Patents

Literature

505 results about "Mechanical joint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A mechanical joint is a section of a machine which is used to connect one or more mechanical part to another. Mechanical joints may be temporary or permanent, most types are designed to be disassembled. Most mechanical joints are designed to allow relative movement of these mechanical parts of the machine in one degree of freedom, and restrict movement in one or more others. Mechanical joints are much cheaper and are usually bought ready assembled.

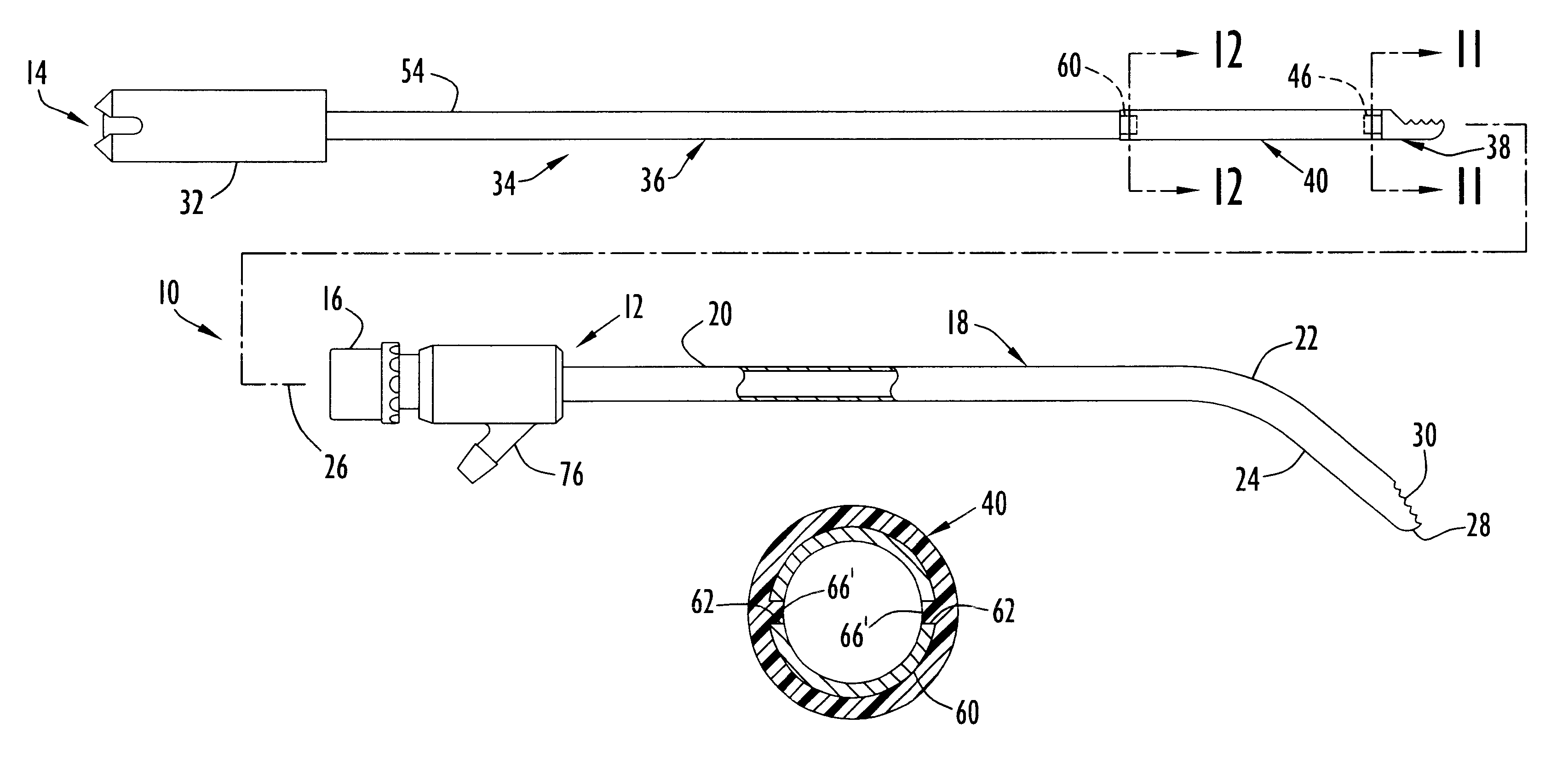

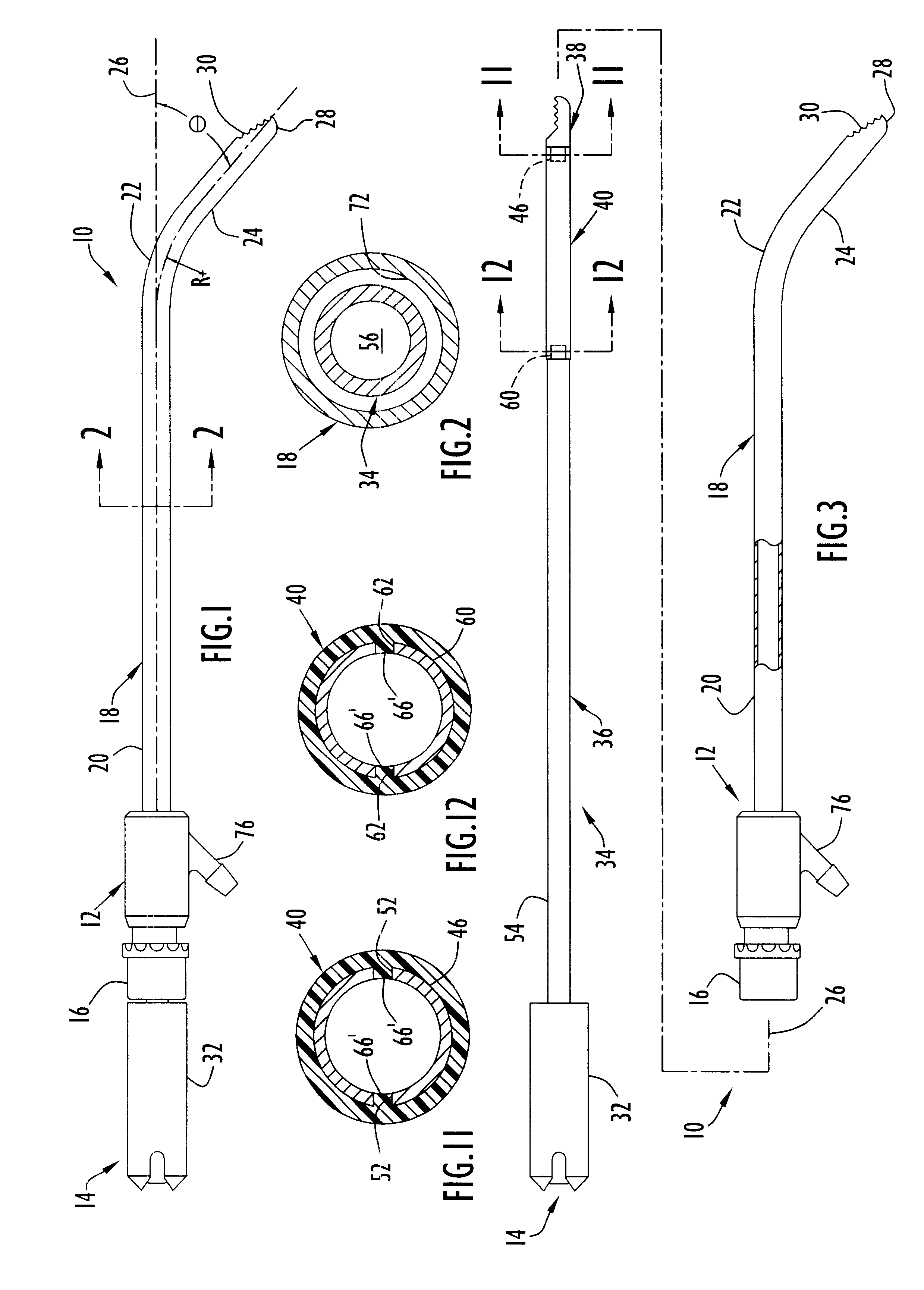

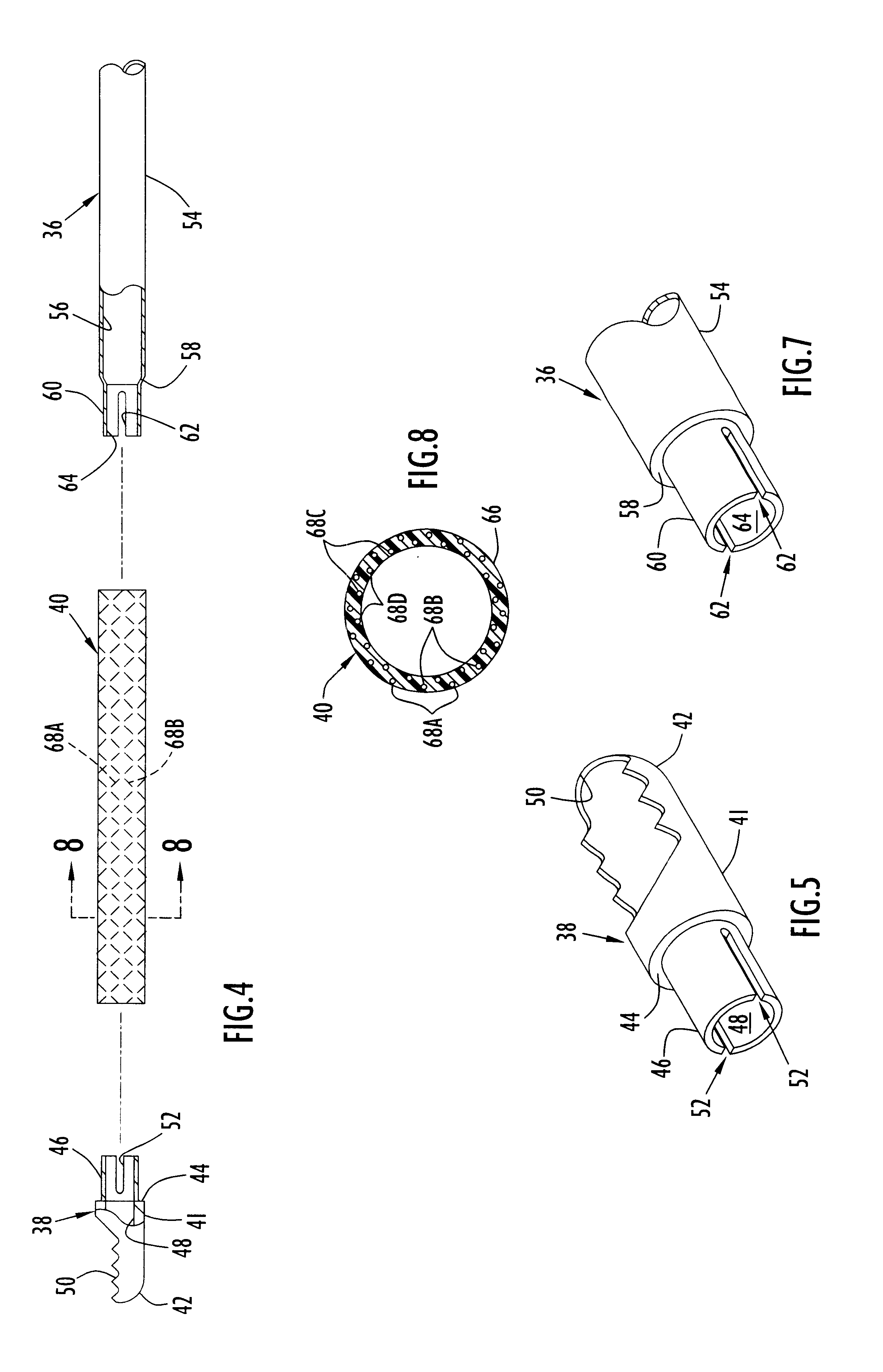

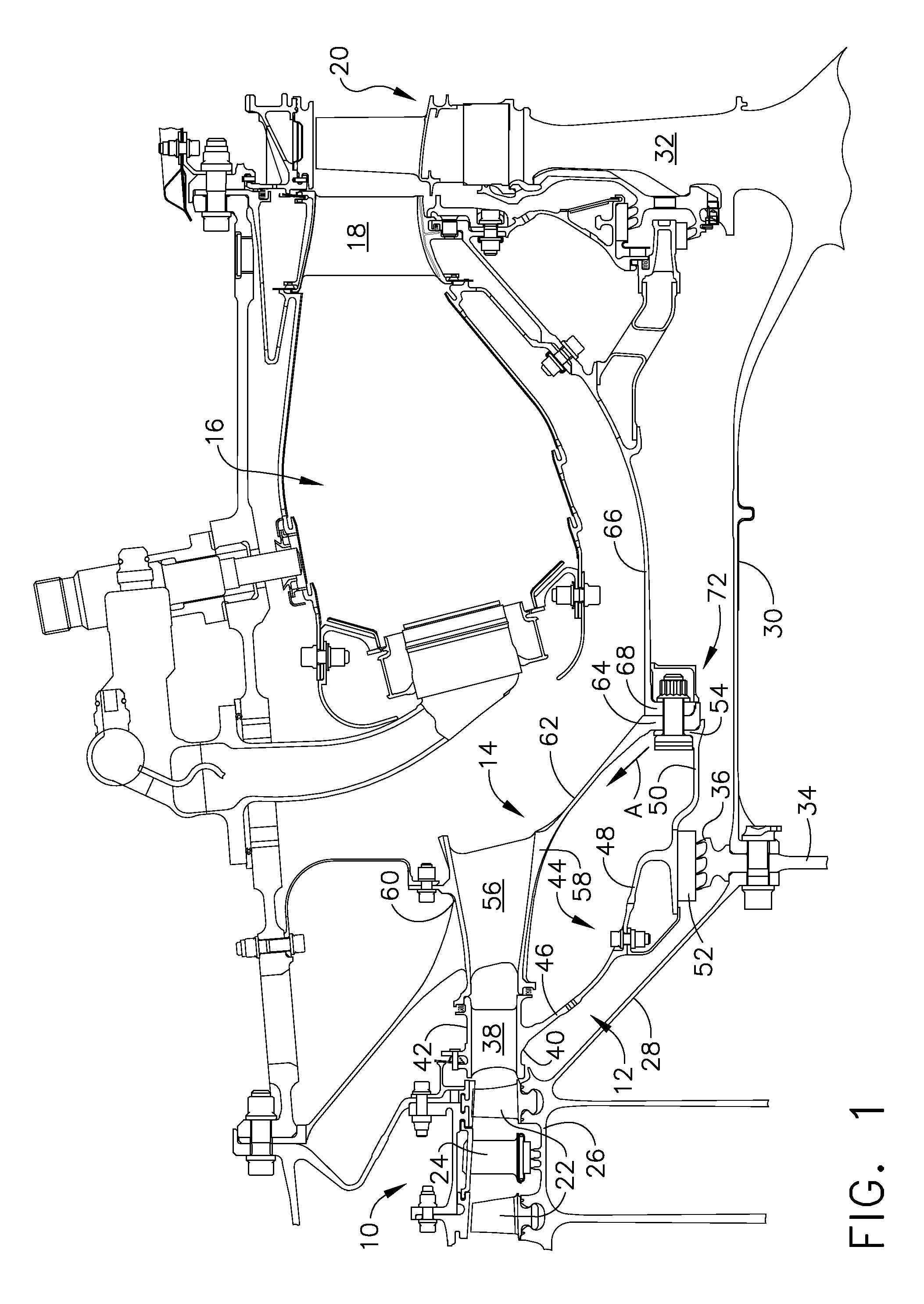

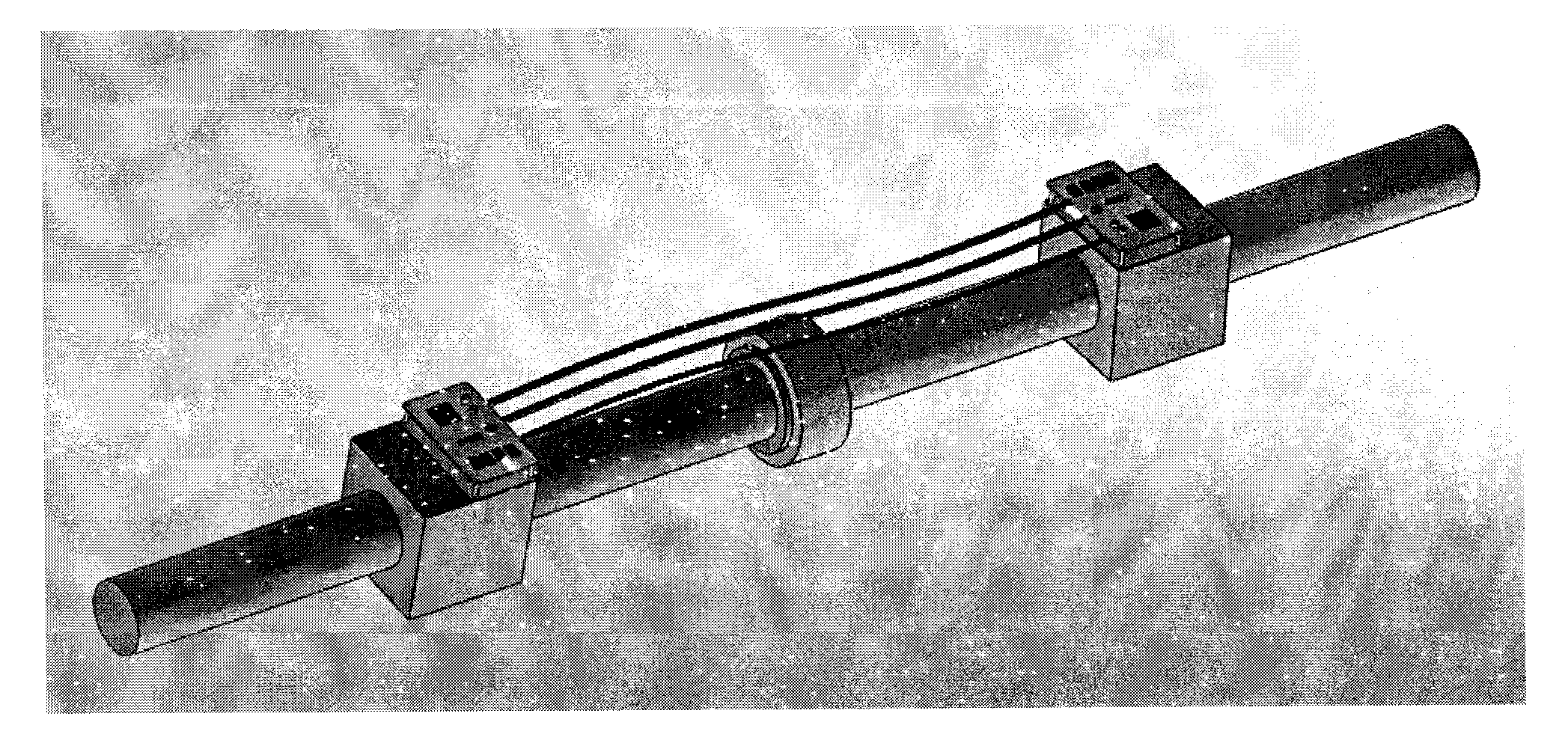

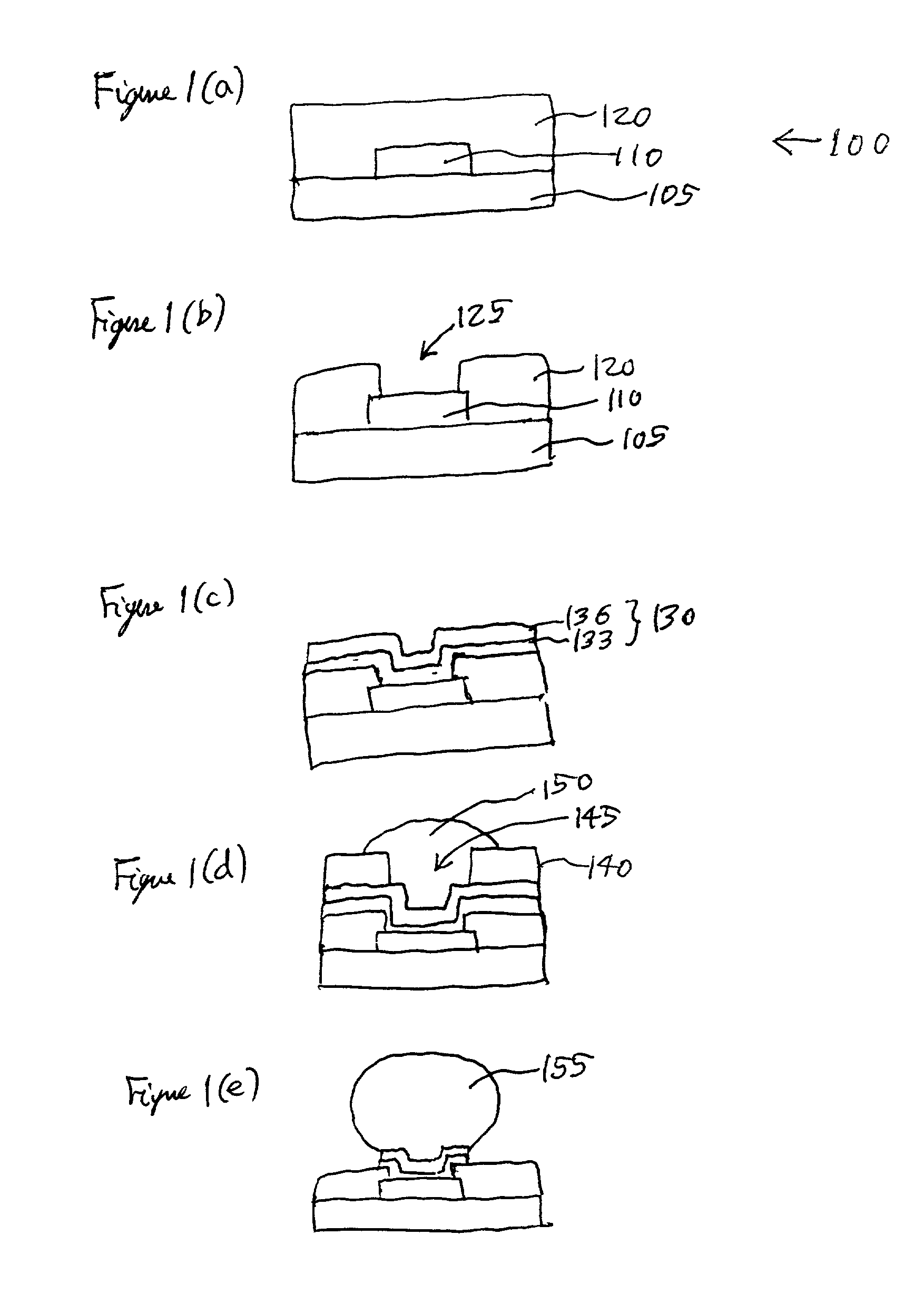

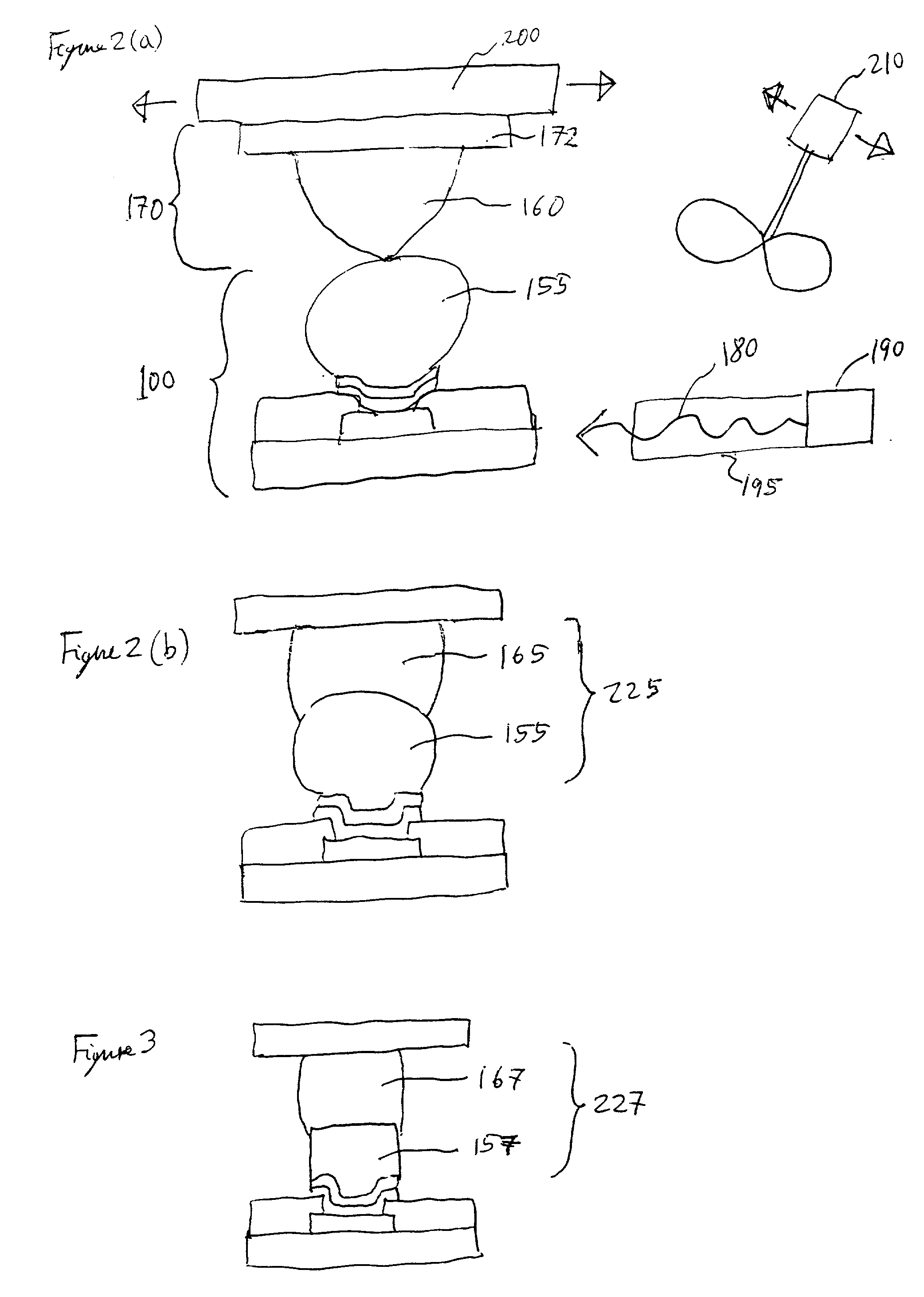

Angled rotary tissue cutting instrument and method of fabricating the same

InactiveUSRE38018E1Increase heightIncrease rangeEndoscopic cutting instrumentsMetal-working hand toolsDistal portionDrive shaft

The present invention is generally characterized in an angled rotary tissue cutting instrument including an outer blade assembly, having a rigid tubular member with proximal and distal portions connected by a bead, and an inner blade assembly rotatably disposed within the outer blade assembly and including a tubular drive shaft at a proximal end, a cutting tip at a distal end, and a flexible coupling disposed between the drive shaft and the cutting tip. The drive shaft and cutting tip include neck portions which are disposed telescopically within proximal and distal ends of the coupling. The flexible coupling is formed of a flexible polymeric material, and each of the neck portions includes a lateral opening defining a predetermined flow path for the polymeric material during fabrication so that the flexible polymeric coupling includes flow portions extending into the openings in the neck portions of the drive shaft and the cutting tip to form permanent, interlocking mechanical joints therewith capable of receiving and transmitting torque.

Owner:MEDTRONIC XOMED INC

Tubular compliant mechanisms for ultrasonic imaging systems and intravascular interventional devices

InactiveUS7115092B2Small sizeHigh resolutionElectrothermal relaysSurgeryCompliant mechanismShape-memory alloy

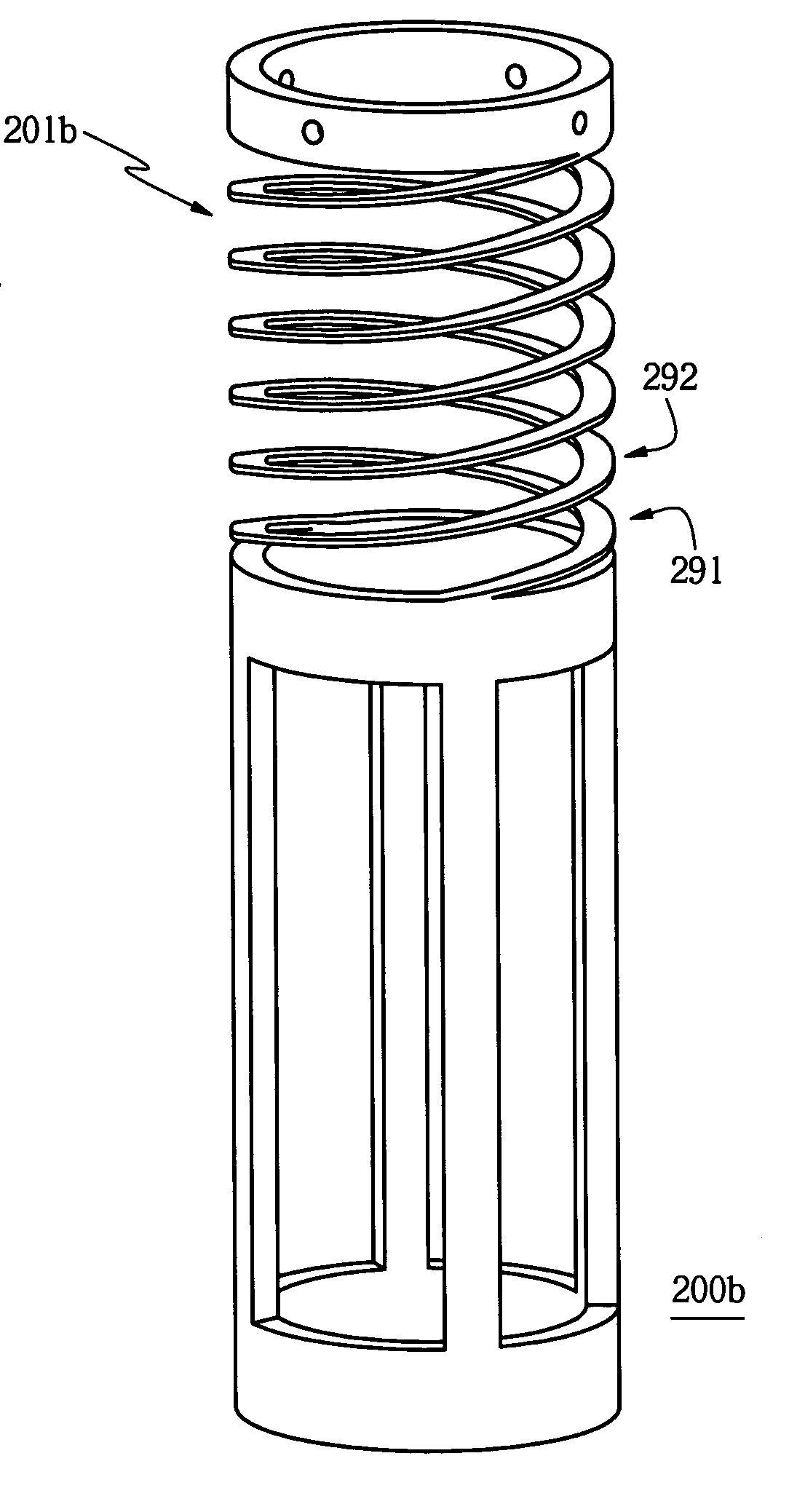

A micromanipulator comprising a tubular structure and a structural compliance mechanism that are formed from a tube made of an elastic and / or superelastic material. Fabricated with laser machining and has no mechanical joints, the micromanipulator can be manipulated in various motions and degree-of-freedoms without permanent deformation. Shape Memory Alloys (SMAs) in one embodiment are implemented as main actuators of the micromanipulator. The micromanipulator can be implemented with multiple SMAs to manipulate the mechanism with multiple degree-of-freedom. In another implementation, multiple segments of the mechanisms are formed and arranged in various configurations, including a “double-helix”-like configuration, for enabling intricate motions of the micromanipulator. The micromanipulator is useful for intravascular interventional applications and particularly ultrasonic imaging when coupled with an ultrasound transducer.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

