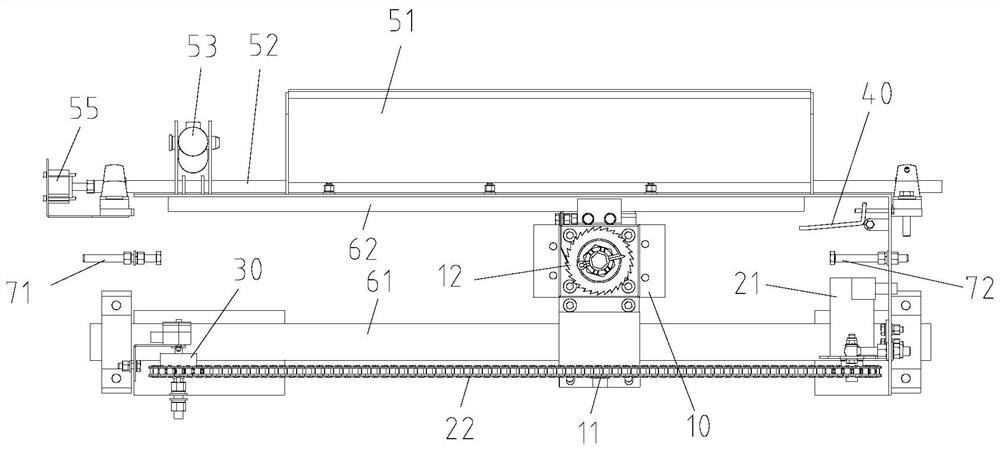

Automatic sharpening device for silage harvester

The invention provides an automatic knife sharpening device for a silage harvester, which is characterized in that it includes a reciprocating mechanism and a knife sharpening feeding mechanism; wherein the reciprocating mechanism includes a guide rail base, two guide rails horizontally installed on the guide rail base, A pair of sliders installed on the two guide rails, a slider plate that fixes the pair of sliders together, a lead screw, a lead screw support, a lead screw nut, a motor and a pawl; the sharpening mechanism includes a grinding Knife housing, knife grinding wheel, worm wheel, worm, shaft, feed sleeve, ratchet wheel; knife grinding feeding mechanism is connected with the slider plate of the reciprocating mechanism through the knife grinding housing. Before grinding the knife, adjust the grinding wheel to be in contact with the moving knife of the hob-type chopper. When grinding the knife, the grinding wheel is driven by the motor to reciprocate by the screw nut, thereby resetting the cutting edge of the moving knife on the drum. sharpen. The structural design is simple and practical, reduces manufacturing difficulty and cost, is easy to operate and control, and improves work efficiency and work quality.

