Patents

Literature

138results about How to "Inexpensive production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

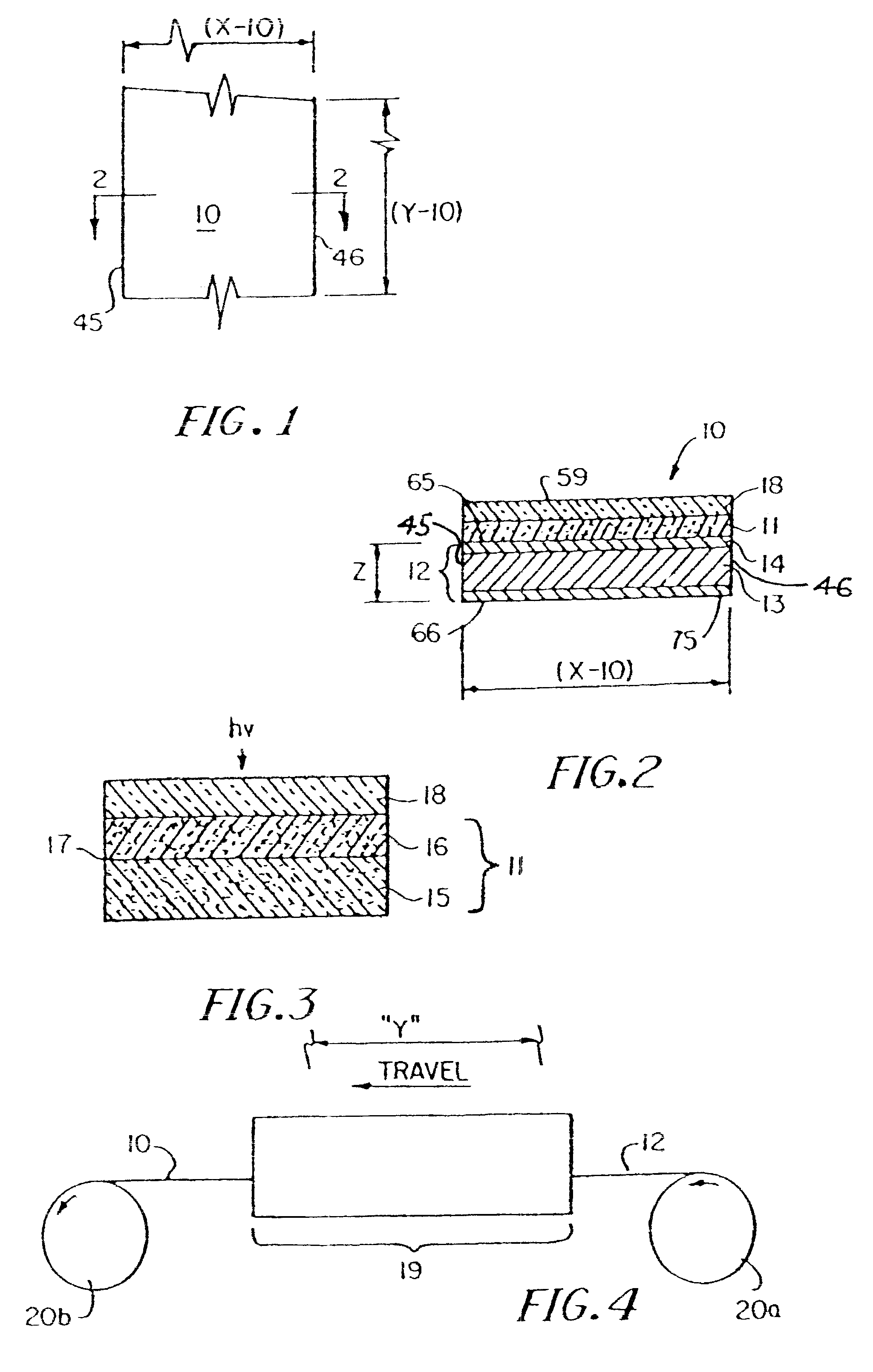

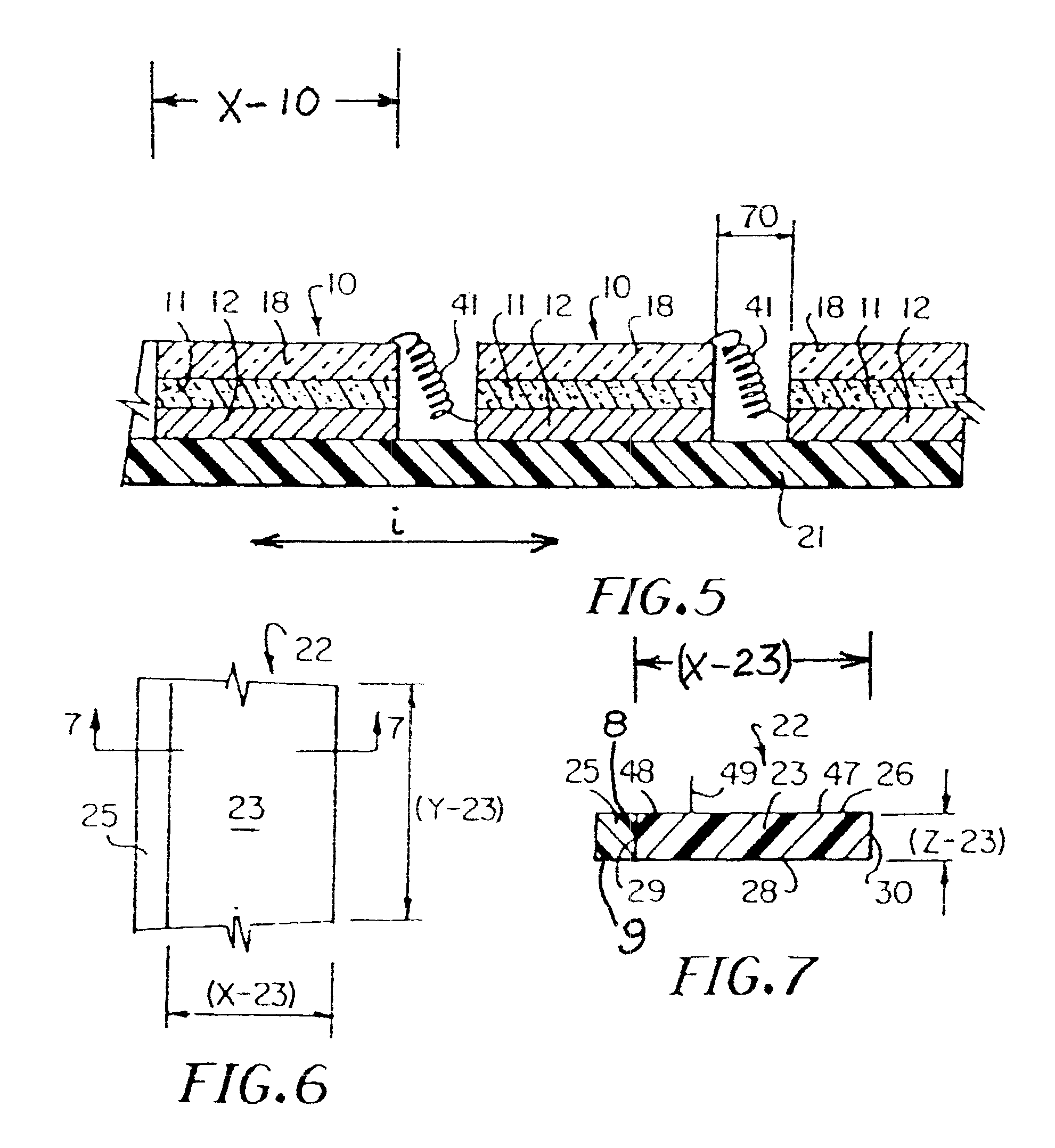

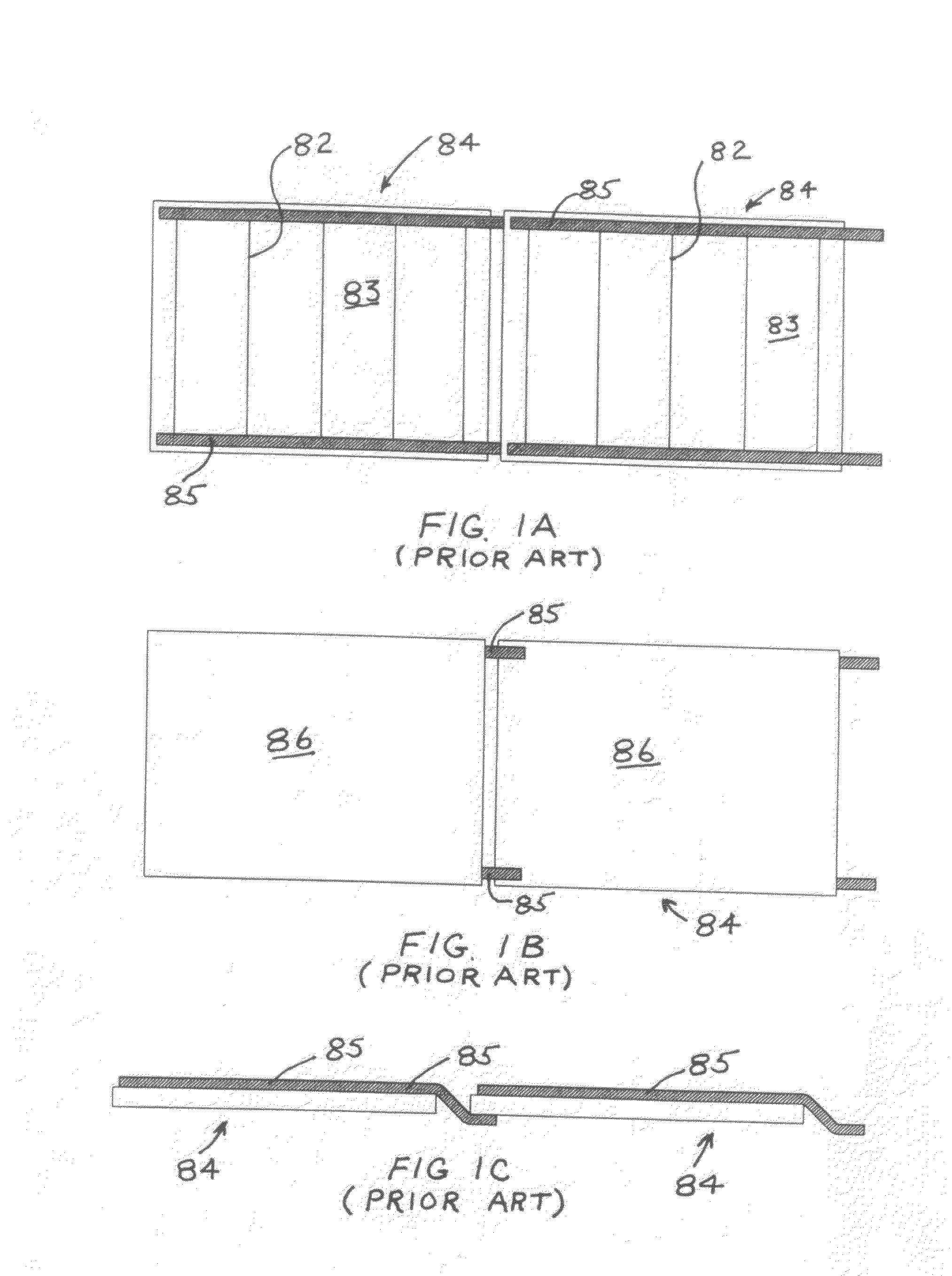

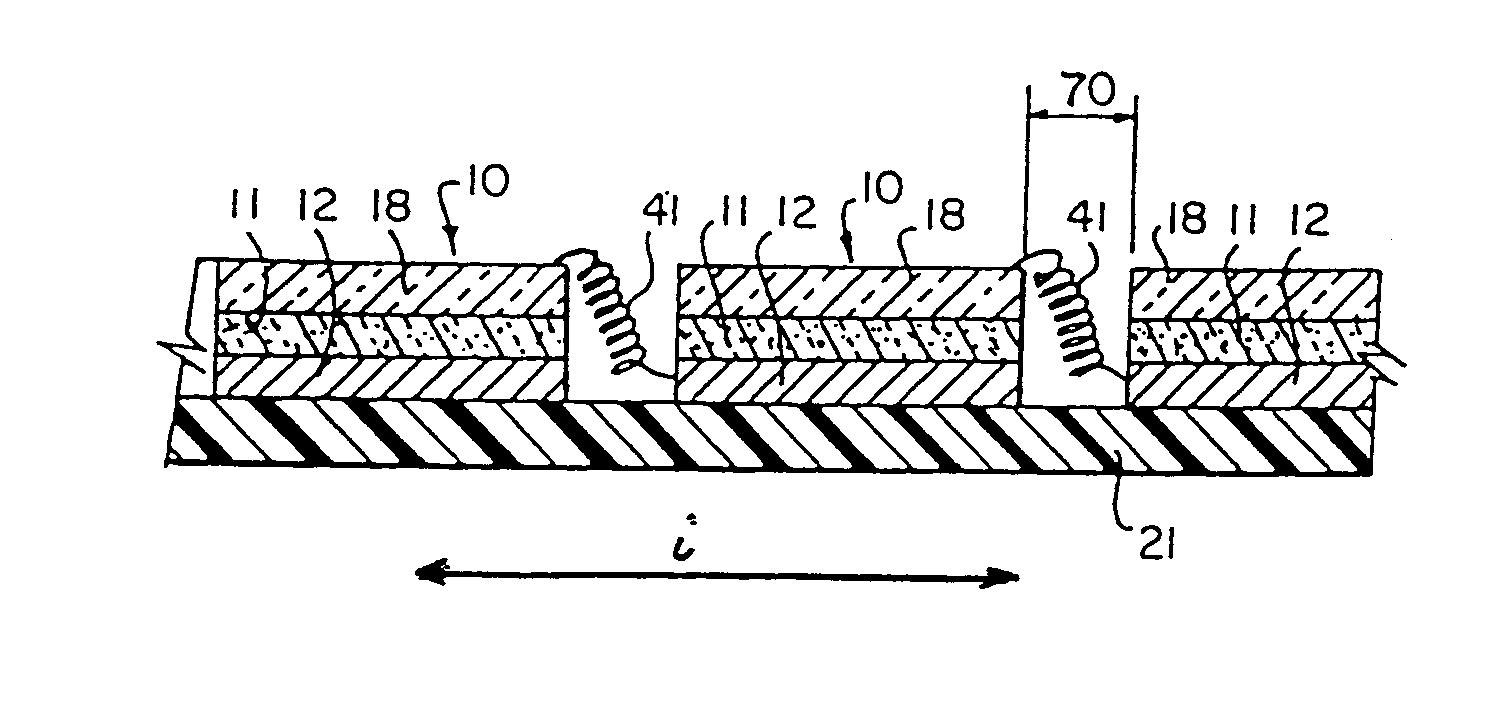

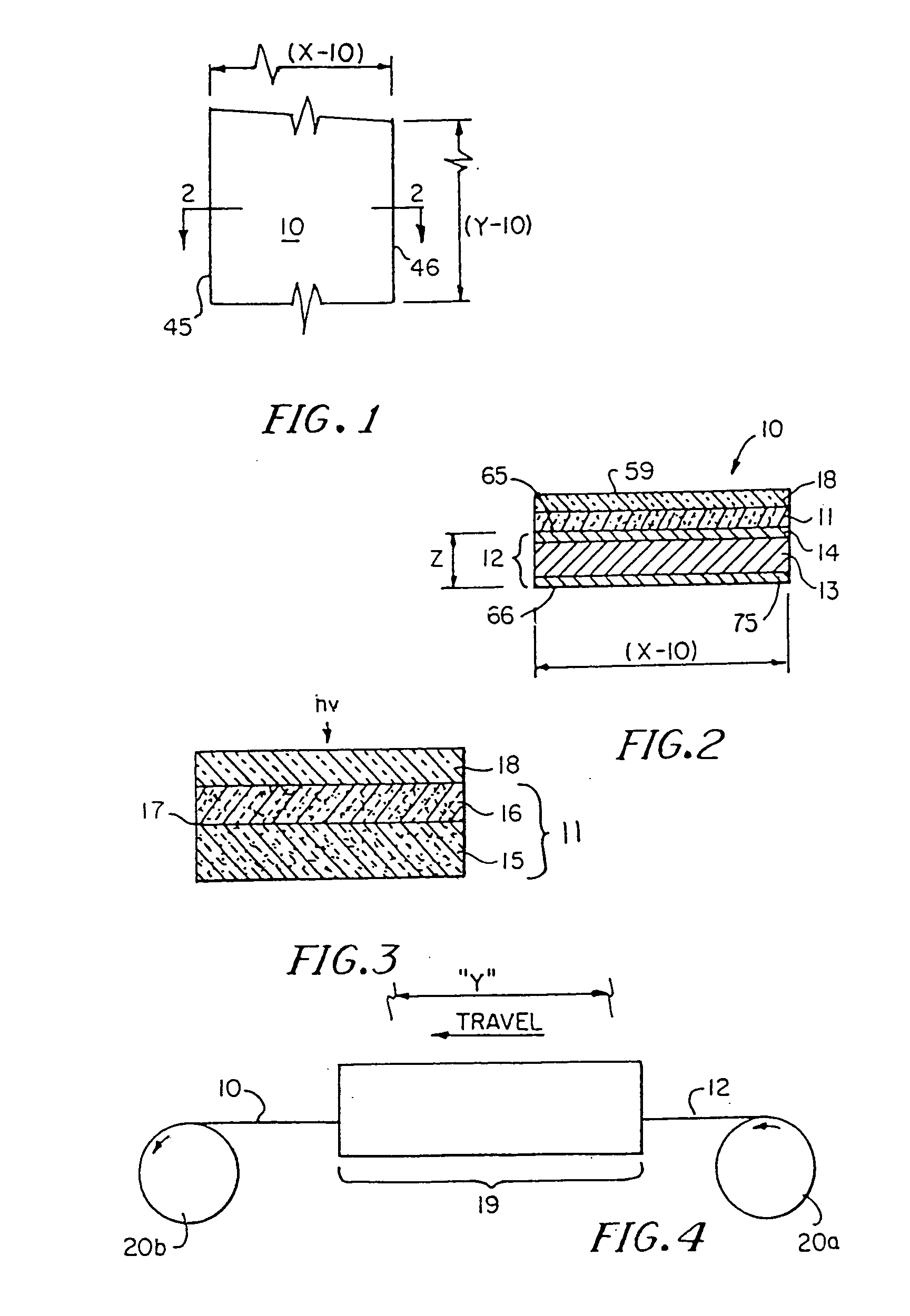

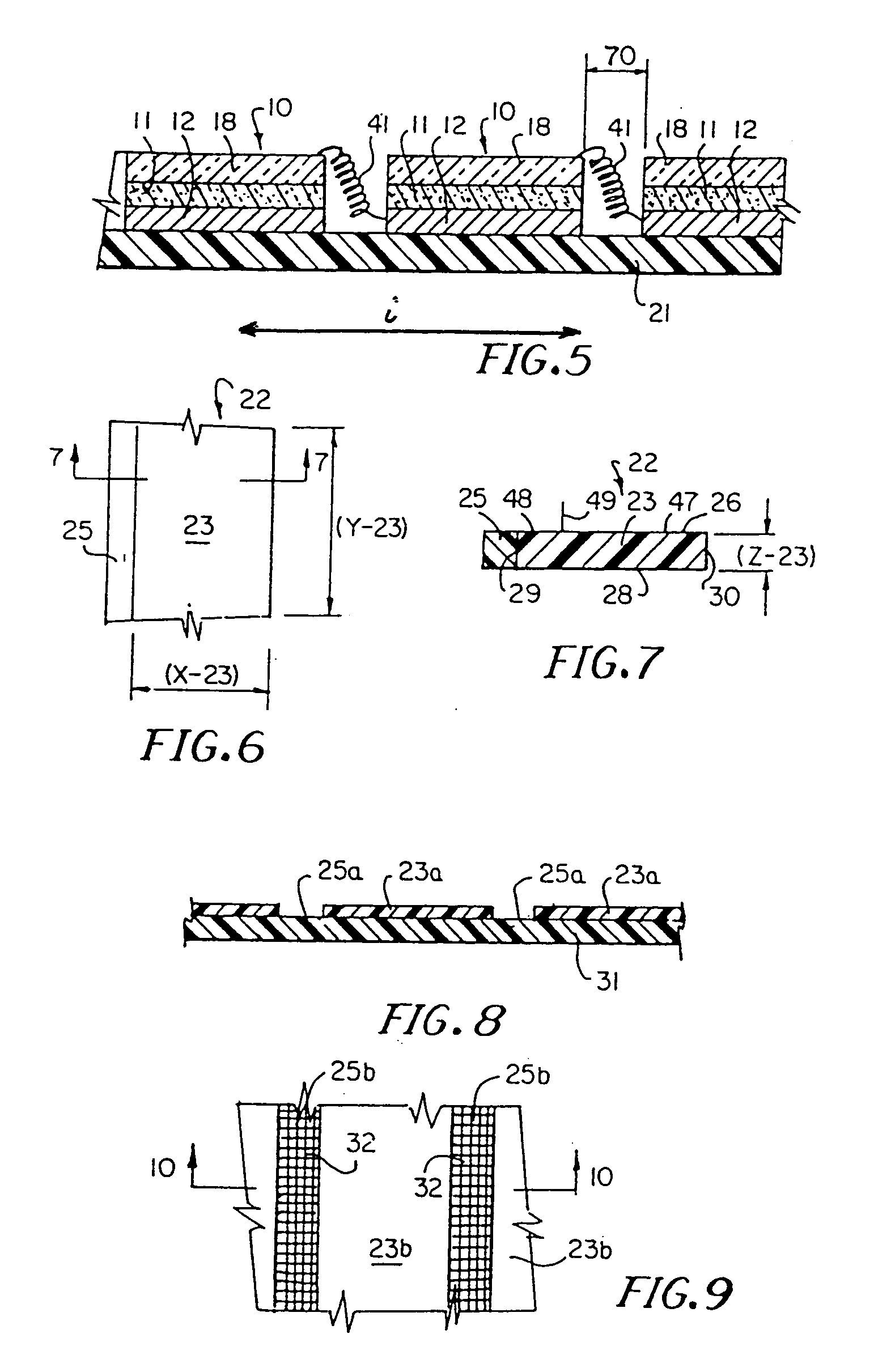

Substrate and collector grid structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS6414235B1Eliminate deficienciesCheap productionPV power plantsElectrode carriers/collectorsRoll-to-roll processingMetal foil