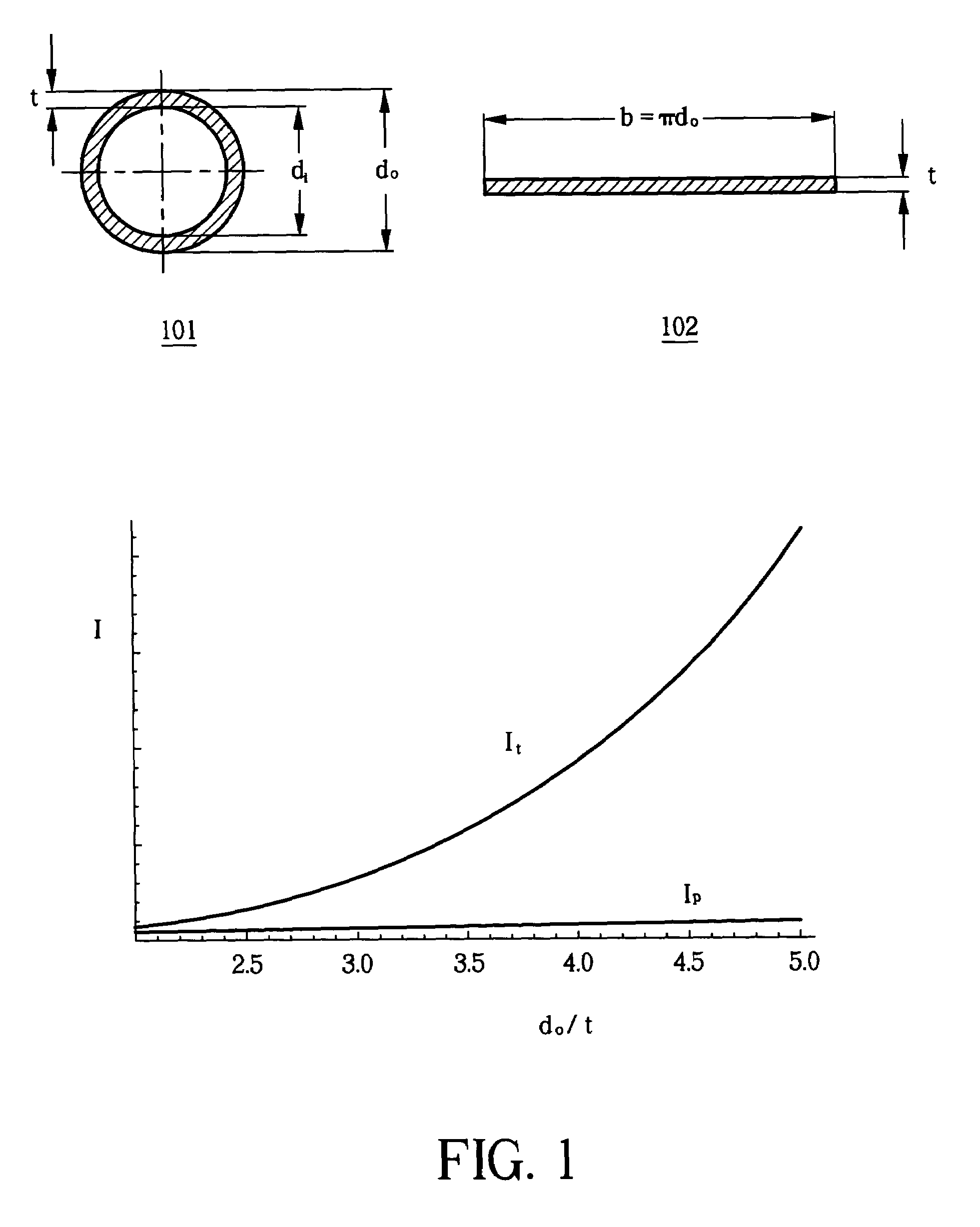

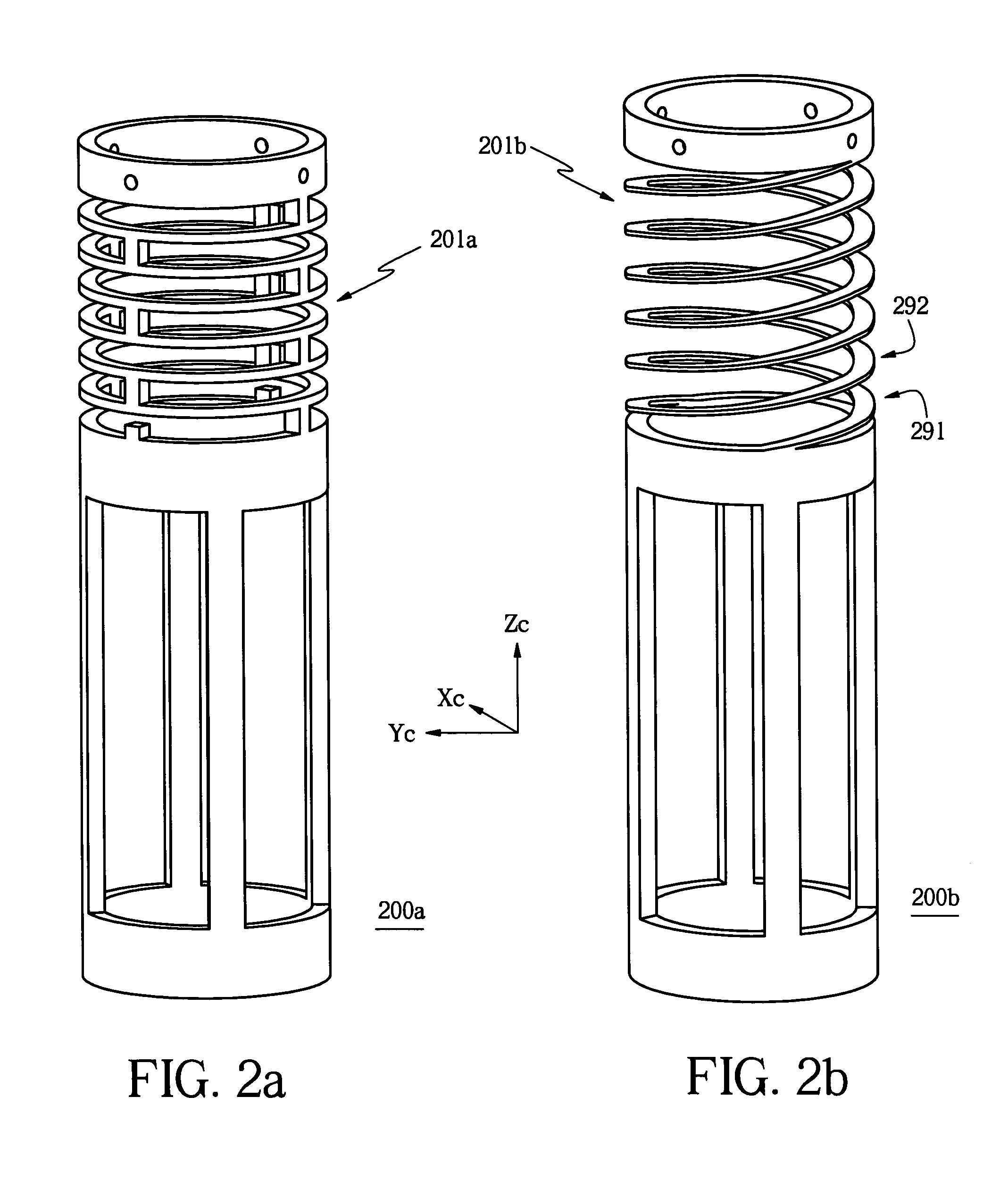

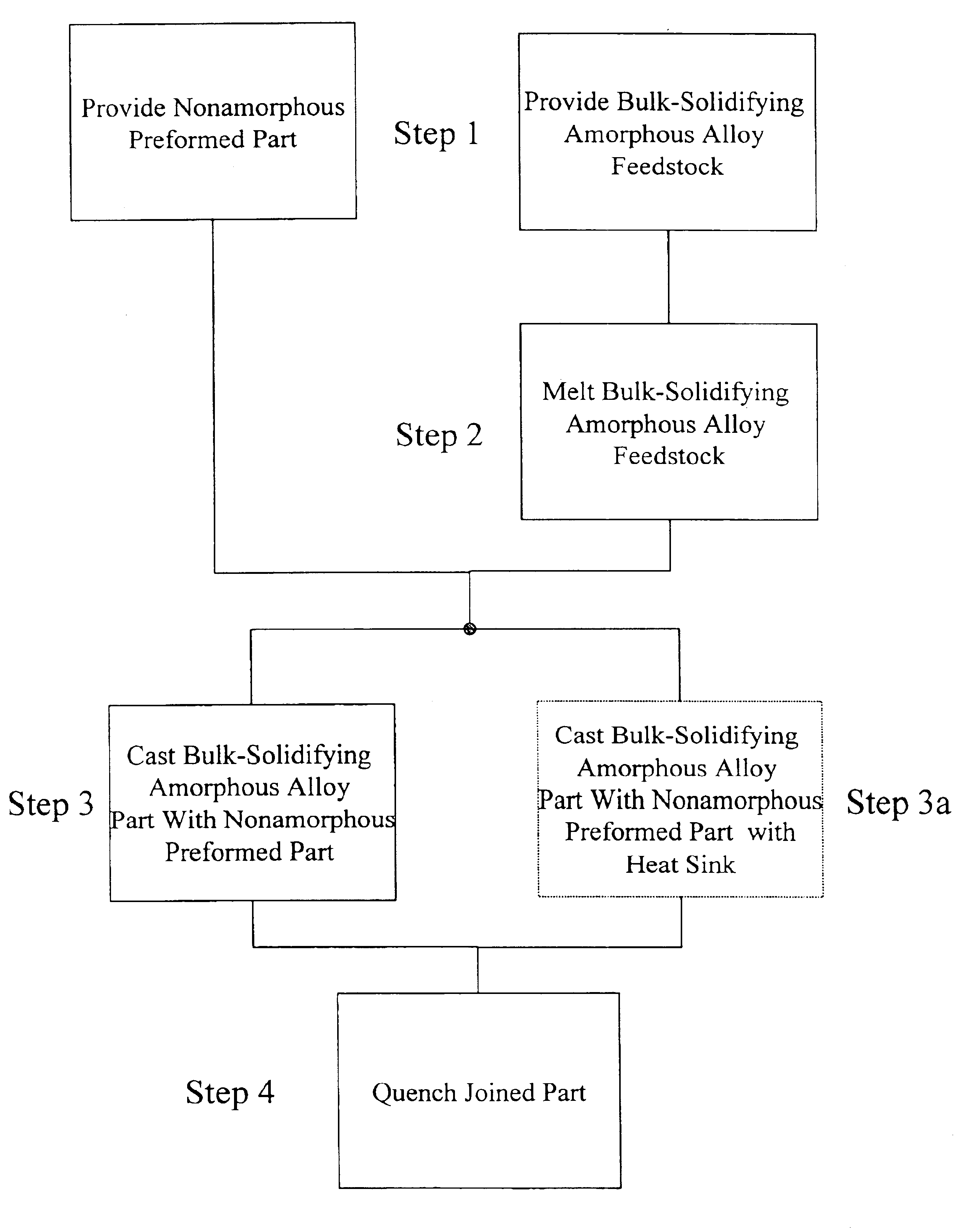

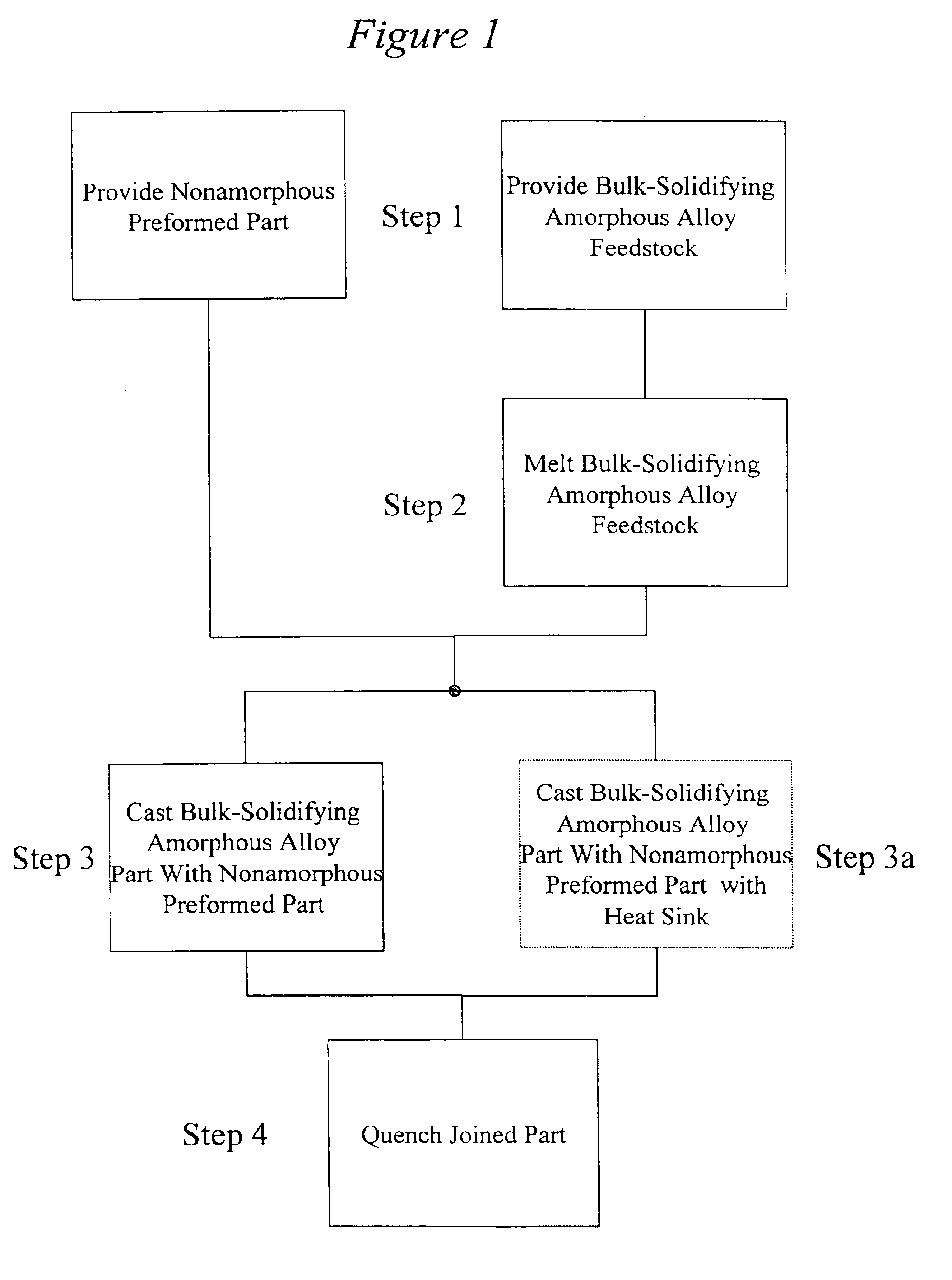

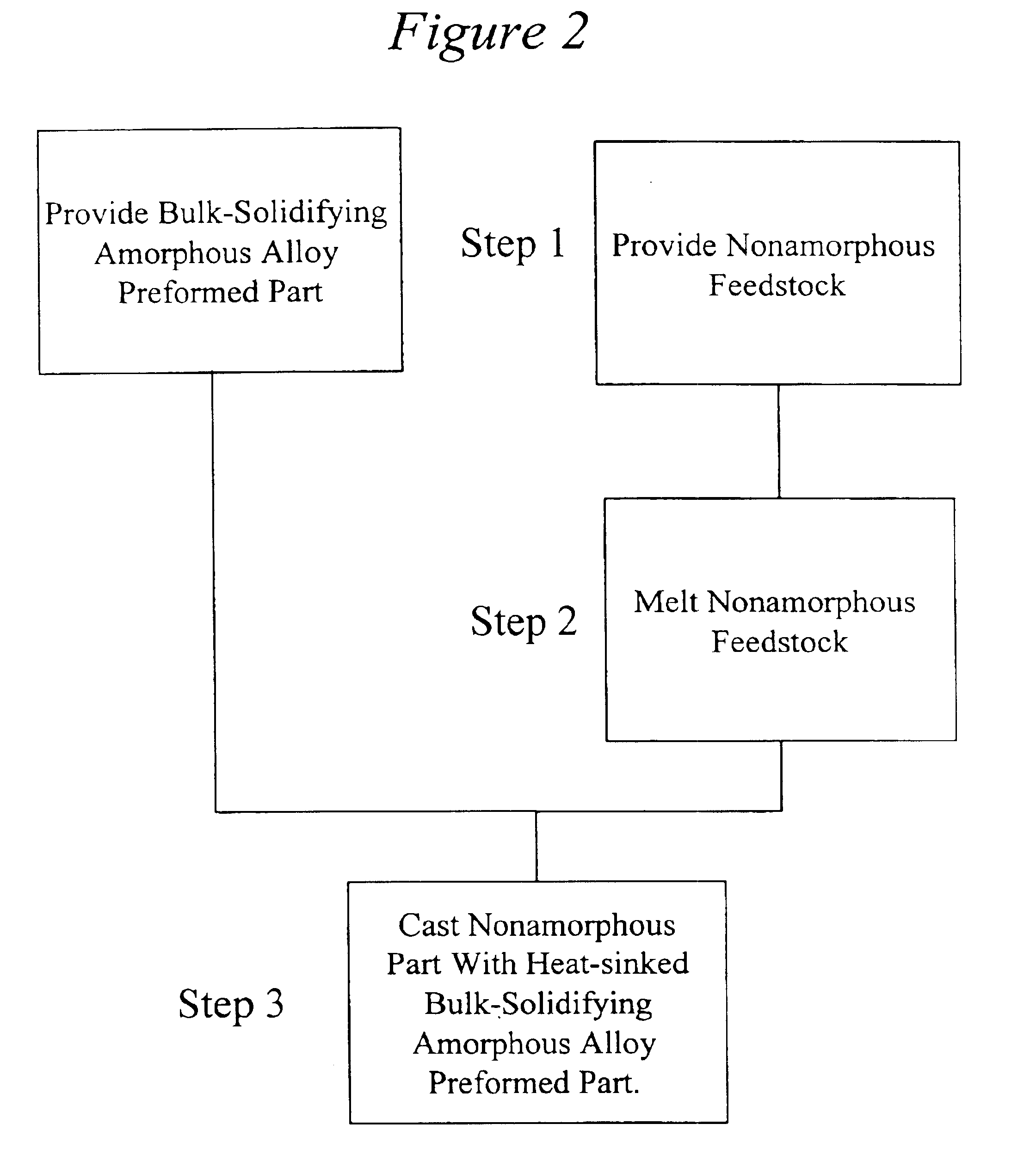

Joining of amorphous metals to other metals utilzing a cast mechanical joint

The present invention is directed to a method of joining an amorphous material to a non-amorphous material including, forming a cast mechanical joint between the bulk solidifying amorphous alloy and the non-amorphous material.

Owner:CRUCIBLE INTPROP LLC

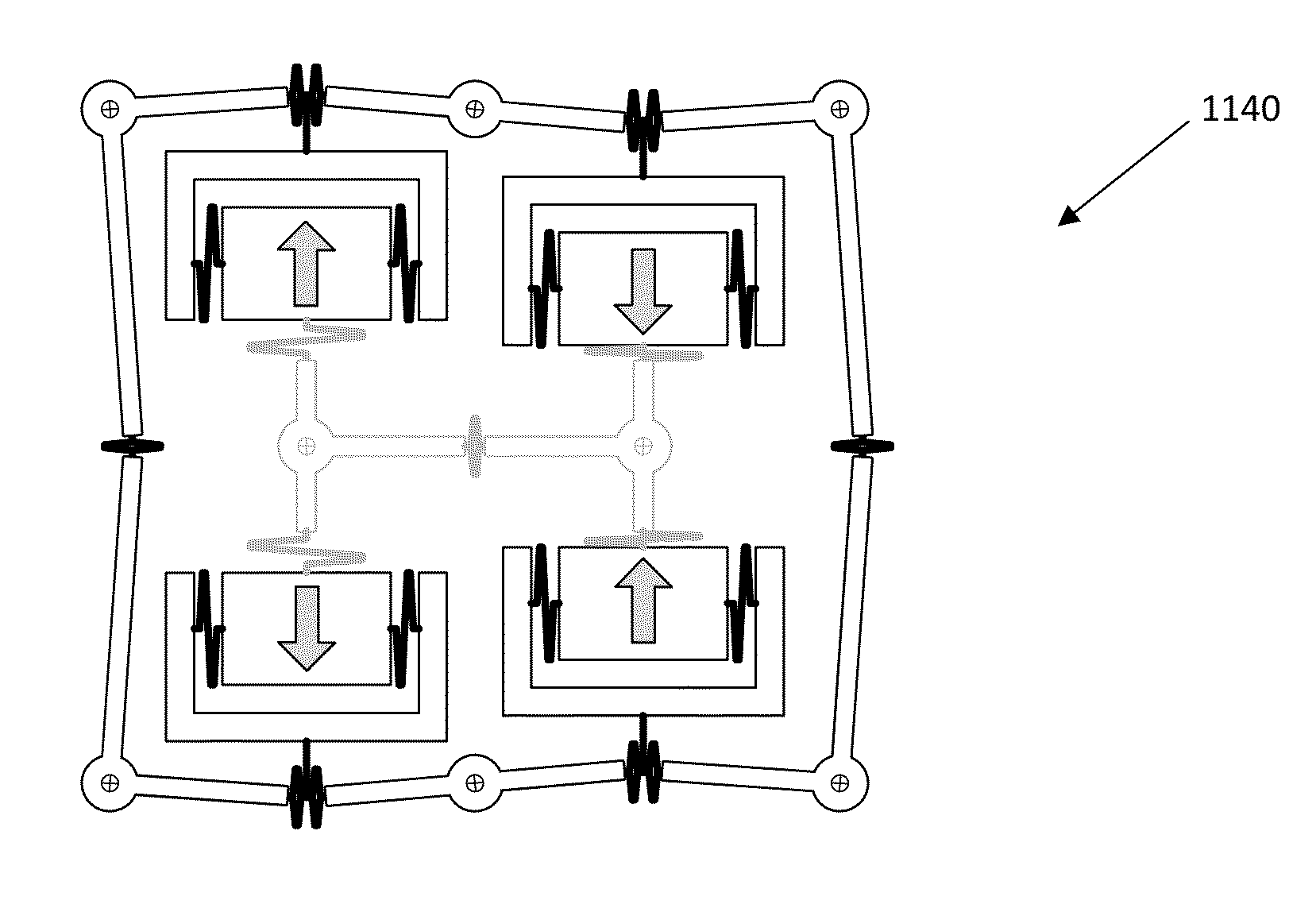

Systems and methods for MEMS gyroscope shock robustness

ActiveUS20150330783A1Improve seismic performanceImprove robustnessAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsGyroscopeEngineering

Various embodiments of the invention allow for increased shock robustness in gyroscopes. In certain embodiments, immunity against undesired forces that corrupt signal output is provided by a chessboard-pattern architecture of proof masses that provides a second layer of differential signals not present in existing designs. Masses are aligned parallel to each other in a two-by-two configuration with two orthogonal symmetry axes. The masses are driven to oscillate in such a way that each mass moves anti-parallel to an adjacent proof mass. In some embodiments of the invention, a mechanical joint system interconnects proof masses to suppress displacements due to mechanical disturbances, while permitting displacements due to Coriolis forces to prevented erroneous sensor signals.

Owner:HANKING ELECTRONICS LTD

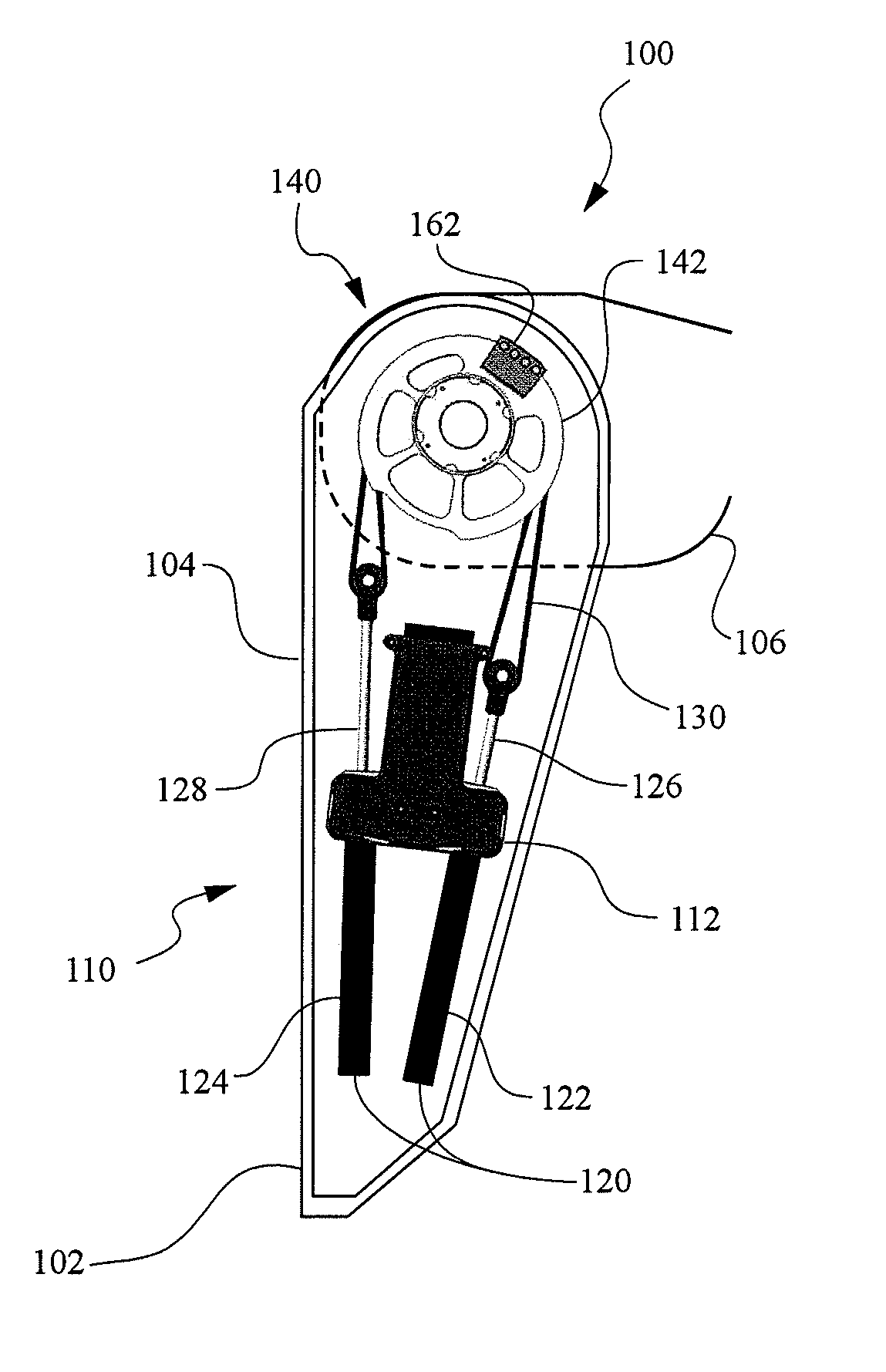

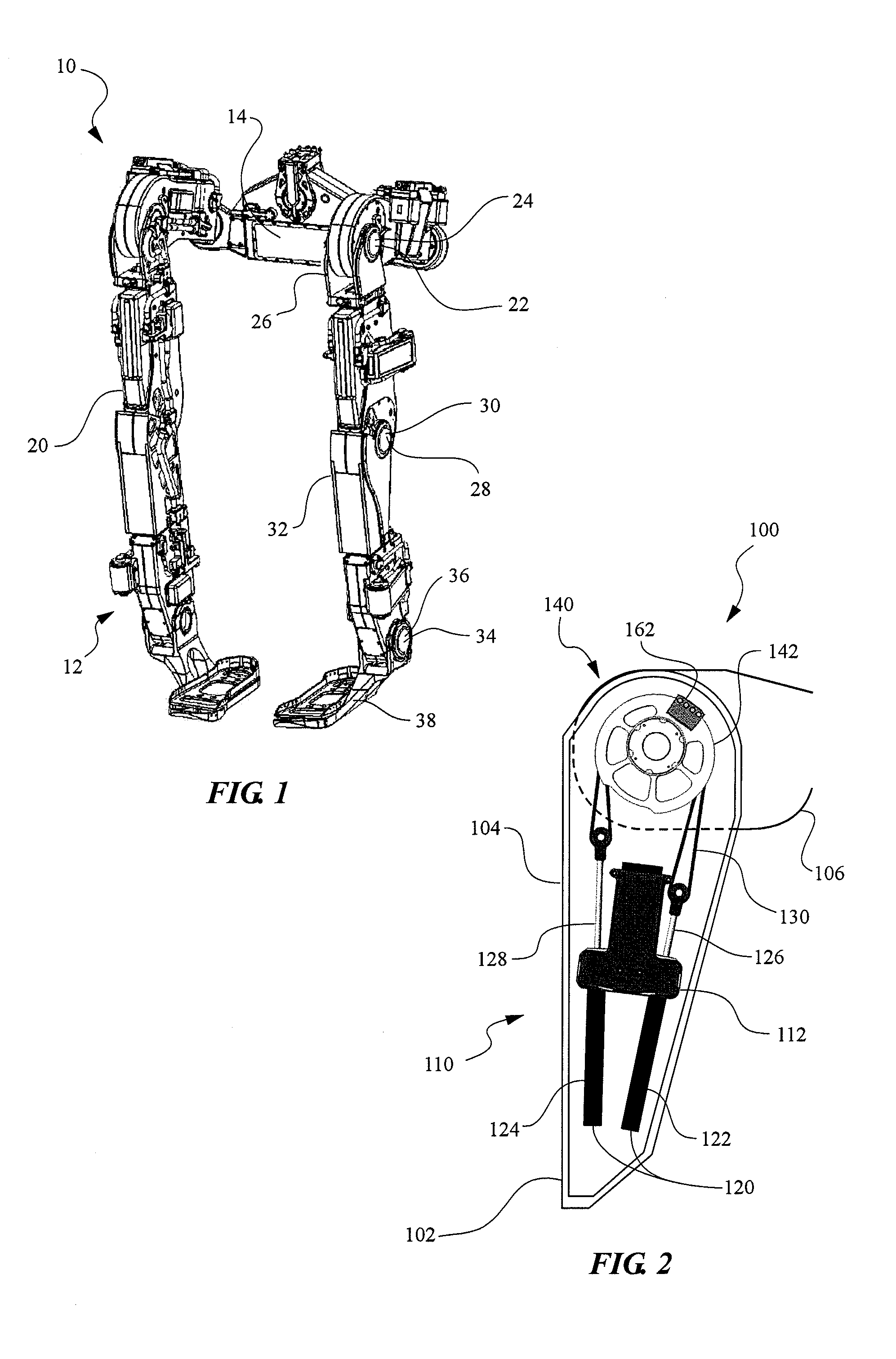

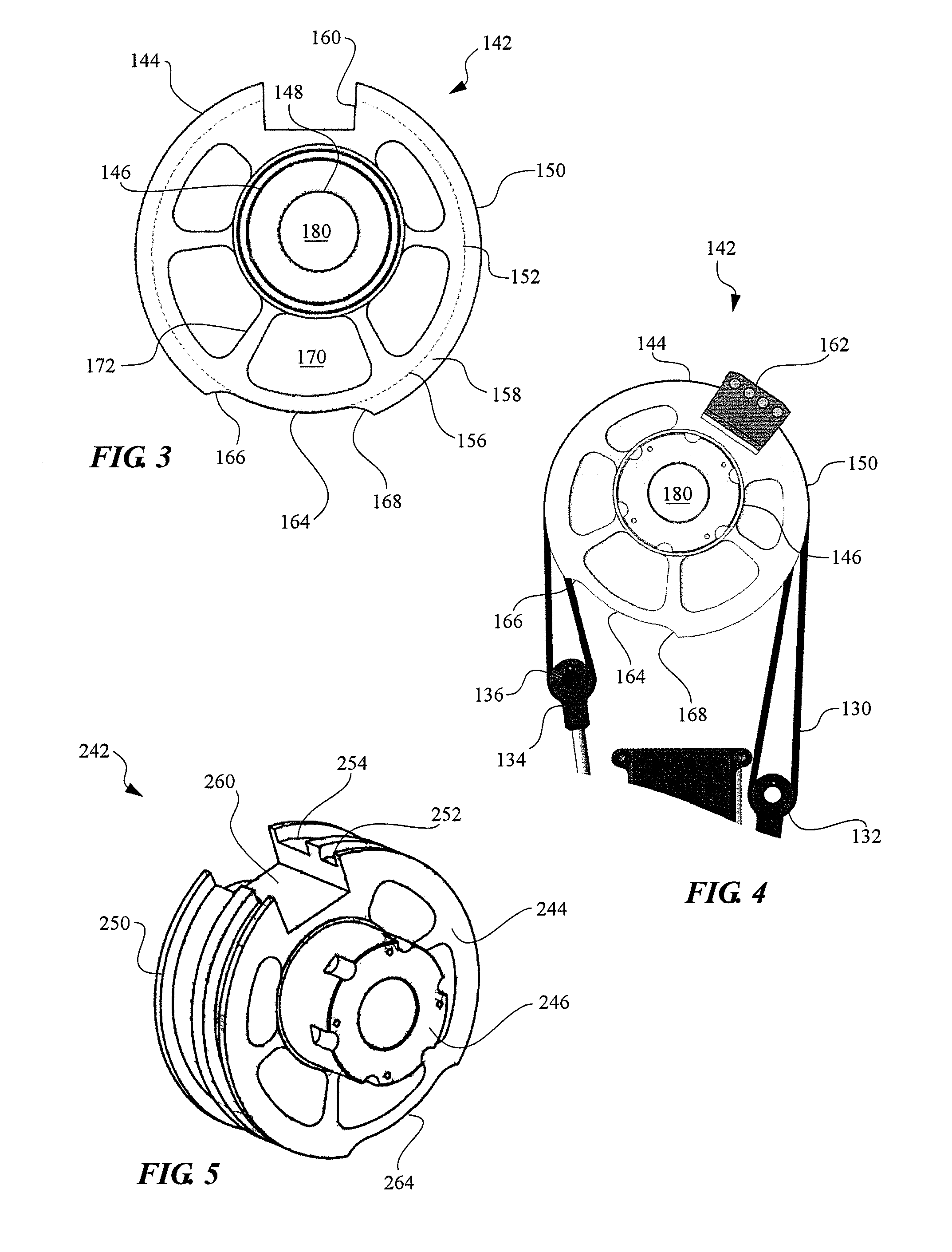

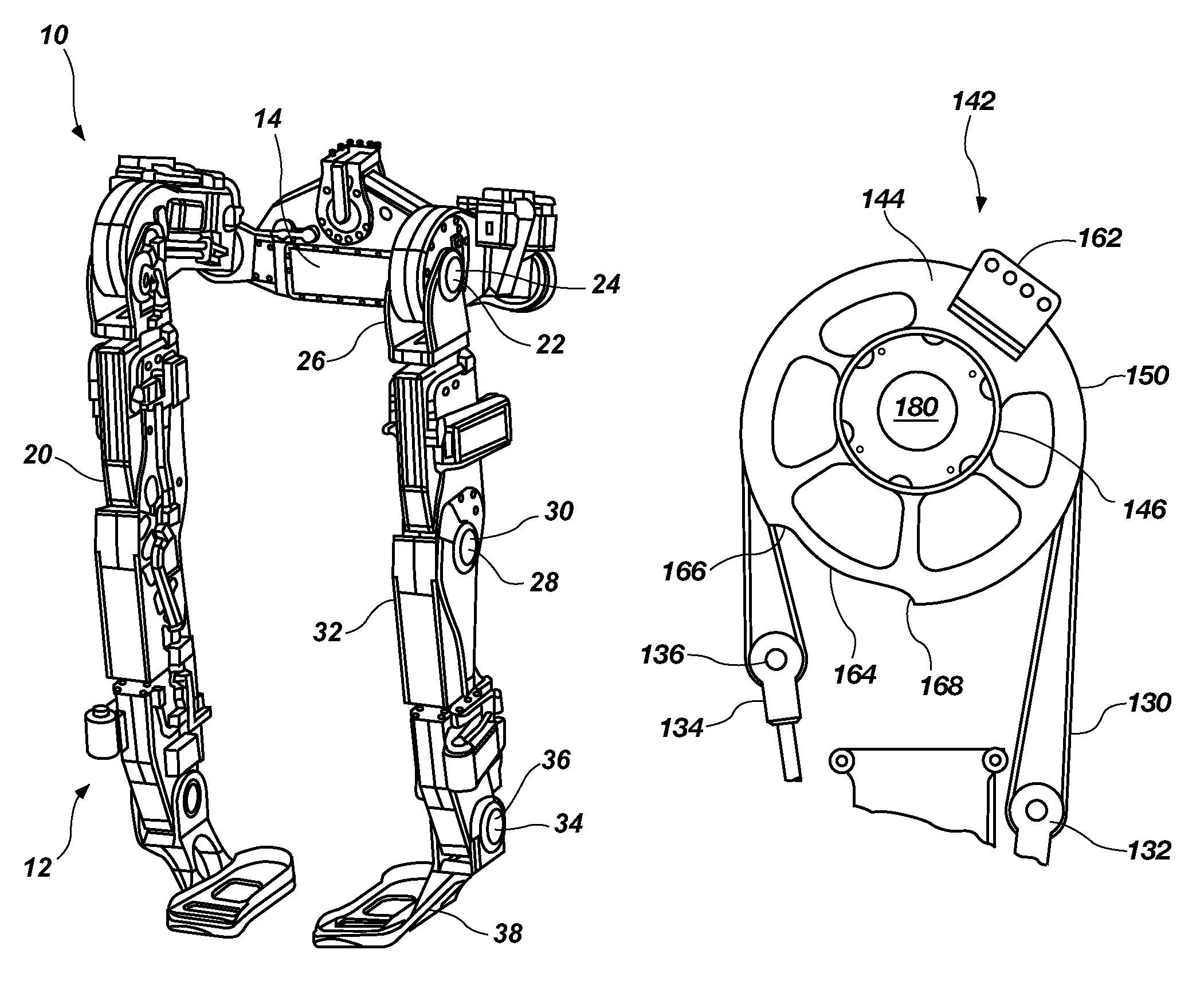

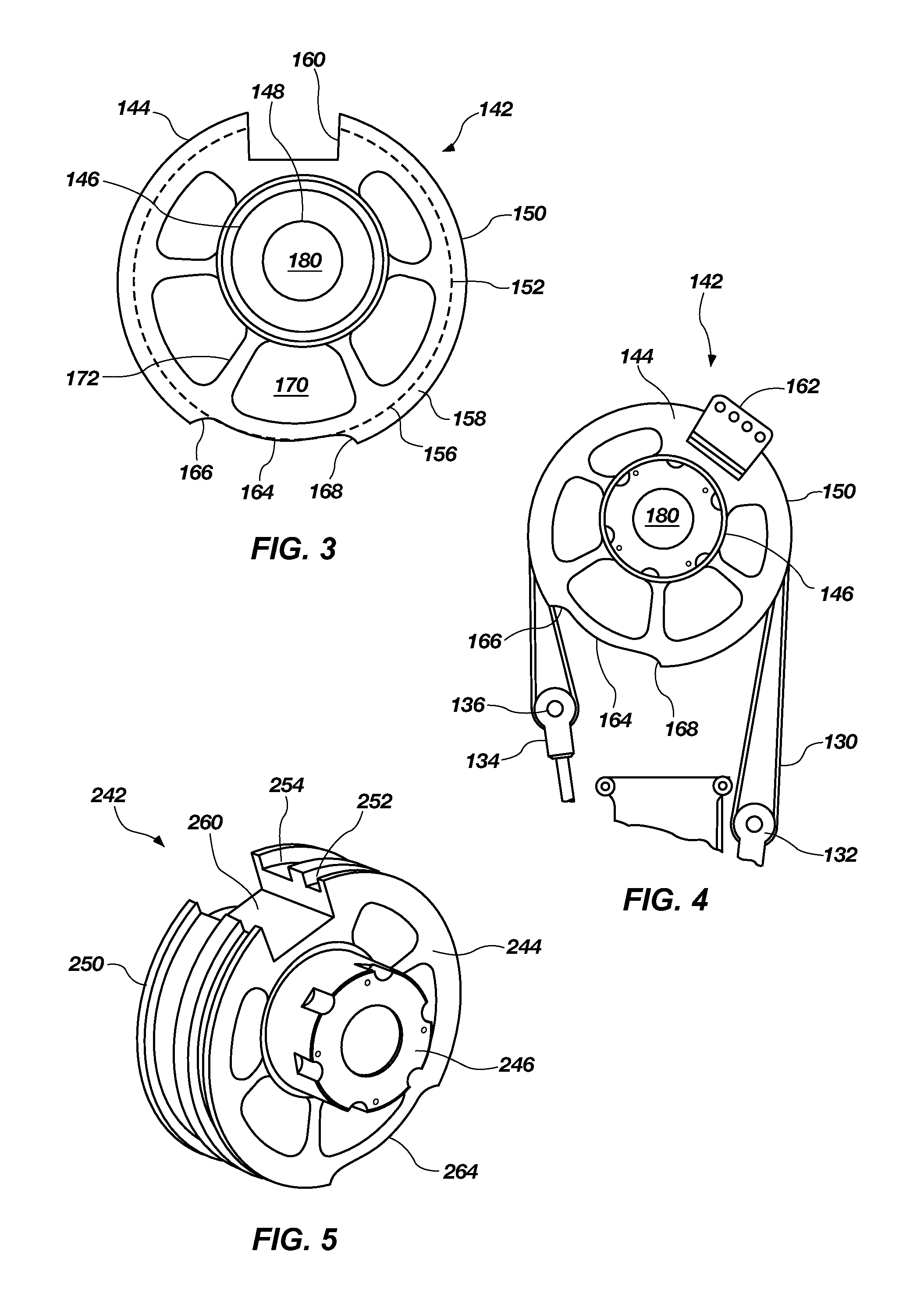

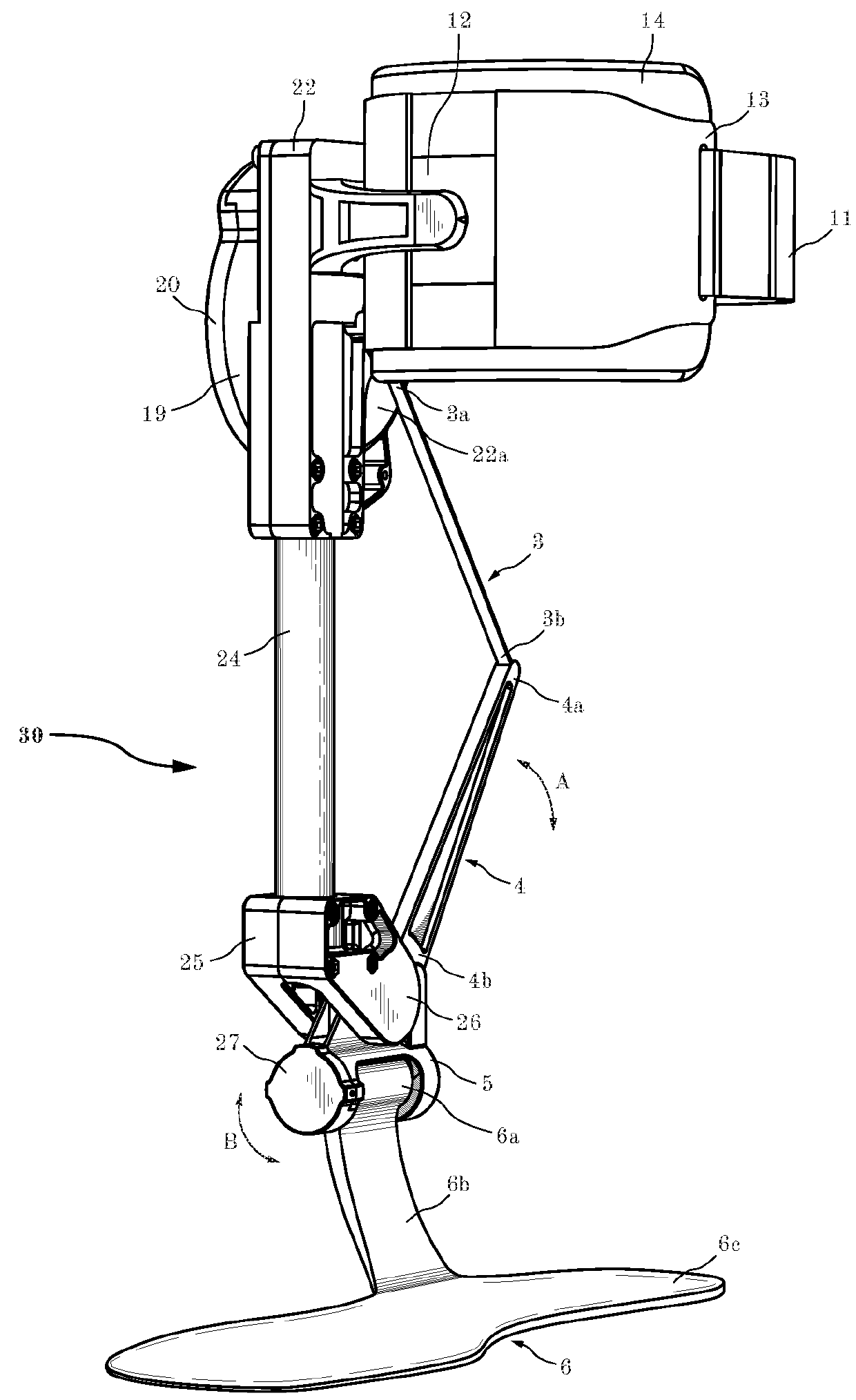

Biomimetic Mechanical Joint

ActiveUS20110214524A1Guaranteed uptimeProgramme-controlled manipulatorMechanical apparatusEngineeringActuator

A biomimetic mechanical joint for generating a variable torque between support members of a biomimetic robotic device, including a base support member, a rotary support member rotatably coupled to the base support member, and a variable-radius pulley operably coupled between the base support member and rotary support member. The variable-radius pulley comprises a sheave body having a variable radius and one or more tendon grooves formed in the circumferential outer surface. The mechanical joint further includes one or more flexible tendons and antagonistic actuator pairs, with each actuator pair being coupled to one or more tendons and configured to operate the tendon around the variable-radius pulley in either direction to create a variable torque between the base and rotary support members.

