Patents

Literature

169results about How to "Eliminate deficiencies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

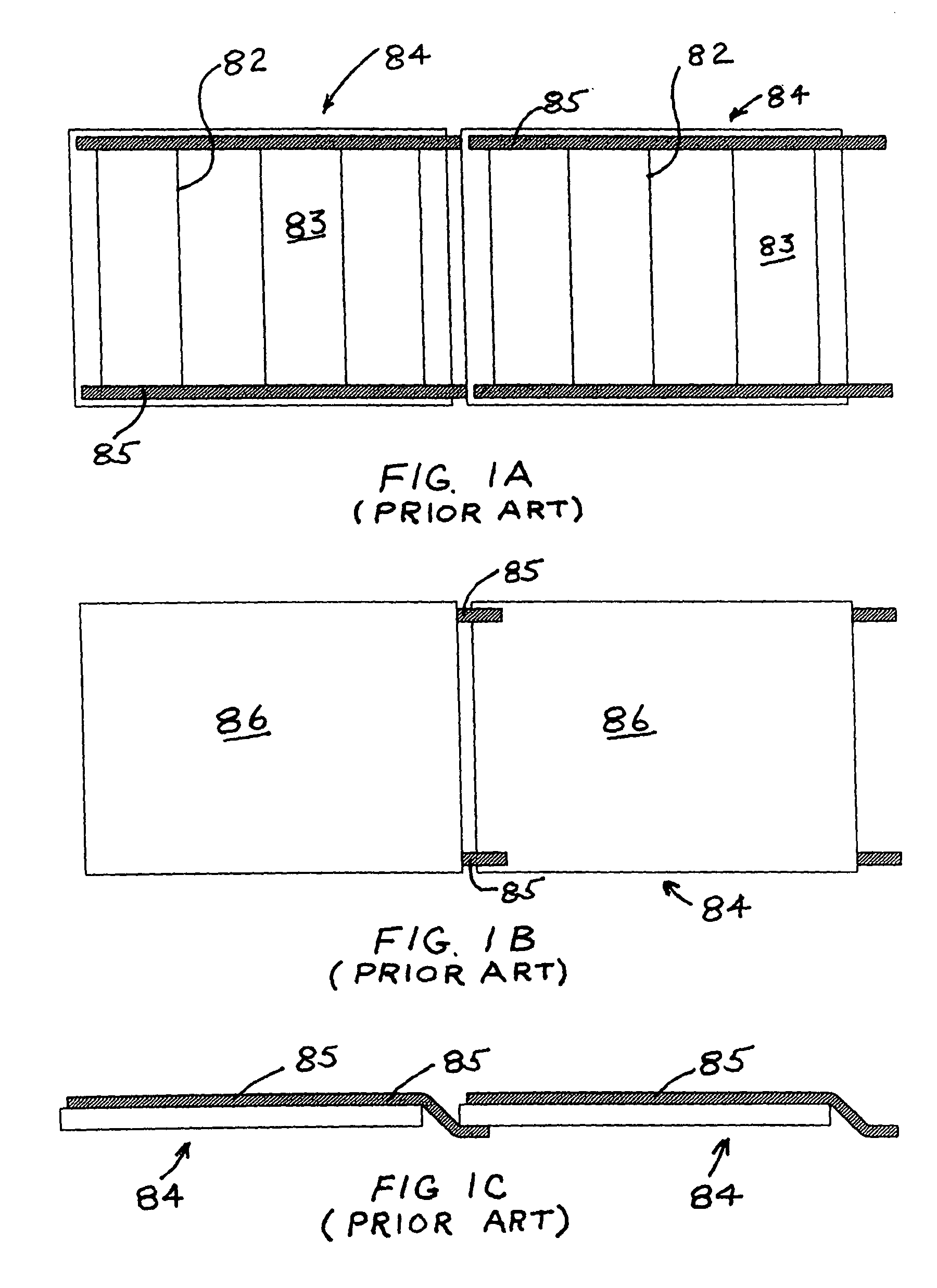

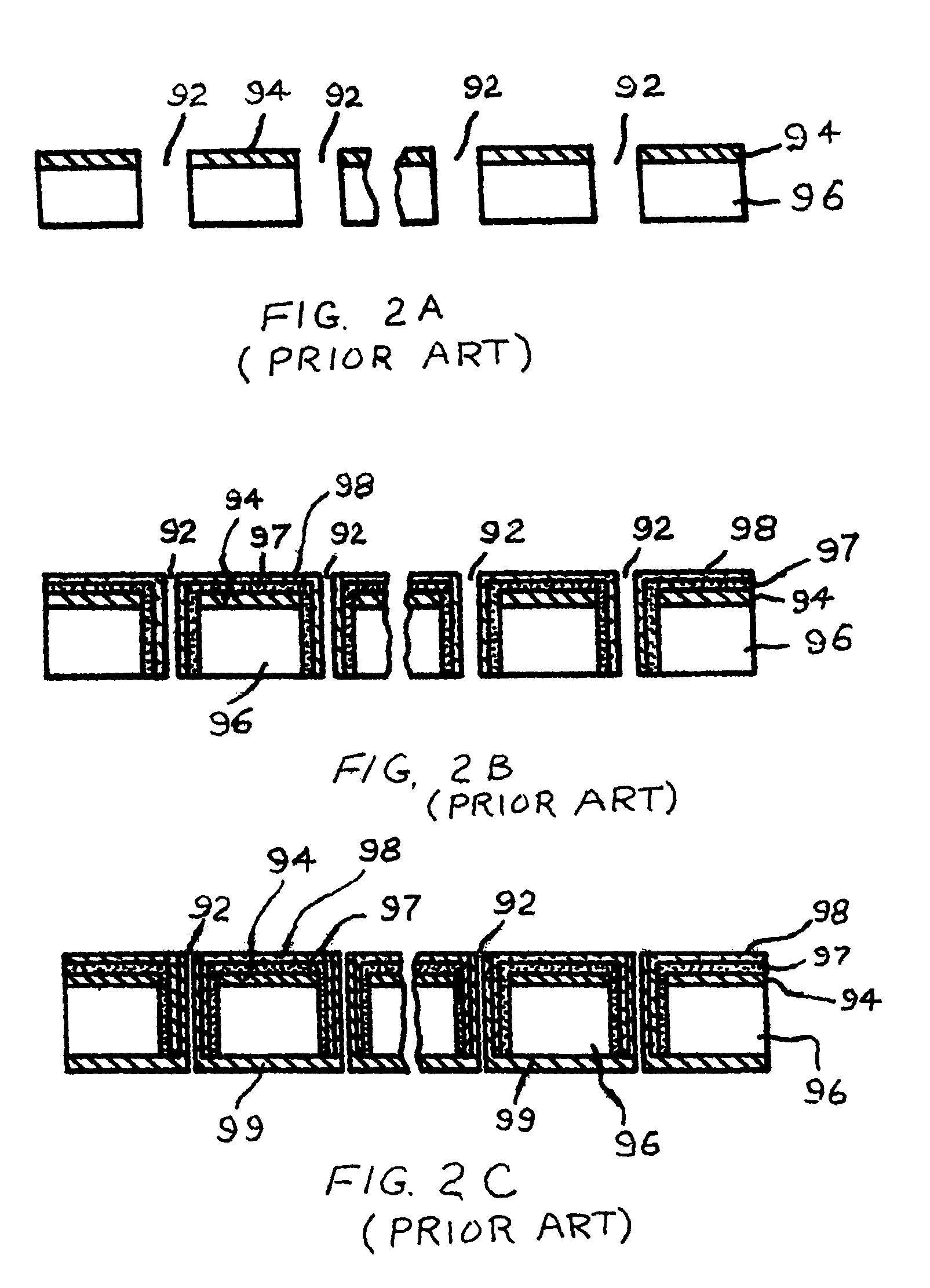

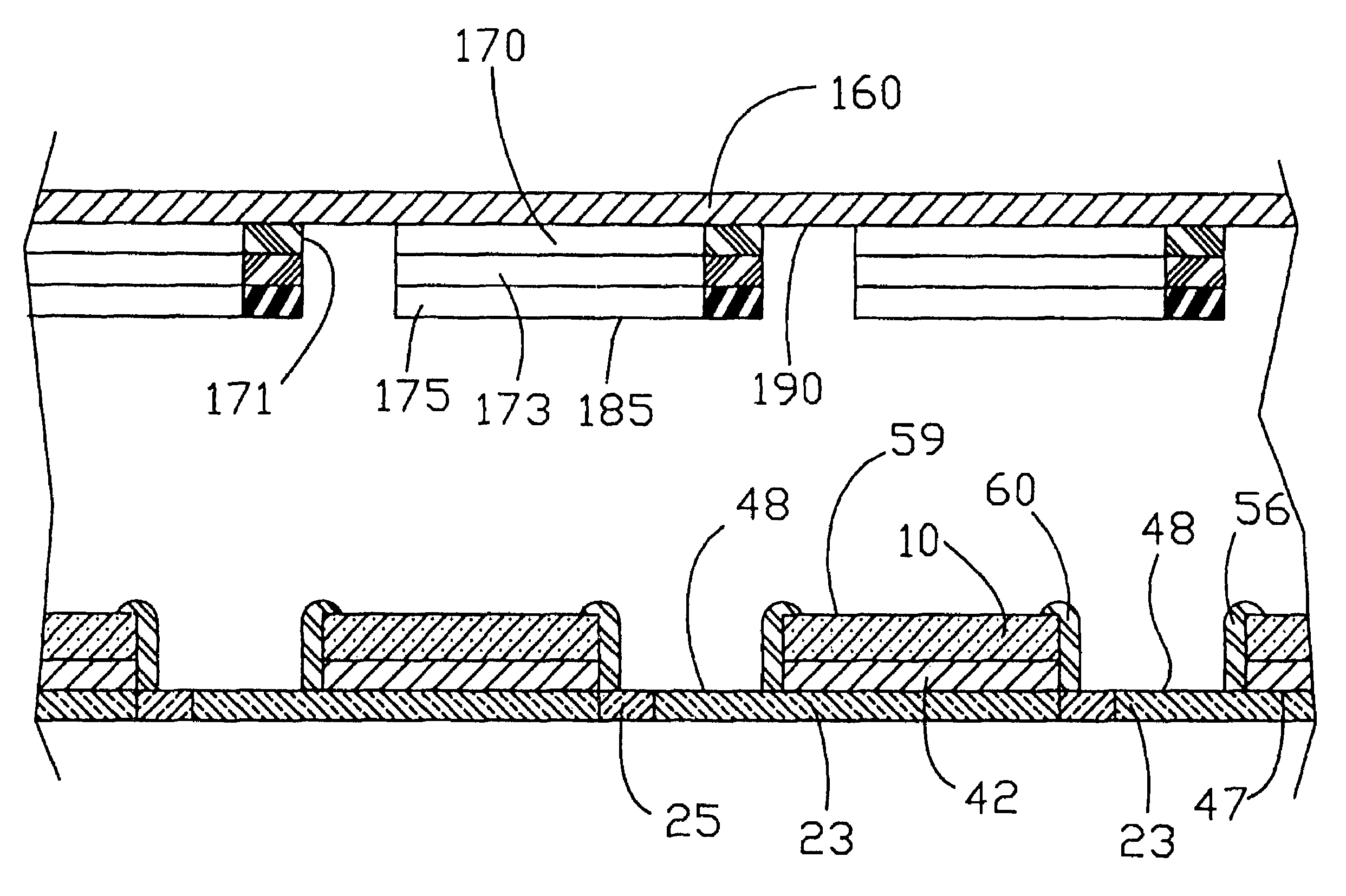

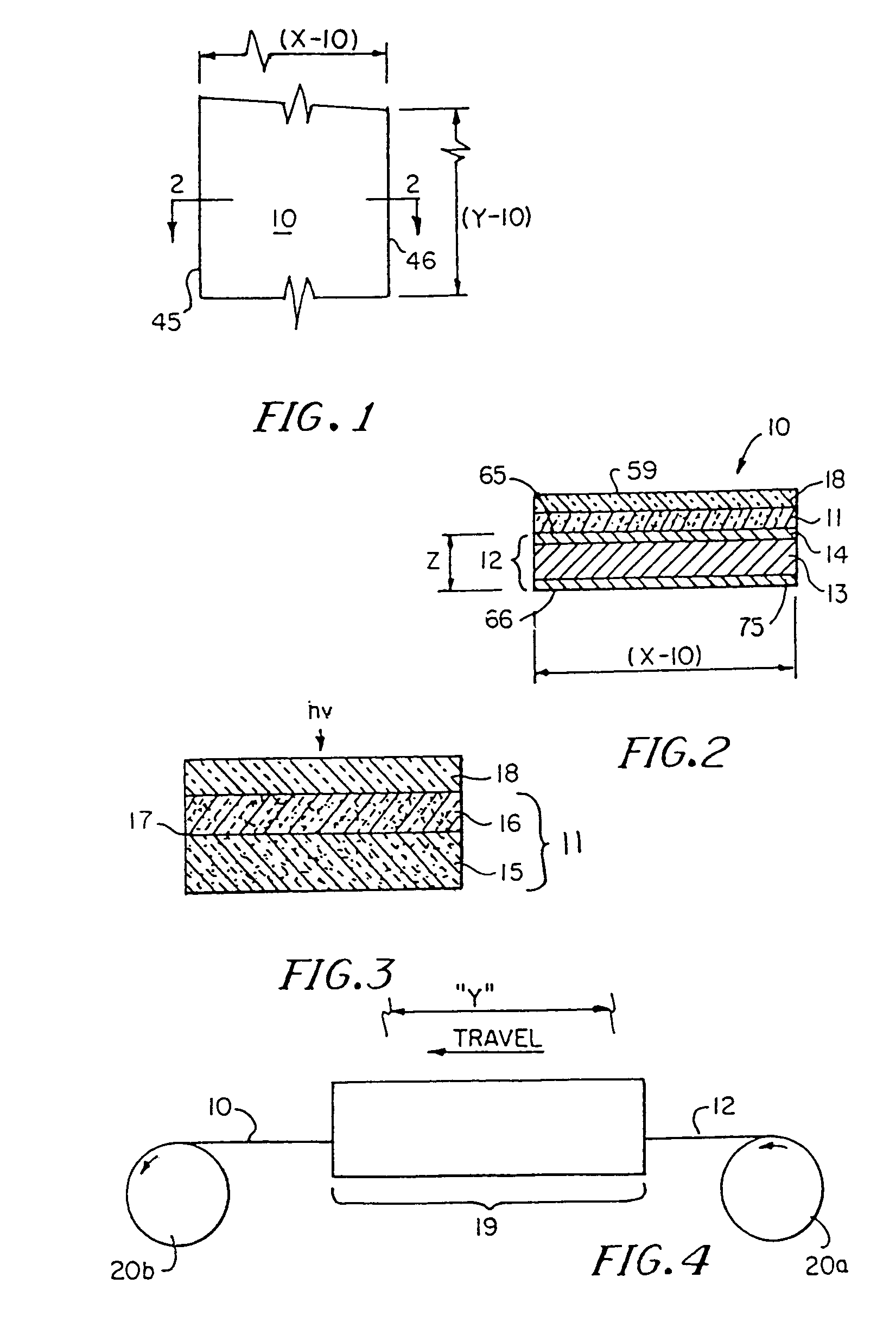

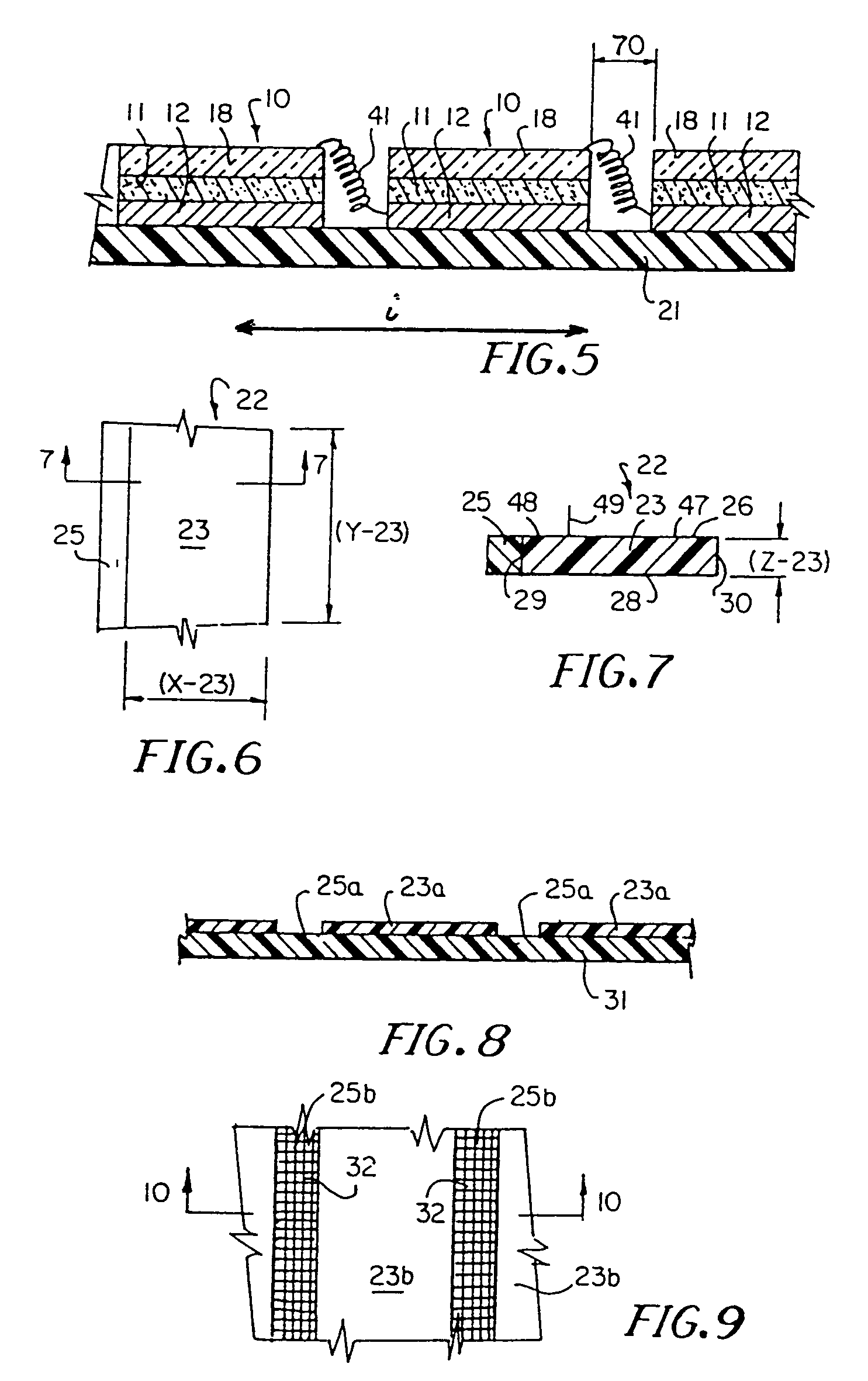

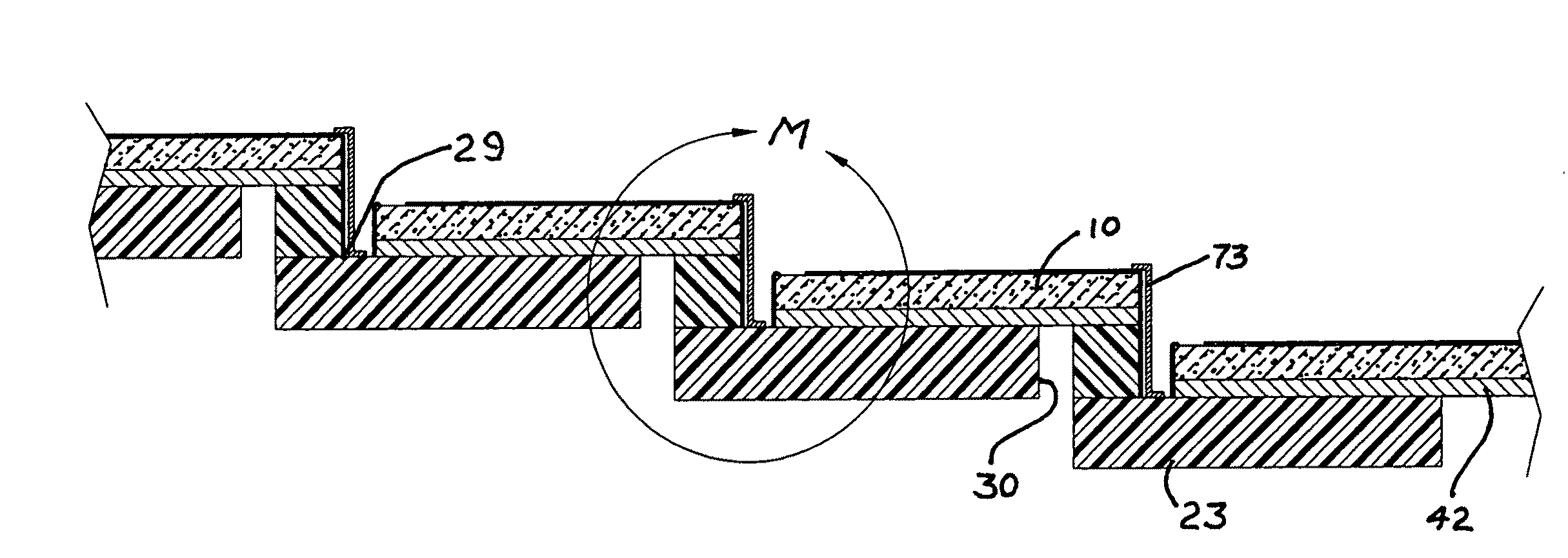

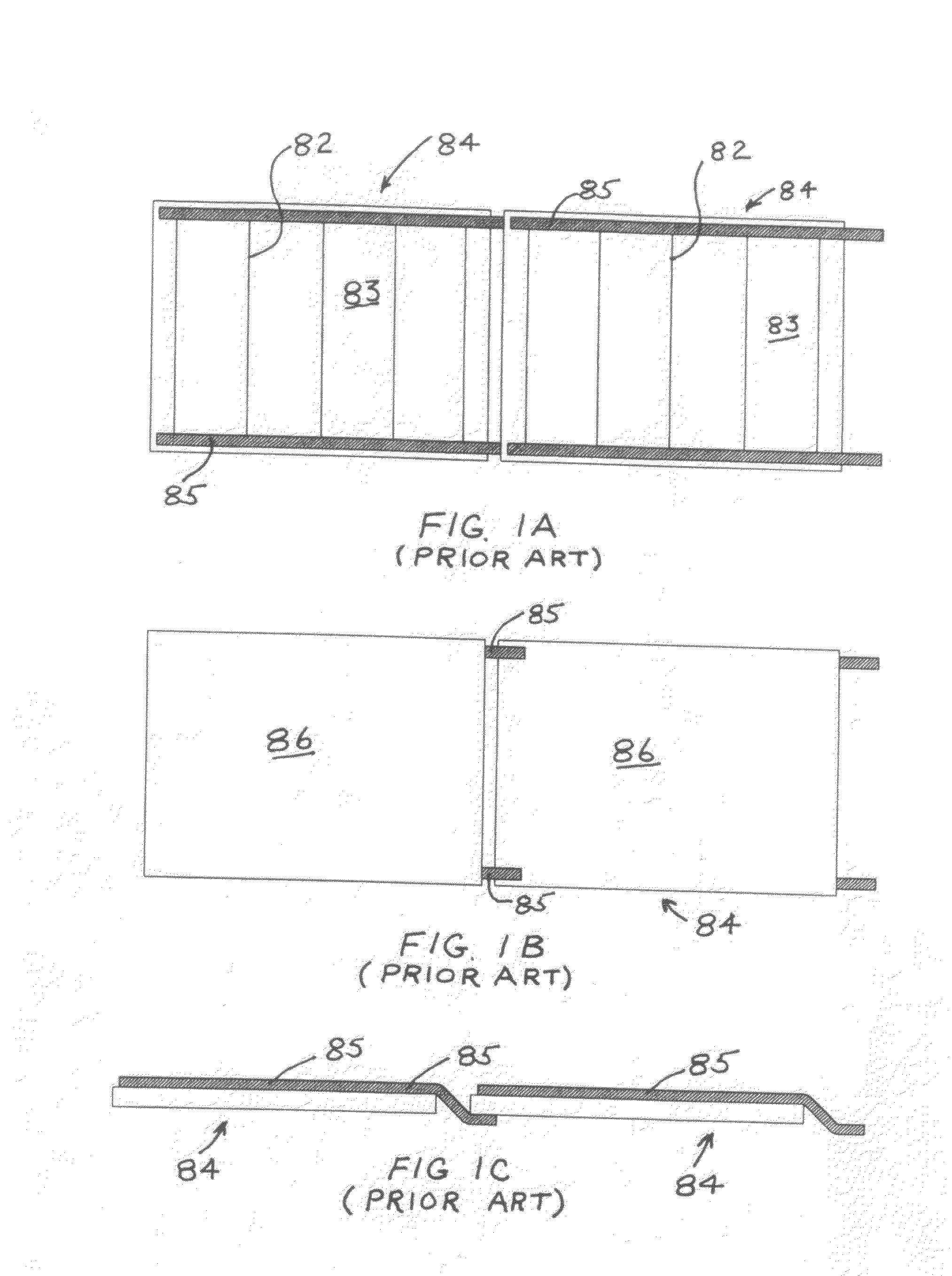

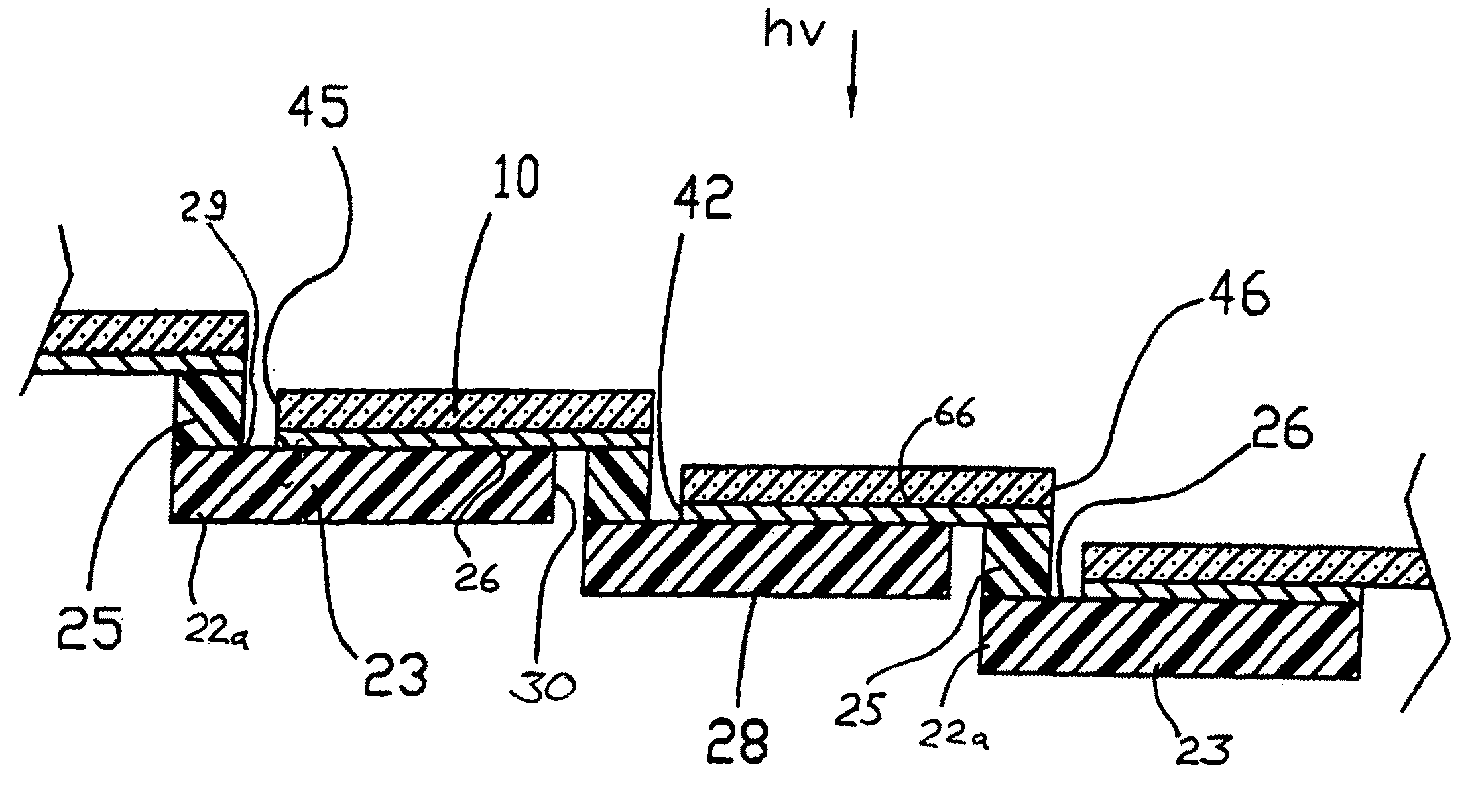

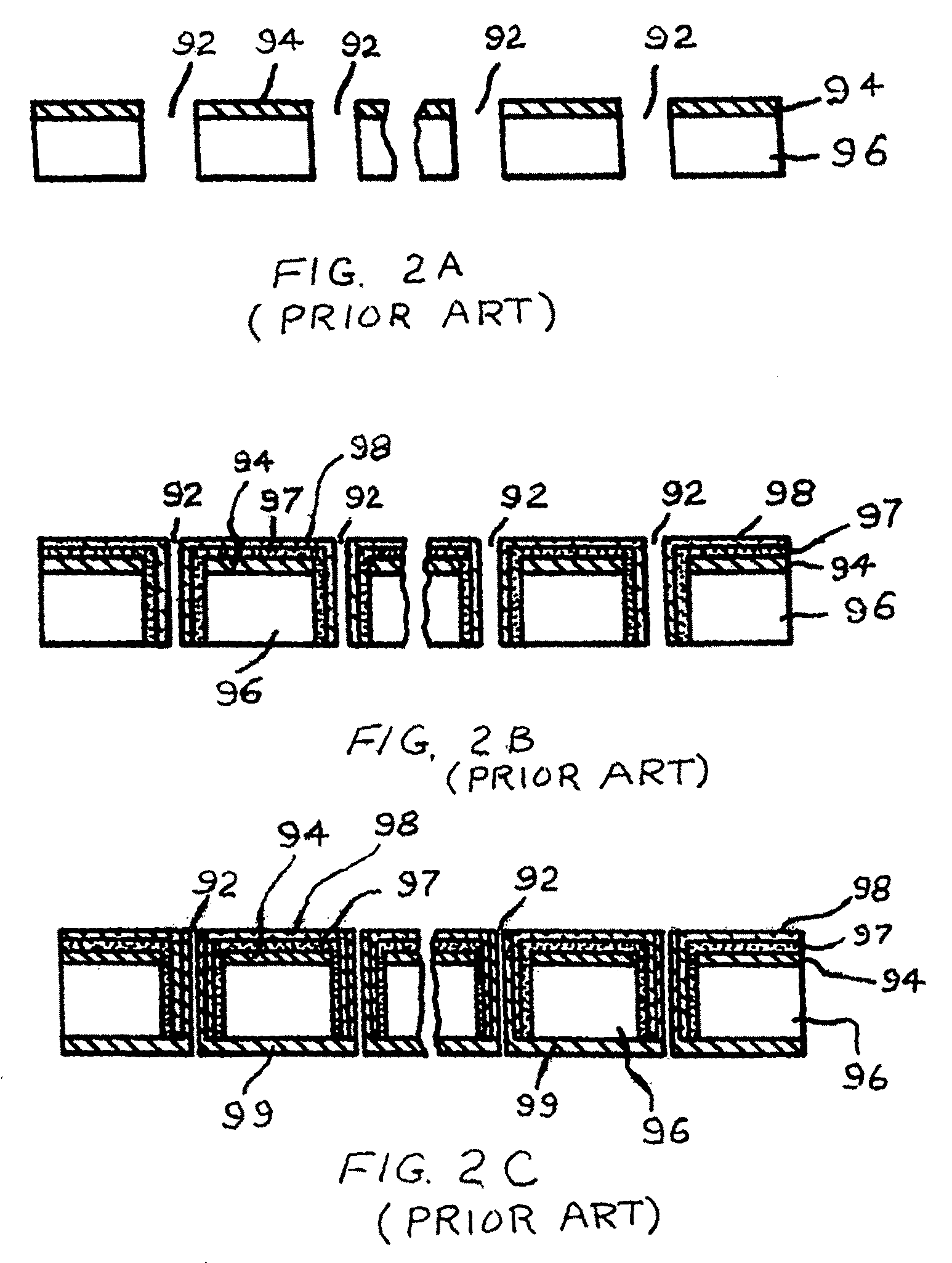

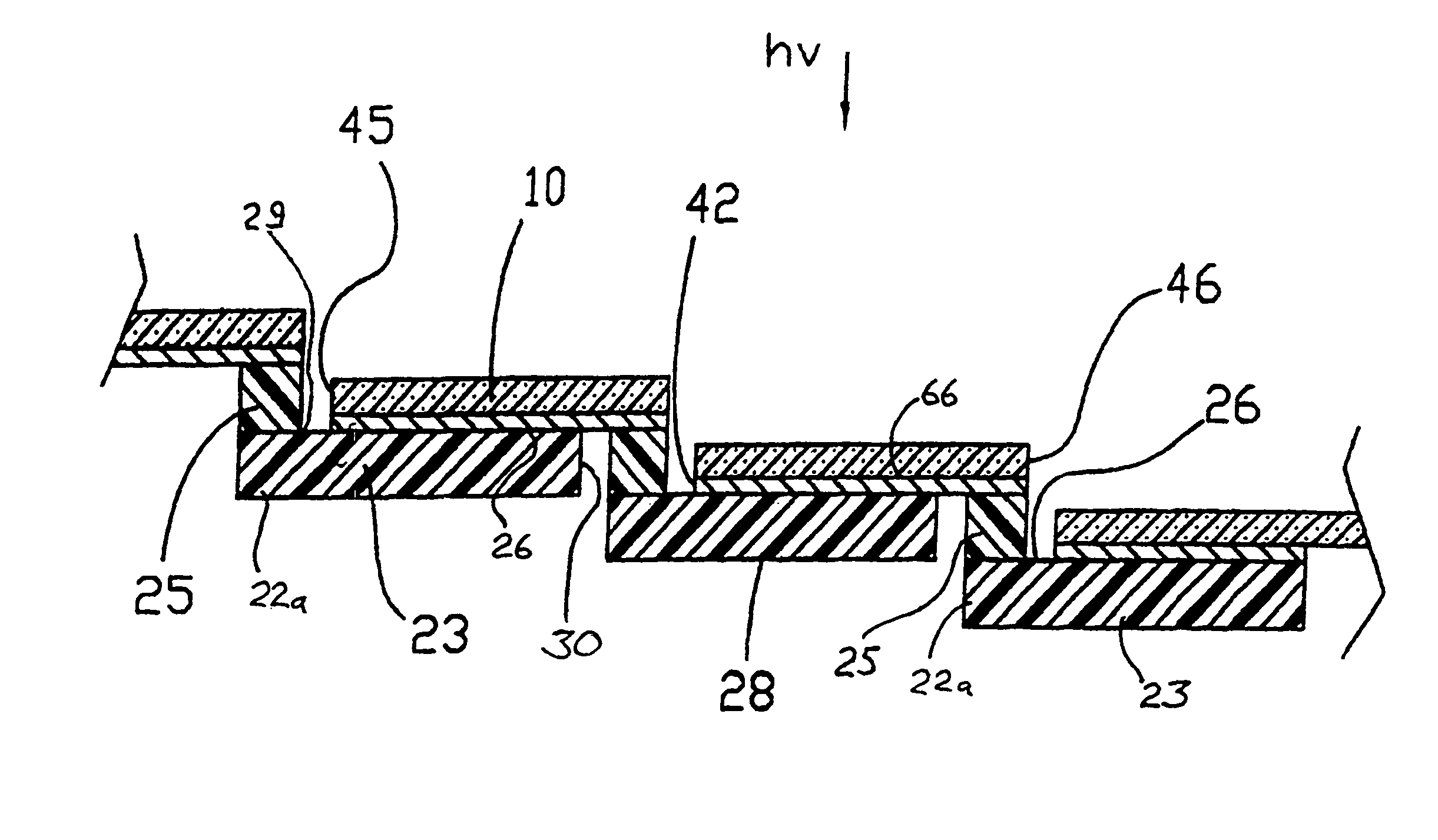

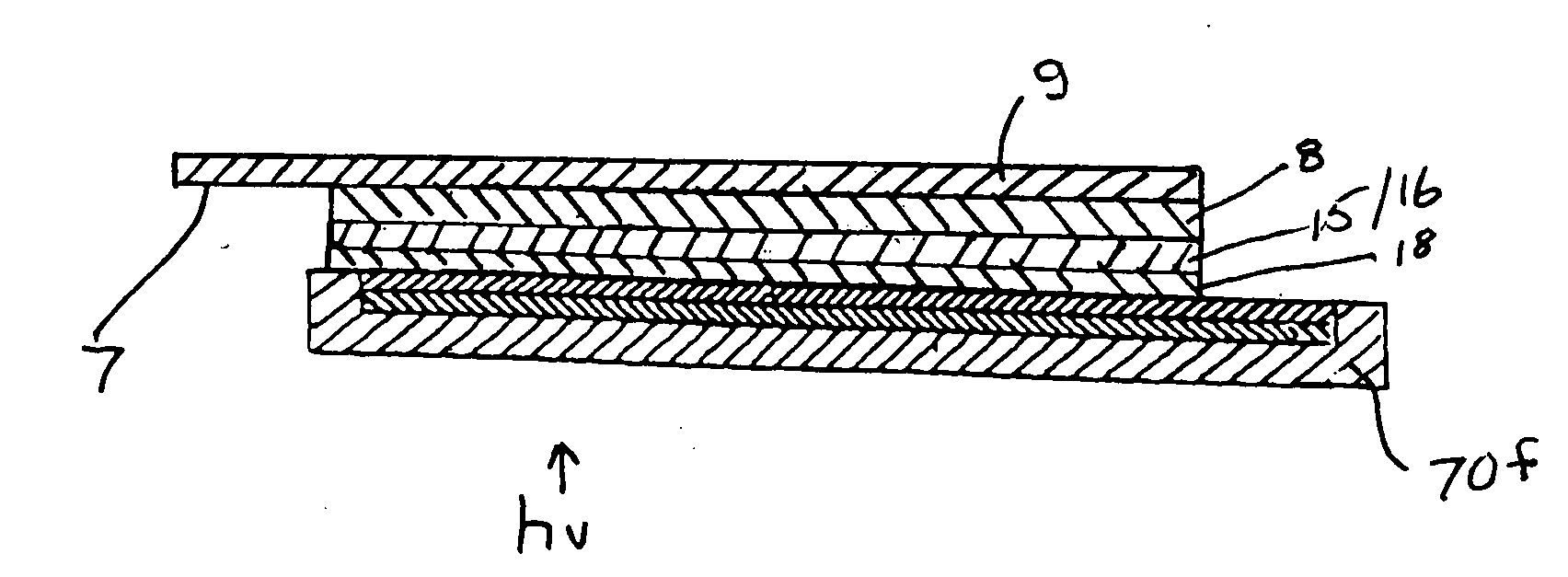

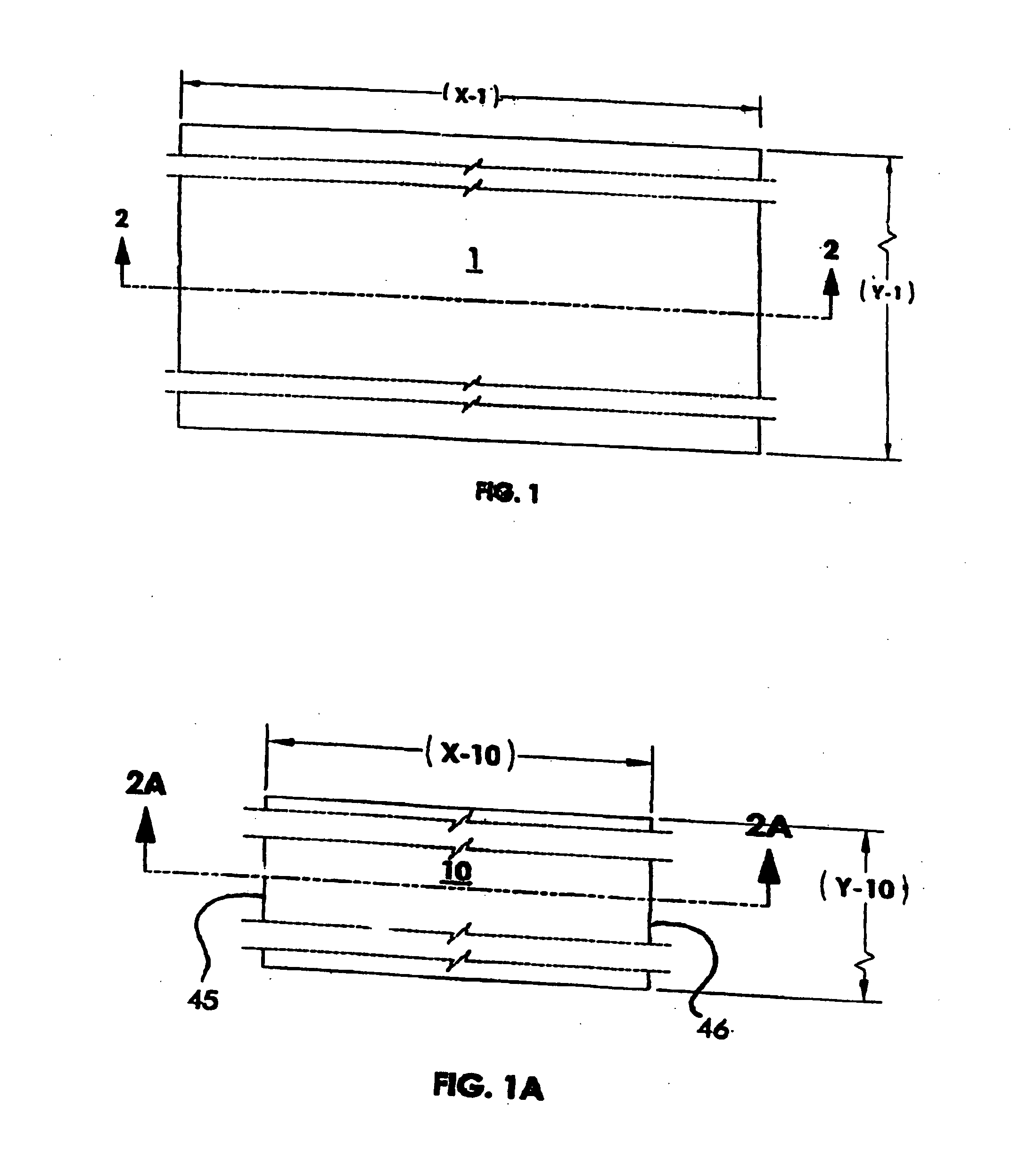

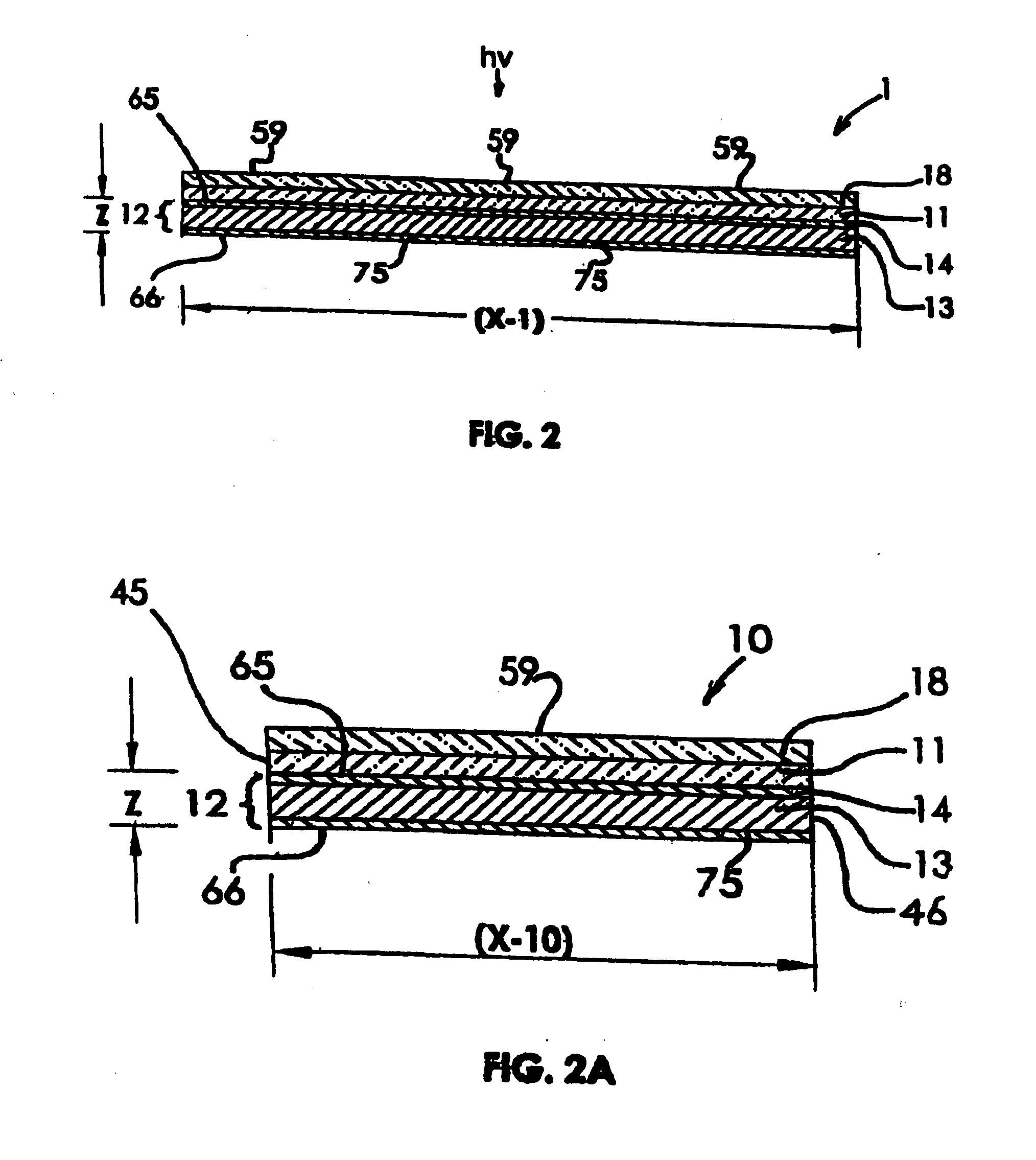

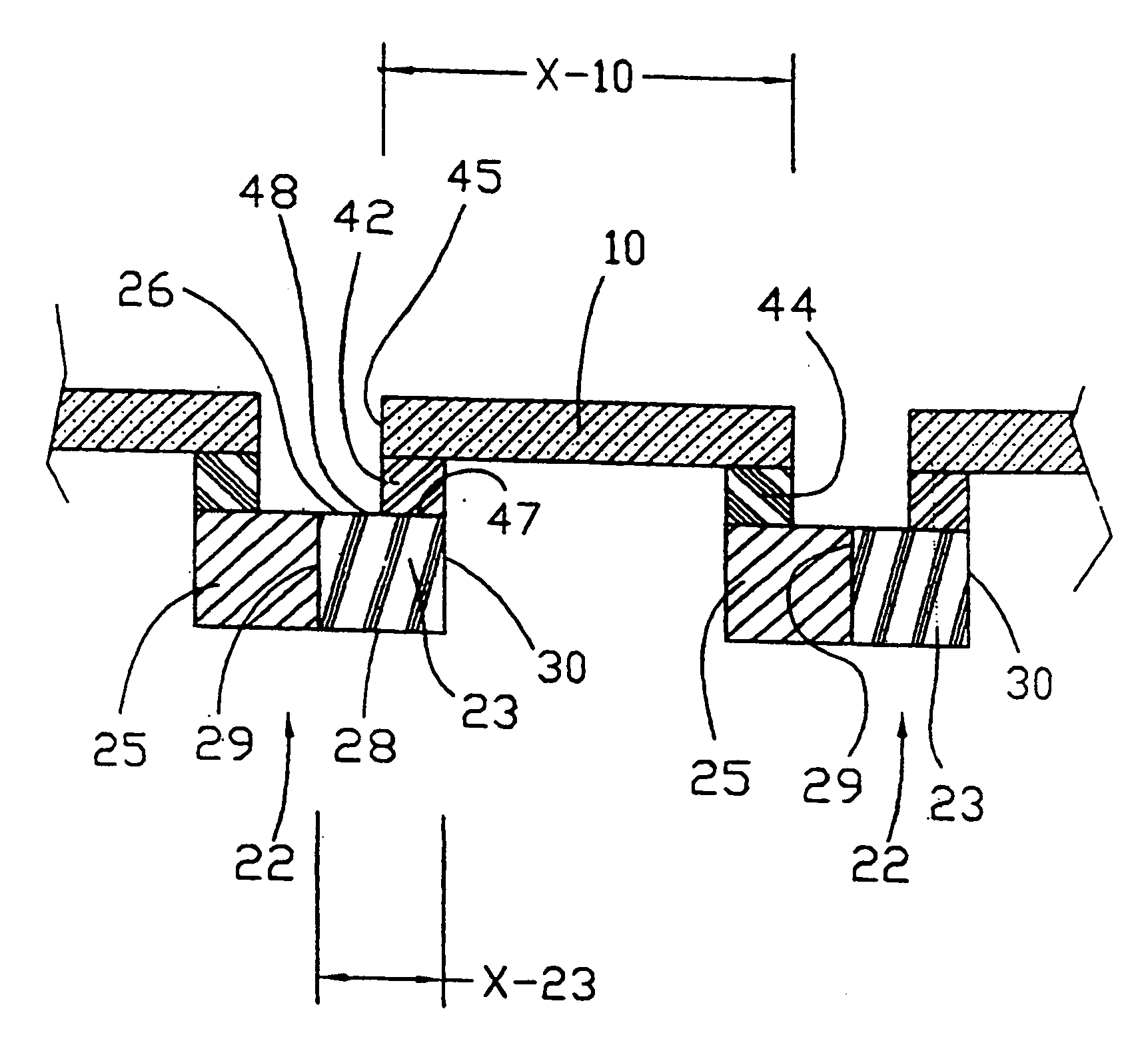

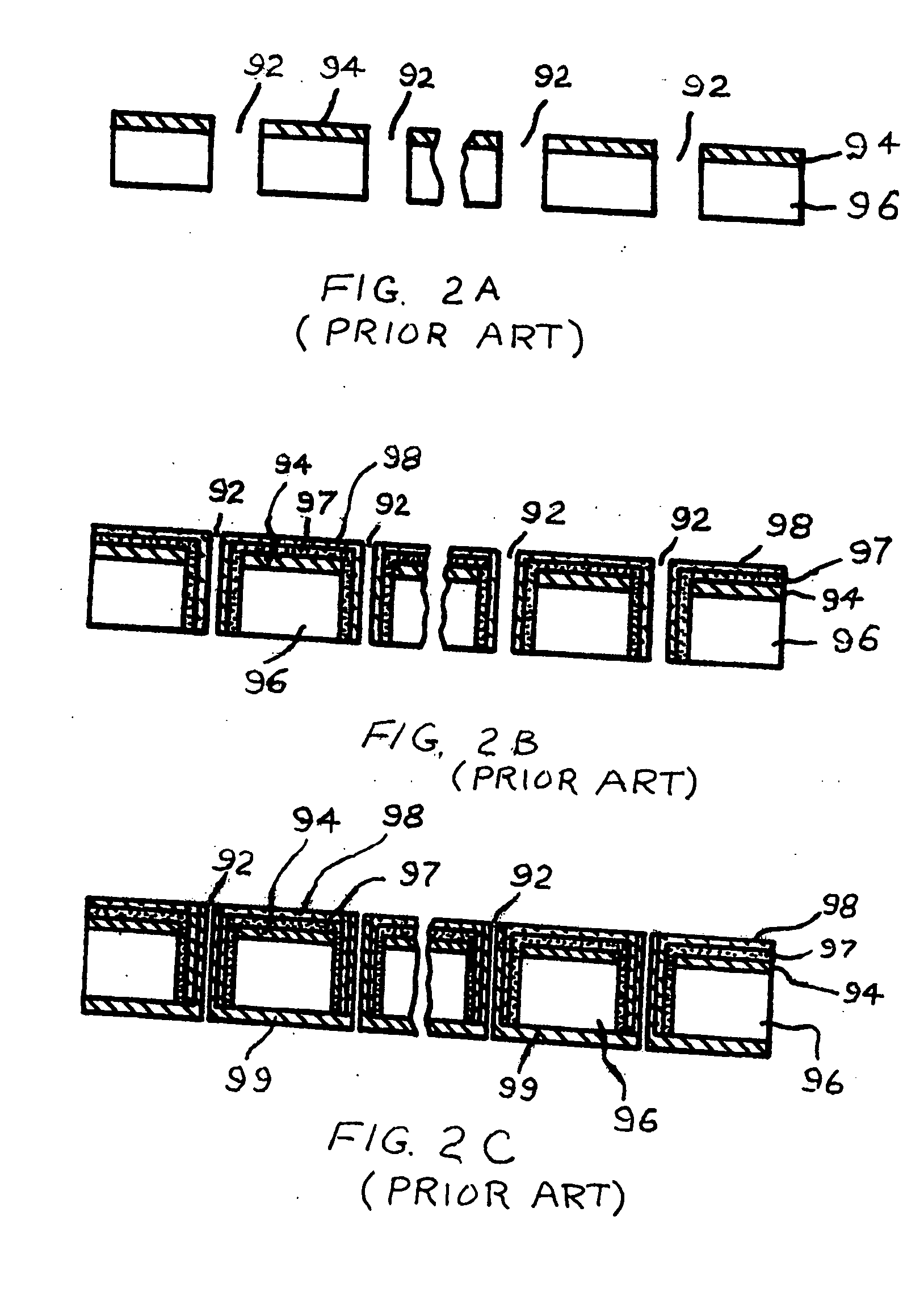

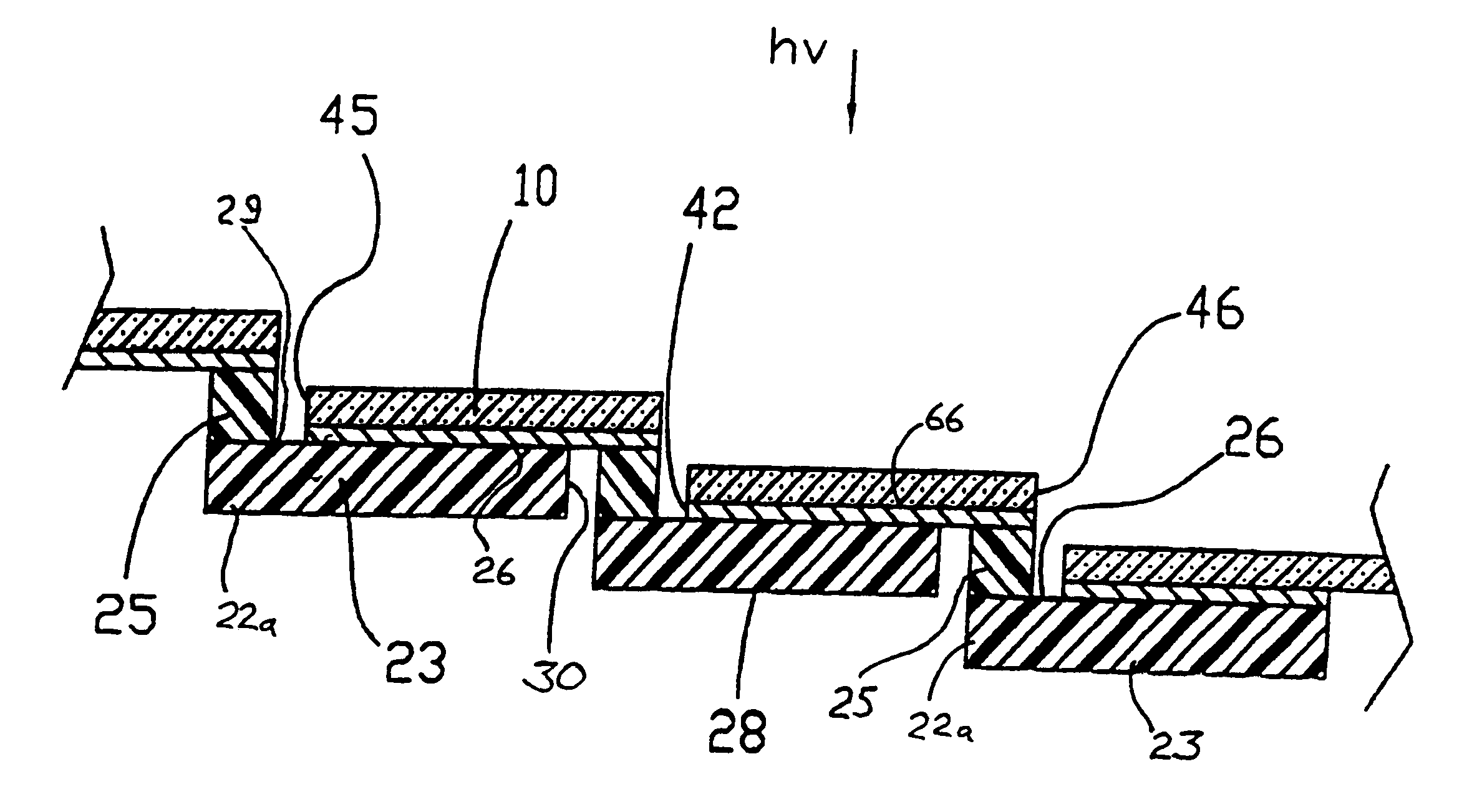

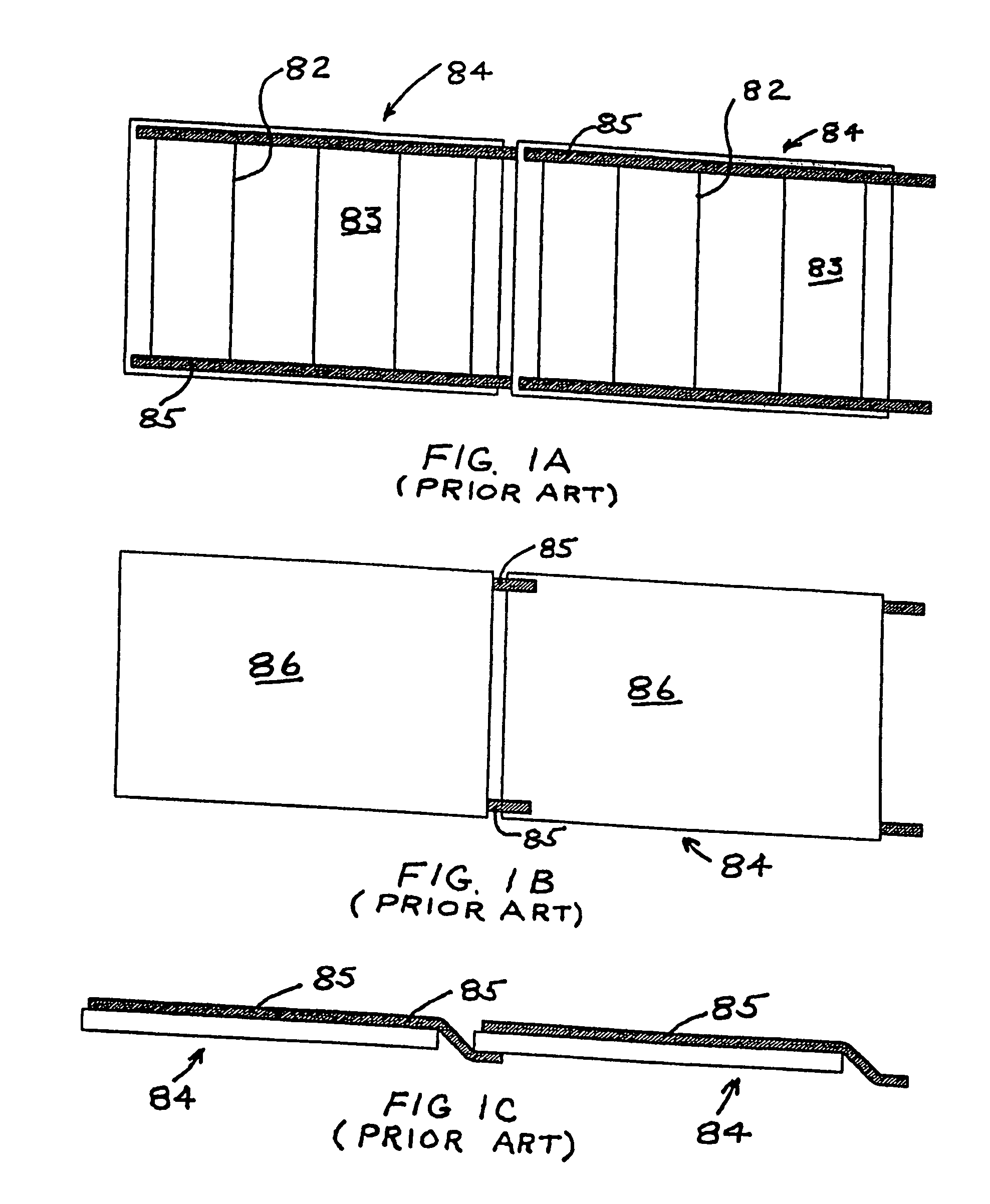

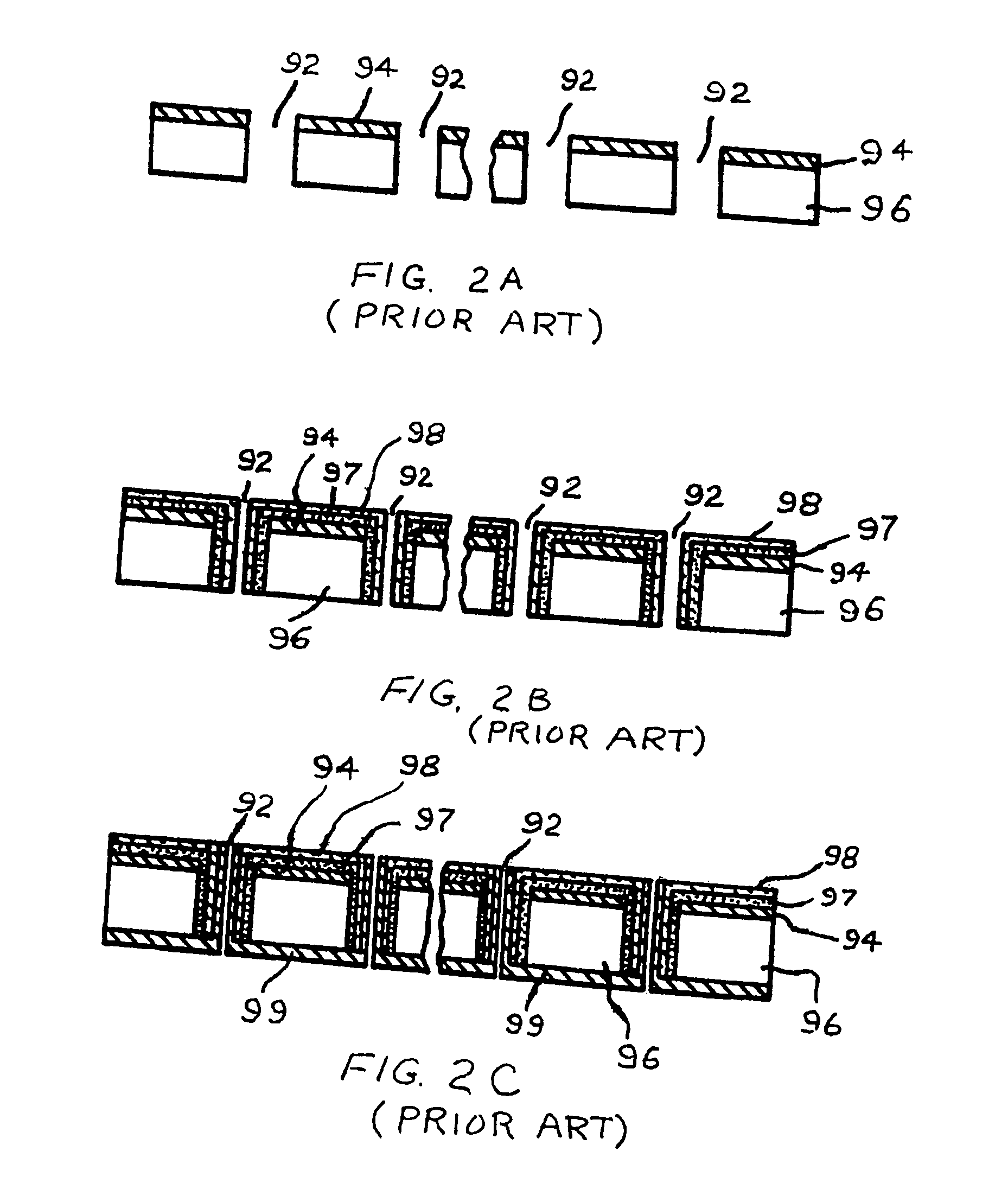

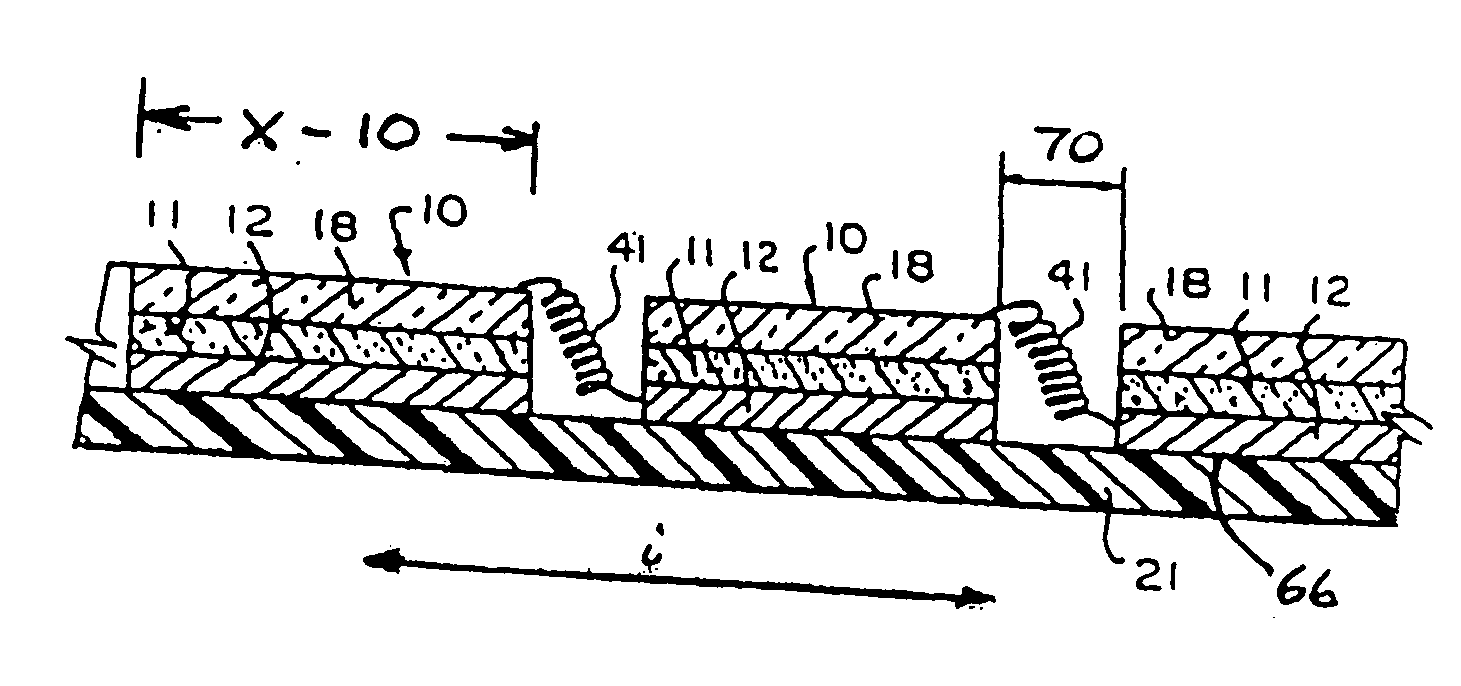