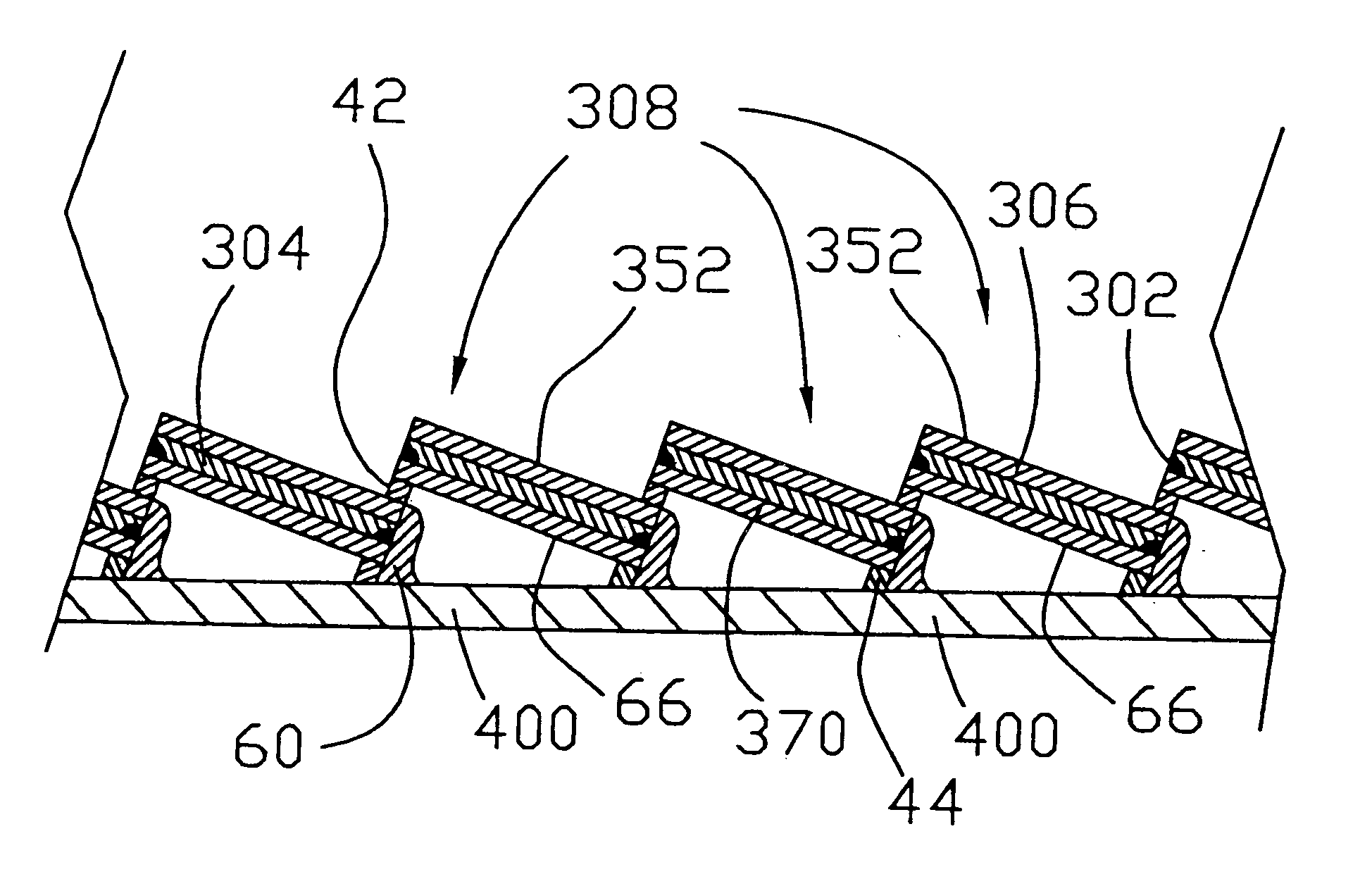

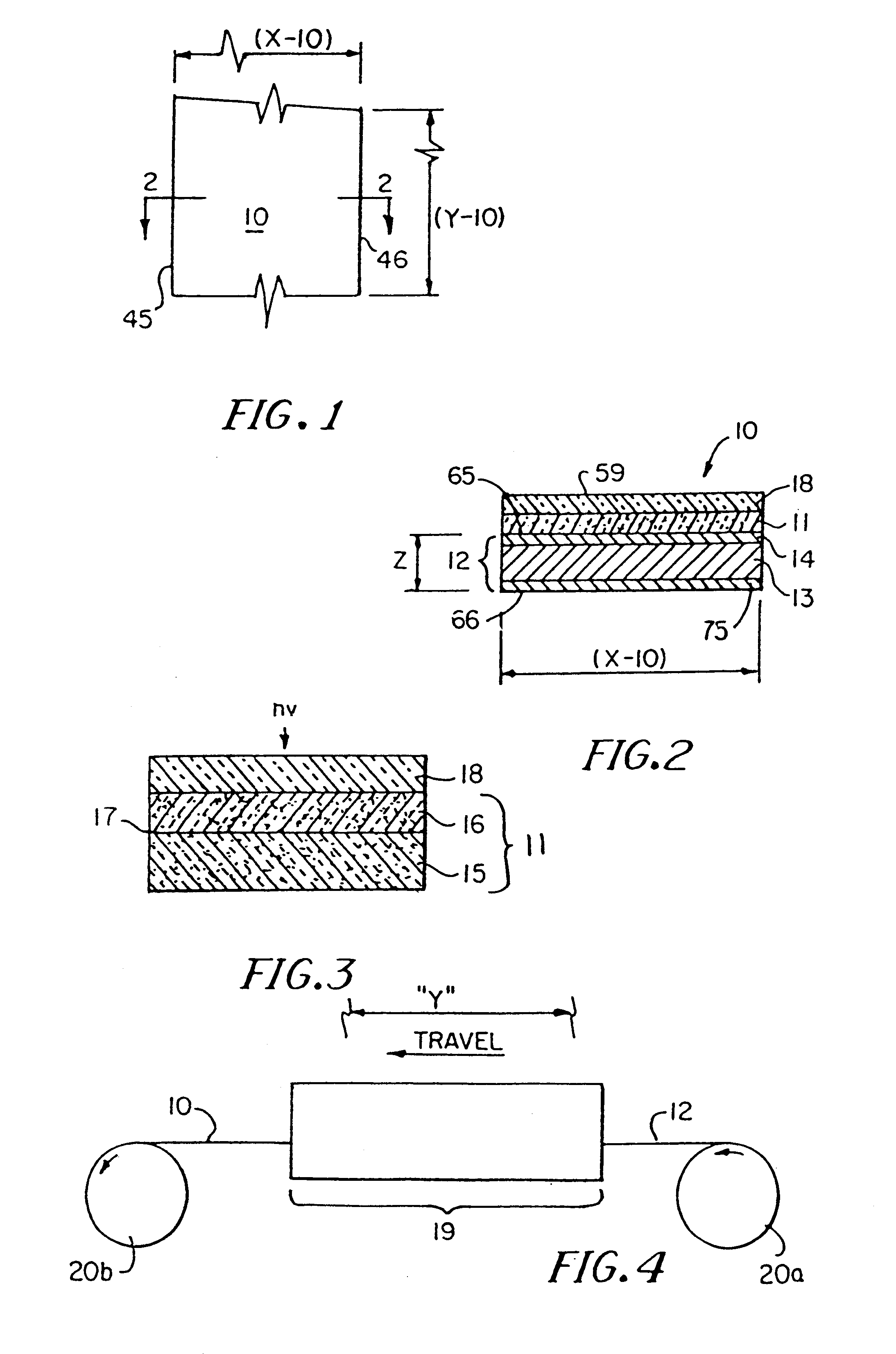

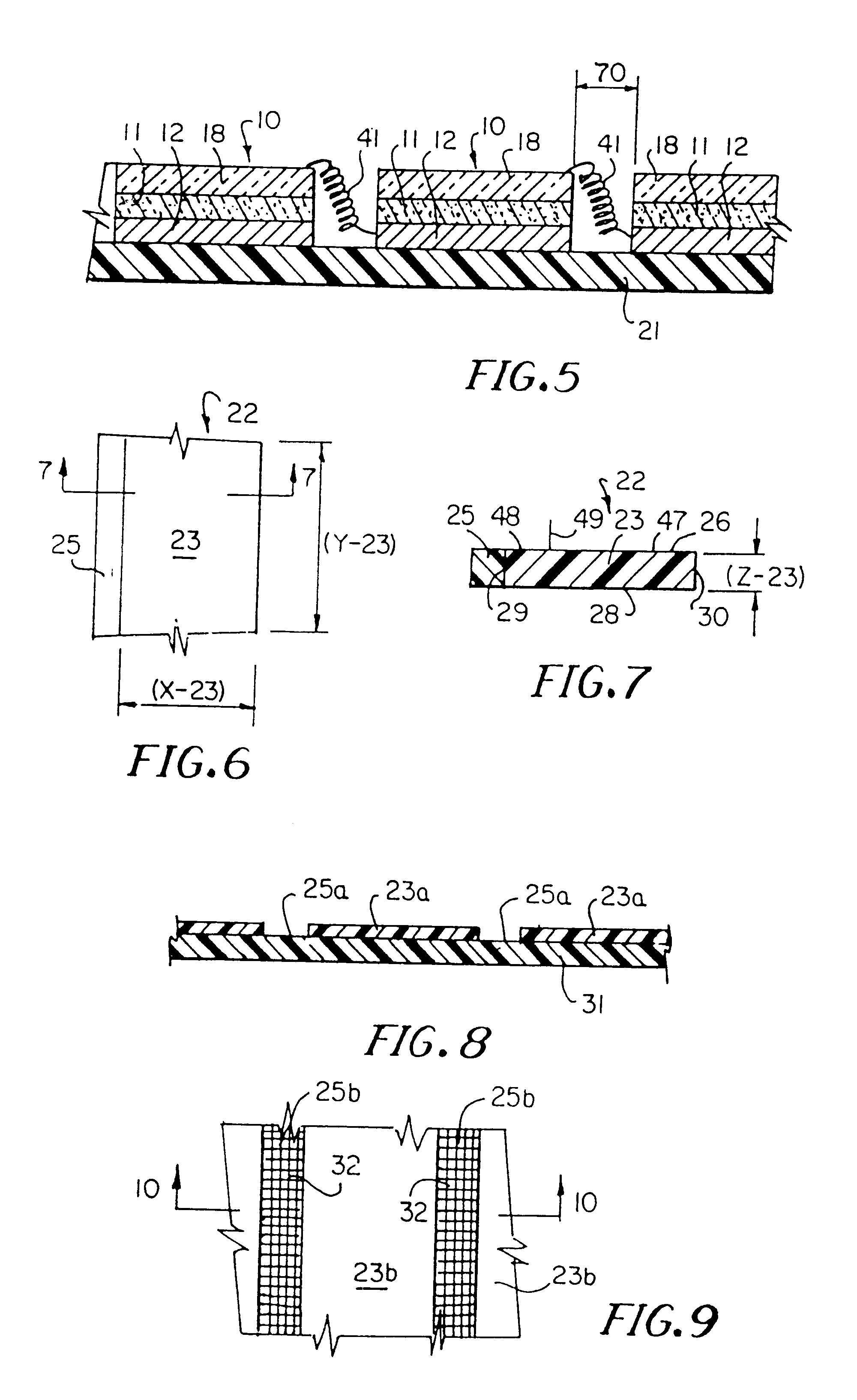

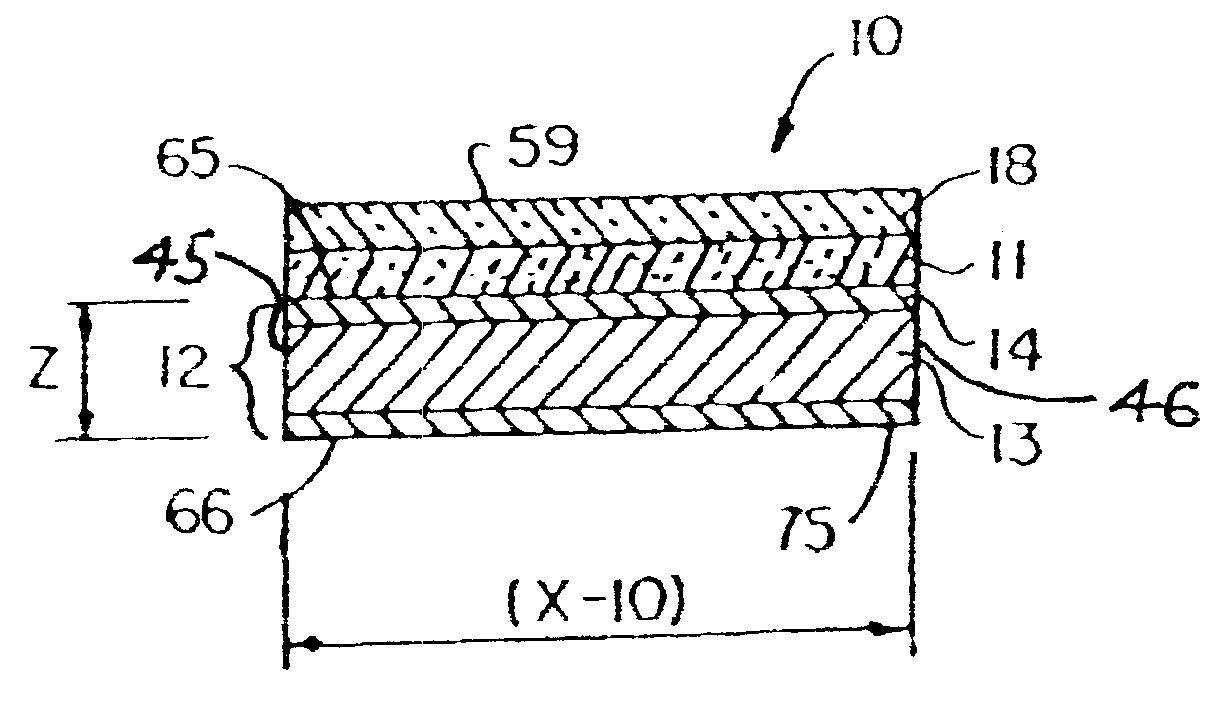

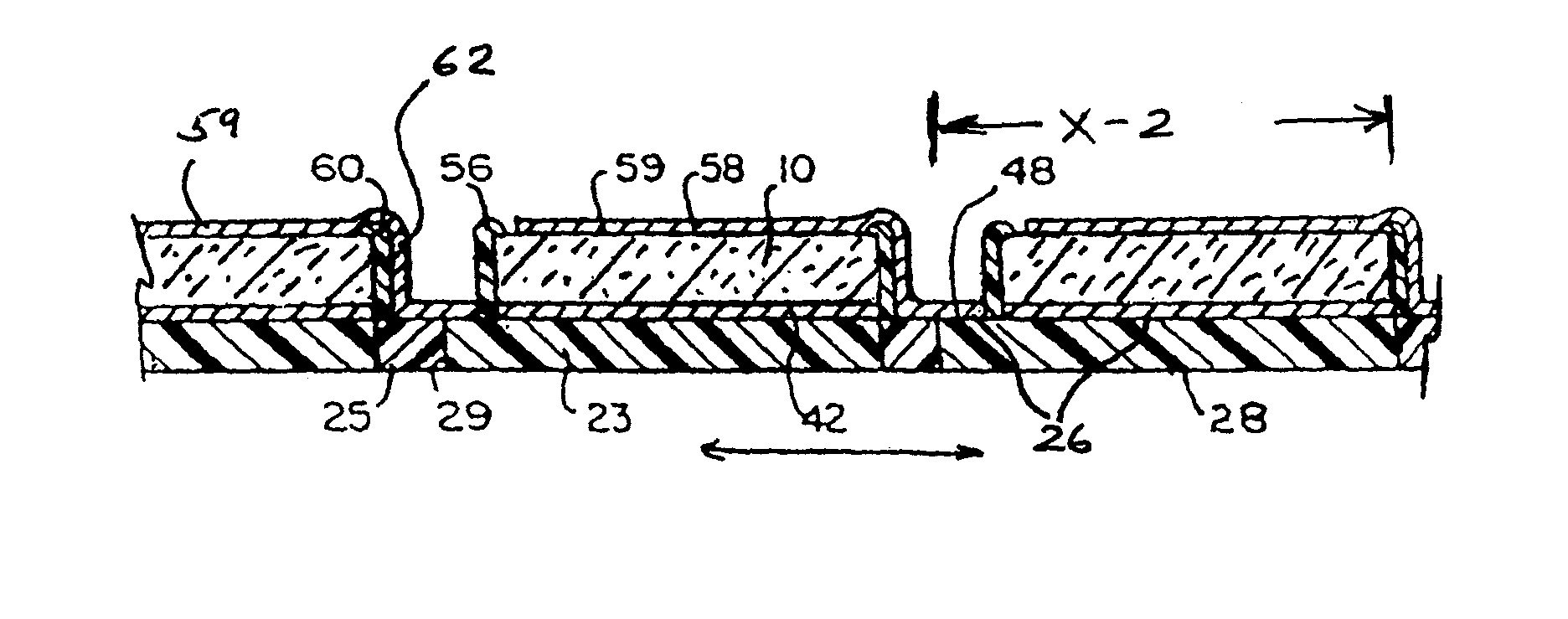

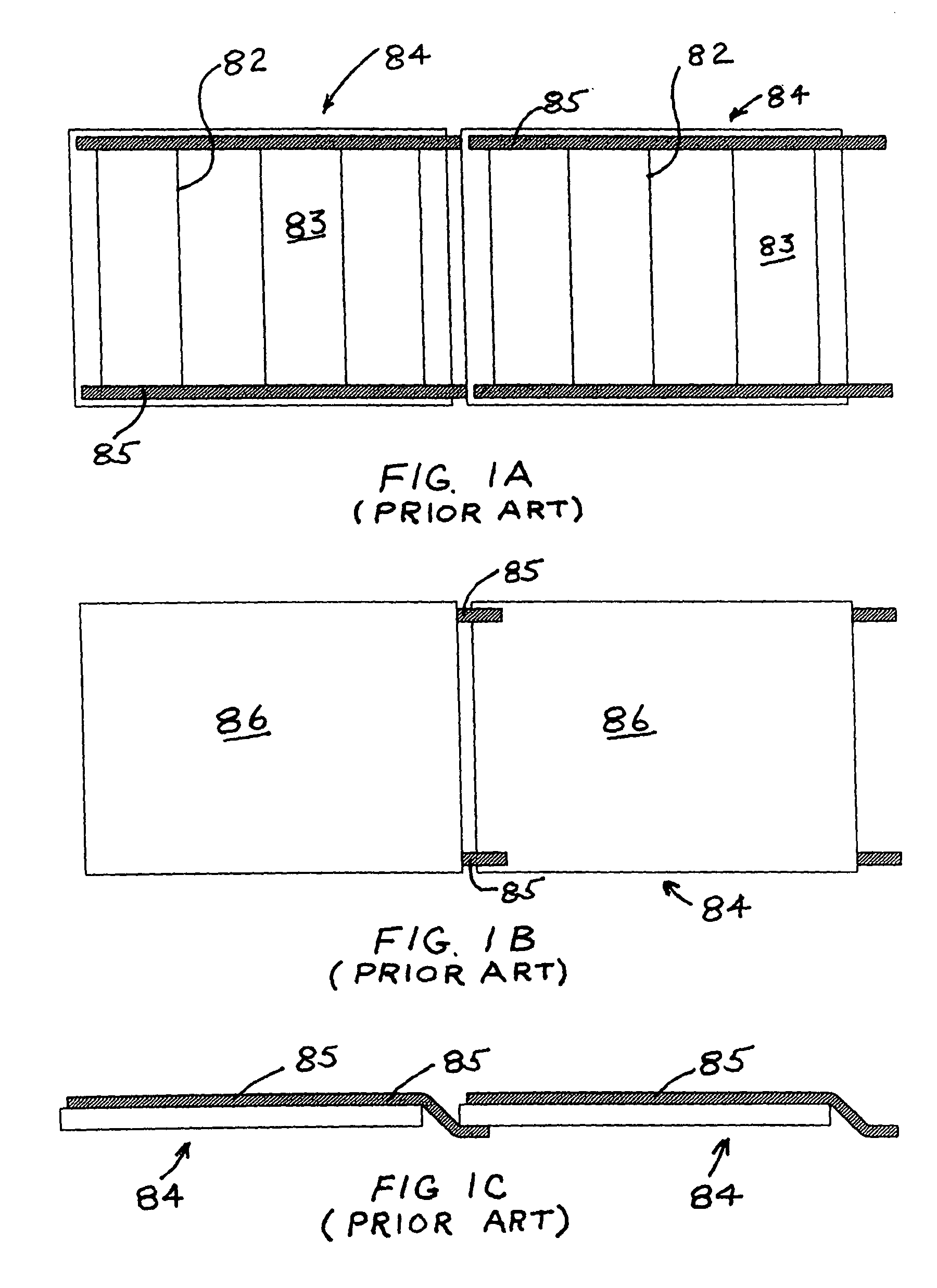

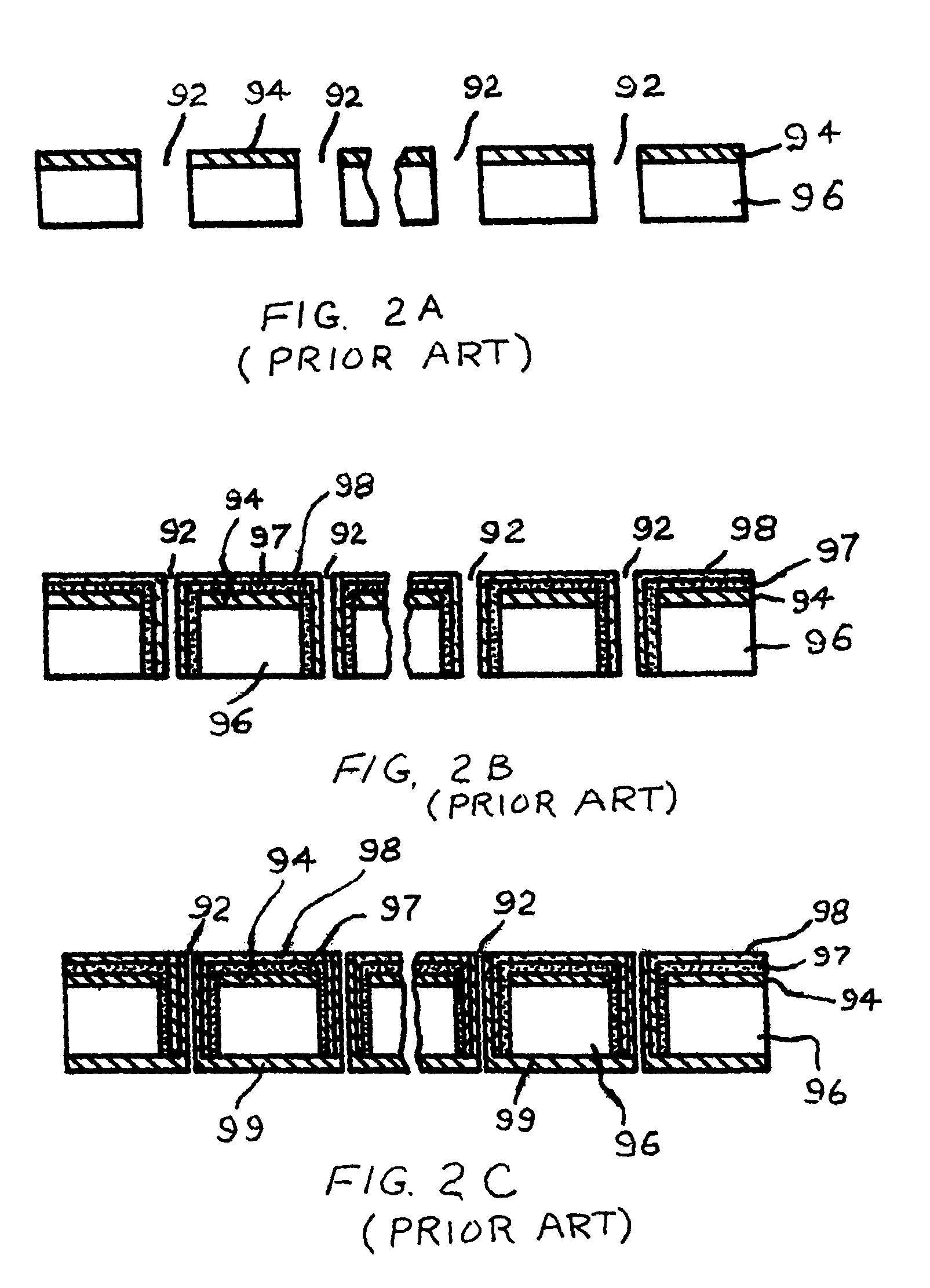

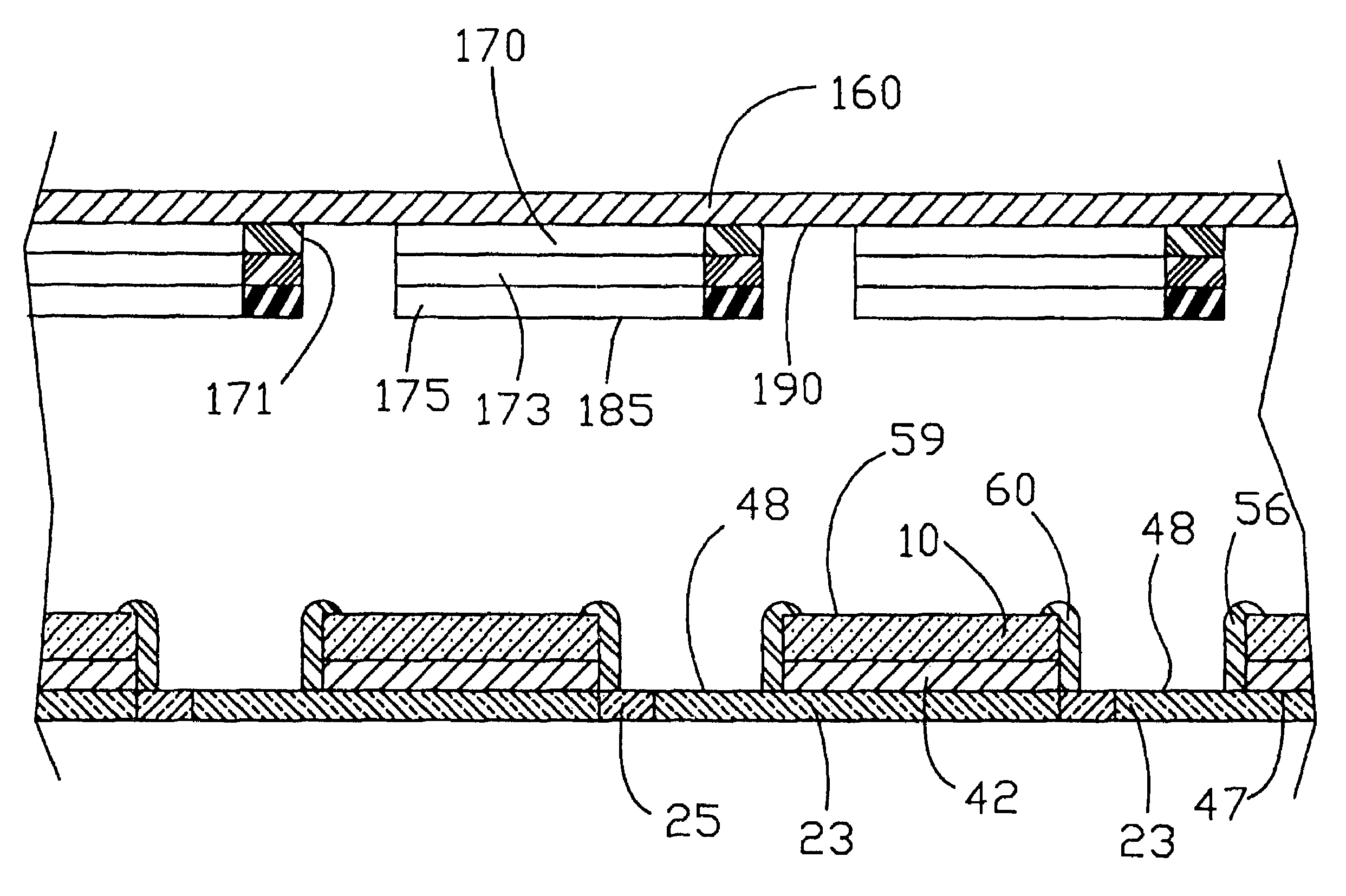

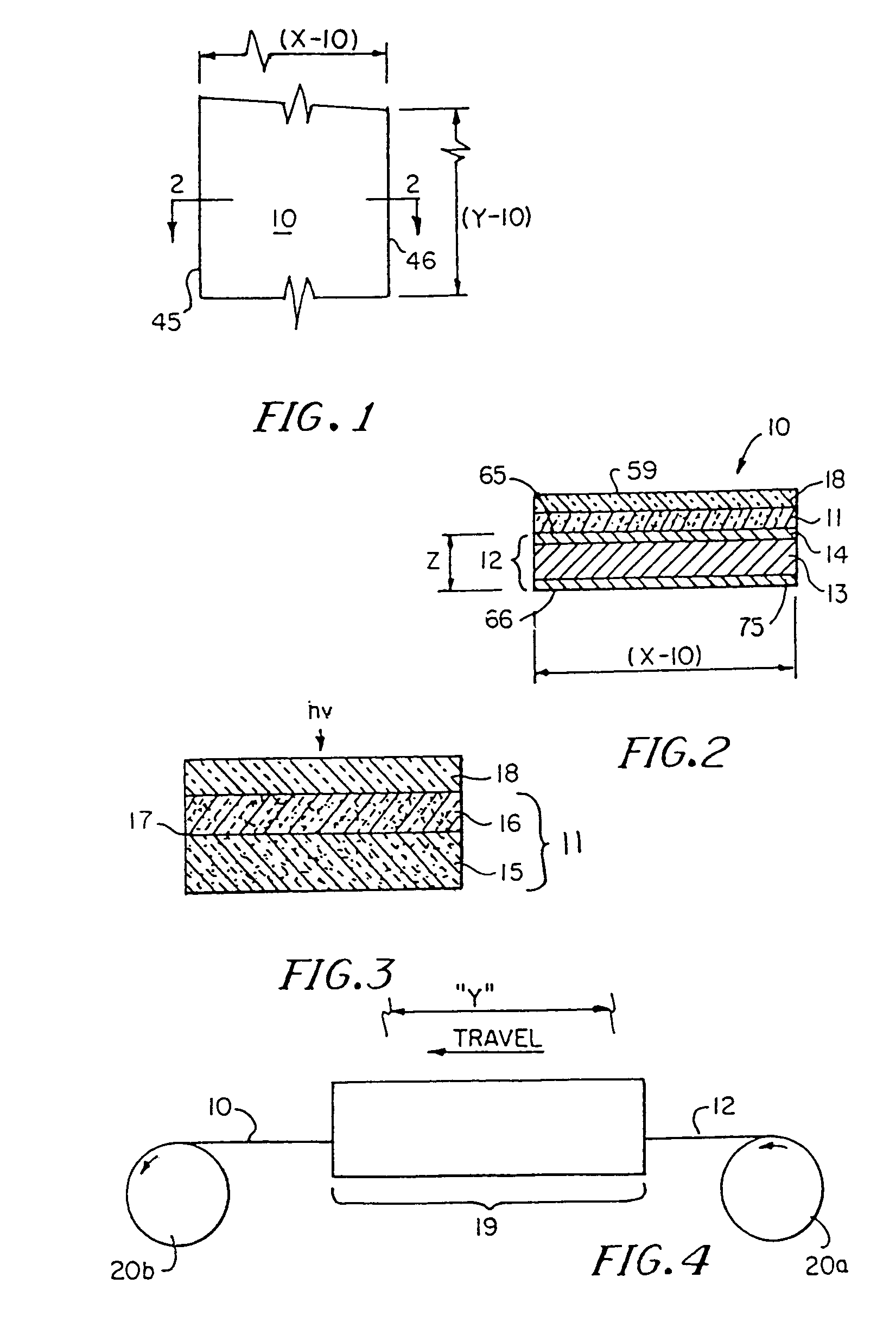

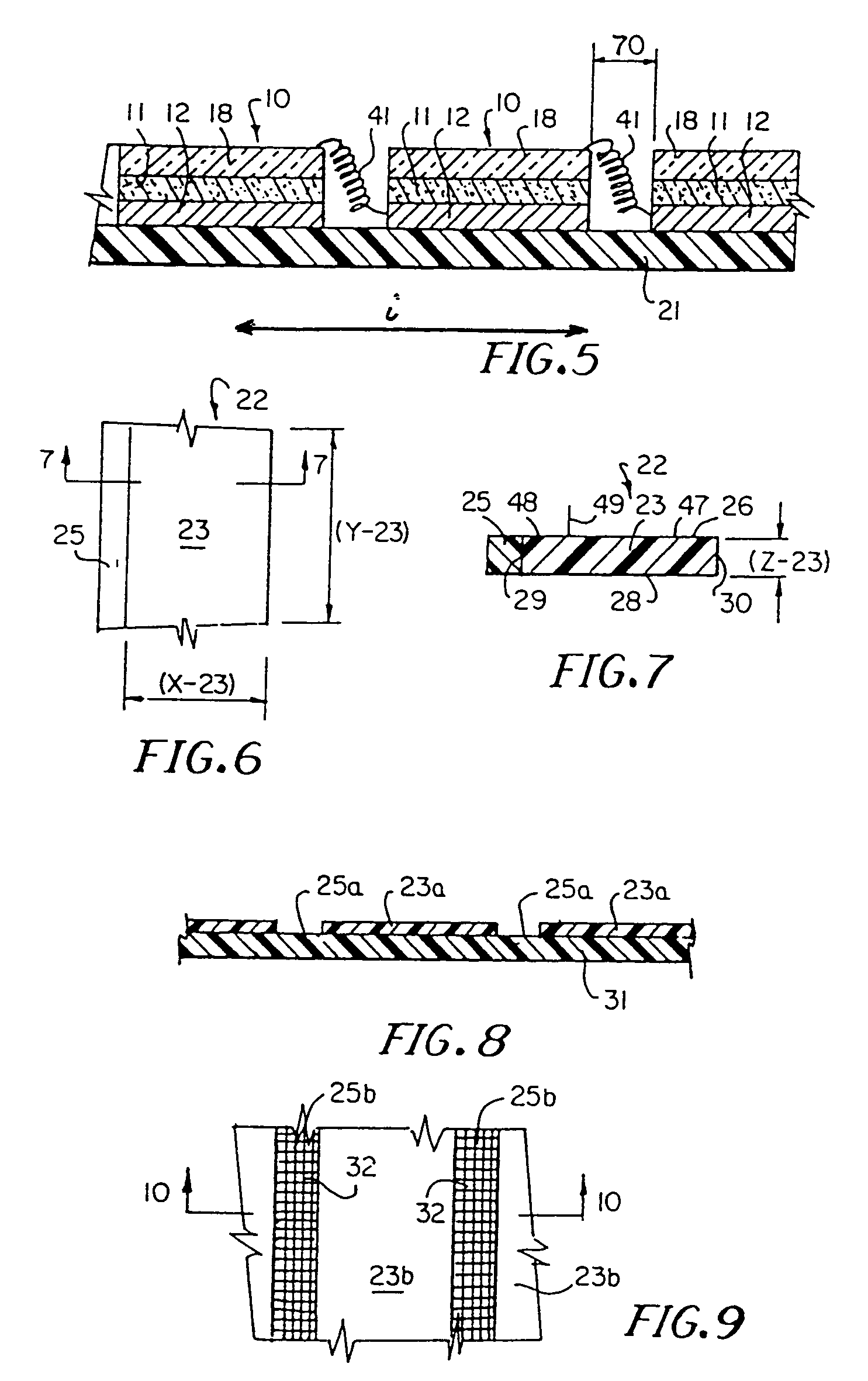

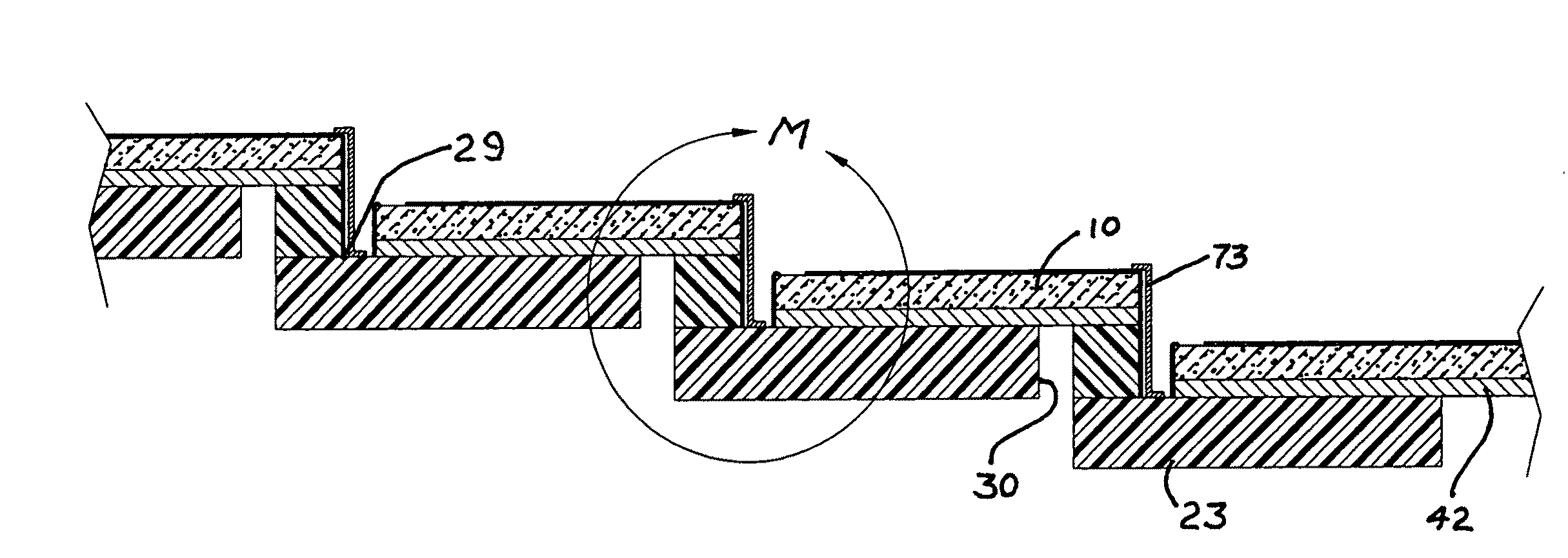

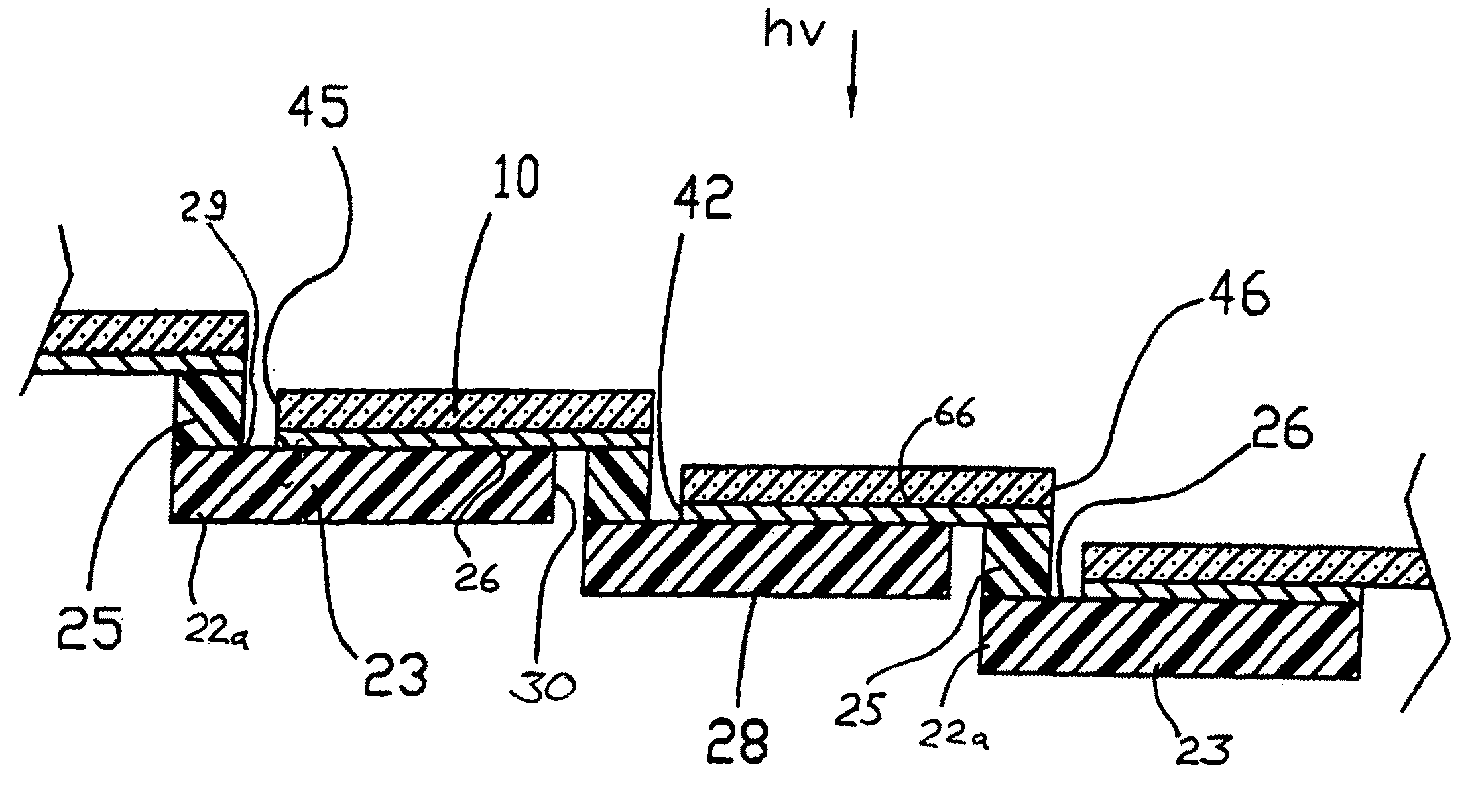

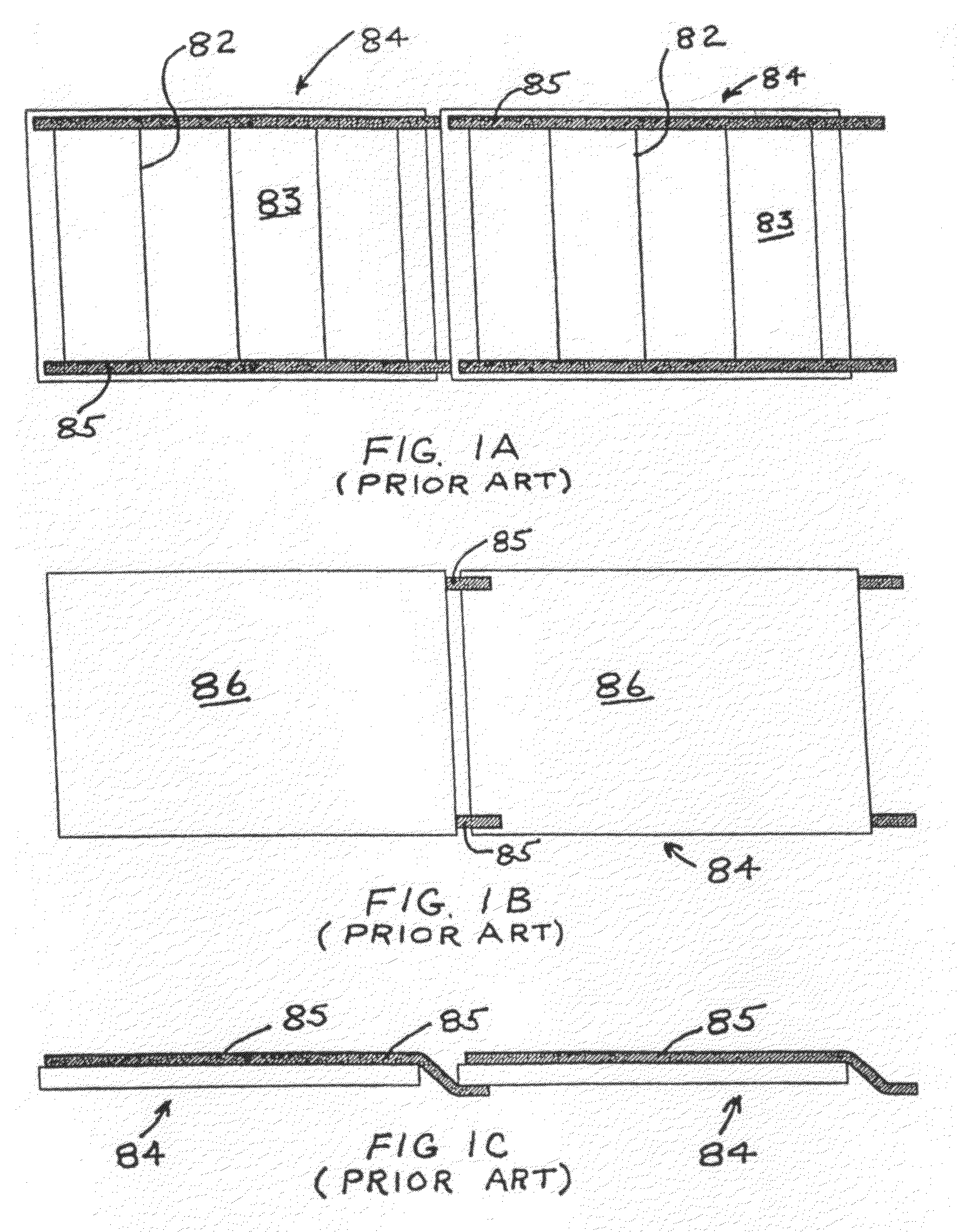

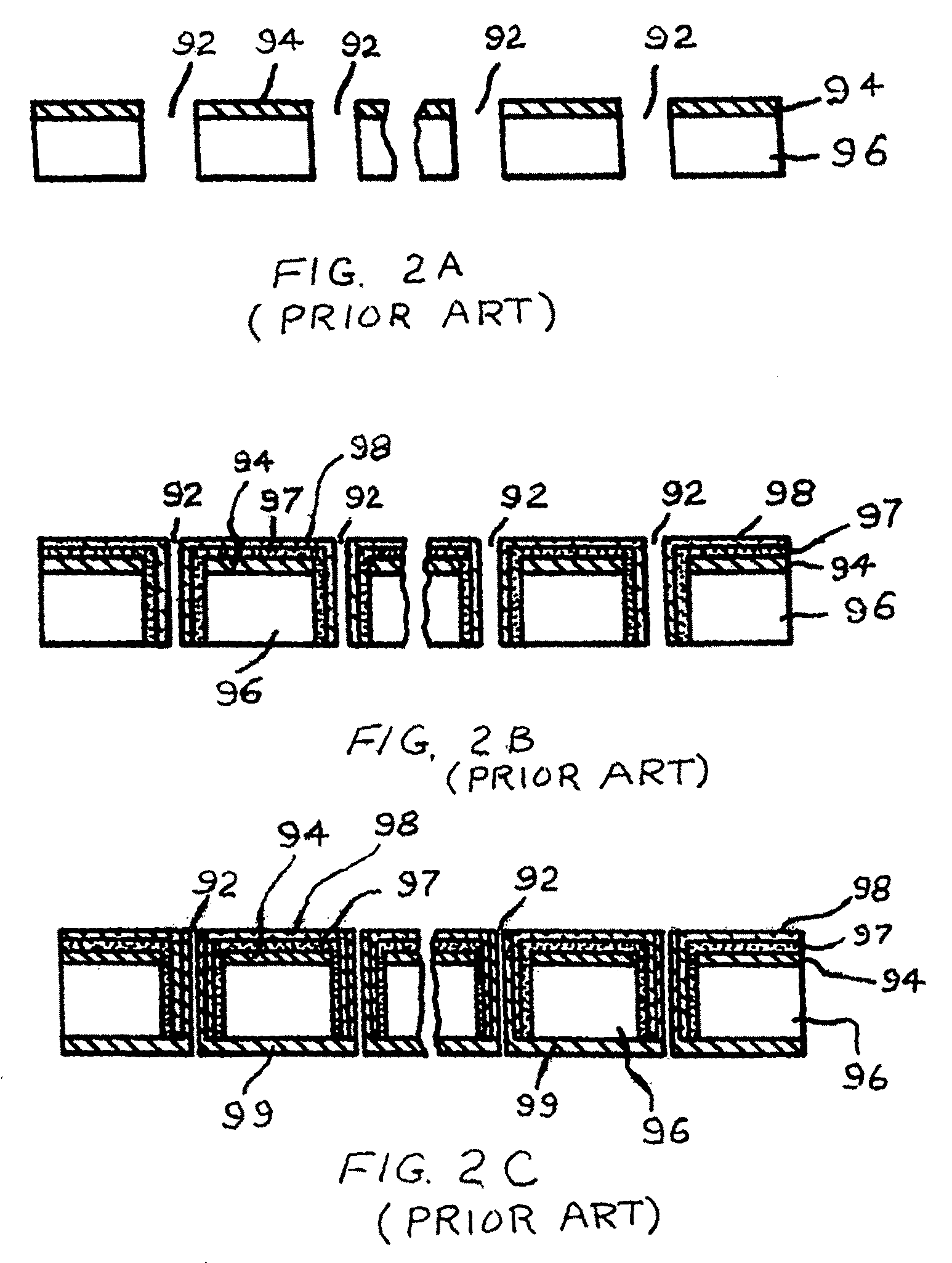

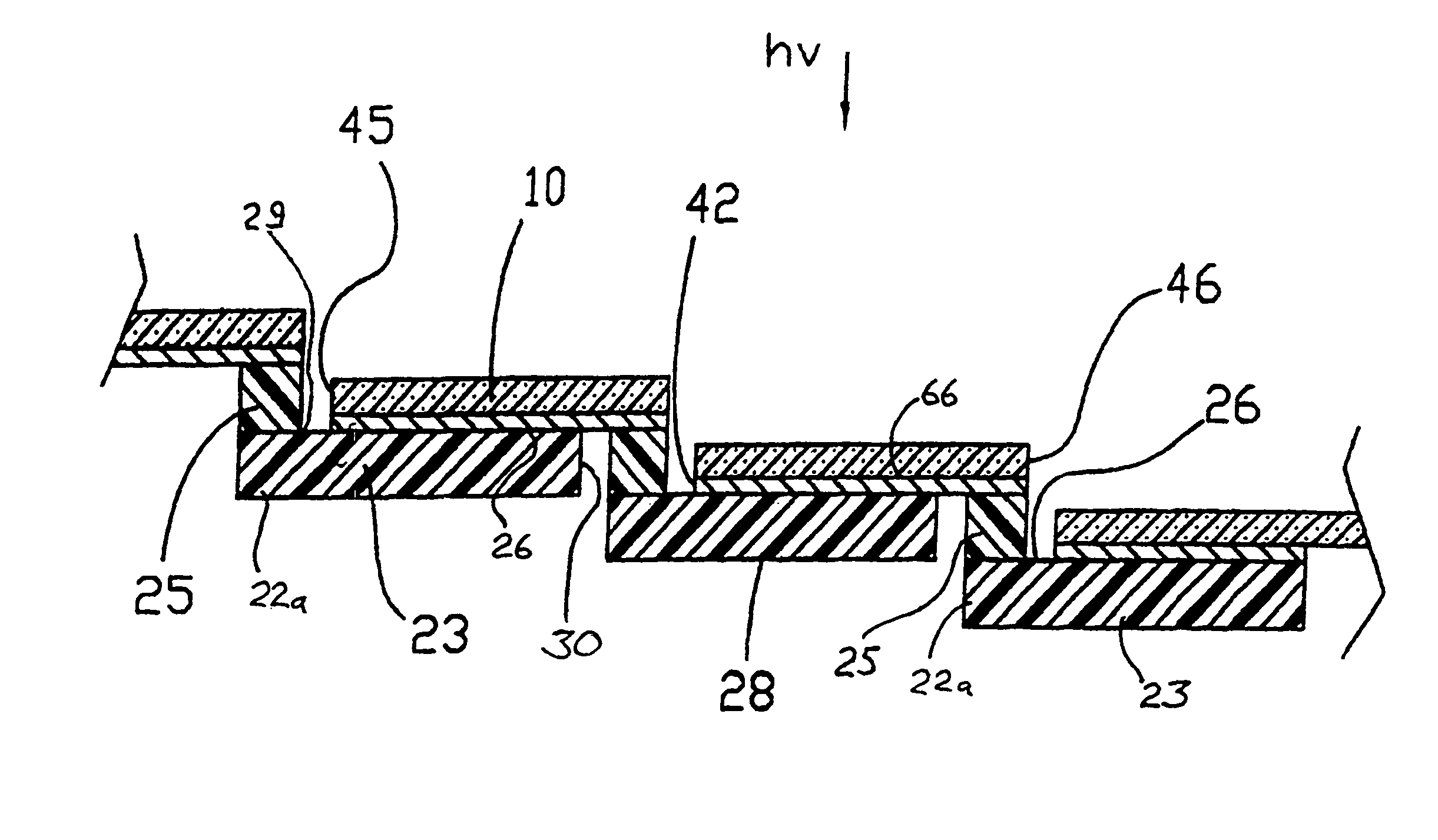

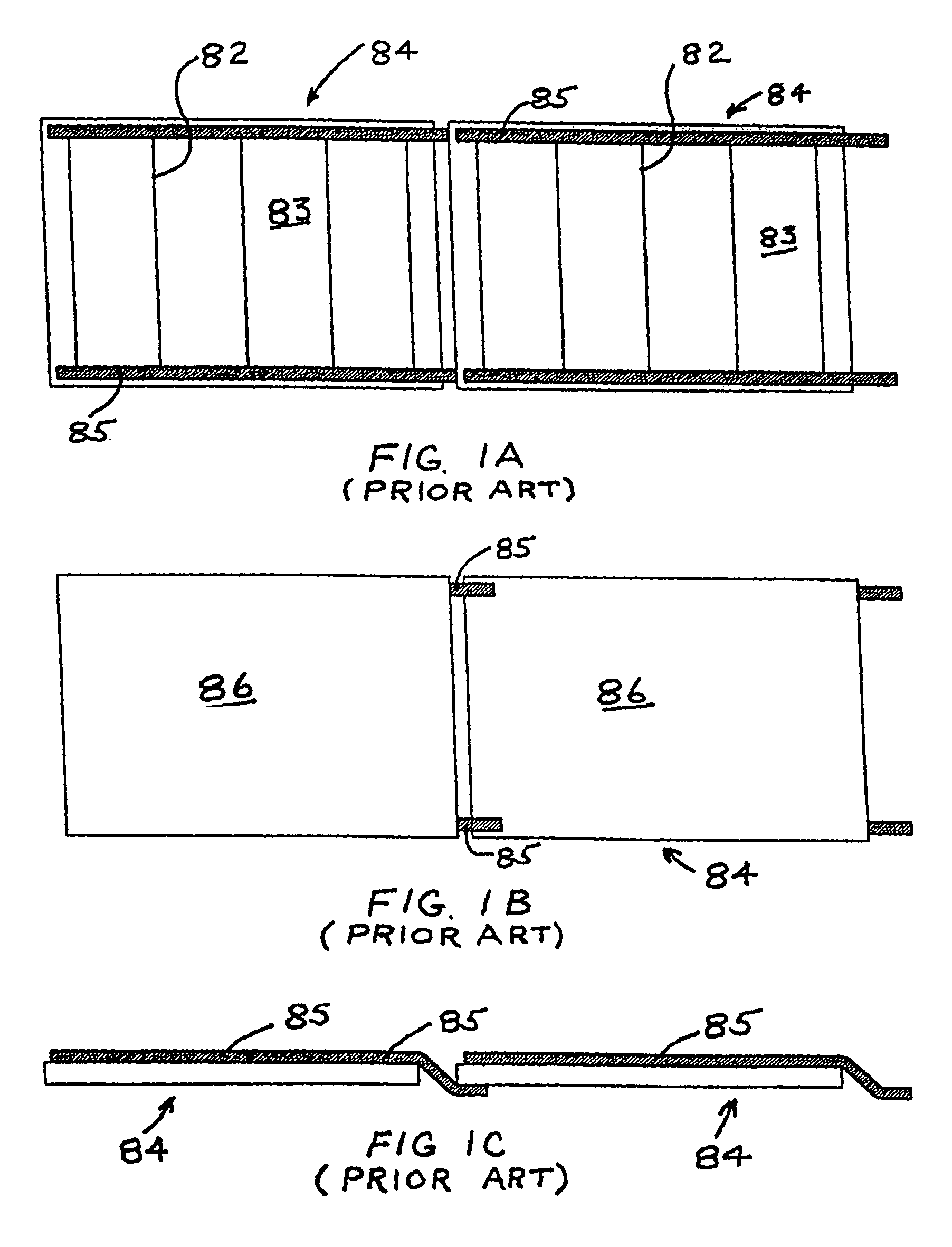

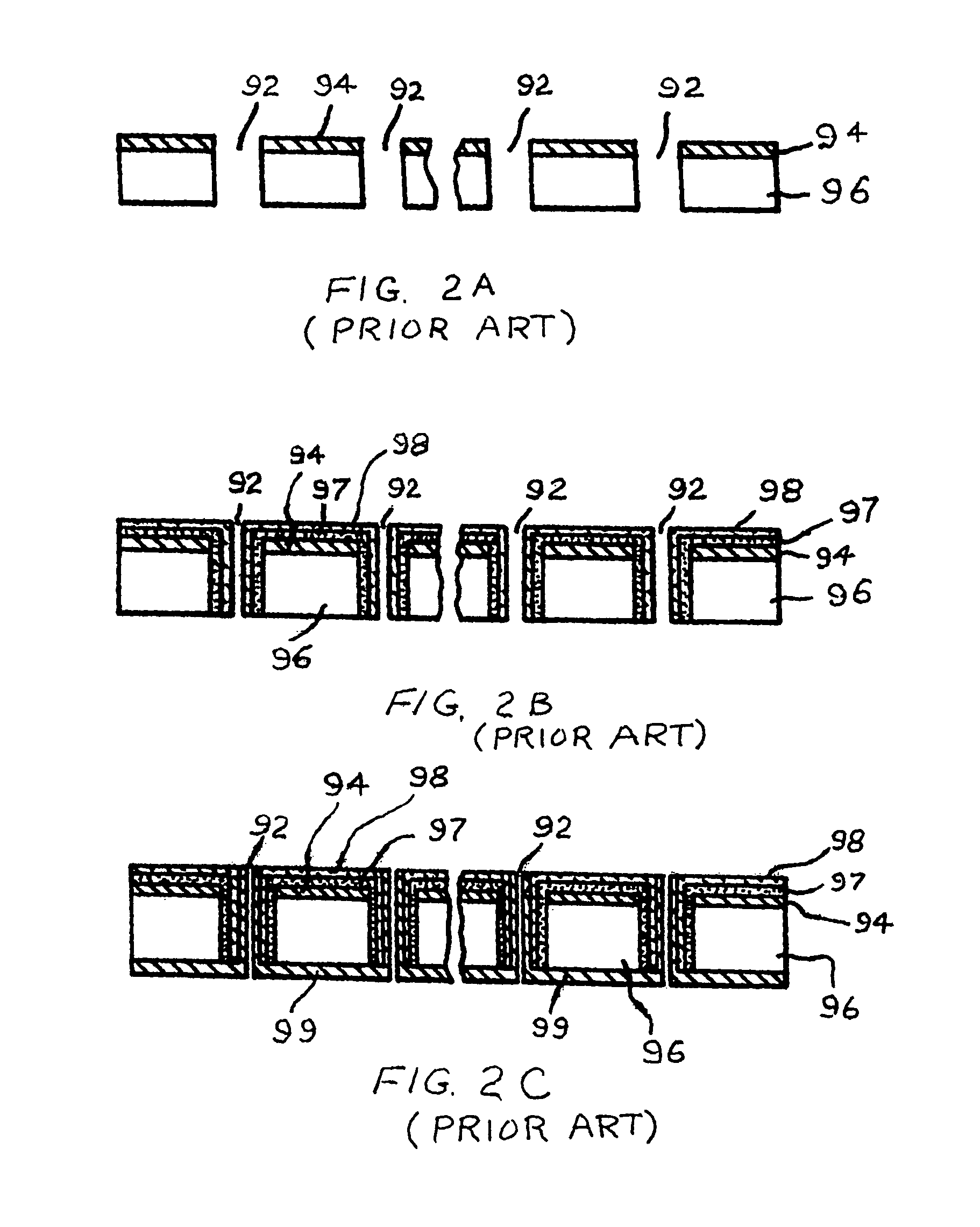

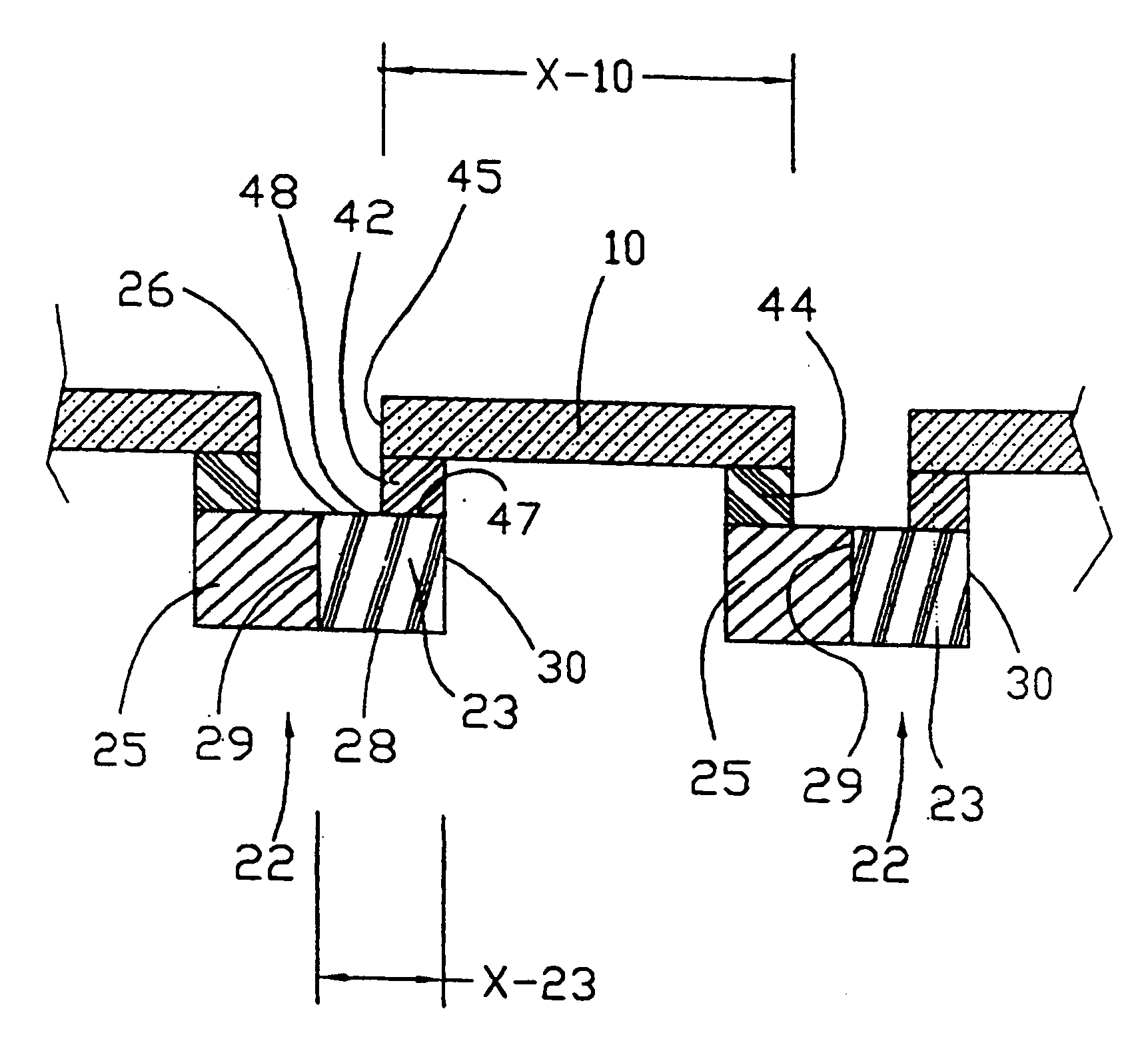

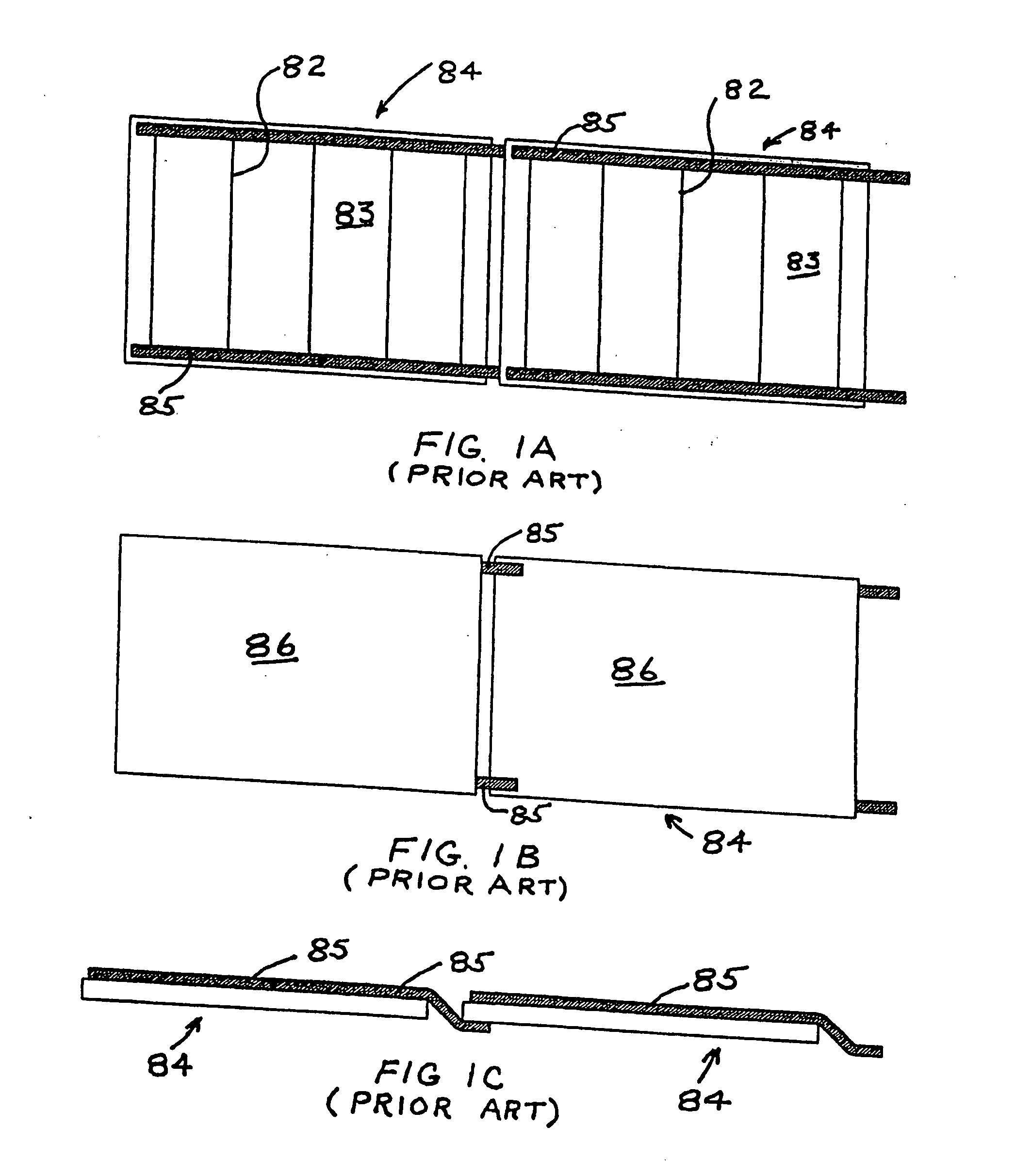

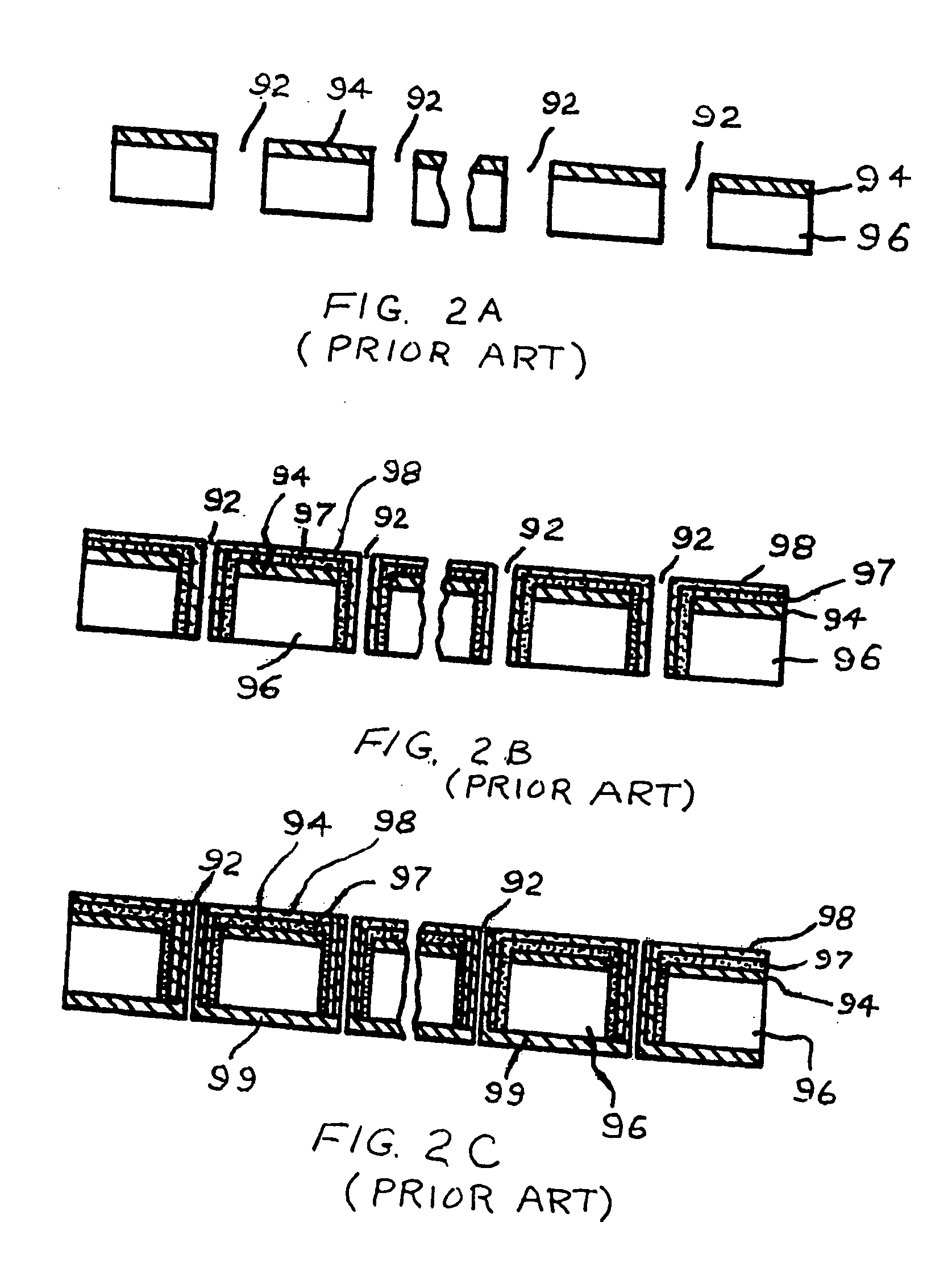

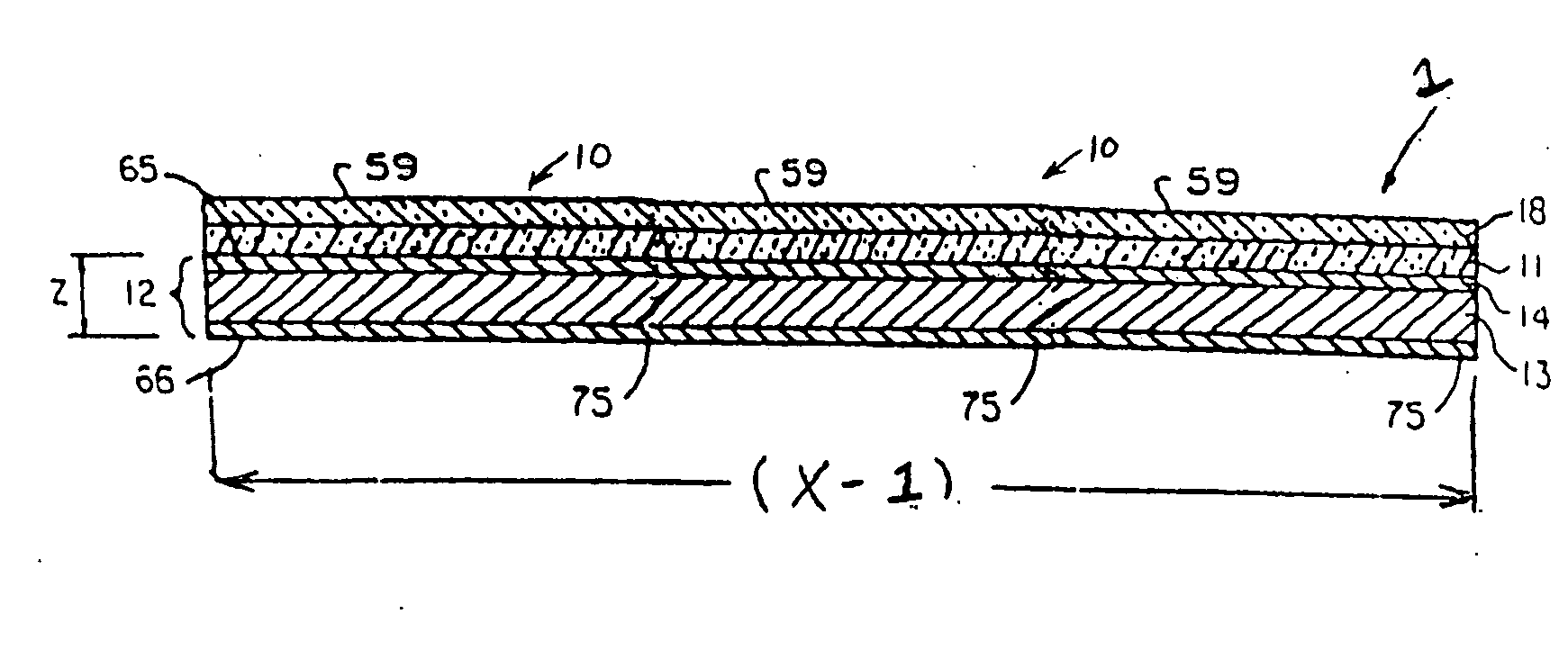

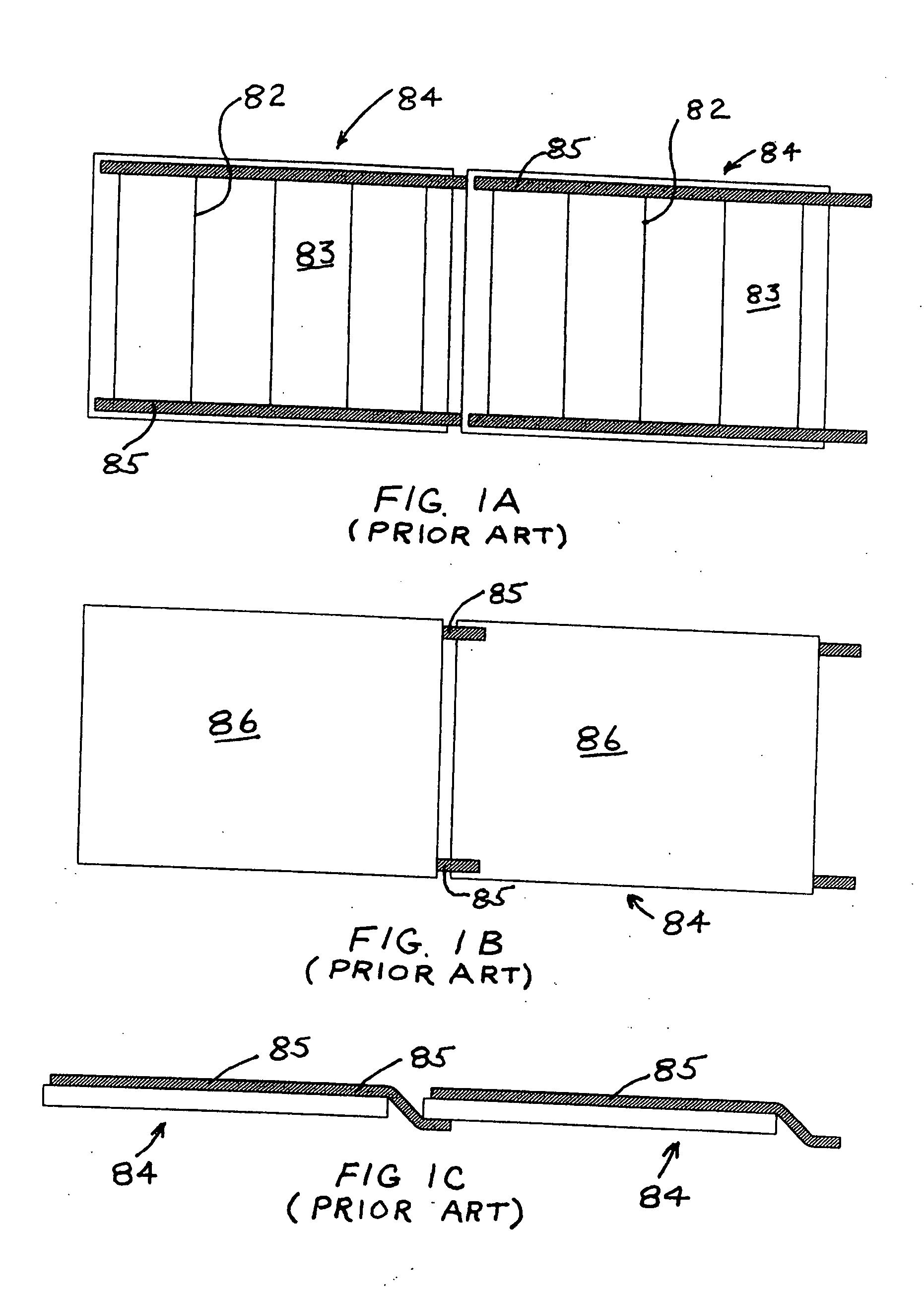

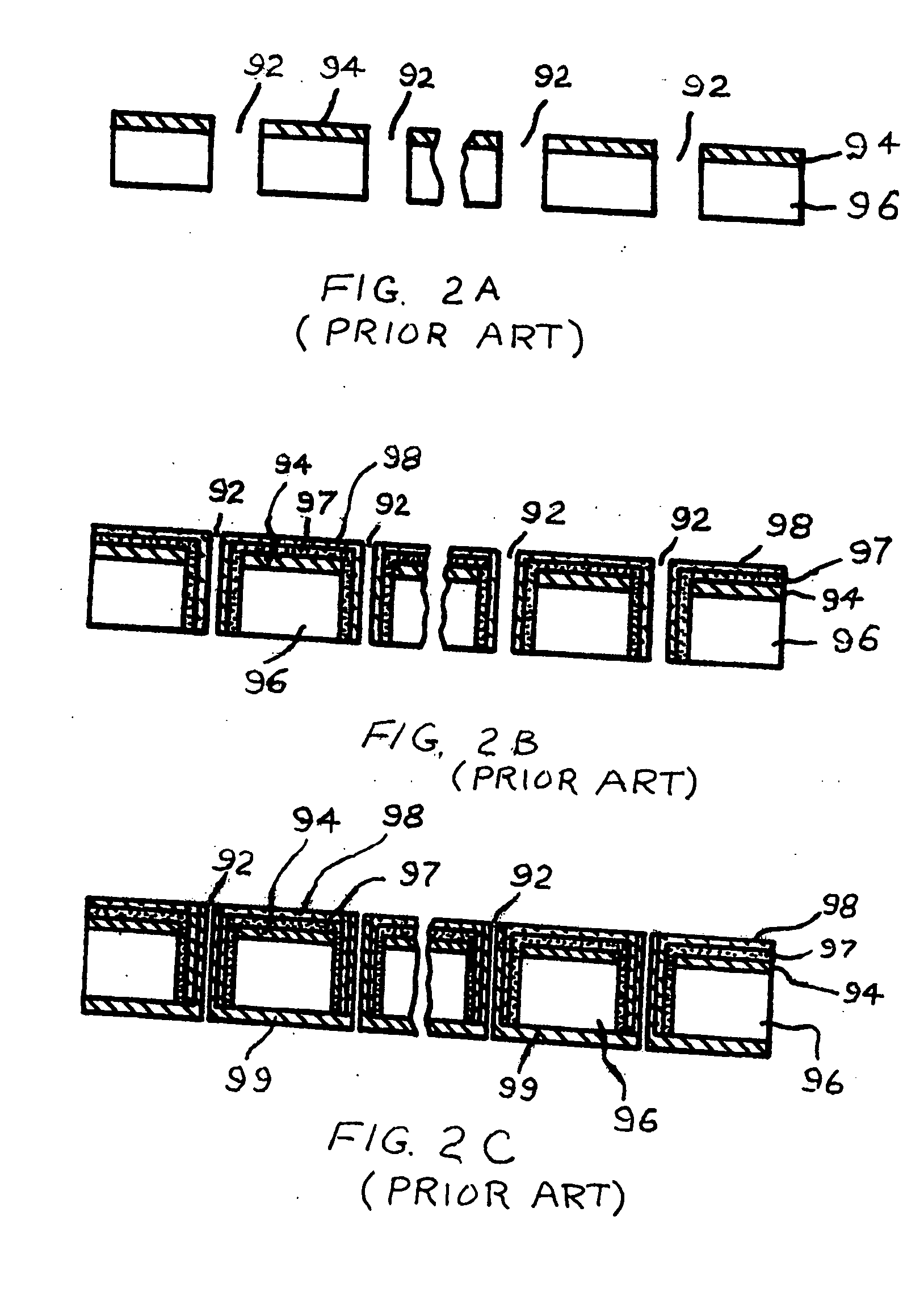

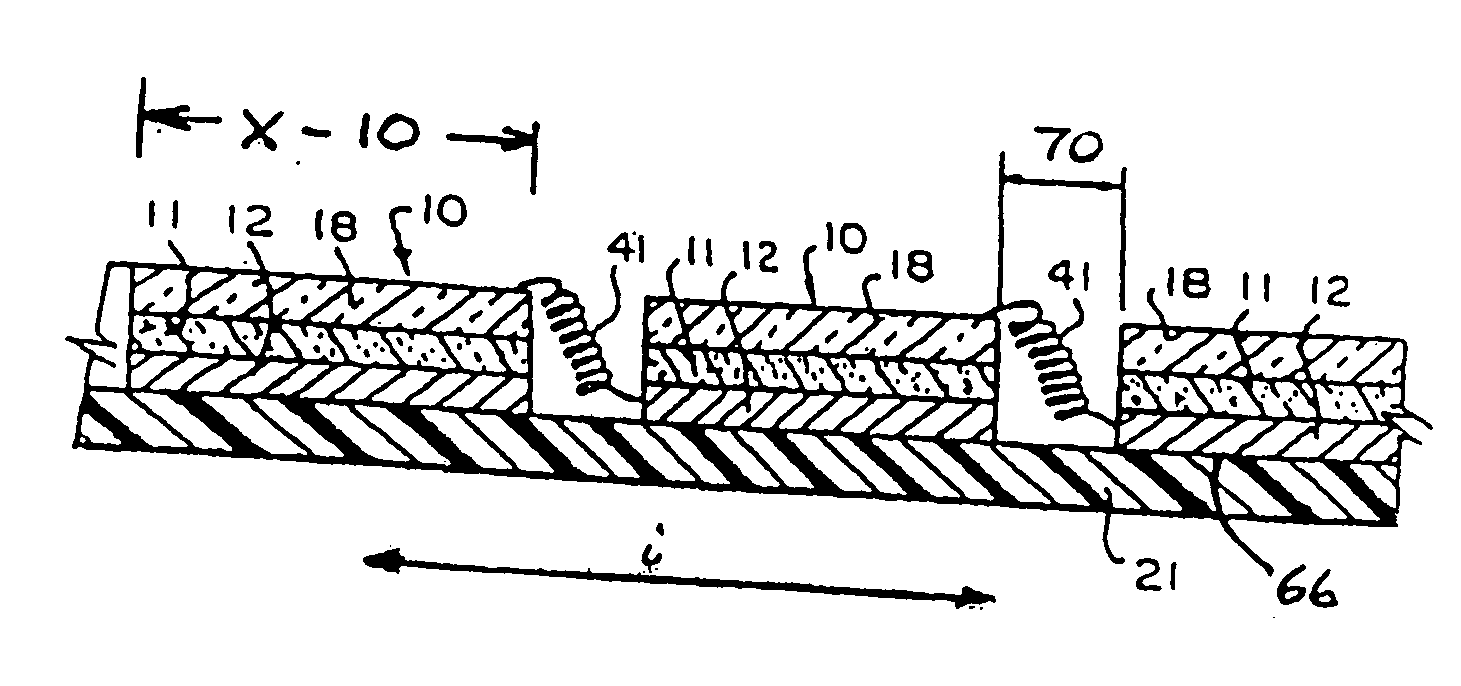

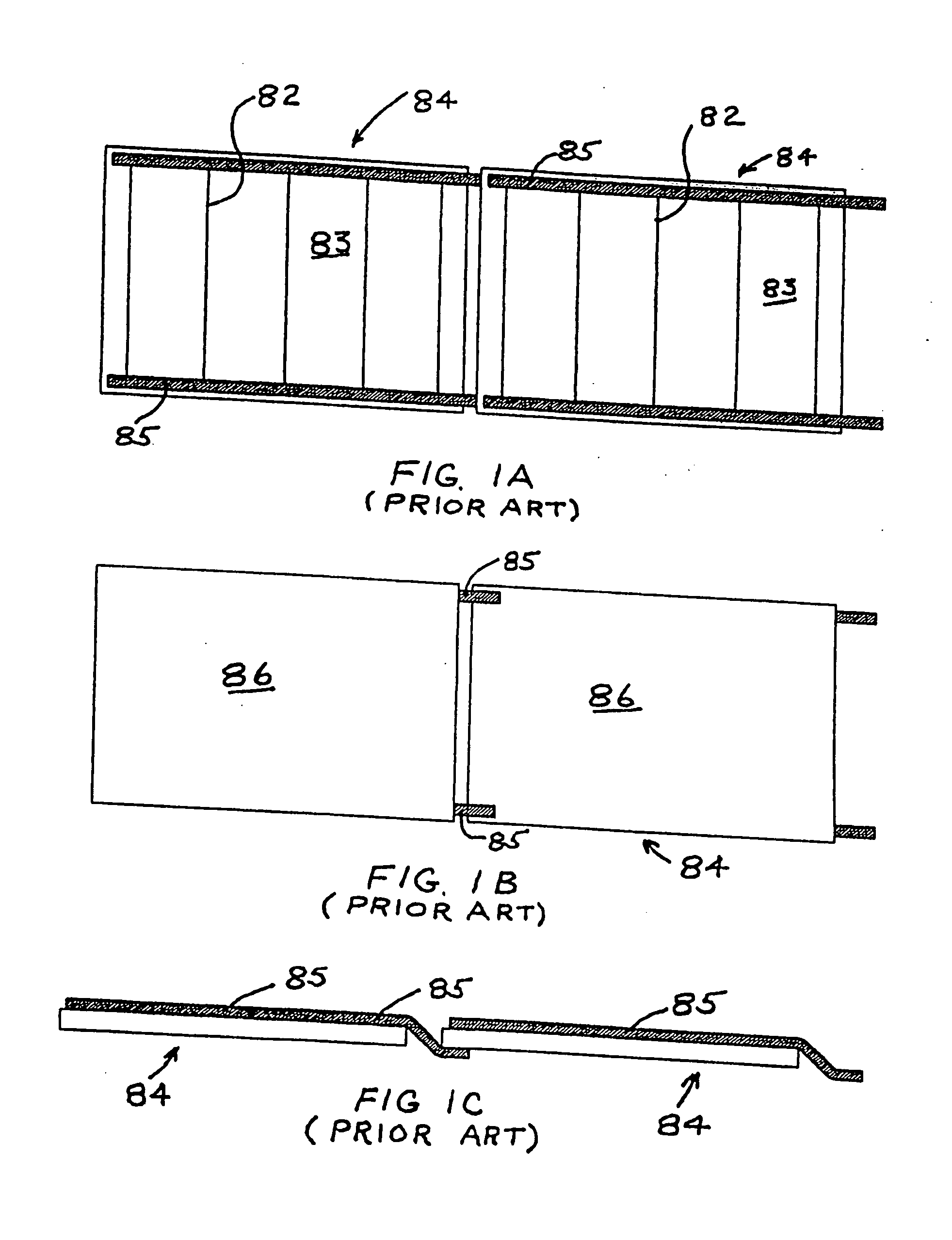

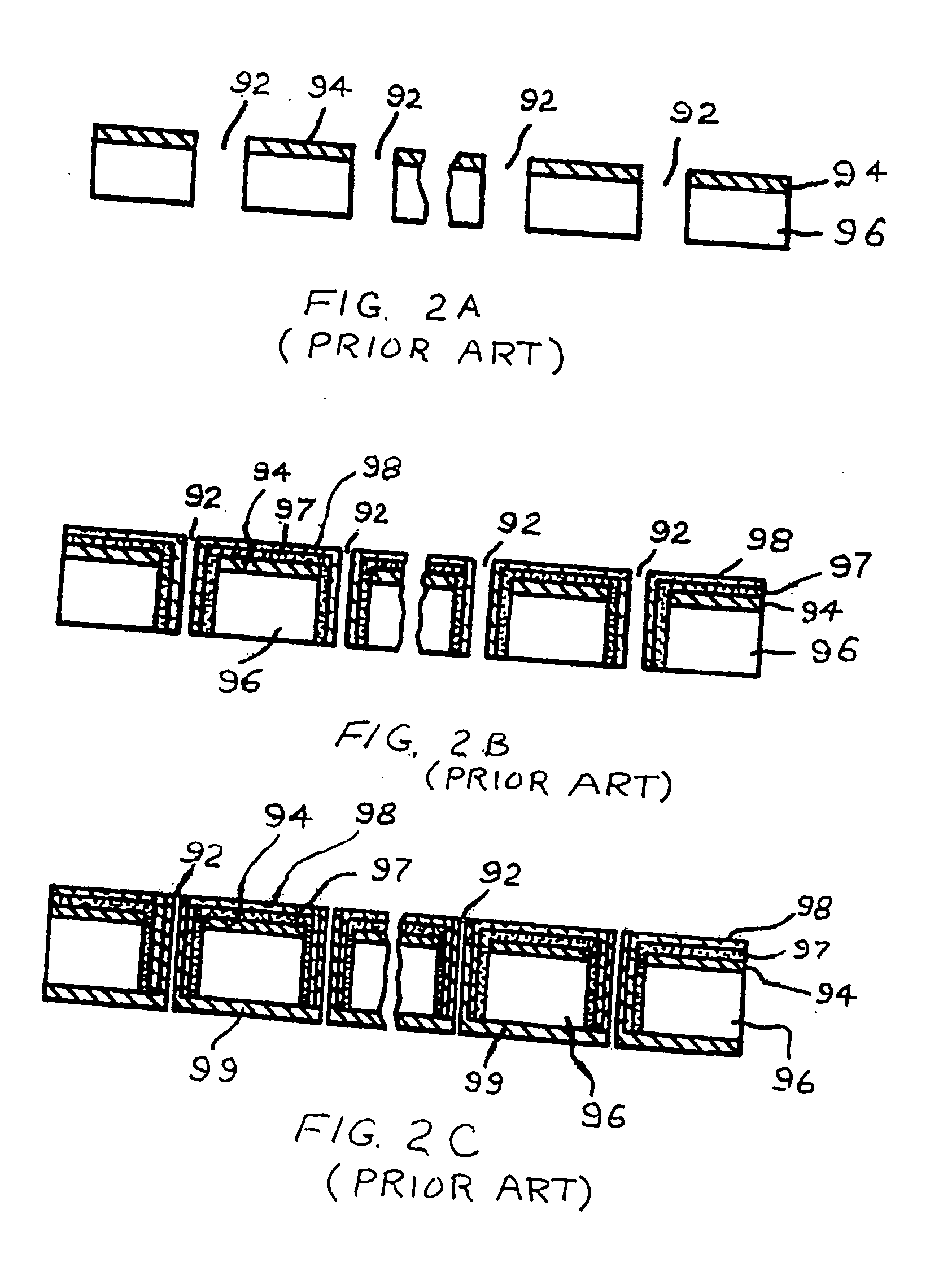

This invention comprises deposition of thin film photovoltaic junctions on metal substrates which can be heat treated following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation an interconnection substrate structure is produced in a continuous roll-to-roll fashion. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials since it does not have to endure high temperature exposure. Cells comprising the metal foil supported photovoltaic junctions are then laminated to the interconnection substrate structure. Conductive interconnections are deposited to complete the array. The conductive interconnections can be accomplished with a separately prepared interconnection component. The interconnected array is produced using continuous roll-to-roll processing which avoids the need to use the expensive and intricate material removal operations currently taught in the art to achieve electrical interconnections among arrays of photovoltaic cells.

Owner:SOLANNEX

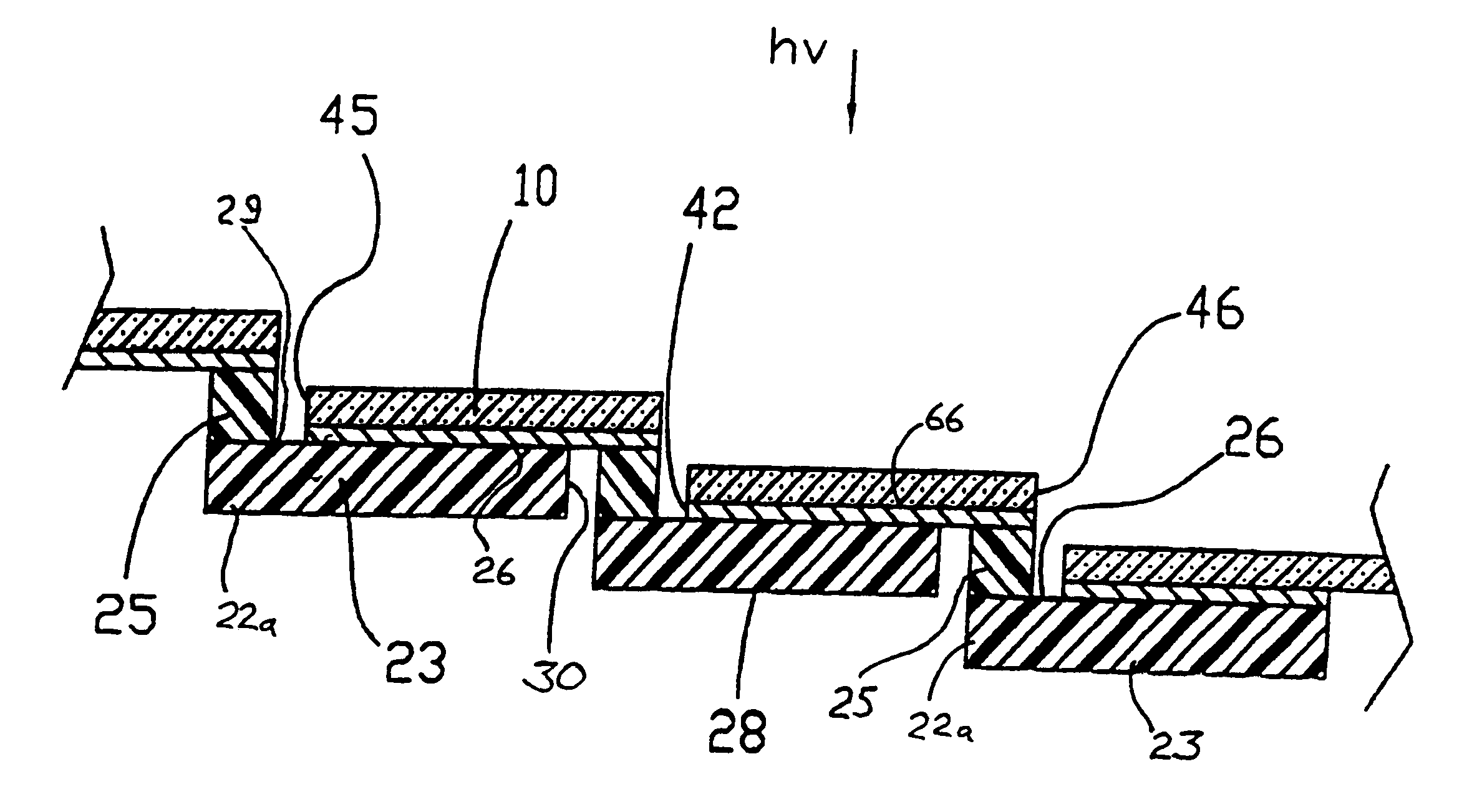

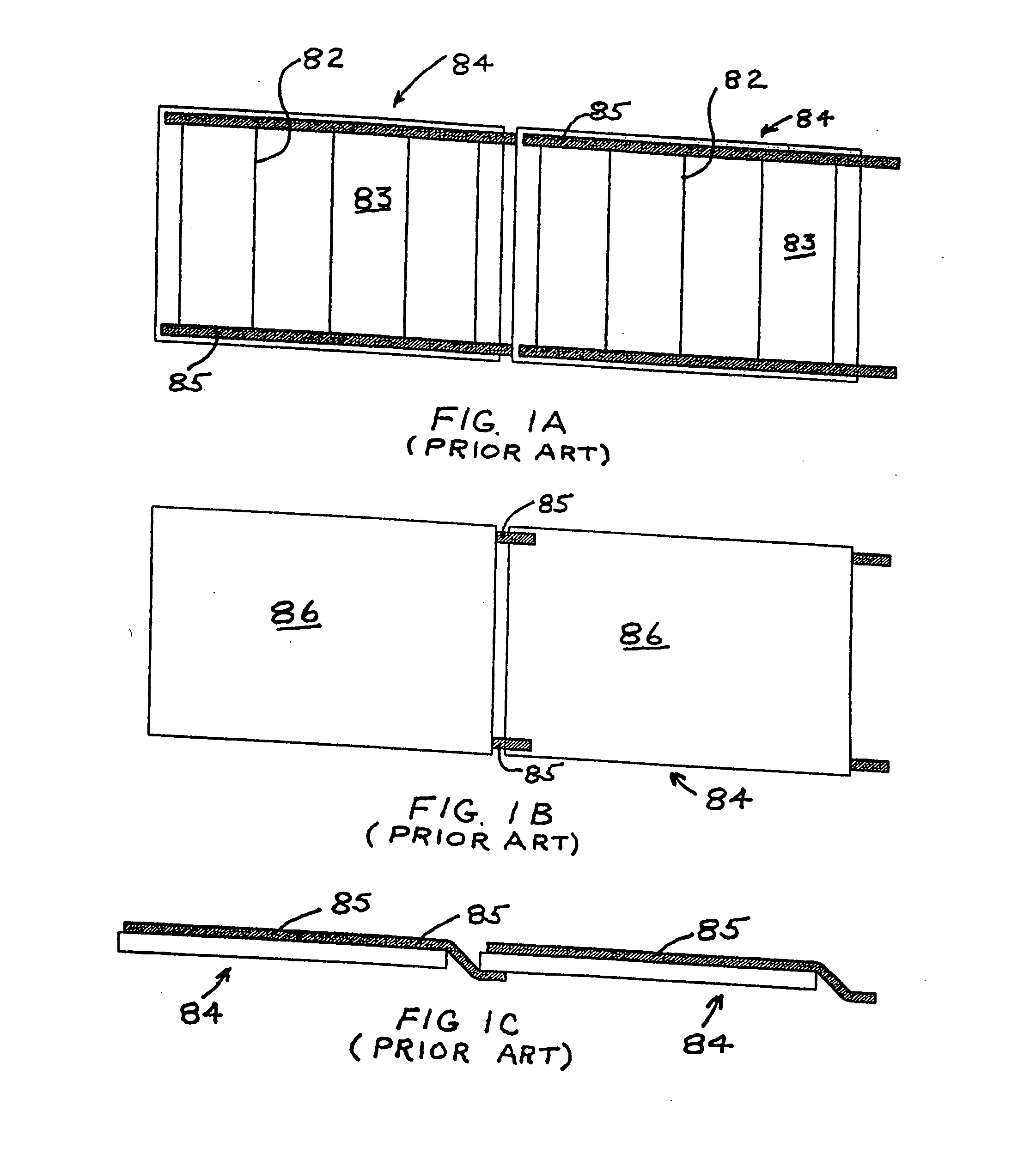

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS6459032B1Eliminate deficienciesCheap productionPV power plantsSolid-state devicesMaterial removalEngineering