Owner:SARCOS LC

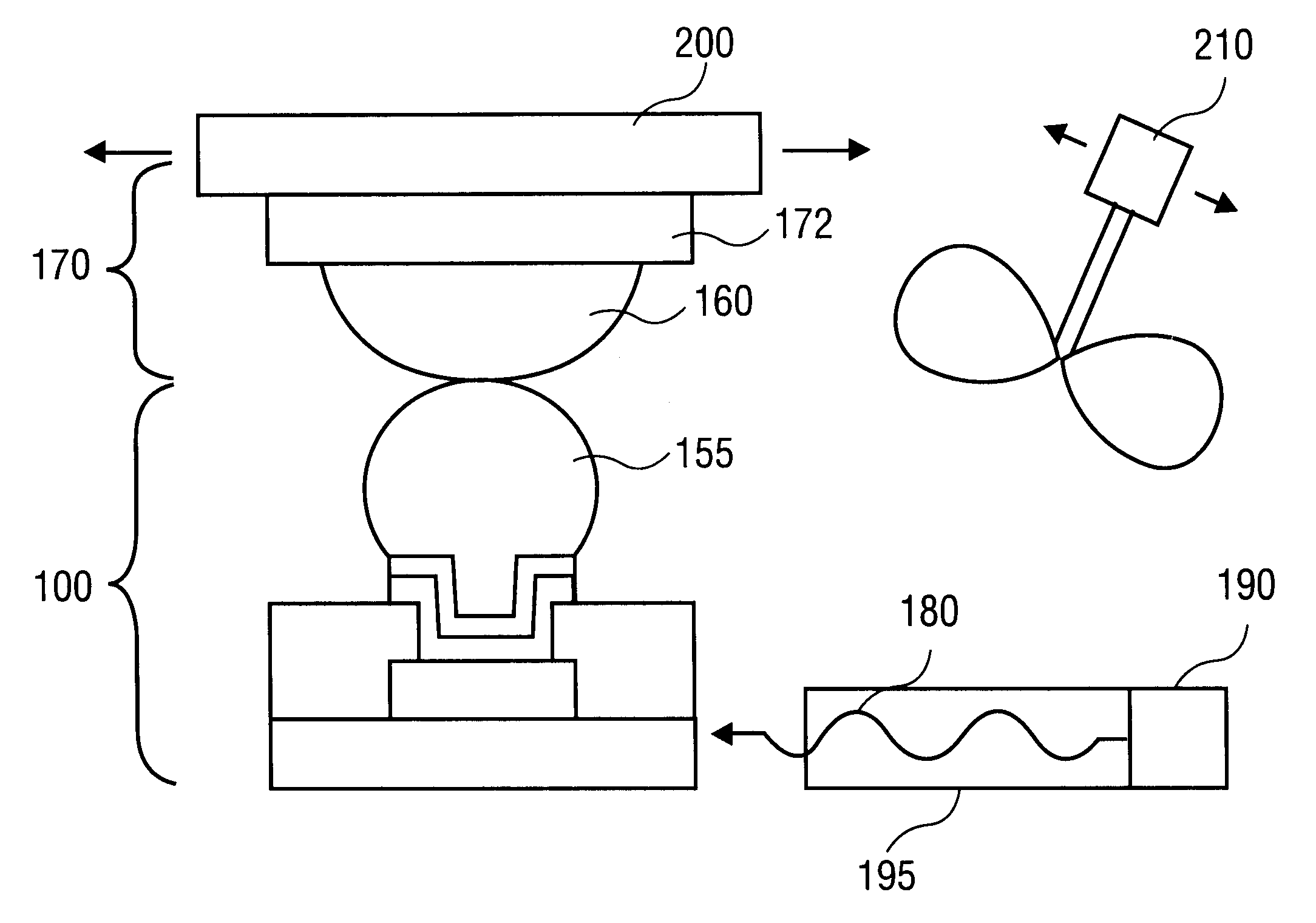

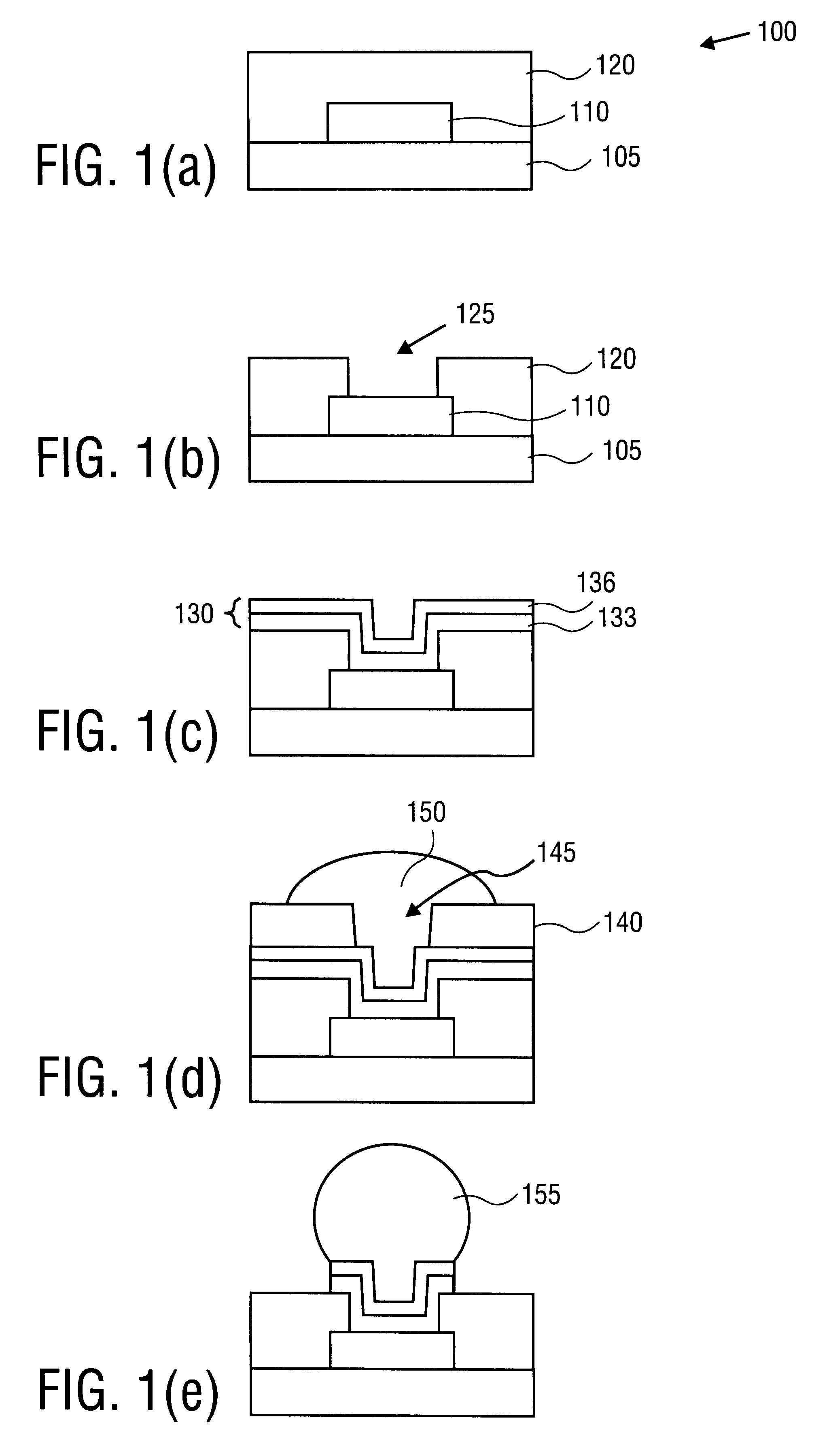

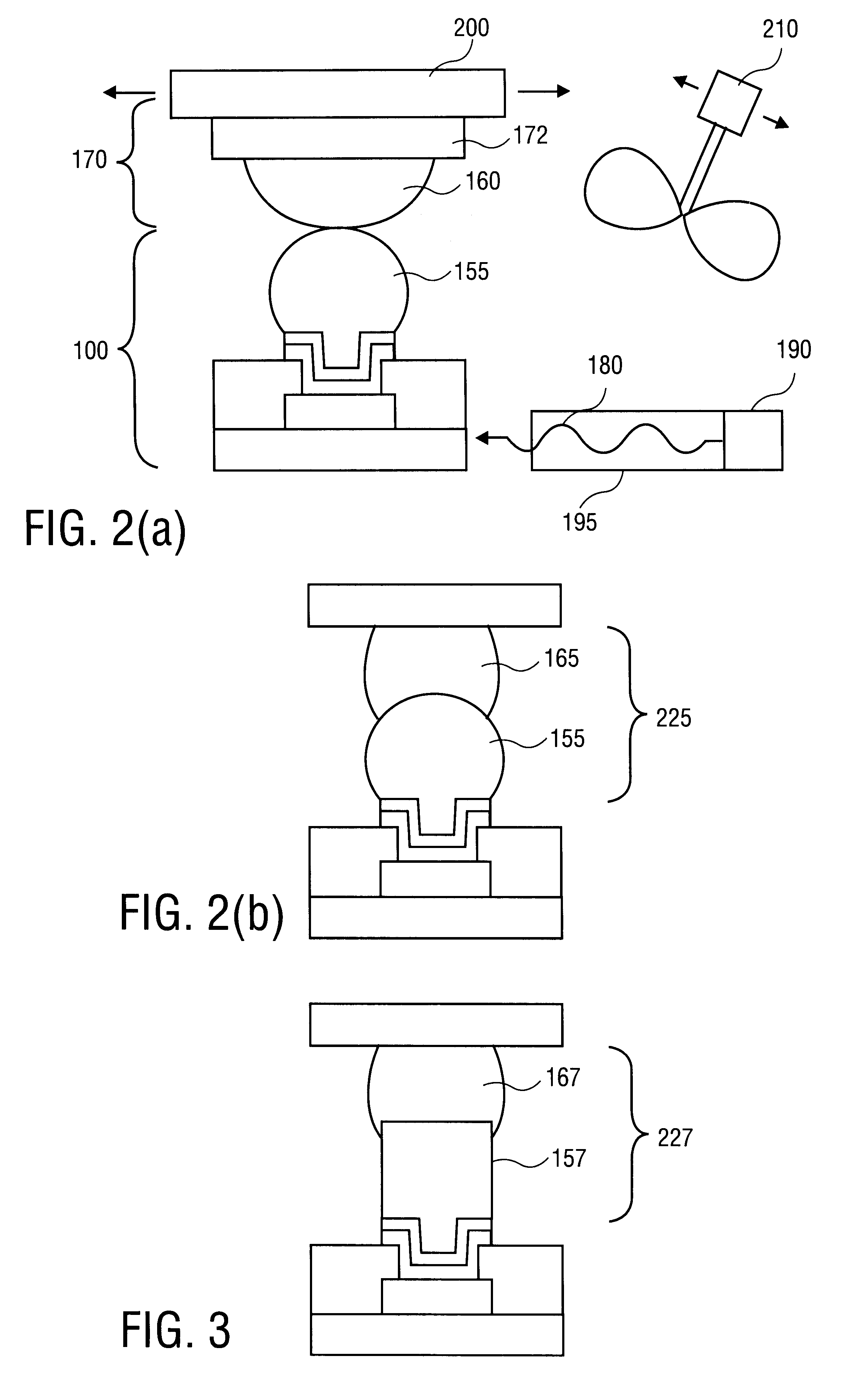

Solder reflow with microwave energy

The present invention includes a mechanical joint between a die and a substrate that is reflowed by microwave energy and a method of forming such a mechanical joint by printing a solder over a substrate, placing the solder in contact with a bump over a die, reflowing the solder with microwave energy, and forming a mechanical joint from the solder and the bump.

Owner:INTEL CORP

Biomimetic mechanical joint

A biomimetic mechanical joint for generating a variable torque between support members of a biomimetic robotic device, including a base support member, a rotary support member rotatably coupled to the base support member, and a variable-radius pulley operably coupled between the base support member and rotary support member. The variable-radius pulley comprises a sheave body having a variable radius and one or more tendon grooves formed in the circumferential outer surface. The mechanical joint further includes one or more flexible tendons and antagonistic actuator pairs, with each actuator pair being coupled to one or more tendons and configured to operate the tendon around the variable-radius pulley in either direction to create a variable torque between the base and rotary support members.

Owner:SARCOS LC

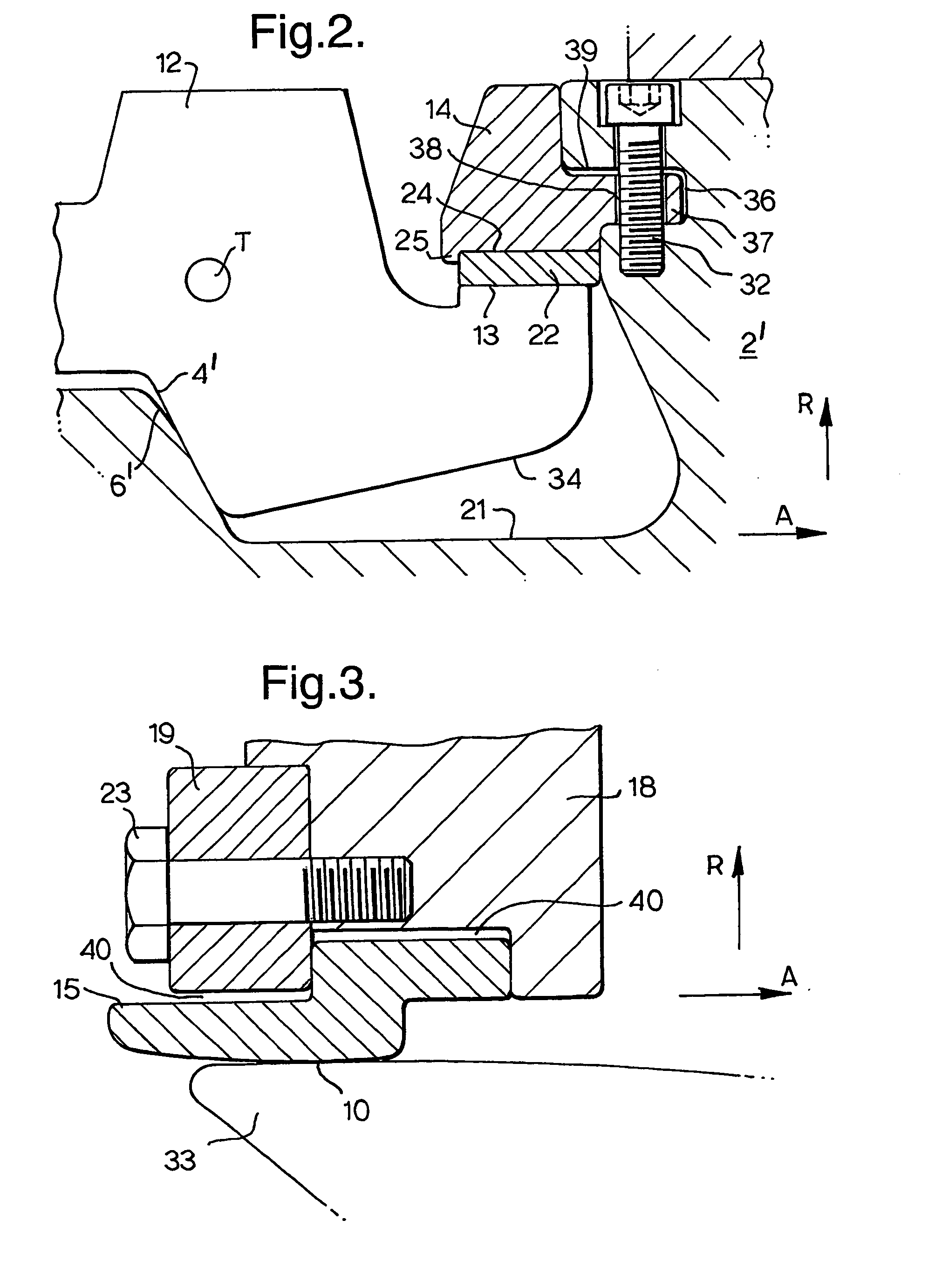

Mechanical joints for subsea equipment

InactiveUS20050146137A1Large dimensional toleranceExpand the scope of workSleeve/socket jointsPipe laying and repairJoint componentEngineering

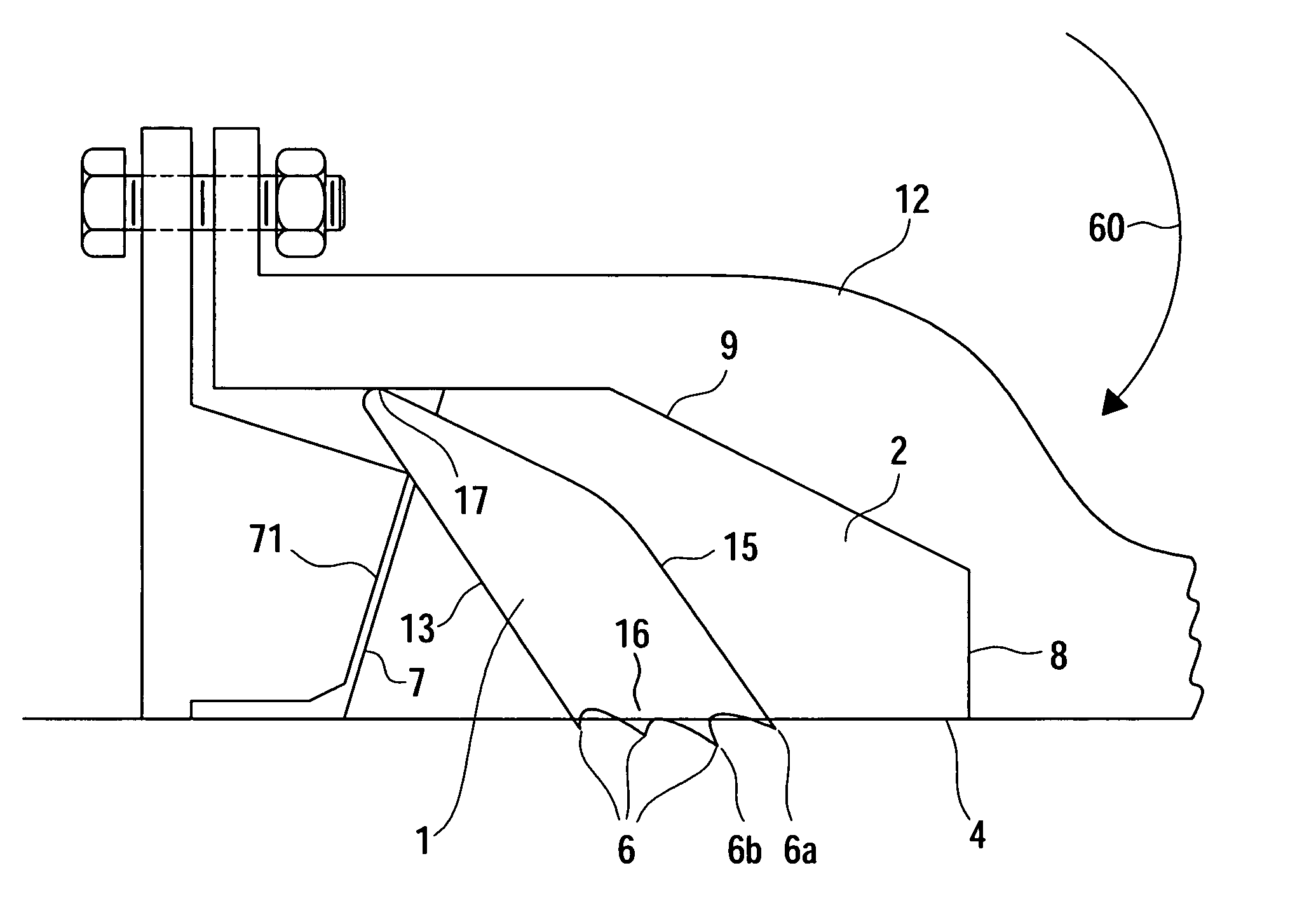

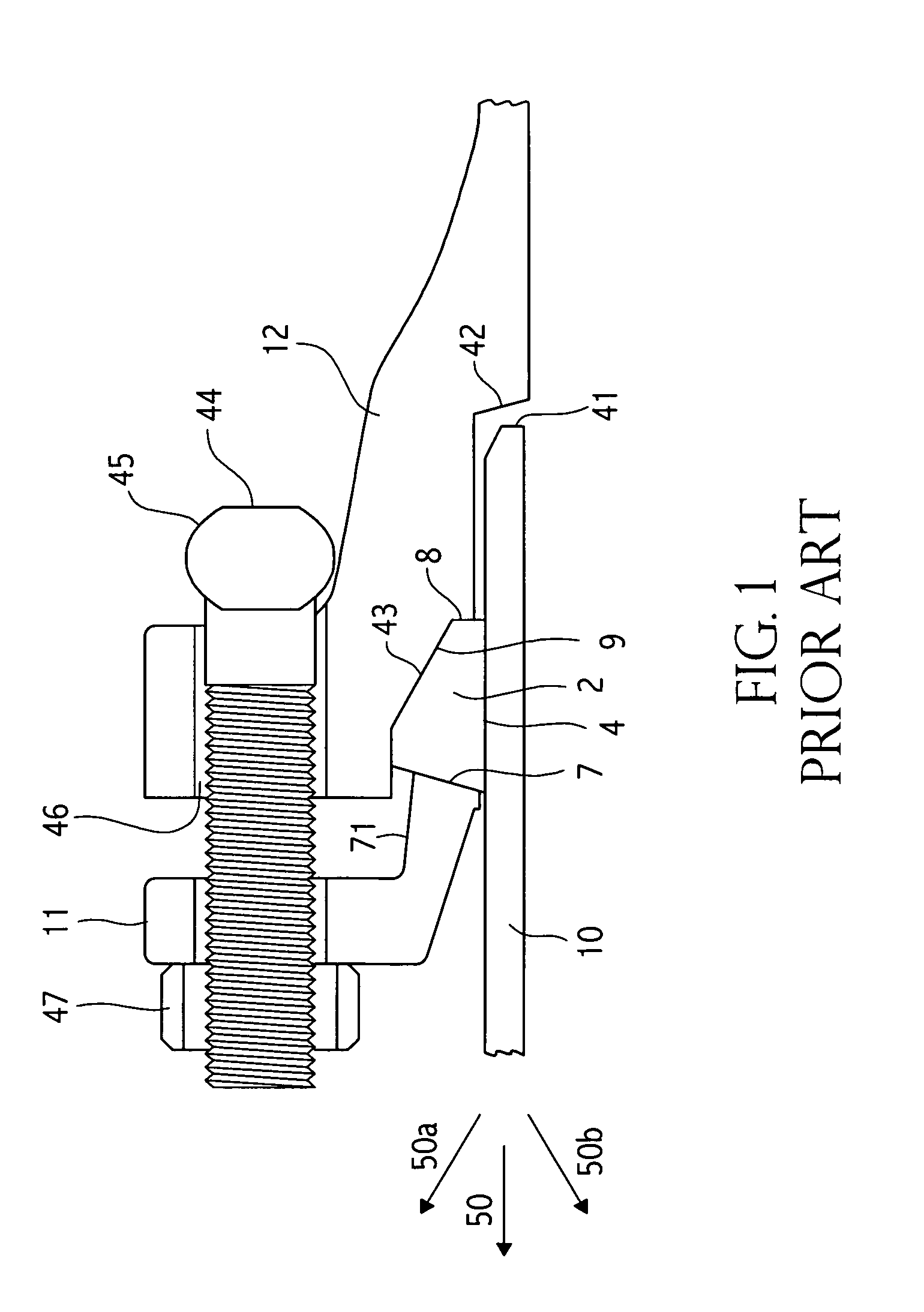

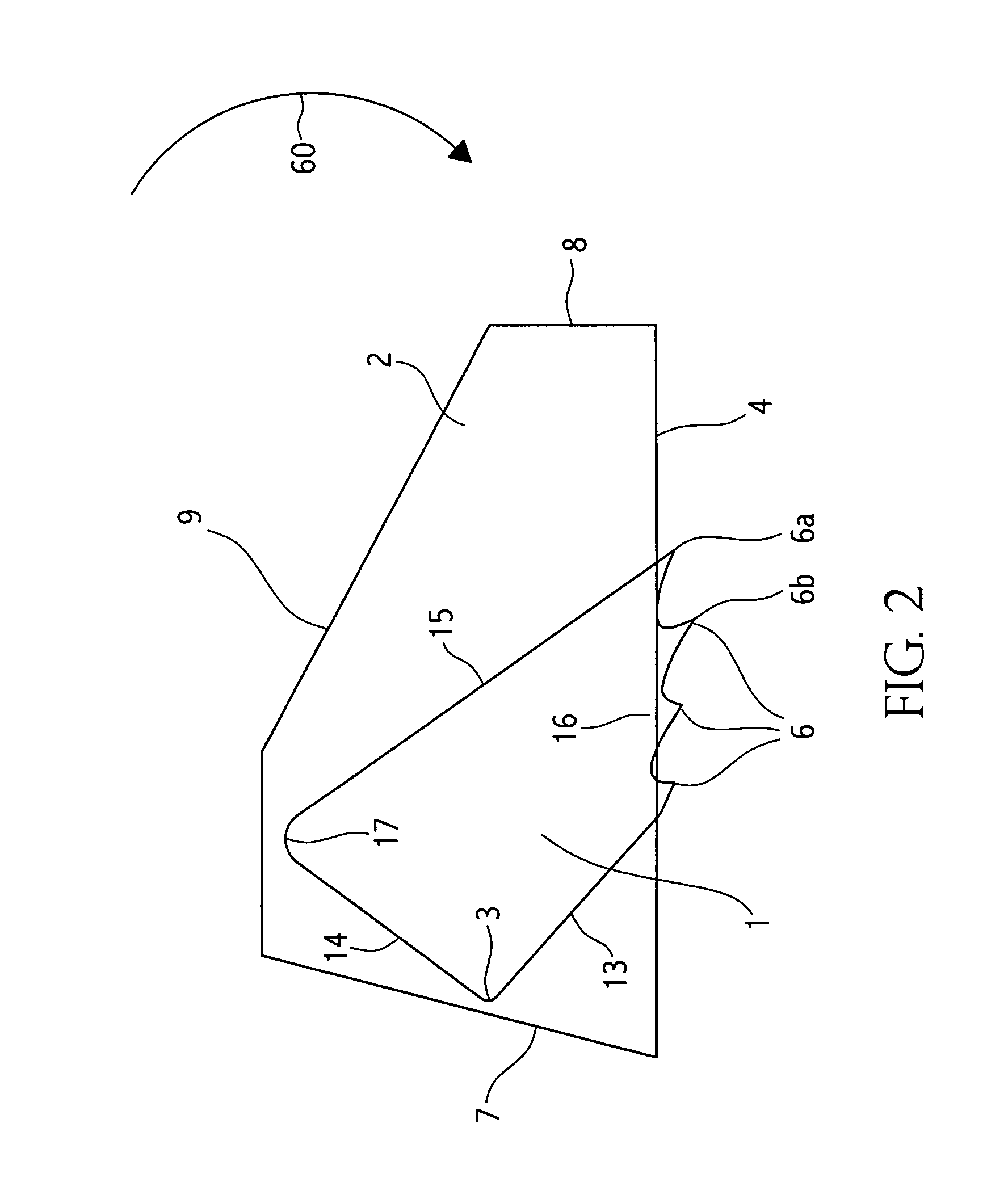

A mechanical connector for oil and gas well apparatus applies a predetermined preload across the connection, the preload being adapted to accommodate relatively large dimensional tolerances in the loadpath of the connector preload by placing a component with a low modulus of elasticity within that load path. In one embodiment, the connector comprises fingers (3) of a pair of pipe flanges (1, 1′), a stationary retainer ring (14) against which a finger reaction surface (13) is pressed, a runner ring (15) located outside the fingers and movable lengthwise along the fingers by an actuator (16), the retainer ring and the runner ring having an elasticity that is so large that deviations in their elongation only have a small influence on the retainer ring and the runner ring radial pressure against the fingers and clamping forces of the fingers against the flanges. In a second embodiment, the connector comprises dogs (103, FIG. 4) located around the circumference of a first tubular joint component, a follower located outside the dogs (103) and movable axially of the dogs, the low elastic modulus component being a ring located in the loadpath below the dogs. In a third embodiment, the connector comprises a lockdown mechanism acting between nested components, the low elastic modulus component being an insert comprising a load shoulder transferring loads between the nested components.