Owner:SHANDONG UNIV OF TECH

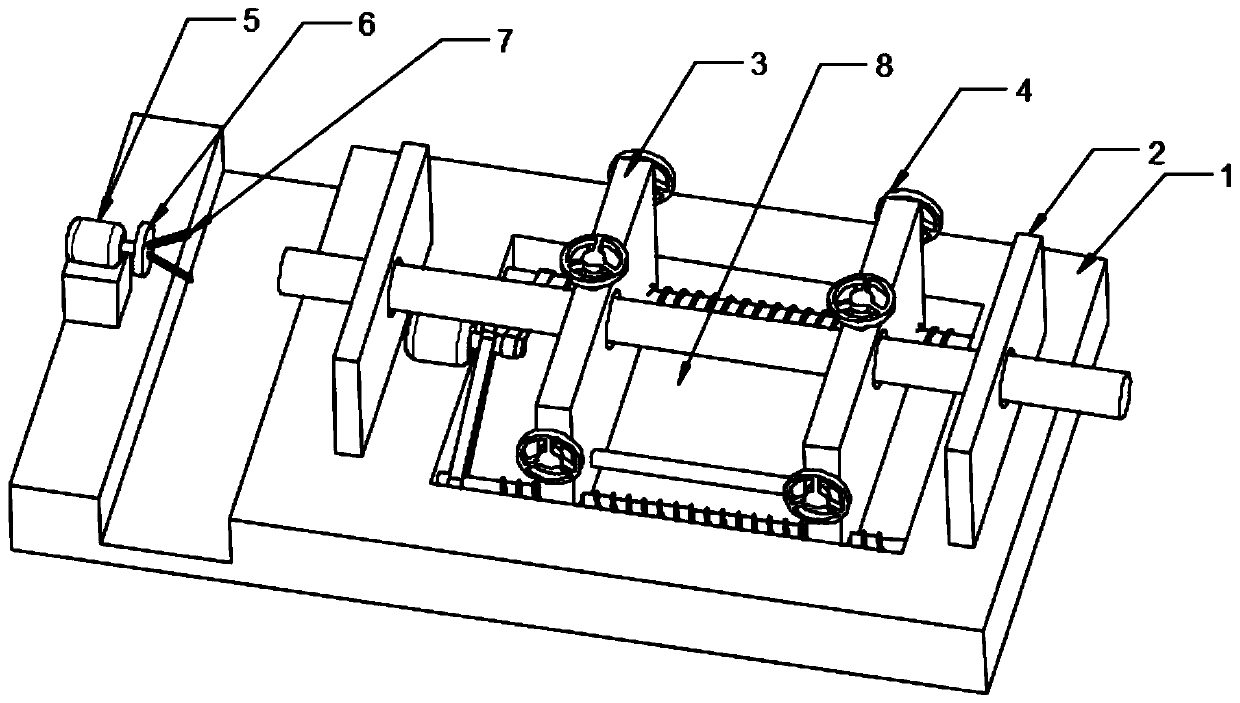

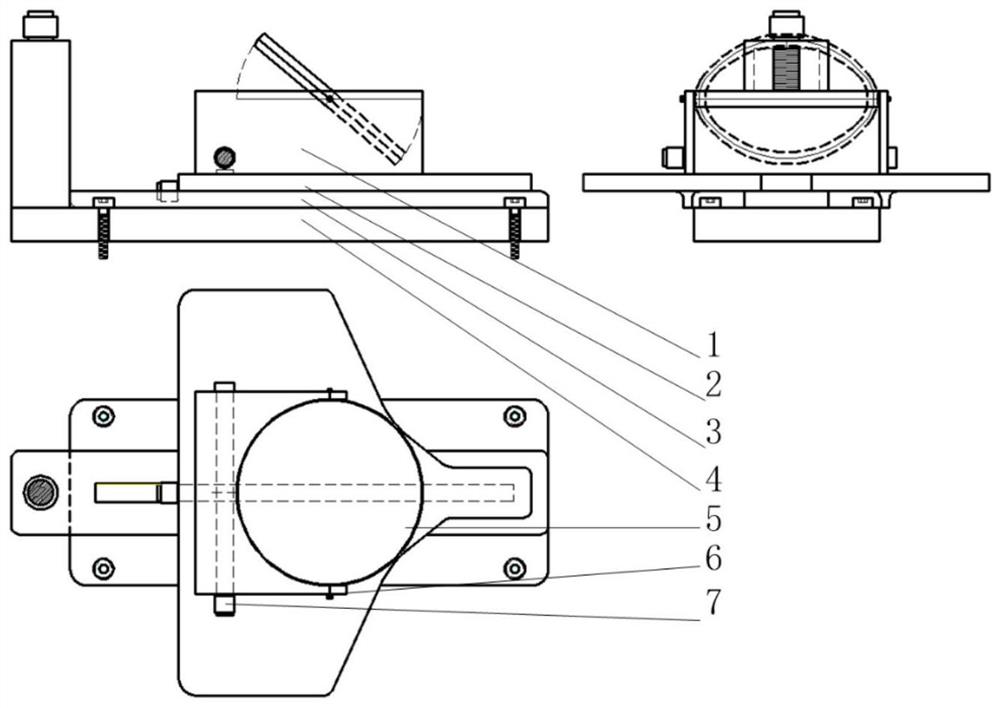

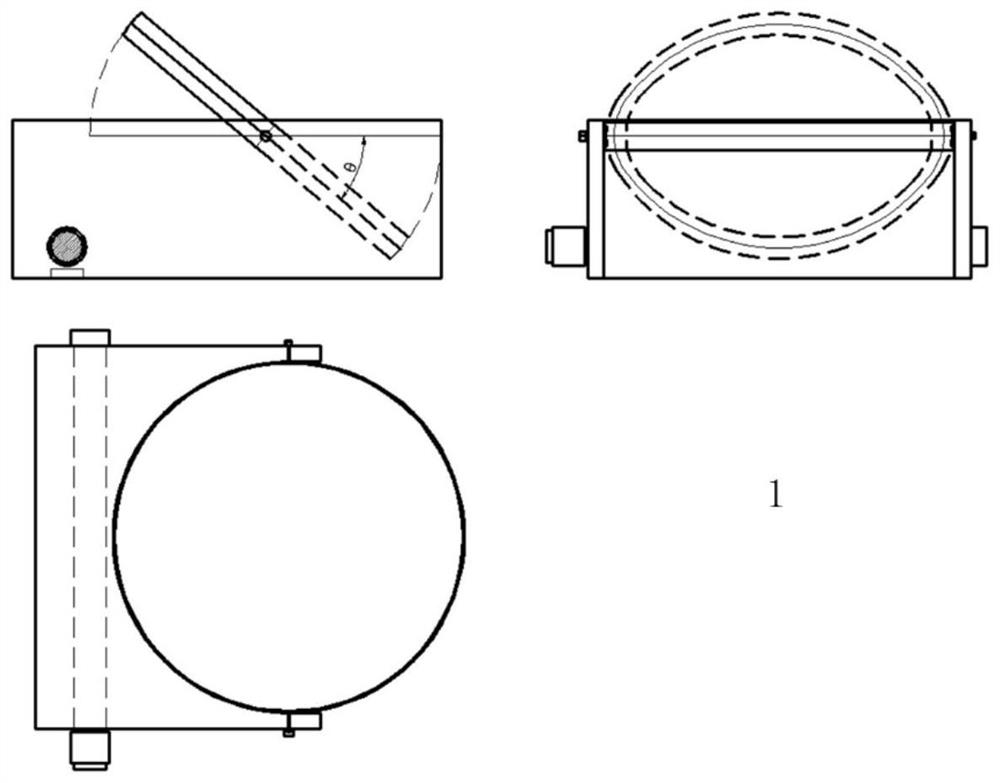

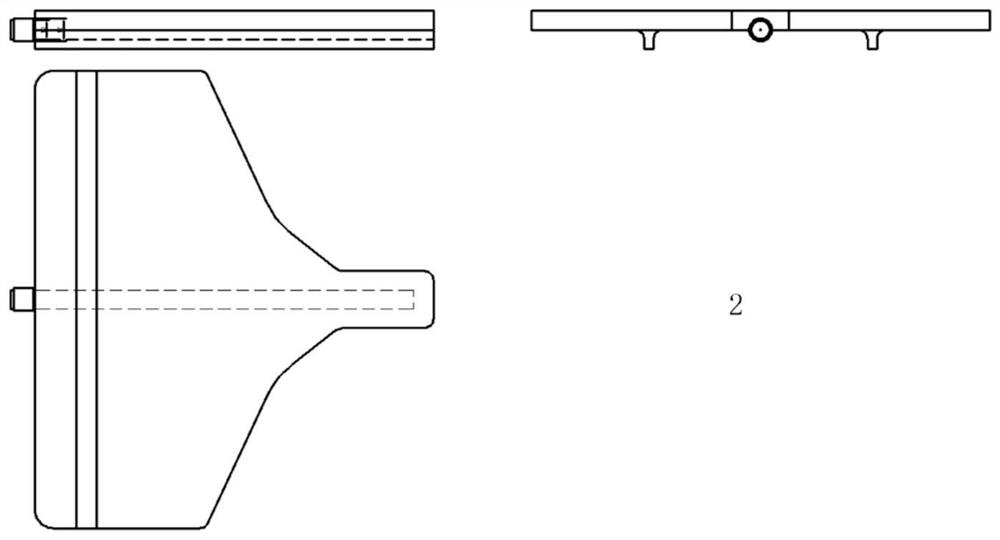

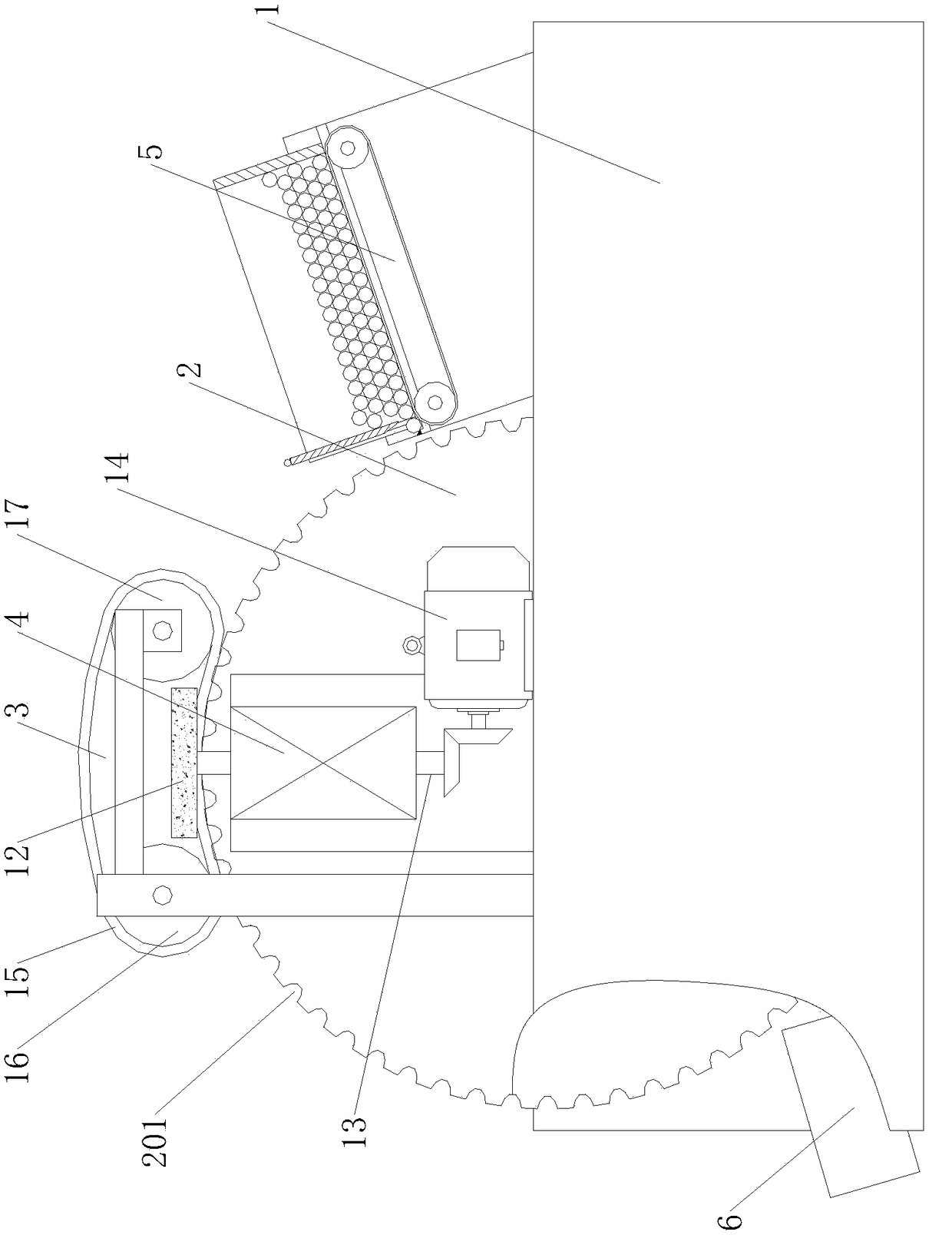

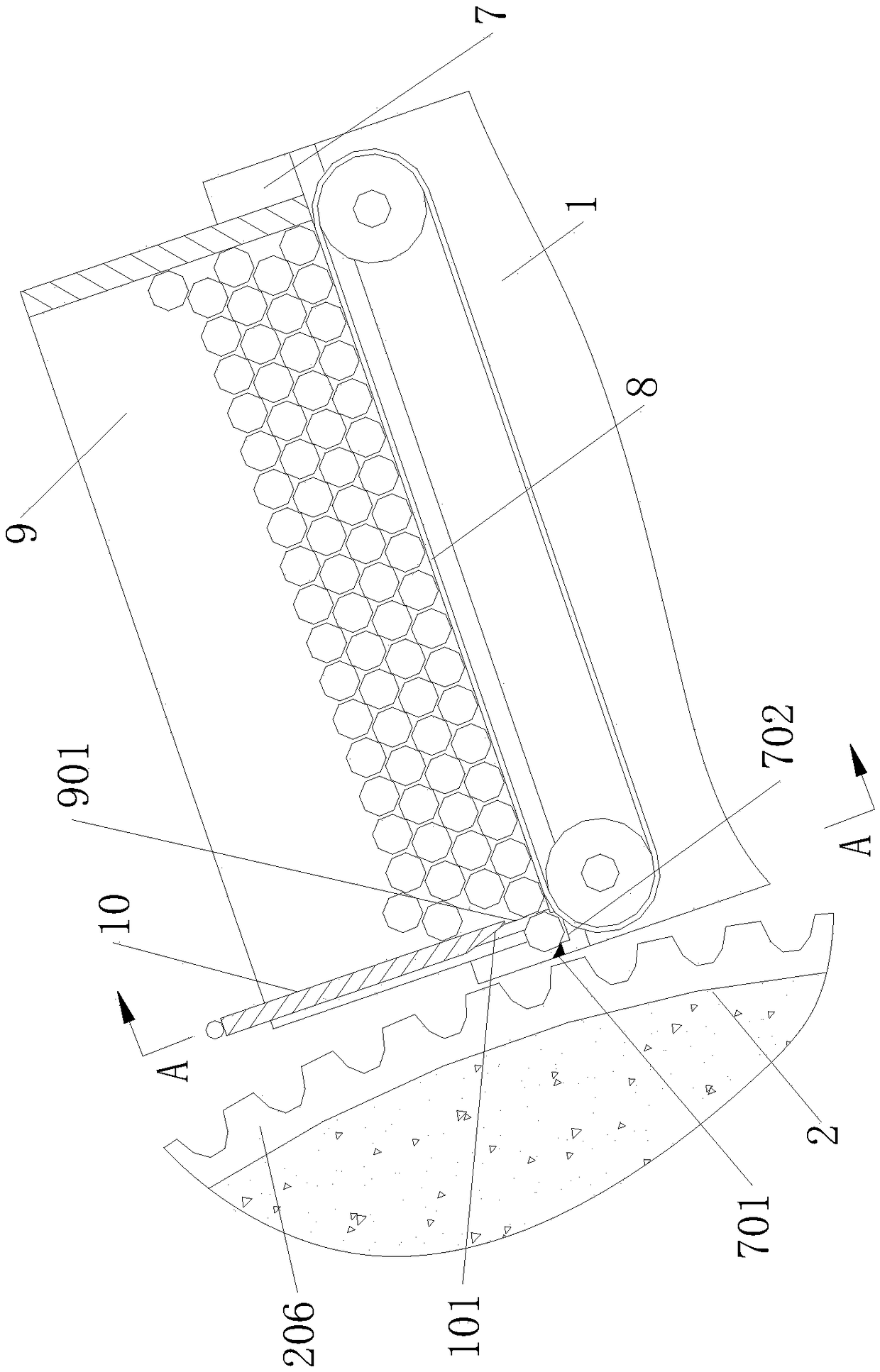

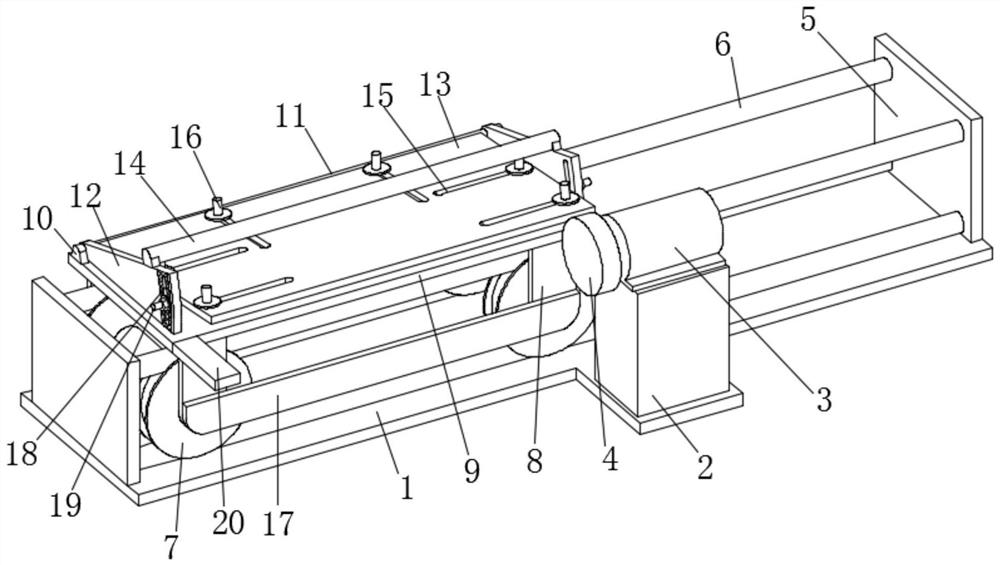

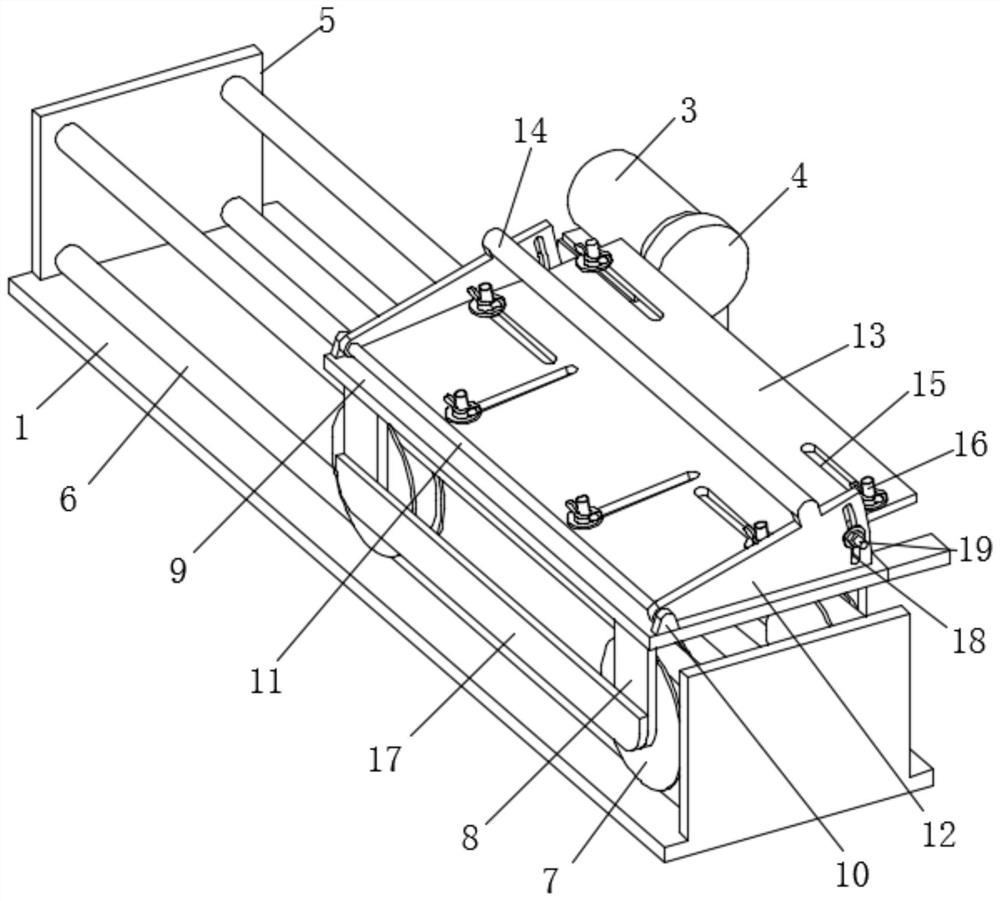

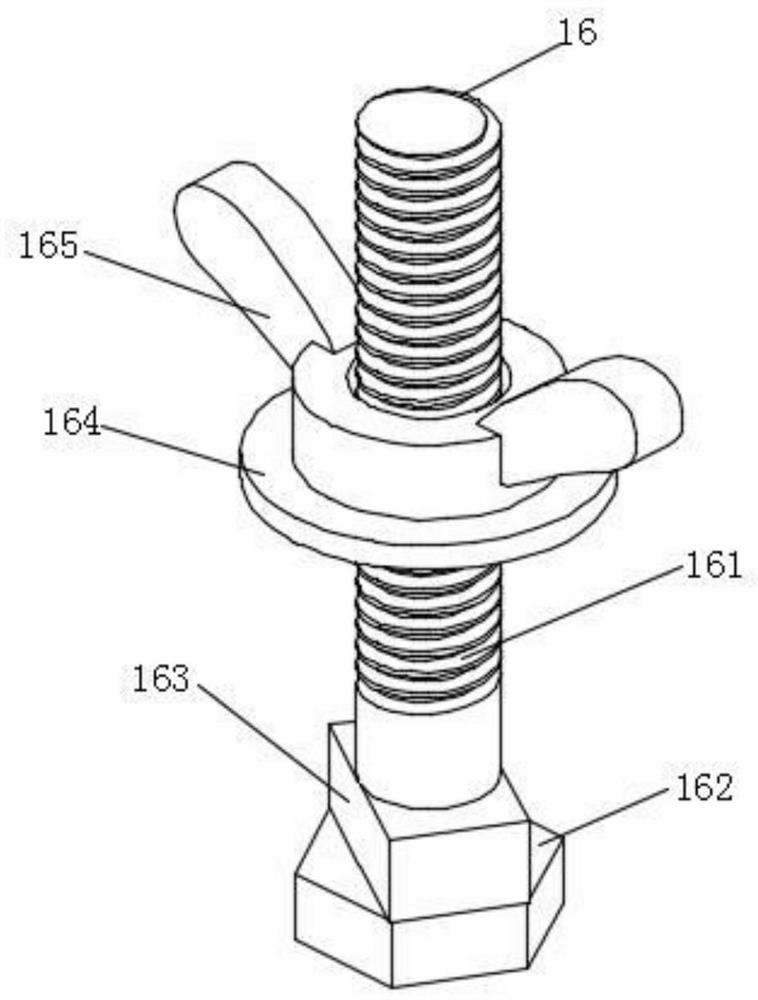

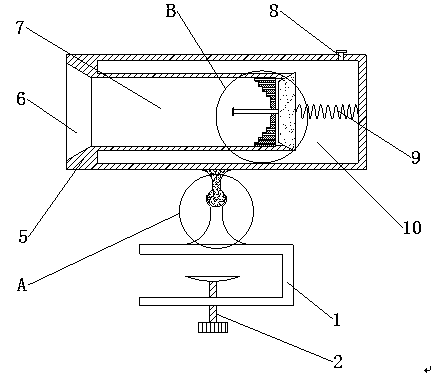

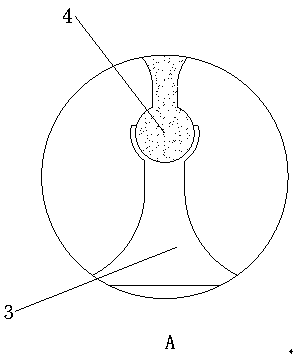

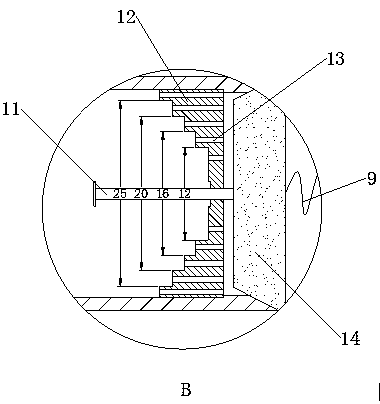

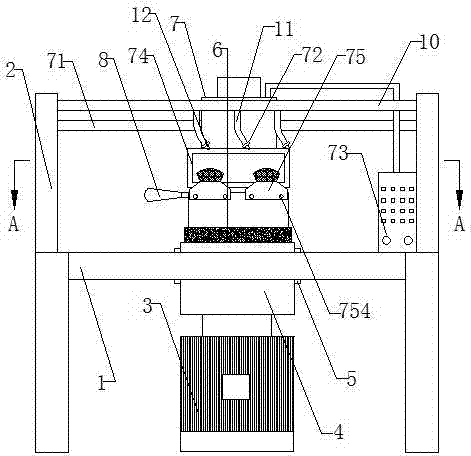

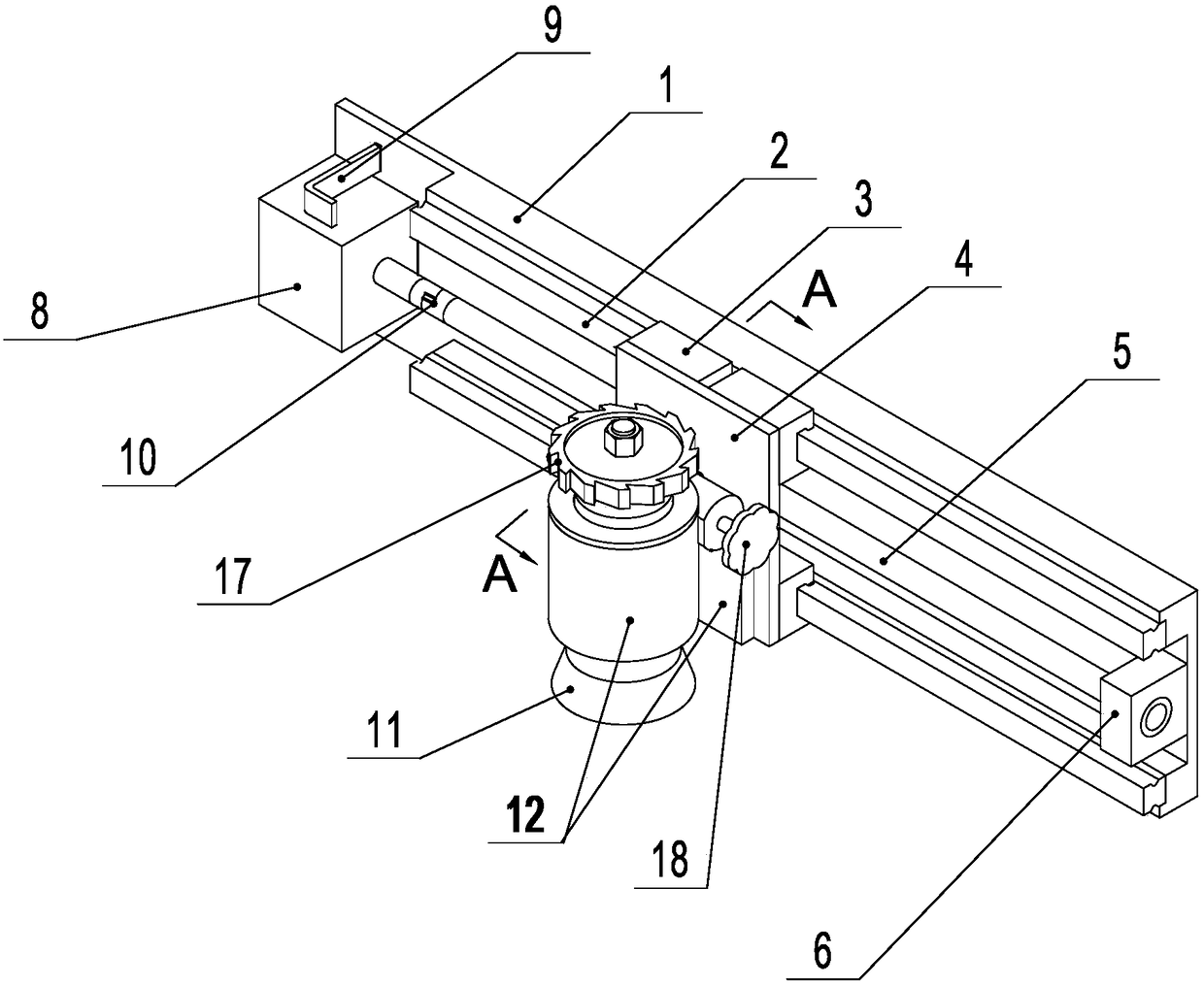

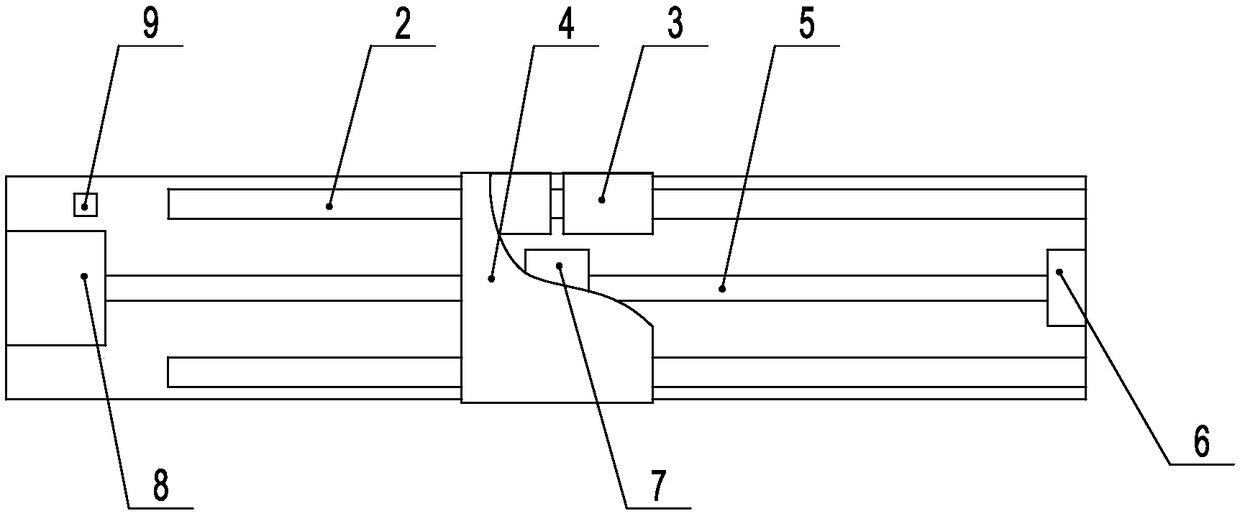

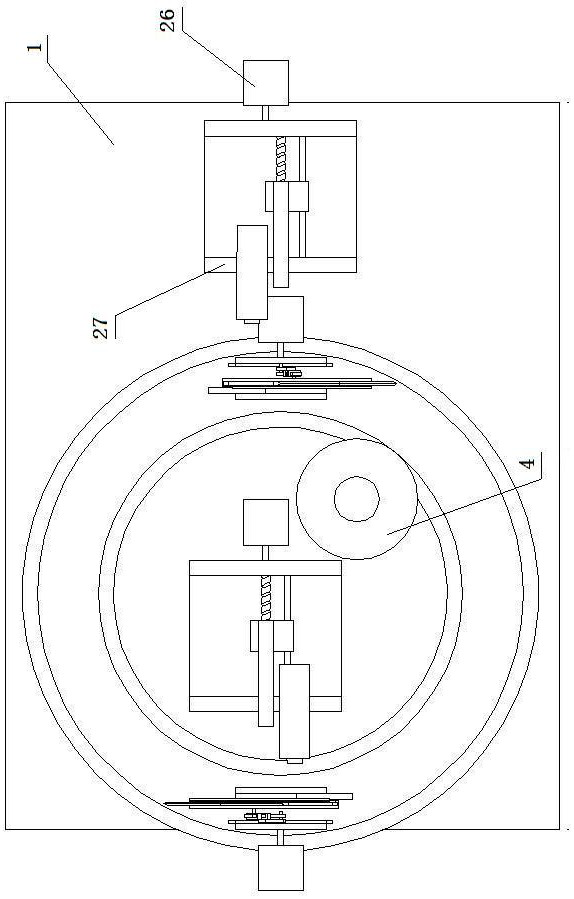

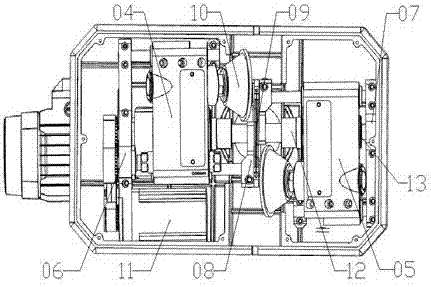

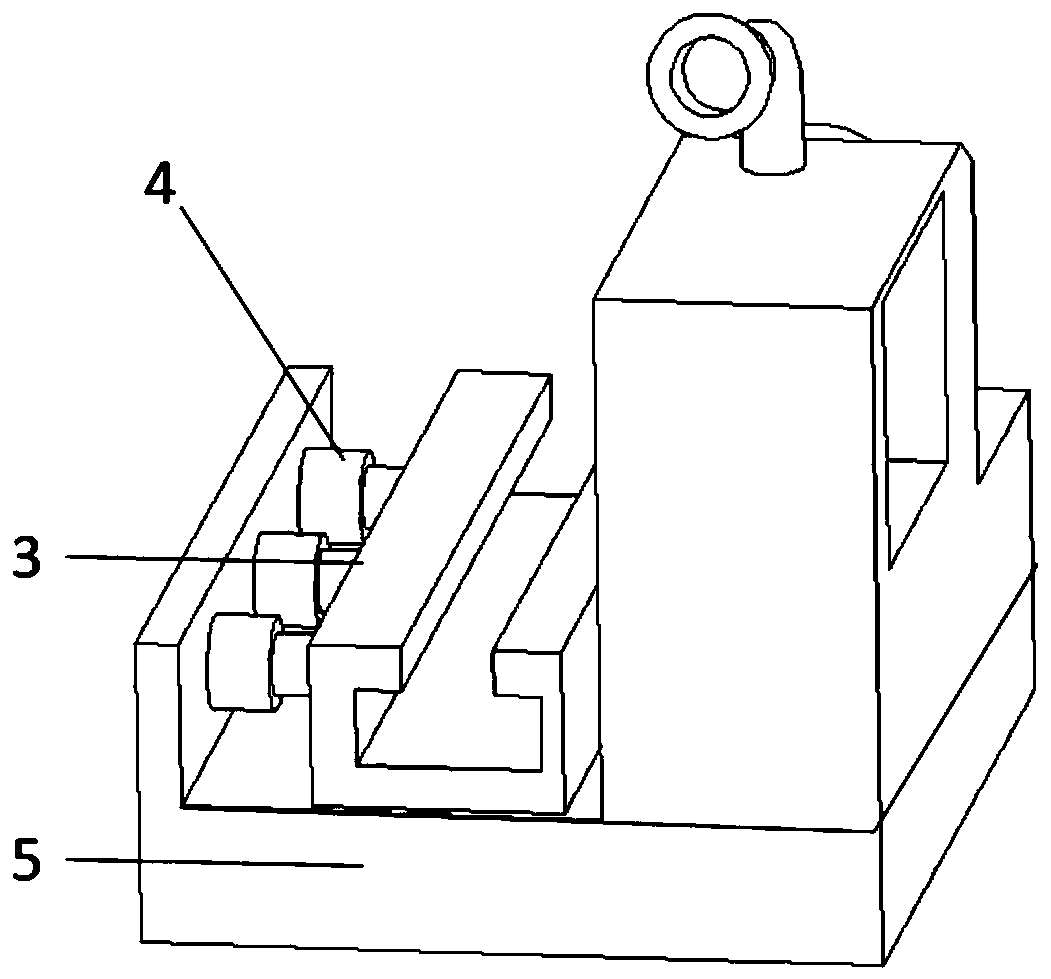

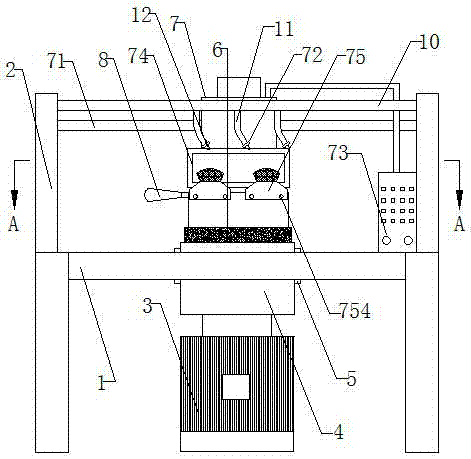

Automatic blade sharpening device with continuous guidable sharpening track and sharpening method

PendingCN113857942AProtect the working environmentImprove sharpening efficiencyGrinding carriagesOther manufacturing equipments/toolsGear wheelEngineering

The invention discloses an automatic blade sharpening device with a continuous guidable sharpening track and a sharpening method. In the prior art, blade sharpening is mainly completed manually, efficiency is low, dust exists, harm to the body is large, the sharpening precision is low, and the cutting edge size after sharpening is not standard. The automatic blade sharpening device comprises a foundation frame (1), two cylindrical protrusions are arranged on the upper plane of the foundation frame, grinding wheel devices are installed on the cylindrical protrusions respectively, a rotating platform frame (2) is installed on the foundation frame, a rotating platform (3) is installed on the rotating platform frame, and an inner ring of the rotating platform is meshed with a gear (4); and an outer side vertical plate A (7), an inner side vertical plate A (6), an inner side vertical plate B (9) and an outer side vertical plate B (8) are sequentially fixed to the upper plane of the rotating platform, the outer side vertical plate A and the outer side vertical plate B are each provided with a crank sliding block device, and the inner side vertical plate A and the inner side vertical plate B are each provided with a blade sharpening track groove device. The sharpening method is used for the automatic blade sharpening device with the continuous guidable sharpening track.

