Patents

Literature

207results about How to "Guaranteed coaxial" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

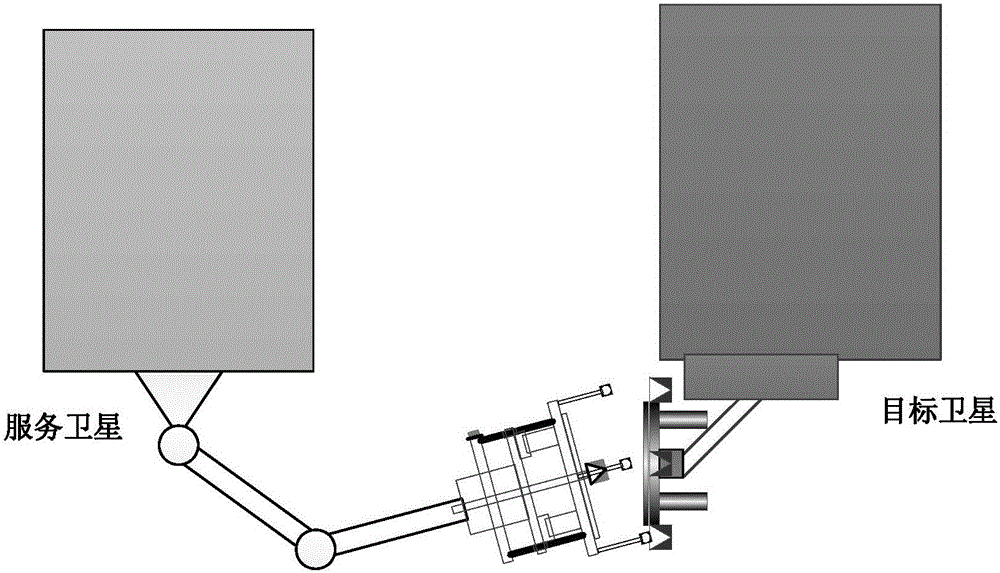

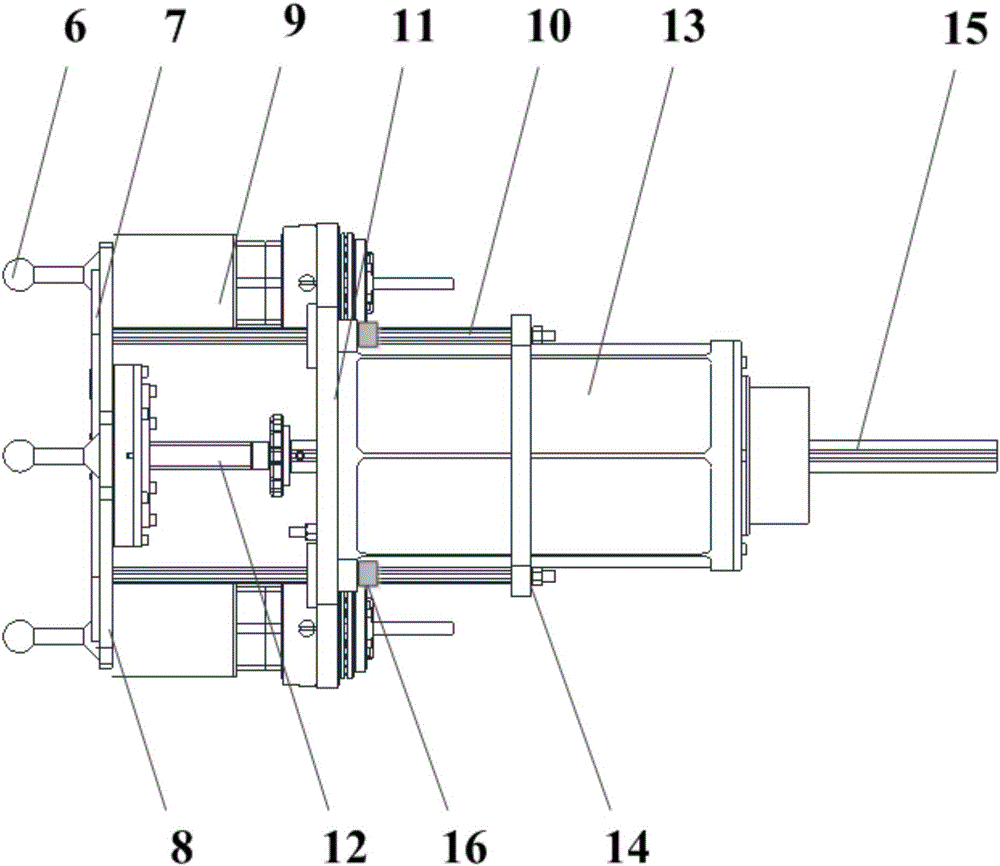

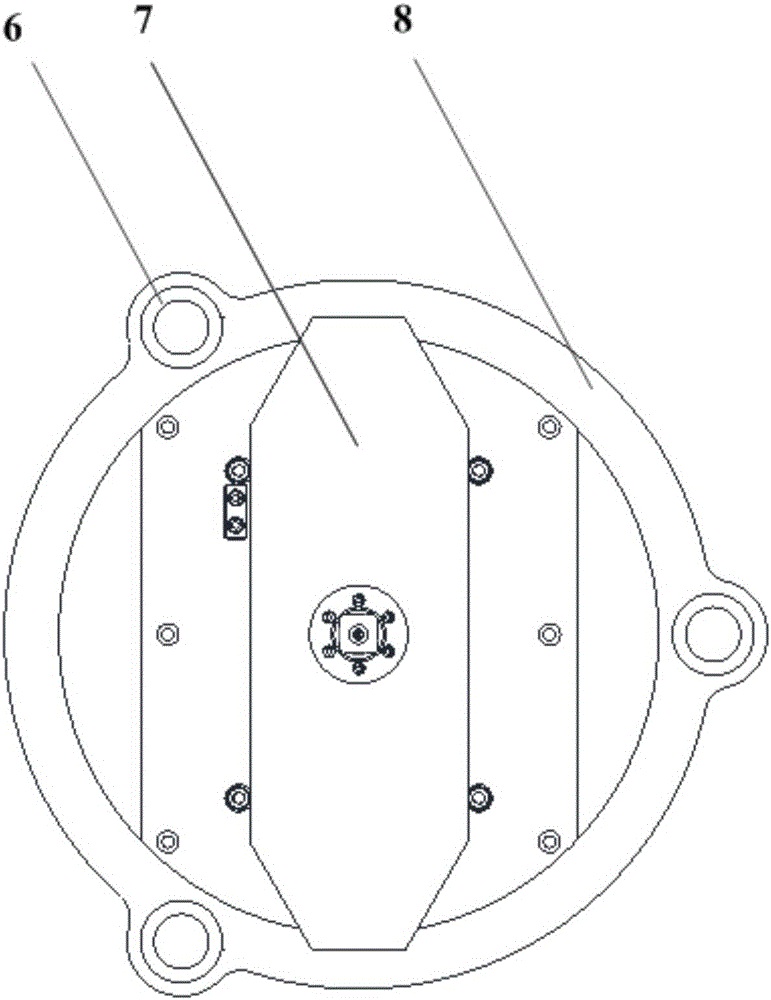

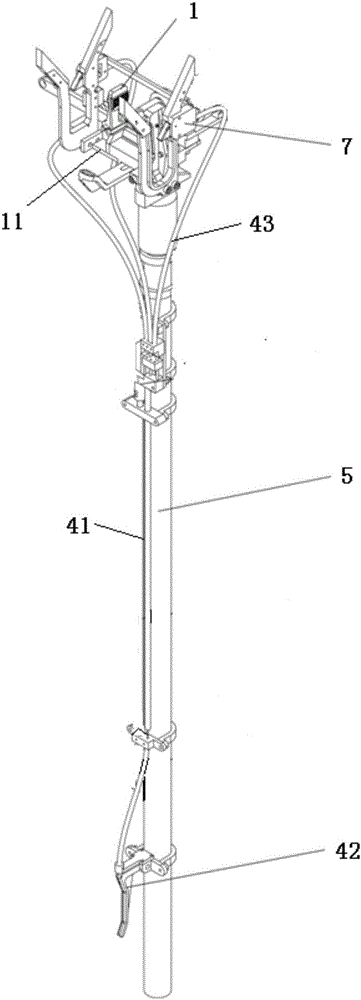

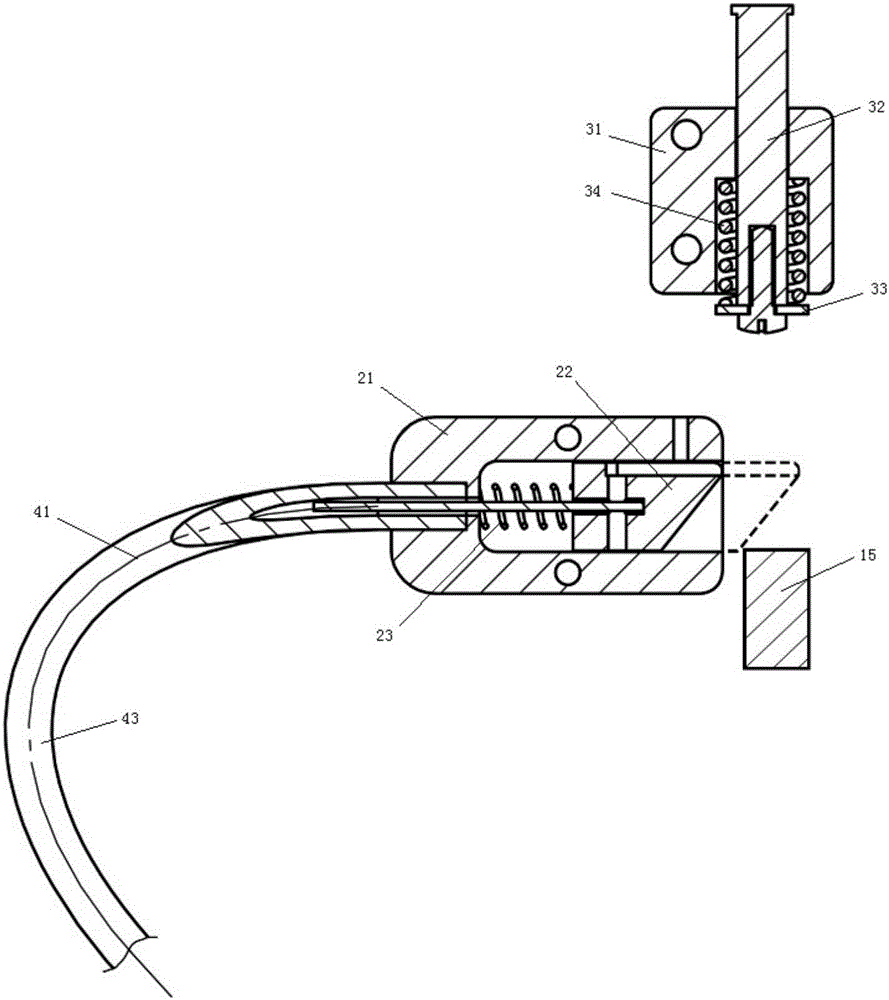

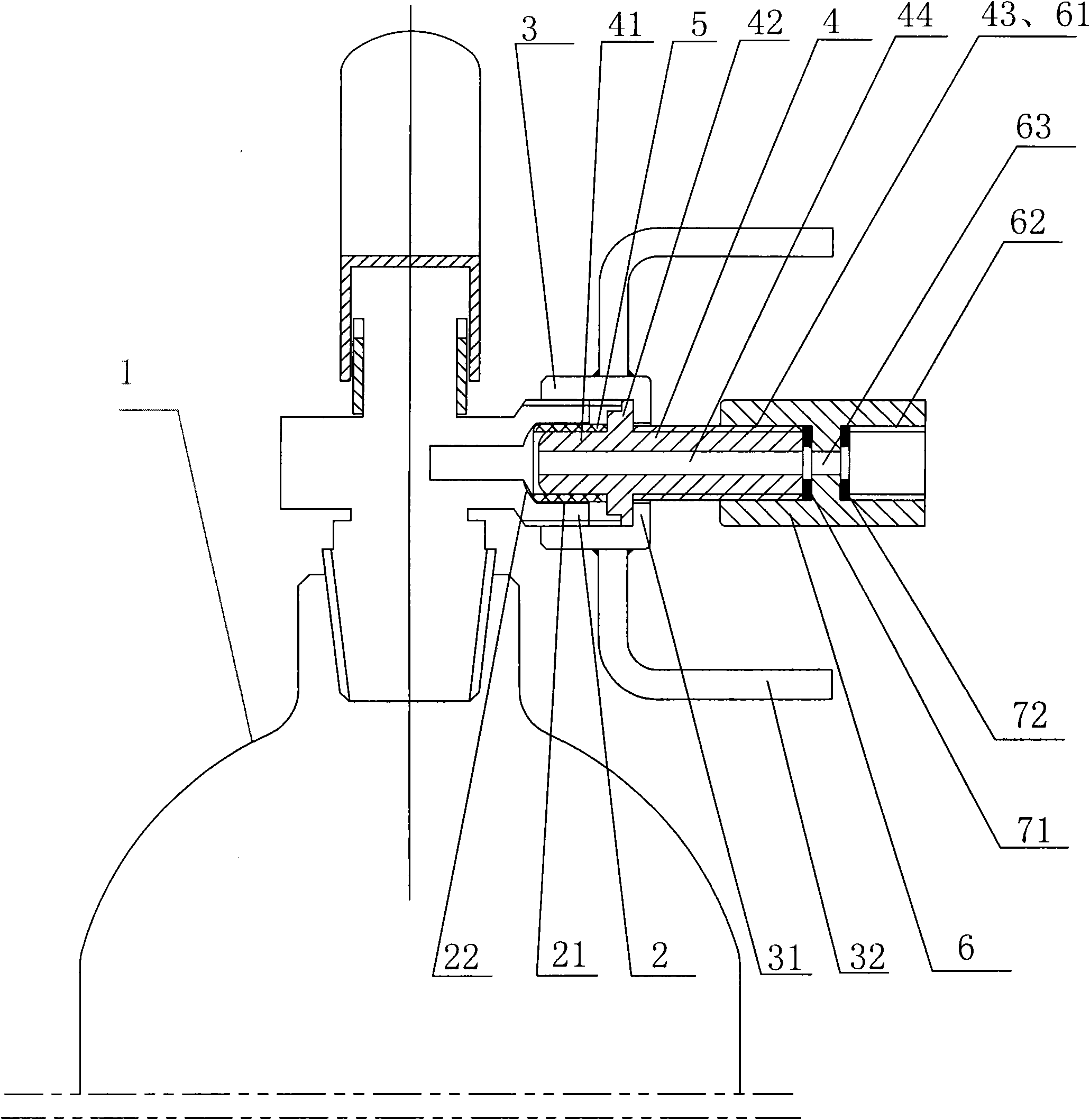

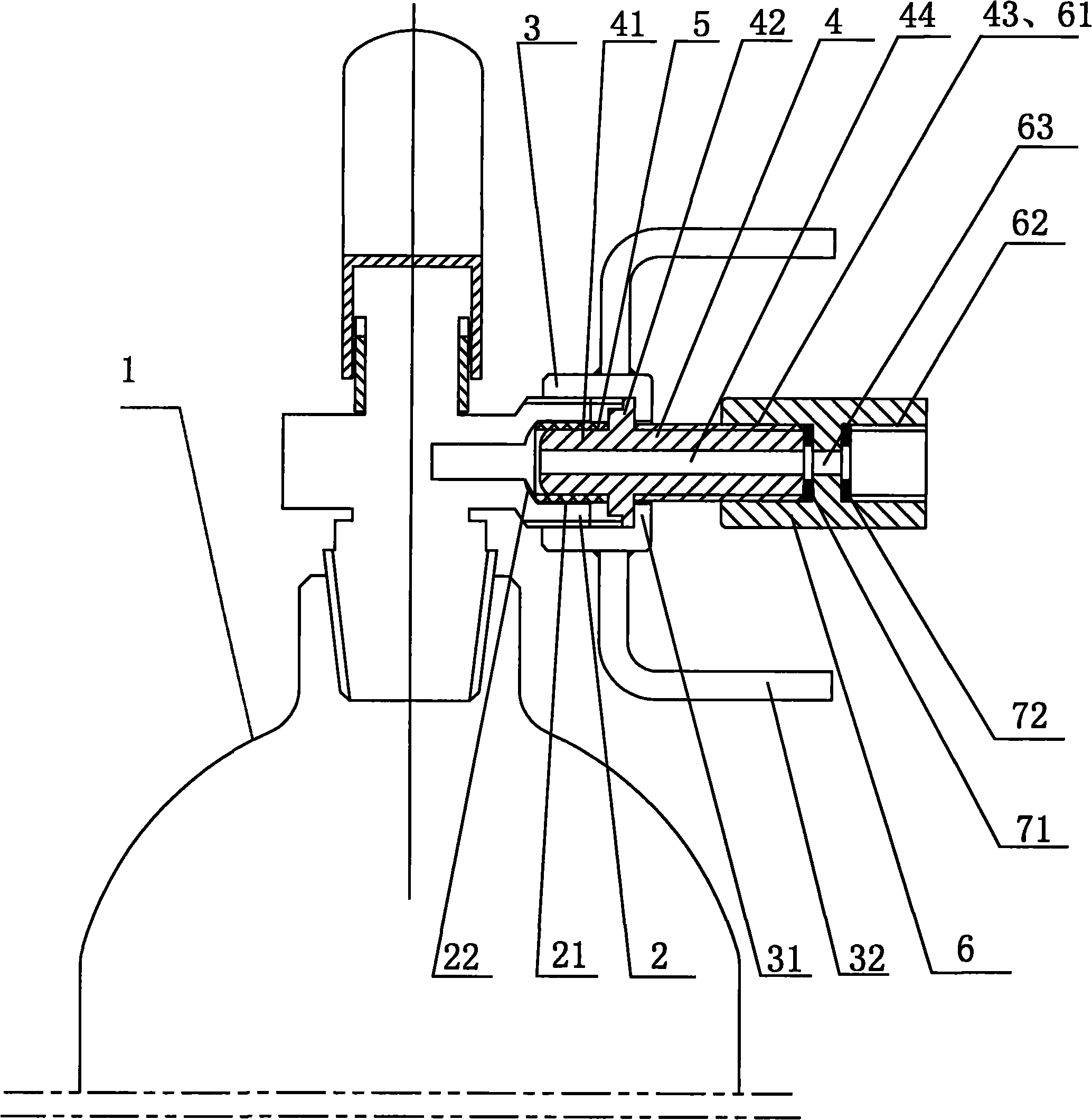

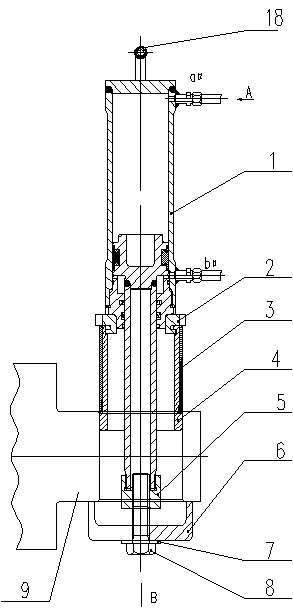

Connector device for replenishing gas and liquid on orbit

ActiveCN105059569AGood flexibilityStrong advancedCosmonautic component separationSatelliteFixed position

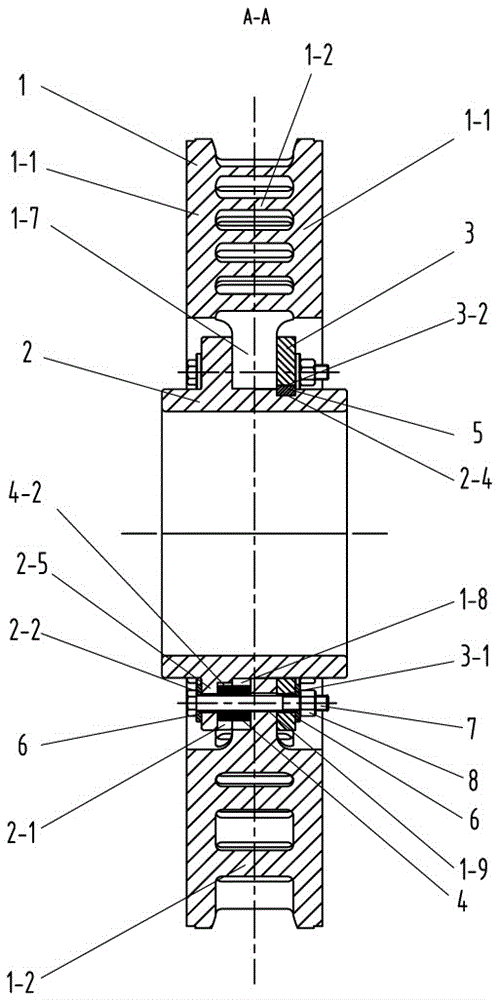

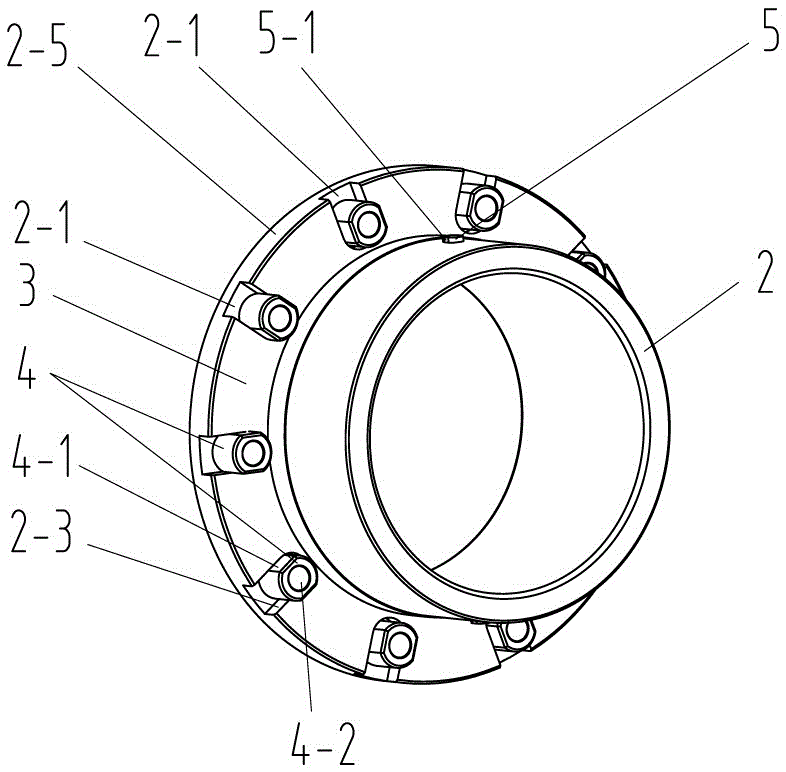

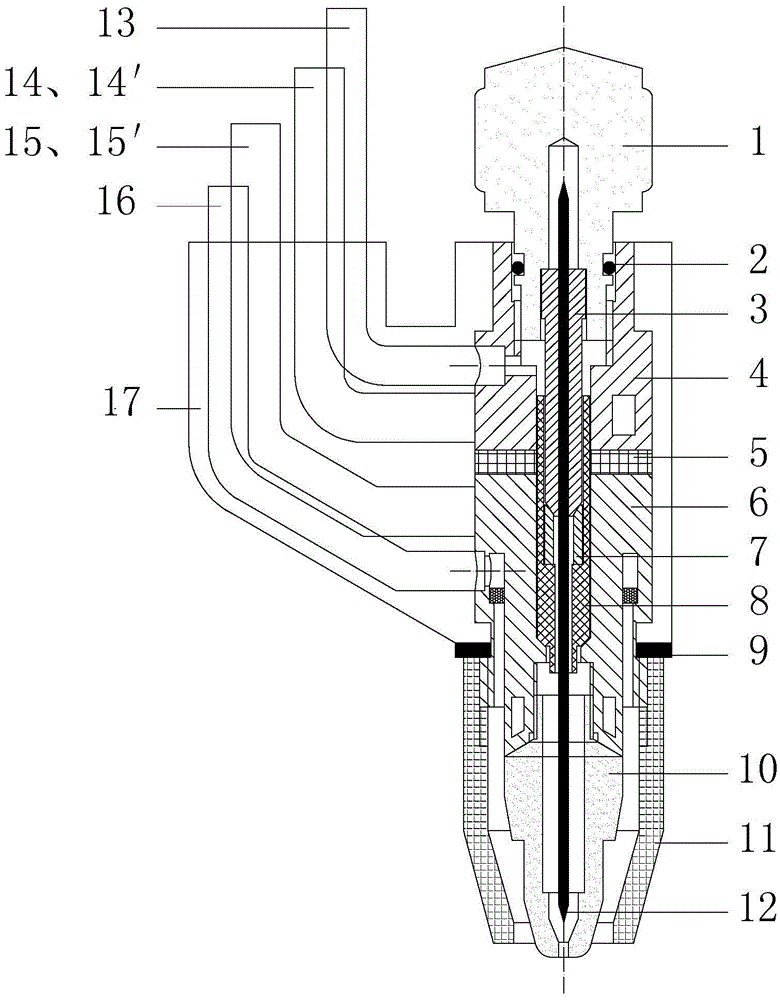

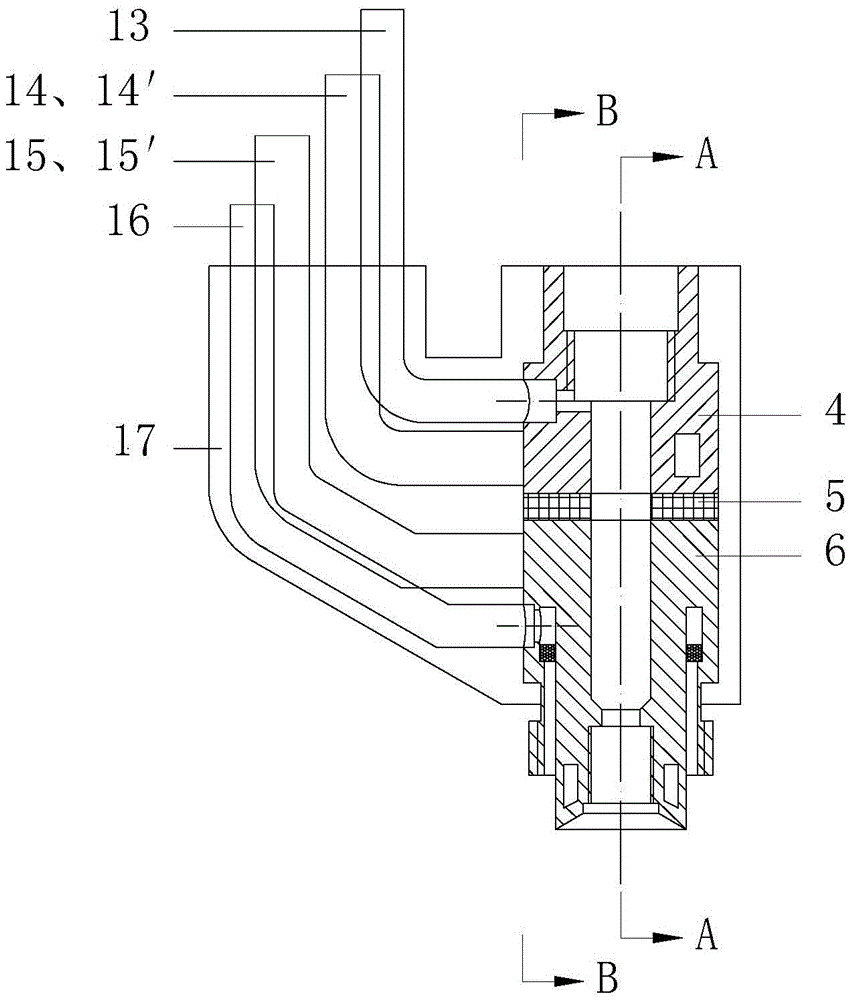

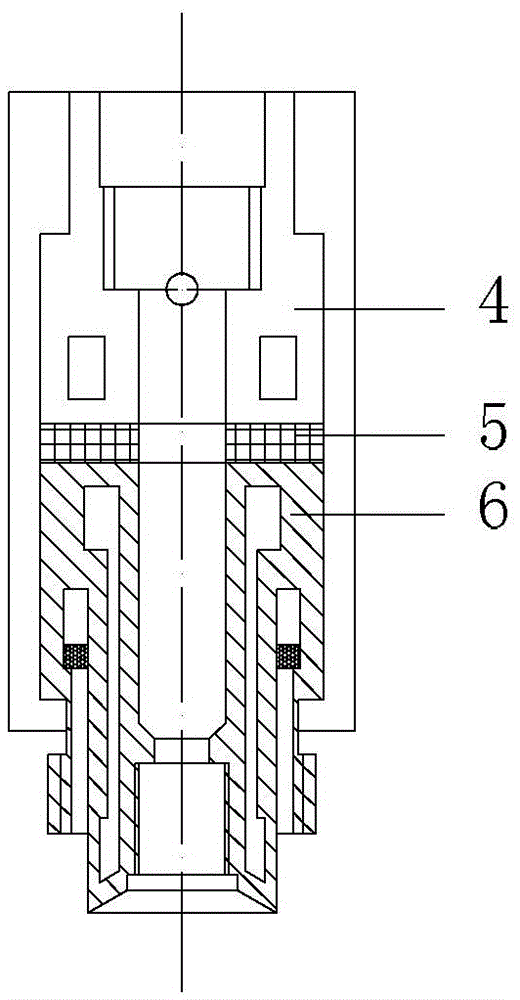

The invention relates to a connector device for replenishing gas and liquid on the orbit. The connector device is used for replenishing gas and liquid for a target satellite by a service satellite on the orbit. The connector device comprises an active mechanism and a passive mechanism. The service satellite and the target satellite are positioned and conveniently separated through guide devices on respective butt-joint surfaces of the active mechanism and the passive mechanism, the service satellite and the target satellite are caused to move relative to each other through a drive mechanism having the axial spacing function, and the service satellite and the target satellite are locked through a positioning locking structure, so that the service satellite and the target satellite are guaranteed to be at fixed positions relative to each other in the on-orbit gas-liquid replenishing process. Through the measures, the efficiency of the on-orbit gas-liquid replenishing process is improved, and the safety of the on-orbit gas-liquid replenishing process is guaranteed.

