Patents

Literature

49results about How to "Realize automatic gluing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

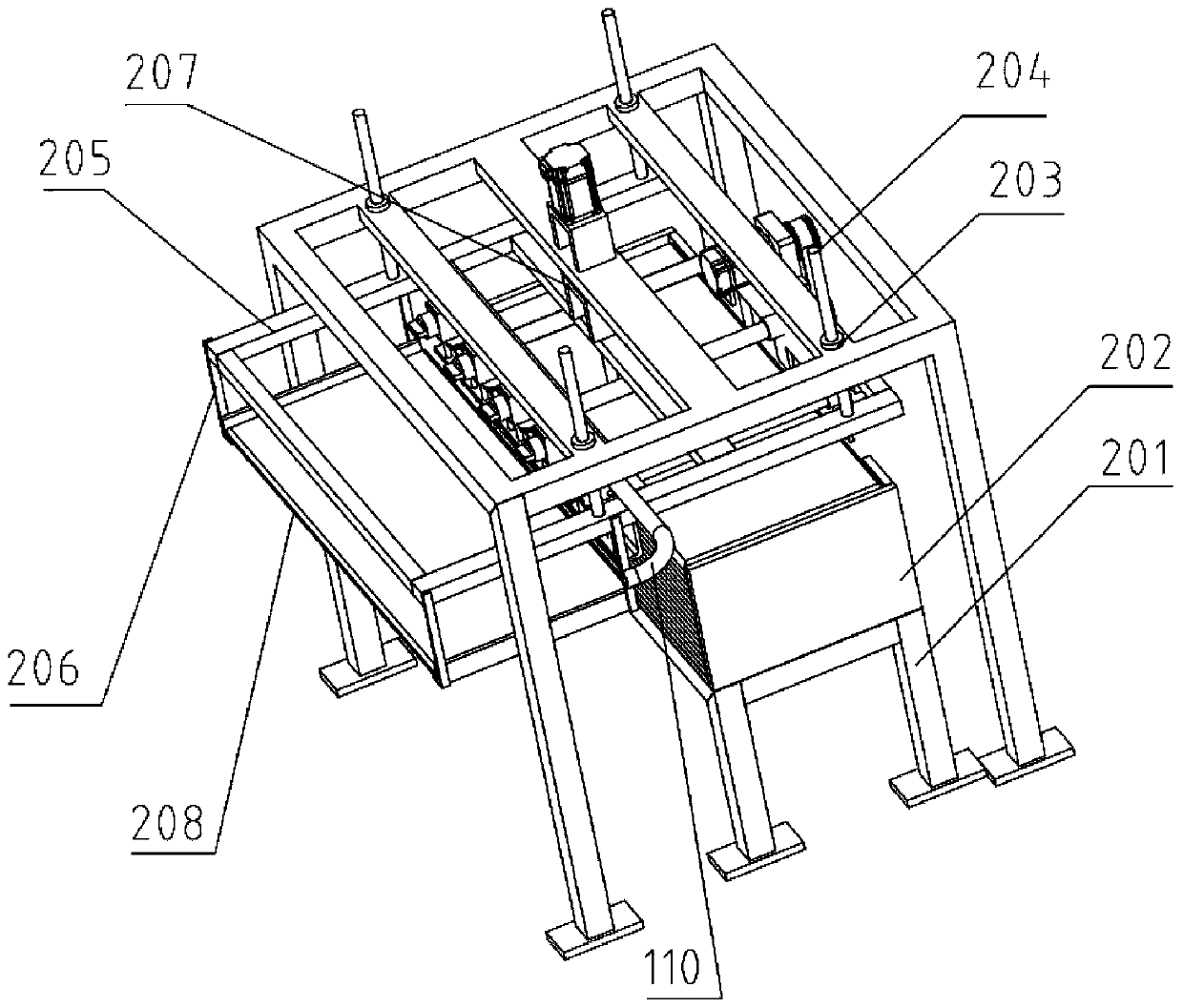

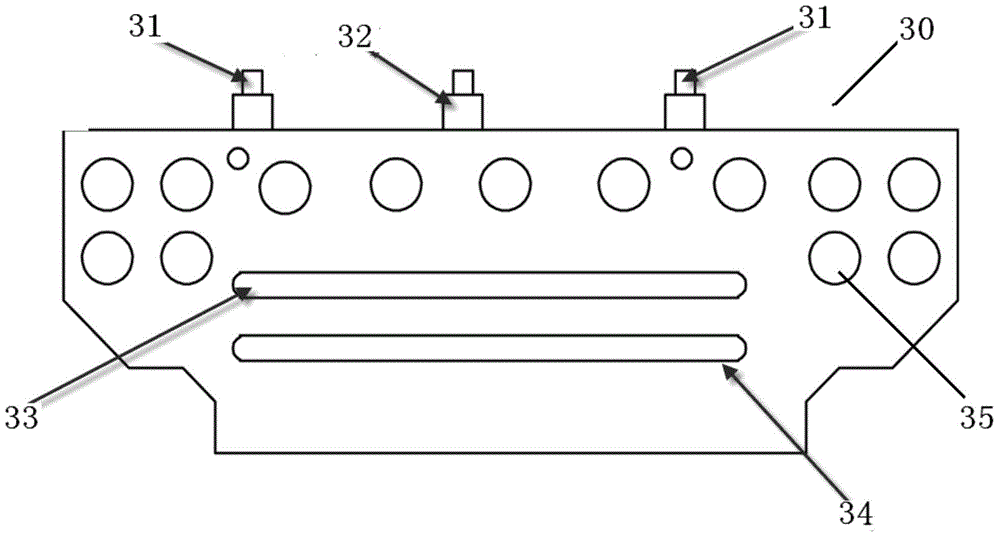

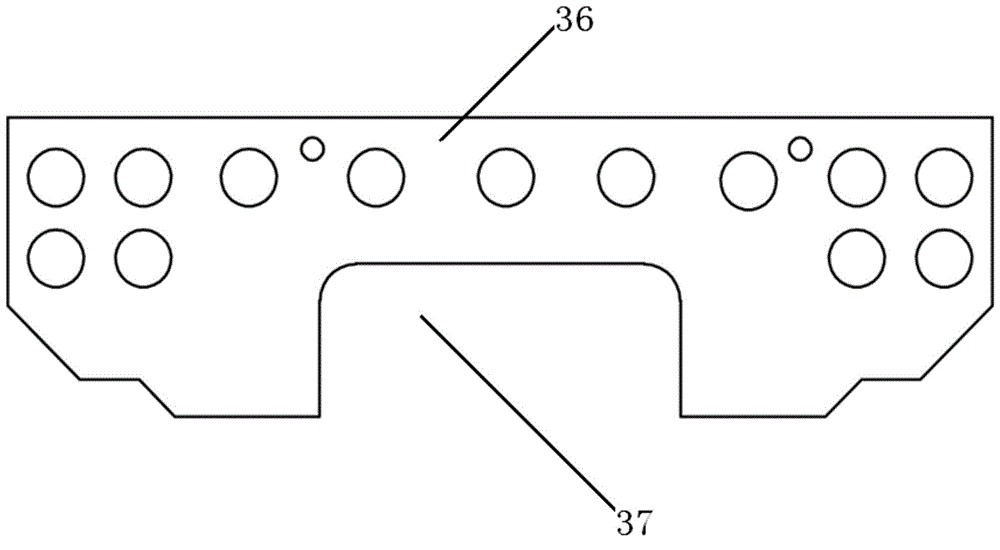

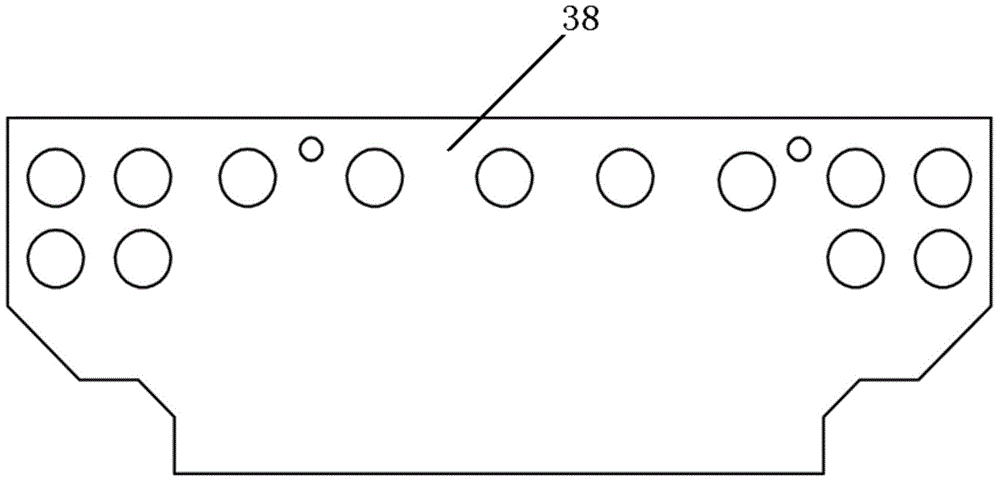

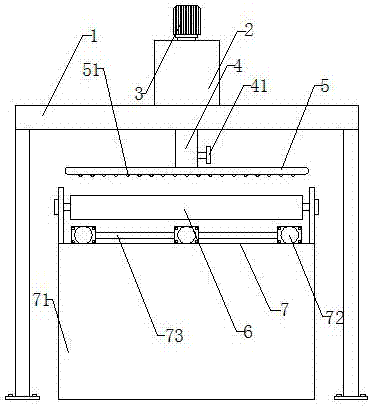

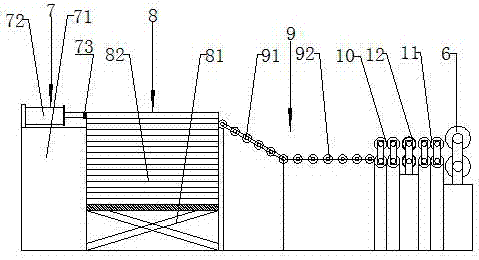

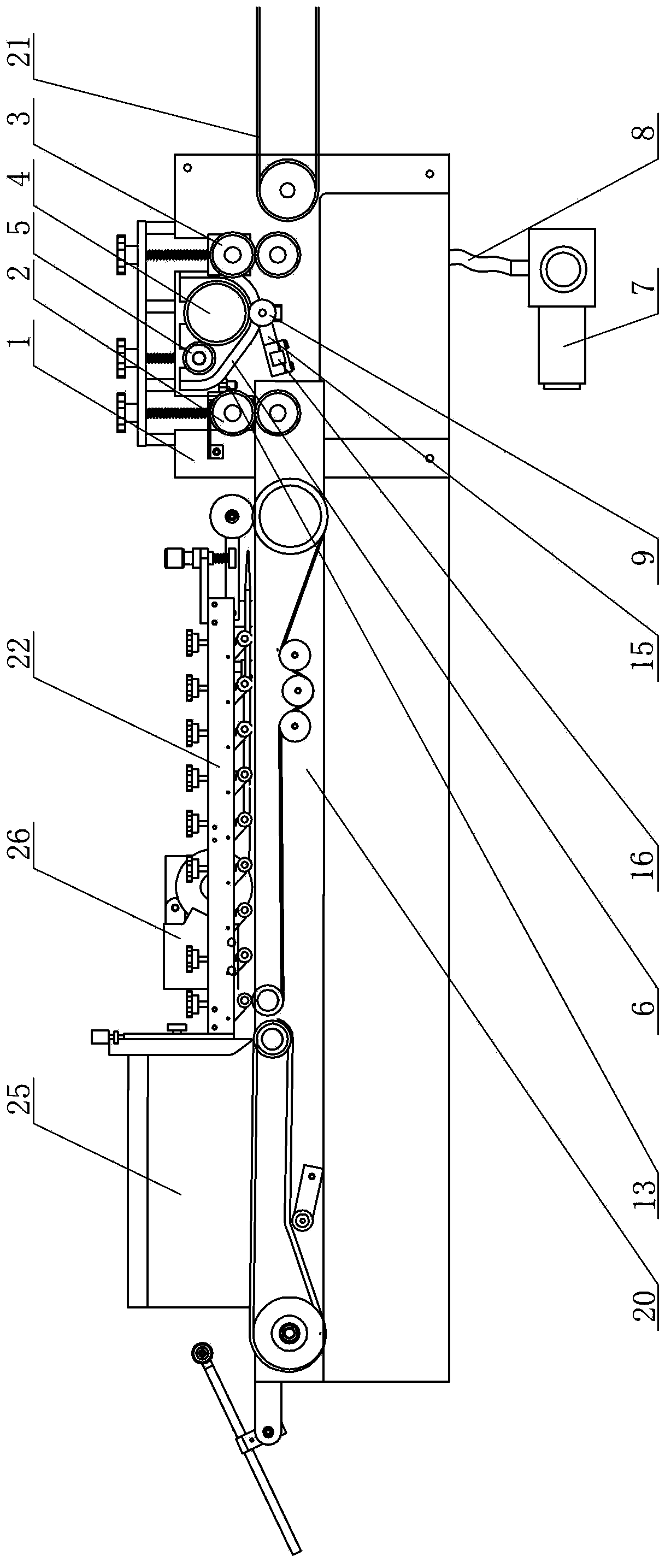

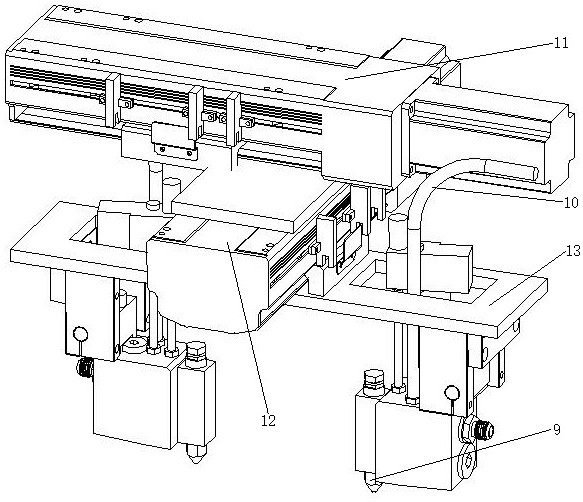

Layer-by-layer automatic feeding, marking and gluing integrated equipment for sheet materials

