Self-contained vacuum source negative pressure adsorption module

A technology of vacuum source and vacuum suction cup, which is applied in the field of robots, can solve the problems of increased failure, reduced adsorption reliability and safety, etc., and achieves the effects of improved reliability, simple structure and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

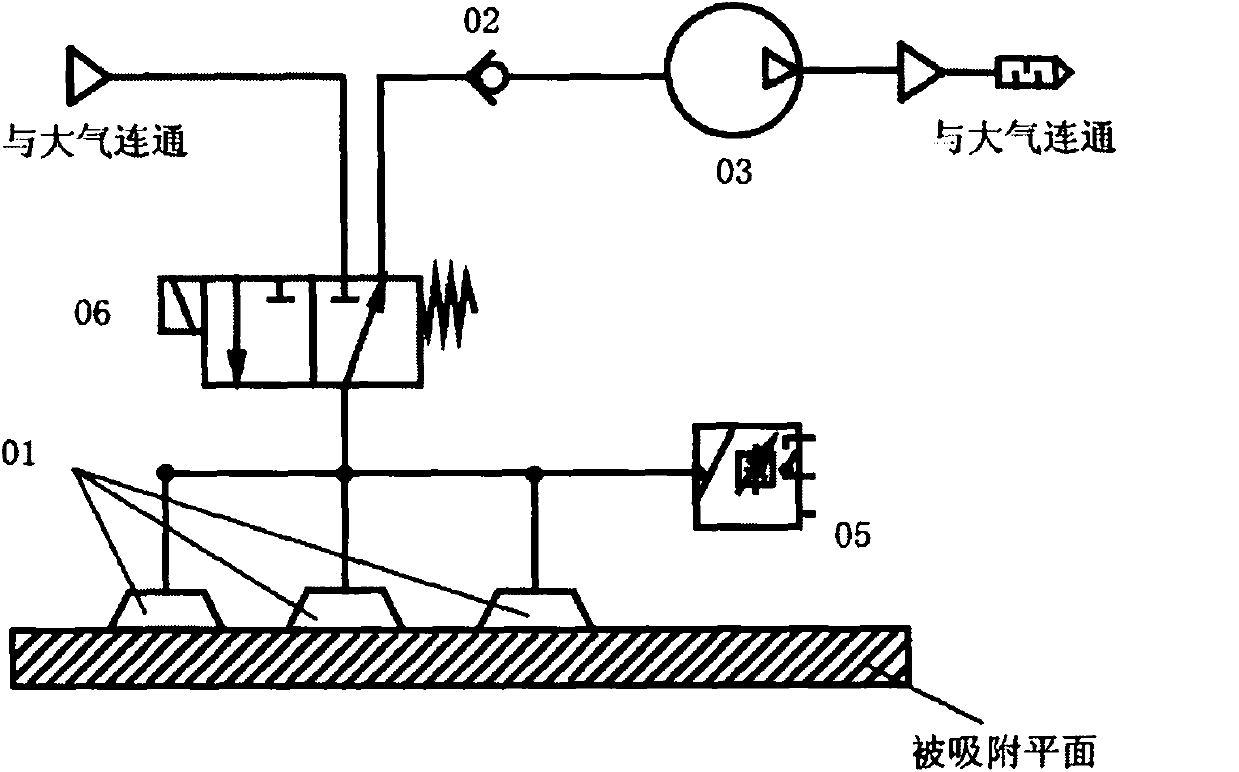

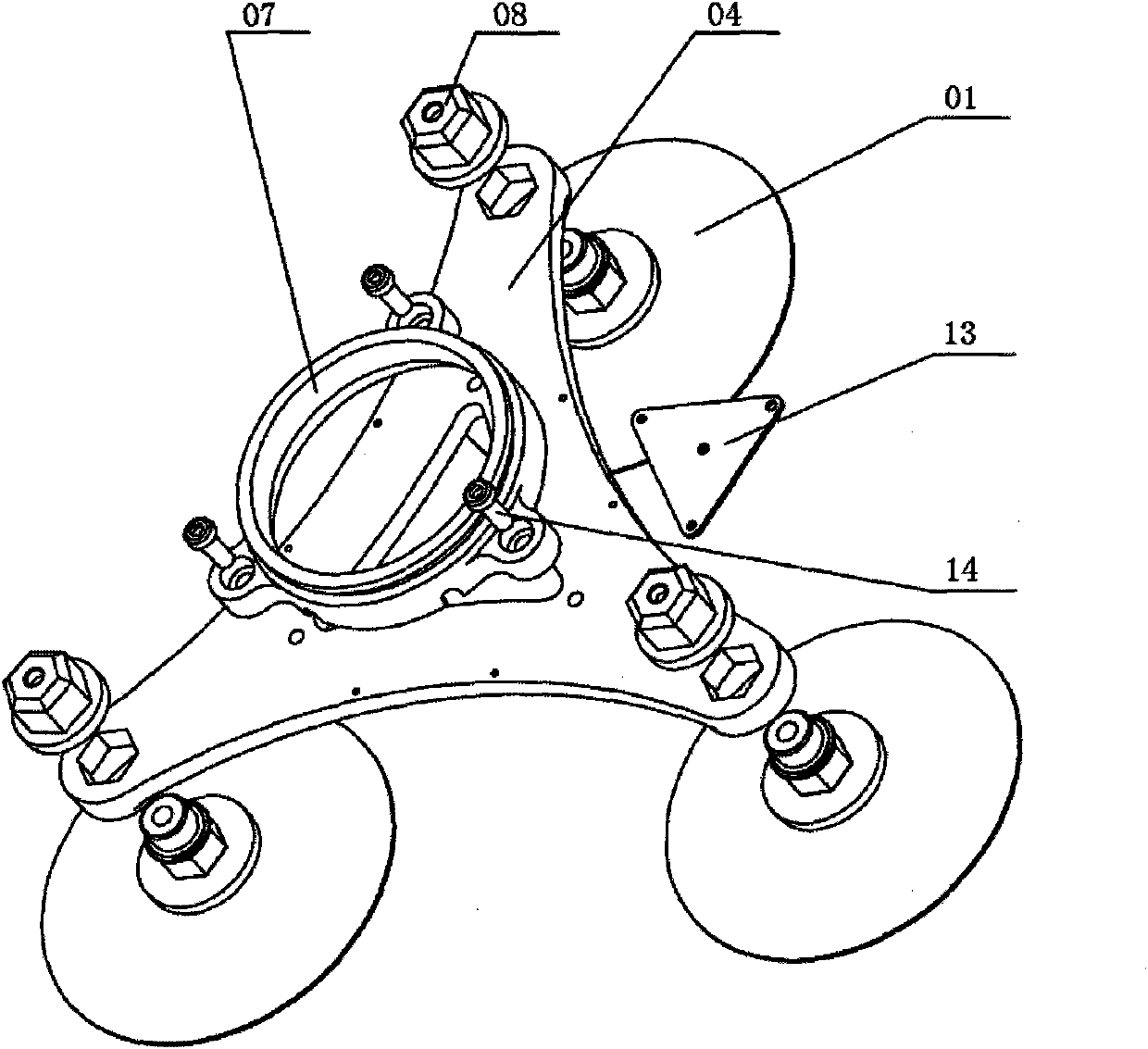

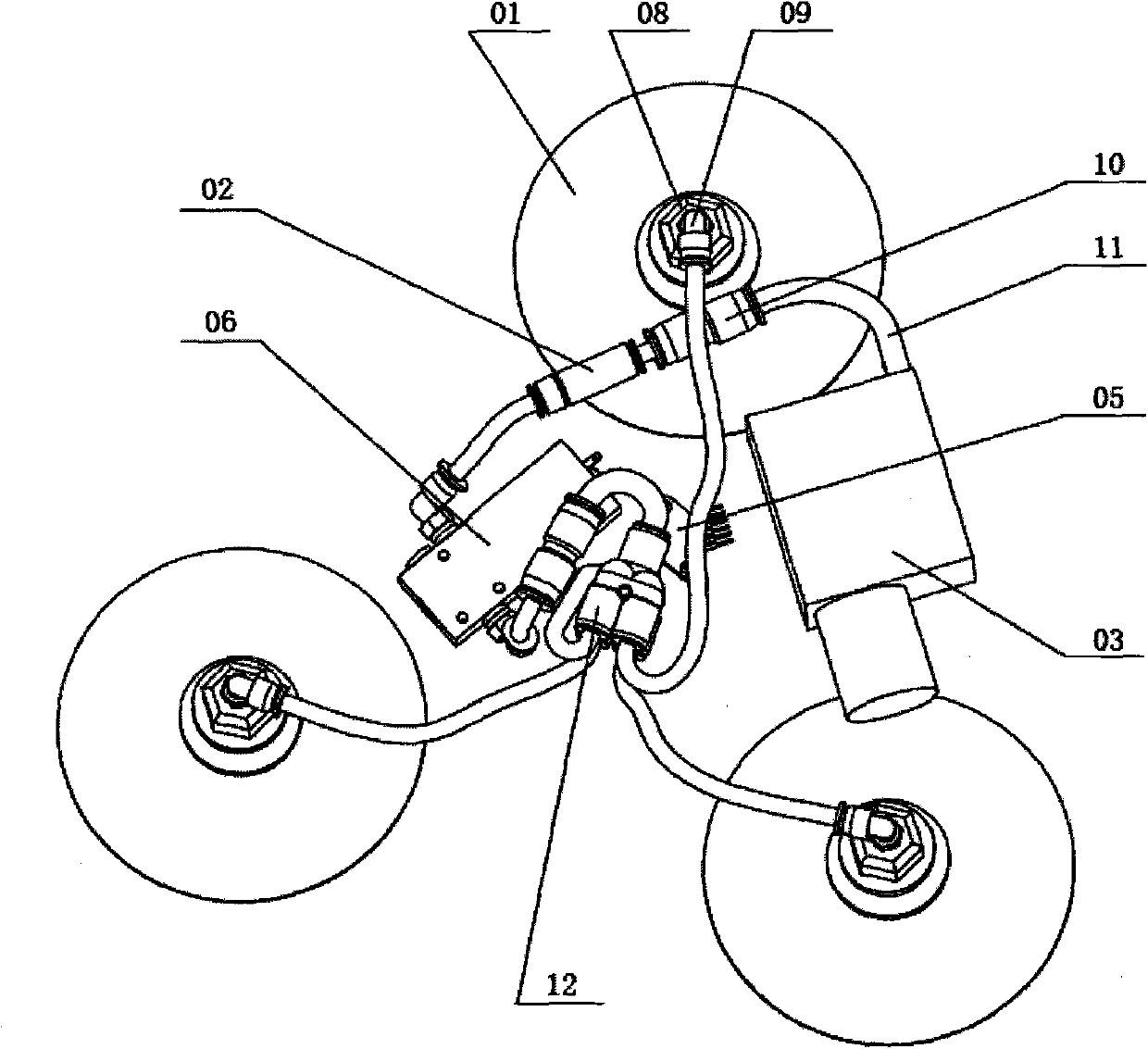

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the negative pressure adsorption module with its own vacuum source includes a vacuum suction cup 01, a one-way valve 02, a vacuum pump 03, a main bracket 04, a vacuum pressure sensor 05, a two-position two-way vacuum solenoid valve 06, a connecting frame 07, and a hexagonal nut 08. Vacuum pump fixing plate 13 and inner hexagon screw 14. The three vacuum suction cups 01 are all conical suction cups, each of which is fixed on the main bracket 04 through a hexagonal nut 08, and is arranged in an equilateral triangle. The three vacuum suction cups 01 are respectively connected to the L-shaped quick-plug threaded joints 09 through the hexagonal nuts 08 with threads on the top, and the air pipes 11 are respectively drawn from the tops of the three L-shaped quick-inserted threaded joints 09, and are distributed by a four-in-one air The joints 12 are gathered together, and then through the quick-plug variable-dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com