Owner:哈尔滨庚祥科技有限公司

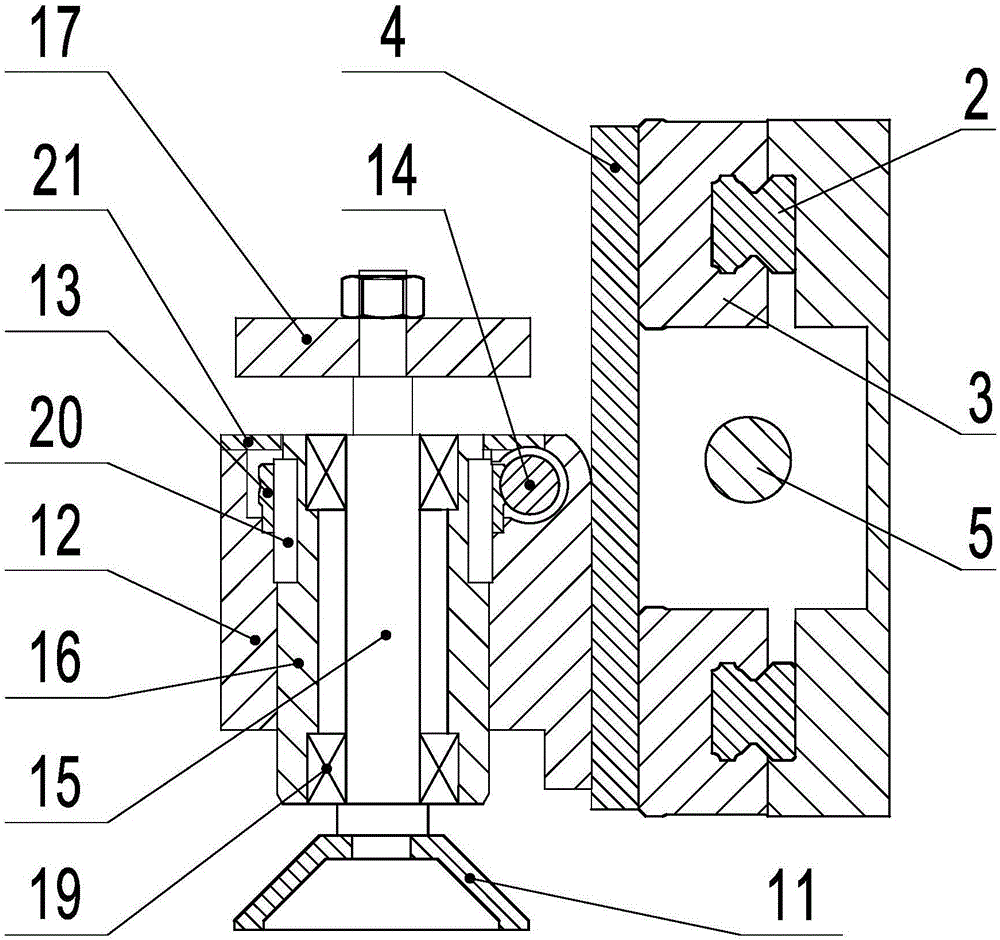

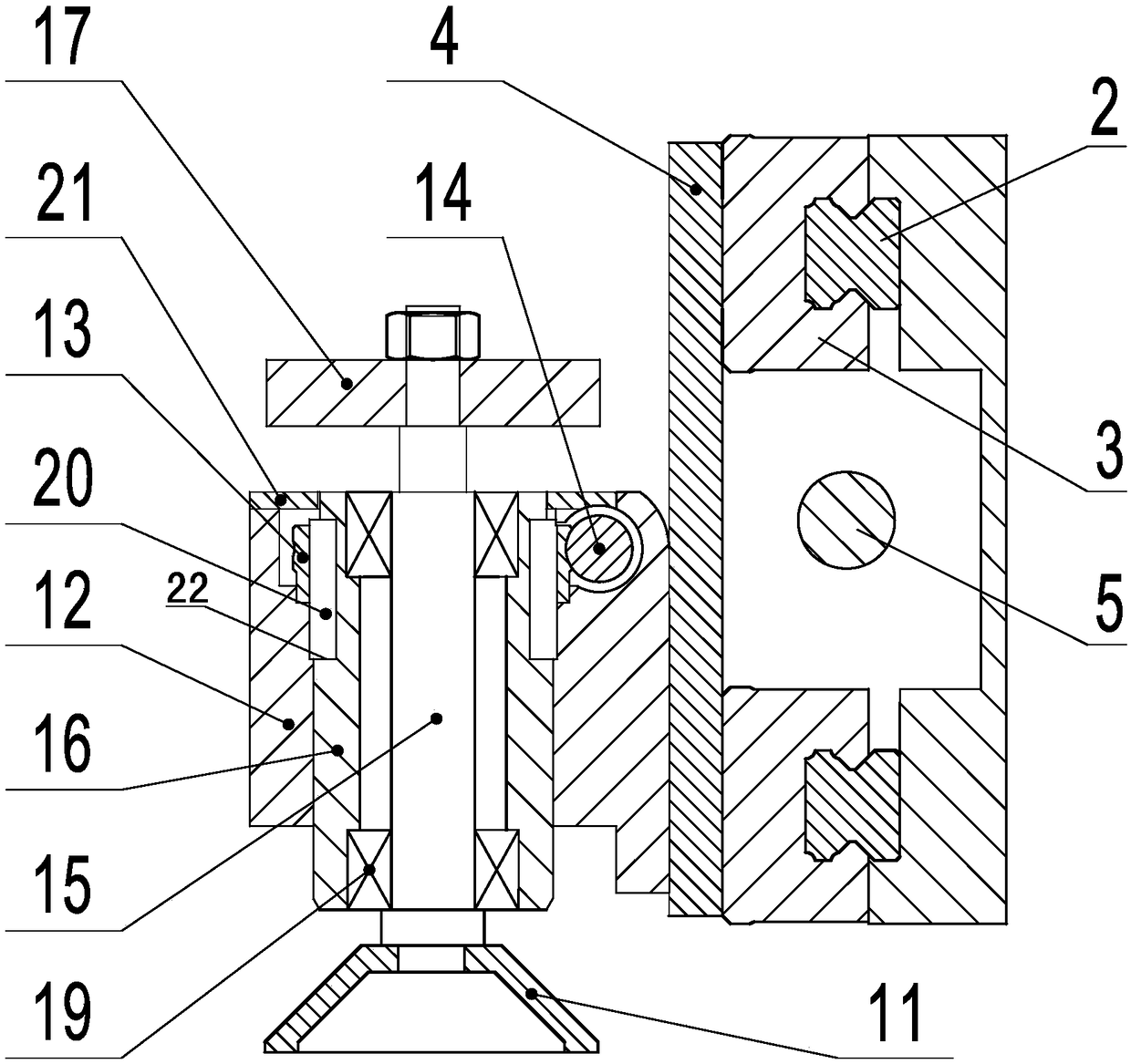

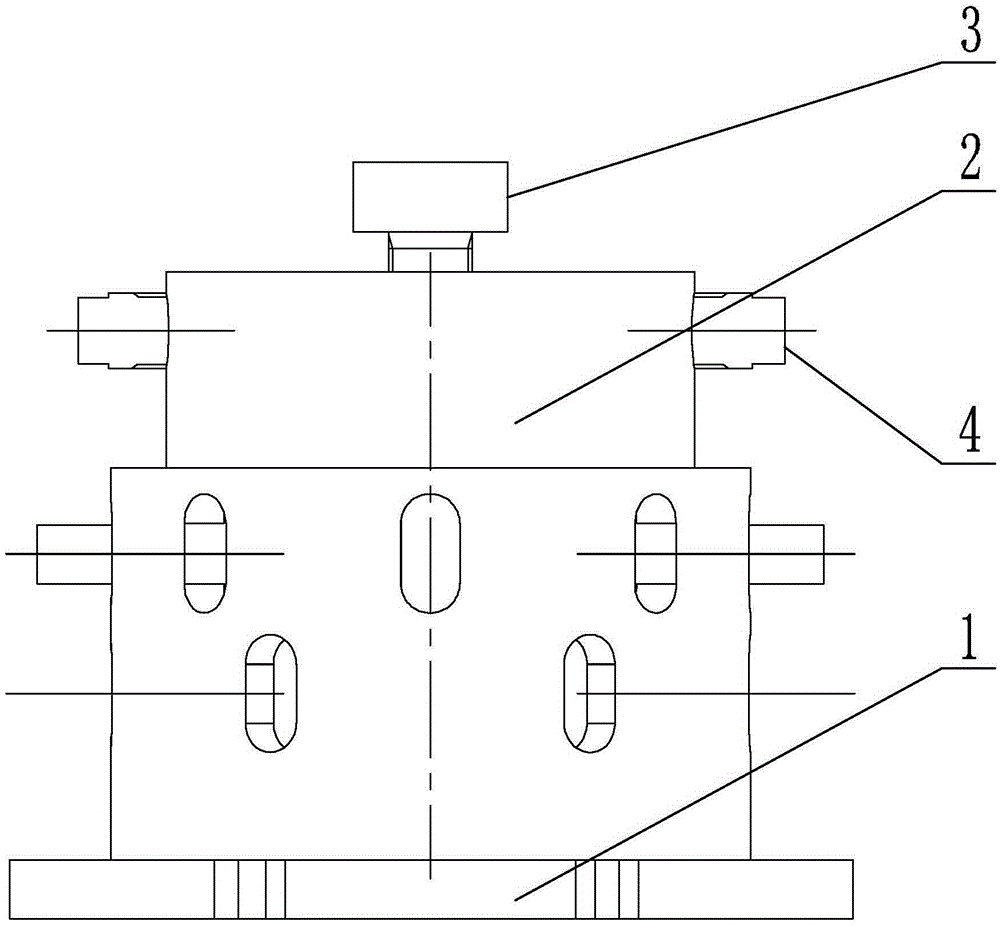

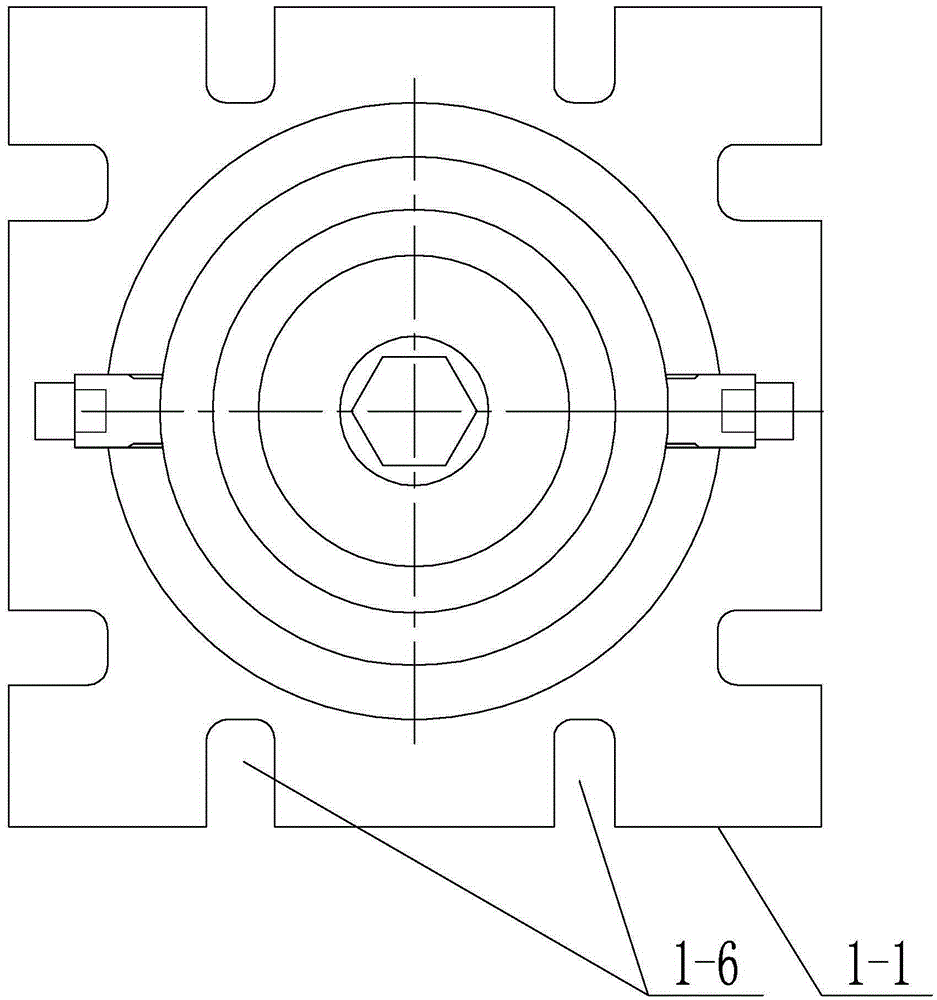

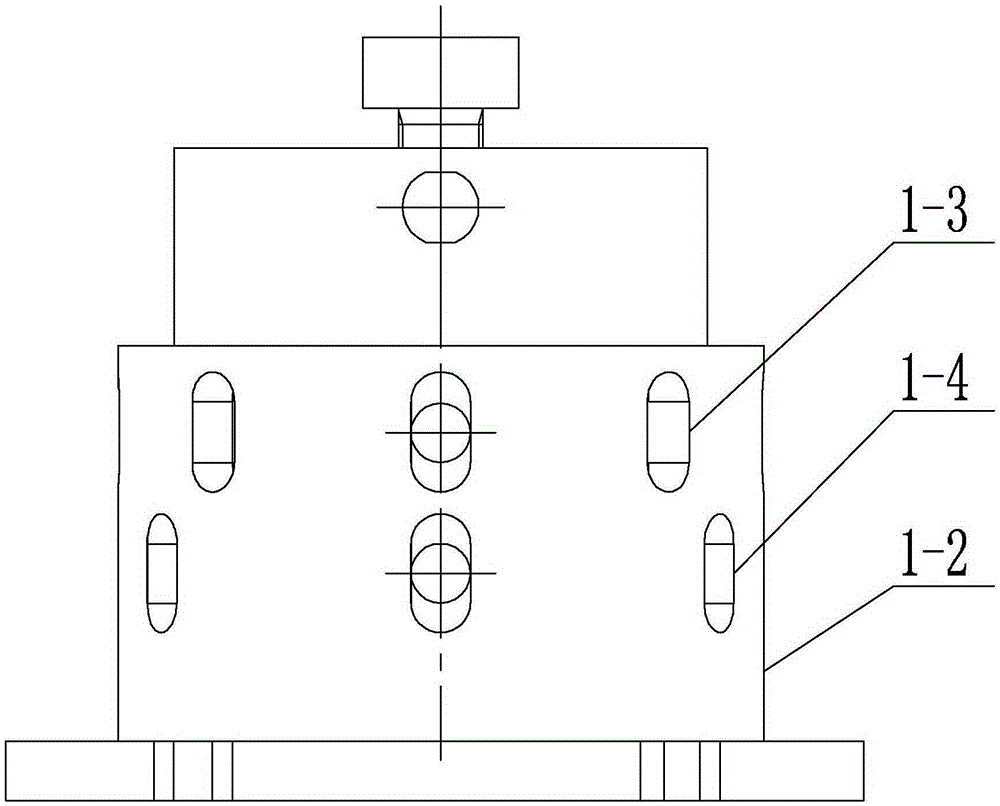

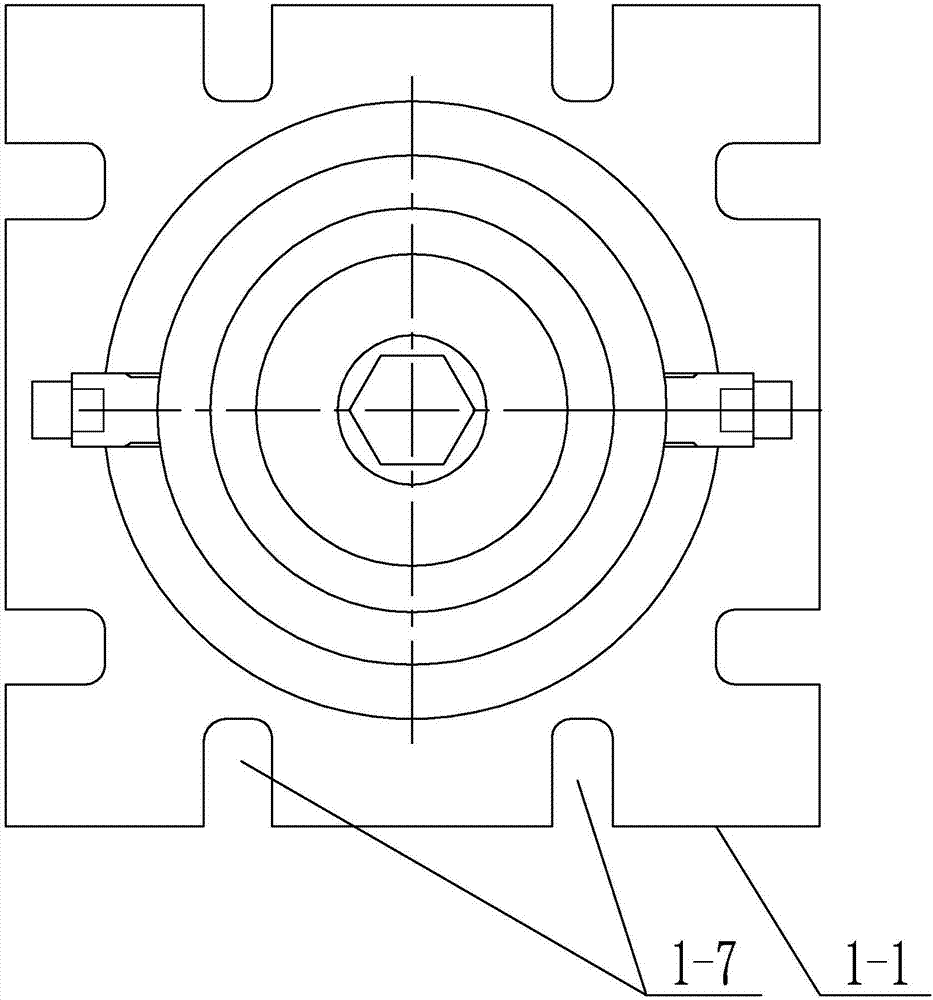

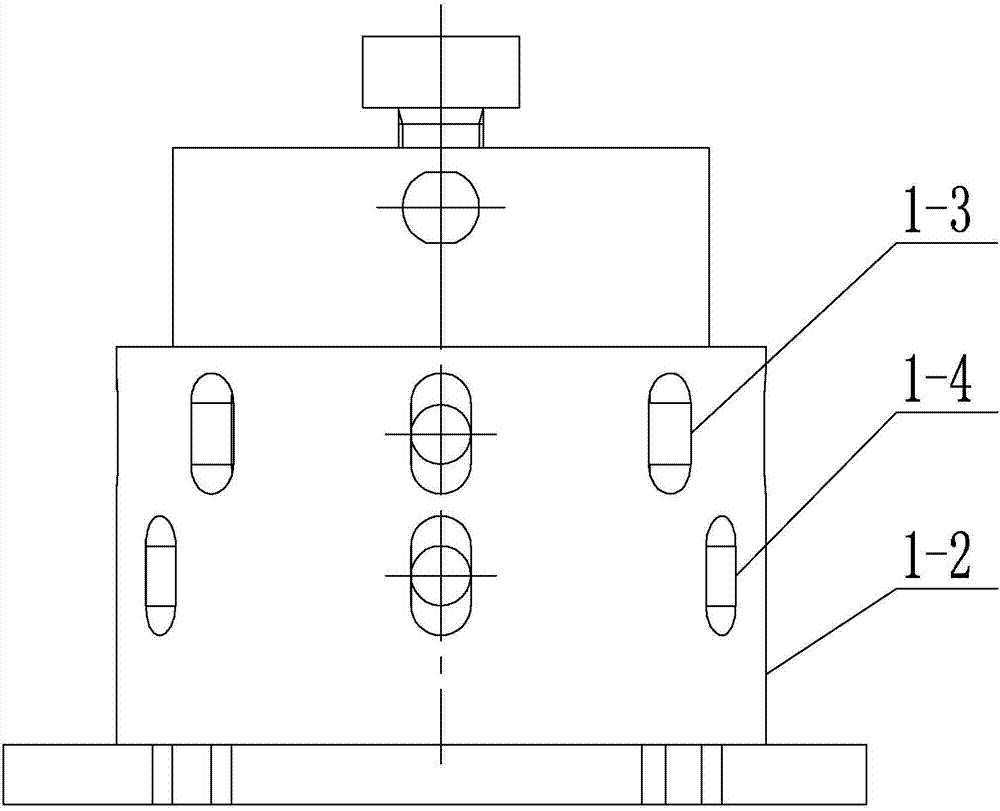

Clamping device for cutter sharpening of large-diameter hollow center taps

ActiveCN105397577AImprove sharpening efficiencySimple structureOther manufacturing equipments/toolsEngineeringSharpening

The invention relates to a clamping device for cutter sharpening of large-diameter hollow center taps. The clamping device solves the problems that in existing clamping devices for cutter sharpening of the large-diameter hollow center taps, the machining efficiency of cutter sharpening of clamps is low and the equipment cost of indexing tables is high. Eight first kidney-shaped through holes are uniformly formed in the upper part of a barrel in the circumferential direction, six second kidney-shaped through holes are uniformly formed in the lower part of the barrel in the circumferential direction, and the lower part of a screw pitch indexing core shaft penetrates into the barrel. An inner hexagon bolt is connected to a threaded hole in a screw mode. Two screw holes are uniformly formed in the outer side wall of the upper part of the screw pitch indexing core shaft in the circumferential direction, and a first double-screw bolt and a second double-screw bolt are arranged on the two screw holes correspondingly. Eight first pin holes corresponding to the first kidney-shaped through holes are formed in the middle of the screw pitch indexing core shaft in the circumferential direction, and six second pin holes corresponding to the second kidney-shaped through holes are formed in the lower part of the screw pitch indexing core shaft in the circumferential direction. The clamping device is used for cutter sharpening of the large-diameter hollow center taps.

Owner:HARBIN TURBINE +1

Domestic automatic knife sharpener

InactiveCN111300174AHigh degree of automationImprove sharpening efficiencyGrinding carriagesGrinding drivesKnife sharpenerElectric machinery

The invention relates to the technical field of knife sharpening machines, in particular to a domestic automatic knife sharpener. A knife fixing table is arranged at the inner bottom of a box. A leadscrew is mounted on the upper portion of the box. Guide rods are mounted on the two sides of the lead screw. One end of the lead screw is connected with a lead screw motor and is rotationally connected with a sliding plate through a nut. The sliding plate is in sliding connection with the guide rods. A side plate is arranged on one side of the sliding plate, and the side plate is arranged on the outer portion of the lead screw in a sleeving manner and is fixed with the box. Knife sharpening motors are mounted at the two ends of the bottom of the sliding plate, and symmetrically-arranged grinding wheels are connected to the knife sharpening motors. A knife fixing trough is arranged on the knife fixing table. A knife containing opening is formed in an end plate on one side of the box. A stopknife is arranged on one side of the knife containing opening and is connected with a stop knife rotary knob on the outer side of the end plate. Fixed needles are fixed to the inner sides of the endplate and the side plate. Locating marbles corresponding to the positions of the fixed needles are arranged in plate holes of the sliding plate. The domestic automatic knife sharpener is high in automation degree and high in knife sharpening efficiency, the labor force is reduced, operation is simple and convenient, and the domestic automatic knife sharpener is suitable for domestic knives.

Owner:曹振勇

Sharpening assembly

PendingCN107457621AReduce wearExtend your lifeGrinding drivesOther manufacturing equipments/toolsDrive motorEngineering