ActiveCN104708689AFast processingSpread evenlyOther plywood/veneer working apparatusAdhesive application devicesProduction lineEngineering

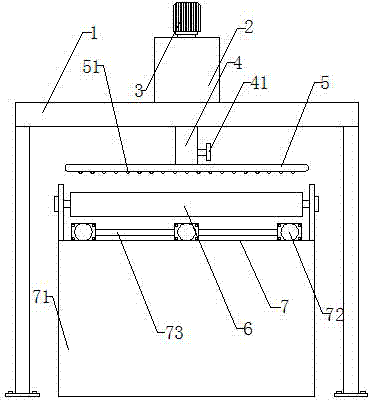

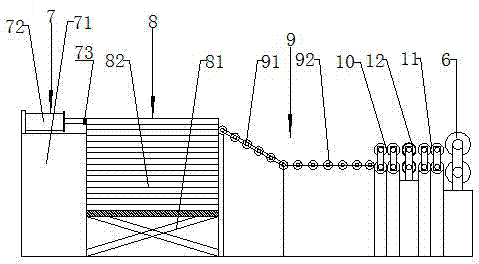

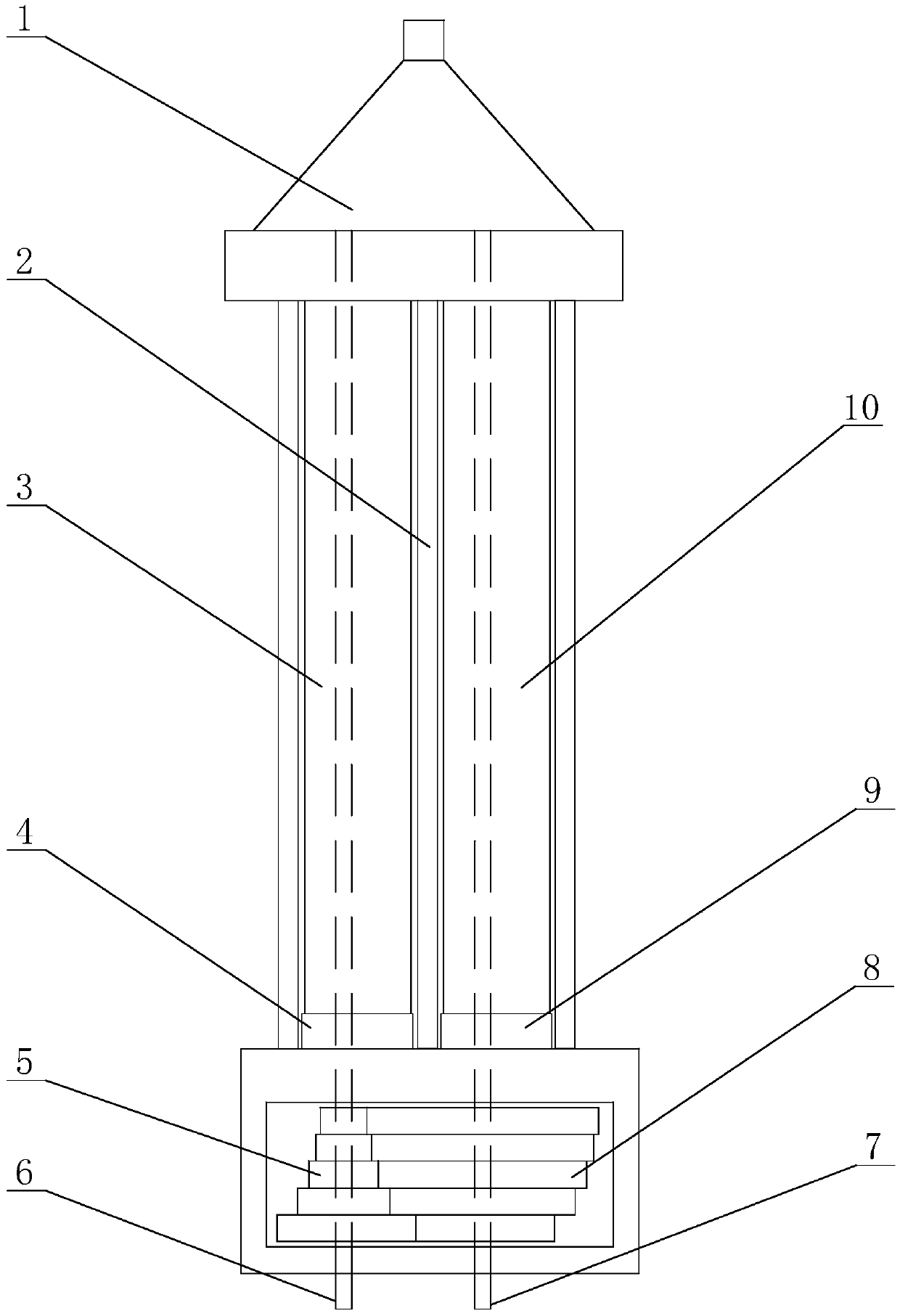

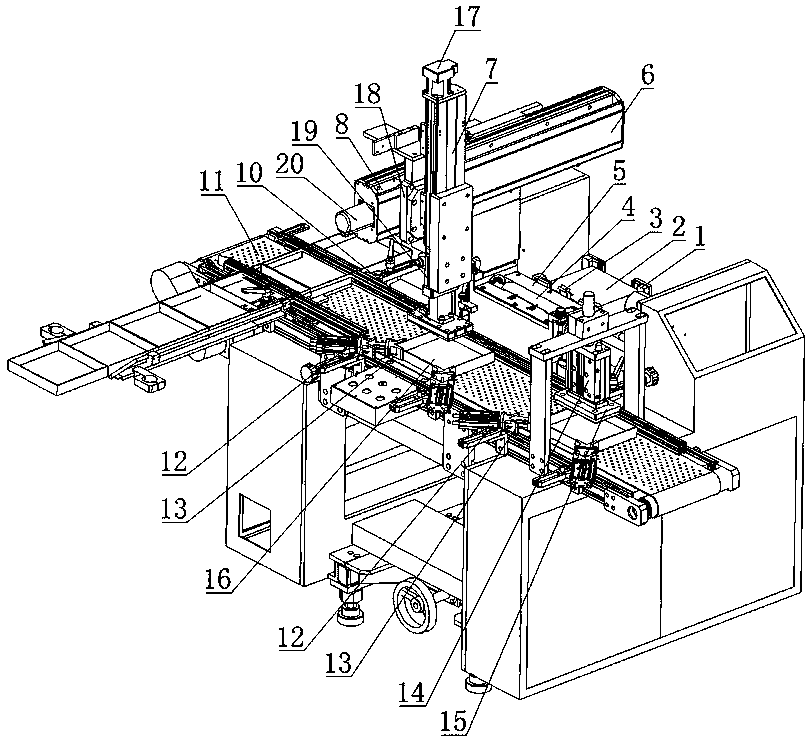

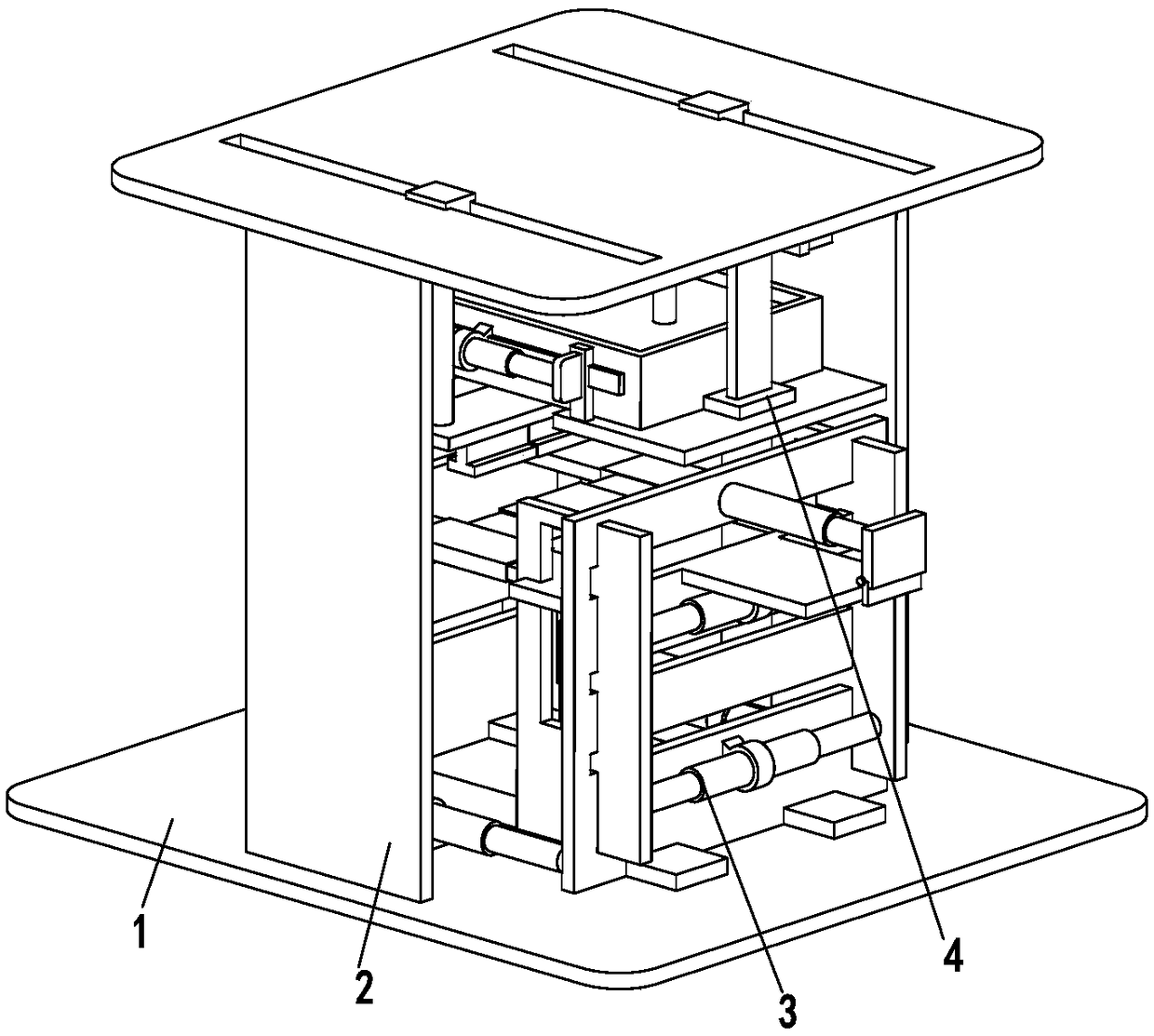

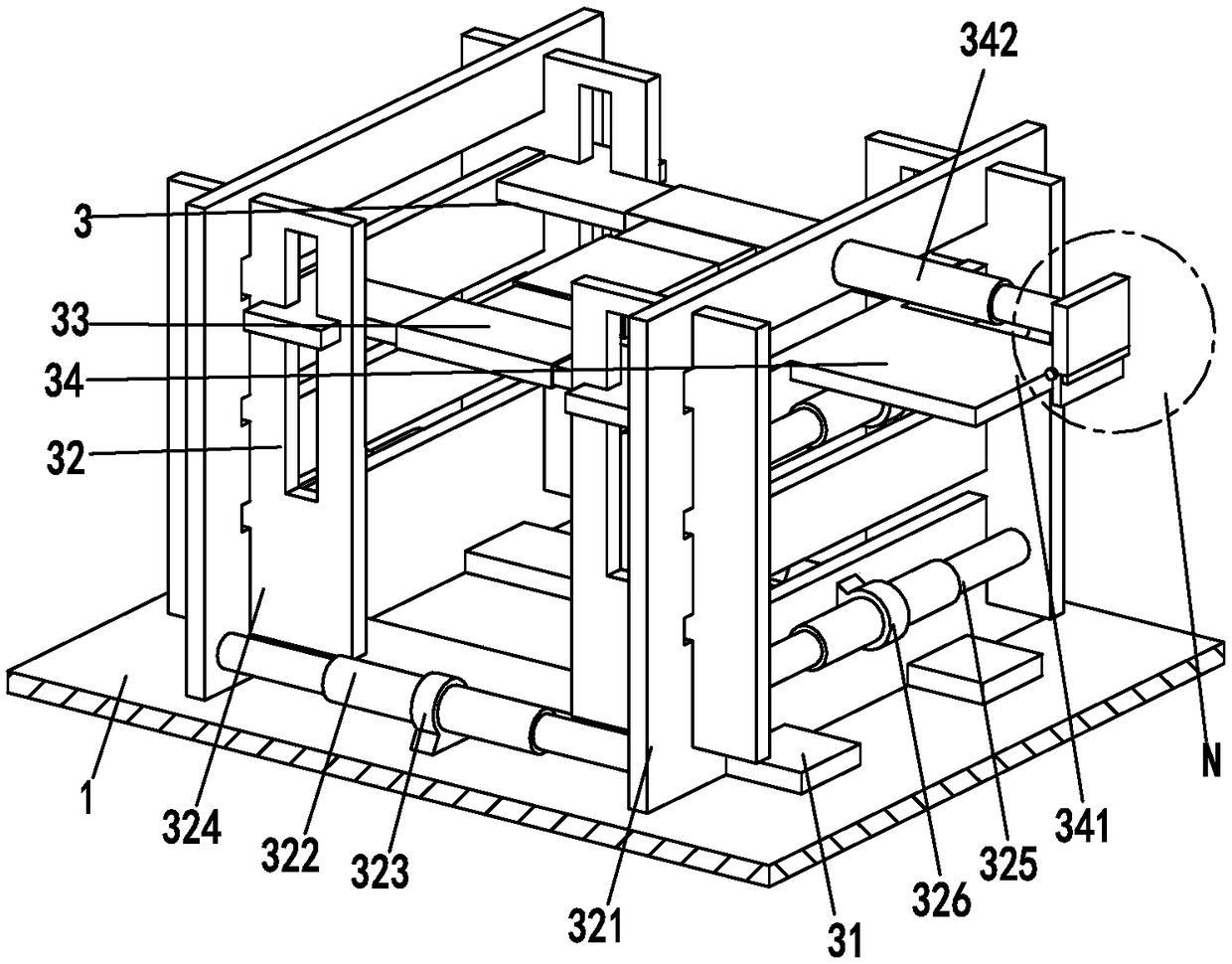

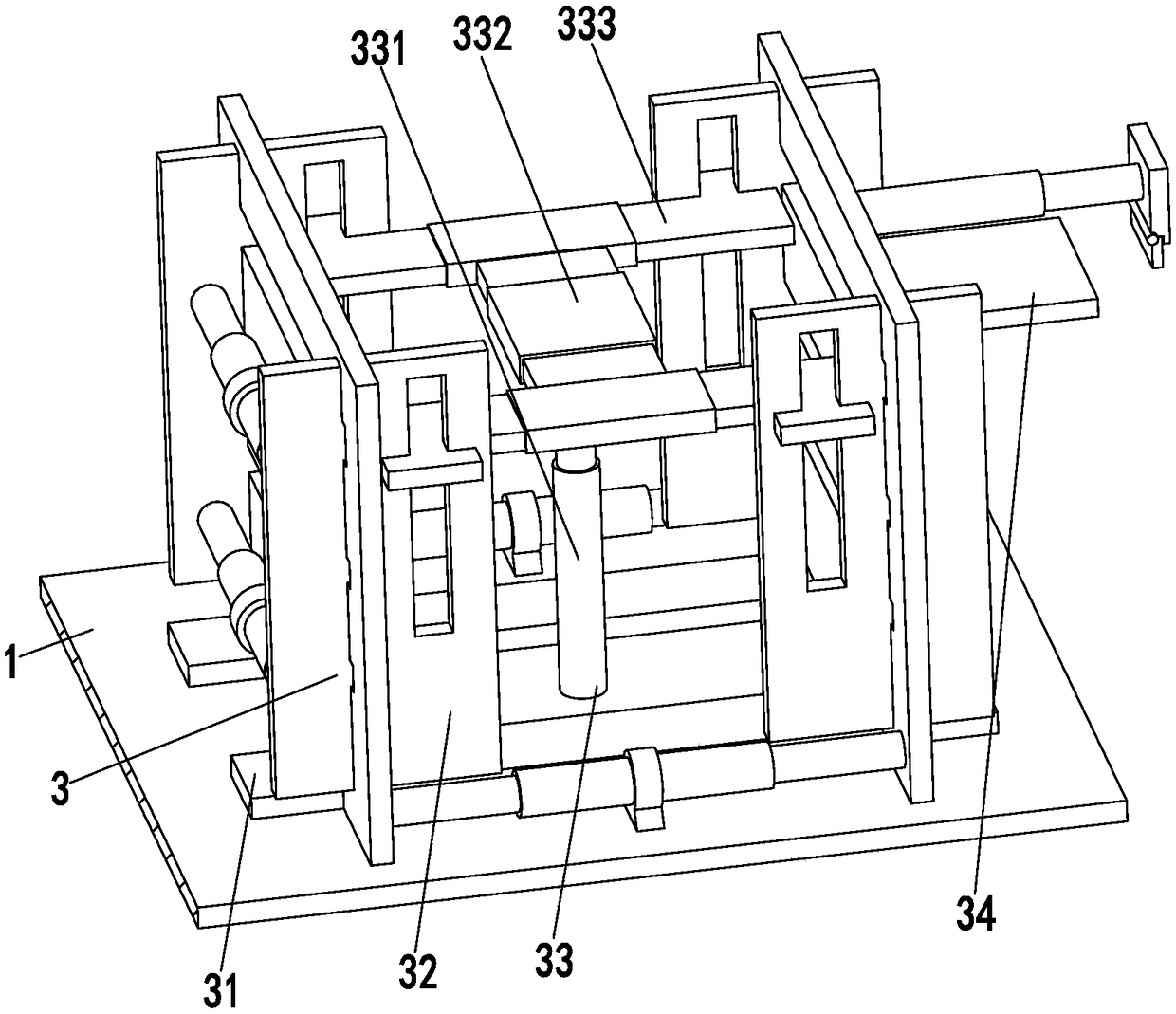

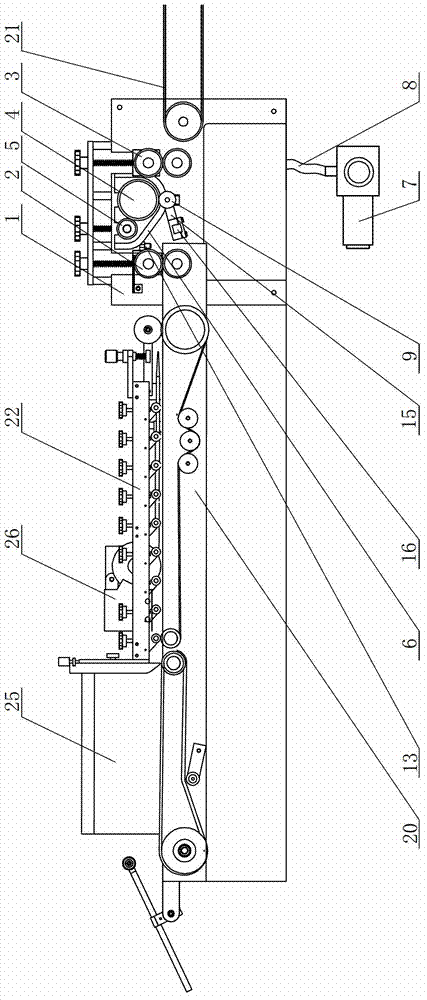

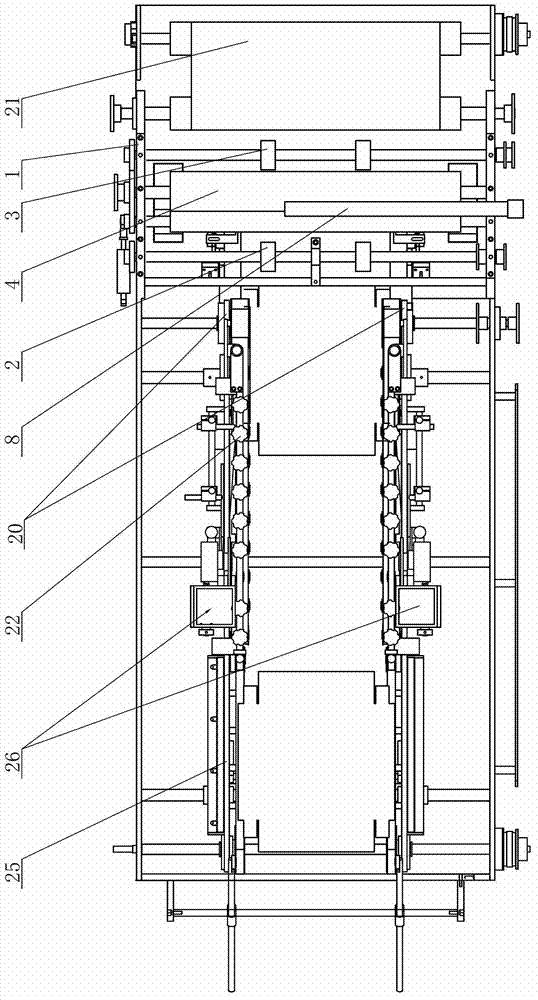

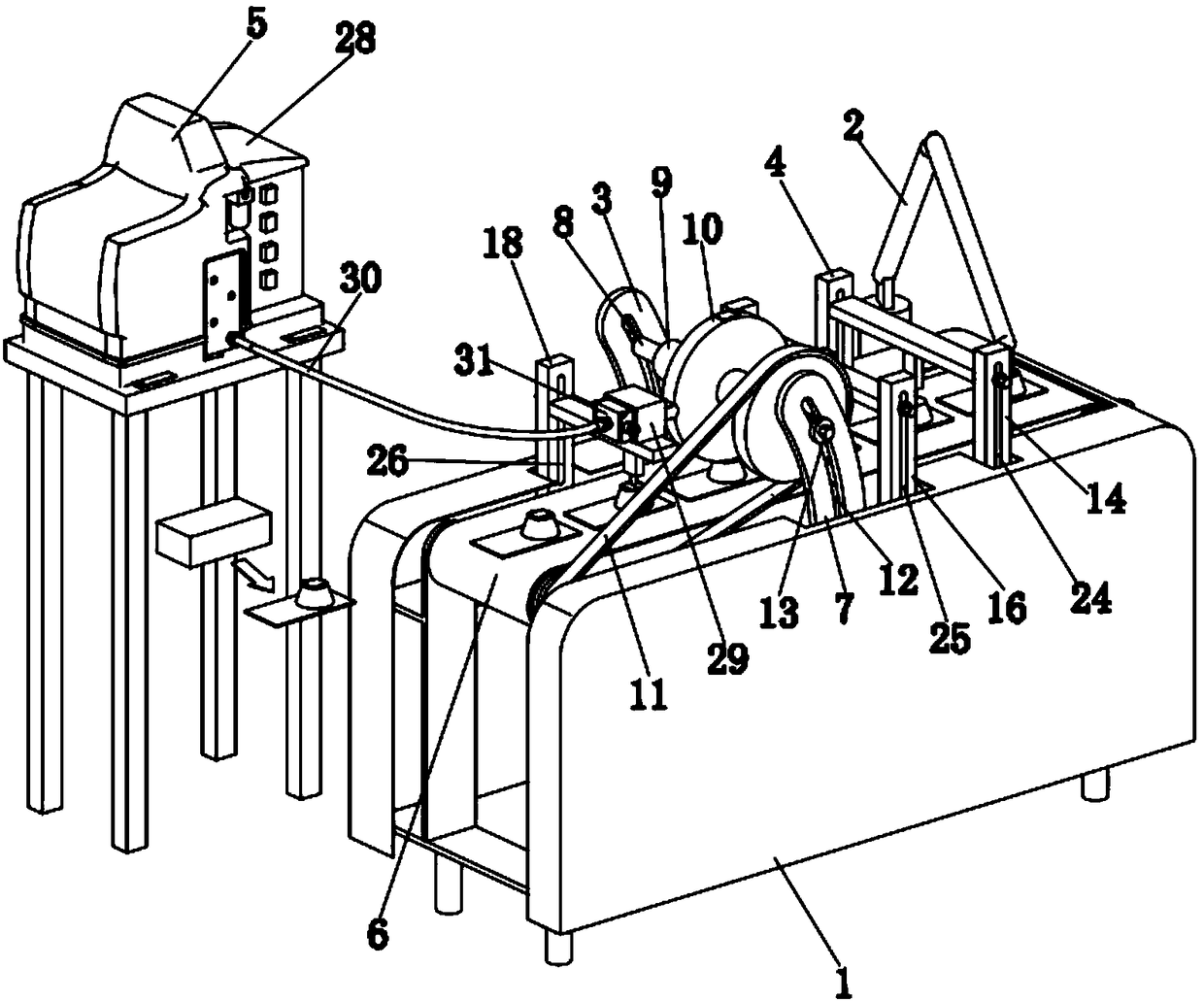

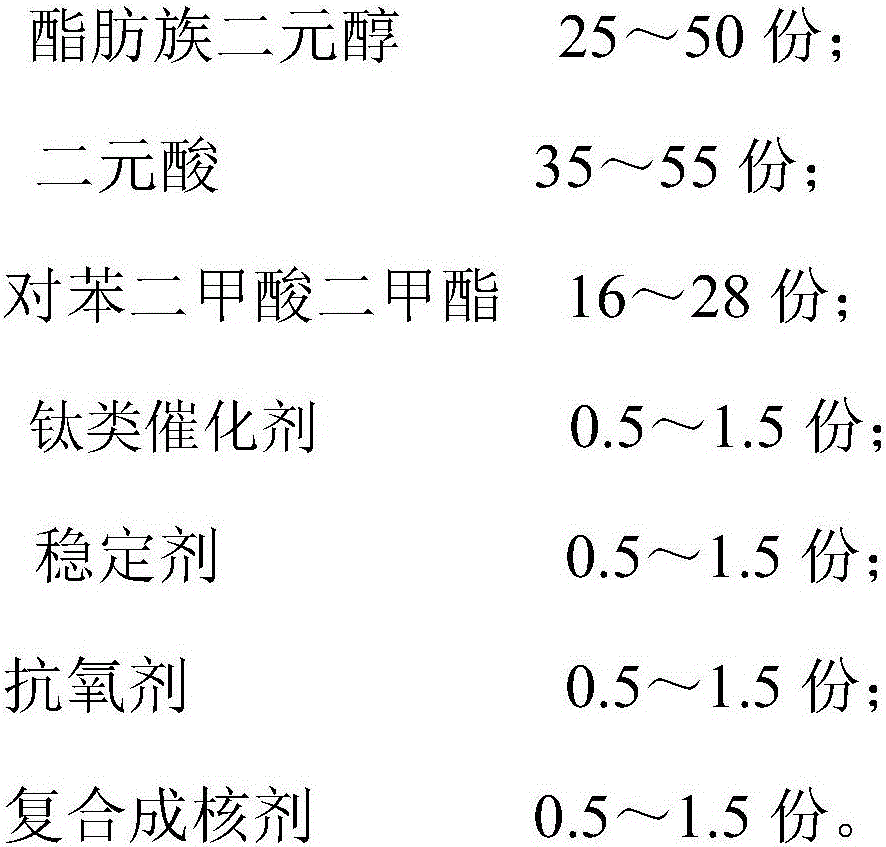

The invention discloses layer-by-layer automatic feeding, marking and gluing integrated equipment for sheet materials. The layer-by-layer automatic feeding, marking and gluing integrated equipment for the sheet materials comprises a marking device and a gluing device; the gluing device is arranged on one side of the marking device and a layer-by-layer automatic feeding device is arranged on the other side of the marking device; the layer-by-layer automatic feeding device comprises a pushing mechanism, a hoisting mechanism and a sliding mechanism in sequence; and the gluing device comprises a supporting framework, a stirring mechanism arranged at the upper end of the supporting framework, a material scattering mechanism arranged at the bottom of a transverse beam of the supporting framework, and a compression roller gluing mechanism arranged under the supporting framework. According to the layer-by-layer automatic feeding, marking and gluing integrated equipment, marking and gluing are integrated, transmission and interruption of machines are reduced in the process and the consistency of a production line is improved; and the machining time of the whole sheet material is shortened, materials can be automatically fed layer by layer, the transmission is buffered, the gluing can be automatically realized and the gluing is uniform.