Owner:FMC TECH INC

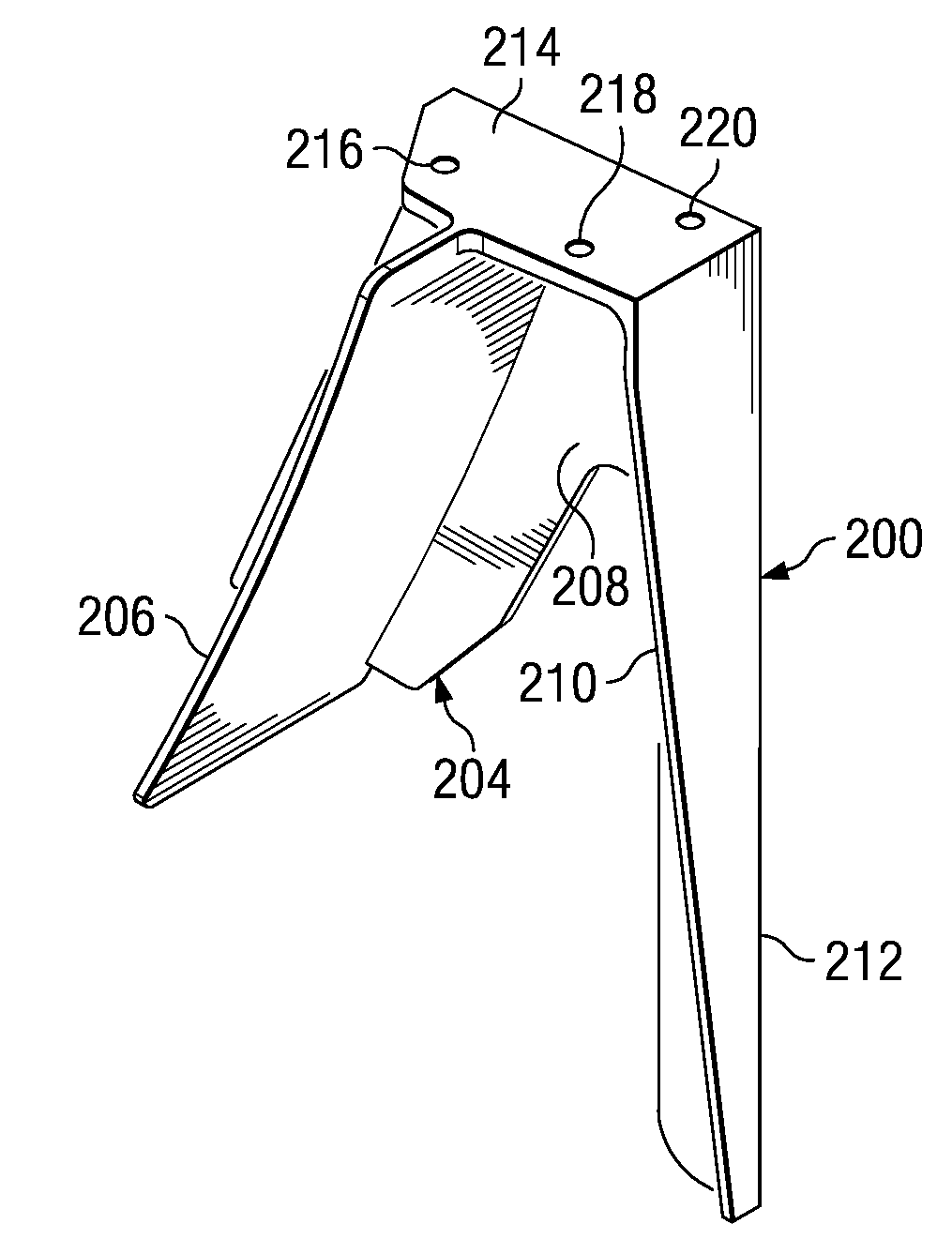

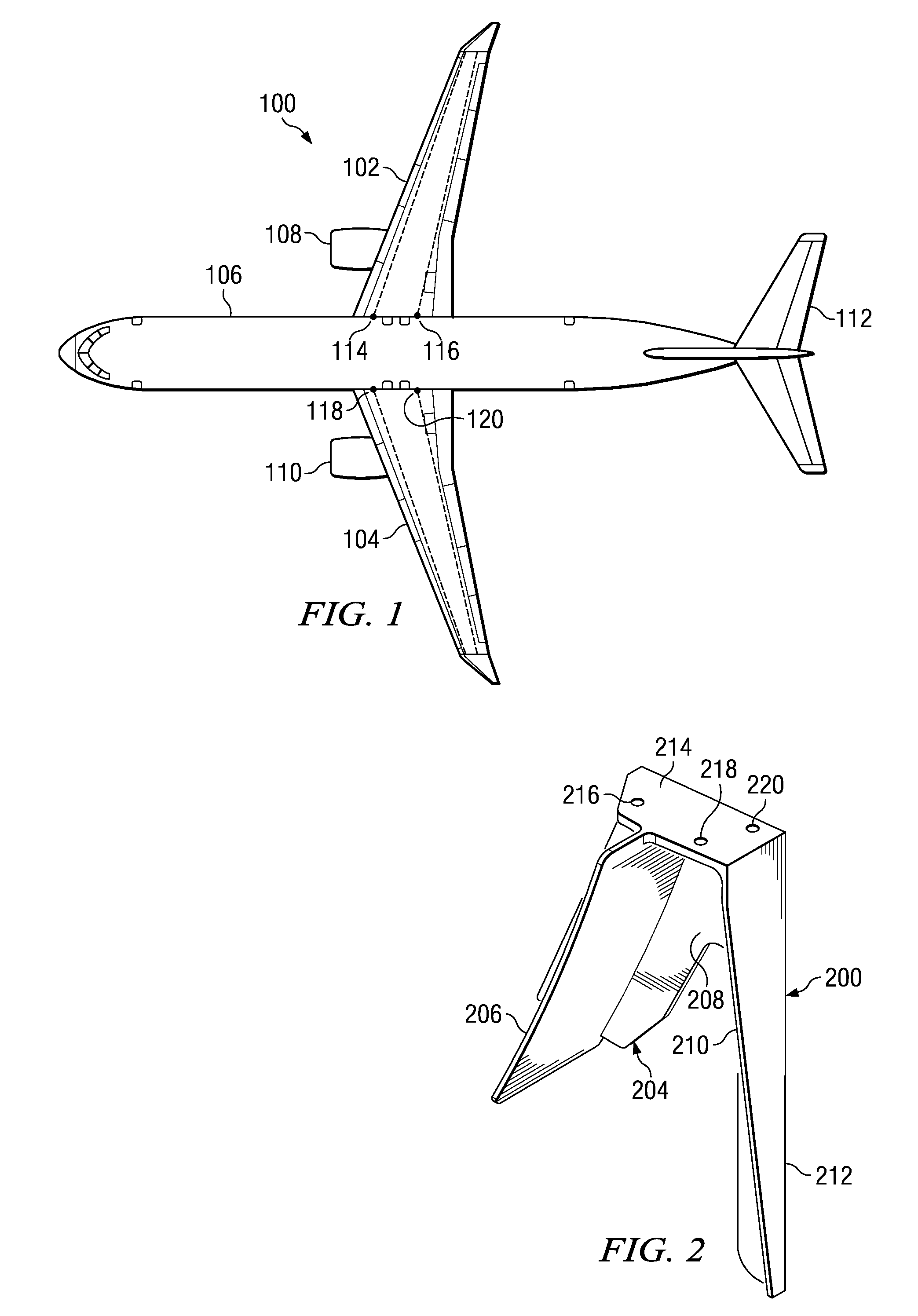

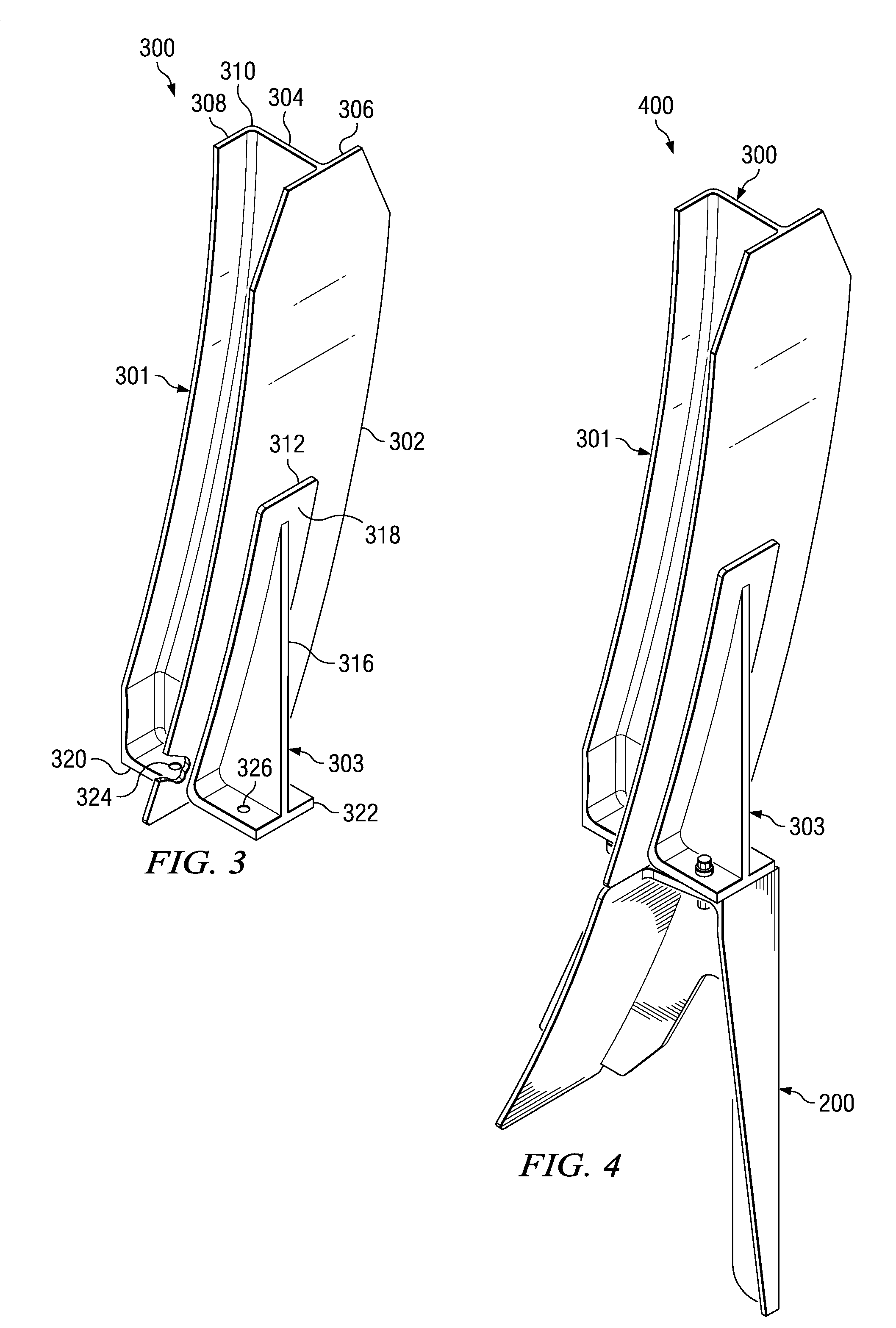

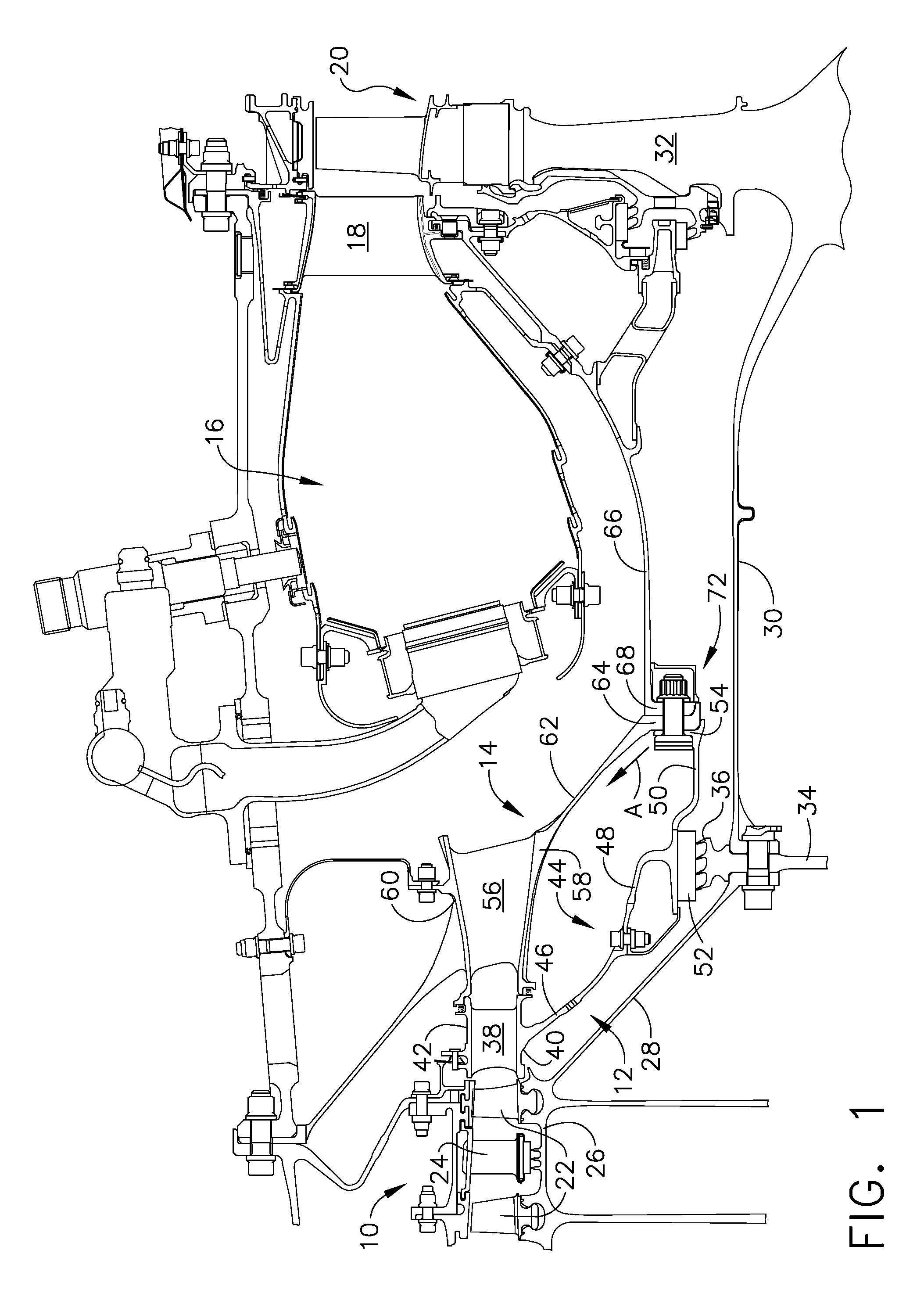

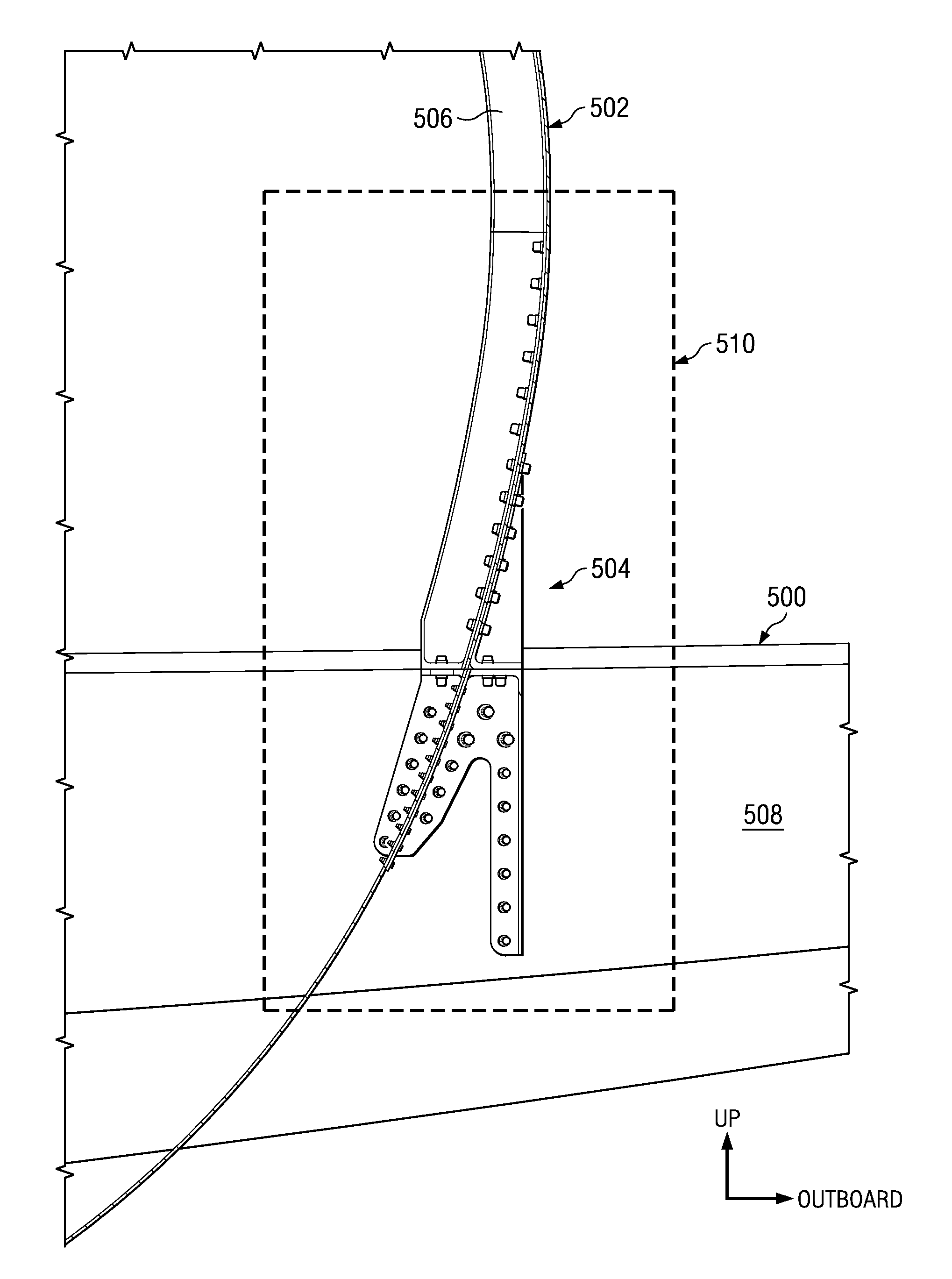

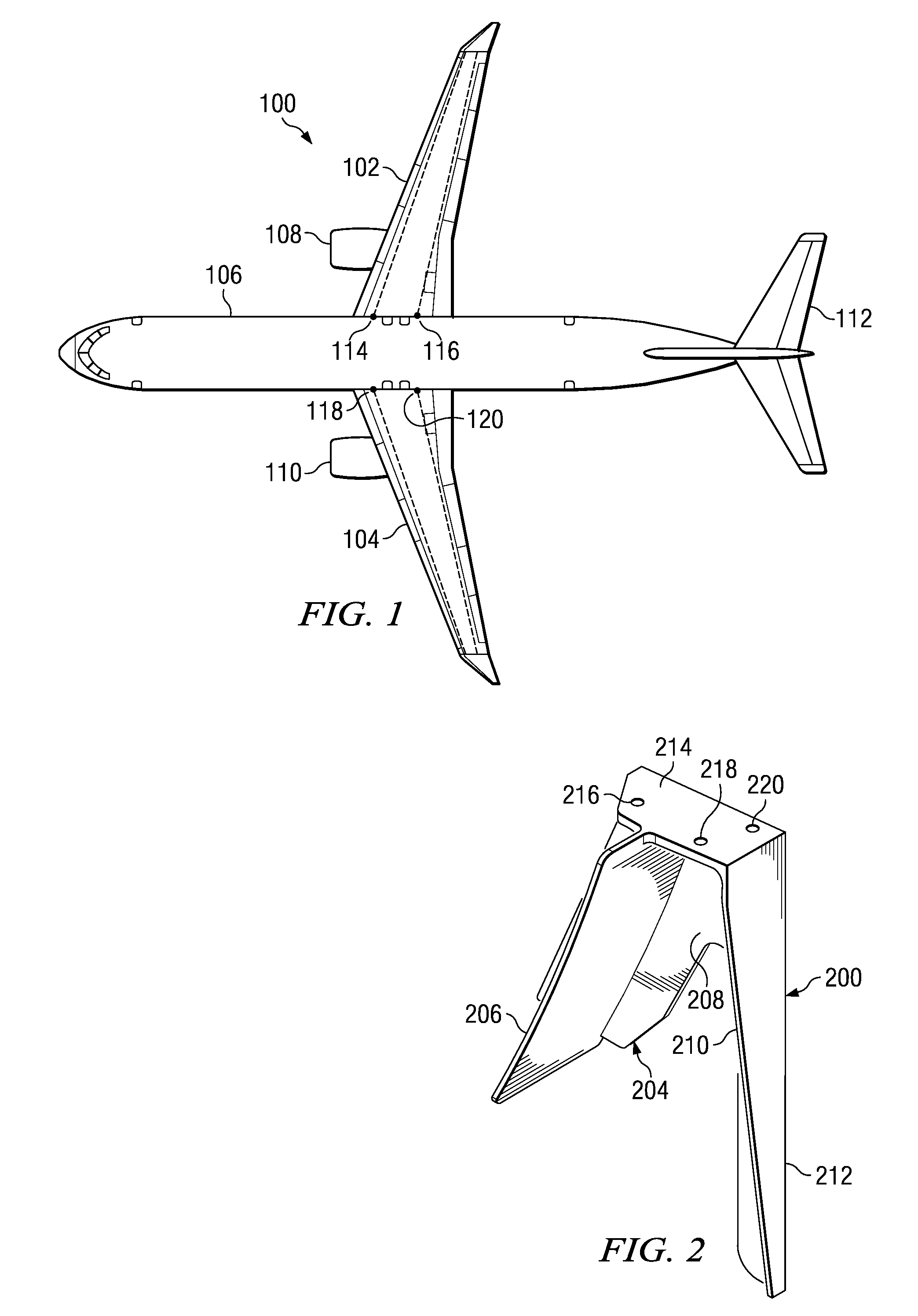

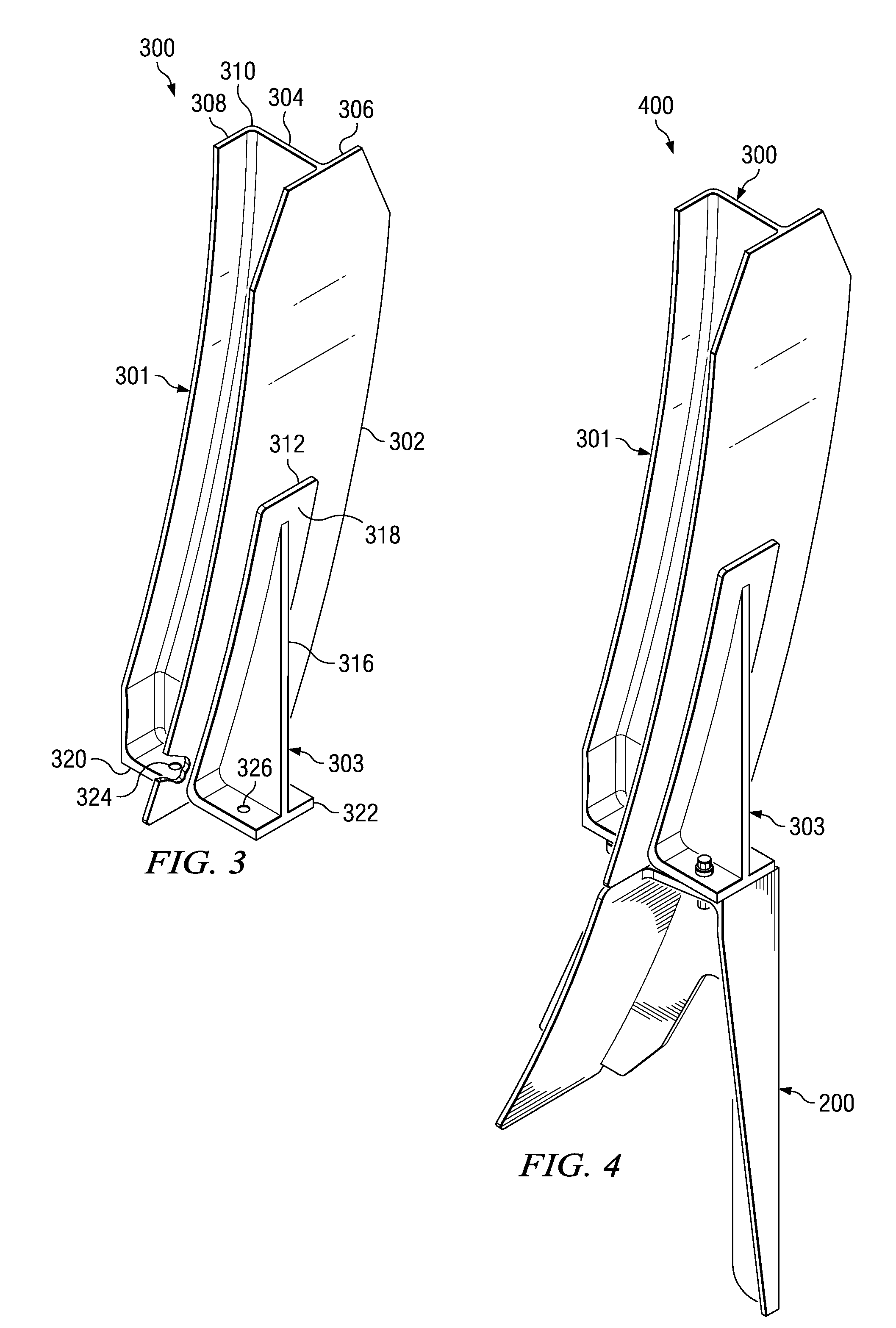

Method and apparatus for attaching a wing to a body

A method and apparatus for assembling an aircraft. A wing spar fitting is connected to a spar in a wing for the aircraft. A body frame fitting is connected to a frame in a body for the aircraft. The locations and orientations of the body frame fitting and the wing spar fitting allow for the body frame fitting to be attached to the wing spar fitting when the wing is positioned for attachment to the body of the aircraft. The wing is positioned with respect to the body of the aircraft for attachment to the body. The body frame fitting and the wing spar fitting are attached to each other with a set of fasteners after the body frame fitting is aligned to the wing spar fitting without penetrating any sealed areas in the wing, wherein the wing is attached to the body by a mechanical joint that is formed by the body frame fitting and the wing spar fitting.

Owner:THE BOEING CO

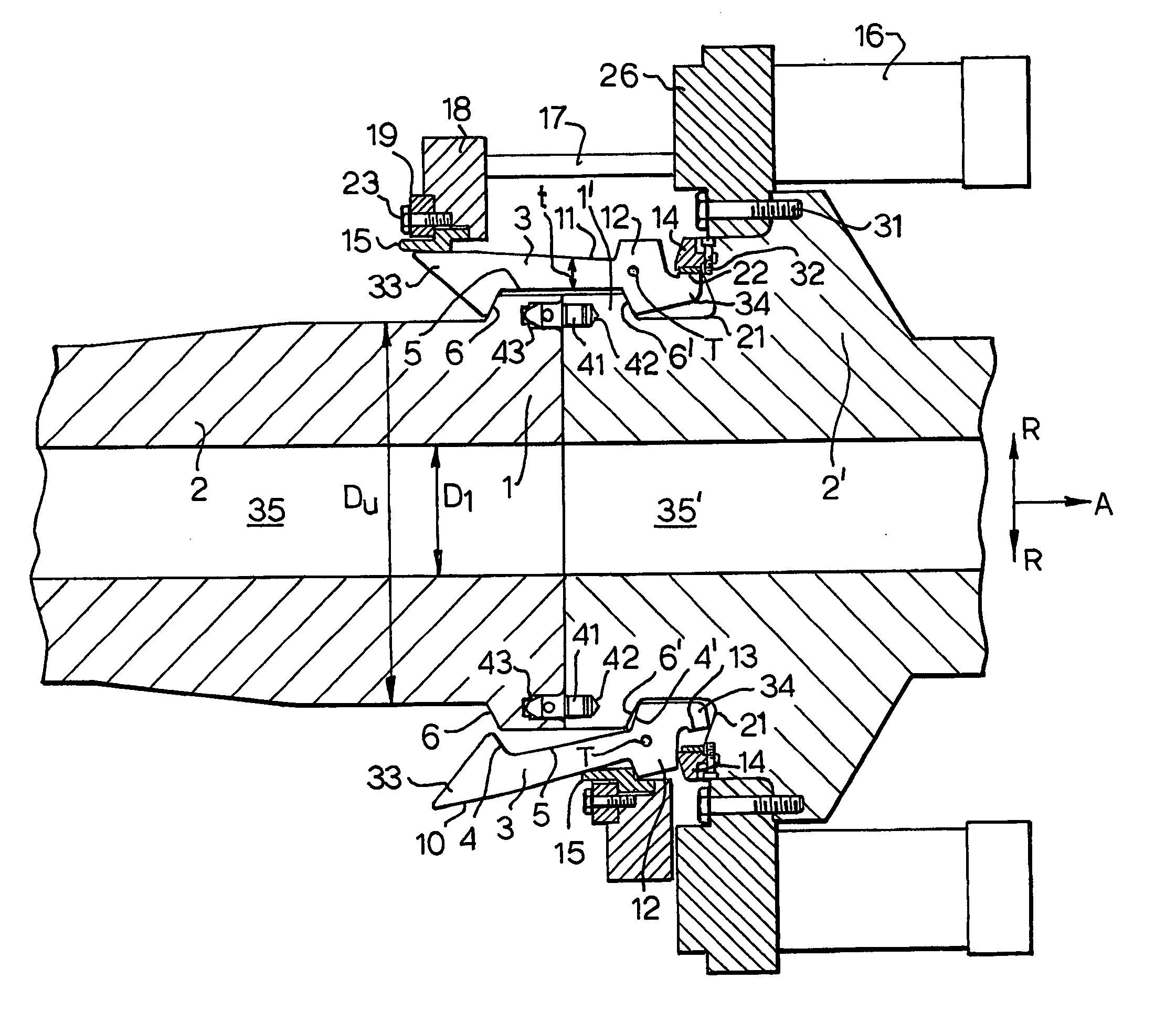

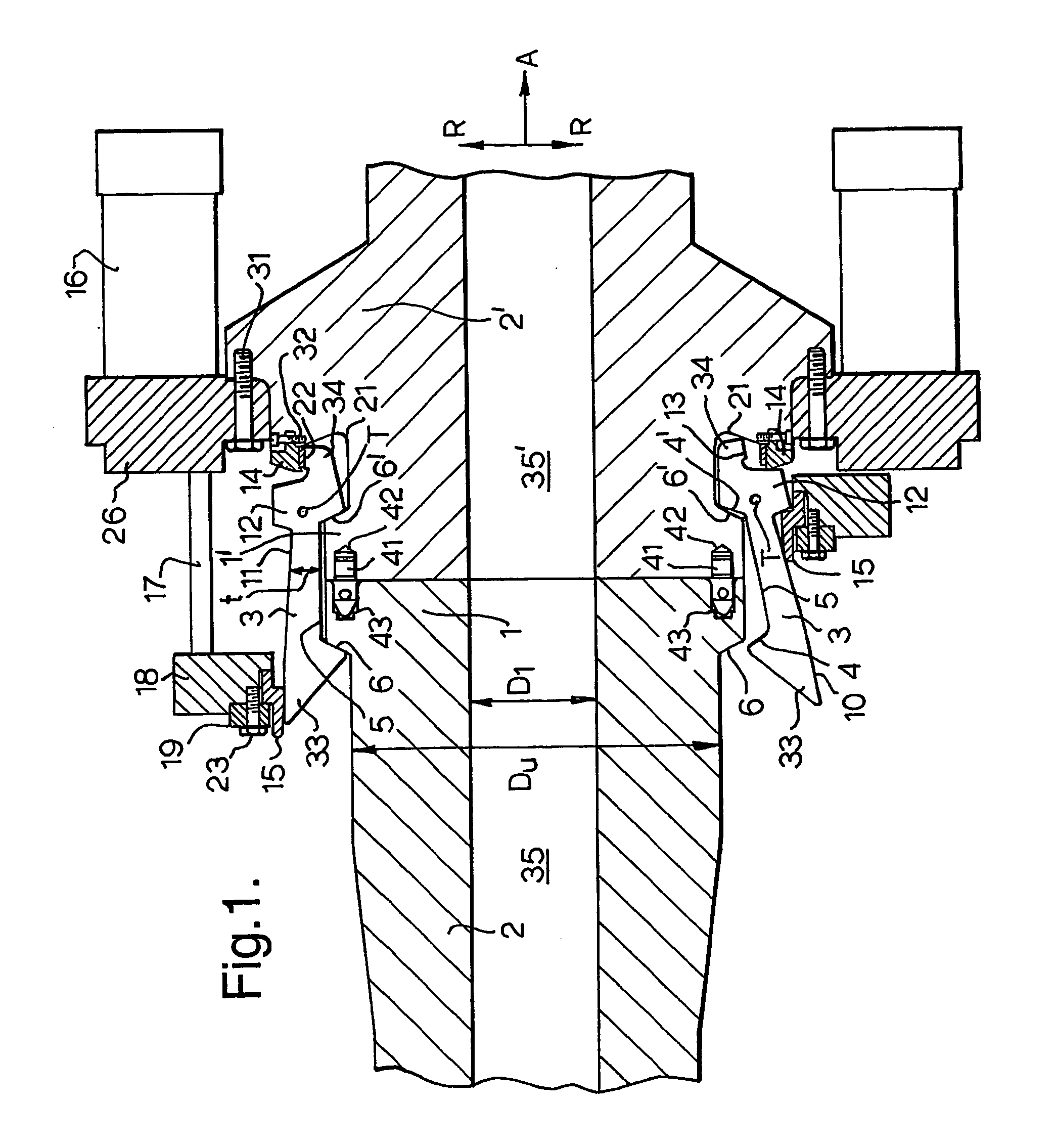

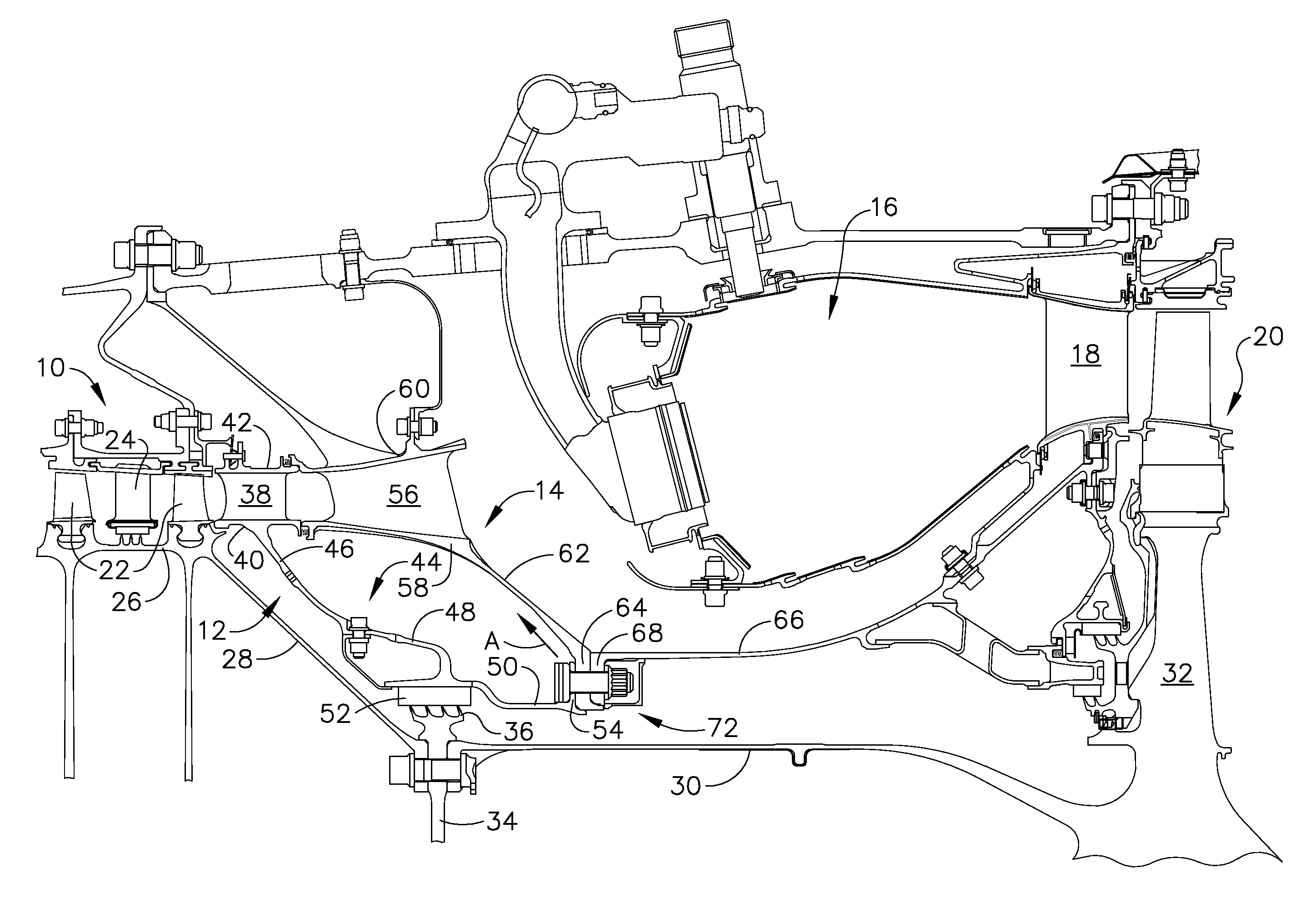

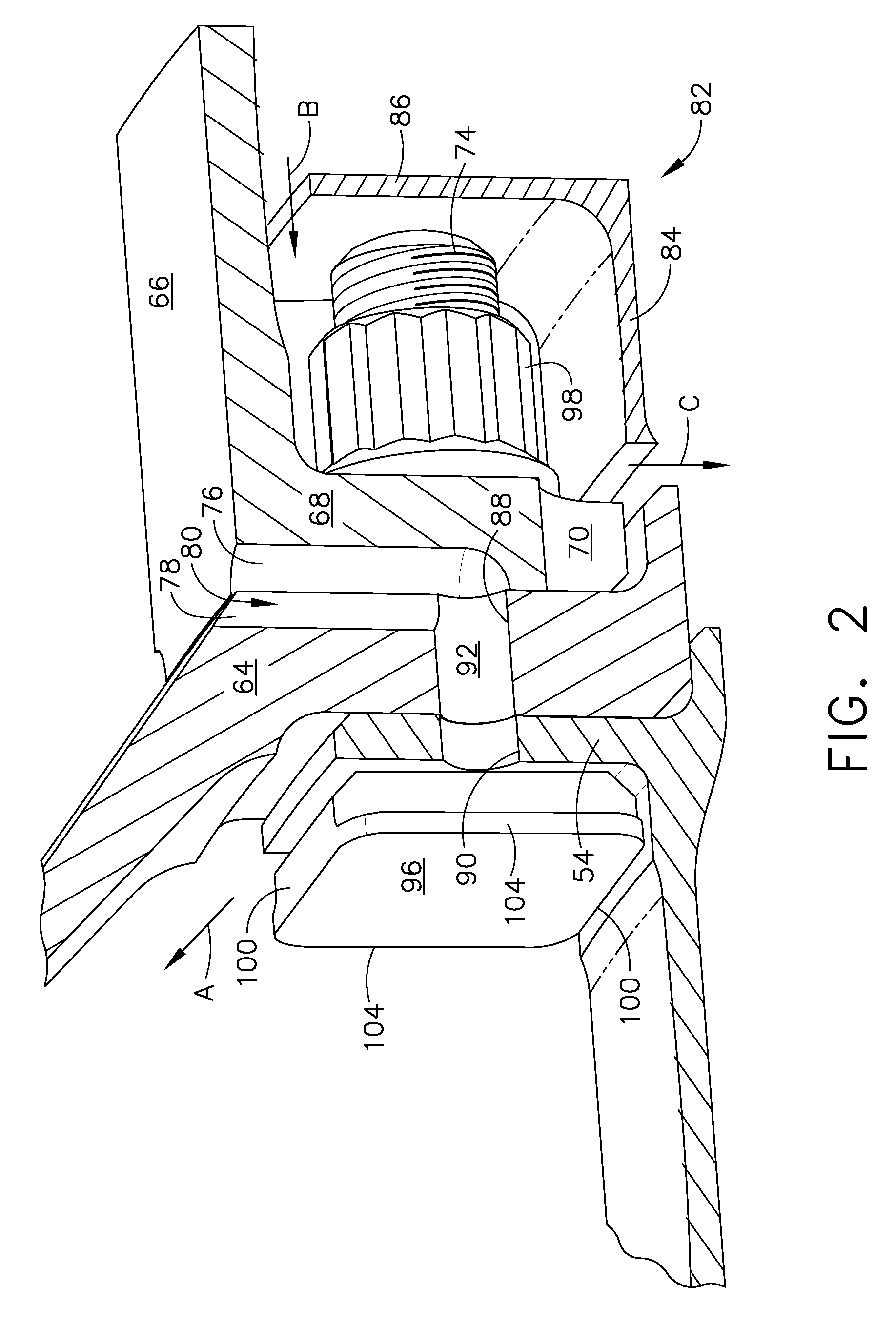

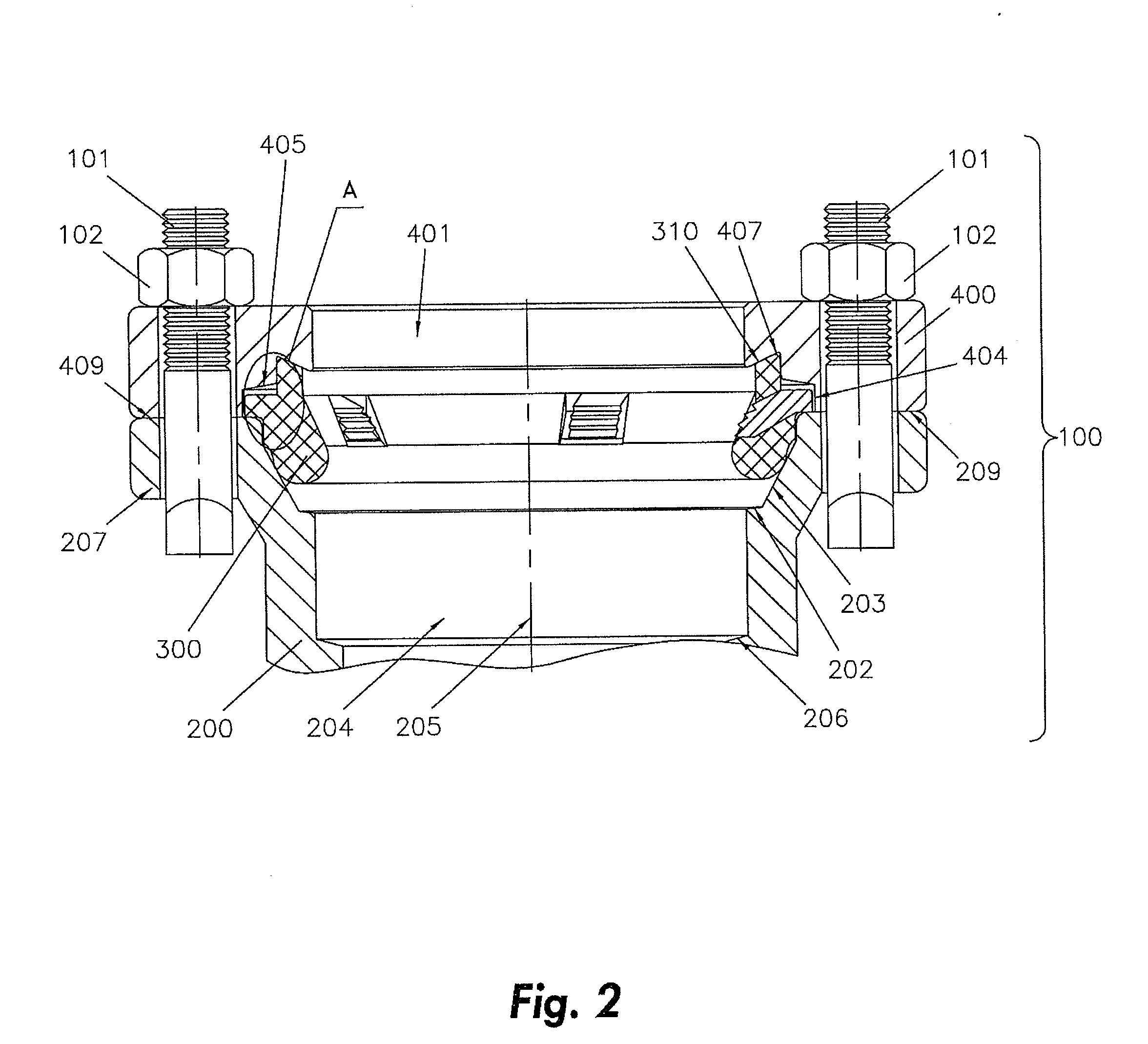

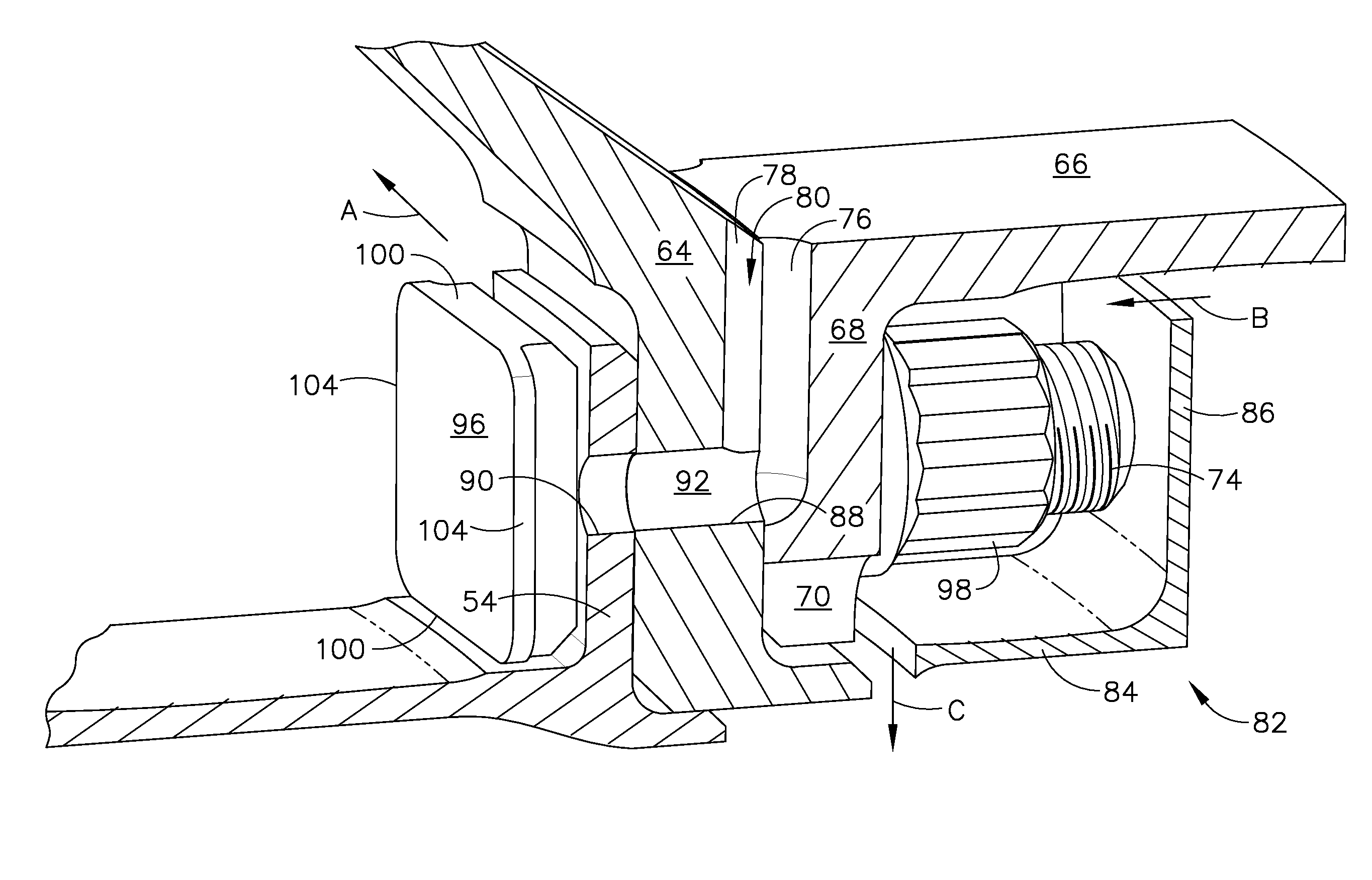

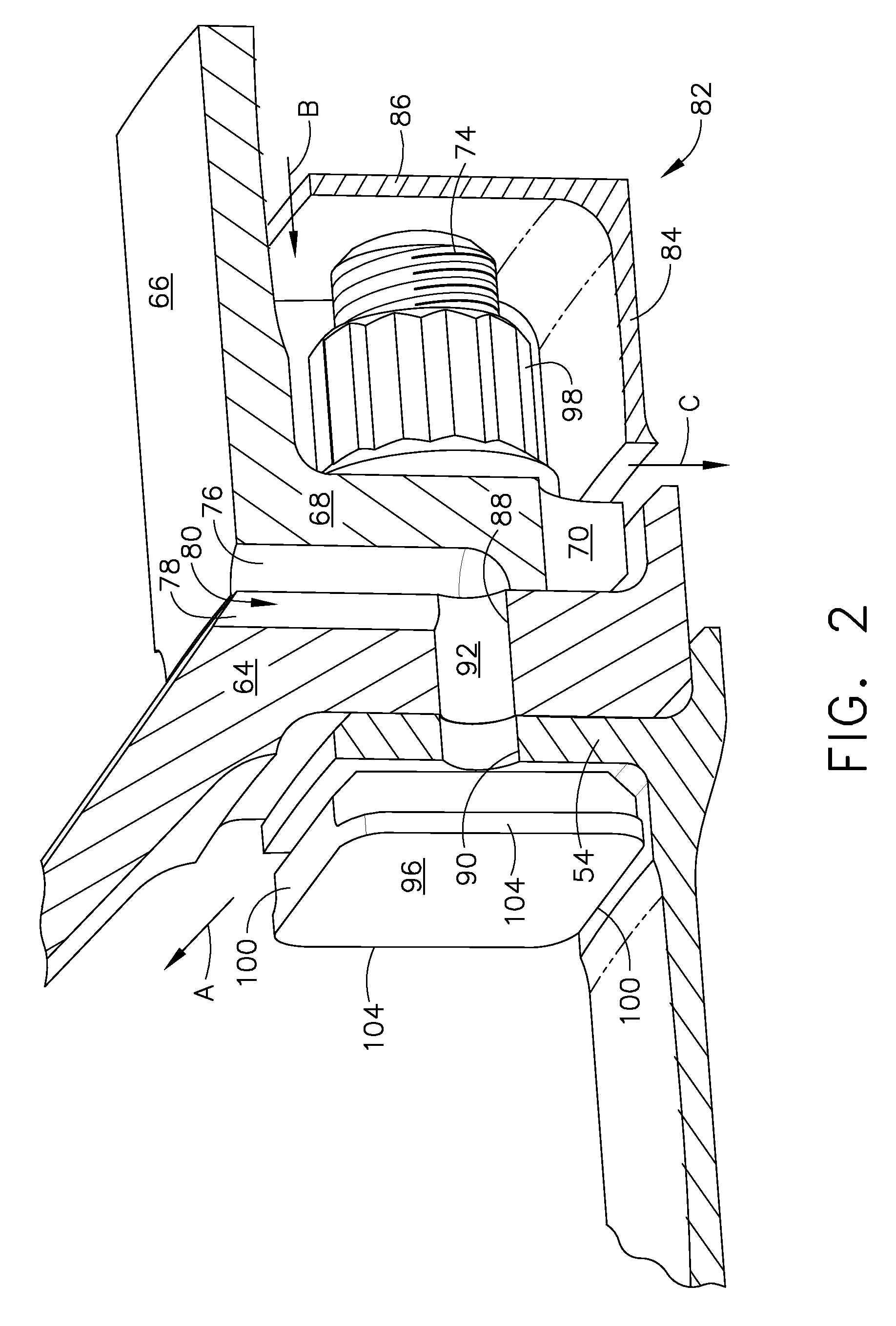

Mechanical joint for a gas turbine engine

ActiveUS20100316484A1Thermal response uniform thermalUniform thermal stressPipeline expansion-compensationPump componentsEngineeringGas turbines

A mechanical joint for a gas turbine engine includes:(a) an annular first component having an annular, radially-extending first flange; (b) an annular second component having an annular, radially-extending second flange abutting the first flange; (c) a plurality of generally radially-extending radial channels passing through at least one of the first and second flanges; (d) a plurality of generally axially-extending channels extending through the first flange and communicating with respective ones of the radial channels; and (e) a plurality of fasteners clamping the first and second flanges together.