Owner:BEIJING INST OF CONTROL ENG

Rapid clamping and wire hanging apparatus for insulation piercing clamps

PendingCN106299730AGuaranteed coaxialWith self-hanging functionElectric connection basesContact members penetrating/cutting insulation/cable strandsMechanical engineeringCord clamping

Owner:STATE GRID CORP OF CHINA +2

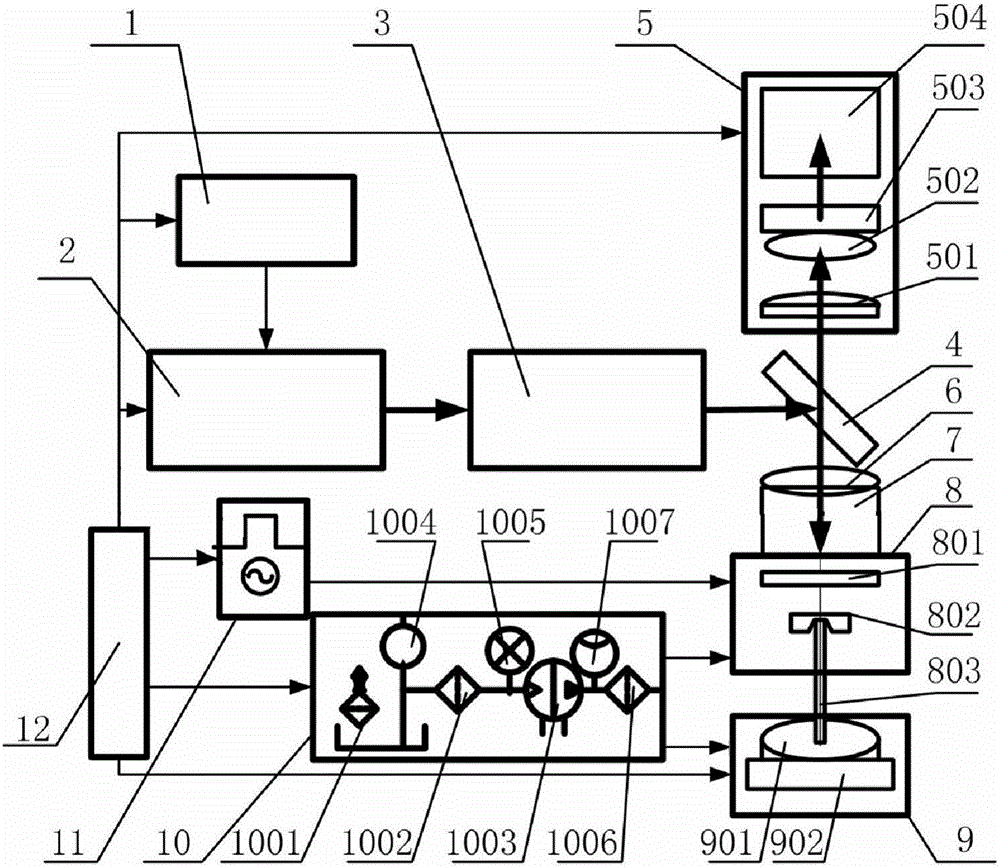

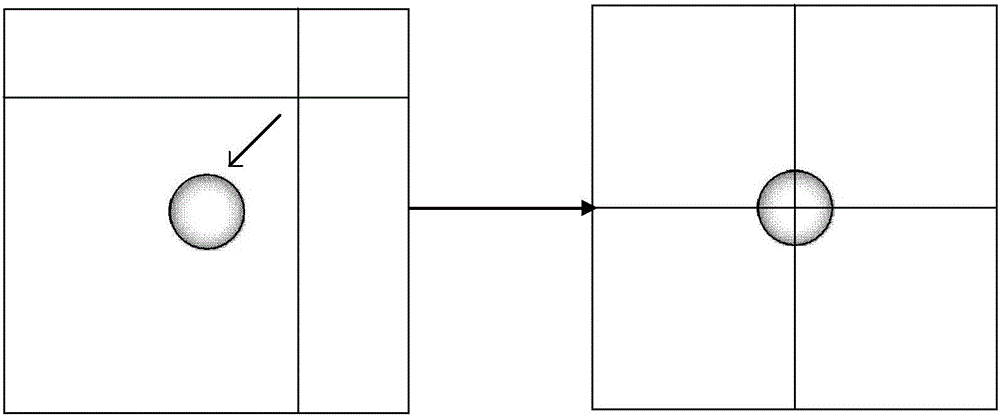

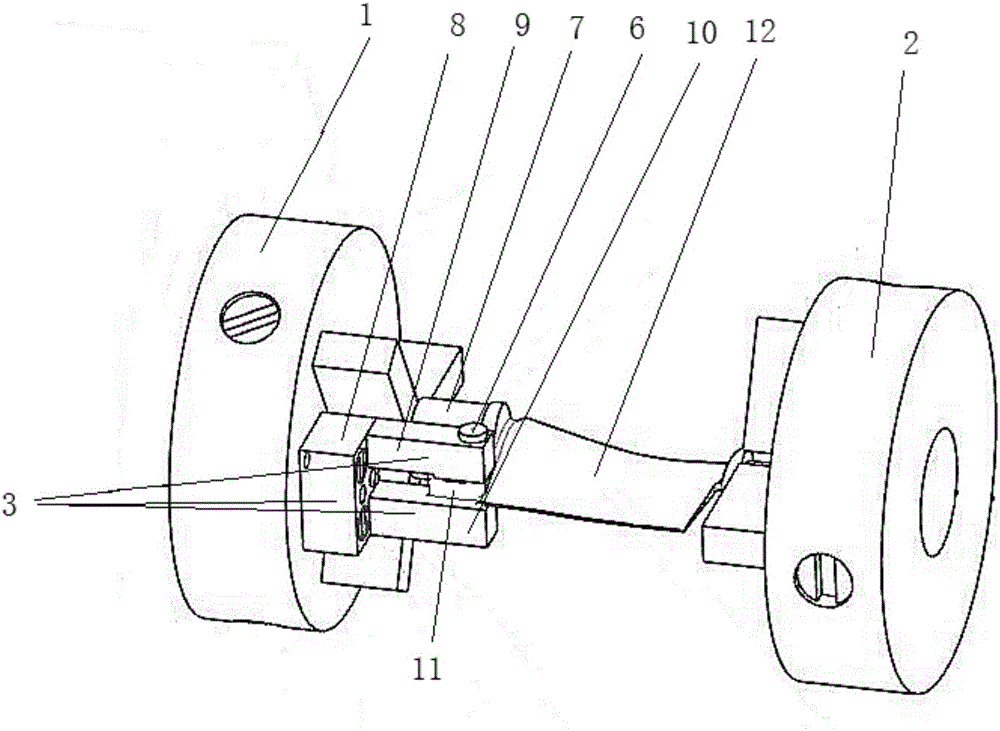

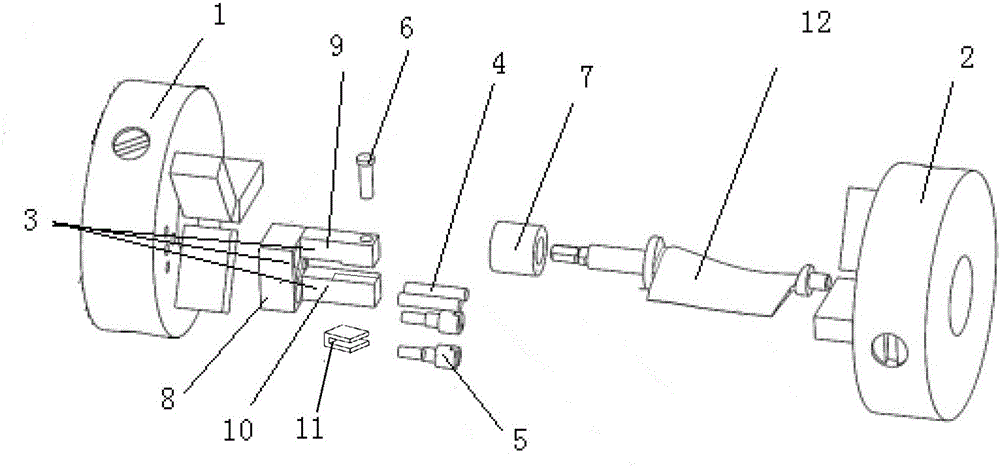

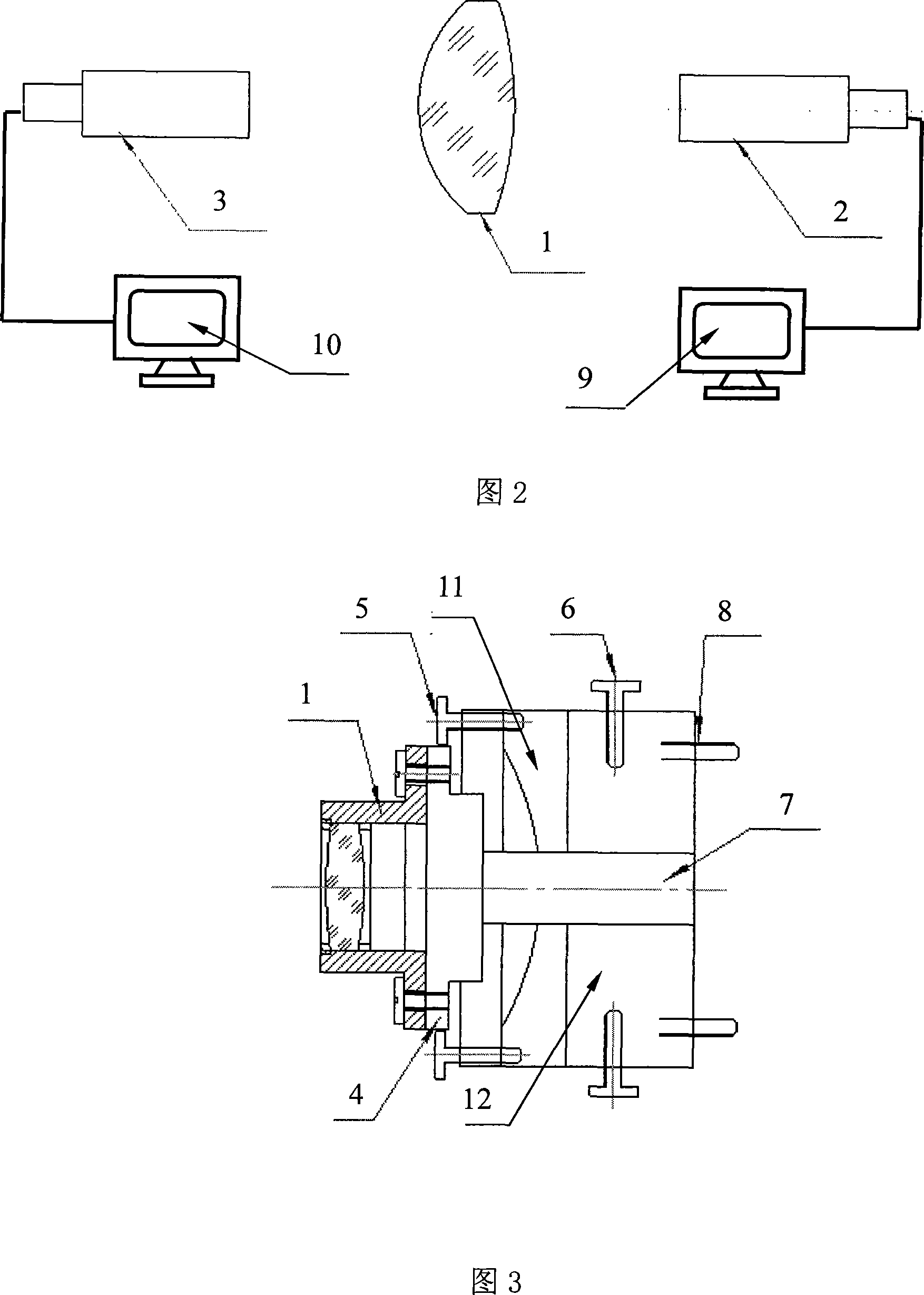

Micro-nano machining method and device for laser composite ejection liquid beam

InactiveCN105880849AIncrease instantaneous powerReduce microcracksNanotechnologyLaser beam welding apparatusMicro nanoControl system

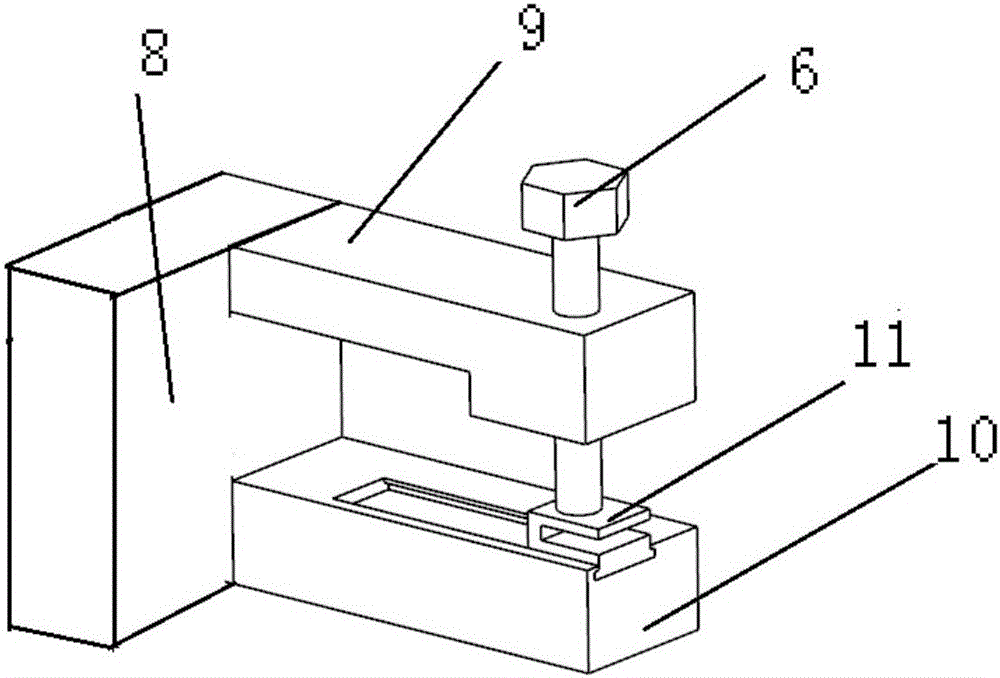

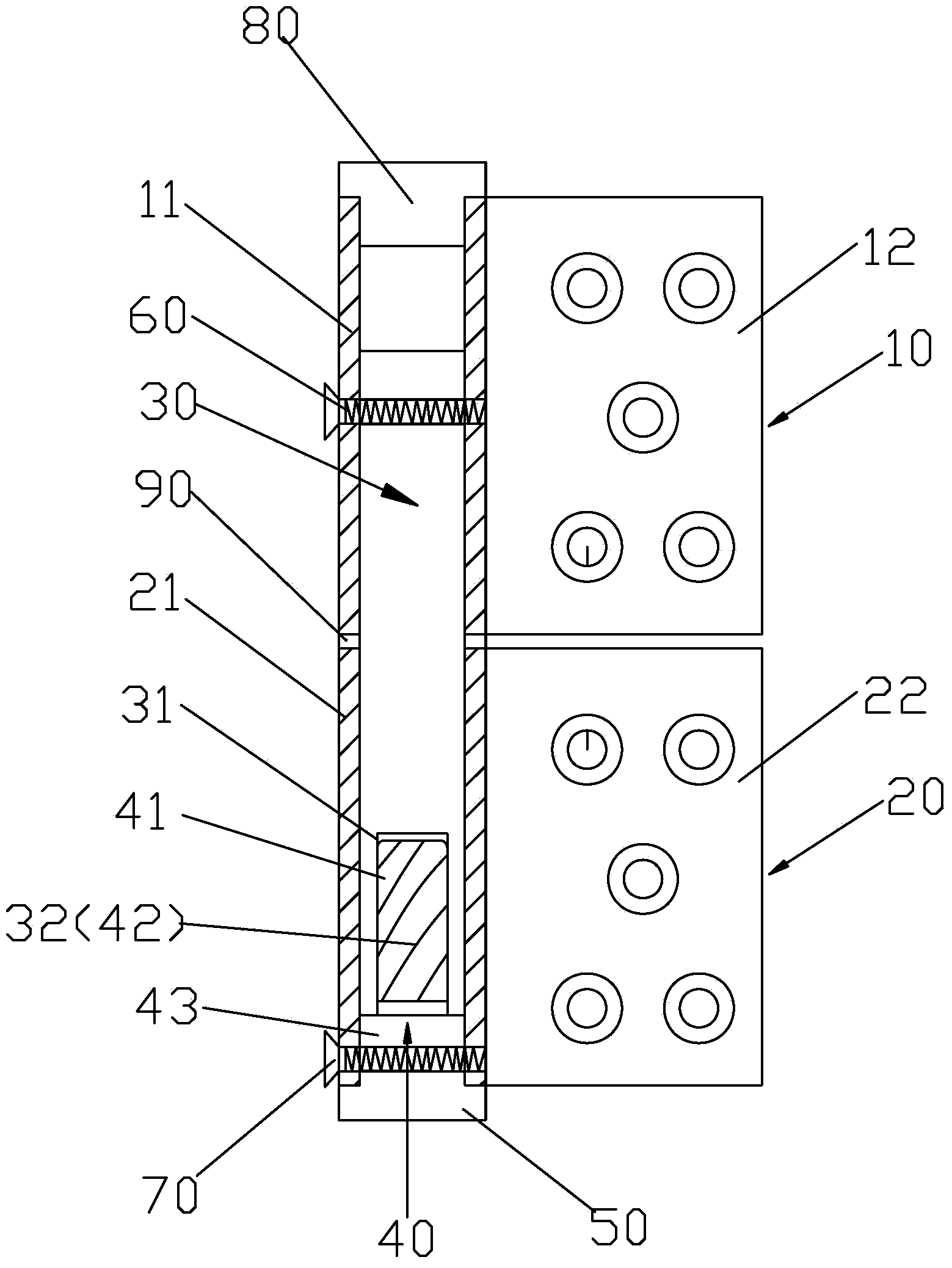

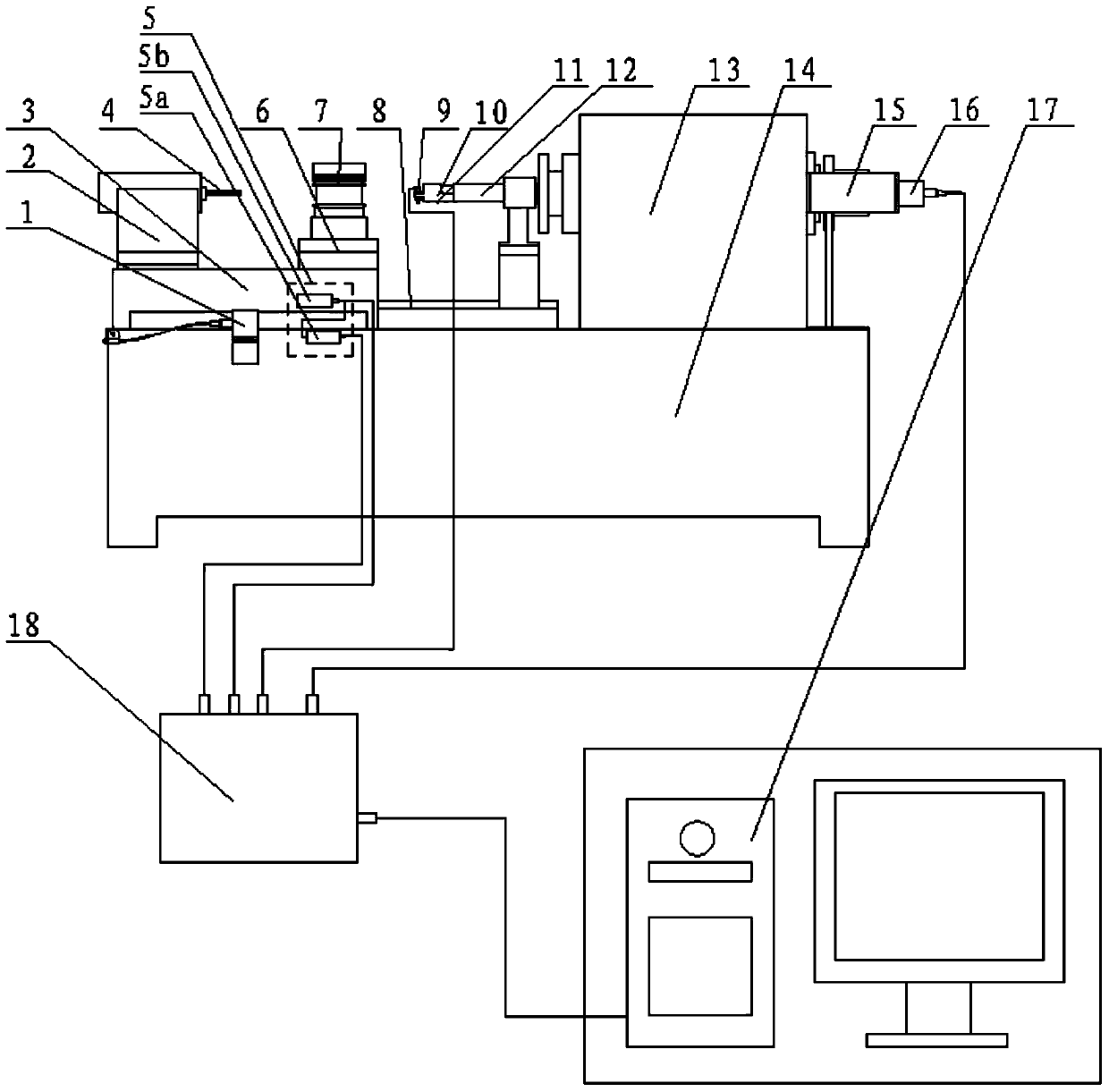

The invention discloses a micro-nano machining method and a micro-nano machining device for a laser composite ejection liquid beam, and belongs to the technical field of micro-nano processing techniques. The micro-nano machining device comprises a laser pulse sequence regulator (1), a laser system (2), a laser beam adjusting system (3), a visible light transmission reflector (4), a laser beam and ejection liquid beam coaxial observation regulation system (5), a focusing lens (6), a regulating and control device (7), an ejection device (8), a micro-nano working table (9), an ejection liquid filtering circulation system (10), a laser power supply (11) and an overall control system power supply (12). The micro-nano machining method comprises a step of implementing micro-nano machining on a workpiece by taking laser beams generated from the laser system (2) and ejection liquid beams generated from the ejection device (8). The micro-nano machining method and the micro-nano machining device are applicable to machining of engine blade film holes.

Owner:HARBIN INST OF TECH

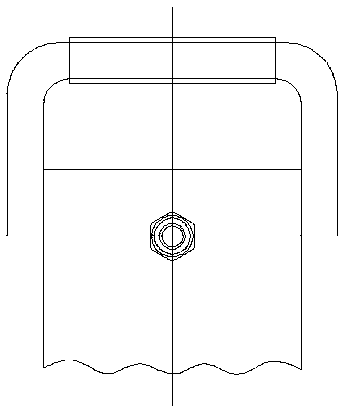

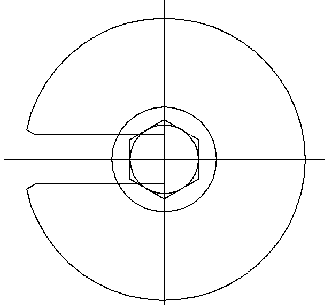

Concentricity jig of flange mounting hole

The invention discloses a concentricity jig of a flange mounting hole. Two pressure plates with the identified structure are provided with holes at the same water level. A pulling rod passes through the holes and is fastened by a bolt. The concentricity jig of the flange mounting hole is characterized in that the pressure plates are semicircular, a plurality of holes are arranged on the pressure plates; the holes on the pressure plates are in the same position with the flange mounting holes. The structure has the advantages that the jig adopts the semicircular pressure plates and corresponding positions of the pressure plates are provided with holes matching with the flange mounting holes. When the flange is connected with insulator gel, the two pressure plates are compressed tightly at two ends and are fastened in the same water level by the pulling rod. The holes on the pressure plates are respectively corresponding to the flange mounting holes and are fastened by bolts. When the connection between the flange and the insulator adhesive is finished, the jig can be demounted. The device can install flanges effectively and rapidly, and the coaxial performance is guaranteed absolutely.

