Hinge positioning jig

一种定位治具、铰链的技术,应用在制造工具、多用途手动工具、仪器等方向,能够解决转动困难、显示模组不能相对于主机转动、很难铰链准确定位主机壳等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

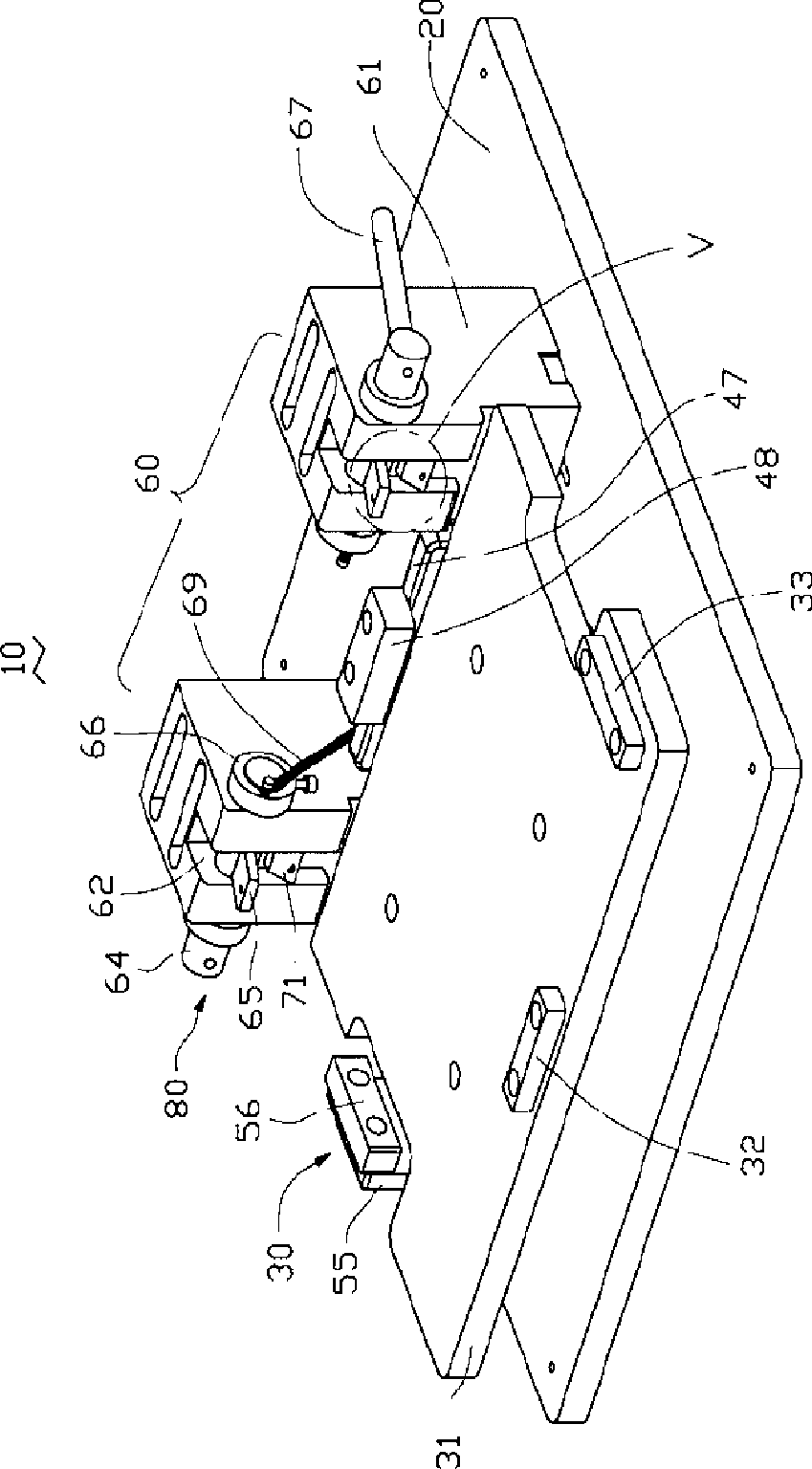

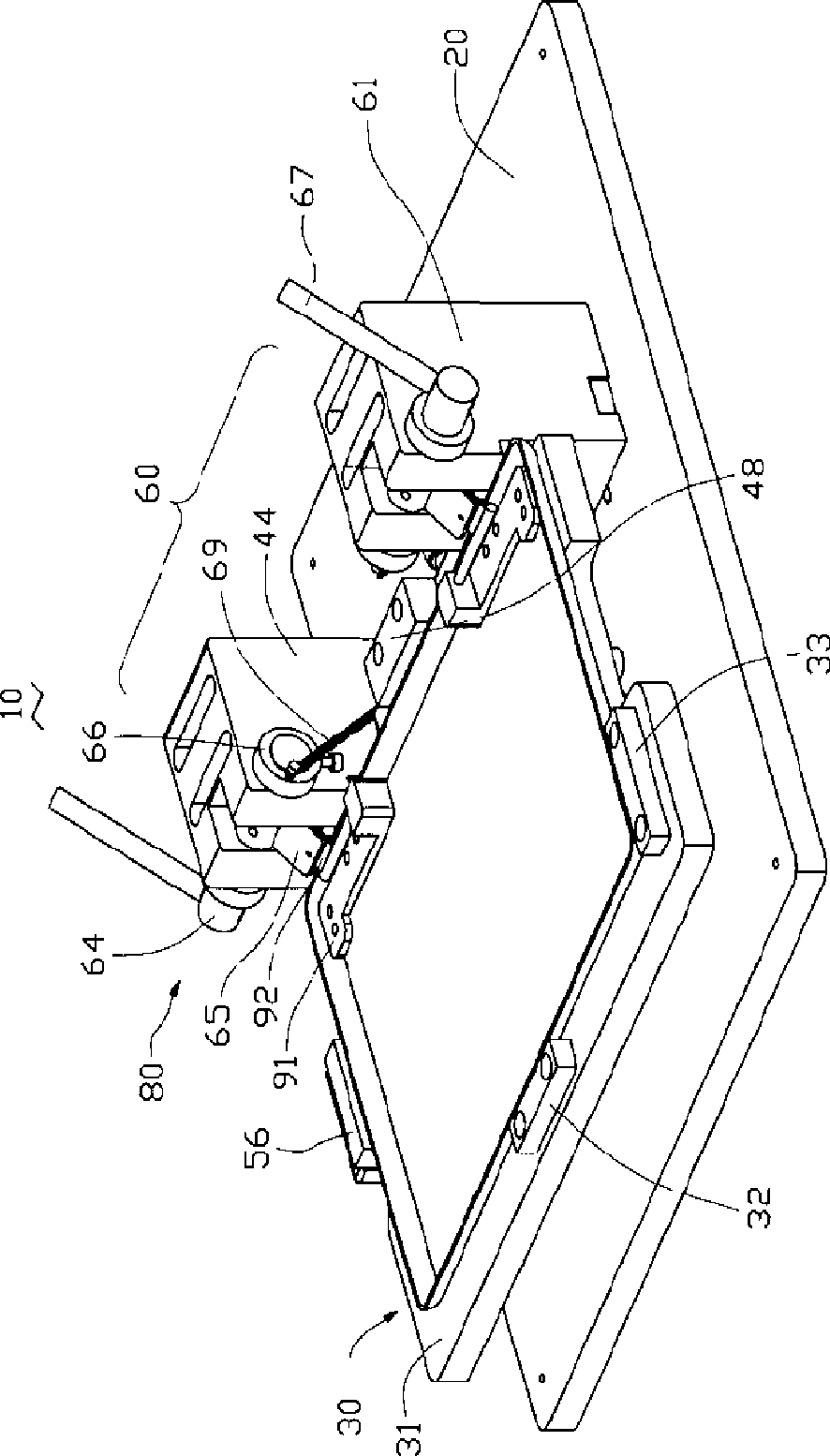

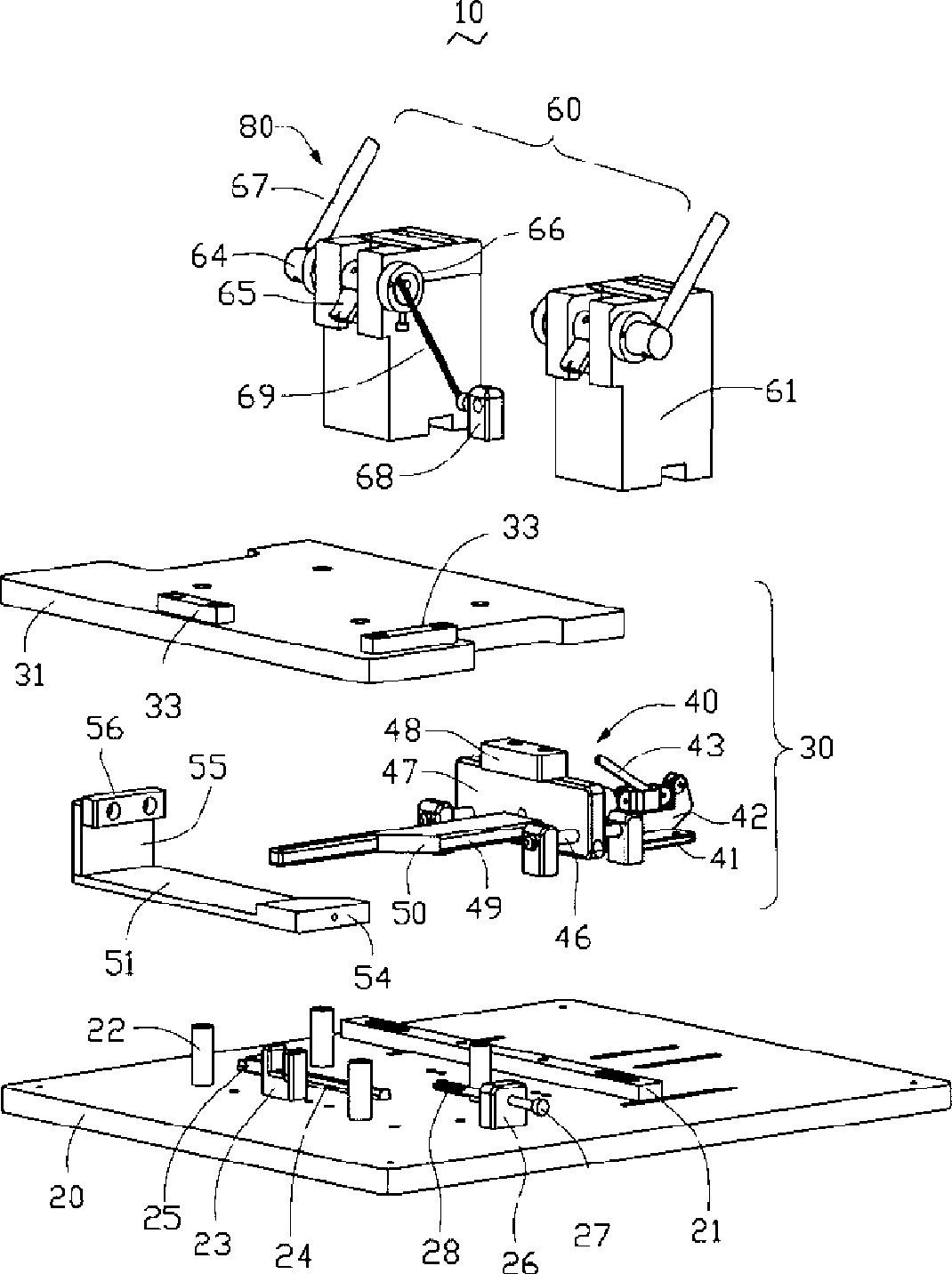

[0011] Please refer to figure 1 , figure 2 , which discloses a positioning jig according to a preferred embodiment of the present invention. The positioning jig 10 includes a rectangular bottom plate 20 and a first positioning mechanism 30 and a second positioning mechanism 60 mounted on the bottom plate 20 respectively. Wherein, the first positioning mechanism 30 is used to fix the main casing 90 of a notebook computer, and the second positioning mechanism 60 is used to fix a pair of hinges 91 of the notebook computer.

[0012] Please also refer to figure 2 , image 3 , Figure 4 , The first positioning mechanism 30 includes a bearing plate 31 , a first locking device 40 and a plurality of limiting blocks 32 , 33 , 48 , 56 . The carrying plate 31 is installed on the base plate 20, and it is used to carry the main casing 90 of the notebook computer. A space for accommodating the first locking device 40 .

[0013] Part of the limiting blocks 32 , 33 are fixed on the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com