The invention relates to a sharpening assembly. The sharpening assembly comprises a sharpening back plate, a sharpening mechanism, a driving mechanism and an adjusting mechanism. The sharpening mechanism comprises a left shell and a right shell, the left shell and the right shell are arranged in the sharpening back plate and correspondingly provided with sharpening grinding wheels, a sharpening cutter box is arranged between the two sharpening grinding wheels, sharpening grooves are formed in the two sides of the sharpening back plate, and the sharpening grooves are located in the same horizontal position with the sharpening cutter box. The driving mechanism comprises a driving motor, and the driving motor is in driving connection with the two sharpening grinding wheels to control the grinding wheels to rotate. The adjusting mechanism comprises a servo motor, and the servo motor is in driving connection with the left shell and the right shell to control the left shell and the right shell to slide horizontally. The sharpening assembly has the advantages that the design is simple and ingenious and convenient to use, manual adjusting is not needed, the sharpening amount can be precisely controlled, it is ensured that sharpening is also achieved during running of equipment, the sharpening efficiency is greatly improved, the equipment cost is reduced, the equipment size is reduced, and the installation is more convenient.

Owner:NANTONG MUYE MACHINERY

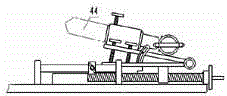

Variable copying tool sharpener

InactiveCN110405547AExtended service lifeImprove sharpening efficiencyGrinding carriagesOther manufacturing equipments/toolsEngineeringSharpening

The invention provides a variable copying tool sharpener. The variable copying tool sharpener is characterized by comprising a rack, a first sliding base is arranged at one end of the rack and can slide along the rack, a second sliding base is arranged on the first sliding base and can slide along the first sliding base, the sliding directions of the first sliding base and the second sliding baseare the horizontal direction and are perpendicular to each other, and a grinding device and a guiding device are arranged on the second sliding base; and a pressing device is arranged at the other endof the rack, and a copying device matched with the guiding device is arranged between the pressing device and the guiding device. By pressing a tool tightly through the pressing device, the copying device positions the radian of a tool edge, the guiding device moves along the positioned radian of the copying device, accordingly, the grinding device performs grinding along the radian of the tool edge, tool sharpening is finished, the service life of the tool is prolonged, and in addition, the tool sharpening efficiency is improved.

Owner:刘贵斌

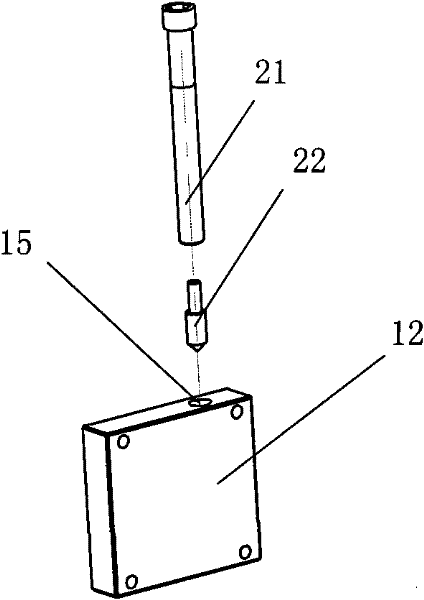

Automatic knife sharpening device and automatic knife sharpening system

PendingCN110757262ASolve the problem of dismantling and grinding one by oneThe degree of grinding is uniformGrinding drivesHarvestersEngineeringFlywheel

The invention relates to the technical field of agricultural machinery, in particular to an automatic knife sharpening device and an automatic knife sharpening system. The automatic knife sharpening system includes the automatic knife sharpening device, the automatic knife sharpening device includes a knife board, a linear feed mechanism and a knife stone, the knife board is used for being detachably connected with a rack of a flywheel knife, the linear feed mechanism is installed on the knife board, the knife stone is installed at the output end of the linear feed mechanism, the grinding surface of the knife stone is arranged perpendicular to the rotation axis of the flywheel knife, and the linear feed mechanism is used for driving the knife stone close to the flywheel knife when the flywheel knife rotates, so that the grinding surface of the knife stone is in contact with a moving blade of the passing flywheel knife. The provided automatic knife sharpening device does not need to beprovided with additional power sources, the knife stone can evenly polish the moving blade of the flywheel knife when the flywheel knife rotates, manpower is saved, the knife sharpening efficiency ishigh, the cutting edge is uniform, and the cutting effect of the flywheel knife is ensured.

