Angled rotary tissue cutting instrument and method of fabricating the same

a cutting instrument and rotary technology, applied in the field of surgical cutting instruments, can solve the problems of inability to bend, inability to transmit sufficient torque at high speed through angles much greater than 15.degree., and less than 2 bend radii, so as to improve the angled rotary tissue cutting instrument, reduce the radius of curvature of the bend, and increase the range of bend angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

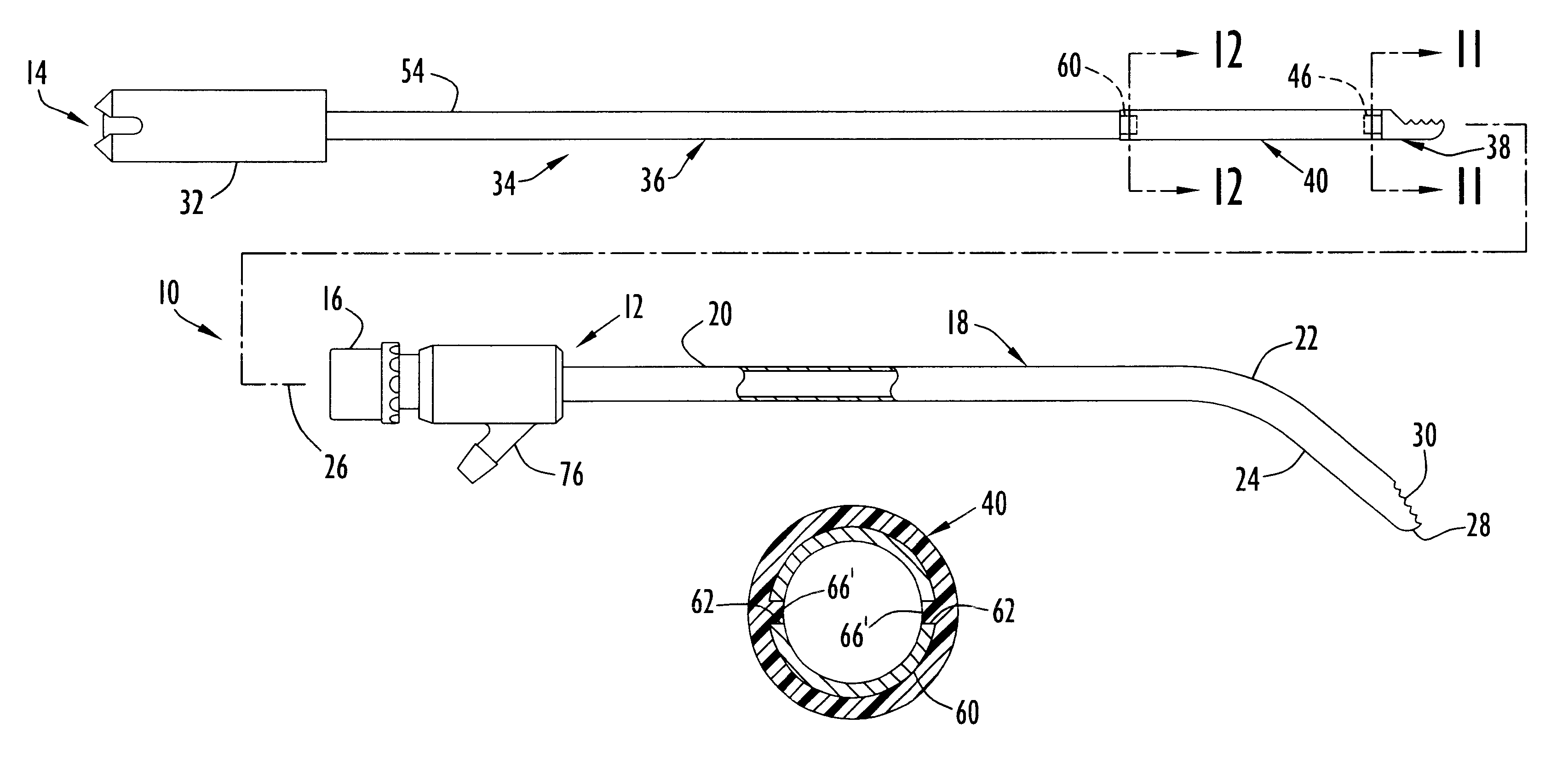