Owner:JIANGSU SHENMA ELECTRIC CO LTD

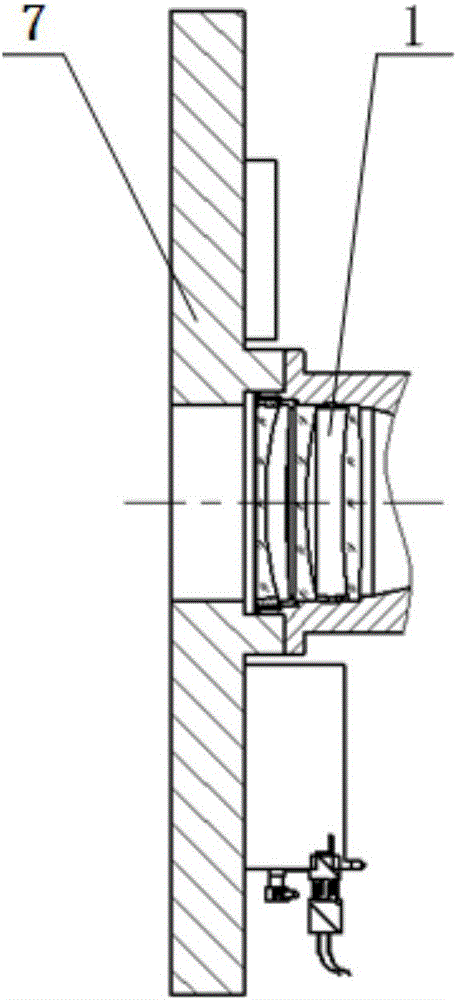

Turning chatter suppression device based on piezoelectric ceramic driver

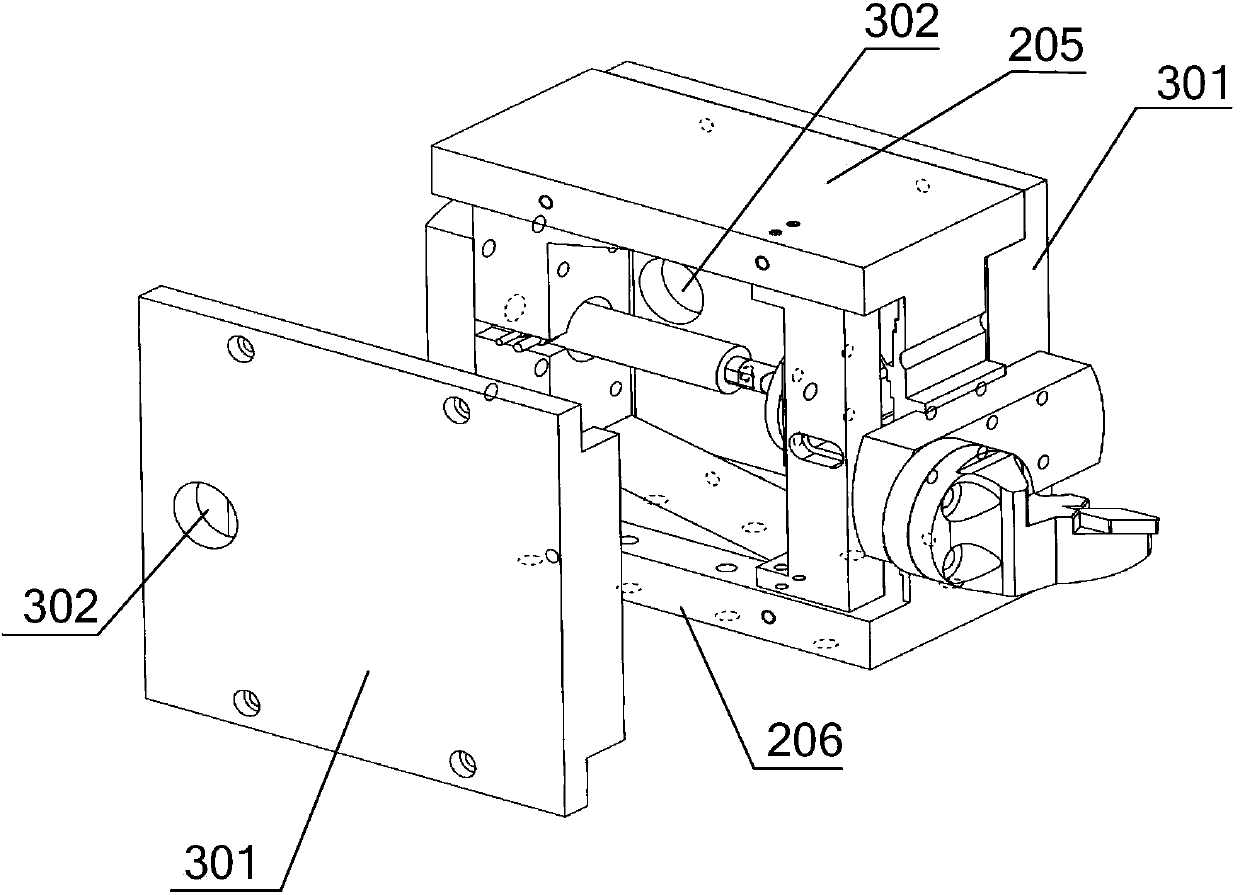

ActiveCN103433516AQuick responseTurning Chatter SuppressionAutomatic control devicesAuxillary equipmentElectricityDisplacement control

The invention discloses a turning chatter suppression device based on a piezoelectric ceramic driver. The turning chatter suppression device comprises a tool rest, a flexible hinge, the piezoelectric ceramic driver, a front flange plate, a rear flange plate, a flexible connector, a vibrating sensor and a controller. The front end of the piezoelectric ceramic driver is connected with the rear end of the front flange plate through the flexible connector, the front end of the front flange plate is fixedly connected with the front end of the tool rest, and the rear end of the piezoelectric ceramic driver is fixedly connected with the rear end of the tool rest through the rear flange plate; the controlled is electrically connected with the vibrating sensor and the piezoelectric ceramic driver; the upper part and the lower part of the flexible hinge are provided with an elastic bending sheet respectively. When precision turning is carried out through the turning chatter suppression device, real-time online position regulation on a tool can be achieved; the turning chatter suppression device has the advantages of being simple in structure, high in rigidity, displacement control precision, response speed and output force, low in power consumption and the like, and can effectively suppress generation of turning chattering.

Owner:SHANGHAI JIAO TONG UNIV

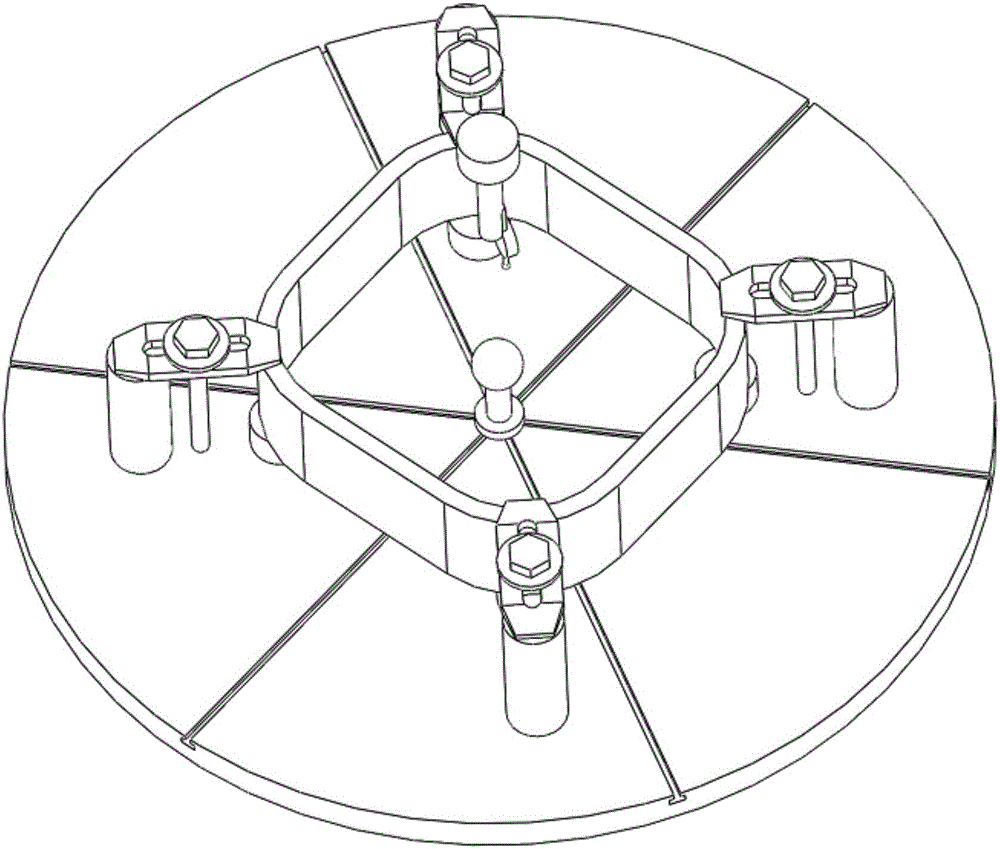

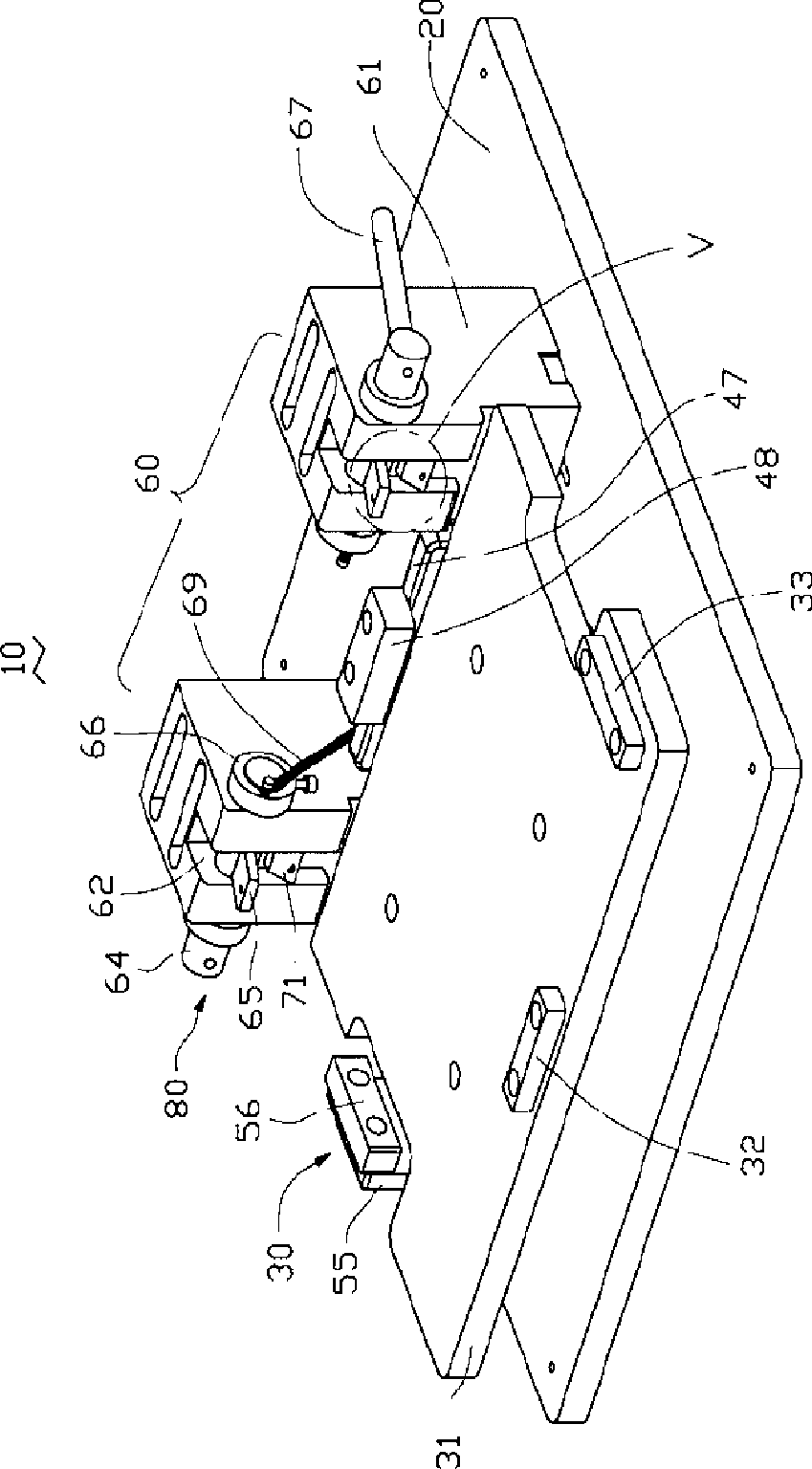

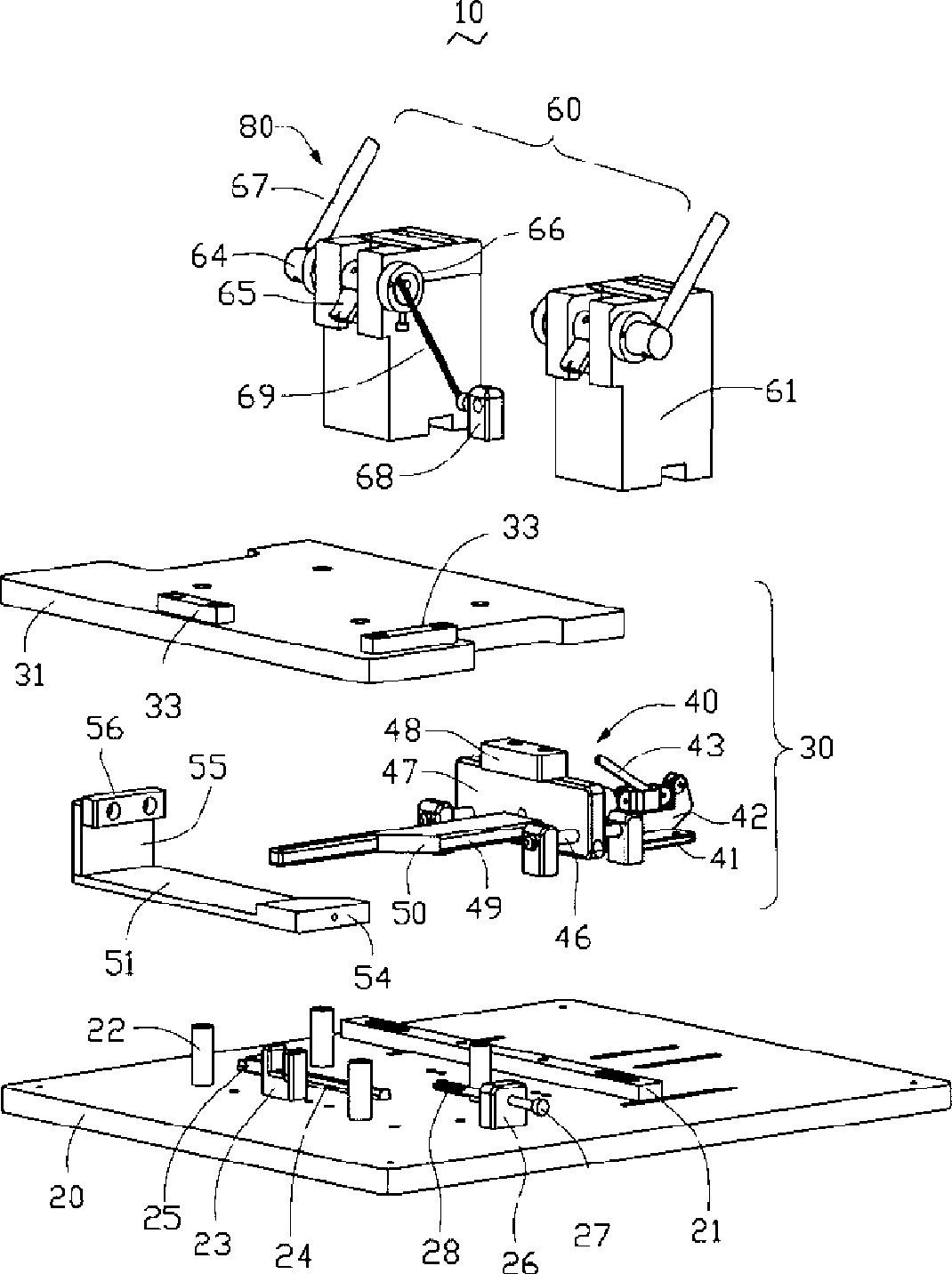

Machining method for improving coaxiality accuracy of opposite holes of part

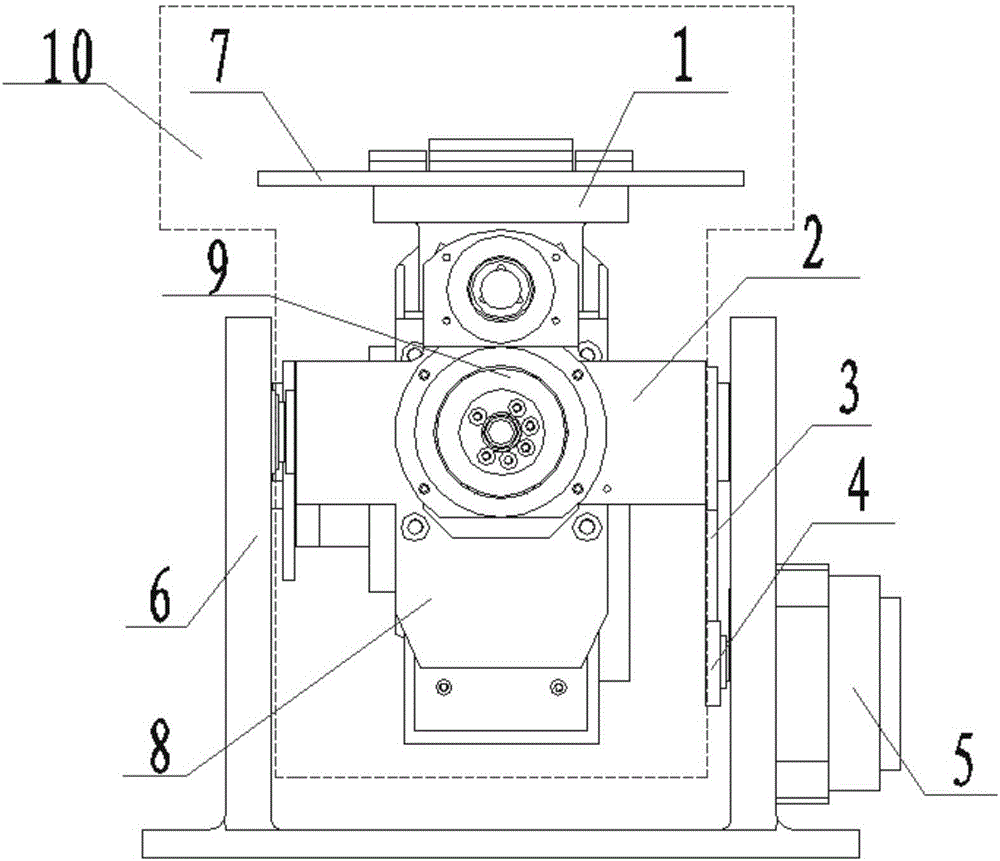

ActiveCN106002377AImprove machining accuracyGuaranteed stabilityMeasurement/indication equipmentsPositioning apparatusRotational axisEngineering

The invention relates to a machining method for improving the coaxiality accuracy of opposite holes of a part. A special error correction tool is designed, the part to be machined is installed on a work table of a numerically-controlled machine tool through the error correction tool, a measuring head measures the position relations between a spherical displacer and a main shaft of the machine tool and between the spherical displacer and the rotational axis of the work table for obtaining the reference positions of vertical machining and horizontal machining of the part, and therefore the machining accuracy of vertical machining and horizontal machining is obviously improved. The error correction tool comprises a calibration assembly, pressing plate assemblies, equal-height blocks and cushion blocks. According to the machining method, kinematic errors of shafts of the numerically-controlled machine tool are eliminated to the maximum degree, the coaxiality of the opposite holes of the part is only related with the alignment accuracy, and the accuracy of the part to be machined is obviously improved.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Auxiliary remover for rivet with head

The invention discloses an auxiliary remover for a rivet with a head. The auxiliary remover comprises a support which is provided with a guide hole used for guiding of a drill head, a positioning hole coaxial with the guide hole is arranged at one end of the guide hole, inner diameter of the positioning hole is larger than that of the guide hole and equal to nominal diameter of the head of the rivet, and a chip discharging structure is formed on the side face of the positioning hole. By the auxiliary remover, demounting efficiency of the rivet with the head can be improved, and removing risk can be lowered.

Owner:SHANDONG TAIKOO AIRCRAFT ENG

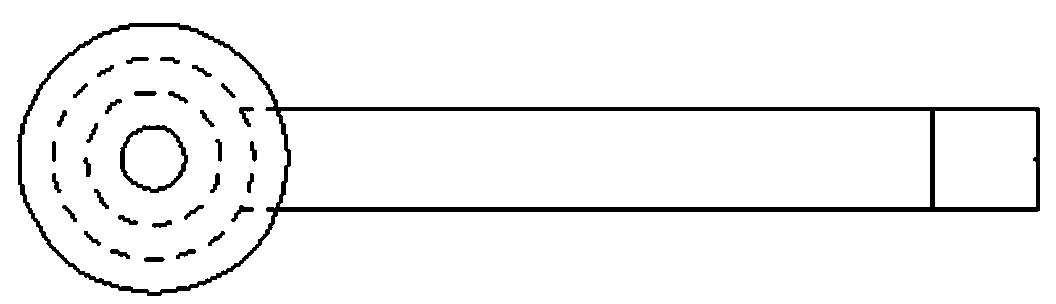

Shaft-mounted brake disc

The invention discloses a shaft-mounted brake disc used for a rail traffic vehicle. The shaft-mounted brake disc comprises a disc body, a hub, space rings, sliding blocks, locating keys, spacers, bolts and nuts; the disc body comprises two friction rings, radiation ribs and a plurality of connecting claws, wherein the radiation ribs are placed in the radial direction of the friction rings and arranged in multiple circles from inside to outside and the connecting claws are placed on the inner circles of the friction rings and arranged in the peripheral direction; each connecting claw is provided with a radial disc body sliding block groove; each hub flange is provided with a radial hub upper sliding block groove; the sliding blocks are correspondingly arranged inside the disc body sliding block grooves and the hub upper sliding block grooves; after installation, the sliding block force transferring faces of the sliding blocks are matched with the force transferring faces of disc body sliding blocks and the force transferring faces of hub upper sliding blocks; each bolt sequentially penetrates through various bolt holes in a loose fit mode and is locked through the corresponding spacer and the corresponding nut; and the shaft-mounted brake disc is high in connection reliability and good in ventilation and heat dissipation performance.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

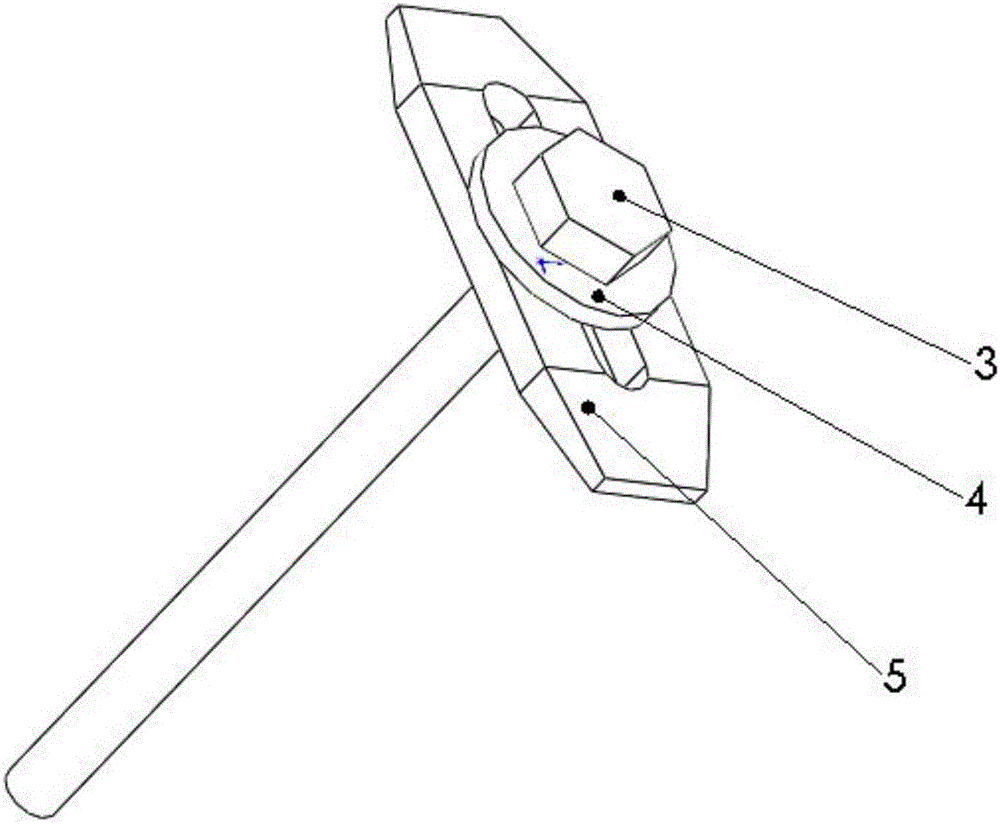

Positioning mechanism

InactiveCN106670719AAchieve positioningHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a positioning mechanism which comprises a dowel pin base, a plurality of positioning cores and a positioning shaft, wherein each positioning core comprises a connecting rod, an inner end positioning plate and an outer end positioning plate, the connecting rod is arranged on the peripheral wall of the dowel pin base in a penetrating mode, the inner end of the connecting rod is equipped with the inner end positioning plate, the outer end of the connecting rod is equipped with the outer end positioning plate, and the connecting rod can move in the radial direction of the peripheral wall relative to the peripheral wall; the positioning shaft is coaxially arranged inside the dowel pin base; the positioning shaft is provided with a positioning tapered surface which is suitable for fitting with the inner end positioning plate, and the positioning shaft can move in the axial direction of the positioning shaft relative to the dowel pin base, so that the positioning cores are driven through the tapered surface to synchronously move in the radial direction. The positioning mechanism disclosed by the invention is simple in structure, is convenient to dismount, and is beneficial for improving precision of a part dimension.