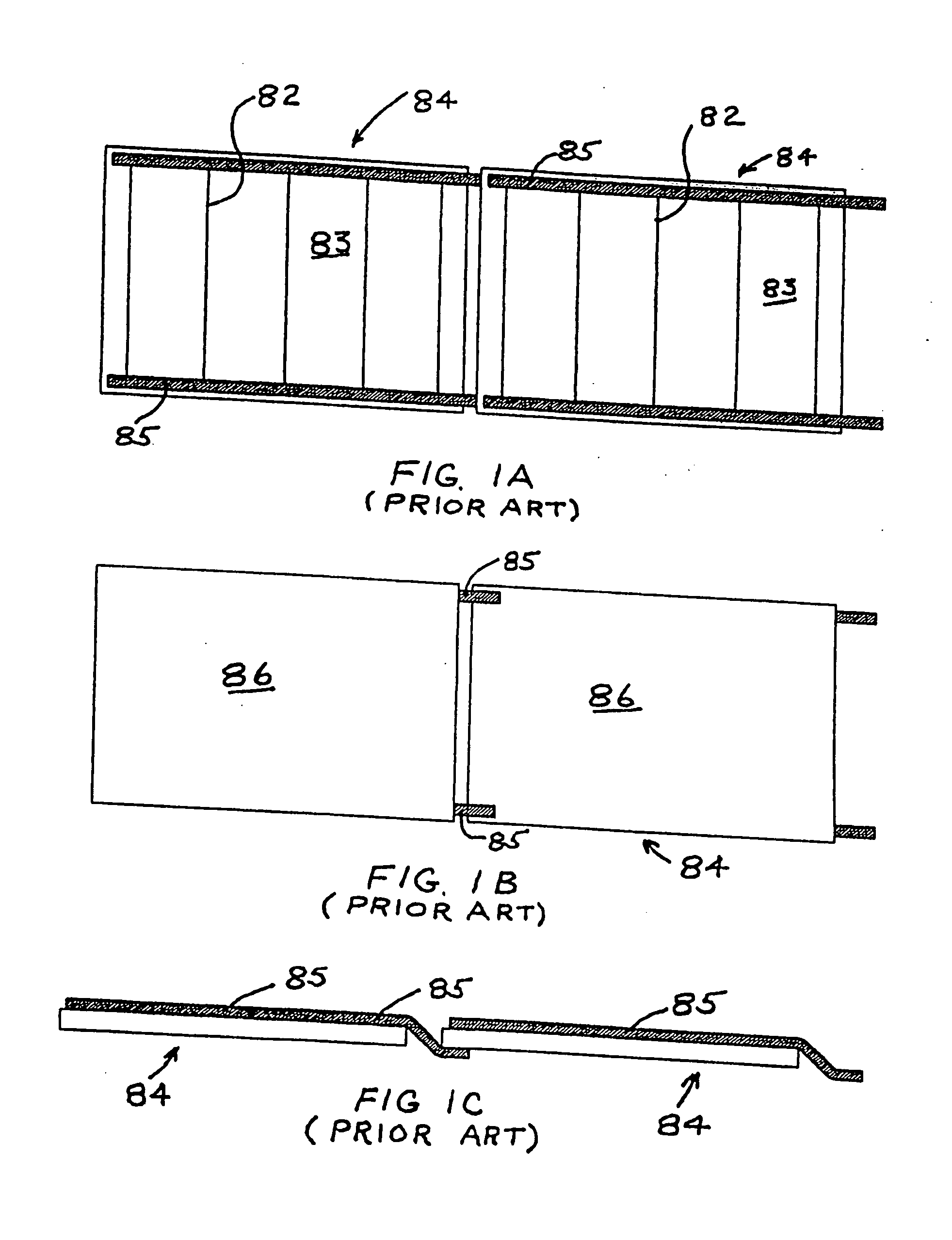

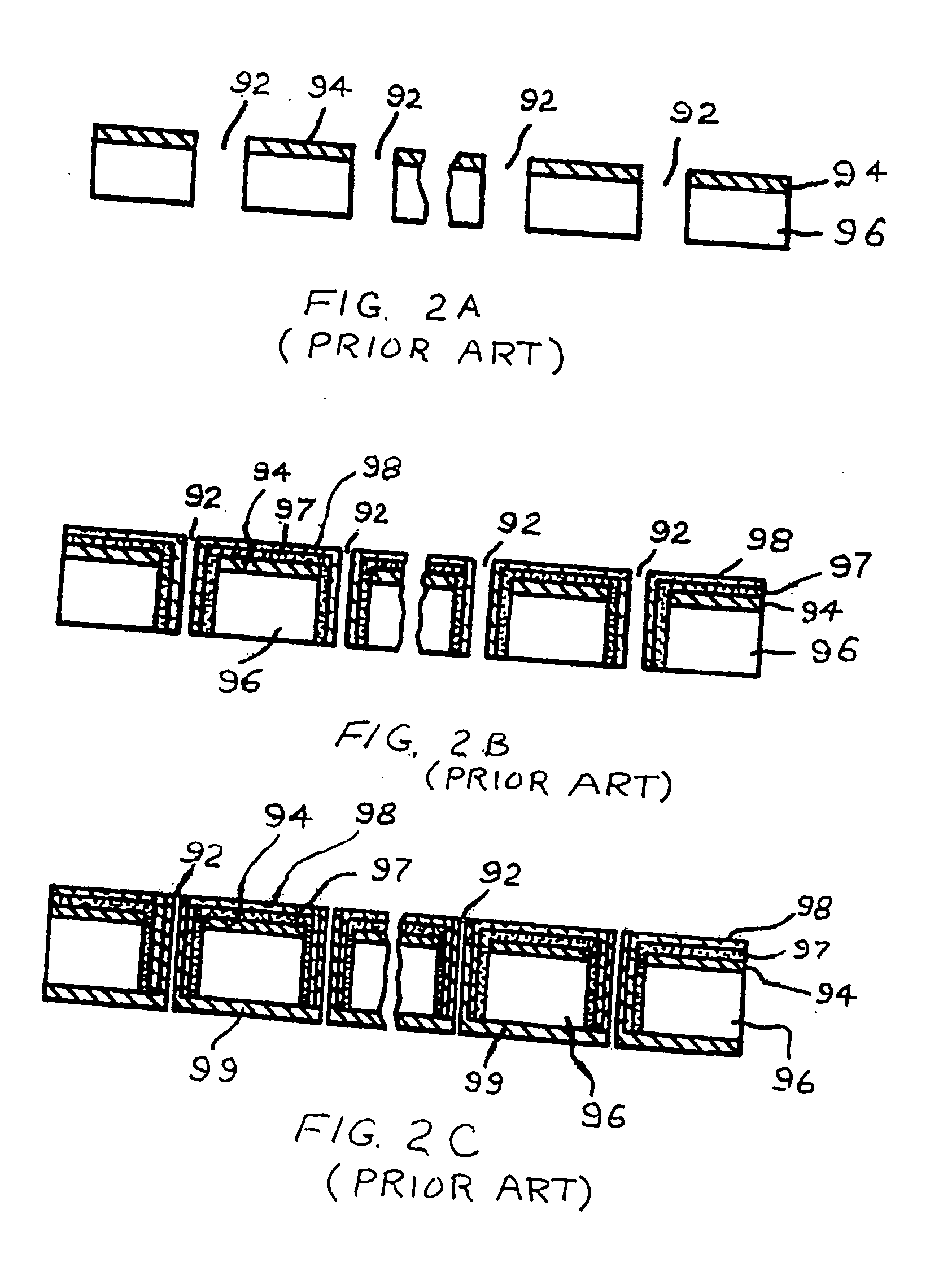

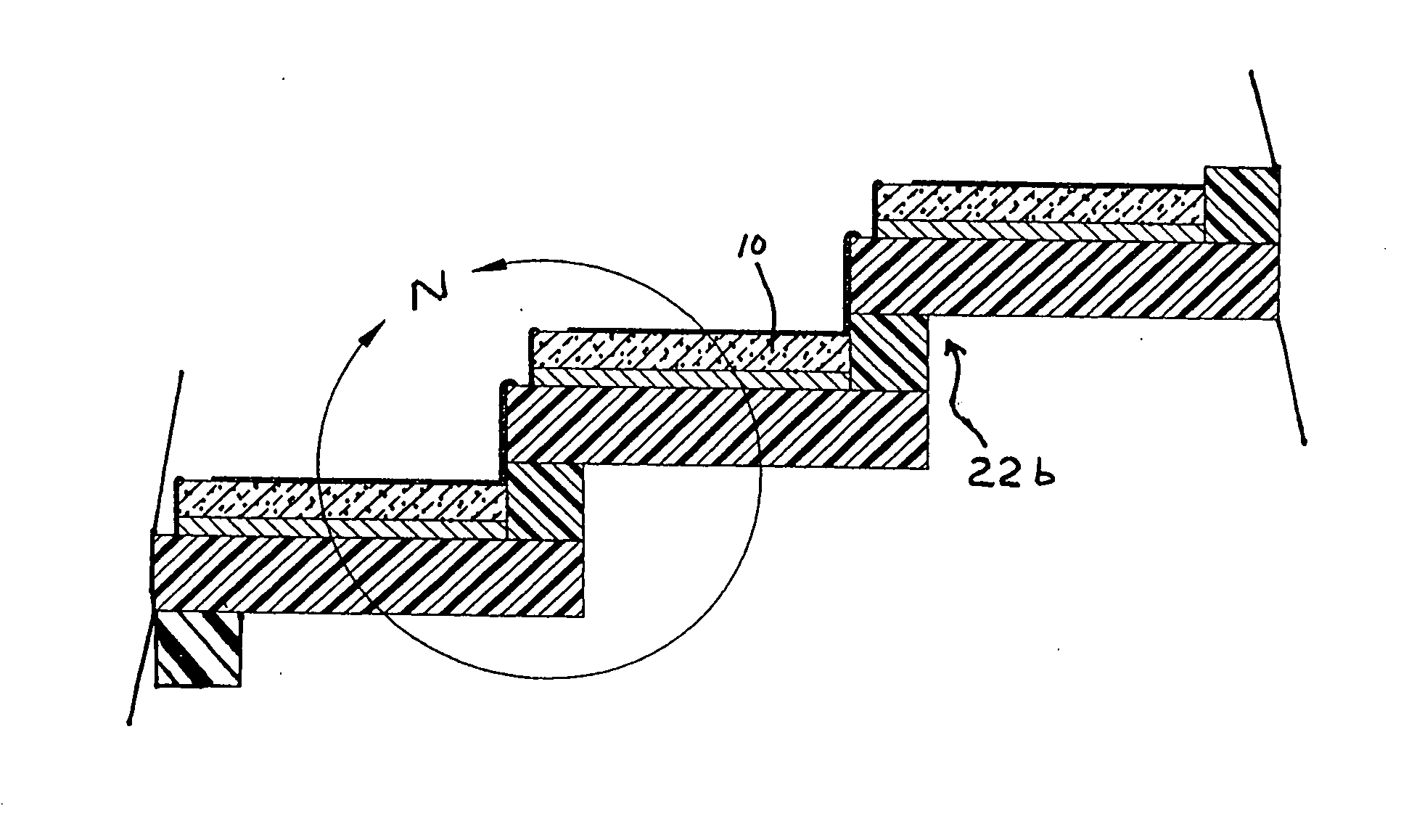

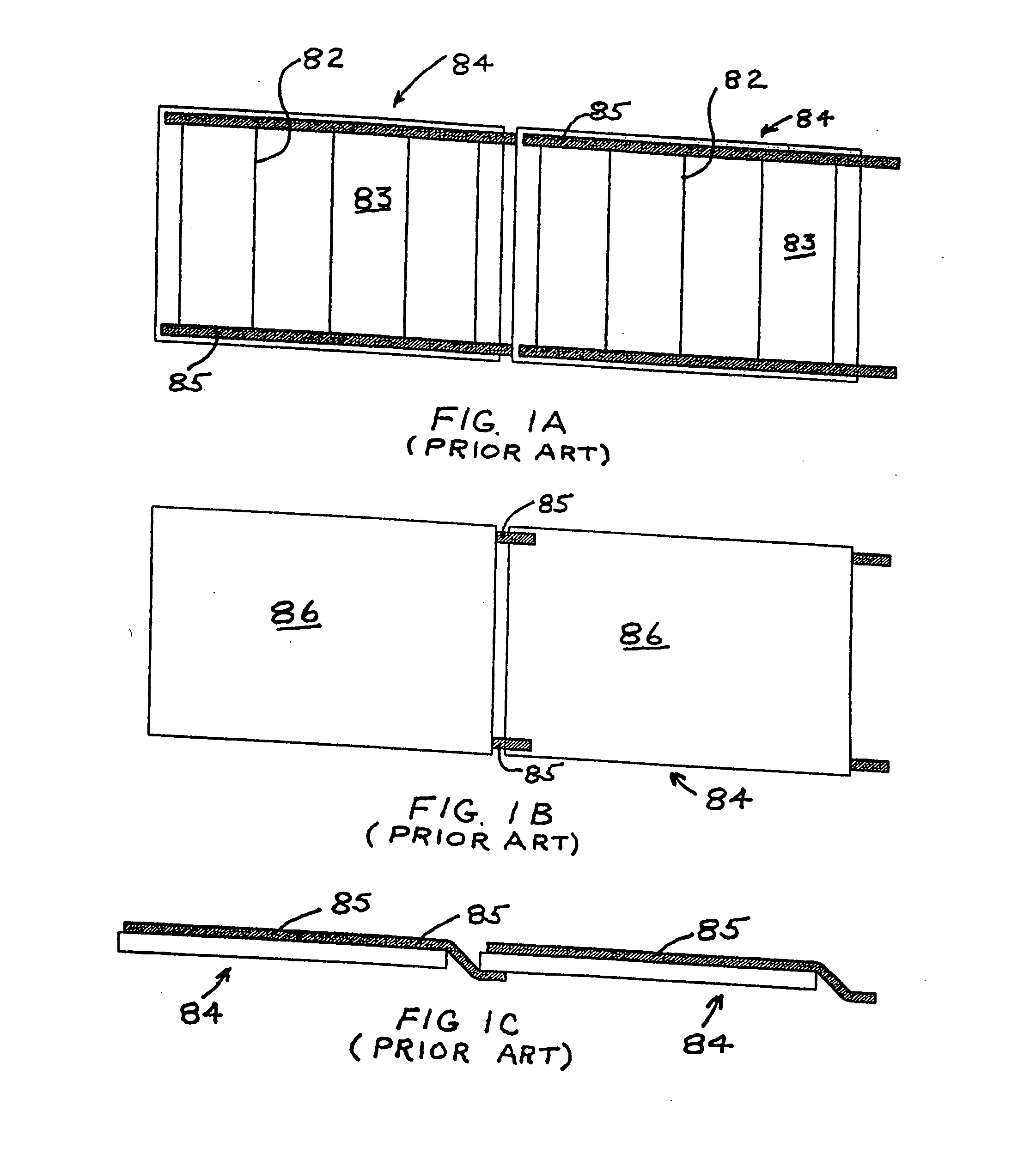

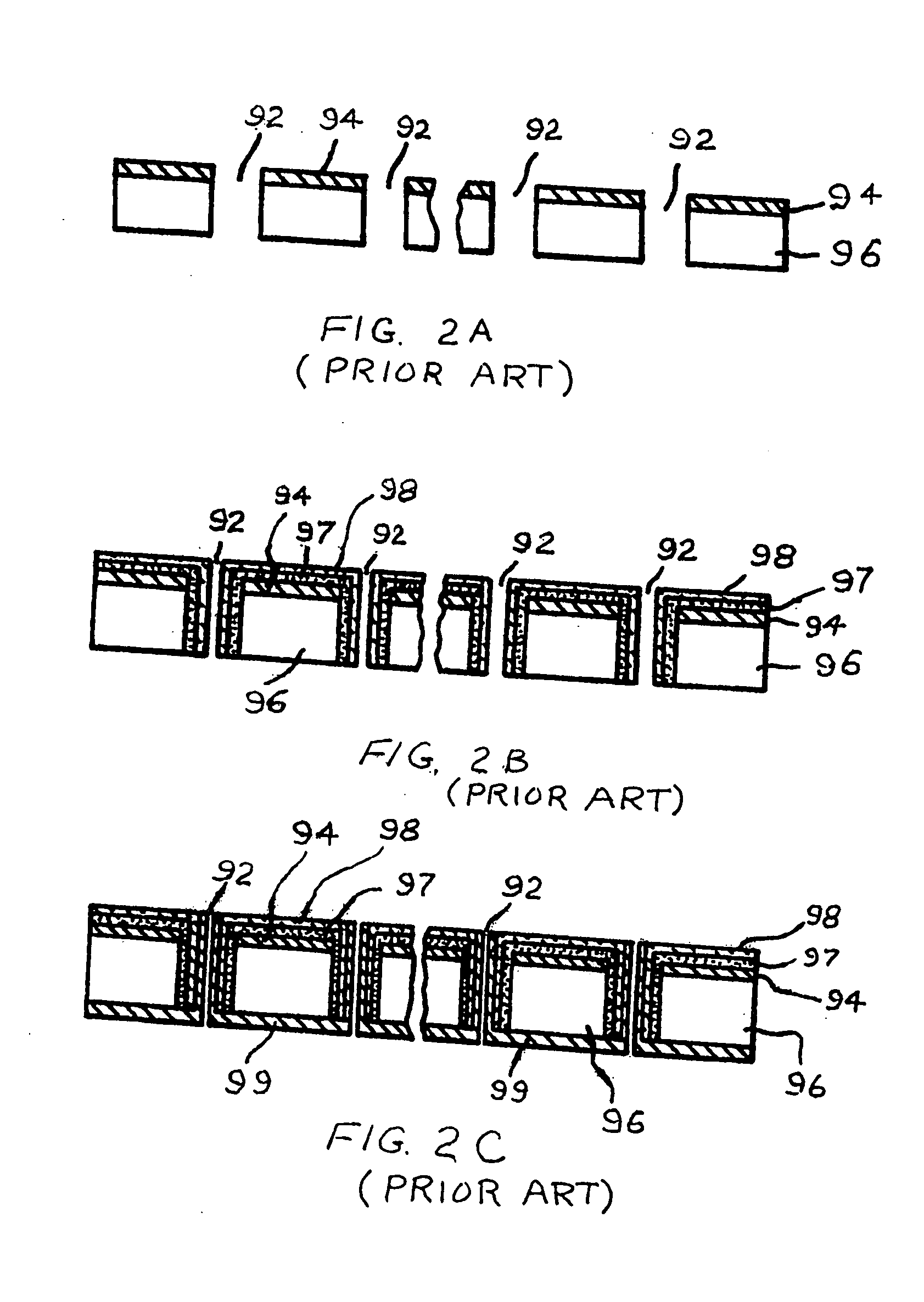

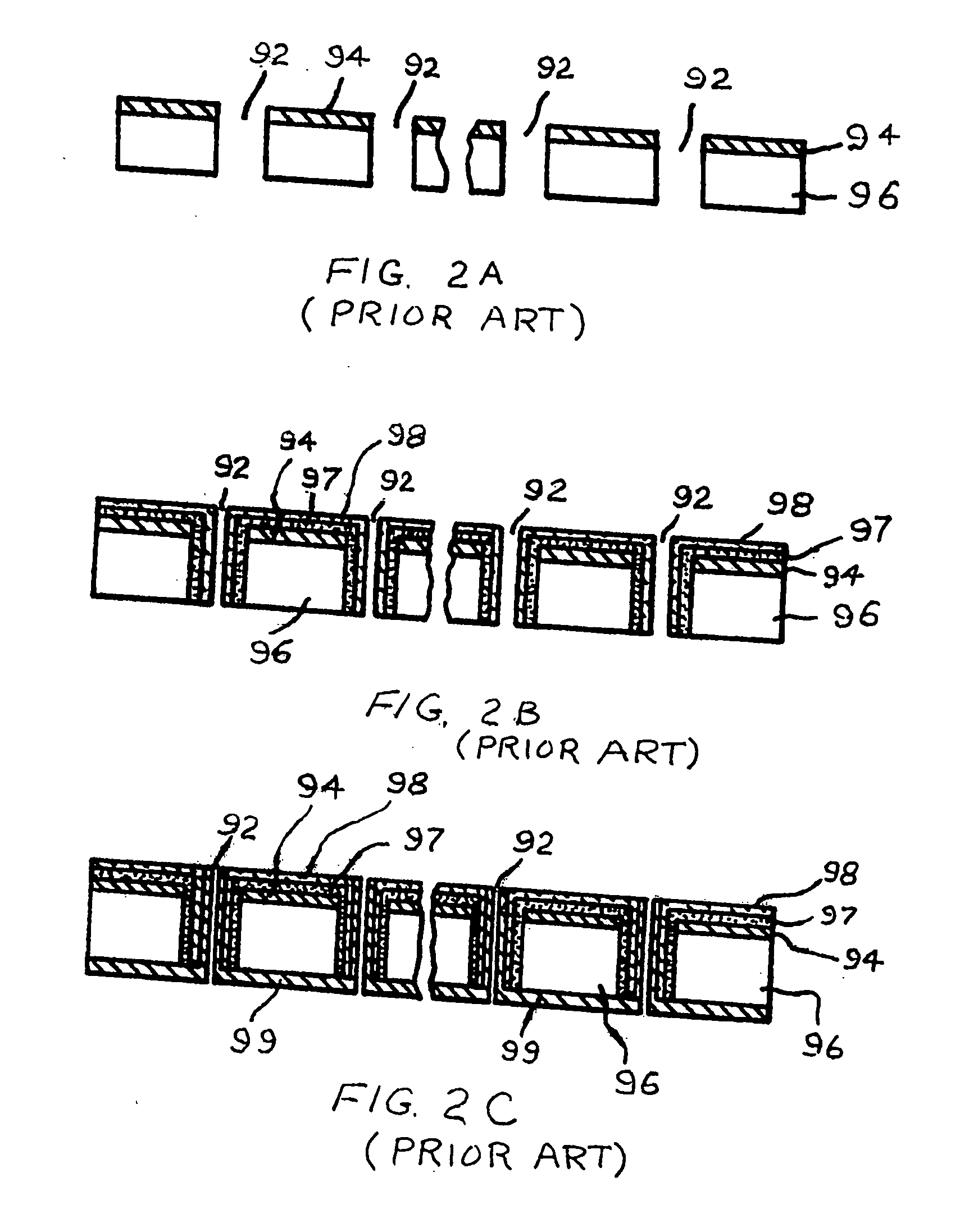

Substrate and collector grid structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

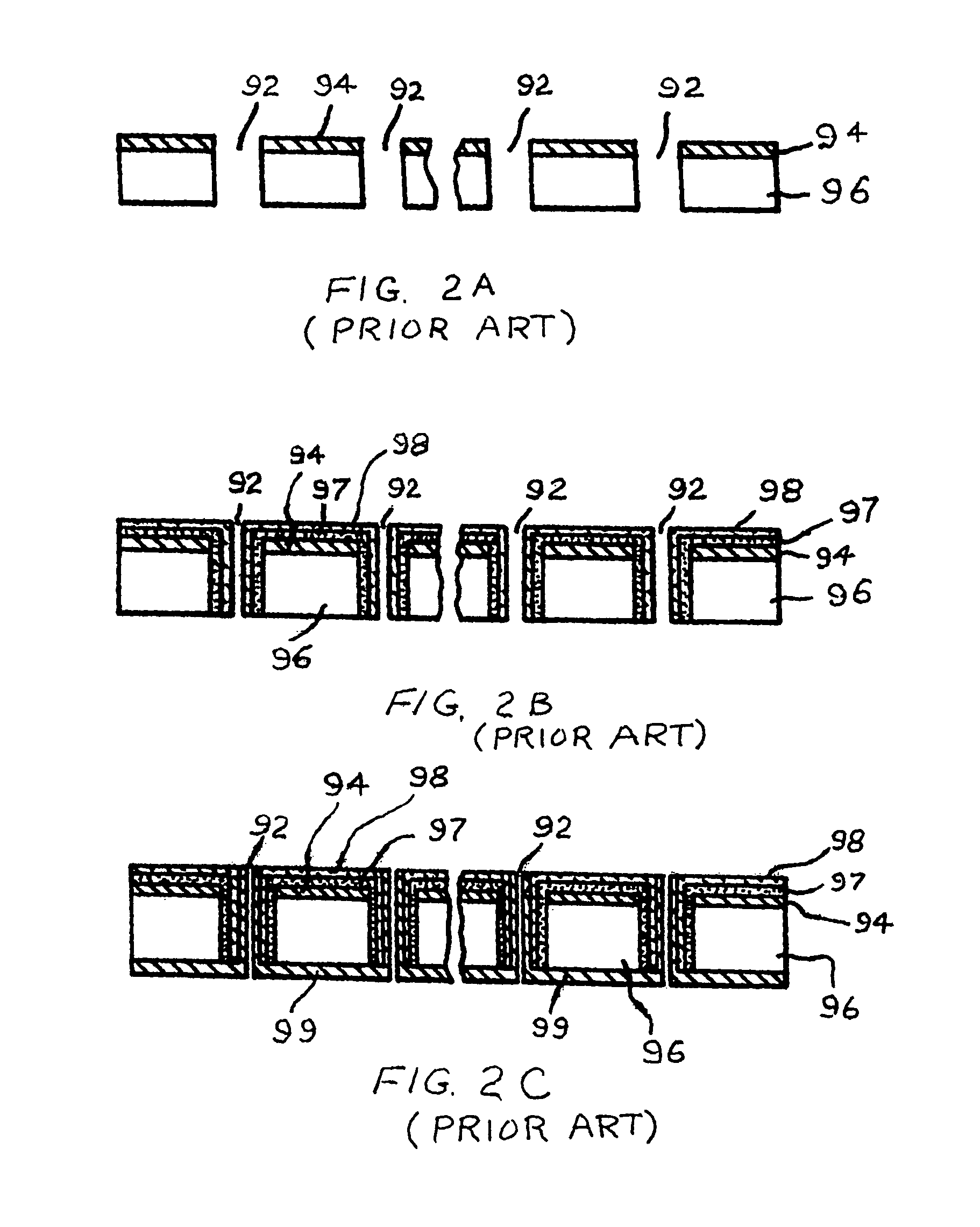

InactiveUS6414235B1Eliminate deficienciesCheap productionPV power plantsElectrode carriers/collectorsRoll-to-roll processingMetal foil

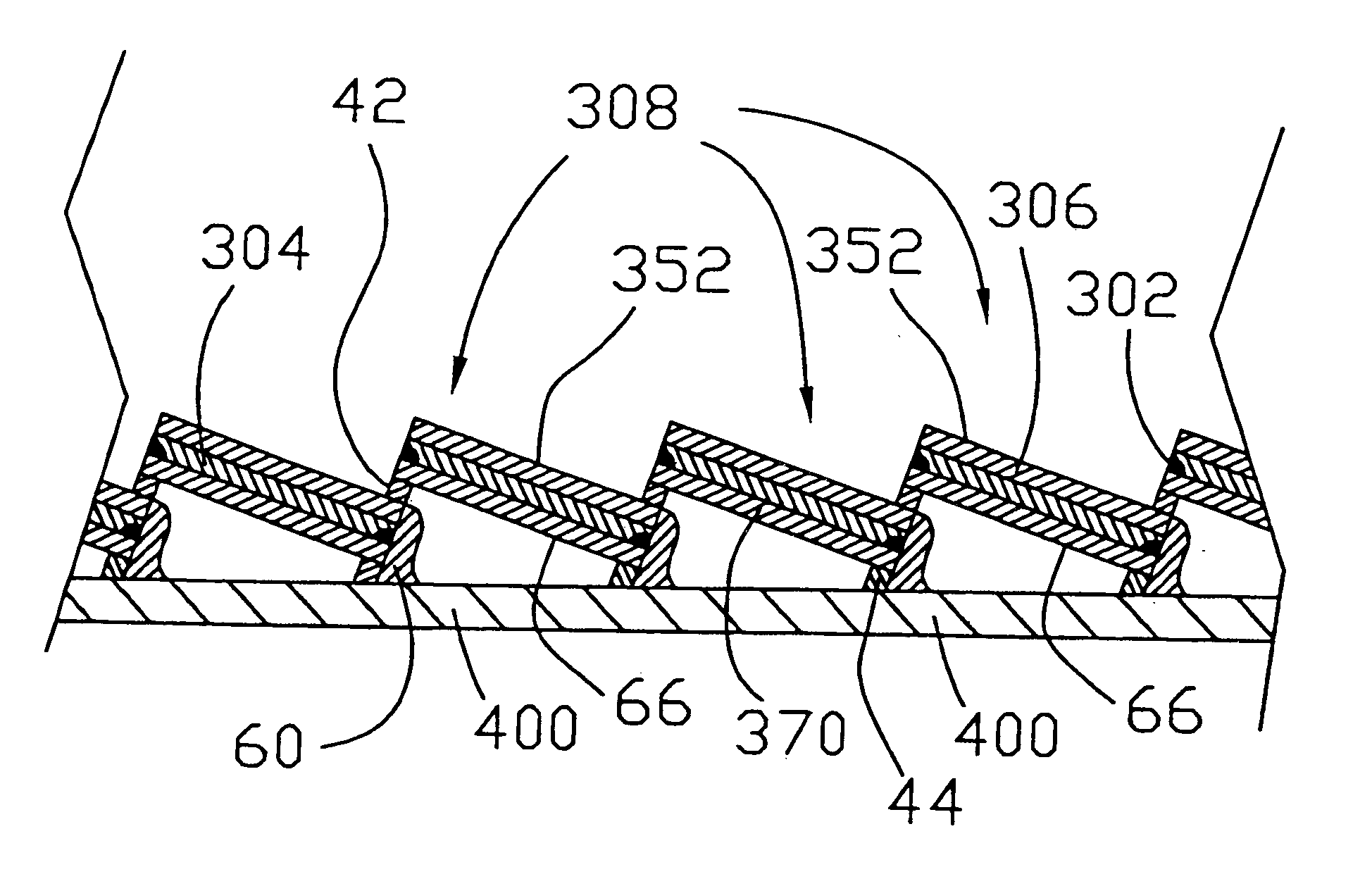

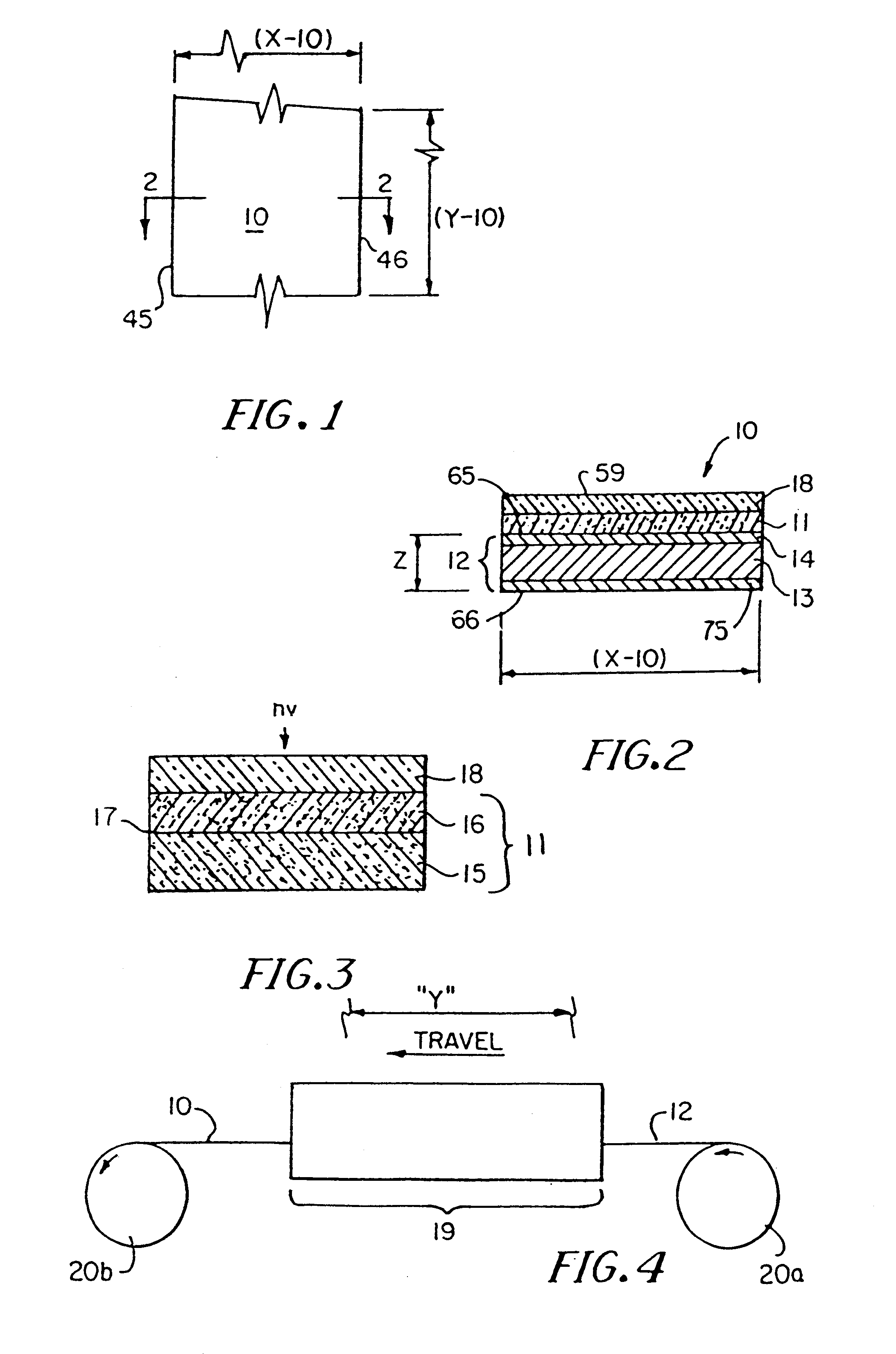

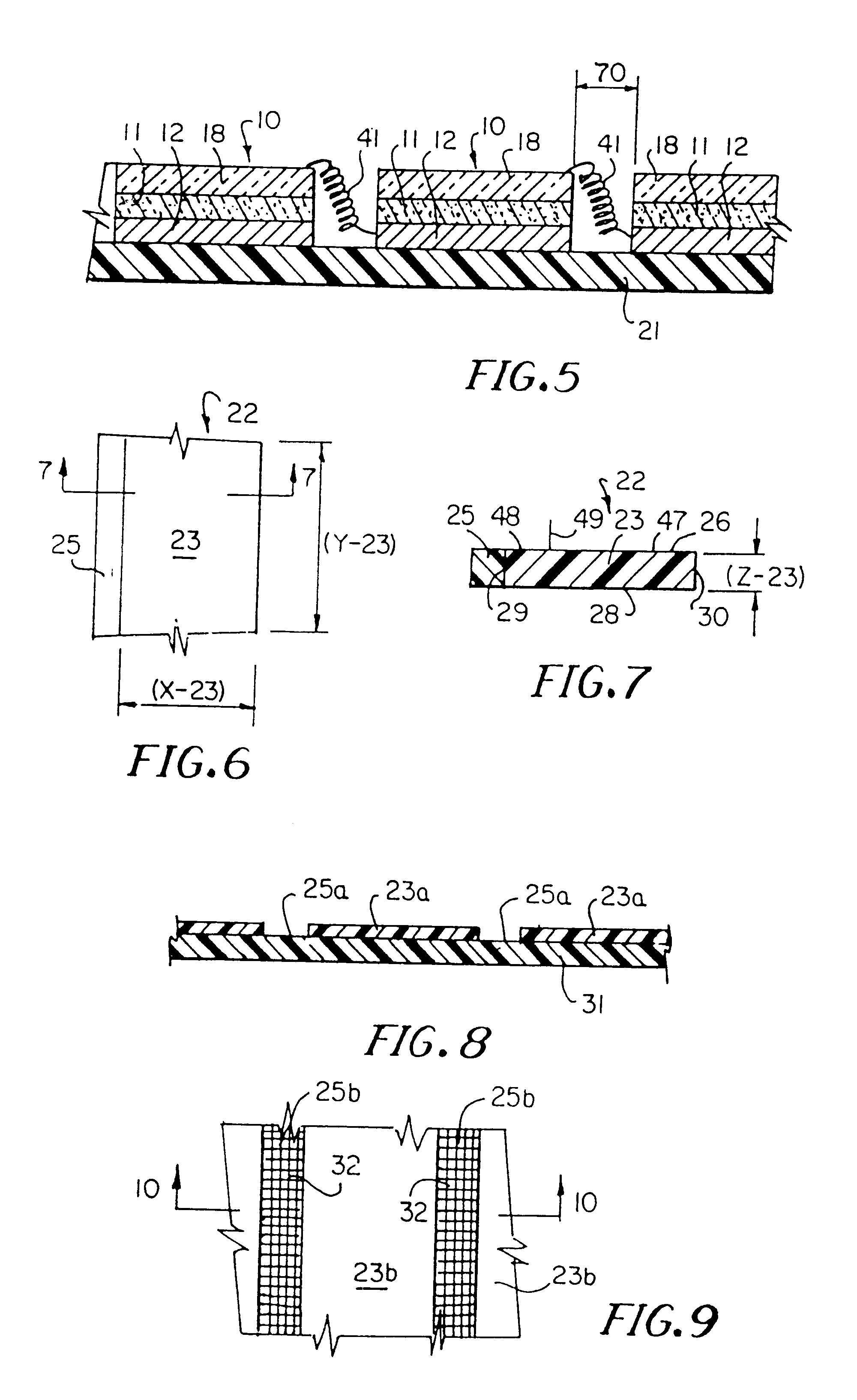

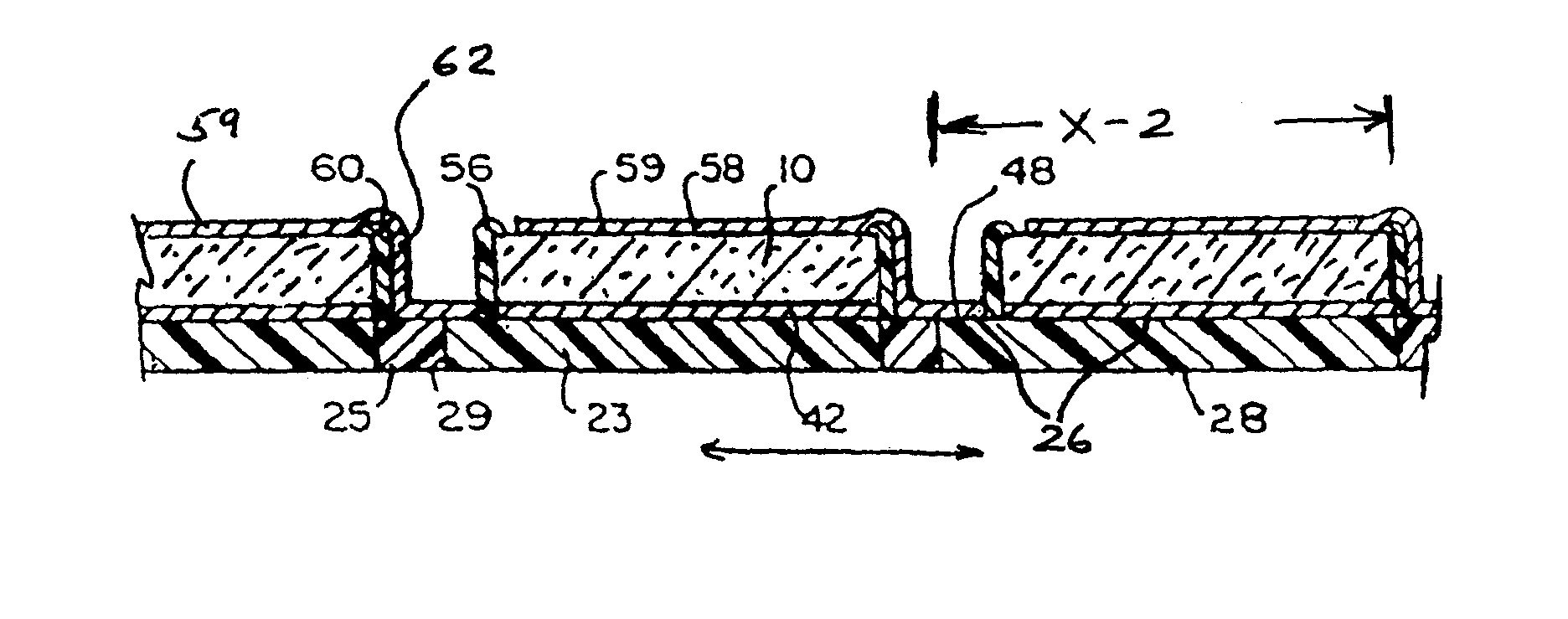

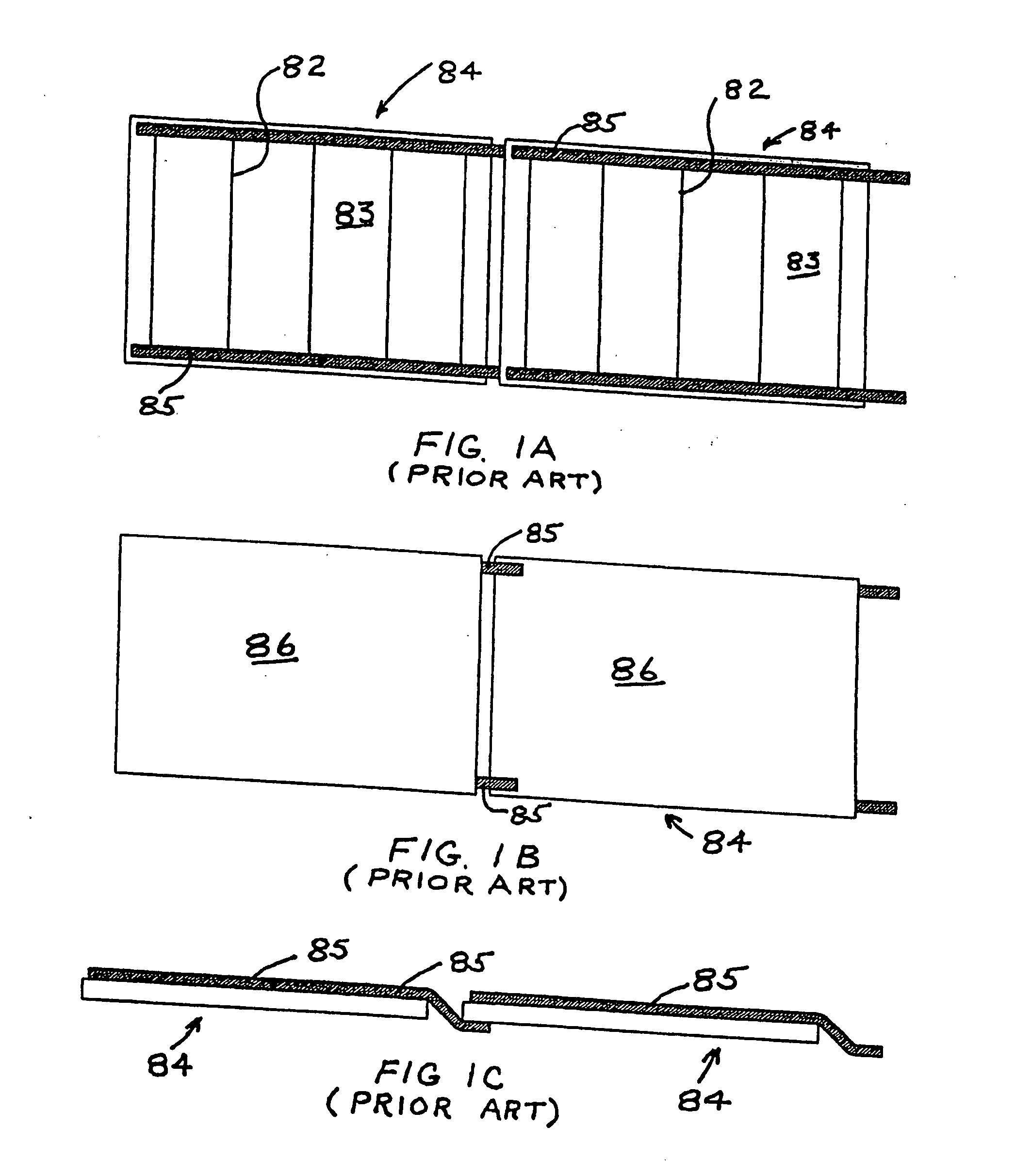

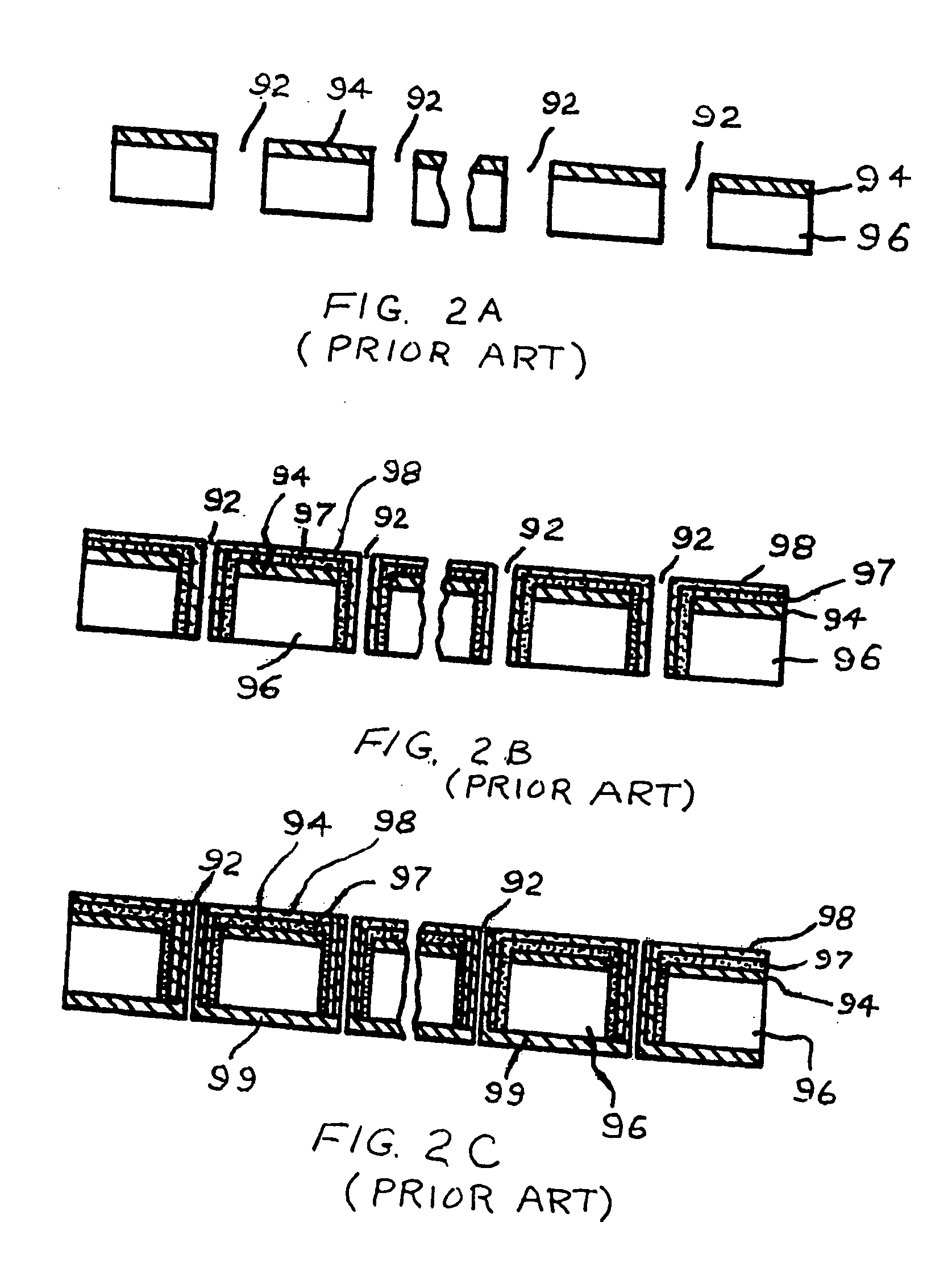

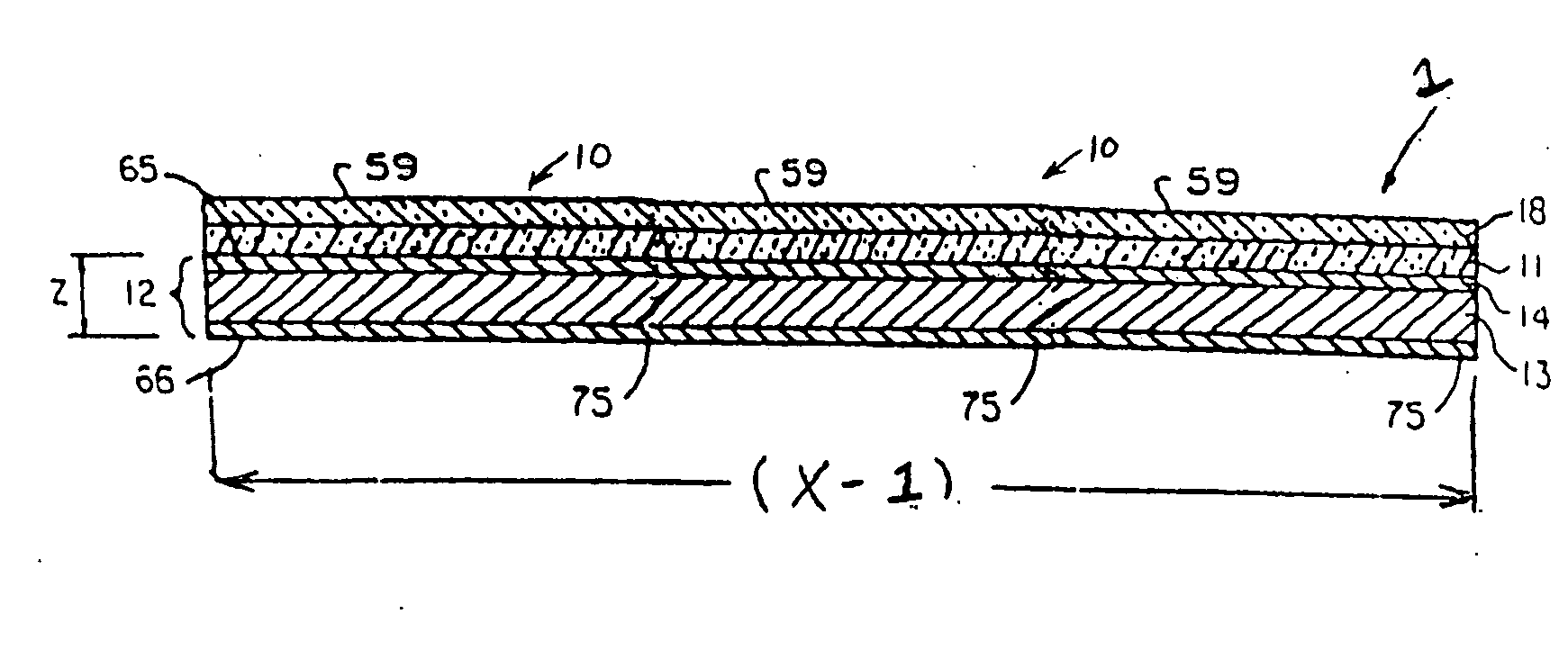

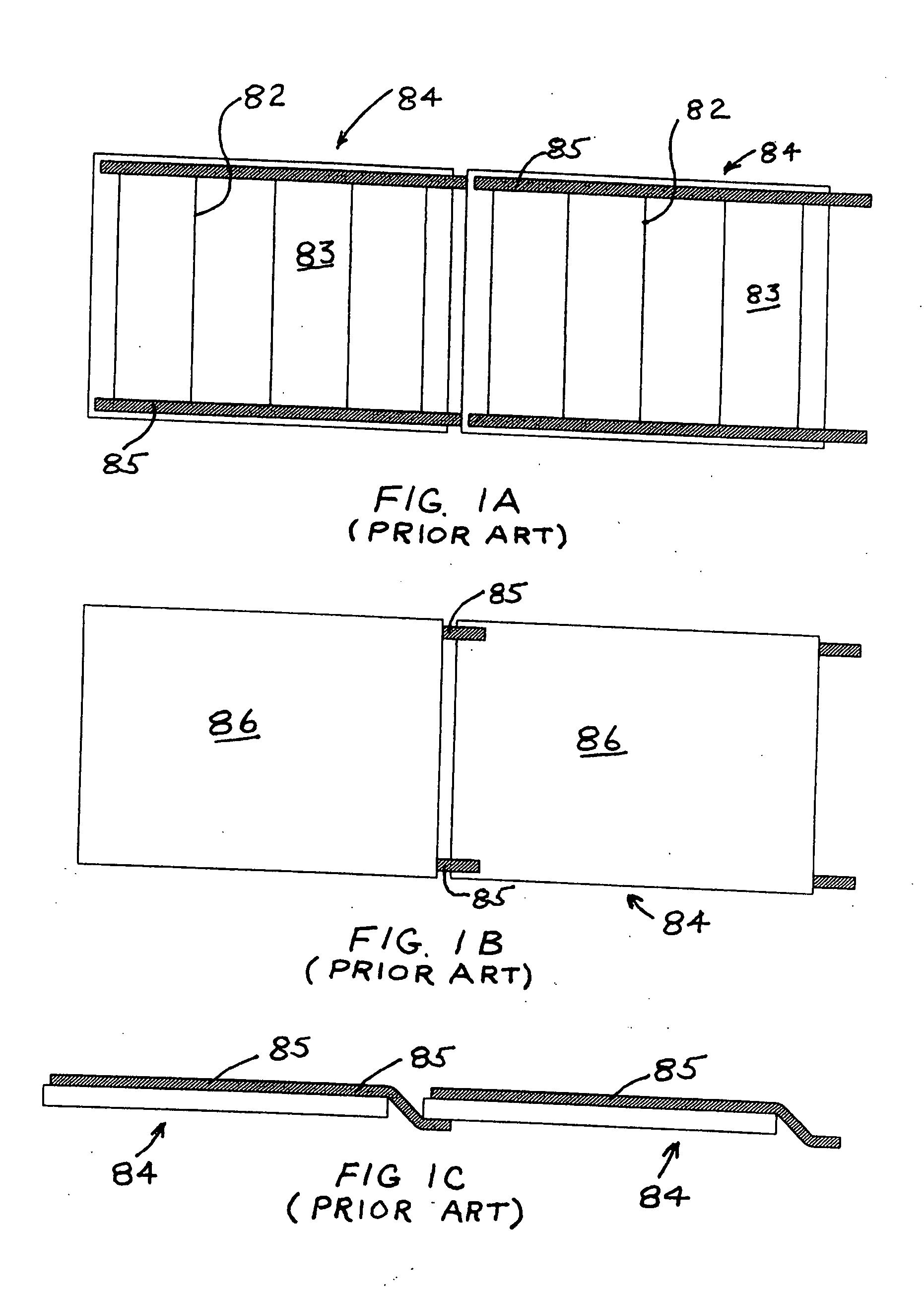

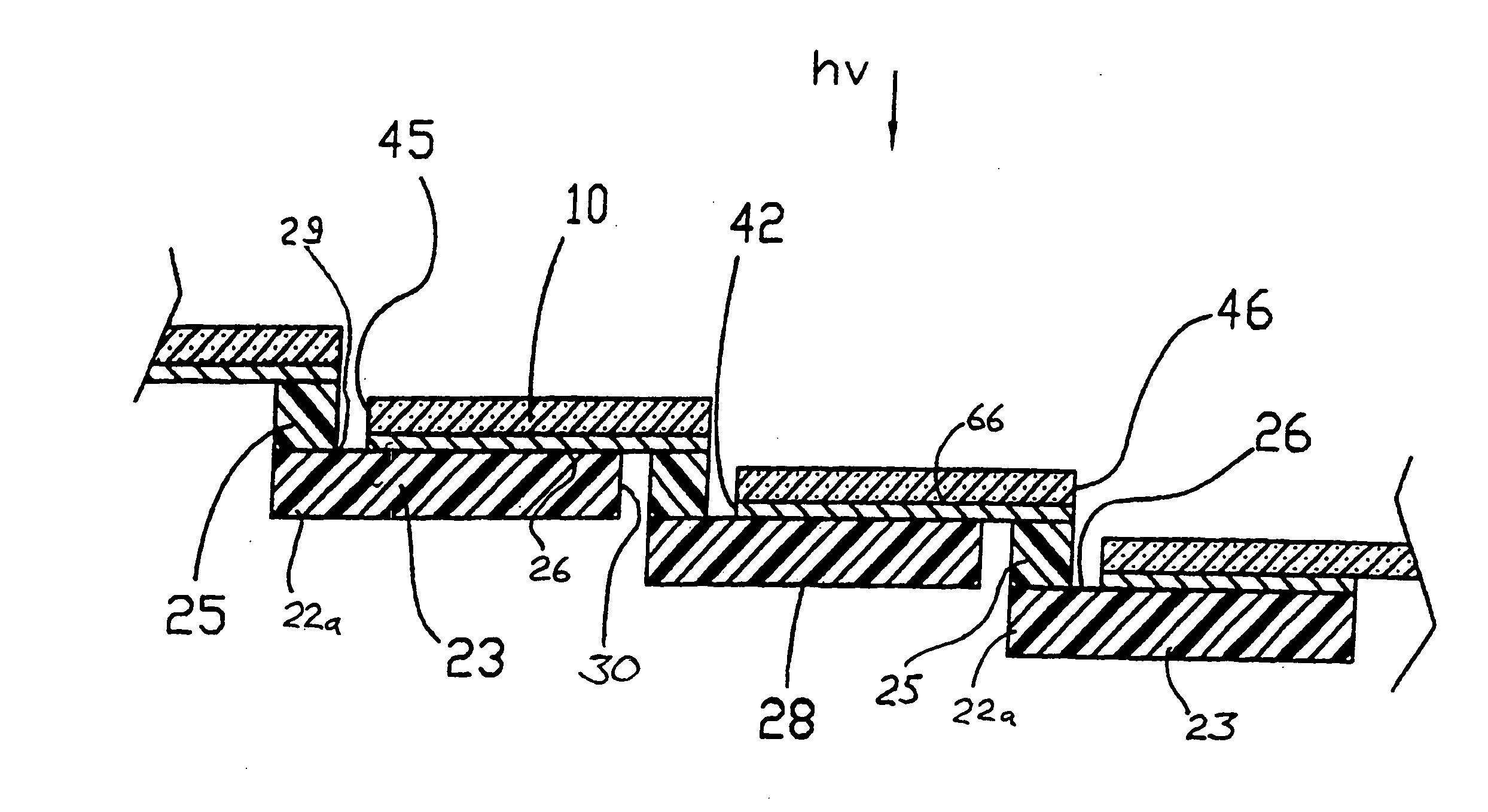

This invention comprises deposition of thin film photovoltaic junctions on metal substrates which can be heat treated following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation an interconnection substrate structure is produced in a continuous roll-to-roll fashion. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials since it does not have to endure high temperature exposure. Cells comprising the metal foil supported photovoltaic junctions are then laminated to the interconnection substrate structure. Conductive interconnections are deposited to complete the array. The conductive interconnections can be accomplished with a separately prepared interconnection component. The interconnected array is produced using continuous roll-to-roll processing which avoids the need to use the expensive and intricate material removal operations currently taught in the art to achieve electrical interconnections among arrays of photovoltaic cells.