This invention comprises deposition of thin film photovoltaic junctions on conductive foil substrates which can be heat treated following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation, an interconnection substrate structure is produced in a continuous roll-to-roll fashion. The conductive foil supported photovoltaic junction is then laminated to the interconnection substrate structure and conductive connections are deposited to complete the module or array. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials since it does not have to endure high temperature exposure. Furthermore, the photovoltaic junction and its conductive foil support can be produced in bulk without the need to use the expensive and intricate material removal operations currently taught in the art to achieve series interconnections.

Owner:SOLANNEX

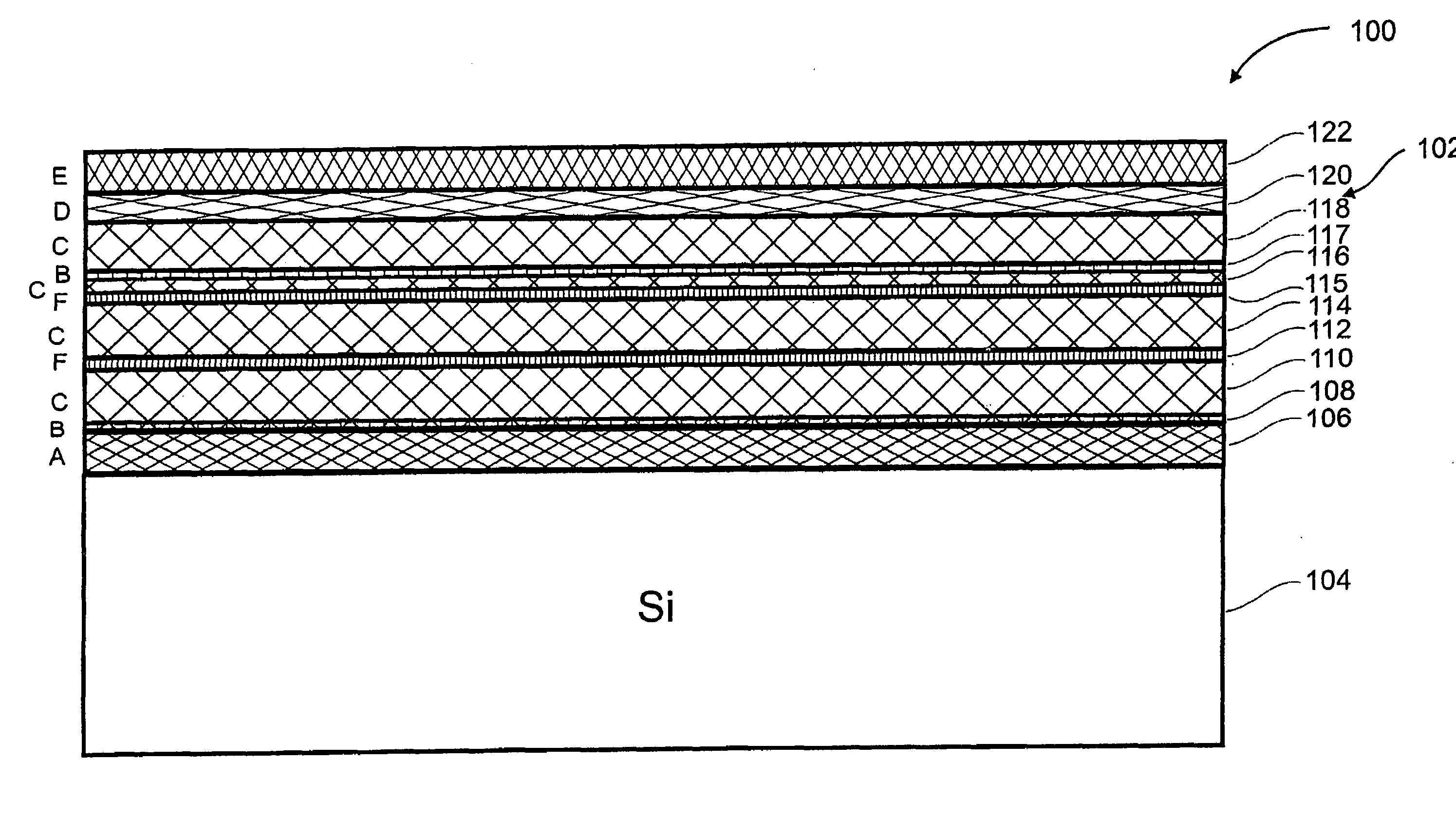

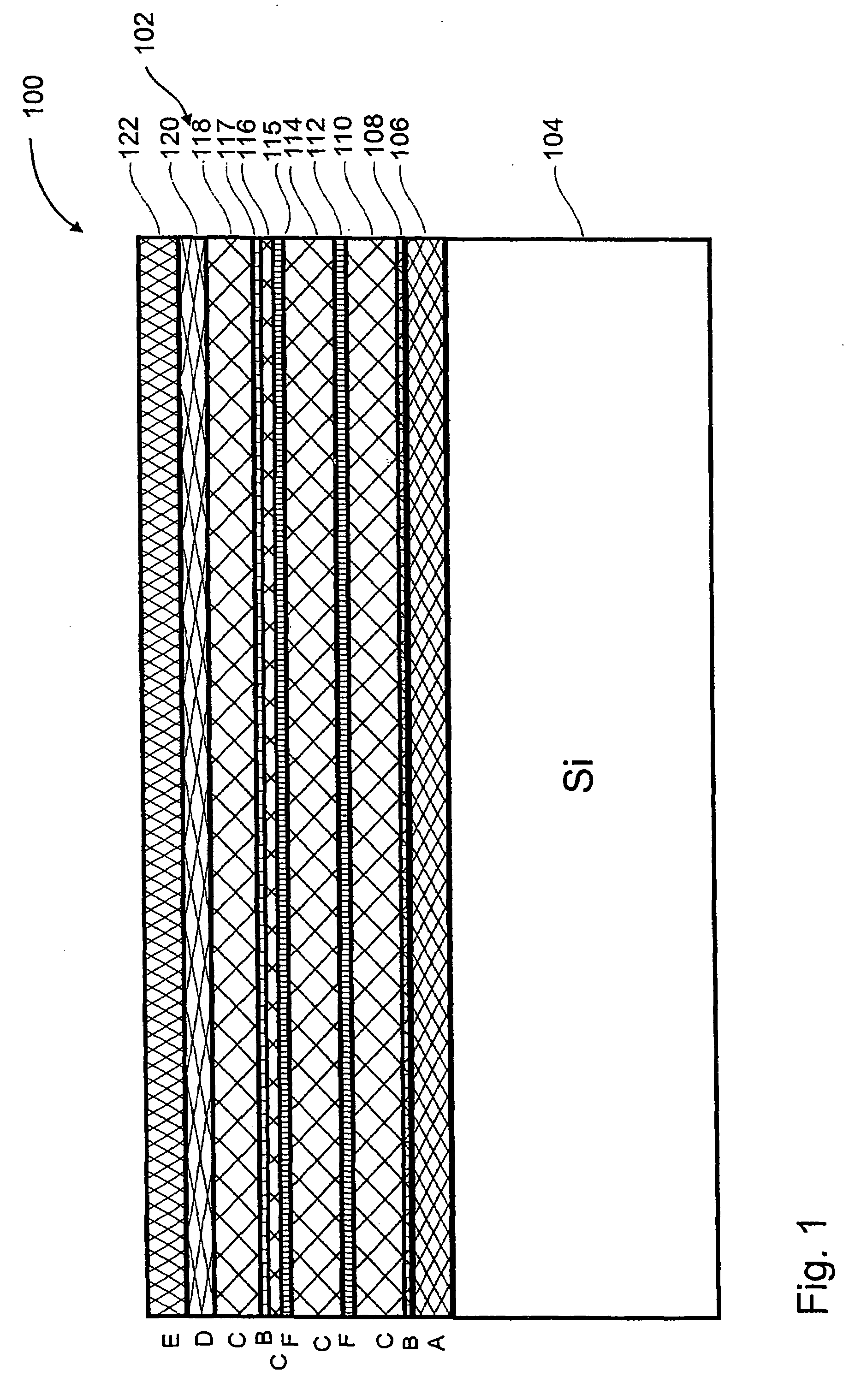

Nitride semiconductor component and process for its production

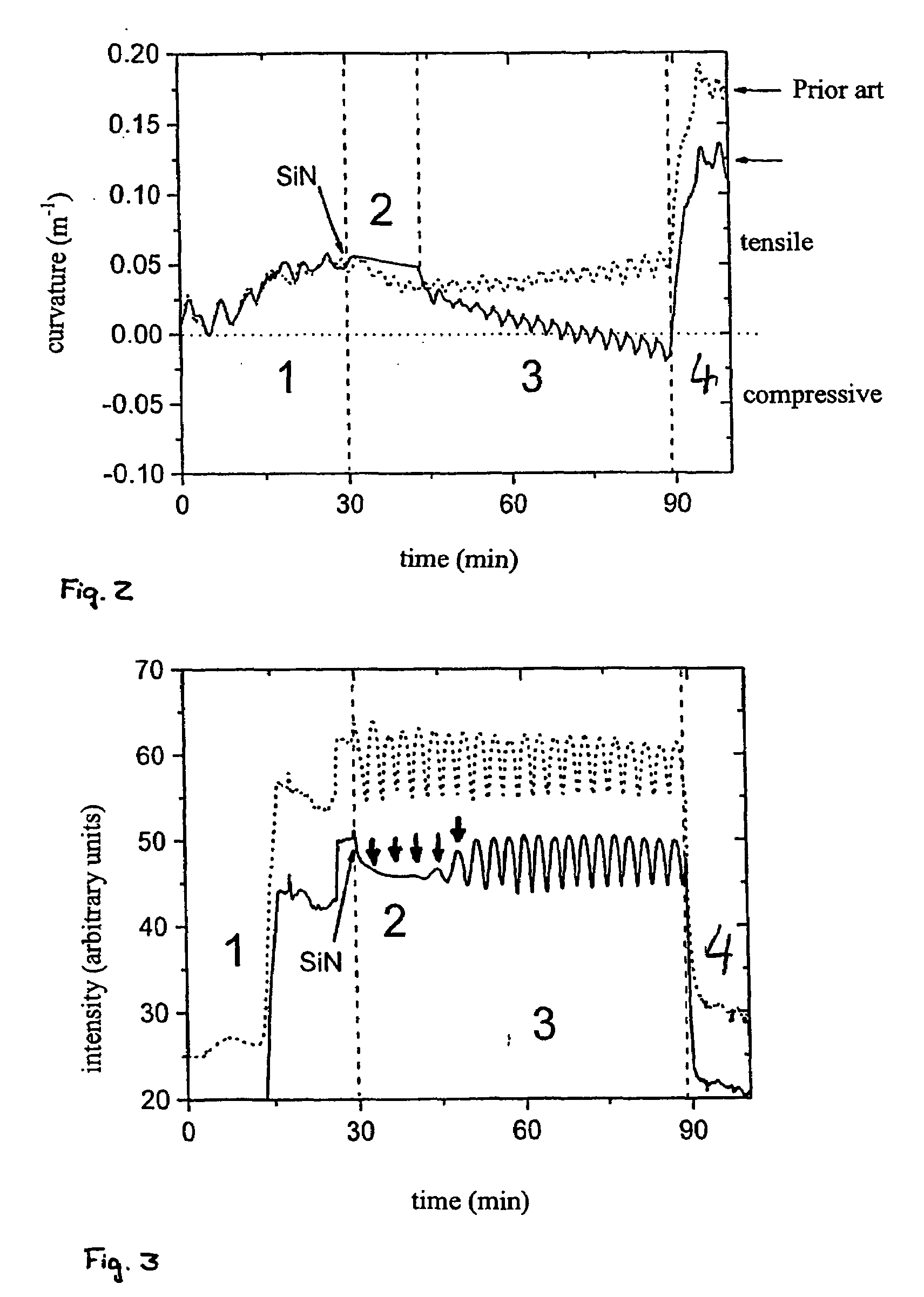

ActiveUS20070197004A1Cheap productionIncrease compressive stressSemiconductor/solid-state device manufacturingSemiconductor devicesLayer thicknessNucleation

The invention relates to a process for the production of a layer structure of a nitride semiconductor component on a silicon surface, comprising the steps:provision of a substrate that has a silicon surface;deposition of an aluminium-containing nitride nucleation layer on the silicon surface of the substrate;optional: deposition of an aluminium-containing nitride buffer layer on the nitride nucleation layer;deposition of a masking layer on the nitride nucleation layer or, if present, on the first nitride buffer layer;deposition of a gallium-containing first nitride semiconductor layer on the masking layer,wherein the masking layer is deposited in such a way that, in the deposition step of the first nitride semiconductor layer, initially separate crystallites grow that coalesce above a coalescence layer thickness and occupy an average surface area of at least 0.16 μm2 in a layer plane of the coalesced nitride semiconductor layer that is perpendicular to the growth direction.