Owner:BAIC MOTOR CORP LTD

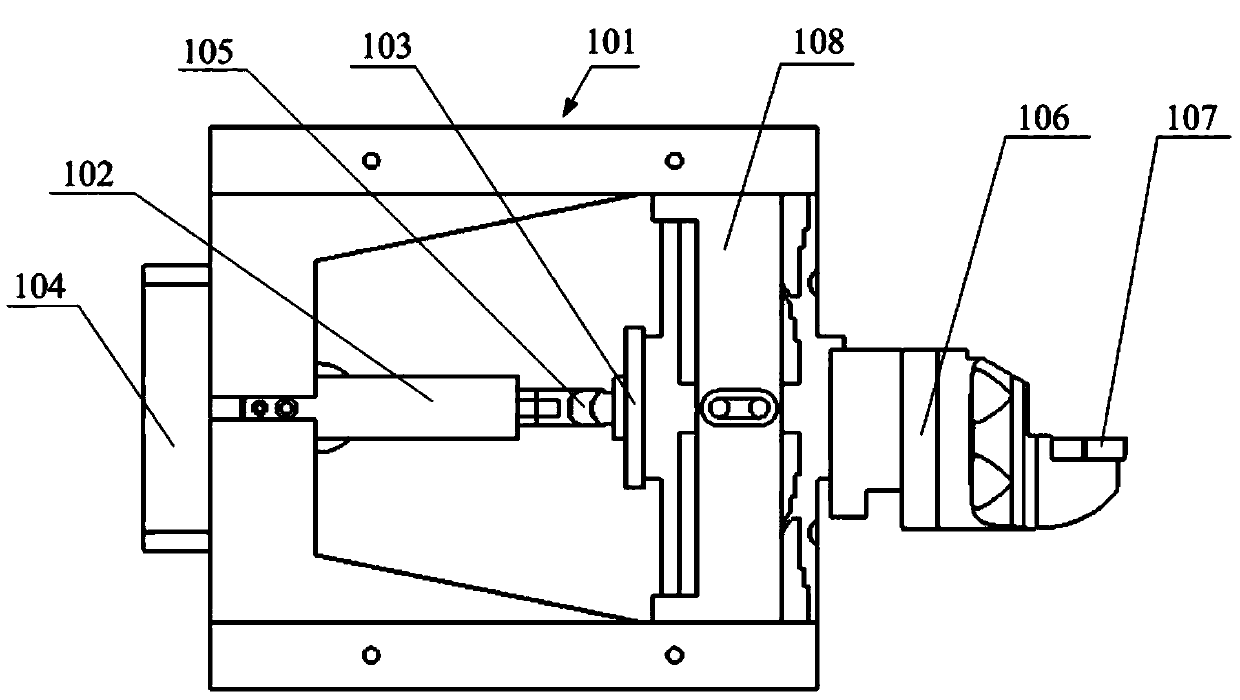

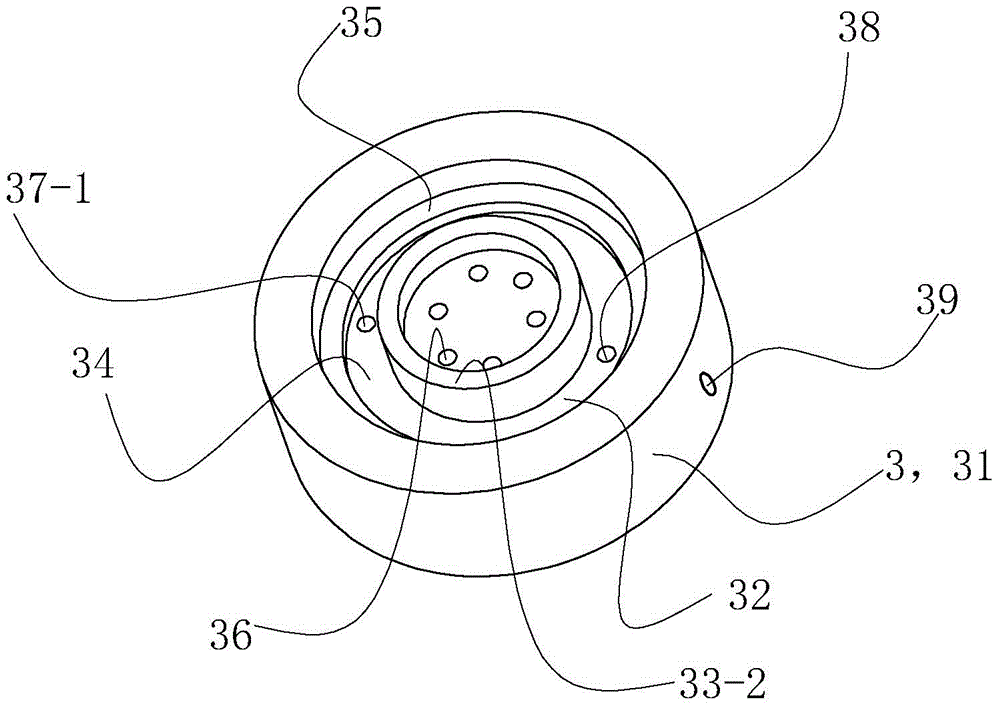

Co-aperture infrared/radar composite seeker

InactiveCN106569205AAdapt to operational tactical requirementsHit the target with precisionRadiation pyrometryRadio wave reradiation/reflectionMiniaturizationDrive motor

The invention discloses a co-aperture infrared / radar composite seeker and belongs to the radar infrared composite detection device technical field. The common aperture infrared / radar composite seeker includes an infrared thermal imager, a radar detection module, a pitching frame, a main support, a mounting plate, a driving motor, azimuth motors, a driving gear and a driven gear; after being fixedly connected with the radar of the radar detection module through a screw in a co-aperture manner, the infrared thermal imager is fixed onto the top of the pitching frame through the mounting plate; the two azimuth motors are installed at the middle of the pitching frame; the pitching frame is installed between two supporting plates of the main support through a connection shaft and a bearing; the driving motor is fixed onto the outer side surface of the supporting plate of the main support; the driving gear is located at the inner side surface of the supporting plate of the main support, and is fixedly connected with the output shaft of the driving motor; and the driven gear is fixed to the bottom of the pitching frame and is engaged with the driving gear. The co-aperture infrared / radar composite seeker of the invention has the advantages of miniaturization and light weight, and is conductive to the improvement of combat capability.

Owner:HEBEI HANGUANG HEAVY IND

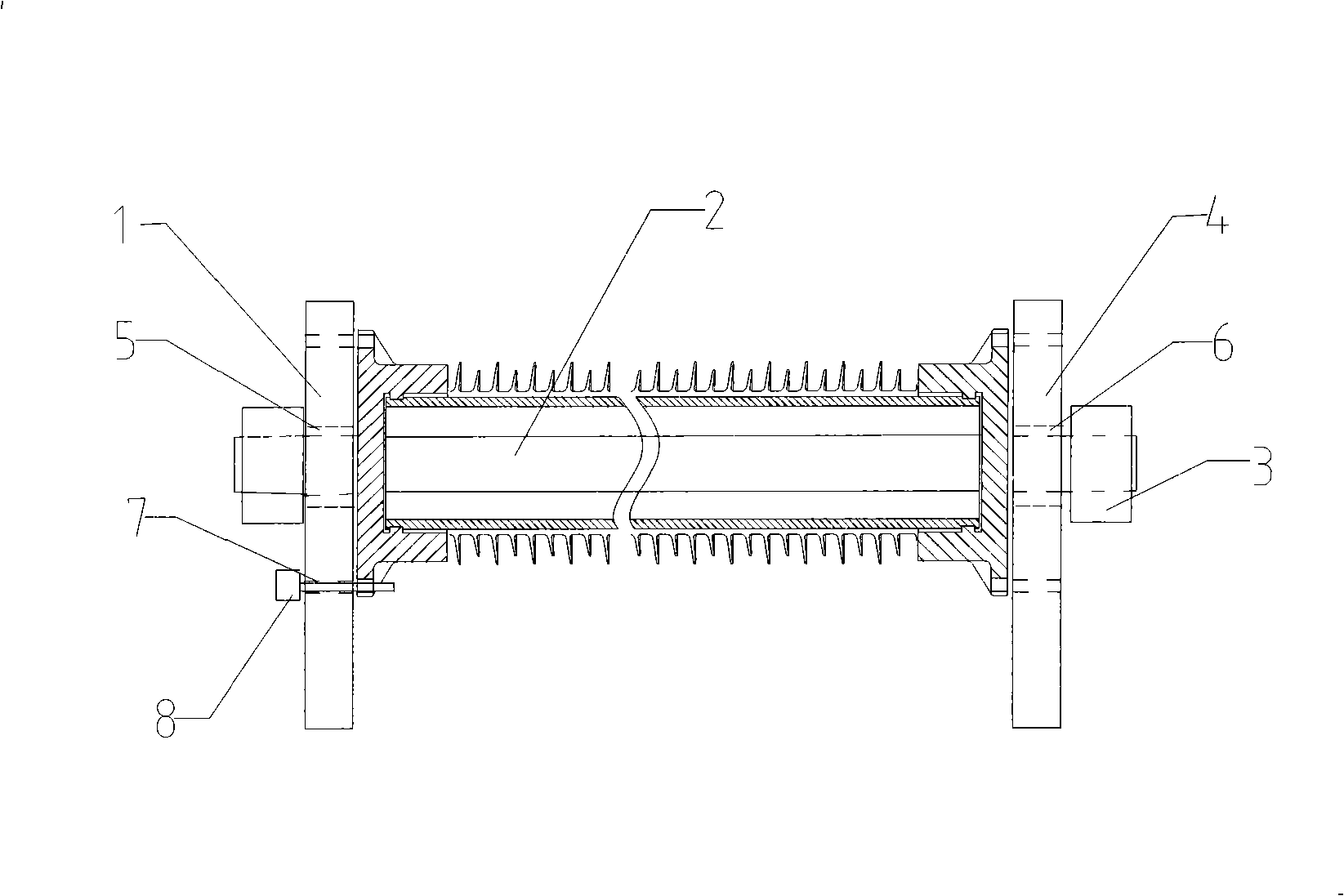

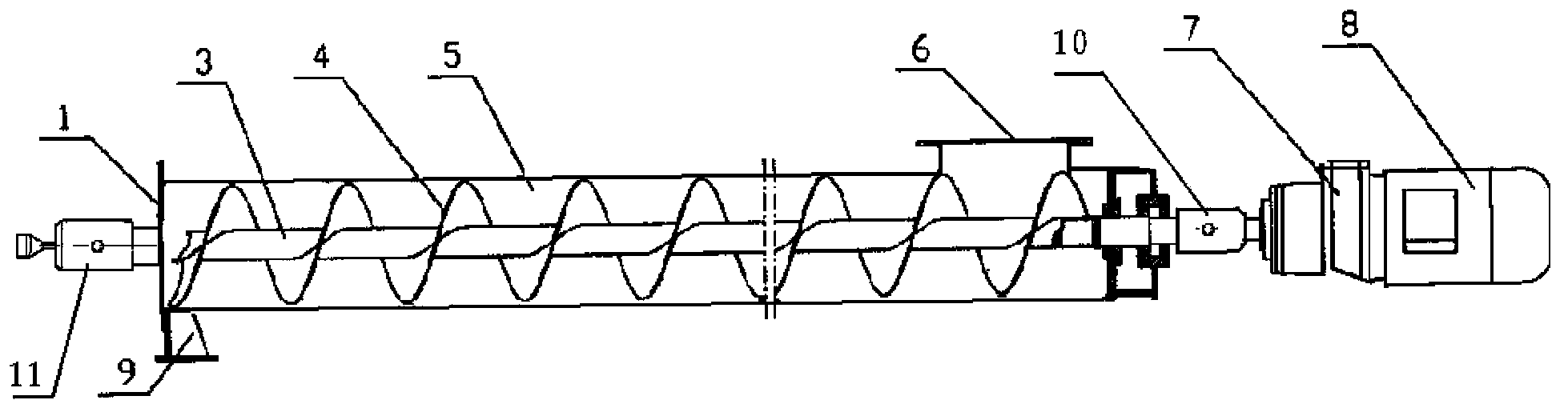

Screw conveyor

The invention discloses a screw conveyor which comprises a framework, a driving mechanism, a conveying drum, a screw shaft, a screw, a head transmission bearing box and a tail transmission bearing box. The conveying drum is supported by the framework, a material access port is formed in the conveying drum, the driving mechanism drives the screw in the conveying drum, a flange support is arranged at an end of the conveying drum, the screw shaft of the screw is supported by the flange support, and the head transmission bearing box and the tail transmission bearing box are respectively positioned on the outer portions of two ends of the screw. The screw conveyor has the advantages that the screw shaft is supported by the flange support, so that the coaxiality of the screw shaft can be guaranteed, and the screw shaft can be prevented from being abraded by the wall of the conveying drum; the head transmission bearing box and the tail transmission bearing box are separated from a shell, so that bearings in the bearing boxes can keep away from materials such as dust and are positioned in lubricated environments for a long time, the service lives of the bearings can be prolonged, a motor cannot be burned out easily, the maintenance frequency can be reduced, and the production efficiency can be improved.

Owner:SHANGHAI SUQIAO MECHANICAL EQUIP

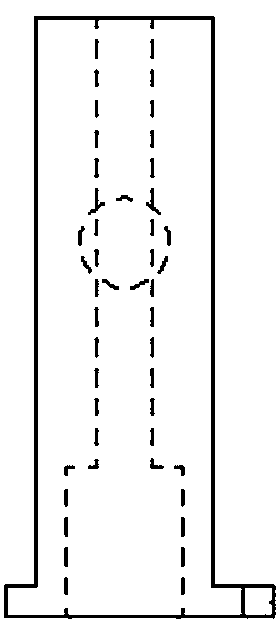

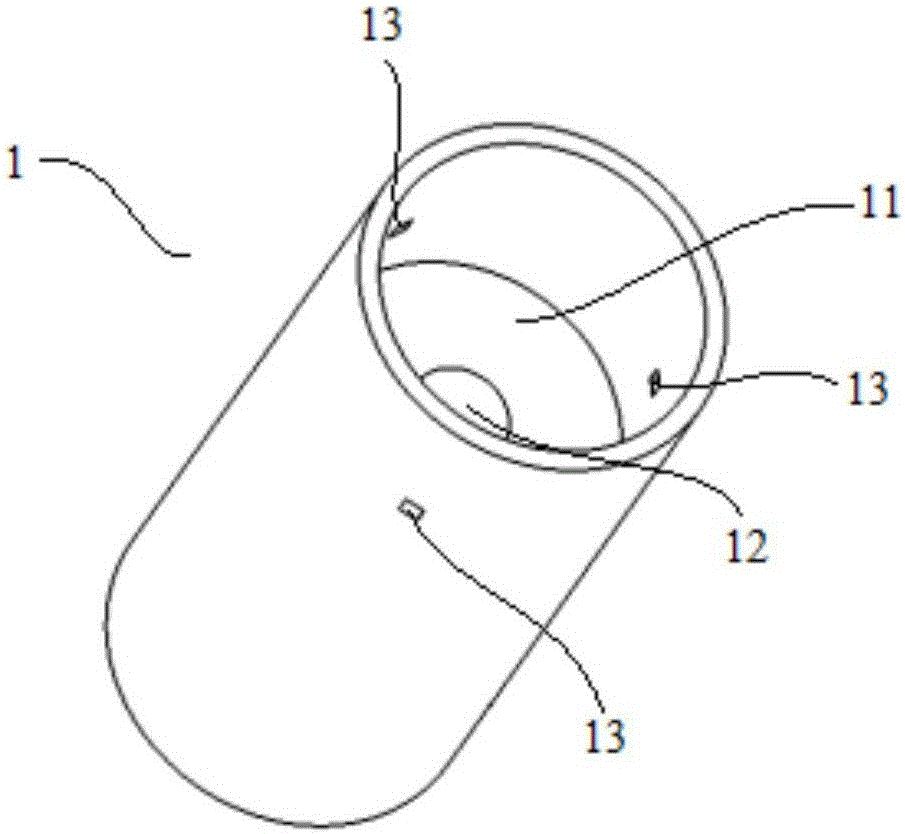

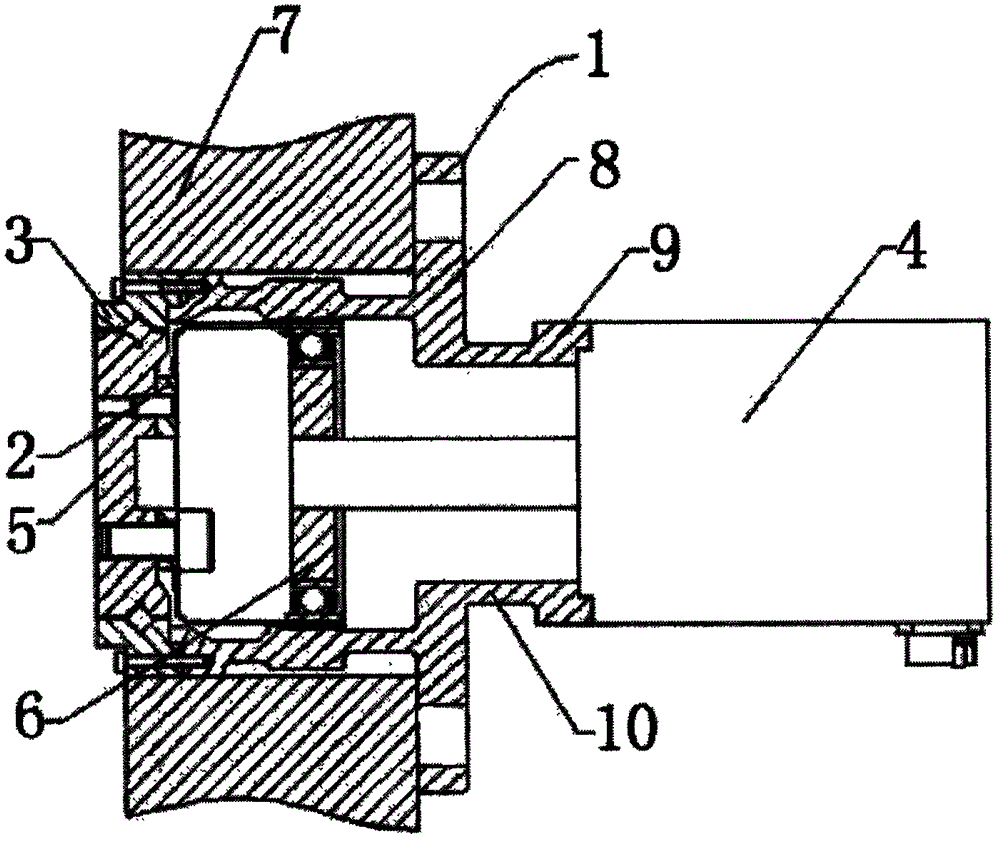

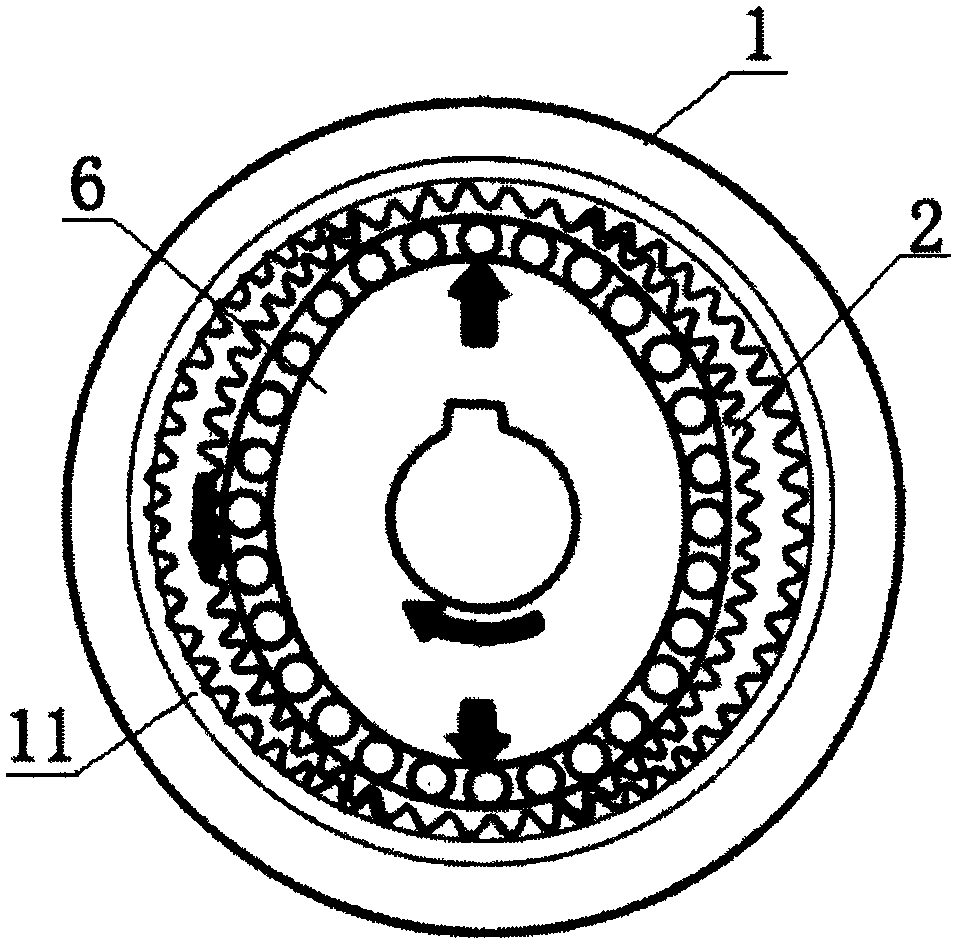

Harmonic reducer with lubricating function

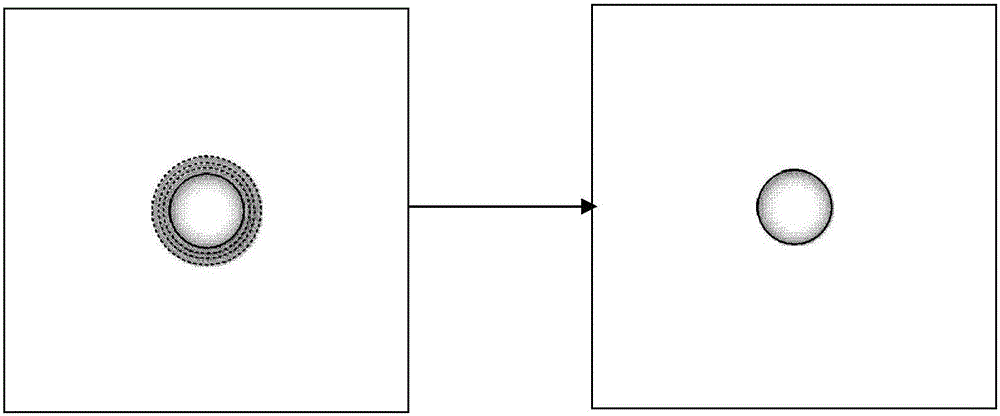

InactiveCN106151472AGuaranteed coaxialGuaranteed meshingGear lubrication/coolingMechanical energy handlingHarmonicEngineering

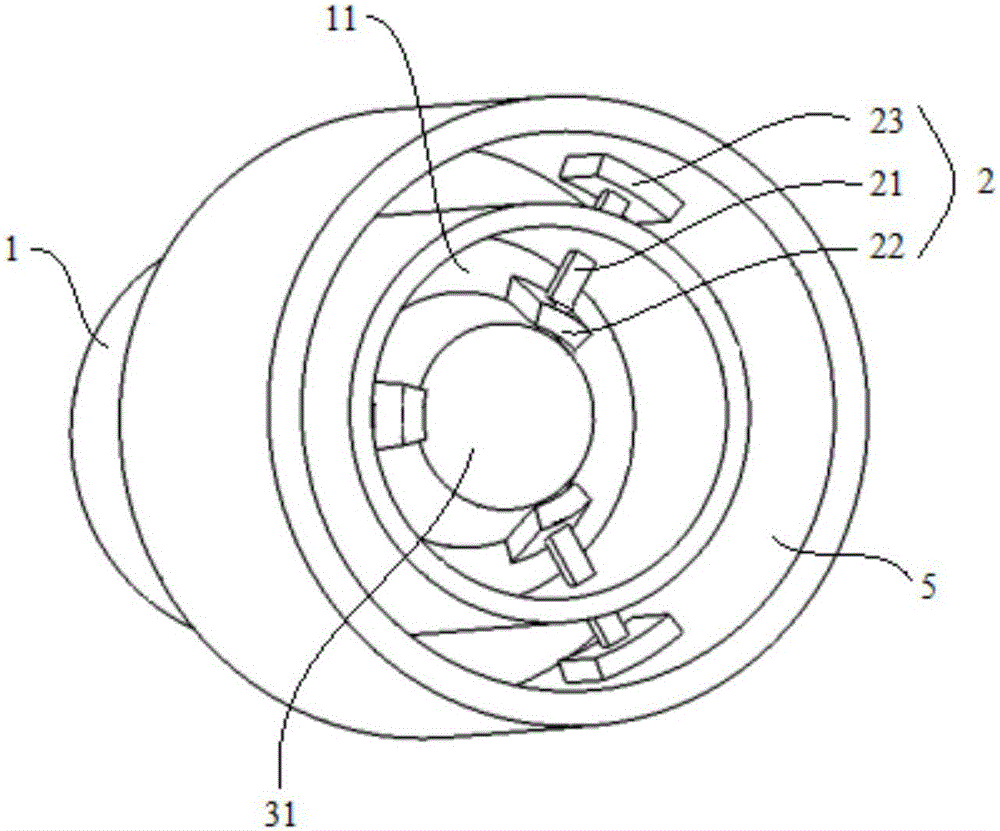

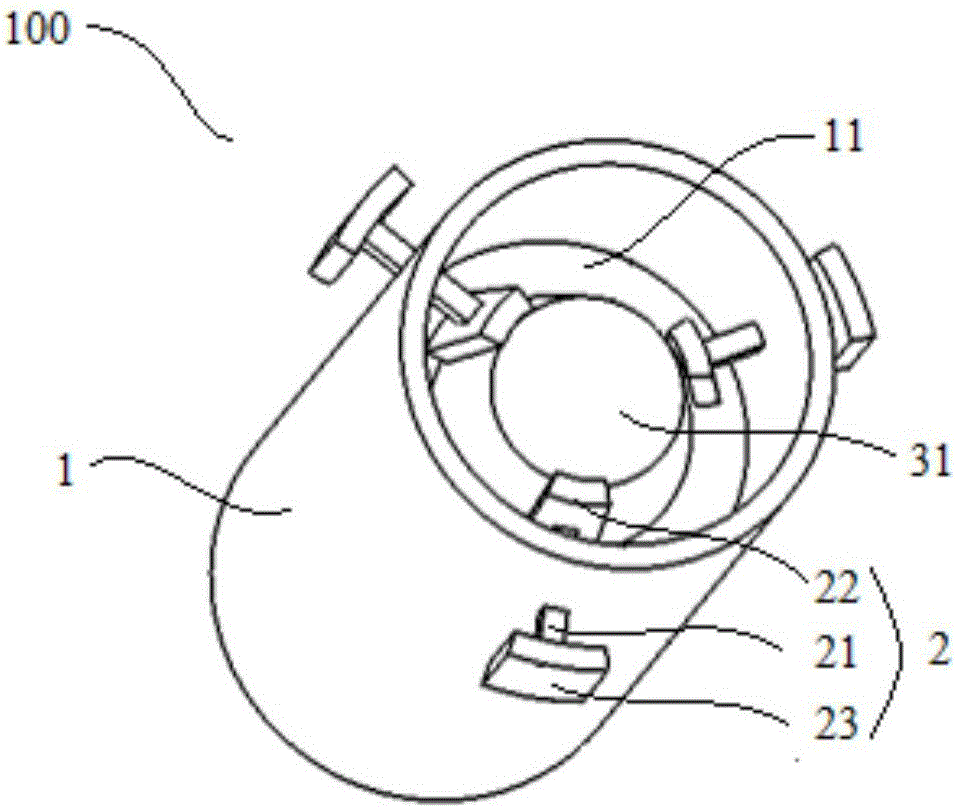

The invention relates to a harmonic reducer with a lubricating function. The harmonic reducer with the lubricating function comprises a rigid wheel. A flexible wheel is connected into the rigid wheel in a transmission mode. A harmonic generator is connected into the flexible wheel in a transmission mode. The harmonic generator is fixedly connected with a power output shaft of a servo motor. The rigid wheel comprises a motor installation base. An elastic connecting device is arranged between one side of the motor installation base and the servo motor and comprises an annular connecting part fixedly connected with the servo motor. An elastic connecting part is arranged between the annular connecting part and the motor installation base. The annular connecting part is coaxial with the elastic connecting part, the inner diameter of the annular connecting part is the same as the inner diameter of the elastic connecting part, and the outer diameter of the elastic connecting part is smaller than the outer diameter of the annular connecting part. Oil storage grooves are formed in the two side edges of the surface of the inner side of the rigid wheel, and the section of each oil storage groove is in the shape of a circle with notches. The effect that a rotary shaft of the motor is kept being coaxial with the harmonic generator is guaranteed through the elastic connecting device, and the contact surfaces of the flexible wheel and the rigid wheel are lubricated through the oil storage grooves, so that the normal engagement and the linkage effect of the flexible wheel and the rigid wheel are guaranteed, and the service life of the harmonic reducer is prolonged.