Owner:SOLANNEX

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS7732243B2Eliminate deficienciesFacilitate electrical interconnectionPV power plantsSolid-state devicesPolymer substrateMaterial removal

Owner:SOLANNEX

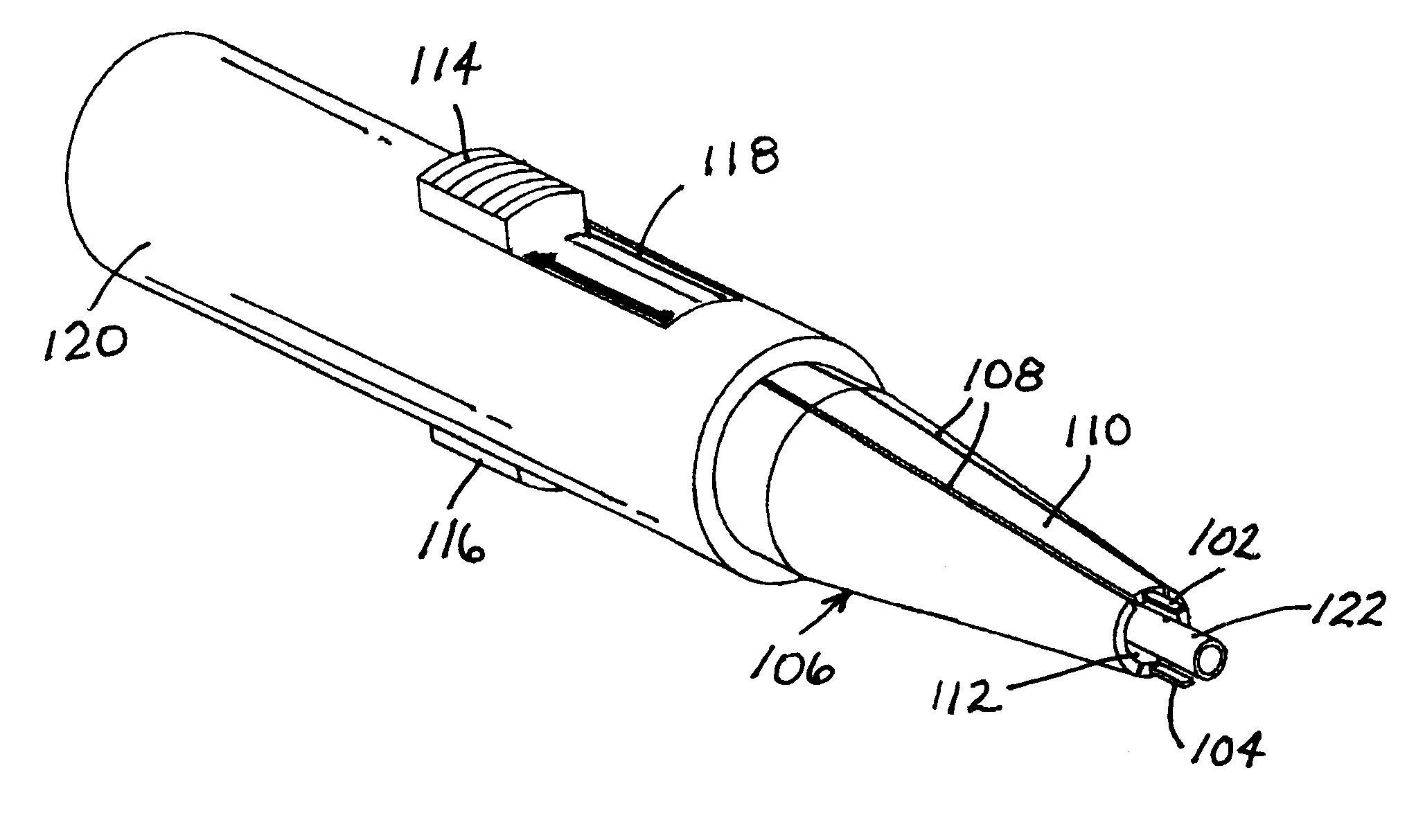

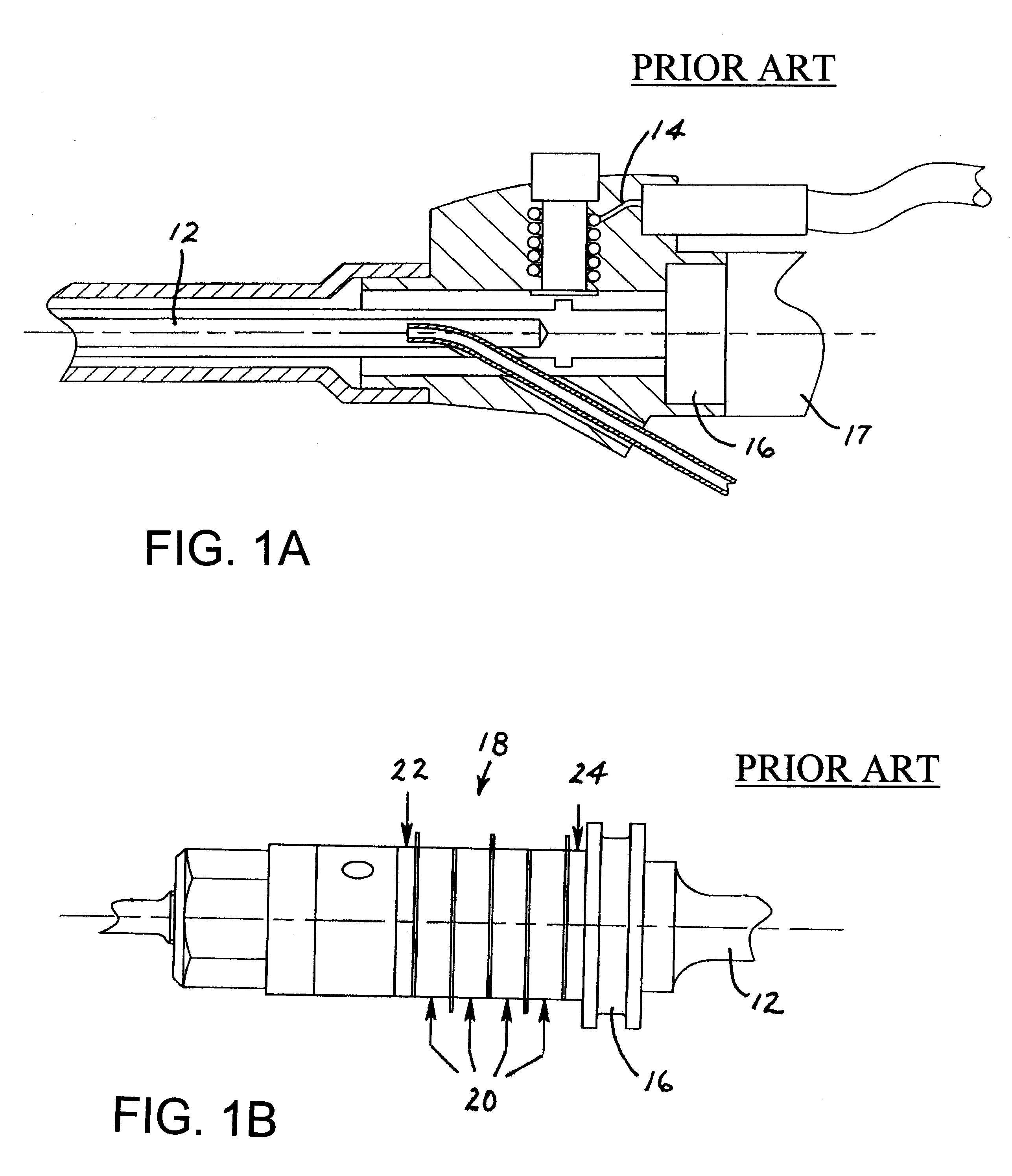

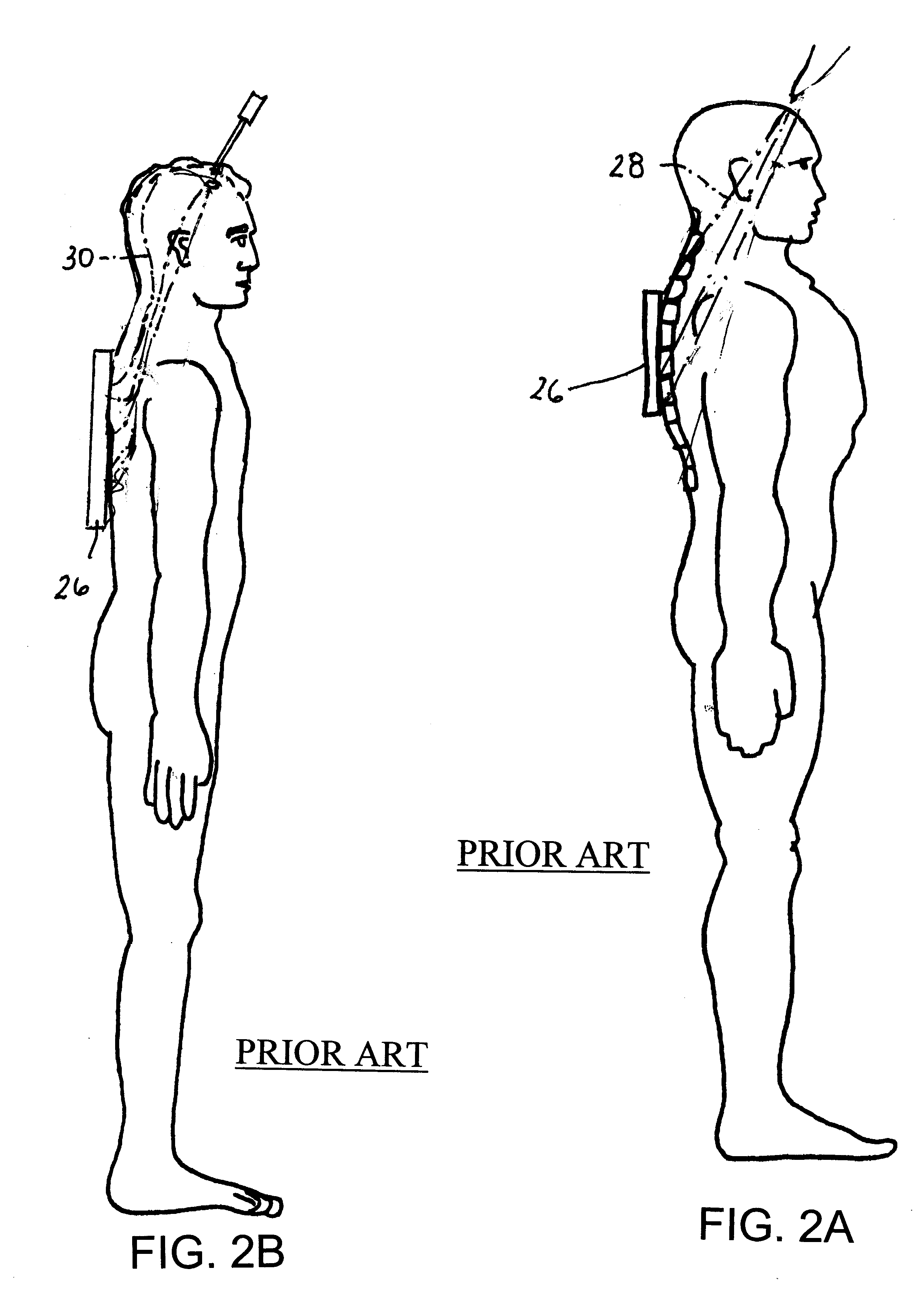

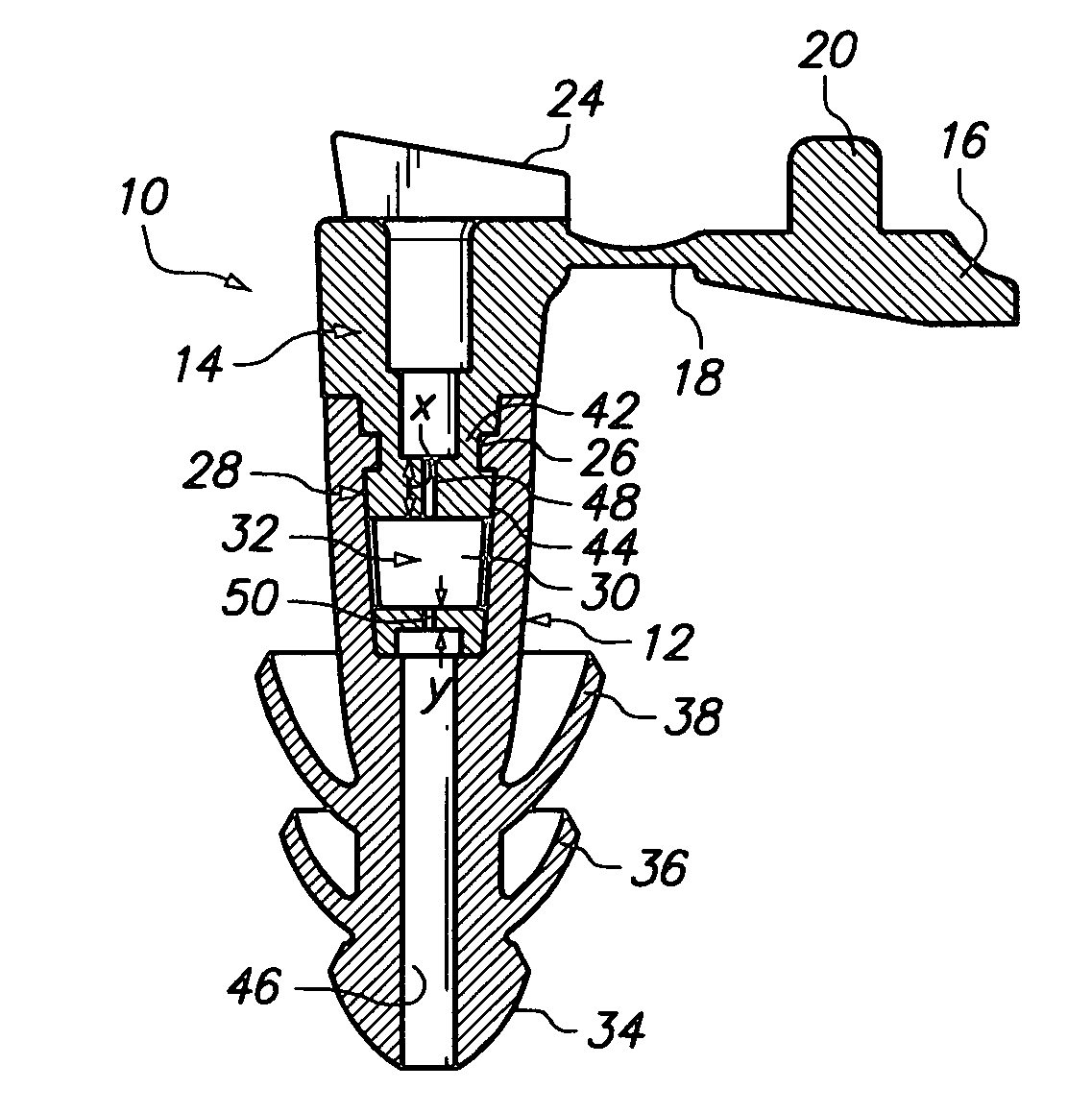

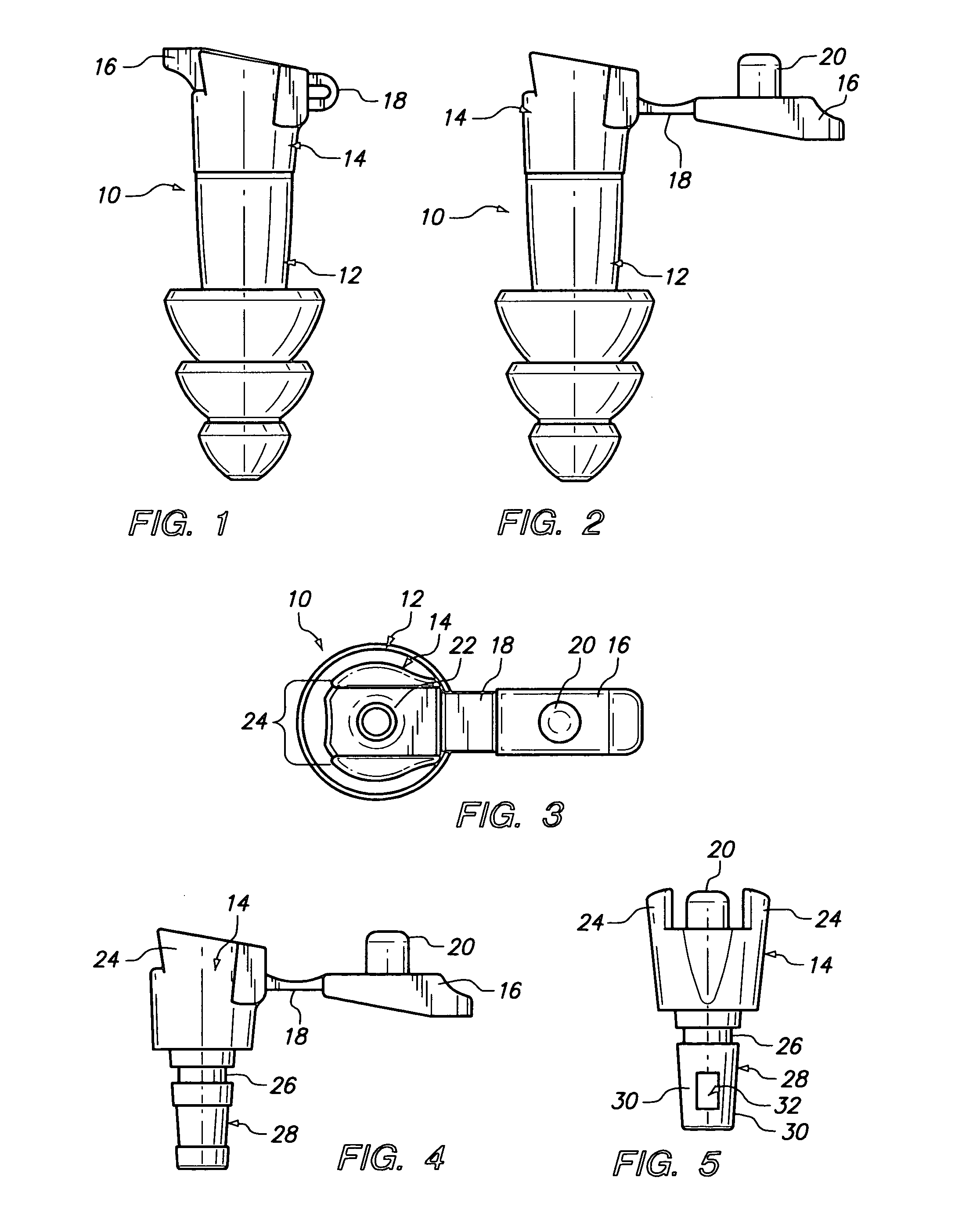

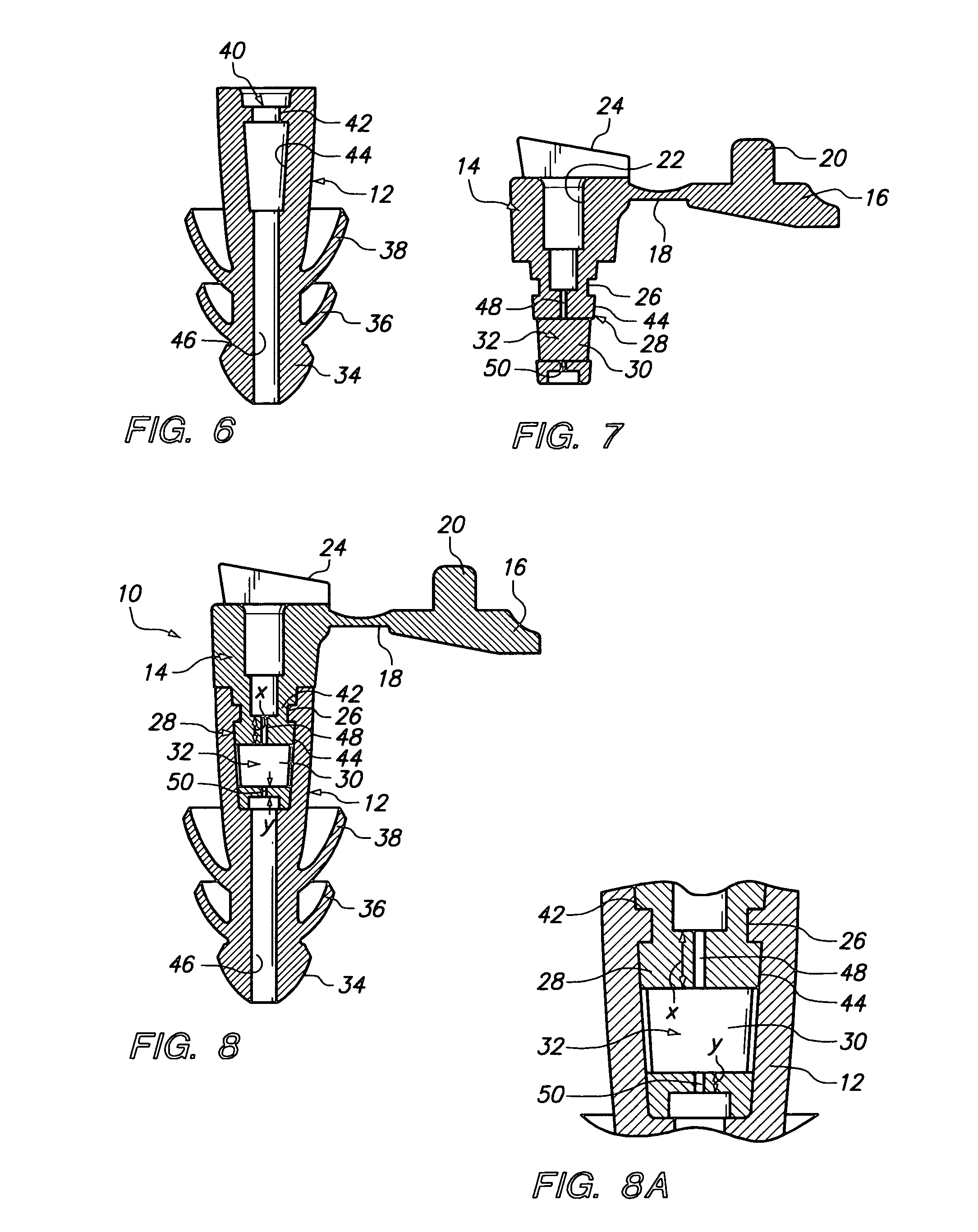

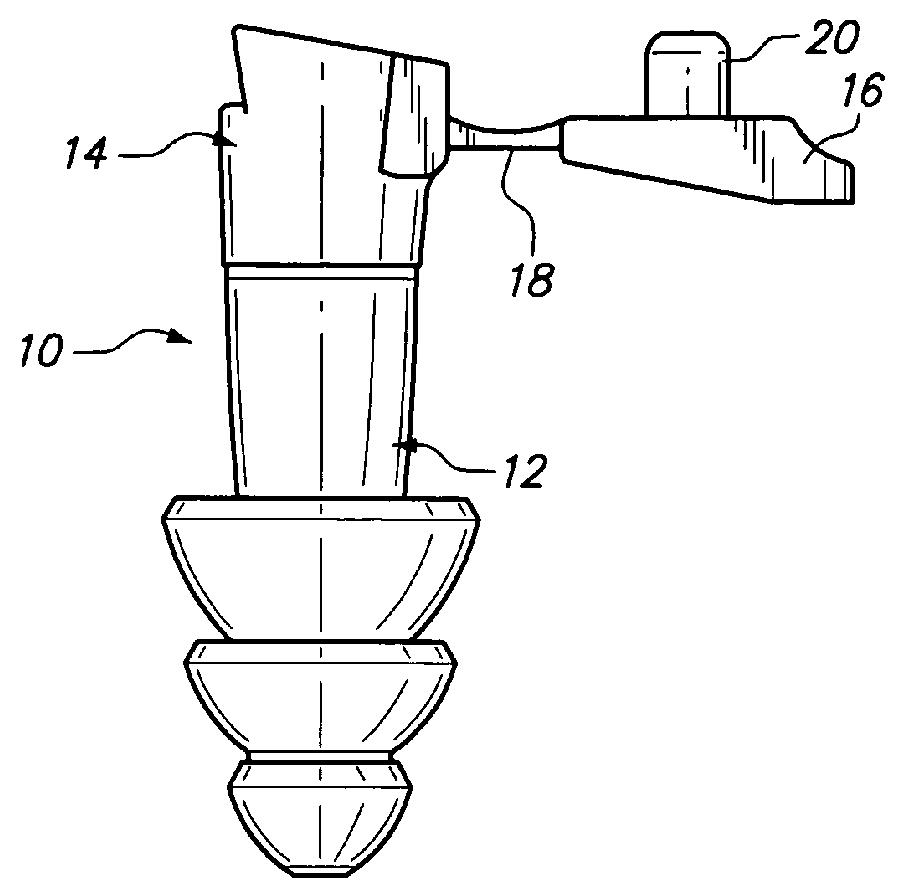

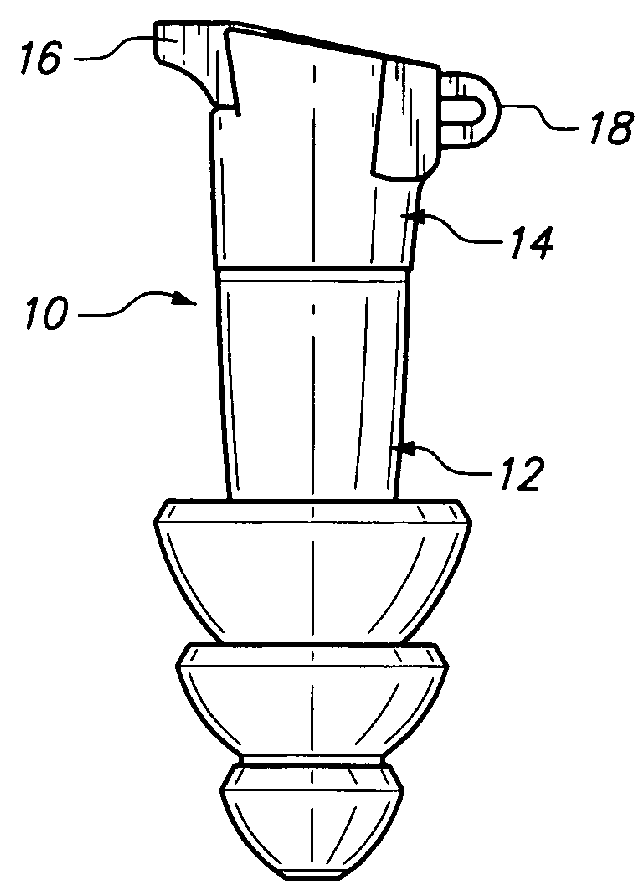

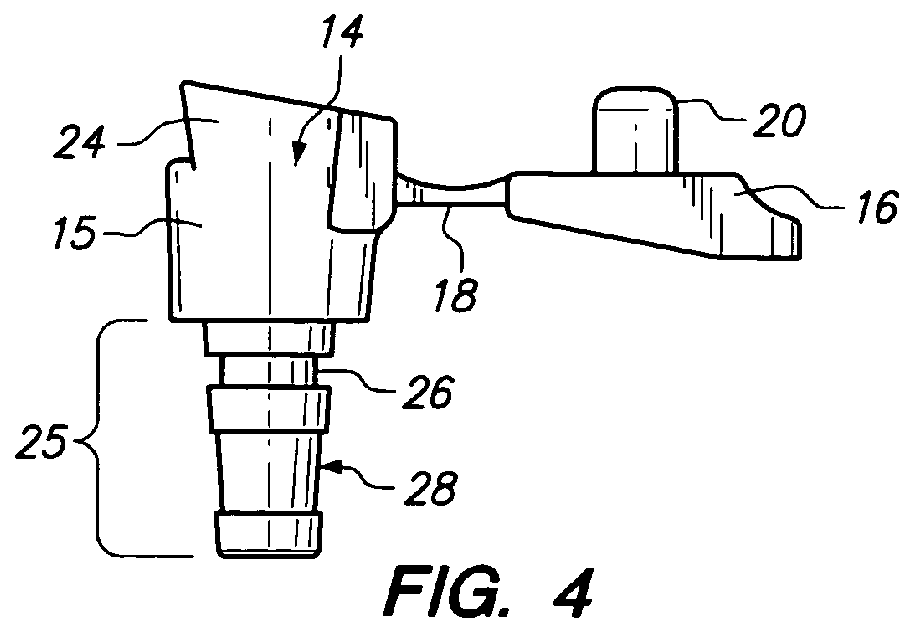

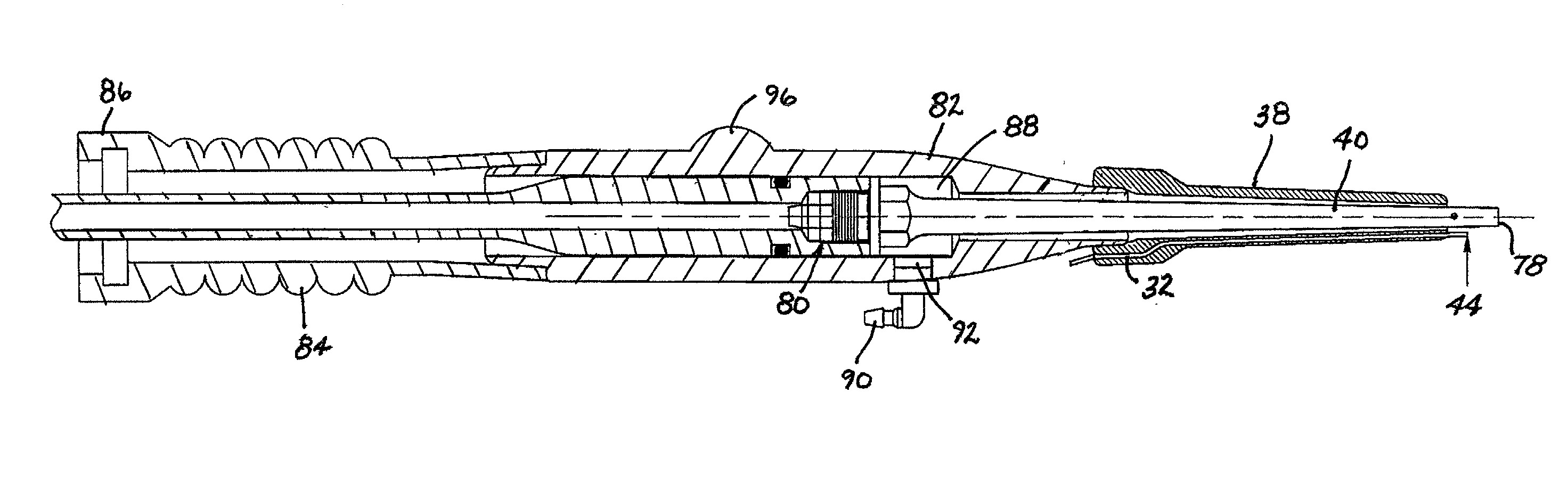

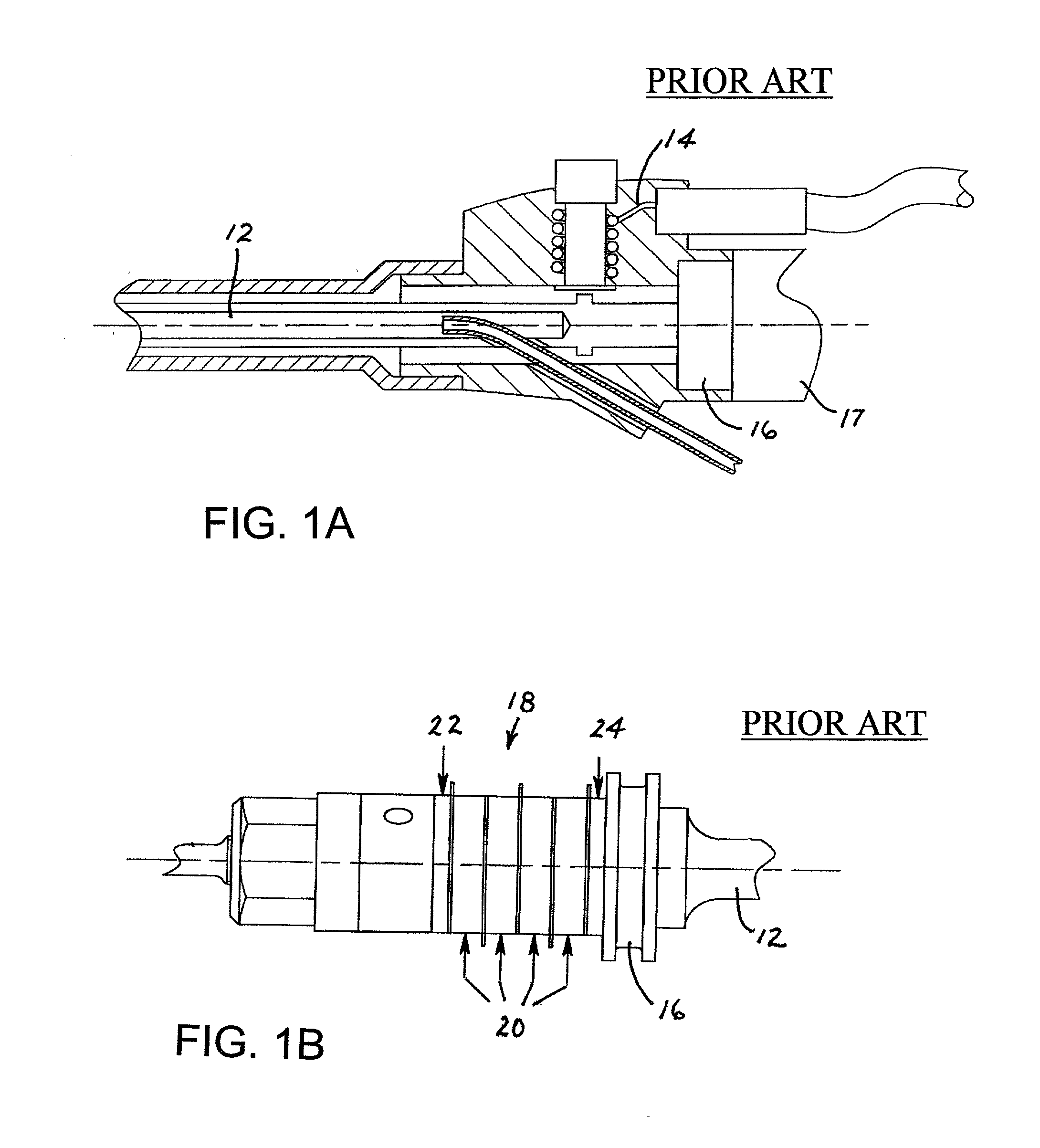

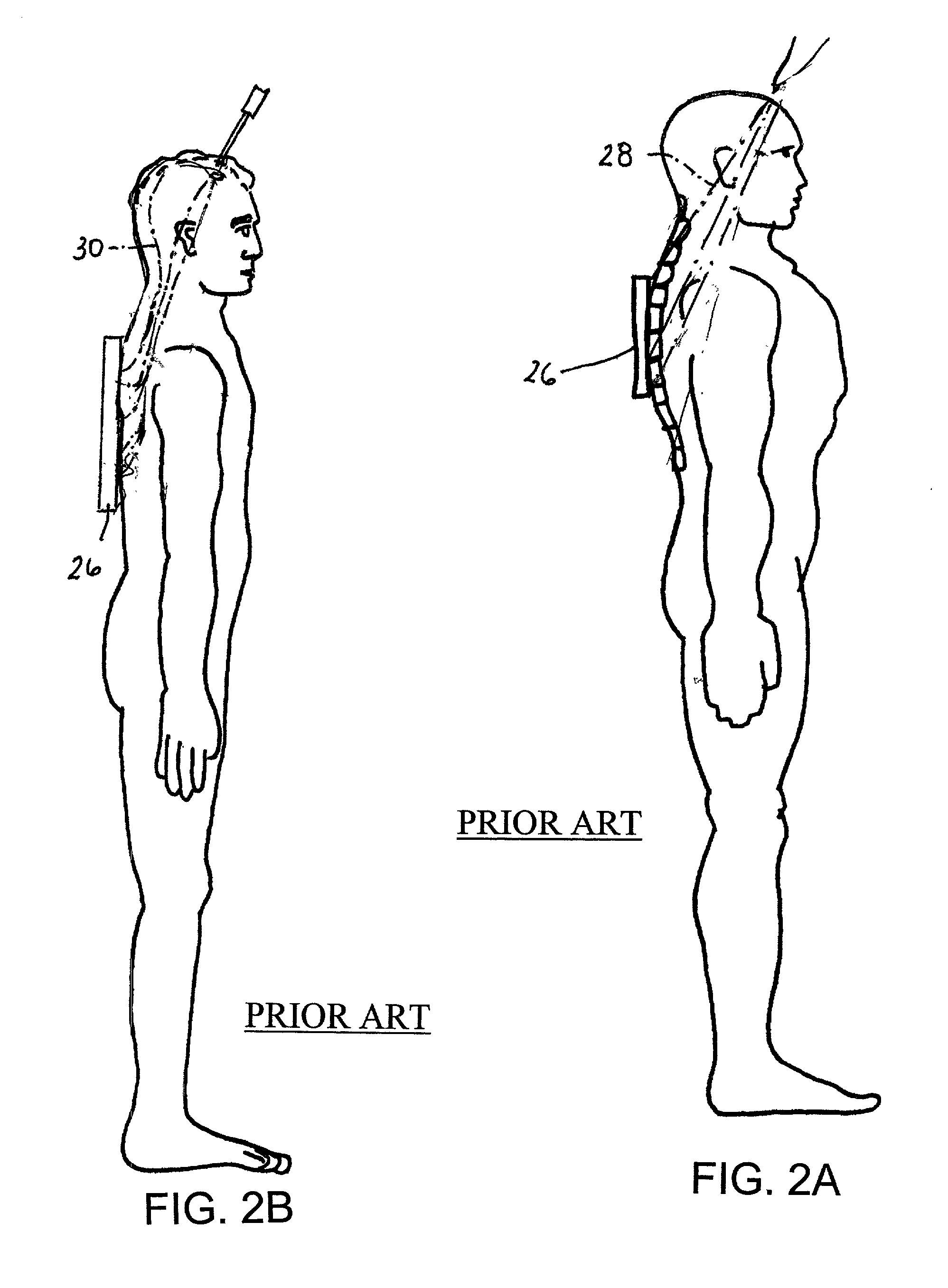

Ultrasonic medical treatment device for bipolar RF cauterization and related method

InactiveUS6736814B2Eliminate deficienciesEasy to useSurgical instruments for heatingSurgical instruments for irrigation of substancesTransducerRelative motion

An ultrasonic medical treatment device has a casing, an elongate probe, a transducer assembly, a sheath and a plurality of electrode members. The probe is mounted to and extends from the casing and has an axis and a free end serving as an operative tip. The transducer assembly is mounted to the casing and is operatively connected to the probe for generating vibrations of at least one ultrasonic frequency in the probe. The sheath surrounds the probe. The electrode members are connectable to an RF voltage source and are mounted at least indirectly to the casing so as to permit relative motion between the electrode members and the probe.

