Liftable hinge device

A technology of hinges and hinges, which is applied in door/window accessories, buildings, wing leaf openers, etc., can solve the problems of short service life, high assembly cost, and unsightly appearance, and achieve long service life and beautiful appearance , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

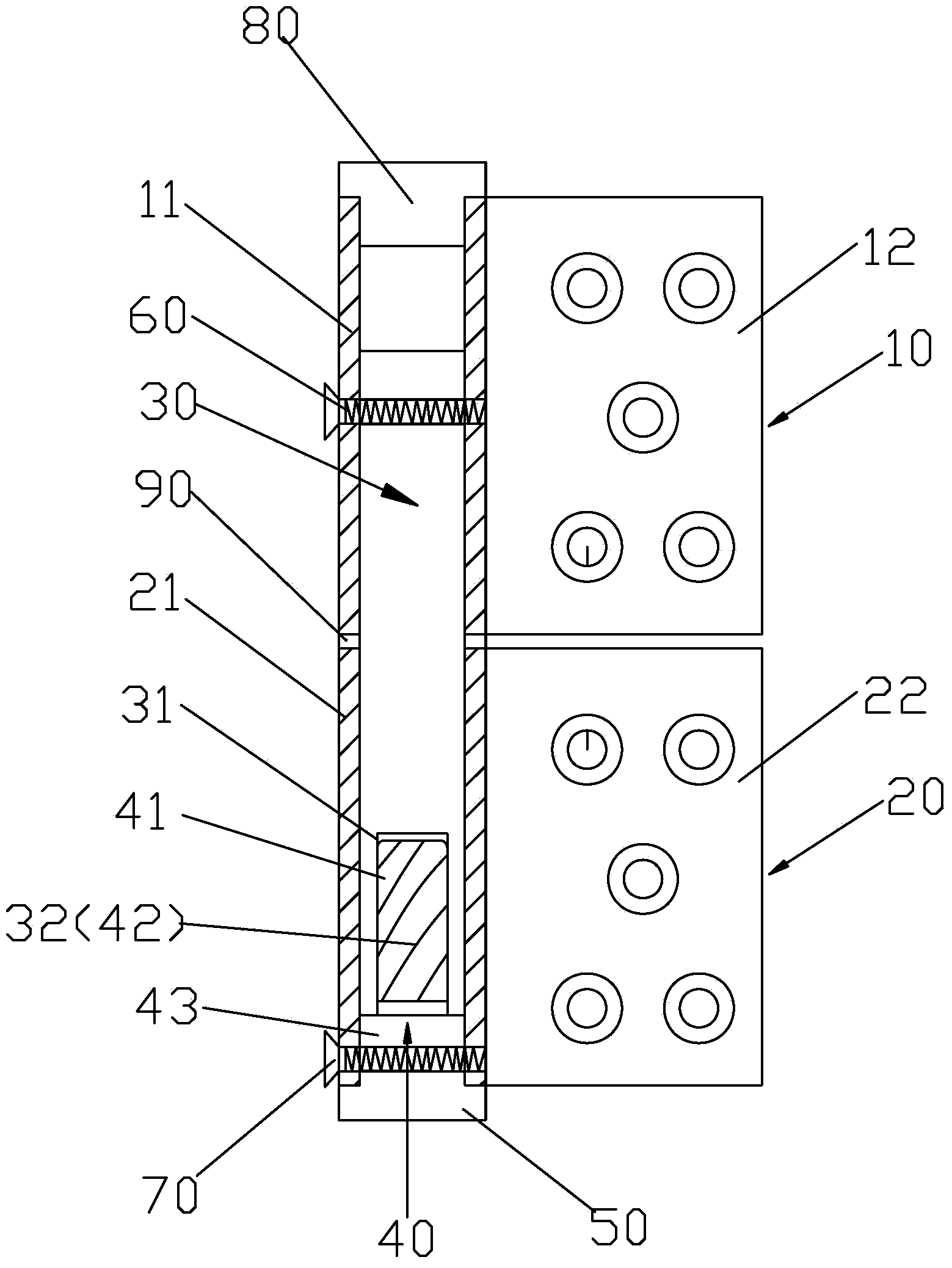

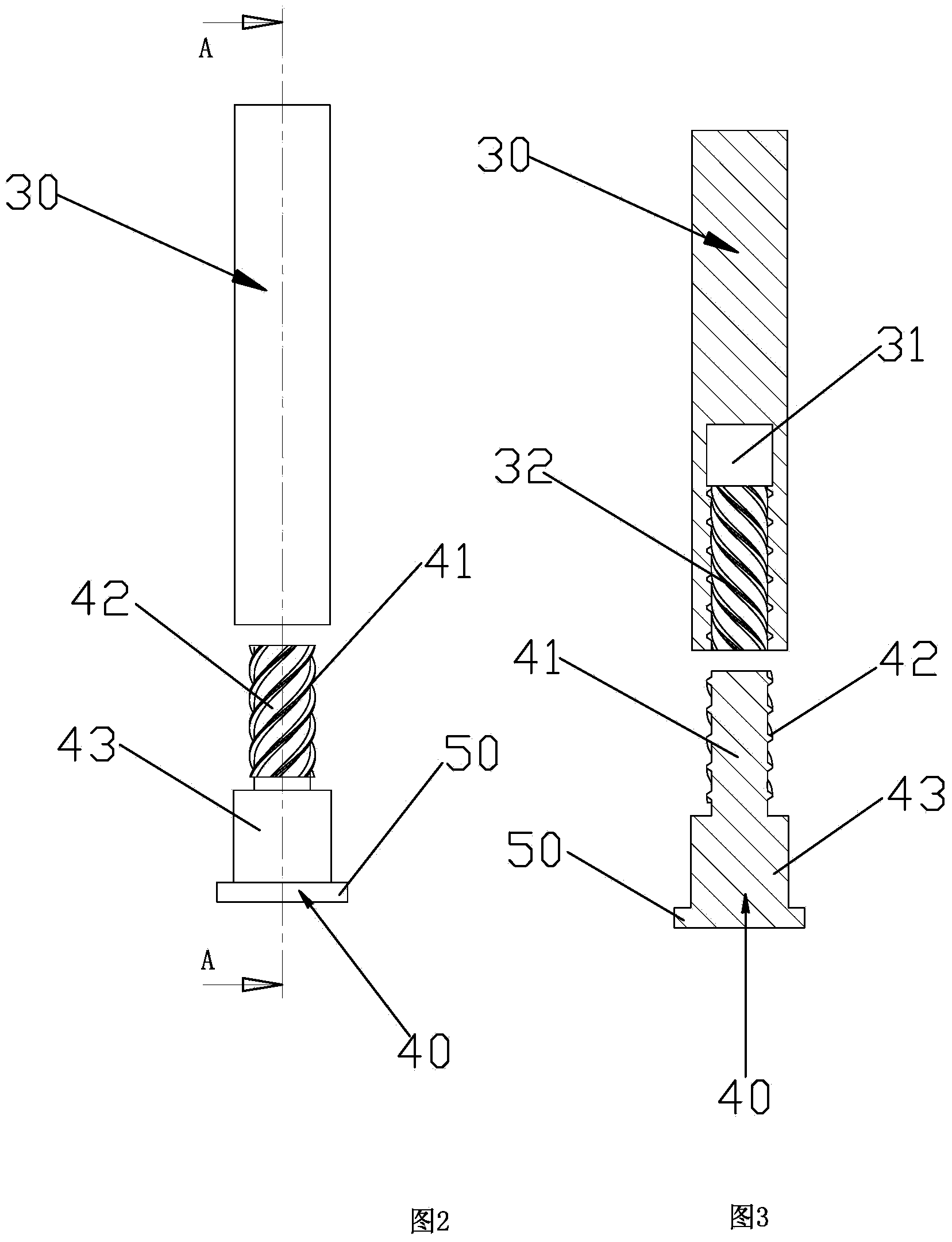

[0046] Please check figure 1 , figure 2 and image 3 , The lifting hinge device, such as the lifting self-closing device, includes an upper hinge 10, a lower hinge 20, a transmission seat 30 and a transmission rod 40.

[0047] The upper hinge 10 includes an upper shaft sleeve 11 and an upper hinge piece 12 fixedly connected to the upper shaft sleeve 11 . The lower hinge 20 includes a lower shaft sleeve 21 and a lower hinge piece 22 fixedly connected to the lower shaft sleeve 21 . In this embodiment, the upper bushing 11 and the upper hinge piece 12 are of the same length and arranged flush with the ends, and the lower bushing 21 and the lower hinge piece 22 are of the same length and arranged with the ends flush with each other. The upper hinge piece and the lower hinge piece are provided with mounting holes for installing door panels or window panels.

[0048]The transmission seat 30 is adapted and fixed in the upper shaft sleeve 11. The adaptation is that the outer diam...