Owner:GENERAL ELECTRIC CO

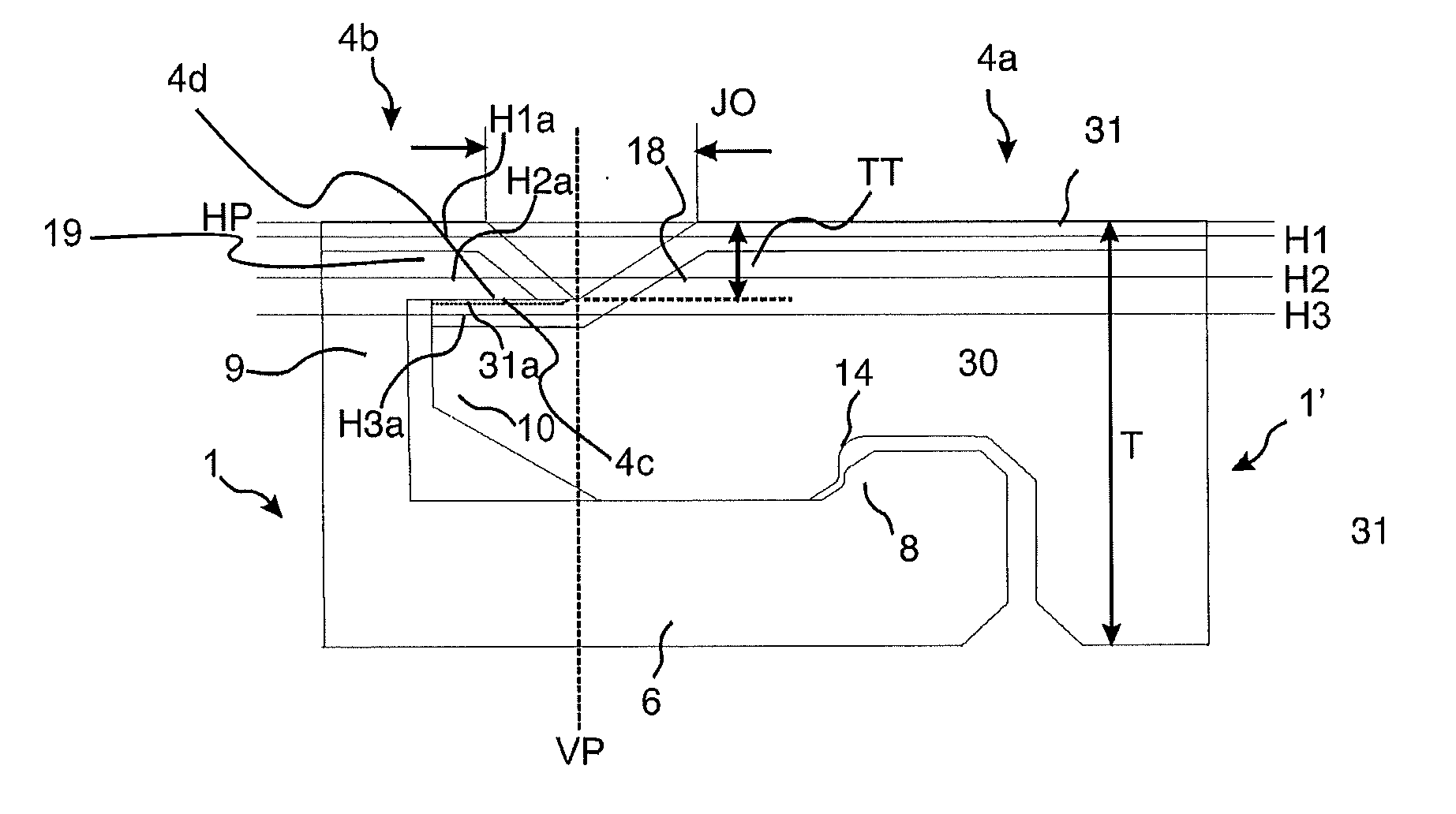

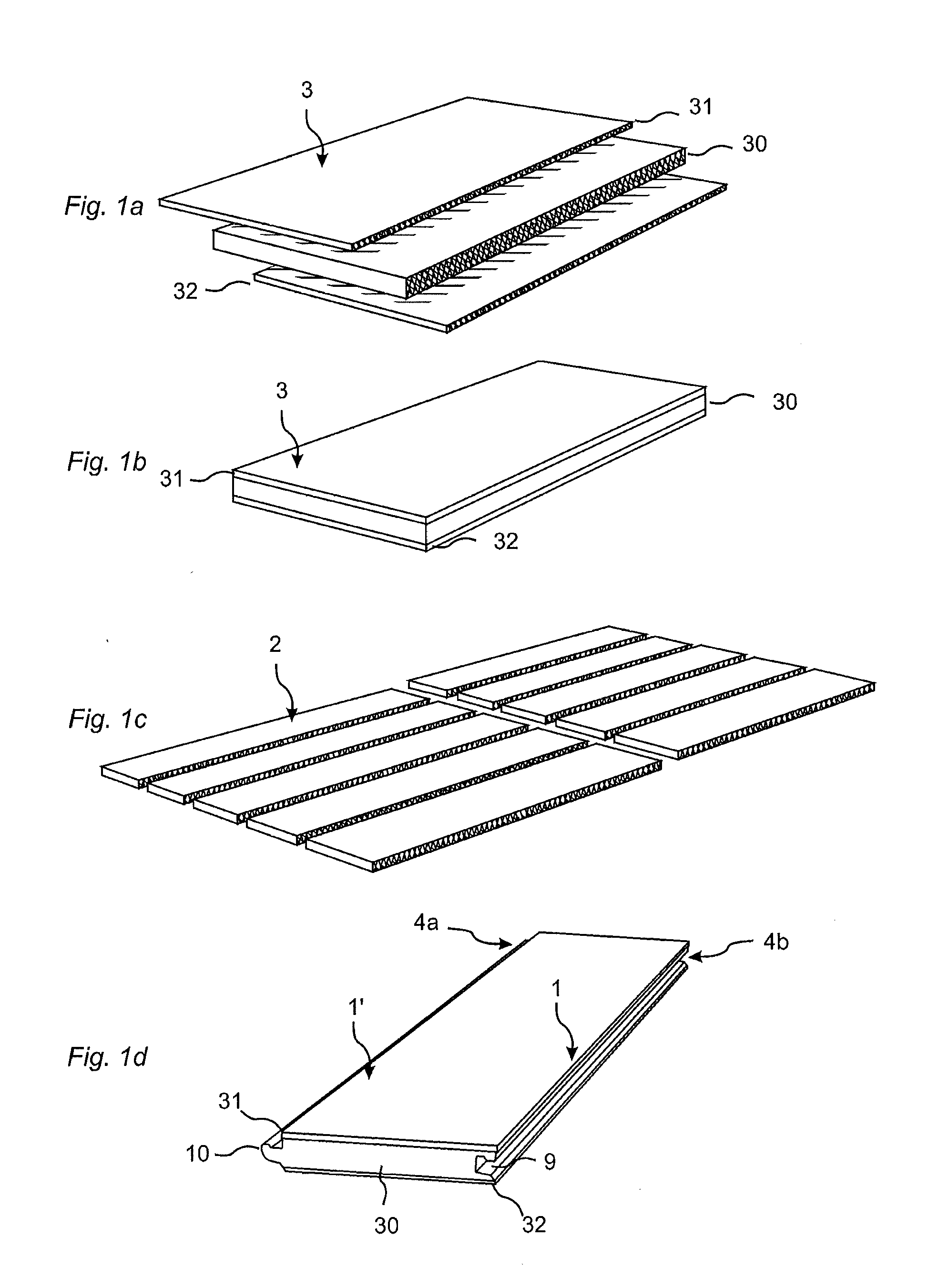

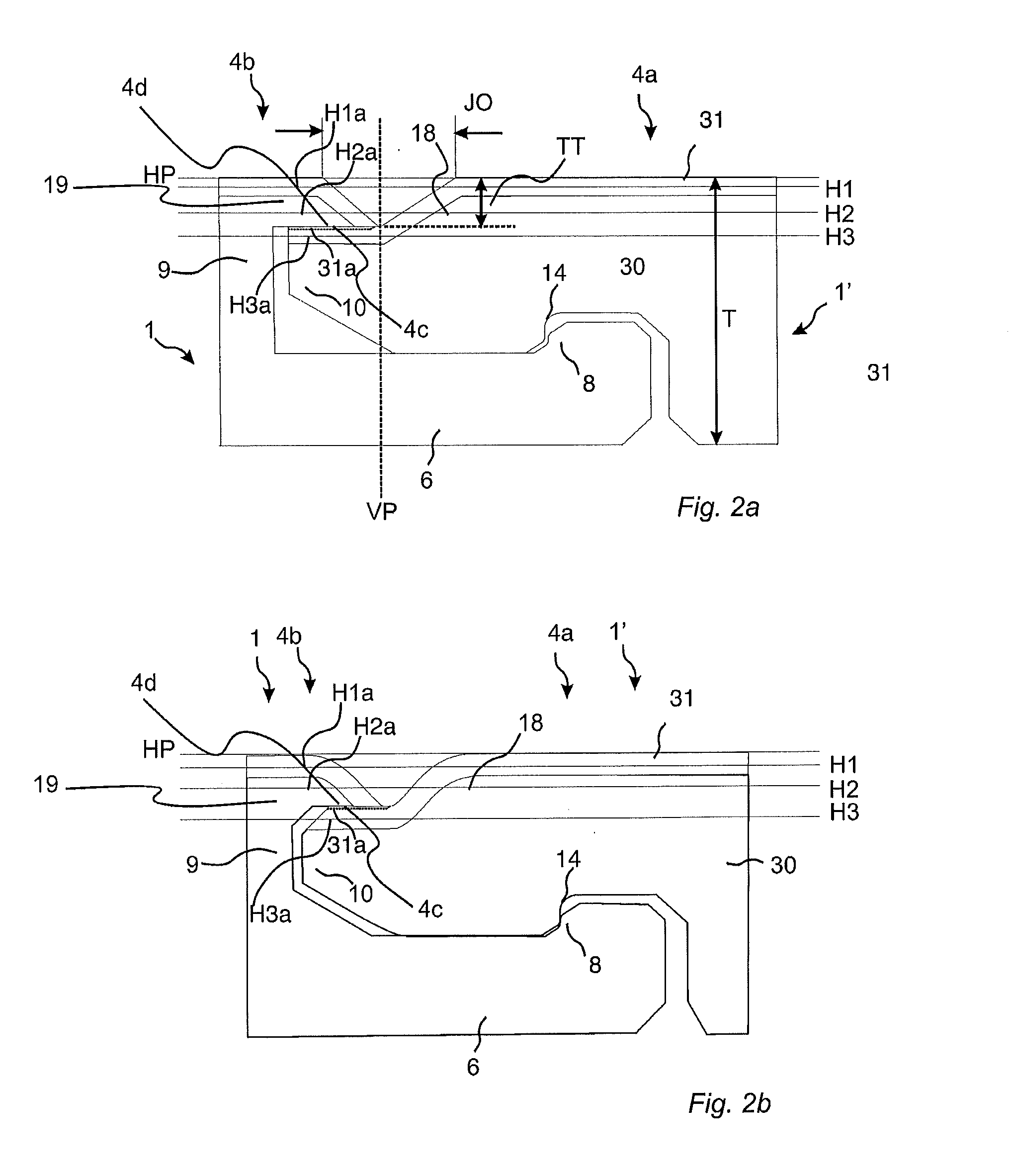

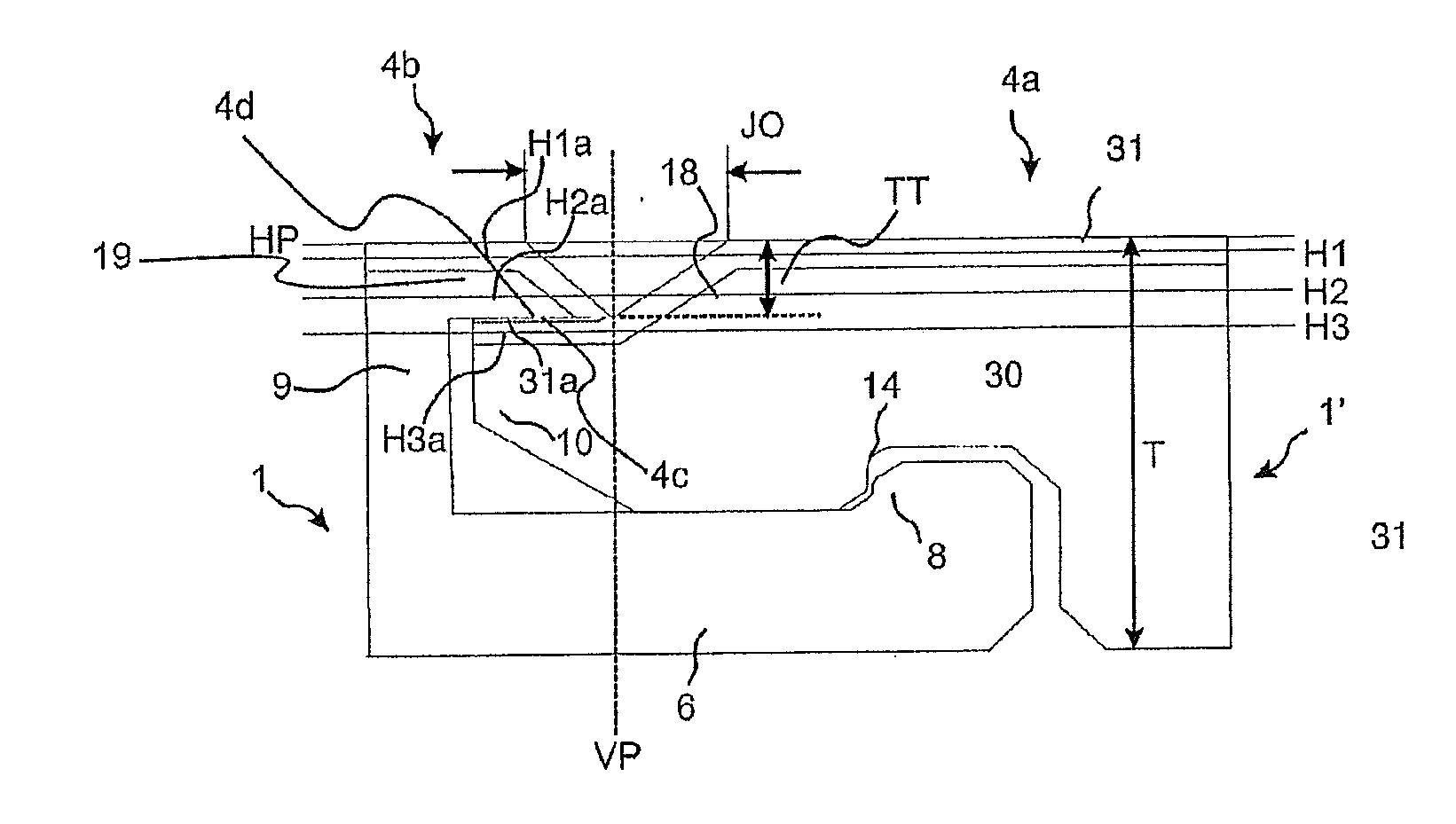

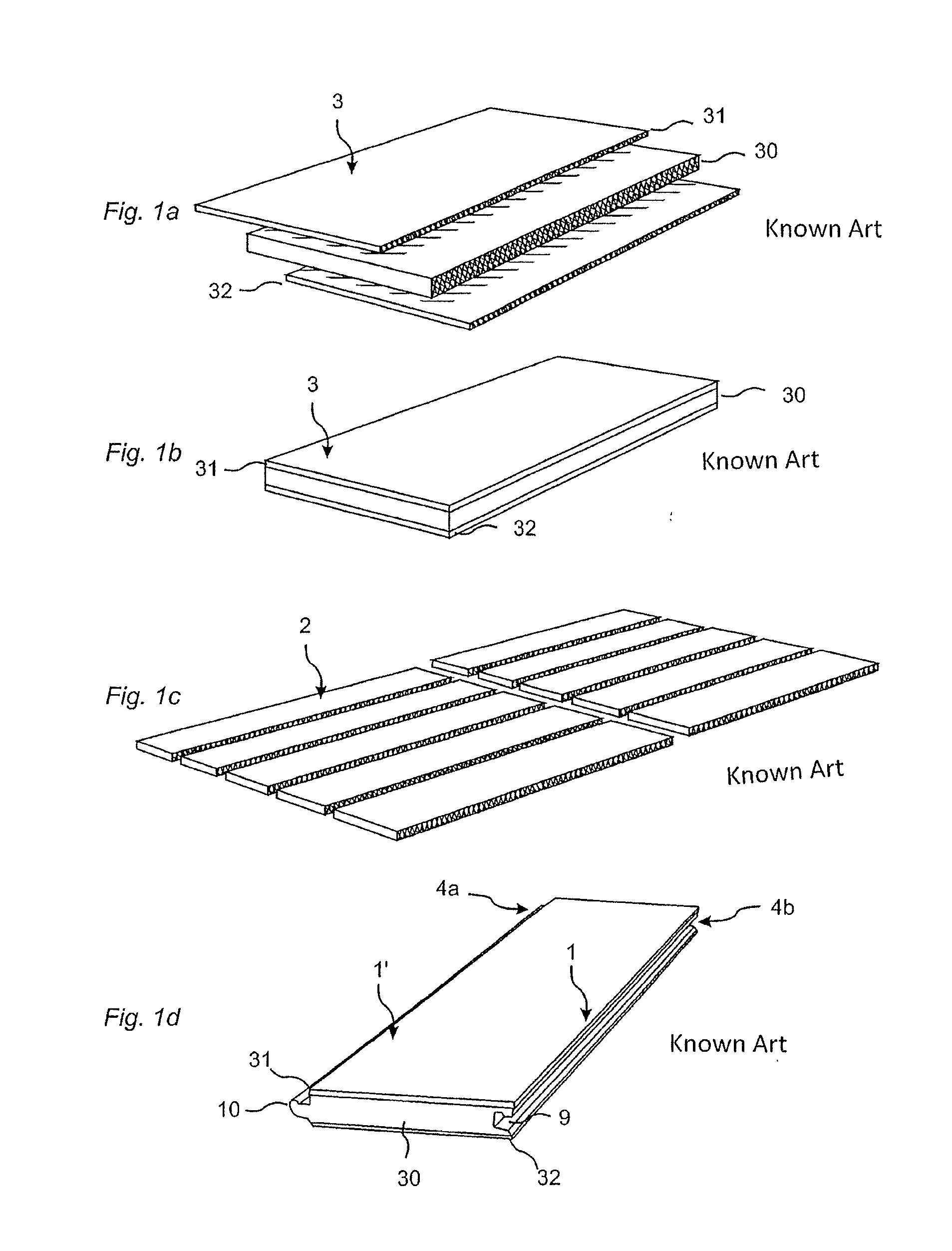

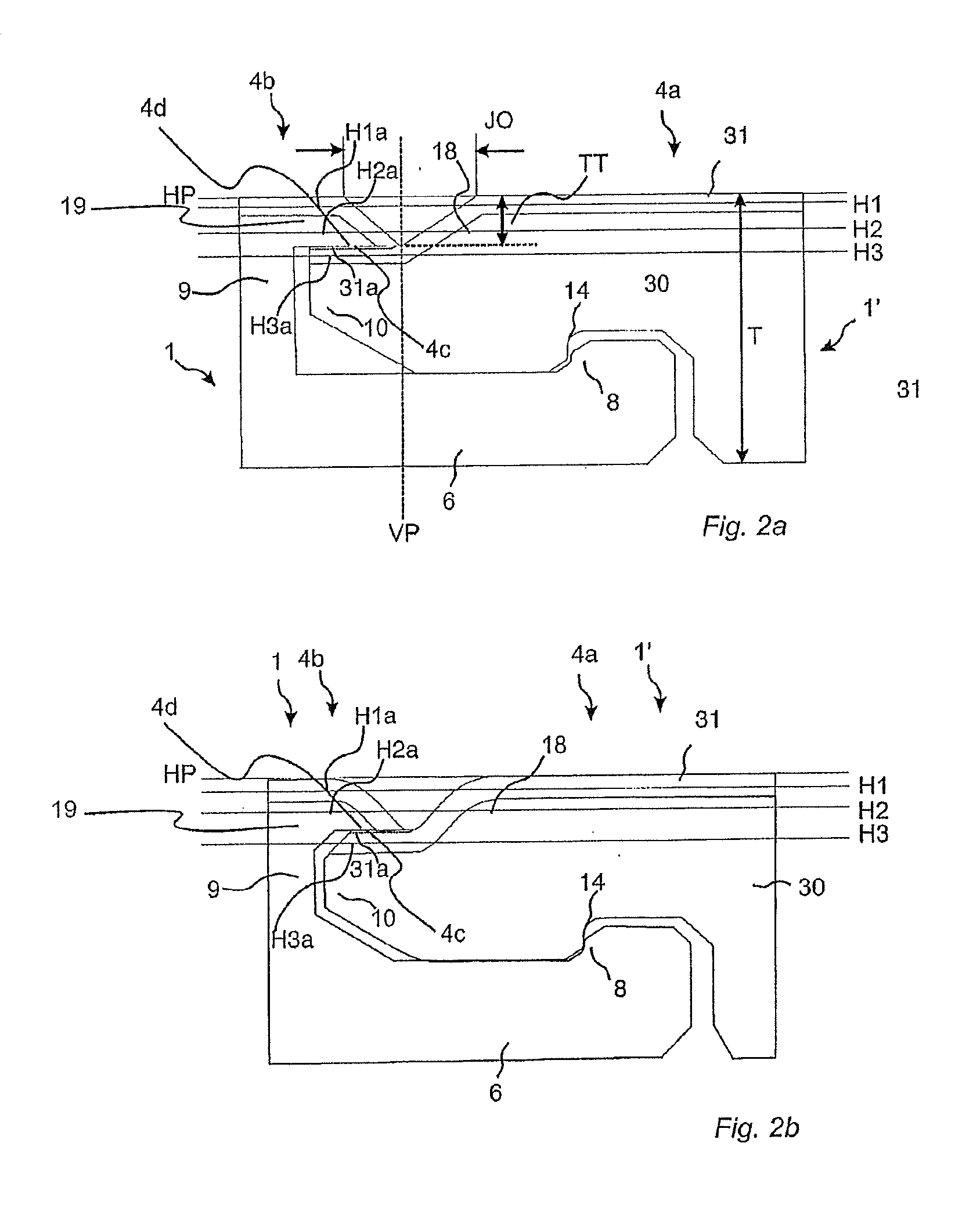

Methods and arrangements relating to surface forming of building panels

ActiveUS20110146188A1Improved joint systemsConsiderable movementLamination ancillary operationsMetal-working apparatusSurface layerSurface structure

Semi-floating floorboards / building panels having mechanical joint systems, a core with curved edge portions so the surface layer on top of the core will be located below the panel surface, and where the edges of the floorboard have a bevel such that in which the joint system, when two floorboards are joined and pressed towards each other, the surface layer 31 and a part of the core 30 of the joint edge portion 19 in the second joint edge 4b overlaps the surface layer 31 that is substantially parallel to the horizontal plane of the first joint edge 4a of the other floorboard. Further, floorboards / building panels are produced by machining the surface structure with a plurality of core grooves 20, 20′ and applying the surface layer 31 on the upper side of the core 30 to at least partly cover a floor element. A pressure is applied and the surface layer 31 forms around the core grooves 20, 20′.

Owner:VÄLINGE INNOVATION AB

Methods and arrangements relating to surface forming of building panels

ActiveUS20140069044A1Improved joint systemsConsiderable movementAdhesivesFlooringSurface layerEngineering

Semi-floating floorboards / building panels having mechanical joint systems, a core with curved edge portions so the surface layer on top of the core will be located below the panel surface, and where the edges of the floorboard have a bevel such that in which the joint system, when two floorboards are joined and pressed towards each other, the surface layer 31 and a part of the core 30 of the joint edge portion 19 in the second joint edge 4b overlaps the surface layer 31 that is substantially parallel to the horizontal plane of the first joint edge 4a of the other floorboard. Further, floorboards / building panels are produced by machining the surface structure with a plurality of core grooves 20, 20′ and applying the surface layer 31 on the upper side of the core 30 to at least partly cover a floor element. A pressure is applied and the surface layer 31 forms around the core grooves 20, 20′.