Owner:MISONIX INC

Substrate and collector grid structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS7507903B2Eliminate deficienciesInexpensive productionPV power plantsSolid-state devicesRoll-to-roll processingMetal foil

This invention comprises deposition of thin film photovoltaic junctions on metal substrates which can be heat treated following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation an interconnection substrate structure is produced in a continuous roll-to-roll fashion. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials since it does not have to endure high temperature exposure. Cells comprising the metal foil supported photovoltaic junctions are then laminated to the interconnection substrate structure. Conductive interconnections are deposited to complete the array. The conductive interconnections can be accomplished with a separately prepared interconnection component. The interconnected array is produced using continuous roll-to-roll processing which avoids the need to use the expensive and intricate material removal operations currently taught in the art to achieve electrical interconnections among arrays of photovoltaic cells.

Owner:SOLANNEX

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS20080314433A1Minimization requirementsIncrease volumePV power plantsPhotovoltaic energy generationPolymer substrateMaterial removal

This invention comprises manufacture of photovoltaic cells by deposition of thin film photovoltaic junctions on metal foil substrates. The photovoltaic junctions may be heat treated if appropriate following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation, an interconnection substrate structure is provided, optionally in a continuous fashion. Multiple photovoltaic cells are then laminated to the interconnection substrate structure and conductive joining methods are employed to complete the array. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials employing optimal processing unique to polymeric materials. Furthermore, the photovoltaic junction and its metal foil support can be produced in bulk without the need to use the expensive and intricate material removal operations currently taught in the art to achieve series interconnections.

Owner:SOLANNEX

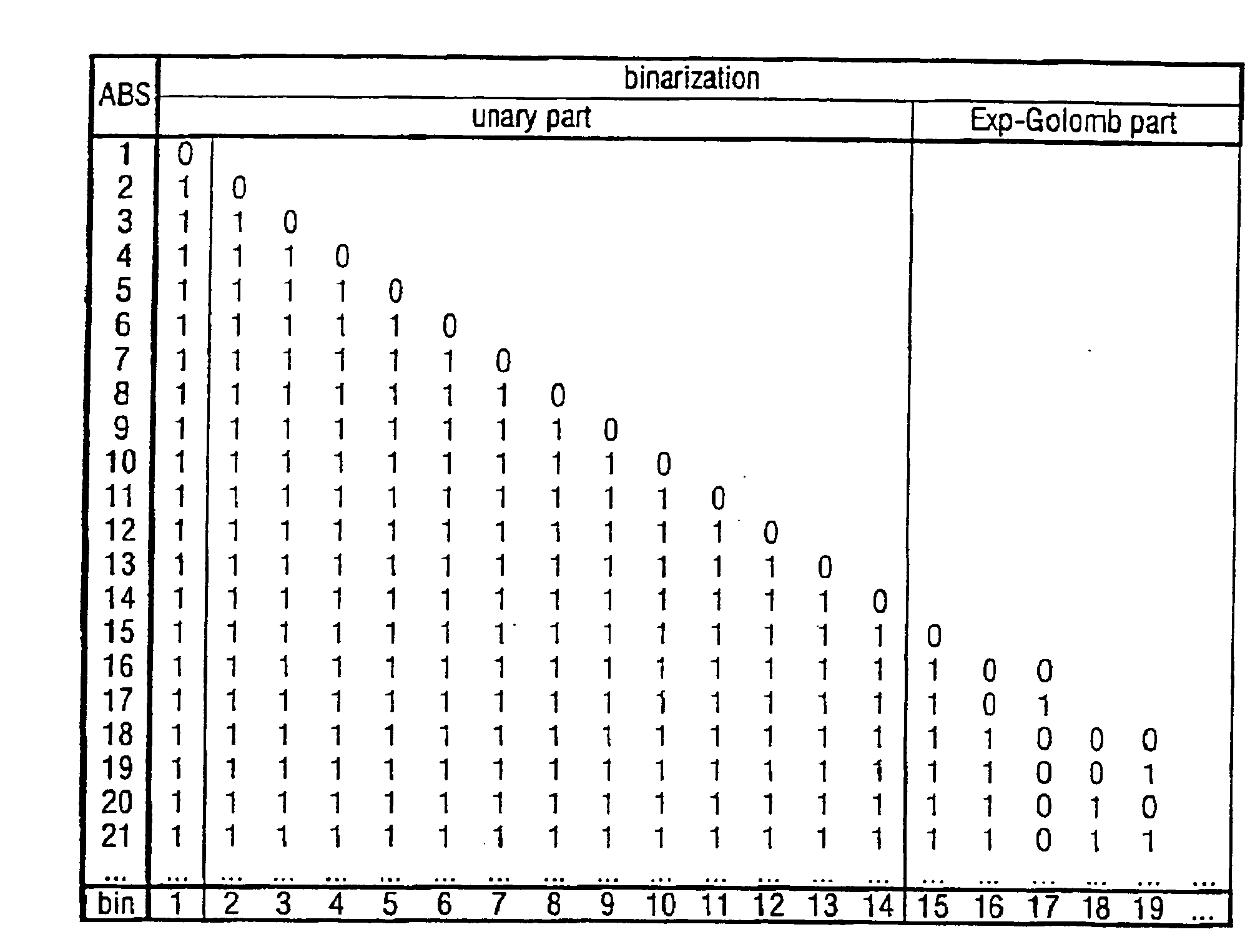

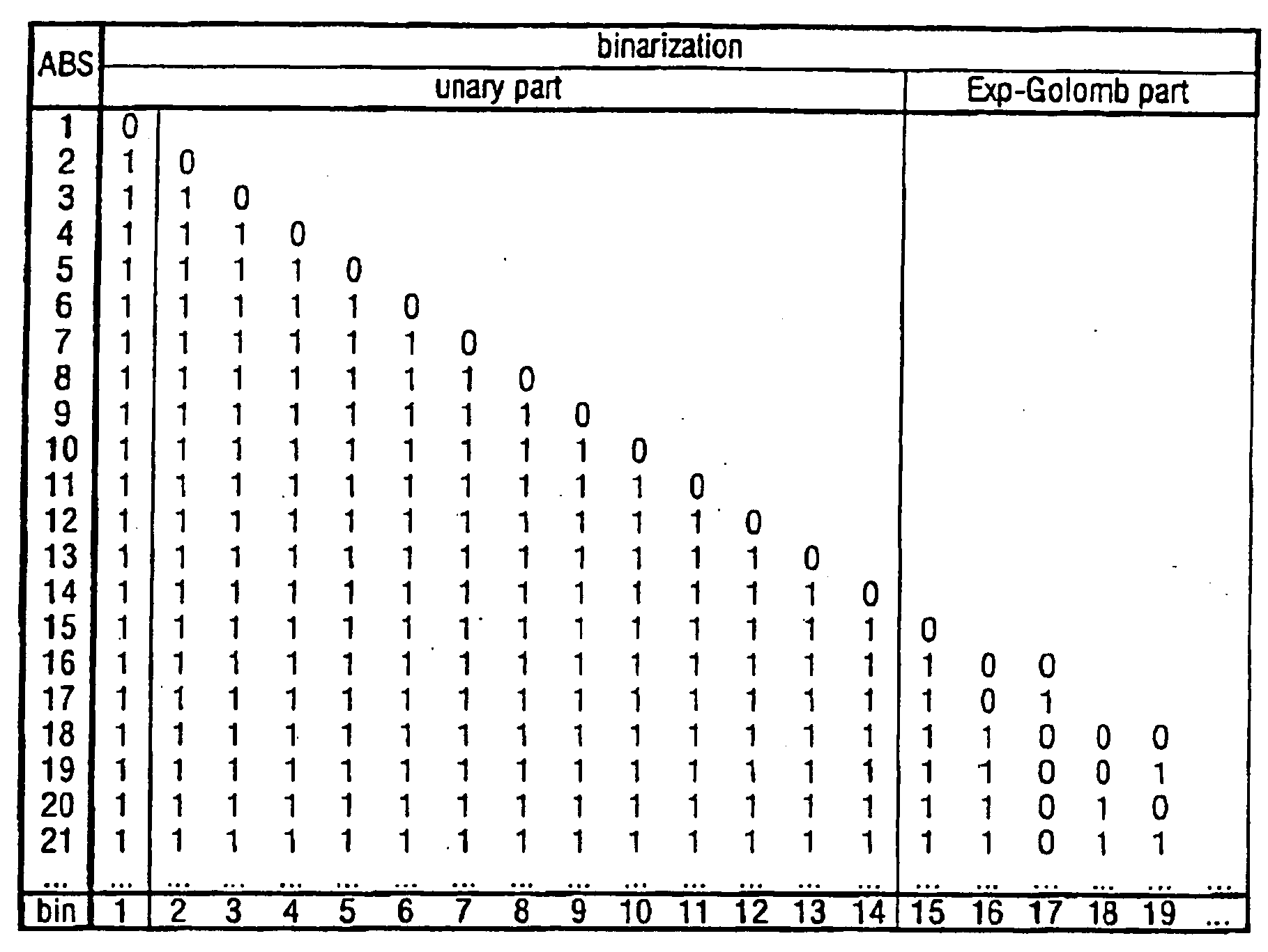

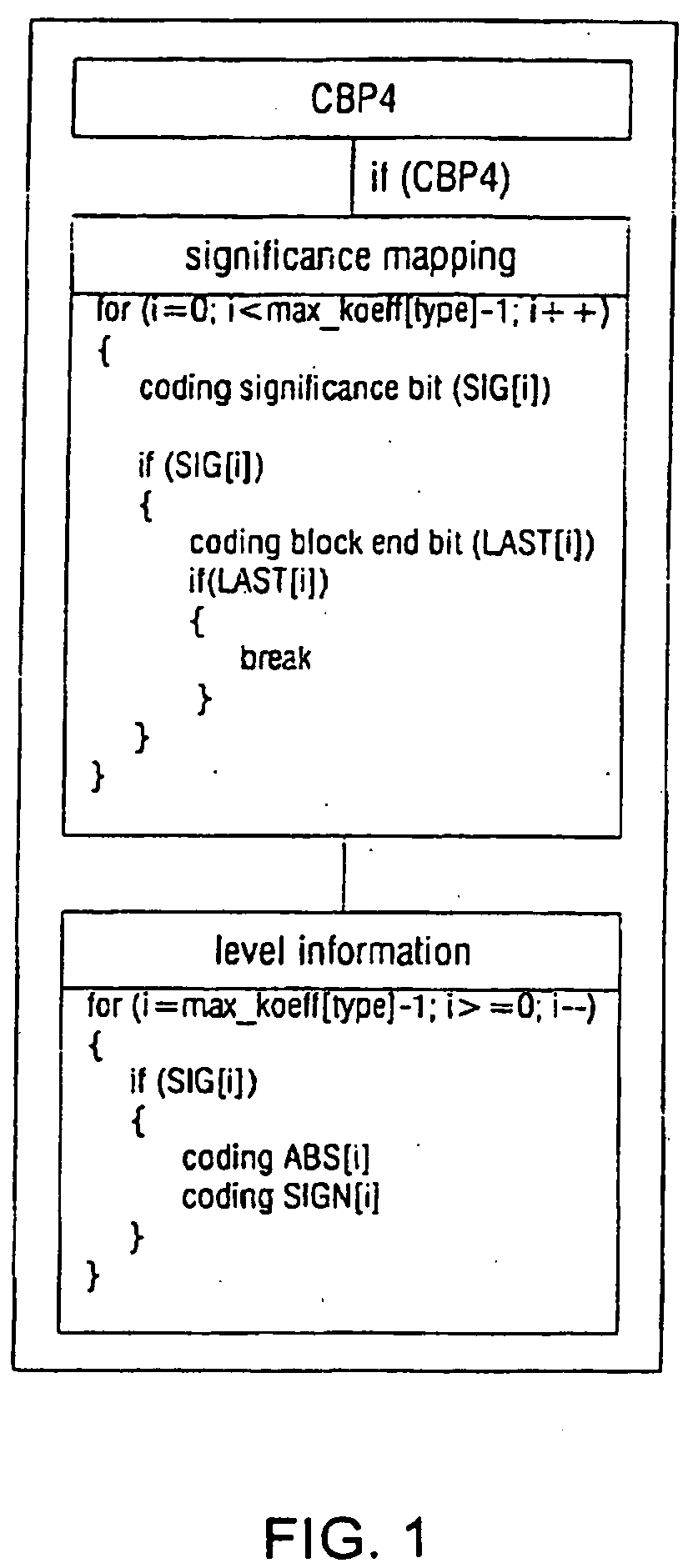

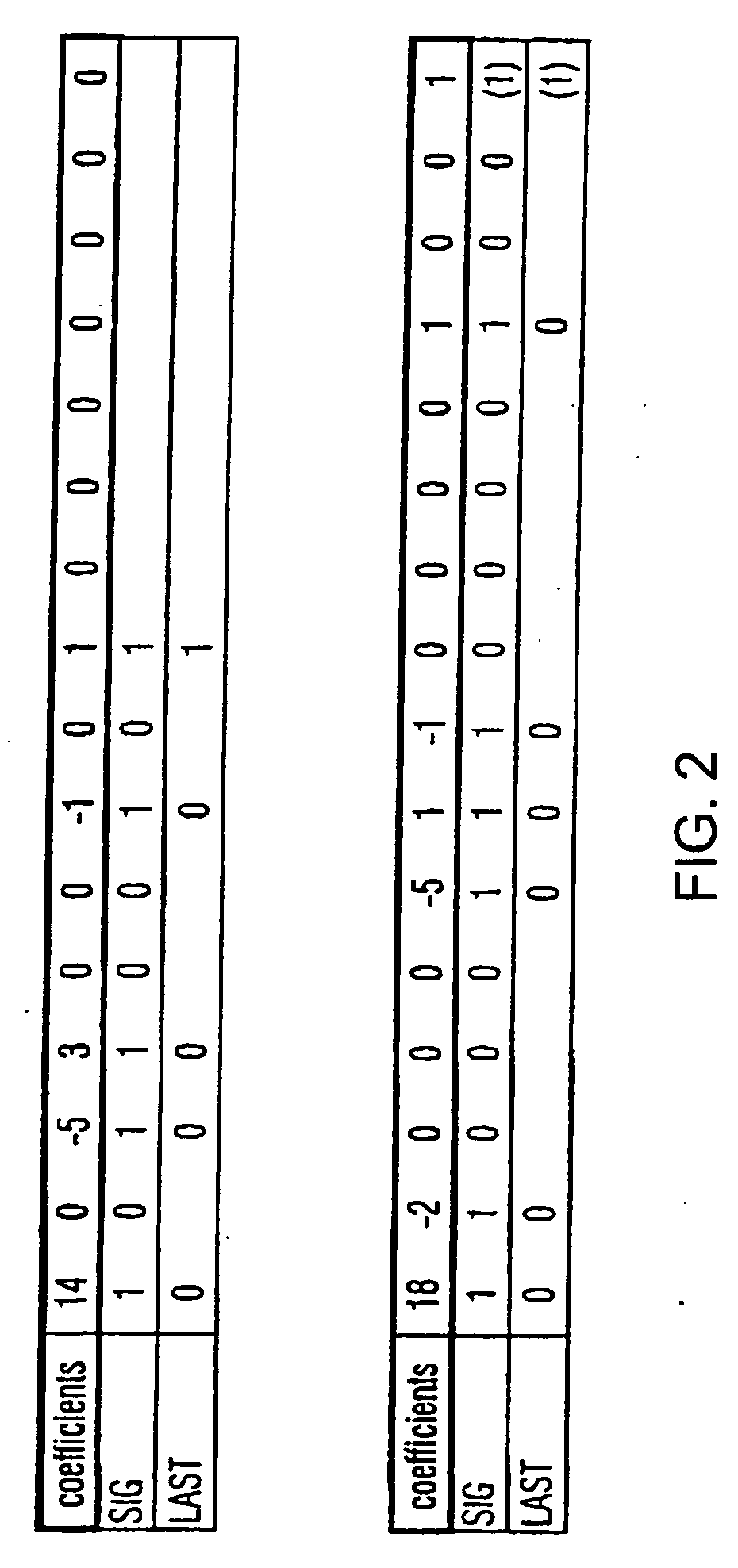

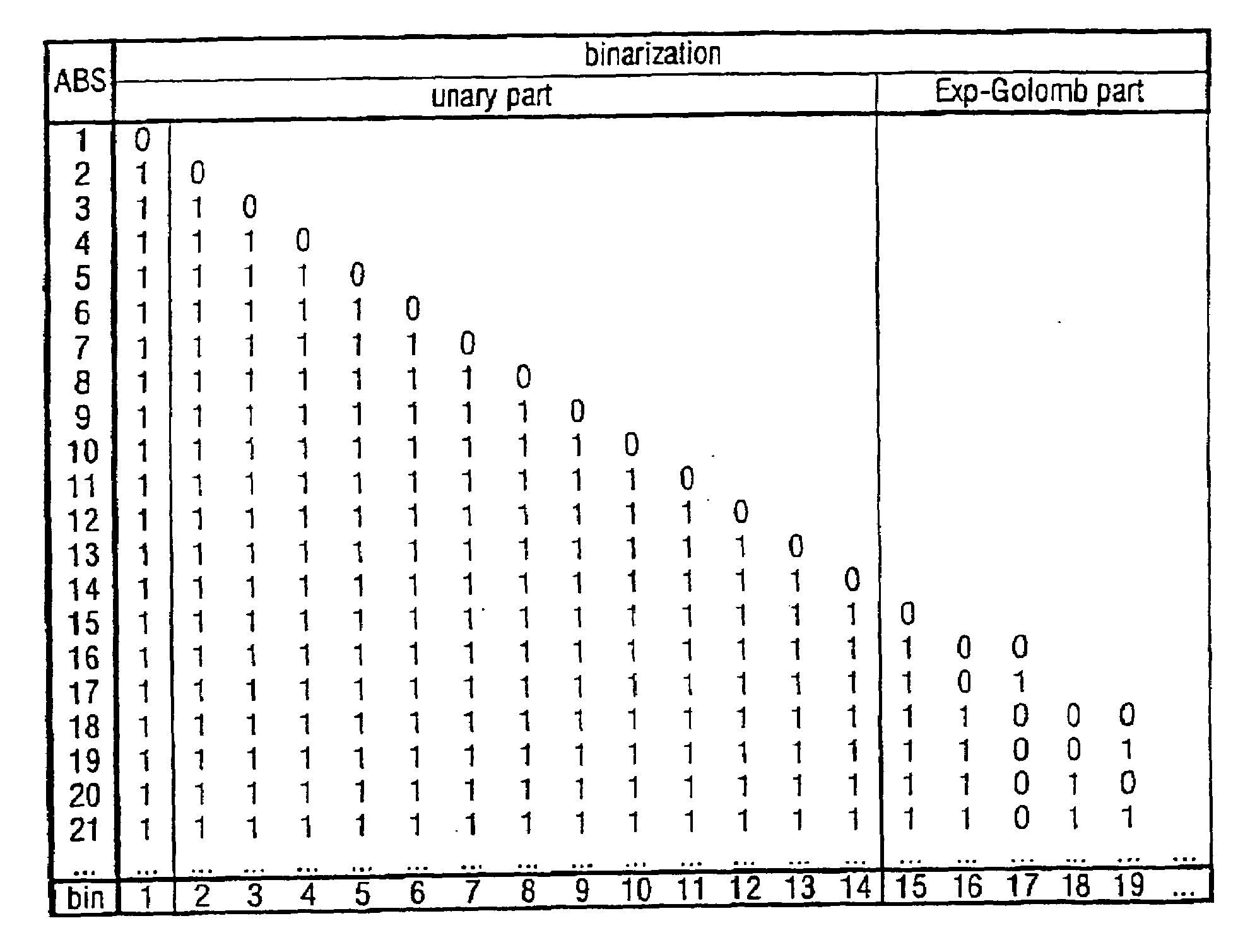

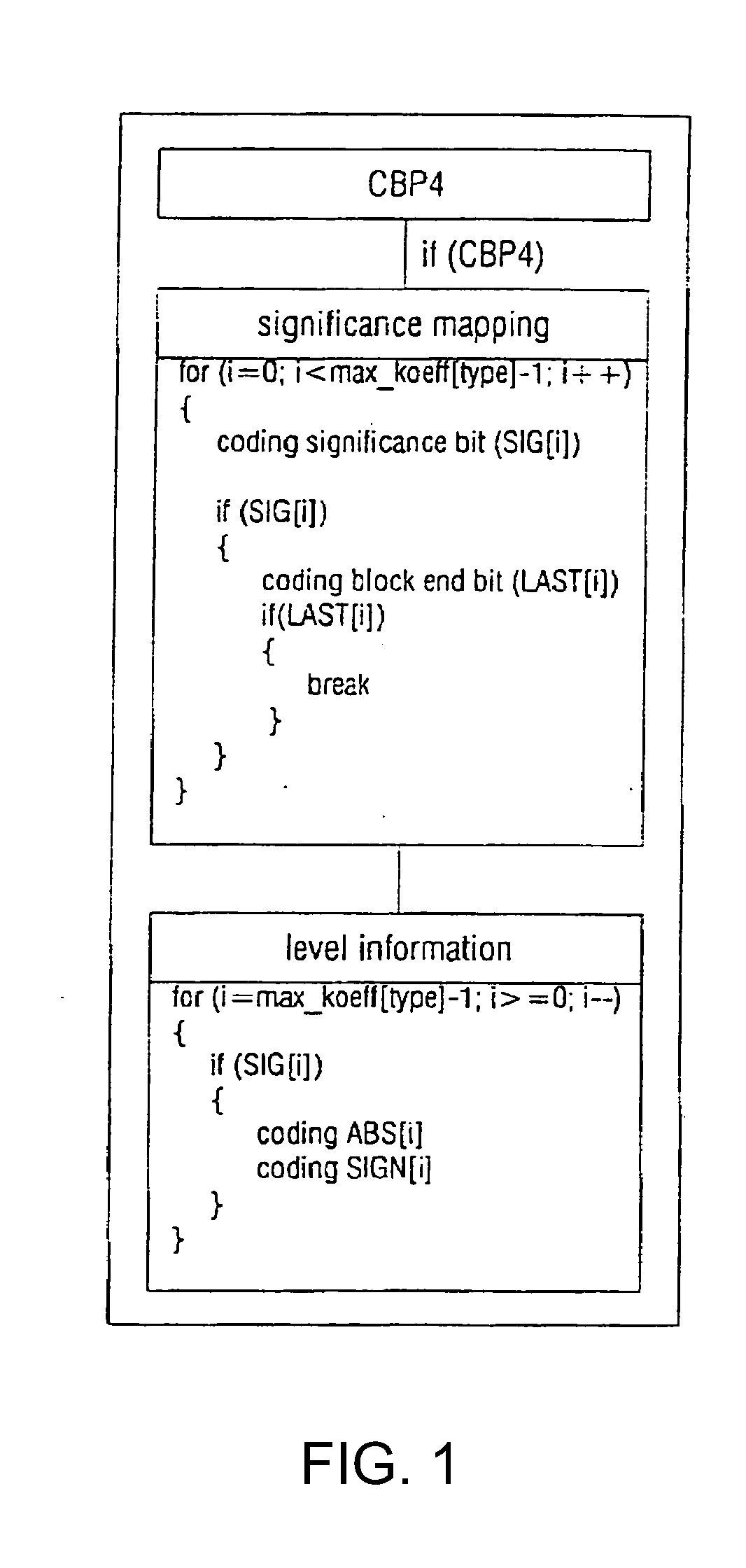

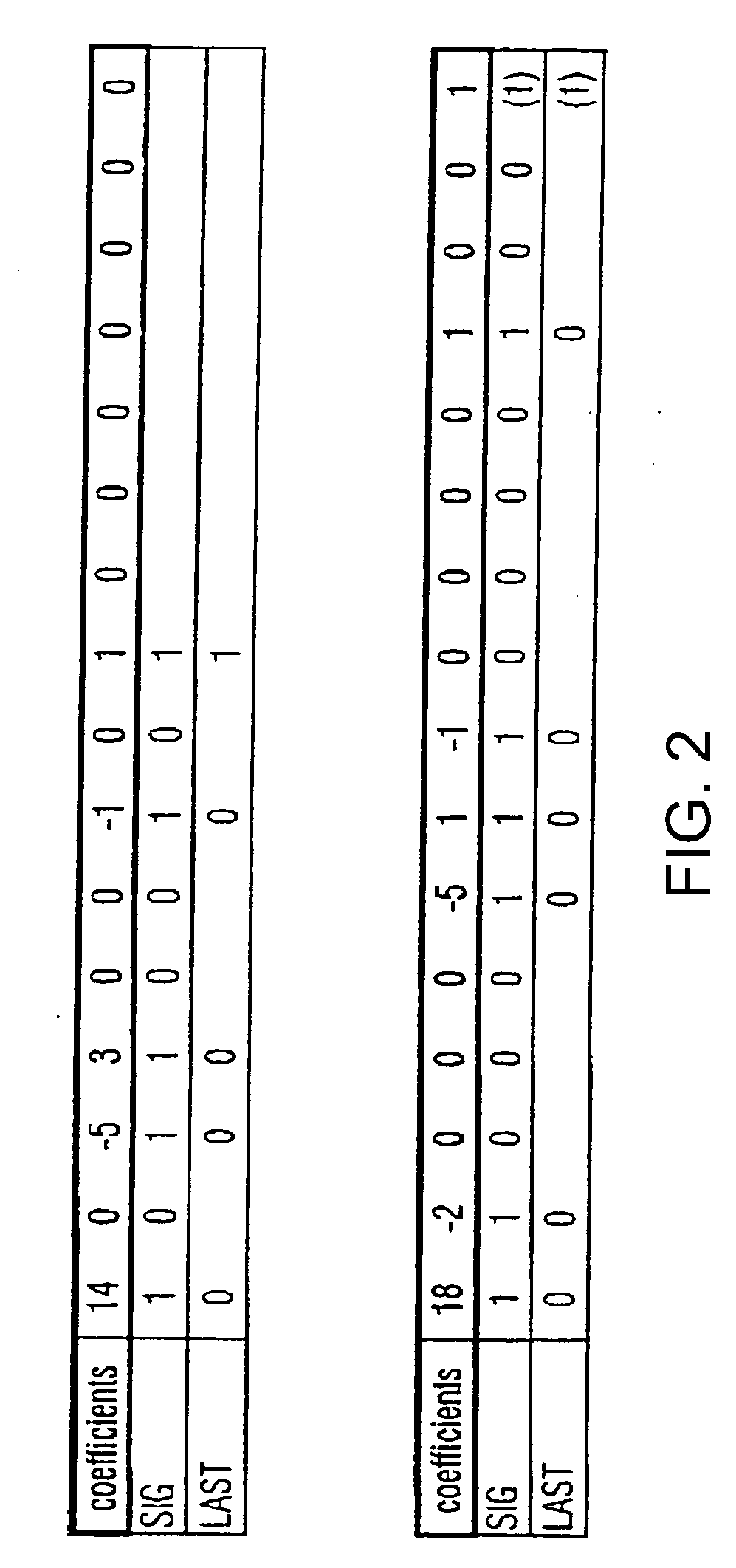

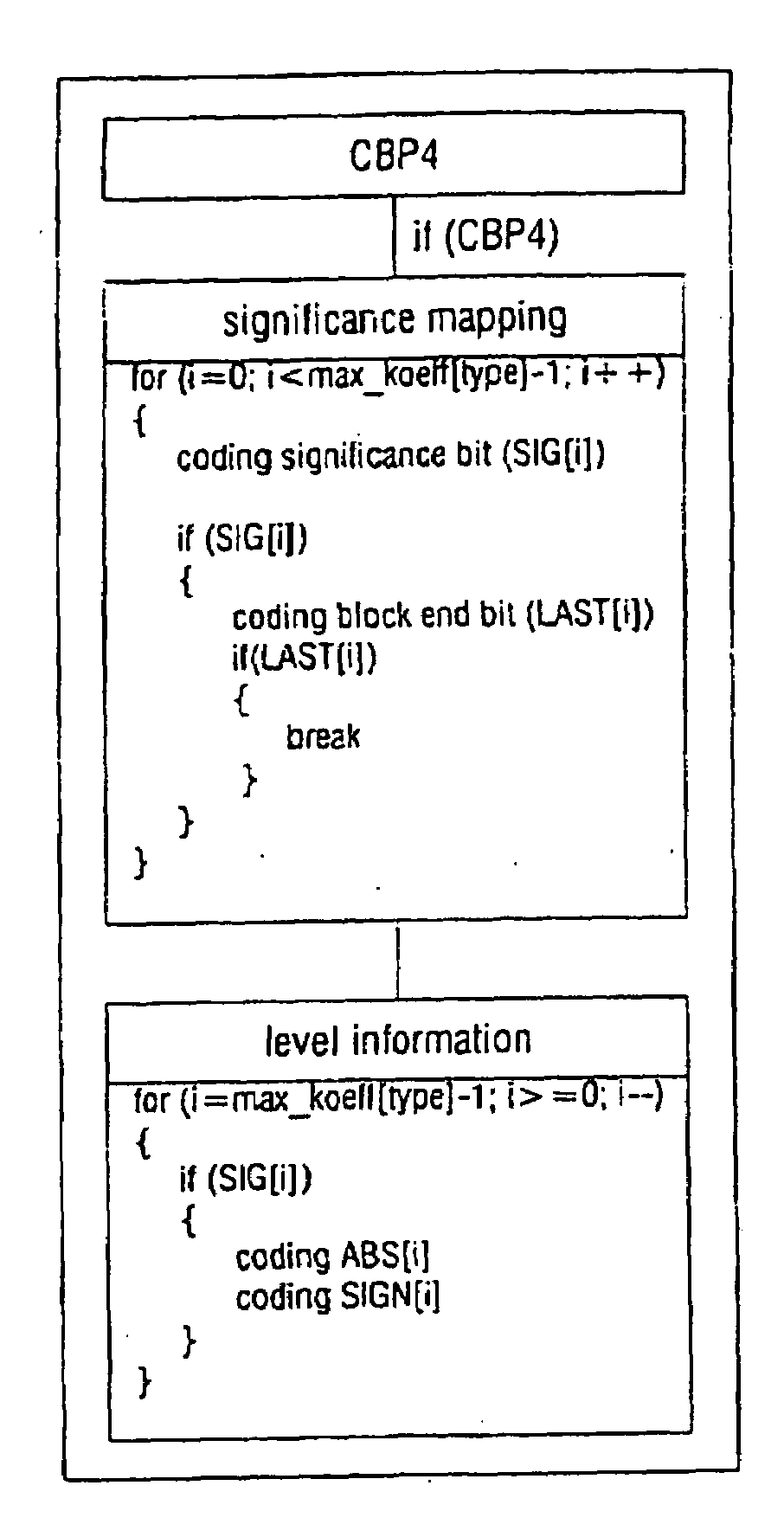

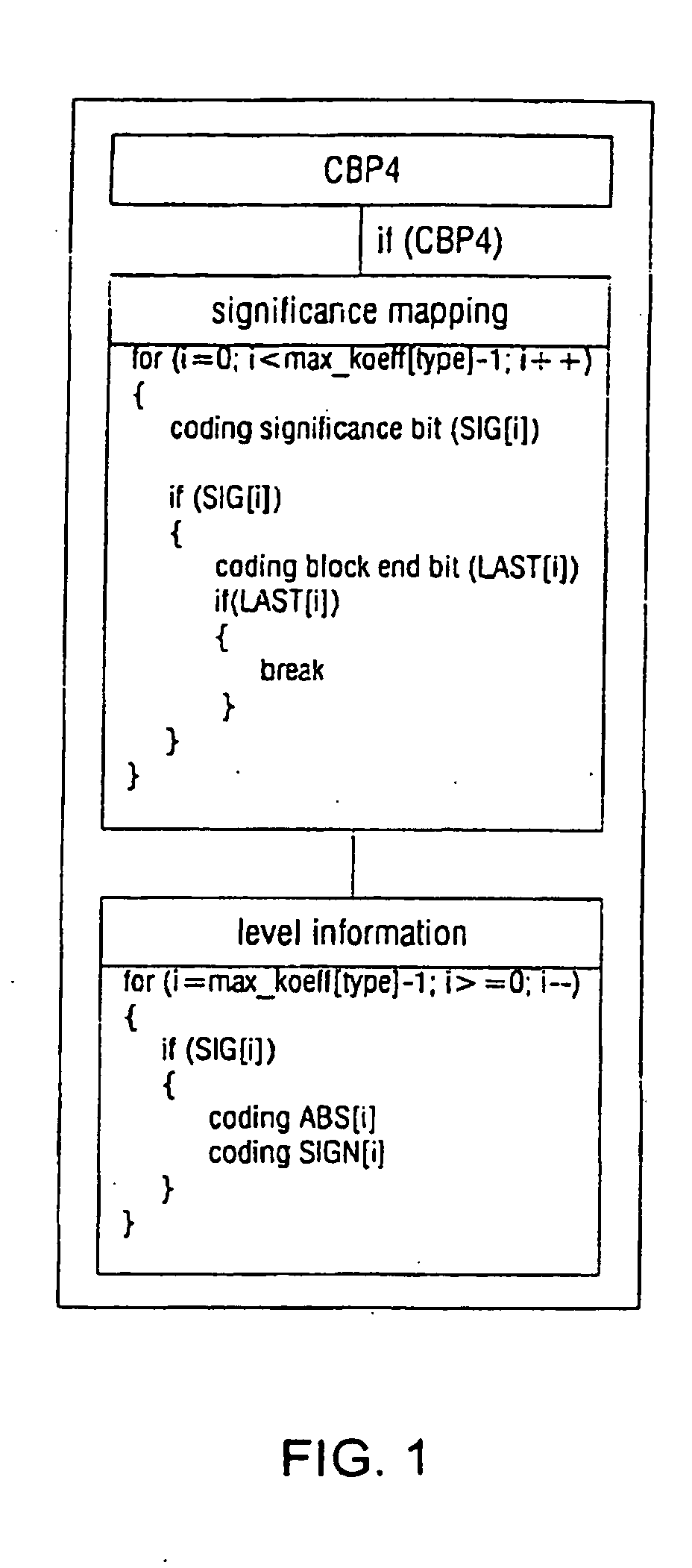

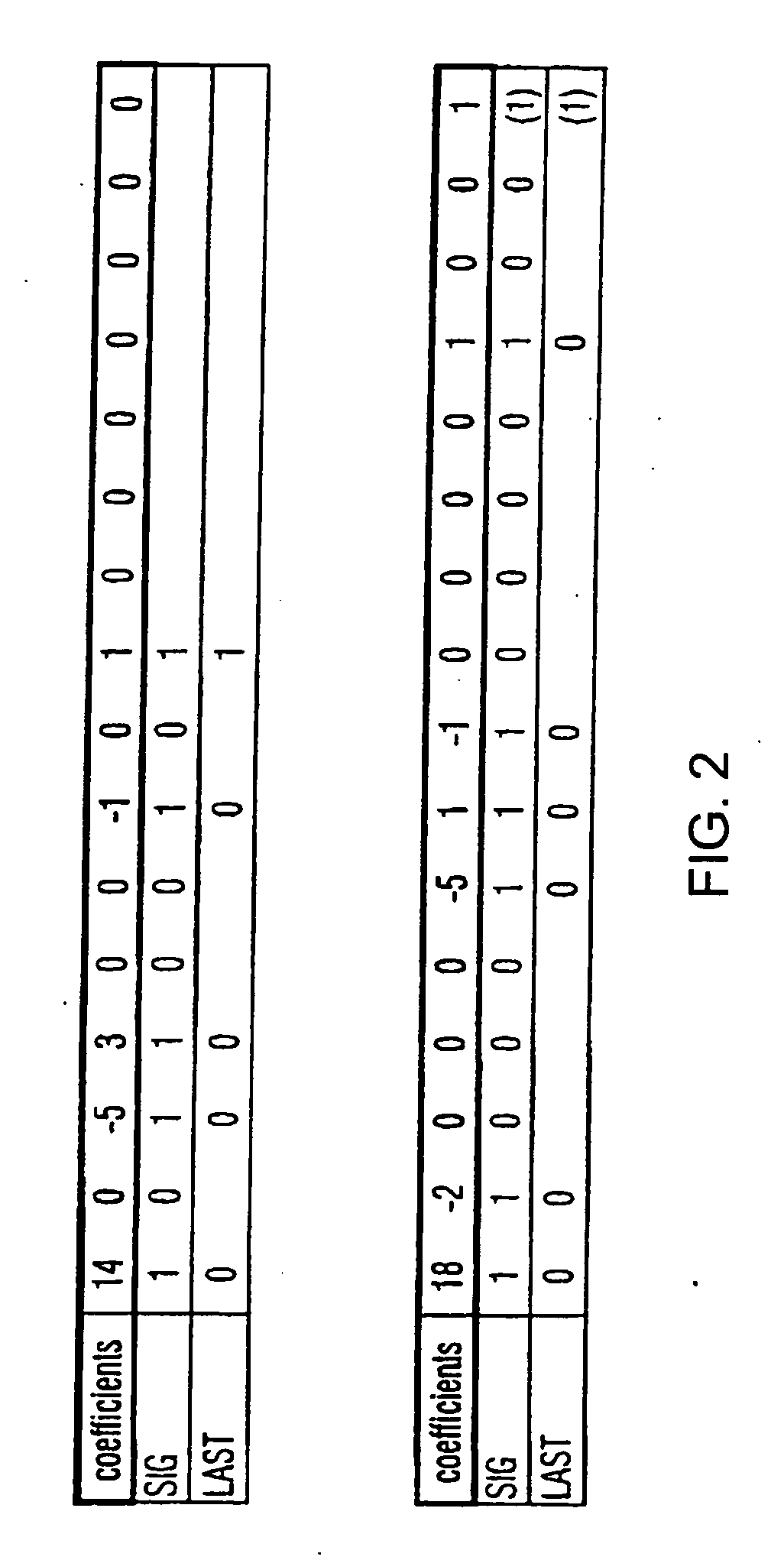

Method and arrangement for coding transform coefficients in picture and/or video coders and decoders and a corresponding computer program and a corresponding computer-readable storage medium

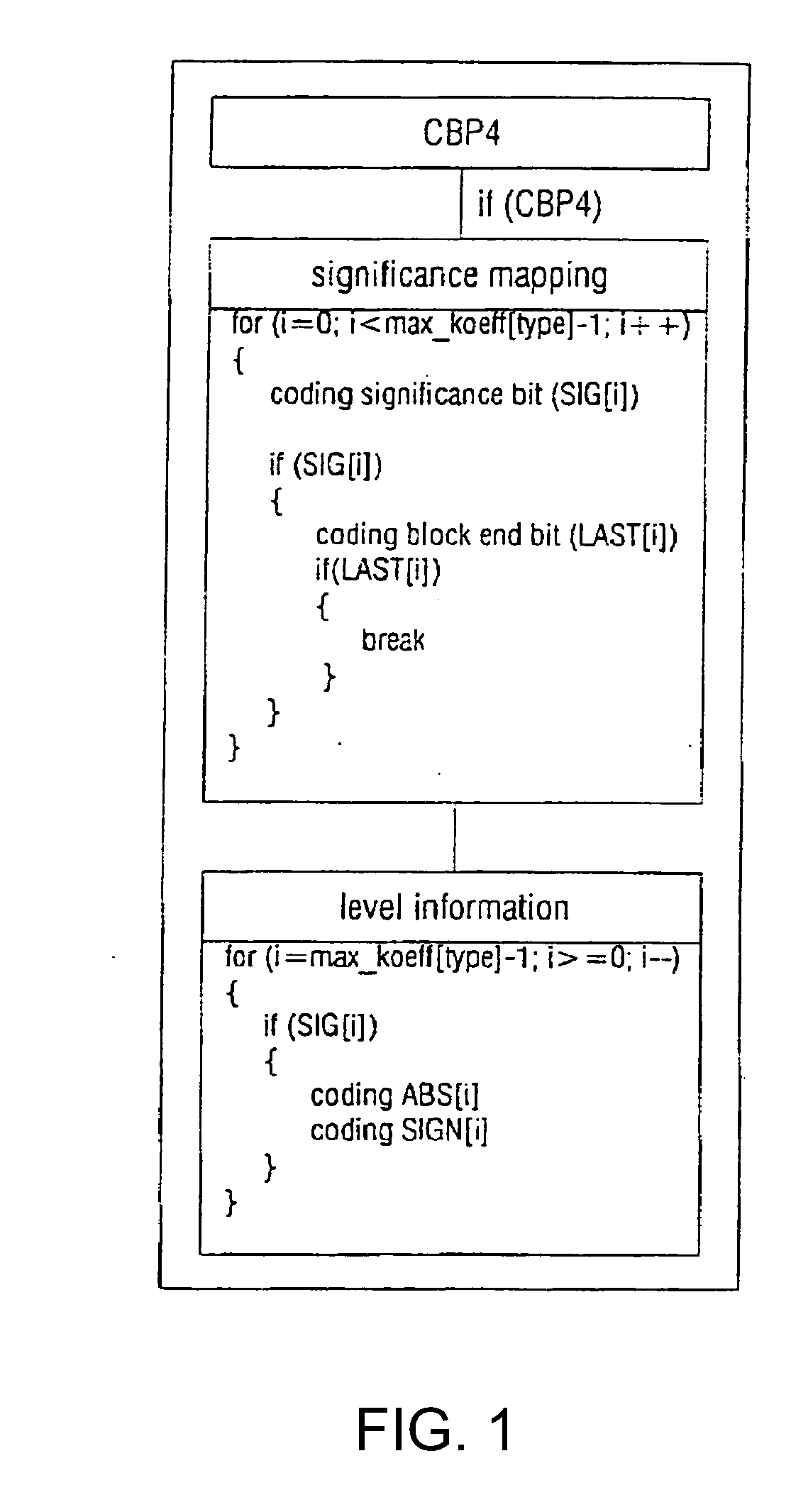

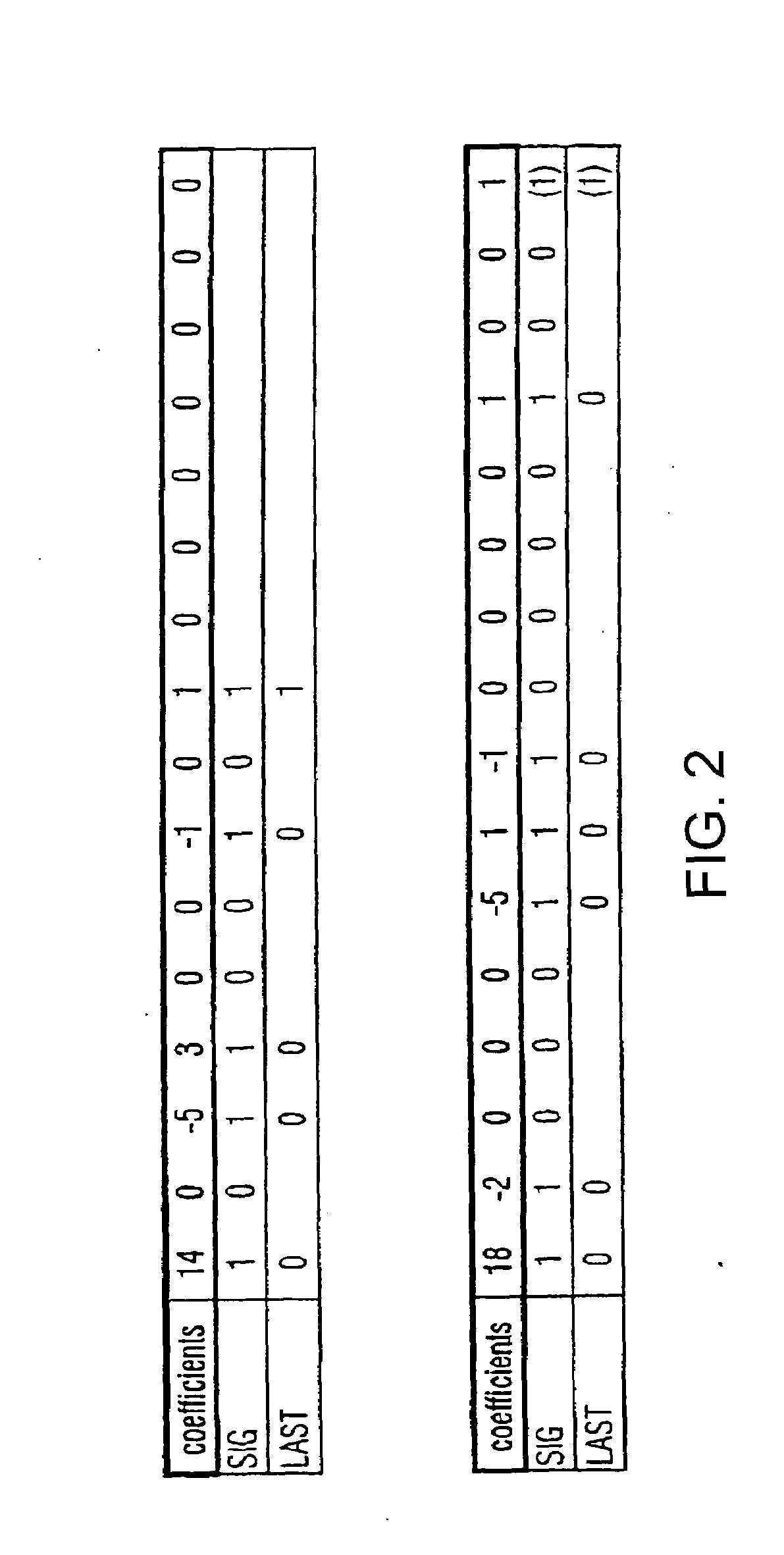

ActiveUS20090201995A1Eliminate deficienciesSmall amount of calculationPicture reproducers using cathode ray tubesCode conversionComputer graphics (images)Video encoding

The present invention describes a method and an arrangement for coding transform coefficients in picture and / or video coders and decoders and a corresponding computer program and a corresponding computer-readable storage medium, which can particularly be employed as a novel efficient method for binary-arithmetic coding transform coefficients in the field of video coding.For this, it is suggested that, for blocks of (video) pictures containing significant transform coefficients, coding of the transform coefficients takes place in such a way that, for each block in a scan process, the positions of significant transform coefficients in the block and subsequently, in a reverse scan order—starting from the last significant transform coefficient within the block—the values (levels) of the significant transform coefficients are determined and coded.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS7898054B2Eliminate deficienciesFacilitate electrical interconnectionFinal product manufacturePV power plantsPolymer substrateMaterial removal

This invention comprises manufacture of photovoltaic cells by deposition of thin film photovoltaic junctions on metal foil substrates. The photovoltaic junctions may be heat treated if appropriate following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation, an interconnection substrate structure is provided, optionally in a continuous fashion. Multiple photovoltaic cells are then laminated to the interconnection substrate structure and conductive joining methods are employed to complete the array. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials employing optimal processing unique to polymeric materials. Furthermore, the photovoltaic junction and its metal foil support can be produced in bulk without the need to use the expensive and intricate material removal operations currently taught in the art to achieve series interconnections.