Owner:广东天太机器人有限公司

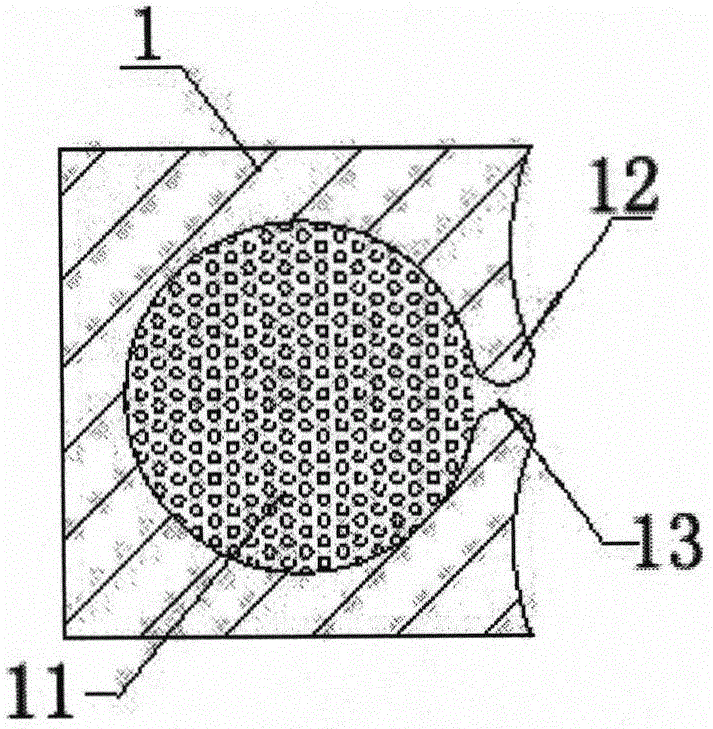

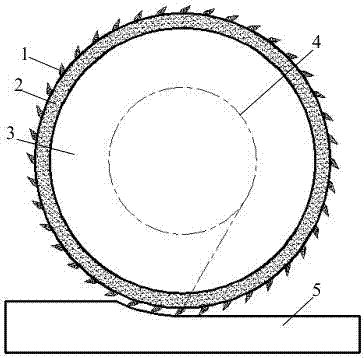

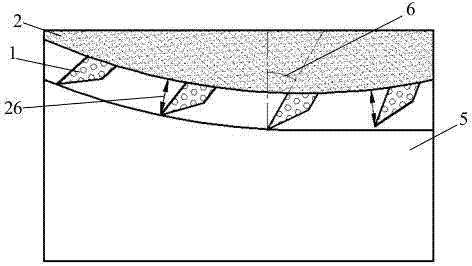

Spiral and orderly arranging fiber tool capable of conducting positive rake angle machining and preparation method thereof

InactiveCN107243848AImprove efficiencyImprove processing efficiencyBonded abrasive wheelsGrinding devicesFiberHelical line

The invention discloses a helically and orderly arranged fiber cutter capable of positive rake angle processing and a preparation method thereof. The fiber cutter includes fiber, carcass and steel matrix; the fiber is tangent to the base circle in the steel matrix, and the fiber can process the workpiece with a positive rake angle during cutting; Arranged in an orderly manner. The preparation method is as follows: the fiber is prepared by wire electric discharge cutting technology; the series of fibers are clamped and sharpened by special clamps; the matrix is prepared on the prefabricated steel base by pressing and sintering technology; A series of small holes arranged in a helical line are processed on the body; epoxy resin is injected into the small holes, the fibers are inserted into the small holes, and the embracing device is used to ensure that the blade height of the fibers is consistent; the fiber cutter is prepared by heating and curing. The helical and orderly arranged fiber cutter prepared by the invention can realize positive rake angle processing, significantly reduce cutting force and cutting temperature, and improve cutting performance.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Hinge positioning jig

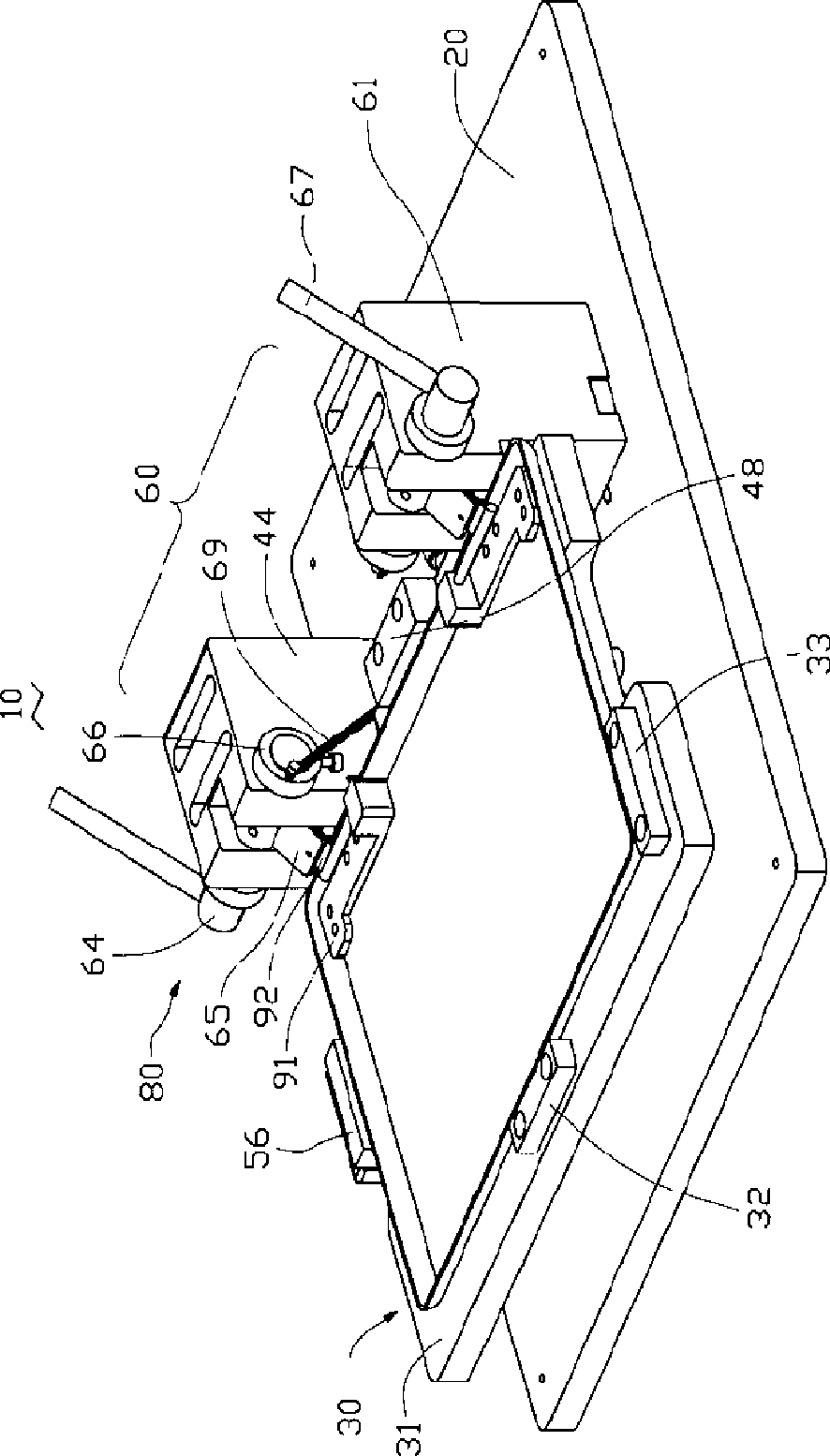

InactiveCN101470465AGuaranteed coaxialPrecise positioningWorkpiece holdersDigital data processing detailsEngineeringMechanical engineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

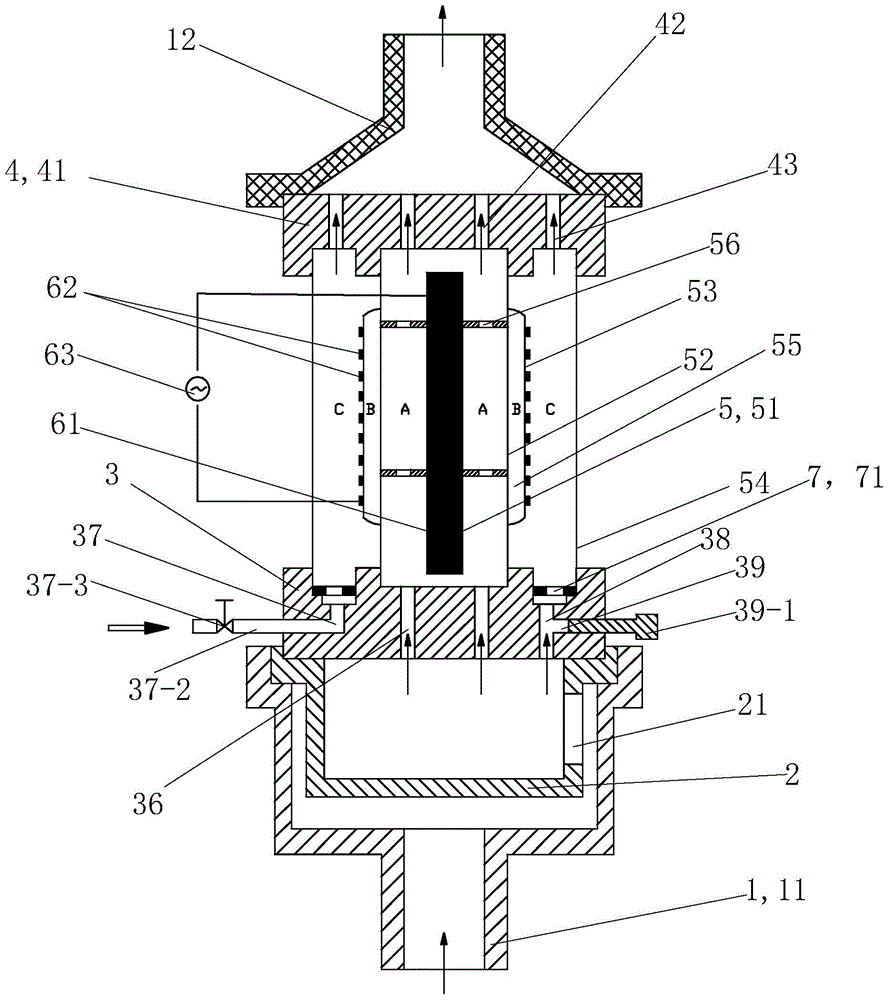

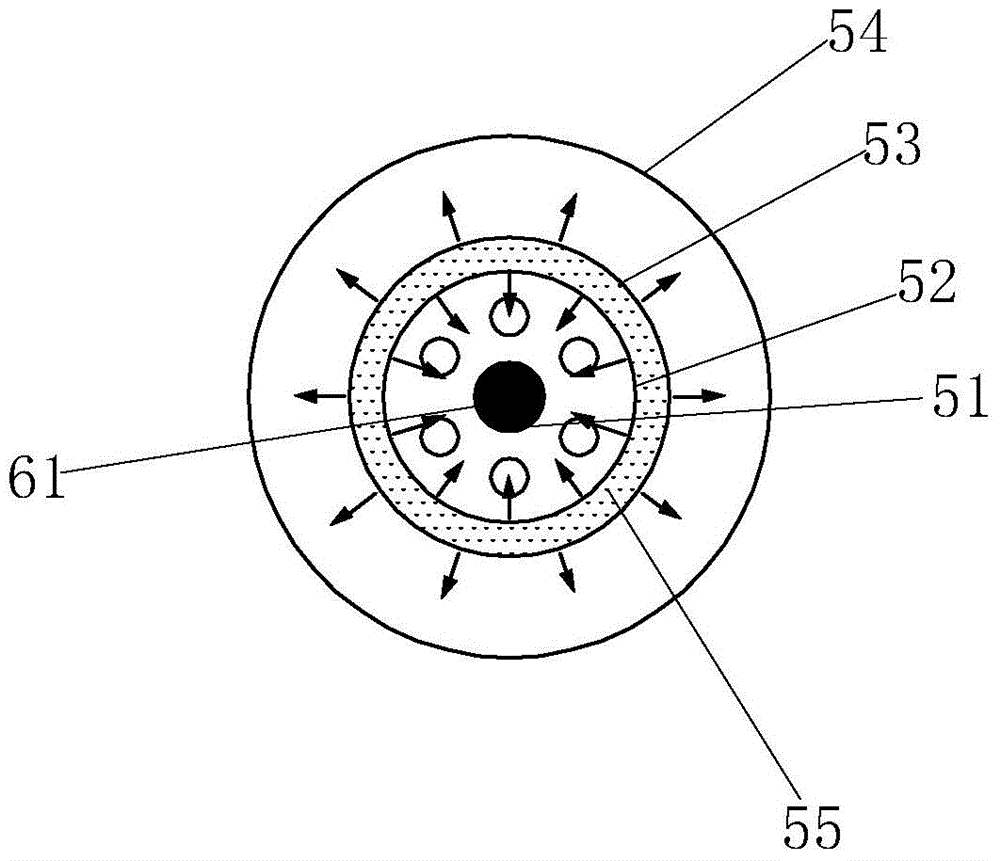

Quasi-molecular ultraviolet radiation and plasma coupling integrated waste gas degrading device

ActiveCN104014233ALower breakdown voltageIncrease profitDispersed particle separationPlasmonic couplingChemical reaction

Owner:赛瑞意(江苏)生物设备有限公司

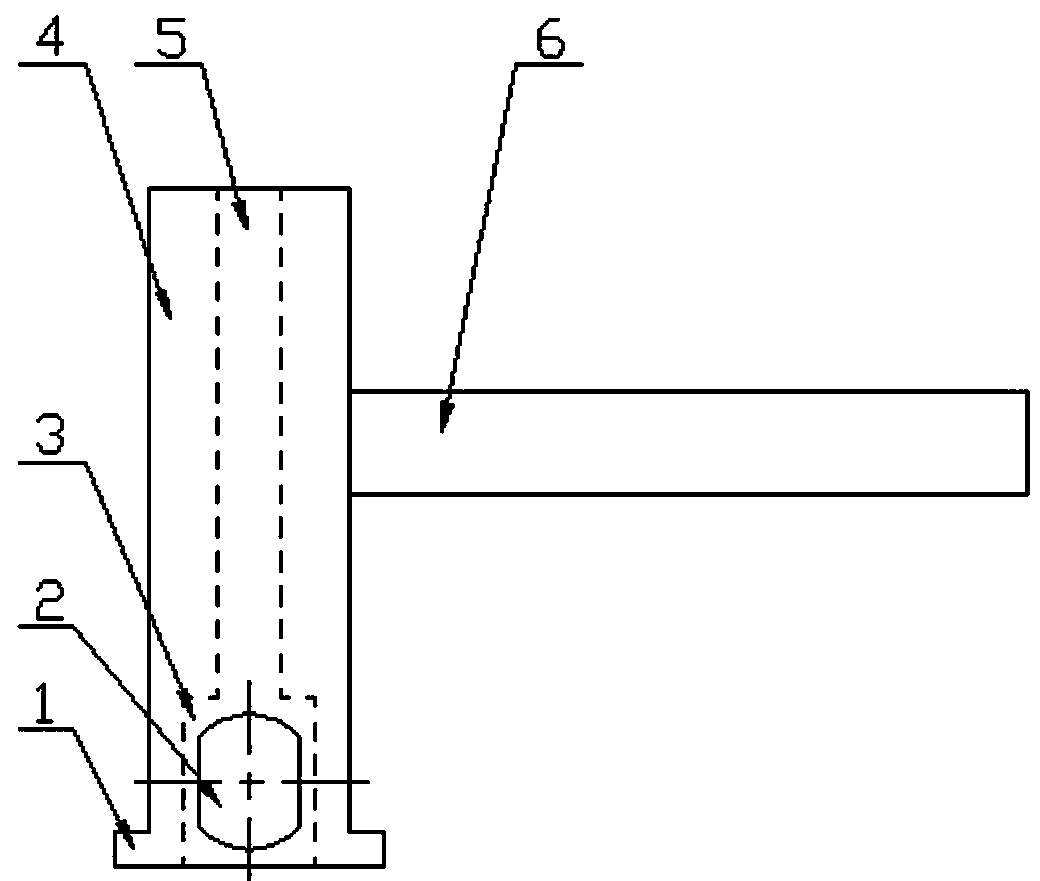

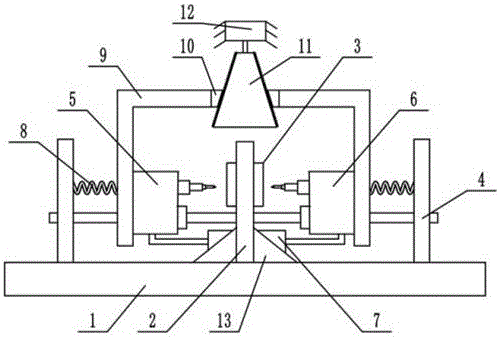

Drilling equipment for drilling center hole of motor shaft

The invention belongs to the field of mechanical grinding, and concretely discloses drilling equipment for drilling a center hole of a motor shaft. The drilling equipment for drilling the center hole of the motor shaft comprises a base and a support plate. A through hole is formed in the support plate; a clamping device is arranged in the through hole and is coaxial to the through hole; a sliding support penetrates through the bottom part of the support plate; a first drilling machine is slidably connected to one end of the sliding support; a second drilling machine is slidably connected to the other end of the sliding support; the first drilling machine and the second drilling machine are jointly connected with a first motor; elastic elements are connected between the first drilling machine and one side wall of the sliding support as well as between the second drilling machine and the other side wall of the sliding support; drill bits of the first drilling machine and the second drilling machine are coaxial to the clamping device; connecting rods are connected onto the first drilling machine and the second drilling machine; threaded plates are arranged on opposite end faces of the two connecting rods; and a threaded cone is matched between the threaded plates. The scheme can prevent the occurrence of the problems that the motor shaft is eccentric during a drilling process, holes in two ends of the motor shaft are non-coaxial, and the like.

Owner:CHONGQING QIANYAN MACHINERY CO LTD

Cylinder filling adaptor

ActiveCN101832468ANo leaksPrevent leakageContainer filling methodsContainer discharging methodsElastomerGas cylinder

The invention provides a cylinder filling adaptor, which aims to solve the problem that the conventional cylinder filling adaptor has the drawbacks of having low sealing and airtight performance and damaging a cylinder component, and comprises an inner core and a connecting sleeve, wherein the inner core is internally provided with an air flue, an elastic body is sleeved around the outside of a connection part at the near end of the inner core, and the outer side, adjacent to the connection part, on the periphery of the inner core is provided with a protrusion; the connecting sleeve is comprised of a connecting section and a thrust section, the connecting section has a cylinder structure with a positively-rotatable internal threads, and the thrust section is an inner step arranged at the far end of the connecting sleeve, the connecting sleeve is sleeved on the inner core from the far end of the inner core with the thrust section clamped at the position of the protrusion of the inner core and the connecting section matched with the positively-rotatable internal thread at the external wall of the inflation inlet to make the connection part, with the elastic body, of the inner core enter the cylinder part at the inner wall of an inflation inlet to form sealed fit. The cylinder filling adaptor has the advantages of avoiding gas leakage in a gas filling process and avoiding damaging the cylinder components in installation and use.

Owner:北京北机机电工业有限责任公司

Ultrahigh pressure radial plunger pump

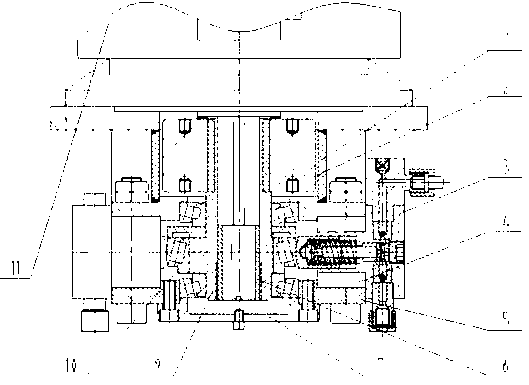

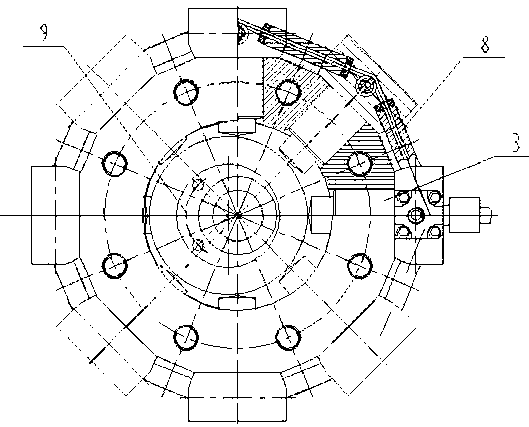

InactiveCN103133291AReduce intermediate linksEnsure adequate lubricationPositive-displacement liquid enginesMulti-cylinder pumpsEngineeringVariable pressure

The invention discloses an ultrahigh pressure radial plunger pump, and belongs to the technical field of hydraulic control. The ultrahigh pressure radial plunger pump comprises a motor which is arranged on a bearing framework, an eccentric shaft is sleeved on an output shaft of the motor, multiple sets of plunger pumps are evenly distributed on the periphery of the eccentric shaft, the multiple sets of plunger pumps with the output shaft of the motor as the center, a conical roller bearing is sleeved on the eccentric shaft, and the outer ring of the conical roller bearing simultaneously contacts with the top ends of the multiple sets of plunger pumps with the output shaft of the motor as the center. The ultrahigh pressure radial plunger pump can achieve variable pressure and variable flow, the multiple plunger pumps can be in parallel connection, oil mass supply of a large-scale hydraulic pressure station is satisfied, sealing performance is good, service life is long, reliability is high, performance cost ratio is high, and the ultrahigh pressure radial plunger pump is suitable for application and popularization.