Owner:新疆牧神机械有限责任公司 +1

Table type edge grinding machine

InactiveCN111331444AImprove sharpening efficiencyHigh precisionGrinding carriagesGrinding drivesReciprocating motionEngineering

The invention provides a table type edge grinding machine, and belongs to the technical field of turning tool edge grinding. The table type edge grinding machine comprises a rack, an edge grinding device, a movable sliding table and a tool feeding device, the edge grinding device is arranged on one side of the rack and comprises a first driving device and a grinding wheel, and the first driving device drives the grinding wheel to rotate; a groove is formed in the middle of the rack, the movable sliding table is arranged in the groove, and an electric telescopic device drives the movable sliding table to do reciprocating motion in the groove in the radial direction; the tool feeding device is arranged at the top of the movable sliding table, and the second driving device drives the tool feeding device to reciprocate in the axial direction of a translation sliding table; the tool feeding device comprises a tool holder, a first angle adjusting device, a second angle adjusting device and athird angle adjusting device; and the horizontal angle, the vertical angle and the rotating angle of the tool holder are correspondingly adjusted. By means of the table type edge grinding machine, stable feeding can be achieved, and good tool grinding precision can be provided by adjusting any angle for clamping the turning tool.

Owner:SUQIAN COLLEGE

Cutter grinding machine

InactiveCN101700636BImprove sharpening efficiencyExtended service lifeOther manufacturing equipments/toolsAbrasive surface conditioning devicesDrive shaftEngineering

The invention discloses a cutter grinding machine comprises a support. Grinding wheels are arranged on the support through a driving shaft, and the driving shaft is connected with a driving device. The cutter grinding machine is characterized in that the support is provided with a grinding wheel truing device, and the grinding wheel truing device is arranged above the grinding wheels. Because theworn grinding wheels can be trued frequently at any time by the grinding wheel truing device, the cutter grinding efficiency and the service lives of the grinding wheels can be obviously improved andprolonged, and accordingly the cutter grinding efficiency and the service lives of the cutter grinding machine which uses the grinding wheels rather than steel wheels can be also obviously improved and prolonged. Moreover, the trued grinding wheels have smooth surface and obviously improved cutter grinding precision.

Owner:中山市百纳缝纫设备有限公司

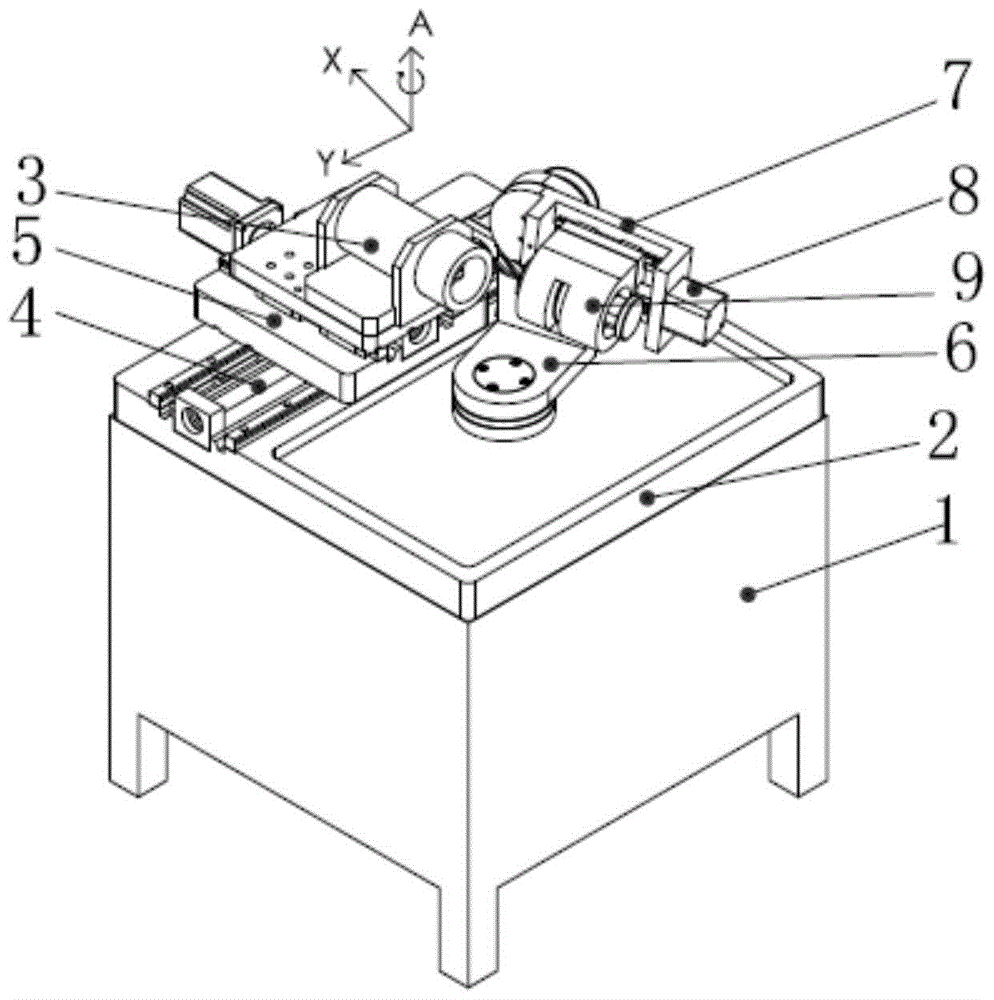

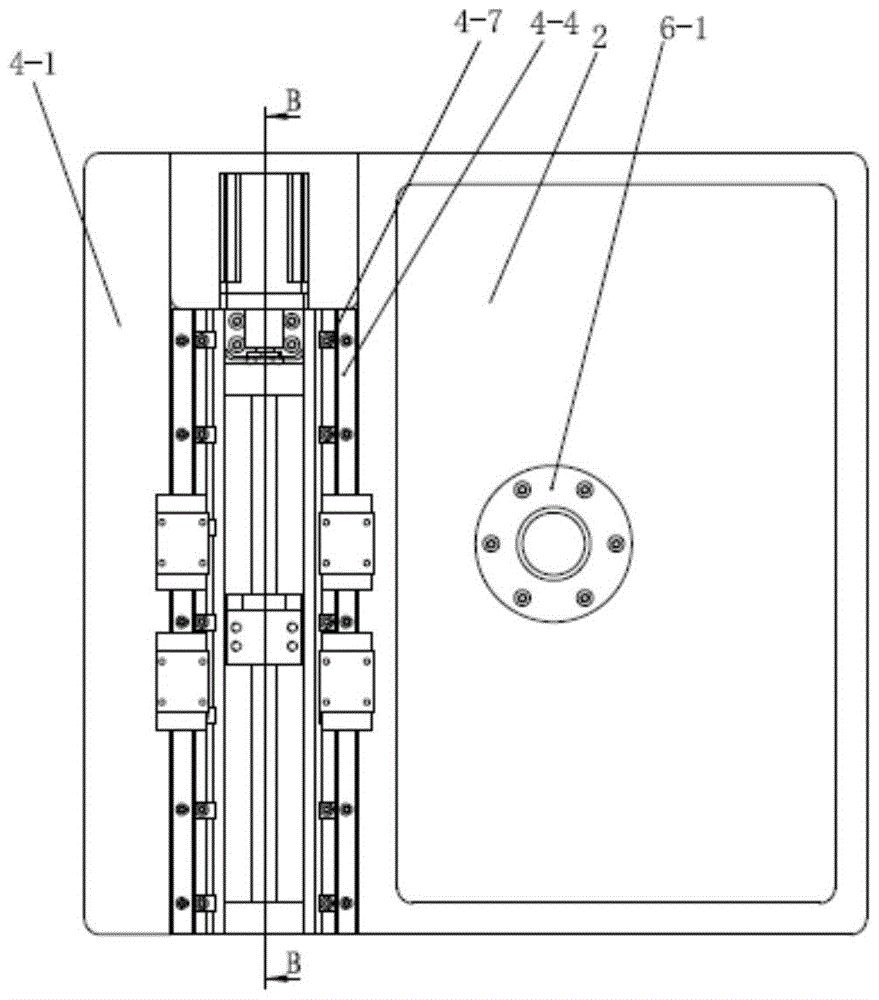

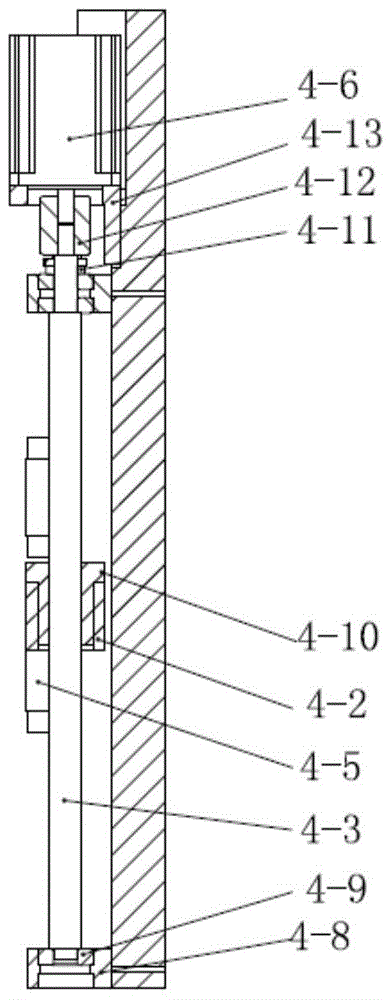

Feed mechanism of a small six-axis linkage sharpening device

InactiveCN103600292BRealize automatic adjustmentCompact structureGrinding drivesGrinding wheelMachine tool

The invention discloses a feeding mechanism of a small six-axis linkage knife grinder. The feeding mechanism of the small six-axis linkage knife grinder comprises a machine tool and a feeding mechanism body arranged on the machine tool. The feeding mechanism is characterized in that the feeding mechanism body consists of a linear feeding mechanism body and a rotary feeding mechanism body; the linear feeding mechanism body comprises an X-axis linear feeding unit, a Y-axis linear feeding unit and a Z-axis liner feeding unit; the rotary feeding mechanism body comprises an A-axis rotary feeding unit, a B-axis rotary feeding unit and a C-axis rotary feeding unit; the Y-axis linear feeding unit and the X-axis linear feeding unit are superposed to each other and are arranged on one side of the machine tool; the A-axis rotary feeding unit, the B-axis rotary feeding unit, the Z-axis linear feeding unit and the C-axis rotary feeding unit are superposed to one another and are arranged on the other side of the machine tool; and the A-axis rotary feeding unit rotates around an A axis, the B-axis rotary feeding unit rotates around a B axis, and the C-axis rotary feeding unit rotates around a C axis, so that the three-axis linkage type rotary feeding mechanism is formed. By six-axis linkage, the relative positions of a knife and a grinding wheel structure are automatically adjusted; and the feeding mechanism has the advantages that the feeding mechanism is convenient to operate, and the machining precision of the knife is high.

