High-efficiency resource transformation method of nonferrous metal zinc-smelting fly ash

A technology for non-ferrous metals and zinc smelting, applied in the direction of chemical instruments and methods, zinc compounds, process efficiency improvement, etc., can solve the problems of difficult recovery, large acid consumption, low zinc oxide leaching rate, etc., to achieve good selectivity, The effect of low leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Utilize a beaker with a volume of 250mL as a zinc ash extraction reactor, add 20g of zinc ash (its zinc content is about 2.0%) in the beaker, and then add 100mL concentration of 0.5mol / L (NH 4 ) 2 SO 4 and 100 mL of ammonia water with a concentration of 0.5 mol / L as the extract. The mixed solution was stirred at normal temperature (25° C.) at a stirring speed of 100 rpm. After stirring for 30 minutes, the ash and the extract were separated by filtration, and the zinc content in the extract after separation was detected. The results showed that about 95% of the zinc was extracted from the zinc ash.

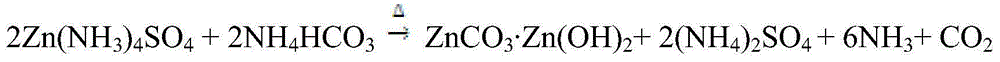

[0046] A glass bubbling absorption device with a volume of 500mL was used as a reactor, and 200mL of the zinc extract obtained in the above examples was installed in the reactor as an absorbent for flue gas desulfurization. The simulated flue gas with a sulfur dioxide concentration of 4000ppm was introduced into the reactor, the flue gas flow rate was controlled at 1L / min...

Embodiment 2

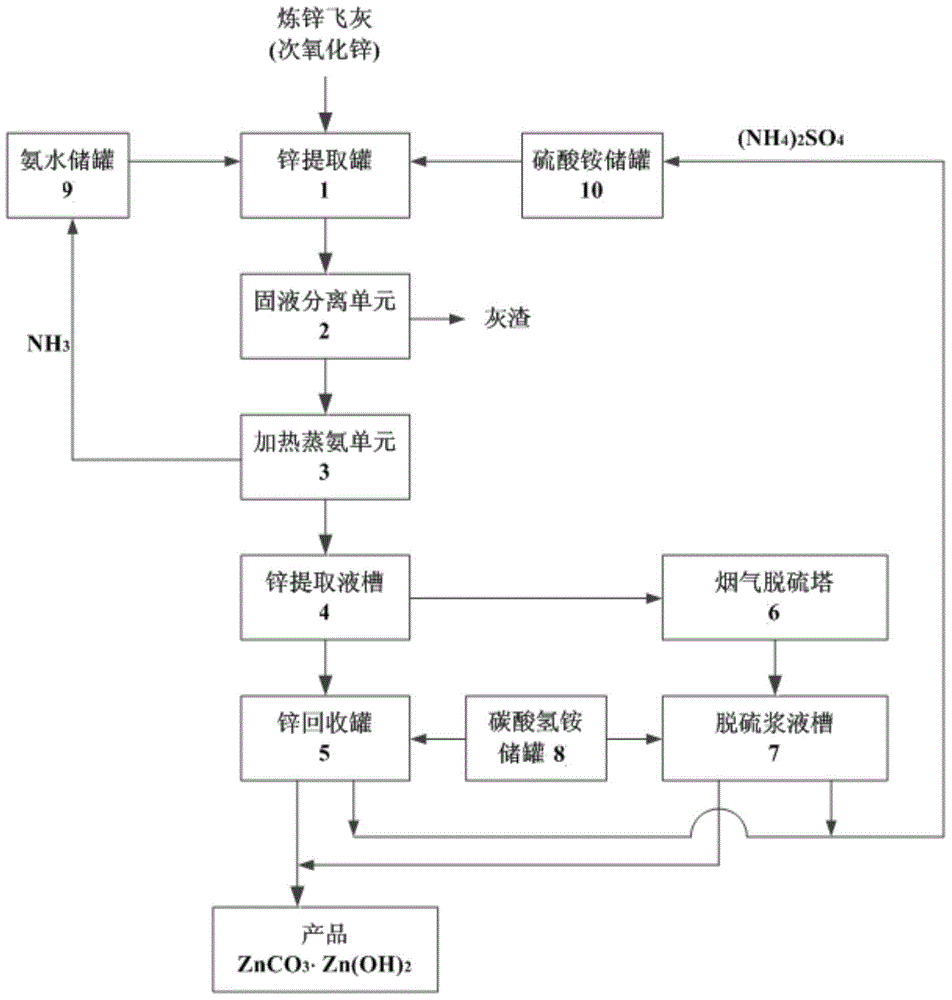

[0048] see figure 1 As shown, a resource-efficient conversion method of non-ferrous metal zinc smelting fly ash comprises the following steps:

[0049] (1) Zinc smelting fly ash is placed in zinc extraction tank 1, and ammonia water and ammonium sulfate solution are added in zinc extraction tank 1 through ammonia water storage tank 9 and ammonium sulfate storage tank 10 respectively, wherein, the concentration of ammonia water is 0.1mol / L, the volume ratio of ammonia water to ammonium sulfate solution is 1:1, the volume ratio of zinc smelting fly ash to ammonium sulfate solution is 1:10, the molar amount of ammonium sulfate in ammonia water, zinc oxide in zinc smelting fly ash and ammonium sulfate solution The ratio is 100:1:100, then stir and mix evenly to obtain a zinc-ammonia mixed solution;

[0050] (2) The zinc-ammonia mixed solution obtained in step (1) is subjected to solid-liquid separation through a centrifugal separation device, wherein the insoluble ash is recycle...

Embodiment 3

[0056] see figure 1 As shown, a resource-efficient conversion method of non-ferrous metal zinc smelting fly ash comprises the following steps:

[0057] (1) Put zinc smelting fly ash into zinc extraction tank 1, add ammonia water and ammonium sulfate solution to zinc extraction tank 1 through ammonia water storage tank 9 and ammonium sulfate storage tank 10 respectively, wherein the concentration of ammonia water is 5mol / L , the volume ratio of ammonia water to ammonium sulfate solution is 1:2, the volume ratio of zinc smelting fly ash to ammonium sulfate solution is 1:100, the molar ratio of ammonia water, zinc oxide in zinc smelting fly ash and ammonium sulfate solution in ammonium sulfate solution 1:1:10, then stir and mix evenly to obtain a zinc-ammonia mixed solution;

[0058] (2) The zinc-ammonia mixed solution obtained in step (1) is subjected to solid-liquid separation through a settling separation device, wherein the insoluble ash is recycled as a precious metal smelt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com