Owner:SICHUAN SHENGBAO ELECTRICAL TECH

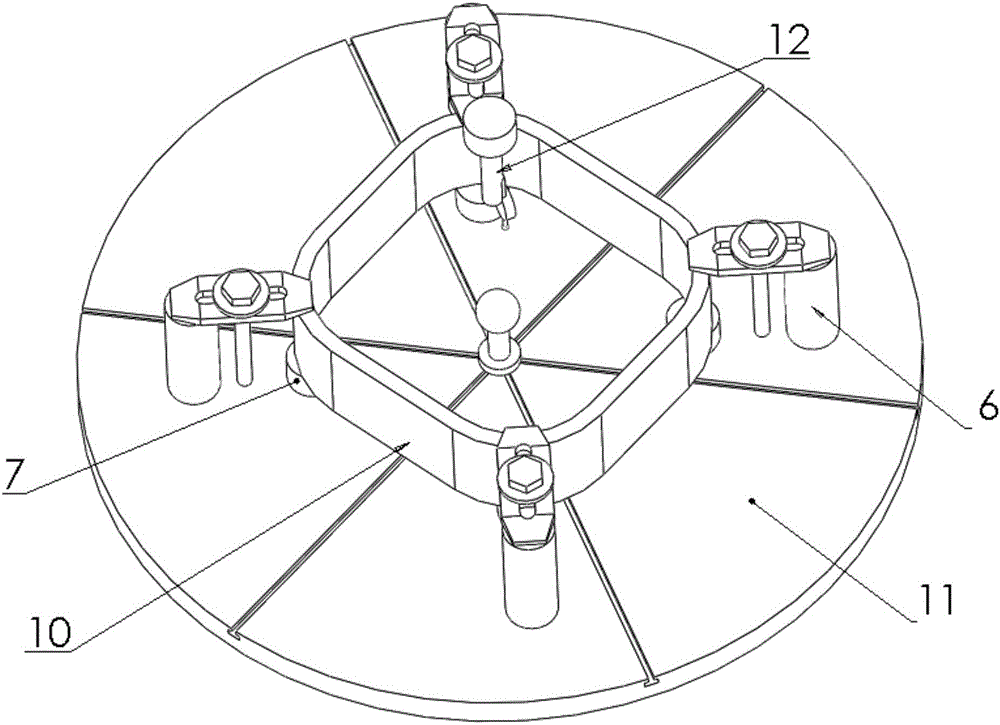

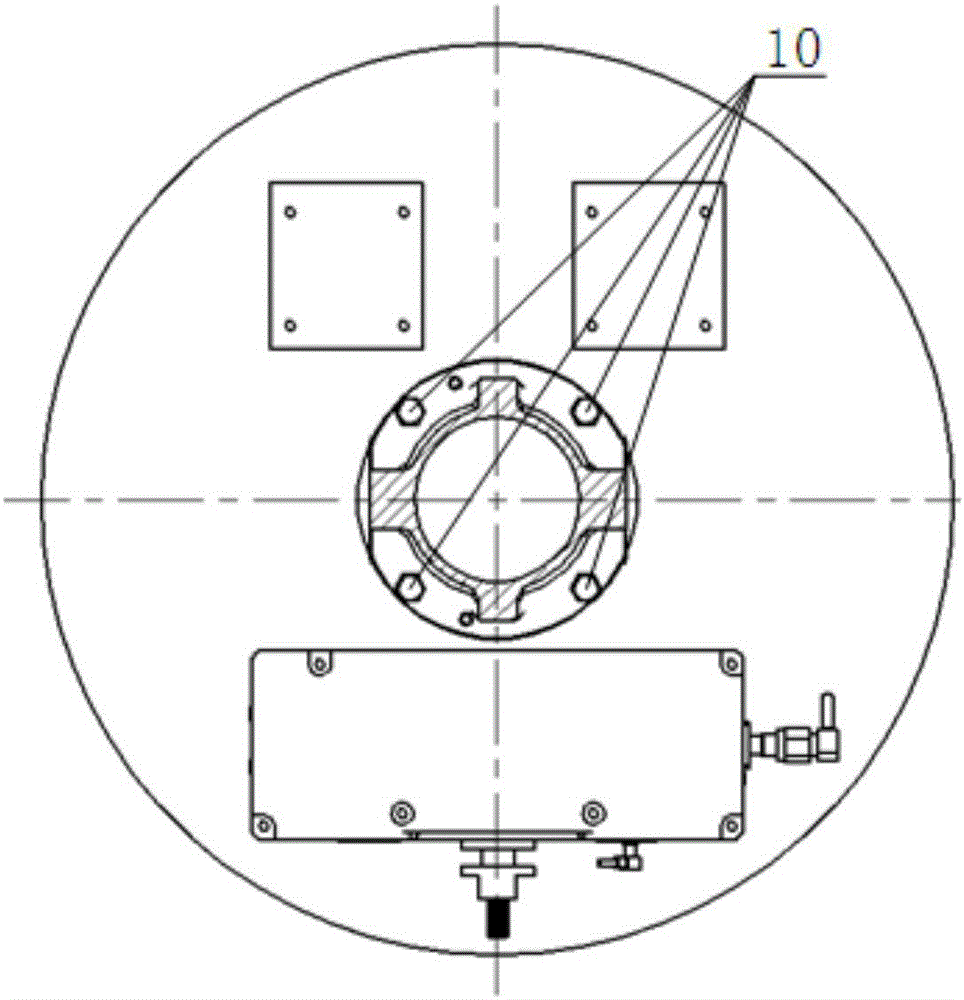

Special positioning fixture for blade numerical control precision machining

InactiveCN105817918AGuaranteed coaxialGuaranteed machining accuracyPositioning apparatusMetal-working holdersNumerical controlEngineering

The invention discloses a special positioning fixture for blade numerical control precision machining. The special positioning fixture comprises a chuck a and a chuck b, the chuck b is connected with a tailstock of a machine tool, the chuck a is connected with a main shaft head of the machine tool, a fixture body and a baffle ring are connected to the end face of the chuck a, and the fixture body is located between two clamping jaws of the chuck a and comprises a fixing block; and an L-shaped connecting rod a and a connecting rod b are vertically connected to the fixing block, a fastening screw is arranged on the connecting rod a, the connecting rod b is provided with a sliding block sliding along the connecting rod b, and the sliding block is located between the connecting rod a and the connecting rod b. When the special positioning fixture for blade numerical control precision machining is used, it is guaranteed that the blade and the main shaft of the machine tool are coaxial; the two ends of the blade are fastened to solve the problems of chattering caused by dynamic cutting force in the cutting process and deformation caused in the machining process. The special positioning fixture is simple and compact in structure, high in positioning accuracy, rapid and convenient to operate and demount, and capable of effectively guaranteeing the machining accuracy of the front face and the back face of the blade.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

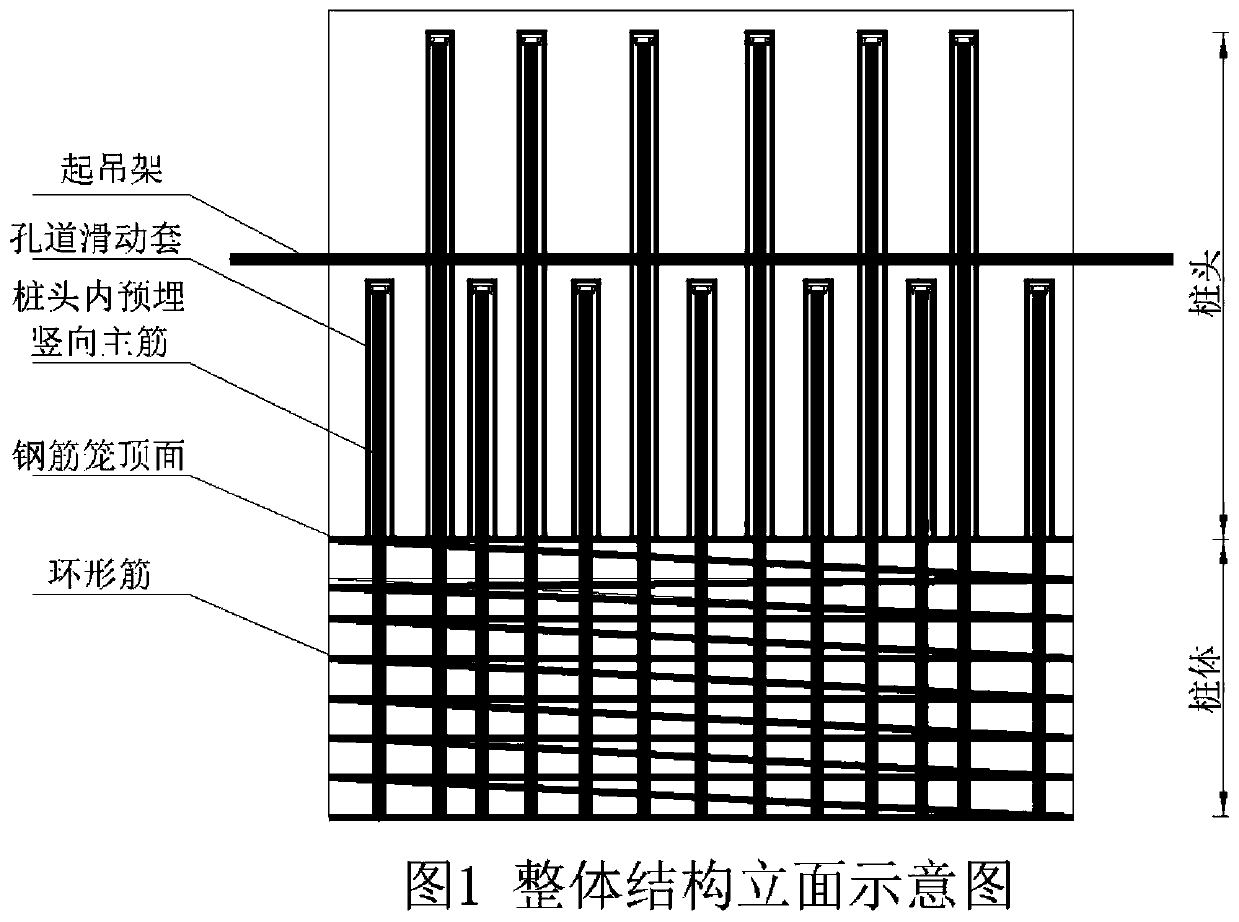

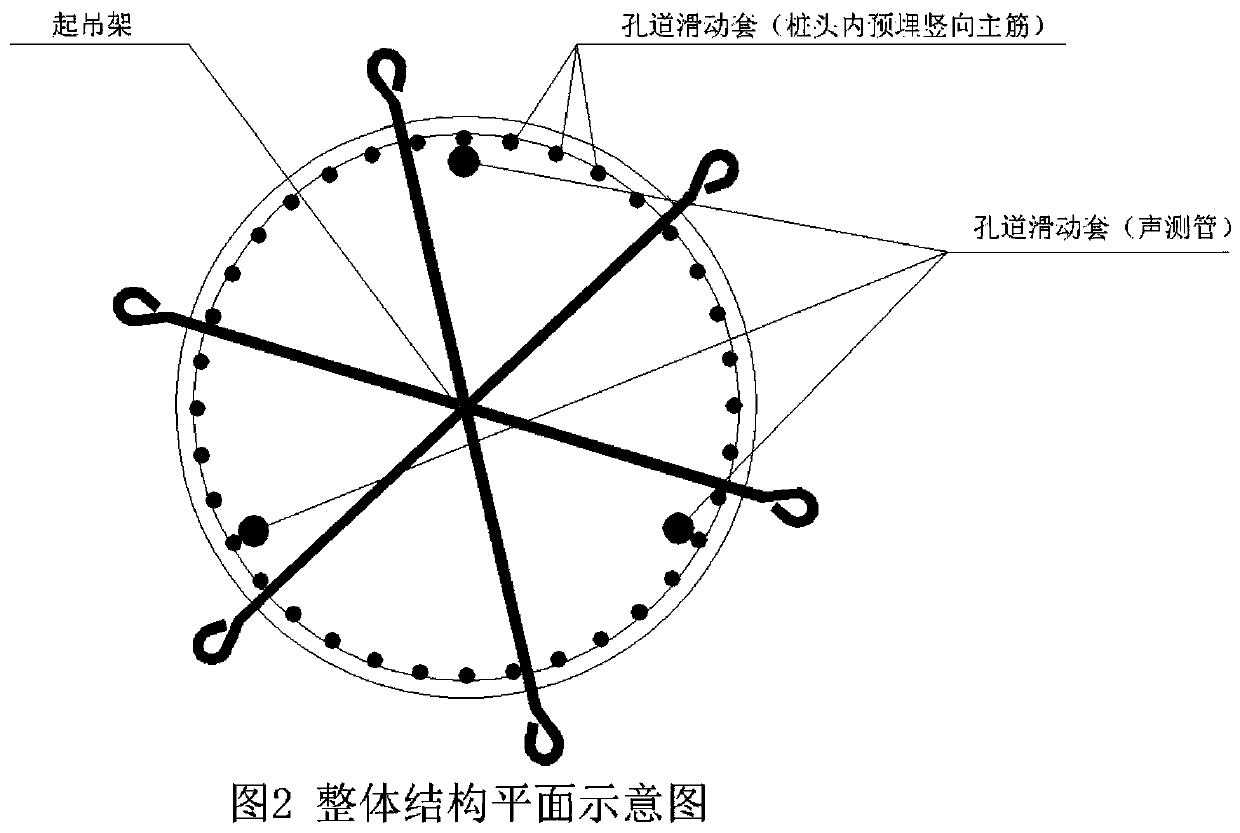

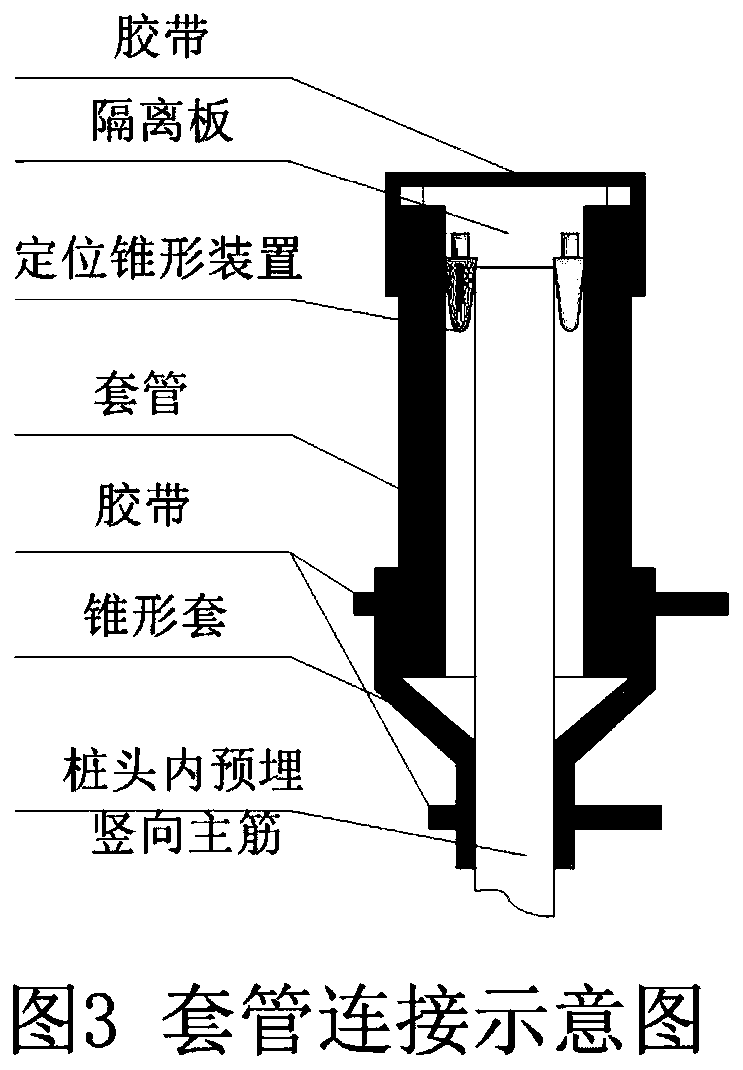

Construction method for quickly and non-destructively breaking pile heads

InactiveCN111218936AEasy to removeGood for guaranteed removalBulkheads/pilesAdhesive beltArchitectural engineering

The invention discloses a construction method for quickly and non-destructively breaking pile heads. In the construction method, a pile body is included. A reinforced cage is arranged inside the pilebody; vertical main reinforcements are reserved in a pile head of the reinforced cage; a pore passage sliding sleeve is arranged on the outer surface of a sound measuring pipe; an isolation plate anda tapered sleeve are separately arranged at the upper and lower ends of the pore passage sliding sleeve; the upper and lower ends of the pore passage sliding sleeve are bonded and sealed with an adhesive tape; a lifting frame (the whole pile head is used as a marking rod before lifting) is arranged at a position where the vertical main reinforcements reserved in the pile head of the reinforced cage are not smaller than 30 cm from the top surface of the reinforced cage; and a concrete pouring pile head is within the range of the vertical main reinforcements reserved in the pile head of the reinforced cage. After the construction of the pile head is completed, a high-pressure water jet technology (also known as hydraulic breaking technology) is used for properly removing concrete from the lifting frame to the top surface of the reinforced cage, and finally the pile head is integrally hoisted by a crane, thereby completing the quick and non-destructive breaking of the whole pile head.

Owner:SHANDONG LUQIAO CONSTR

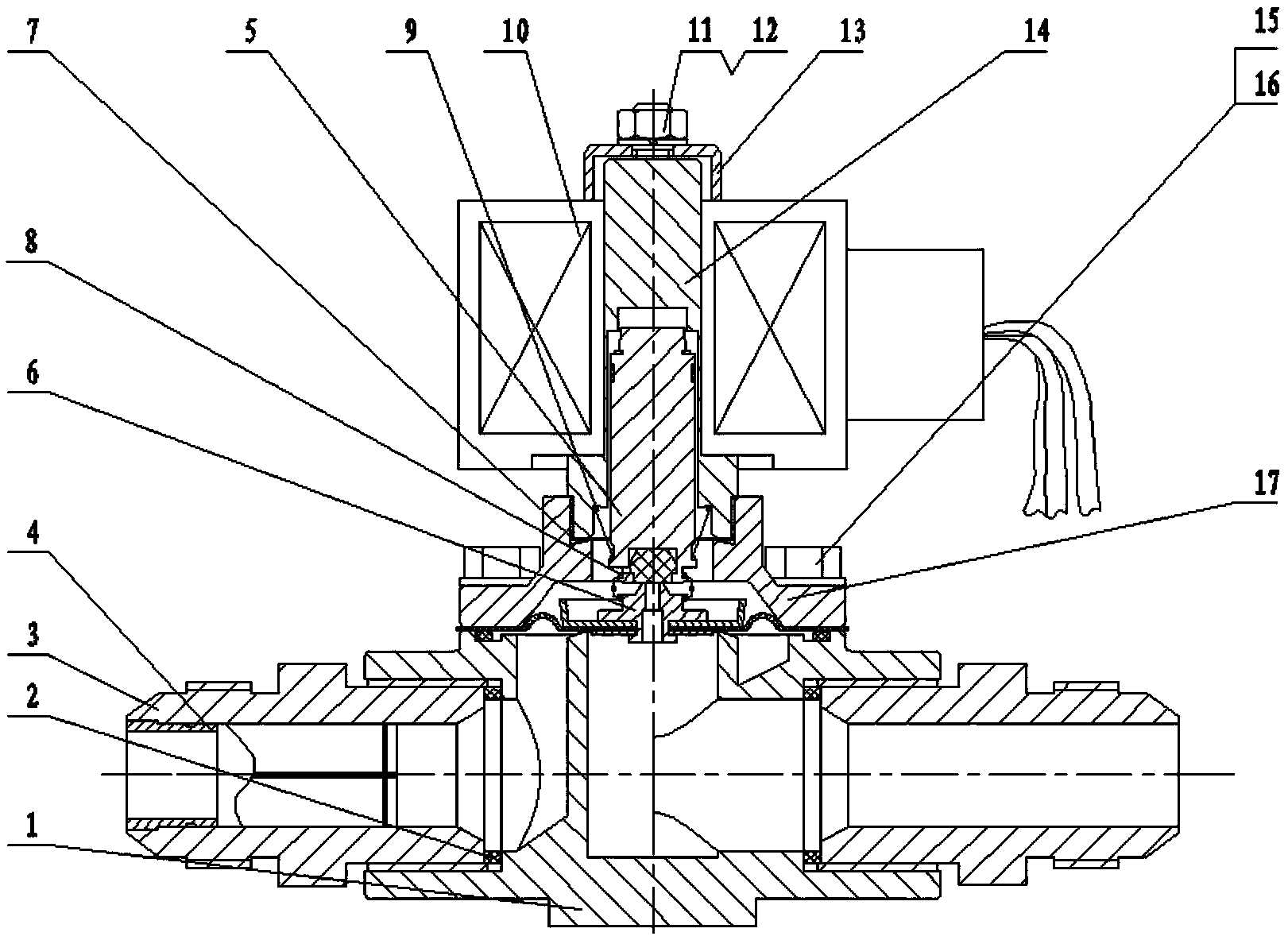

Natural gas solenoid valve

InactiveCN103644337AImprove sealingOpen quicklyDiaphragm valvesOperating means/releasing devices for valvesAutomatic controlSolenoid valve

The invention provides a natural gas solenoid valve, and belongs to the technical field of solenoid valves. The natural gas solenoid valve comprises a valve body, a hard-core membrane, a valve deck, a permeable sleeve, a guide sealing head, a tension spring and an explosion-proof solenoid coil. The hard-core membrane and the valve body are sealed. A control gas nipple of the hard-core membrane and the guide sealing head are in joint seal through the tension spring. The guide sealing head is matched with a cylindrical surface of the permeable sleeve. The explosion-proof solenoid coil is installed on the permeable sleeve. The hard-core membrane is formed by riveting a membrane body, a liner bowl, a liner pad and the control gas nipple, wherein the diameter of the liner bowl is 1.3-1.5 times that of a gas outlet channel of the valve body, the diameter of the liner pad is smaller than that of the gas outlet channel of the valve body, and the diameter of the control gas nipple is larger than that of a gas inlet hole of the waveform membrane body. The natural gas solenoid valve is simple in structure, fast to assemble, convenient to maintain, and capable of being widely applied to the natural gas industry. The natural gas solenoid valve realizes automatic control in the transmission process of natural gas, and is quick in response, high in reliability and particularly suitable for emergency cut-off.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

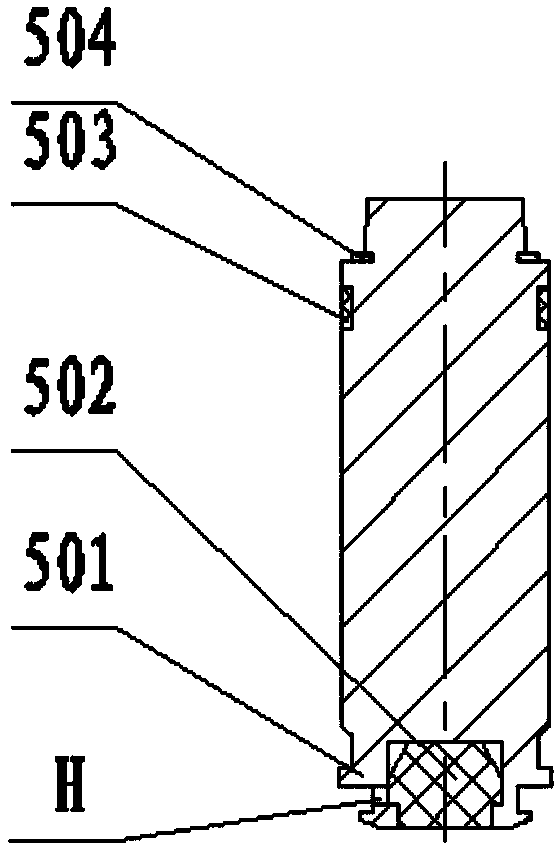

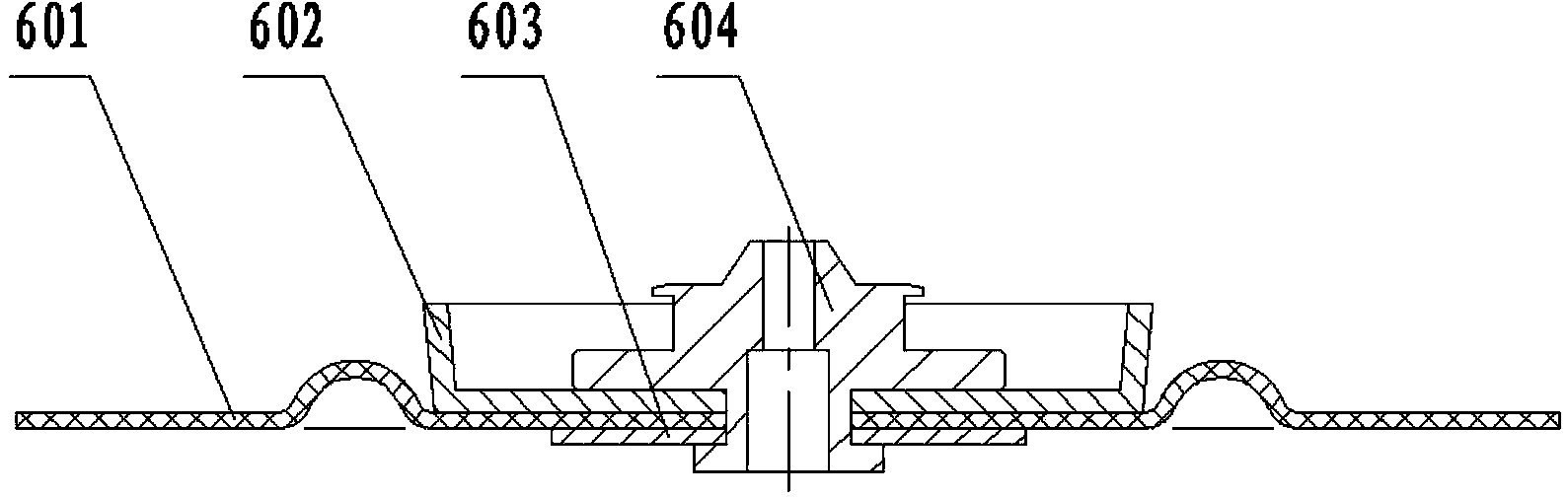

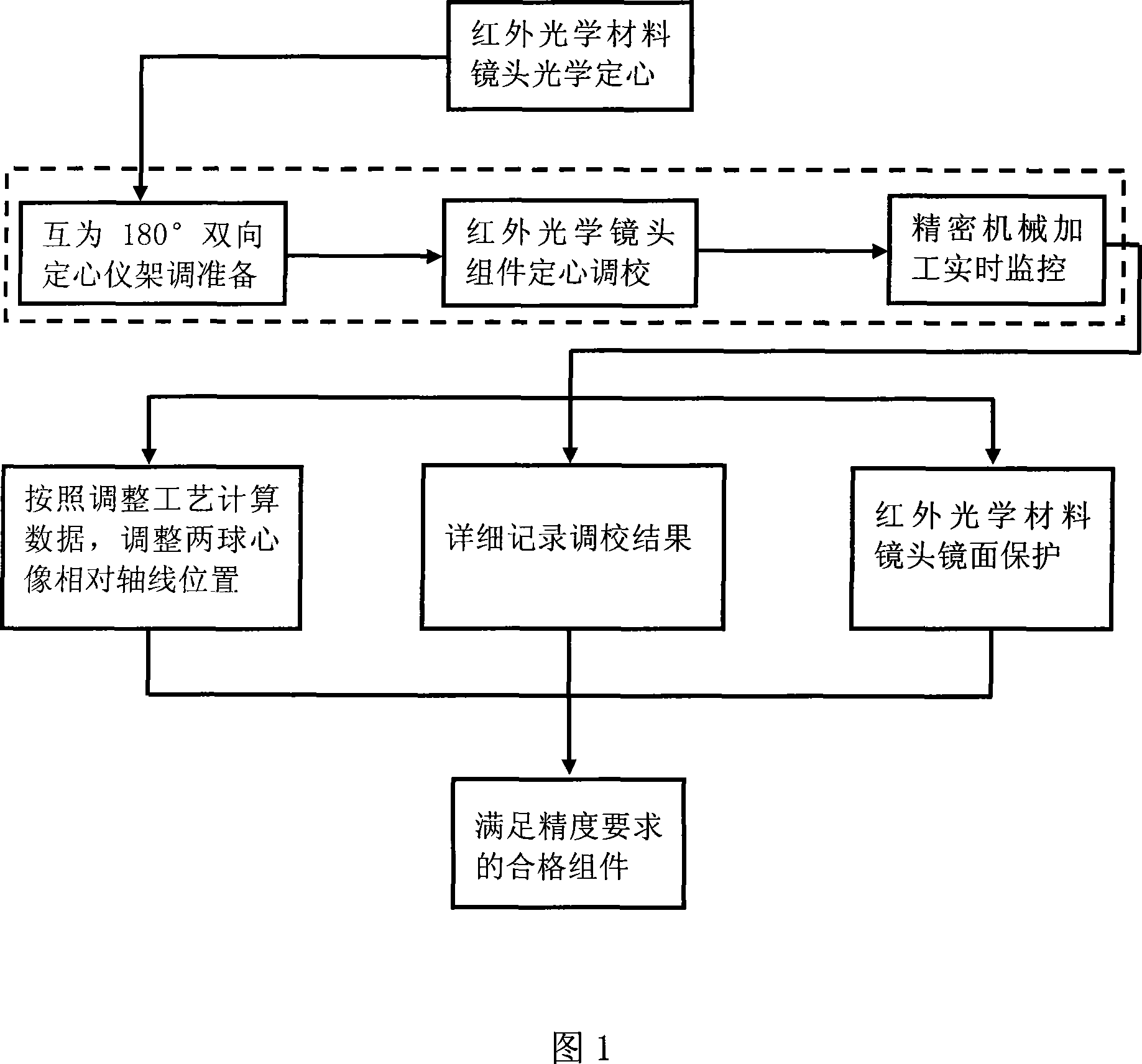

Infrared optical lens component bidirectional transverse alignment processing method and equipment