Owner:AZUR SPACE SOLAR POWER +1

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS7732243B2Eliminate deficienciesFacilitate electrical interconnectionPV power plantsSolid-state devicesPolymer substrateMaterial removal

Owner:SOLANNEX

Substrate and collector grid structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS7507903B2Eliminate deficienciesInexpensive productionPV power plantsSolid-state devicesRoll-to-roll processingMetal foil

This invention comprises deposition of thin film photovoltaic junctions on metal substrates which can be heat treated following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation an interconnection substrate structure is produced in a continuous roll-to-roll fashion. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials since it does not have to endure high temperature exposure. Cells comprising the metal foil supported photovoltaic junctions are then laminated to the interconnection substrate structure. Conductive interconnections are deposited to complete the array. The conductive interconnections can be accomplished with a separately prepared interconnection component. The interconnected array is produced using continuous roll-to-roll processing which avoids the need to use the expensive and intricate material removal operations currently taught in the art to achieve electrical interconnections among arrays of photovoltaic cells.

Owner:SOLANNEX

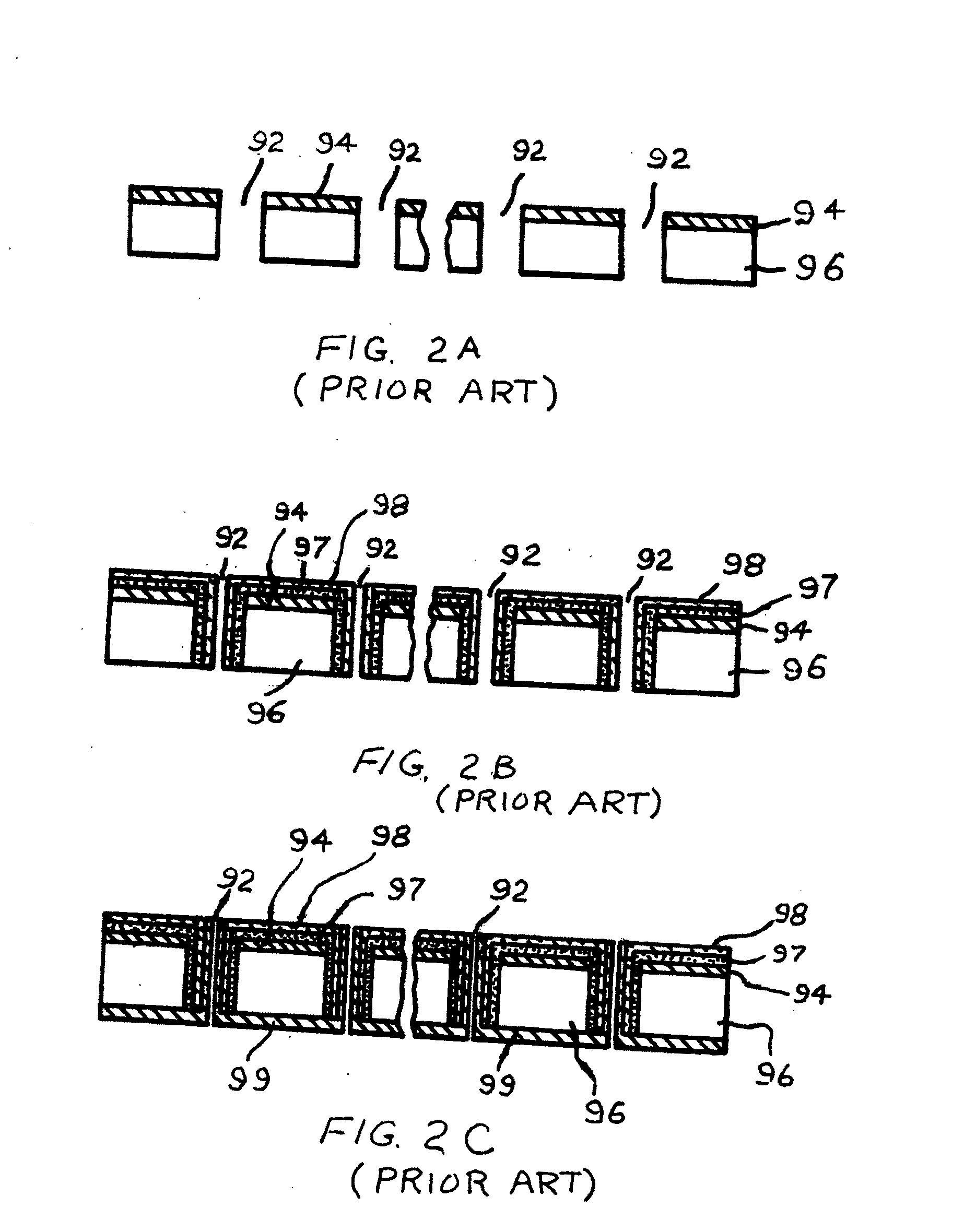

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS20080314433A1Minimization requirementsIncrease volumePV power plantsPhotovoltaic energy generationPolymer substrateMaterial removal

This invention comprises manufacture of photovoltaic cells by deposition of thin film photovoltaic junctions on metal foil substrates. The photovoltaic junctions may be heat treated if appropriate following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation, an interconnection substrate structure is provided, optionally in a continuous fashion. Multiple photovoltaic cells are then laminated to the interconnection substrate structure and conductive joining methods are employed to complete the array. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials employing optimal processing unique to polymeric materials. Furthermore, the photovoltaic junction and its metal foil support can be produced in bulk without the need to use the expensive and intricate material removal operations currently taught in the art to achieve series interconnections.

Owner:SOLANNEX

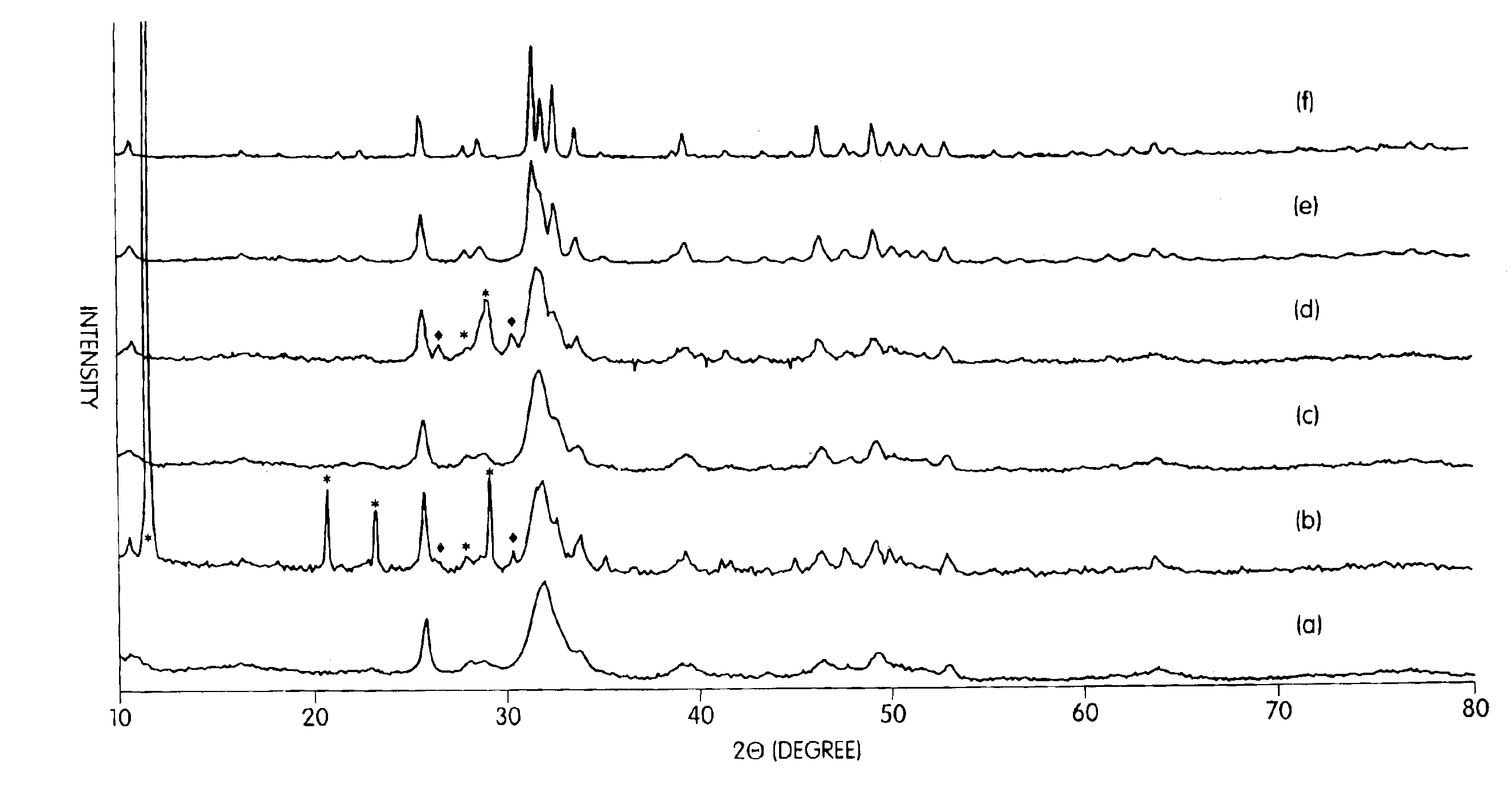

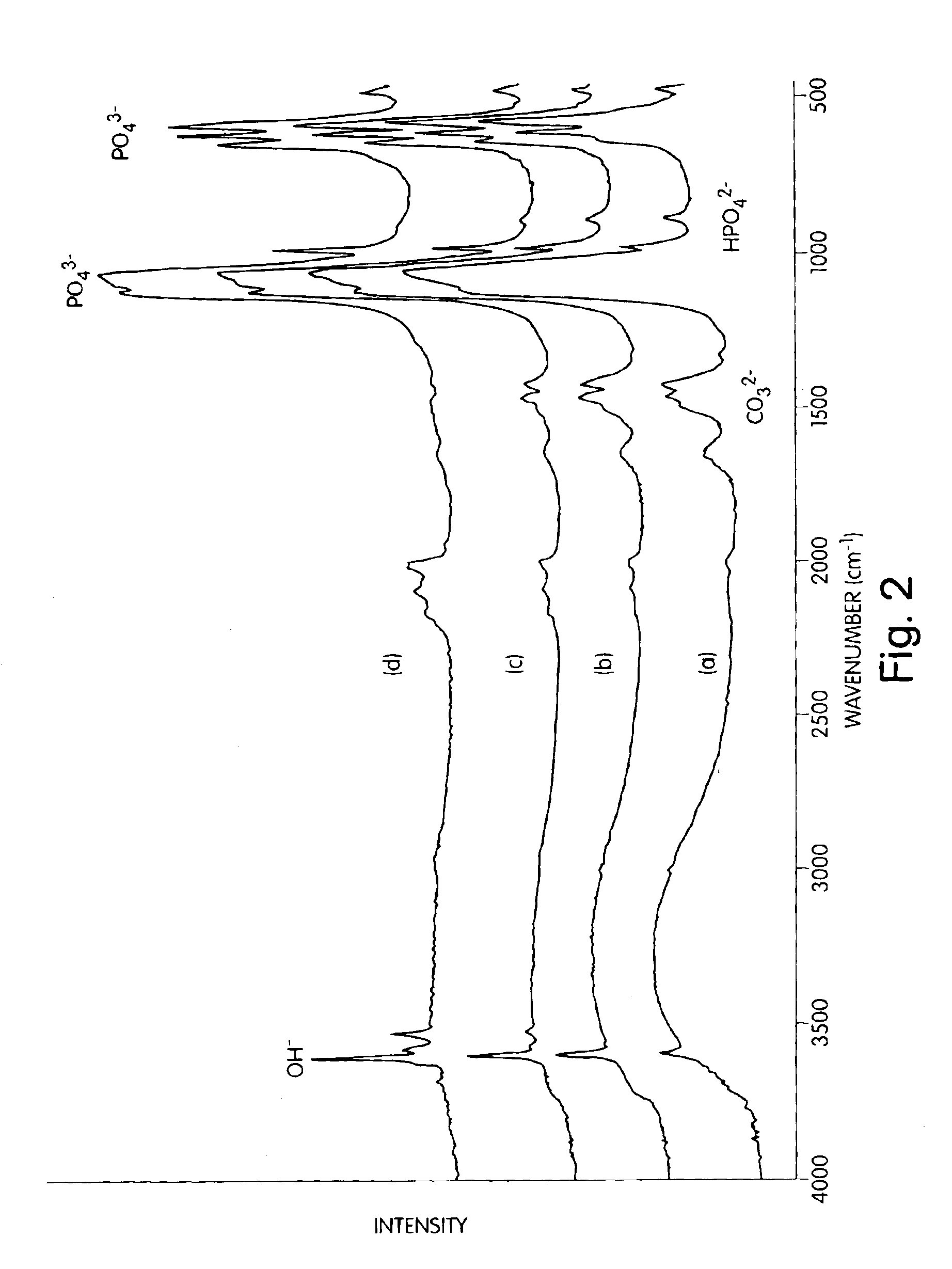

Nanocrystalline apatites and composites, prostheses incorporating them, and method for their production

InactiveUSRE39196E1Defect size be reduceInexpensive productionMaterial nanotechnologyOther chemical processesChemistryProsthesis

Methods for synthesis of nanocyrstalline apatites are presented, as well as a series of specific reaction parameters that can be adjusted to tailor, in specific ways, properties in the recovered product. Particulate apatite compositions having aveage crystal size of less than 150 nm are provided. Products also can have a surface area of at least 40 m2 / g and can be of high density.Hydroxyapatite material is investigated in particular detail. Compositions of the invention can be used as prosthetic implants and coatings for prosthetic implants.

Owner:MASSACHUSETTS INST OF TECH

Substrate and collector grid structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS20040069340A1Eliminate deficienciesInexpensive productionPV power plantsSolid-state devicesRoll-to-roll processingMaterial removal

This invention comprises deposition of thin film photovoltaic junctions on metal substrates which can be heat treated following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation an interconnection substrate structure is produced in a continuous roll-to-roll fashion. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials since it does not have to endure high temperature exposure. Cells comprising the metal foil supported photovoltaic junctions are then laminated to the interconnection substrate structure. Conductive interconnections are deposited to complete the array. The conductive interconnections can be accomplished with a separately prepared interconnection component. The interconnected array is produced using continuous roll-to-roll processing which avoids the need to use the expensive and intricate material removal operations currently taught in the art to achieve electrical interconnections among arrays of photovoltaic cells.

Owner:SOLANNEX

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS7898054B2Eliminate deficienciesFacilitate electrical interconnectionFinal product manufacturePV power plantsPolymer substrateMaterial removal

This invention comprises manufacture of photovoltaic cells by deposition of thin film photovoltaic junctions on metal foil substrates. The photovoltaic junctions may be heat treated if appropriate following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation, an interconnection substrate structure is provided, optionally in a continuous fashion. Multiple photovoltaic cells are then laminated to the interconnection substrate structure and conductive joining methods are employed to complete the array. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials employing optimal processing unique to polymeric materials. Furthermore, the photovoltaic junction and its metal foil support can be produced in bulk without the need to use the expensive and intricate material removal operations currently taught in the art to achieve series interconnections.

Owner:SOLANNEX

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS7898053B2Eliminate deficienciesFacilitate electrical interconnectionPV power plantsSolid-state devicesManufacturing technologyPolymer substrate

This invention comprises manufacture of photovoltaic cells by deposition of thin film photovoltaic junctions on metal foil substrates. The photovoltaic junctions may be heat treated if appropriate following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation, an interconnection substrate structure is provided, optionally in a continuous fashion. Multiple photovoltaic cells are then laminated to the interconnection substrate structure and conductive joining methods are employed to complete the array. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials employing optimal processing unique to polymeric materials. Furthermore, the photovoltaic junction and its metal foil support can be produced in bulk without the need to use the expensive and intricate material removal operations currently taught in the art to achieve series interconnections.

Owner:SOLANNEX

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS20110067754A1Minimization requirementsIncrease volumePhotovoltaic energy generationSemiconductor devicesMaterial removalPolymer substrate

This invention comprises manufacture of photovoltaic cells by deposition of thin film photovoltaic junctions on metal foil substrates. The photovoltaic junctions may be heat treated if appropriate following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation, an interconnection substrate structure is provided, optionally in a continuous fashion. Multiple photovoltaic cells are then laminated to the interconnection substrate structure and conductive joining methods are employed to complete the array. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials employing optimal processing unique to polymeric materials. Furthermore, the photovoltaic junction and its metal foil support can be produced in bulk without the need to use the expensive and intricate material removal operations currently taught in the art to achieve series interconnections.

Owner:SOLANNEX

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS20080227236A1Eliminate deficienciesFacilitate electrical interconnectionPV power plantsSolid-state devicesPolymer substrateMaterial removal

This invention comprises manufacture of photovoltaic cells by deposition of thin film photovoltaic junctions on metal foil substrates. The photovoltaic junctions may be heat treated if appropriate following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation, an interconnection substrate structure is provided, optionally in a continuous fashion. Multiple photovoltaic cells are then laminated to the interconnection substrate structure and conductive joining methods are employed to complete the array. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials employing optimal processing unique to polymeric materials. Furthermore, the photovoltaic junction and its metal foil support can be produced in bulk without the need to use the expensive and intricate material removal operations currently taught in the art to achieve series interconnections.

Owner:SOLANNEX

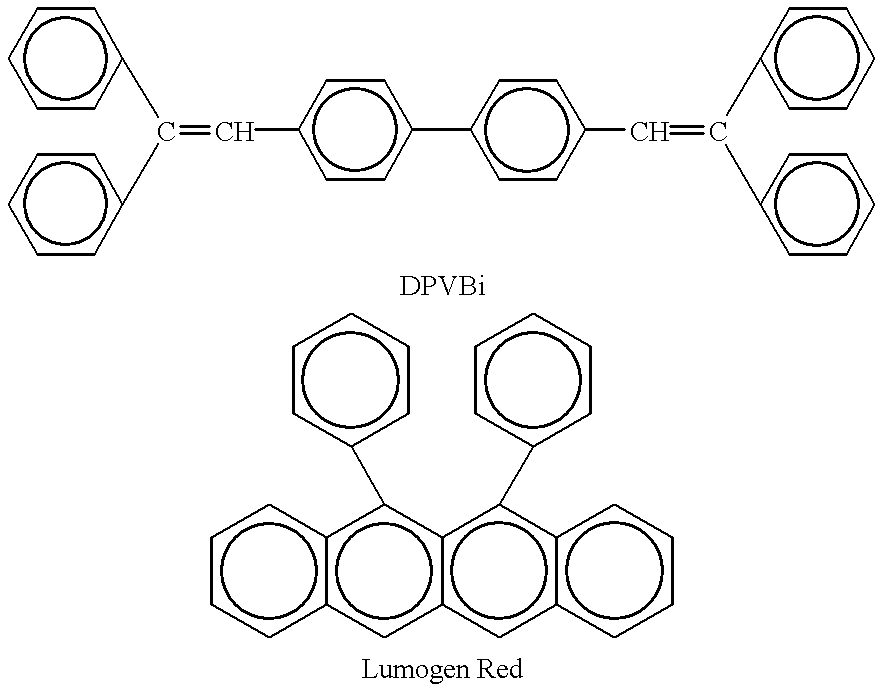

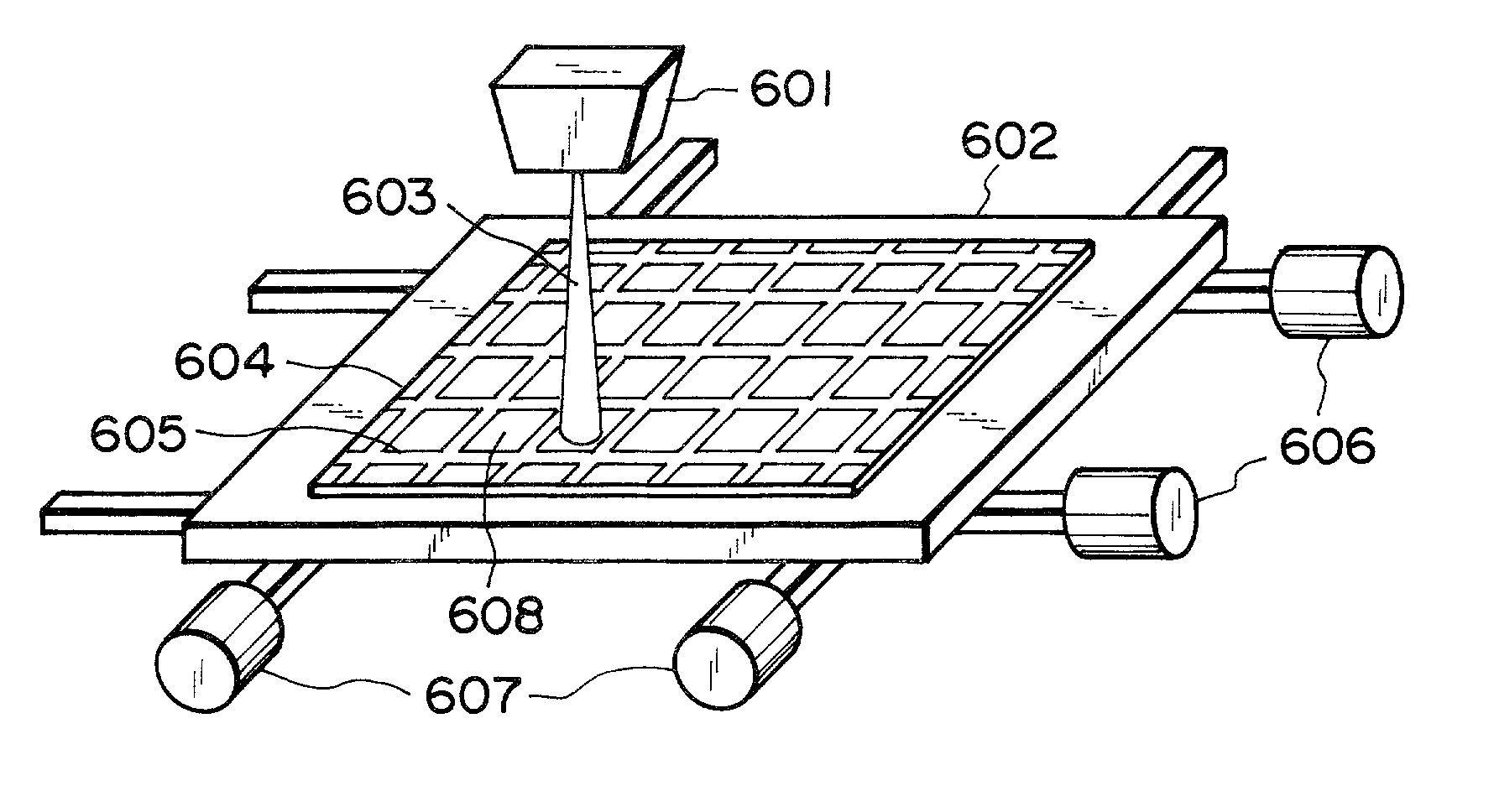

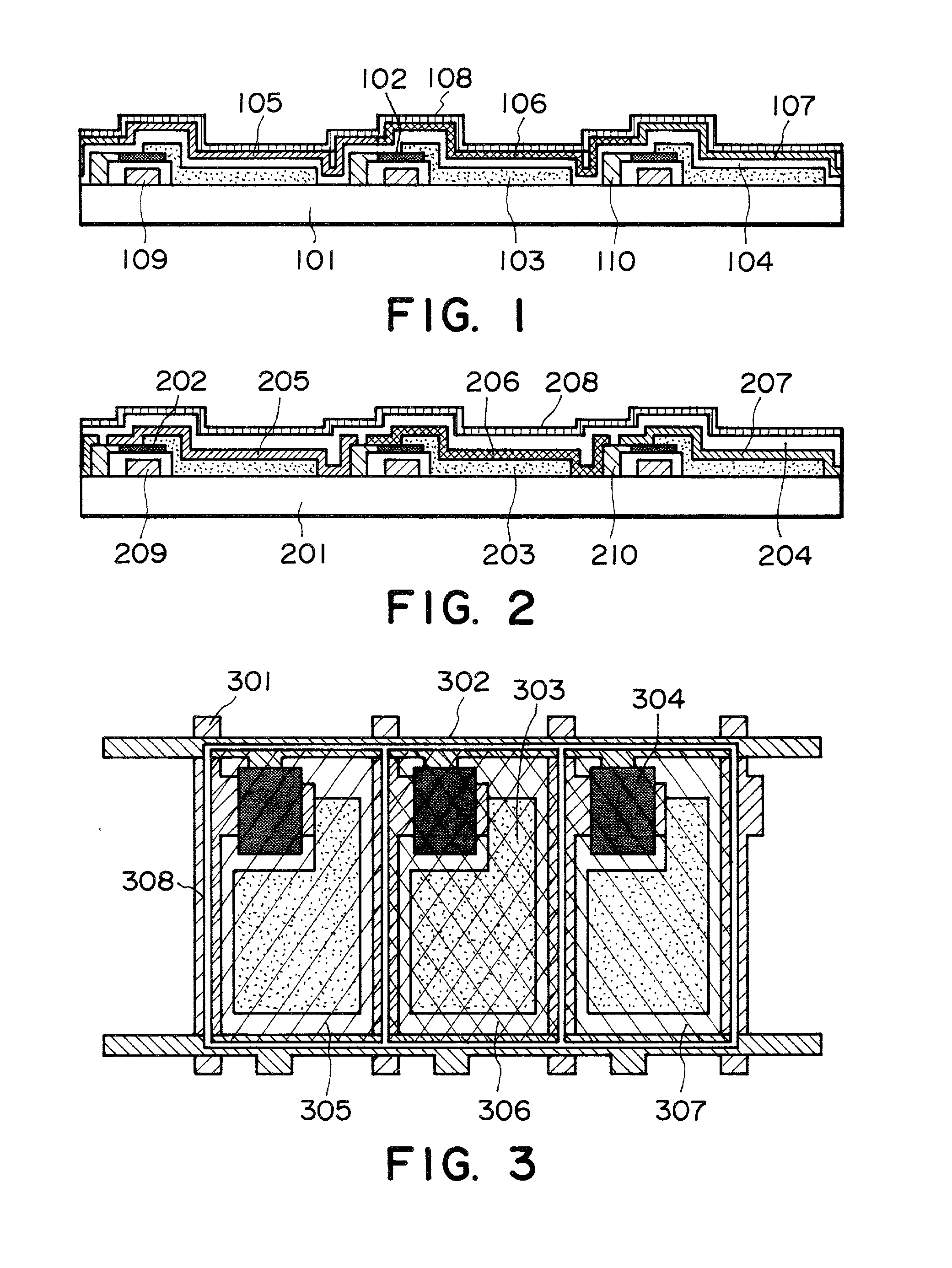

Production of organic luminescence device

InactiveUS20020001026A1Full-color displayWell formedElectroluminescent light sourcesSolid-state devicesOrganic solventOrganic light emitting device

An organic luminescence device is formed from a pair of electrodes, and a layer of organic material disposed between the electrodes so as to cause luminescence in response to a voltage applied between the electrodes. The type of organic luminescence device may be provided with improved luminescence performance if it is produced through a process including a wet-patterning step using an ink of the organic material within a hydrophobic organic solvent having a dissolving power of at most 5 wt. % of water at room temperature for producing the organic material layer.

