Device and method for testing normal stiffness of mechanical joint surface

A technology of normal stiffness and testing equipment, which is applied in the testing of machines/structural components, measuring equipment, elastic testing, etc., can solve the problems of lack of relatively mature testing equipment and methods, achieve simple structure, reduce measurement errors, The effect of the rigor of the derivation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In the following, the device for testing the normal stiffness of the mechanical joint surface of the present invention will be further described in detail in conjunction with the working principle and the structural drawings.

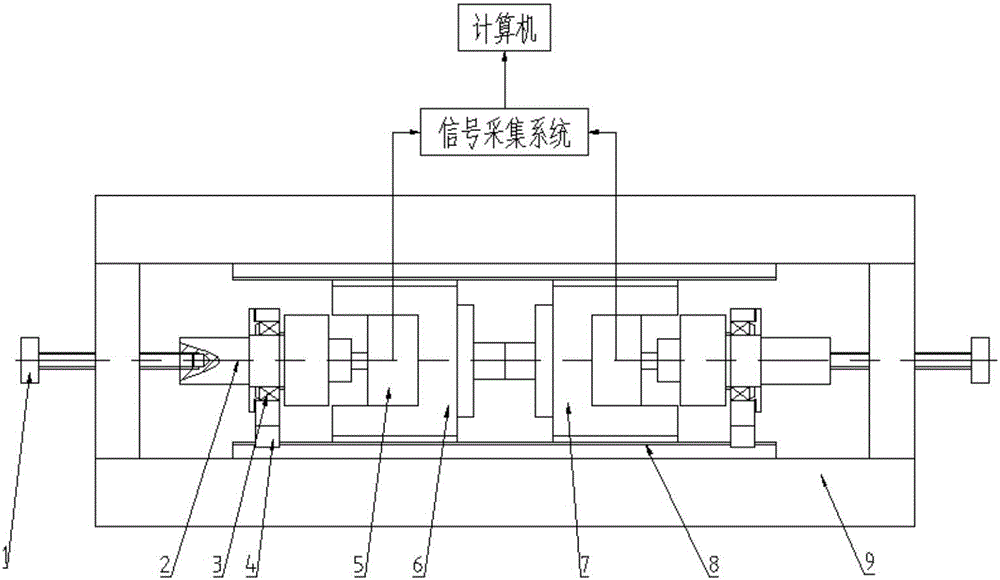

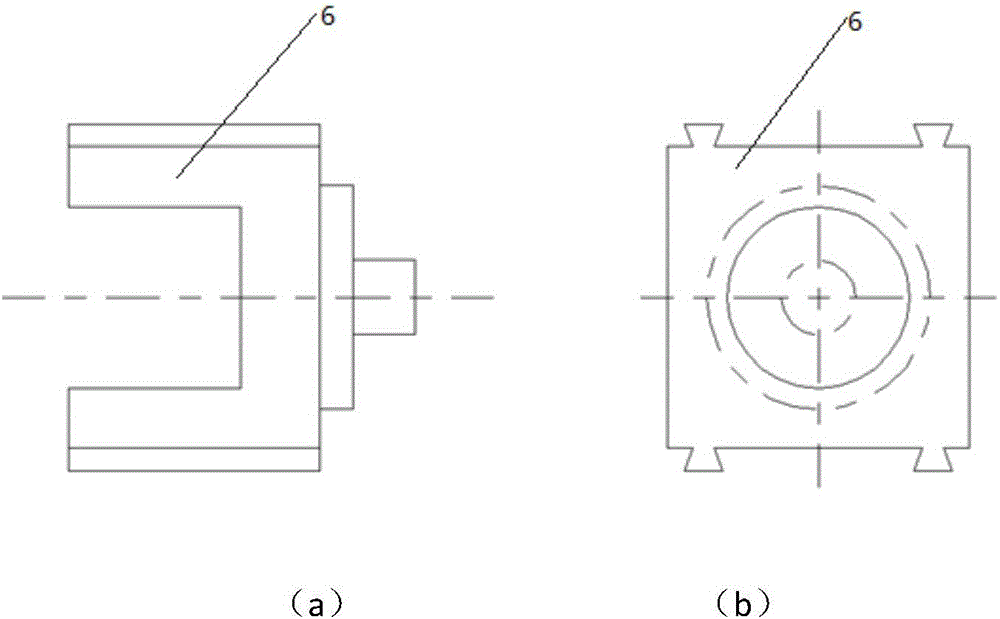

[0055] Such as Figure 1 to Figure 2 As shown, a device for testing the normal stiffness of a mechanical joint surface includes: a bolt 1, a connecting shaft 2, a thrust bearing 3, a bearing seat 4, a force sensor 5, a first test piece 6, a second test piece 7, and a linear guide rail 8. Frame type stand 9. Signal acquisition system and computer.

[0056] Due to the symmetrical arrangement of the measuring devices, for the convenience of explanation, the patent of the present invention only describes the working principle of the left device, and the principle of the right device is the same. The bolt 1 is connected to the left side of the connecting shaft 2, the connecting shaft 2 is installed on the bearing seat 4 through the thrust bearing 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com