InactiveCN101158726ASolve optical centering processingGuaranteed coaxialOptical articlesGlass severing apparatusCamera lensInfrared

The invention discloses a two-way centering and processing method of an infrared optical scene component, which has the following processing steps: centering apparatuses are respectively arranged at the left side of a principal shaft of an lathe and on a tailstock of the lathe, with the shafts running oppositely to each other; a fixture chuck is arranged on the principal shaft of the lathe, and a scene component is fixed on the fixture chuck; simultaneously the center offset of two spheres is observed and repeatedly adjusts the center offset of spheres according to the observing information, until the two sphere centers satisfy the coaxal requirement correspondingly to the axes; the scene component is processed into a semi-finished products. The equipment of the invention consists of the lathe, a fixture chuck arranged on the principal shaft of the lathe, a first centering apparatus fixed on the tailstock of the lathe, a secondary centering apparatus fixed at the left side of the principal shaft of the lathe, and the first and secondary centering apparatuses are coaxal. The invention resolves the technical problems that images of two sphere centers cannot be observed simultaneously in the existing uni-directional centering and processing technique, and consequently the coaxiality of two sphere centers cannot be ensured to achieve the ideal optical axis, and the invention can ensure the autologous coaxiality of the sphere center of each optical scene component, as well as the coaxiality between optical components.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

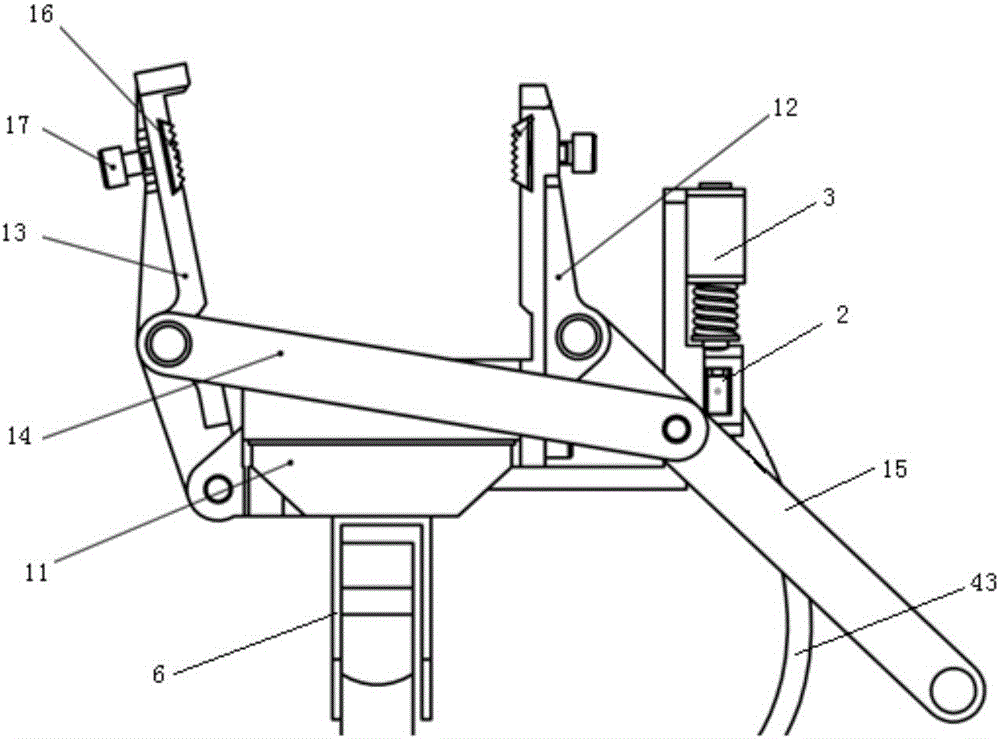

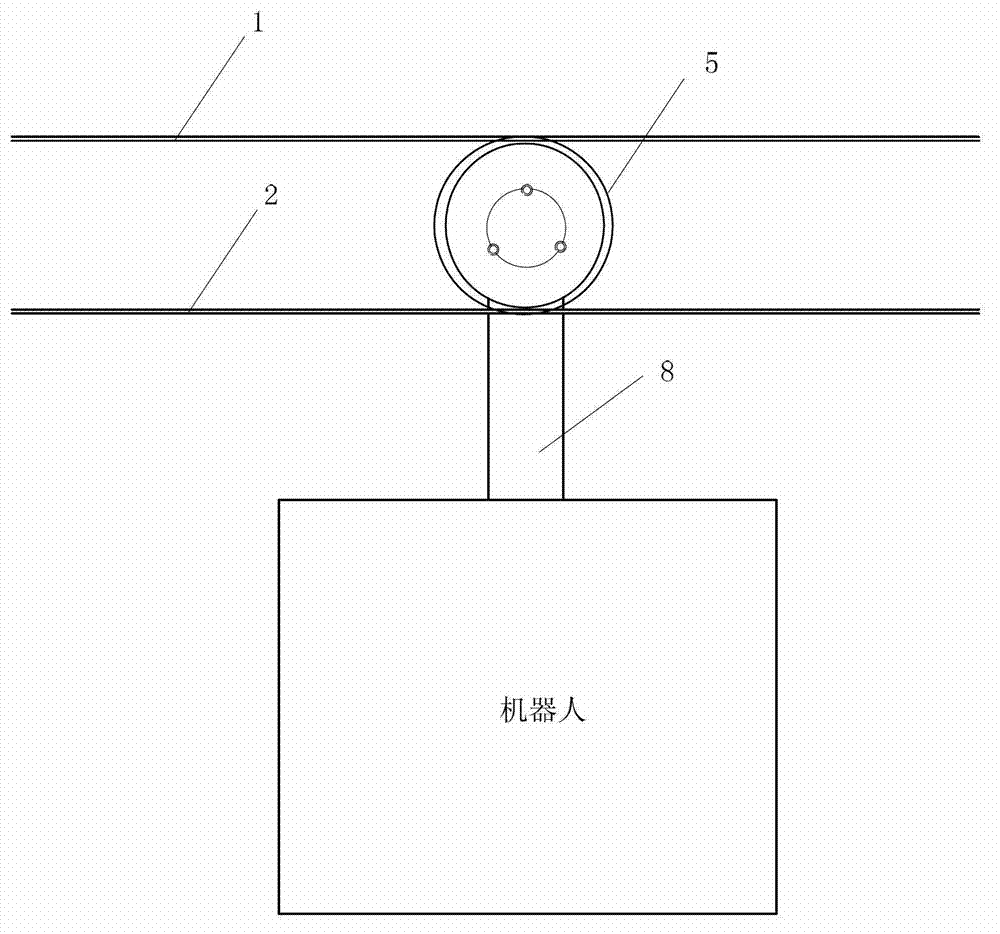

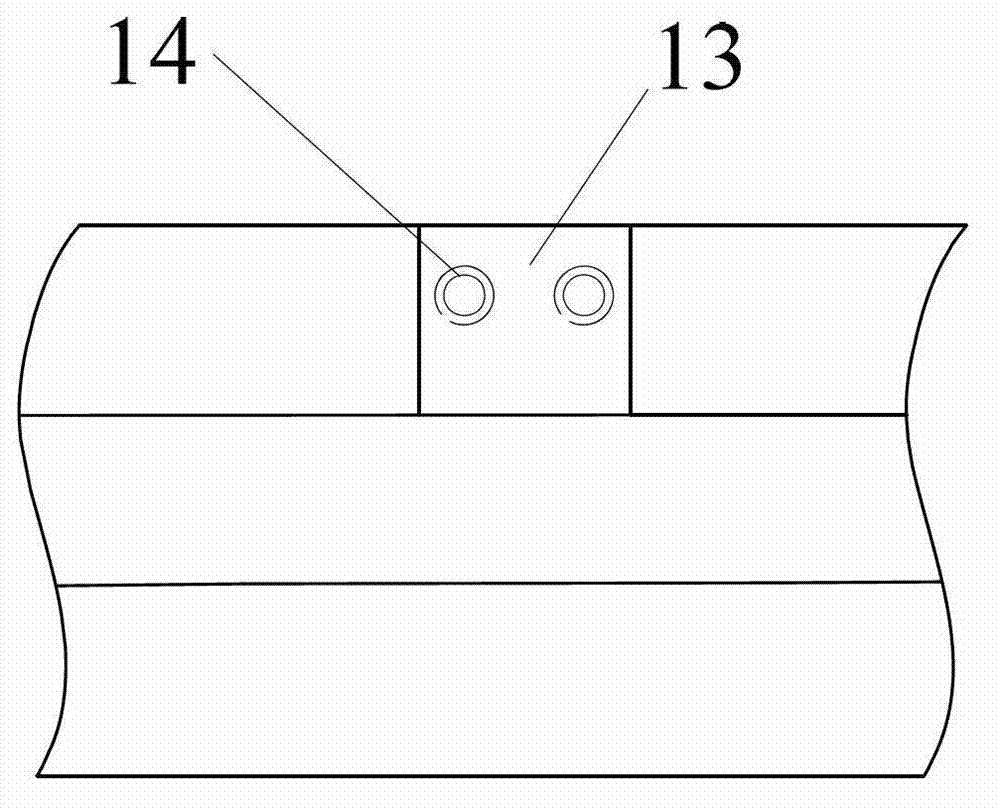

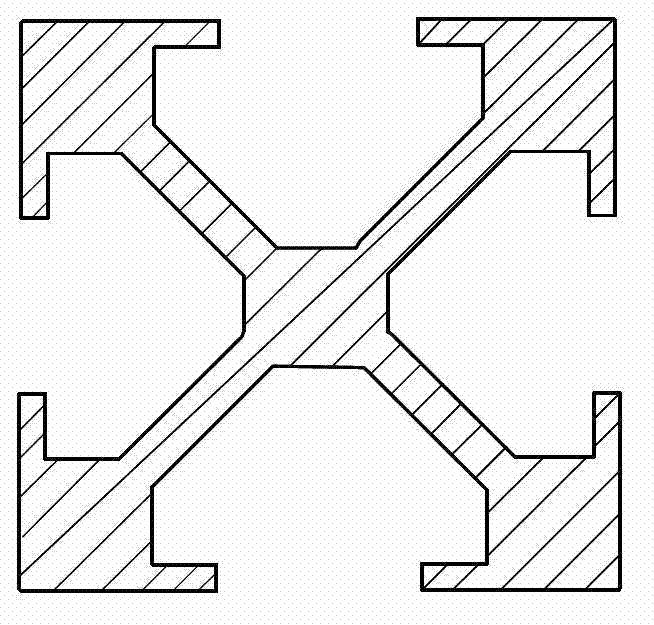

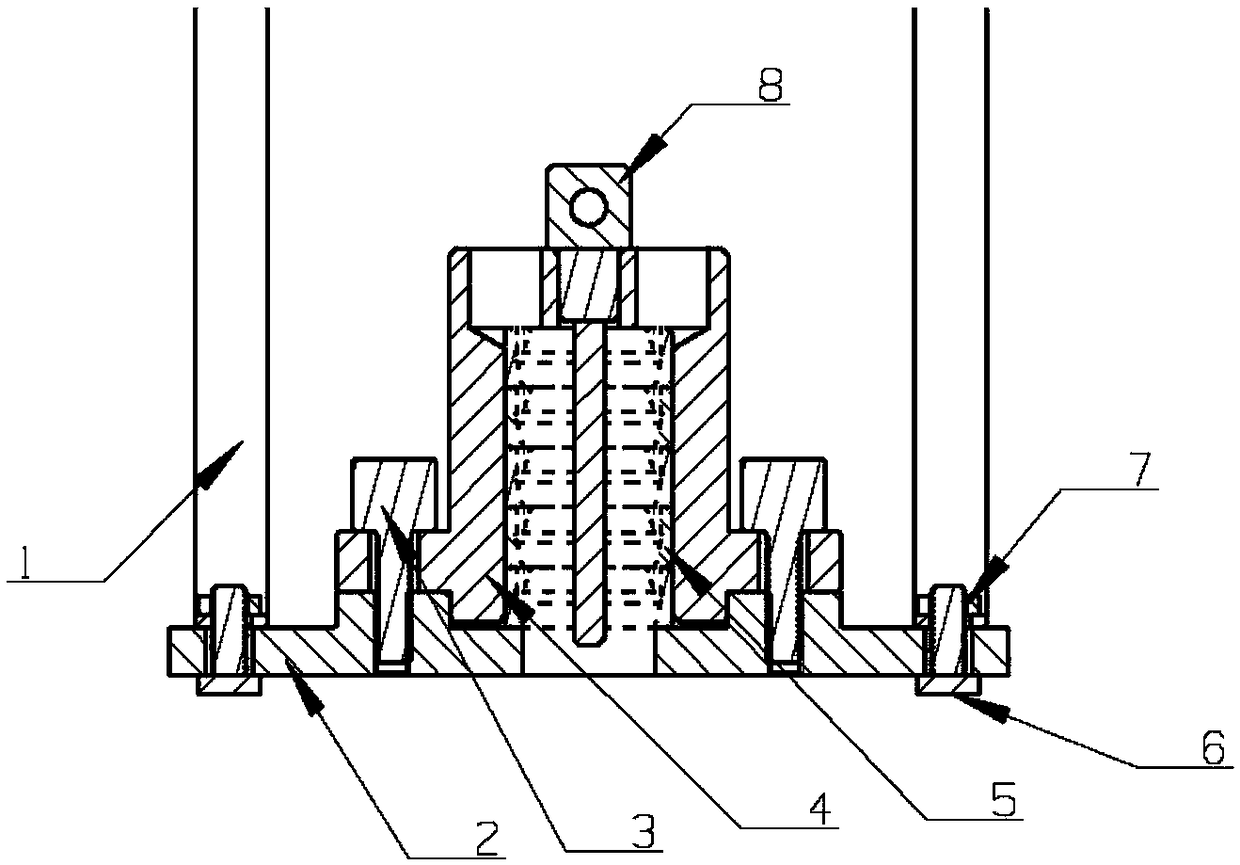

Independent arm wheel type movement mechanism of tunnel cable inspection robot

The invention belongs to the field of a rail wheel type structure and particularly relates to an independent arm wheel type movement mechanism of a tunnel cable inspection robot. The movement mechanism is divided into two parts including an independent arm wheel type inspection robot and a rail, the rail is divided into an upper rail and a lower rail, the middle of each surface of the rail is respectively provided with a V-shaped groove, and the cross section of the V-shaped groove is respectively in an X shape. The independent arm wheel type inspection robot is structurally characterized in that a wheel shaft of a wheel are connected with a motor through a shaft coupling, a ladder-shaped protecting frame is arranged outside the shaft coupling, the lower end of the ladder-shaped protecting frame is connected with a groove-shaped connecting arm , the lower end of the groove-shaped connecting arm is connected with the inspection robot, and one side of the groove-shaped connecting arm near the wheel is provided with a charger. Two sides of the wheel are respectively provided with inner rubber sleeve wheels connected through screws, and outer rings of the inner rubber sleeve wheels are provided with outer rubber sleeve wheels. The independent arm wheel type movement mechanism has the advantages that the structure is simple, the space is saved, and the independent arm wheel type movement mechanism can be used for the tunnel cable inspection robot and can also be applied to all single wheel motor vehicles and equipment running on the rail.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

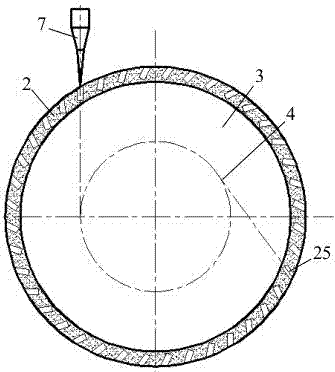

Micro-plasma arc welding gun

ActiveCN105537743ASmall diameterRelieve stiffnessPlasma welding apparatusWelding/soldering/cutting articlesAmpereHigh energy

The invention discloses a micro-plasma arc welding gun which comprises a tungsten electrode press head, a sealing ring, a tungsten electrode clamp, an upper gun body, an insulator, a lower gun body, a centering support pillar, a centering sleeve, a gun mouth, a protecting gas cap, a tungsten electrode and a handle. The micro-plasma arc welding gun disclosed by the invention has the following beneficial effects that the upper gun body and the lower gun body are high in heat conduction efficiency; due to an optimally designed lower gun body cooling water channel, the heat conduction travel is reduced, and the cooling effect of the gun mouth is improved; the tungsten electrode clamp, the centering support pillar and the centering sleeve can ensure that the tungsten electrode is coaxial with the gun mouth; on the premise that advantages such as small plasma diameter and high energy density are maintained for the gun mouth, the stiffness of the plasma arc can be reduced, low current overlaying under 50 amperes can be achieved, and the sizes of thin-wall components made of materials such as titanium alloy and nickel base alloy can be recovered through overlaying. In addition, the micro-plasma arc welding gun is compact in structure, so that the accessibility of the welding gun in working is improved.

Owner:CIVIL AVIATION UNIV OF CHINA

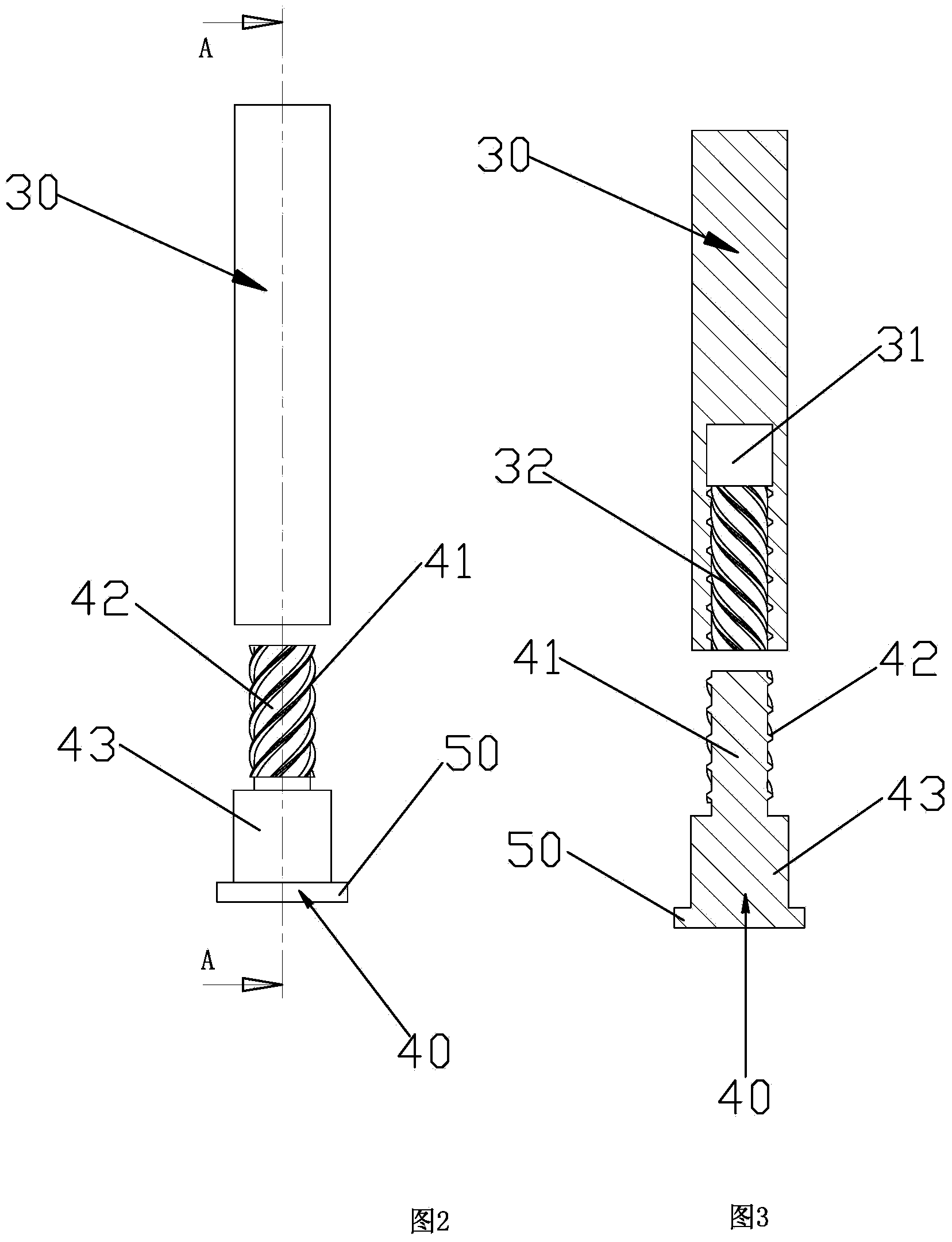

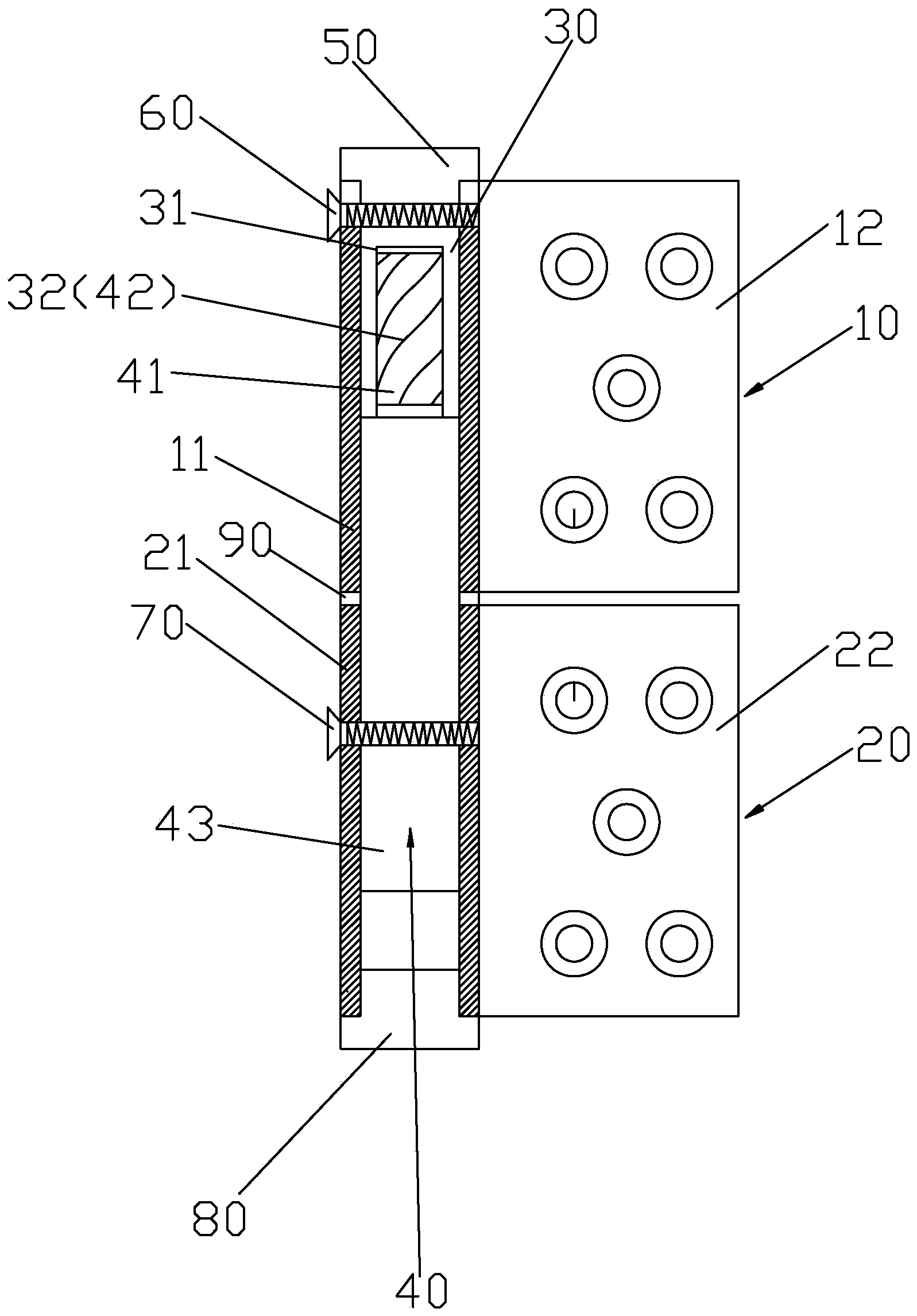

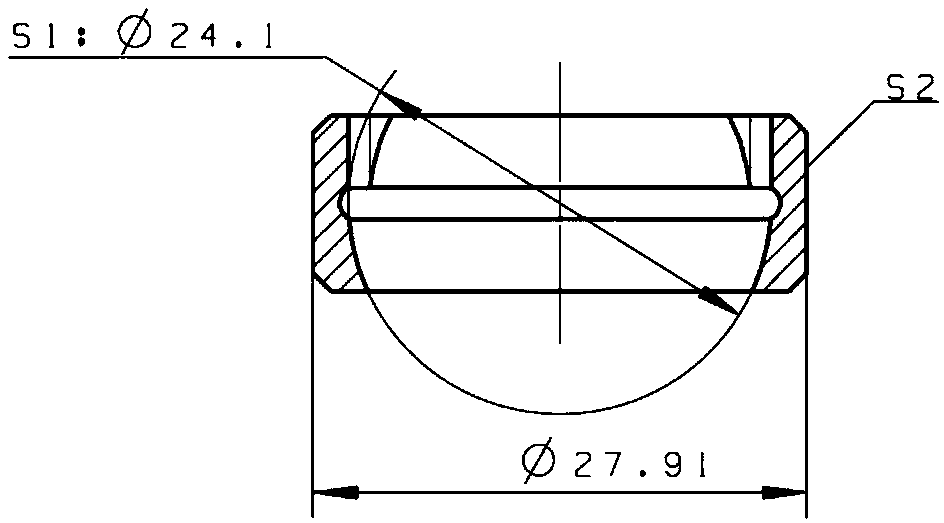

Liftable hinge device

ActiveCN104343307ALow costImprove connection strengthWing openersWing closersEngineeringUltimate tensile strength

The invention discloses a liftable hinge device. The liftable hinge device comprises an upper hinge, a lower hinge, a transmission base and a transmission rod, wherein the upper hinge comprises an upper shaft sleeve and an upper hinge sheet fixedly connected with the upper shaft sleeve; the lower hinge comprises a lower shaft sleeve and a lower hinge sheet fixedly connected with the lower shaft sleeve; the transmission base is fixedly connected with the upper shaft sleeve; a transmission cavity is concavely formed in the bottom end surface of the transmission base; a first spiral part is arranged on an internal rotary surface of the transmission cavity; the transmission rod is fixedly connected with the lower shaft sleeve; a second spiral part is arranged on an external rotary surface of the transmission rod; the transmission rod is connected with the transmission cavity; the first spiral part is adapted and meshed with the second spiral part; the upper hinge is pushed to rotate relative to the lower hinge, and the upper hinge is lifted through matching of the first spiral part and the second spiral part; a pushing action is released to decline the upper hinge under the action of gravity, and the upper hinge can automatically return to a closed state through matching of the first spiral part and the second spiral part. The liftable hinge device has the advantages of low cost, high connection strength, high stability, difficult damage, long service life and attractive appearance.

