Patents

Literature

204results about How to "Not easy to waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

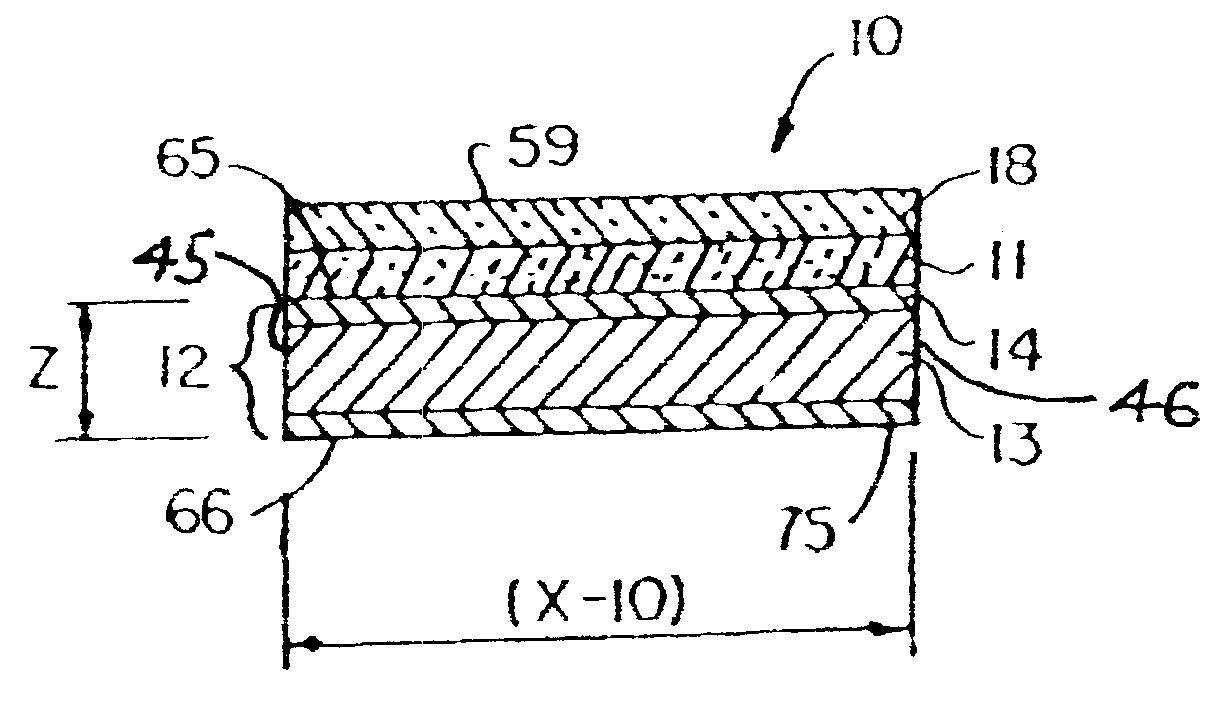

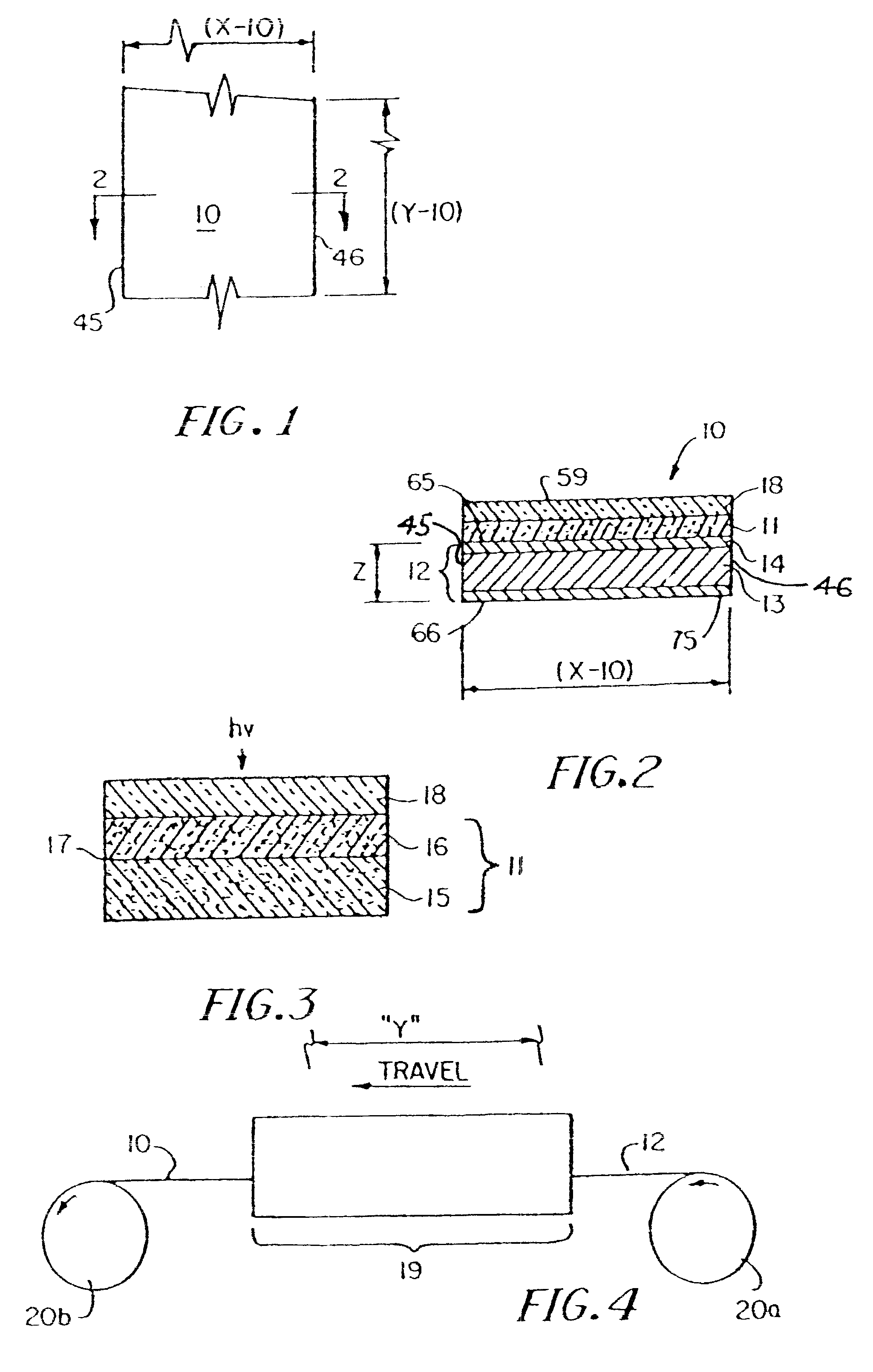

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS6459032B1Eliminate deficienciesCheap productionPV power plantsSolid-state devicesMaterial removalEngineering

This invention comprises deposition of thin film photovoltaic junctions on conductive foil substrates which can be heat treated following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation, an interconnection substrate structure is produced in a continuous roll-to-roll fashion. The conductive foil supported photovoltaic junction is then laminated to the interconnection substrate structure and conductive connections are deposited to complete the module or array. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials since it does not have to endure high temperature exposure. Furthermore, the photovoltaic junction and its conductive foil support can be produced in bulk without the need to use the expensive and intricate material removal operations currently taught in the art to achieve series interconnections.

Owner:SOLANNEX

Method of plating and pretreating aluminium workpieces

InactiveUS6846401B2Increasing Al-ion concentrationClean enoughDuplicating/marking methodsSurface reaction electrolytic coatingPre treatmentElectroplating

A method for applying a metal layer onto at least one surface of an aluminium or aluminium alloy workpiece, including the steps of pretreating the surface and applying the metal layer by plating, wherein the pretreating step includes a non-electrolytic treatment by immersion of the workpiece in a single acidic solution, preferably a sulphuric acid solution, having a temperature of at most 100° C. A brazed assembly comprising at least one component of an aluminium workpiece made by this method is also disclosed.