Owner:SOLANNEX

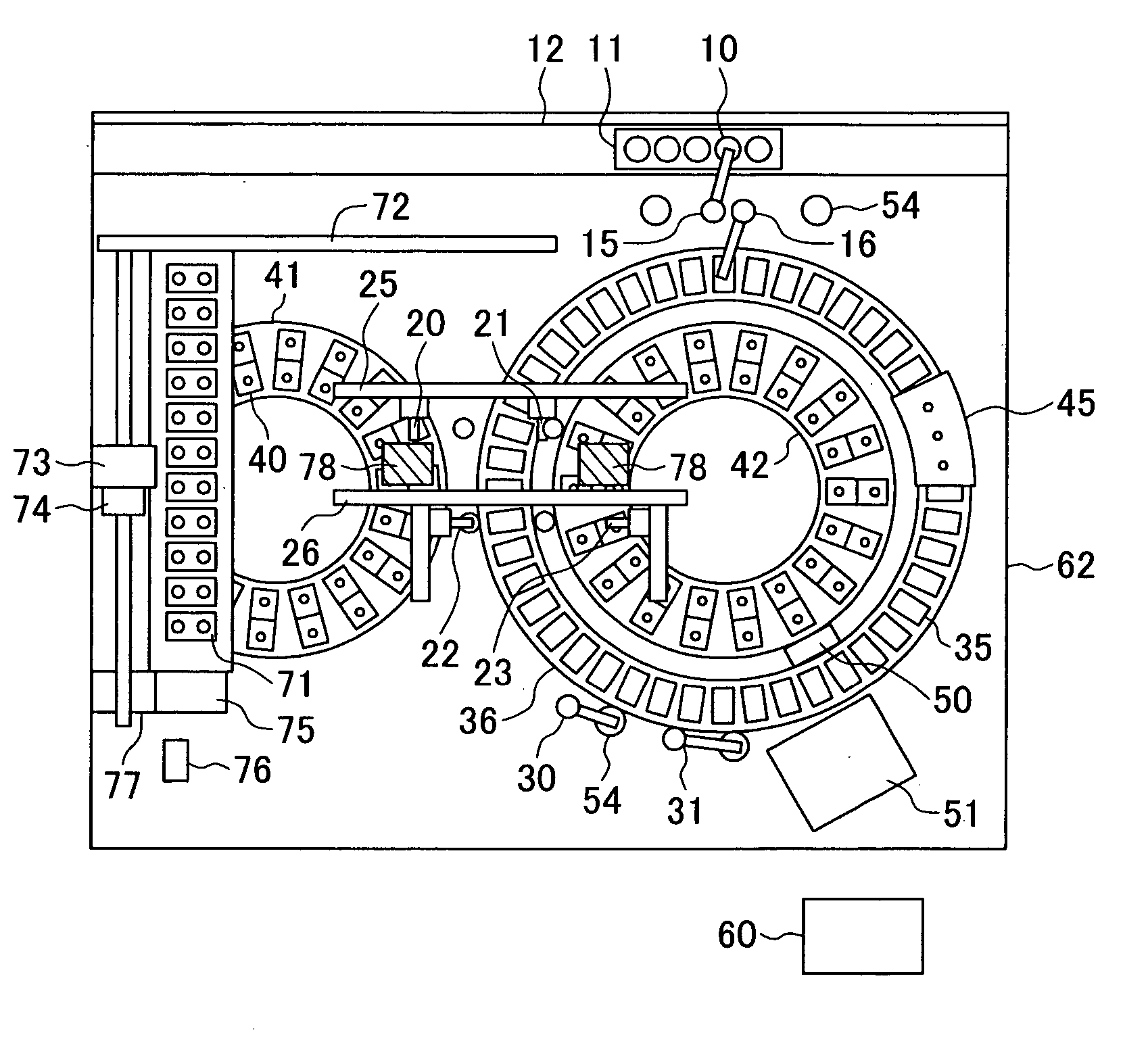

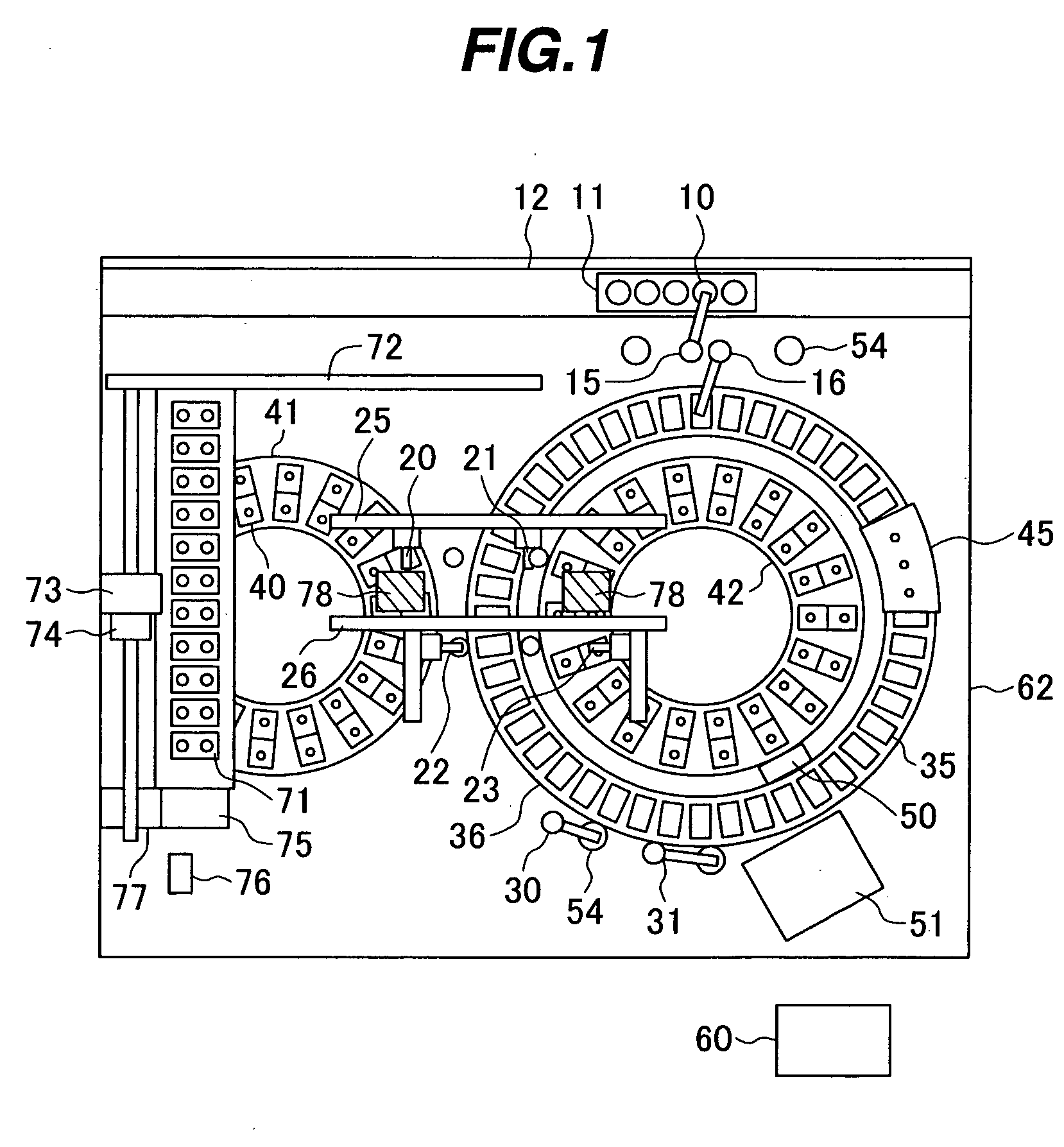

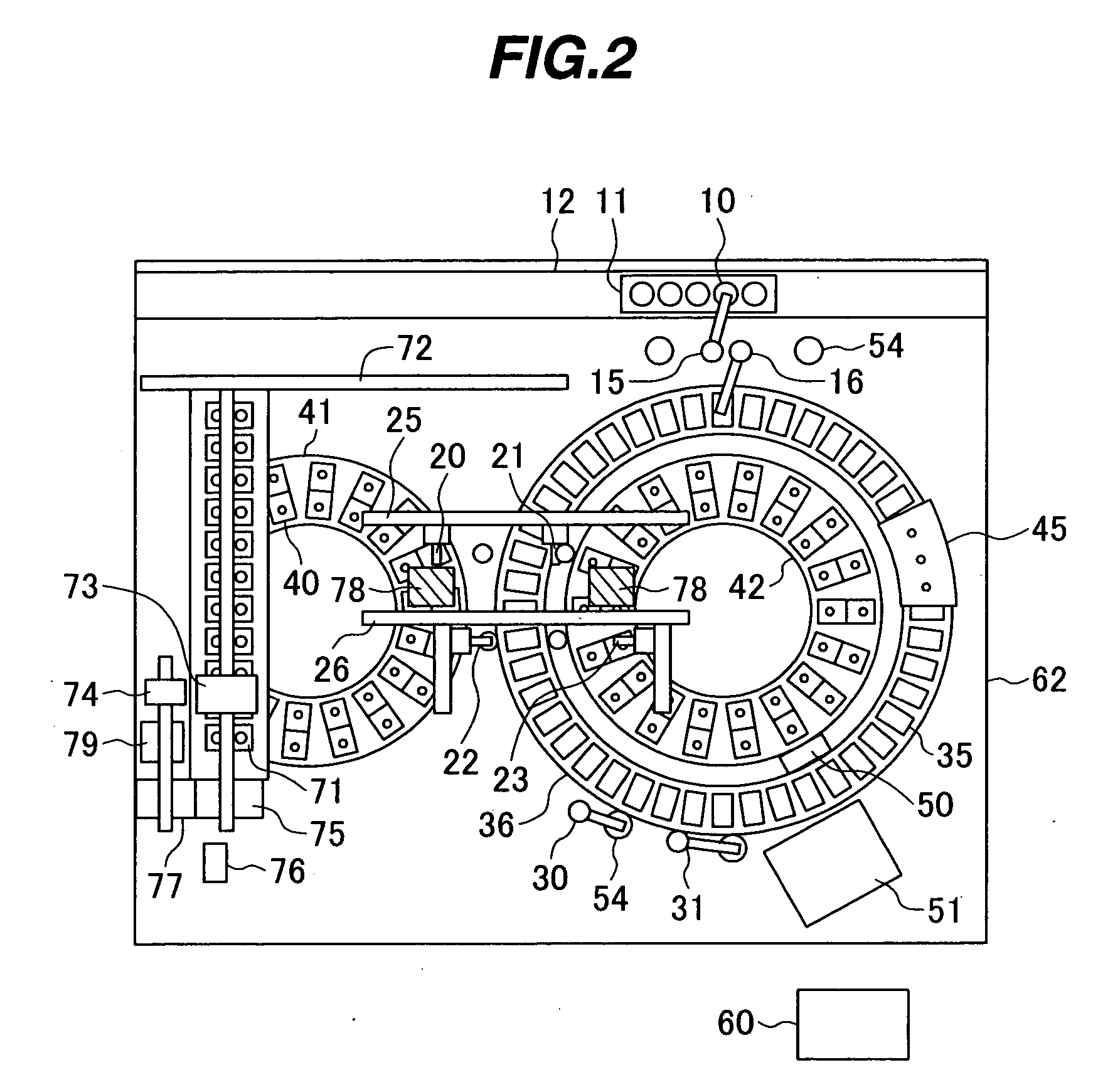

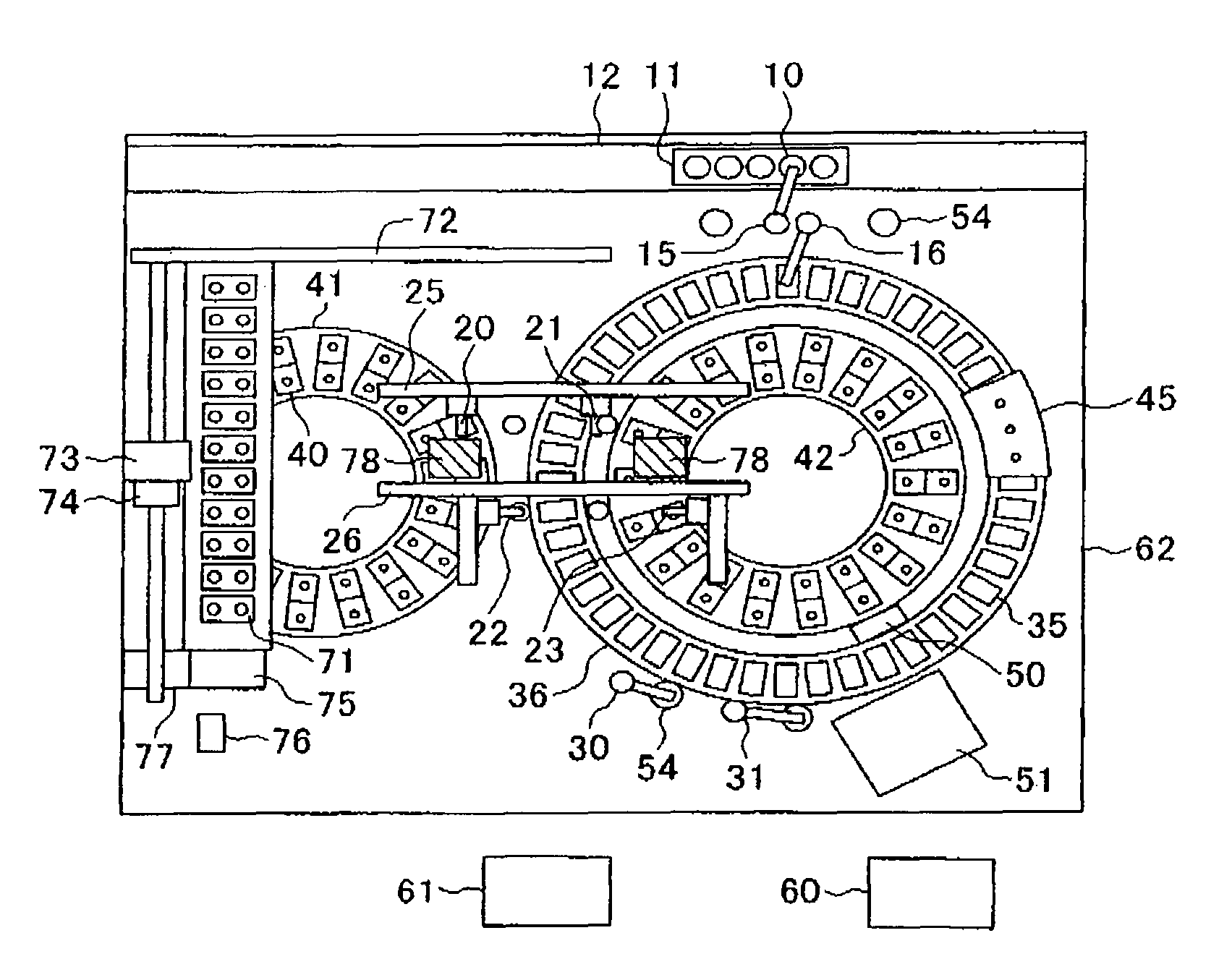

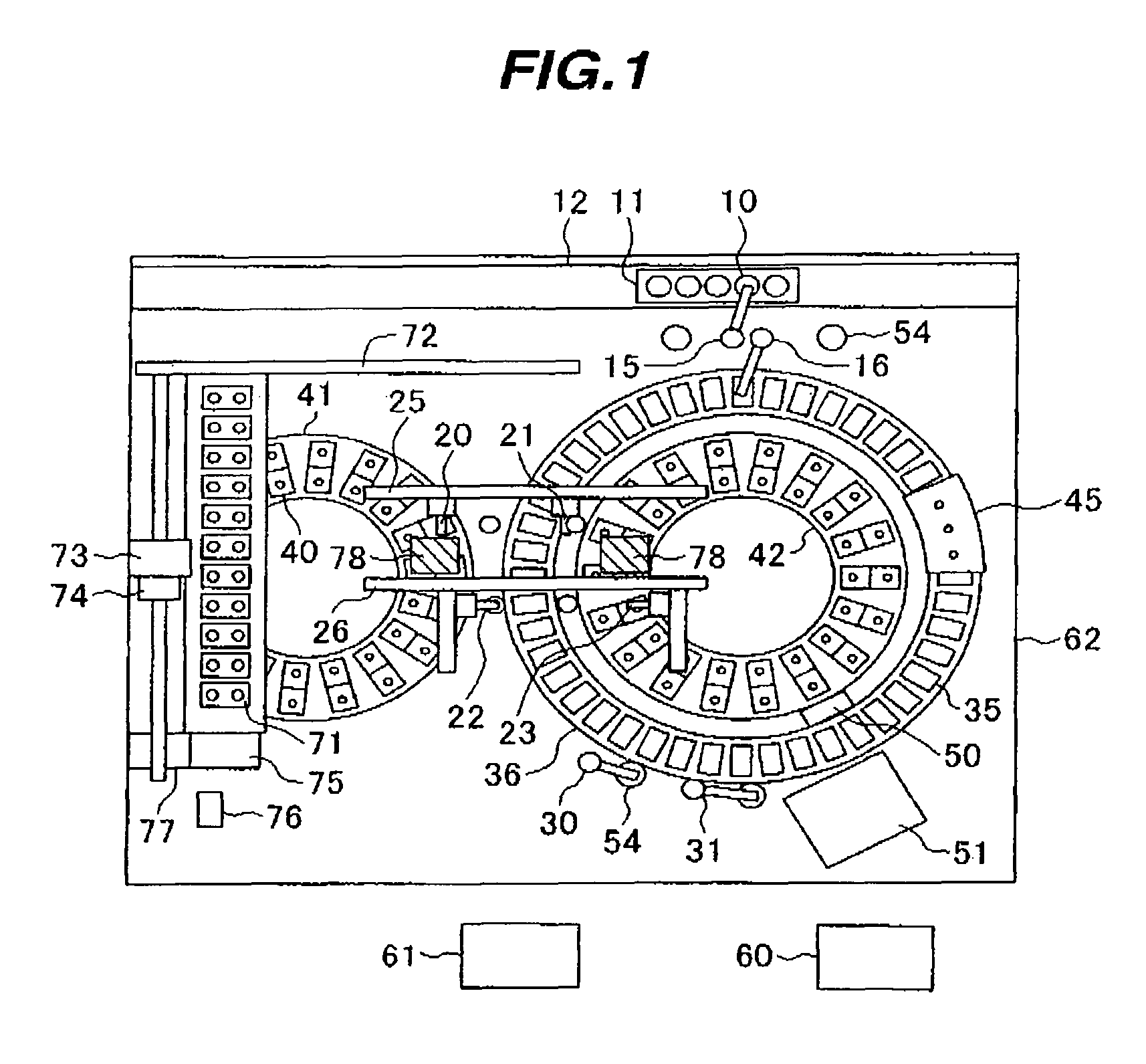

Automatic analyzer

ActiveUS20050207938A1Time for analysisImprove speed of analysisMaterial analysis by optical meansBiological testingReagentAnalytical chemistry

An automatic analyzer is disclosed that dispenses a sample and a reagent into each of a plurality of reaction vessels to allow them to react with each other, and that measures the liquid formed as a result of the reaction. This automatic analyzer includes a first reagent storage case for storing the reagent to be used for the reaction, a second reagent storage case for storing the reagent for supplemental purpose, and a reagent conveying unit for conveying the reagent from the second reagent storage case to the first reagent storage case.

Owner:HITACHI HIGH-TECH CORP +1

Dual mode impulse noise protecting earplug (D-182)

ActiveUS20100294285A1Eliminate deficienciesEasy constructionSubstation/switching arrangement detailsStethoscopeNormal speechUltrasound attenuation

A two piece dual mode earplug including an integrally molded elongated member having a nose end and an open rear end and a channel extending through the elongated member. An integrally molded insert member is formed with a base portion and a rod portion and with the rod portion seated within the open rear end of the elongated member. The insert member additionally includes an attenuation filter integrally molded as part of the rod portion and includes first and second openings located on each side of a chamber and with the size and length of the openings together with the chamber providing attenuation of impulse noise while allowing the passage of normal speech through the channel. The insert member also includes the base portion integrally molded to have a third opening larger than the first and second openings in the rod portion and with the first, second and third openings together forming a passageway through the insert member to the channel extending through the elongated member. The insert member further includes an integrally molded cap member and with the cap member having a plug portion of a size complementary to the third opening of the base member. The insertion of the plug portion into the third opening of the base portion seals off the third opening. The positioning of the cap member provides for the earplug being in a first mode of operation where the passageway is open and a second mode of operation where the passageway is closed.

Owner:MOLDEXMETRIC

Method and Arrangement for Coding Transform Coefficients in Picture and/or Video Coders and Decoders and a Corresponding Computer Program and a Corresponding Computer-Readable Storage Medium

ActiveUS20090201996A1Eliminate deficienciesSmall amount of calculationPicture reproducers using cathode ray tubesCode conversionComputer graphics (images)Video encoding

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS7898053B2Eliminate deficienciesFacilitate electrical interconnectionPV power plantsSolid-state devicesManufacturing technologyPolymer substrate

This invention comprises manufacture of photovoltaic cells by deposition of thin film photovoltaic junctions on metal foil substrates. The photovoltaic junctions may be heat treated if appropriate following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation, an interconnection substrate structure is provided, optionally in a continuous fashion. Multiple photovoltaic cells are then laminated to the interconnection substrate structure and conductive joining methods are employed to complete the array. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials employing optimal processing unique to polymeric materials. Furthermore, the photovoltaic junction and its metal foil support can be produced in bulk without the need to use the expensive and intricate material removal operations currently taught in the art to achieve series interconnections.

Owner:SOLANNEX

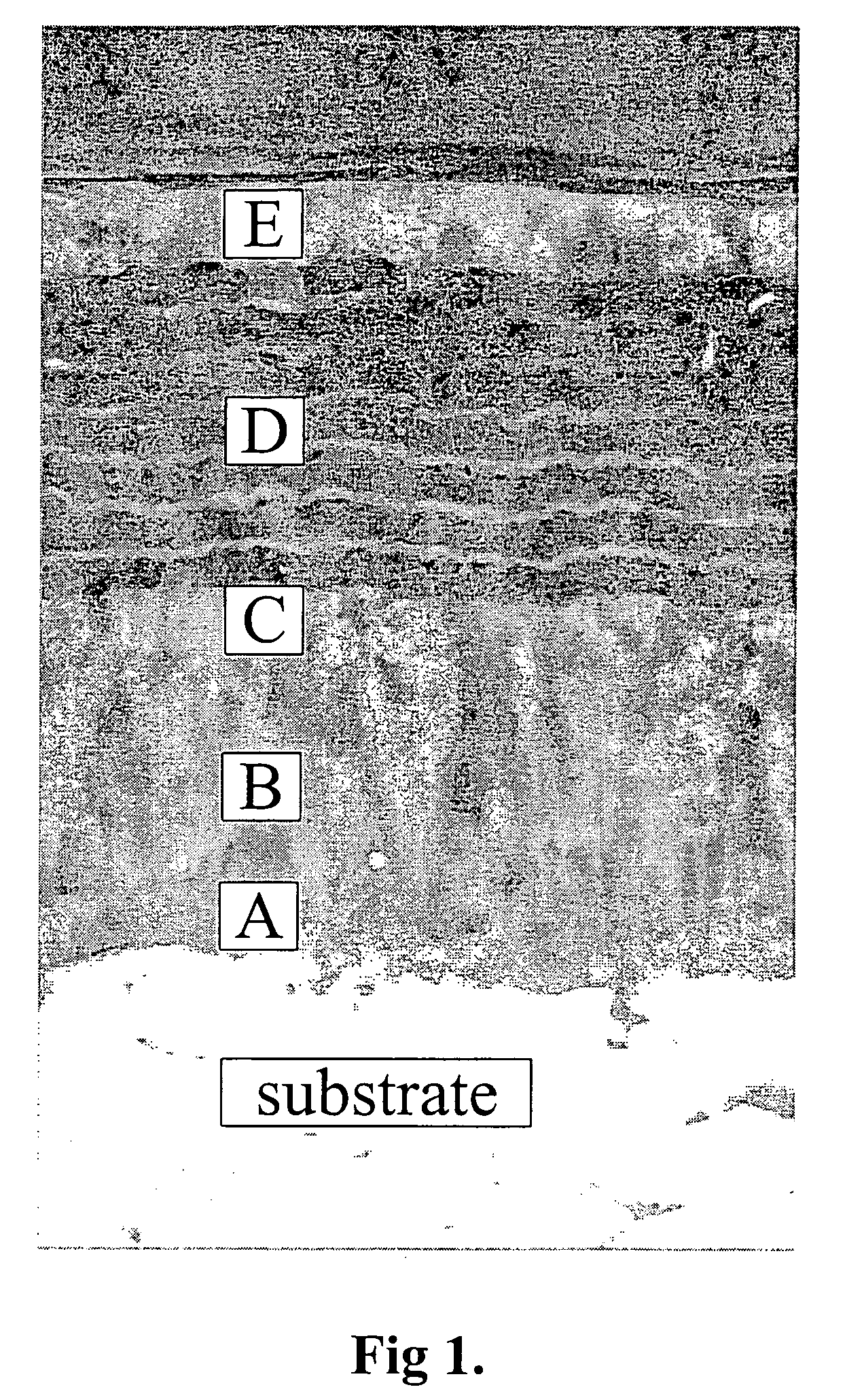

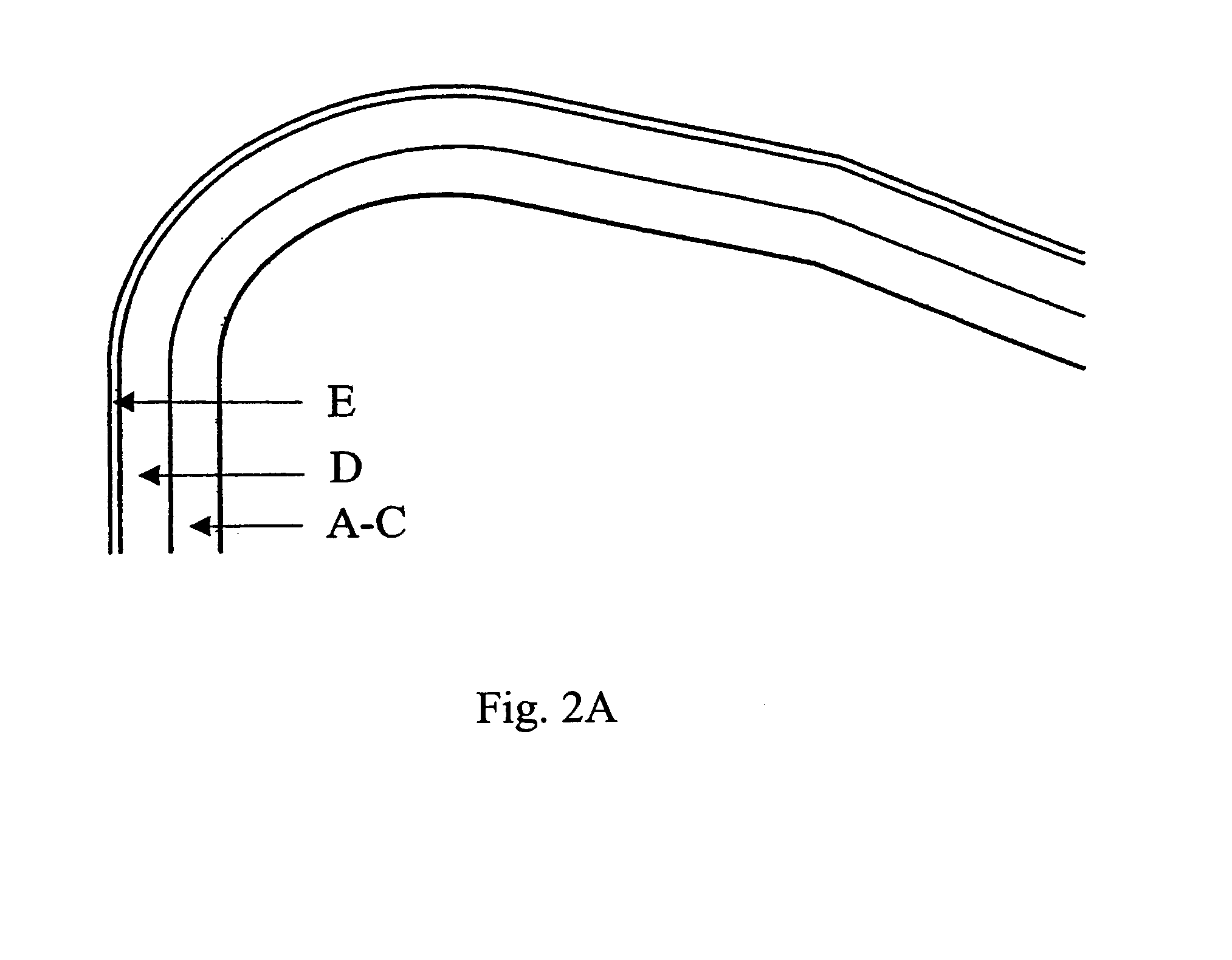

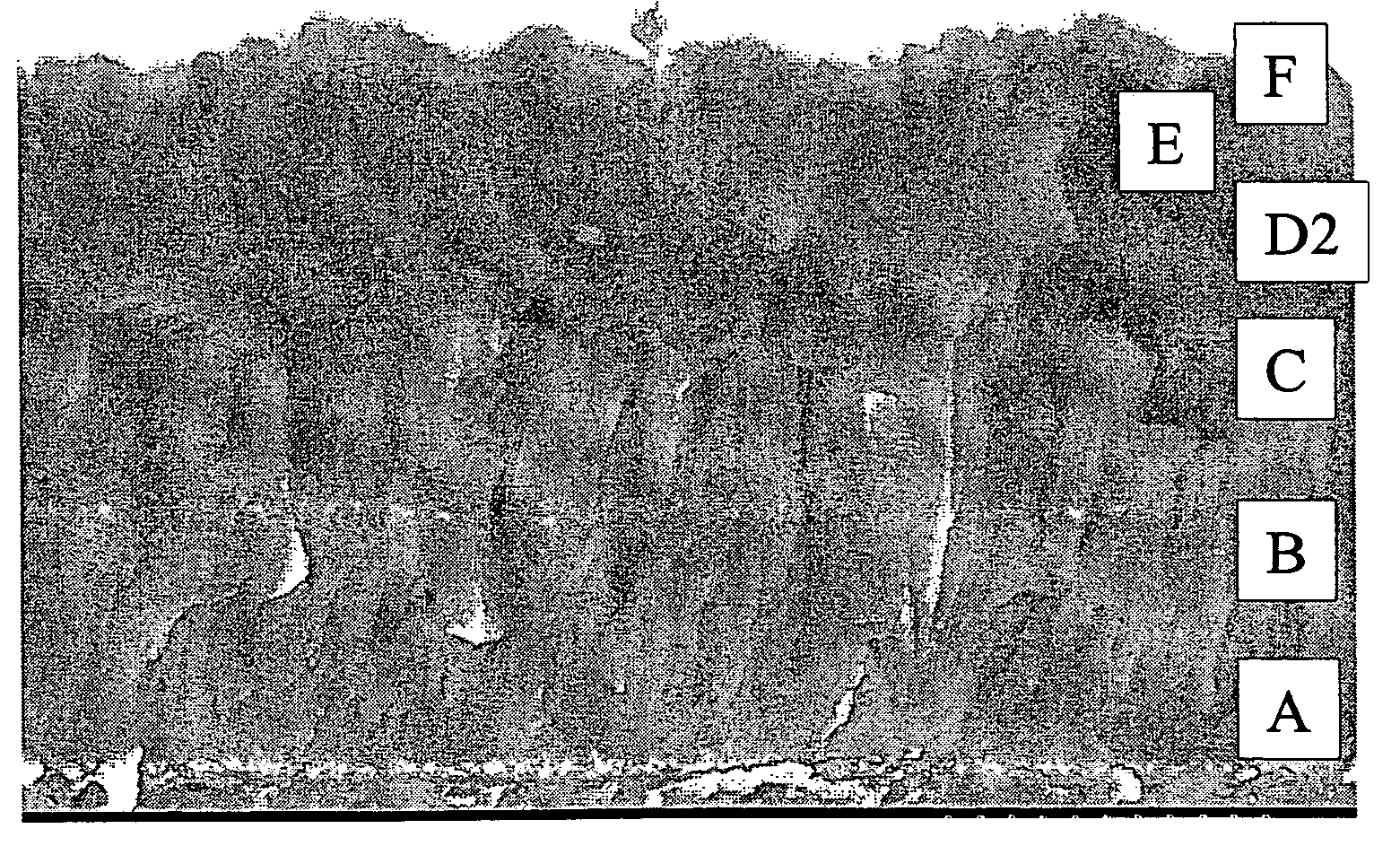

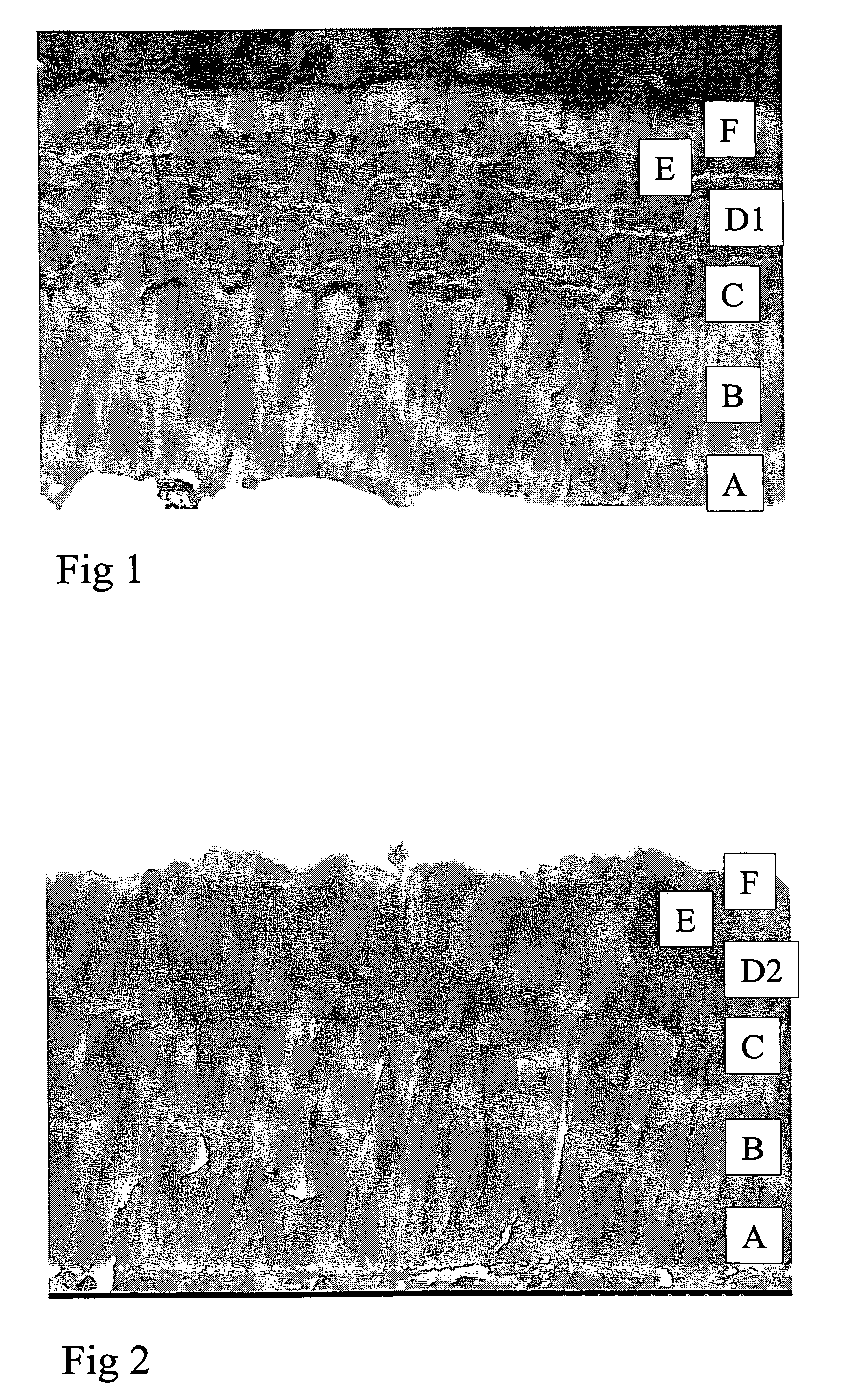

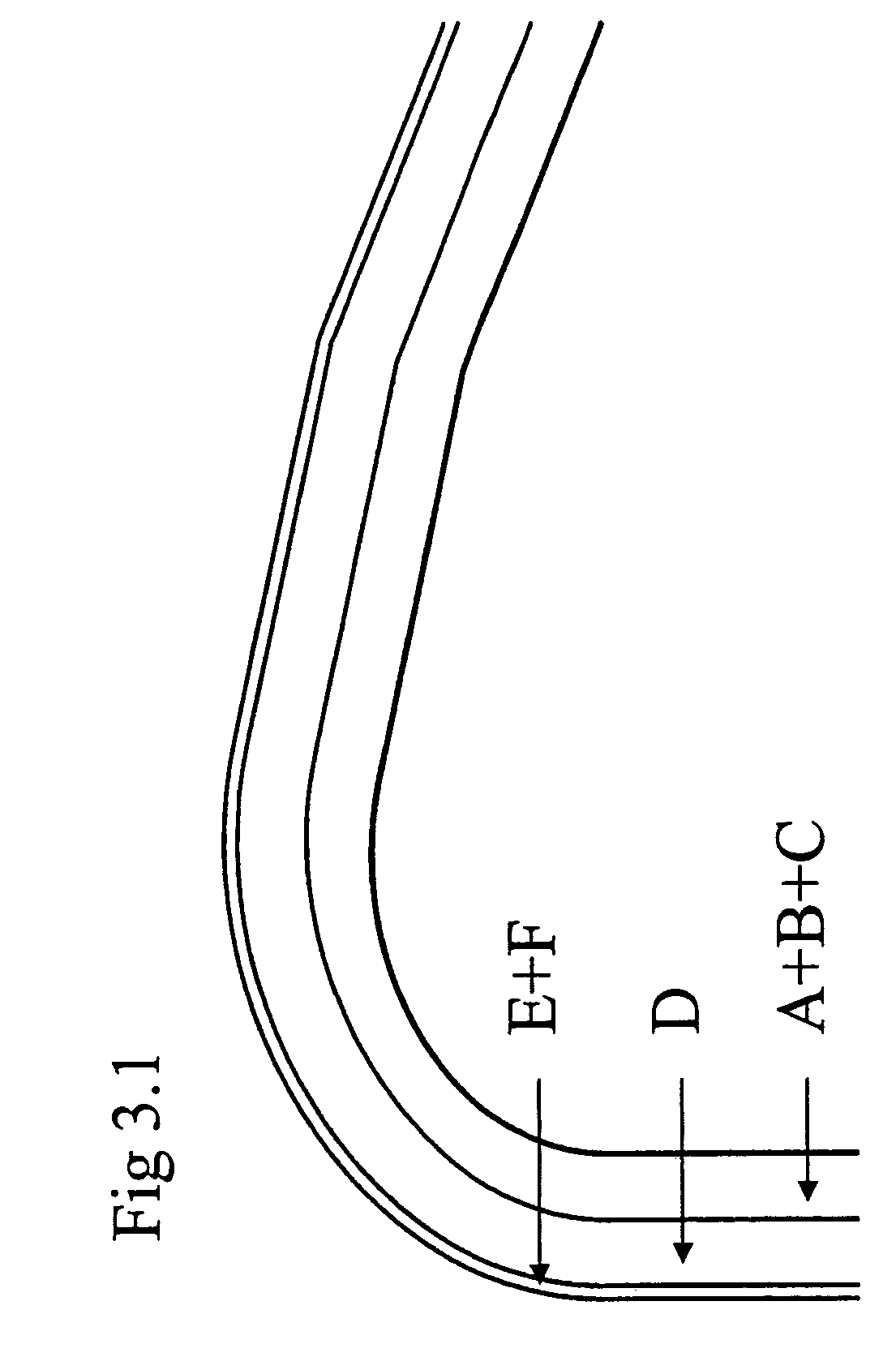

Coated cemented carbide insert

ActiveUS7153562B2Eliminate deficienciesImprove performancePigmenting treatmentCutting insertsAlloyCemented carbide