Owner:CANON KK

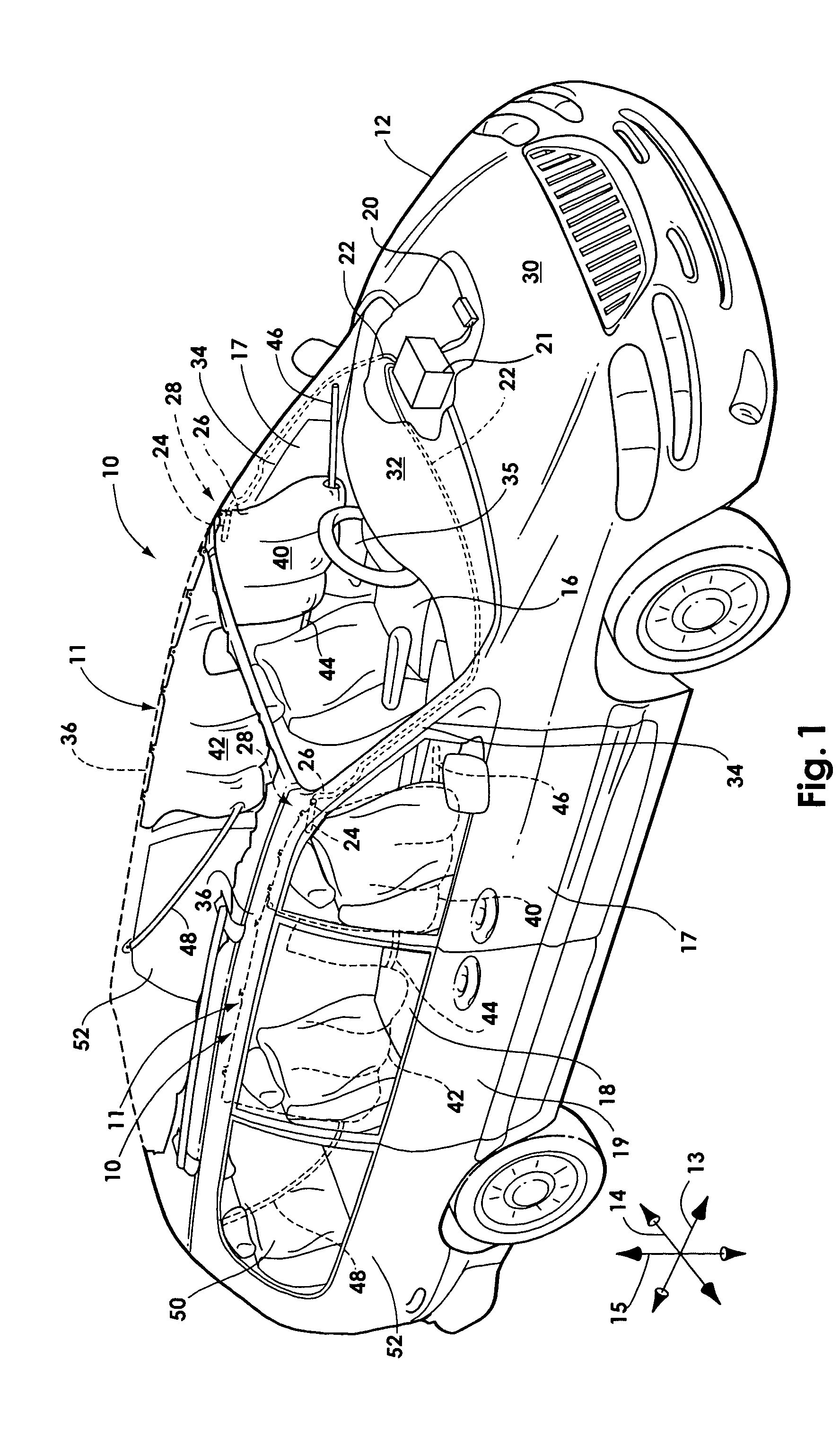

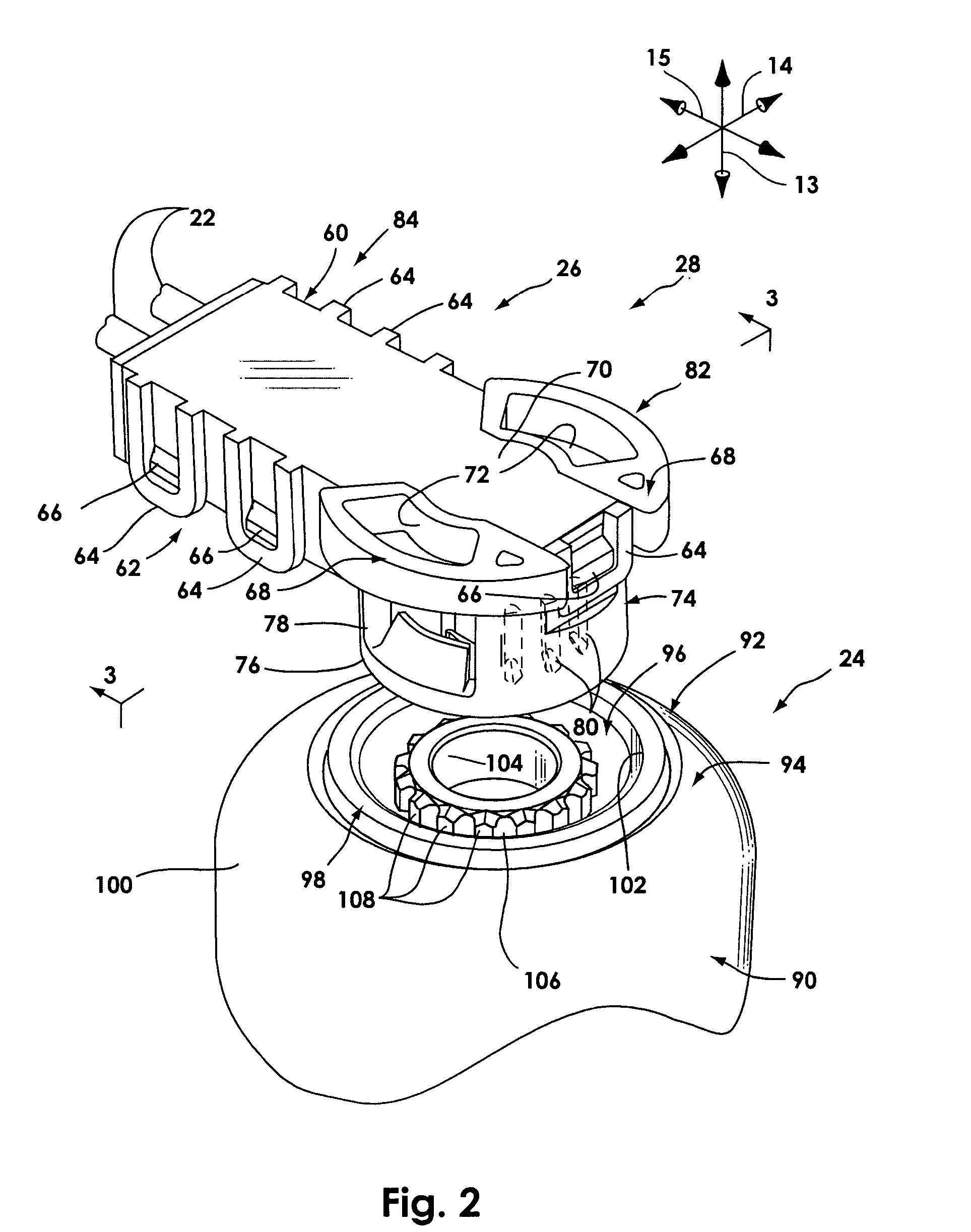

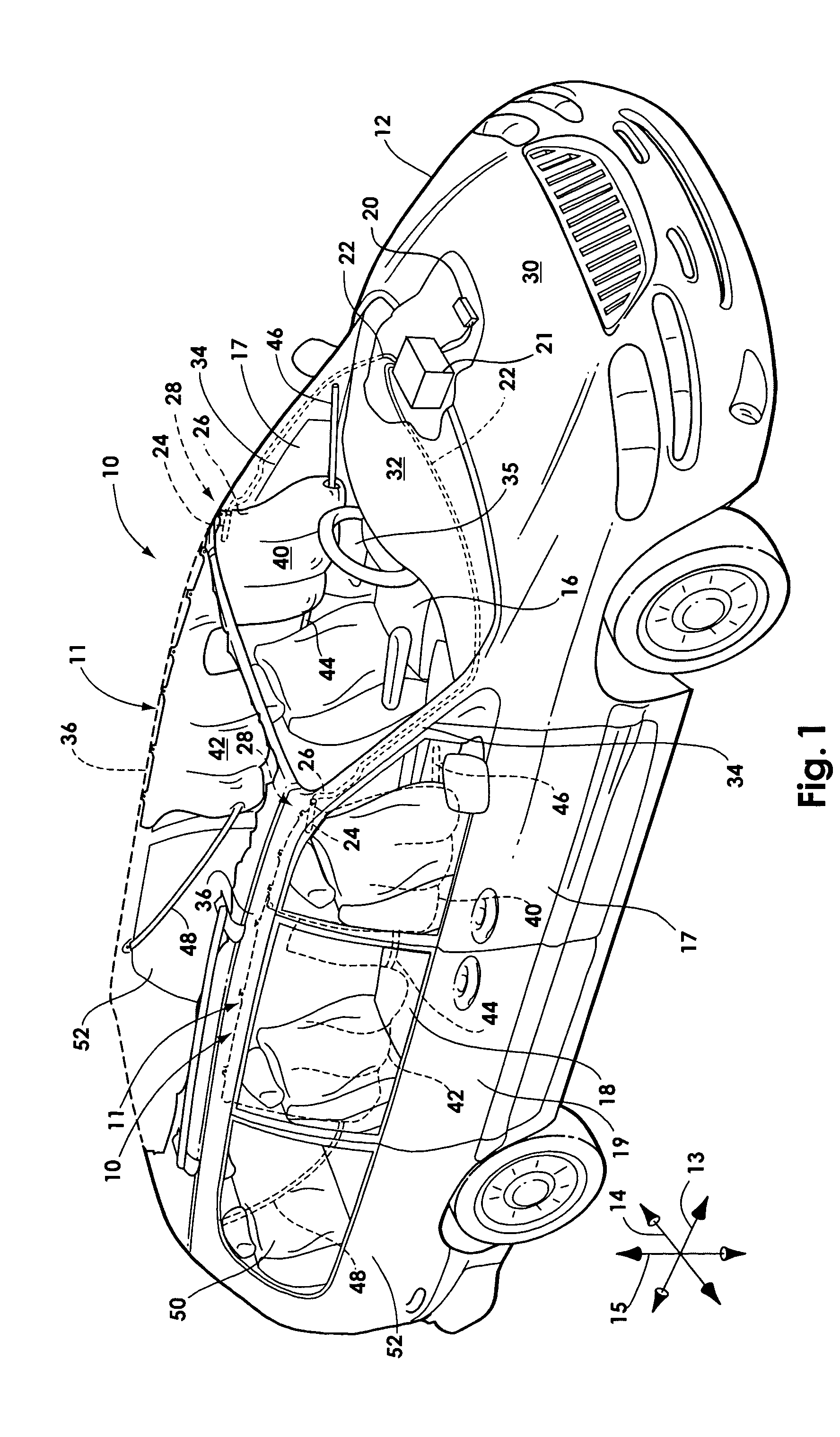

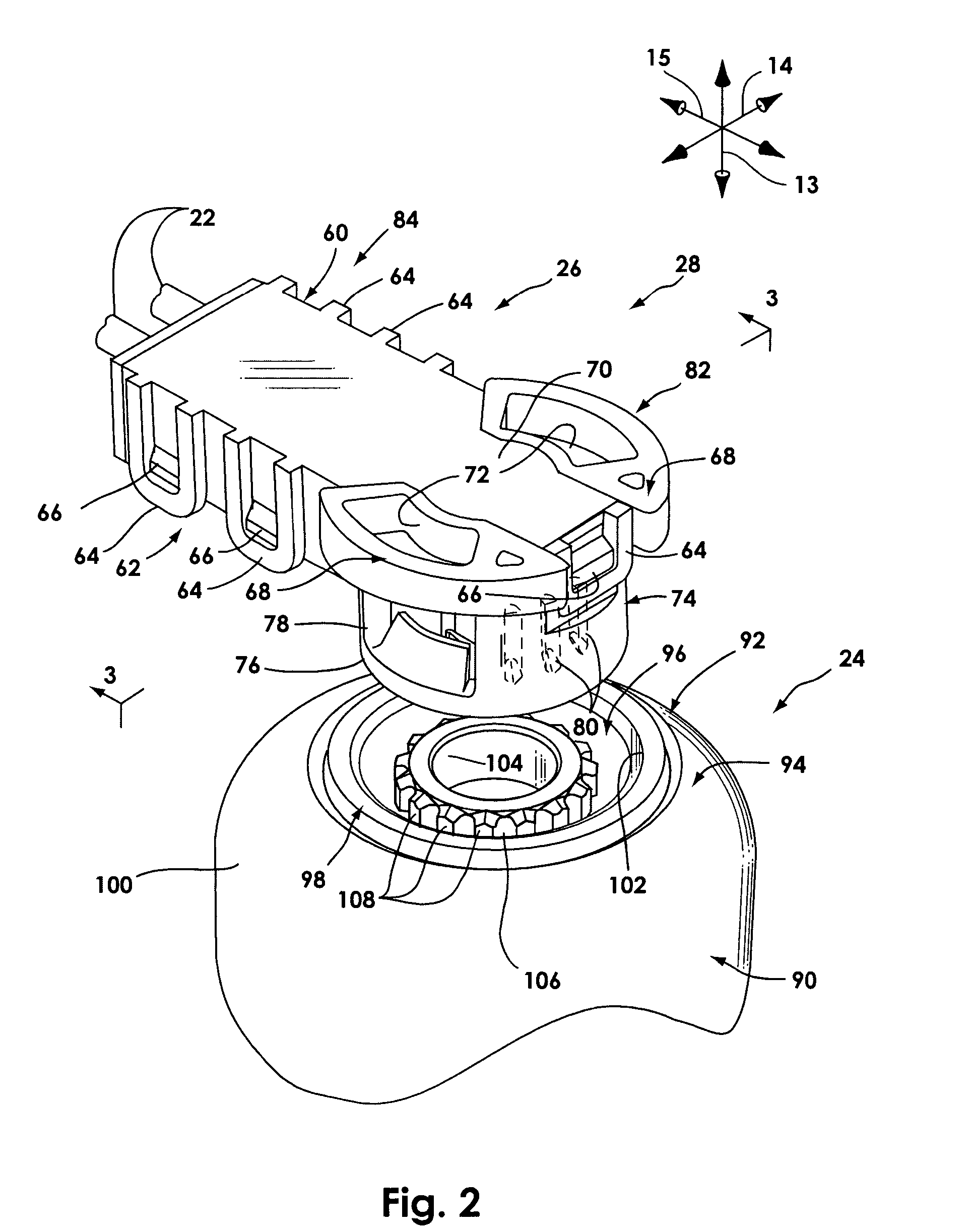

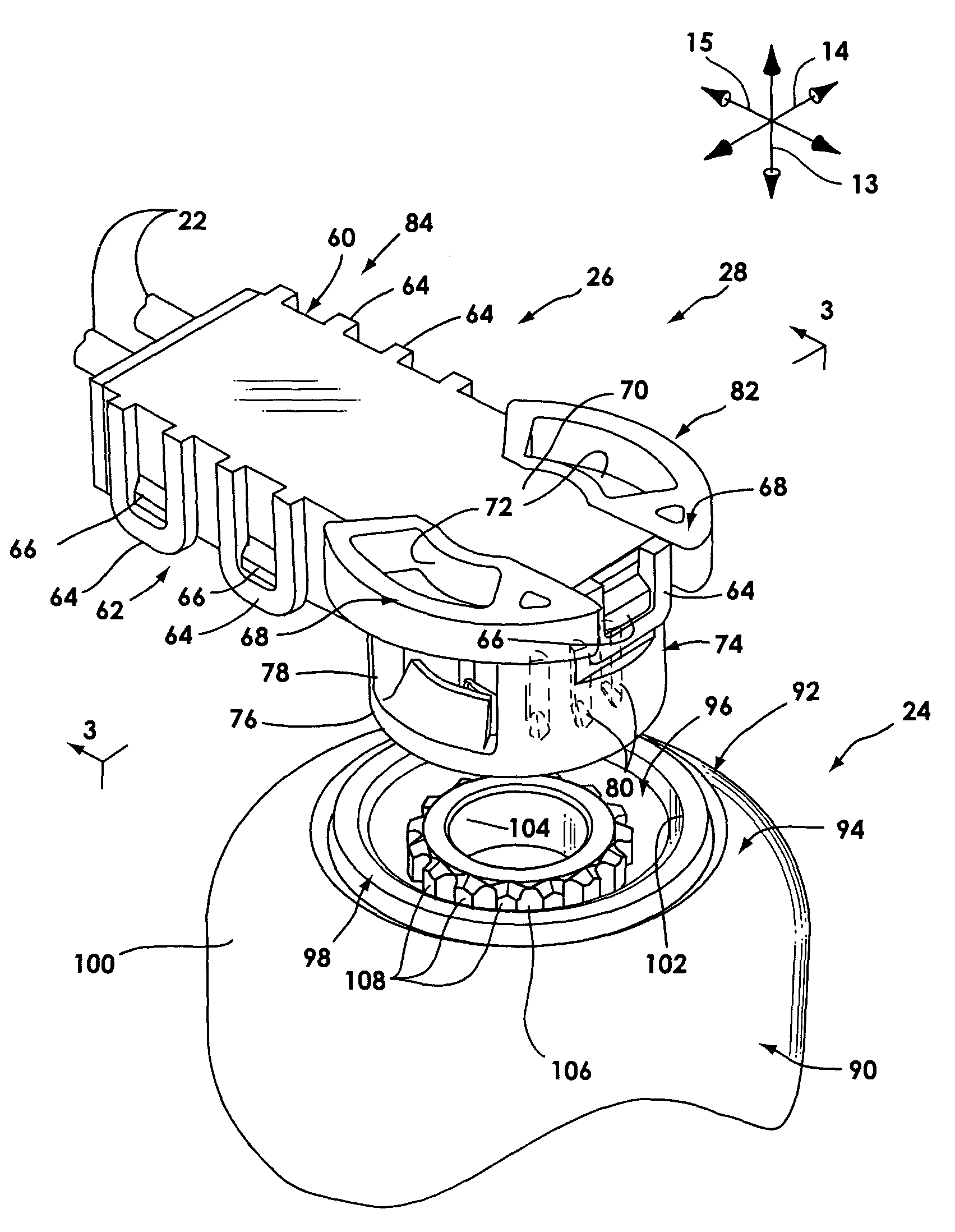

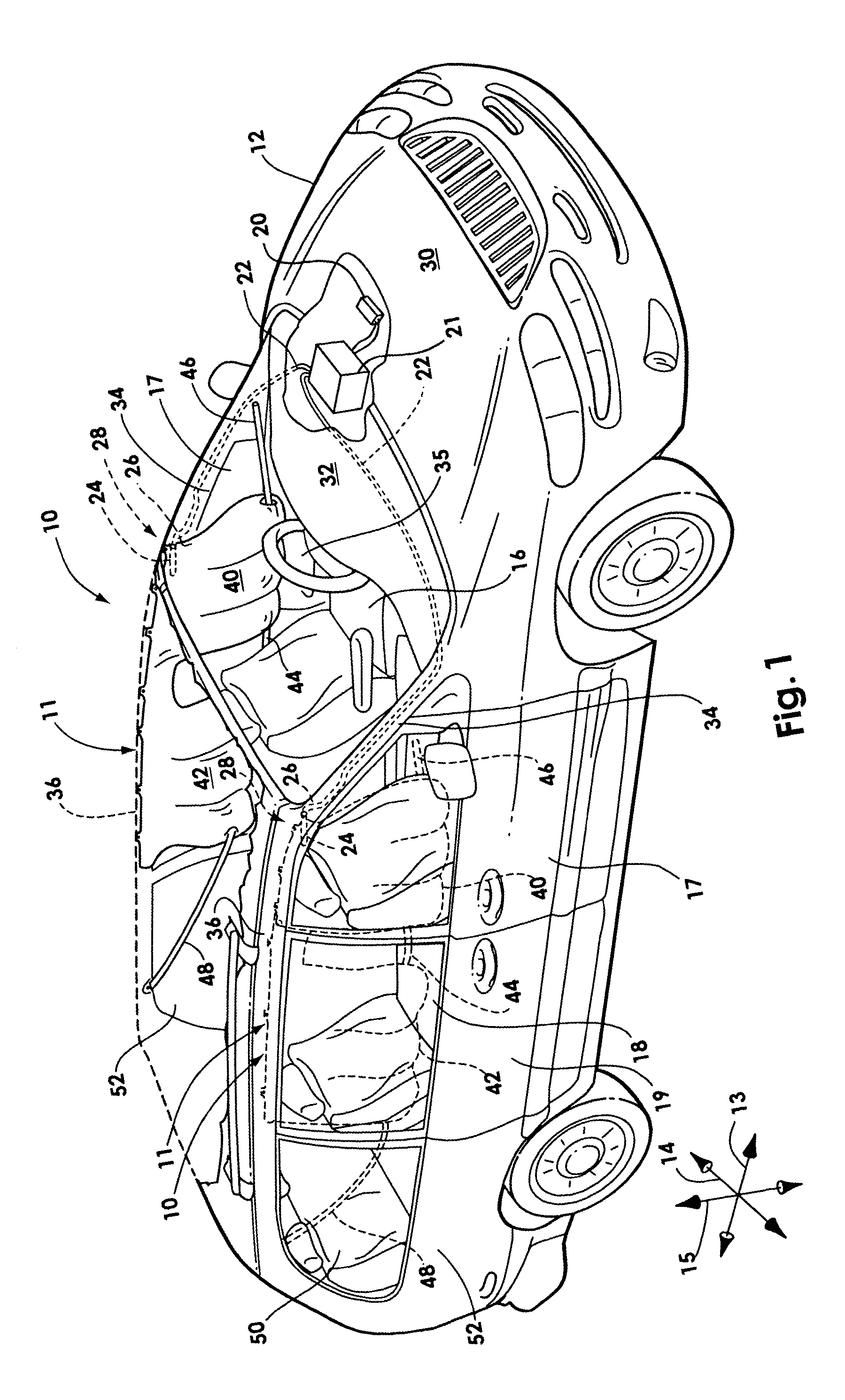

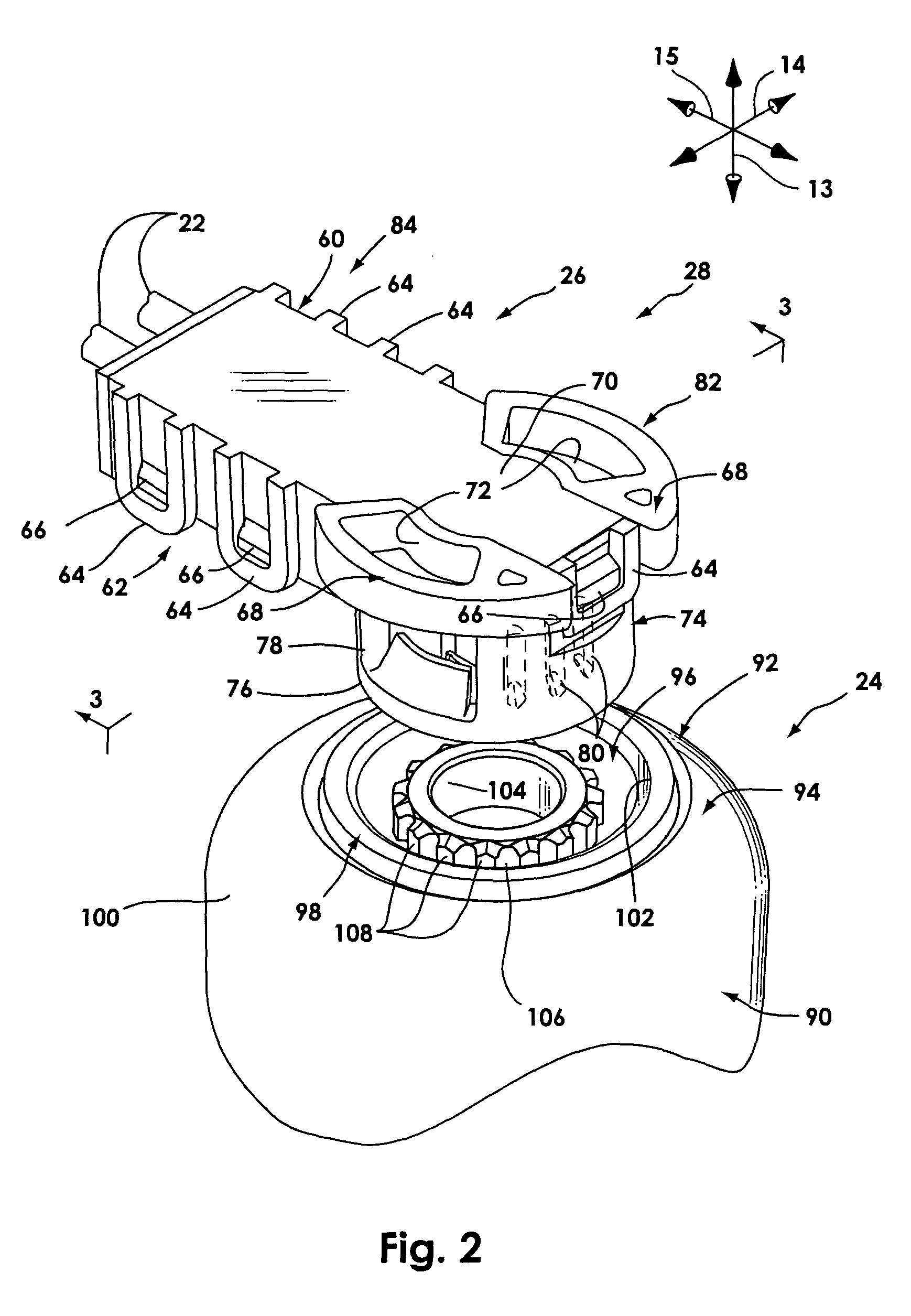

Electrical connection apparatus and method for an airbag inflator

InactiveUS20050009390A1Inexpensive productionSimplifies electrical connectionsEngagement/disengagement of coupling partsRelieving strain on wire connectionMating connectionElectrical connection

An airbag module has an inflator activated via an electrical connector. The inflator includes an initiation assembly having an initiator and a receptacle that retains the connector. The initiator may have a single, center pin. The initiator may be encased by a body and cover, which may be attached together by molding, vibratory welding, electromagnetic welding, or snap fitting. The connector may have projections that extend from a main body to facilitate retention of the connector by a collar, washer, a retainer attached to the body, or by the inflator housing. The body may be seated in a collar having an annular ridge that presses into the body to form a seal. The connector may have a rib designed to mesh with splines of the receptacle to enable engagement of the connector with the receptacle in multiple orientations, while preventing relative rotation between the connector and the initiator after assembly.

Owner:AUTOLIV ASP INC

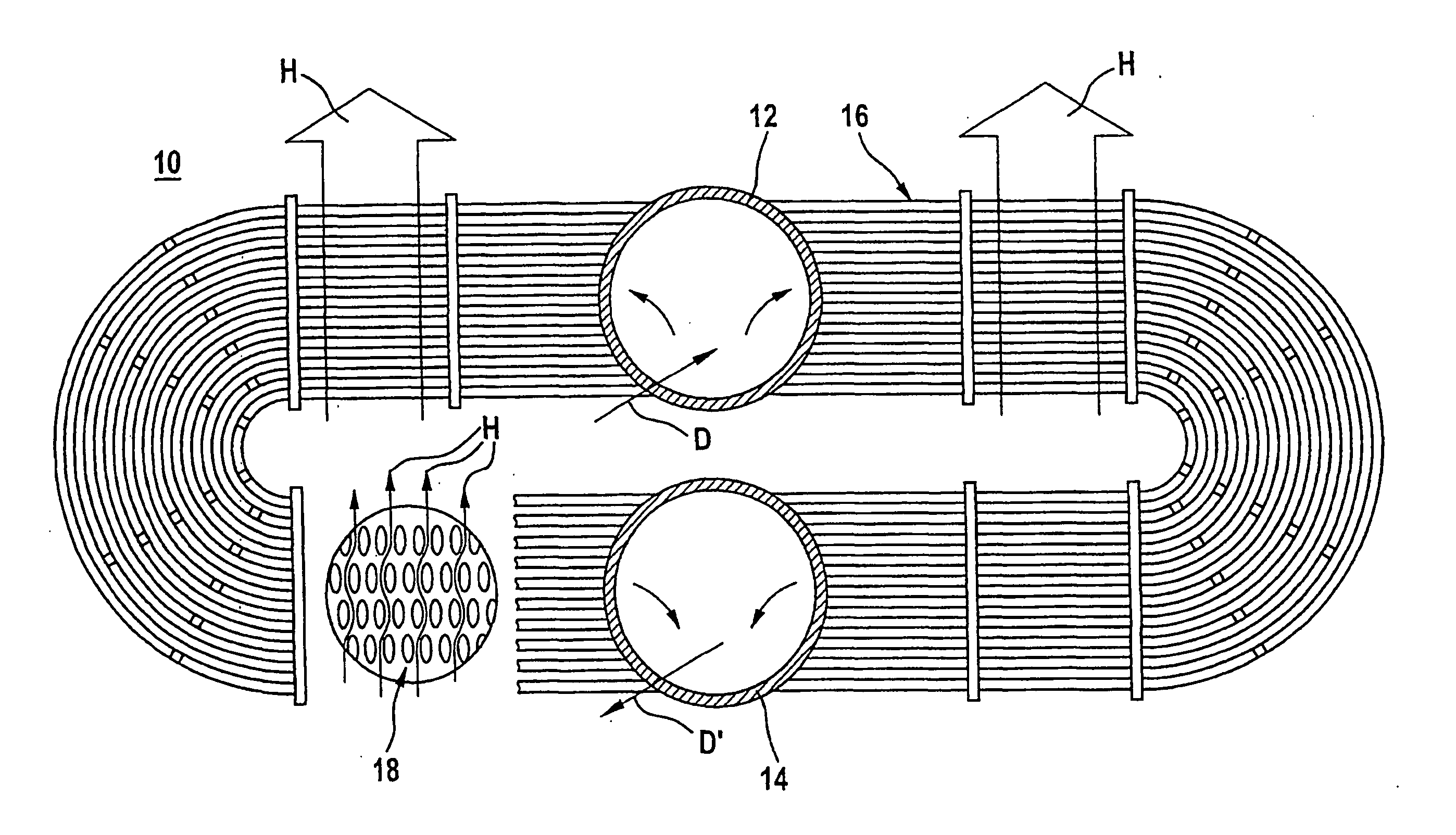

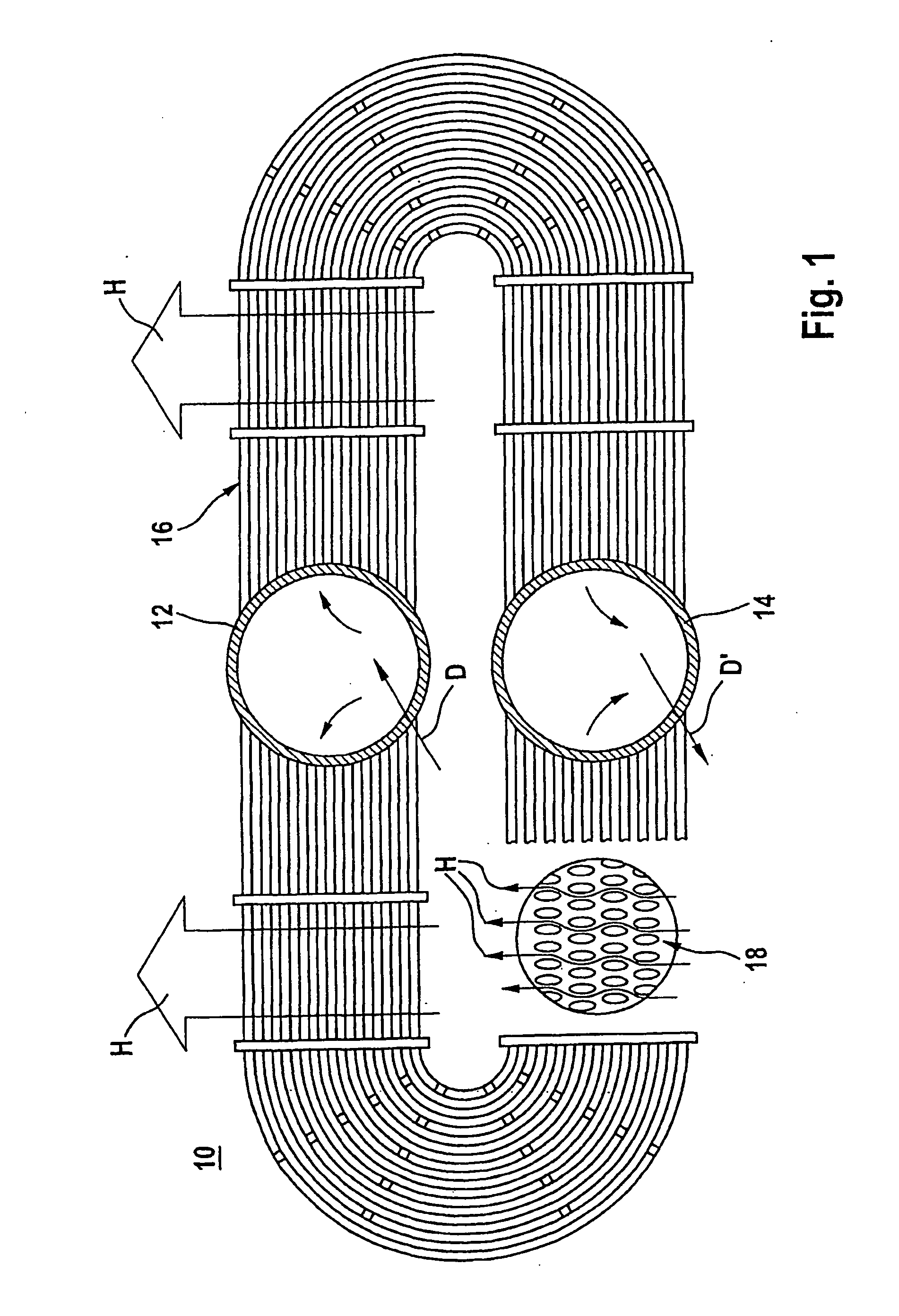

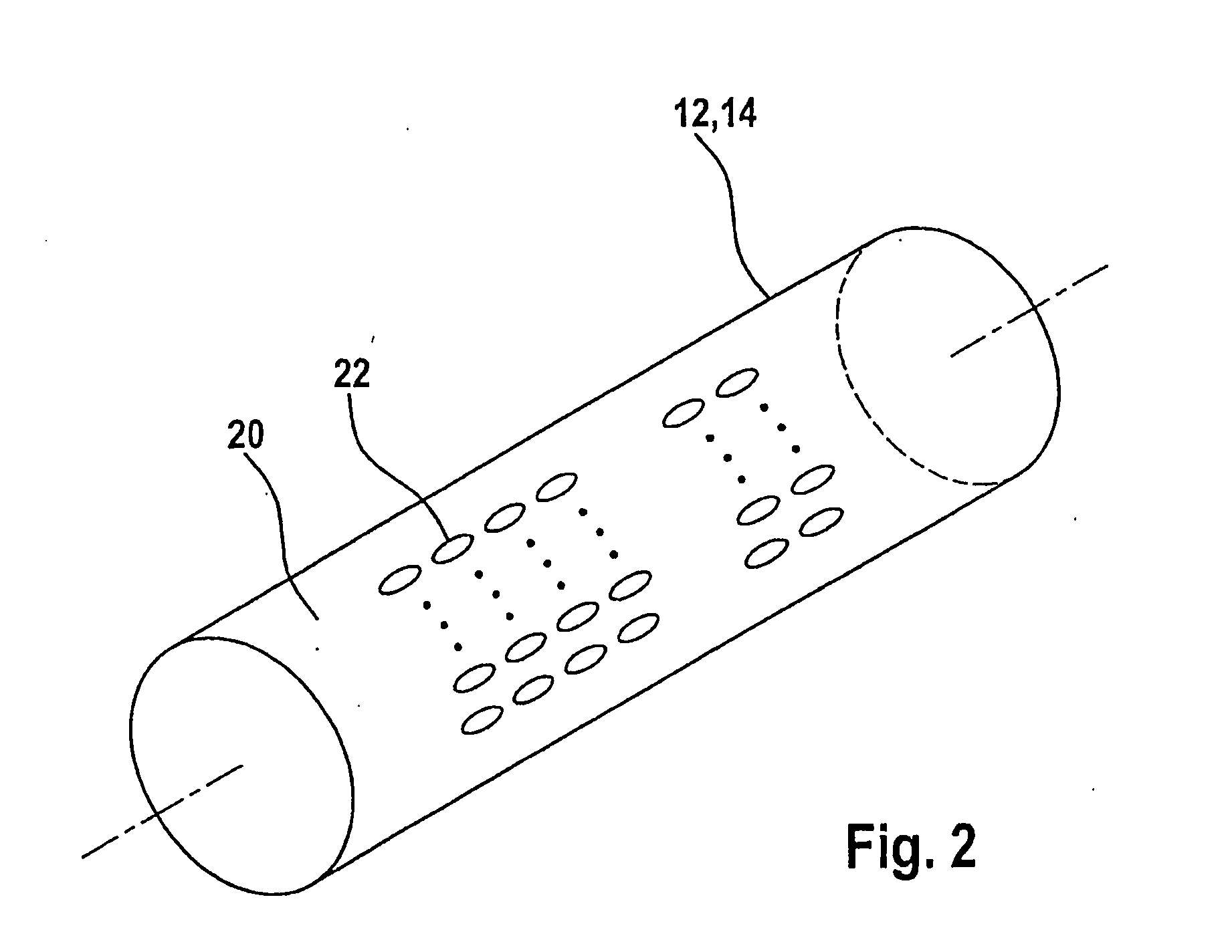

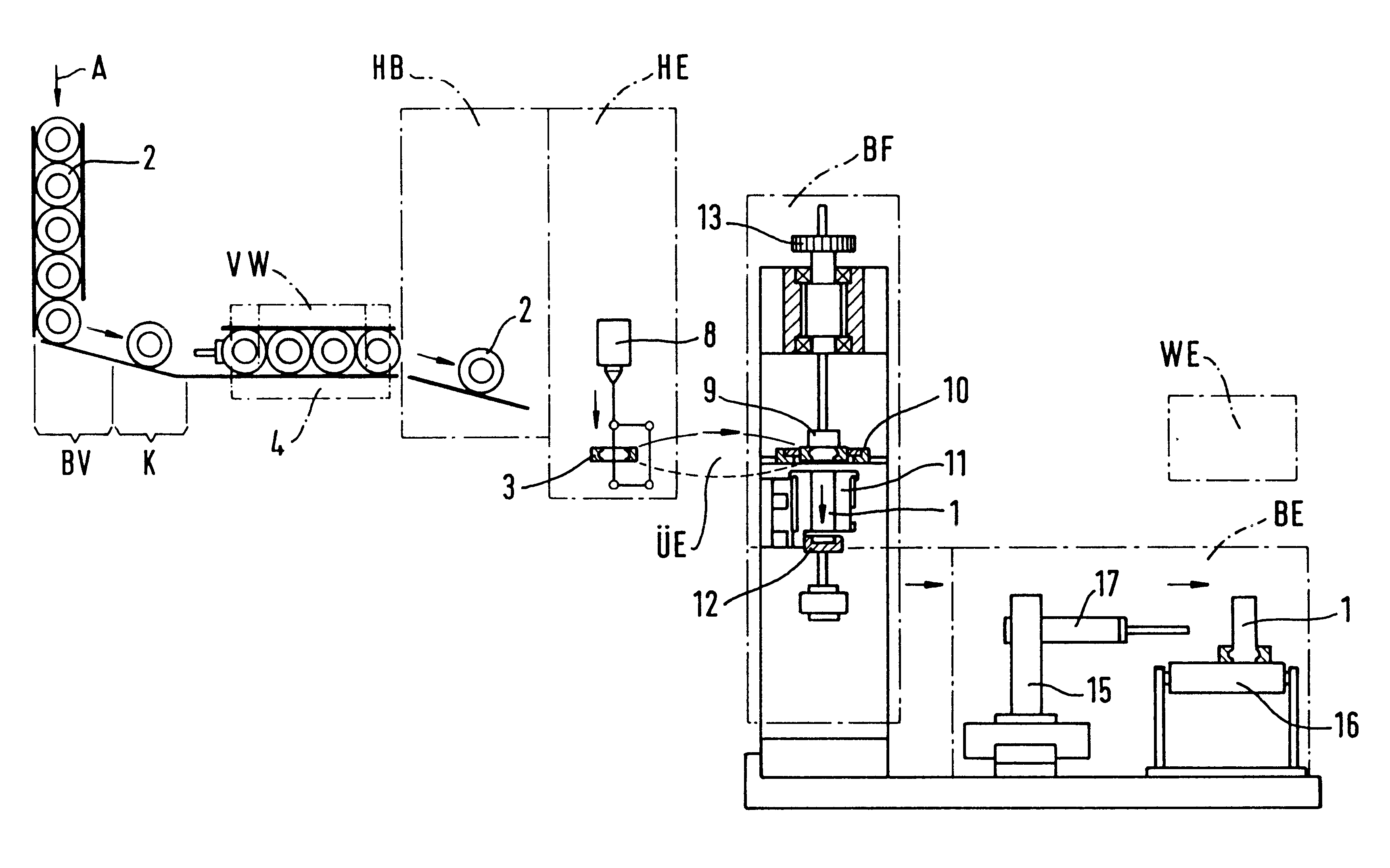

Method for producing heat exchanger tubes, which consist of half-tubes or complete tubes and which are provided for recuperative exhaust gas heat exchanger

InactiveUS20060137869A1Inexpensive productionProduction be quite quickFoundry mouldsHeat exchanger casingsExhaust gasProcess engineering

In a process for the production of half-tubes or tubes of a recuperative waste gas heat exchanger using a precision casting process, the half-tubes or tubes consisting of a high-temperature-resistant metallic material have a plurality of elliptical openings passing through their surface.

Owner:MTU AERO ENGINES GMBH

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS8198696B2Eliminate deficienciesFacilitate electrical interconnectionPV power plantsSolid-state devicesPolymer substrateMaterial removal

This invention comprises manufacture of photovoltaic cells by deposition of thin film photovoltaic junctions on metal foil substrates. The photovoltaic junctions may be heat treated if appropriate following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation, an interconnection substrate structure is provided, optionally in a continuous fashion. Multiple photovoltaic cells are then laminated to the interconnection substrate structure and conductive joining methods are employed to complete the array. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials employing optimal processing unique to polymeric materials. Furthermore, the photovoltaic junction and its metal foil support can be produced in bulk without the need to use the expensive and intricate material removal operations currently taught in the art to achieve series interconnections.

Owner:SOLANNEX

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS20120031461A1Minimization requirementsIncrease volumePV power plantsPhotovoltaic energy generationPolymer substrateMaterial removal

This invention comprises manufacture of photovoltaic cells by deposition of thin film photovoltaic junctions on metal foil substrates. The photovoltaic junctions may be heat treated if appropriate following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation, an interconnection substrate structure is provided, optionally in a continuous fashion. Multiple photovoltaic cells are then laminated to the interconnection substrate structure and conductive joining methods are employed to complete the array. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials employing optimal processing unique to polymeric materials. Furthermore, the photovoltaic junction and its metal foil support can be produced in bulk without the need to use the expensive and intricate material removal operations currently taught in the art to achieve series interconnections.

Owner:SOLANNEX

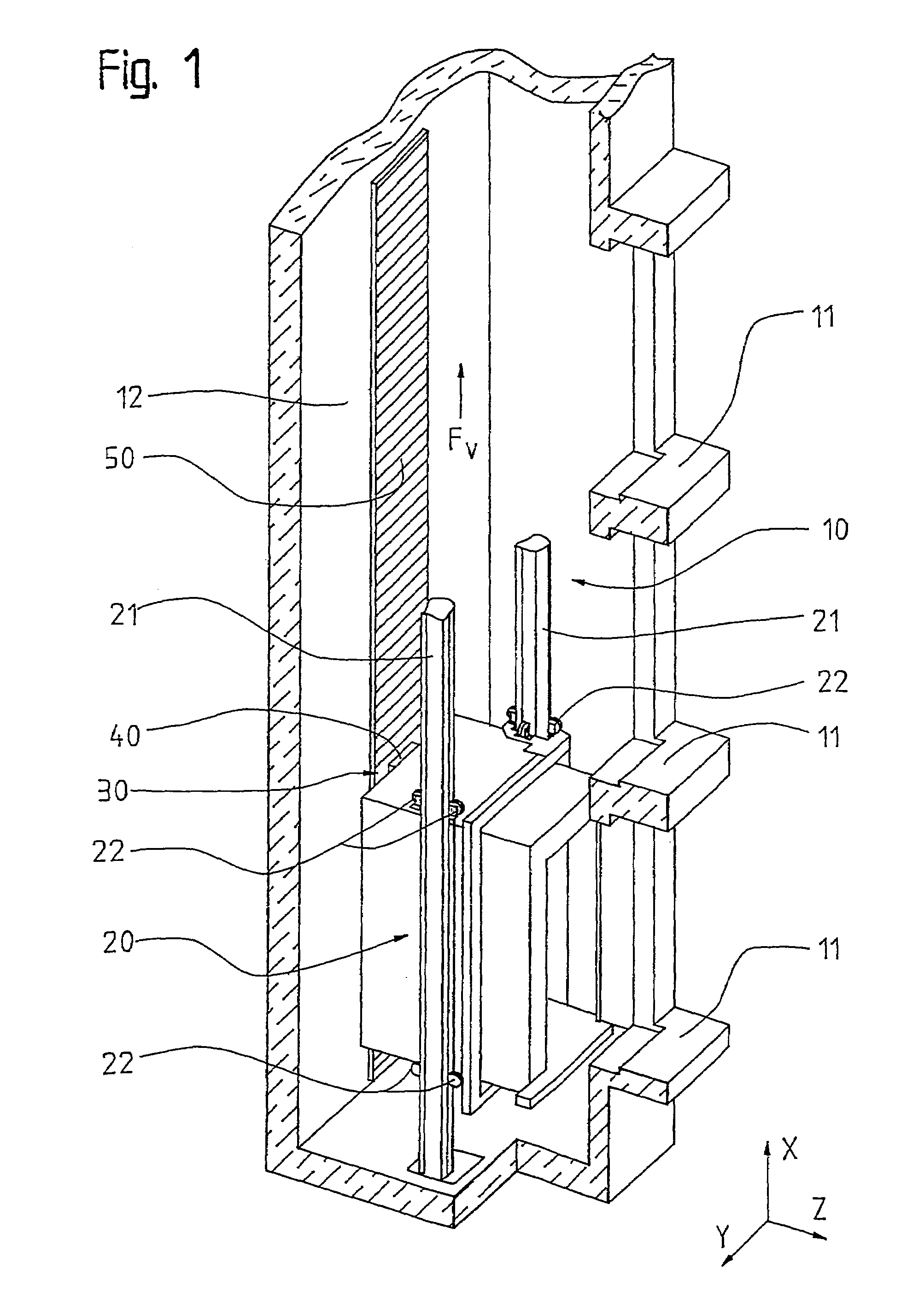

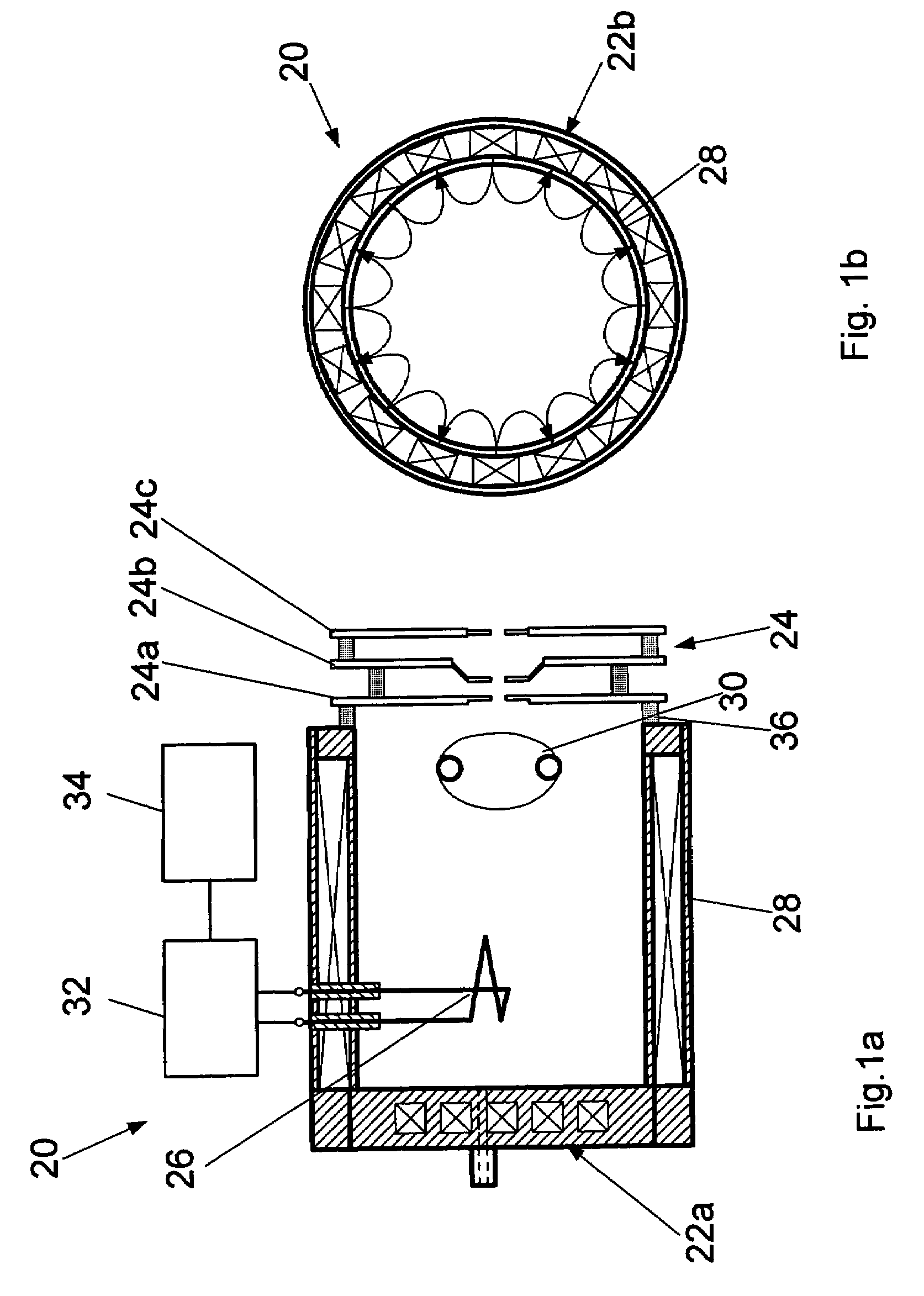

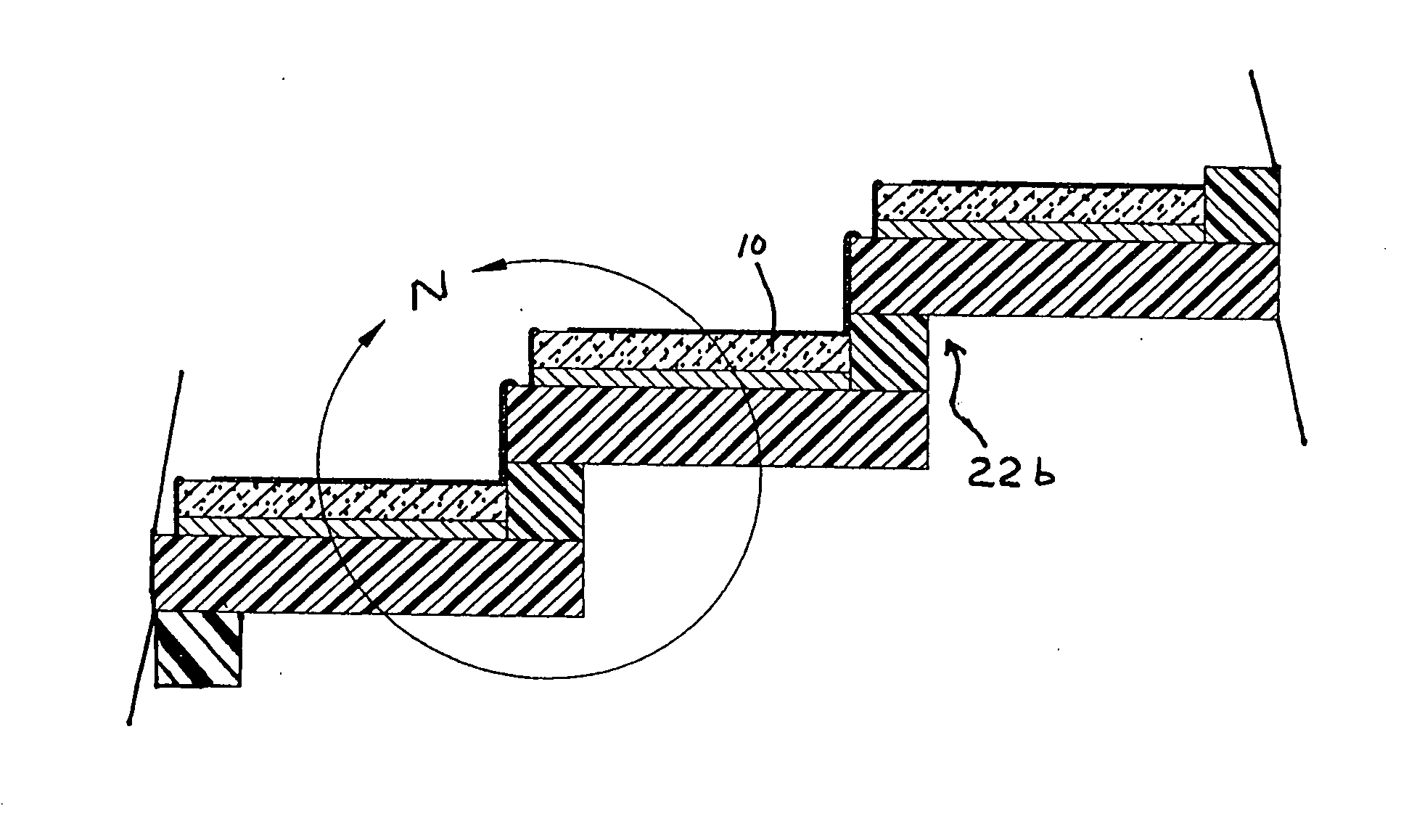

Elevator with transverse flux drive

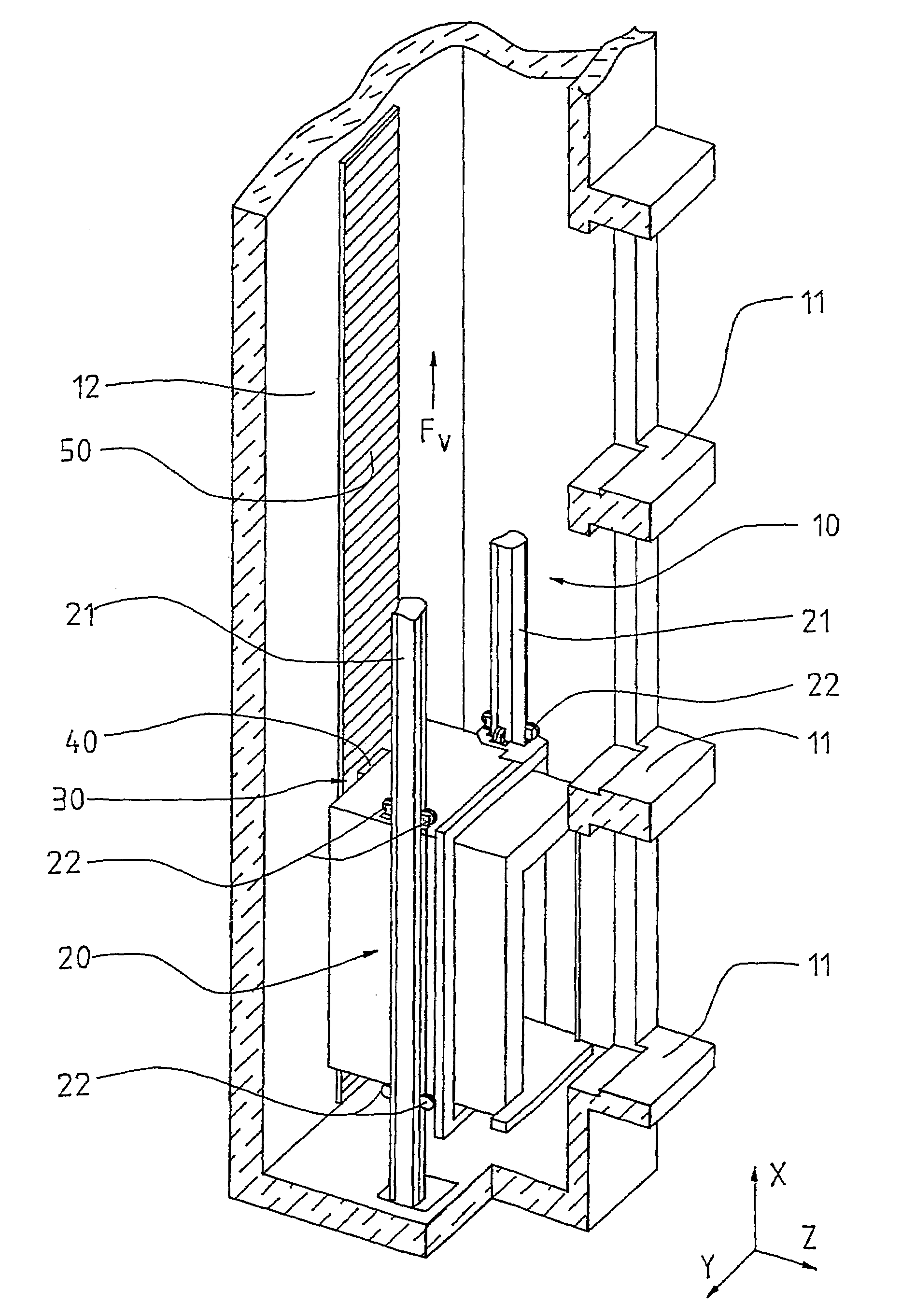

InactiveUS7261186B2Improve power performanceLow production costMotor/generator/converter stoppersDC motor speed/torque controlTransverse fluxDrive motor

An elevator, particularly for transporting passengers, has an elevator car guided in an elevator shaft a direct drive motor. The drive motor includes an active primary part at the elevator car and a passive secondary part that is fixed in the elevator shaft and is spaced from the primary part by an air gap. In order to achieve a high power capability, the drive motor is configured as a transverse flux motor that moves the primary part linearly relative to the secondary part under the influence of an electromagnetic propulsive force. The secondary part has at least one rail made of a soft magnetic material and subdivided into a plurality of segments having a predetermined length. The segments are fixed to a wall of the elevator shaft by intermediate elements.