Embodiment 2

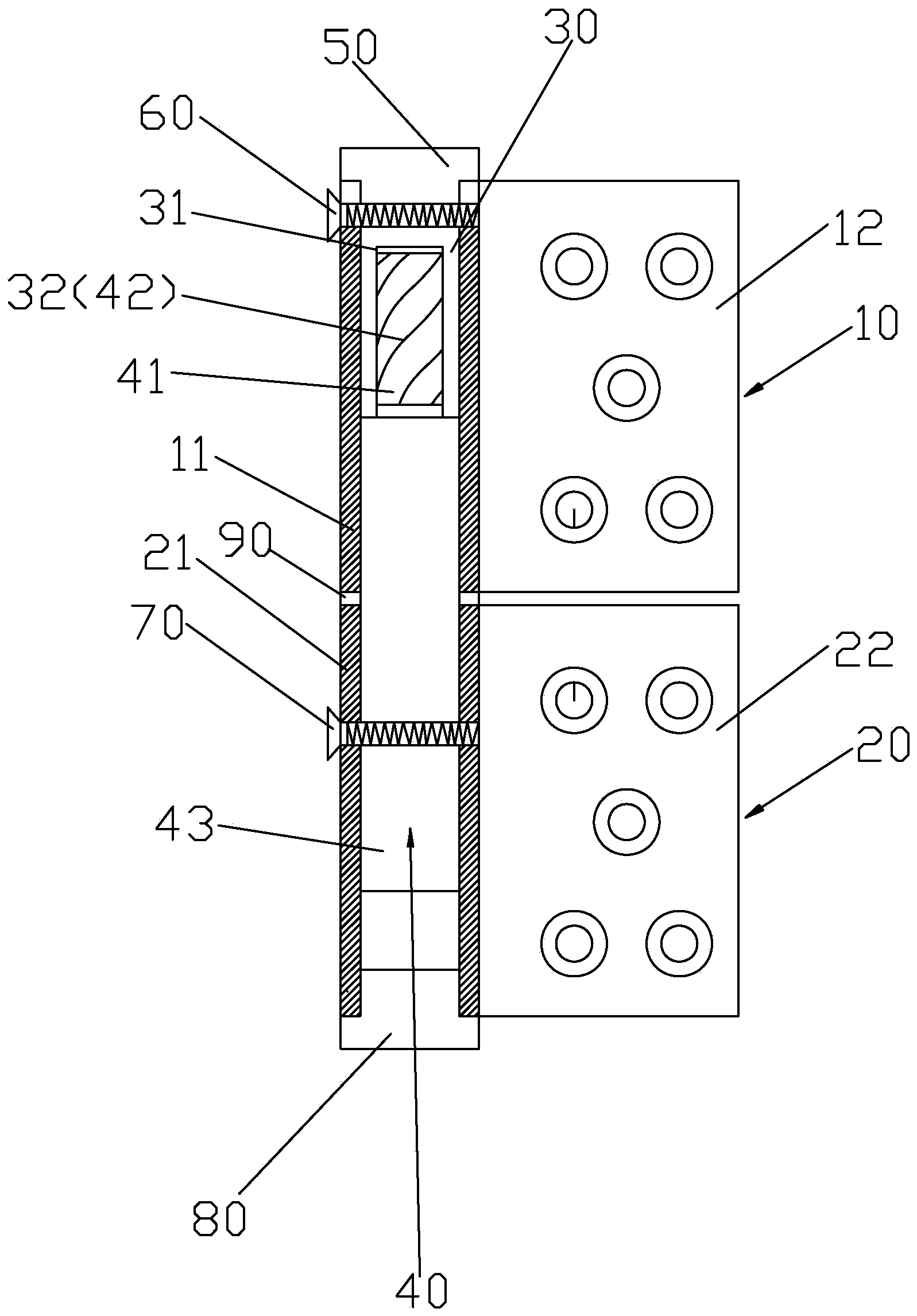

[0054] It differs from Embodiment 1 in that: Please refer to Figure 4 , Figure 5 and Figure 5-1 , the upper part of the solid seat 43 protrudes above the lower bushing 21, and the upper bushing 11 is adapted to be movably socketed outside the upper part of the solid seat 43. The fixed seat 43 of the transmission rod 40 is used to ensure the accuracy of the rotation of the hinge device. The transmission seat 30 is adapted to be fixed in the upper shaft sleeve 11, and a plug seat 50 is fixed at the end of the transmission seat 30. The outer diameter of the plug seat 50 is larger than the outer diameter of the transmission seat 30. The annulus outside the seat 30, the annulus is adapted to lean against the top end surface of the upper bushing, and the outer diameter of the plug seat is compatible with the outer diameter of the upper bushing. The plug 80 is attached to the lower port of the lower sleeve.

[0055] The check Figure 5 , wherein, the first helical part 32 and...

Embodiment 3

[0057] It differs from Embodiment 1 in that: Please refer to Figure 6 , Figure 7 and Figure 7-1 , the transmission rod 40 is fixedly connected in the upper shaft sleeve 11 , and the outer rotating surface of the transmission rod 40 is provided with a second helical part 42 . The transmission seat 30 is fixedly connected in the lower shaft sleeve 21 , the top surface of the transmission seat 30 is concavely provided with a transmission chamber 31 , and the inner rotating surface of the transmission chamber 31 is provided with a first helical part 32 . The upper part of the transmission seat 30 protrudes above the lower shaft sleeve 21, and the upper shaft sleeve is also movably sleeved outside the upper part of the transmission seat. The upper end of the transmission rod 40 is fixed with a plug seat 50, that is, the plug seat 50 is fixed on the solid seat 43, and the outer diameter of the plug seat 50 is greater than the outer diameter of the solid seat 43. The annulus ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com