Owner:VÄLINGE INNOVATION AB

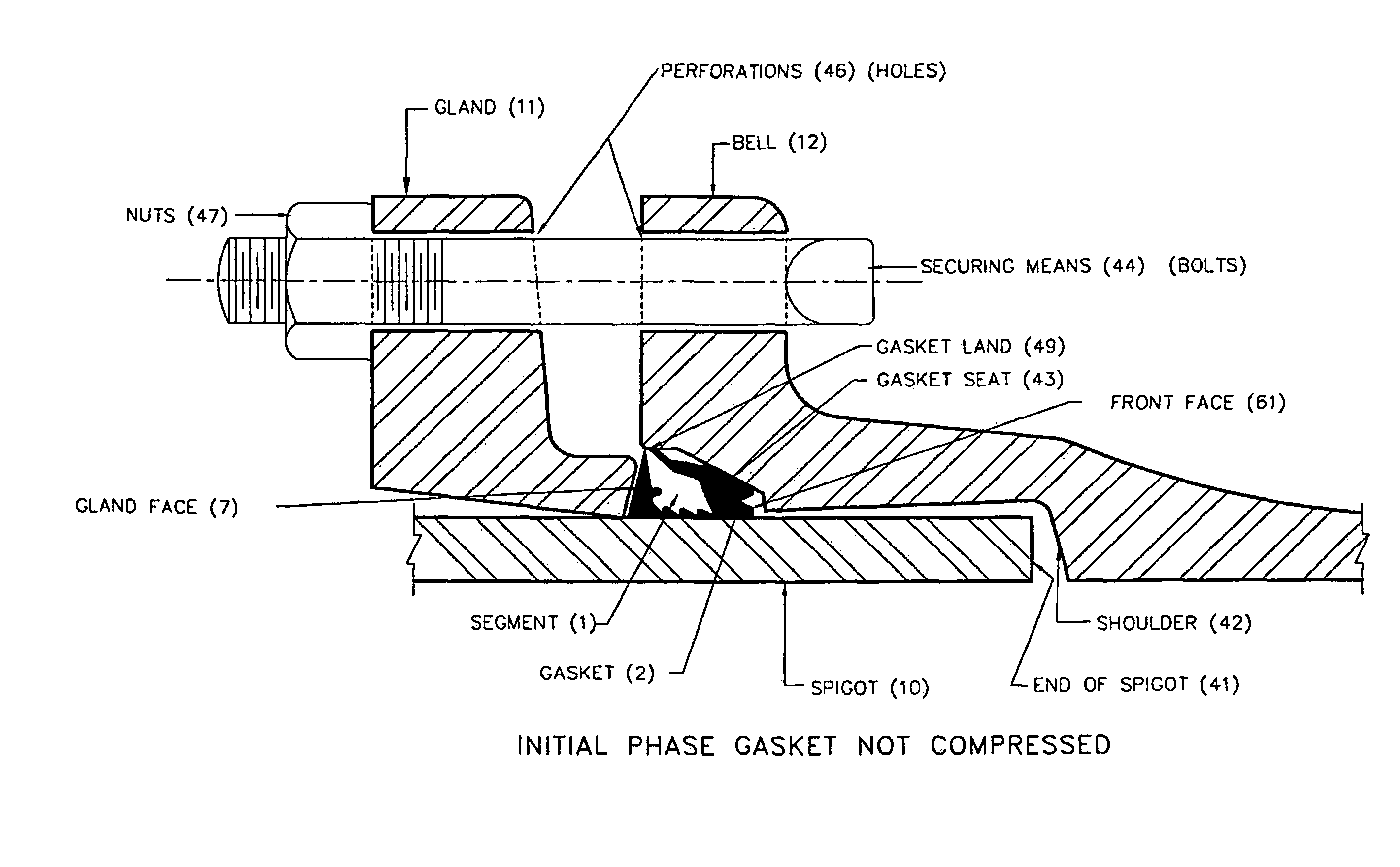

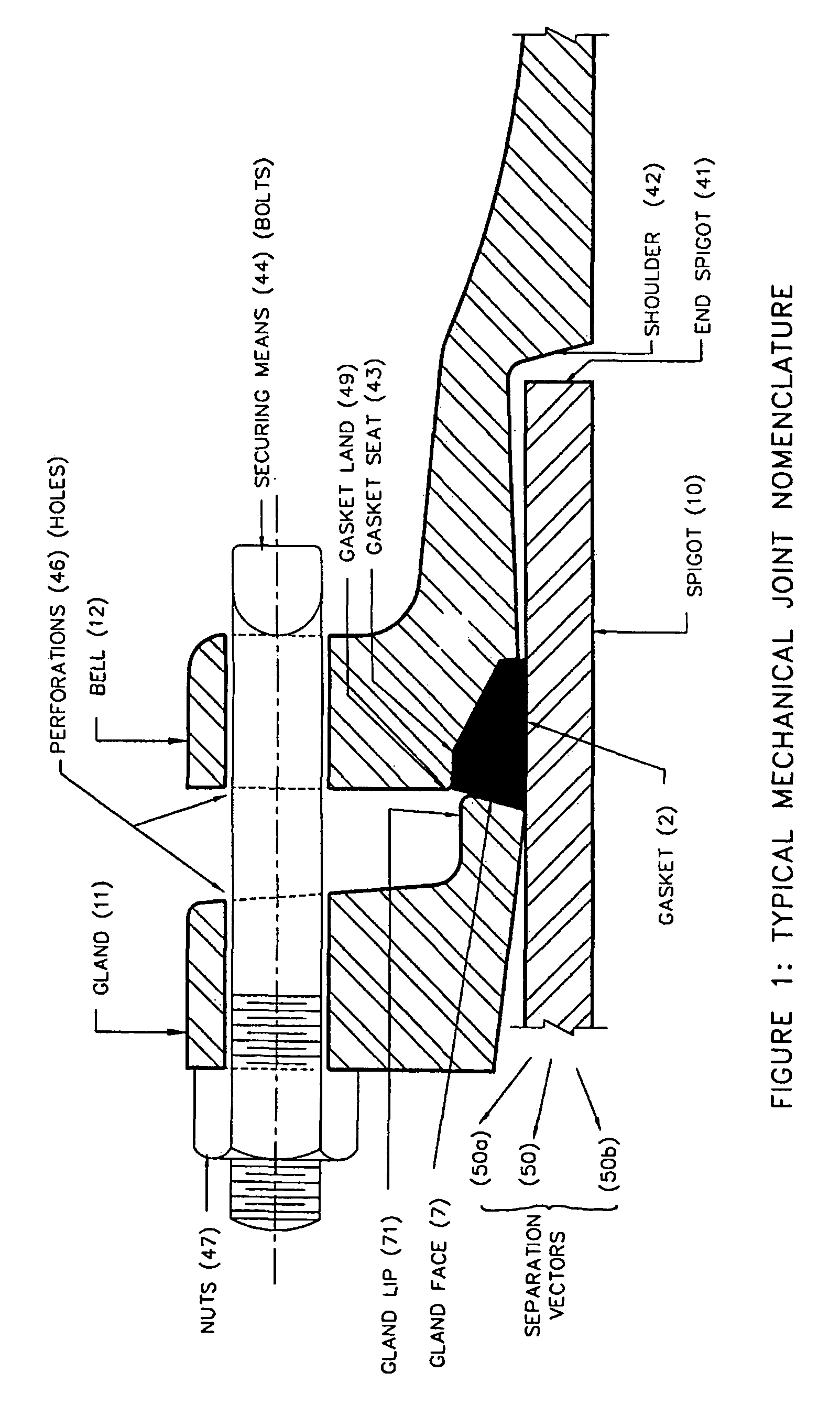

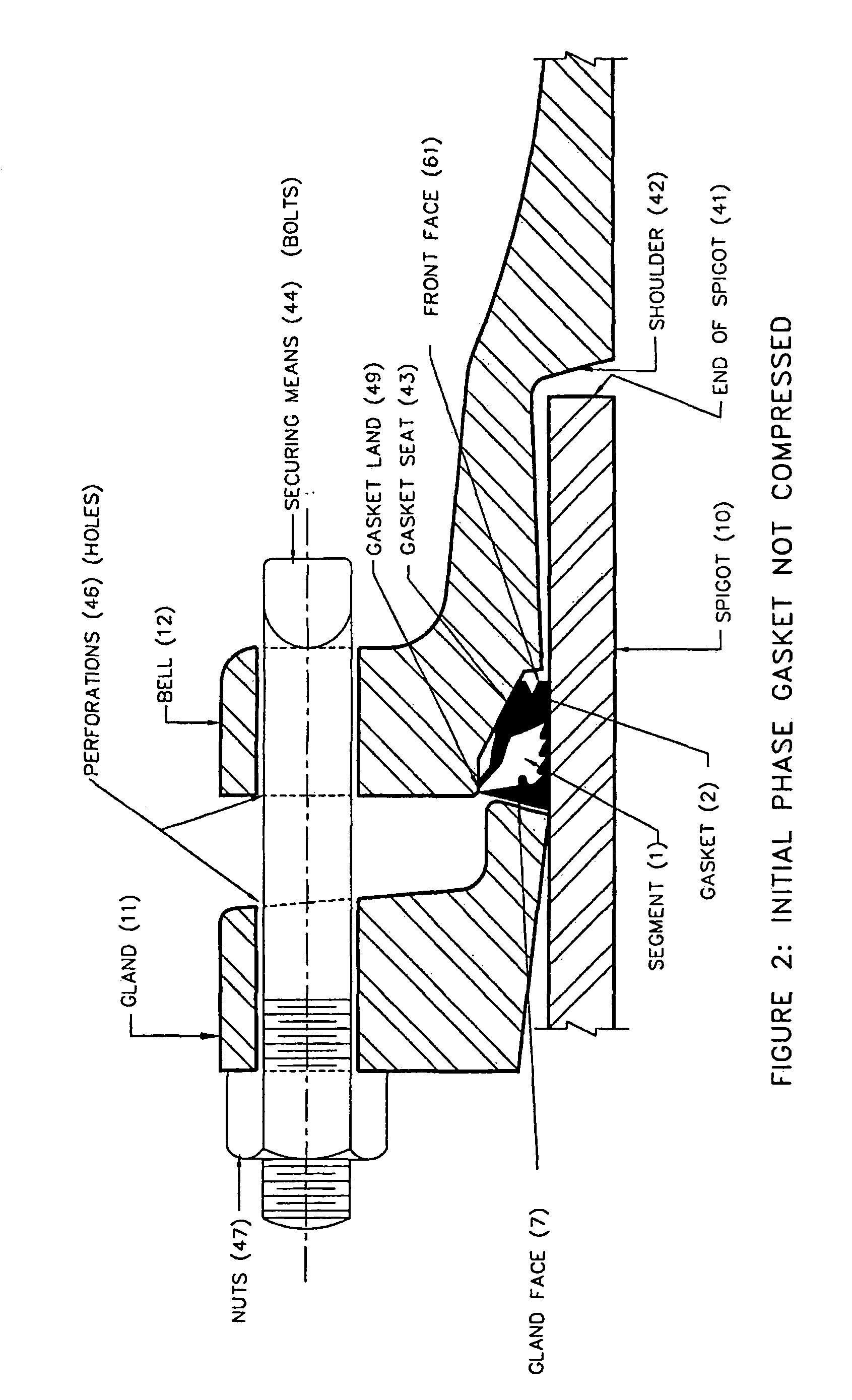

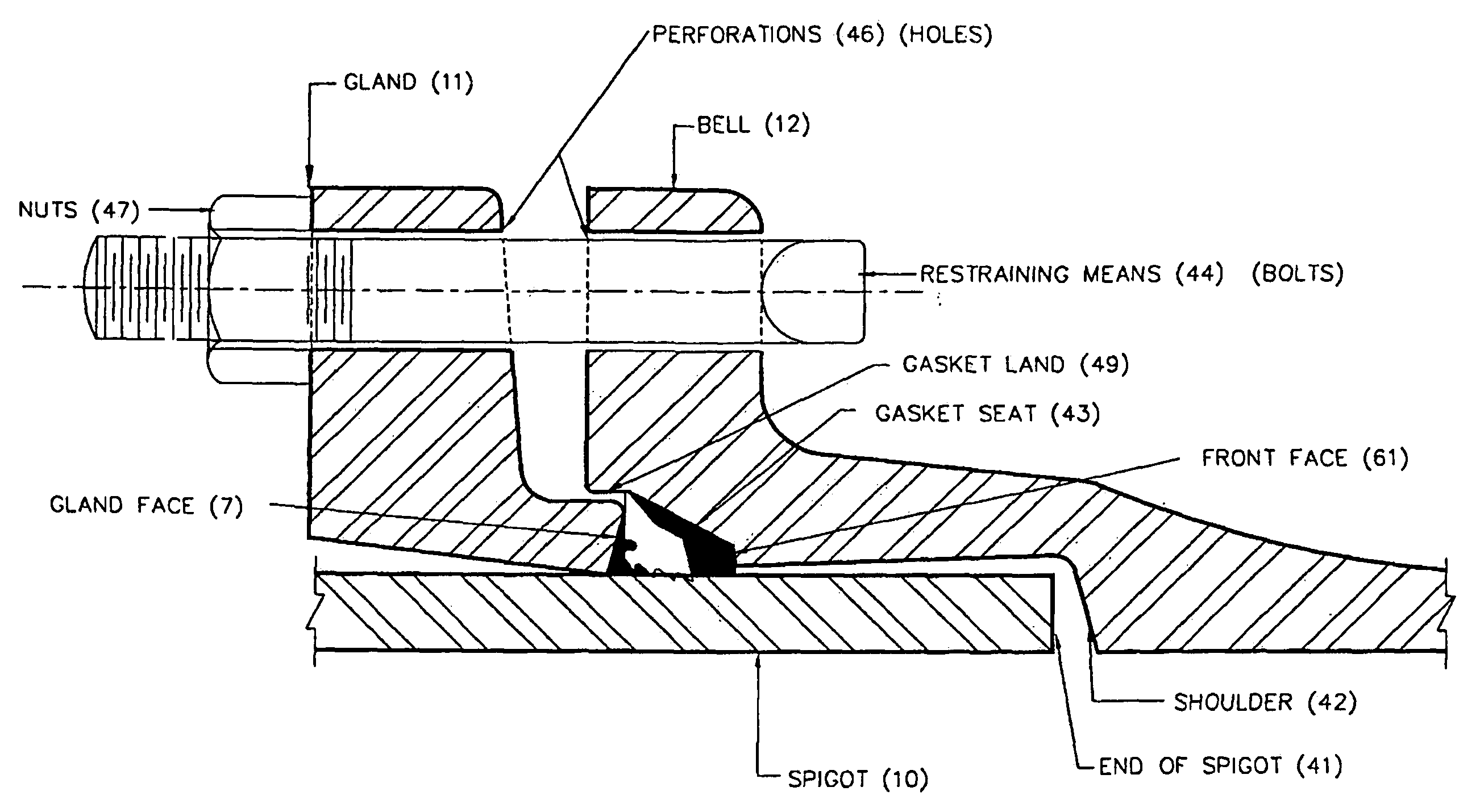

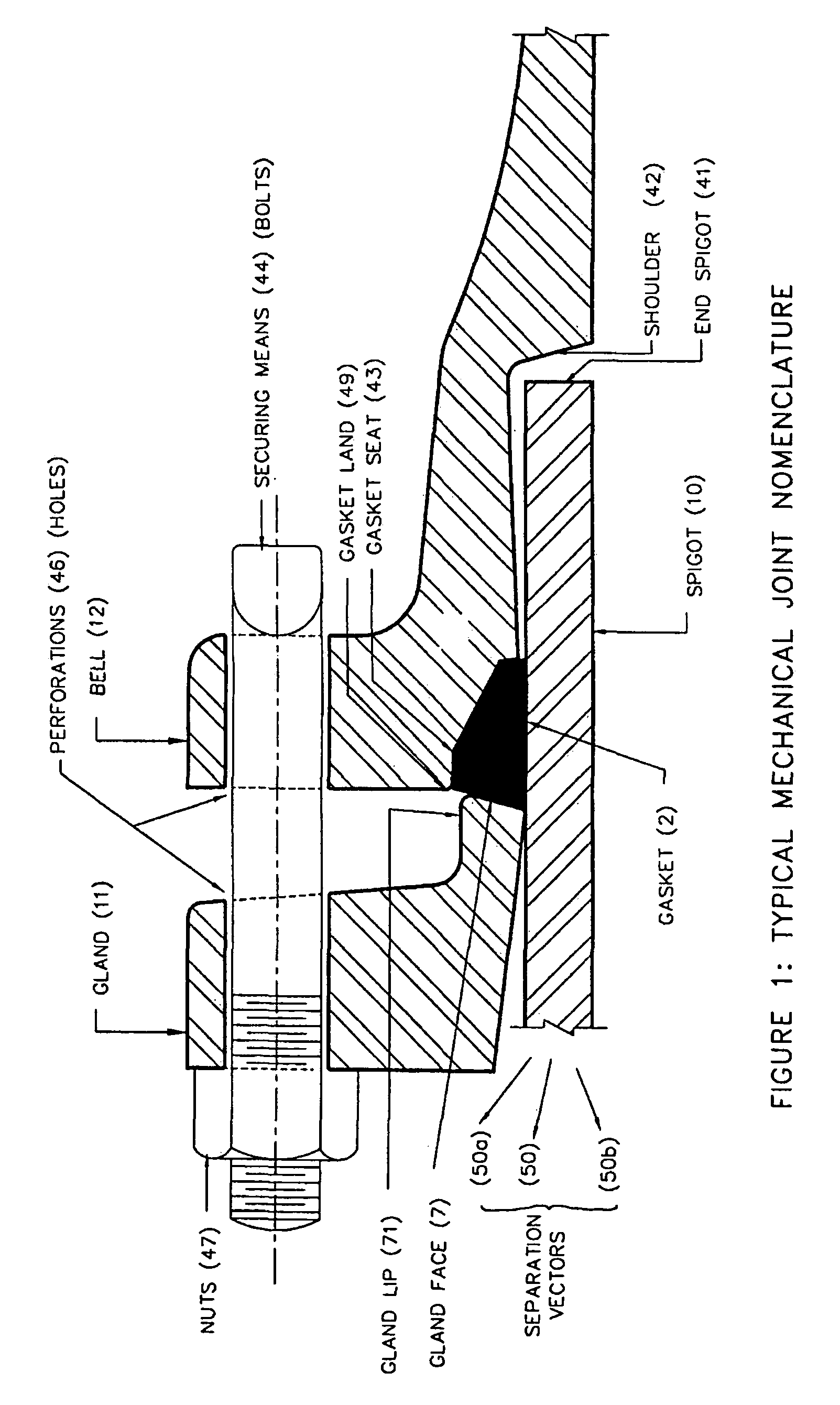

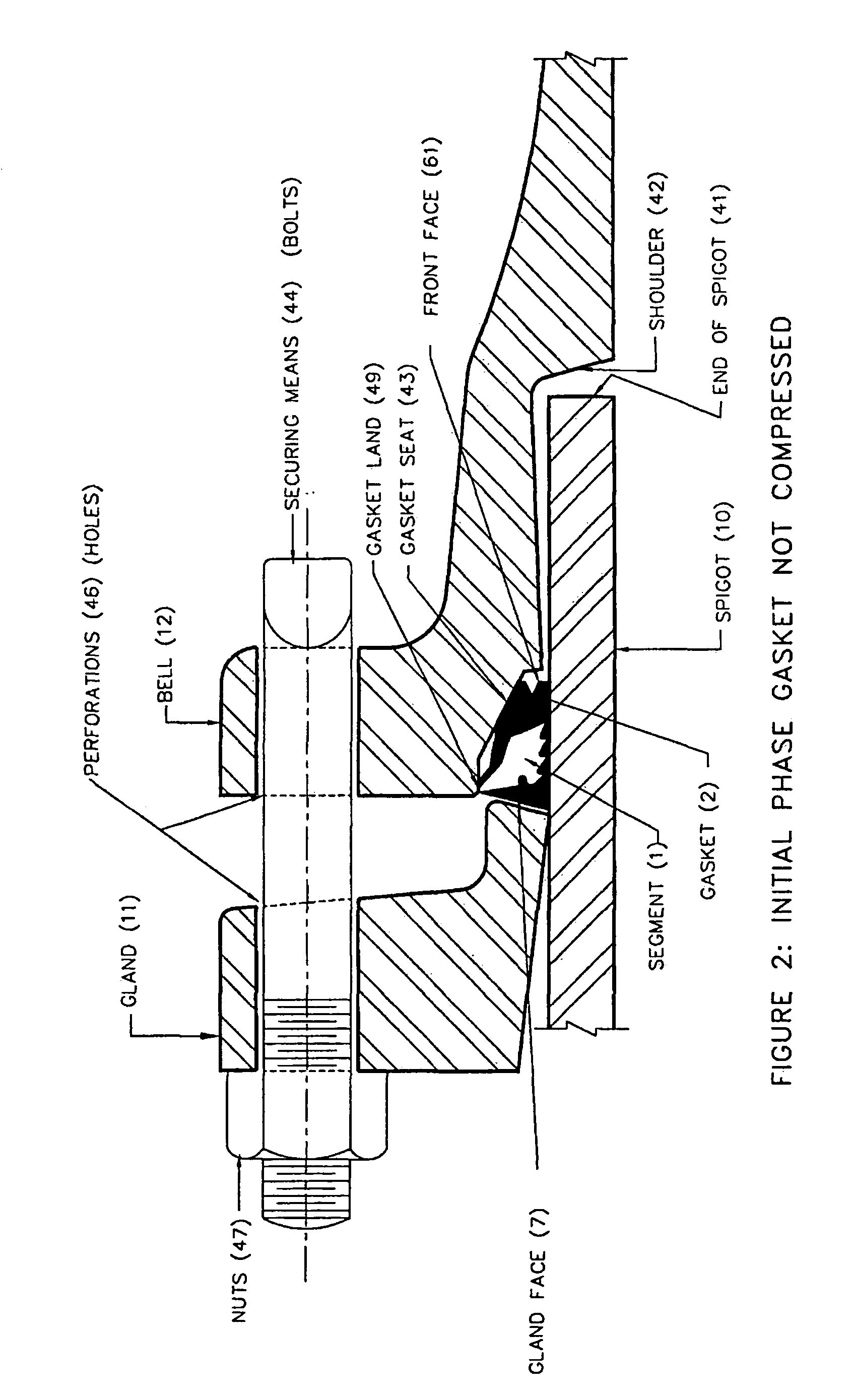

Restraining gasket for mechanical joints of pipes

InactiveUS7093863B2Easy to disassembleSleeve/socket jointsFluid pressure sealed jointsEngineeringMechanical joint

A gasket for connecting two lengths of pipe in a standard mechanical joint, which gasket maximizes the advantages of both restrained push-on joints as well as mechanical joints, as are known commonly in the art. The invention has application to long-run pipe lengths as well as appurtenances, including fittings and connections. The gasket contains locking members that act to restrain separation upon the instance of any force tending to separate the connected pipe lengths.

Owner:US PIPE & FOUNDRY

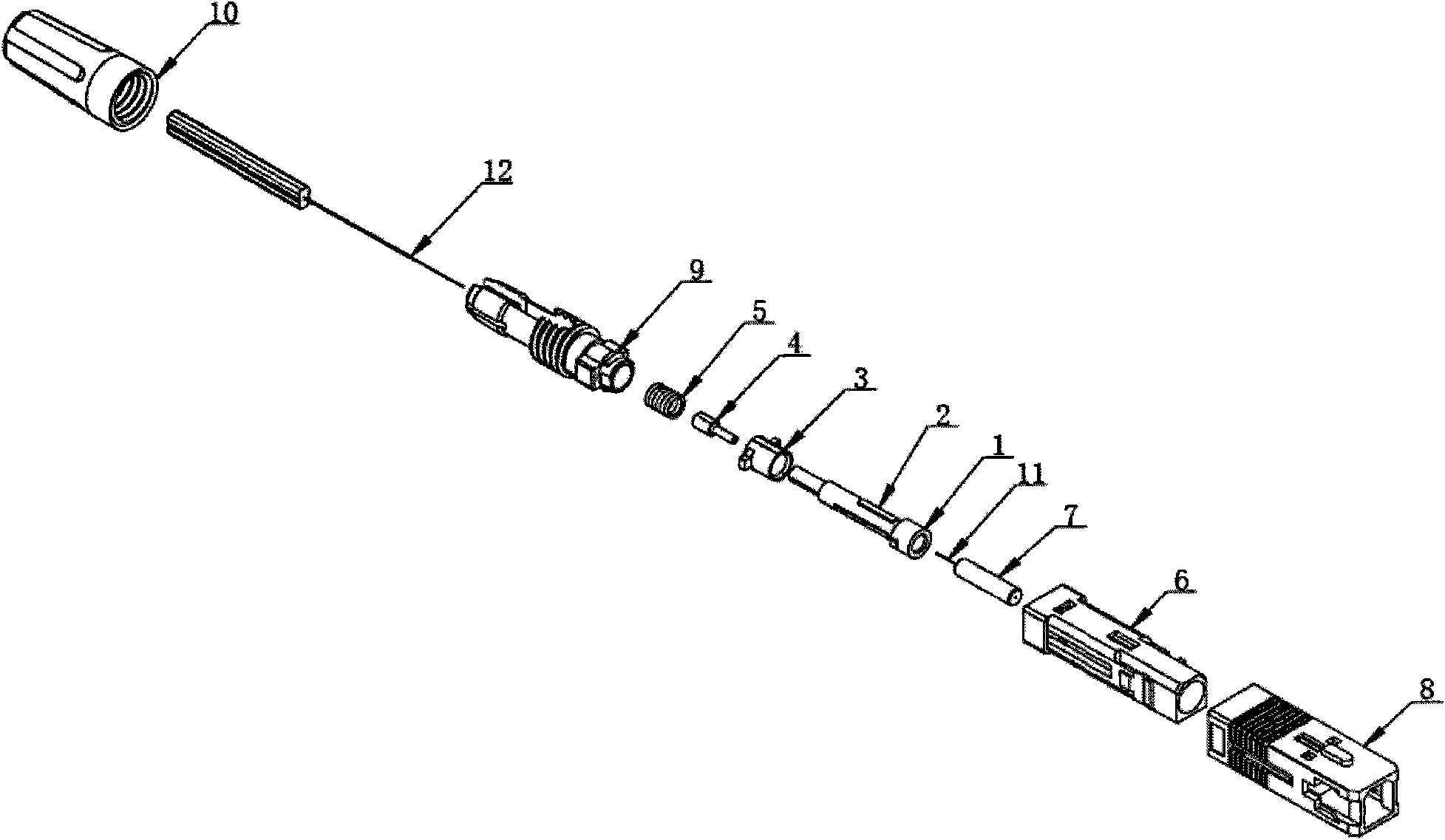

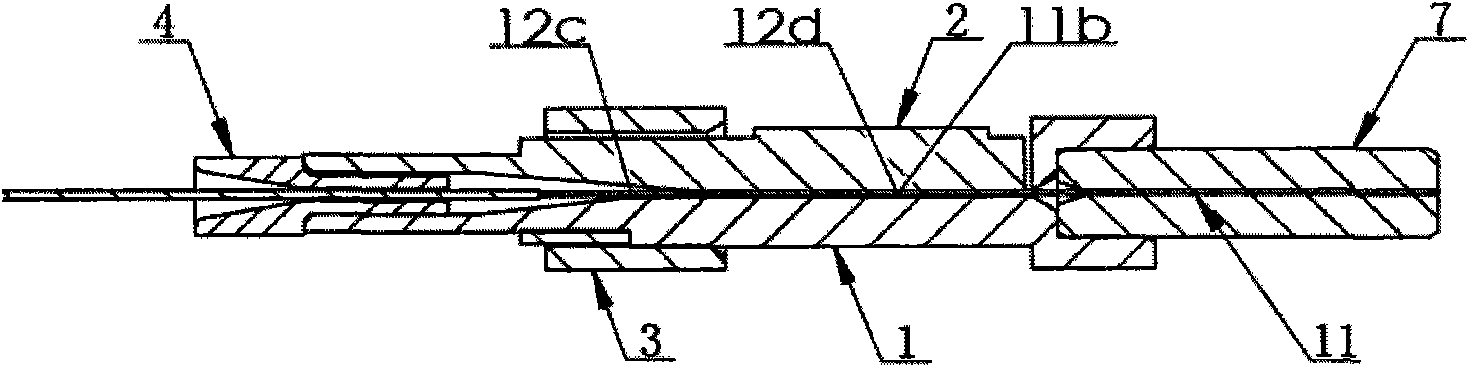

Optical fiber field connector

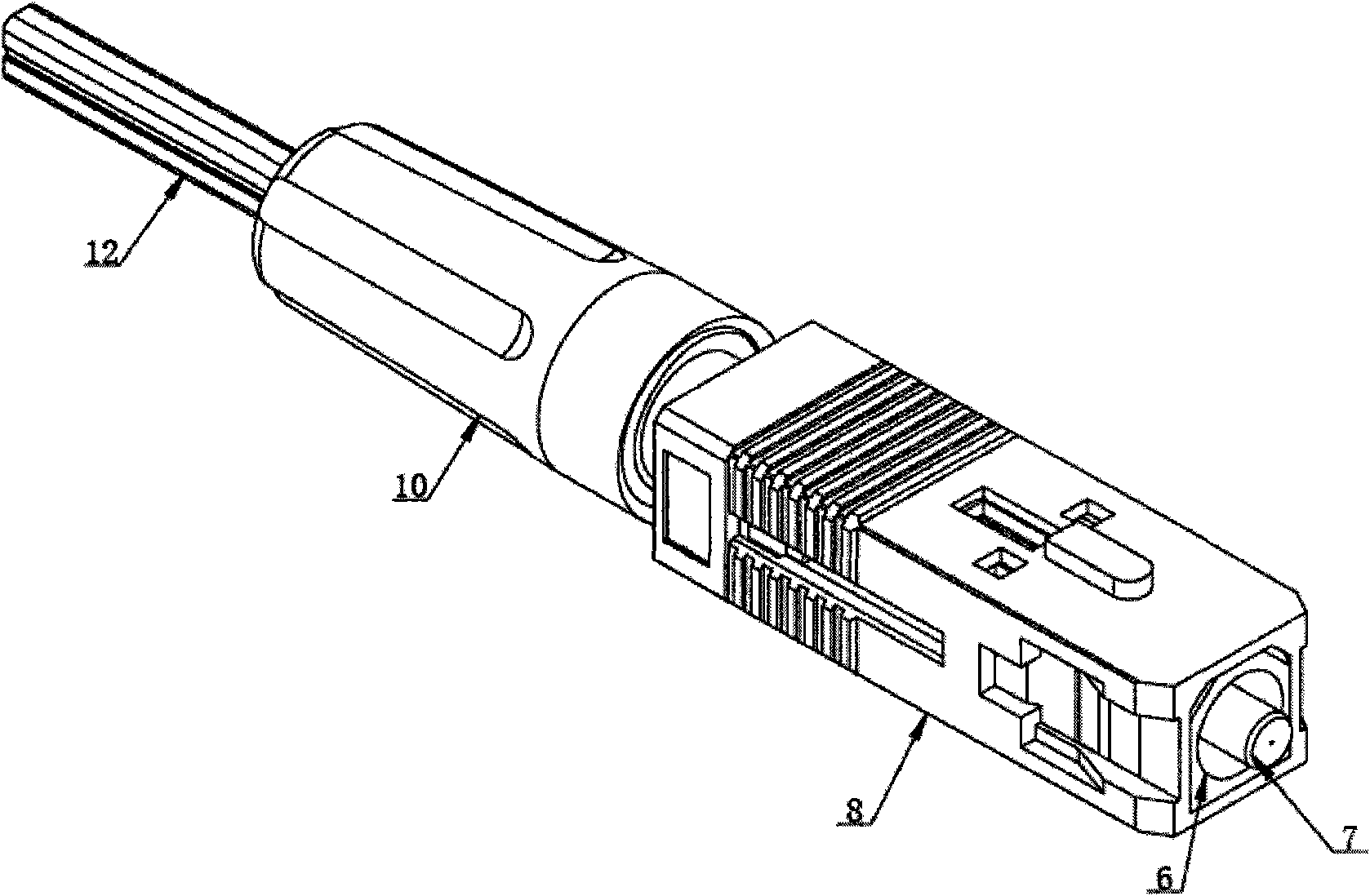

InactiveCN101806940AEliminates the need for storage protectionCoupling light guidesEngineeringPlastic optical fiber

The invention relates to an optical fiber field connector. A dismountable sleeve bin is sleeved outside a main body; the main body and the dismountable sleeve bin are provided with standard type interfaces; the main body is in a hollow structure; an optical fiber core insert is arranged at the front end of the main body; a preset optical fiber is arranged in the optical fiber core insert; a tail sleeve is arranged at the back end of the optical fiber core insert; a mechanical joint consisting of a substrate, a splint and a lantern ring is arranged in the main body; the front end of the mechanical joint is abutted with the optical fiber core insert, and the back end of the mechanical joint is connected with the tail sleeve through a guiding device and a damping device; a second optical fiber is arranged in the tail sleeve; and an outer protecting sleeve adopts a rotary screw thread structure to clamp the tail sleeve to prevent the second optical fiber from falling off and sliding. In the optical fiber field connector of the invention, the second tail end of the preset optical fiber is connected with the second optical fiber, a connection protecting box is not needed, storage protection for a bare optical fiber is unnecessary, when the optical fiber field connector is assembled, a special tool and grinding are not needed, whether the connection is successful can be detected at the field, and after installation, the field connector can be repeatedly opened for use.

Owner:FENGHUO COMM SCI & TECH CO LTD

Self-restrained pipe joint system and method of assembly

A self-restrained pipe joint system and method of assembly to connect two lengths of pipe in a mechanical joint, which maximizes the advantages of both restrained push-on joints as well as mechanical joints, as are known commonly in the art. The invention has application to long-run pipe lengths as well as to appurtenances, including fittings and connections. The gasket contains locking members that act to restrain separation upon the instance of any force tending to separate the connected pipe lengths.

Owner:MUELLER INT LLC

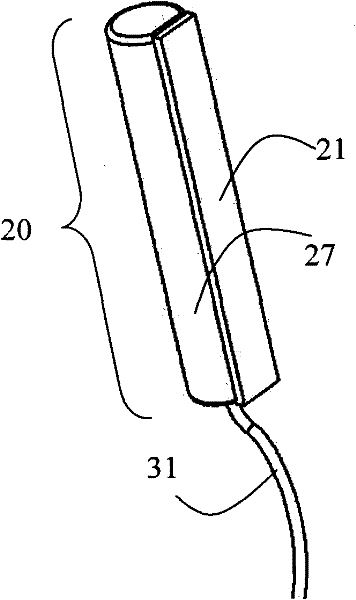

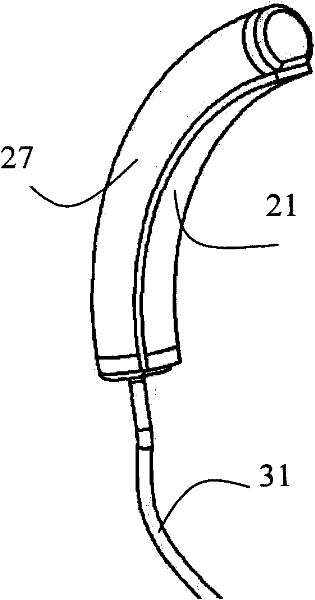

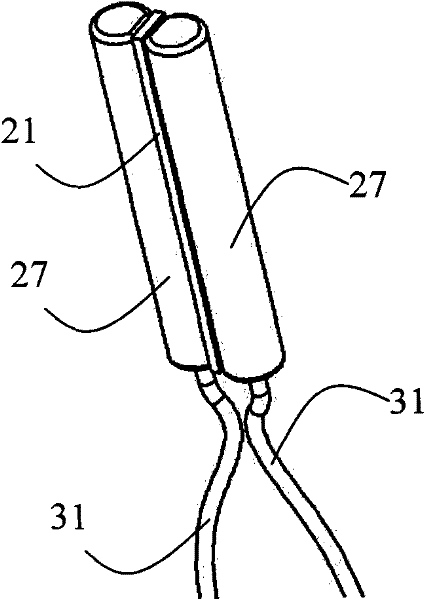

Bendable structure and endoscopic device, gastric tube and mechanical joint using the same

Owner:JOHNSON ELECTRIC GUANGDONG CO LTD

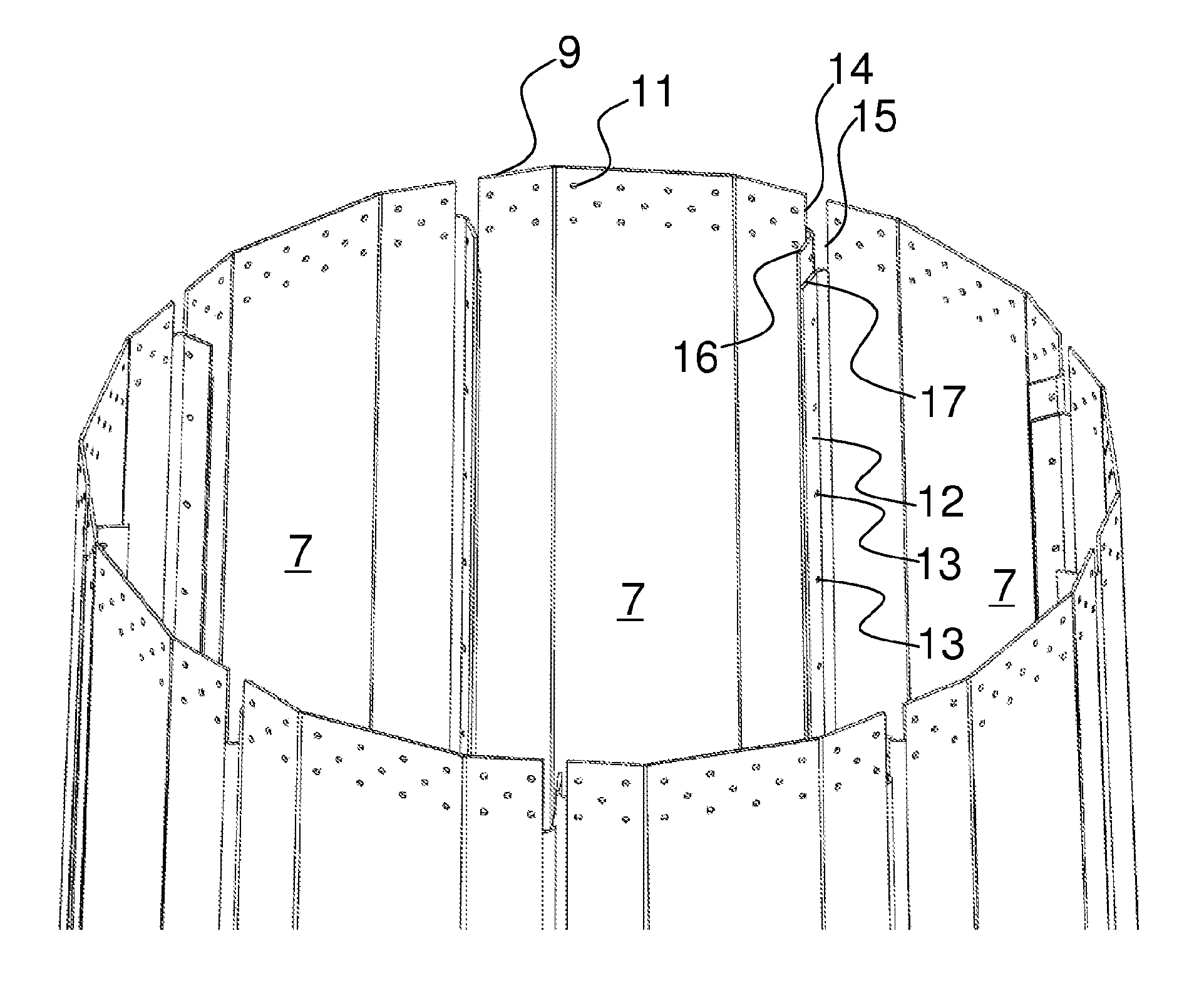

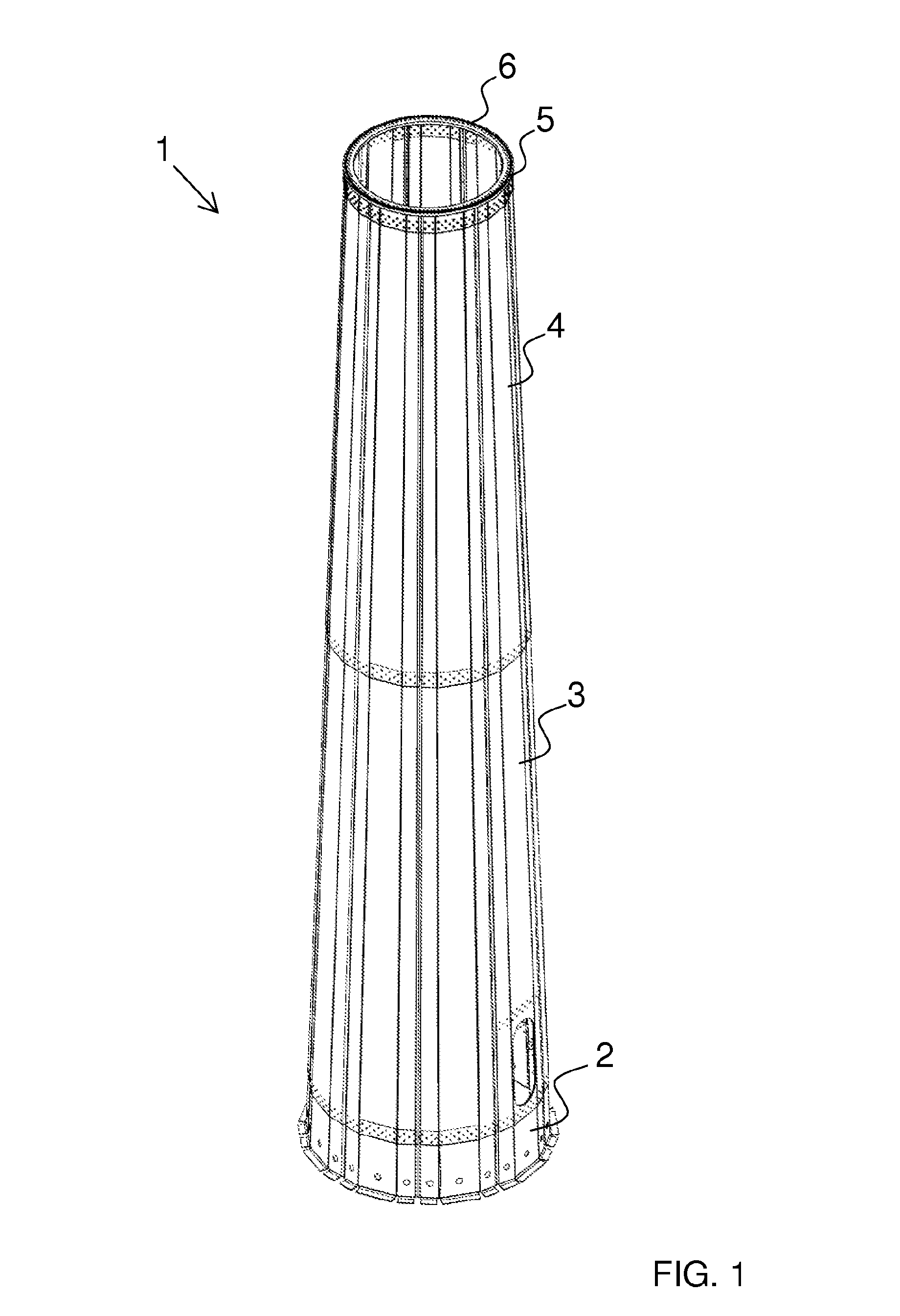

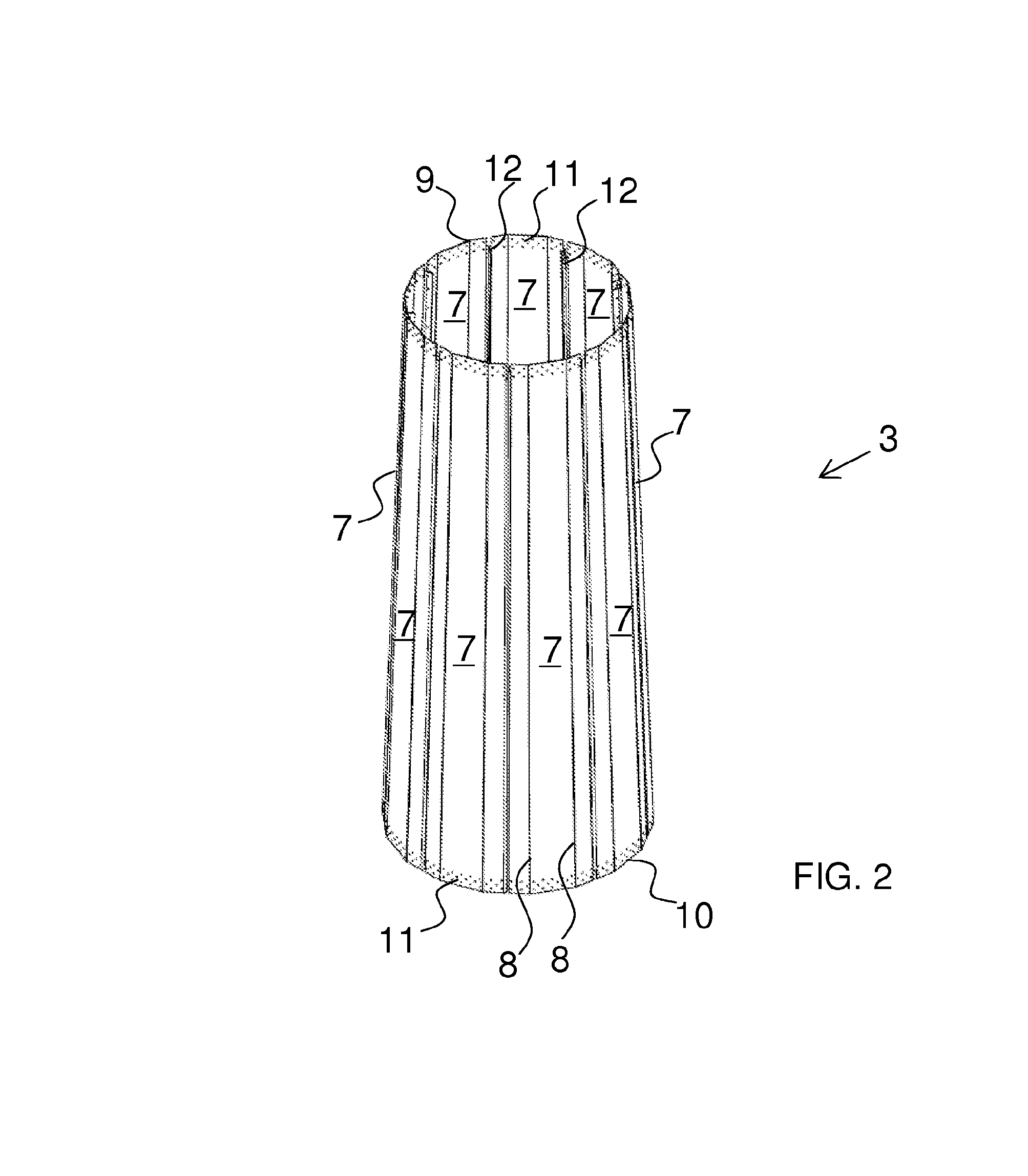

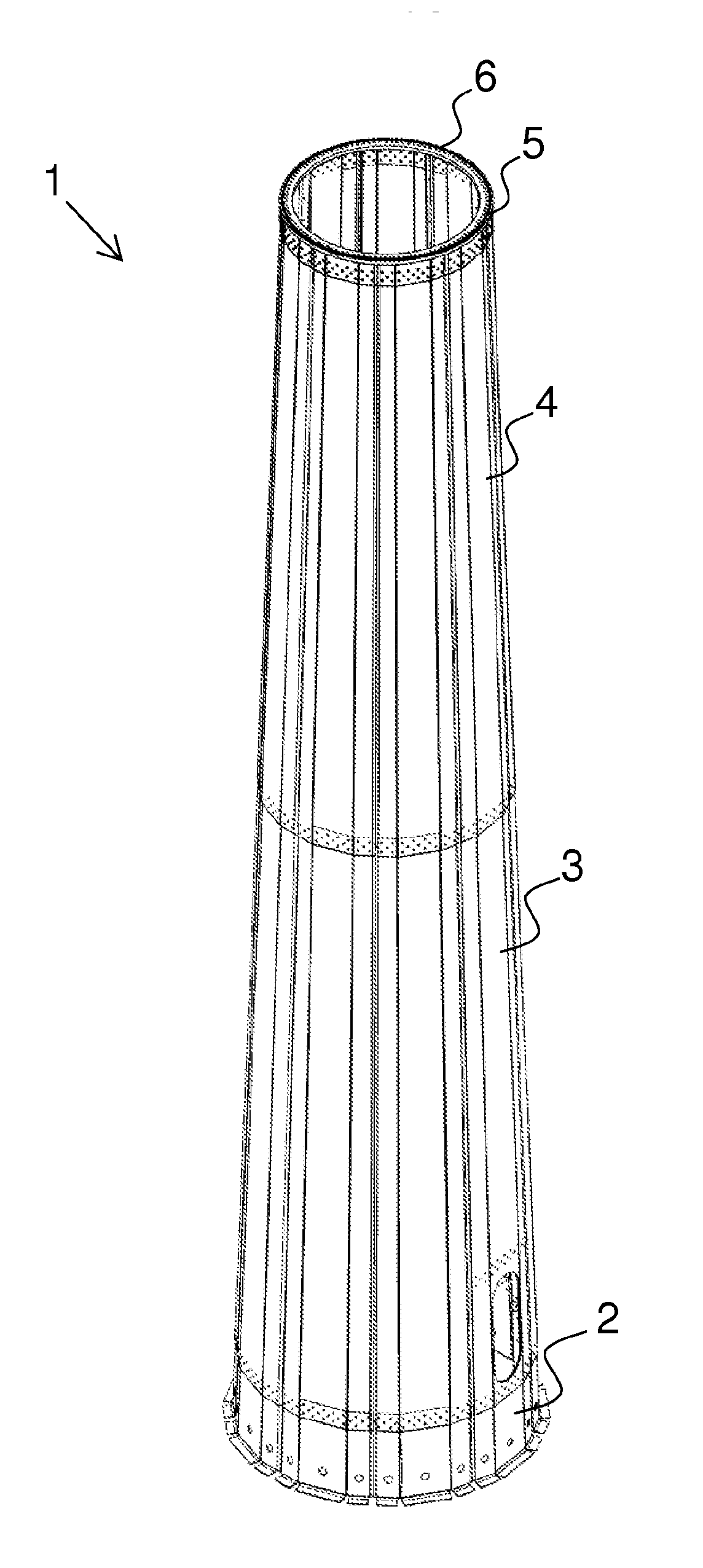

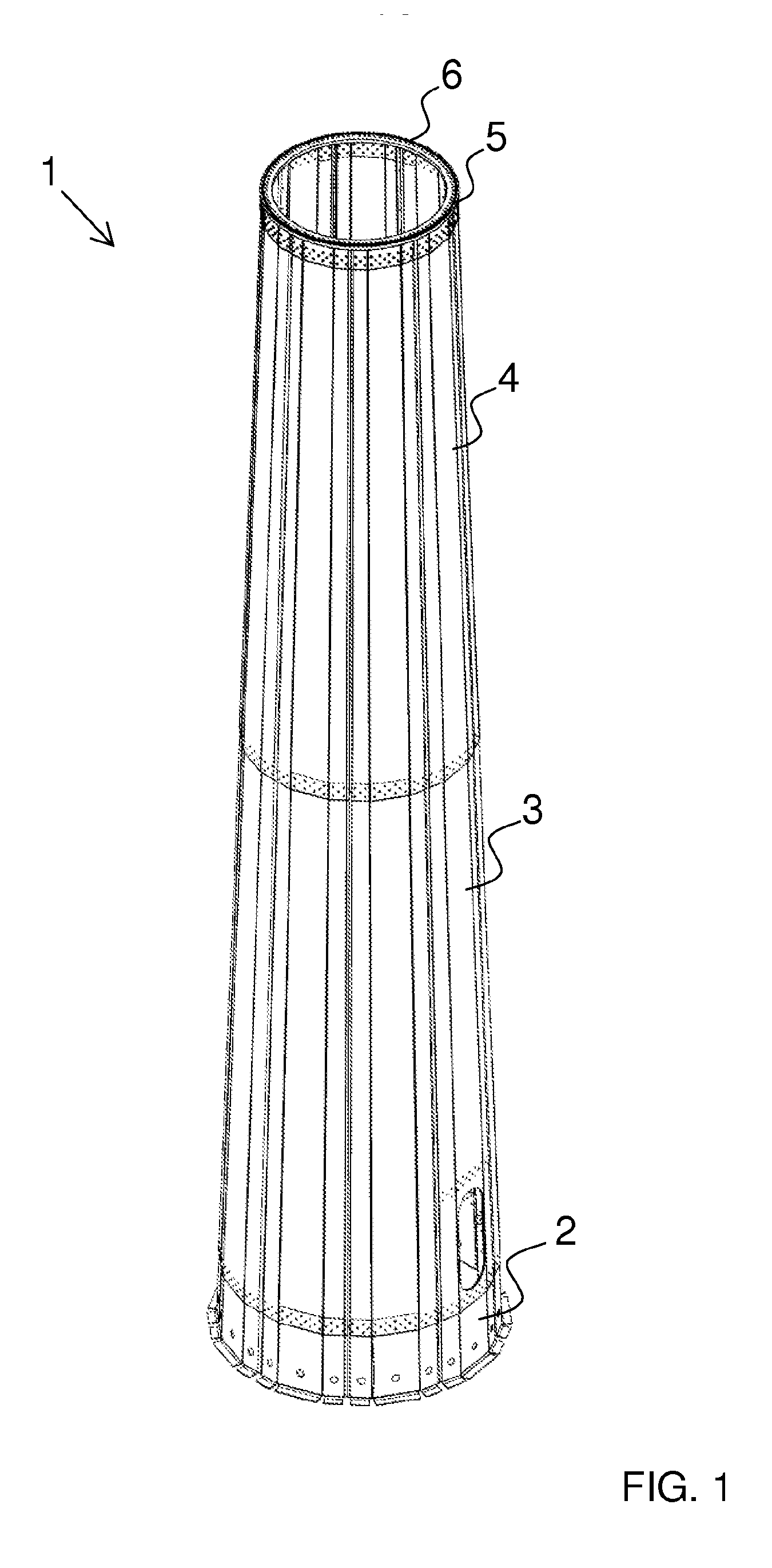

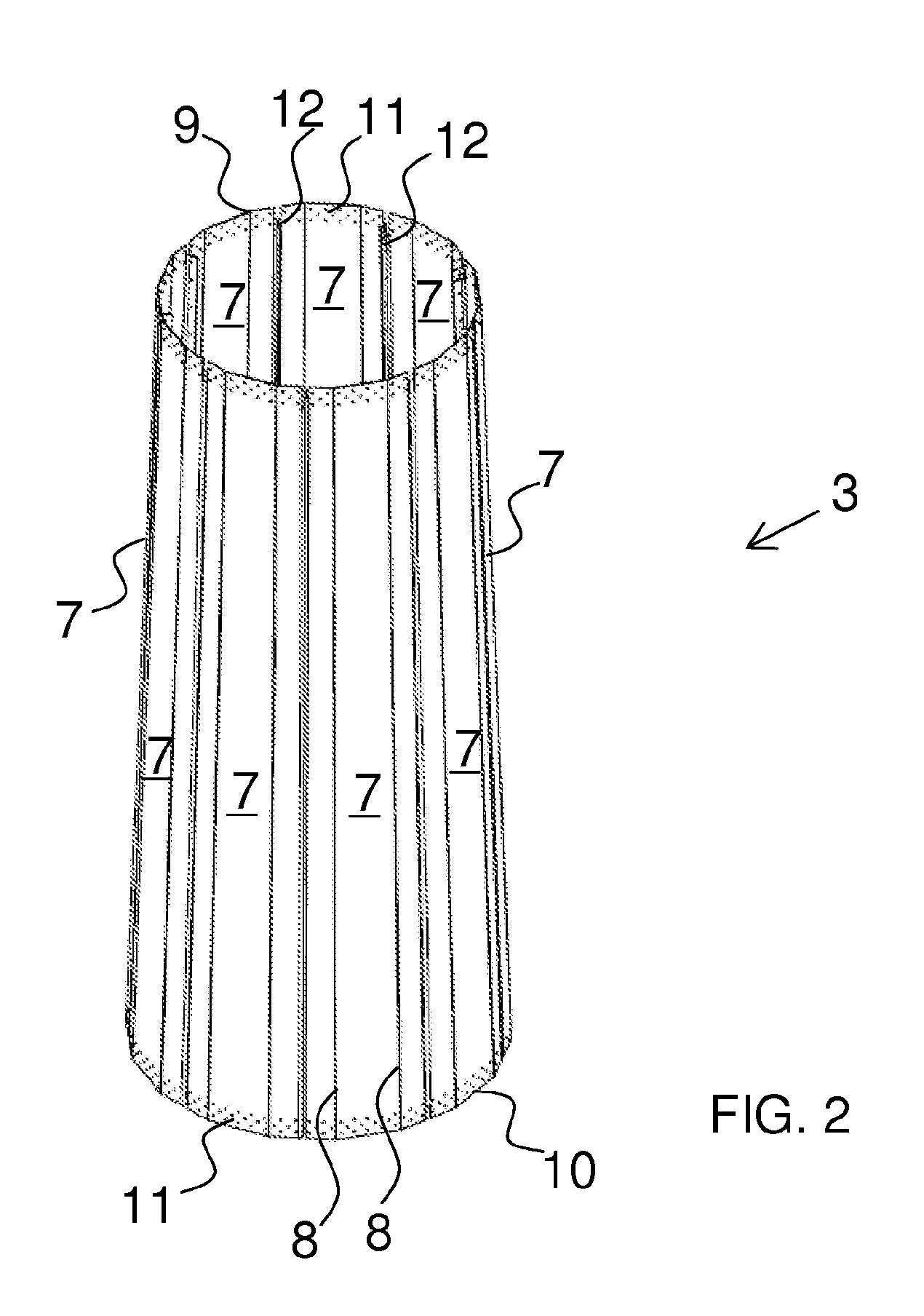

Tower element

InactiveUS8590276B2Less rigidImprove rigidityFinal product manufactureWind motor supports/mountsPower stationButt joint

The invention concerns a tower element for a tower, preferably for a wind power plant, where several tower elements with an outer surface and an inner surface are mounted on top of each other, where the periphery of the tower element is made up of a number of segments provided with inwardly facing flanges at the longitudinal sides, the flanges being connected to corresponding flanges on laterally arranged segments. The individual segments are made with an overlap on the outer surface in the transverse joints and with a butt joint at the inwardly facing flanges. By the invention there is achieved flexibility in production and during transport and mounting. With an overlap on the outer surface between two segments, mechanical joining can be performed between two segments in transverse direction. This mechanical joint between two segments results in a more stable construction and a rigidity substantially corresponding to the rigidity that may be achieved in segments joined by welding.