Owner:INVENTIO AG

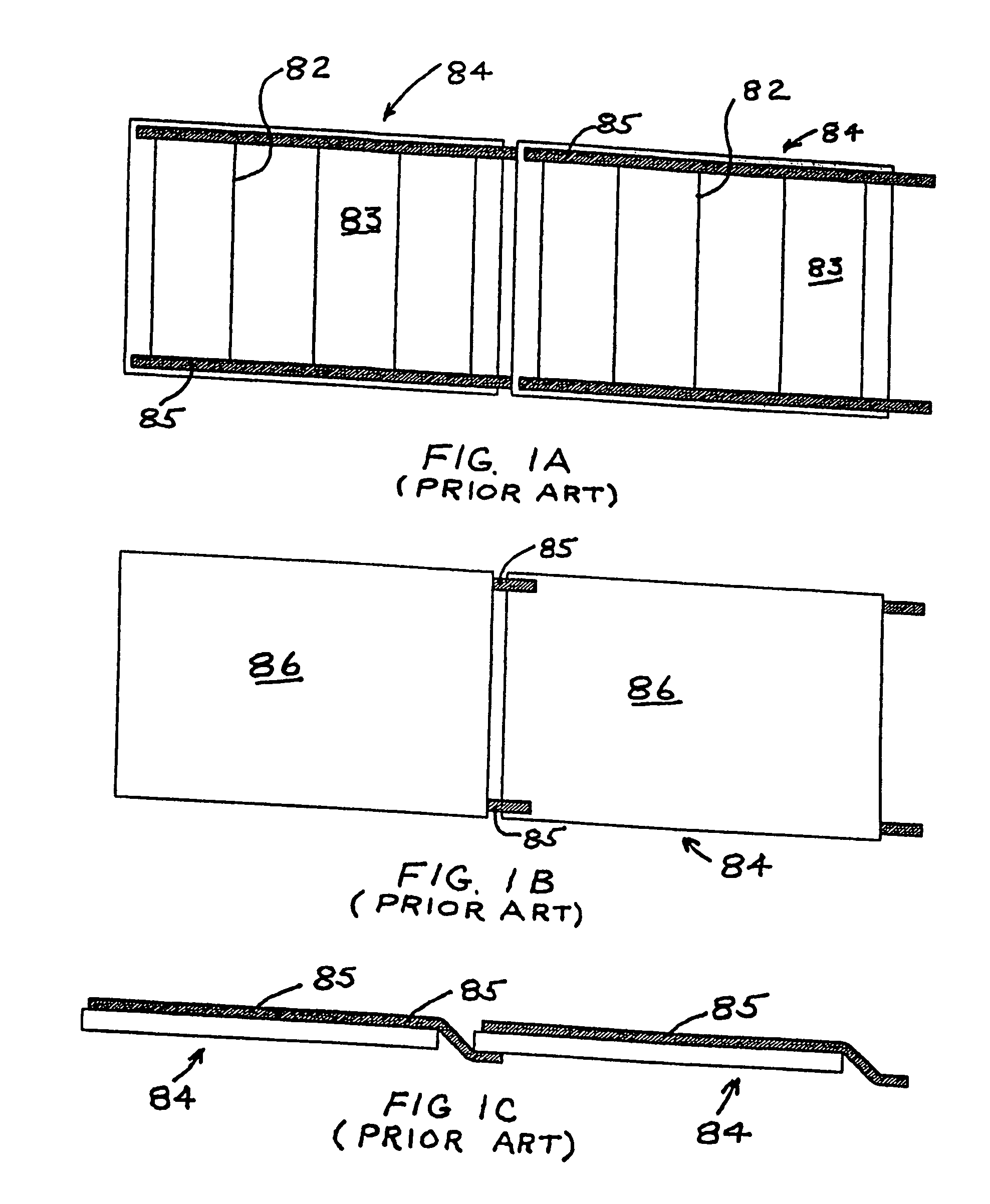

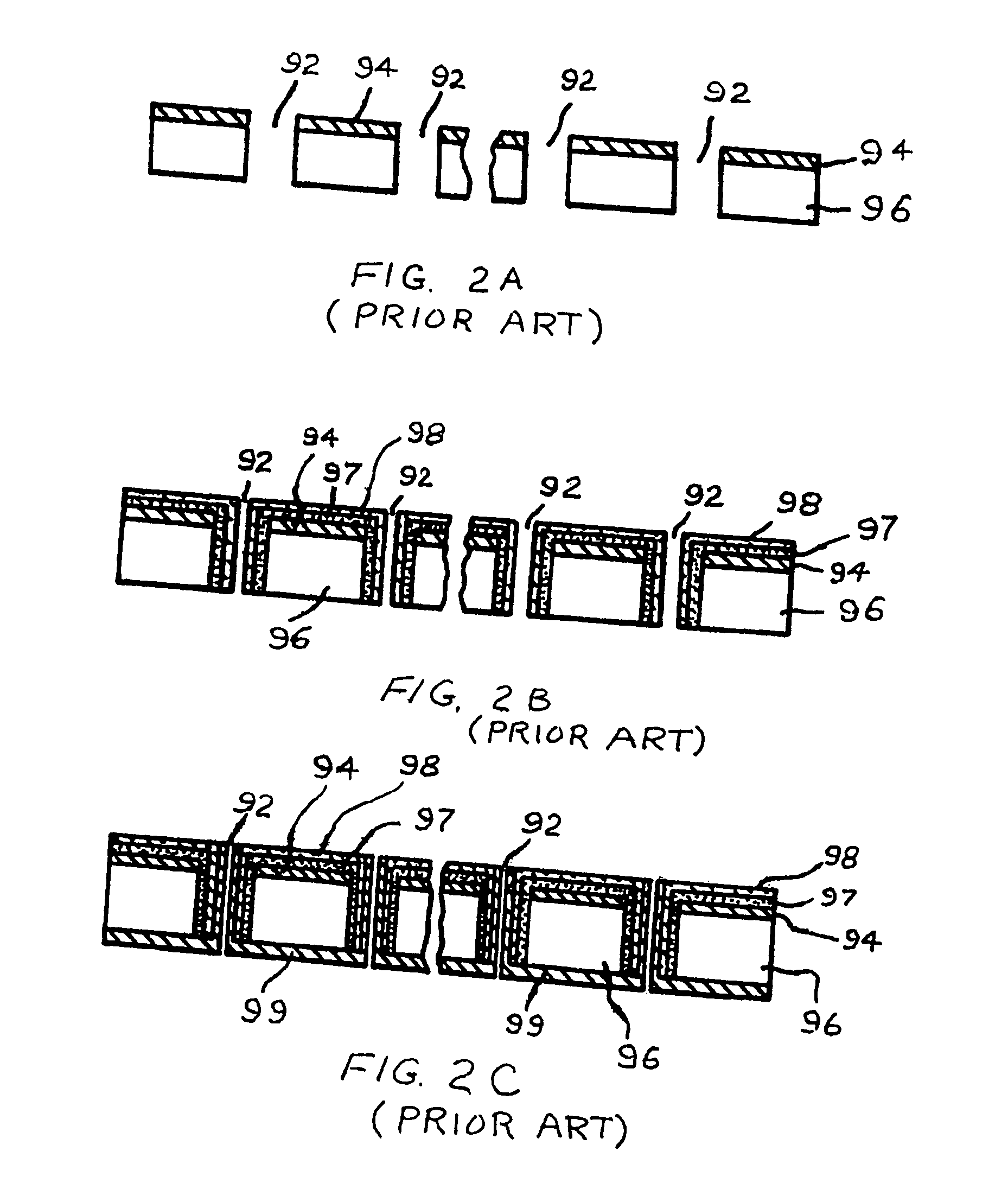

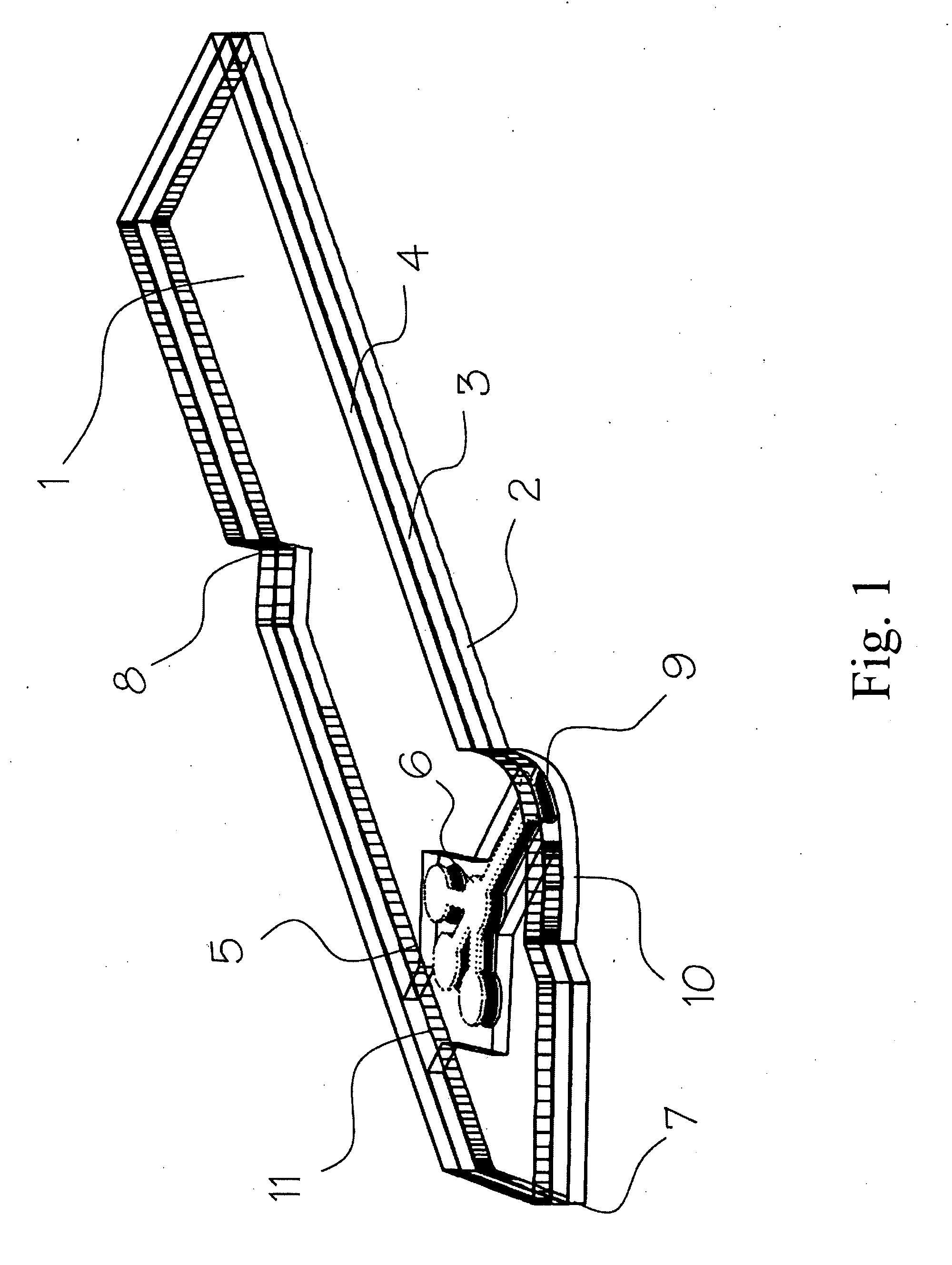

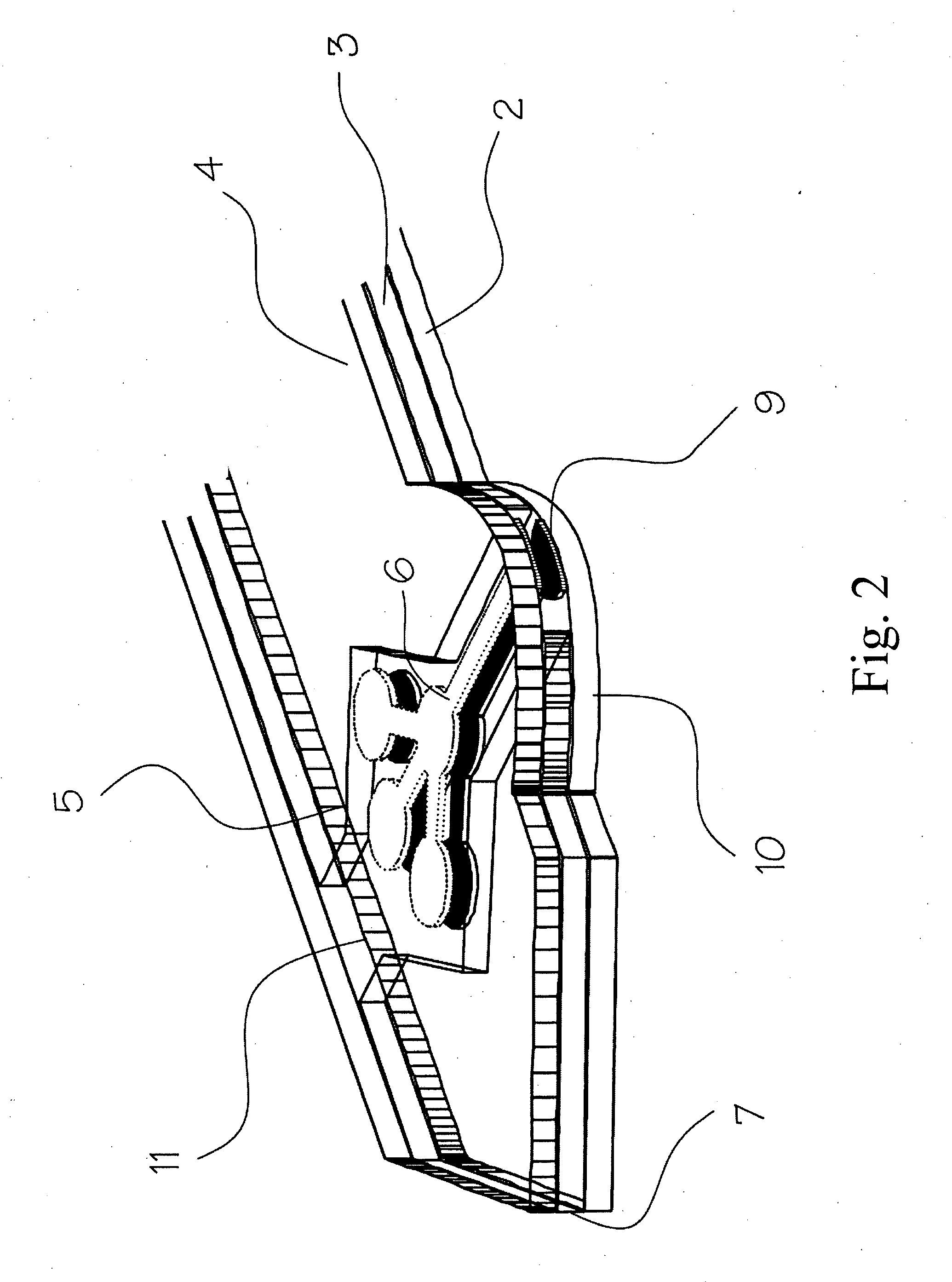

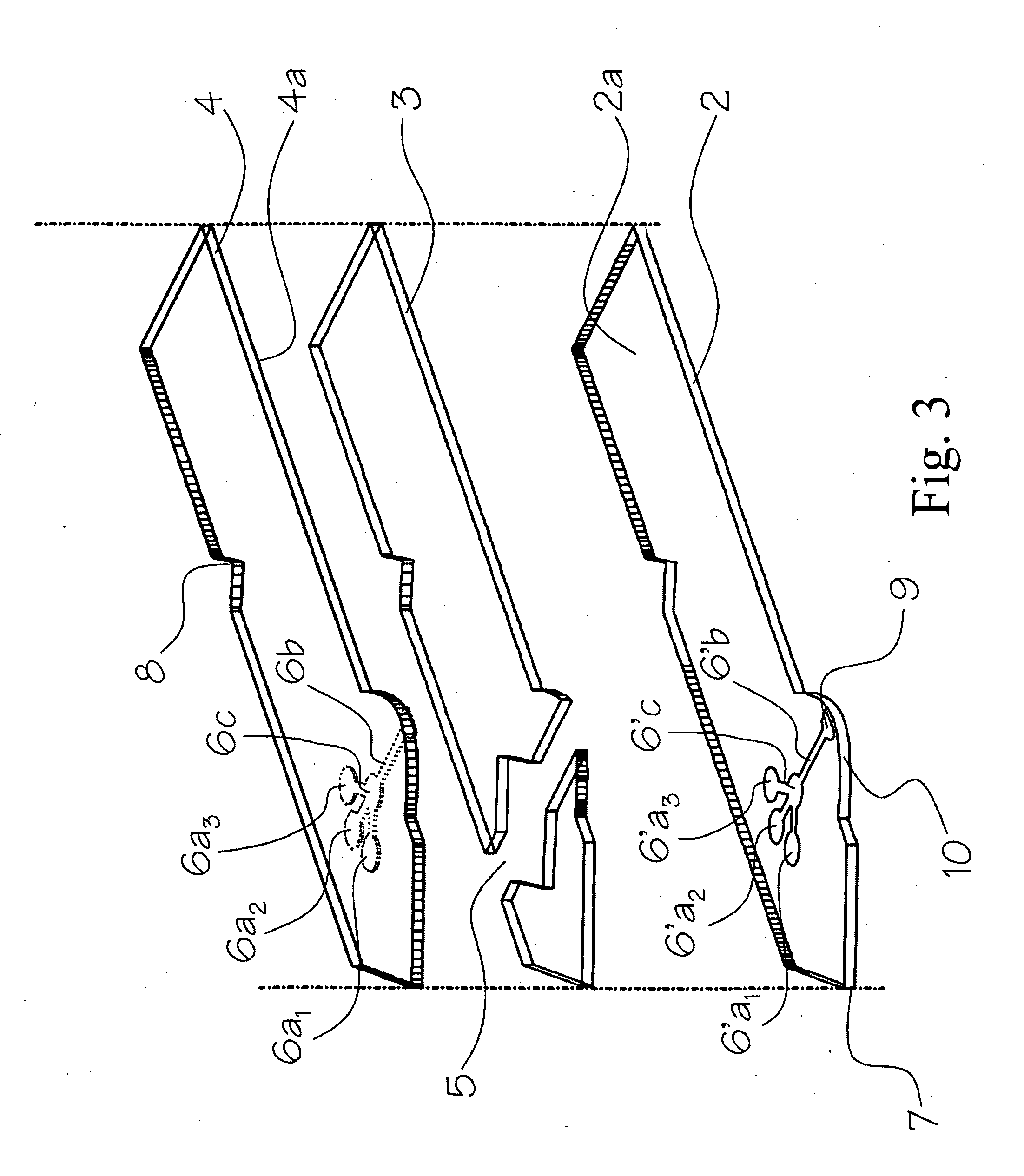

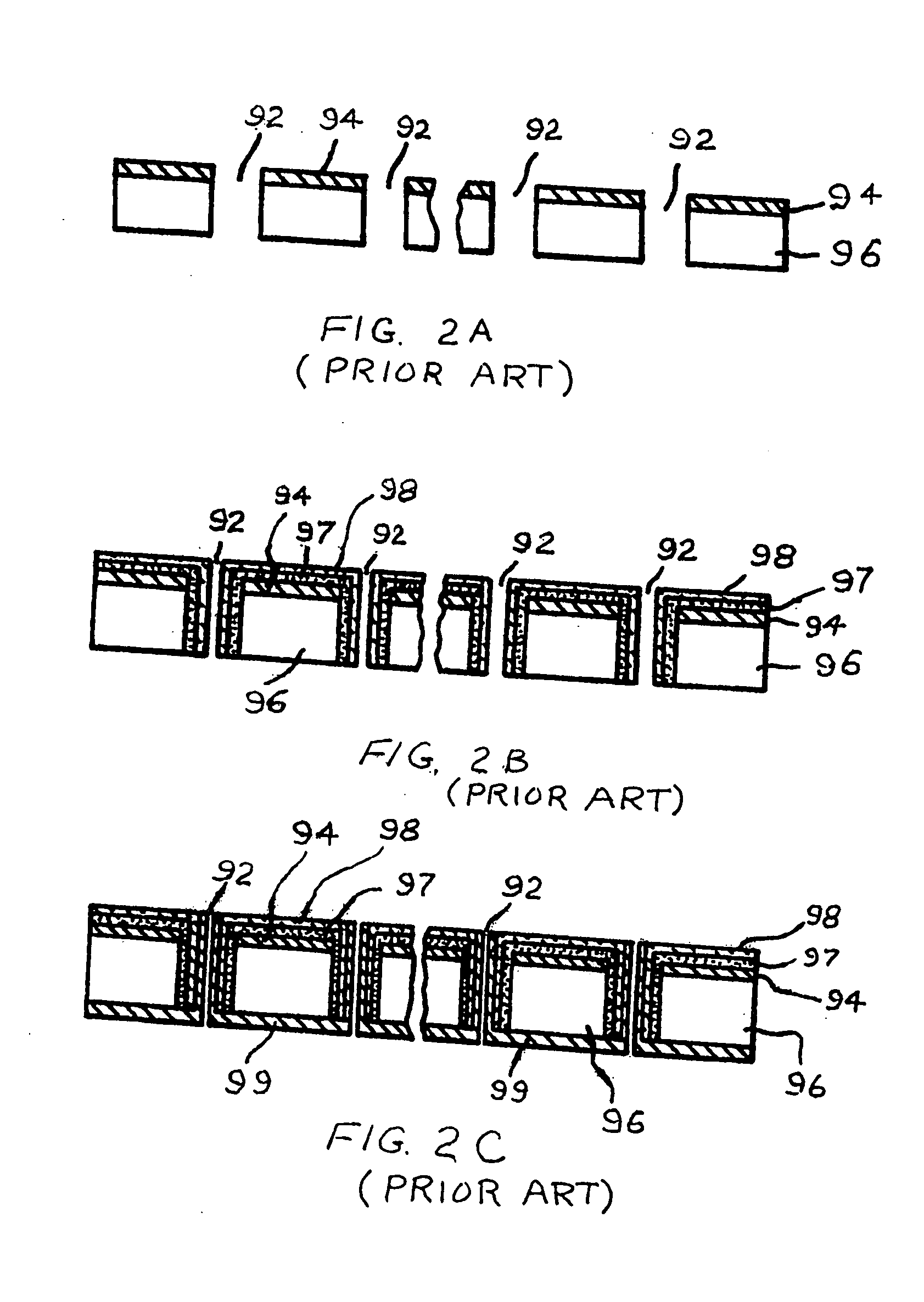

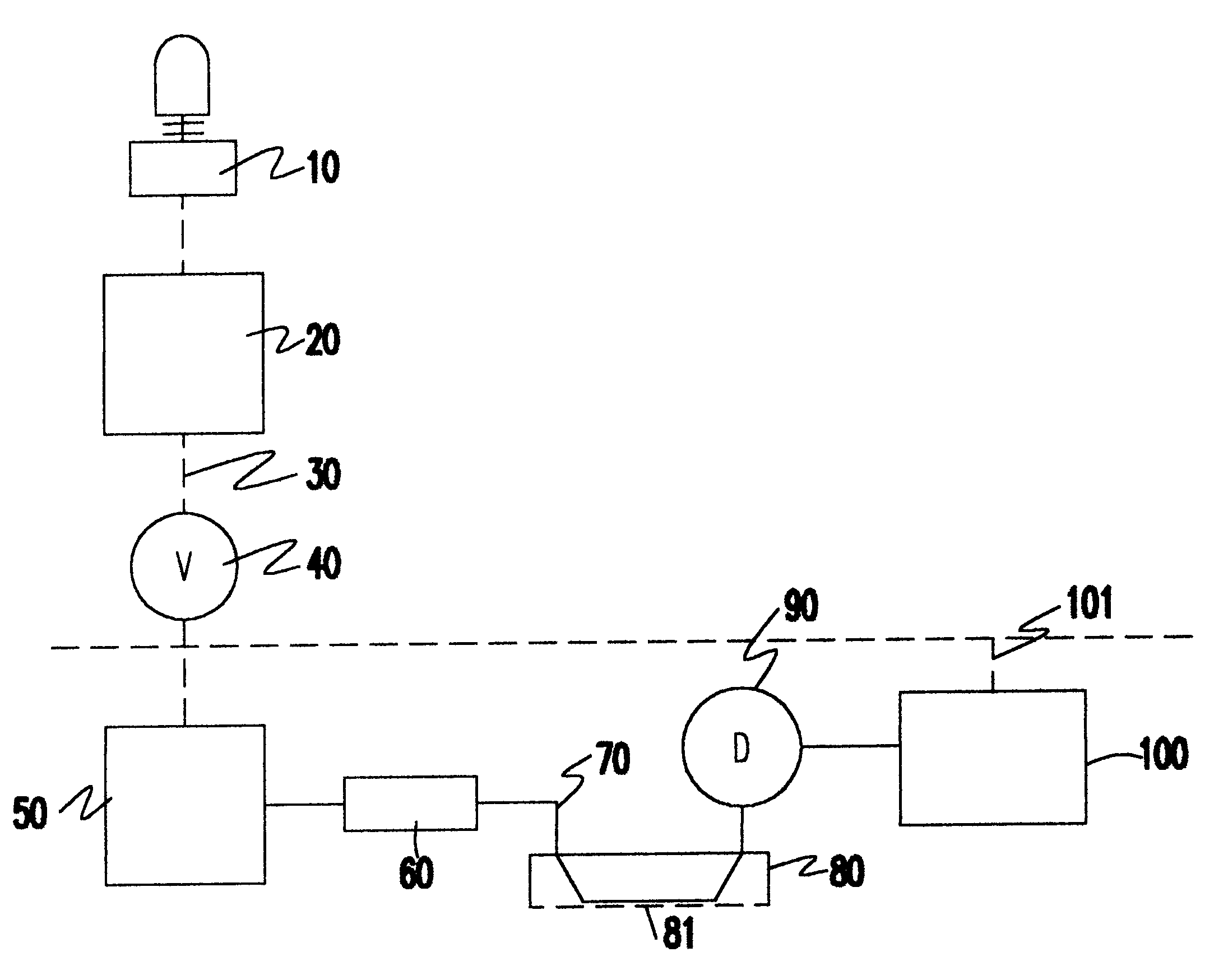

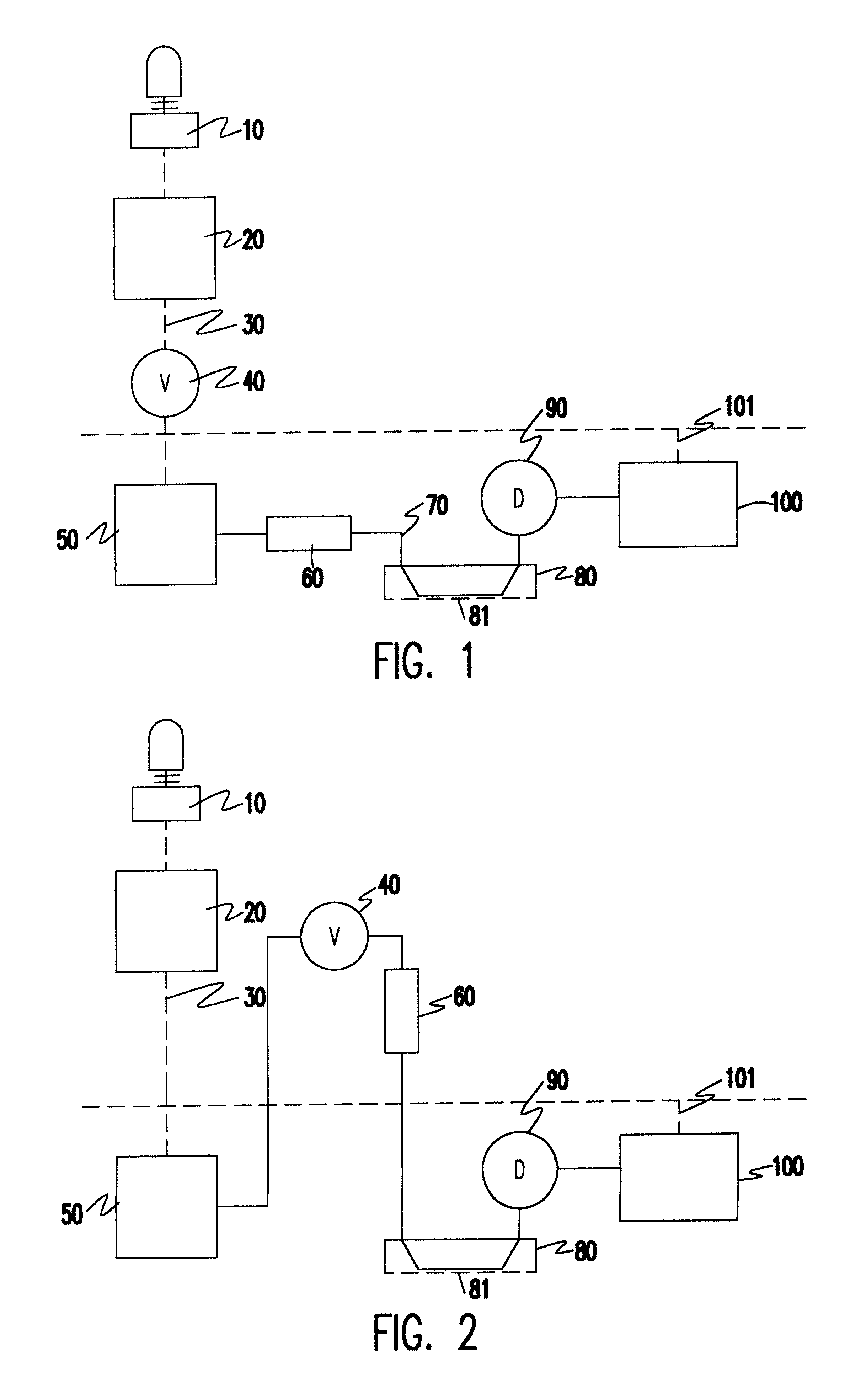

Analyte test system using non-enzymatic analyte recognition elements

InactiveUS20100035245A1Simple wayCheap productionBioreactor/fermenter combinationsBiological substance pretreatmentsPoint of careTarget analysis

An analyte test element for the qualitative and / or quantitative determination of at least one analyte in a physiological or aqueous sample fluid having a first surface (2a) and a second surface (4a) in a predetermined distance opposite from each other, said both surfaces are provided with two substantially equivalent patterns forming areas of high and low surface energy which are aligned mostly congruent, whereby the areas of high surface energy (6, 6′) create a sample distribution system with at least two detection areas (6a, 6′a), said at least one of the detection areas (6a, 6′a) of the first and second surfaces (2a, 4a) is provided with at least one non-enzymatic recognition element (32). The analyte test element is suitable for analyte test systems evaluating the affinity reaction between an analyte of interest and a recognition element and therefore provides a suitable test system to perform immunoassays, receptor-assays, or other affinity assays with a simple test element containing qualitative or quantitative calibration mechanisms suitable for point of care and home settings.

Owner:EGOMEDICAL TECH

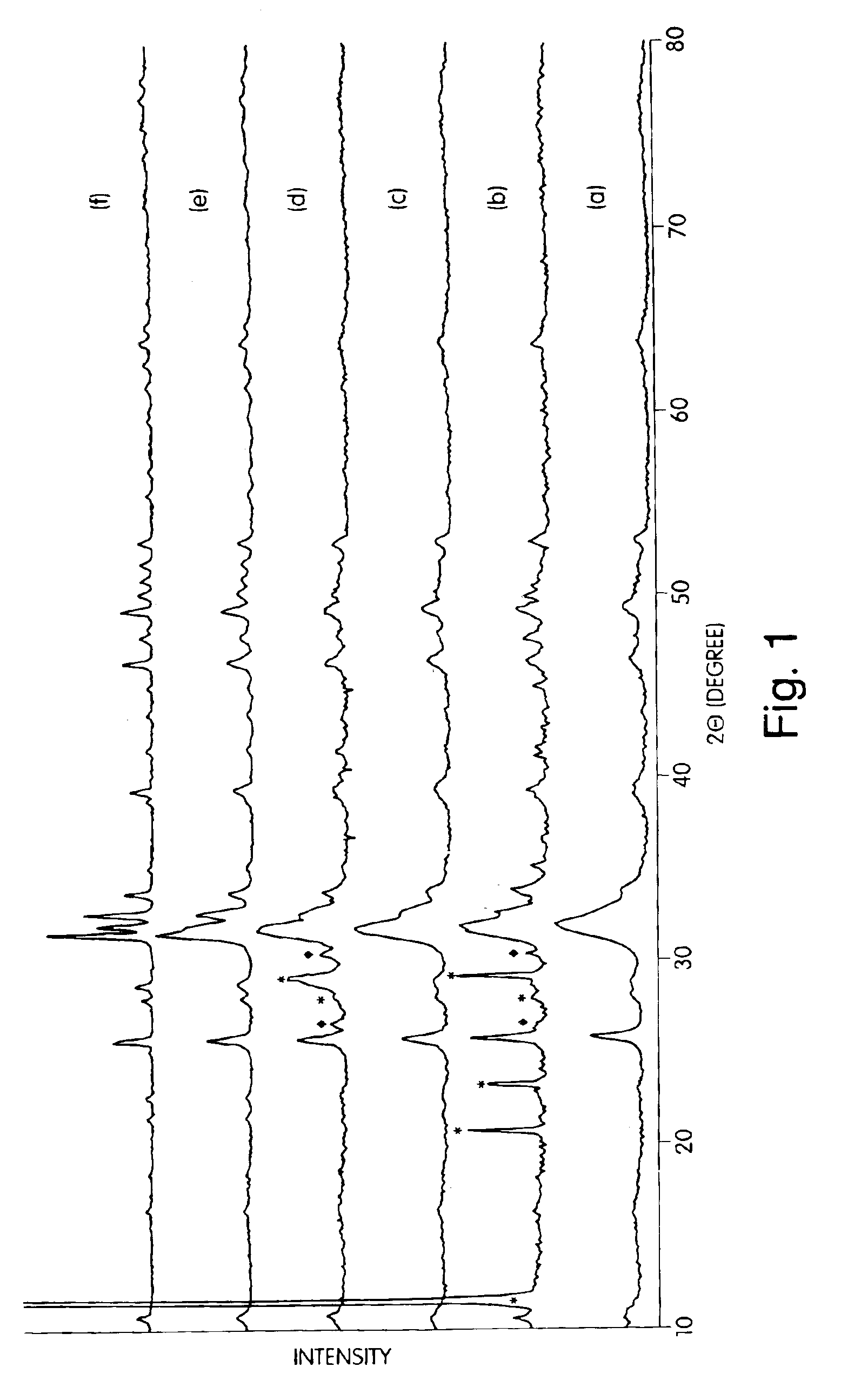

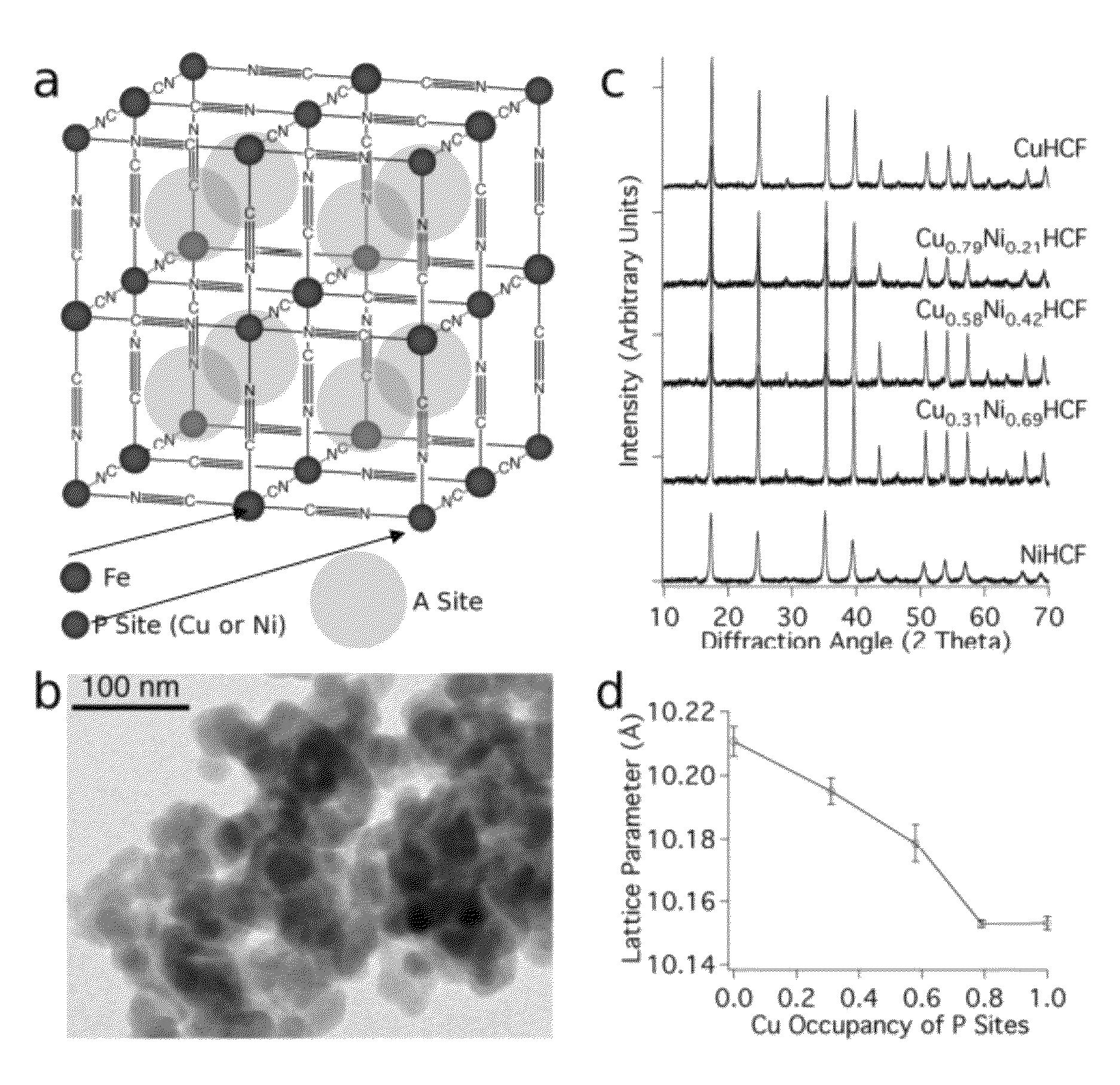

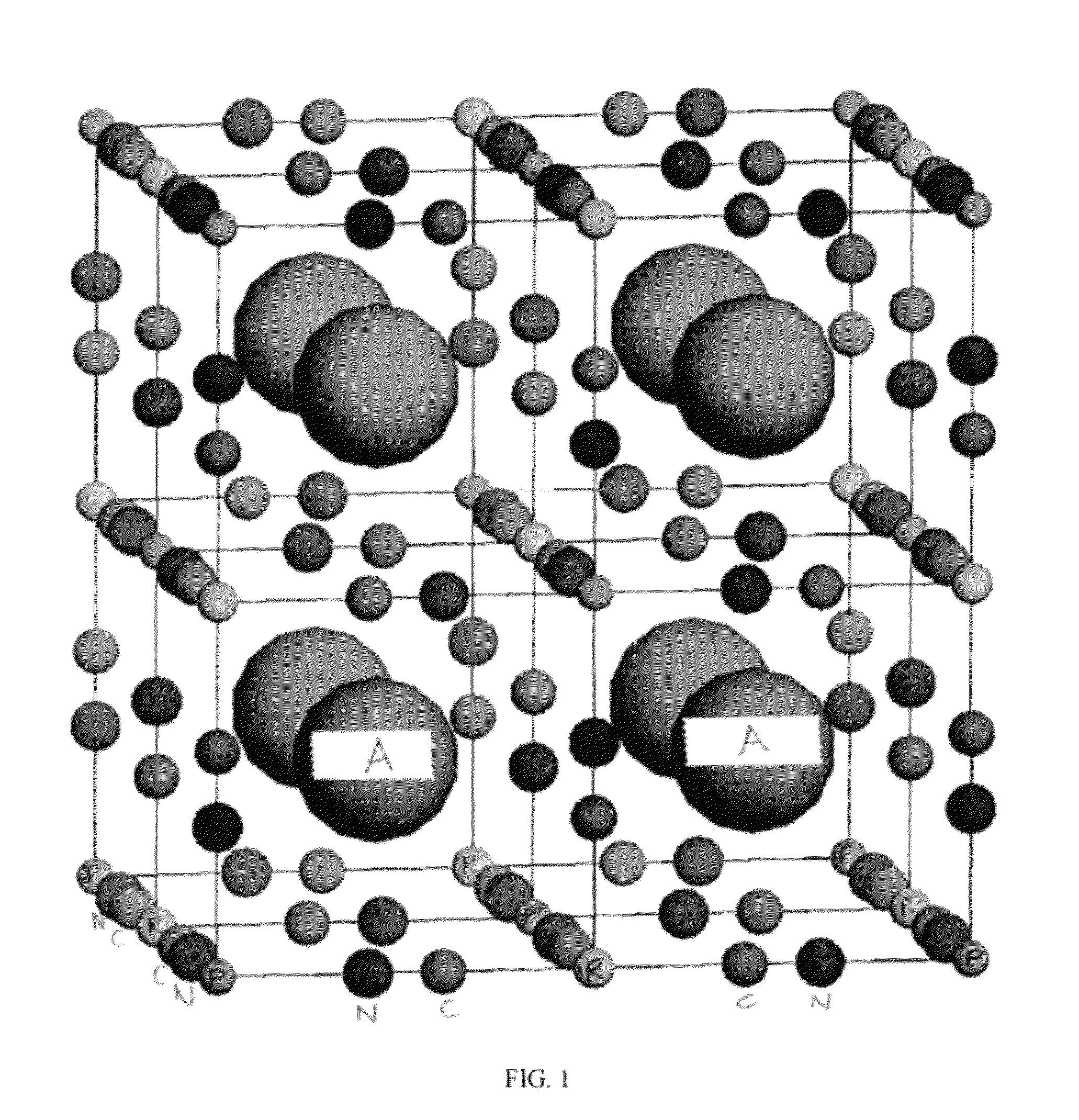

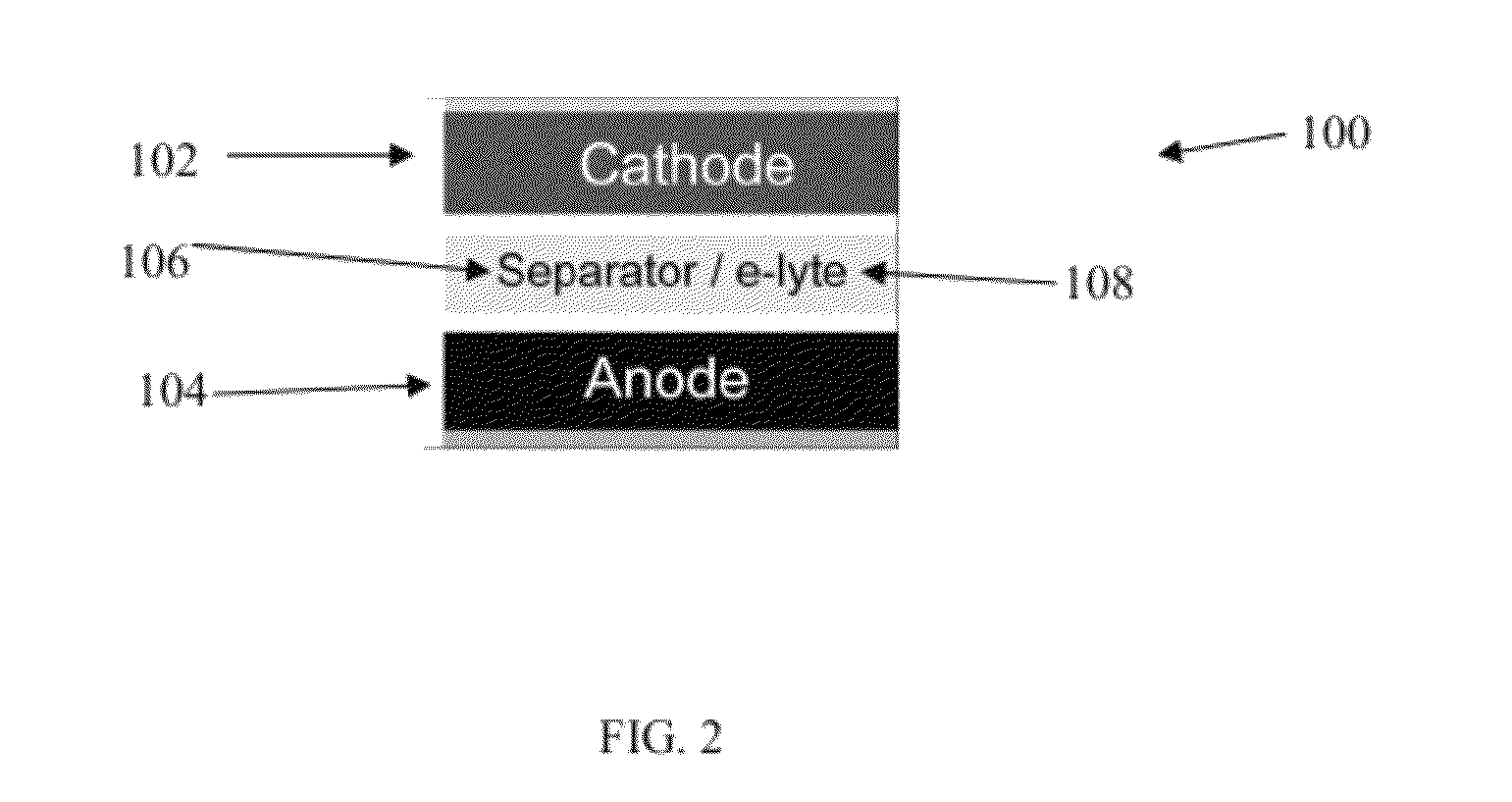

High rate, long cycle life battery electrode materials with an open framework structure

