Abrasive wheel micro-point abrasive particle electric heating chemical sharpening device and online control method thereof

A control method and micro-tip technology, applied in the control of workpiece feed movement, manufacturing tools, grinding machine parts, etc., can solve the problem of inconvenient control of abrasive sharpening and leveling effect, prone to arc discharge, uncontrollable Pulse discharge trimming parameters and other issues, to avoid the detection and data processing process, and improve the efficiency of trimming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

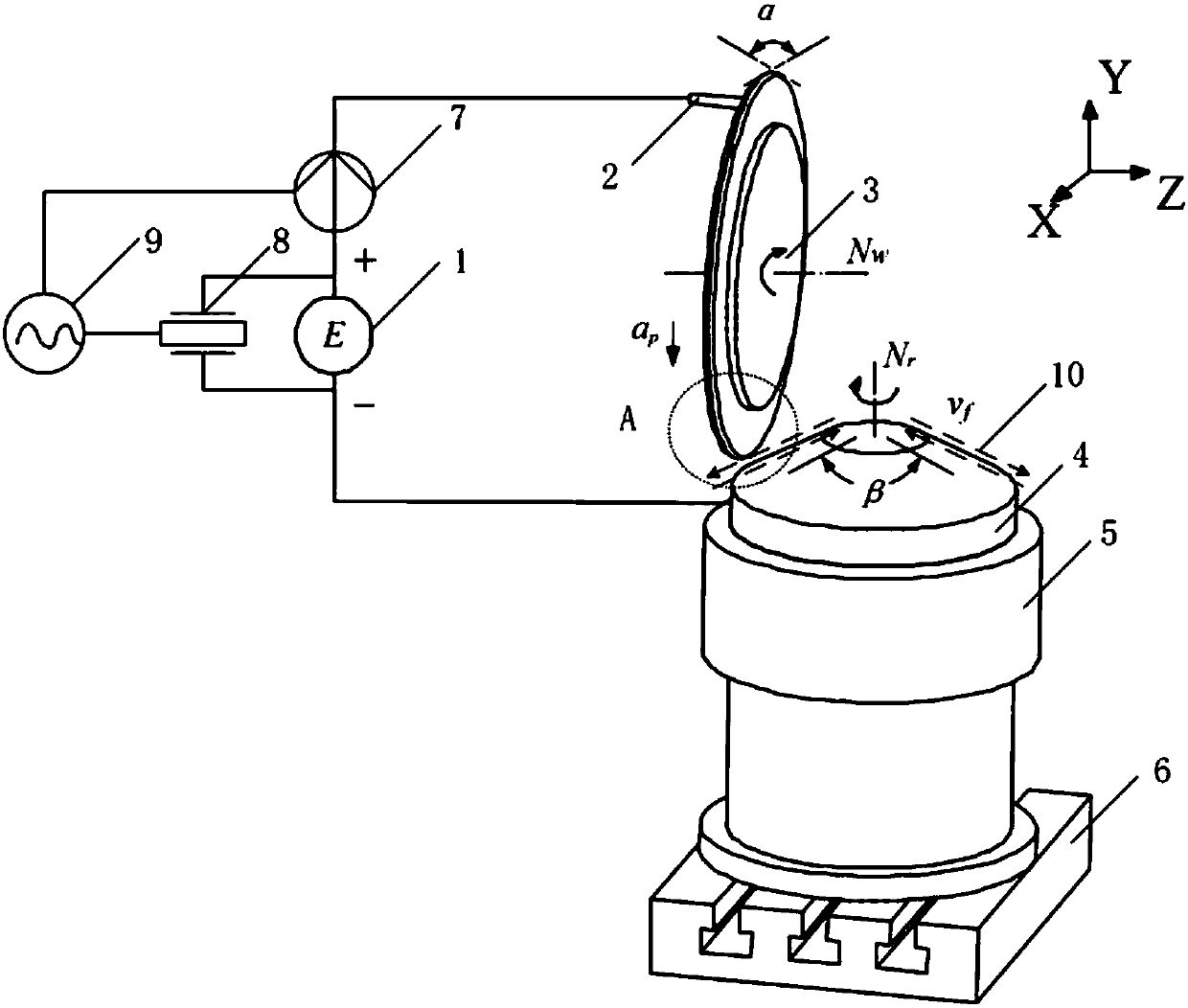

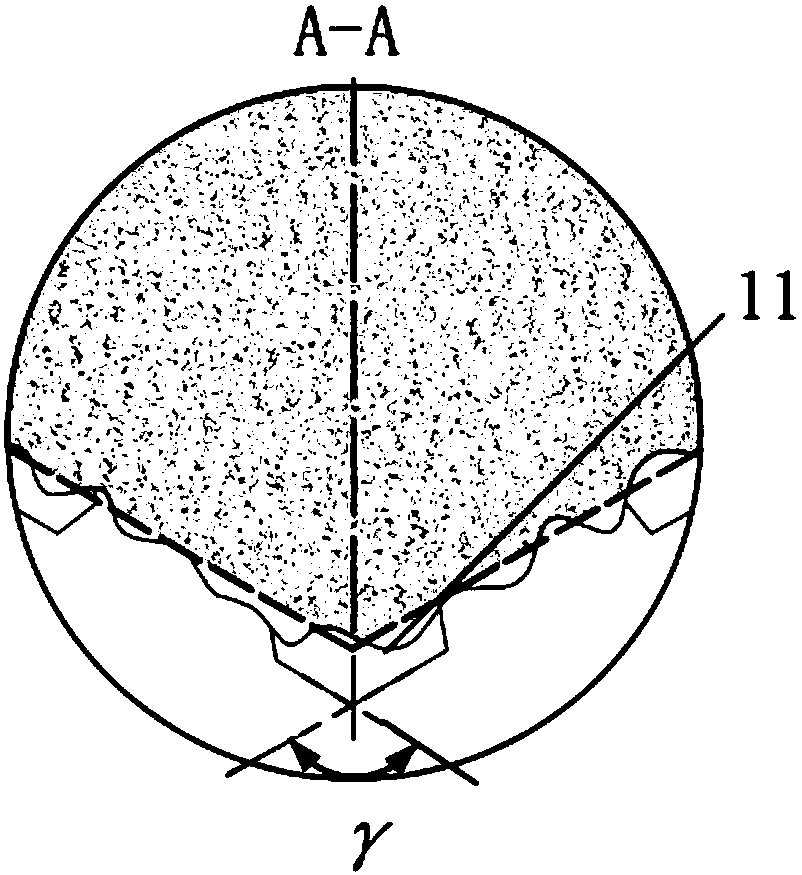

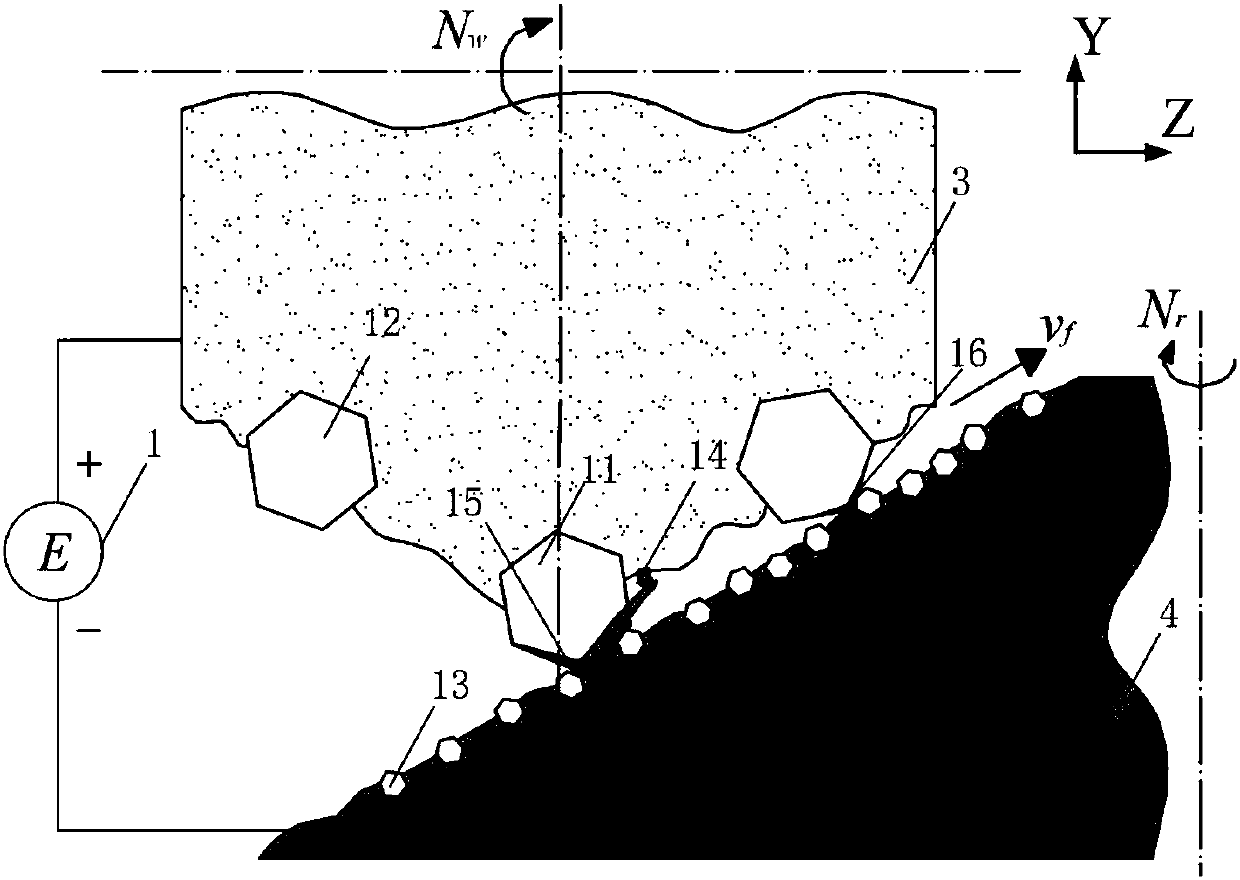

[0056] like figure 1 As shown, an electrothermochemical sharpening device for grinding wheel micro-tip abrasive grains, including power supply 1, graphite brush 2, micro-tip grinding wheel 3, grinding cone 4, rotating device 5, CNC grinding machine table 6, current sensor 7 , voltage sensor 8, oscilloscope 9, described rotating device 5 is fixed on the numerically controlled grinder workbench 6, and described grinding cone table 4 is fixed on the rotating device 5, and the center line micro-tip grinding wheel 3 of described rotating device 5 The center line of the center line is vertical, and the micro-tip grinding wheel 3, the graphite brush 2, the current sensor 7, the power supply 1, and the grinding cone 4 are connected in order to form a discharge circuit in a posit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com