Anti-winding locating device for 360-degree rotary joint of robot

A technology of robot joints and positioning devices, which is applied in the direction of manipulators, program-controlled manipulators, joints, etc., which can solve the problems of low precision, joint working space less than 360 degrees, and inability to solve joint electrical wiring, etc., to improve zero positioning Accuracy and automation, and the effect of reducing the chance of electrical wires being entangled in mechanical joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

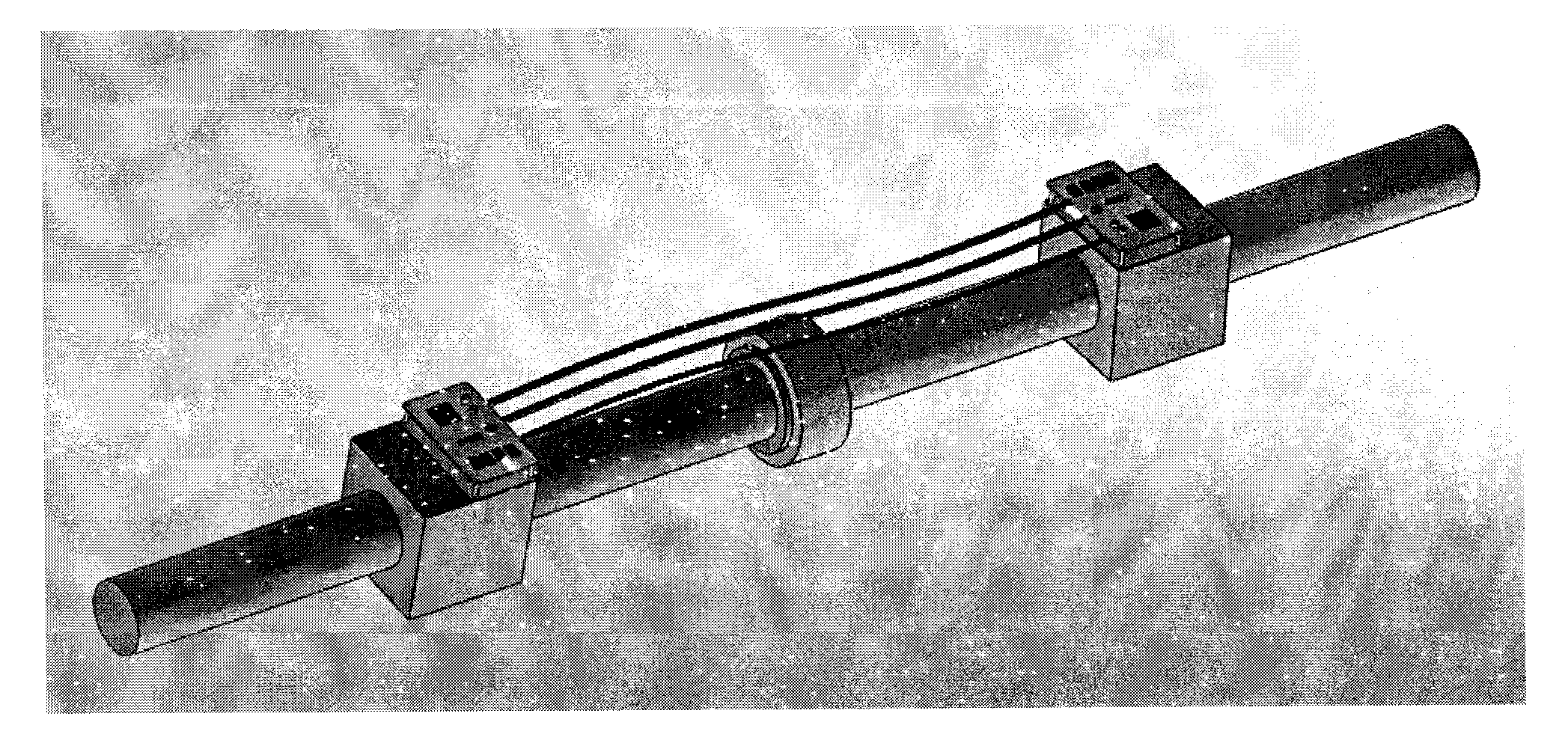

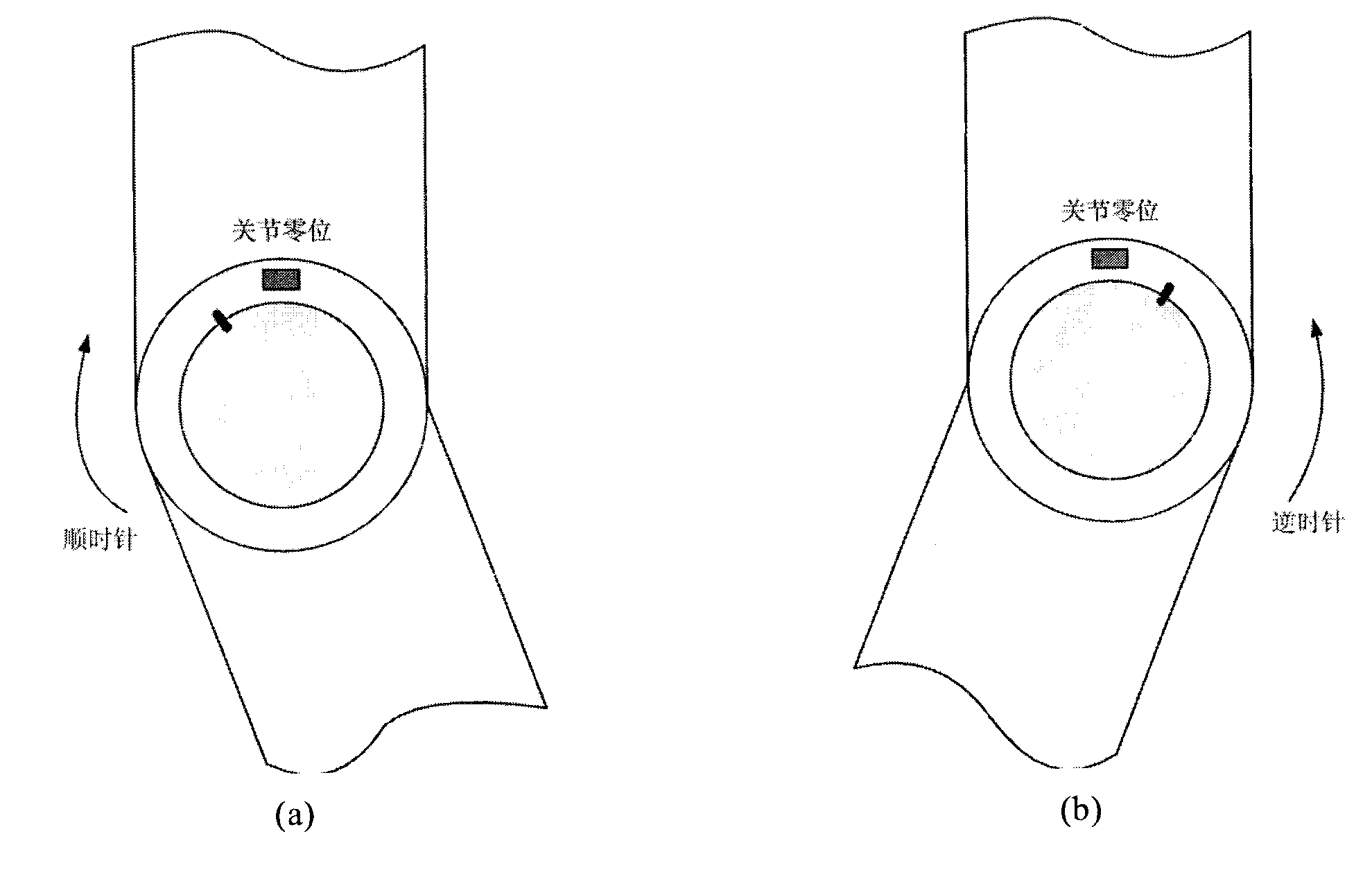

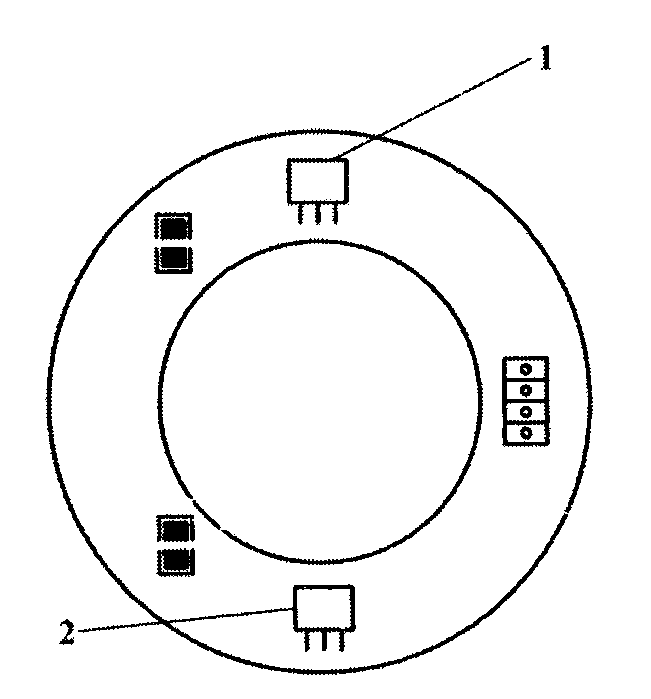

[0044] Such as figure 1 As shown, the positioning device includes: zero Hall switch, limit Hall switch, and magnetic steel. Among them, the zero Hall switch, the limit Hall switch and the auxiliary circuit are made into a ring circuit according to the size of the joint, which is called a Hall plate, such as image 3 shown. At the same time, the incremental encoder and the controller at the joint of the robot are required to cooperate. The system composition is as follows: Figure 4 shown. The joint controller determines the motion and position of the joint through the feedback signal of the Hall switch and the incremental encoder. Figure 5 It is a system structure diagram, in which the joint connects the first connecting rod 4 and the second connecting rod 5, and the motor realizes the movement of the second connecting rod 5 by driving the joint rotation; the encoder is connected with the motor shaft, accurately records the rotation angle of the motor and feeds it back to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com