InactiveUS8951673B2Extreme durabilityImprove rate performanceFinal product manufactureActive material electrodesHigh rateReference rate

A battery includes a cathode, an anode, and an aqueous electrolyte disposed between the cathode and the anode and including a cation A. At least one of the cathode and the anode includes an electrode material having an open framework crystal structure into which the cation A is reversibly inserted during operation of the battery. The battery has a reference specific capacity when cycled at a reference rate, and at least 75% of the reference specific capacity is retained when the battery is cycled at 10 times the reference rate.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

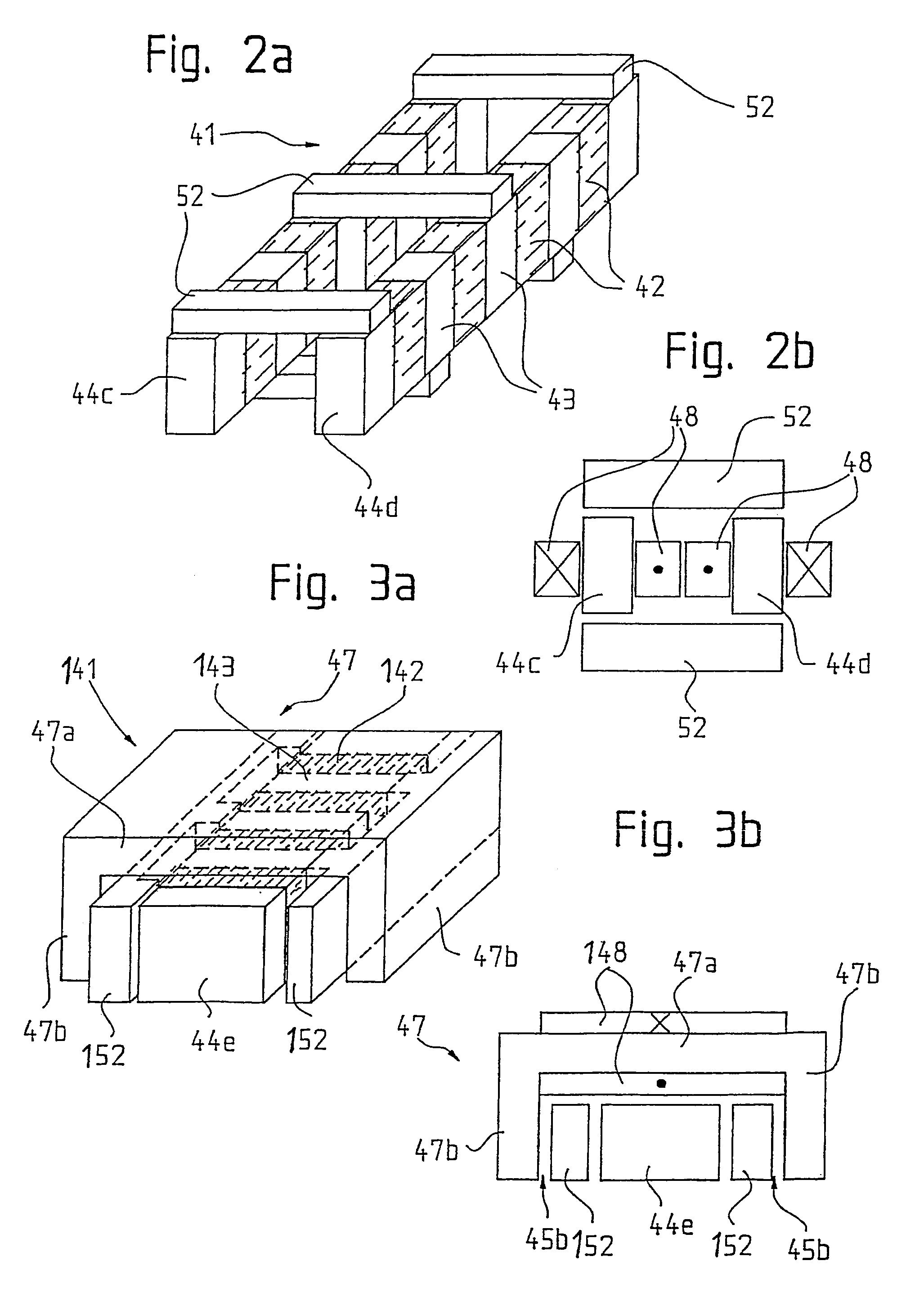

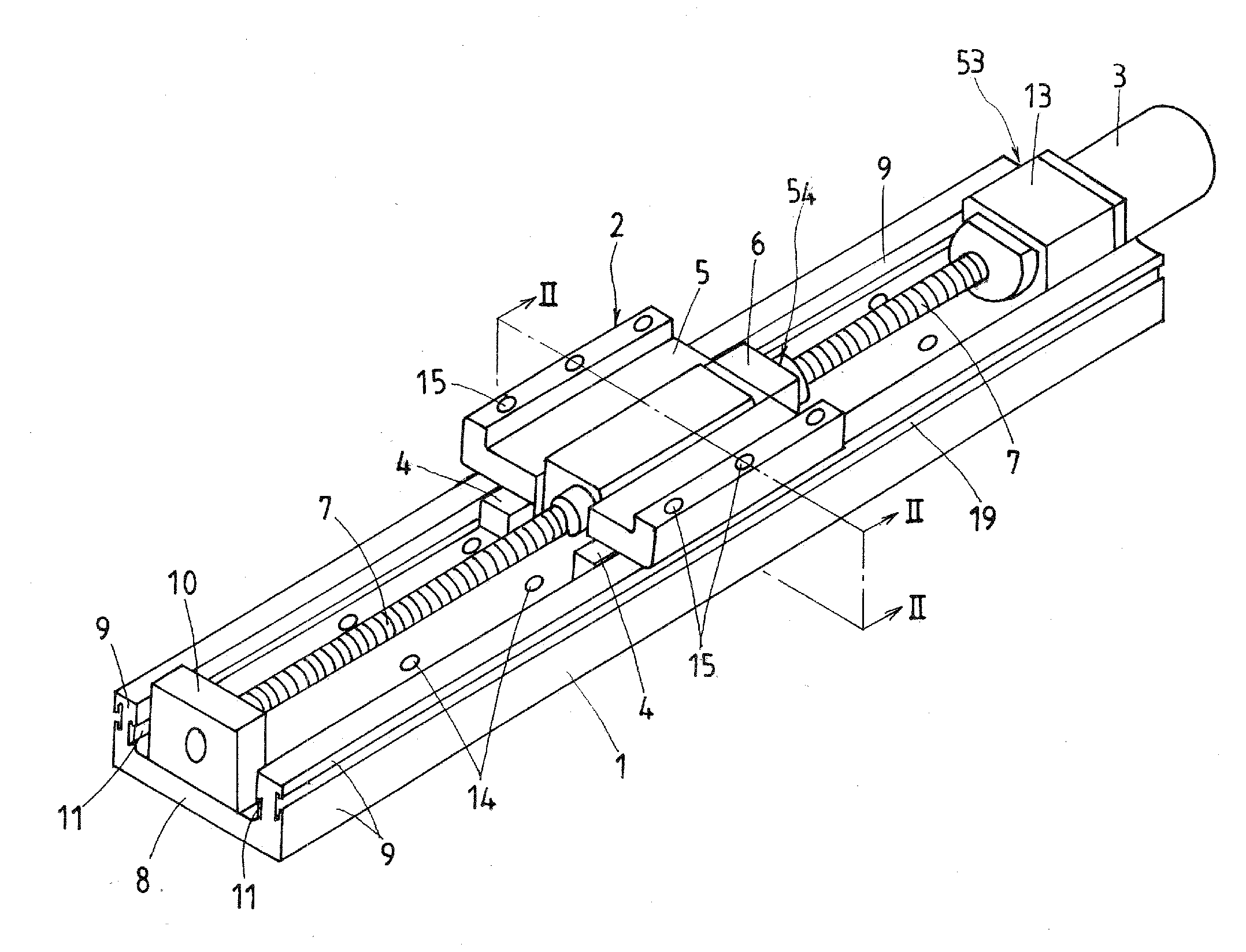

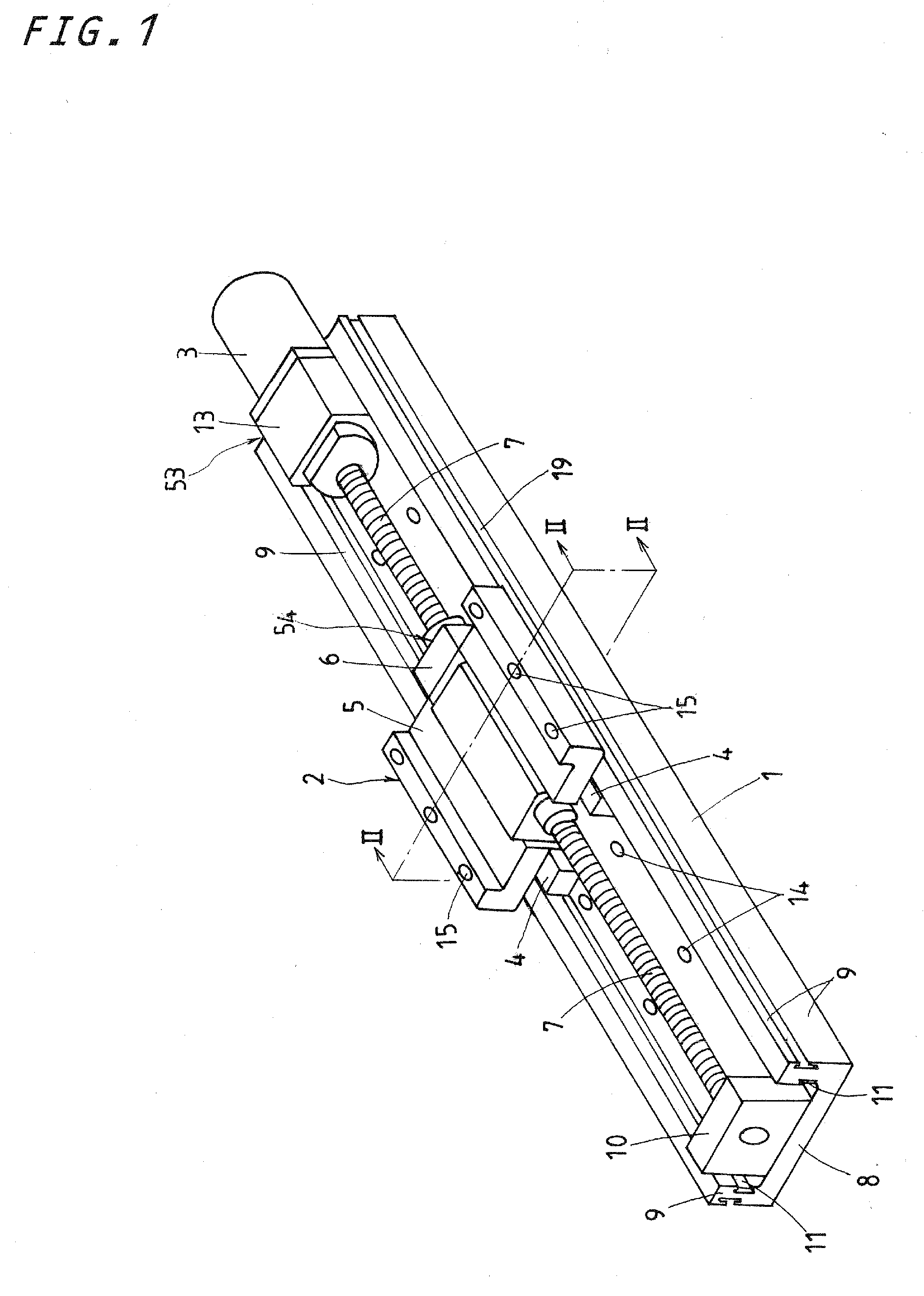

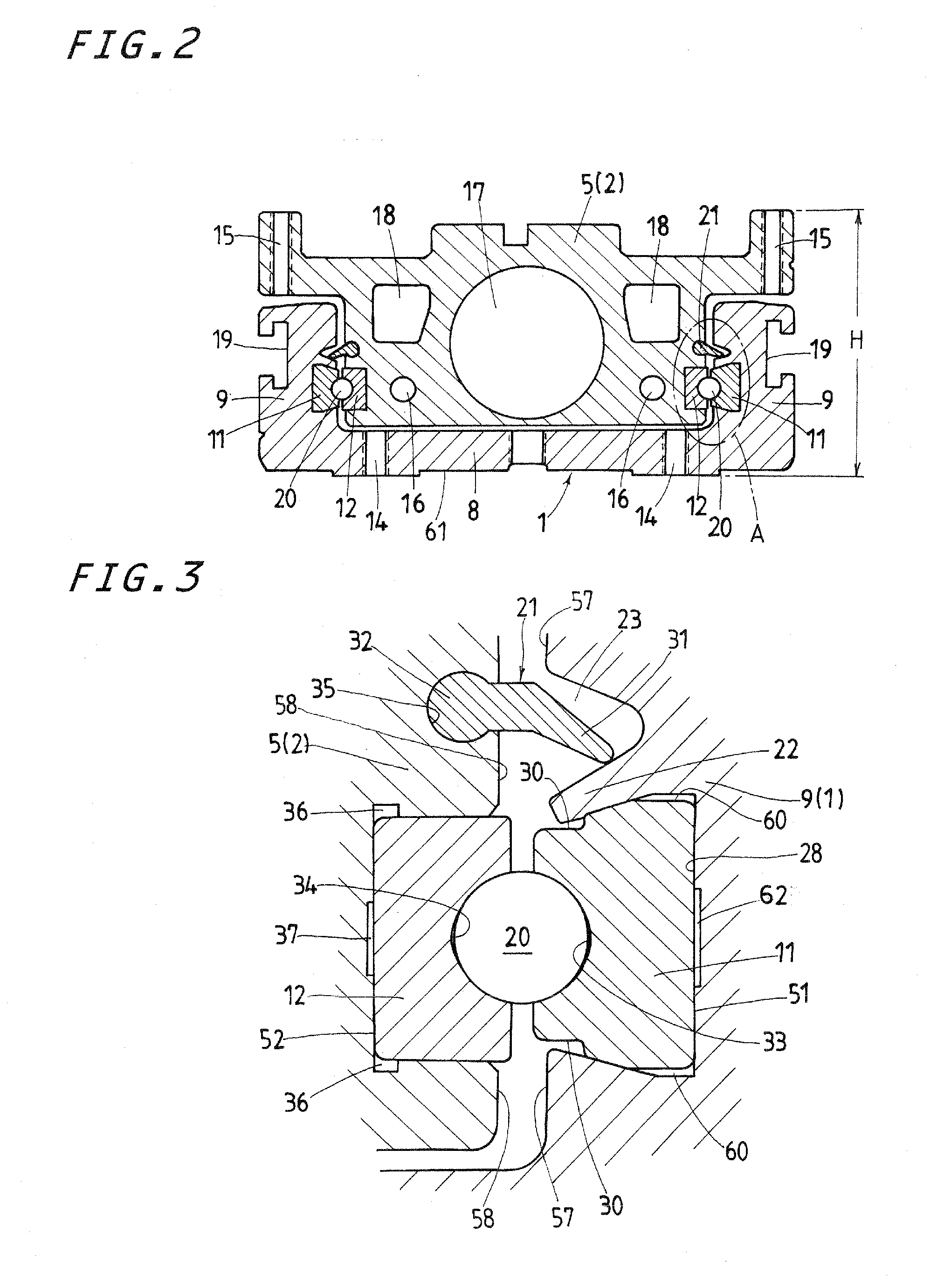

Actuator

ActiveUS20100139426A1Easily cutInexpensive productionLinear bearingsToothed gearingsEngineeringFlange

An actuator has a frame and a slider body which are both made of extruded shapes of light-metal alloy. A first rail member is fastened to the frame by means of a simple construction. An upper sealing member is placed between the frame and the slider body. With the actuator constructed as stated earlier, the frame is an elongated extrusion of U-shape in transverse section whose side walls have first recesses of dovetail configuration to fit over first rail members and flanges. A slider has therein the slider body having second recesses of rectangular shape to fit over second rail members. There is further provided a driving unit to force the slider with respect to the frame. The first rail members each have the wedged configuration including tapered contours and dents, while the second rail members each have the rectangular shape.

Owner:NIPPON THOMPSON

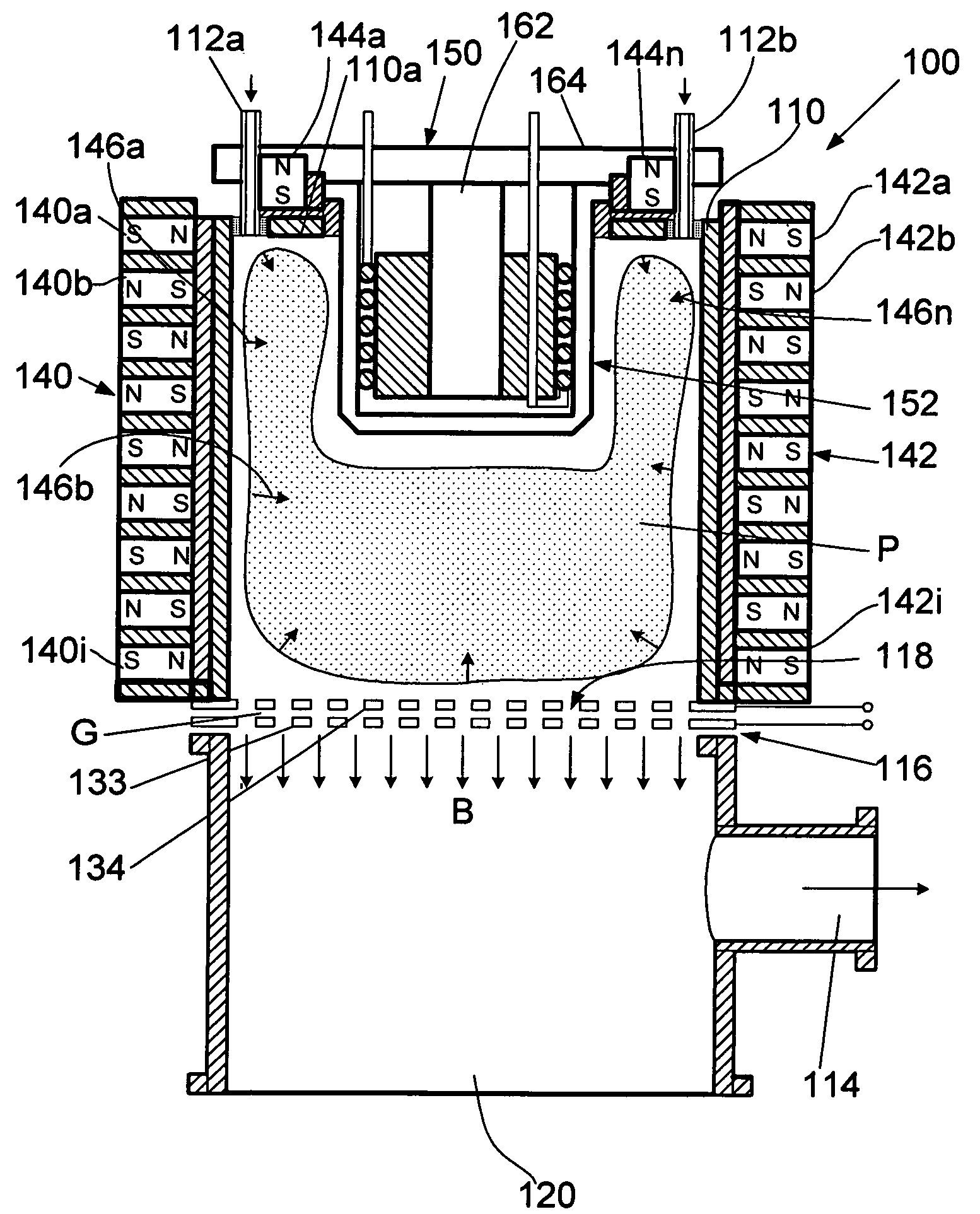

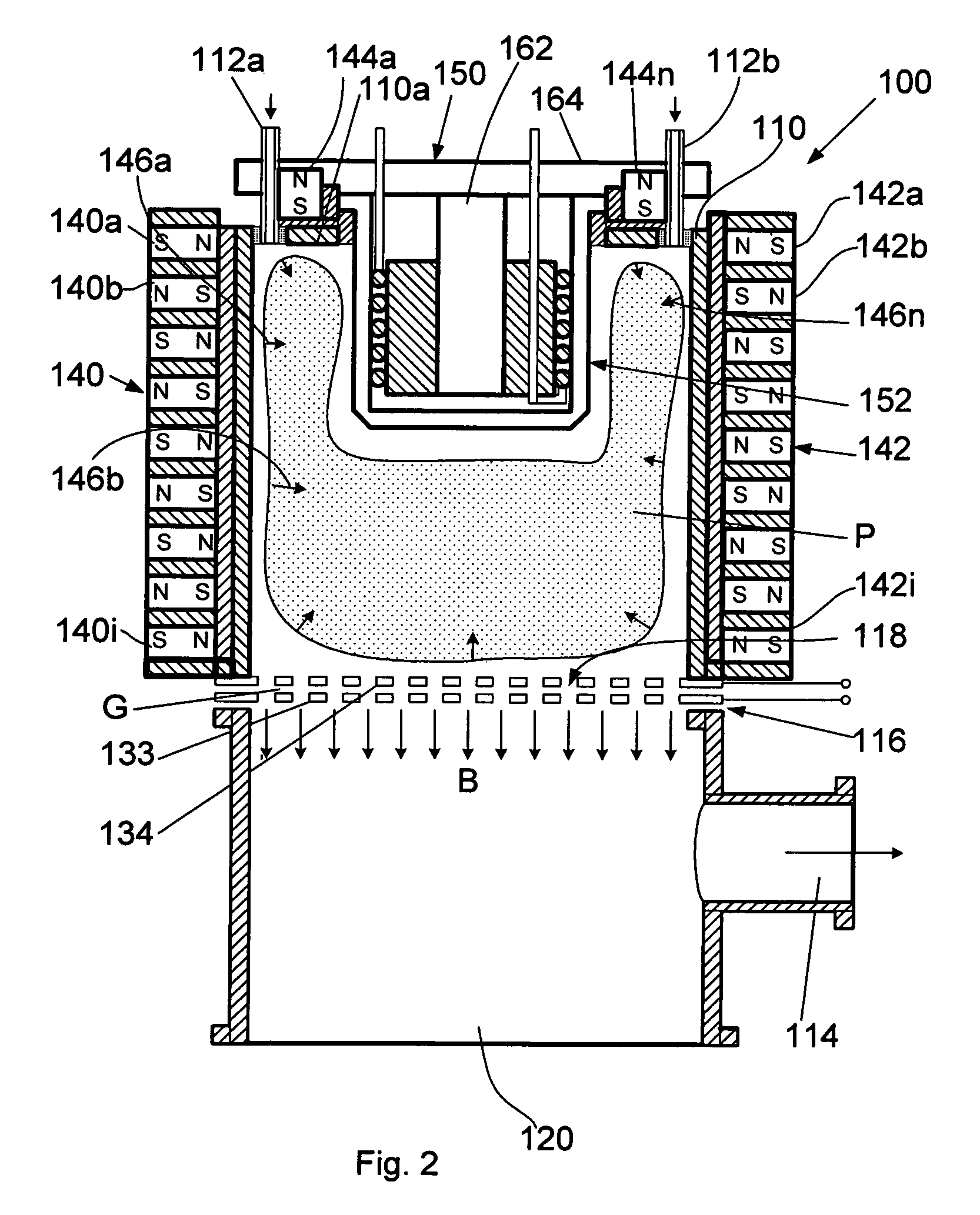

Ion-beam source

ActiveUS20090189083A1Enhanced couplingImprove efficiencyMaterial analysis by optical meansIon beam tubesElectrical conductorIon beam

An ion-beam source comprising: a plasma-generation unit for generating plasma and an ion-extraction unit for extraction and acceleration of ions from the aforementioned plasma, where the ion-extraction unit is made in the form of at least one grid under a negative potential. The plasma generating unit consists of a working chamber having a deeply immersed antenna cell. The cell contains a ferromagnetic core, a heat conductor with a heat sink, at least one inductive coil wound onto the ferromagnetic core, and a cap made from a dielectric material that sealingly covers the ferromagnetic core and the inductive coil.

Owner:GODYAK VALERY

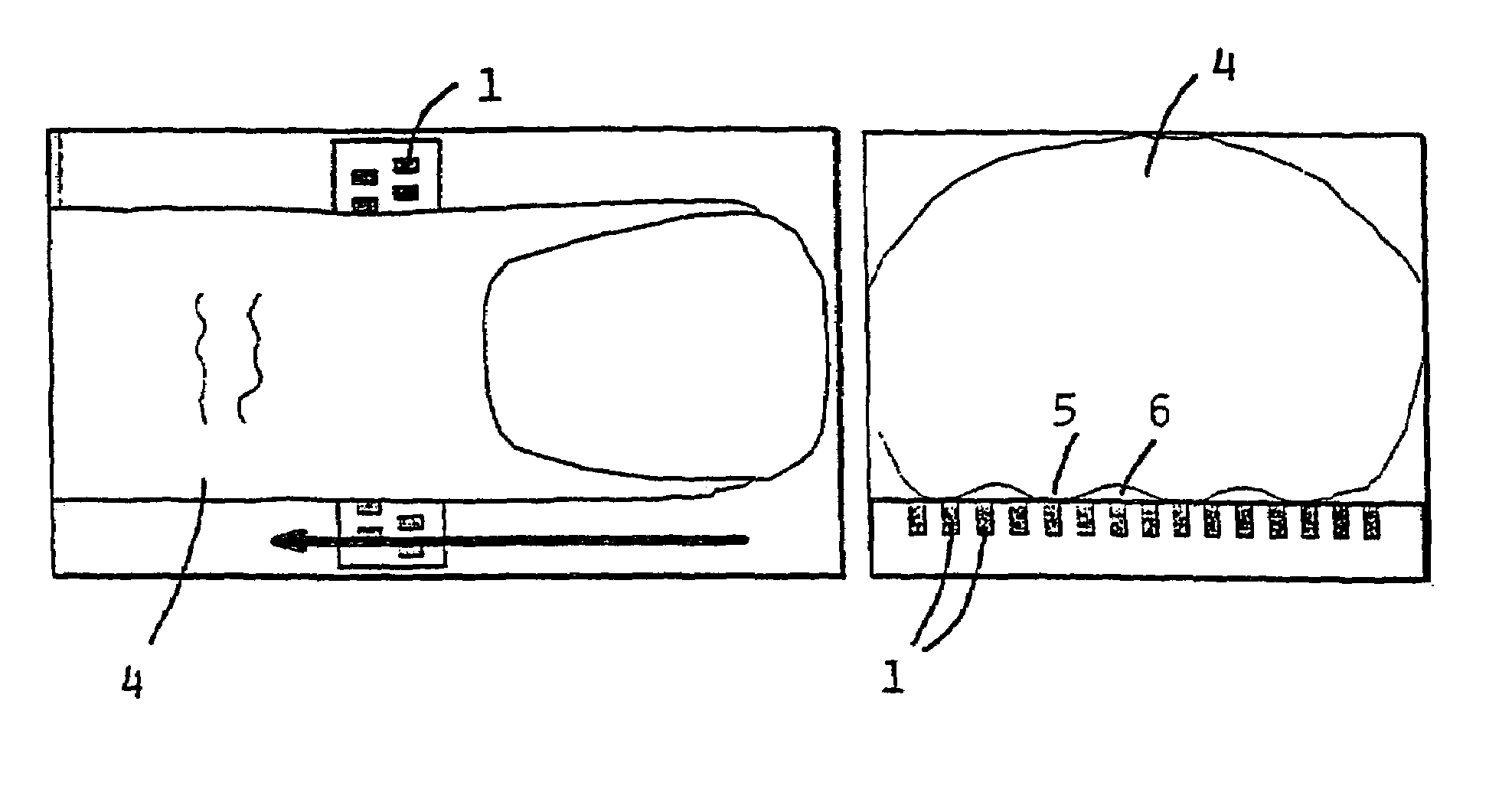

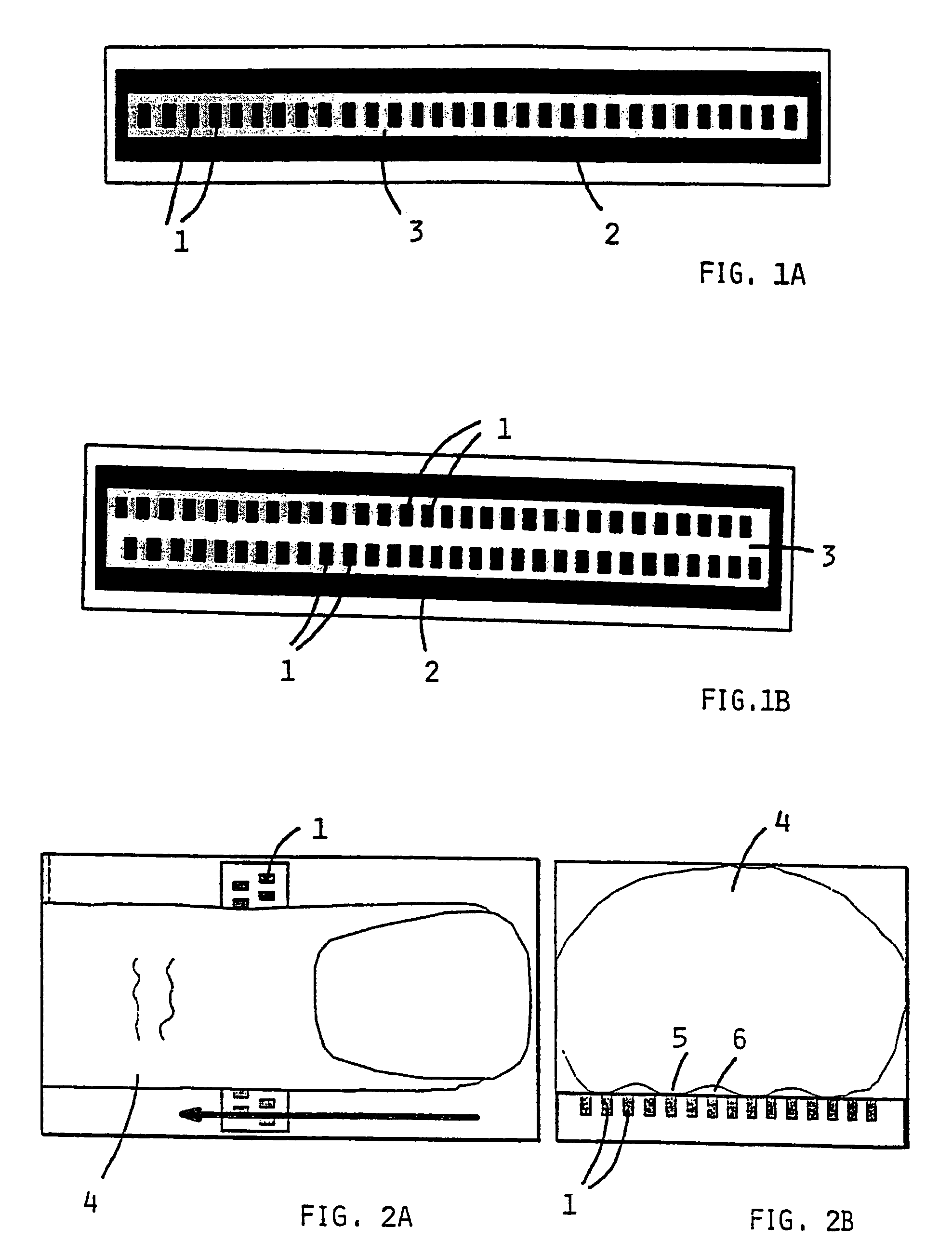

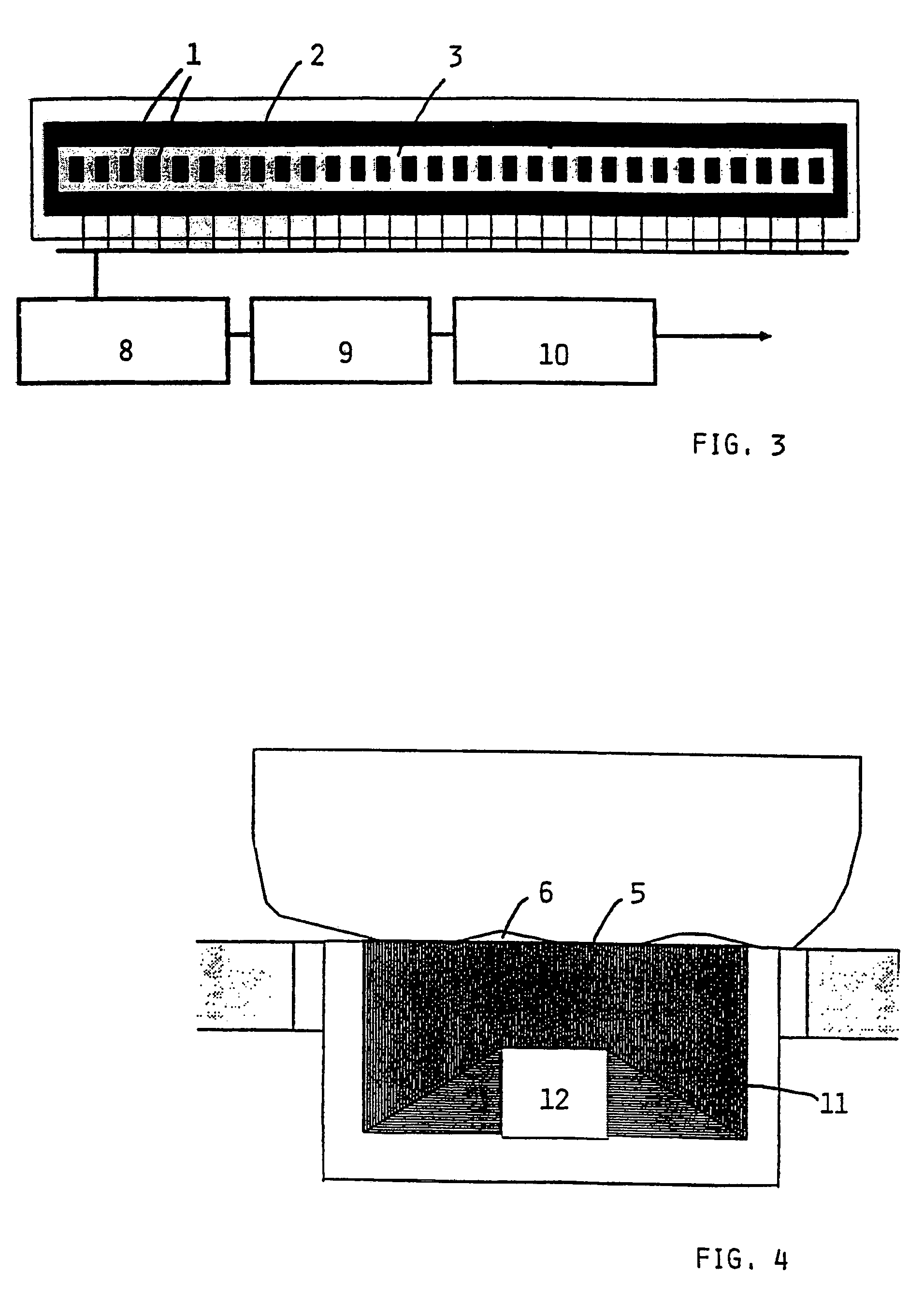

Method and apparatus for measuring structures in a fingerprint

InactiveUS7054471B2Simple processSurfaces with very littlePerson identificationElectric/magnetic contours/curvatures measurementsSensor arrayCapacitance transducer

A plurality of images of portions of a fingerprint surface is generated by measuring structural features the portions of the surface with a sensor array as the surface is moved relative to the array. A two-dimensional image of the fingerprint surface is constructed from a portion of the plurality of images. In one embodiment, a varying voltage is applied to a finger positioned over an exciting electrode and a capacitive sensor array, and the capacitance or impedance through the finger is measured between the electrode and the array to detect variations in capacitance or impedance caused by variations in the structural features of the fingerprint surface. In one embodiment, the speed of the fingerprint surface relative to the sensor array is determined by sensing features of the fingerprint surface at two spaced-apart sensing elements and determining the speed from the distance between the sensing elements and the time lapse between passage of identical features of the fingerprint surface from one of the sensing elements to the other.

Owner:SINTEF

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS20100218824A1Minimization requirementsIncrease volumeFinal product manufacturePV power plantsMaterial removalMetal foil

This invention comprises manufacture of photovoltaic cells by deposition of thin film photovoltaic junctions on metal foil substrates. The photovoltaic junctions may be heat treated if appropriate following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation, an interconnection substrate structure is provided, optionally in a continuous fashion. Multiple photovoltaic cells are then laminated to the interconnection substrate structure and conductive joining methods are employed to complete the array. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials employing optimal processing unique to polymeric materials. Furthermore, the photovoltaic junction and its metal foil support can be produced in bulk without the need to use the expensive and intricate material removal operations currently taught in the art to achieve series interconnections.