Owner:JIANGSU KENTIER WOOD

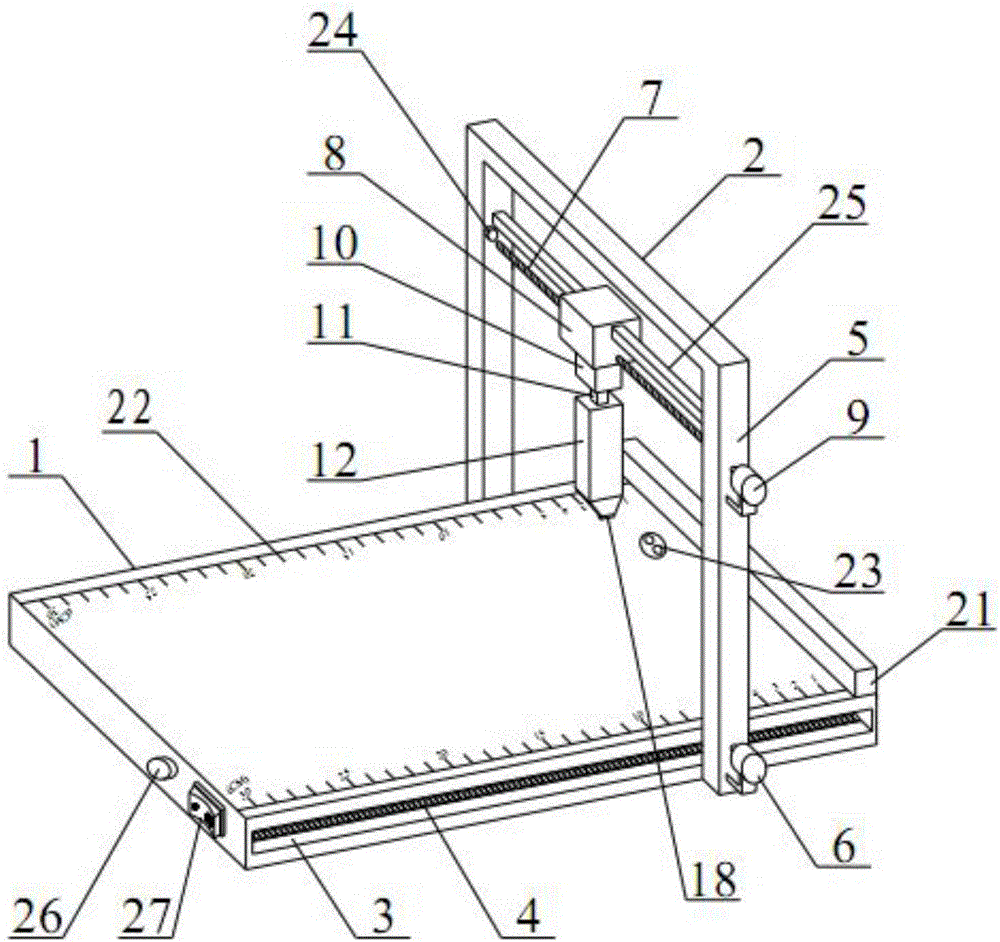

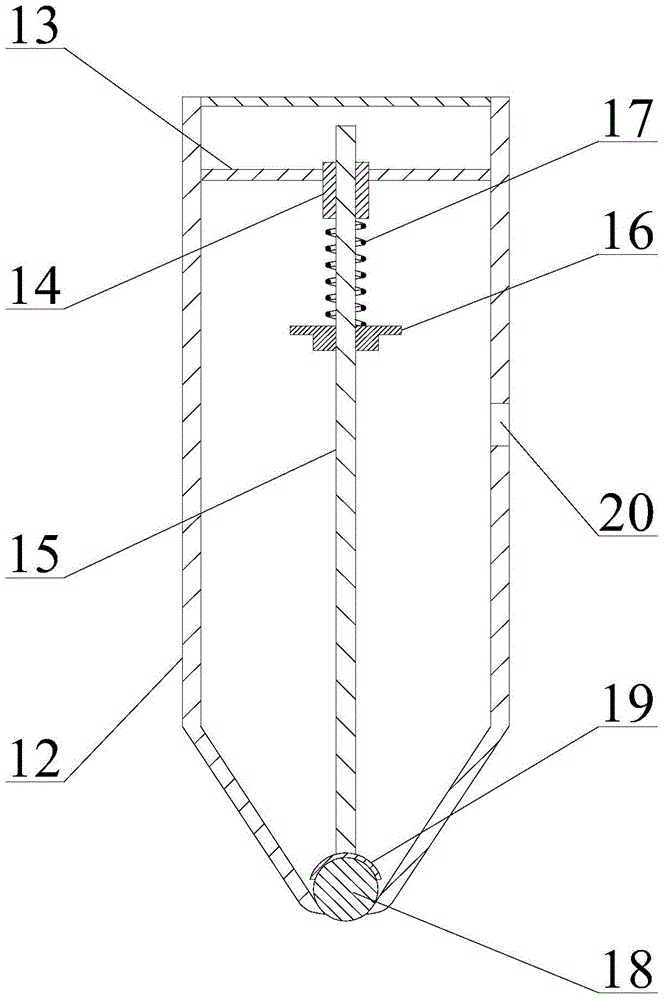

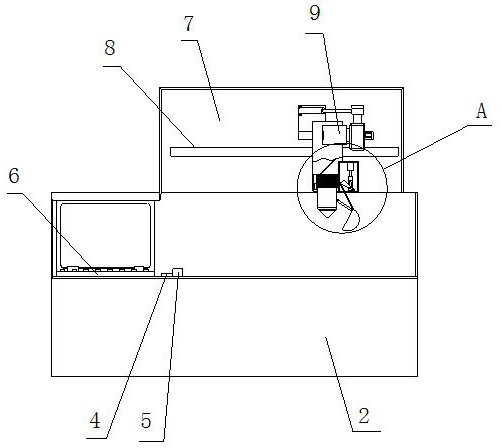

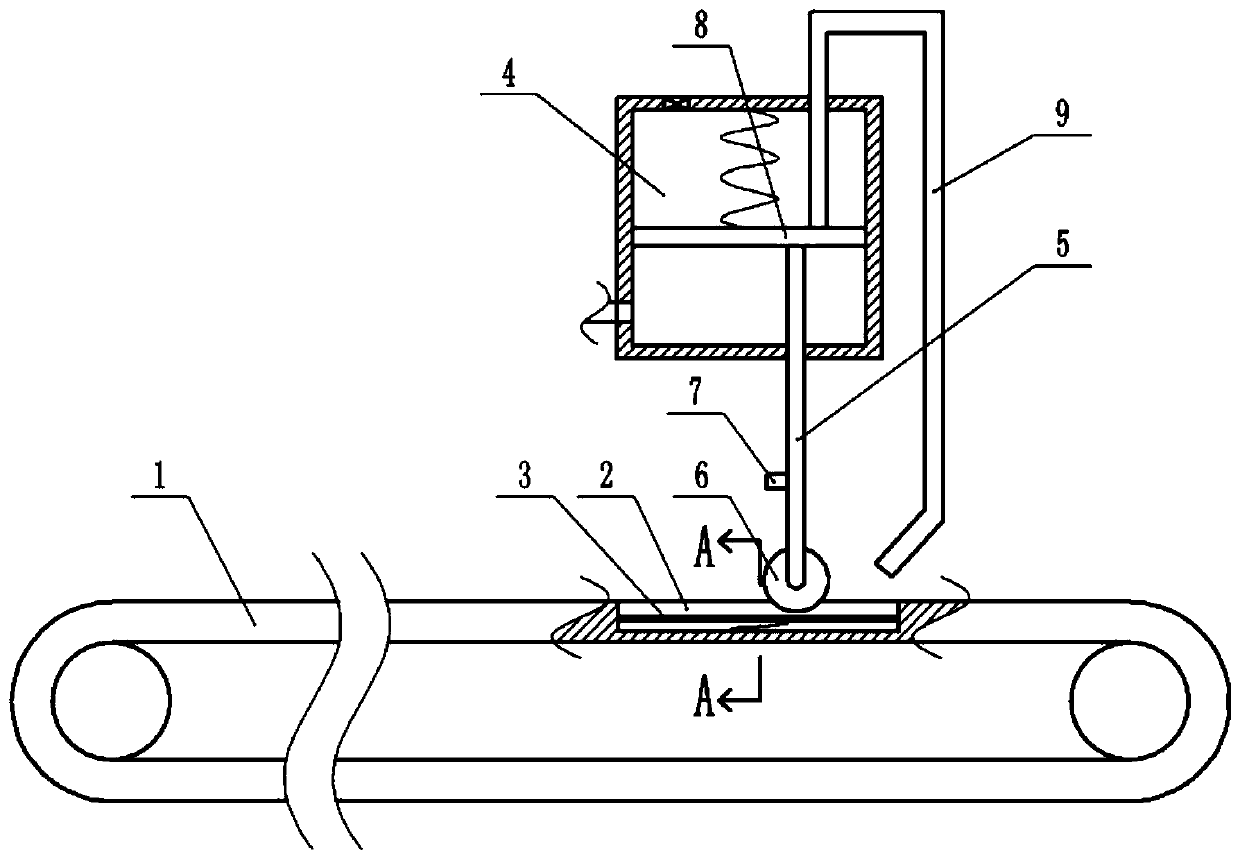

Small alternating current-direct current automatic glue spreader

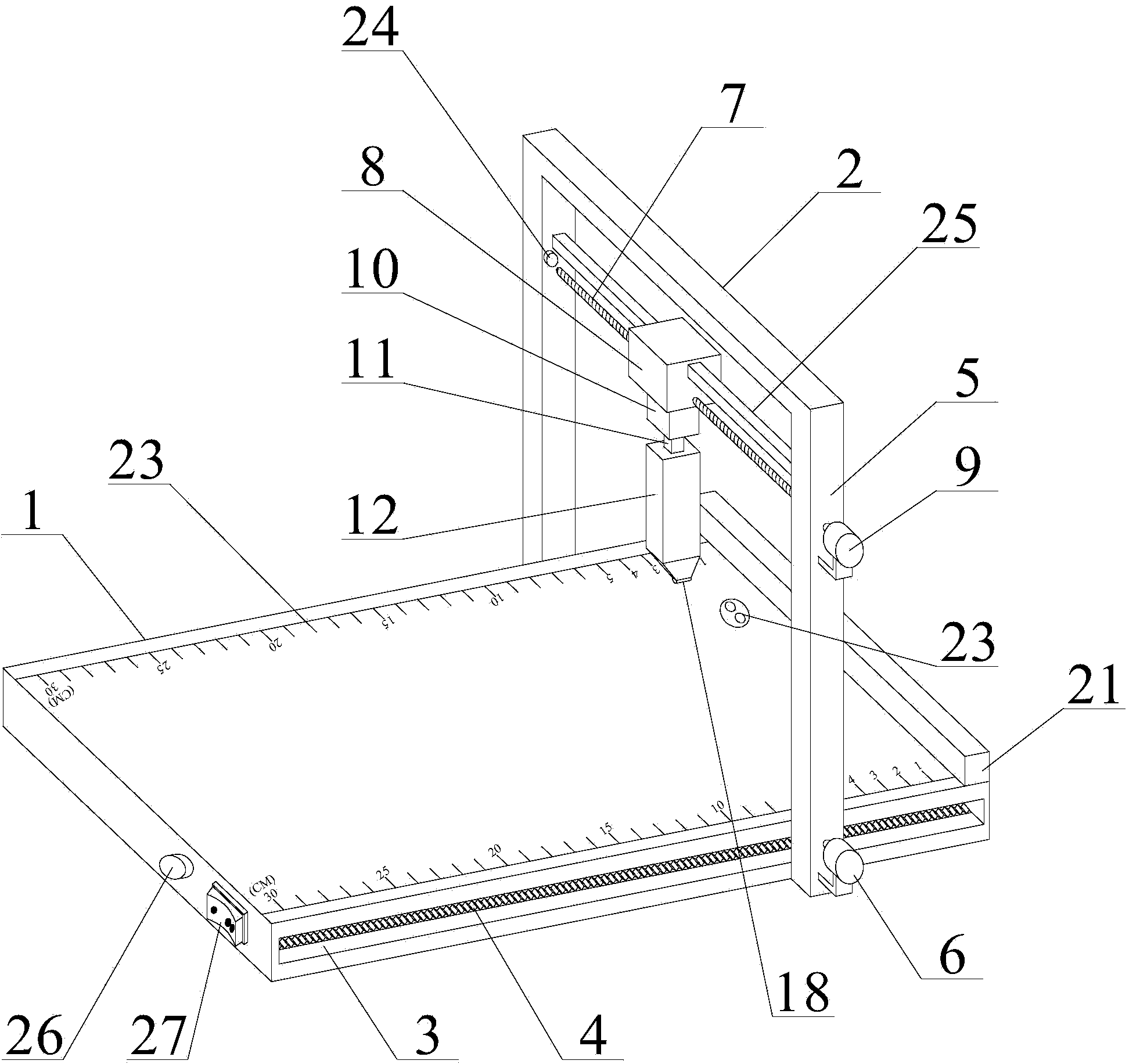

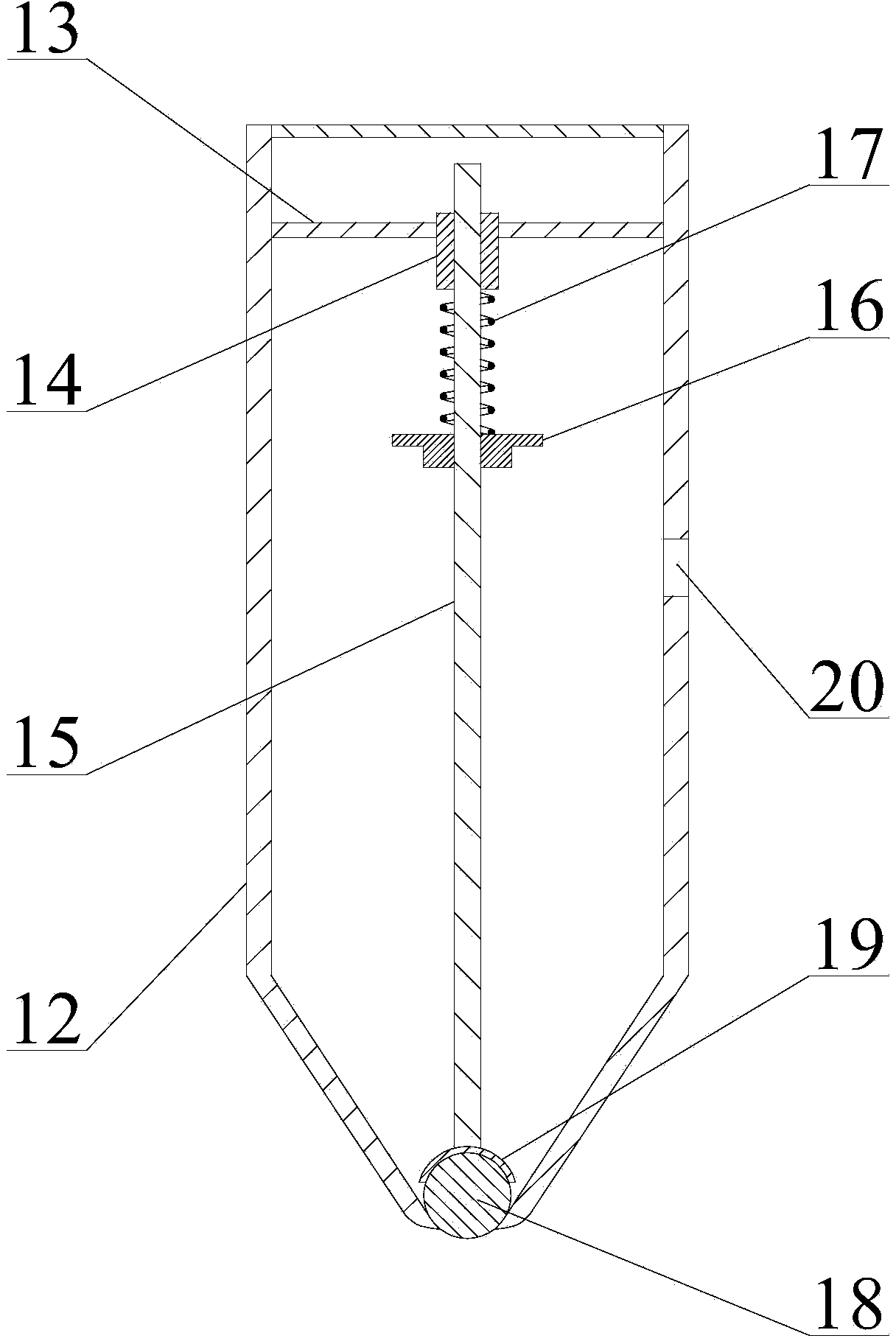

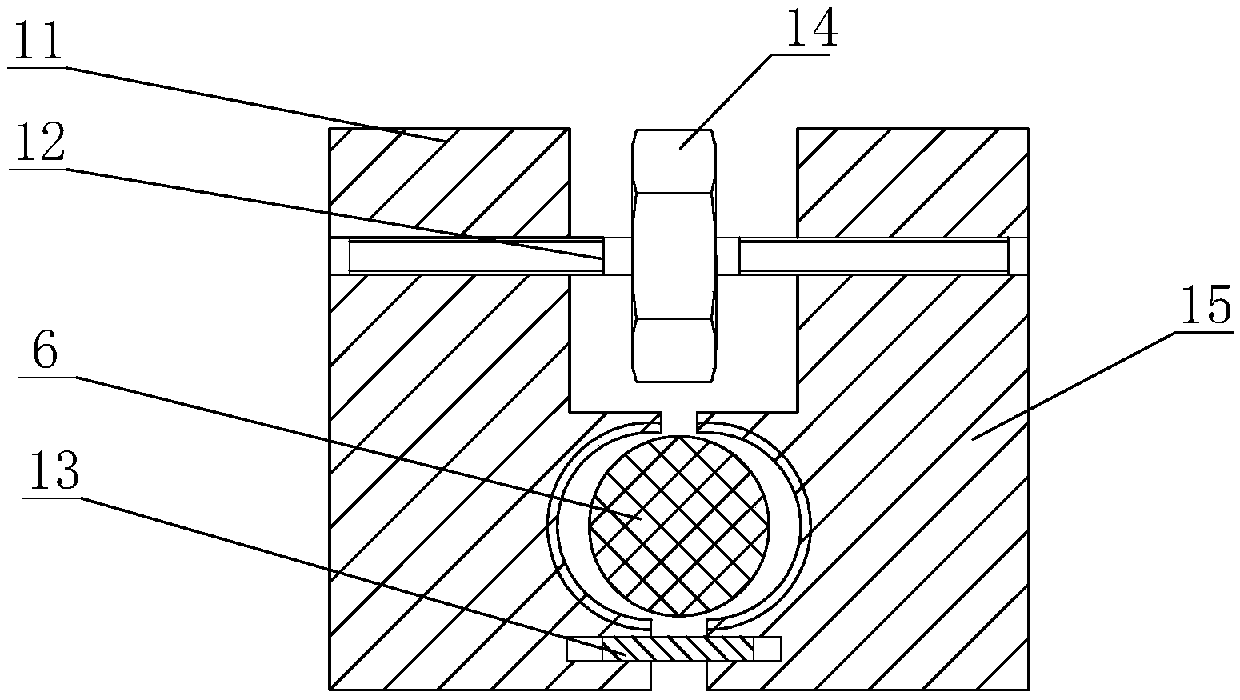

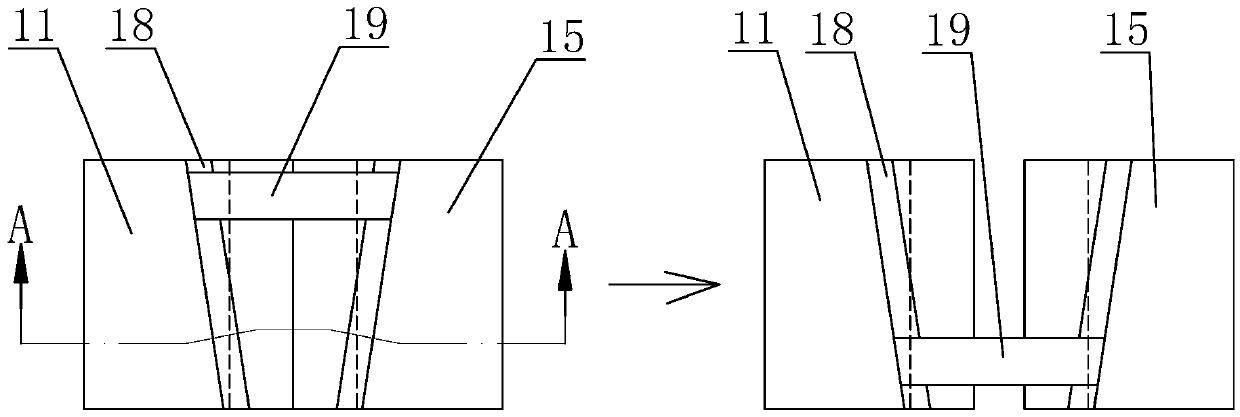

InactiveCN103586163AAvoid stickingReduce cumbersome operationsLiquid surface applicatorsCoatingsElectric machinePush pull

The invention discloses a small alternating current-direct current automatic glue spreader, and belongs to the field of office supplies. The glue spreader solves the problems that the manual glue spreading speed is low, the spreading is nonuniform, and adhesion is caused easily. Racks (4) are fixed in a cavity (3) of a bottom plate (1) of the glue spreader; gears meshed with the racks (4) are fixed on a cross rod of a gantry (2); a first motor (6) is fixed with one end of the cross rod; a screw rod (7) between two uprights (5) is sleeved with a slide block (8); a second motor (9) is fixed with one end of the screw rod (7); a push-pull electromagnet (10) is fixed below the slide block (8); a glue bottle (12) is fixed at the lower end of the push-pull electromagnet (10); the lower end of the glue bottle (12) is in an inverted trapezoid shape; a glue outlet is a strip-shaped port, and is closed by a cylindrical pressure head (18); and a pressure sheet (19) is fixed at the lower end of a threaded rod (15). The glue spreader has the advantages that the glue spreader is high in glue spreading speed, uniform in glue spreading, time-saving, labor-saving, and convenient to move and carry.