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

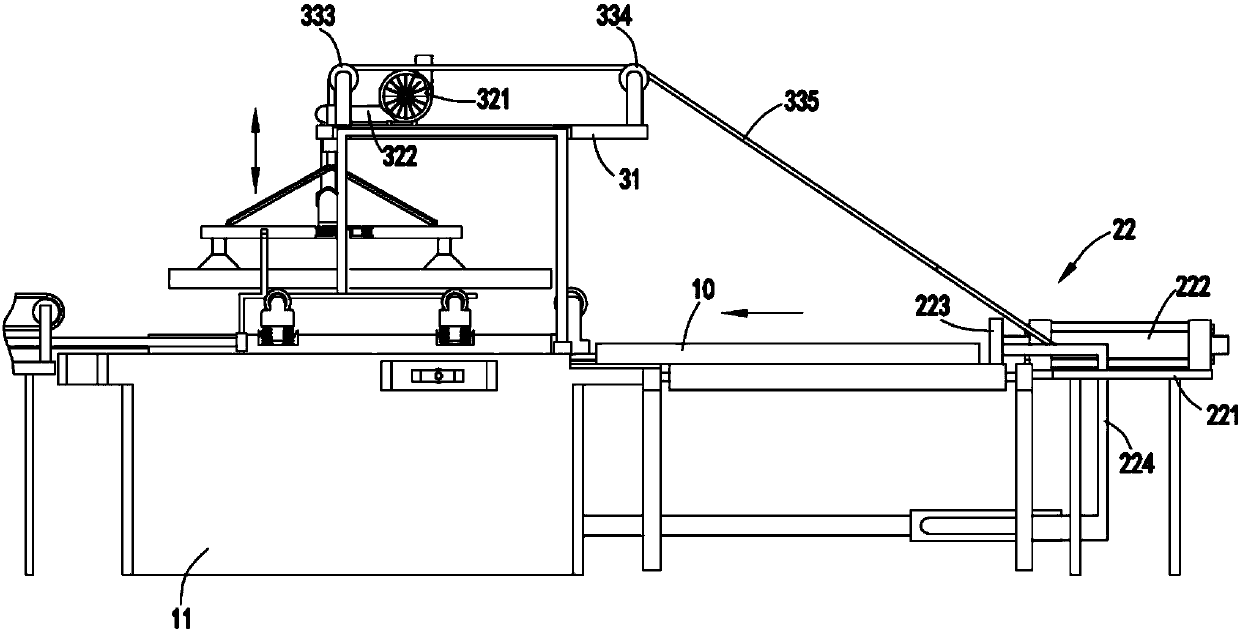

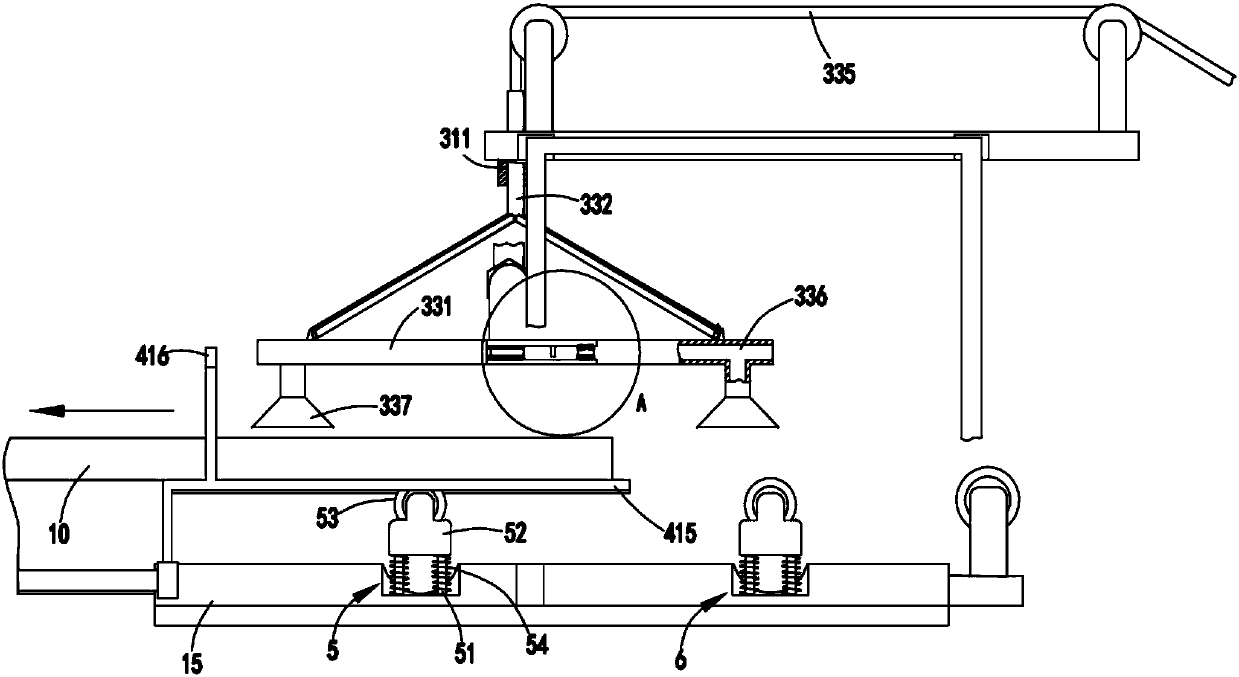

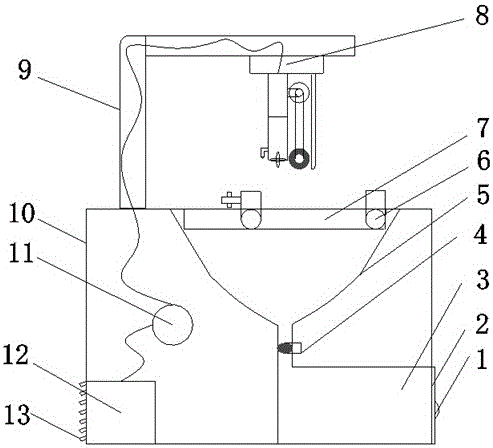

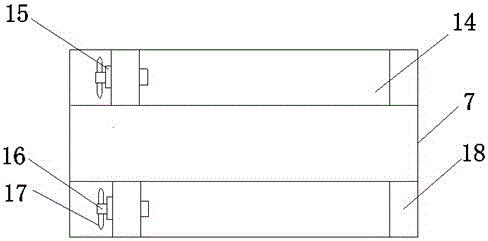

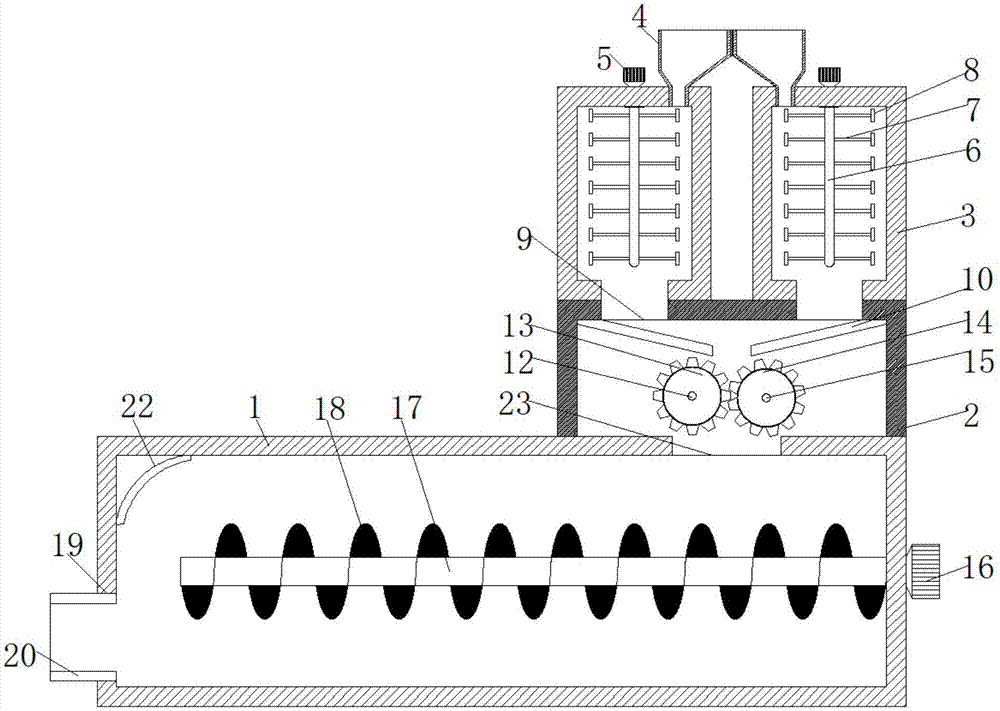

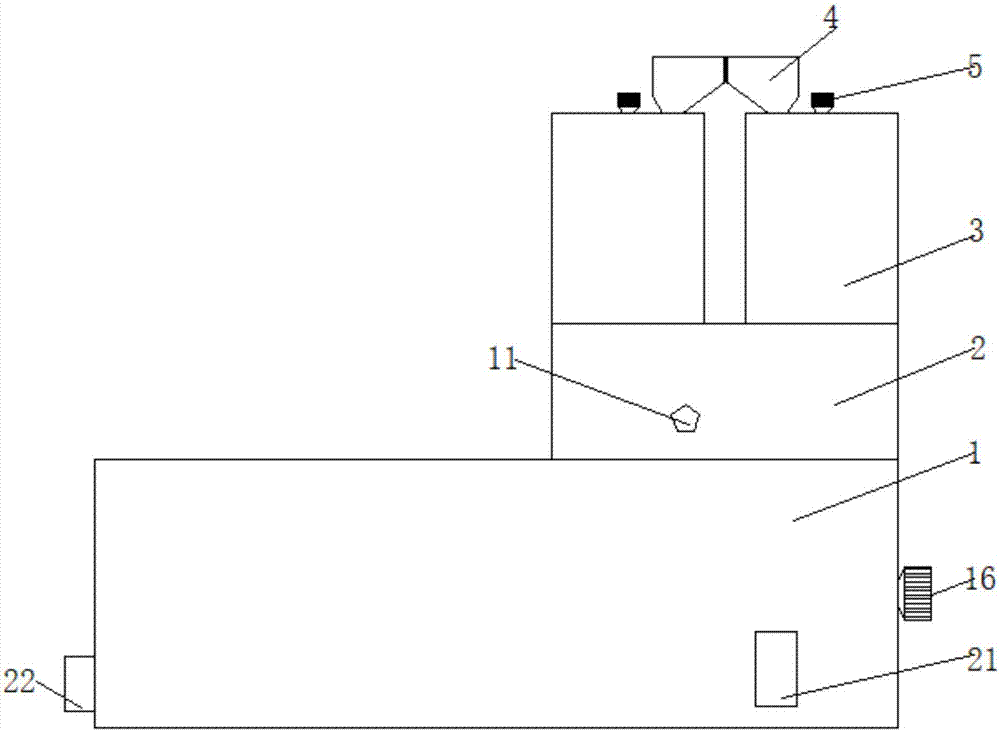

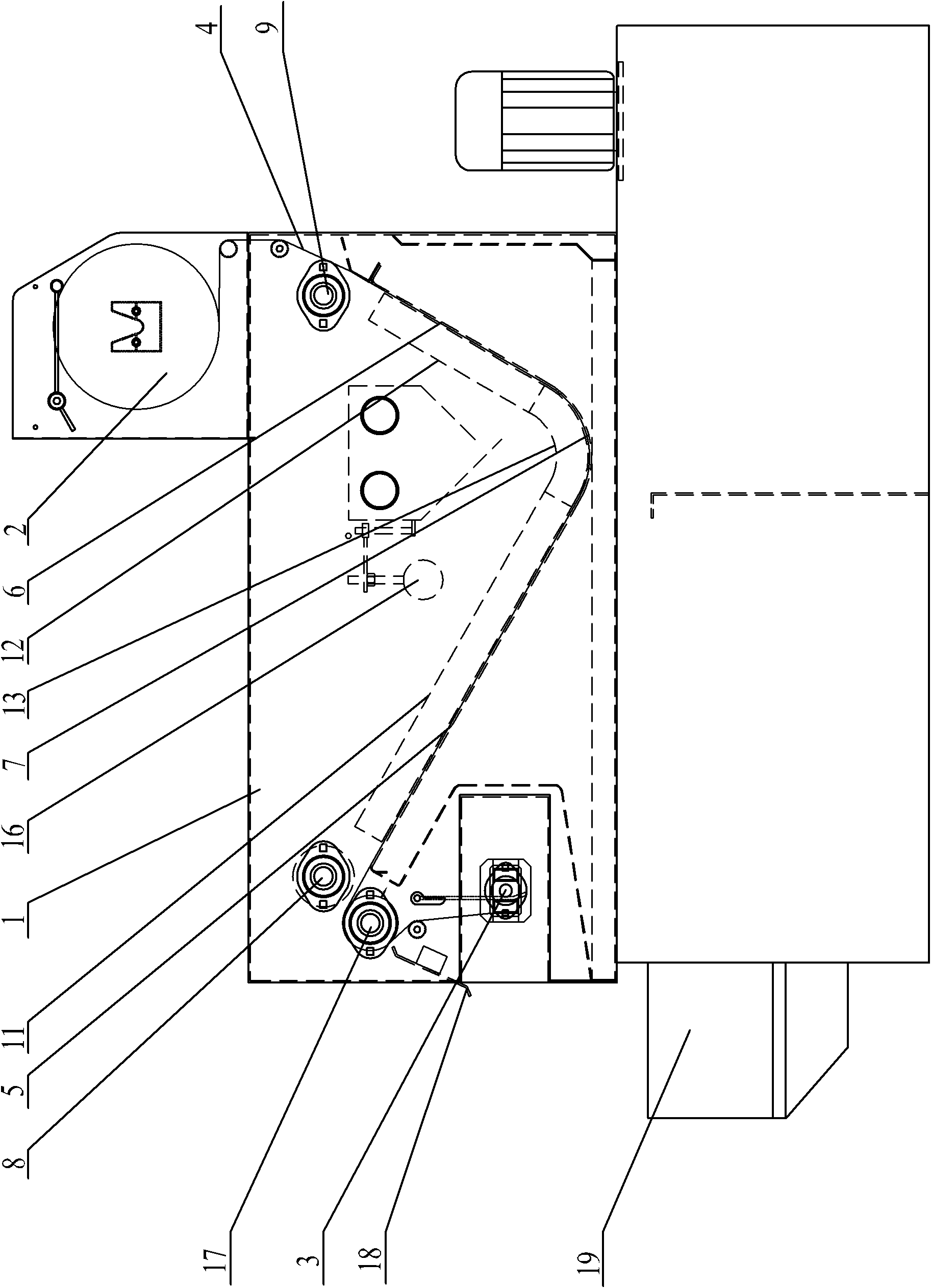

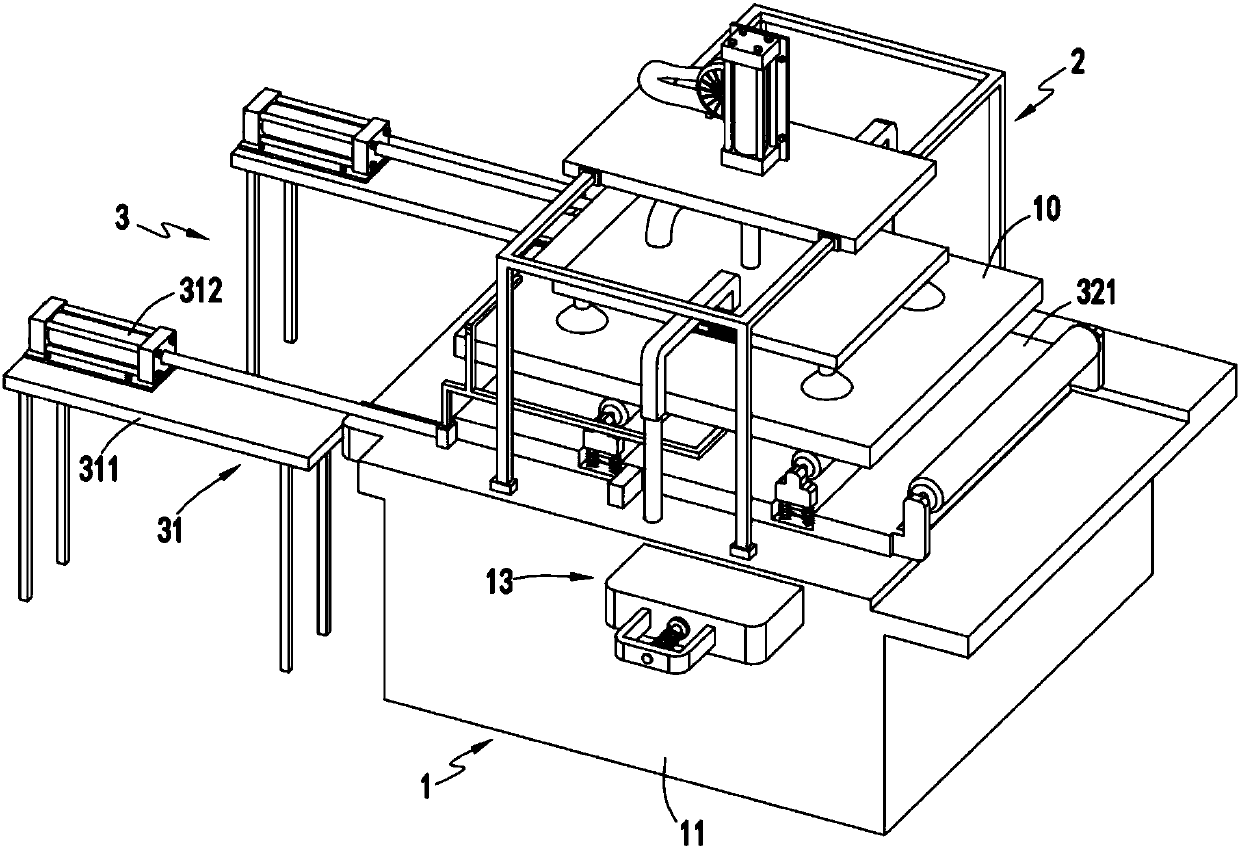

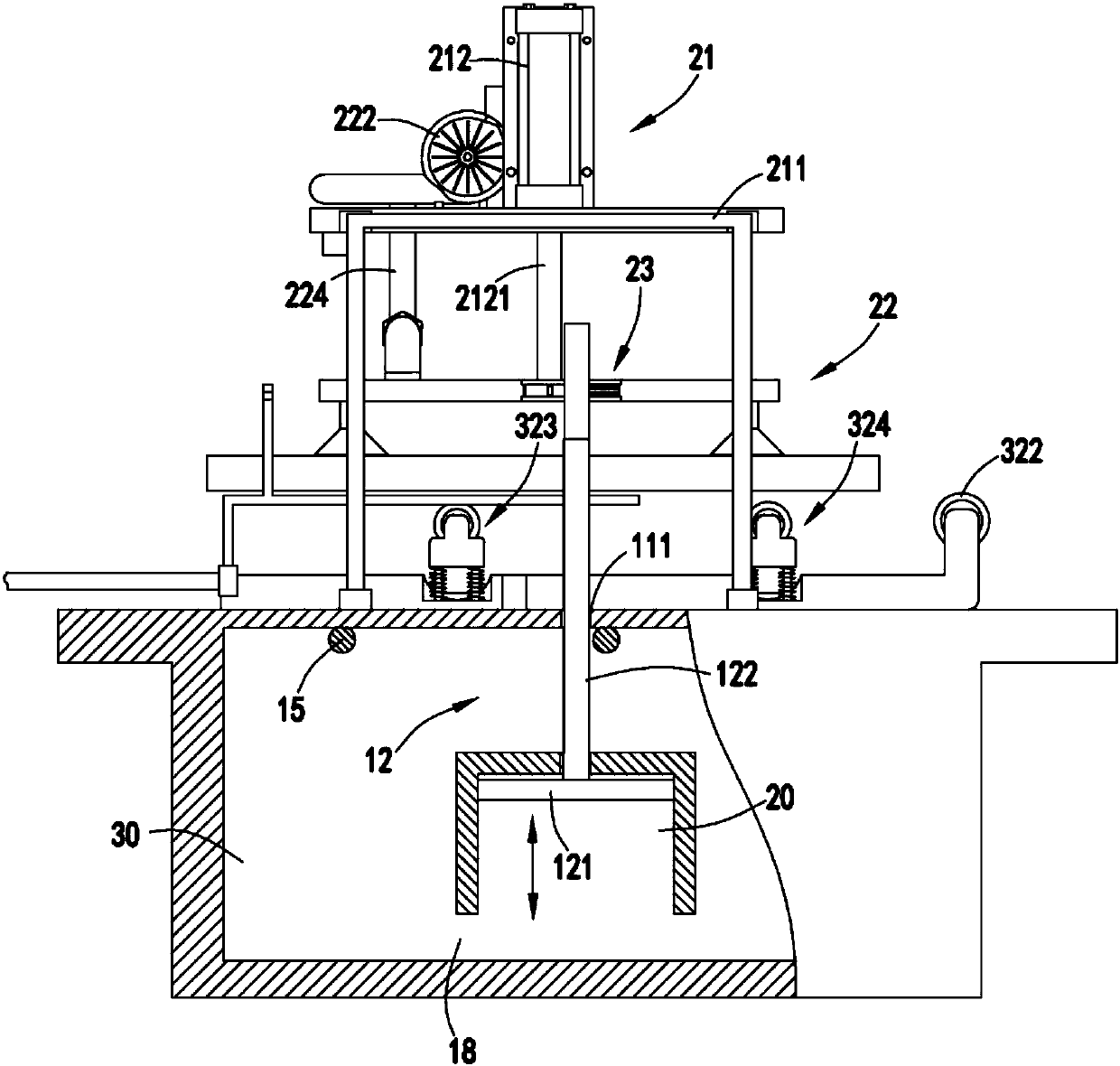

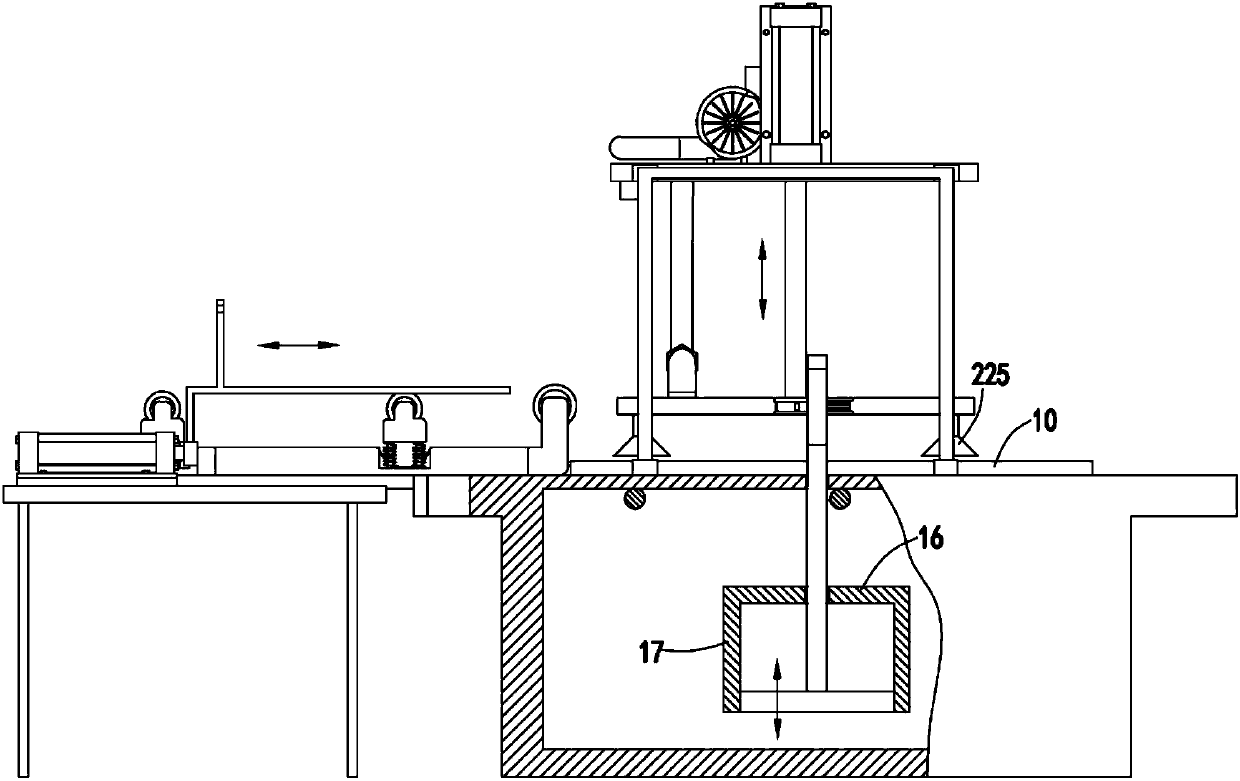

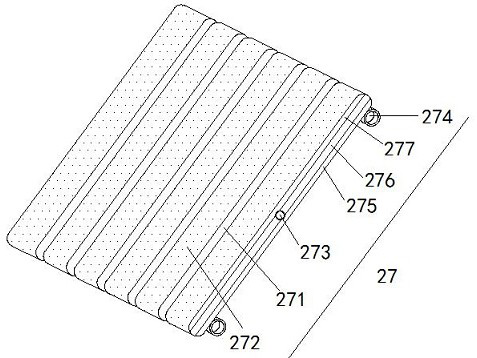

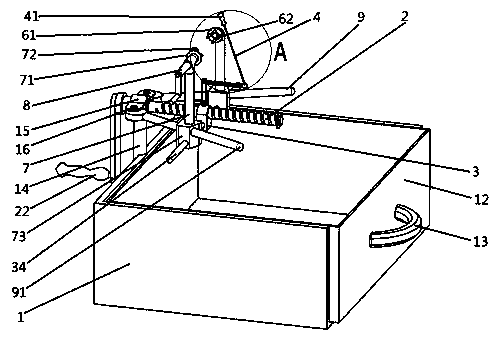

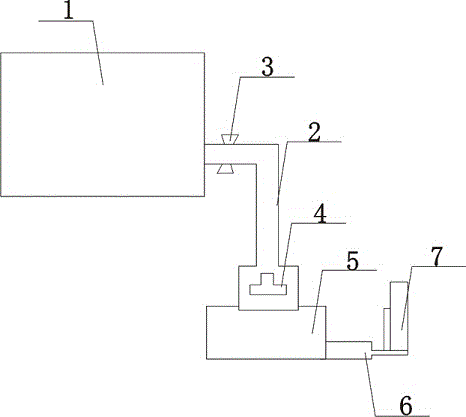

Automatic plate production device

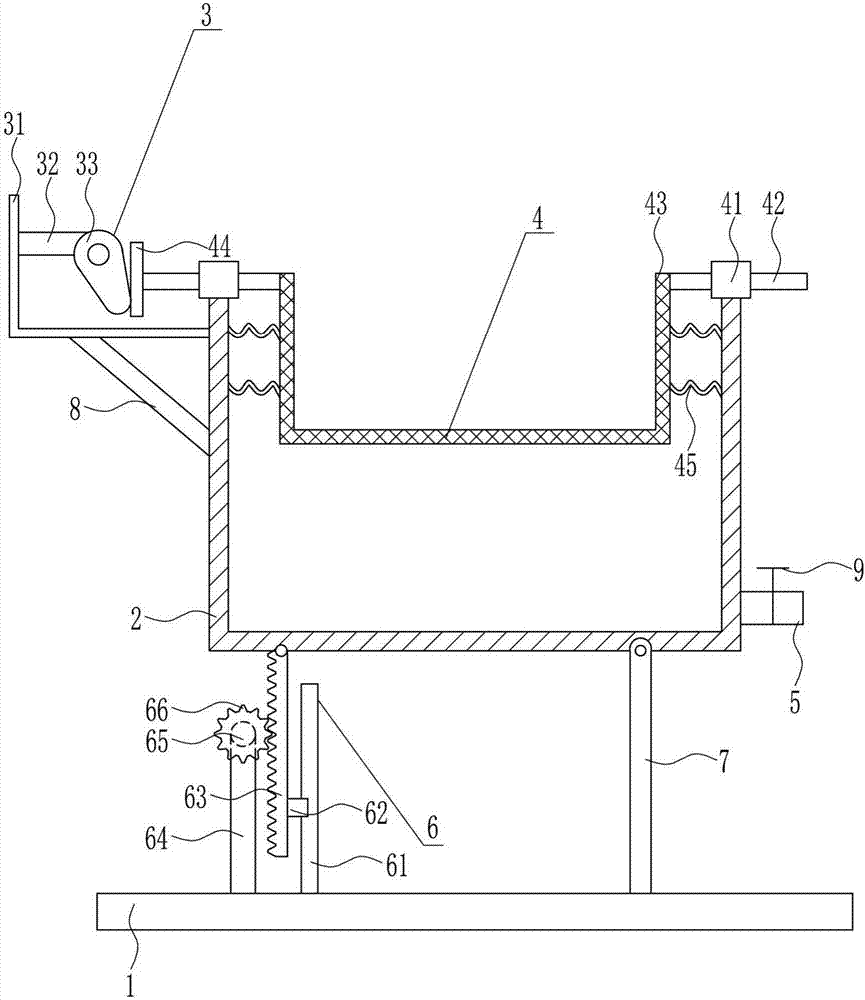

The invention relates to an automatic plate production device which comprises a coating device, a feeding device, an absorption device and an output device. The coating device comprises a coating box,a squeezing mechanism and an overflowing mechanism, wherein the squeezing mechanism is arranged in the coating box and squeezes the coating in the coating box, and the overflowing mechanism is arranged on the side edge of the coating box; and the coating box is provided with an opening, and the opening is provided with a cover plate. The feeding device is arranged at the front end of the coatingbox and comprises a feeding roller set and a push mechanism, wherein the push mechanism pushes a plate to move along the upper end of the opening and meanwhile pushes the plate to move away. The absorption device is arranged on the coating box and comprises a bracket, a suction mechanism and an absorption mechanism, wherein the suction mechanism and the absorption mechanism are installed on the bracket; and the absorption mechanism absorbs the coated plate and drives the plate to move upwards. The output mechanism is arranged at the rear end of the coating box and comprises a push-pull mechanism and a conveyer belt, and the push-pull mechanism pushes the cover plate to cover the opening and drives the plate to the conveyer belt to be output in the reset process. By means of the automatic plate production device, the problems that the operation of plate coating is troublesome, the coating is prone to falling, waste is caused, coating efficiency is low, and a coating layer is prone to bedamaged are solved.

Owner:爱耐福(山东)新材料科技有限公司

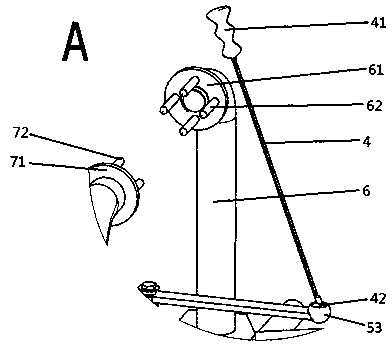

Small-scale automatic feeding device for pet birds

Owner:浏阳市恒泰烟花贸易有限公司

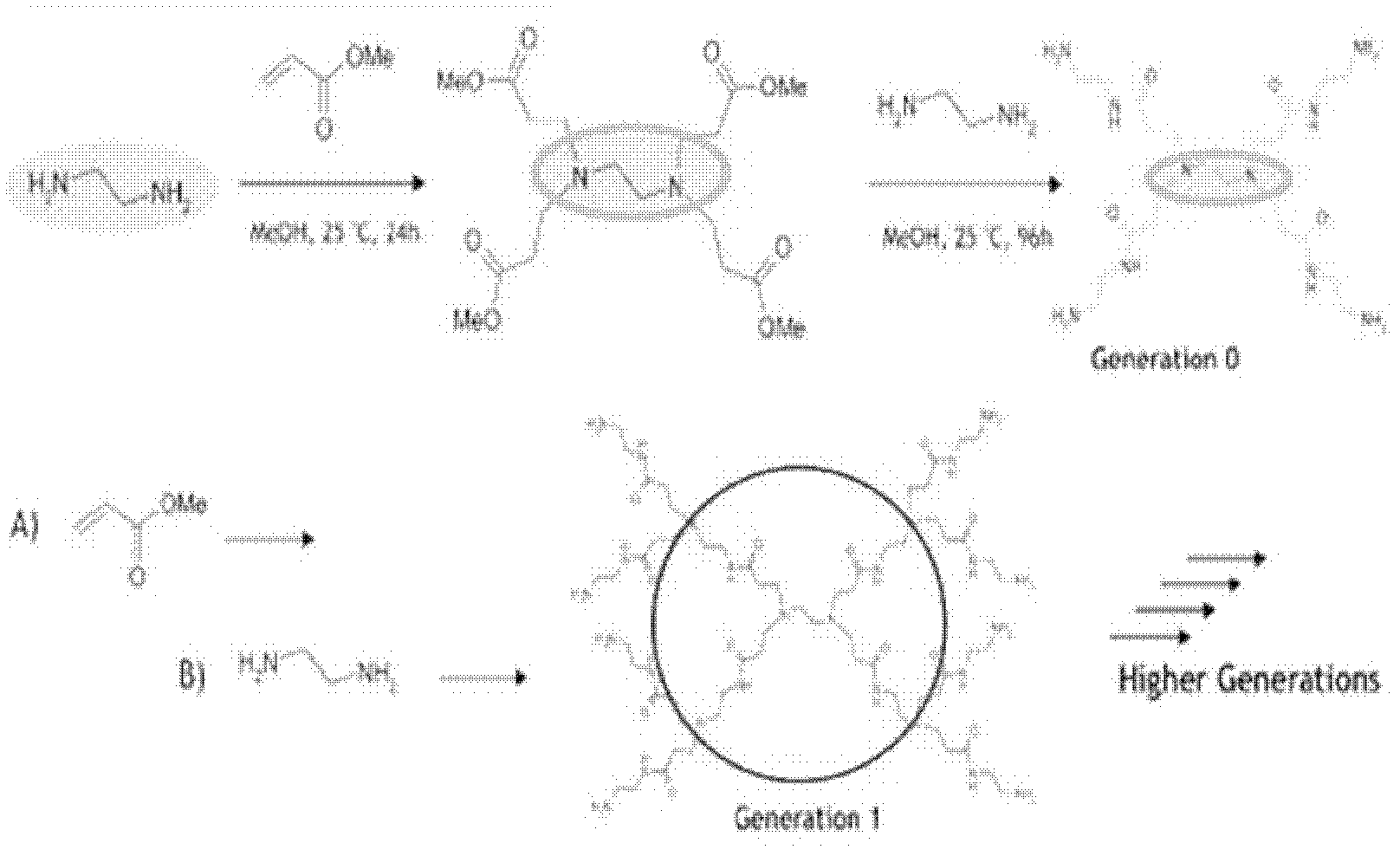

Activation method for electromagnetic shielding fabrics before chemical plating based on PAMAM (polyamidoamine)/ palladium ligand

InactiveCN102634778ANot easy to fall offSolve associativityMagnetic/electric field screeningFibre treatmentActivation methodChemical plating

The invention relates to an activation method for electromagnetic shielding fabrics before chemical plating based on PAMAM (polyamidoamine) / palladium ligand. The activation method includes four steps of preparing PAMAM dendrimer solution; preparing dendrimer PAMAM-palladium activating finishing liquor; performing fabric activation; and performing chemical plating. Compared with the prior art, theinvention provides a simple, convenient and stable preparation method for an activating agent with a high-efficient catalysis effect and the activation processing method before chemical plating. Accordingly, the activation method has excellent advantages that metal chemical initial plating of the electromagnetic shielding fabrics is easy, a plating layer is uniform and firm, and the like.