Owner:SOLANNEX

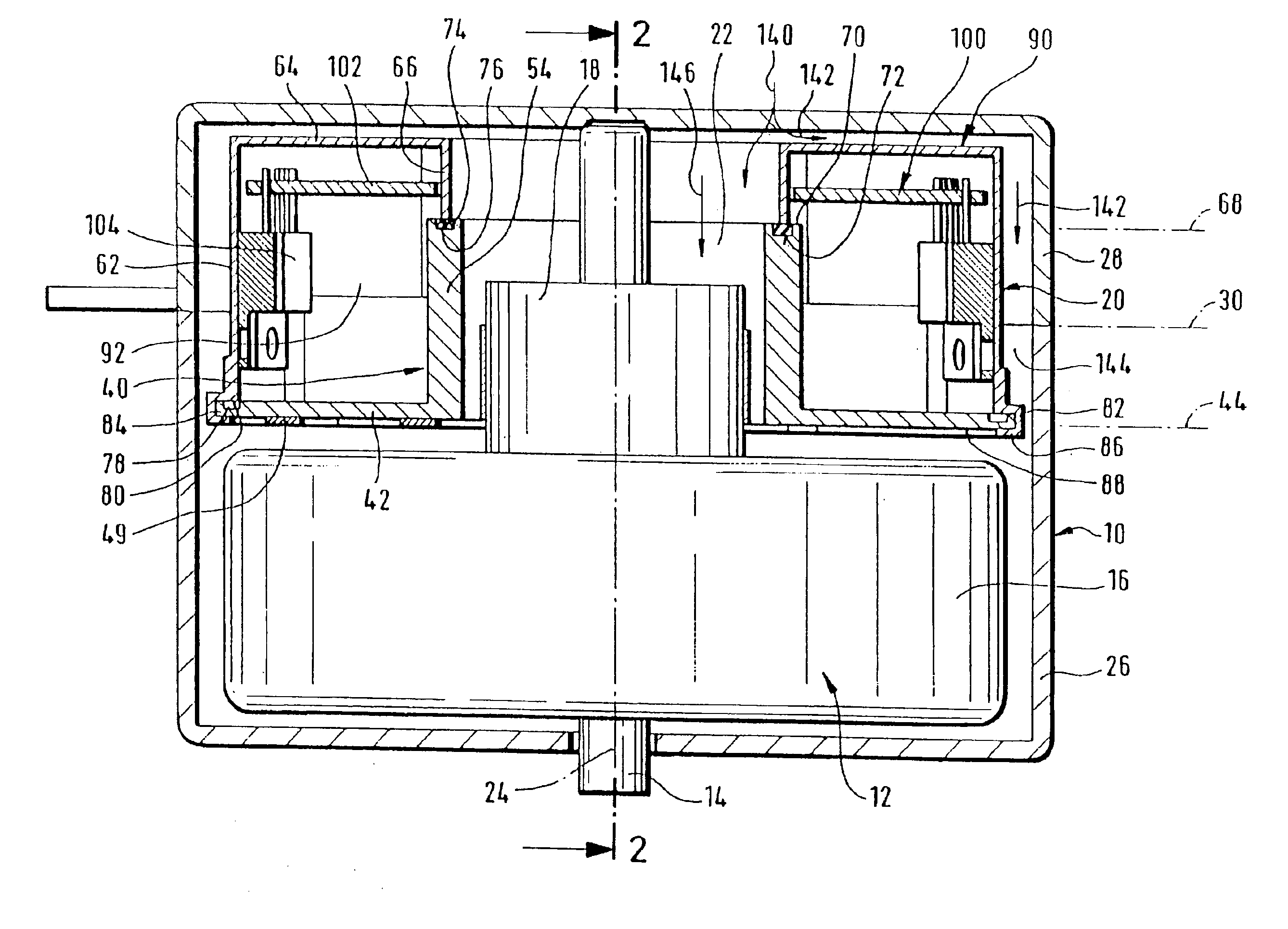

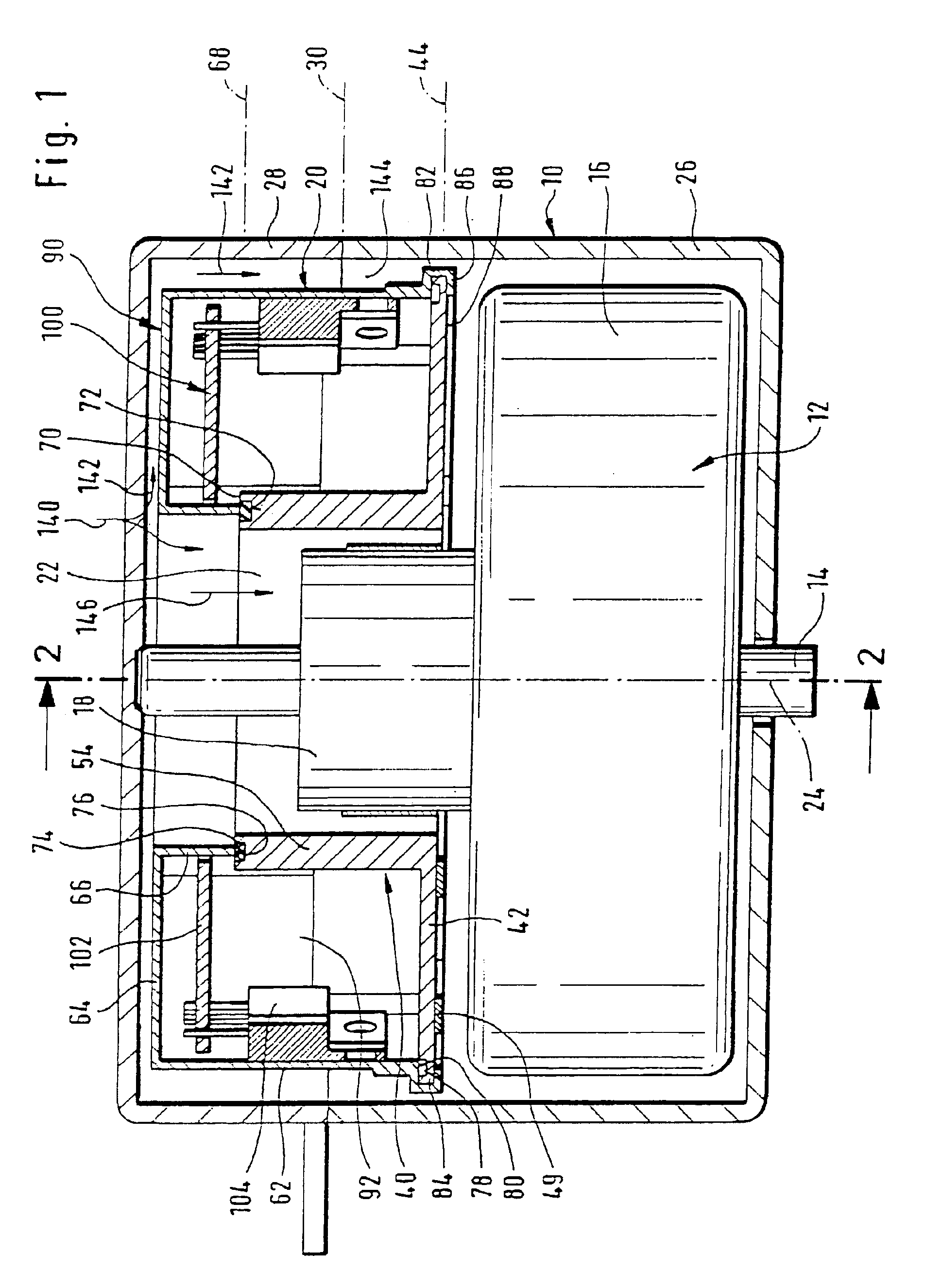

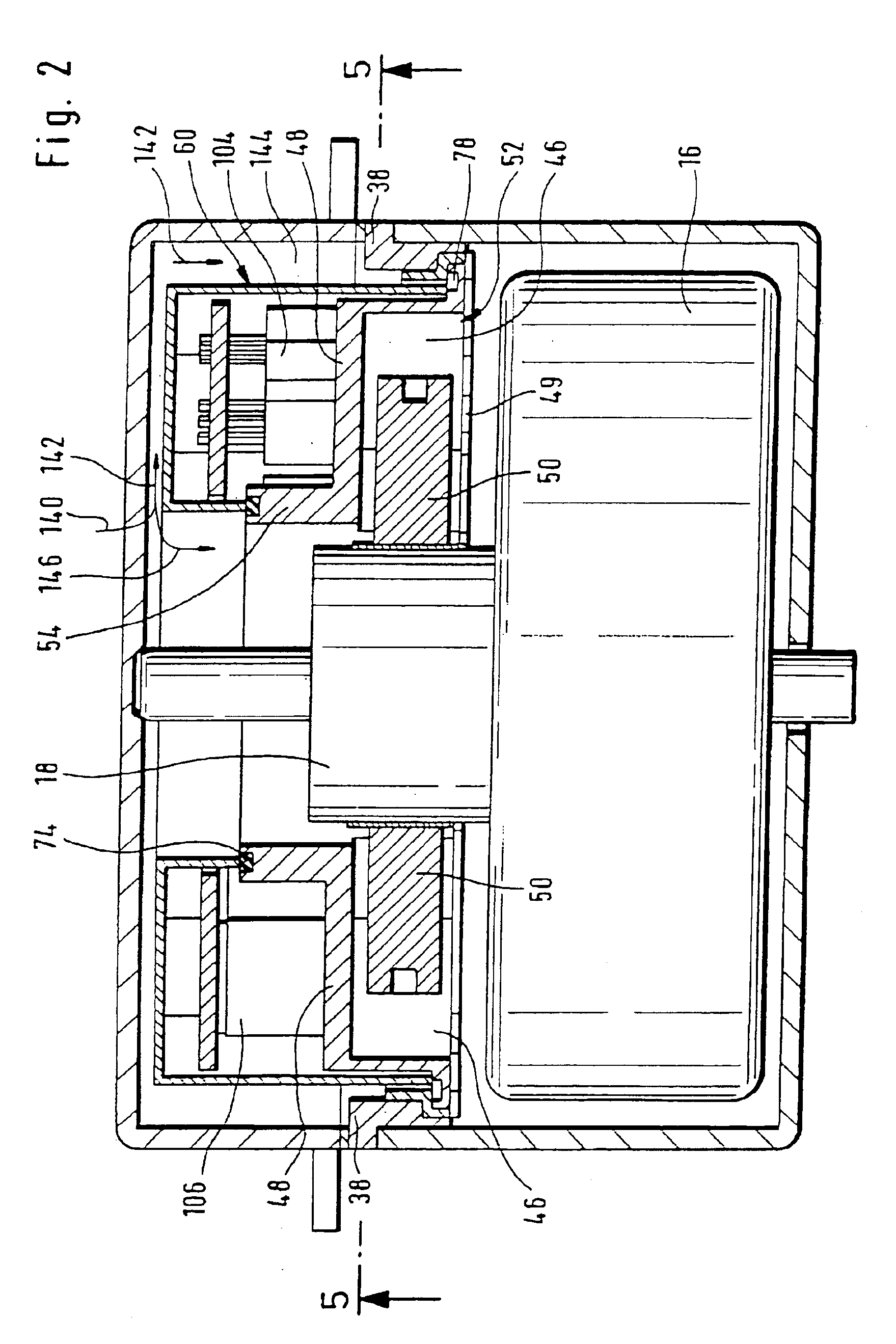

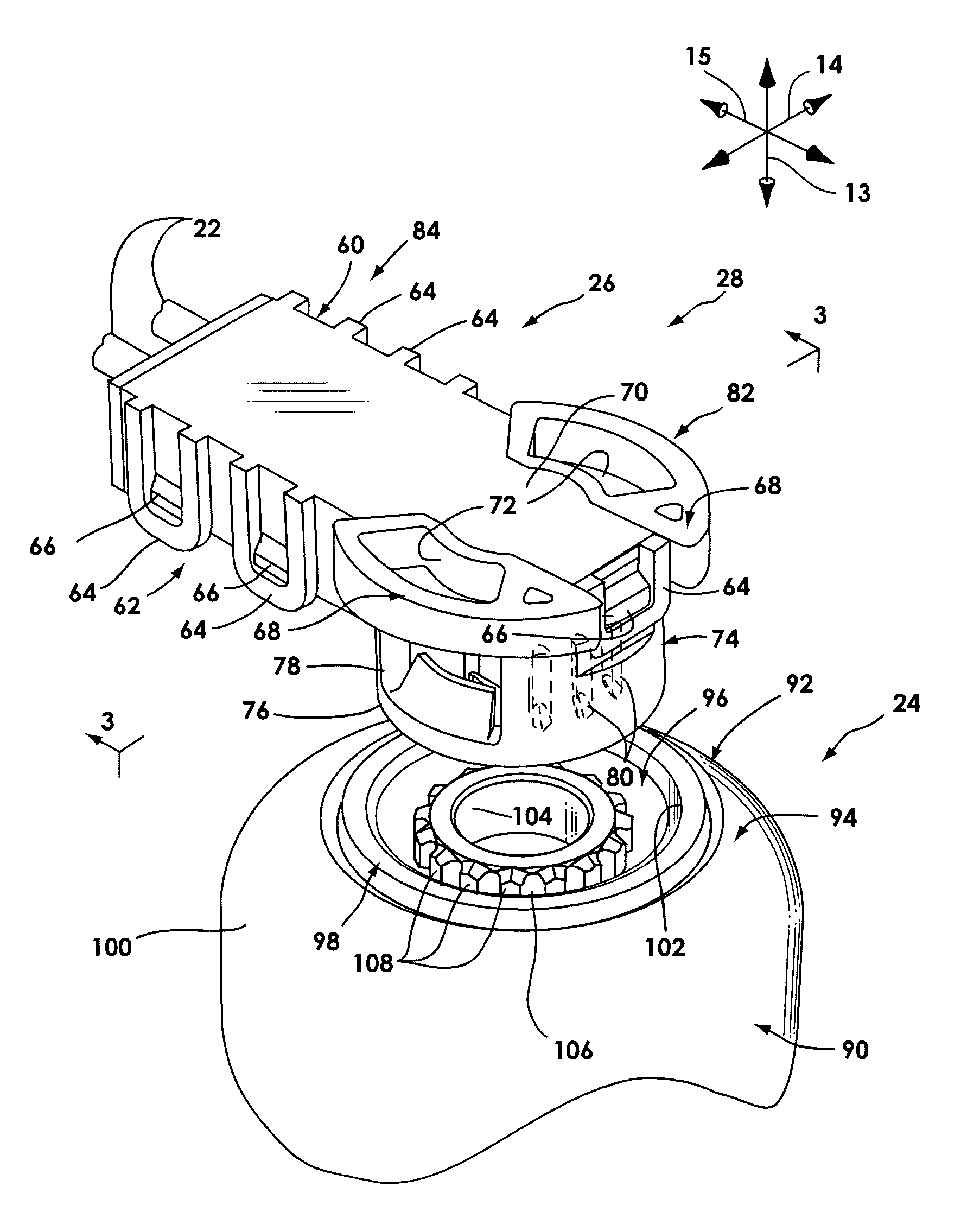

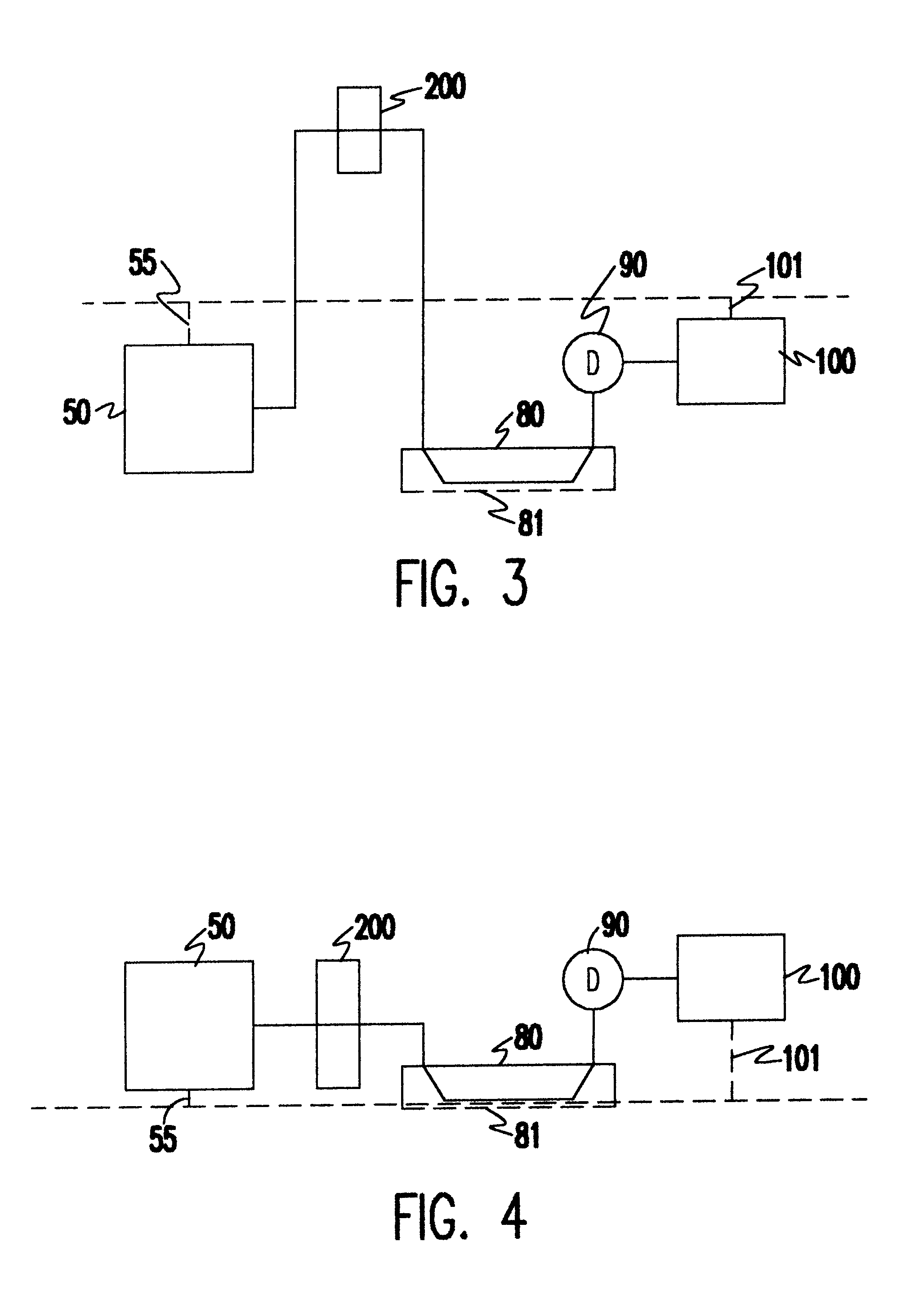

Power supply unit

ActiveUS6927522B2Inexpensive productionSimplify assemblyAssociation with control/drive circuitsRotary current collectorElectronic circuitElectricity

In order to improve a power supply unit for a commutator of an electric motor, comprising a brush holder support with brushes arranged in it and interacting with the commutator, in such a manner that this can be produced as inexpensively and in as functionally reliable a manner as possible it is suggested that the power supply unit comprise an electronics housing which is formed by the brush holder support and a protective cover connected to it and that the electronics housing seal an electronic circuit module arranged in an interior thereof in a functionally reliable manner in relation to the surroundings.

Owner:MYPAQ HLDG LTD

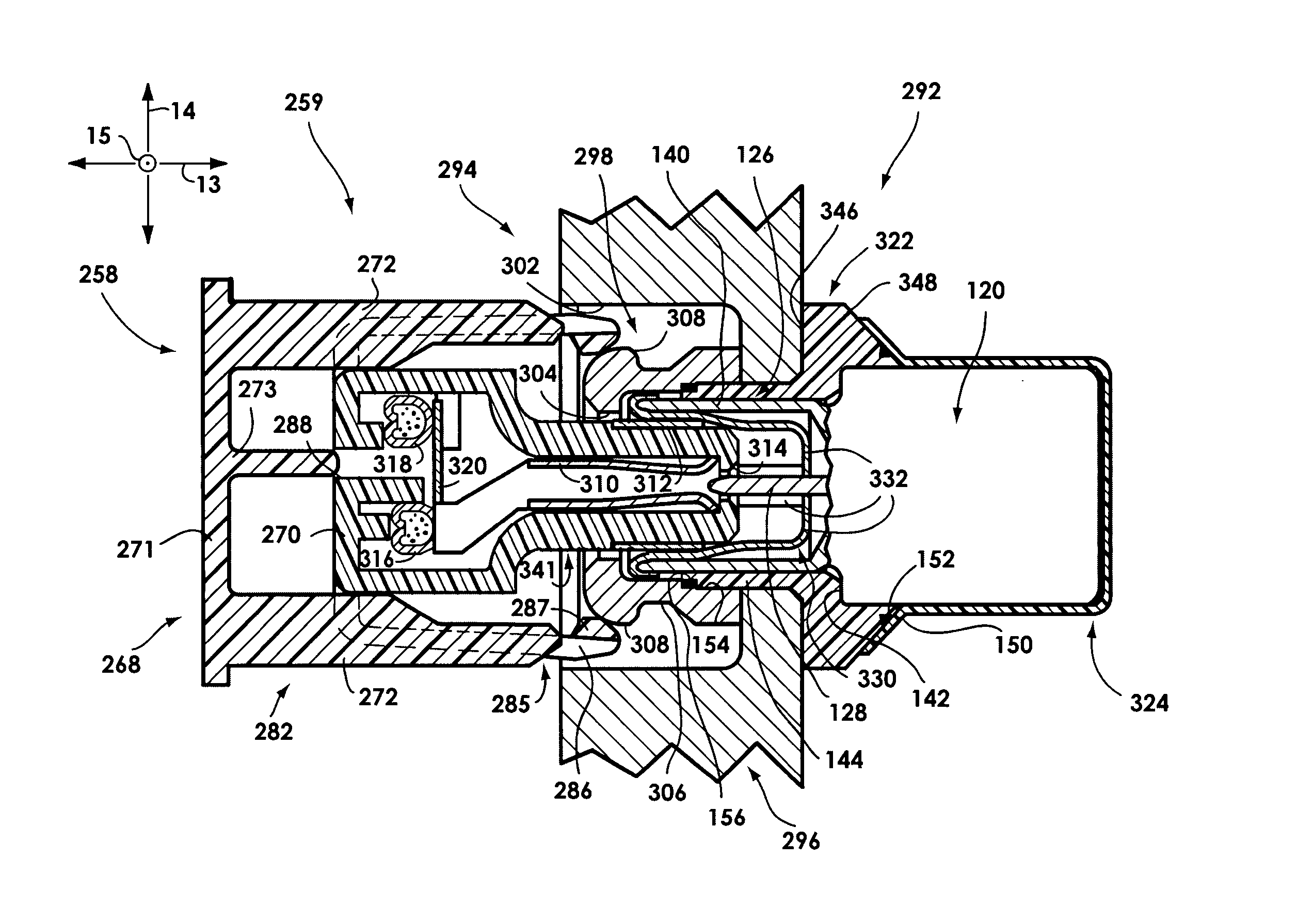

Electrical connection apparatus and method for an airbag inflator

InactiveUS7004778B2Inexpensive productionSimplifies electrical connectionsEngagement/disengagement of coupling partsRelieving strain on wire connectionMating connectionElectrical connection

An airbag module has an inflator activated via an electrical connector. The inflator includes an initiation assembly having an initiator and a receptacle that retains the connector. The initiator may have a single, center pin. The initiator may be encased by a body and cover, which may be attached together by molding, vibratory welding, electromagnetic welding, or snap fitting. The connector may have projections that extend from a main body to facilitate retention of the connector by a collar, washer, a retainer attached to the body, or by the inflator housing. The body may be seated in a collar having an annular ridge that presses into the body to form a seal. The connector may have a rib designed to mesh with splines of the receptacle to enable engagement of the connector with the receptacle in multiple orientations, while preventing relative rotation between the connector and the initiator after assembly.

Owner:AUTOLIV ASP INC

Airbag initiator cover attachment apparatus and method

InactiveUS7077428B2Inexpensive productionSimplifies electrical connectionsIncandescent ignitionPedestrian/occupant safety arrangementMating connectionEngineering

An airbag module has an inflator activated via an electrical connector. The inflator includes an initiation assembly having an initiator and a receptacle that retains the connector. The initiator may have a single, center pin. The initiator may be encased by a body and cover, which may be attached together by molding, vibratory welding, electromagnetic welding, or snap fitting. The connector may have projections that extend from a main body to facilitate retention of the connector by a collar, washer, a retainer attached to the body, or by the inflator housing. The body may be seated in a collar having an annular ridge that presses into the body to form a seal. The connector may have a rib designed to mesh with splines of the receptacle to enable engagement of the connector with the receptacle in multiple orientations, while preventing relative rotation between the connector and the initiator after assembly.

Owner:AUTOLIV ASP INC

Process and measuring system for detection of substances emitted or perspired through the skin

InactiveUS6183418B1Minimize impactInexpensive productionTesting beveragesPreparing sample for investigationDiffusionQuantitative determination

The process for detection and for quantitative determination of substances emitted or perspired through the skin is derived from flow diffusion analysis. The measuring system conceived for this purpose uses a diffusion half cell through which an acceptor medium flows and which is closed by a membrane. For the duration of the measurement, the membrane is brought into contact with the skin or a closed gas volume formed over the skin. With the process and the related measuring system, the blood alcohol level can be determined with a good degree of precision indirectly via the quantity of (gaseous) ethanol emitted through the skin.

Owner:MOLLER MEDICAL +2

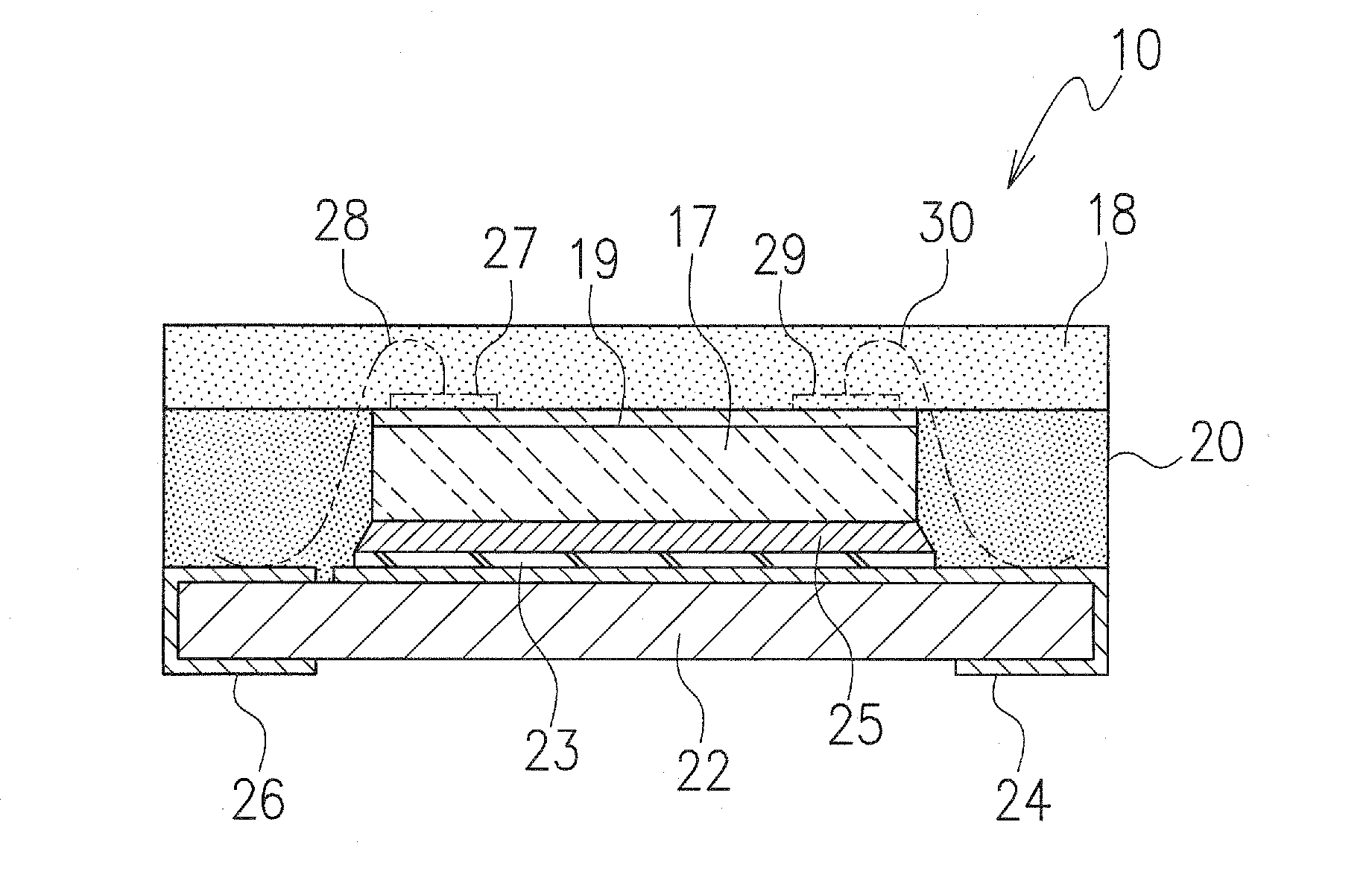

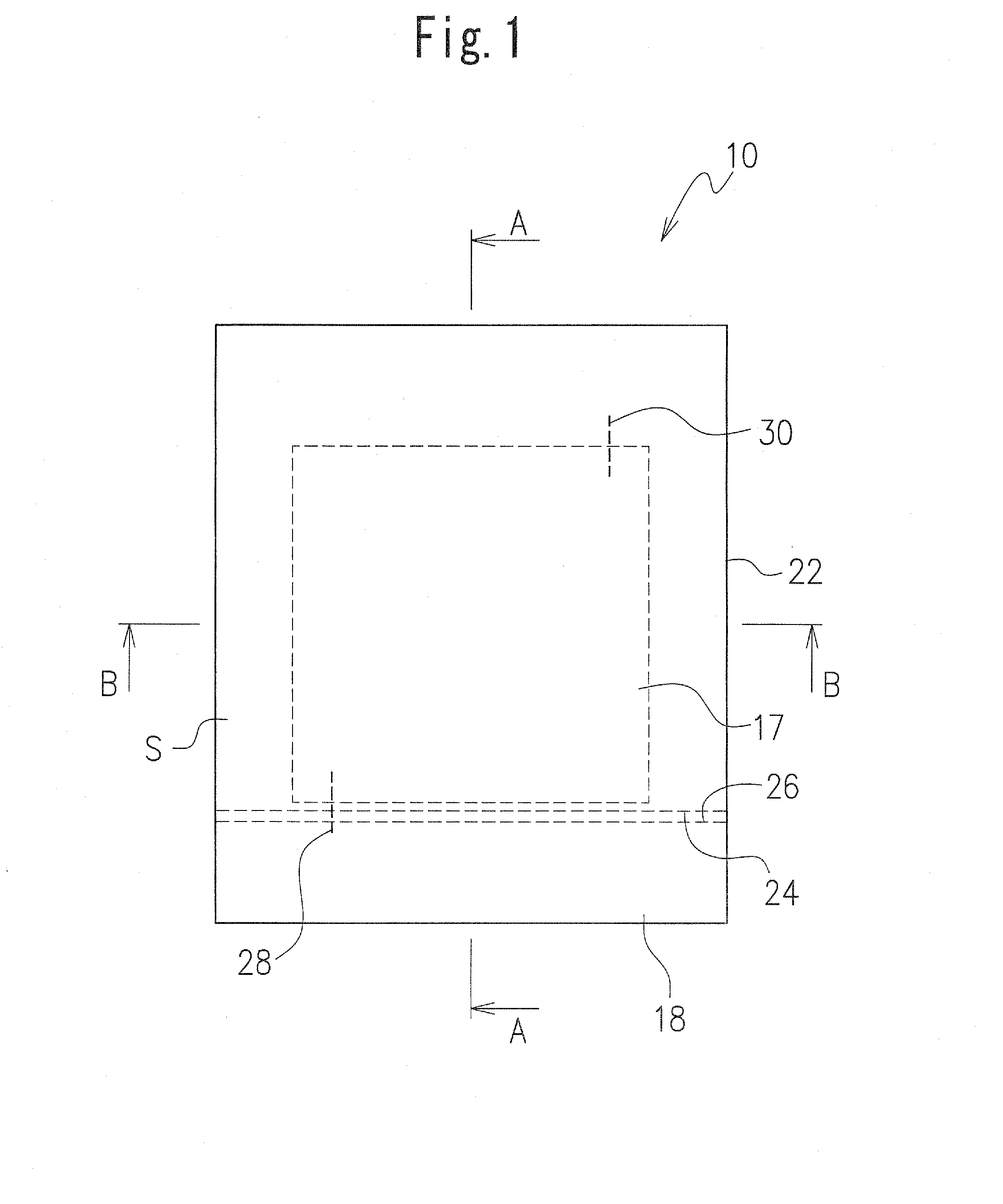

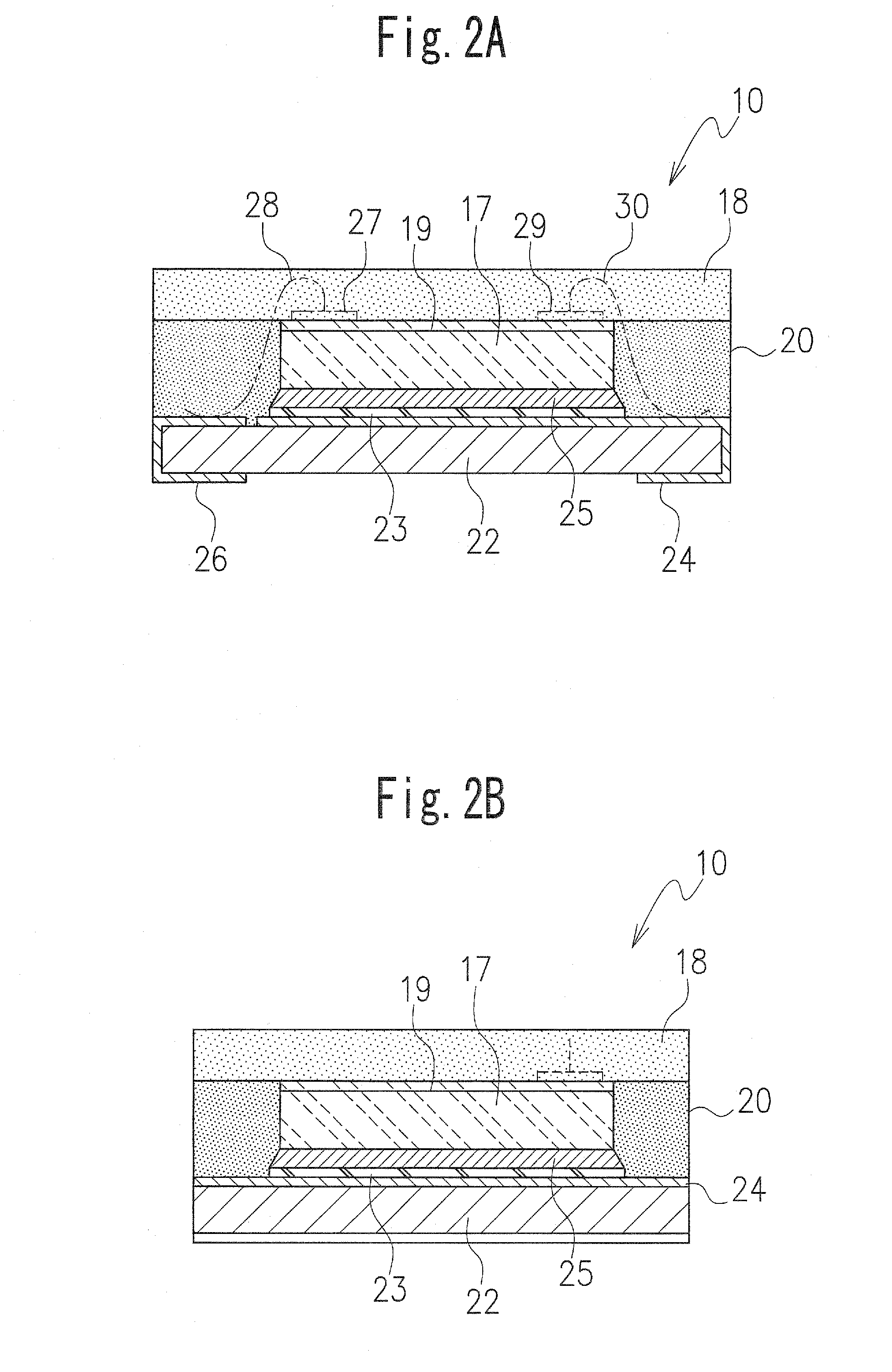

Light-emitting diode and method for producing it

InactiveUS20080254650A1Improve emission efficiencyMiniaturizationPrinted circuit assemblingSolid-state devicesEngineeringPrinted circuit board

An LED includes a printed circuit board, at least one LED element including a junction and mounted on the printed circuit board, a first sealing member disposed to cover side surfaces of the LED element, and a second sealing member disposed to cover side surfaces of the LED element. The first sealing member is configured to reflect and shield light emitted from the junction of the LED element, and the second sealing member is configured to transmit light emitted from the LED element.

Owner:CITIZEN ELECTRONICS CO LTD

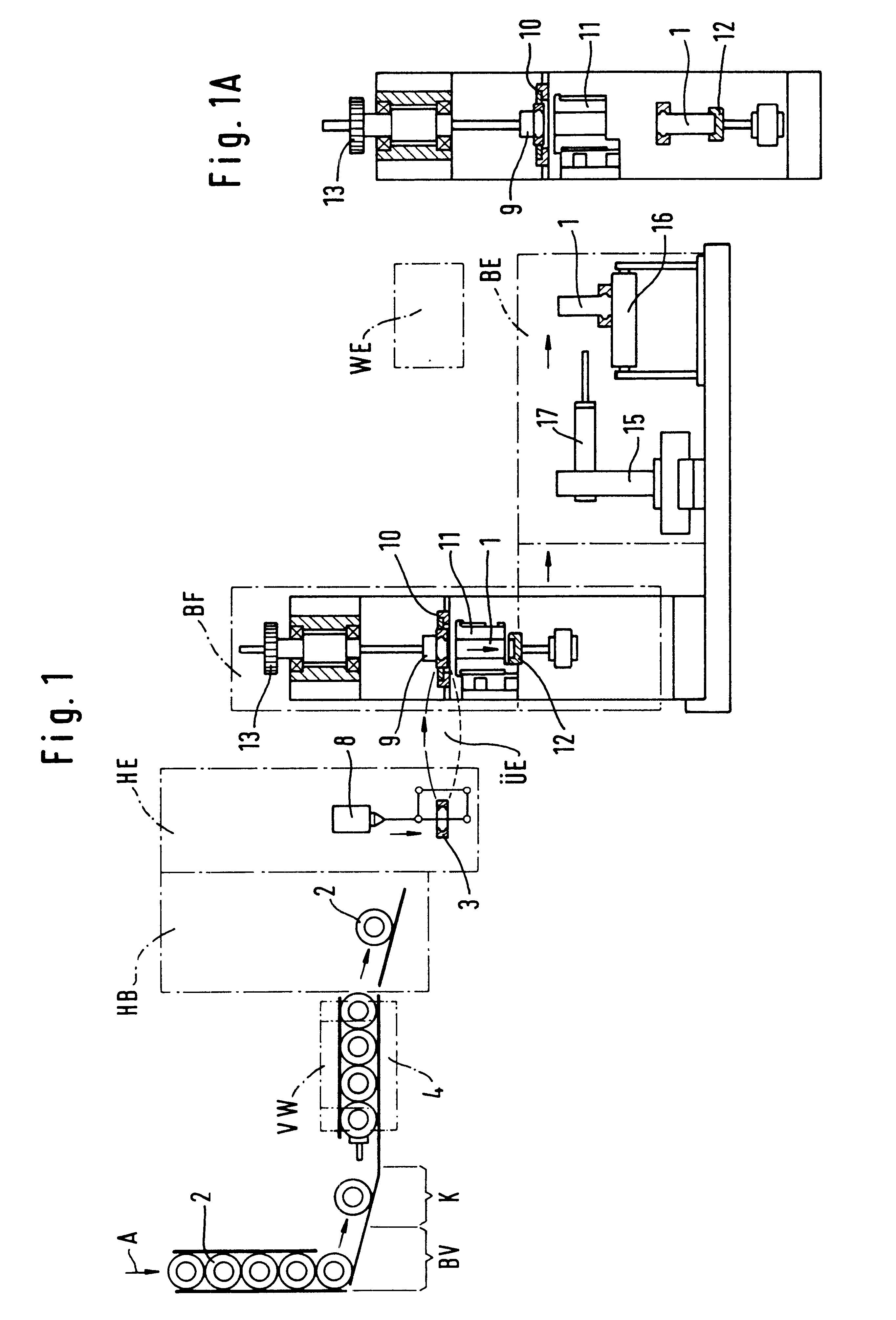

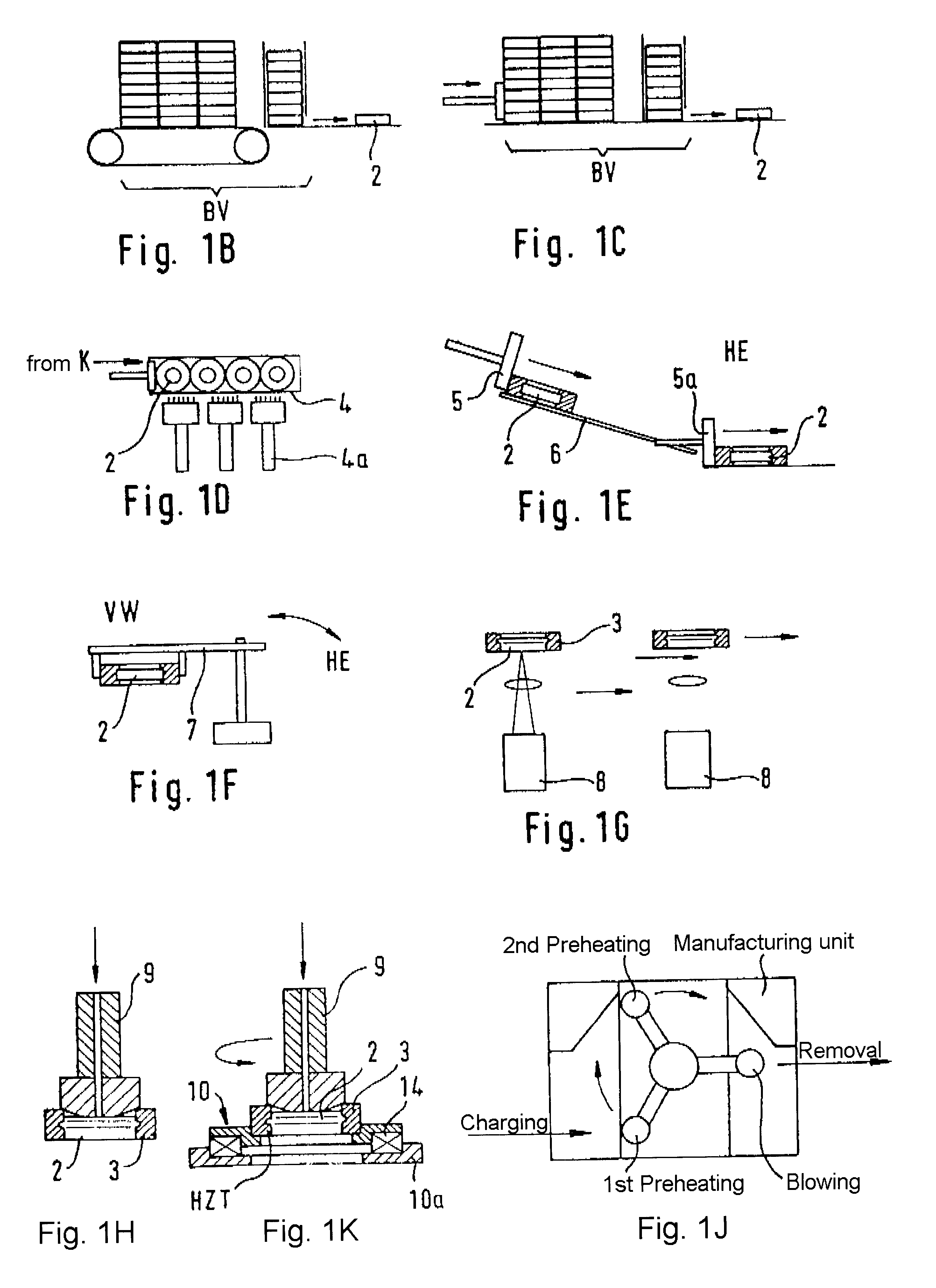

Method for producing glass goblets, tumblers and similar hollow glasses, and corresponding device for carrying out said method

InactiveUS6497119B1Cheap productionInexpensive productionBlowing machine gearingsGlass drawing apparatusBlow moldingEngineering

A device and process for forming hollow glassware comprising producing solid glass blanks in a manufacturing line, storing the blanks, feeding the blanks to a manufacturing line for forming hollow glassware, preheating the blanks during the feeding step, supplying the preheated blanks to a heating stage, heating to form solid plastically deformable glass globs, transferring the glass gobs to a blow molding stage and blow molding the glass gobs supported by a bottom lifter in a blow mold.

Owner:SCHOTT ZWIESEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com