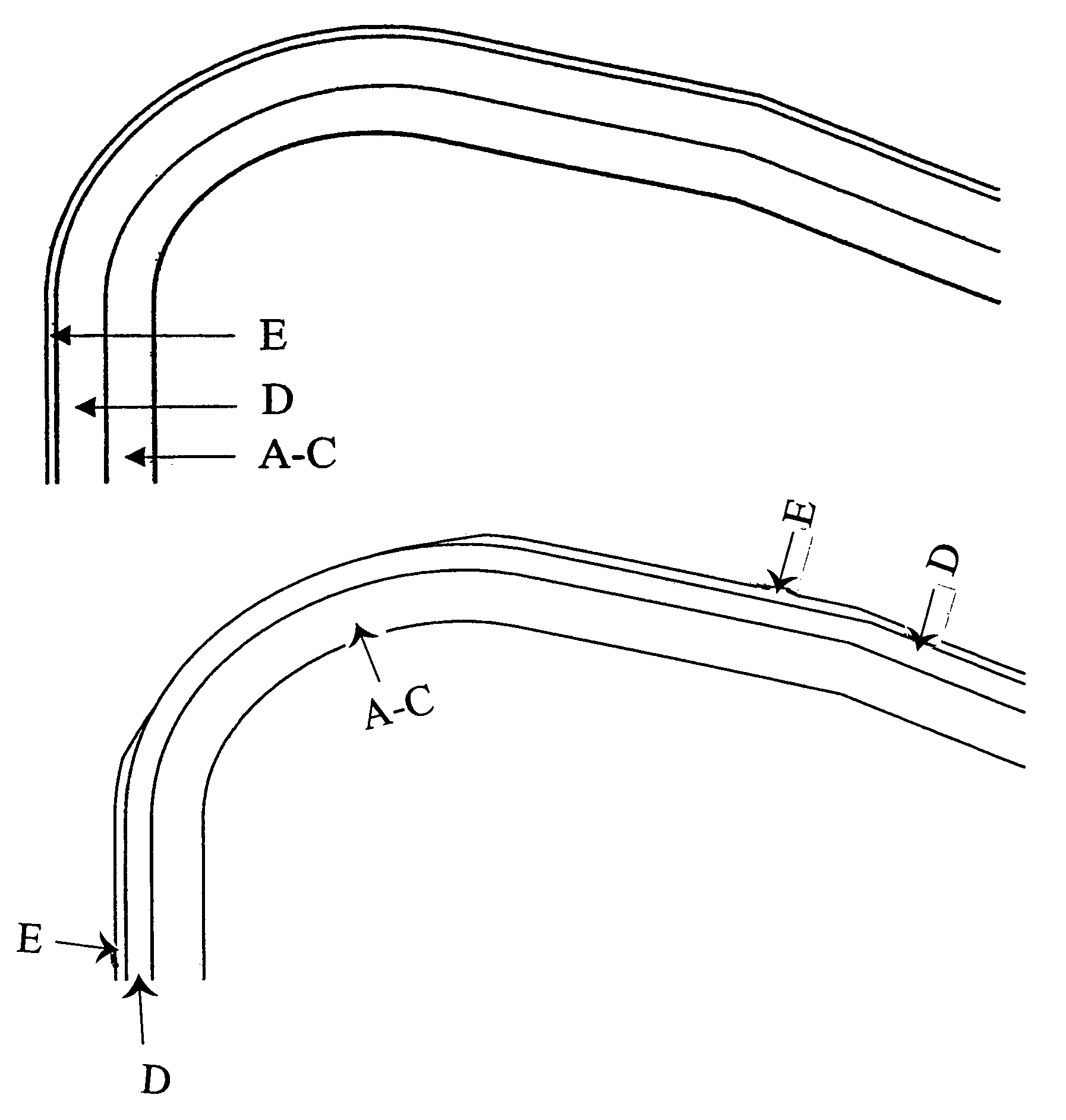

The present invention relates to a cutting tool insert particularly for turning of steel comprising a cemented carbide body, a coating with a post treatment witha first, innermost layer system of one or several layers of TiCxNyOz with x+y+z≦1 with a total thickness of 0.7–4.5 μma second multilayer system consisting of a totally 5–31 alternating Al2O3 and TiCxNyOz (x+y+z≦1), preferably κ-Al2O3 and TiN, the Al2O3-layers having an individual layer thickness of <0.5 μm and the TiCxNyOz-layers 0.01–0.2 μm with a total thickness of the multilayer of 1.0–4.0 μm. The multilayer is exposed along the edge line and into the rake and flank face, at least 0.02 mm, from the edge line on the rake face, preferably the contact length of the chip at most 0.9 mm, and 0.02–0.20 mm on the flank face.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

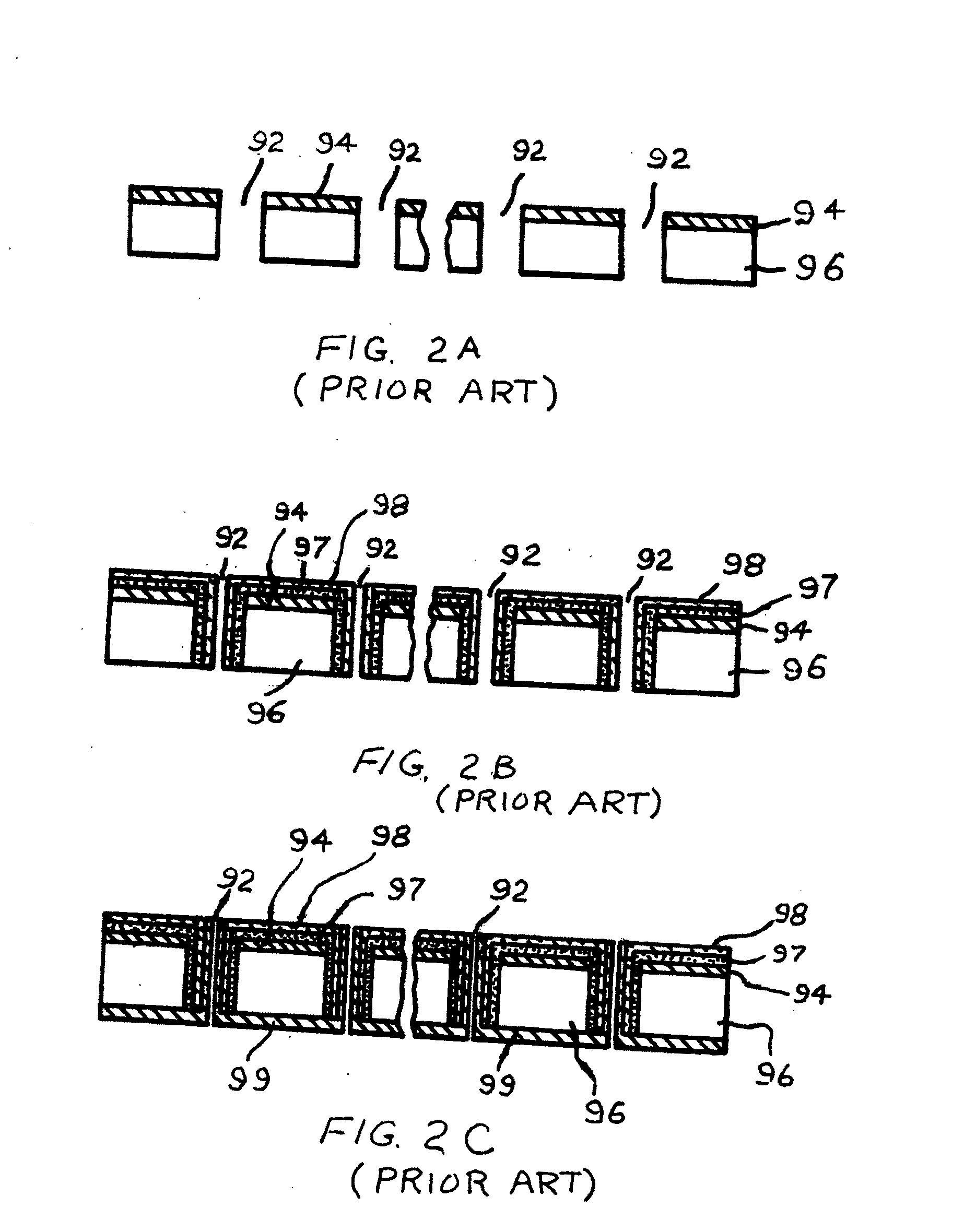

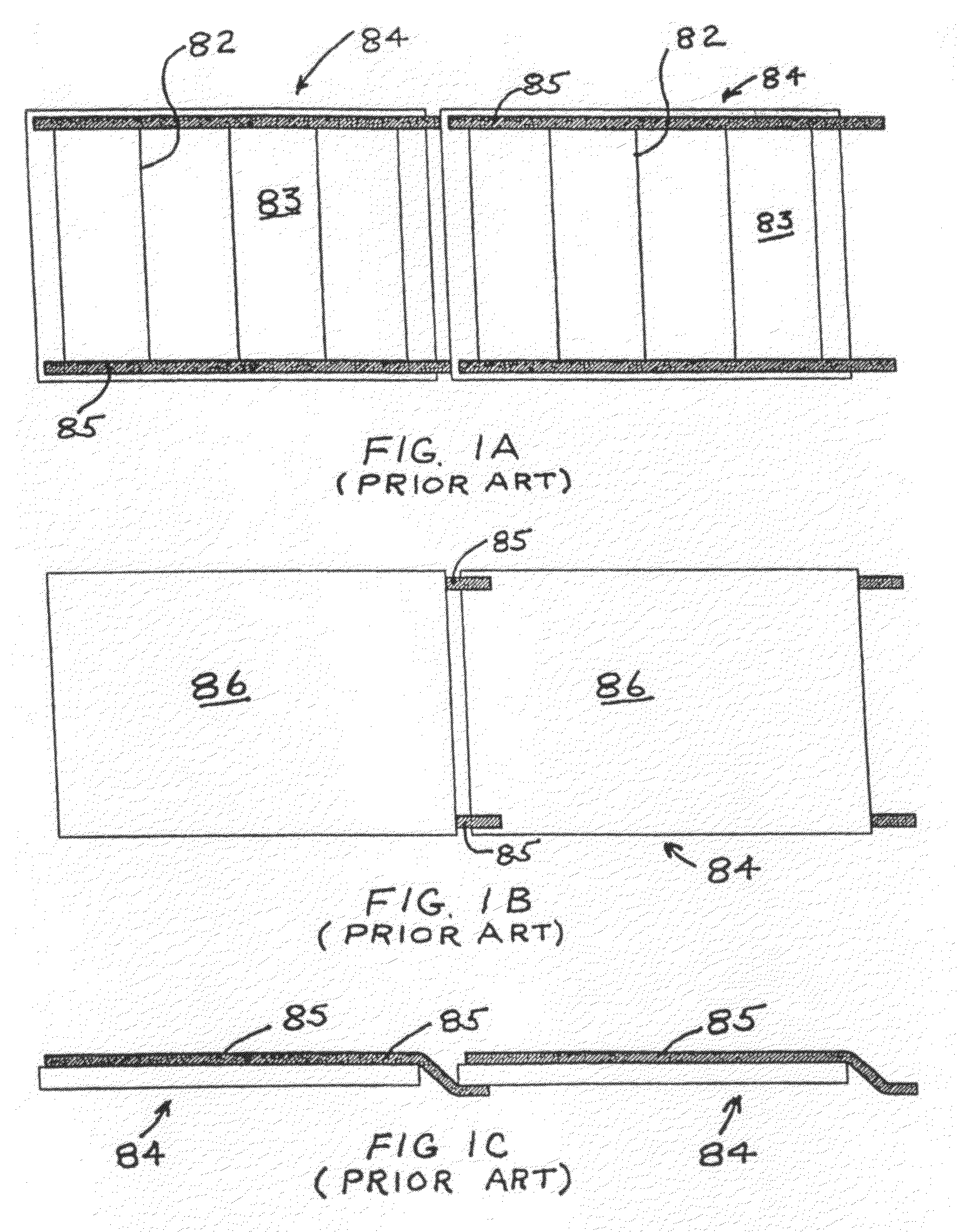

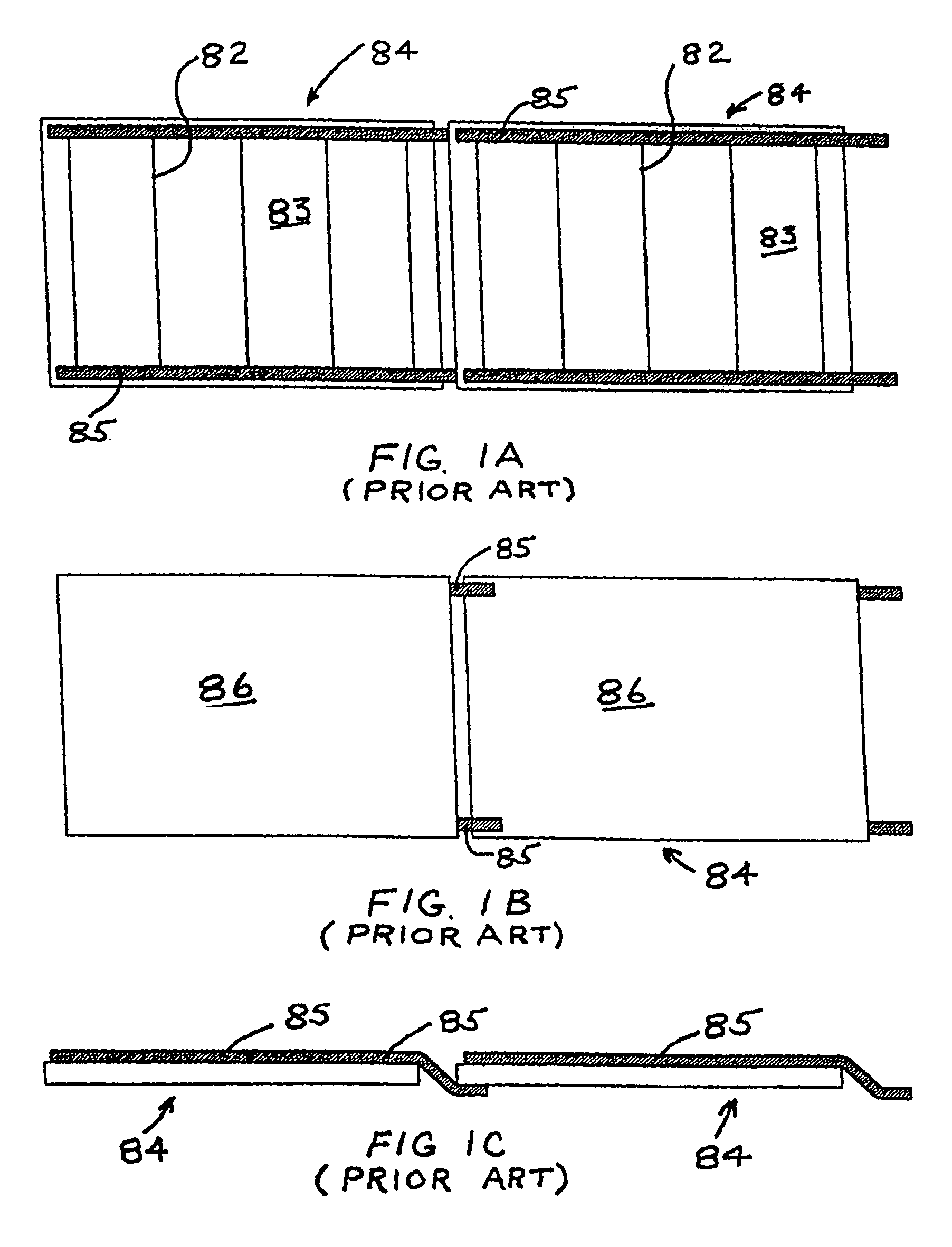

Collector grid and interconnect structures for photovoltaic arrays and modules

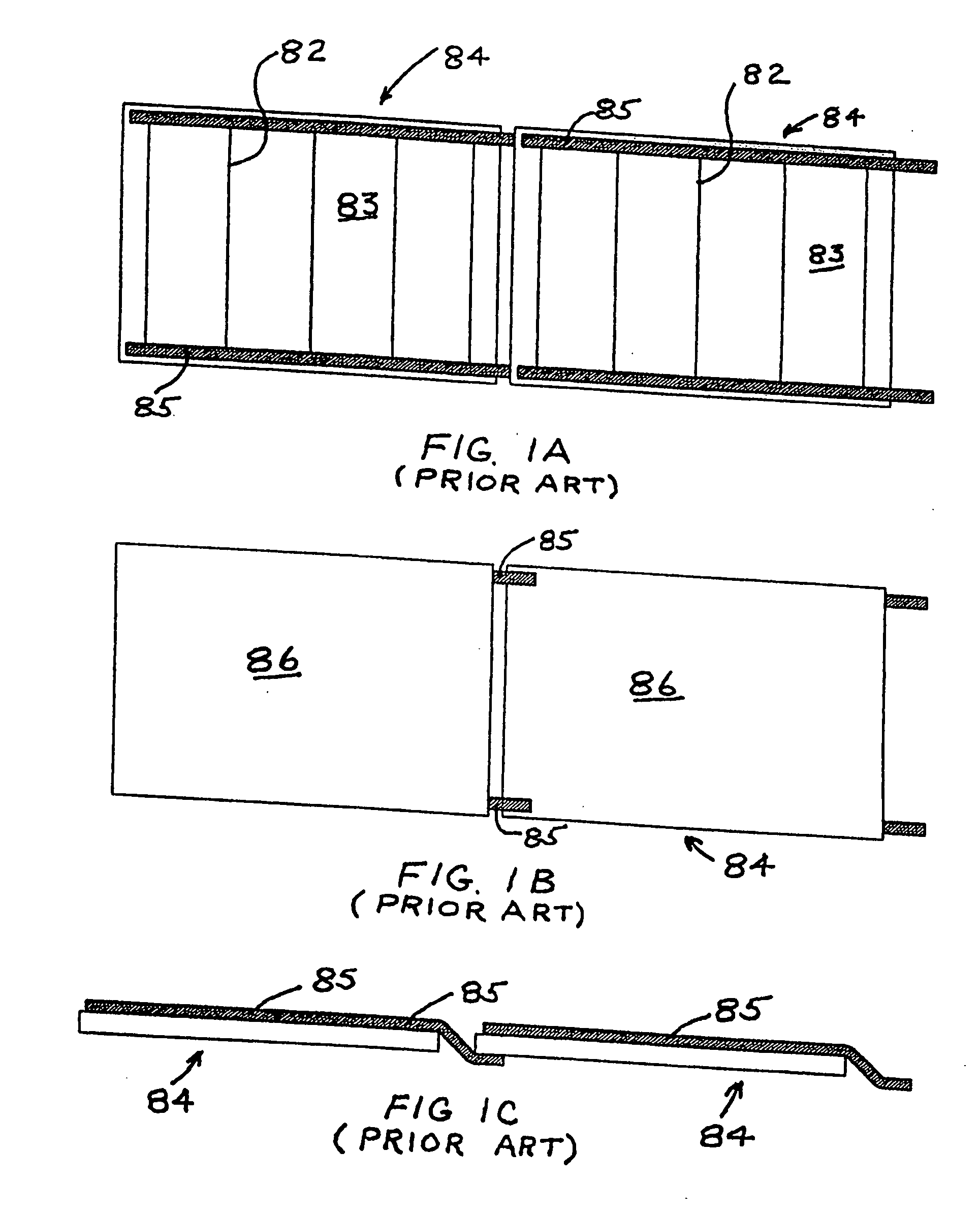

InactiveUS20120171802A1Eliminate deficienciesEase of mass productionSemiconductor/solid-state device manufacturingPhotovoltaic energy generationPhotovoltaic arraysConductive materials

An interconnected arrangement of photovoltaic cells is achieved using laminating current collector electrodes. The electrodes comprise a pattern of conductive material extending over a first surface of sheetlike substrate material. The first surface comprises material having adhesive affinity for a selected conductive surface. Application of the electrode to the selected conductive surface brings the first surface of the sheetlike substrate into adhesive contact with the conductive surface and simultaneously brings the conductive surface into firm contact with the conductive material extending over first surface of the sheetlike substrate. Use of the laminating current collector electrodes allows facile and continuous production of expansive area interconnected photovoltaic arrays.

Owner:LUCH DANIEL +1

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS20110067754A1Minimization requirementsIncrease volumePhotovoltaic energy generationSemiconductor devicesMaterial removalPolymer substrate

This invention comprises manufacture of photovoltaic cells by deposition of thin film photovoltaic junctions on metal foil substrates. The photovoltaic junctions may be heat treated if appropriate following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation, an interconnection substrate structure is provided, optionally in a continuous fashion. Multiple photovoltaic cells are then laminated to the interconnection substrate structure and conductive joining methods are employed to complete the array. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials employing optimal processing unique to polymeric materials. Furthermore, the photovoltaic junction and its metal foil support can be produced in bulk without the need to use the expensive and intricate material removal operations currently taught in the art to achieve series interconnections.

Owner:SOLANNEX

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS20080227236A1Eliminate deficienciesFacilitate electrical interconnectionPV power plantsSolid-state devicesPolymer substrateMaterial removal

This invention comprises manufacture of photovoltaic cells by deposition of thin film photovoltaic junctions on metal foil substrates. The photovoltaic junctions may be heat treated if appropriate following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation, an interconnection substrate structure is provided, optionally in a continuous fashion. Multiple photovoltaic cells are then laminated to the interconnection substrate structure and conductive joining methods are employed to complete the array. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials employing optimal processing unique to polymeric materials. Furthermore, the photovoltaic junction and its metal foil support can be produced in bulk without the need to use the expensive and intricate material removal operations currently taught in the art to achieve series interconnections.

Owner:SOLANNEX

Dual mode impulse noise protecting earplug (D-182)

ActiveUS8161975B2Avoid damageEliminate deficienciesSubstation/switching arrangement detailsStethoscopeUltrasound attenuationDual mode

A two piece dual mode earplug including an integrally molded elongated member having a nose end and an open rear end and a channel extending through. An integrally molded insert member is formed with a base portion and a rod portion and with the rod portion seated within the open rear end of the elongated member and includes an attenuation filter integrally molded as part of the rod portion and includes first and second openings located on each side of a chamber and with the size and length of the openings together with the chamber providing attenuation of impulse noise. The insert member also includes the base portion integrally molded to have a third opening larger than the first and second openings in the rod portion and with the first, second and third openings together forming a passageway through the insert member to the channel extending through the elongated member.

Owner:MOLDEXMETRIC

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS8198696B2Eliminate deficienciesFacilitate electrical interconnectionPV power plantsSolid-state devicesPolymer substrateMaterial removal

This invention comprises manufacture of photovoltaic cells by deposition of thin film photovoltaic junctions on metal foil substrates. The photovoltaic junctions may be heat treated if appropriate following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation, an interconnection substrate structure is provided, optionally in a continuous fashion. Multiple photovoltaic cells are then laminated to the interconnection substrate structure and conductive joining methods are employed to complete the array. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials employing optimal processing unique to polymeric materials. Furthermore, the photovoltaic junction and its metal foil support can be produced in bulk without the need to use the expensive and intricate material removal operations currently taught in the art to achieve series interconnections.

Owner:SOLANNEX

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS20120031461A1Minimization requirementsIncrease volumePV power plantsPhotovoltaic energy generationPolymer substrateMaterial removal

This invention comprises manufacture of photovoltaic cells by deposition of thin film photovoltaic junctions on metal foil substrates. The photovoltaic junctions may be heat treated if appropriate following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation, an interconnection substrate structure is provided, optionally in a continuous fashion. Multiple photovoltaic cells are then laminated to the interconnection substrate structure and conductive joining methods are employed to complete the array. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials employing optimal processing unique to polymeric materials. Furthermore, the photovoltaic junction and its metal foil support can be produced in bulk without the need to use the expensive and intricate material removal operations currently taught in the art to achieve series interconnections.

Owner:SOLANNEX

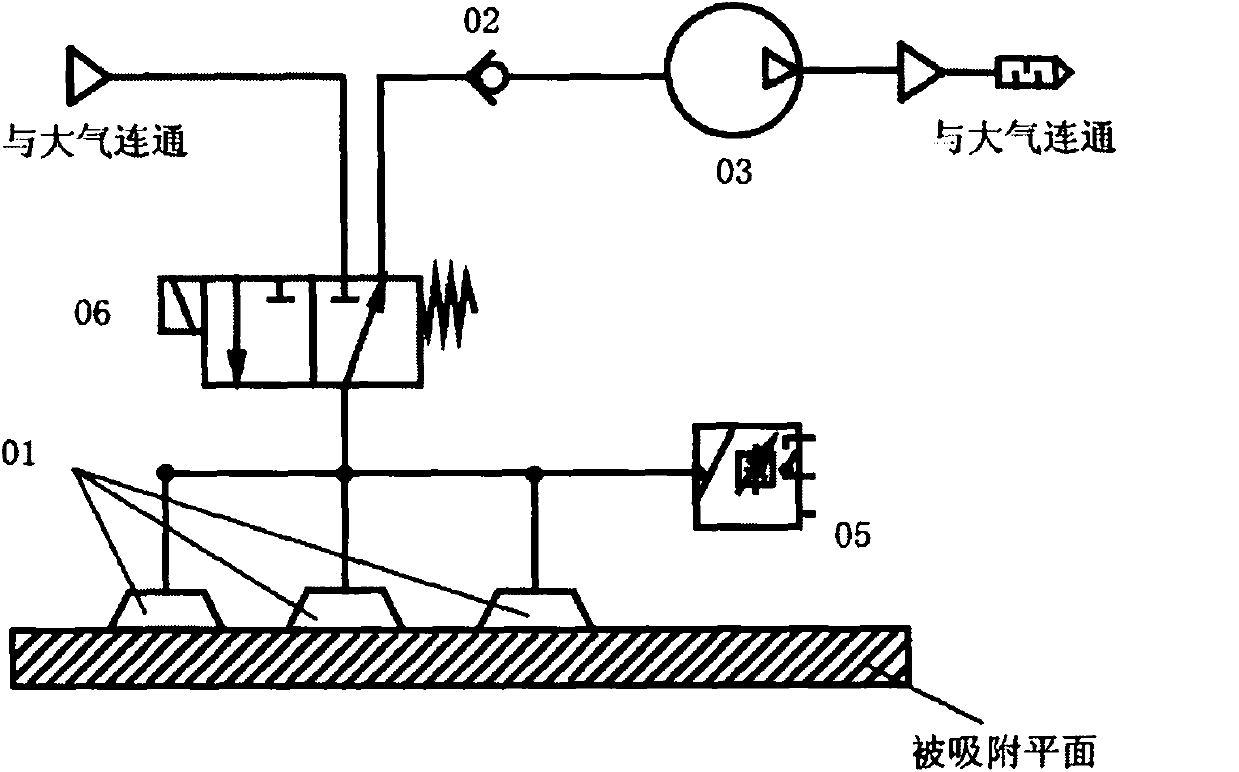

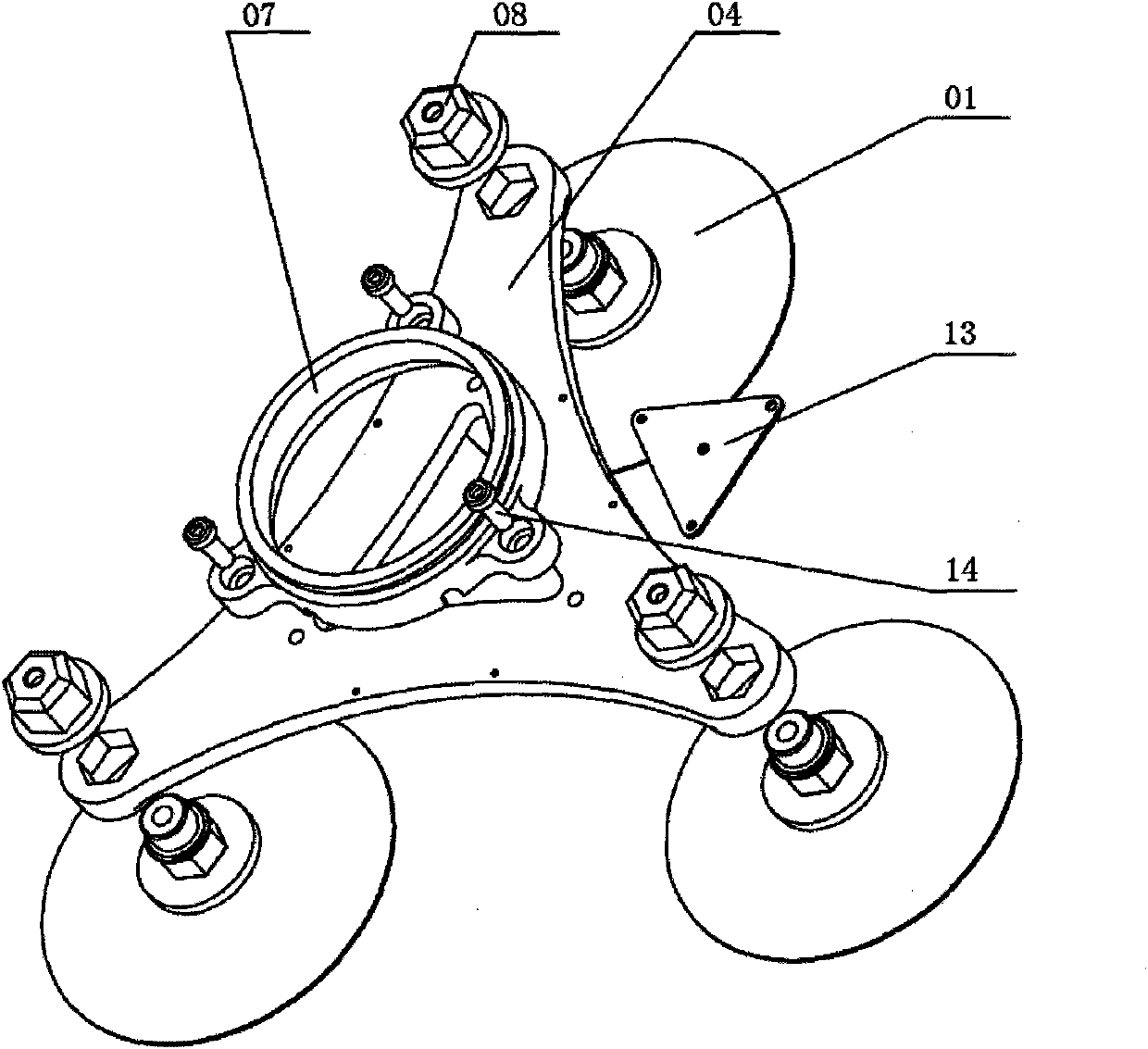

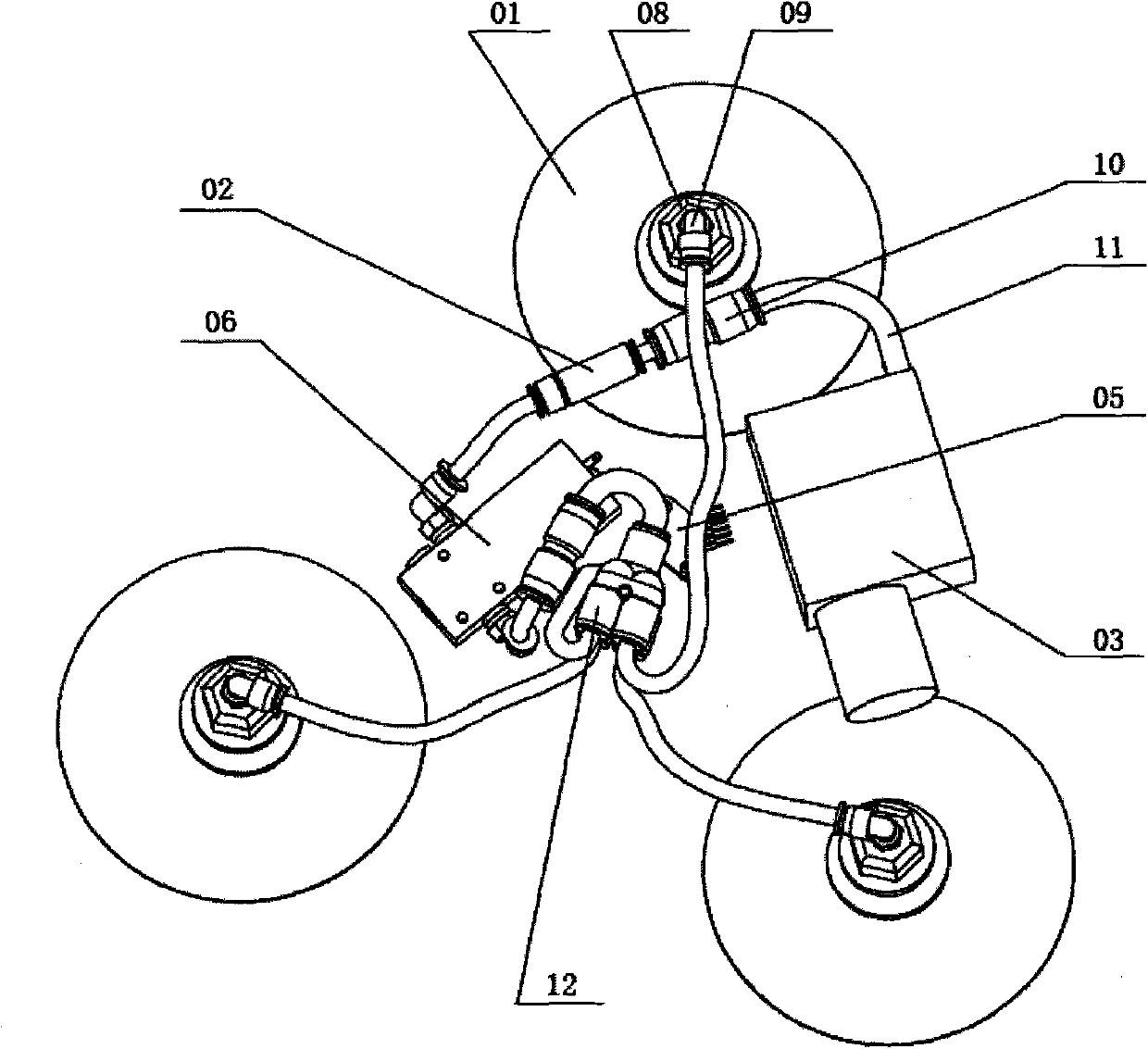

Self-contained vacuum source negative pressure adsorption module

InactiveCN101907121AGet rid of the bondageEliminate deficienciesSuction cupsVacuum pressureAtmospheric air

The invention relates to a self-contained vacuum source negative pressure adsorption module. Three vacuum chucks are connected together through the module, and a self-contained vacuum pump of the module simultaneously vacuumizes to form negative pressure. The module mainly comprises the vacuum chucks, a one-way valve, the vacuum pump, a main bracket, a vacuum pressure sensor, a two-position two-way vacuum solenoid valve, a connecting frame, an air pipe, and the like. The two-position two-way vacuum solenoid valve controls the communication between inner cavities of the three vacuum chucks and the atmosphere; during non-communication, the vacuum chucks and the adsorbed surface form a sealed cavity, and the vacuum pump works to make the negative pressure formed in the cavity so as to generate the adsorption function; and during communication, the negative pressure of the vacuum chucks is relieved so as to separate the module from the adsorbed surface. The module has the advantages of simple structure, self-contained property, independent completion, and convenient connection with other modules or components, and can be used as an adsorption foot of a wall climbing robot or an end executor of a manipulation arm.

Owner:SOUTH CHINA UNIV OF TECH

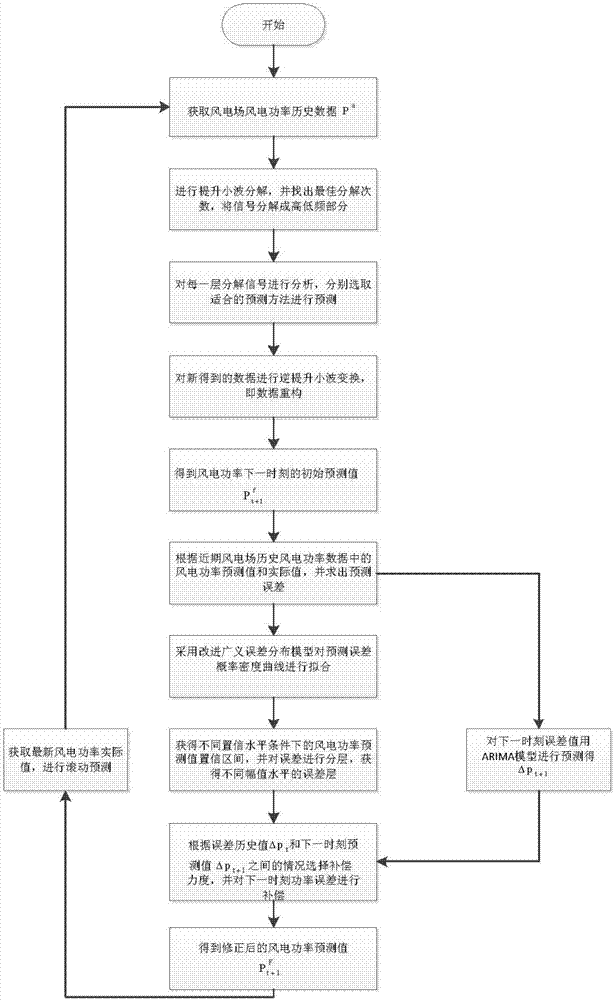

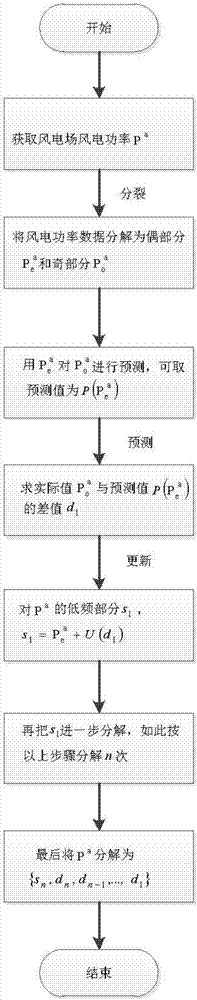

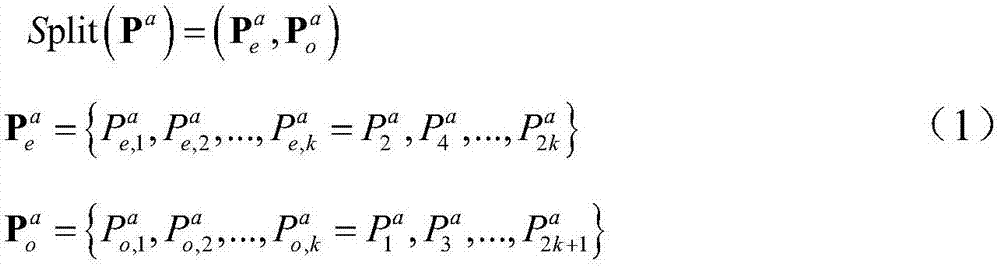

Wind power forecast method based on error correction and promotion wavelet combination forecast model

InactiveCN107230977ACancel noiseEliminate deficienciesForecastingAc network circuit arrangementsWavelet decompositionForward error correction

The invention discloses a wind power forecast method based on an error correction and promotion wavelet combination forecast model. According to the method, wind power history data is processed through utilization of a promotion wavelet decomposition technology, main characteristics of a power data sequence can be improved, frequency components with relatively obvious characteristics can be obtained, and the denoising effect can be achieved, thereby applying to various forecast algorithms. A suitable forecast model is selected according to the characteristics of high and low frequency components, the deficiency of a single forecast method can be removed, and the forecast precision can be greatly improved. According to the method, processing errors are corrected through utilization of an error layered analysis method. Compared with the method of obtaining a next moment error forecast value by directly using the forecast model, the method has the advantage that under the condition that relatively high fluctuation occurs in the errors, the next moment error condition and compensation strength can be analyzed precisely, the errors resulting from an error forecast process can be reduced, and the errors of the integrated forecast method can be reduced.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS20100218824A1Minimization requirementsIncrease volumeFinal product manufacturePV power plantsMaterial removalMetal foil

This invention comprises manufacture of photovoltaic cells by deposition of thin film photovoltaic junctions on metal foil substrates. The photovoltaic junctions may be heat treated if appropriate following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation, an interconnection substrate structure is provided, optionally in a continuous fashion. Multiple photovoltaic cells are then laminated to the interconnection substrate structure and conductive joining methods are employed to complete the array. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials employing optimal processing unique to polymeric materials. Furthermore, the photovoltaic junction and its metal foil support can be produced in bulk without the need to use the expensive and intricate material removal operations currently taught in the art to achieve series interconnections.