Owner:SHANGHAI UNIV OF ENG SCI

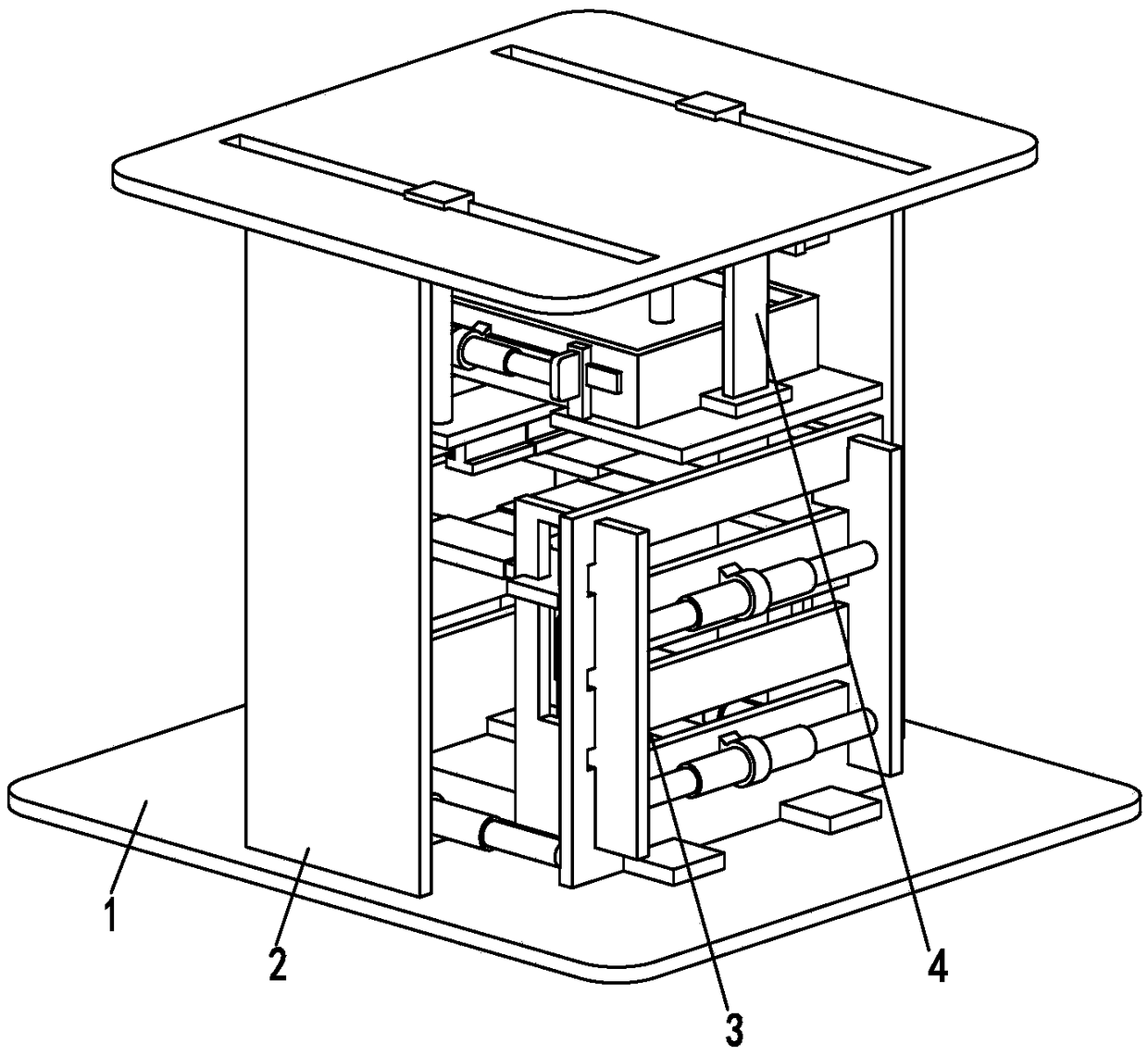

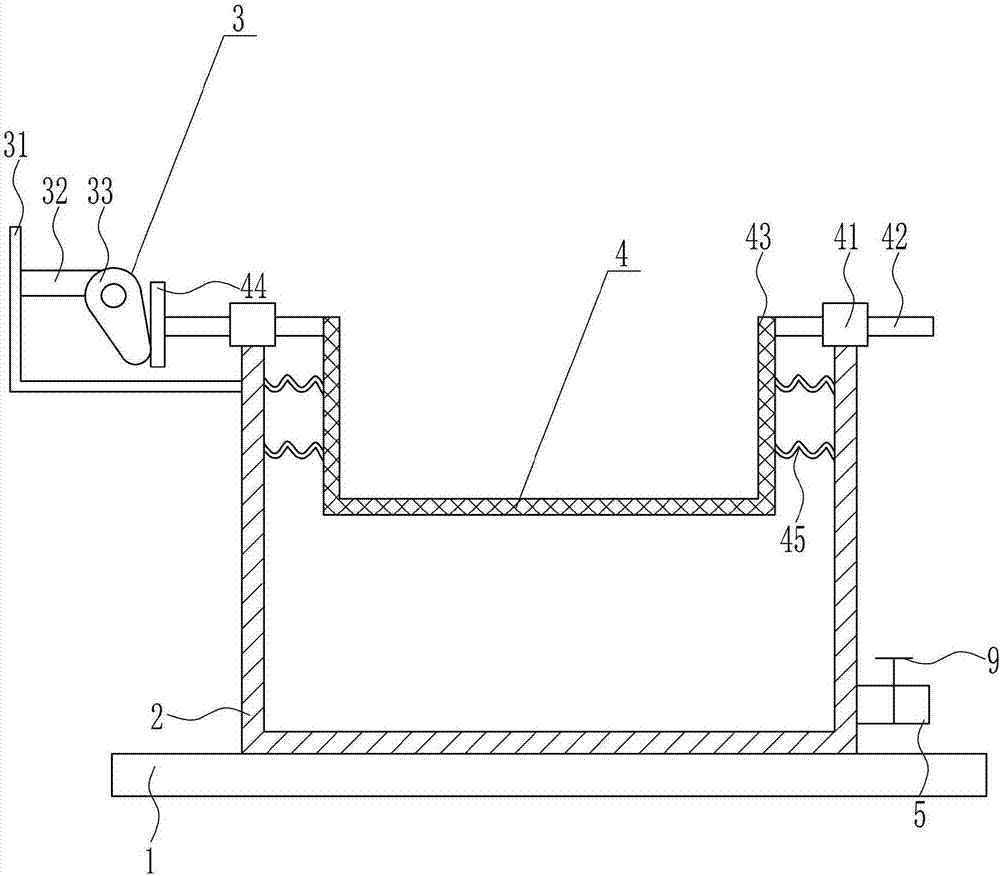

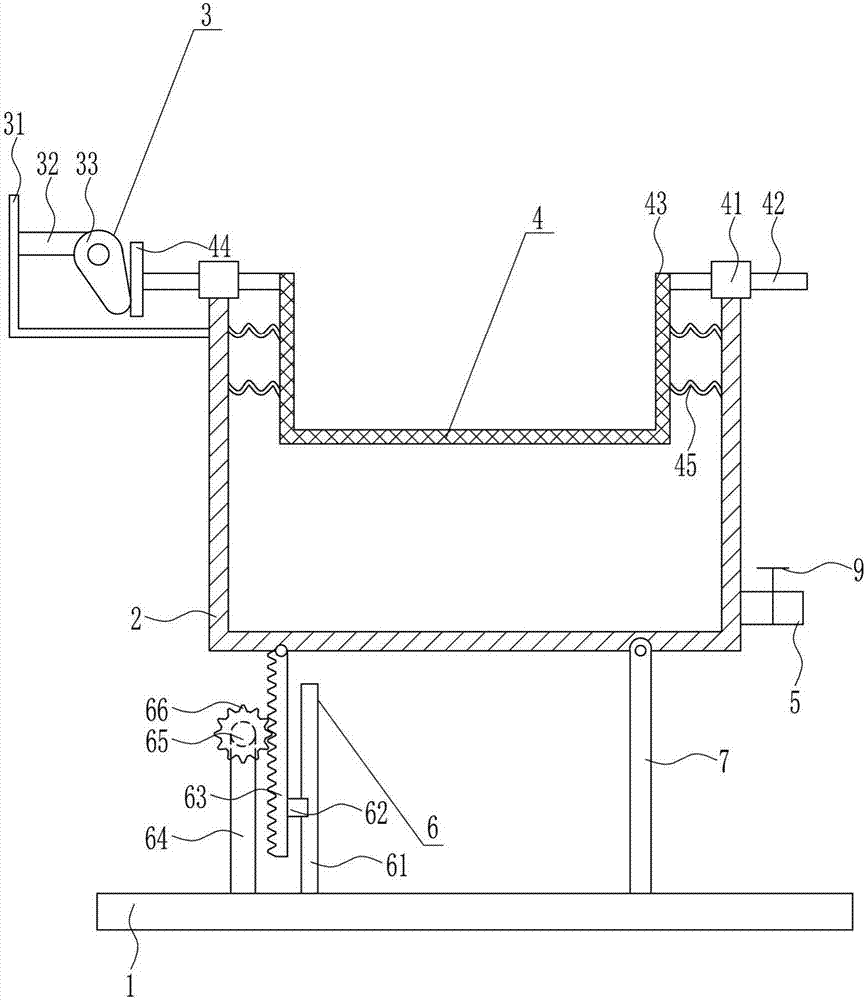

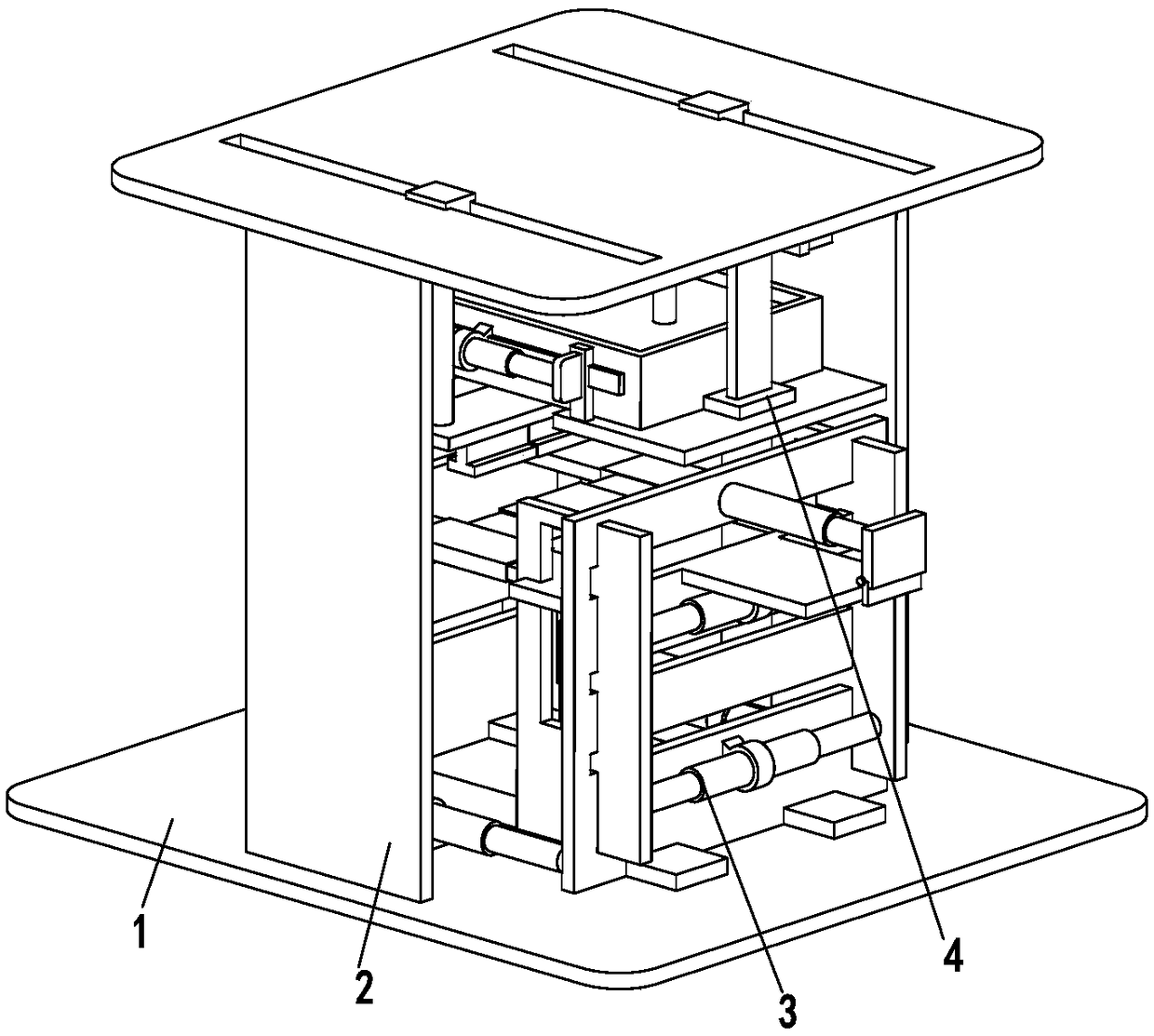

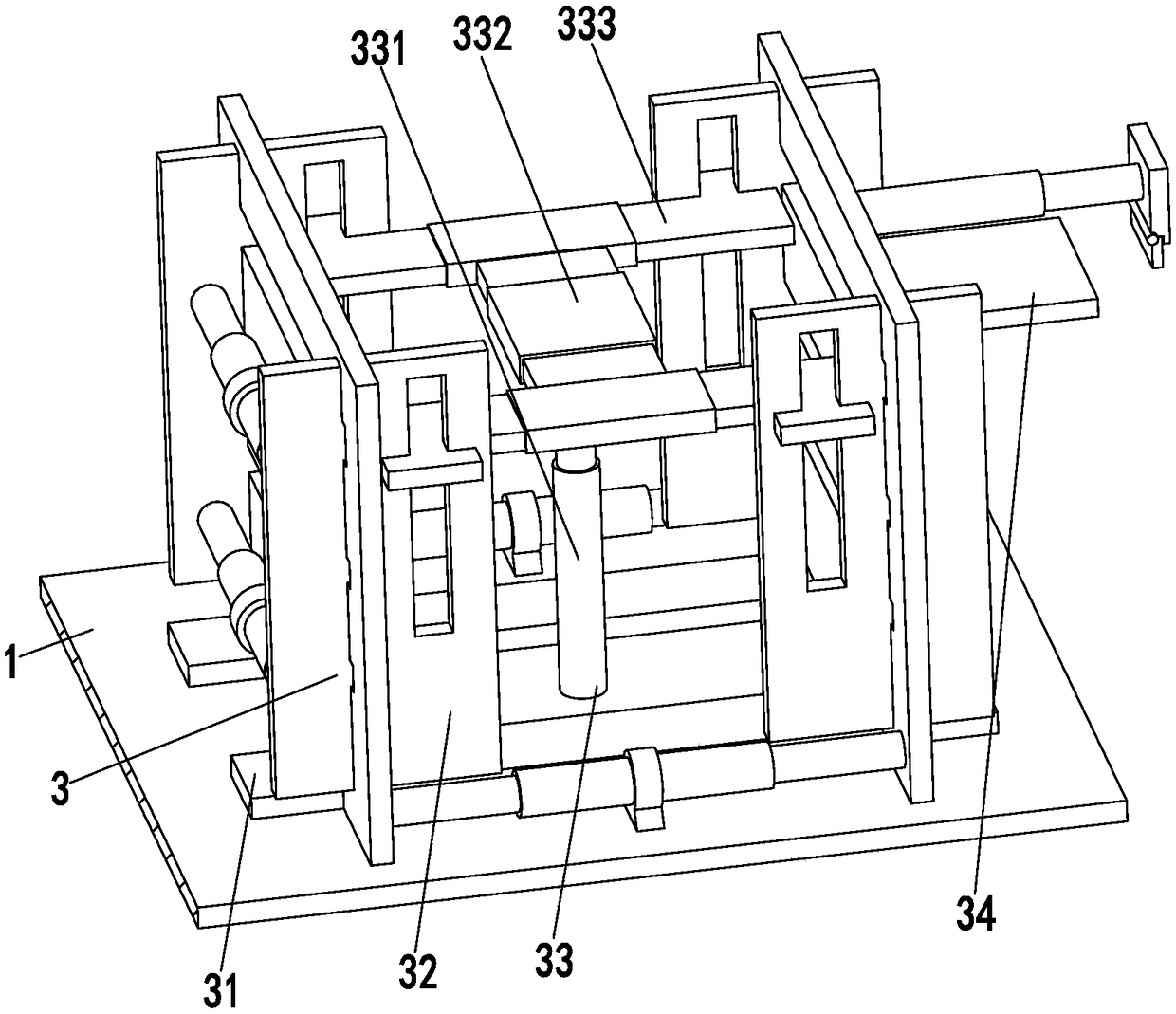

Composite board automatic gluing device

ActiveCN108656260AMeet work needsAvoid affecting work progressAdhesive application devicesEngineeringMechanical engineering

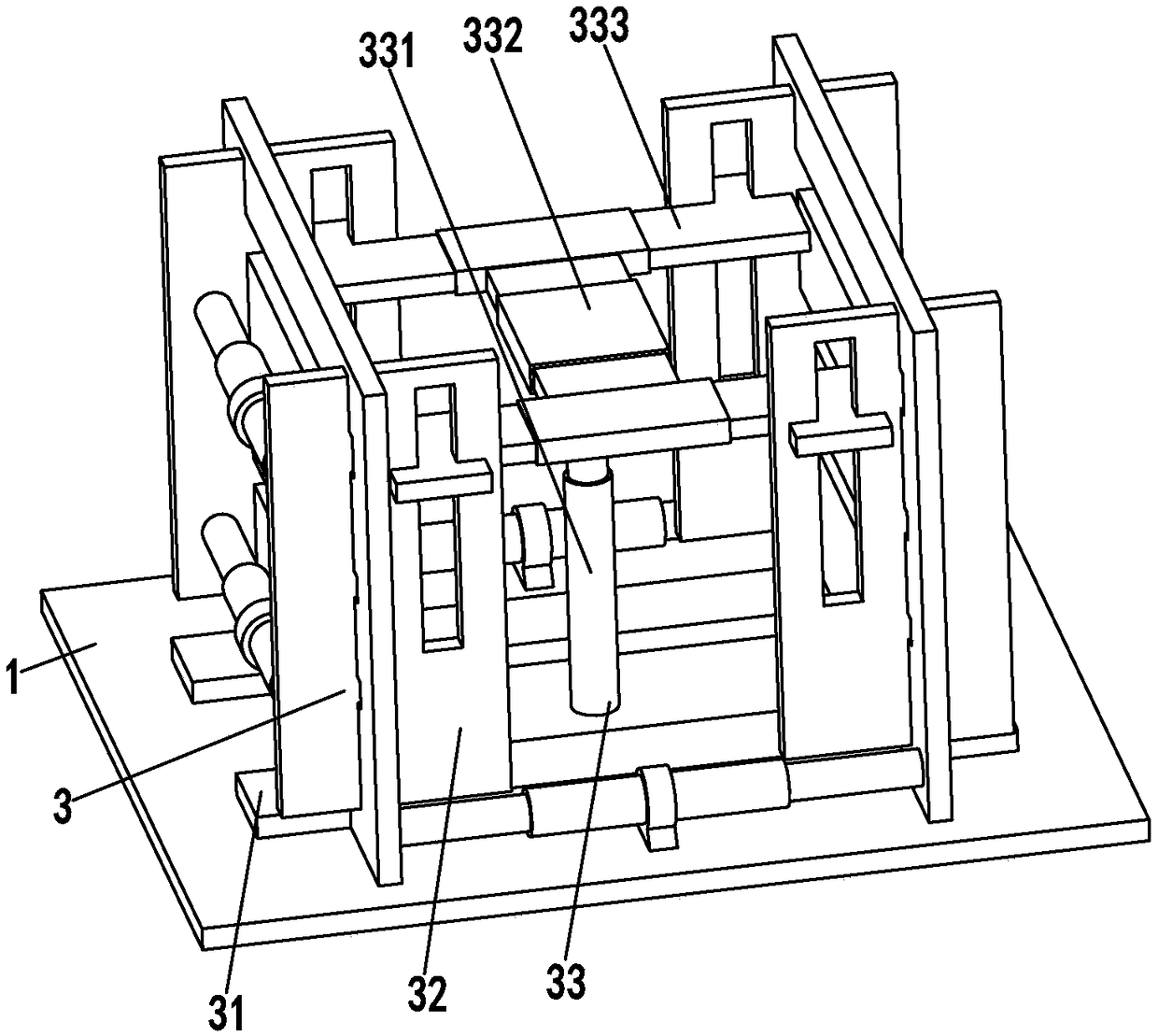

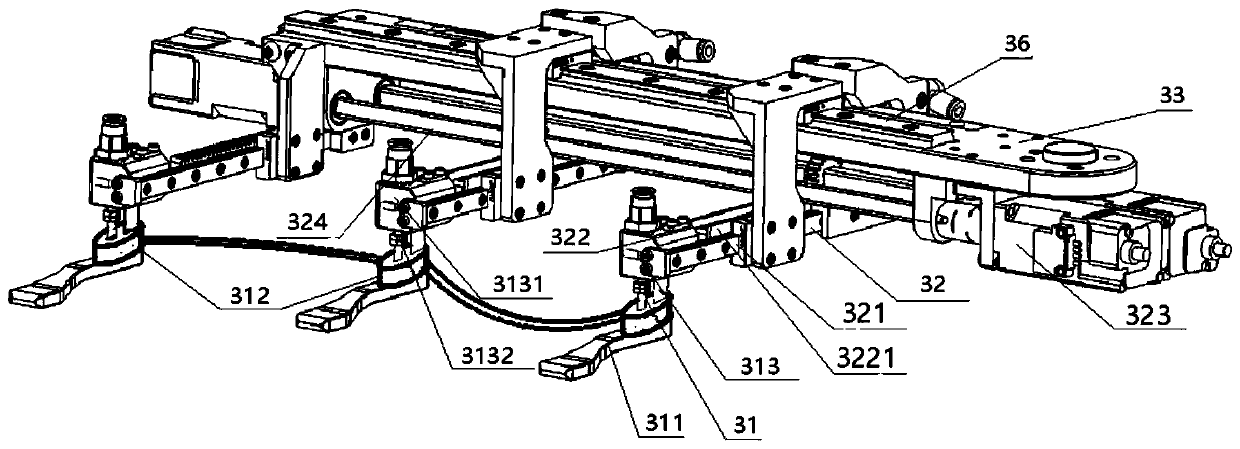

The invention relates to a composite board automatic gluing device. The device comprises a bottom plate, a mounting rack, a stacking device and a gluing device; the mounting rack is installed on the bottom plate, sliding chutes are formed in the mounting rack, the gluing device is installed in the sliding chutes, and the stacking device is installed at the lower end of the gluing device; the stacking device is installed on the bottom plate, and the stacking device comprises a linear guide rail, a limiting mechanism and a supporting mechanism; the gluing device comprises a glue discharging mechanism and a leveling mechanism; and the leveling mechanism comprises sliding blocks, sliding rods, a transverse plate, a telescopic leveling frame, a fixed supporting plate, an adjusting length air cylinder, a connecting ring and a driving branched chain. According to the composite board automatic gluing device, the problems that board codes are not even, gluing are non-uniform, glue is easy to waste, the adjustability is poor and the like in an existing composite board gluing process are solved; and the function of automatically gluing the composite board can be achieved, and the device has the advantages of being neat in stacking, uniform in gluing, not easy to waste glue, and flexible to adjust.

Owner:江苏林德曼新材料科技有限公司

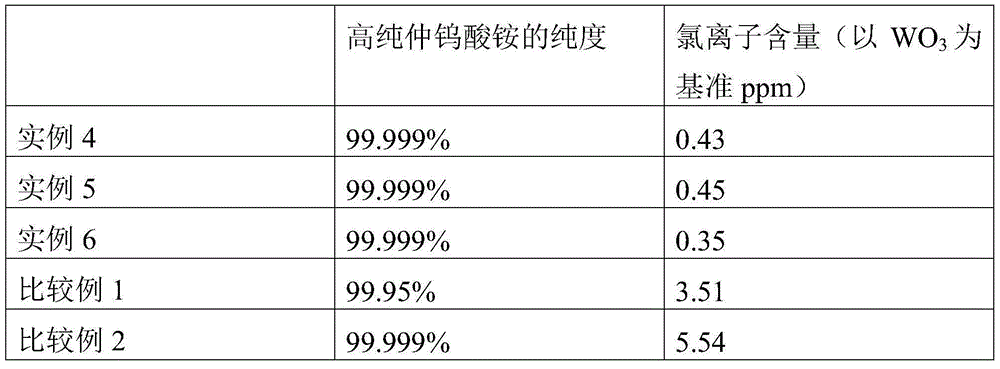

Method for removing impurities by deeply purifying ammonium paratungstate

The invention discloses a method for removing impurities by deeply purifying ammonium paratungstate. The method comprises the following steps of dissolving international zero-grade or first-grade ammonium paratungstate to prepare a to-be-treated solution; sequentially adsorbing the to-be-treated solution with cation exchange resin and anion exchange resin; then analyzing wolframate radical ions adsorbed by the anion exchange resin by using an analytical agent to obtain a analyzed solution; performing evaporation crystallization on the analyzed solution to obtain high-purity ammonium paratungstate. The method disclosed by the invention has the advantages of simple process, easiness in realization and wide application; in addition, the obtained ammonium paratungstate is high in purity.

Owner:CNMC GUANGXI PGMA

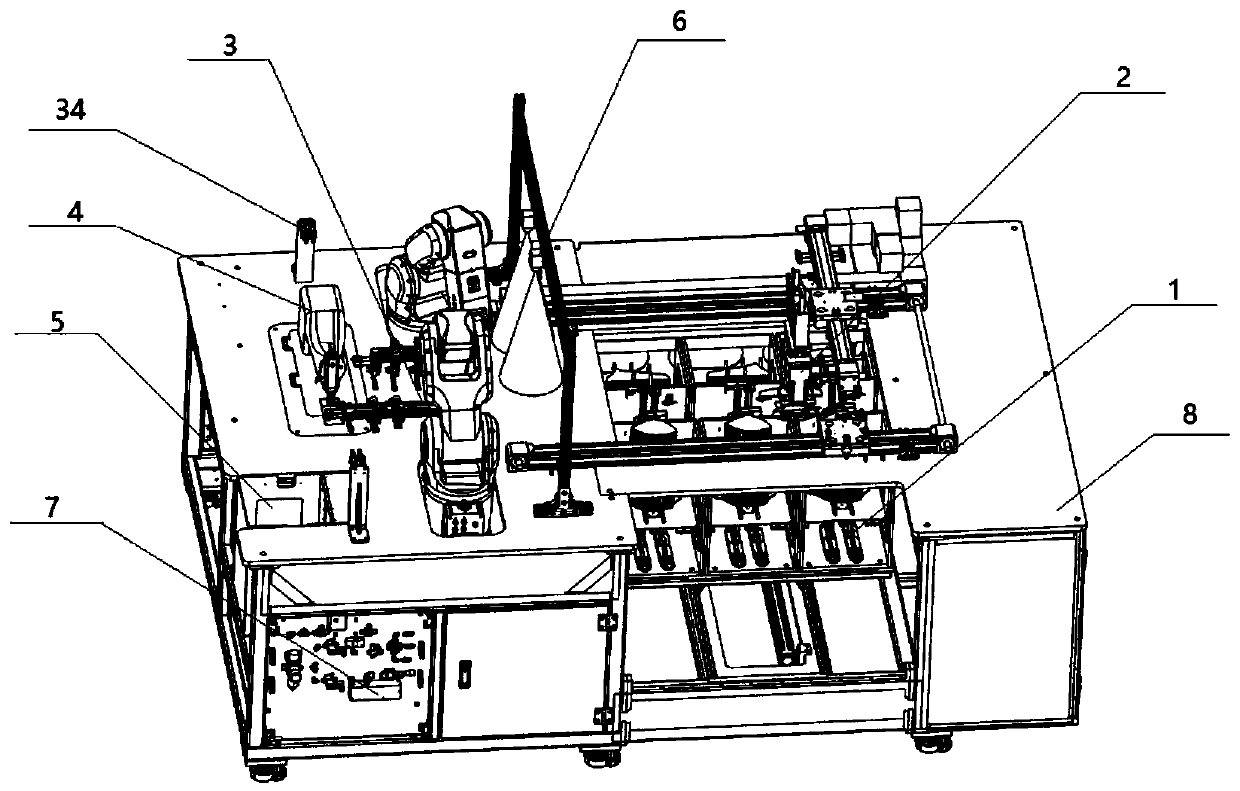

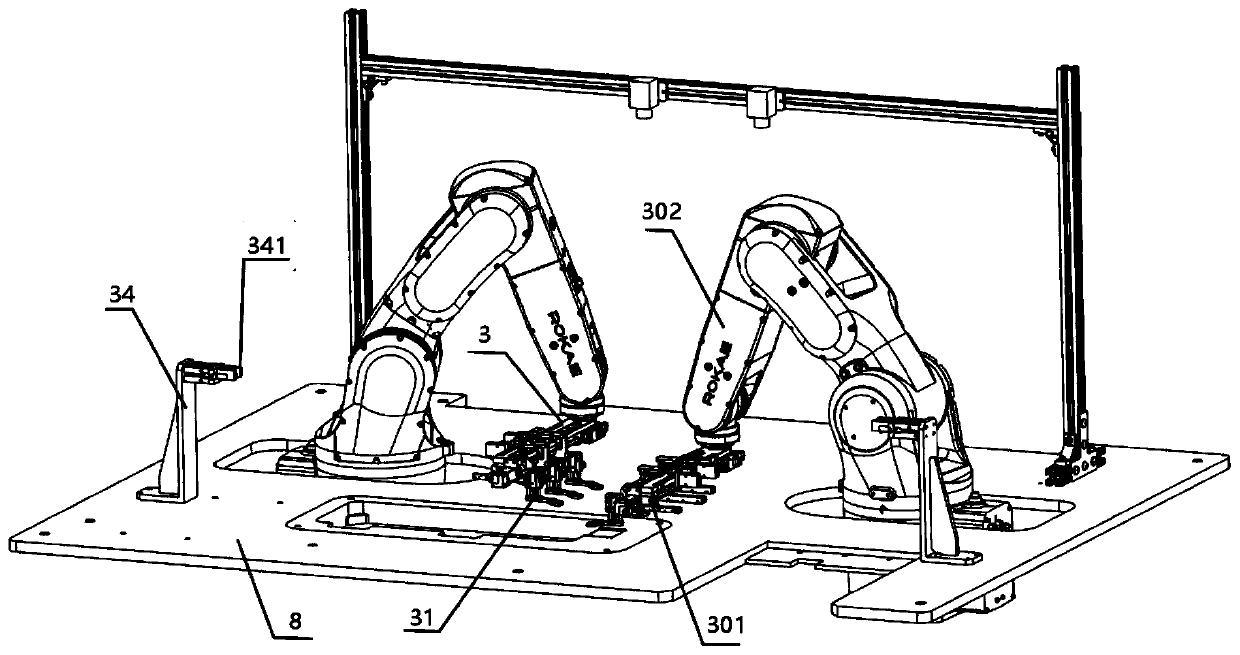

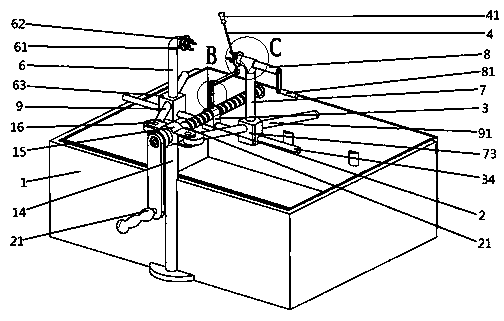

Sewing equipment and using method thereof

ActiveCN110820181ANot easy to wasteImprove work efficiencySewing-machine elementsControl systemVisual recognition

The invention relates to sewing equipment and a using method thereof. The sewing equipment comprise a workbench, two or more grabbing devices, sewing equipment, a visual recognition device and a control system, wherein the grabbing devices, the sewing equipment, the visual recognition device and the control system are respectively arranged on the workbench. The control system is respectively in signal connection with the grabbing devices, the sewing equipment and the visual recognition device and controls the operation of the grabbing devices, the sewing equipment and the visual recognition device; the visual recognition device recognizes the shape of cloth and feeds back the shape and size of the cloth to the control system; the control system controls the grabbing devices to adjust the grabbing angle and then convey the cloth to sewing equipment; the cloth is conveyed to the sewing equipment to be sewn; and the grabbing devices can keep pressing area on the cloth unchanged. By usingthe sewing equipment, the cloth can be fed, taken, grabbed, sewed and collected, the time and labor are saved, and the labor cost is reduced while the work efficiency is improved. Compared with manualsewing, the sewing equipment has the advantages that the finished product rate is high, and moreover, the smoothness of the cloth in the whole process can be guaranteed.