Owner:广州市技师学院

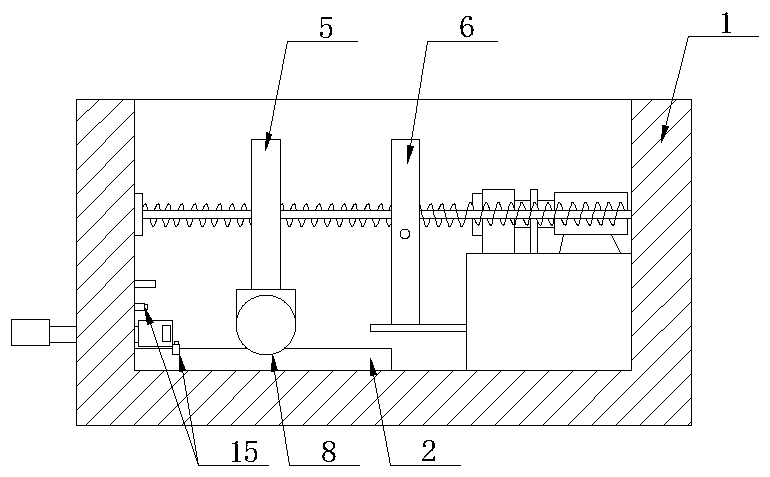

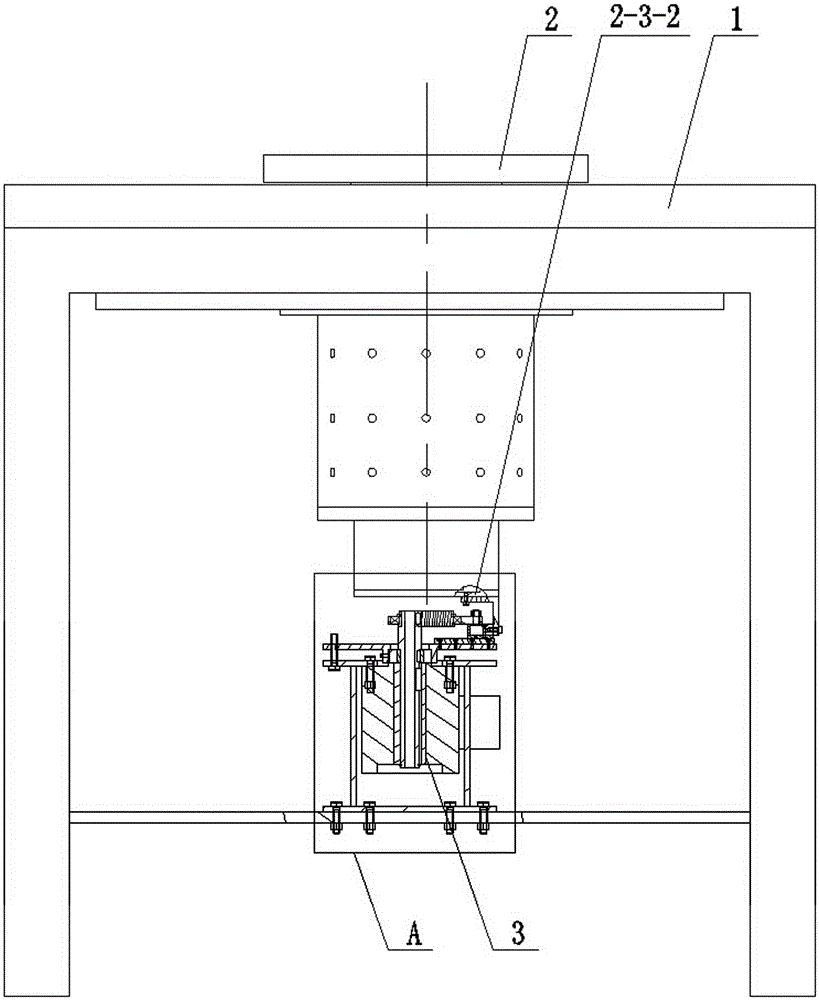

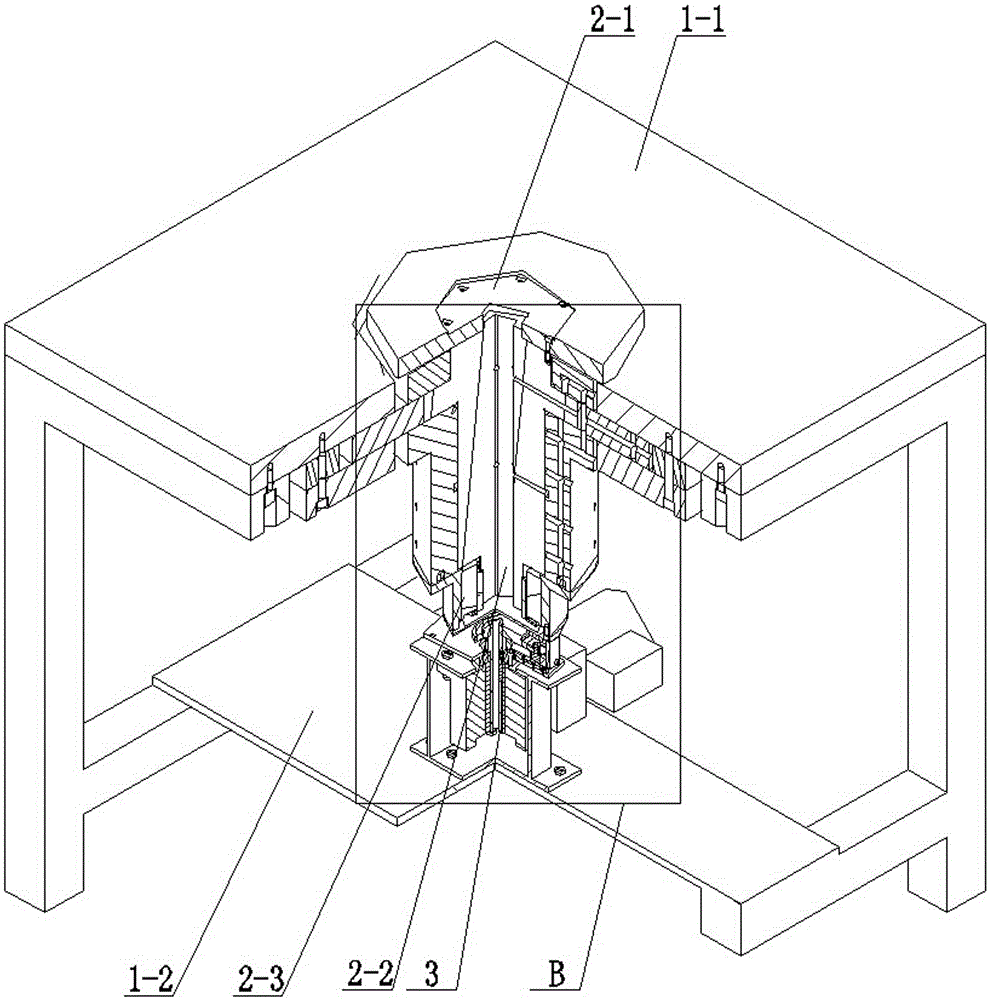

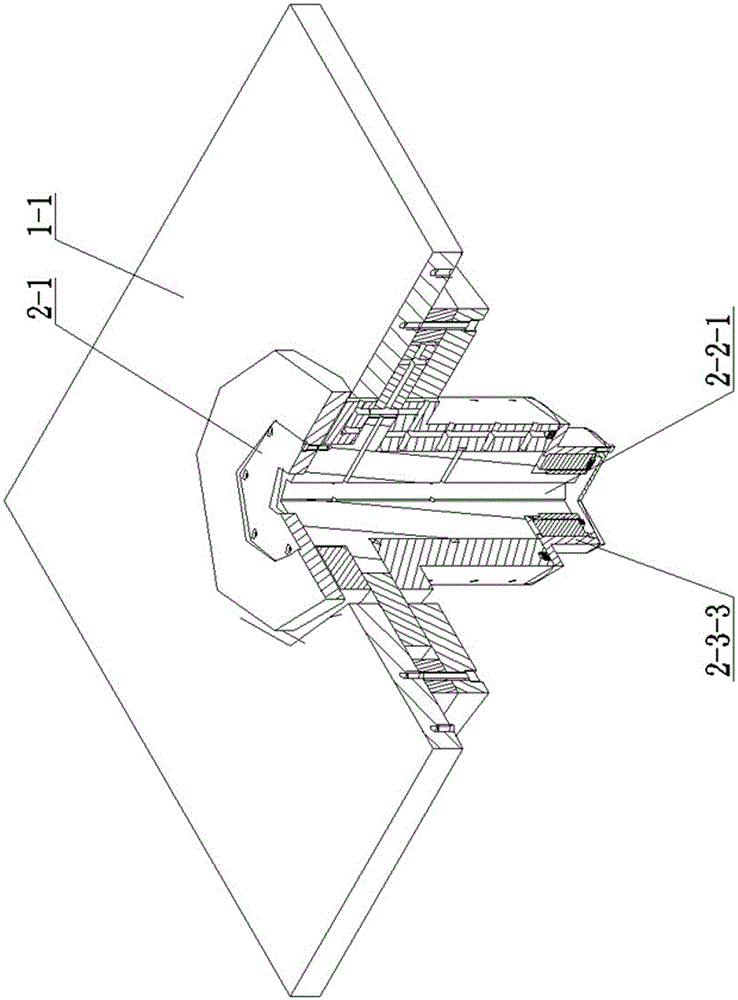

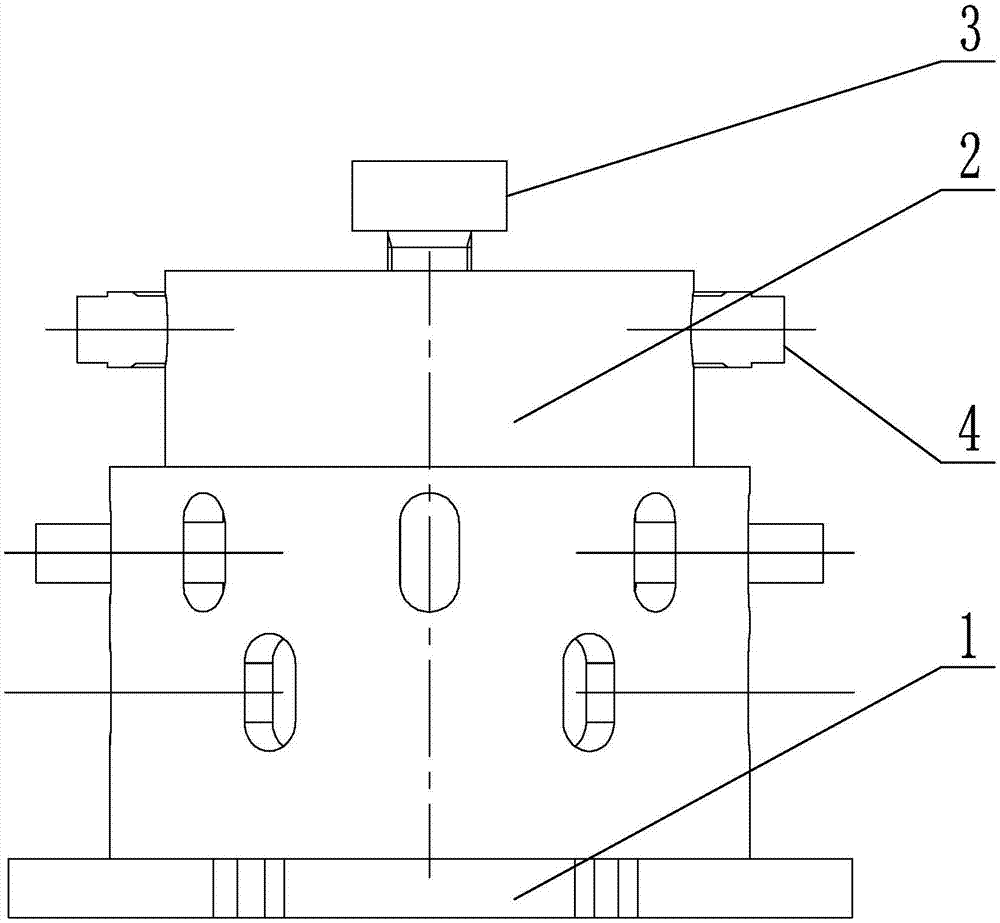

A Planar Decoupling Complicated Trajectory Polishing Equipment

ActiveCN104148996BSatisfy the requirements of sharpening processImprovement of problems such as uniform wear controlGrinding drivesOther manufacturing equipments/toolsNeedle roller bearingBall bearing

Owner:黑龙江哈工华粹智能装备有限公司

A clamping device for sharpening large-diameter taps with internal chips

ActiveCN105397577BImprove sharpening efficiencySimple structureOther manufacturing equipments/toolsSharpeningScrew thread

The invention relates to a clamping device for cutter sharpening of large-diameter hollow center taps. The clamping device solves the problems that in existing clamping devices for cutter sharpening of the large-diameter hollow center taps, the machining efficiency of cutter sharpening of clamps is low and the equipment cost of indexing tables is high. Eight first kidney-shaped through holes are uniformly formed in the upper part of a barrel in the circumferential direction, six second kidney-shaped through holes are uniformly formed in the lower part of the barrel in the circumferential direction, and the lower part of a screw pitch indexing core shaft penetrates into the barrel. An inner hexagon bolt is connected to a threaded hole in a screw mode. Two screw holes are uniformly formed in the outer side wall of the upper part of the screw pitch indexing core shaft in the circumferential direction, and a first double-screw bolt and a second double-screw bolt are arranged on the two screw holes correspondingly. Eight first pin holes corresponding to the first kidney-shaped through holes are formed in the middle of the screw pitch indexing core shaft in the circumferential direction, and six second pin holes corresponding to the second kidney-shaped through holes are formed in the lower part of the screw pitch indexing core shaft in the circumferential direction. The clamping device is used for cutter sharpening of the large-diameter hollow center taps.