Owner:SOLANNEX

Method and Arrangement for Coding Transform Coefficients in Picture and/or Video Coders and Decoders and a Corresponding Computer Program and a Corresponding Computer-Readable Storage Medium

ActiveUS20090201994A1Eliminate deficienciesSmall amount of calculationPicture reproducers using cathode ray tubesCode conversionComputer graphics (images)Video encoding

The present invention describes a method and an arrangement for coding transform coefficients in picture and / or video coders and decoders and a corresponding computer program and a corresponding computer-readable storage medium, which can particularly be employed as a novel efficient method for binary-arithmetic coding transform coefficients in the field of video coding.For this, it is suggested that, for blocks of (video) pictures containing significant transform coefficients, coding of the transform coefficients takes place in such a way that, for each block in a scan process, the positions of significant transform coefficients in the block and subsequently, in a reverse scan order—starting from the last significant transform coefficient within the block—the values (levels) of the significant transform coefficients are determined and coded.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Method and Arrangement for Coding Transform Coefficients in Picture and/or Video Coders and Decoders and a Corresponding Computer Program and a Corresponding Computer-Readable Storage Medium

ActiveUS20090201986A1Eliminate deficienciesSmall amount of calculationPicture reproducers using cathode ray tubesCode conversionComputer graphics (images)Video encoding

The present invention describes a method and an arrangement for coding transform coefficients in picture and / or video coders and decoders and a corresponding computer program and a corresponding computer-readable storage medium, which can particularly be employed as a novel efficient method for binary-arithmetic coding transform coefficients in the field of video coding.For this, it is suggested that, for blocks of (video) pictures containing significant transform coefficients, coding of the transform coefficients takes place in such a way that, for each block in a scan process, the positions of significant transform coefficients in the block and subsequently, in a reverse scan order—starting from the last significant transform coefficient within the block—the values (levels) of the significant transform coefficients are determined and coded.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Automatic analyzer

ActiveUS7749441B2Improve analysisIncrease consumptionMaterial analysis by optical meansBiological testingReagentAnalytical chemistry

An automatic analyzer is disclosed that dispenses a sample and a reagent into each of a plurality of reaction vessels to allow them to react with each other, and that measures the liquid formed as a result of the reaction. This automatic analyzer includes a first reagent storage case for storing the reagent to be used for the reaction, a second reagent storage case for storing the reagent for supplemental purpose, and a reagent conveying unit for conveying the reagent from the second reagent storage case to the first reagent storage case.

Owner:HITACHI HIGH-TECH CORP +1

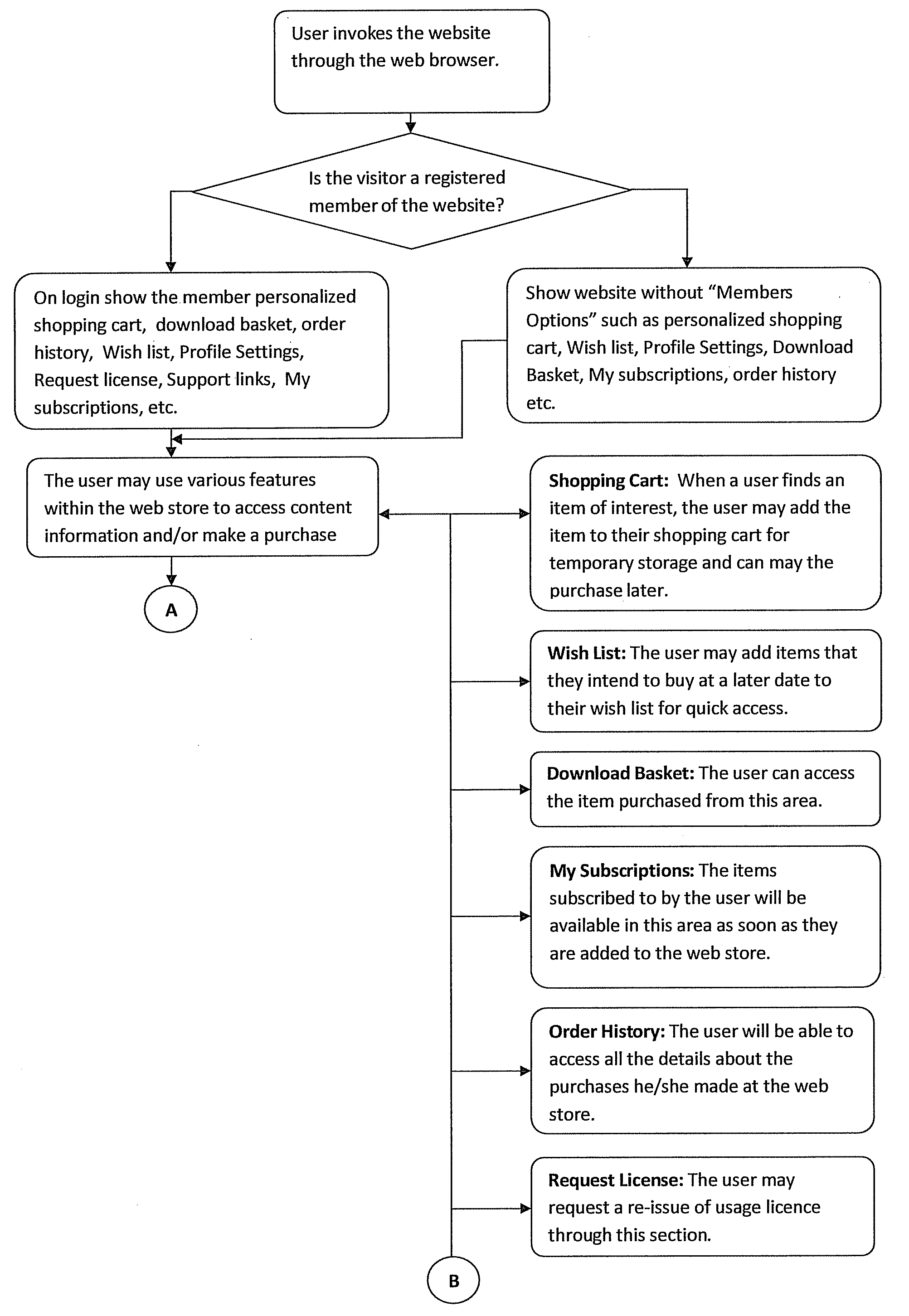

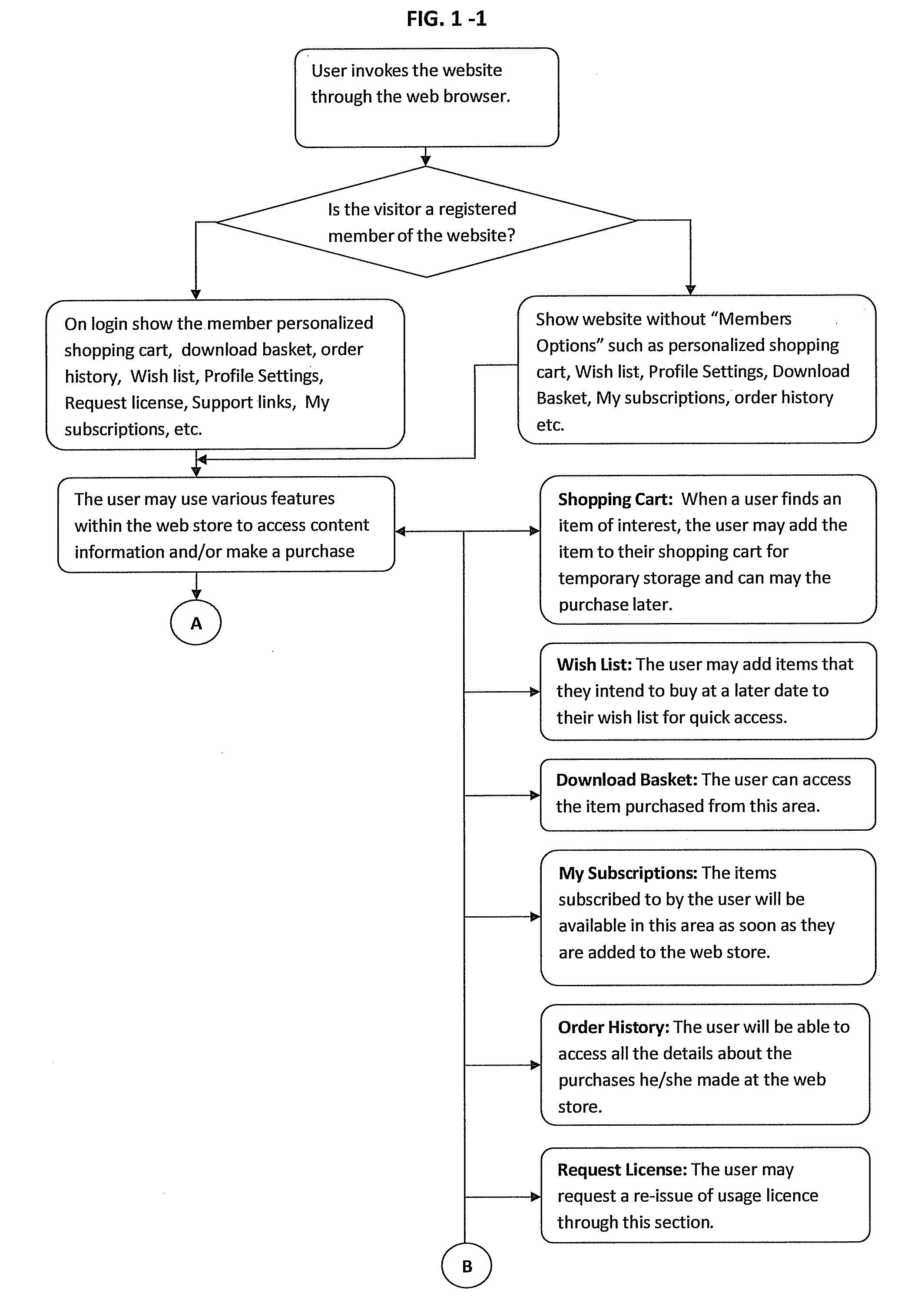

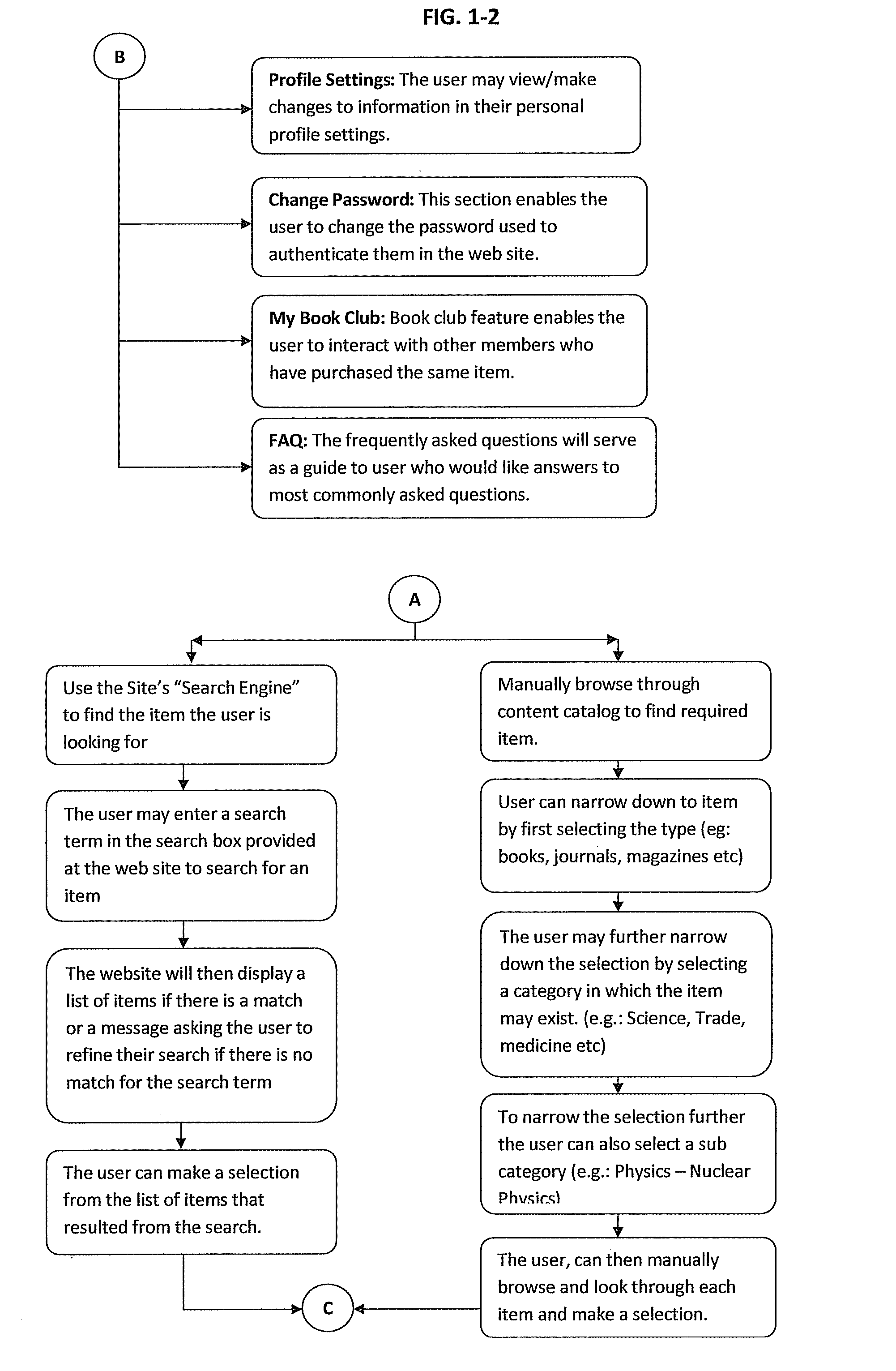

Automated Publishing Systems and Methods

InactiveUS20120150680A1Eliminate deficienciesEliminate drawbackDigital data processing detailsWebsite content managementGraphicsGraphical user interface

Provided is an automated publishing system that can include a database indexed to store contribution data that includes portions of works of authorship, a user authentication system configured to authenticate a member to the system, and a virtual work area having a graphic user interface accessible by the member. The interface can include content searching and content collating features such that a member can generate a custom work by selecting a plurality of different portions of works of authorship which are combined to generate the custom publication. The interface in addition contains an option for a member to add content at the end of each chapter, when such member is authorized by the publisher. The custom publication can be sent to the publisher for approval and is made available only after the publisher grants approval.

Owner:QBEND

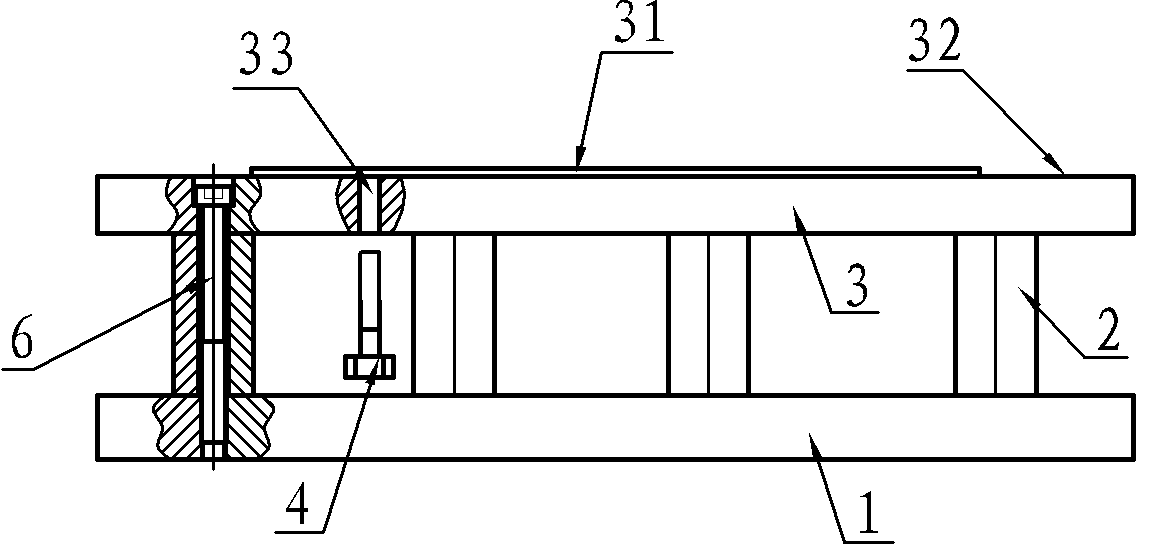

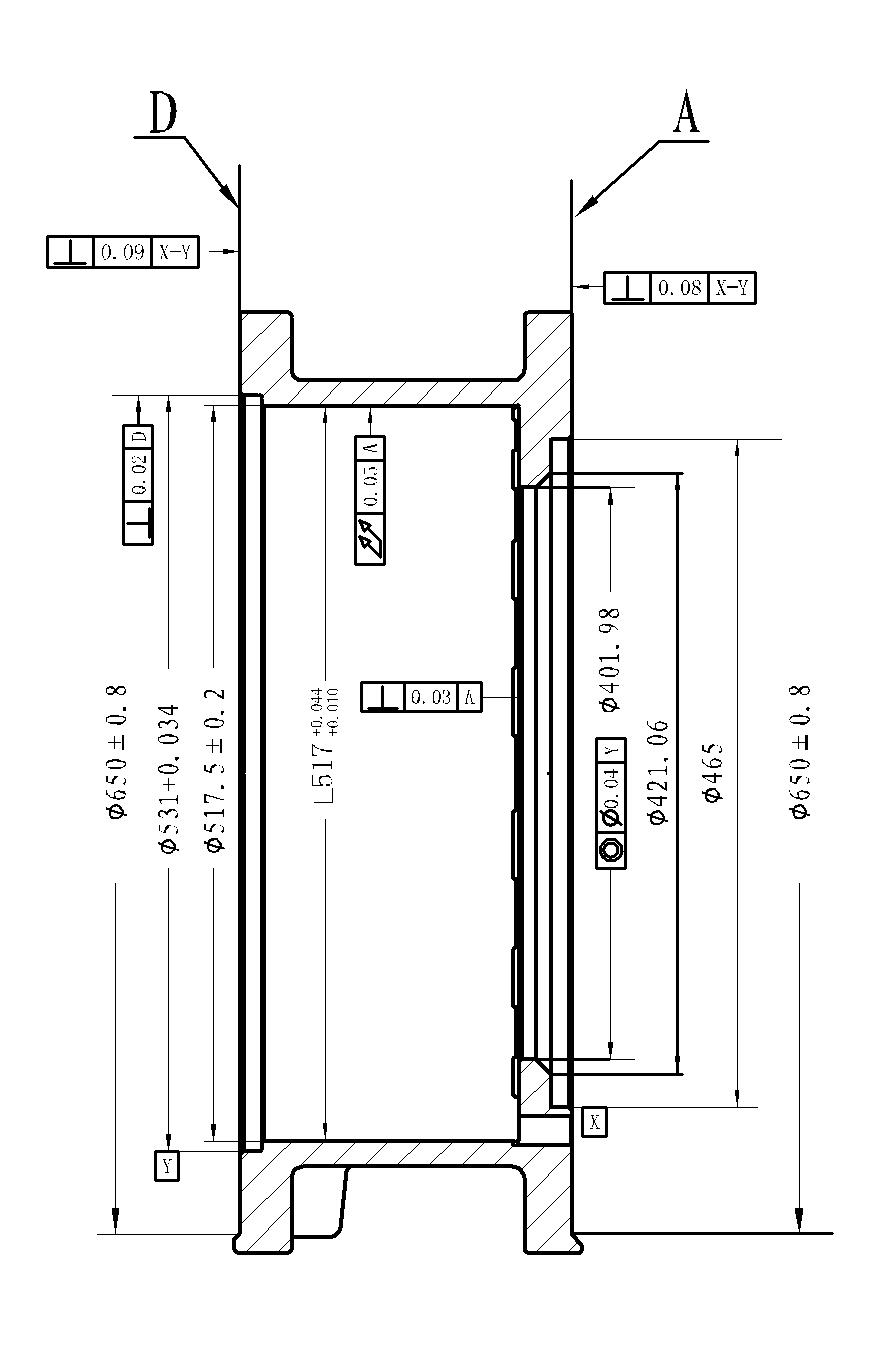

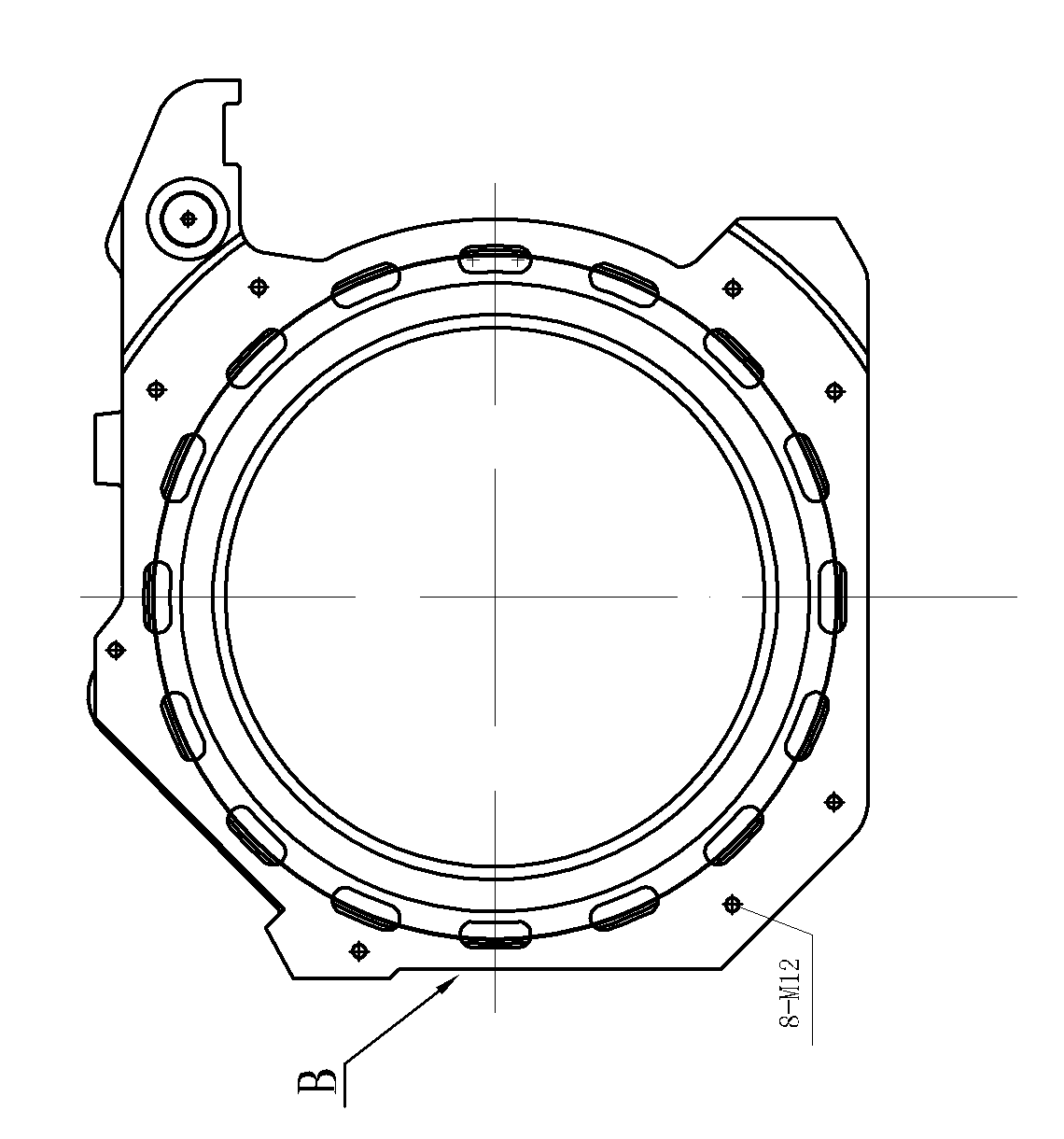

Special clamp for motor shell macropore series for fine boring rail train

InactiveCN102091806AEliminate freedom of movementEliminate deficienciesPositioning apparatusBoring/drilling componentsEngineeringDimensional precision

The invention discloses a special clamp for a motor shell macropore series for a fine boring rail train. The special clamp comprises a base, a supporting post, a positioning clamping plate and a tightening bolt; the upper end face of the positioning clamping plate is provided with a positioning seam allowance, a positioning plane and a tightening fixing hole; the positioning seam allowance is matched with a phi 465mm hole on a workpiece end face A; the tightening fixing hole corresponds to a mounting screw hole on a workpiece to be processed; the positioning clamping plate is fixed on the base through the supporting post; and the workpiece is fixed on the upper end face of the positioning clamping plate through the tightening bolt. The end face A, the phi 465mm hole on the face and a lateral surface B are adopted for positioning, and the workpiece is clamped by the tightening bolt 4, so the workpiece is positioned accurately and installed stably; axial tightening and fixing are performed by using a direct screwing mode of the tightening bolt and the existing screw hole on the workpiece, and the magnitude of the tightening force does not generate stress deformation in the radial direction of the processed pore series so as to ensure the dimensional precision and the form and position precision of the processed pore series.

Owner:CHANGZHOU HUADE MACHINERY

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS20100229942A1Minimizing needHigh volumePV power plantsSolid-state devicesMetal foilPolymer substrate

This invention comprises manufacture of photovoltaic cells by deposition of thin film photovoltaic junctions on metal foil substrates. The photovoltaic junctions may be heat treated if appropriate following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation, an interconnection substrate structure is provided, optionally in a continuous fashion. Multiple photovoltaic cells are then laminated to the interconnection substrate structure and conductive joining methods are employed to complete the array. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials employing optimal processing unique to polymeric materials. Furthermore, the photovoltaic junction and its metal foil support can be produced in bulk without the need to use the expensive and intricate material removal operations currently taught in the art to achieve series interconnections.

Owner:SOLANNEX

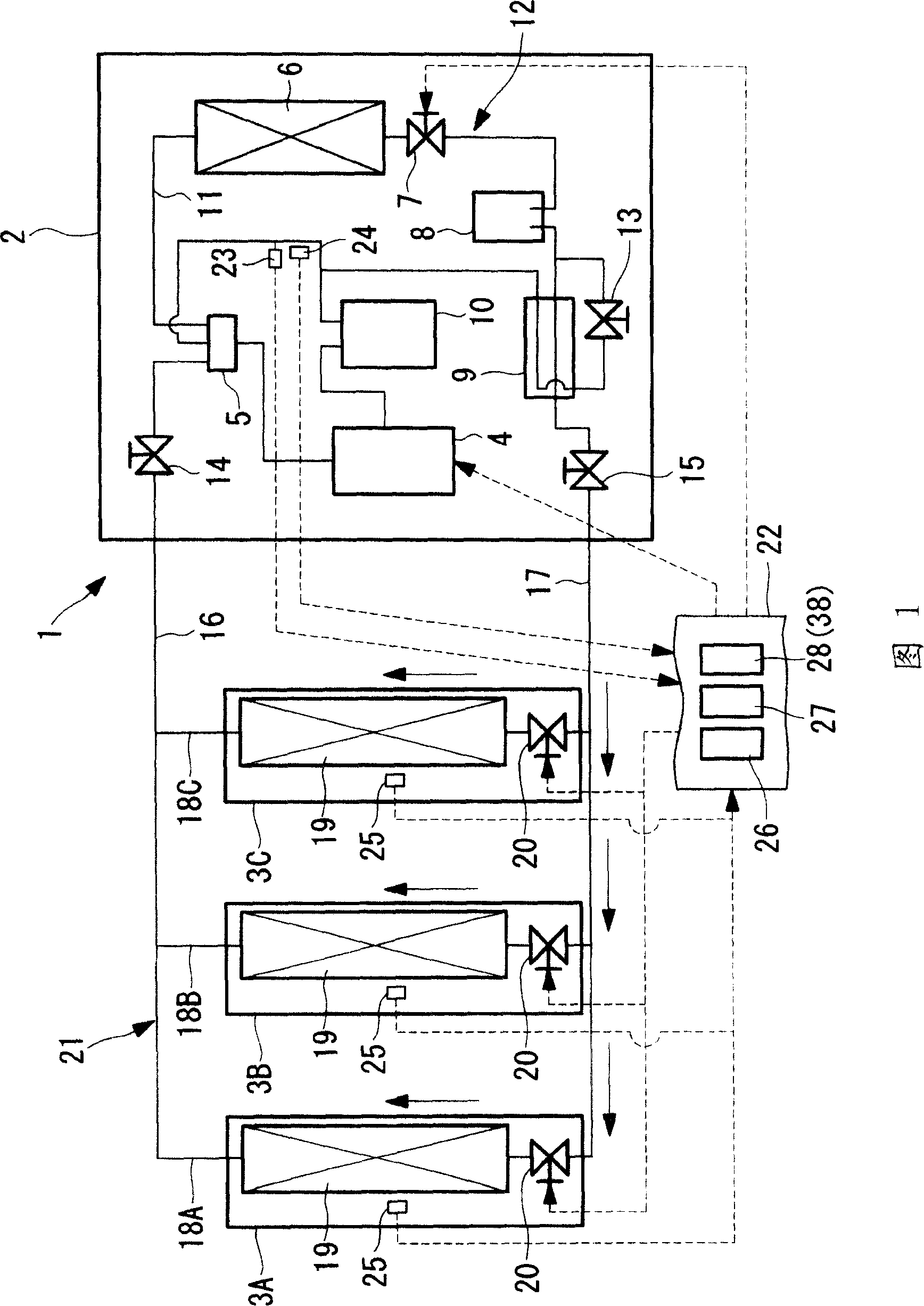

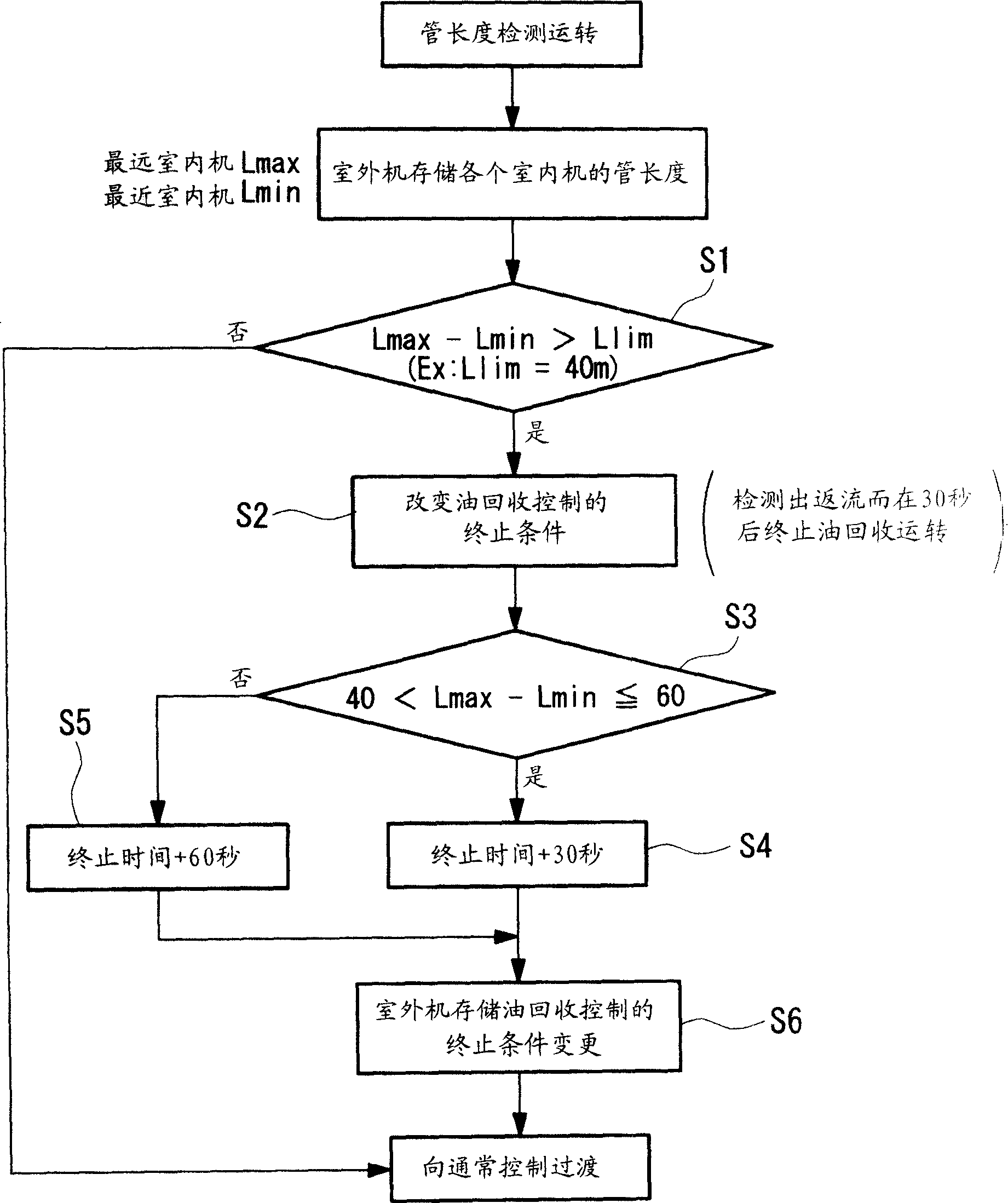

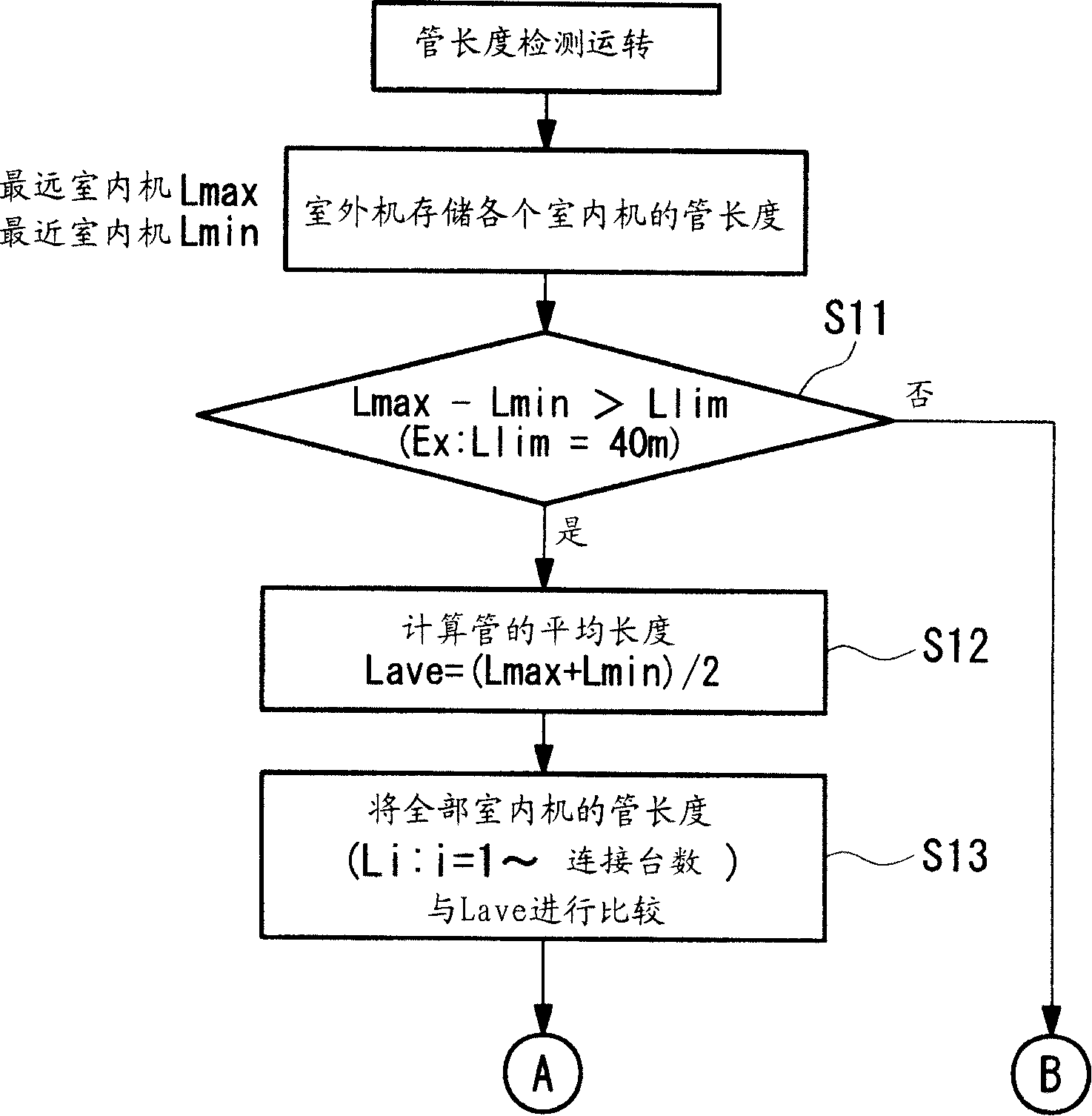

Air-conditioning apparatus

InactiveCN101162104AEliminate deficienciesEliminate lubricationCompressorSpace heating and ventilation safety systemsAir conditioningRefrigerant

An air-conditioning apparatus (1) capable of reliably recovering lubricant accumulated in indoor units (3A,3B,3C) and their refrigerant circuit, regardless of the refrigerant-pipe length differences of the indoor units connected to each other, has been desired, and includes an operating unit (22) configured to carry out liquid return at each indoor unit, to carry out an oil-recovery operation for recovering lubricant accumulated in the refrigerant circuit, and to complete the oil-recovery operation when liquid return is detected at the outdoor unit (2). The operating unit includes a detecting unit configured to detect the refrigerant pipe length of each of the indoor units, a storing unit configured to store the refrigerant pipe lengths detected by the detecting unit, and a control unit configured to change the operation time during the oil-recovery operation on the basis of the refrigerant pipe length of each of the indoor units stored in the storing unit.

Owner:MITSUBISHI HEAVY IND THERMAL SYST

Coated insert and method of making same

ActiveUS7470296B2Eliminate deficienciesImprove performancePigmenting treatmentCutting insertsEngineeringTotal thickness

A cutting tool insert particularly for turning of steel comprising a body and a coating with a first (innermost) layer system of at least two layers of TiCxNyOz with x+y+z≦1 with a total thickness of from about 0.7 to about 4.5 μm, a second layer system to a large extent consisting of Al2O3 and an outermost layer system comprising one or several layers in sequence of TiCxNy (x+y≦1) with individual thicknesses of greater than about 0.15 to about 0.8 μm and a layer with Al2O3 with a thickness greater than about 0.1 to about 0.4 μm with a total thickness of the outermost layer system thinner than about 2.5 μm and a total thickness of the coating in the range of from about 2.0 to about 12.0 μm.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Ultrasonic medical treatment device for bipolar RF cauterization and related method

InactiveUS20030163130A1Easy to useReliable cautery effectSurgical instruments for heatingSurgical instruments for irrigation of substancesTransducerRelative motion

An ultrasonic medical treatment device has a casing, an elongate probe, a transducer assembly, a sheath and a plurality of electrode members. The probe is mounted to and extends from the casing and has an axis and a free end serving as an operative tip. The transducer assembly is mounted to the casing and is operatively connected to the probe for generating vibrations of at least one ultrasonic frequency in the probe. The sheath surrounds the probe. The electrode members are connectable to an RF voltage source and are mounted at least indirectly to the casing so as to permit relative motion between the electrode members and the probe.

Owner:MISONIX INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com