Owner:BEIJING HUAMEILI CLOTHING

Wet-and-dry automatic feeding trough

ActiveCN102763603AImprove toggle effectAvoid cakingAnimal feeding devicesEngineeringAnimal husbandry

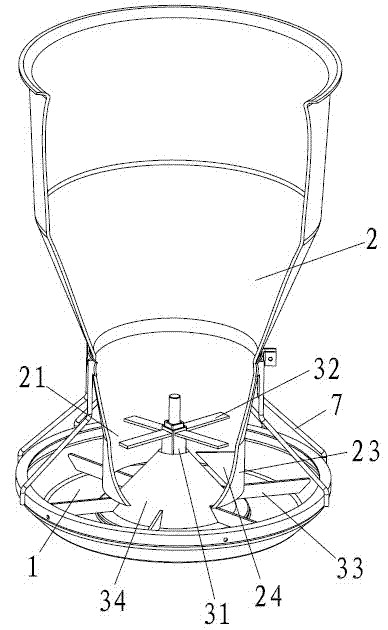

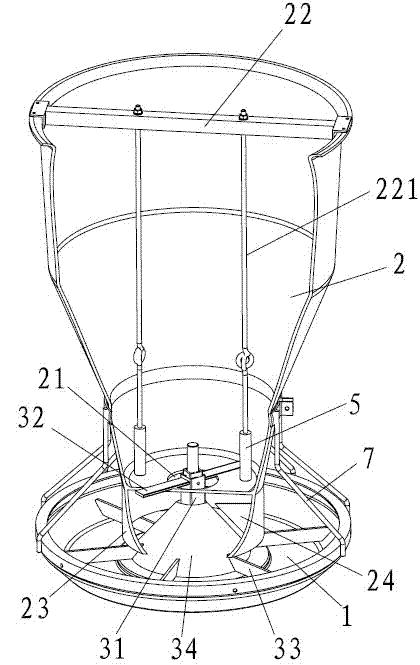

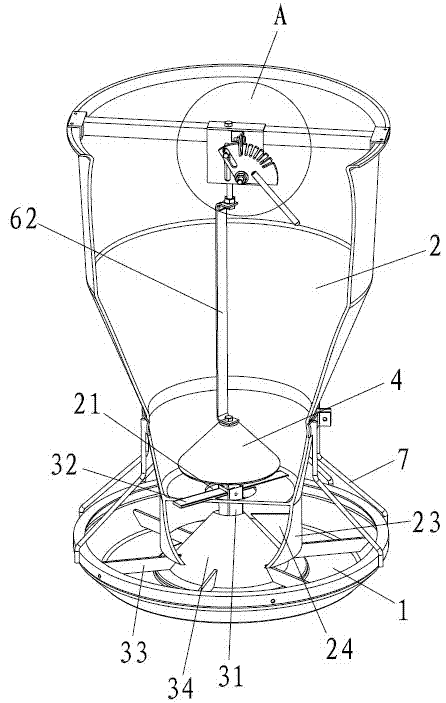

The invention relates to the technical field of animal husbandry equipment, and particularly relates to a wet-and-dry automatic feeding trough which is especially suitable for being applied to the feeding of live pigs. According to the technical scheme, the wet-and-dry automatic feeding trough comprises a feed trough, a feed basket and a driving lever structure, wherein the feed basket is arranged above the feed trough and provided with a discharge hole, and the driving lever structure is used for achieving an effect of automatic feeding; and the automatic feeding trough is characterized in that the driving lever structure comprises a rotating shaft, a rotating arm, a driving lever and a material dispersing platform, wherein the rotating arm is arranged on the rotating shaft and close to the discharge hole and extends outwards along the middle part of the discharge hole, the driving lever is arranged on the rotating shaft and used for driving the rotating arm to rotate through the rotating shaft, and the material dispersing platform is arranged below the discharge hole, sleeved on the exterior of the rotating shaft, linked with the driving lever, and used for enabling feeds to slide towards the periphery of the feed trough along the rotating shaft in the horizontal direction. The automatic feeding trough disclosed by the invention has the advantages of uniformity in feeding, smoothness in feeding and blocking avoidance, and is suitable for not only dry feeds, but also wet feeds.

Owner:COMAX LIVESTOCK TECH JIANGSU CO LTD

Cutting device with ash removing function

InactiveCN105835135AReduce wasteNot easy to wasteProfiling/shaping machinesBark-zones/chip/dust/waste removalNumerical controlSurface mounting

The invention discloses a cutting device with a built-in dust cleaning function, which includes a fixing device, a moving rod and a working body. A power device is installed on the left side of the working body, and a numerical control device is installed above the power device. The numerical control device Connected with the moving rod through the control line, the upper left side of the working body is equipped with a working bracket, the working frame is equipped with a moving rod, the upper surface of the working body is equipped with a fixing device, and the bottom of the fixing device is installed with a crushing device. A chip chute, a dustbin is connected to the bottom of the swarf chute, a flip cover is installed on the right side of the dustbin, rail loading surfaces are installed on the front and rear sides of the fixing device, a card slot is installed on the fixing device, and the card slot A pulley is installed below, an adjusting nut is installed on the left side of the card slot, the fastening screw is connected with the card slot through an adjusting nut, and a telescopic rod is installed under the left side of the moving rod. The present invention has reasonable design and long service life. Improve cutting efficiency.

Owner:苏清安

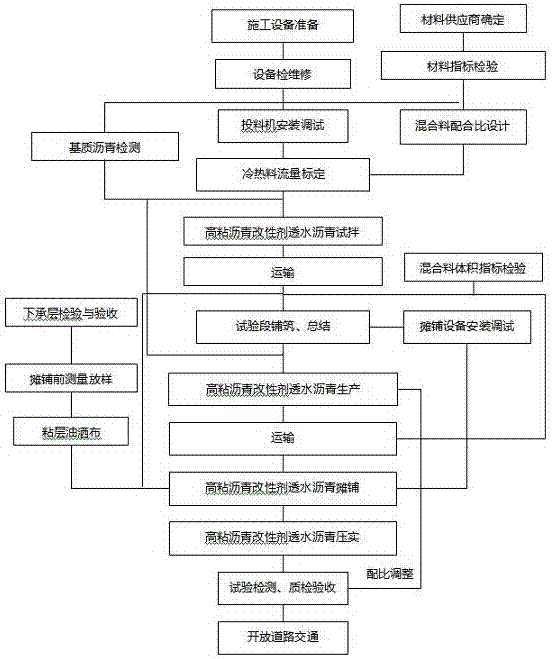

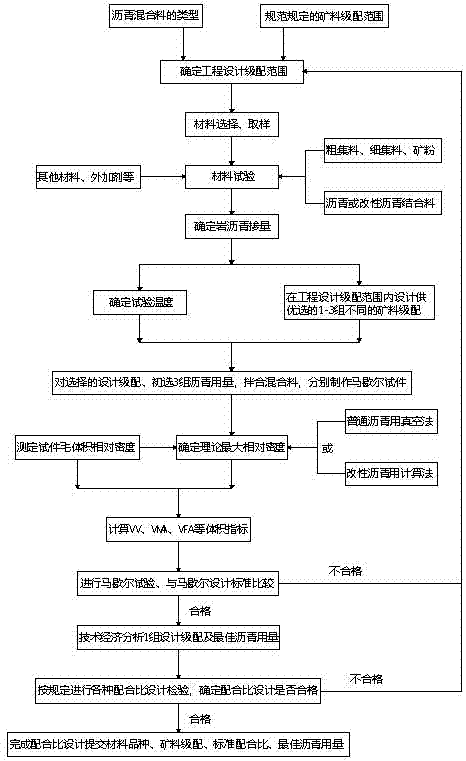

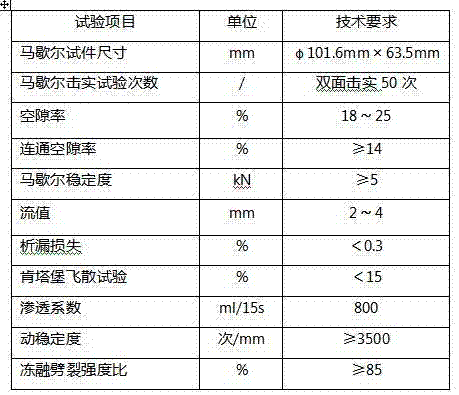

High-viscosity asphalt modifier porous asphalt pavement construction method

InactiveCN107142810ASimple production processNot easy to wasteIn situ pavingsRoads maintainencePorous asphaltRoad engineering

The invention belongs to the technical field of road engineering construction, and particularly relates to a high-viscosity asphalt modifier porous asphalt pavement construction method. The high-viscosity asphalt modifier porous asphalt pavement construction method is characterized by sequentially including the steps that construction equipment prepares to work; the mixing proportion of a direct-putting high-viscosity asphalt modifier porous asphalt mixture is designed; the direct-putting high-viscosity asphalt modifier porous asphalt mixture is produced; the direct-putting high-viscosity asphalt modifier porous asphalt mixture is transported; preparation work is conducted before the direct-putting high-viscosity asphalt modifier porous asphalt mixture is laid; use parameters of a laying machine are selected and adjusted; laying work is conducted; the direct-putting high-viscosity asphalt modifier porous asphalt mixture is rolled and formed; joint treatment is conducted. The method has the advantages of obvious construction method advantages and economic and social benefits.

Owner:SHANDONG HUITONG CONSTR GRP CO LTD

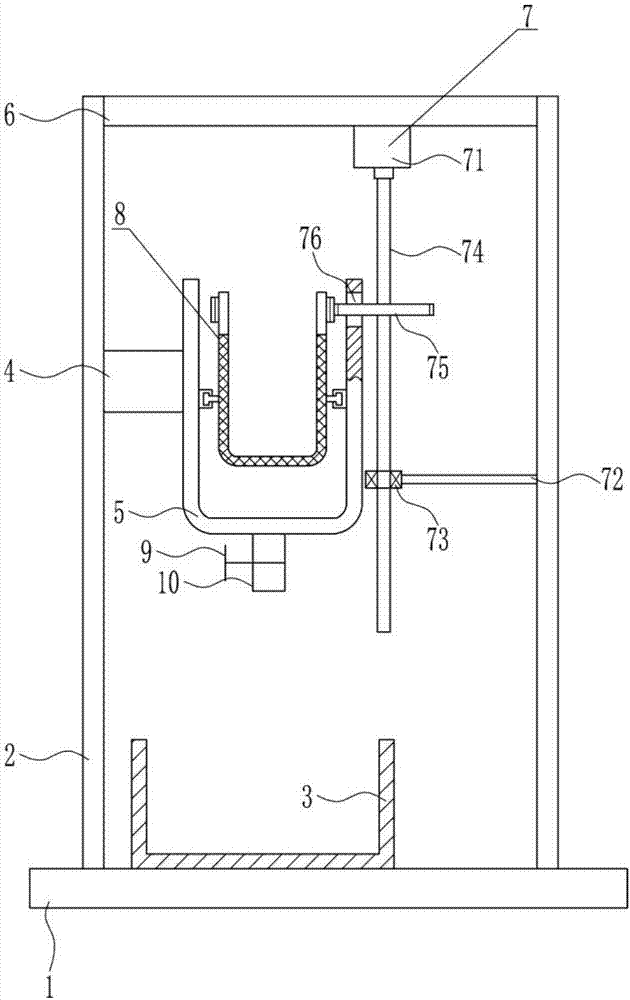

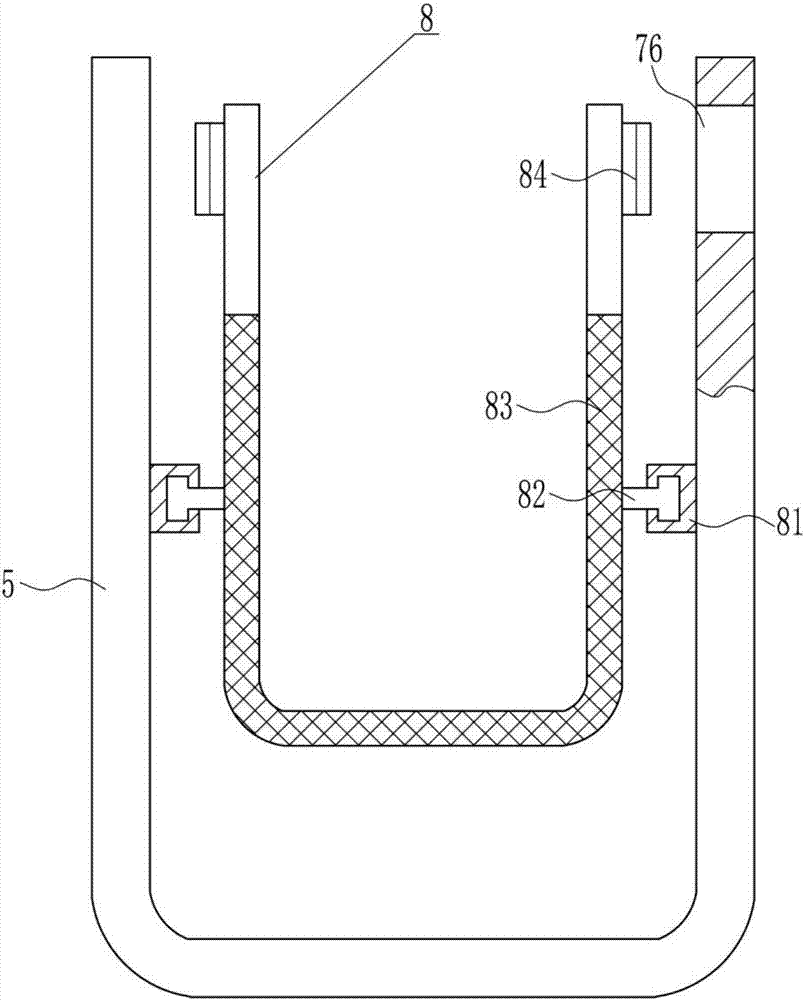

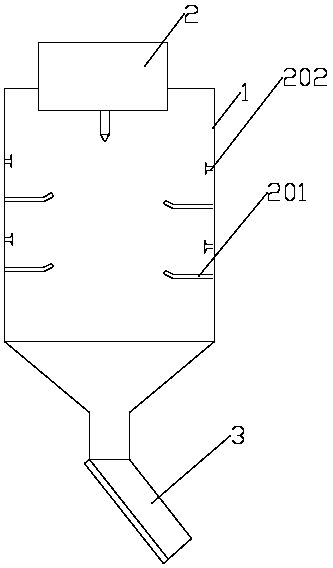

Rapid petroleum filter device for collecting petroleum

InactiveCN107252581ANot easy to wasteEasy to operateMoving filtering element filtersPetroleumPetroleum engineering

The invention relates to a petroleum filter device and particularly relates to a rapid petroleum filter device for collecting petroleum and aims at solving the technical problem of providing a rapid petroleum filter device for collecting petroleum, which is convenient to operate, does not easily cause petroleum waste and reduces the economic loss. In order to solve the technical problem, the invention provides the rapid petroleum filter device for collecting the petroleum. The rapid petroleum filter device comprises a bottom plate and the like, wherein a frame body is arranged at the top of the bottom plate; a drive device is arranged at the upper part of the left side surface of the frame body, and a filter device is arranged at the upper part in the frame body; the bottom of the right side surface of the frame body is connected with an oil outlet pipe; and the oil outlet pipe is connected with a valve and communicates with the inside of the frame body. The effects that the operation is convenient, the petroleum waste is not caused and the economic loss is reduced are achieved.

Owner:沈晓兰

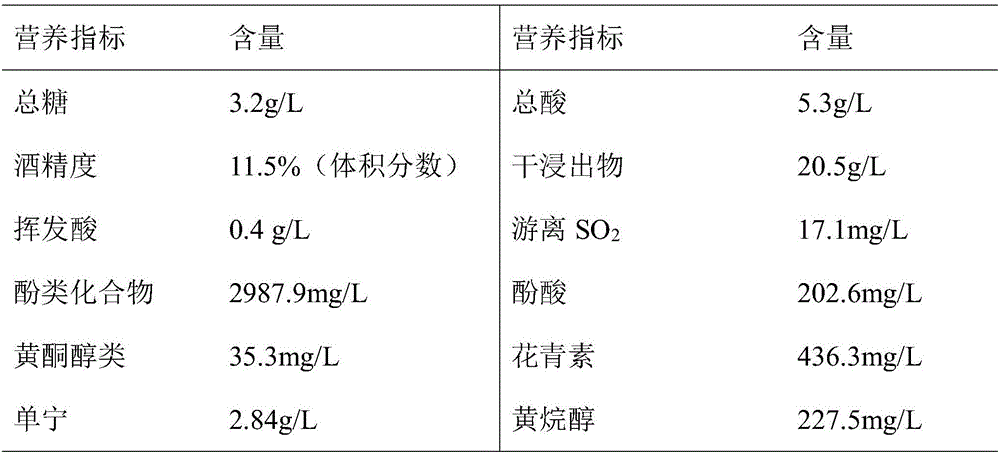

Black chokeberry fruit wine and preparation method thereof

ActiveCN105670866AMellow and soft tasteGreat tasteMicroorganism based processesAlcoholic beverage preparationAmylasePectinase

The invention relates to a black chokeberry fruit wine which is prepared from the following raw materials in parts by weight: 105-130 parts of apple, 135-165 parts of black chokeberry, 135-165 parts of white granulated sugar, 0.09-0.11 part of food-grade sodium metabisulfite, 0.27-0.33 part of pectinase, 0.025-0.035 part of yeast powder, 0.45-0.55 part of yeast nutrient material and 0.09-0.11 part of amylase. The preparation method comprises the following steps: taking the apples, and pressing to obtain crude apple juice; carrying out enzyme treatment on the crude apple juice, filtering, and sterilizing to obtain sterilized apple juice; and taking the black chokeberry, crushing, adding the white granulated sugar, water, the rest pectinase, yeast powder, yeast nutrient material and food-grade sodium metabisulfite, uniformly mixing, fermenting, filtering, adding the sterilized apple juice into the obtained liquid, fermenting, filtering, taking the clear solution, and carrying out high static pressure treatment, thereby obtaining the black chokeberry fruit wine. The black chokeberry fruit wine has pure vinous flavor and natural aroma of the raw material fruits, and has the health care functions of resisting oxidation, lowering the blood sugar, softening the blood vessels and the like.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

Wall surface whitewashing equipment

ActiveCN109898809AQuality assuranceGuaranteed timelinessBuilding constructionsEvaporationMoving frame

The invention relates to wall surface whitewashing equipment. The wall surface whitewashing equipment comprises a moving frame, and a whitewashing device and a feeding device are arranged on the moving frame; the whitewashing device comprises a supporting frame on the moving frame, a traction mechanism on one side of the supporting frame and a whitewashing mechanism driven by the traction mechanism to move up and down along the supporting frame; the feeding device comprises a feeding mechanism for supplying coating for the whitewashing mechanism and an adjusting mechanism arranged on one sideof the feeding mechanism and used for adjusting the feeding pressure; and the whitewashing mechanism comprises a whitewashing roller, a switching mechanism is further arranged at the position of the whitewashing mechanism, when the whitewashing mechanism moves upwards, the switching mechanism controls the coating to be sprayed to the whitewashing roller from the upper right part, and when the whitewashing mechanism moves downwards, the coating is controlled to be sprayed to the whitewashing roller from the lower right part. According to the wall surface whitewashing equipment, the problems that the coating supplied onto the surface of the whitewashing roller is prone to drippage and causes waste and pollution on the equipment and the bottom face, the sprayed part coating cannot be whitewashed on the wall surface and water evaporation is prone to occurring to affect the performance, and the coating spraying amount affected by gravity is uneven when whitewashing is carried out at different height positions are solved.

Owner:东营硕明信息技术有限公司

Concrete stirring device capable of stirring evenly for building construction

PendingCN107379248AEasy to useIncrease surface areaMixing operation control apparatusPretreatment controlArchitectural engineeringBuilding construction

The invention discloses a concrete stirring device capable of stirring evenly for building construction. The concrete stirring device comprises a connection box. The top of the connection box is fixedly connected with a first stirring box, and the top of the first stirring box is fixedly connected with two second stirring boxes. The two second stirring boxes are symmetrically arranged, and the midperpendicular of the first stirring box serves as the symmetry axis. The close sides of the tops of the two second stirring boxes are connected with material inlet hoppers in an inserted manner, and the centers of the tops of the second stirring boxes are fixedly connected with first motors. The first motors are controlled to work by a controller, first rotating shafts are made to rotate, first stirring rods are made to conduct rotating and stirring, the surface areas of auxiliary stirring rods are increased, the auxiliary stirring rods are made to conduct auxiliary stirring, materials are input from the two material inlet hoppers, stirring can be conducted more adequately and evenly, the concrete stirring device is convenient to use for users, the stirring cycle is shortened, the use requirements are met, and it is beneficial to conduction of the project.