Owner:ANDRESEN TOWERS

Process of roughening thermoplastic films and roughed plastic films

InactiveUS6444080B1Eliminate deficienciesEliminates drawbackAdhesive processesBagsPlastic materialsEngineering

The invention relates to process for roughening thermoplastic films and roughed films. The invention further relates to process for preventing thermoplastic packaging films from slipping on each other and a suitable system for such purpose. The essence of the roughening process is that practicles consisting of the same polymer as that of the film and / or other plastic material being able to weld together with that, and having suitable size and / or abrasion resistance are brought to the surface to be roughened of semi-finished product having sufficient reserved heat content to maintain condition appropriate for welding said particles on said thermoplastic film surface to be roughened or on one or on both film surfaces being re-heated to such temperature and are dispersed in suitable closeness and configuration and that condition of the roughened surface is maintained until desired welding process is completed. Process for preventing thermoplastic packaging films from slipping on each other characterised in that a system comprising films to be stacked-at least one of which is roughed-and has protrusions of suitable closeness on its surface; a binding element having a loose fibrous structure and stability is placed on the film or on its specified parts, on the entire surface or on surface pan(s); said binding element comprises fiber of such closeness and layer thickness that between the fiber of the binding element and the protrusions of the roughed film a mechanical joint is formed.

Owner:MANDZSU SEN JOZSEF +2

Energized restraining gasket for mechanical joints of pipes

InactiveUS7104573B2Improve pressure resistanceSleeve/socket jointsFluid pressure sealed jointsEngineeringMechanical joint

Owner:US PIPE & FOUNDRY

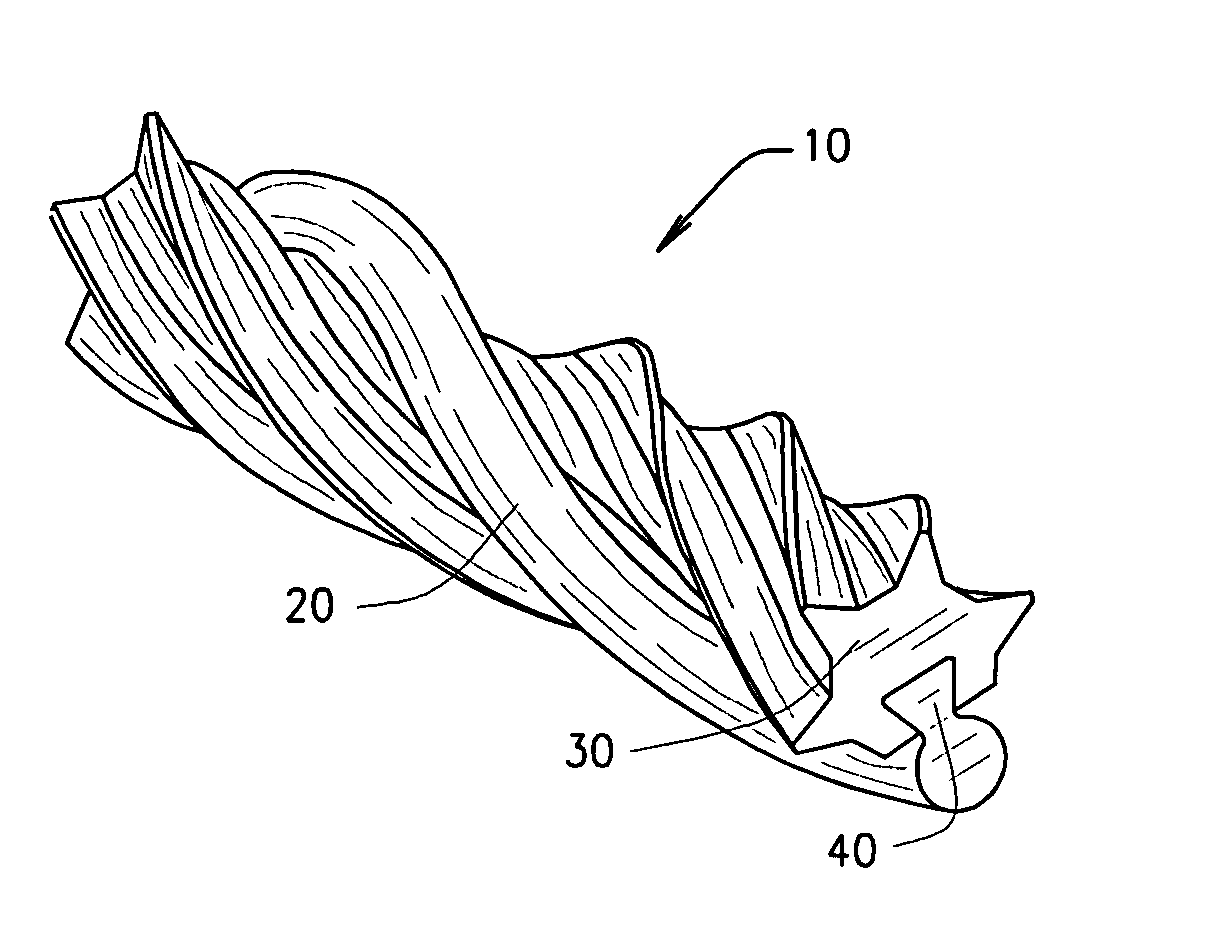

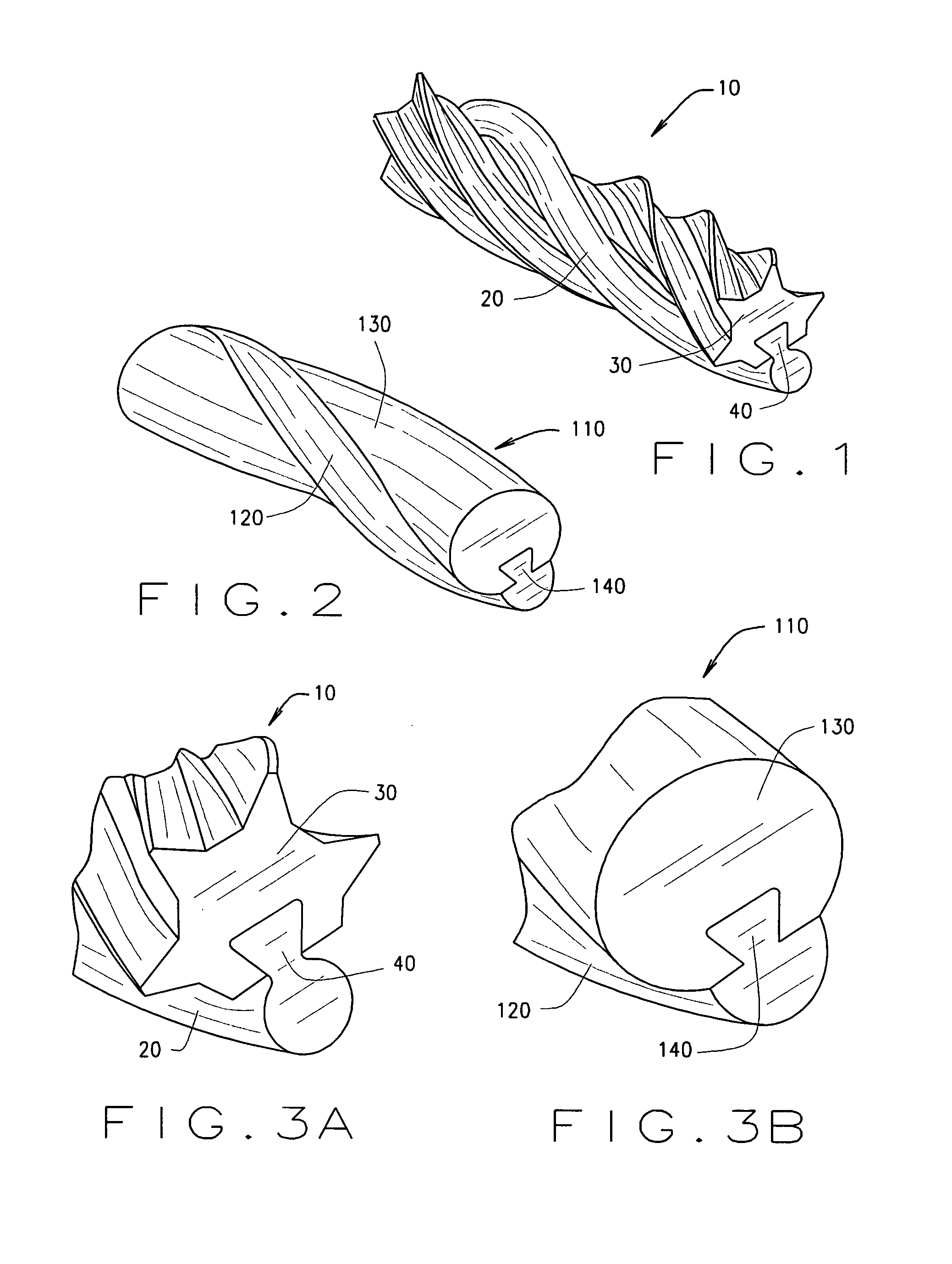

Multi-textured animal treats

The invention provides multi-textured animal treats and methods for making the multi-textured animal treats. In a general aspect, the multi-textured animal treat includes one or more soft component comprising a mechanical joint that is wrapped around a hard component fixedly attached to the mechanical joint on the soft component. The soft component can include a mechanical joint alone or a combination of edible adhesives and a mechanical joint for providing an additional attachment mechanism to the hard component.

Owner:NESTEC SA

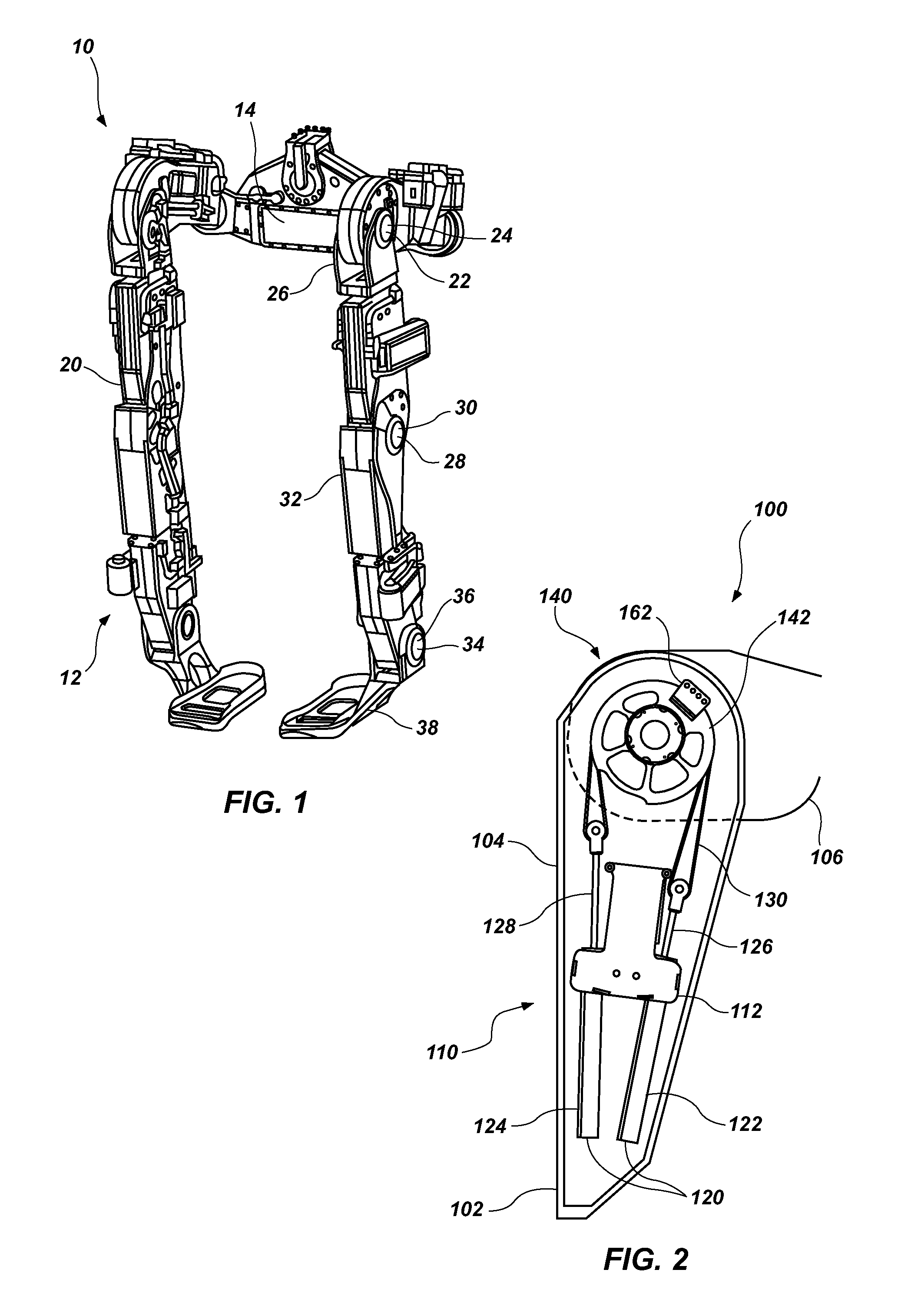

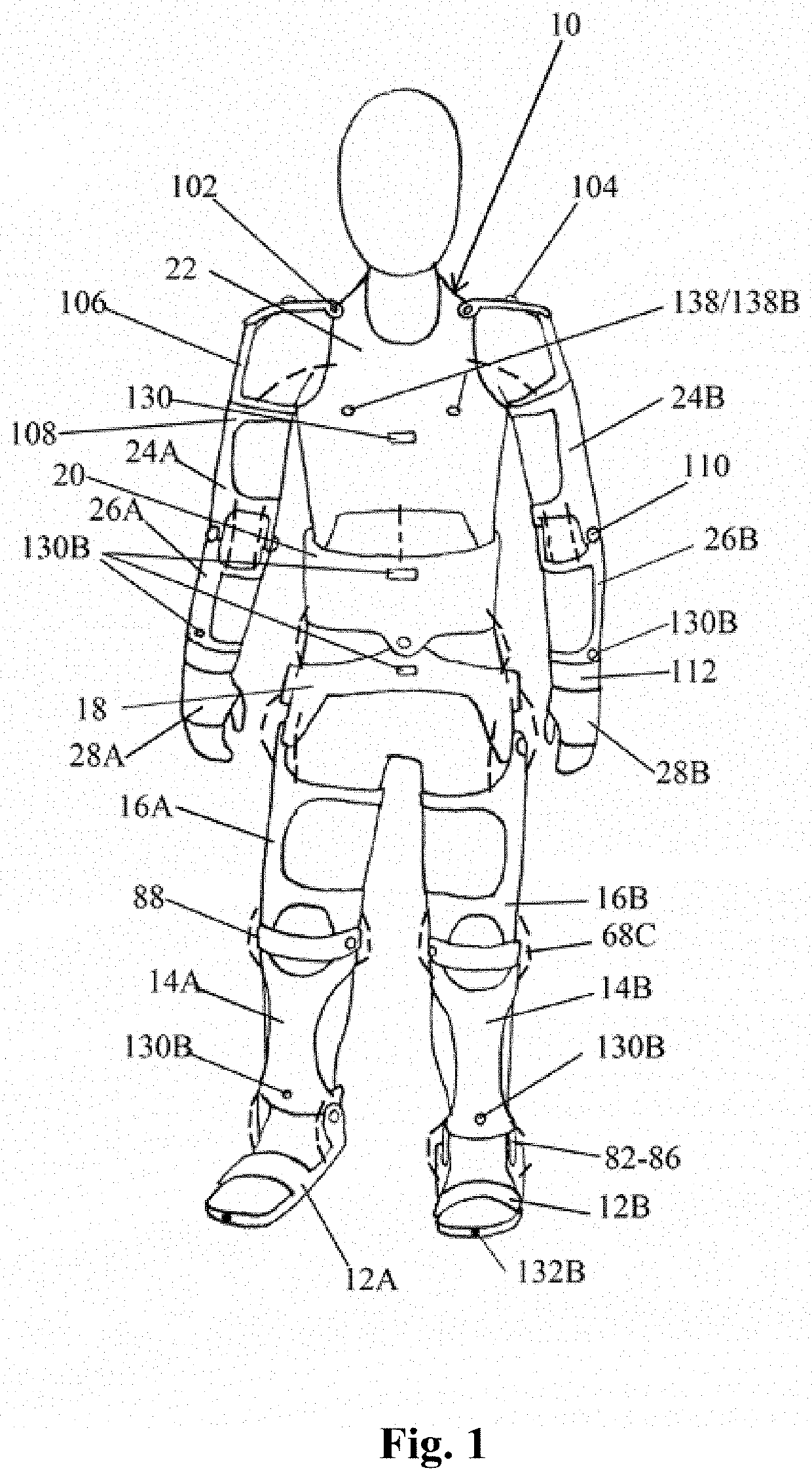

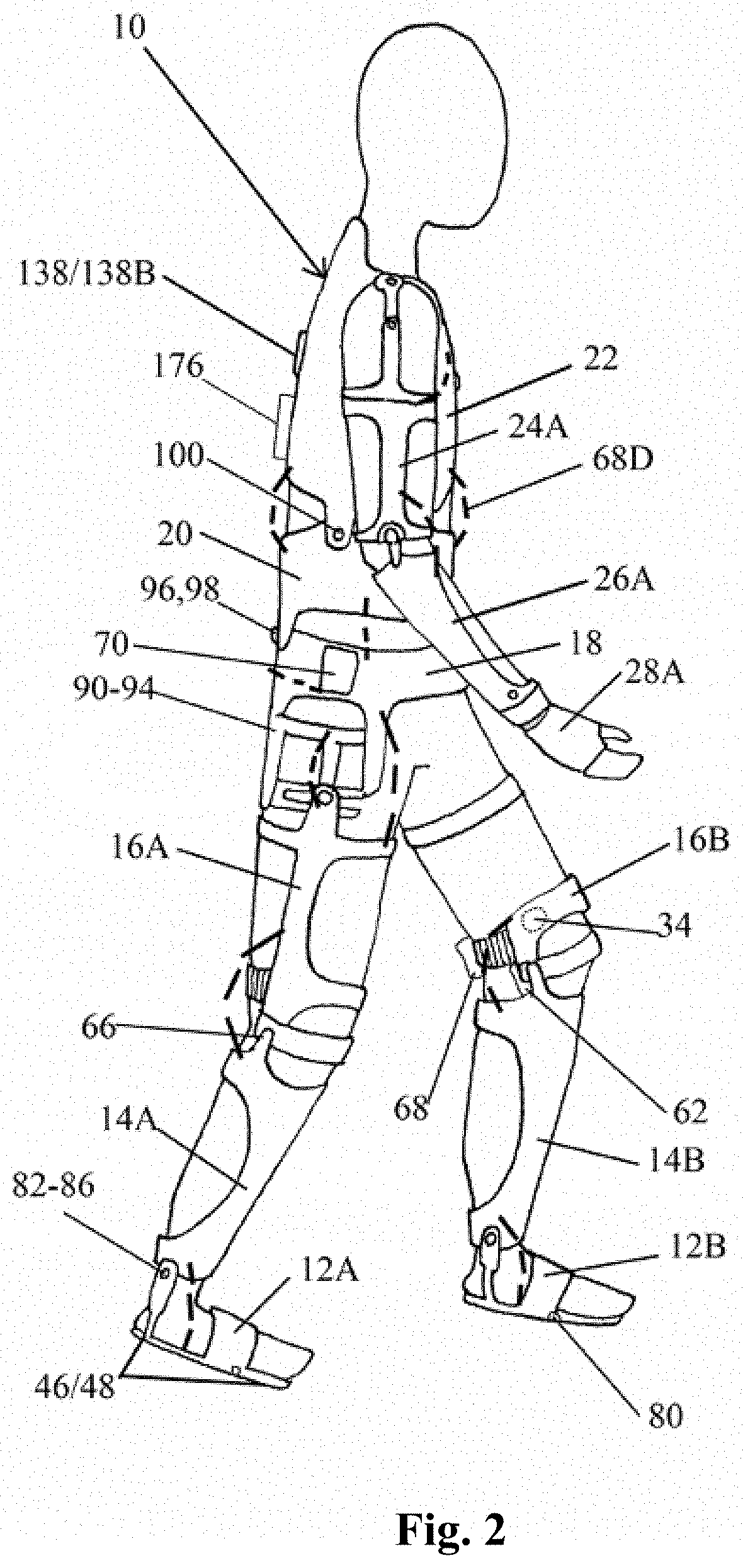

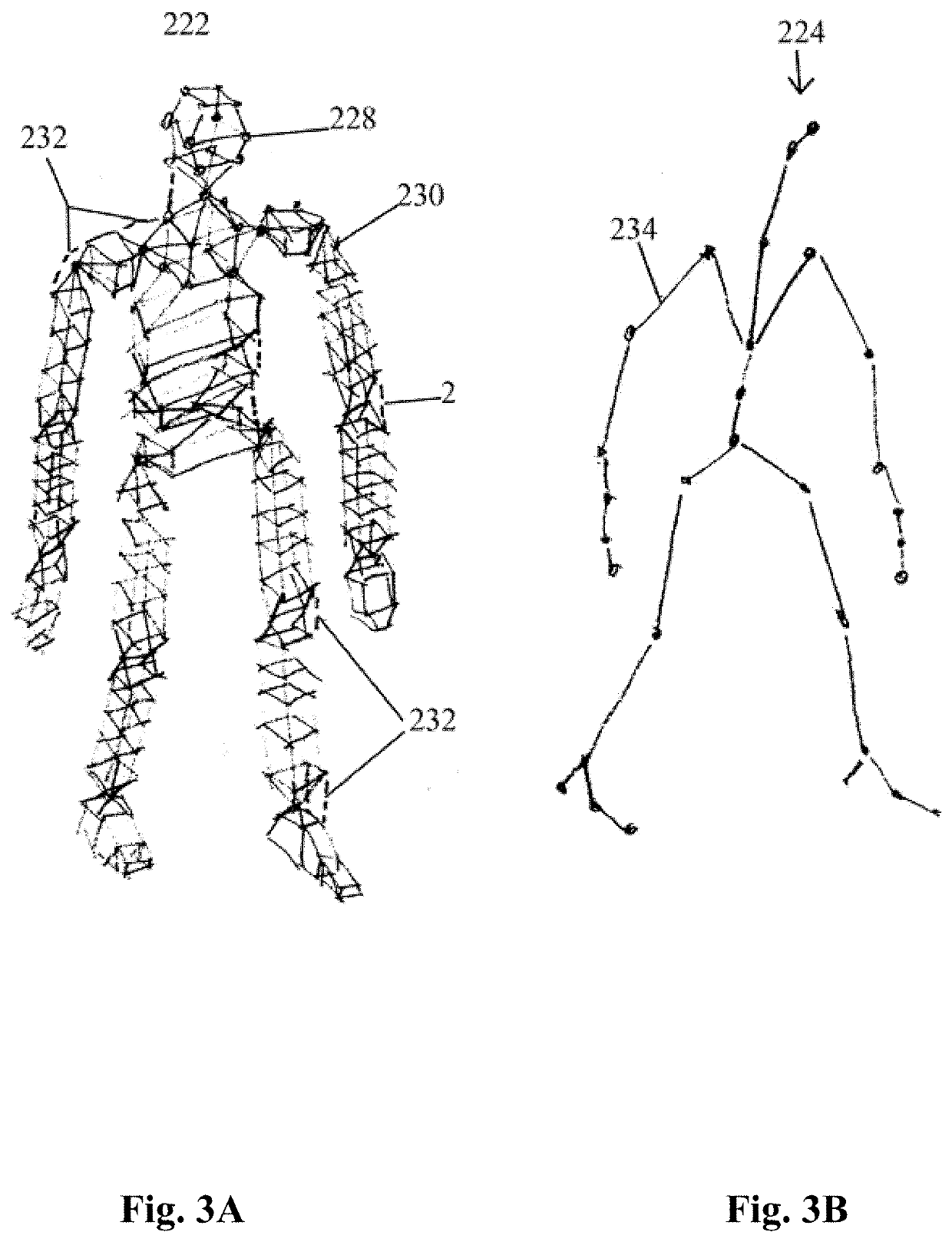

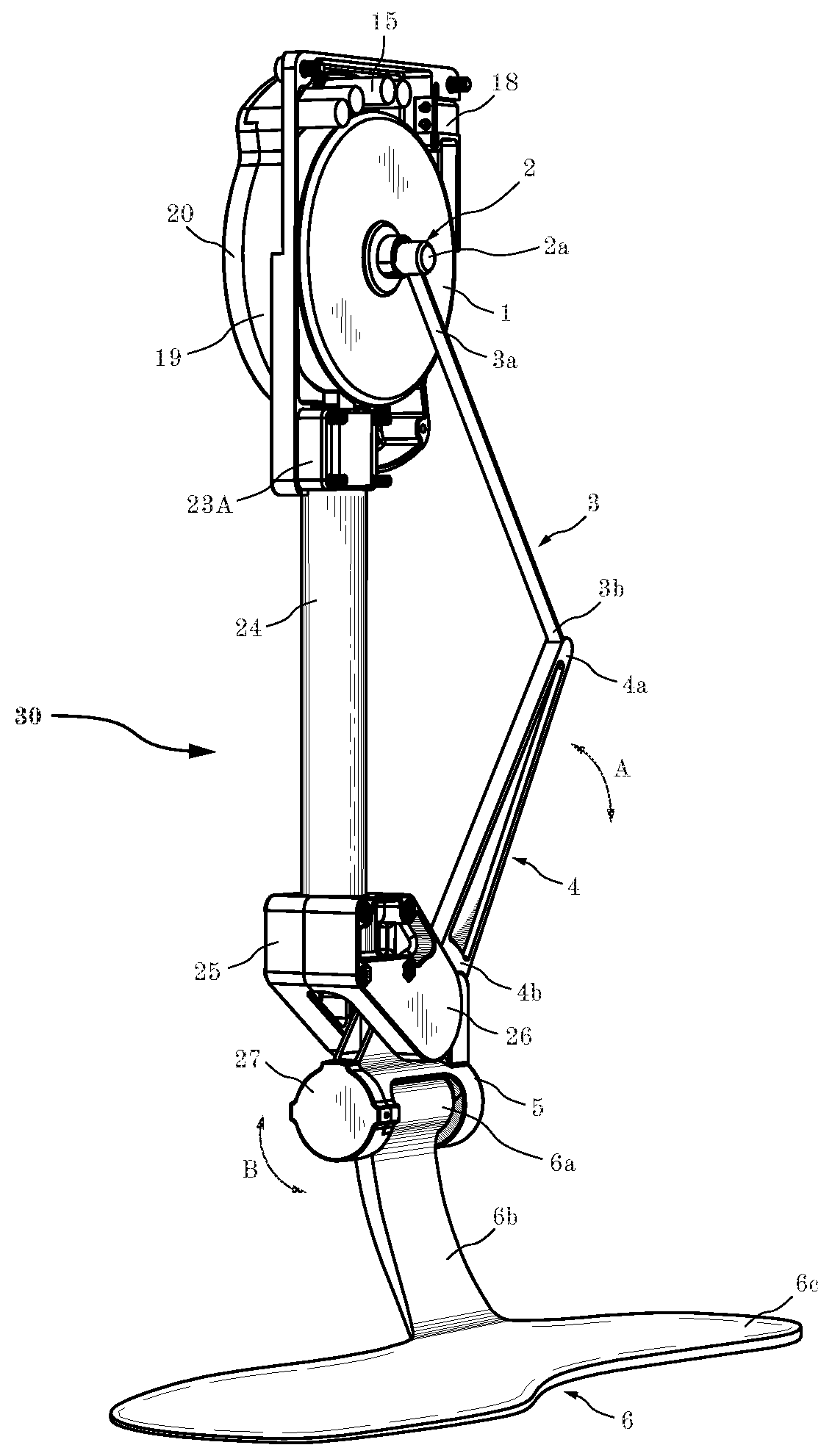

Robotic mobility device and control

ActiveUS10576620B1Optimize energy conversionImprove system efficiencyProgramme-controlled manipulatorWalking aidsControl systemRelative motion

Robotic mobility assistant exoskeleton with frame members, which are attached adjacent to biological joints, supplements relative movement between skeletal members. Mechanical joint defines a center of relative rotation of frame members about three mutually perpendicular axes with the center of relative rotation of frame members being displaced from the outer surfaces of skeletal members to correspond in position with the center of biological joint. Actuation devices including powered cable springs rotate frame members. Control system executes calibrated user specific posture sequences and activates power. Mechanical joint exhibits cylindrical guide surfaces defining a slidable or rotatable connection of frame members and has a radius intersecting the center of the biological joint. Node control network distributes computing load and reduces communications overhead. Map unit has object recognition system for monitoring environment. Standard posture data derived from rules of ambulation and posture provide positioning control, optimized by energy-timed margins for balance maintenance.

Owner:IKUTUKI

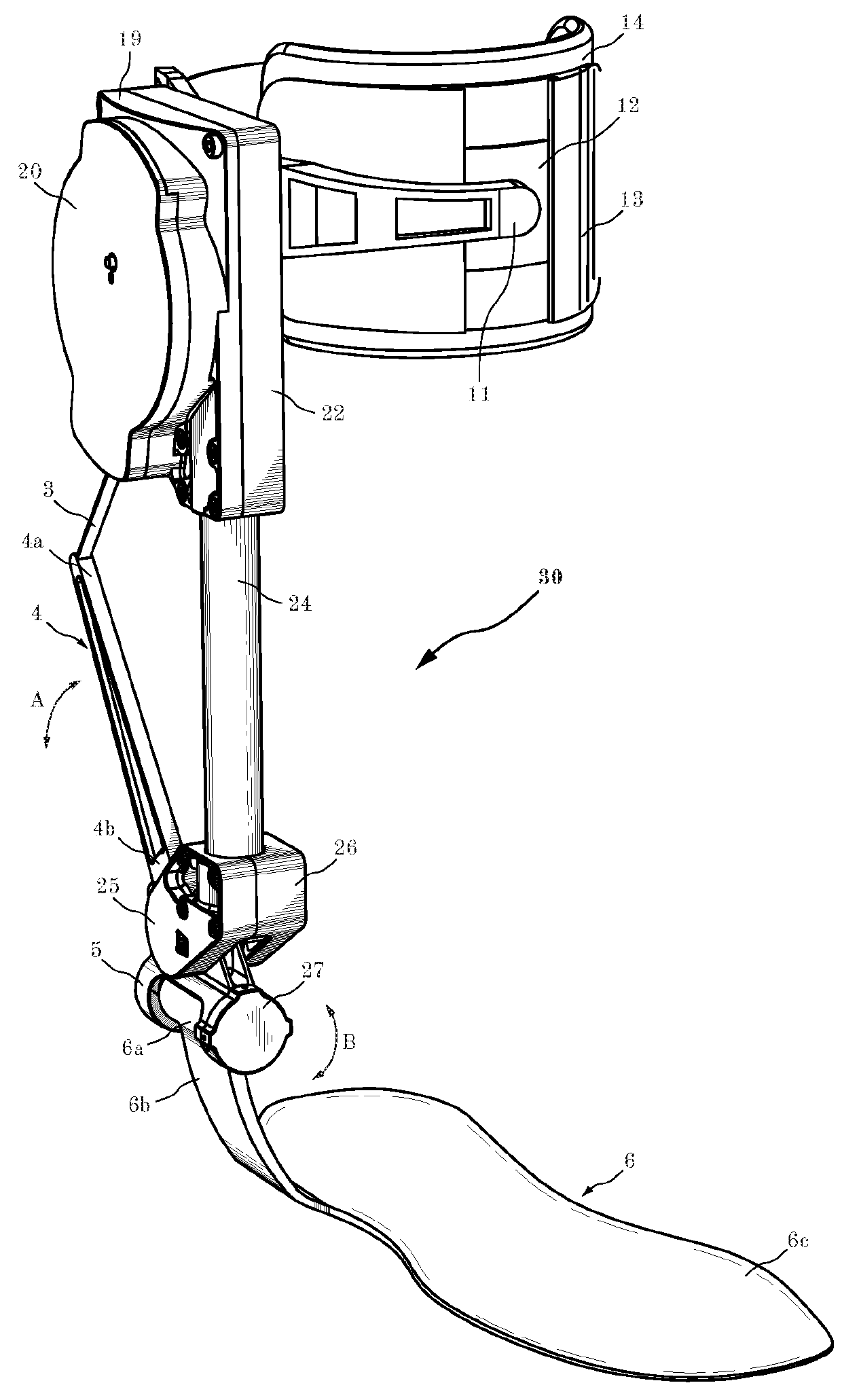

Unidirectional actuated exoskeleton device

ActiveUS20180104075A1Reduce manufacturing costPowerfulChiropractic devicesWalking aidsEngineeringCam

The present invention is directed to an autonomous exoskeleton device that includes one or more actuators, one or more controllers, one or more sensors with one or more unidirectional transmissions. The present invention provides a mechanical joint in parallel with a biological joint. The exoskeleton device preferably includes and electric motor and winch, chain, belt, cam transmission or other mechanism for providing unidirectional force to assist rotation about the biologic joint. Moreover, a controller, a motor angle sensor, joint angle sensor and / or force sensor may be used for additional control and monitoring of the device. The motor may be any type of motor, but is preferably brushless in configuration where its diameter is larger than its length to provide a compact and lightweight exoskeleton device.

Owner:DEPHY INC

Energized restraining gasket for mechanical joints of pipes

The present invention may be basically described as a gasket for converting a standard mechanical joint into a restrained mechanical joint without the need for altered configuration of the bell, spigot, or gland of the joint, and without the need for additional fittings or devices. In the practice of the present invention, a standard mechanical joint's bell and gland configuration can be employed to connect a spigot end of one pipe length to the bell end of another pipe length in a restrained relationship, with the restraint based on forces superior to rubber-to-pipe friction. In more particular discussion of the embodiments taught, the invention includes forming the gasket to fit within the bell in such a manner that a void, or gutter, exists during rest, into which void the gasket compresses, which in turn influences the rotational motion of the segment. In this manner, the configuration of the gasket influences the timing and extent of rotation throughout the process of securing the gland to the bell.