Owner:HARBIN TURBINE +1

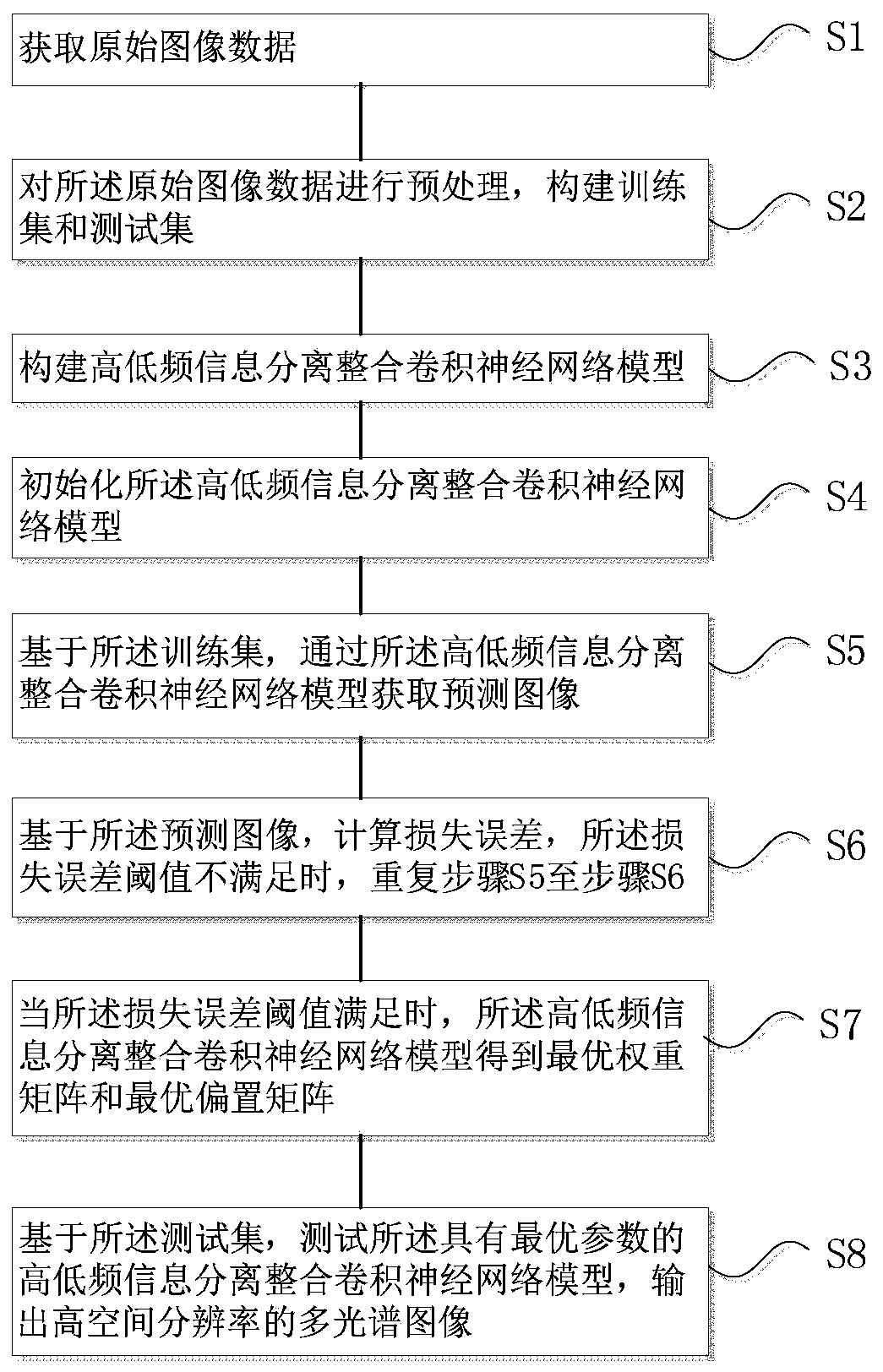

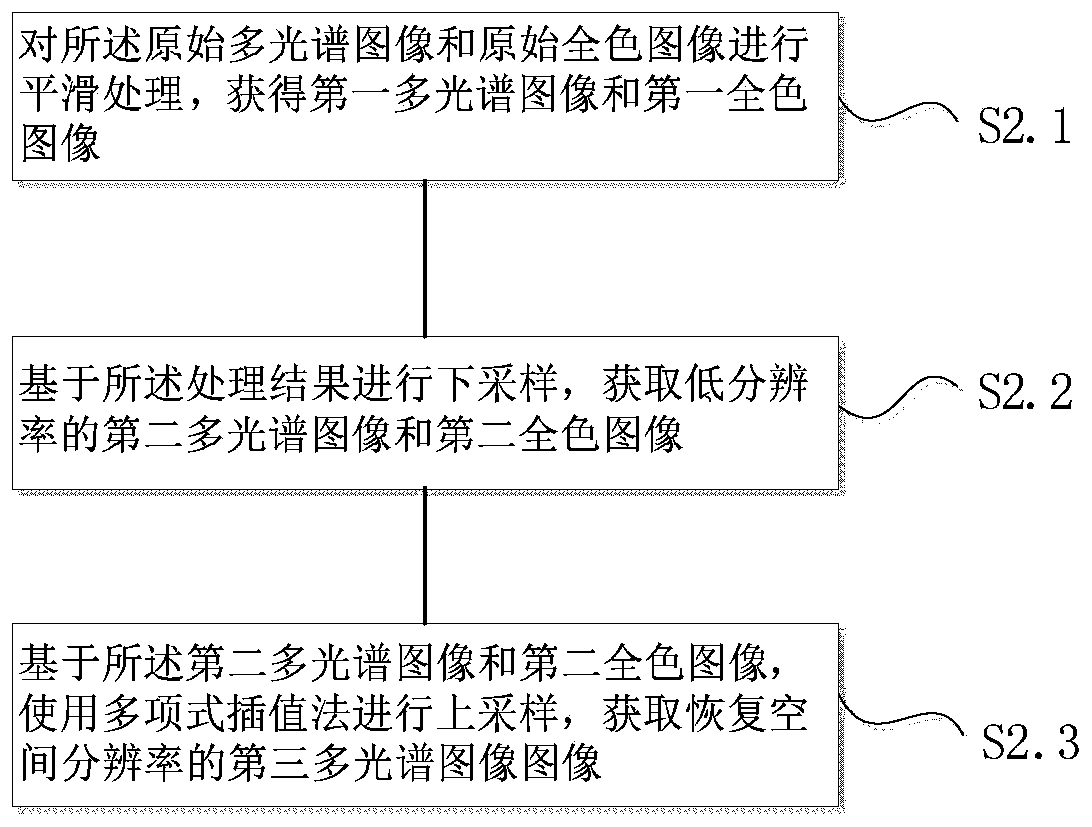

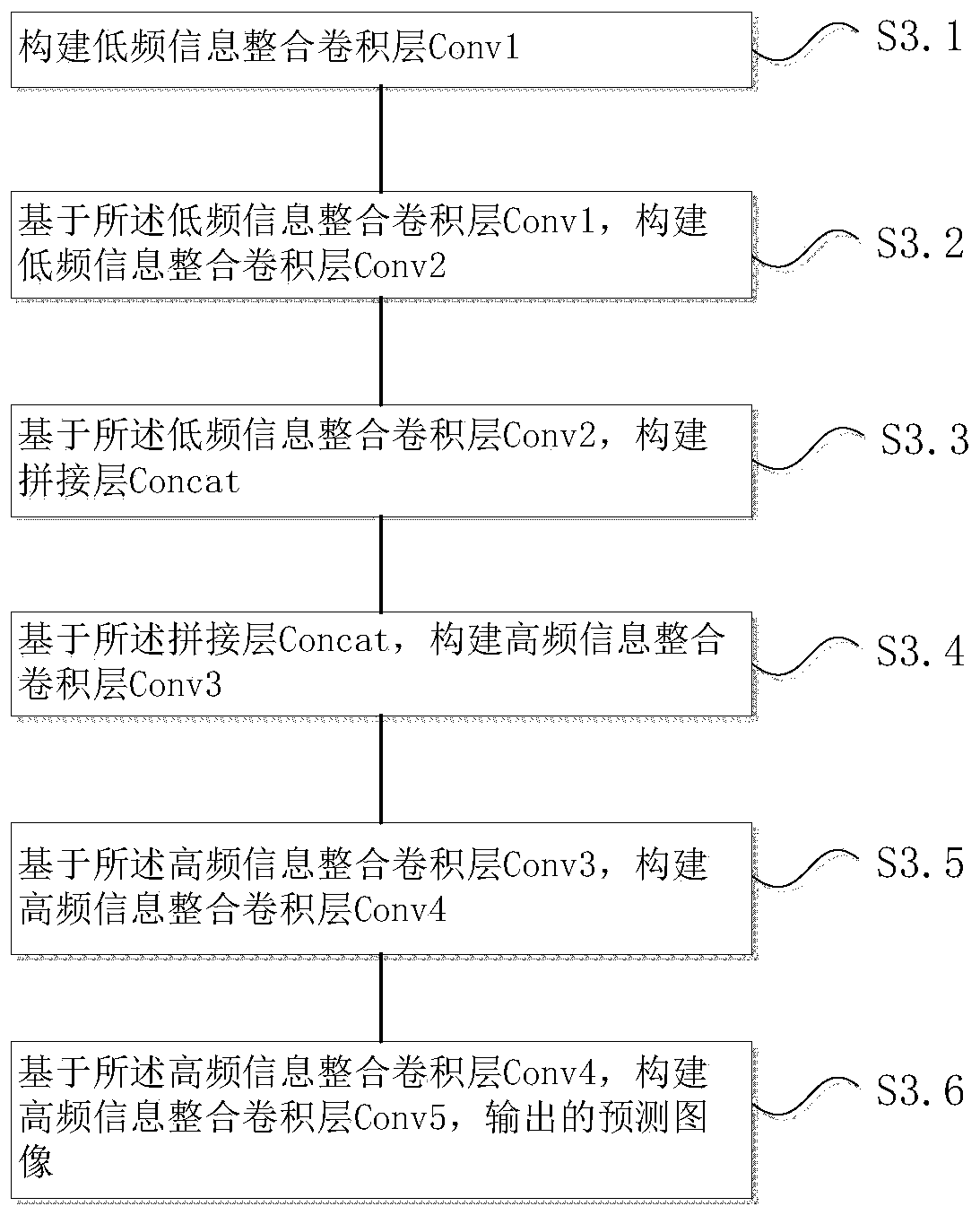

Image sharpening method, electronic equipment and computer readable storage medium

PendingCN110619613AReduce lossesReduce time lossImage enhancementImage analysisNetwork modelHigh frequency

The invention relates to the technical field of image processing, in particular to an image sharpening method, electronic equipment and a computer readable storage medium. The invention provides an image sharpening method, and the method mainly comprises the following steps: obtaining original image data which comprises a multispectral image and a panchromatic image which is completely registeredwith the multispectral image; preprocessing the original image data, and constructing a training set and a test set; constructing a high-frequency and low-frequency information separation and integration convolutional neural network model; training neural network model; when the loss error is greater than or equal to the loss error threshold, repeating the step S5 to the step S6; and when the losserror is smaller than the loss error threshold, obtaining an optimal neural network model.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

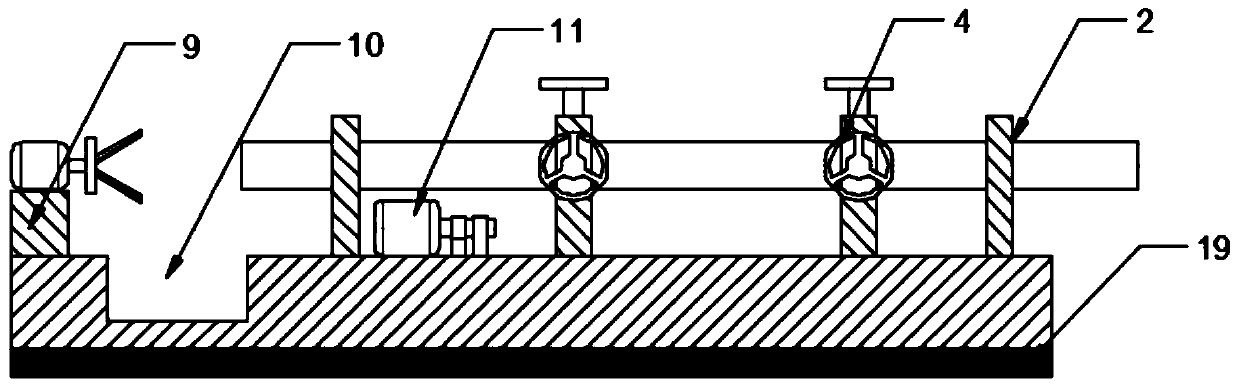

Knife sharpening device and method for sharpening knives for silage machines

ActiveCN112846956BImprove sharpening efficiencySave sharpening timeGrinding feed controlOther manufacturing equipments/toolsControl engineeringKnife blades

A knife sharpening device and a knife sharpening method for a silage machine. The knife sharpening device includes a grinder, a driving part, a rotation detection part and a control part. The shaft drives the grinding tool to move along a preset route. The rotation detection part is used to detect the operation data of the rotation output shaft of the drive part. The rotation detection part is electrically connected to the control part, and the control part controls the operation of the drive part according to the data detected by the rotation detection part. state. The sharpening equipment has a movable grinding tool, which sharpens the blade on the moving path during the moving process, and can be used for sharpening the knife setting roller, which has high sharpening efficiency. The knife sharpening method for the silage machine adopts the above knife sharpening equipment to sharpen the knife rollers of the silage machine, and the knife can be sharpened without disassembling the blade, which shortens the sharpening time and improves the sharpening efficiency.

Owner:新疆牧神机械有限责任公司 +1

Universal drill sharpening machine

ActiveCN102785132BUnique structureExtended service lifeMilling cuttersOther manufacturing equipments/toolsEngineeringSharpening

The invention relates to a sharpening machine, in particular to a universal drill sharpening machine, which comprises a sharpening machine chassis, wherein a sharpening head is fixedly arranged at one side of the sharpening machine chassis, and a drill matched with the sharpening head is fixedly arranged at the other side of the sharpening machine chassis; the sharpening head comprises a sharpening head moving guide rail, and a grinding wheel, a sharpening head rotating disc, a sharpening head power source, a sharpening head moving screw 20 and a sharpening head moving screw 22 which are sequentially arranged on the sharpening moving guide rail from top to bottom, and the grinding wheel is fixed with a grinding wheel compaction flange, and the sharpening head power source is fixedly arranged on the sharpening head rotating disc; and the sharpening head moving screw 20 is supported by a support, and the sharpening head moving screw 22 is used for controlling the sharpening head moving screw. The sharpening machine has the advantages of unique structure, accuracy, efficiency, practicality, resistance and high sharpening efficiency, various problems caused by artificial grinding of drill are solved, the service life of the drill is prolonged, and the drilling precision is high.

Owner:KOCEL EQUIP

Double whetstone automatic sharpening device for kitchen knife processing

ActiveCN104493648BPlay a protective effectImprove clamping effectOther manufacturing equipments/toolsGrinding work supportsFailure rateEngineering

The invention discloses an automatic double-grindstone knife grinding device for processing kitchen knives. The automatic double-grindstone knife grinding device for processing kitchen knives comprises an operation table, wherein side brackets are vertically arranged on two sides of the upper end surface of the operation table; a water spraying mechanism is arranged between the two side brackets; a horizontal moving device is arranged between the two side brackets; a rotary driving mechanism is arranged at the bottom of the operation table; a rotation shaft which penetrates through the operation table is arranged atthe upper end of the rotary driving mechanism; double grindstone sets are fixedly arranged on the rotation shaft; a bearing is fixedly arranged on a part at the periphery of the rotation shaft on the operation table; the bearing is embedded into the operation table and sleeves the rotation shaft. The automatic double-grindstone knife grinding device has the benefits that the knife grinding device is capable of simultaneously grinding blades of two sides of knife bodies; the knife grinding efficiency and uniformity of the ground blades of the knife bodies on two sides are improved; the automatic double-grindstone knife grinding device is simple in structure, easy to operate, low in cost, high in knife grinding efficiency, low in failure rate, high in automatic degree and firm to clamp; the time is reduced; the labor is alleviated; the water is conveniently and uniformly sprayed; the knife bodies are convenient to fix and demount.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com