Owner:安吉智居装饰设计工程有限公司

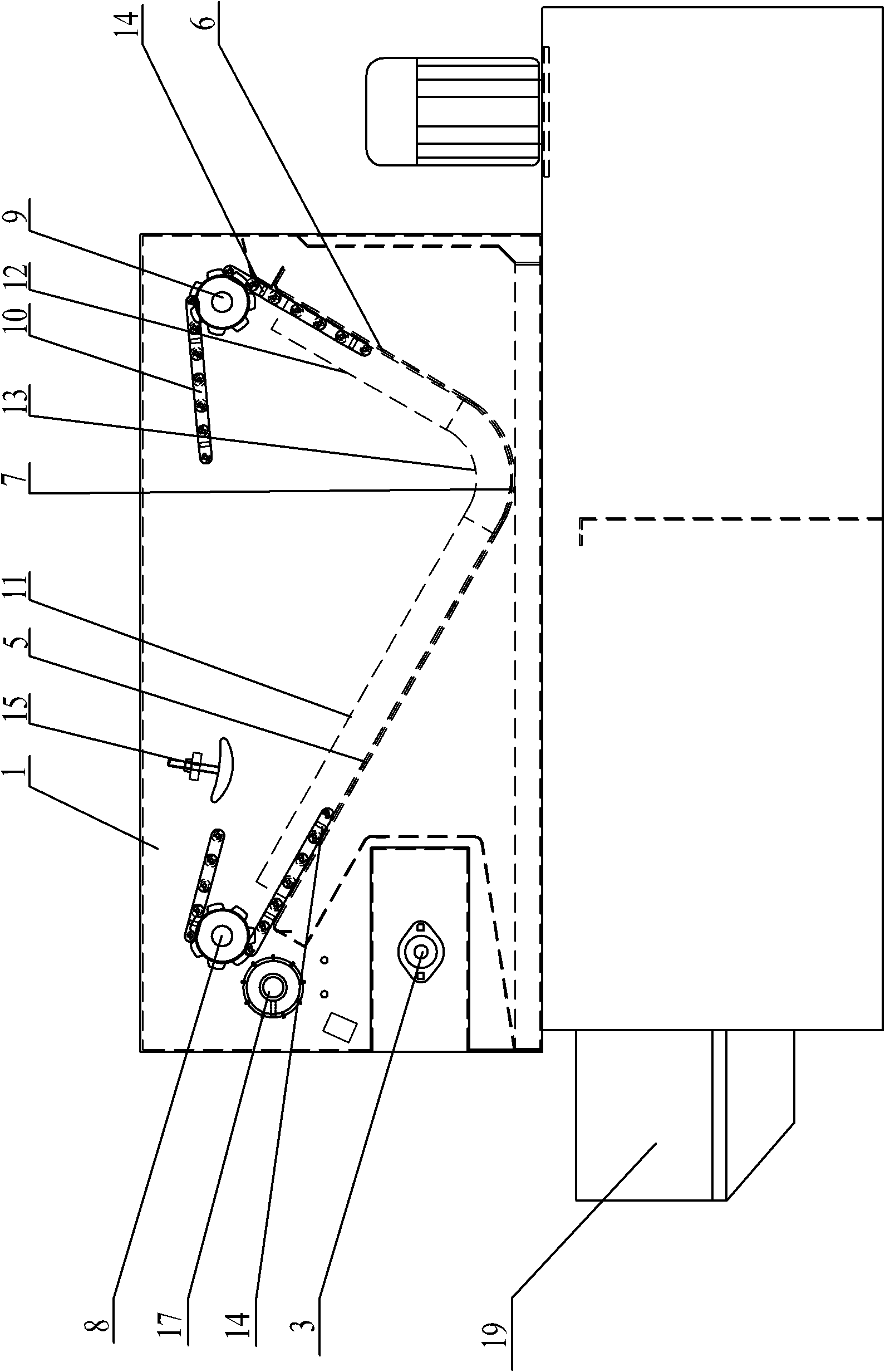

Automatic filter cloth scraping filter

ActiveCN102179087ANot easy to wasteAvoid easy cloggingStationary filtering element filtersEngineeringSecond screen

The invention relates to an automatic filter cloth scraping filter wherein an unreeling mechanism and a reeling mechanism are mounted on a shell; filter cloth is wound on the unreeling mechanism and the reeling mechanism; a V-shaped filter cloth supporting leakage tank formed by connecting a first screen plate, a second screen plate and an arc connecting screen plate is fixed on the shell; a first chain wheel and a second chain wheel are in rotatable connection with the shell at the top end position of the first screen plate; scraping plates are mounted on chains; a chain limiting groove is formed by combining the space between the bottom end of a first limiting plate and the upper surface of the first screen plate, the space between the bottom end of a second limiting plate and the upper surface of the second screen plate and the space between the bottom end of a third limiting plate and the upper surface of the arc connecting screen plate; the middle pieces of the chains are restricted in the chain limiting groove; and the middle piece of the filter cloth is clamped between the chains in the chain limiting groove and the filter cloth supporting leakage tank. When the automatic filter cloth scraping filter is at work, all filter cloth can be used as far as possible, the filter cloth is not prone to be wasted, the blockage is not prone to happen, the filter flow rate is higher, and the degree of automation is high.

Owner:无锡强工机械工业有限公司

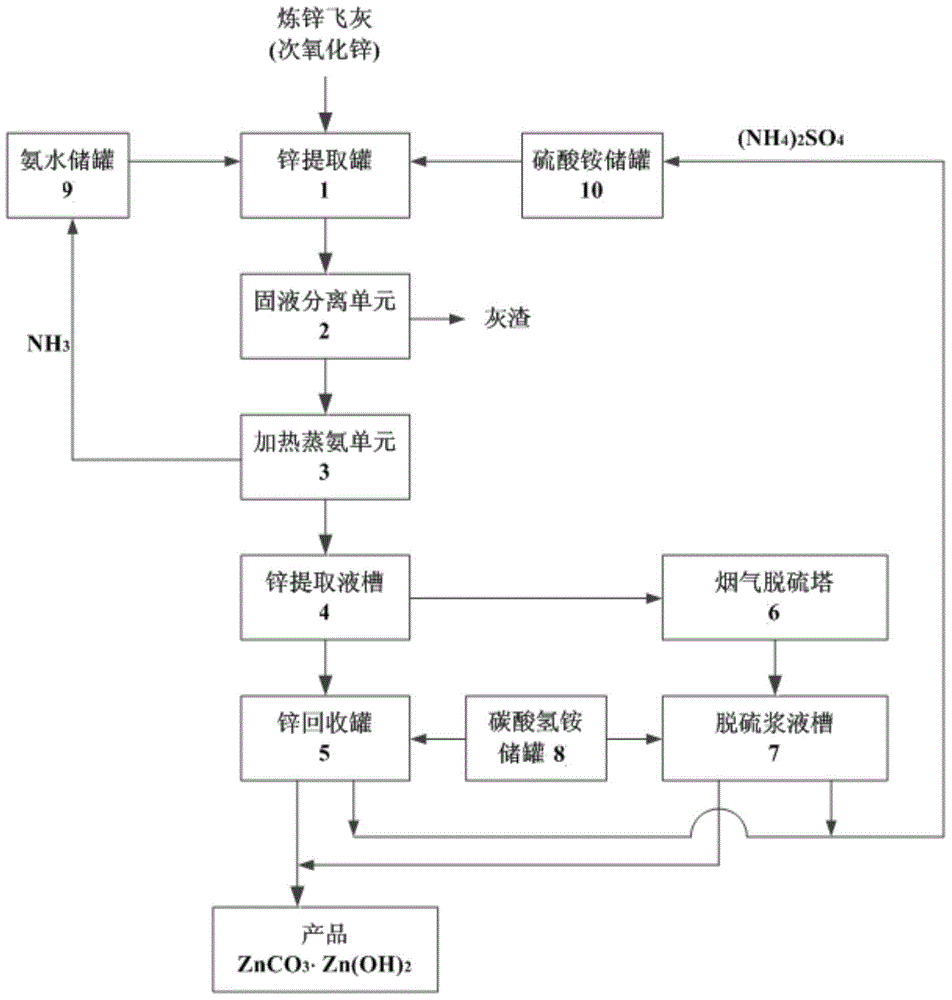

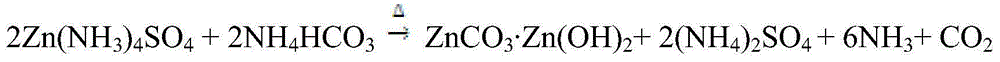

High-efficiency resource transformation method of nonferrous metal zinc-smelting fly ash

ActiveCN104862487AGood choiceReduce leachingAmmonium sulfatesZinc compoundsResource utilizationSlurry

The invention relates to a high-efficiency resource transformation method of nonferrous metal zinc-smelting fly ash. The method comprises the following steps: firstly, zinc-smelting fly ash, excessive ammonia water and ammonium sulfate solution are mixed and reacted; then, the solid-liquid separation is performed for the reacted mixed solution; soluble zinc-ammonia complexing solution is fed into a heating ammonia distilling unit; excessive ammonia gas in the solution is removed by a steam gas stripping method; one part of the treated zinc-ammonia complexing solution is fed into a zinc recovery tank, and the other part of the zinc-ammonia complexing solution, serving as desulfurization slurry, is sprayed into a smoke desulfurization tower to desulfurize the smoke, and is fed into a desulfurization slurry tank; then, ammonium bicarbonate is added in the zinc recovery tank and the desulfurization slurry tank for treating to obtain basic zinc carbonate and ammonium sulfate; the basic zinc carbonate is separated and purified to sell as a product; and the ammonium sulfate is purified for recycling. Compared with the prior art, the method has such advantages as high resource utilization rate, high recovery rate of zinc in the zinc-smelting fly ash, simple treatment process, energy conservation, cleanness and environmental protection.

Owner:SHANGHAI JIAO TONG UNIV

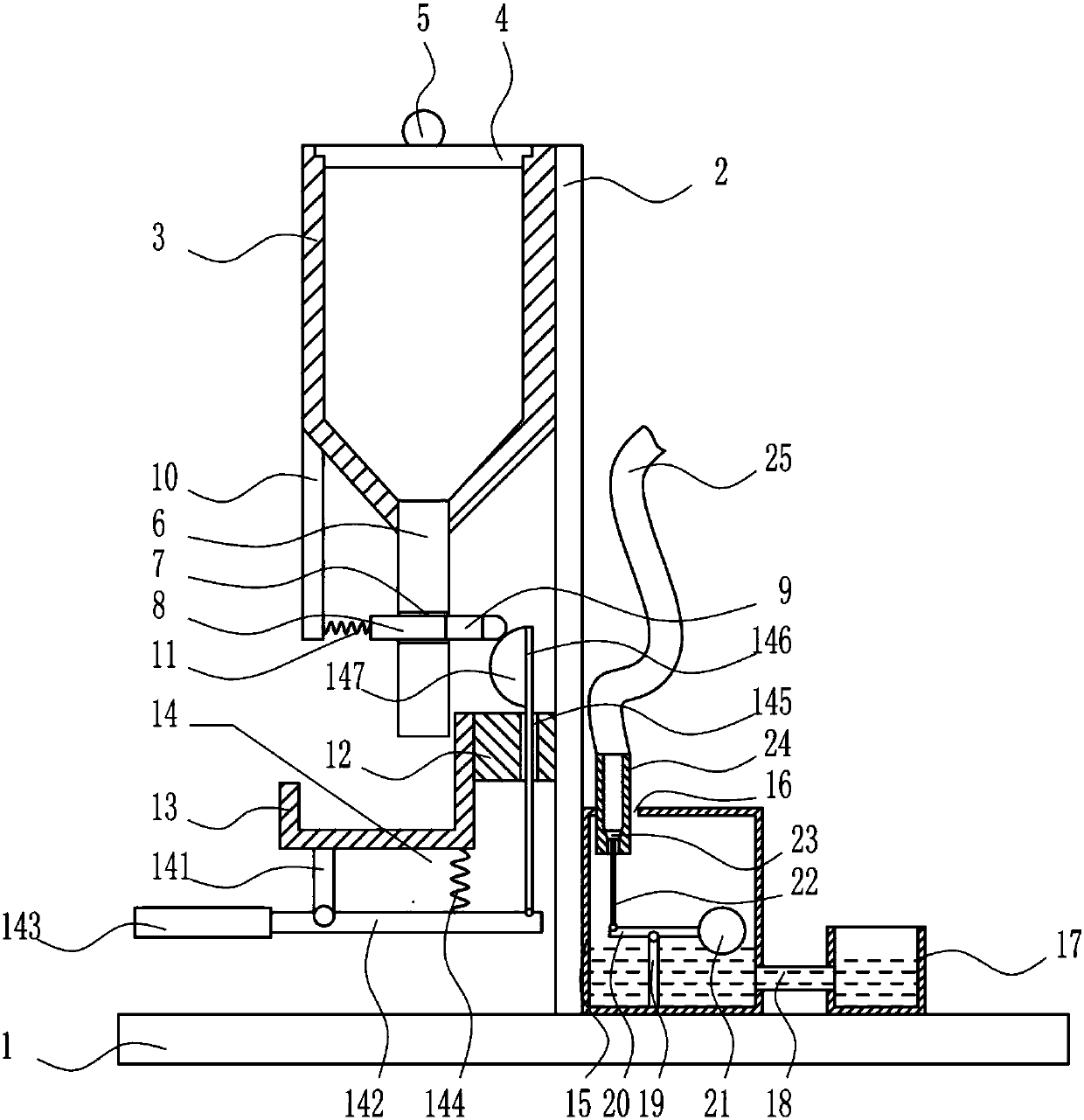

Bagging machine for salt processing

ActiveCN110884721ANot easy to wasteEasy to bundle and handlePackagingStructural engineeringMechanical engineering

The invention relates to a bagging machine, in particular to a bagging machine for salt processing. The invention aims to design a bagging machine for salt processing which is capable of convenientlyloading salt into a bag, low in labor cost, and capable of preventing waste caused by the salt falling to the ground. The bagging machine for salt processing comprises a base, a supporting rod, a hopper, a first guide sleeve, a baffle, a first spring, a contact block, a connecting rod, a supporting plate and the like; and the left side of the top of the base is fixedly connected with the supporting rod, the top end of the supporting rod is fixedly connected with the hopper capable of containing salt, the first guide sleeve is embedded in the lower portion of the right side of the hopper, and the baffle is arranged in the first guide sleeve in a sliding mode. According to the bagging machine, a bag is placed in a fixed arc-shaped plate in a sleeving manner, and an L-shaped rod is pulled, sothat a movable arc-shaped plate can press and fix the bag, the salt in the hopper falls into the bag, and the salt bagging operation does not need the cooperation by two workers, so that the labor cost is low, and the situation that the salt falls onto the ground and the waste is caused is prevented.