Owner:NORTHEAST GASOLINEEUM UNIV

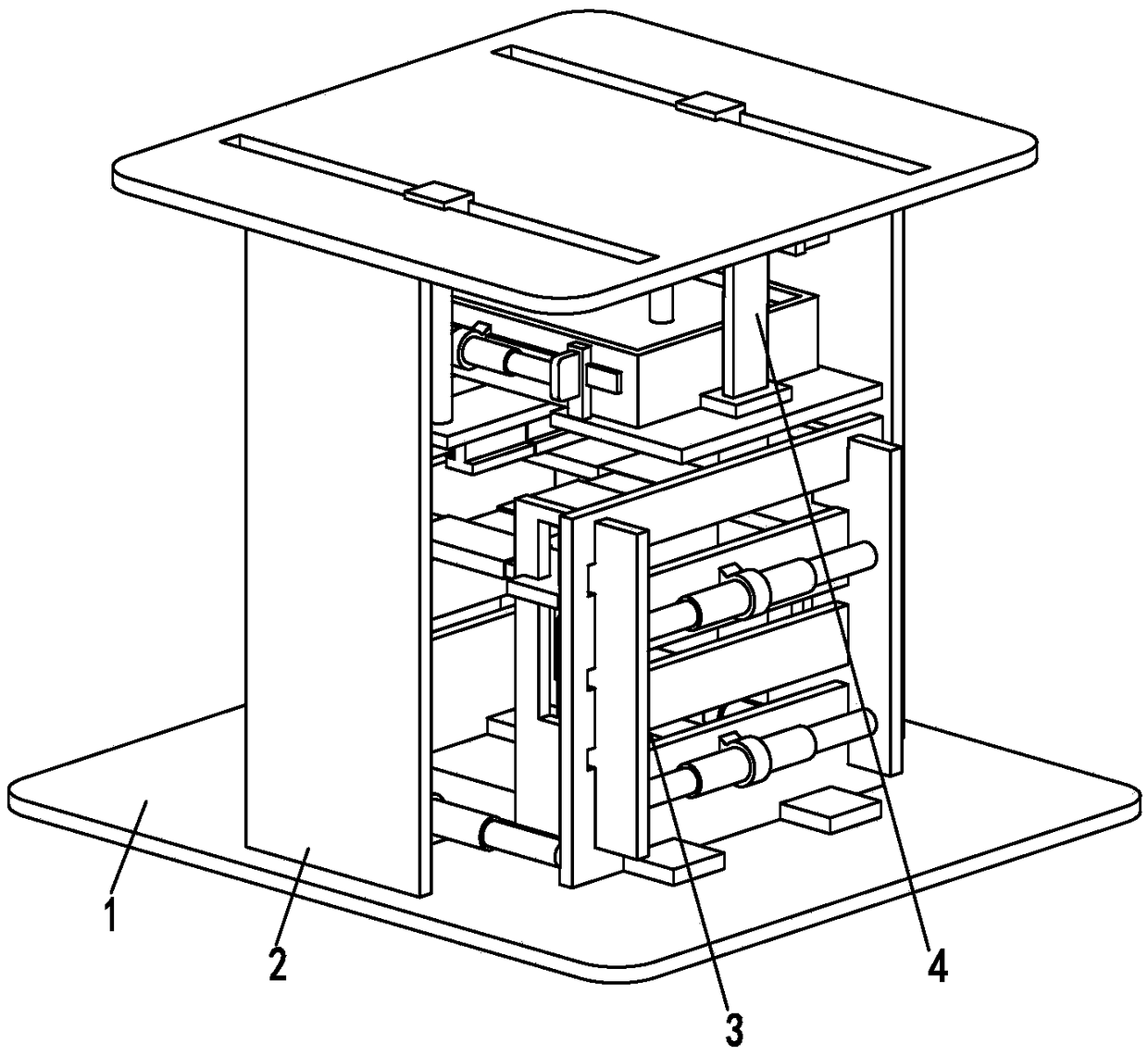

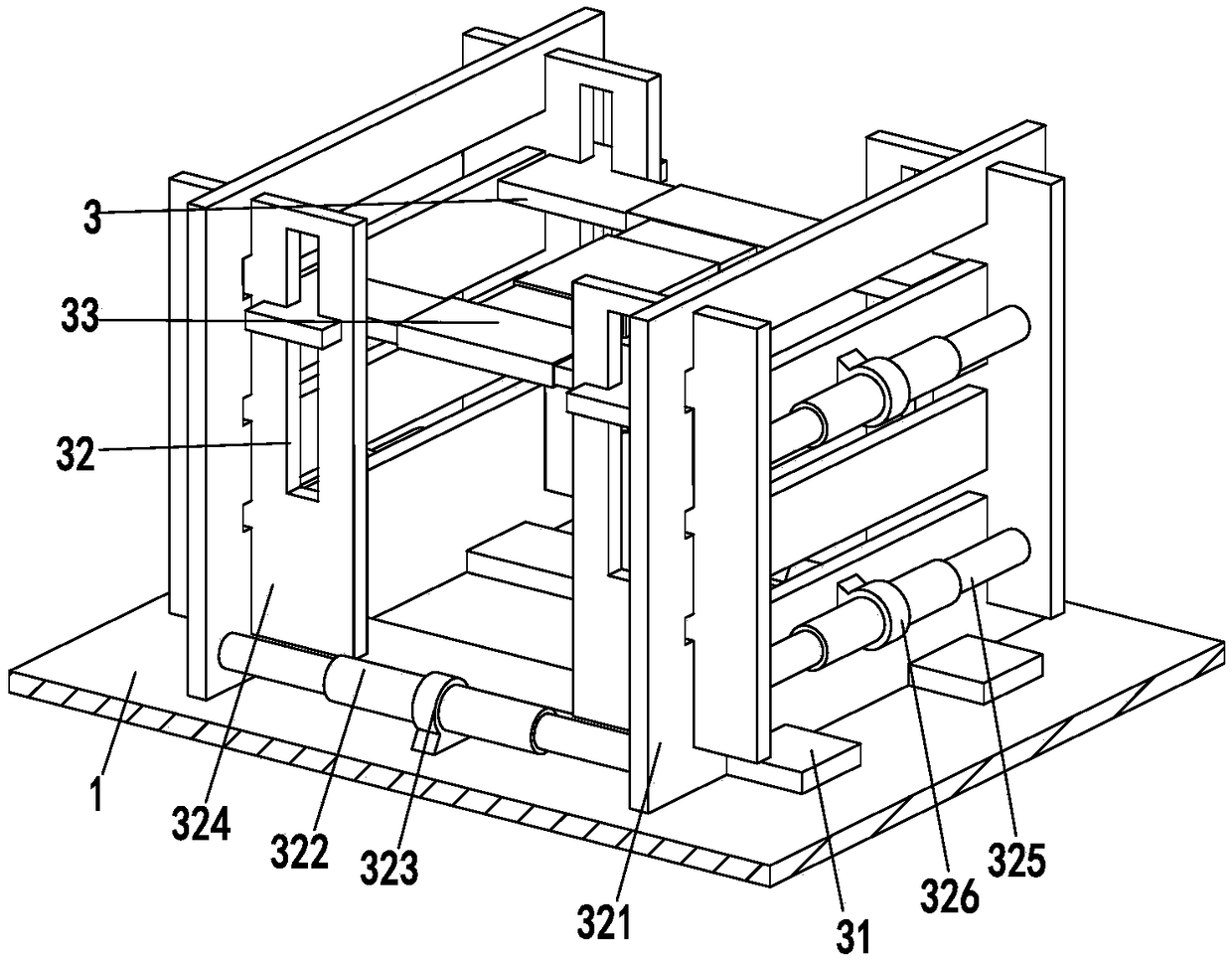

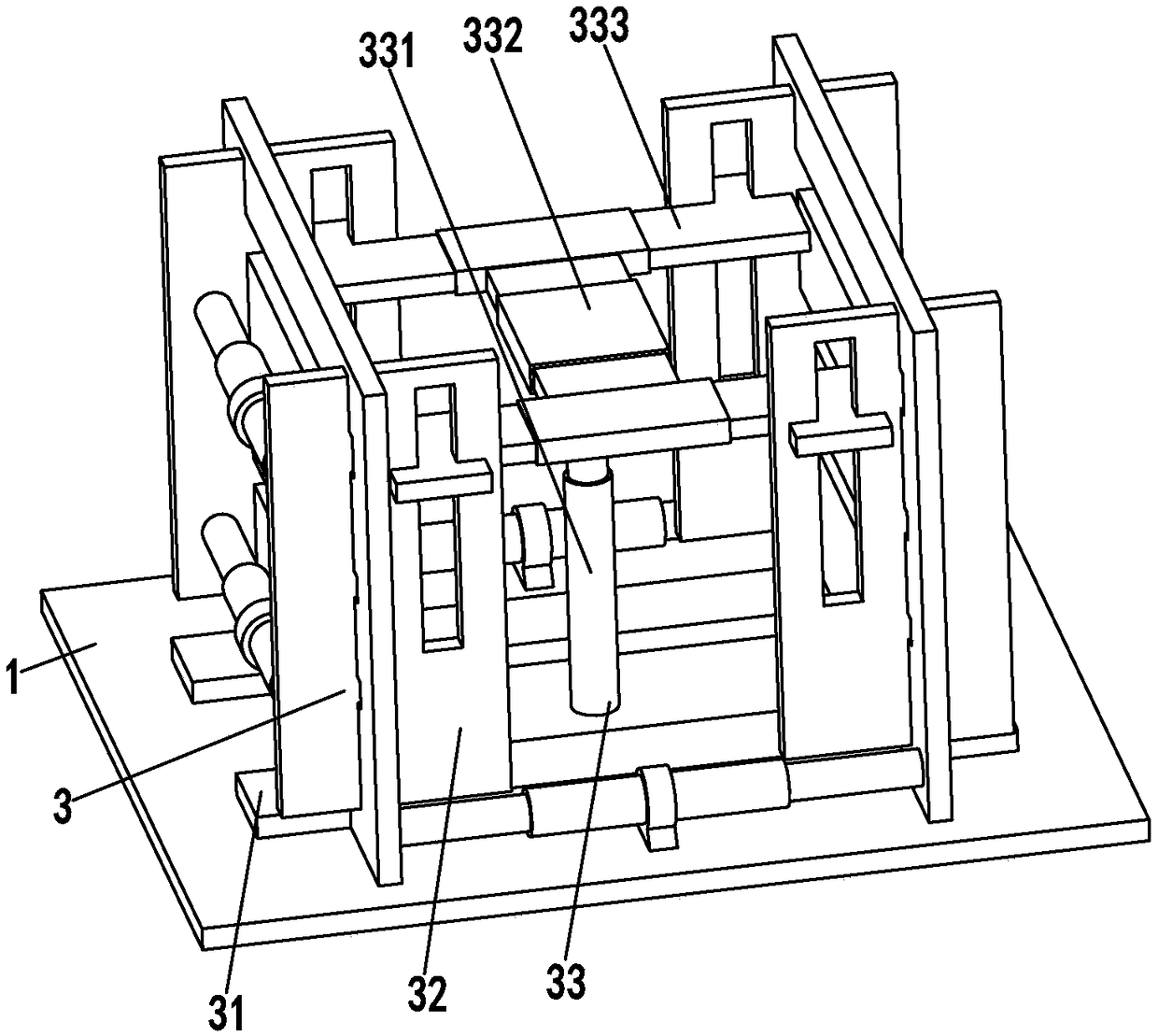

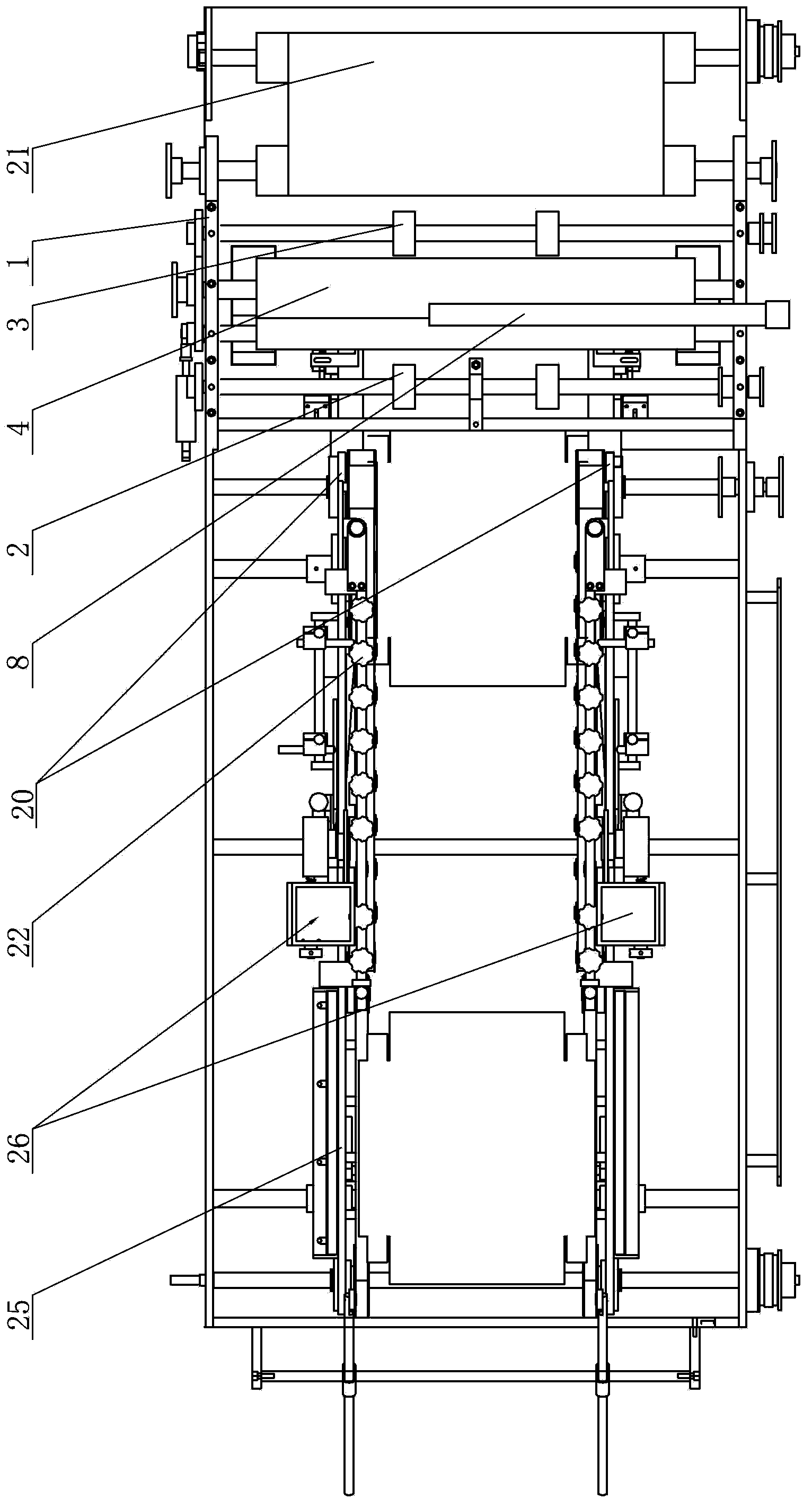

Composite board automatic gluing device

ActiveCN108656260AMeet work needsAvoid affecting work progressAdhesive application devicesEngineeringMechanical engineering

The invention relates to a composite board automatic gluing device. The device comprises a bottom plate, a mounting rack, a stacking device and a gluing device; the mounting rack is installed on the bottom plate, sliding chutes are formed in the mounting rack, the gluing device is installed in the sliding chutes, and the stacking device is installed at the lower end of the gluing device; the stacking device is installed on the bottom plate, and the stacking device comprises a linear guide rail, a limiting mechanism and a supporting mechanism; the gluing device comprises a glue discharging mechanism and a leveling mechanism; and