Owner:吴裕龙 +2

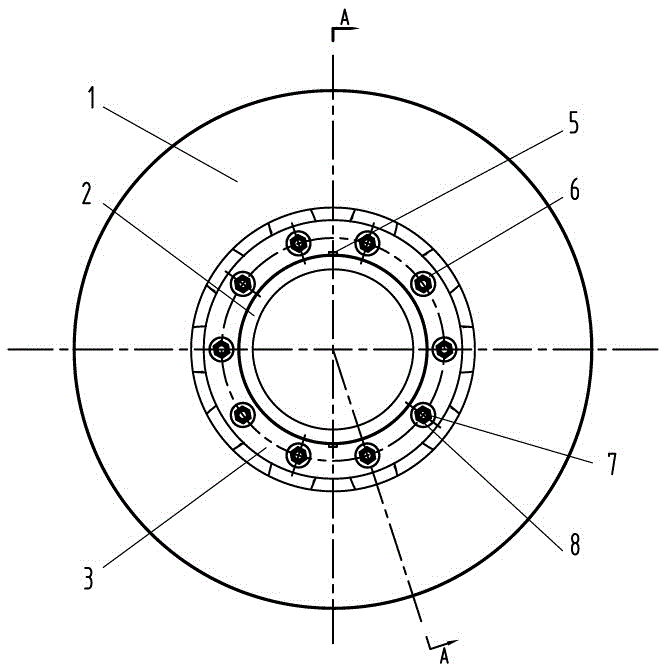

Ball cup inner-outer surface chroming device

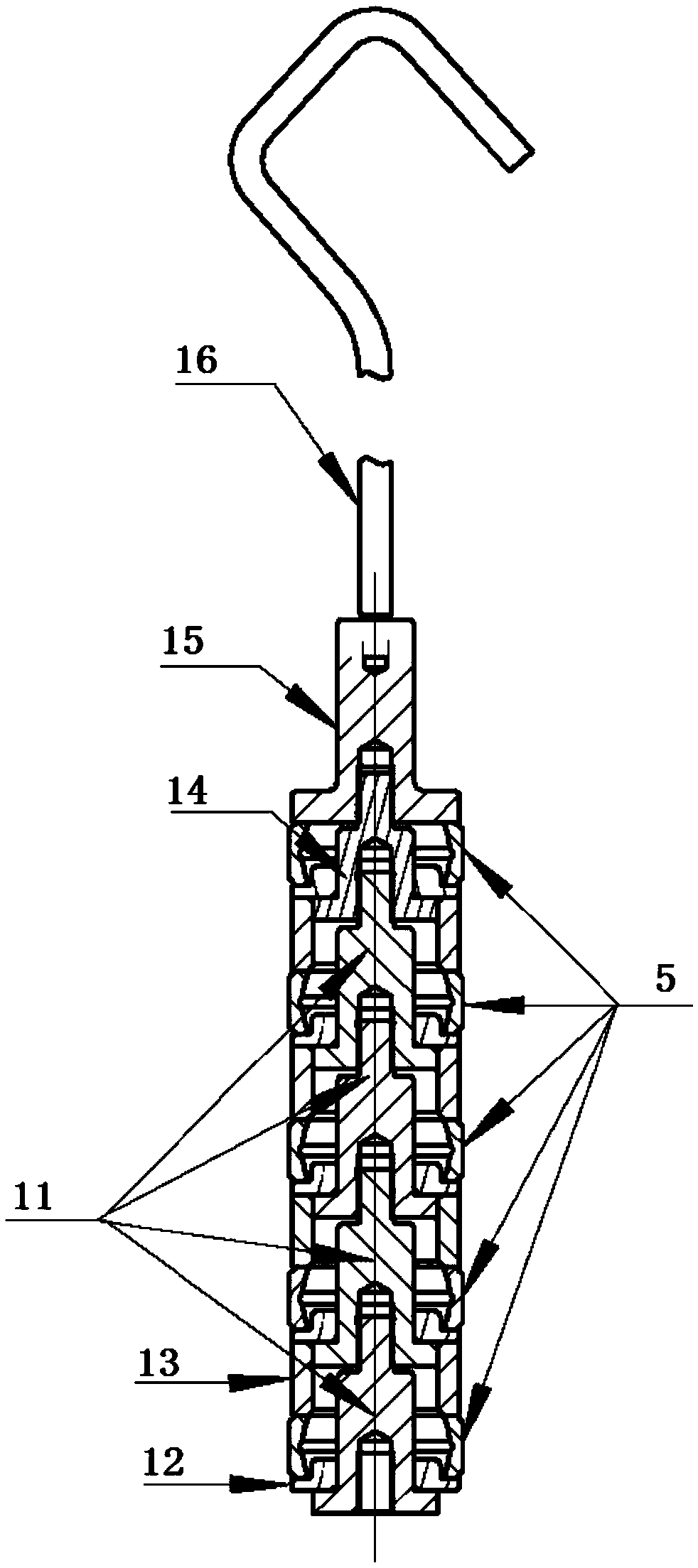

ActiveCN109402687AIncrease the number ofIncrease productivityElectrolysis componentsEngineeringSurface coating

The invention discloses a ball cup inner-outer surface chroming device which comprises an inner surface chroming component and an outer surface chroming component. The inner surface chroming componentcomprises a first hook (1), a conductive plate (2), a positioning member (4) and an auxiliary anode electrode (8), and the outer surface chroming component comprises a first mandrel (11), a gasket (12), a washer (13), a second mandrel (14) and a connection block (15). The inner surface and the outer surface are chromed separately, so that inner-outer surface coating quality can be improved more easily, the problem of product quality stability is solved, production efficiency is improved, and the ball cup inner-outer surface chroming device plays an active role in scientific and research production.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

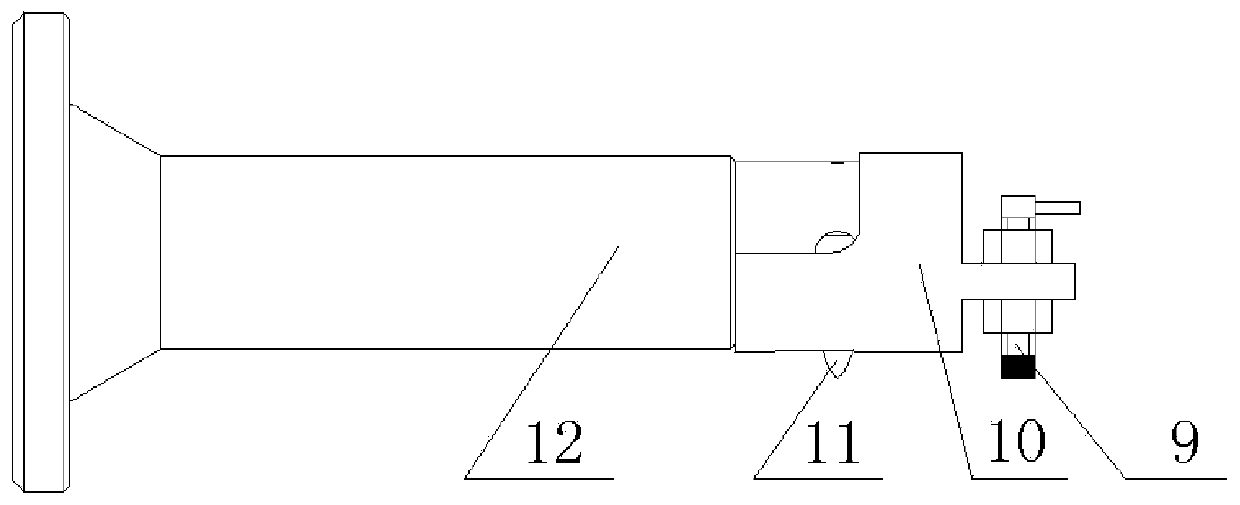

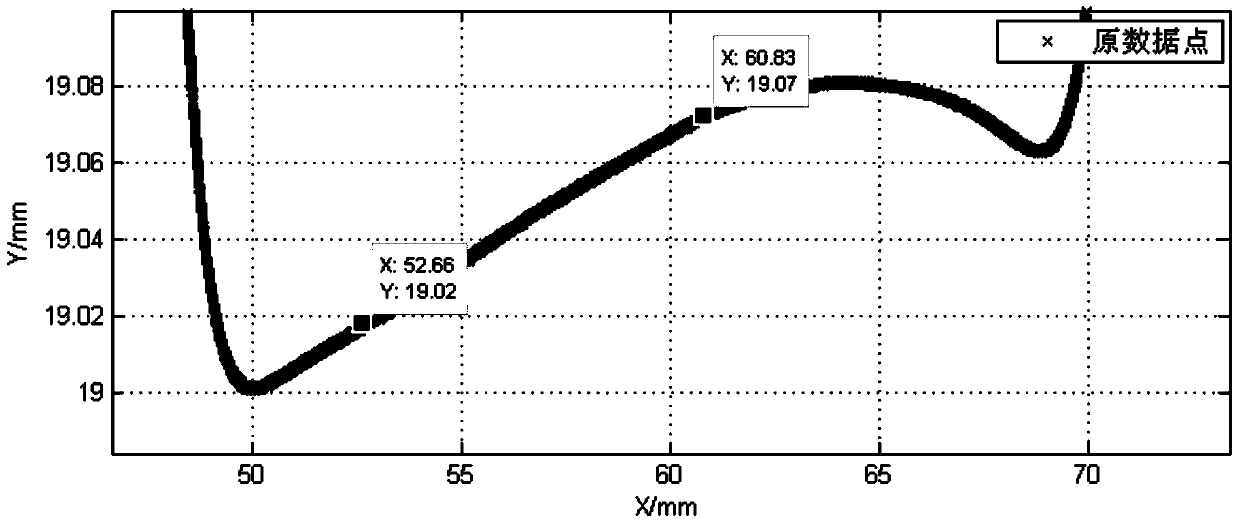

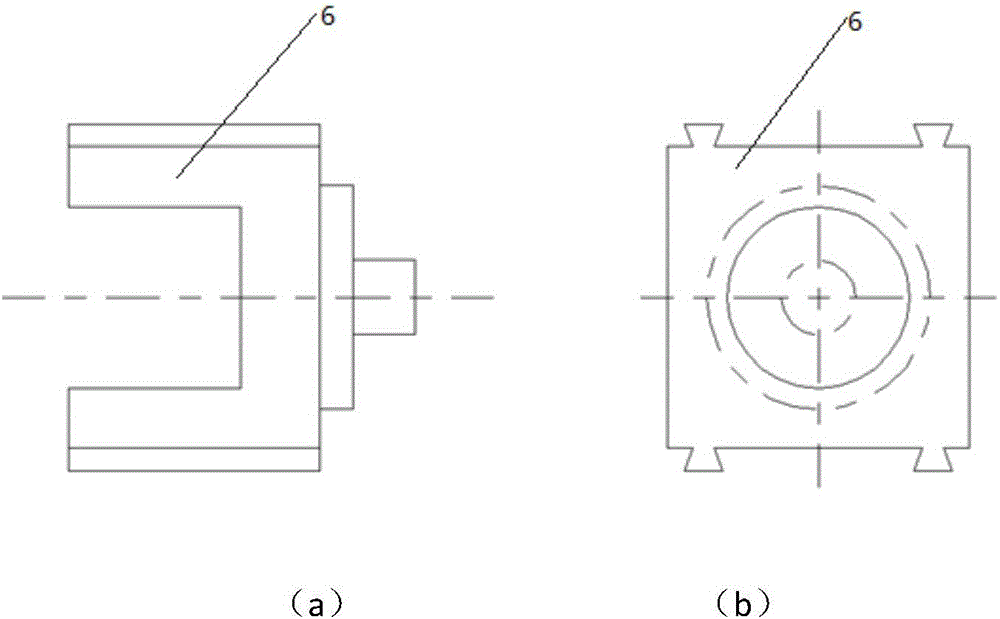

Contour error on-line measuring device of non-circular pin-hole of piston

InactiveCN103465108AMeet testing needsGuaranteed coaxialMeasurement/indication equipmentsData acquisitionContour error

The invention discloses a contour error on-line measuring device of the non-circular pin-hole of a piston. According to the measuring device, guide rails are horizontally fixed onto a machine tool base, a support board is mounted on the guide rails and moves horizontally along the guide rails, a centering rod is mounted on the support board through a centering rod support, the piston is fixedly mounted on the support board through a clamping device, and the piston pin-hole is aligned with the centering rod; a box is mounted on the machine tool base, a measuring rod is connected with a machine tool main shaft inside the box, a measuring sleeve is fixedly sleeved outside the tail end of the measuring rod, the measuring head is mounted on the measuring sleeve, a photoelectric encoder is connected with the machine tool main shaft through an encoder support, and the measuring rod coincides with the central axis of the piston pin-hole and is parallel to the guide rails; a sensing synchronizer and a limit switch is mounted on the machine tool base, and the sensing synchronizer, the measuring head and the photoelectric encoder are all connected with a computer through data acquisition cards. The contour error on-line measuring device of the non-circular pin-hole of the piston works in an on-line measuring mode, is simple in structure, achieves measuring convenience, omits secondary clamping, has high precision and a wide application range, and can measuring the axial cross section and the radial cross section of the non-circular pin-hole of the piston.

Owner:ZHEJIANG UNIV

Hand-held hydraulic bushing press-mounting device

The invention discloses a hand-held hydraulic bushing press-mounting device, and belongs to the technical field of machining equipment. A circle of steps is arranged on the outer circumferential surface of the lower end of a steering tool, and the outer circumferential surfaces of the steps are matched with cylinder bottom hinged holes. An internal thread is arranged on the inner circumferential surface of the upper end of the steering tool. A bushing is sleeved on the steering tool, and the lower end of the bushing abuts against on the steps of the lower end of the steering tool. An externalthread matched with the internal thread of the upper end of the steering tool is arranged on the outer circumferential surface of the lower end of a positioning sleeve. A circle of steps is arranged on the outer circumferential surface of the upper end of the positioning sleeve, and the upper end of the bushing abuts against the lower end faces of the steps of the upper end of the positioning sleeve. The diameter of the steps of the positioning sleeve is larger than that of the cylinder bottom hinged holes. A outer seam allowance matched with the upper end of the positioning sleeve is formed in one end of a cylinder cover of a hydraulic oil cylinder. The piston rod end of the hydraulic oil cylinder is detachably connected with a quick-change sleeve with the diameter larger than the diameter of the cylinder bottom hinged holes. The hand-held hydraulic bushing press-mounting device has a compact and portable structure and can be lifted by hand. By adopting the quick-change structure, thehand-held hydraulic bushing press-mounting device is simple in operation and can be suitable for press-mounting of large workpiece bushings. For different specifications, only the tool needs to be replaced.

Owner:XCMG HYDRAULICS CO LTD

Method for assembling mobile static pressure bearing

The invention belongs to a machine work class and in particular relates to a method for assembling a hydro-hybrid bearing, which is characterized in that: a bearing shell is fixed on a base; two ends of an axis is propped by the finial of the axis; the finial is also fixed on the base; two bearing inner rings are machined and respectively sleeved between the axis and the shell; an oil circuit on each inner ring is switched on in order that a hydrostatic system between the inner ring and the axis can operate; the inner rings float on the axis; adhesive is input in the gap between the shell and the inner rings; after the adhesive is solidified, the axis and the shell are dismounted from the base, that is completing the assembly of the hydro-hybrid bearing. As the homogenization of hydrostatic oil film in the method for assembling the hydro-hybrid bearing, the isotropic gaps between two inner rings and the axis are uniform, thereby ensuring the coaxiality between two inner rings; as the two inner rings are respectively machined, the degree of symmetry of each oil sink can be ensured. The hydro-hybrid bearing assembled by the assembling method of the invention has high precision, a reasonable structure and small axis vibration.

Owner:潘旭华

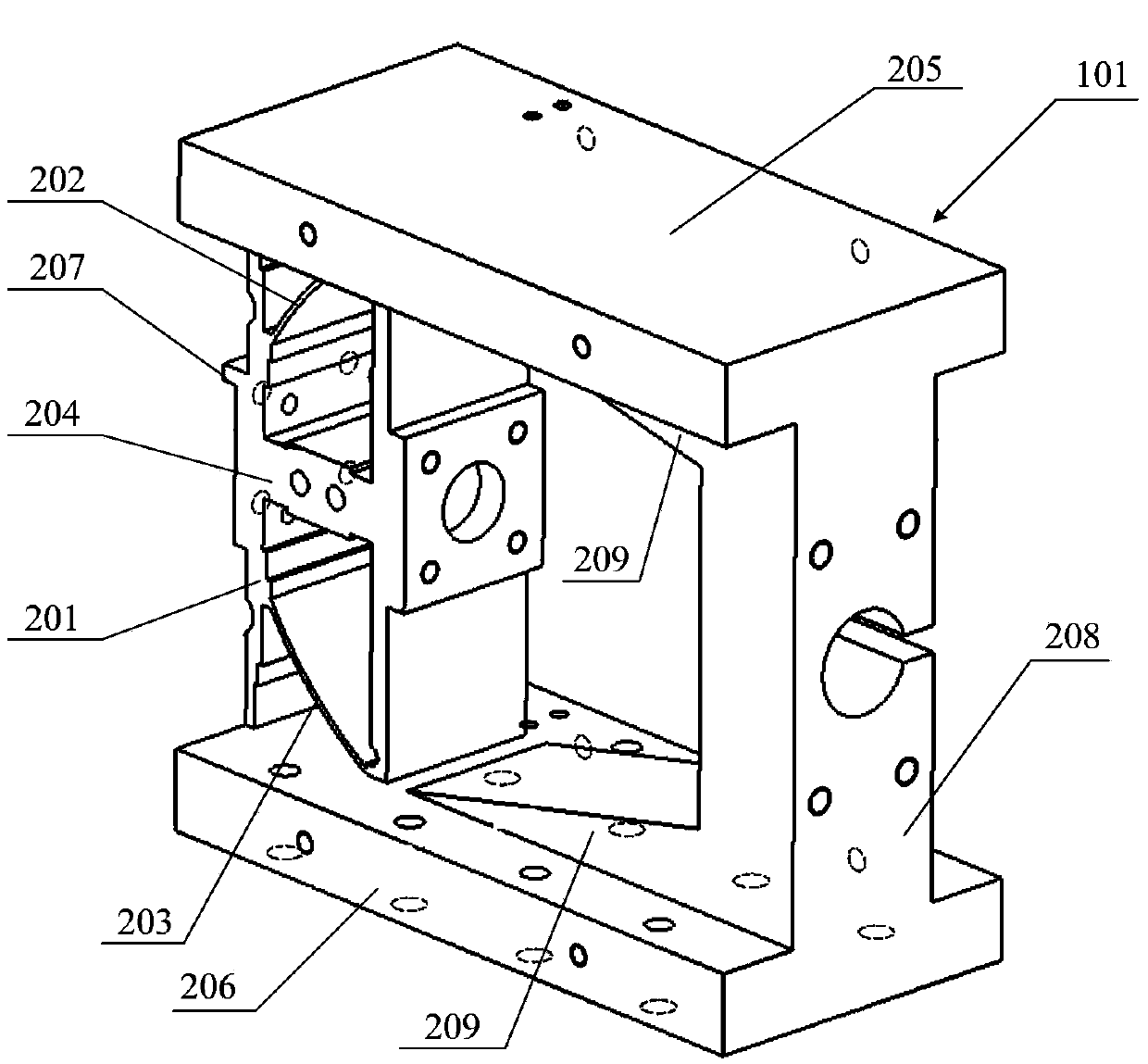

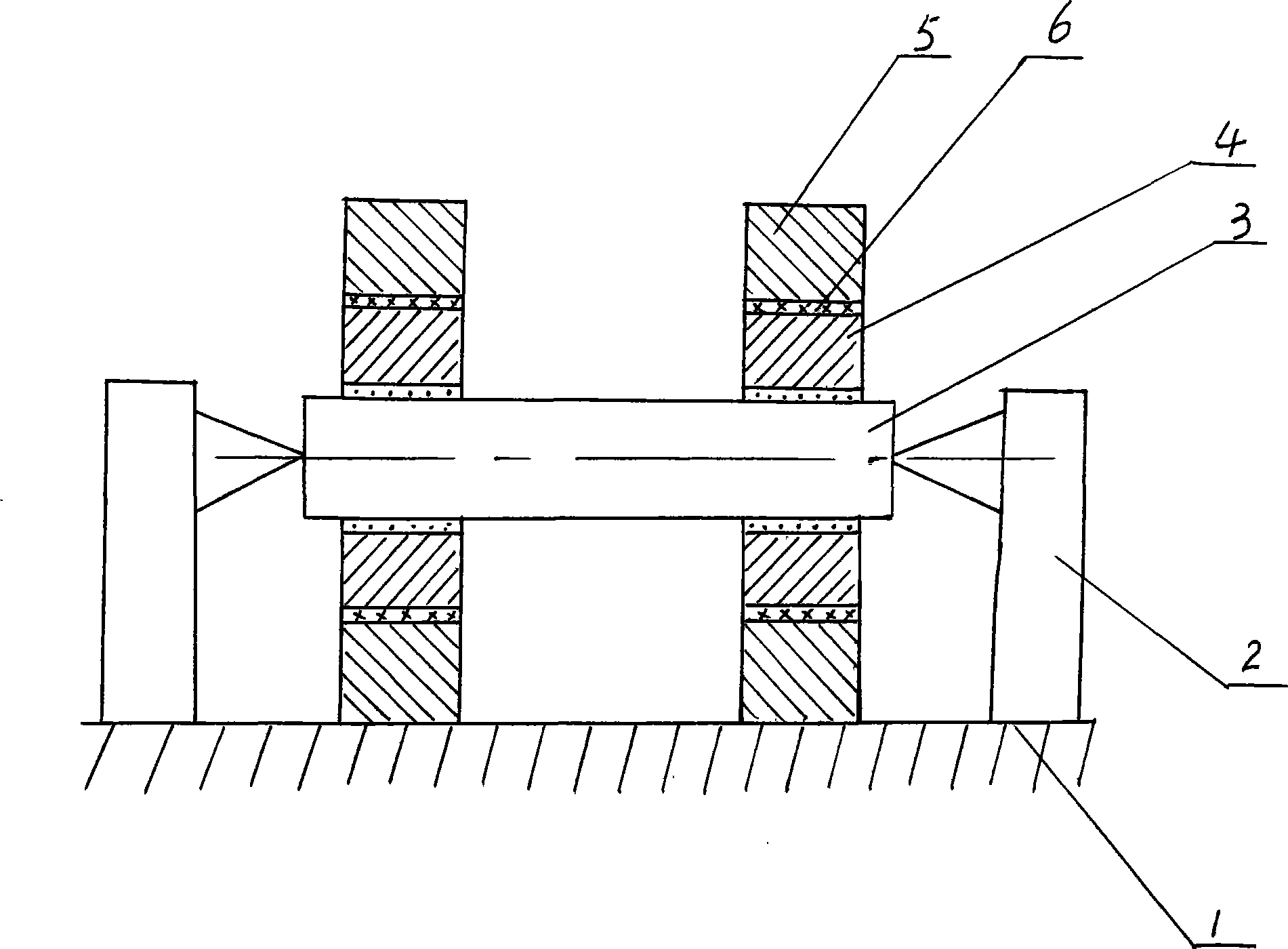

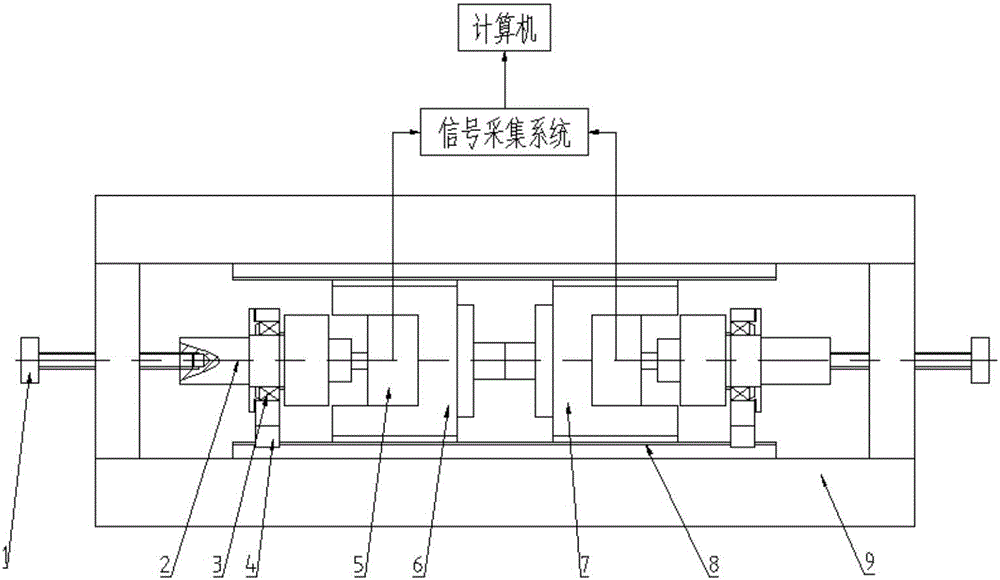

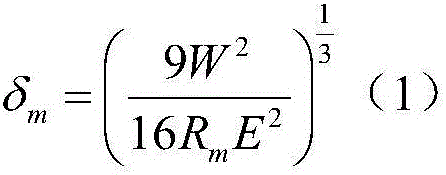

Device and method for testing normal stiffness of mechanical joint surface

ActiveCN106768745AAccurately derive the effect of normal stiffnessSimple structureSustainable transportationElasticity measurementEngineeringForce sensor

The invention discloses a device and method for testing the normal stiffness of a mechanical joint surface. The device is characterized in that a frame type rack in the device is of a rectangular structure; a linear guide rail is arranged on the frame type rack; a first test piece and a second test piece are slidably arranged on the linear guide rail; a left frame and a right frame are provided with threaded holes allowing a first bolt and a second bolt to penetrate correspondingly; the first bolt is connected with the threaded hole of the left frame in a threaded manner, and the end of the first bolt penetrates the left frame to be connected with the left end of a first connecting shaft; the second bolt is connected with the threaded hole of the right frame in a threaded manner, and the end of the second bolt penetrates the right frame to be connected with the right end of a second connecting shaft; a first force sensor connected with the first connecting shaft is arranged at the left end of the first test piece, and a second force sensor connected with the second connecting shaft is arranged at the right end of the second test piece; the output ends of the first force sensor and the second force sensor are connected with a computer through a signal collecting system. The device has the advantages that the device is simple in structure, convenient to mount and demount and easy to perform repeated tests, and the normal stiffness of the mechanical joint surface can be well analyzed.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com