Owner:范太明

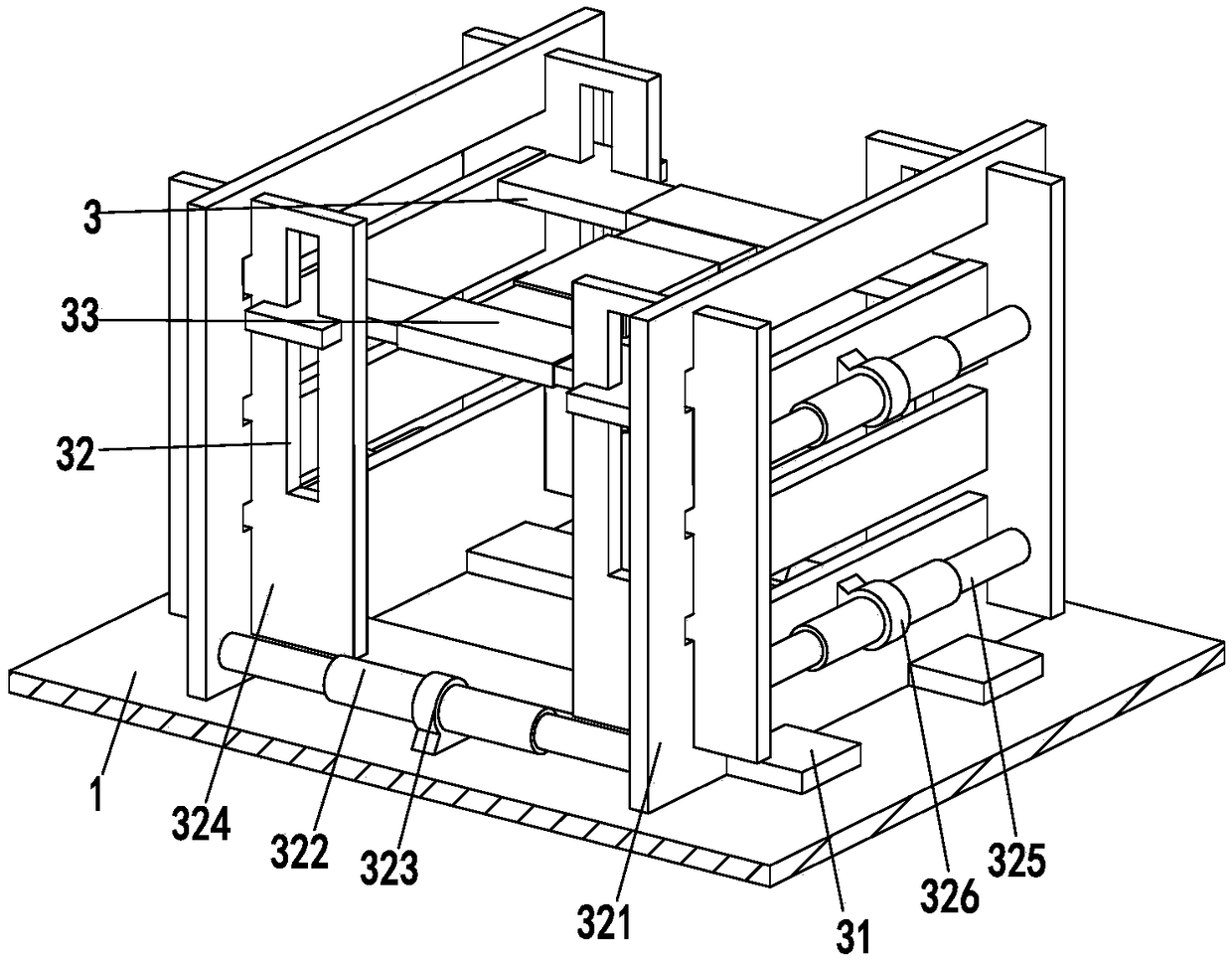

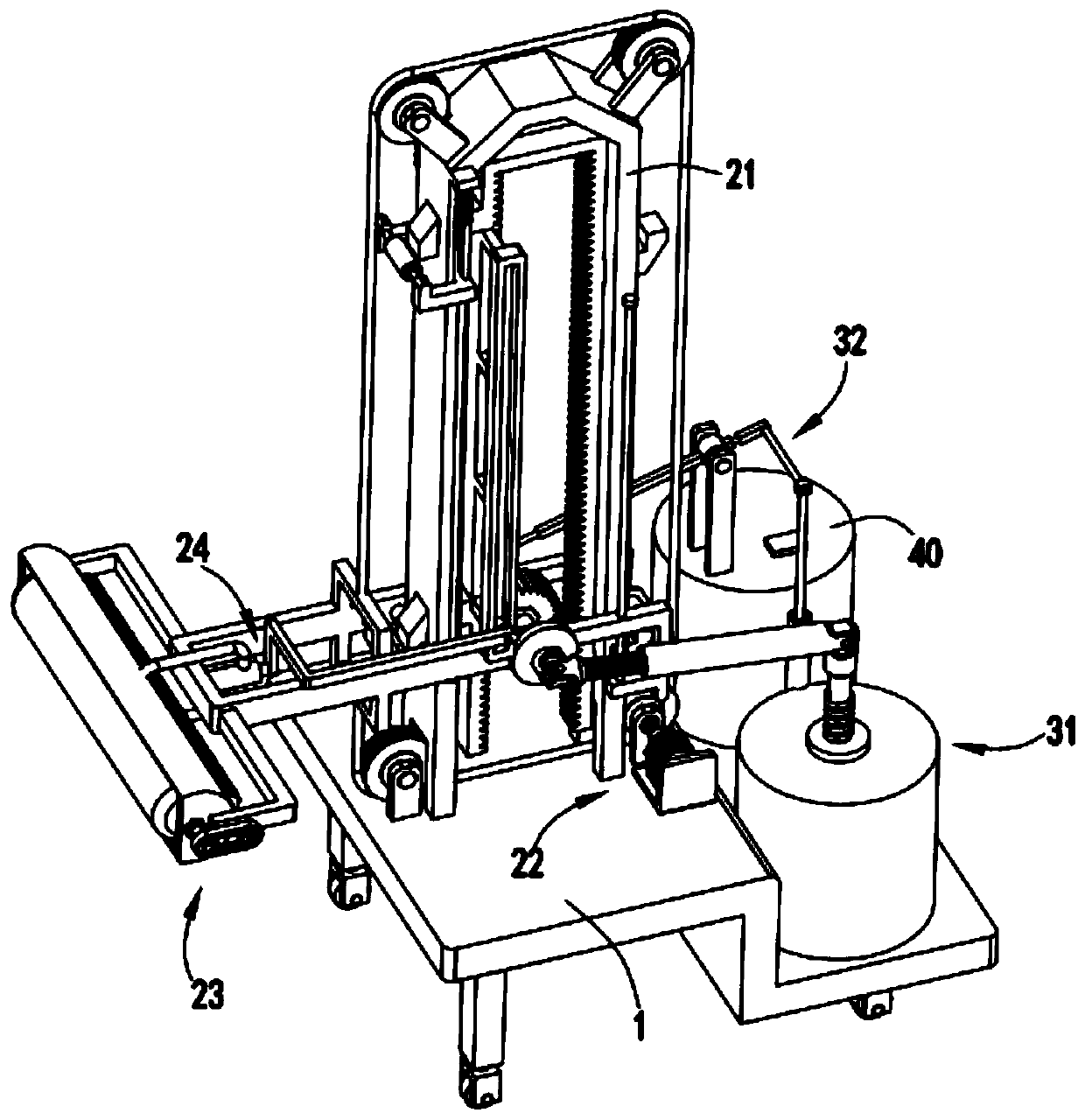

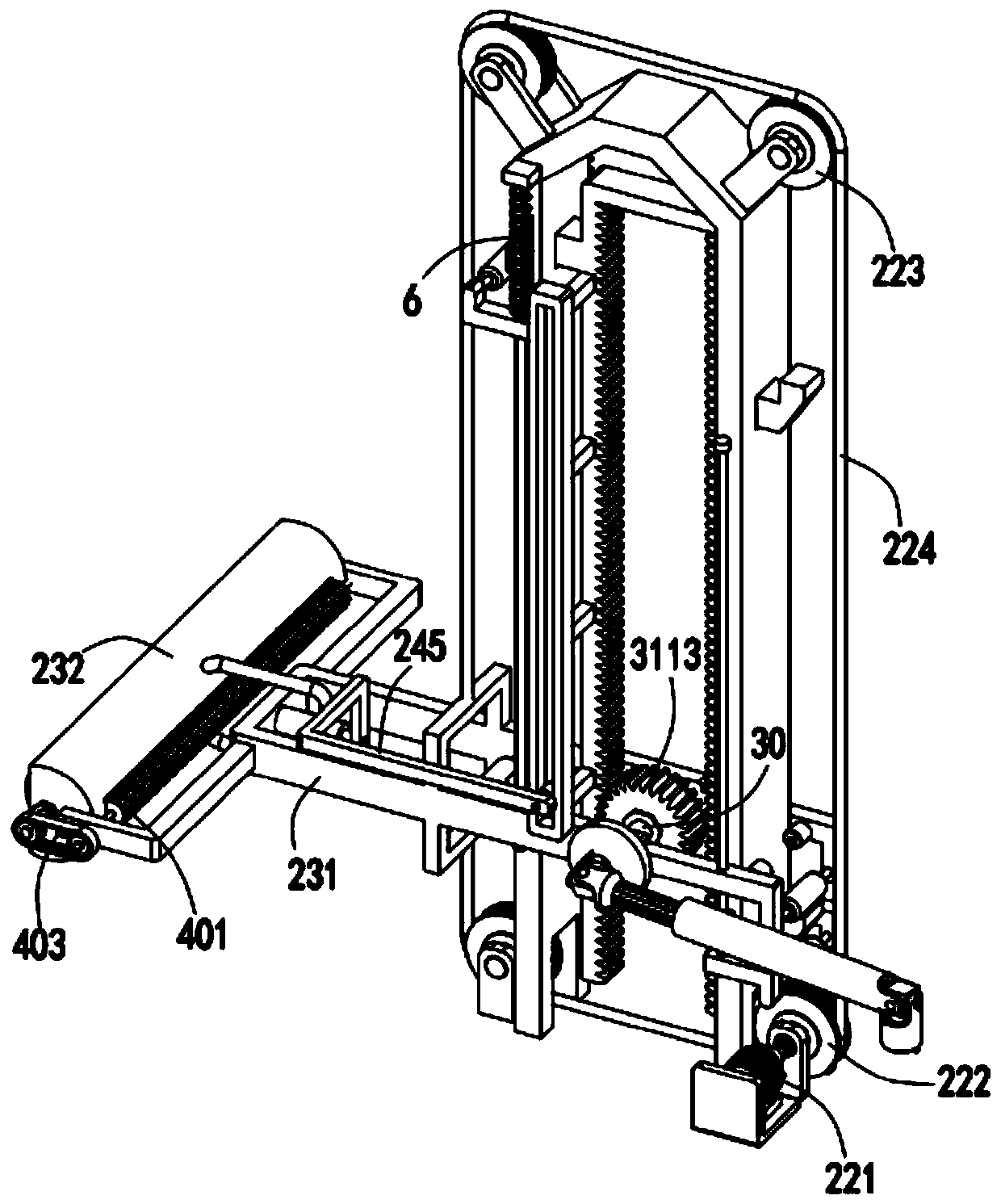

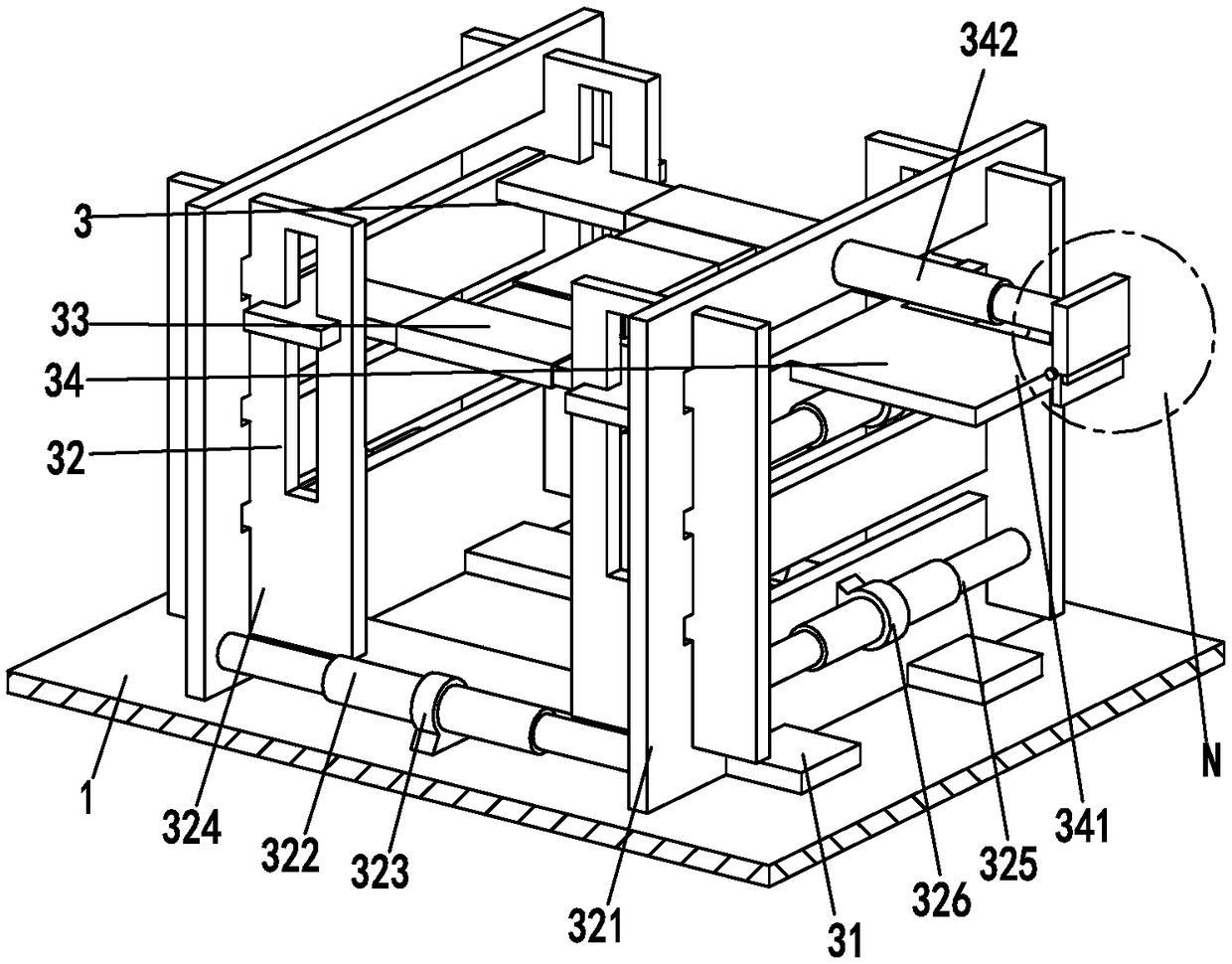

Composite wood board gluing machine

ActiveCN108687893ARealize automatic gluingWasteful realizationAdhesive application devicesPulp and paper industryWood panel

The invention relates to a composite wood board gluing machine. The composite wood board gluing machine comprises a bottom plate, an installing frame, a stacking device and a gluing device; the installing frame is installed on the bottom plate, and provided with a slide groove; the gluing device is installed in the slide groove, and the stacking device is arranged at the lower end of the gluing device, and installed on the bottom plate; the stacking device comprises a linear guide rail, a limiting mechanism, a supporting mechanism and a feeding mechanism; the gluing device comprises a glue outflow mechanism and a uniform smearing mechanism; and the uniform smearing mechanism comprises a sliding block, a sliding rod, a cross plate, a telescopic uniform smearing frame, a fixed supporting plate, a length adjusting cylinder, a connection ring and a driving branched chain. The composite wood board gluing machine can solve the problems that in the existing composite wood board gluing process, wood boards are stacked in disorder, gluing is not uniform, glue waste can be caused easily, and adjustability is poor, the function of performing automatic gluing on composite wood boards can be achieved, and the beneficial effects that stacking is in order, gluing is uniform, glue waste is not likely to be caused, and adjusting is flexible are achieved.

