Spiral and orderly arranging fiber tool capable of conducting positive rake angle machining and preparation method thereof

A technology of cloth fibers and fibers, which is applied in the field of helically arranged fiber cutters and its preparation, can solve the problems of not considering the residual material and the roughness of the workpiece processing surface, so as to reduce the processing surface roughness, improve cutting performance and The processing efficiency and fiber blade height remain consistent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

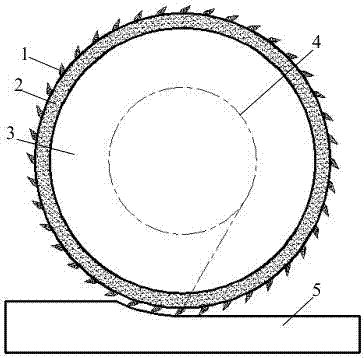

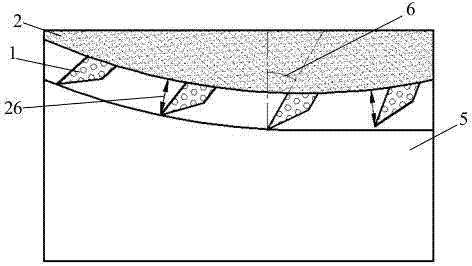

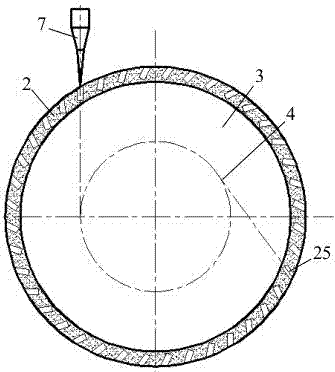

[0036] see Figure 1 to Figure 10, the helically arranged fiber cutters capable of processing positive rake angles include: fiber 1, carcass 2 and steel matrix 3. The fiber 1 is tangent to the base circle 4 in the steel matrix 3, and the fiber 1 is in contact with the workpiece 5 at a positive rake angle 6 during cutting, which can realize the processing of the fiber cutter 18 with a positive rake angle 6, which is larger than that of a traditional grinding wheel. Compared with negative rake angle processing, the grinding force ratio and grinding temperature are greatly reduced, and the cutting performance and processing efficiency are significantly improved. The fibers 1 are arranged in a multi-head helix 24 on the outer circumferential surface of the carcass 2 and are arranged in an orderly manner with front and rear dislocations, and ens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com