Optical fiber field connector

A connector and optical fiber technology, applied in the field of optical fiber field connectors and their installation components, can solve problems such as non-reusable, scrapped hot-melt protective sleeves, and reduced connection quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

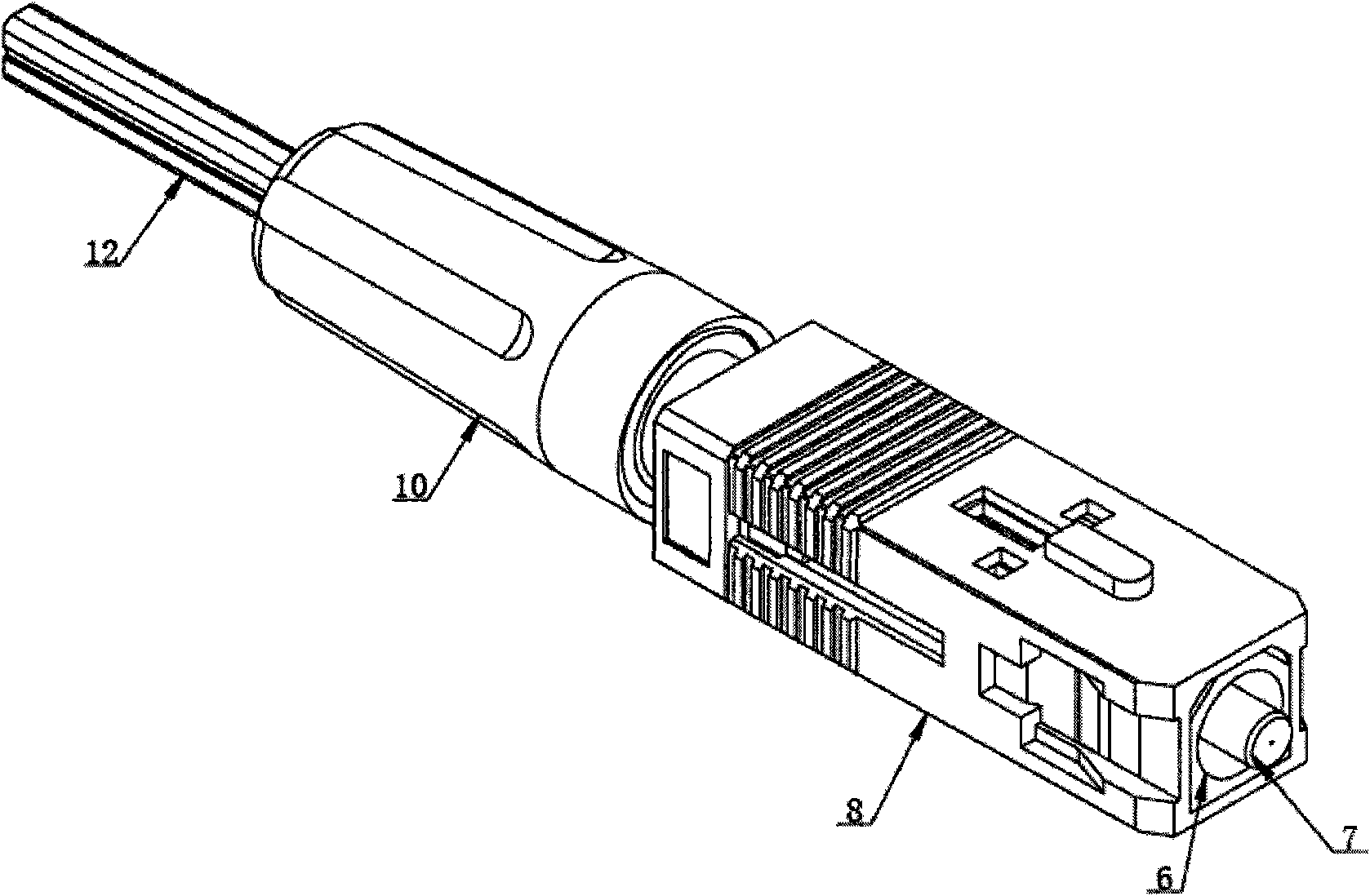

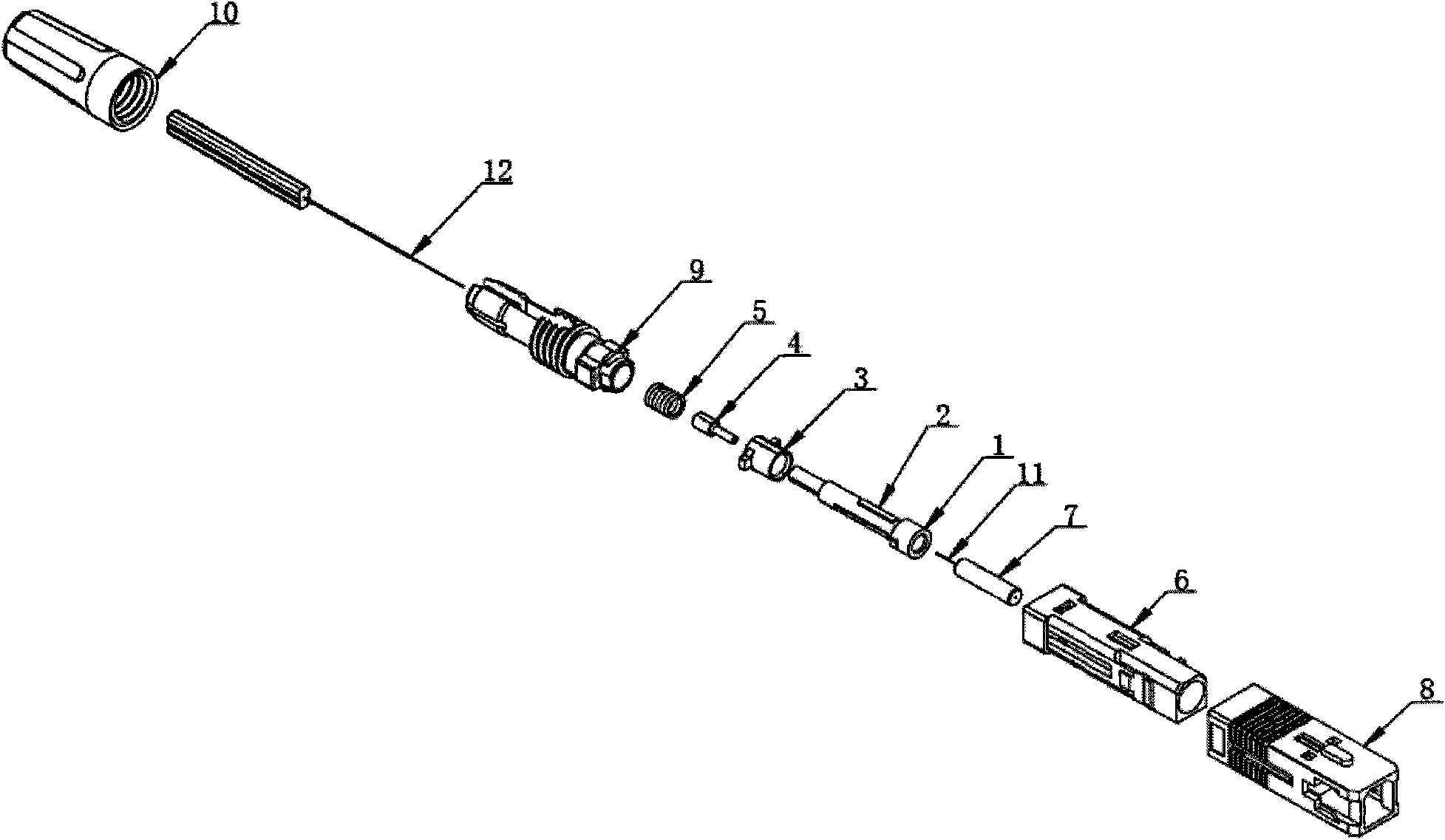

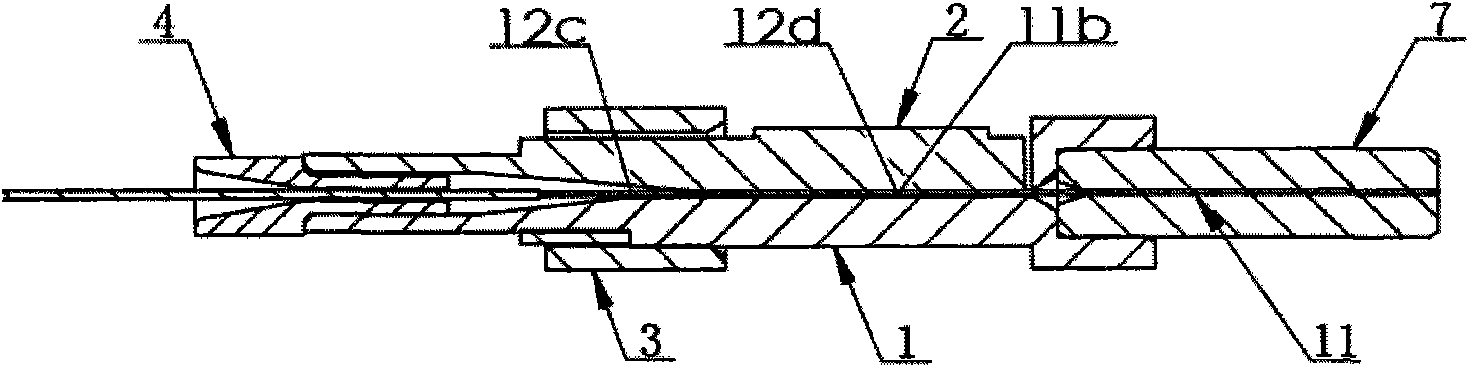

[0081] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0082] While the invention is susceptible to various changes and substitutions, details thereof have been shown by way of example in the drawings and will be described in detail hereinafter. It should be understood, however, that the intention is not to limit the invention to the particular embodiments described. On the contrary, the intention is to cover all modifications, equivalents, and alternatives falling within the scope of the invention as defined by the appended claims.

[0083] The invention relates to an optical fiber field connector. Specifically, the fiber optic field connector is capable of direct field termination. Assembly time during field termination can also be reduced by using simple mounting components as described in this article. For fiber-to-the-home (FTTH) network installations, the exemplary connectors described herein are simple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com