Owner:桃江县万众木业股份有限公司

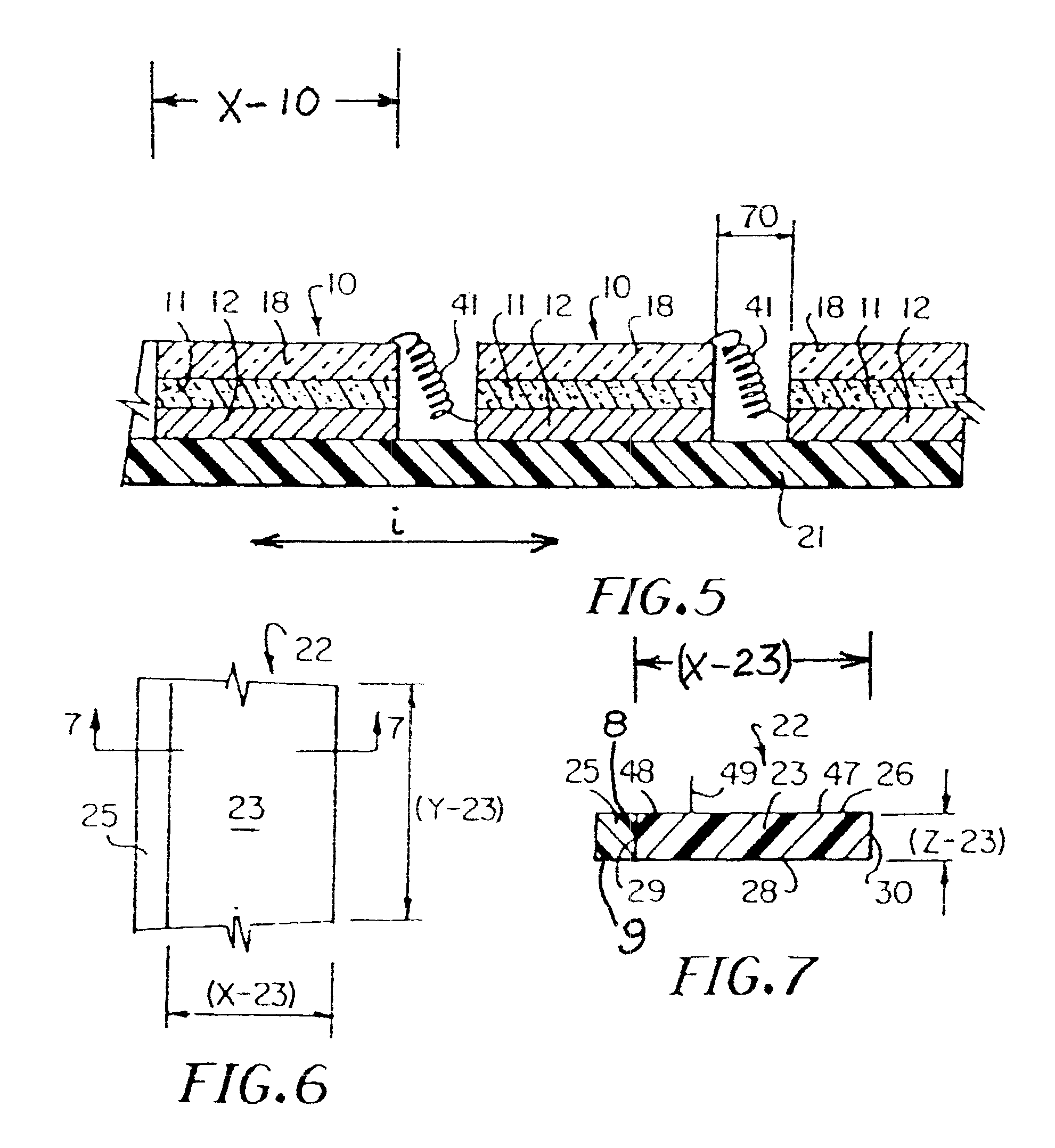

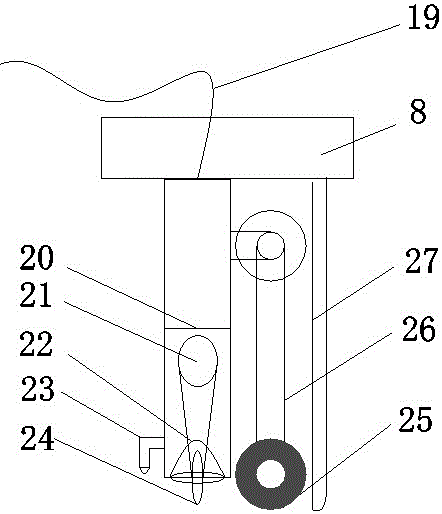

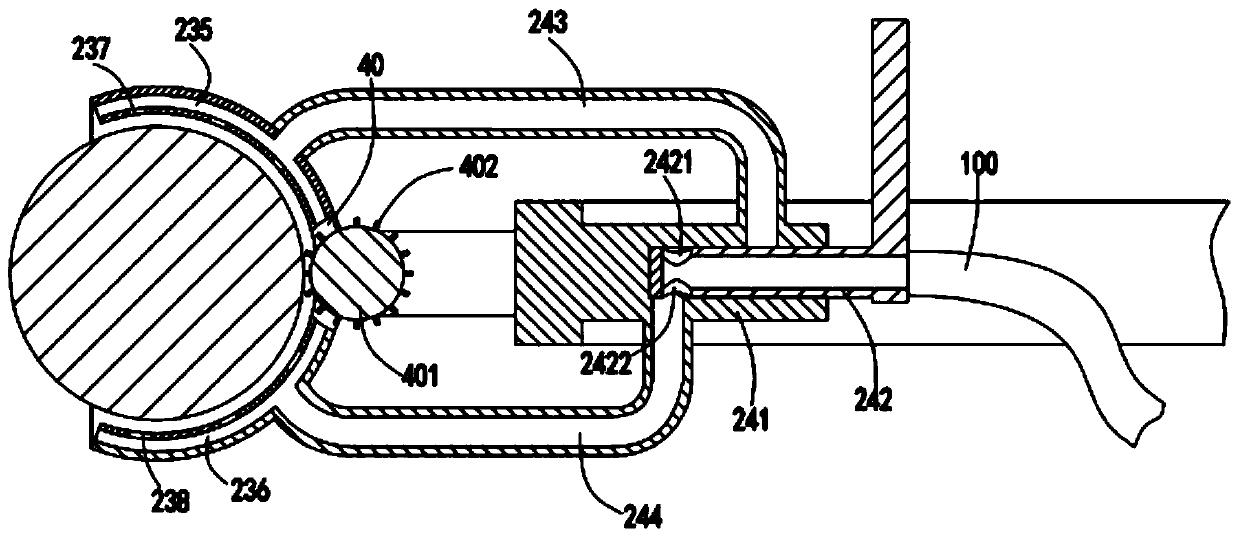

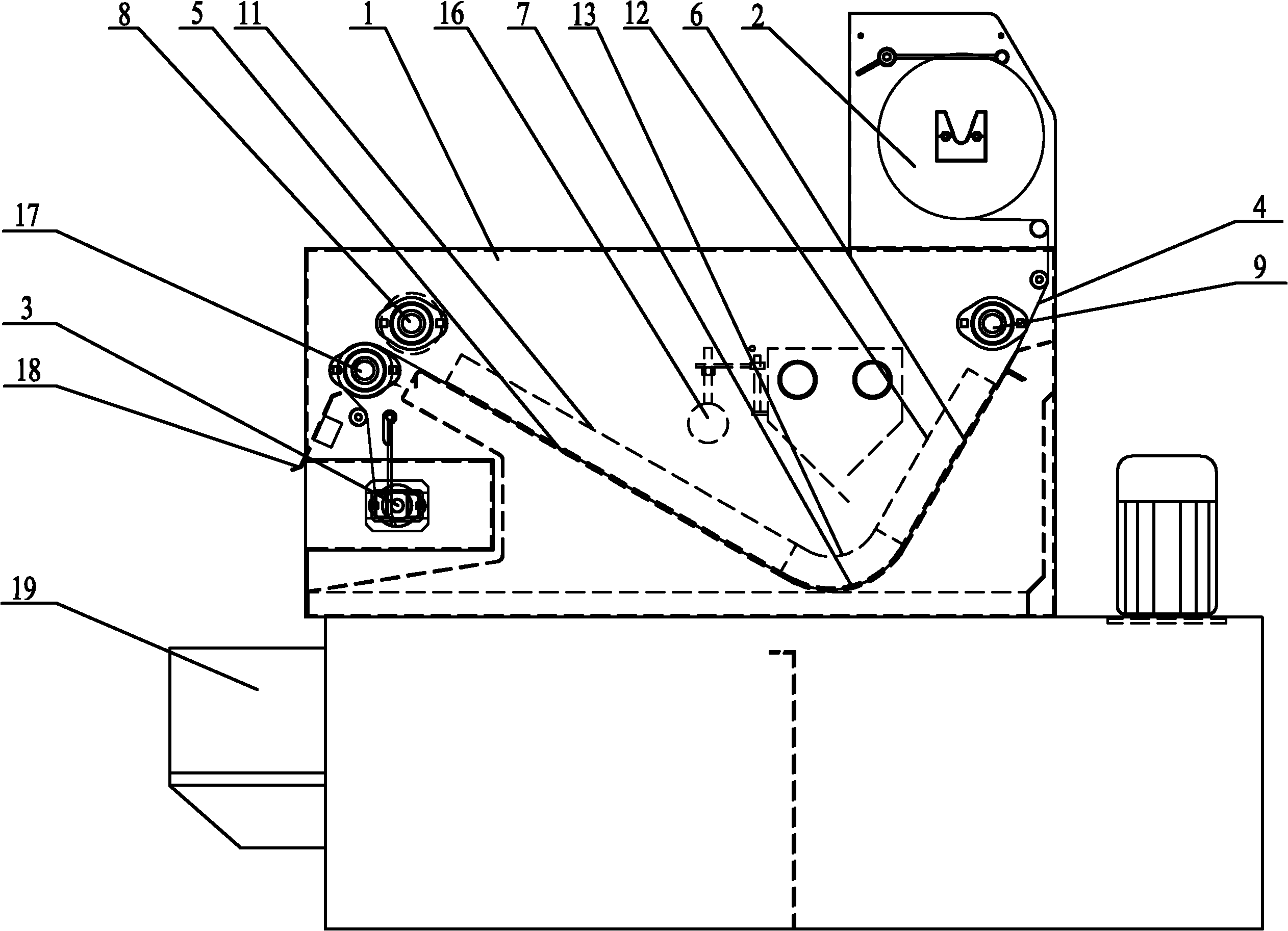

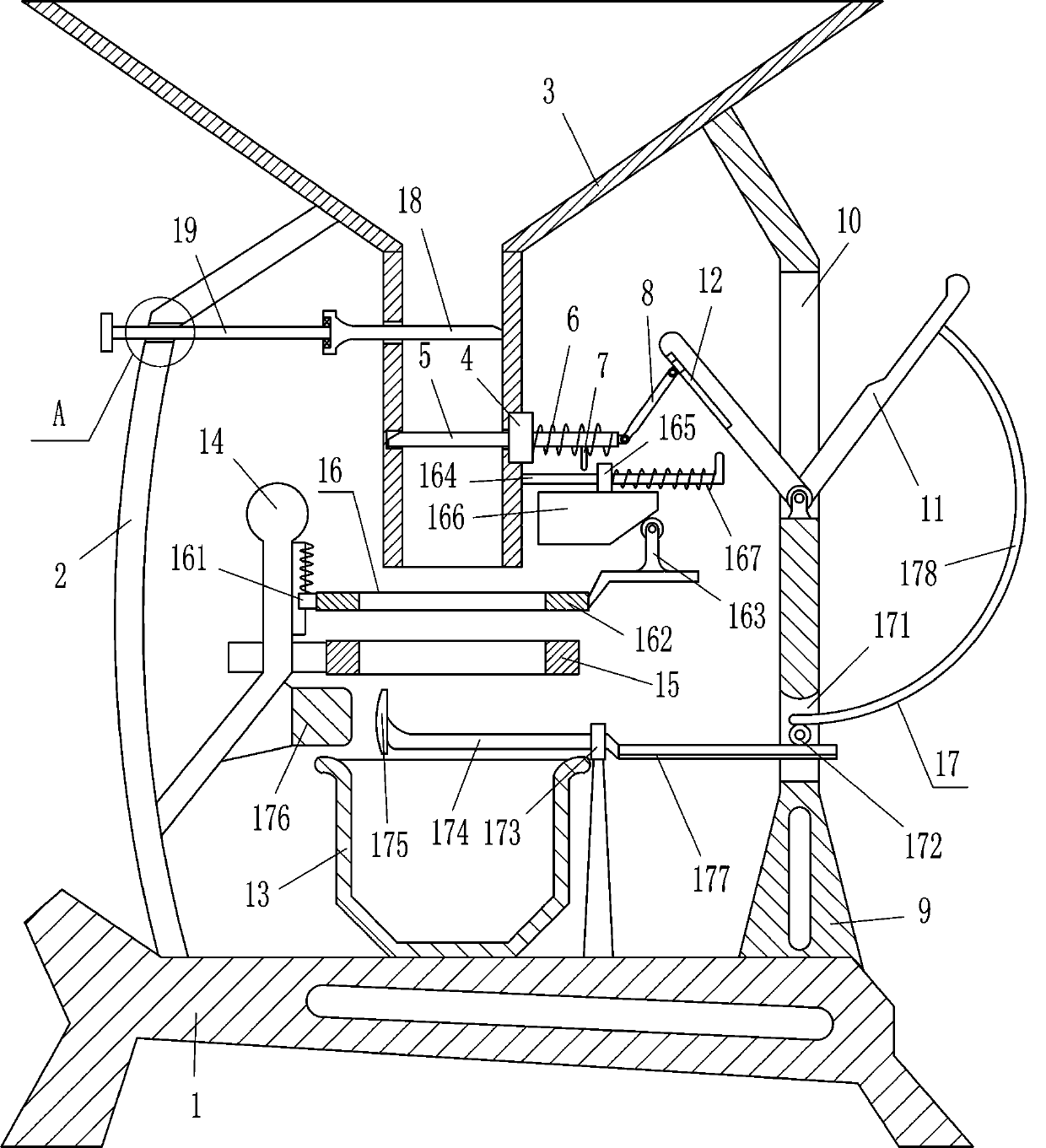

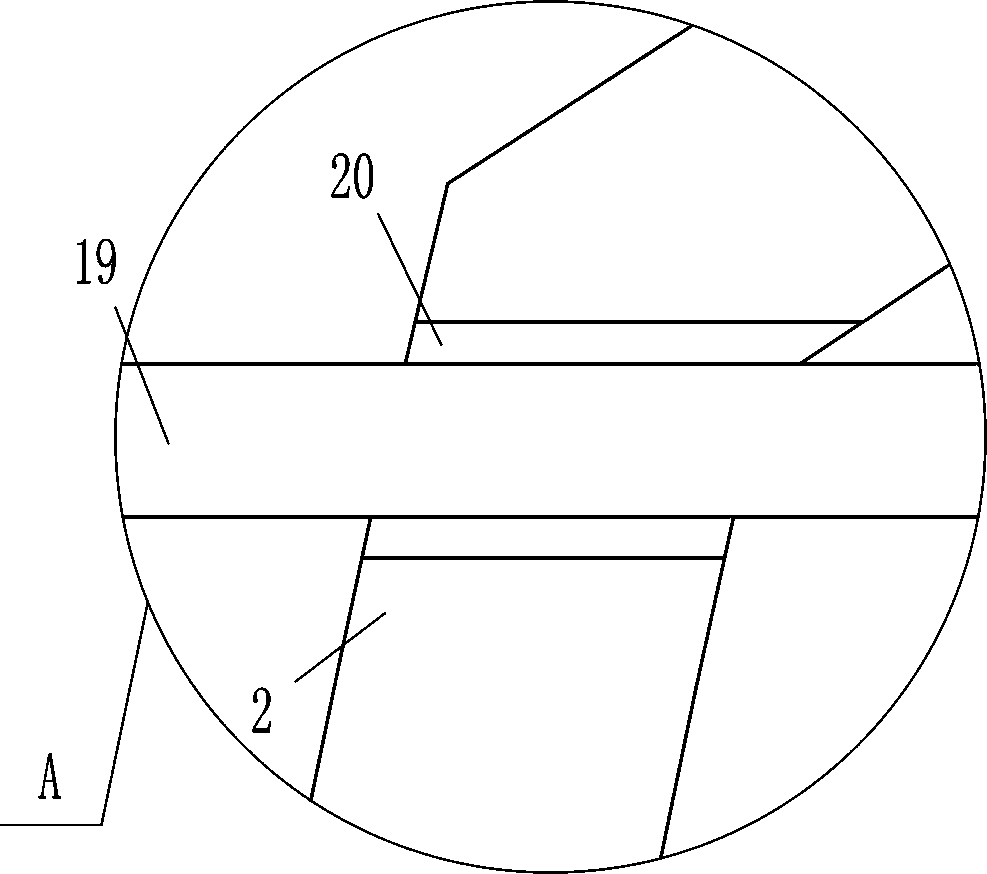

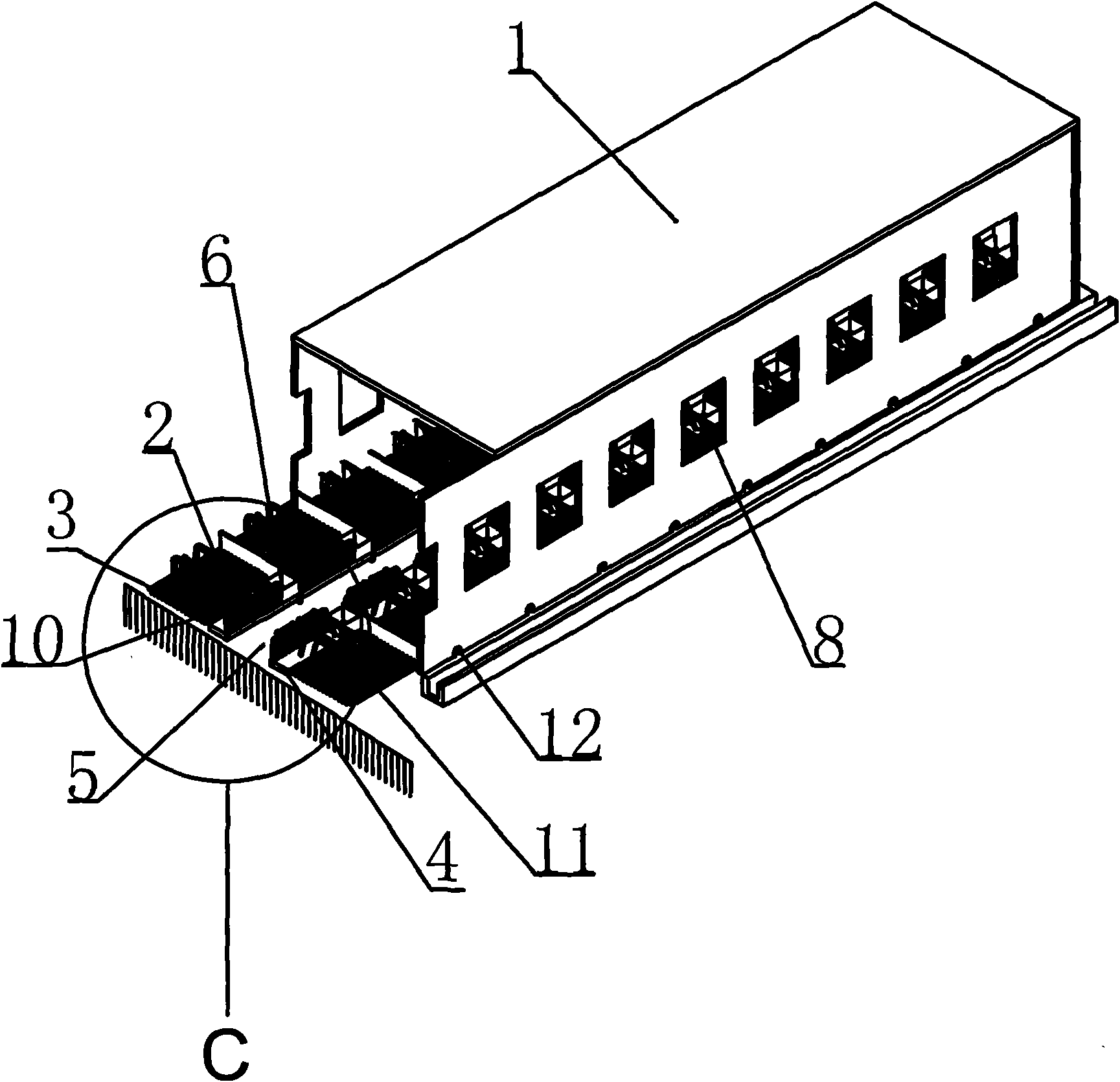

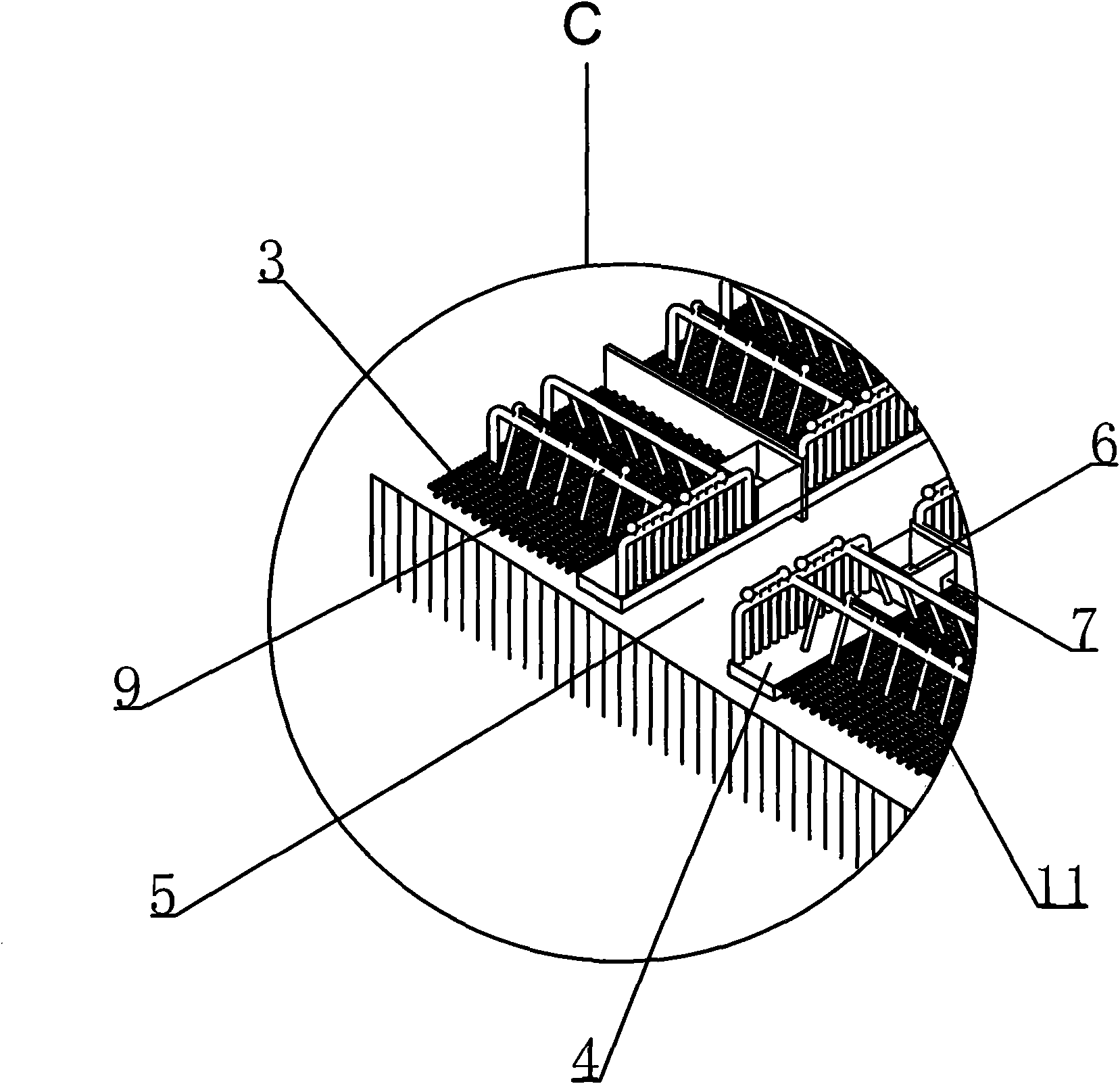

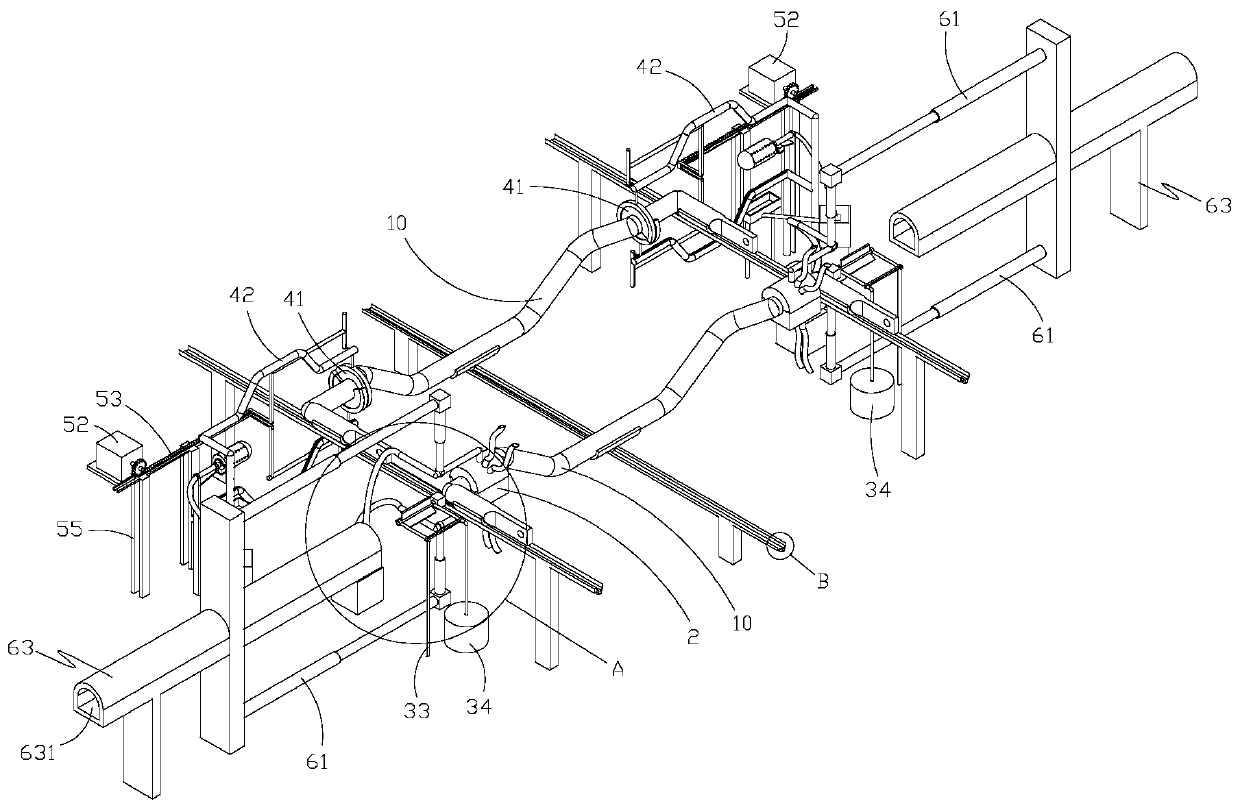

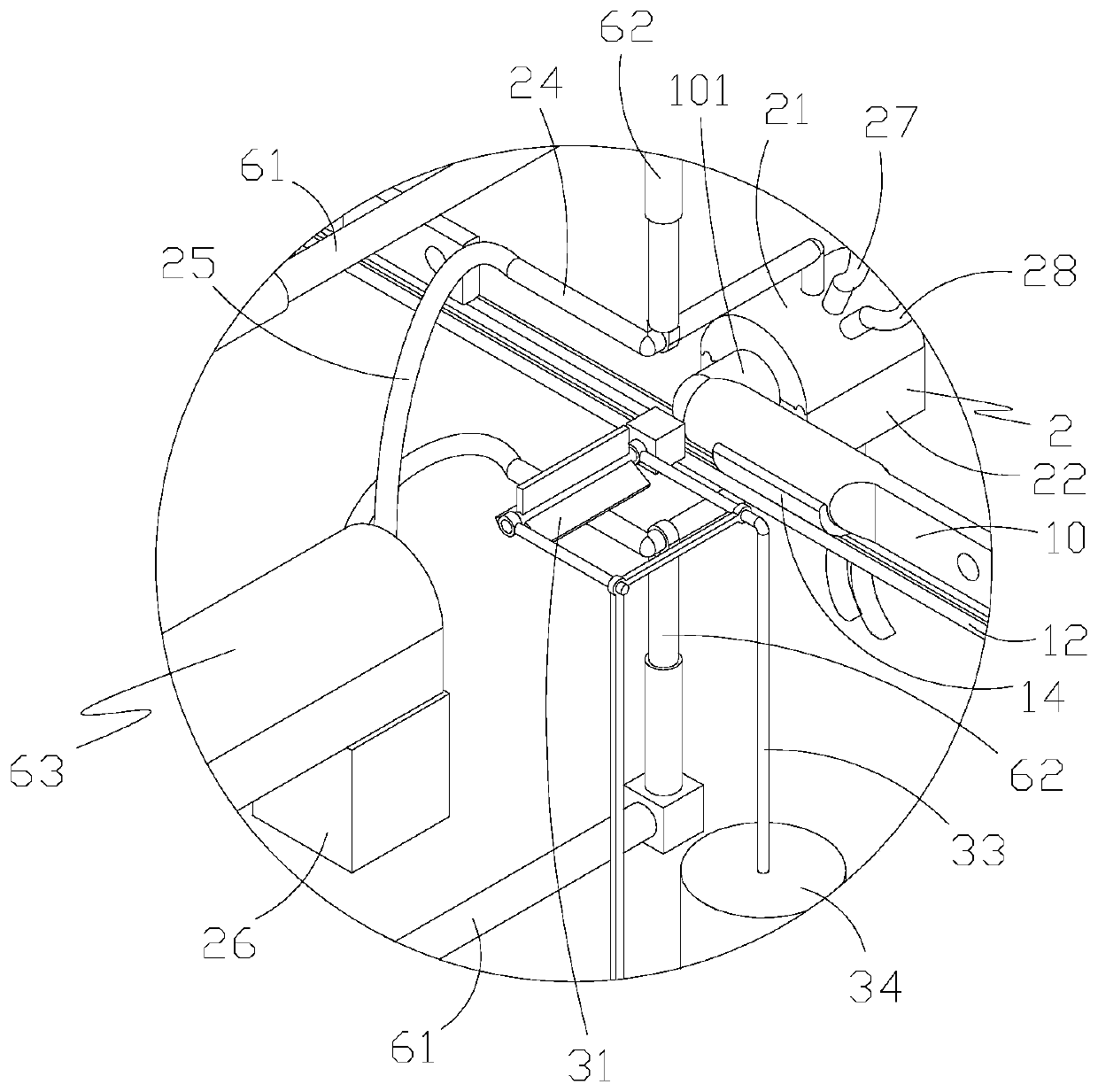

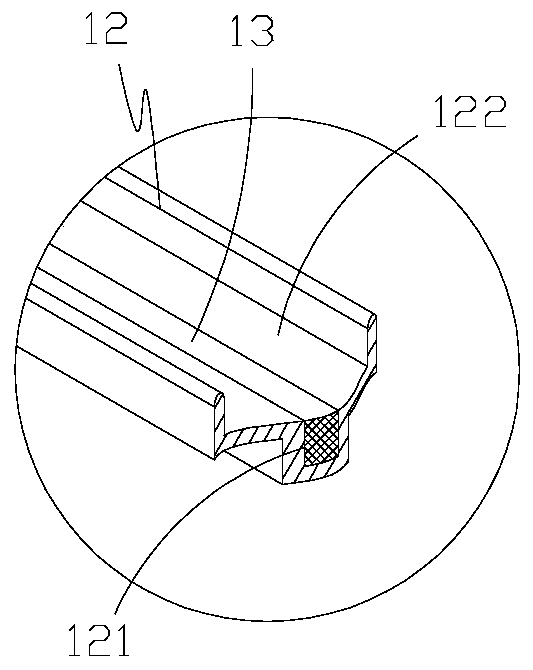

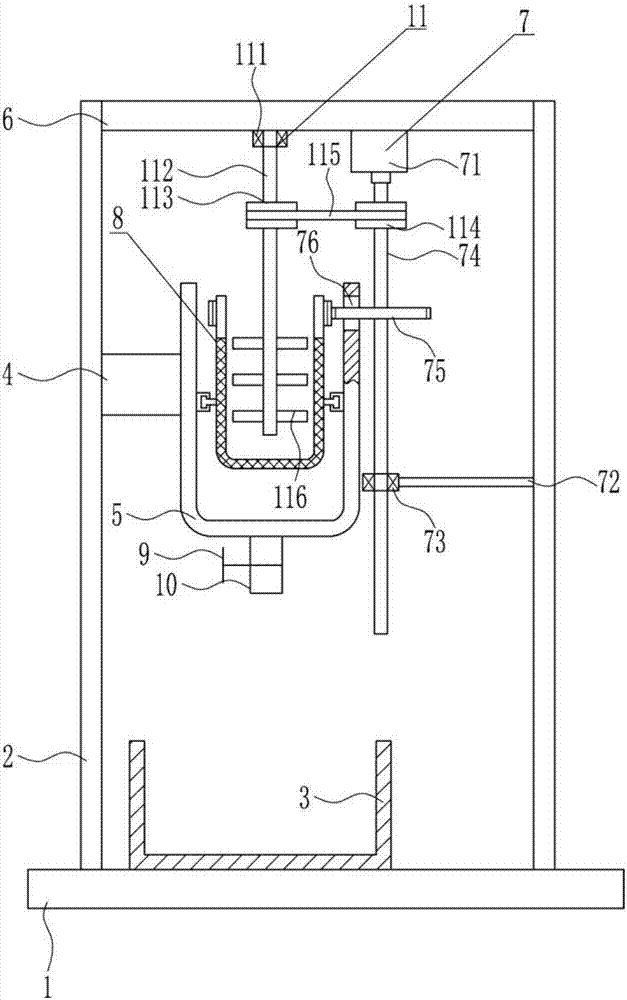

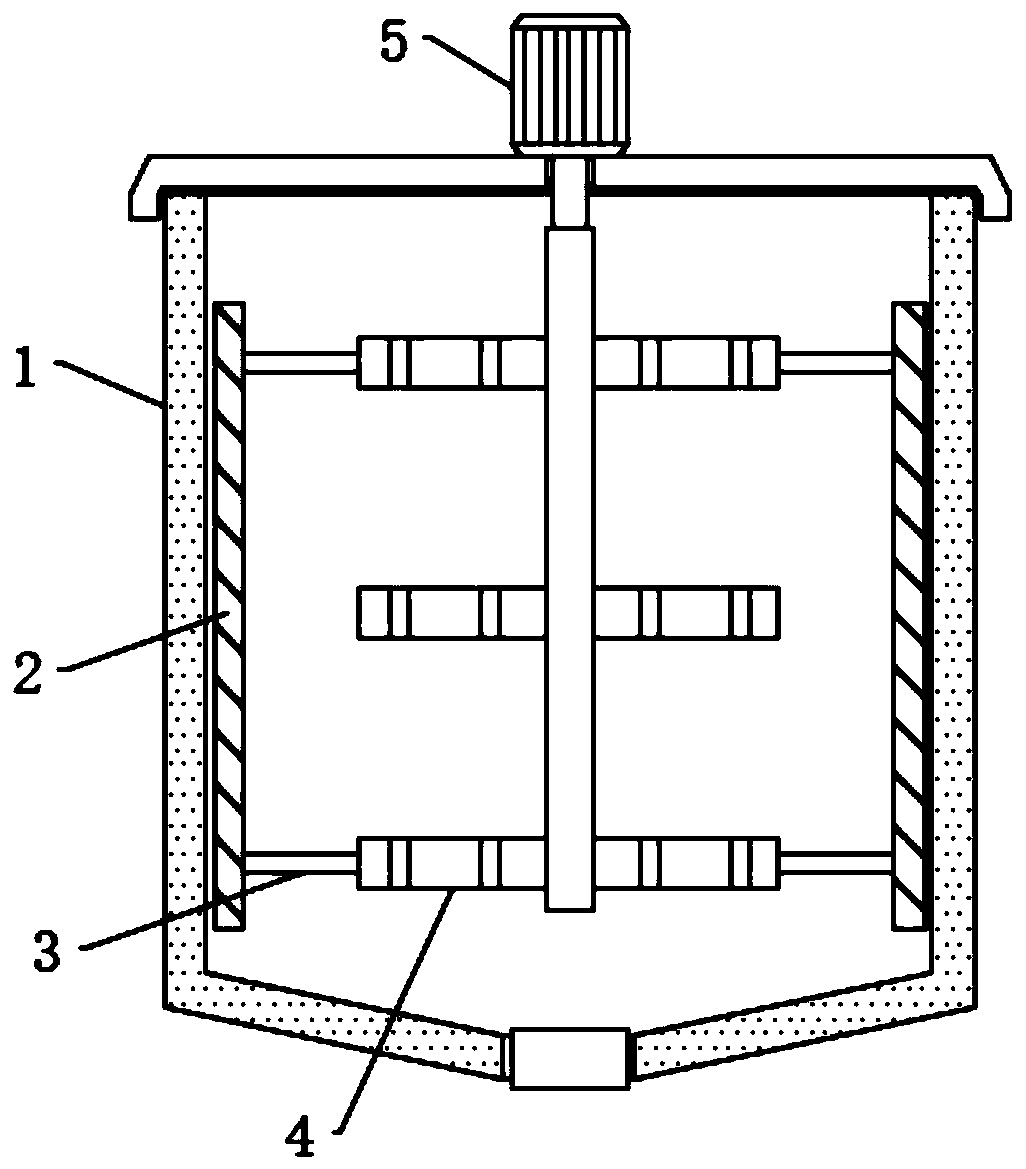

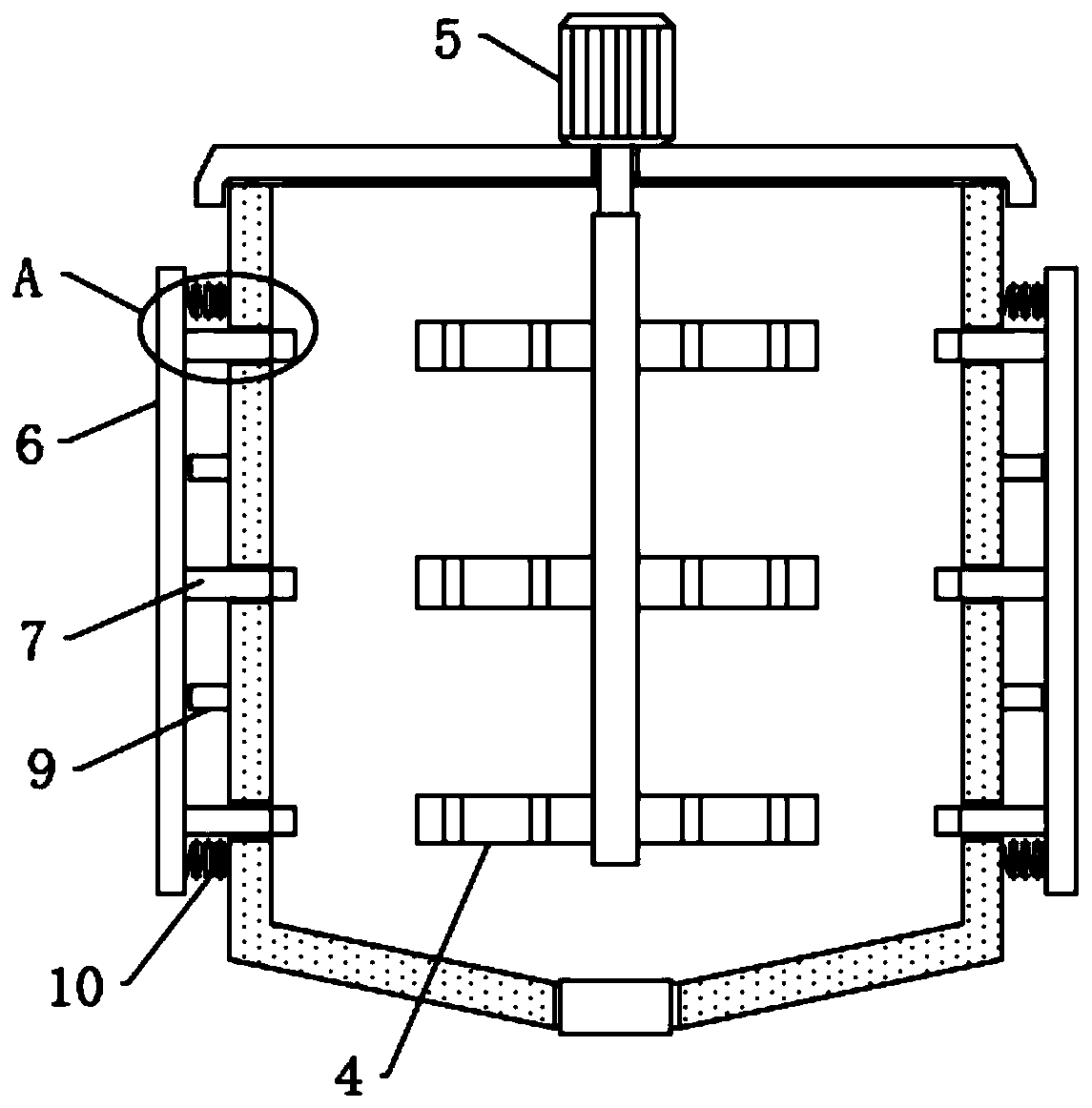

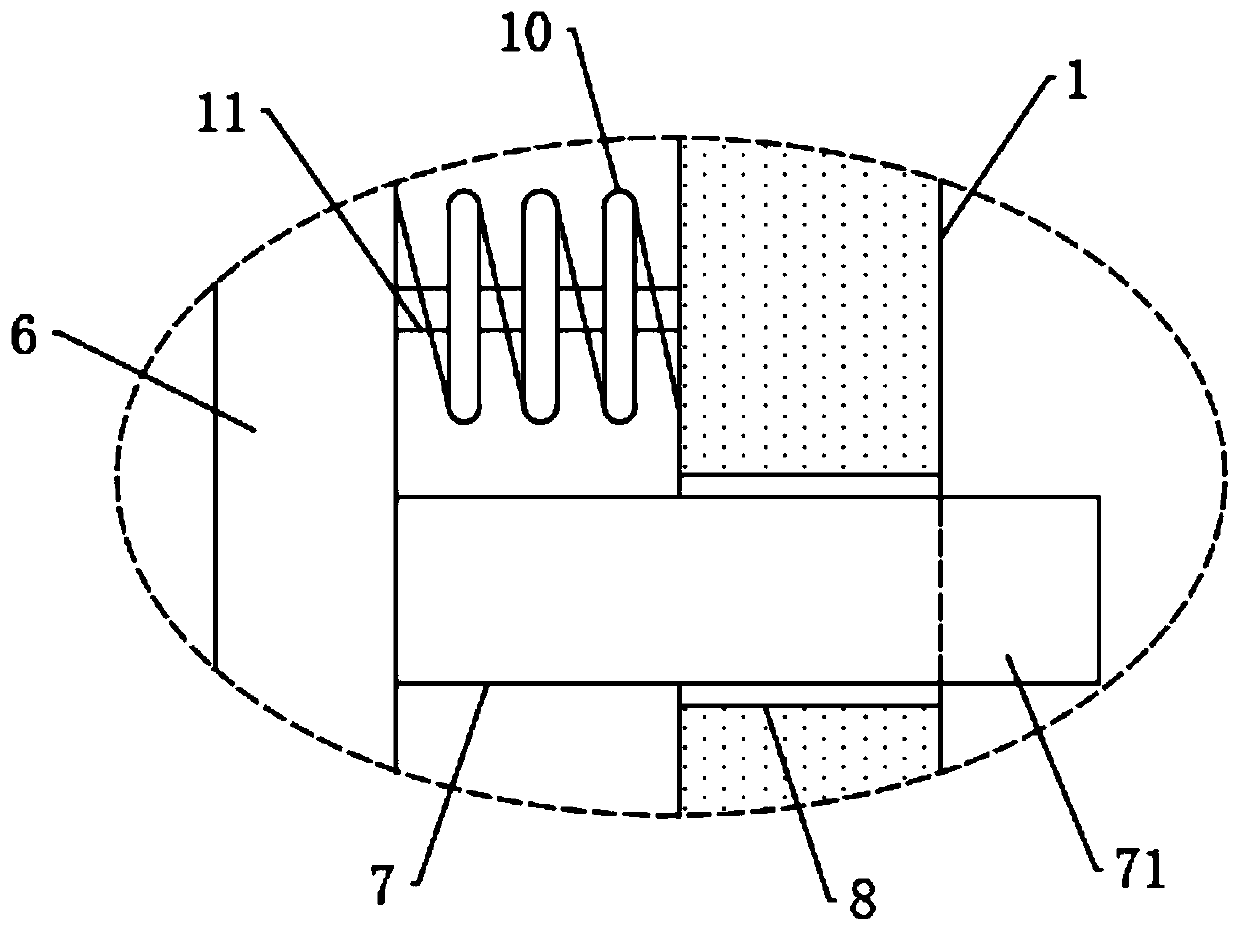

Automatic environment-friendly coating reflective heat-insulating coating wallboard continuous production system

InactiveCN107744915AImprove coating efficiencyNot easy to wasteLiquid surface applicatorsCoatingsSuction forcePush pull

The invention relates to an environment-friendly continuous production system for automatically coating reflective heat-insulating paint wallboards, which includes a coating device, which includes a box body, an extrusion mechanism arranged in the box body, and an overflow mechanism arranged on the side of the box body. A coating port is opened on the upper surface of the box, and the extrusion mechanism squeezes the paint in the box to apply paint to the lower surface of the plate at the coating port; the lifting device is installed above the box, including the lifting mechanism, which is driven by the lifting mechanism. The adsorption mechanism for the absorption and transfer of the plate and the control mechanism for controlling the adsorption force of the adsorption mechanism; the roller uniform output device, the roller uniform output device is set at the rear end of the box, including the push-pull mechanism and the roller uniform mechanism, the push-pull mechanism pushes the roller uniform mechanism along the The upper end of the coating port moves to evenly coat the plate, and drives the plate to output when it is reset; the present invention overcomes the troublesome coating operation and uneven coating when the plate needs to be coated on one side, which may easily cause paint waste and The problem of low coating efficiency.