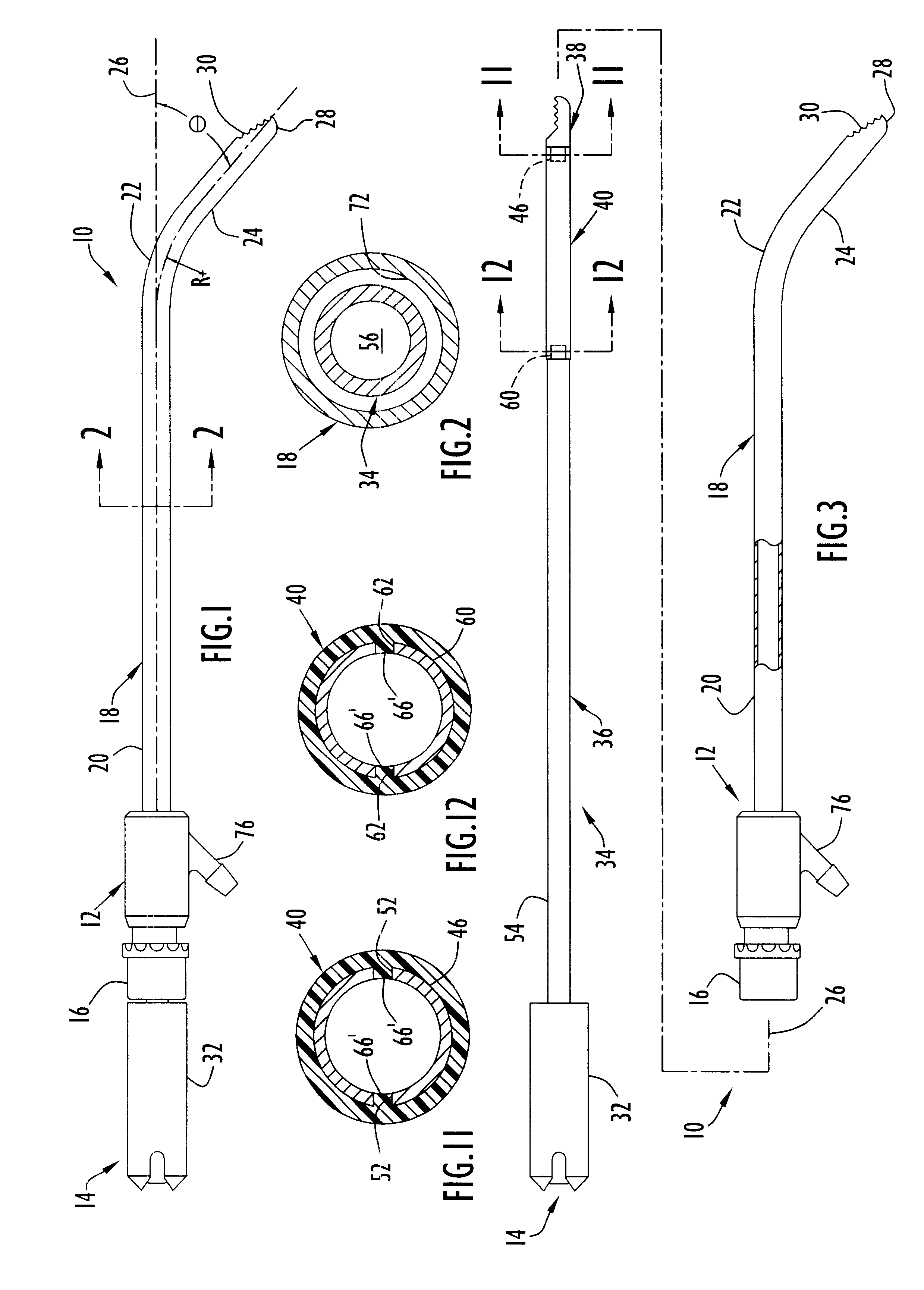

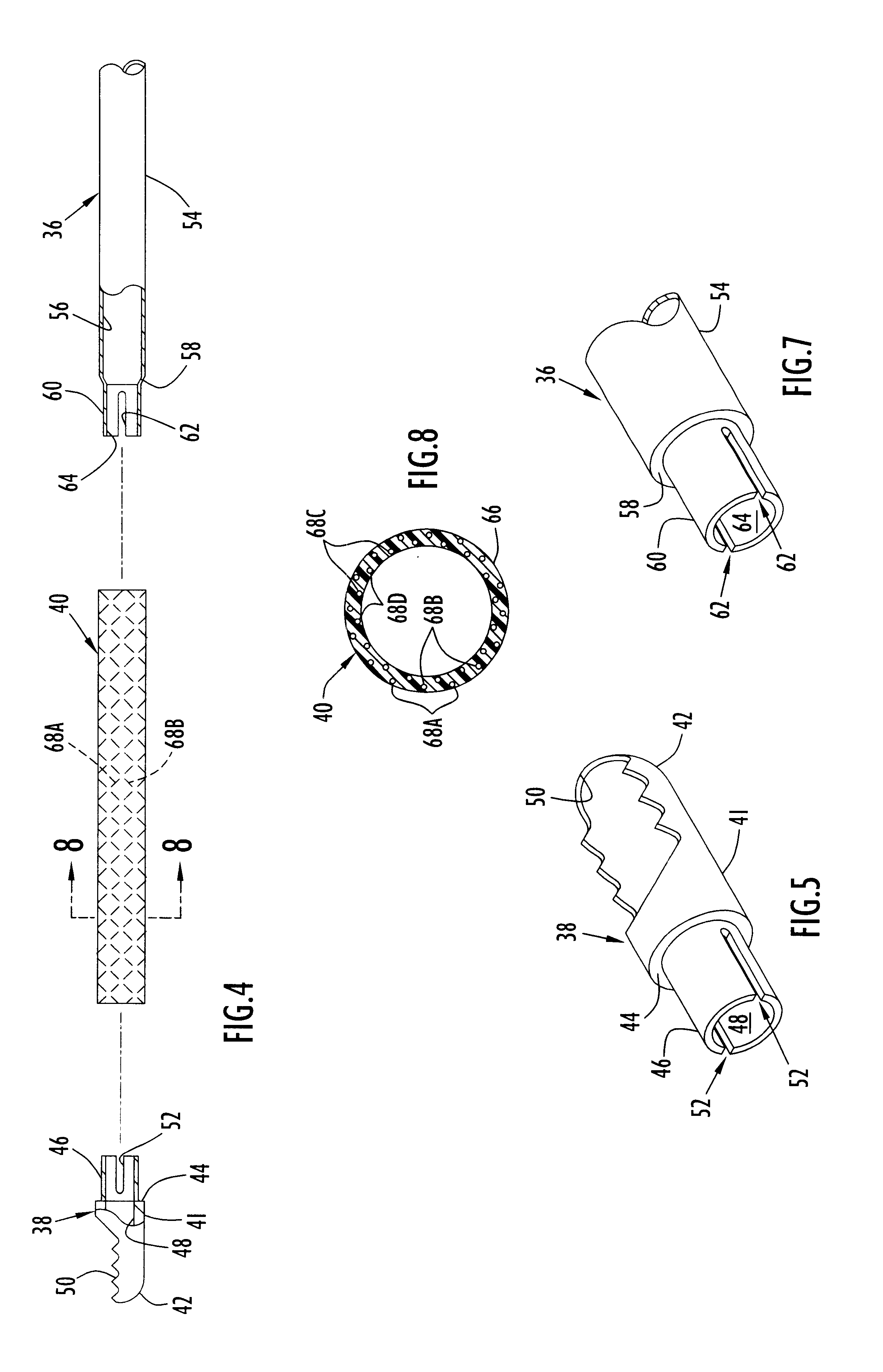

A rotary tissue cutting instrument or blade 10 according to the present invention, as illustrated in FIGS. 1-3, includes an outer blade member or assembly 12 and an inner blade member or assembly 14 rotatably received within the outer blade member. Outer blade member 12 includes a hub 16 and an outer tubular member or sleeve 18 having a proximal portion 20 of straight configuration extending distally from the hub to a bend 22 connecting the proximal portion with a distal portion 24 oriented at an angle .theta. of about 40.degree. relative to the longitudinal axis 26 of the proximal portion. Angled portion 24 of the outer tubular member extends downwardly from bend 22, looking at FIG. 1, to a rounded distal end 28 having an opening facing upwardly, away from the center of curvature of the bend, to define a cutting port or window 30. The orientation of the cutting window as well as the radius of curvature and location of the bend relative to the distal end of the angled portion are de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com