the leveling mechanism comprises sliding blocks, sliding rods, a transverse plate, a telescopic leveling frame, a fixed supporting plate, an adjusting length air cylinder, a connecting ring and a driving branched chain. According to the composite board automatic gluing device, the problems that board codes are not even, gluing are non-uniform, glue is easy to waste, the adjustability is poor and the like in an existing composite board gluing process are solved; and the function of automatically gluing the composite board can be achieved, and the device has the advantages of being neat in stacking, uniform in gluing, not easy to waste glue, and flexible to adjust.

Owner:江苏林德曼新材料科技有限公司

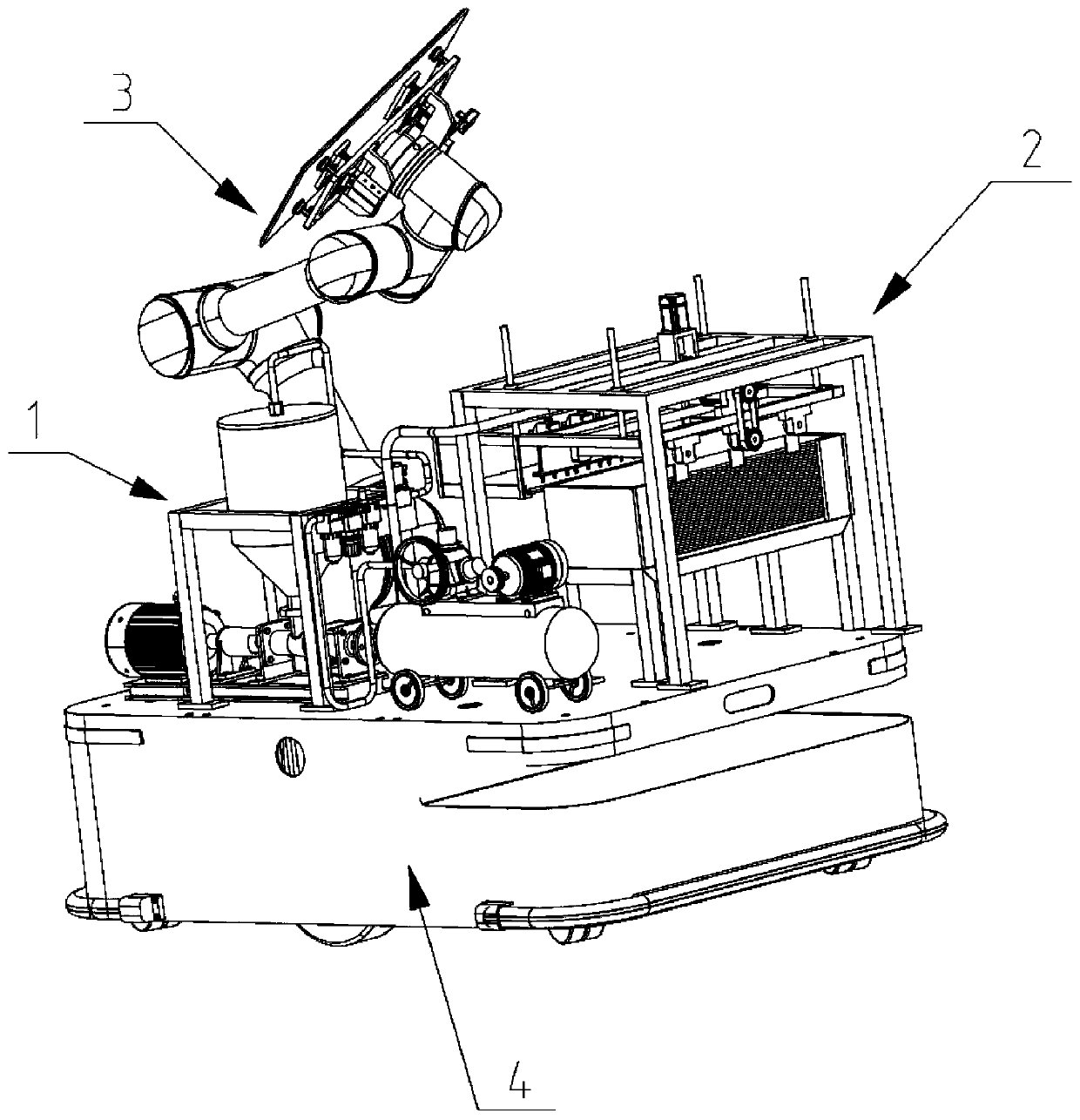

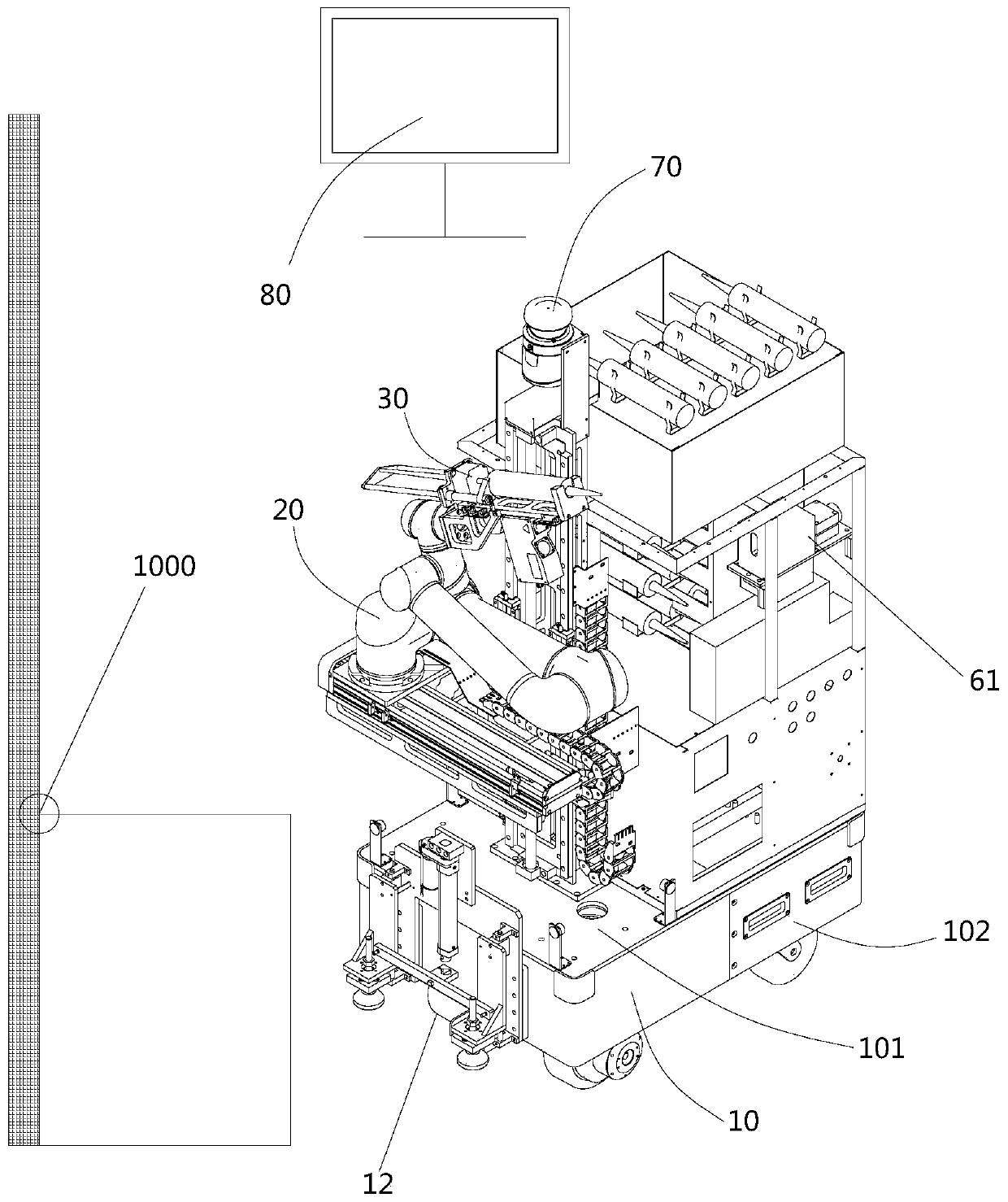

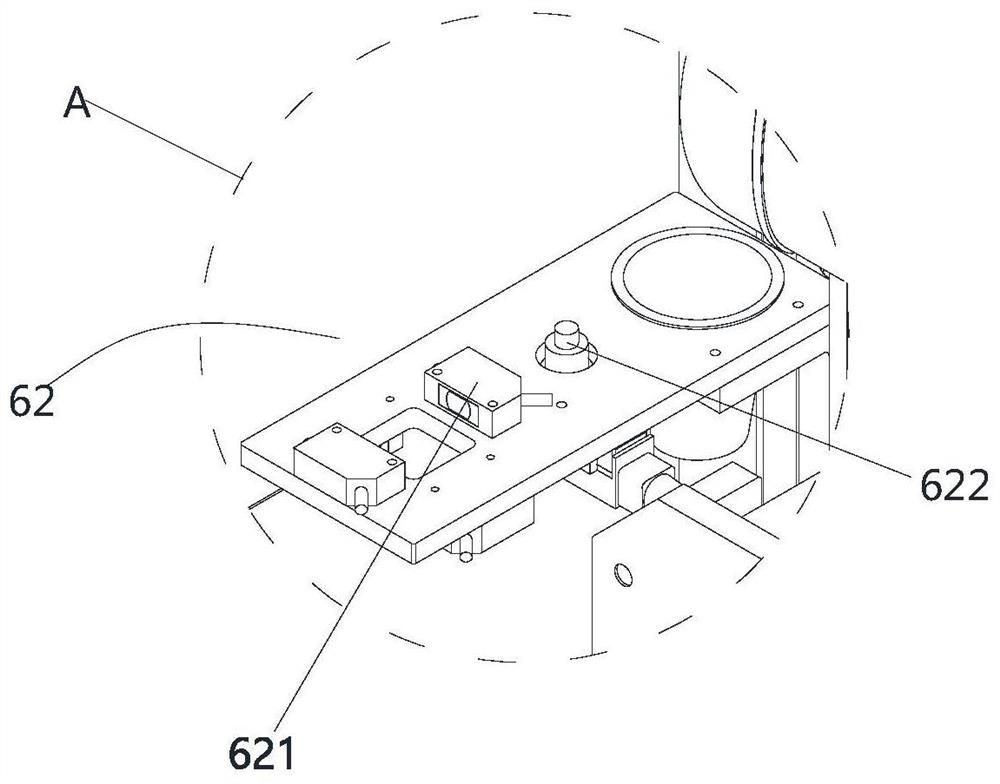

Wall tile gluing device and wall tile gluing and laying robot

ActiveCN110607896AImprove gluing efficiencySmall footprintBuilding constructionsEngineeringMechanical engineering