Owner:安徽家思特涂料有限责任公司

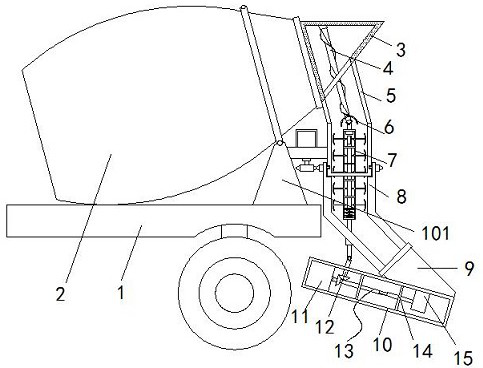

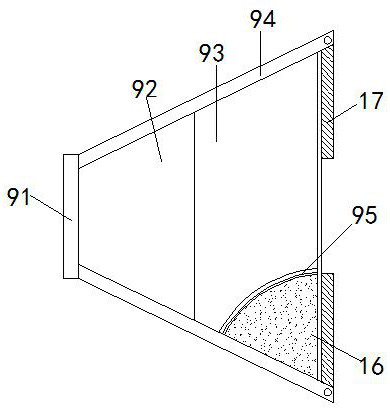

Semi-flexible pavement construction process and quality control method

PendingCN113188663ANot easy to measure inaccurate problemsQuick guideRadiation pyrometryIn situ pavingsAdhesive cementArchitectural engineering

The invention provides a semi-flexible pavement construction process and a quality control method, the construction process comprises the following steps: S1, paving a matrix asphalt mixture, S2, preparing cement-based adhesive cement, S3, pouring the cement-based adhesive cement, S4, curing, S5, opening traffic, and S6, treating a construction joint. According to the semi-flexible pavement construction process and the quality control method, the problems that in the prior art, in the semi-flexible pavement construction process, asphalt needs to be packaged during transportation, so that the temperature is not prone to loss, and tarpaulin which is commonly used at present does not have multifunctionality and is prone to adhering to asphalt, in the construction process, pouring of the cement mortar has certain defects, the discharging speed and the discharging amount cannot be controlled according to the actual situation in the moving process of a mixer truck, and the cement mortar conveyed in a discharging pipe all the year round is inconvenient to clean and prone to coagulation and blockage.

Owner:广东云津工程建设有限公司 +1

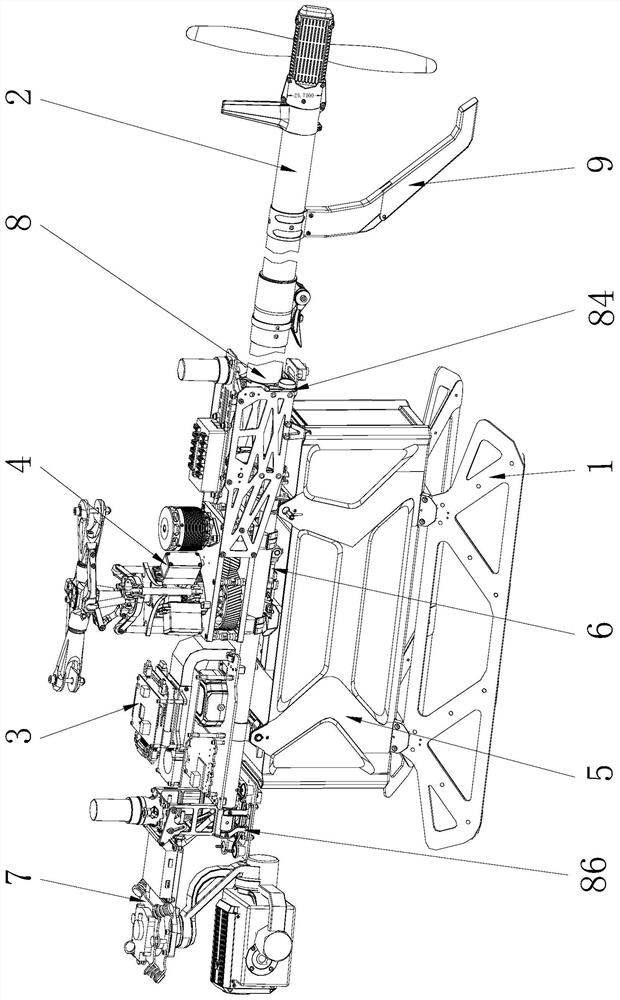

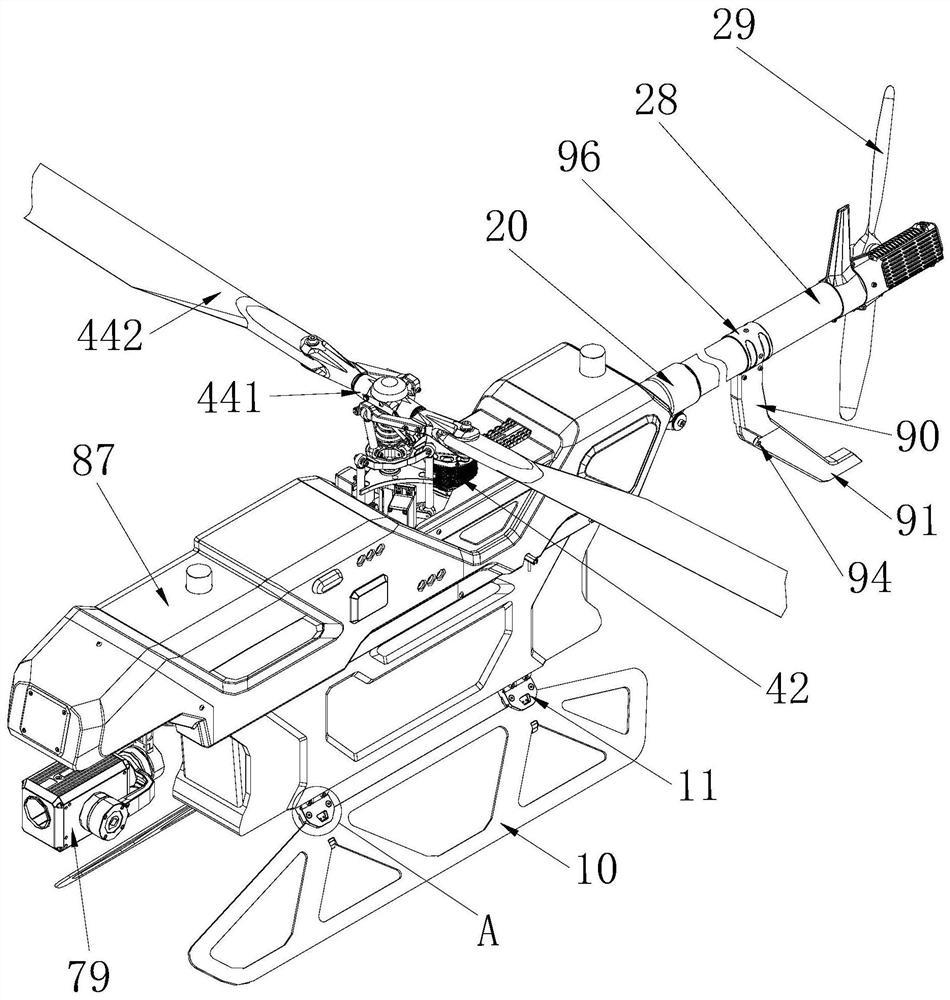

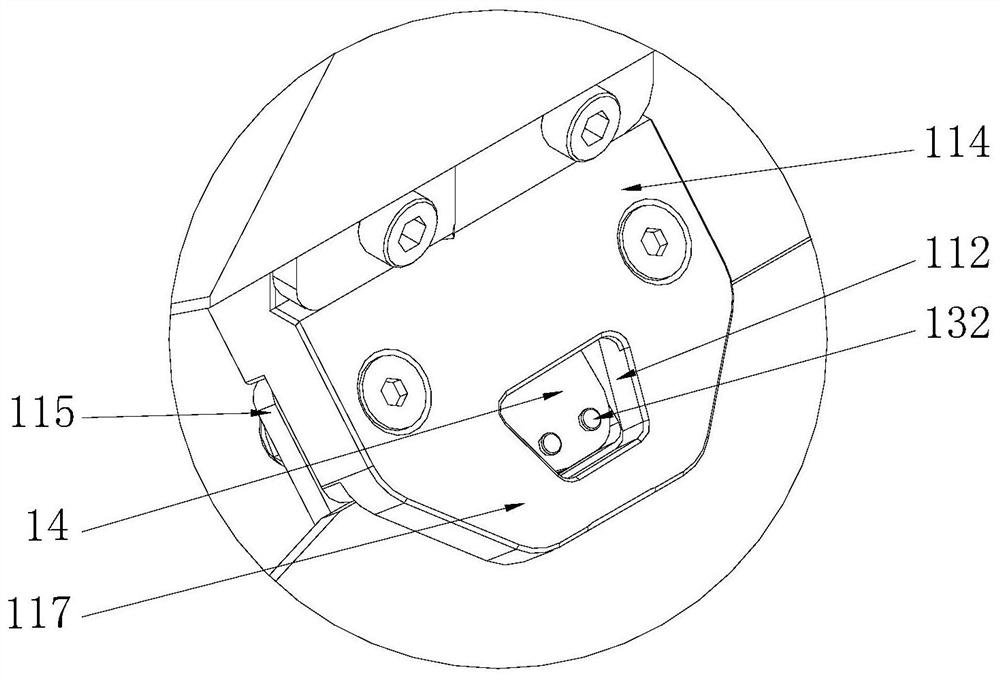

Unmanned helicopter

ActiveCN112896497AHighly integratedGuaranteed accuracyFuselage framesAircraft stabilisationTail rotorStructural engineering

The invention relates to the technical field of unmanned aerial vehicles, and discloses an unmanned helicopter which comprises a rack and a battery assembly, a power assembly, an avionics assembly, an empennage assembly and a foot stool assembly which are arranged on the rack, and the battery assembly comprises a battery box detachably installed on the rack and a battery arranged in the battery box; the power assembly comprises a fixing frame detachably installed on the rack, a main shaft, a motor and a plurality of steering engines, the main shaft, the motor and the steering engines are installed on the fixing frame, the avionics assembly comprises a cabin bottom plate detachably installed on the rack and an installation frame arranged at the upper end of the cabin bottom plate, and a first circuit board and a second circuit board are installed on the installation frame and the cabin bottom plate respectively. The empennage assembly comprises a tail pipe detachably installed on the rack and a tail rotor wing arranged at the tail of the tail pipe, and the foot stool assembly comprises a foot stool body detachably installed at the lower end of the rack. The whole large system of the unmanned helicopter is divided into functional units which can be separated from one another, and each functional unit is high in integration level and convenient to design, assemble, maintain, transport and the like.

Owner:ZHUHAI ZIYAN UAV CO LTD

Novel energy-saving high-efficiency sow farrowing bed

The invention discloses a novel energy-saving high-efficiency sow farrowing bed, which is mainly characterized in that the energy-saving high-efficiency sow farrowing beds are symmetrically arranged in a farrowing house which has a span of 5.8m to 6m; each farrowing bed is an independent unit, and the bed body of the farrowing bed is a grille which is flatly arranged; one side of the grille adjacent to a channel is provided with a concrete prefabricated plate; the grille and the prefabricated plate are connected into one body and supported on the ground by concrete columns; the prefabricated plate is also provided with a manger; and the side of the prefabricated plate adjacent to the channel is provided with a barrier which is provided with an opening. Due to the adopted technical scheme,compared with the prior art, the novel energy-saving high-efficiency sow farrowing bed has the advantages of saving construction cost, having small building area and small occupied area, being hard toinfect diseases for the sow and piglet and saving pig feed.

Owner:南召县康源养殖有限公司

Environment-friendly machining process for vulcanizing stabilizer bar and wear-resistant rubber bushing into whole

InactiveCN110395083ANot easy to wearImprove driving experienceInterconnection systemsWear resistantEngineering

The invention discloses an environment-friendly machining process for vulcanizing a stabilizer bar and a wear-resistant rubber bushing in a whole. The environment-friendly machining process comprisesthe stabilizer bar and the rubber bushing, wherein the rubber bushing comprises a bushing body and an adhesive layer; the environment-friendly machining process comprises the following steps that a, amounting part of the stabilizer bar is coat with a base glue; b, the mounting surface of a rubber bushing or the mounting part of the stabilizer bar is coated with a surface glue; c, the rubber bushing is moved to the mounting part; and d, the rubber bushing and at least part of the mounting part are baked until the rubber bushing and at least part of the mounting part are bonded into a whole. According to the environment-friendly machining process, the stabilizer bar and the rubber bushing are coated with the base glue or the surface glue, the rubber bushing and the stabilizer bar are adhered to form a whole, so that when the stabilizer bar is twisted, the rubber bushing does not rotate relative to the stabilizer bar, but adapts to the torsion of the stabilizer bar through elastic deformation of the rubber bushing, the generation of abnormal sounds is fundamentally avoided, and the service life is prolonged; and the processing can realize automation and more efficient, and the cost is saved.

Owner:浙江创城汽车零部件有限公司

Pineapple peeling device capable of achieving rapid clamping and positioning

The invention relates to a pineapple peeling device capable of achieving rapid clamping and positioning. The device is characterized in that a supporting frame, a center sliding block, a screw and a peeling knife are adopted as a body; the upper end of the supporting frame is provided with a kidney-shaped fixing plate and a first longitudinal guide rail and a second longitudinal guide rail which are connected to the two sides of the kidney-shaped fixing plate and centrally symmetric about the kidney-shaped fixing plate; the upper end and the lower end of the center sliding block are provided with a center positioning column and a transverse guide rail respectively, and a first clamping sliding block and a second clamping sliding block are arranged between the transverse guide rail and thefirst longitudinal guide rail and between the transverse guide rail and the second longitudinal guide rail respectively; an L-shaped tool rest supporting rod which is inserted into the center positioning column and can slide up and down is arranged on the center positioning column; in the pineapple clamping fixing process, the center sliding block drives the tool rest supporting rod to be rapidlypositioned to the center of the bottom of a pineapple, and the device is exquisite in design, convenient to operate and easy to use; the pineapple is clamped in two ways, clamping is firm, the pineapple is not likely to fall down, and no waste is caused.

Owner:SUQIAN ZHIPENG INTELLIGENT TECH CO LTD

Efficient filtering equipment for juice and residues in raw materials for sugar processing

InactiveCN107297098ANot easy to wasteImprove filtering effectMoving filtering element filtersEngineeringRaw material

The invention belongs to the technical field of sugar processing and particularly relates to efficient filtering equipment for juice and residues in raw materials for sugar processing. The invention aims at achieving the effects that juice is unlikely to waste, the filtering speed is high, the filtering effect is good, and the working efficiency is high. The efficient filtering equipment comprises a base plate, brackets, a collecting frame, a transverse plate, a cylinder body, a top plate, a driving device, a first filtering device and the like, wherein the two brackets is symmetrically and vertically mounted on the left and right ends of the top of the base plate in a bolt connection manner, and the collecting frame is connected to the top of the base plate between the two brackets through bolts. According to the efficient filtering equipment, the effects that juice is unlikely to be wasted, the filtering speed is high, the filtering effect is good, and the working efficiency is high are achieved.

Owner:闫存

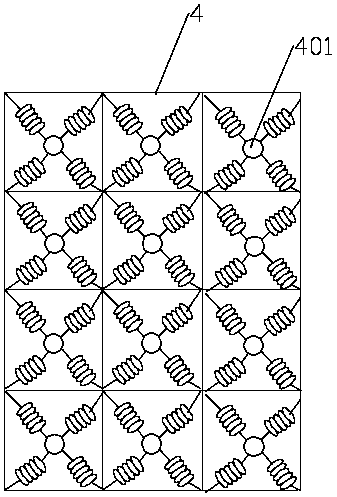

Efficient powder mixing equipment

InactiveCN111013460ASmooth Squeeze OperationStir wellShaking/oscillating/vibrating mixersTransportation and packagingProcess engineeringMechanical engineering

The invention discloses efficient powder mixing equipment, which belongs to the field of mixing equipment, the invention discloses the efficient powder mixing equipment, which comprises a mixing equipment body with an upper cover, wherein a stirring structure for uniformly mixing materials is arranged in the mixing equipment body; at least one group of scraping pieces for preventing materials frombeing easily attached to the inner wall of the mixing equipment body are also arranged in the mixing equipment body; the scraping piece is arranged, on one hand, materials attached to the inner wallof the mixing equipment body in the stirring process can be scraped off, on the other hand, a stirring area of the stirring rod can be further increased, material stirring is more sufficient, the stirring efficiency is improved, meanwhile, a vibration part is arranged; so that vibration is generated between the vibration part and the material mixing equipment body, the relative positions of part of materials can be changed while the materials splashed to the inner wall of the material mixing equipment body in the stirring process are shaken off, the materials are mixed more uniformly, the material mixing efficiency is improved in the process, and the production cost is saved.

Owner:杭州欣禾工程管理咨询有限公司

Garden irrigating device

InactiveCN105284555ASimple structureEasy to operateWatering devicesCultivating equipmentsWater channelWater source

The invention discloses a garden irrigating device which comprises a water tank, wherein a water pipe is connected at one side of the water tank; the water pipe communicates with the water tank; a straw is arranged at the connection of the water tank and the water pipe; a valve is mounted on the water pipe; a motor is arranged at one end, far from the water tank, of the water pipe; the motor is mechanically connected with the water pipe; one end, far from the water tank, communicates with a water channel; a buffer pipe is mounted on the side face of the water channel; one end of the buffer pipe communicates with the water channel while the other end of the buffer pipe is connected with an irrigating opening; the irrigating opening is in an adjustable irrigating opening structure. The garden irrigating device disclosed by the invention is simple in structure and convenient to operate, good soil humidity of soil can be ensured, and water sources are not easily wasted, so that the garden irrigating device brings convenience to staff and is convenient to operate and high in practicality.

Owner:CHENGDU GERUISI CULTURAL COMM

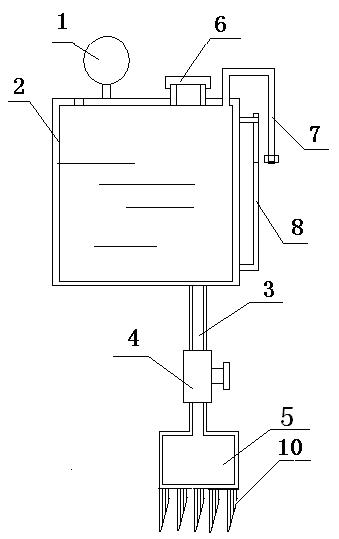

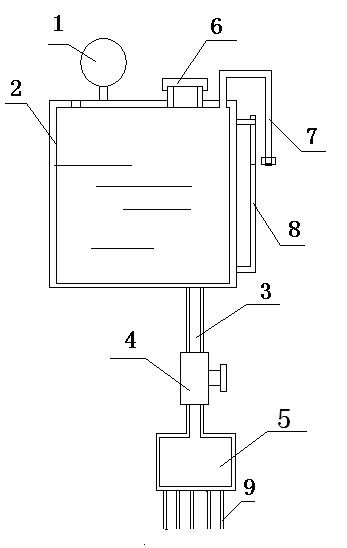

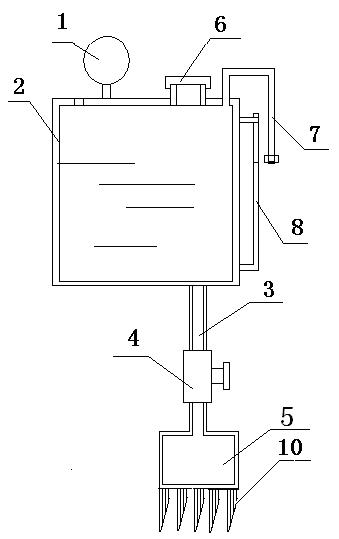

Controllable portable fruit tree fertilizing device

InactiveCN102090198APrevent fallingEasy to control the lengthRoot feedersLiquid fertiliser distributionFruit treeSprayer

The invention relates to a sprayer for fertilizing and spraying a pesticide, in particular to a controllable portable fruit tree fertilizing device. The controllable portable fruit tree fertilizing device is characterized in that a flow divider (5) is connected with a regulating valve (4) together; and a needle head plug (10) is arranged at the lower end of the flow divider (5). The fertilizing device has a simple structure and a good fertilizer saving effect, is convenient to carry, is simple to operate, ensures that a fertilizer is easily adsorbed, not only can be used for foliage spray of fruit trees, but also can be used for fertilizing the roots of the fruit trees.

Owner:西安谦坤商务咨询管理有限公司

Manufacturing technique and manufacturing equipment of silicon iron powder for secondary aluminum and diamond flotation

The invention discloses a manufacturing technique and manufacturing equipment of silicon iron powder for secondary aluminum and diamond flotation. The steps of raw material pretreatment, smelting, water atomization, drying and screening and the production equipment are included, a vacuum atomization system of the production equipment comprises an atomization furnace, a vacuum induction furnace, water spraying equipment and discharging equipment arranged at the lower end of the atomization furnace, and a heating device is arranged inside the atomization furnace; the water spraying device comprises a water tank, a first high pressure spraying nozzle and a second high pressure spraying nozzle, the first high pressure spraying nozzle and the second high pressure spraying nozzle are connected to the water tank, and one end of the first high pressure spraying nozzle extends into the atomization furnace; and the discharging equipment comprises a filtering net and a waste water collecting groove, and powder prepared after atomization is subjected to initial water removal. By means of the manufacturing technique and the manufacturing equipment of the silicon iron powder for secondary aluminum and diamond flotation, waste resources and powder are sufficiently used as hollow spheres, so that the density is low, the iron amount is high, the magnetism rate is high, and the mineral separation efficiency is improved; and the production finished product rate of the production equipment is high.

Owner:安阳新创冶金材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com