Owner:US PIPE & FOUNDRY

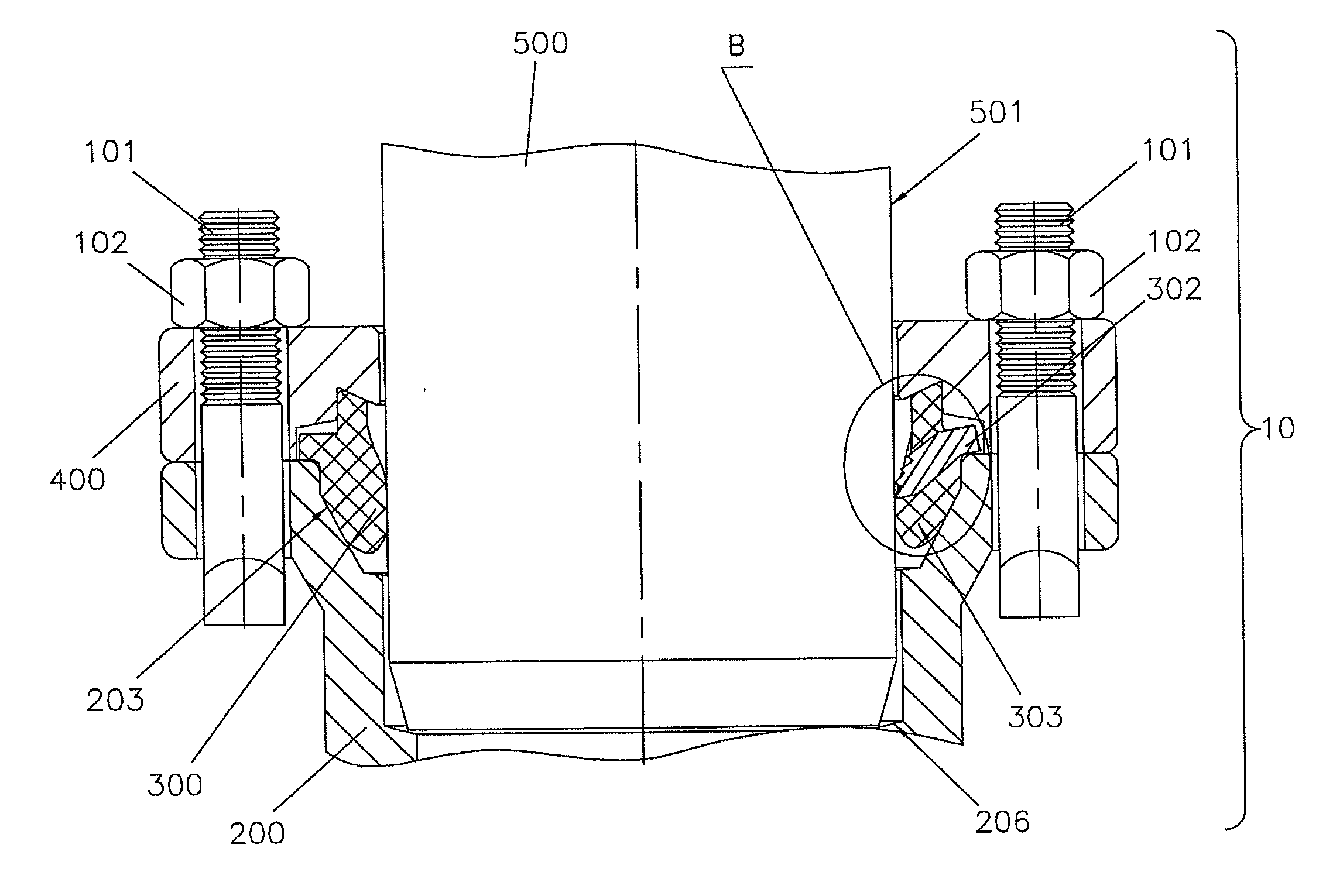

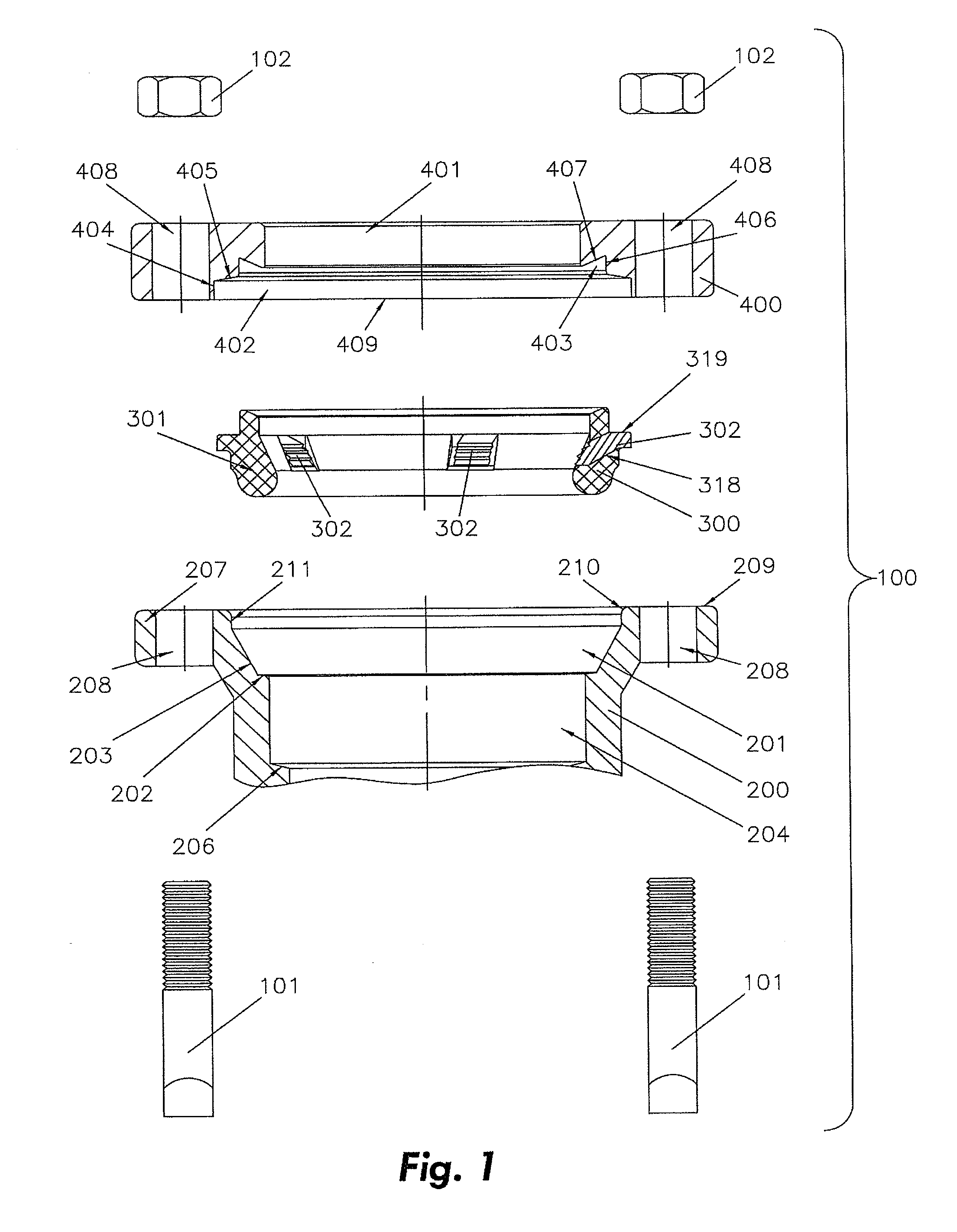

Mechanical joint for a gas turbine engine

ActiveUS8459941B2Controls are responsiveUniform thermal stressLocking fastenersReaction enginesEngineeringGas turbines

A mechanical joint for a gas turbine engine includes:(a) an annular first component having an annular, radially-extending first flange; (b) an annular second component having an annular, radially-extending second flange abutting the first flange; (c) a plurality of generally radially-extending radial channels passing through at least one of the first and second flanges; (d) a plurality of generally axially-extending channels extending through the first flange and communicating with respective ones of the radial channels; and (e) a plurality of fasteners clamping the first and second flanges together.

Owner:GENERAL ELECTRIC CO

Tower element

InactiveUS20100319276A1Less rigidImprove rigidityRoof covering using slabs/sheetsRoof covering using tiles/slatesPower stationButt joint

The invention concerns a tower element for a tower, preferably for a wind power plant, where several tower elements with an outer surface and an inner surface are mounted on top of each other, where the periphery of the tower element is made up of a number of segments provided with inwardly facing flanges at the longitudinal sides, the flanges being connected to corresponding flanges on laterally arranged segments. The individual segments are made with an overlap on the outer surface in the transverse joints and with a butt joint at the inwardly facing flanges. By the invention there is achieved flexibility in production and during transport and mounting. With an overlap on the outer surface between two segments, mechanical joining can be performed between two segments in transverse direction. This mechanical joint between two segments results in a more stable construction and a rigidity substantially corresponding to the rigidity that may be achieved in segments joined by welding.

Owner:ANDRESEN TOWERS

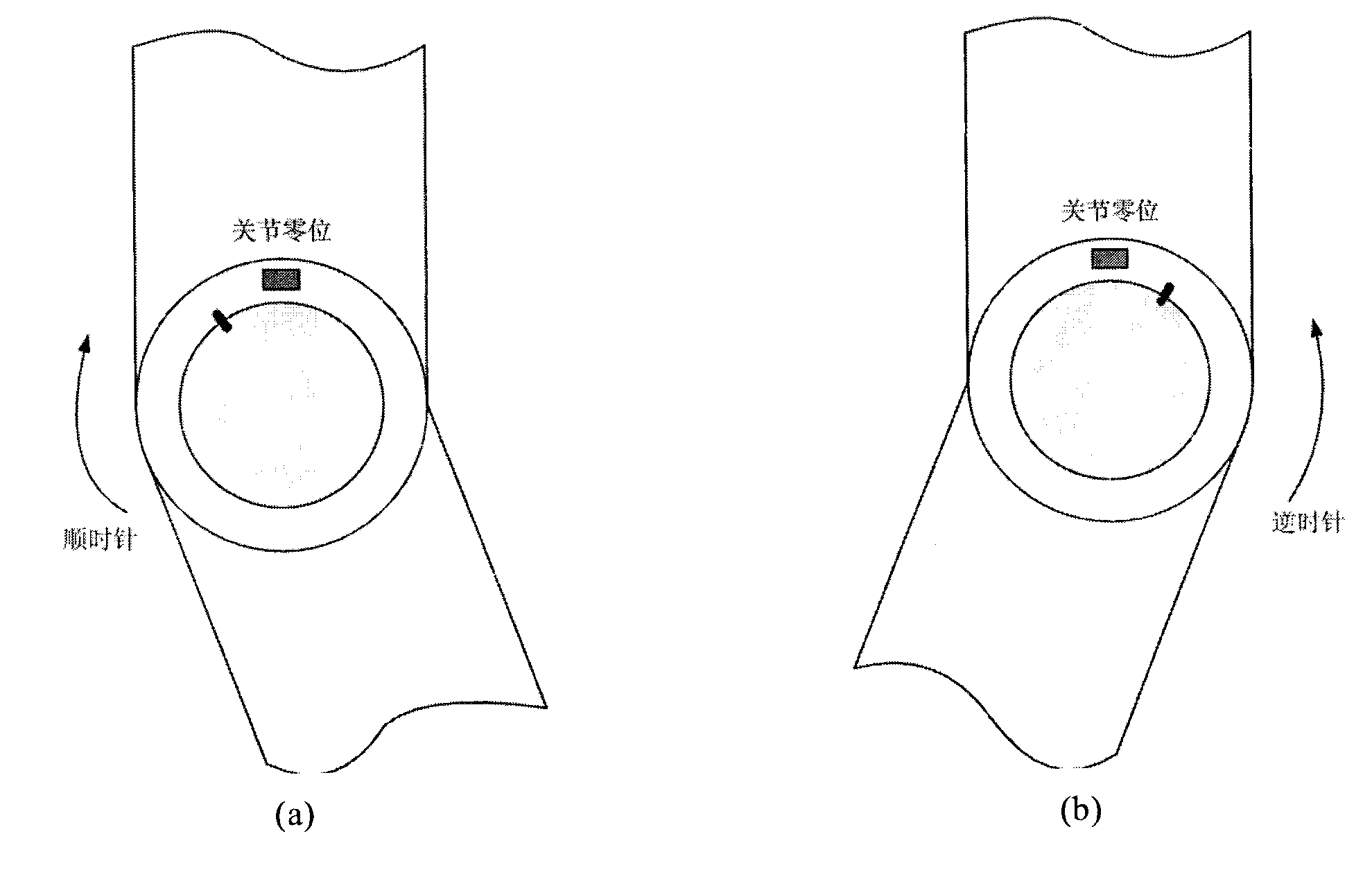

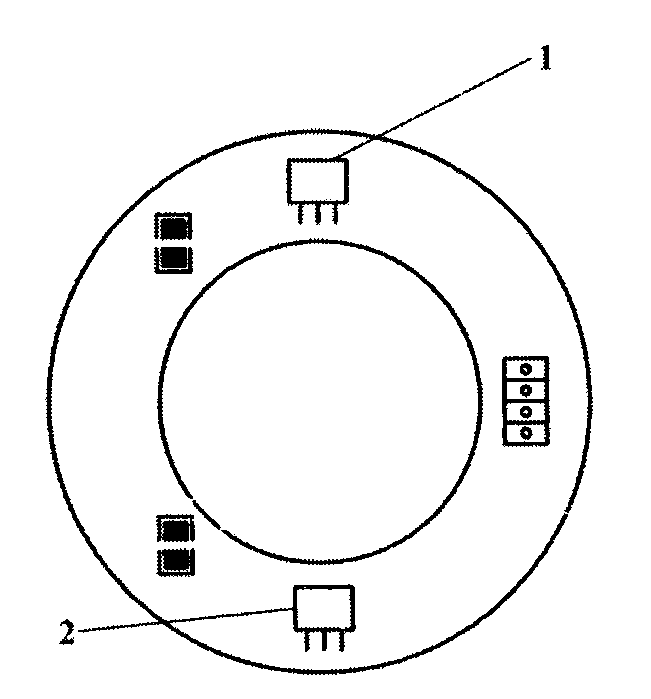

Anti-winding locating device for 360-degree rotary joint of robot

InactiveCN102837309AHigh precisionHigh degree of automationProgramme-controlled manipulatorJointsConductor CoilMechanical joint

The invention discloses an anti-winding locating device for a 360-degree rotary joint of a robot. Locating of the joint is achieved by an edge signal of a zero Hall switch, a Z-pulse signal of an incremental encoder and an edge signal of a limiting Hall switch on the basis of the zero Hall switch and the limiting Hall switch. Thus, on one hand, the precision and the automatic degree are improved when the robot carries out zero locating, and the problem that an electric lead is wound on a mechanical joint is solved; on the other hand, the problem that the electric lead is wound when the joint normally moves is solved under the situation that a work space is 360 degrees. The anti-winding locating device has the advantages of low cost, simple structure, ease in operation and high precision.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

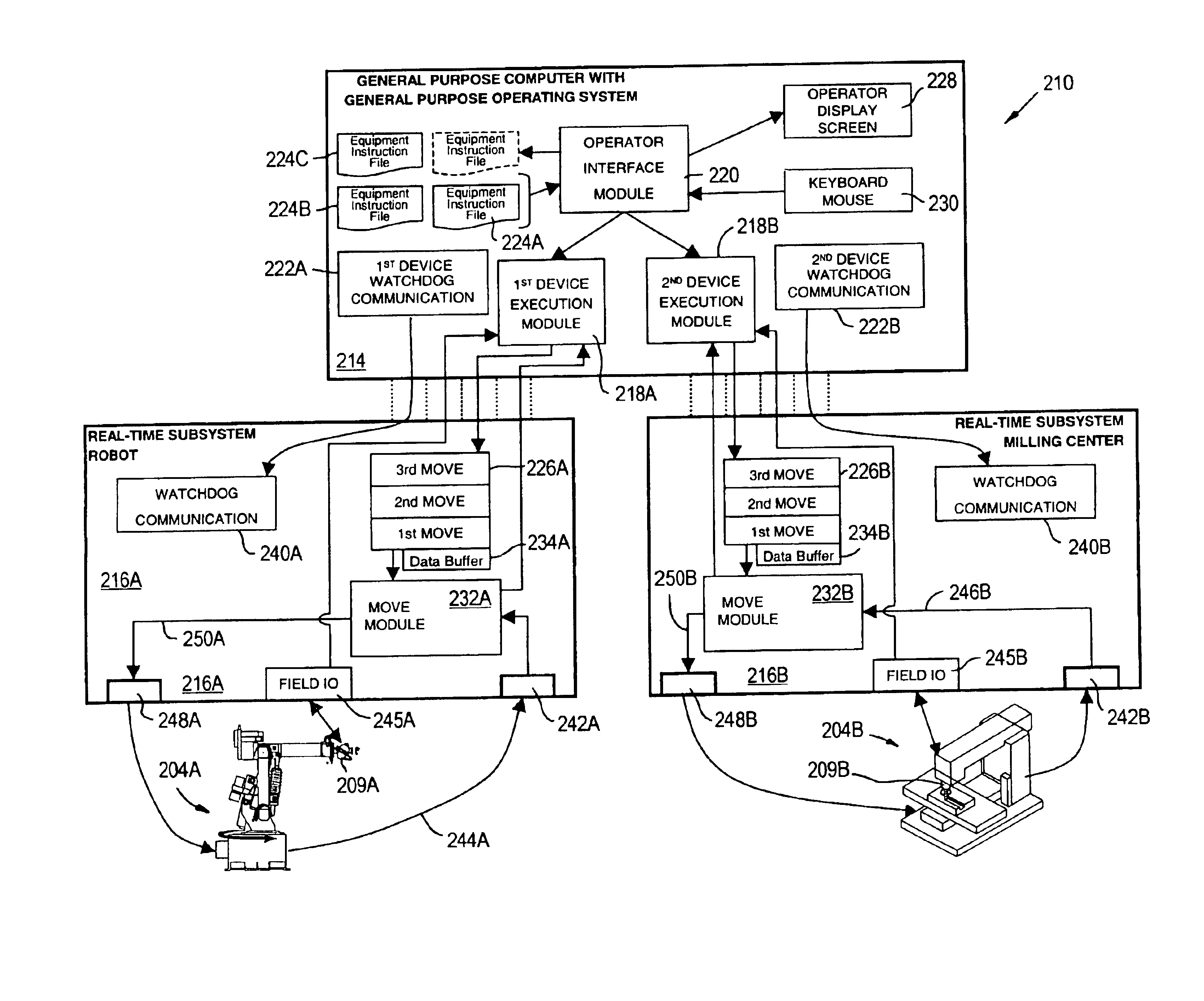

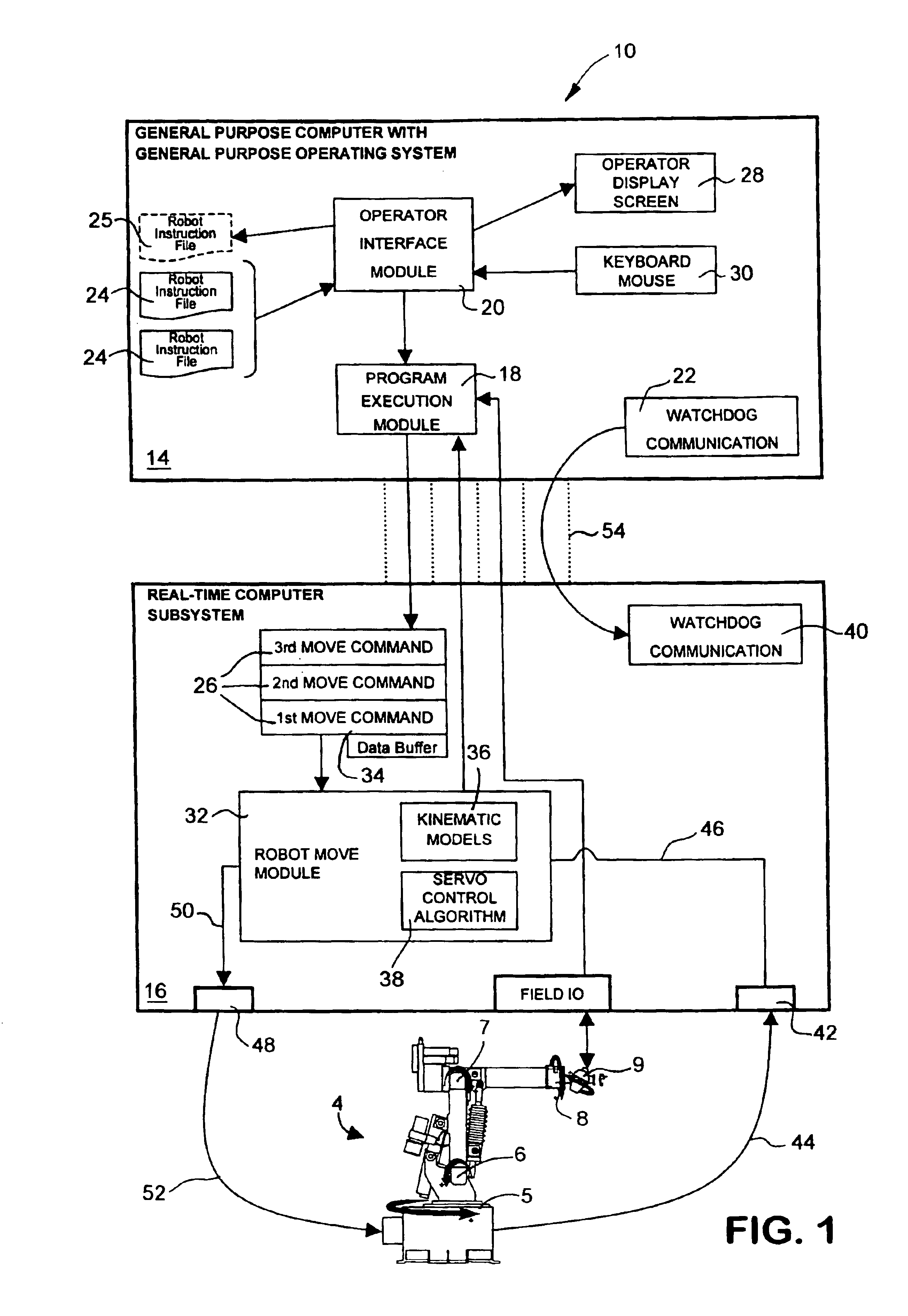

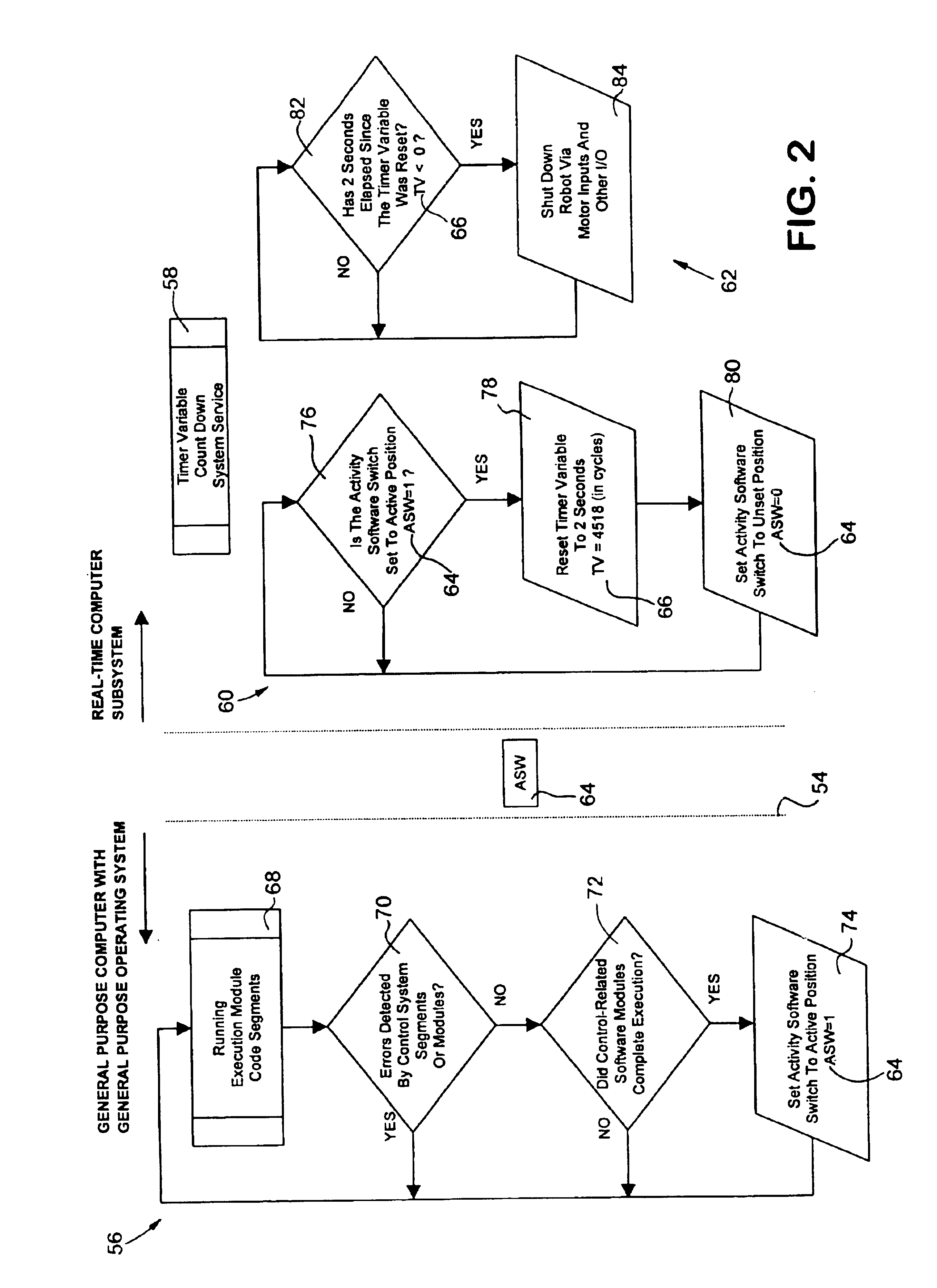

Automation equipment control system

InactiveUS6922611B2Programme-controlled manipulatorEndoscopesOperational systemGeneral purpose computer

A automation equipment control system comprises a general purpose computer with a general purpose operating system in electronic communication with a real-time computer subsystem. The general purpose computer includes a program execution module to selectively start and stop processing of a program of equipment instructions and to generate a plurality of move commands. The real-time computer subsystem includes a move command data buffer for storing the plurality of move commands, a move module linked to the data buffer for sequentially processing the moves and calculating a required position for a mechanical joint. The real-time computer subsystem also includes a dynamic control algorithm in software communication with the move module to repeatedly calculate a required actuator activation signal from a joint position feedback signal.

Owner:INTELLECTUAL VENTURES II

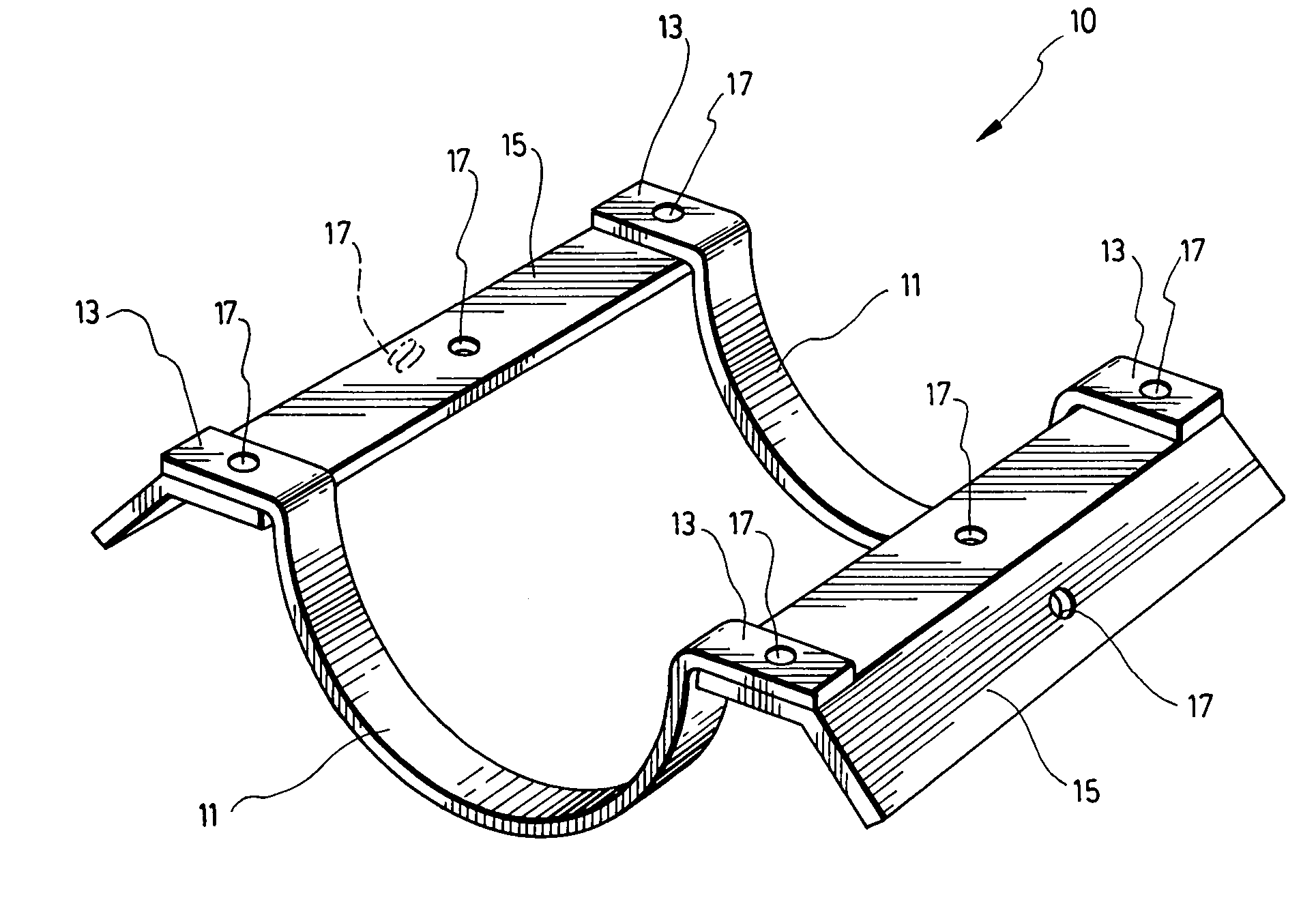

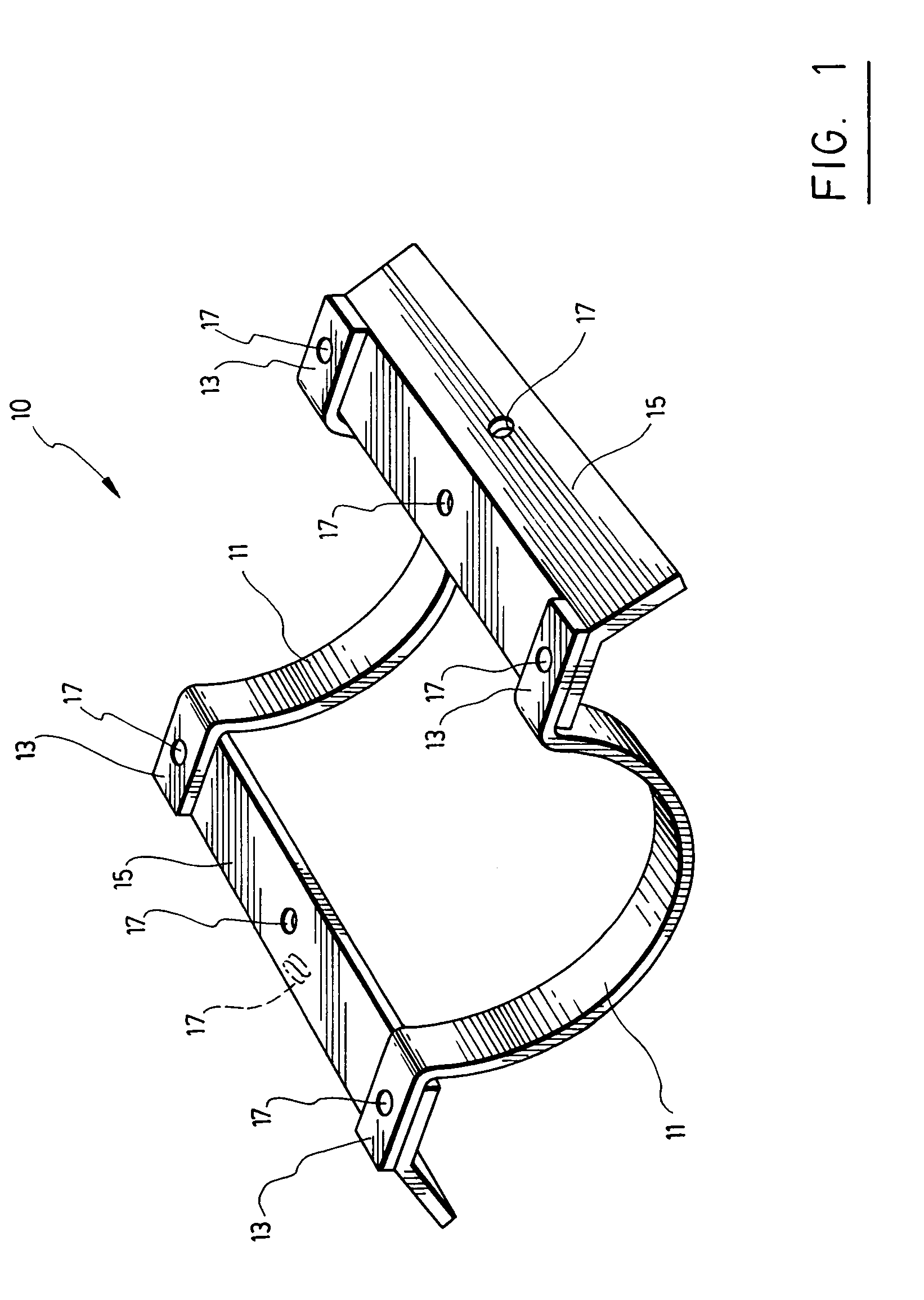

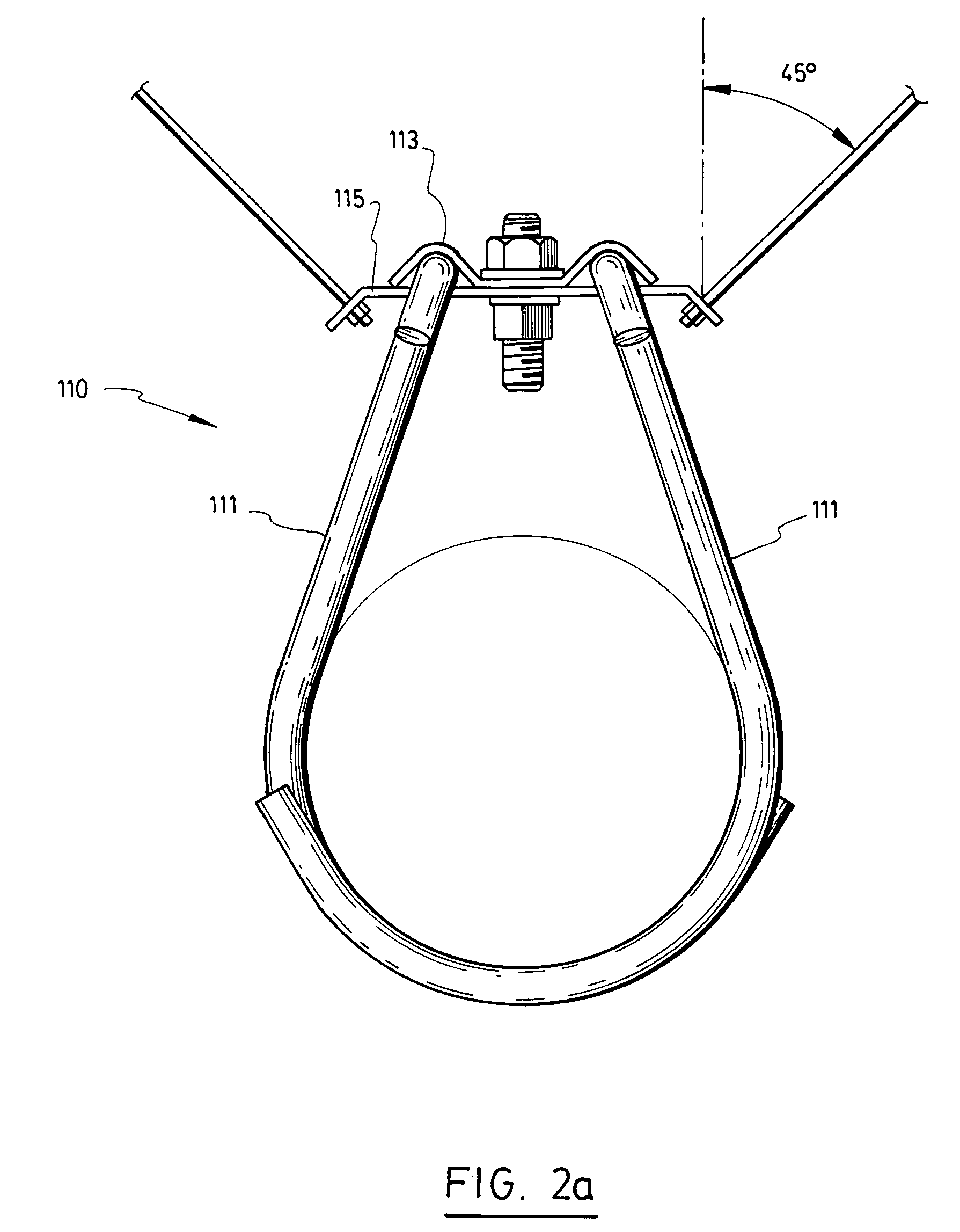

Para-seismic support for pipes

A para-seismic support for pipes is disclosed. The support has two support members, each for supporting an end of a pipe on either side of a mechanical joint. The support members are joined to each other. The support is provided with a plurality of holes, at least one of which is for supporting the pipes, and at least one of which is for providing para-seismic protection by attaching the support to a ceiling and by attaching said support to a structure at an angle of no more than 90° from a vertical direction.

Owner:SUPPORTS SCH INC

Method and apparatus for attaching a wing to a body

A method and apparatus for assembling an aircraft. A wing spar fitting is connected to a spar in a wing for the aircraft. A body frame fitting is connected to a frame in a body for the aircraft. The locations and orientations of the body frame fitting and the wing spar fitting allow for the body frame fitting to be attached to the wing spar fitting when the wing is positioned for attachment to the body of the aircraft. The wing is positioned with respect to the body of the aircraft for attachment to the body. The body frame fitting and the wing spar fitting are attached to each other with a set of fasteners after the body frame fitting is aligned to the wing spar fitting without penetrating any sealed areas in the wing, wherein the wing is attached to the body by a mechanical joint that is formed by the body frame fitting and the wing spar fitting.

Owner:THE BOEING CO

Solder reflow with microwave energy

The present invention includes a mechanical joint between a die and a substrate that is reflowed by microwave energy and a method of forming such a mechanical joint by printing a solder over a substrate, placing the solder in contact with a bump over a die, reflowing the solder with microwave energy, and forming a mechanical joint from the solder and the bump.

Owner:INTEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com