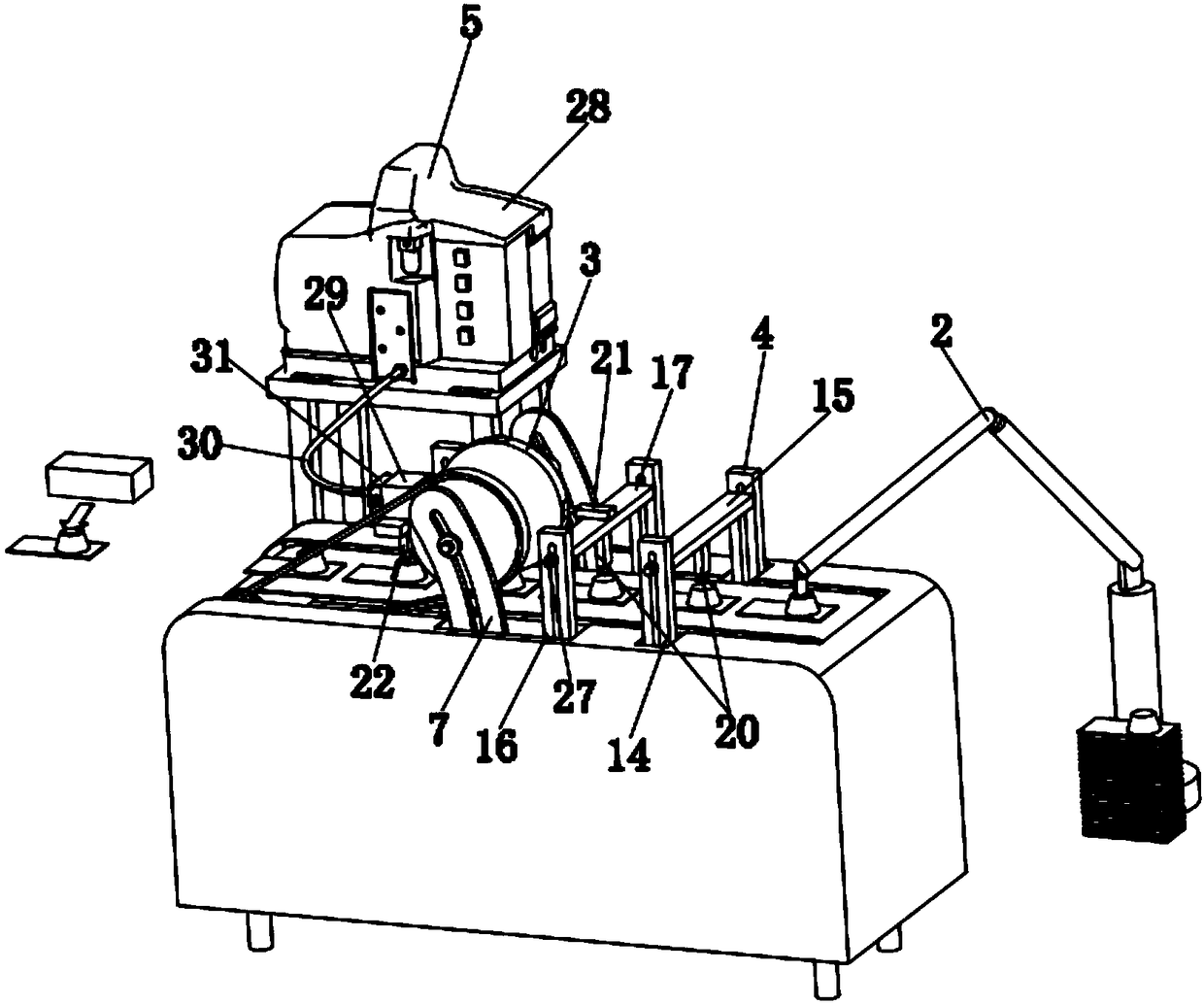

The invention discloses a wall tile gluing device and a wall tile gluing and laying robot. The wall tile gluing device comprises a tile discharging box for storing to-be-glued tiles, a tile receivingbox for receiving the glued tiles, a gluing mechanism, a tile conveying mechanism and a lifting driving mechanism, wherein the gluing mechanism is used for coating the back surface of the tiles with tile glue; the tile conveying mechanism is used for conveying the to-be-glued tiles from the tile discharging box to the gluing mechanism and conveying the glued tiles to the tile receiving box; the lifting driving mechanism is configured to drive the tile receiving box, the tile conveying mechanism and the gluing mechanism to lift together. The wall tile gluing device achieves automatic gluing andgreatly improves gluing efficiency of the wall tiles, the tile receiving box, the tile conveying mechanism and the gluing mechanism can be driven to descend together by distance of one tile after gluing of one tile, the next tile is glued continuously, and space can be saved by the structural design.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

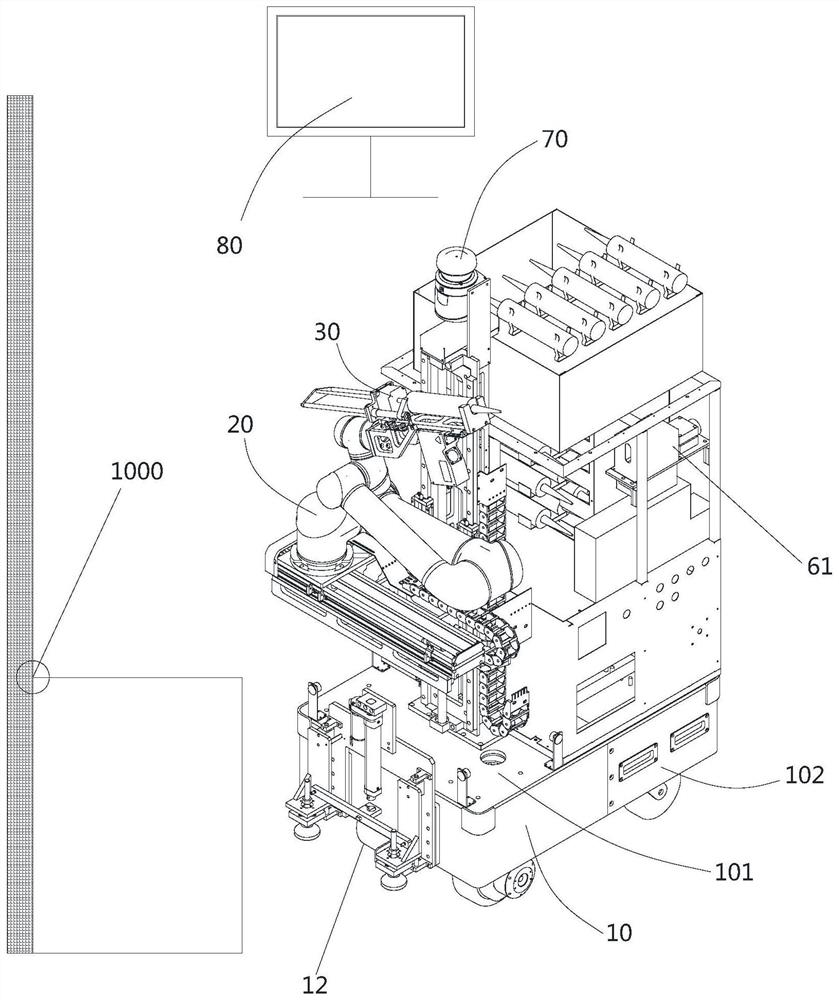

Gluing robot

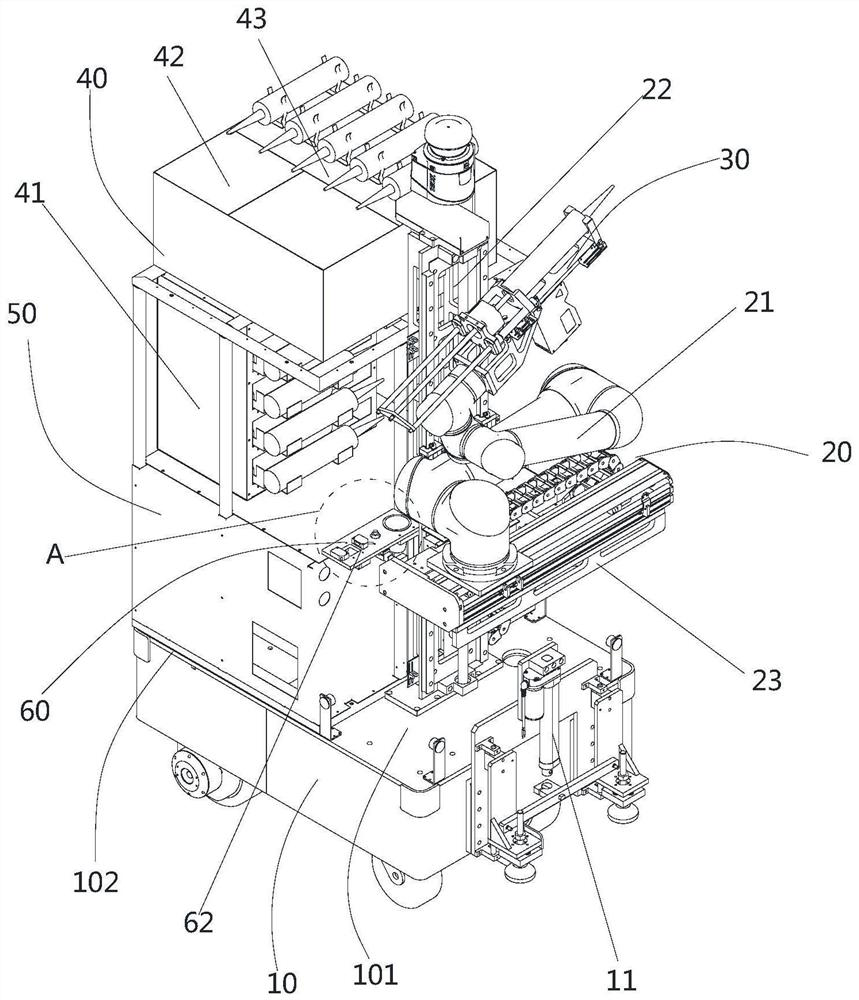

ActiveCN110962144AImprove stabilityConvenient glue workLiquid surface applicatorsCoatingsLarge rangeRolling chassis

The invention provides a gluing robot. The gluing robot comprises a movable chassis, a gluing moving device, a gluing device and a stock bin; the movable chassis is used for providing walking power, and is provided with a gluing implementation area and a glue barrel supply area in the front end and the rear end respectively; the gluing device and the gluing moving device are both arranged in the gluing implementation area, the gluing moving device is connected to the movable chassis, and the gluing device is arranged on the gluing moving device and used for automatically clamping a glue barrelto conduct gluing or loosening the glue barrel to replace the glue barrel; and the stock bin is arranged in the rubber barrel supply area. The movable chassis, the gluing device, the gluing moving device and the stock bin are arranged, the stock bin is arranged at the rear end of the movable chassis, and the gluing device and the gluing moving device are arranged at the front end of the movable chassis, so that the space above the chassis is reasonably utilized, gluing in a larger range is conveniently completed, the weight of the gluing implementation area is matched with that of the glue barrel supply area, and the stability of the gluing robot is improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

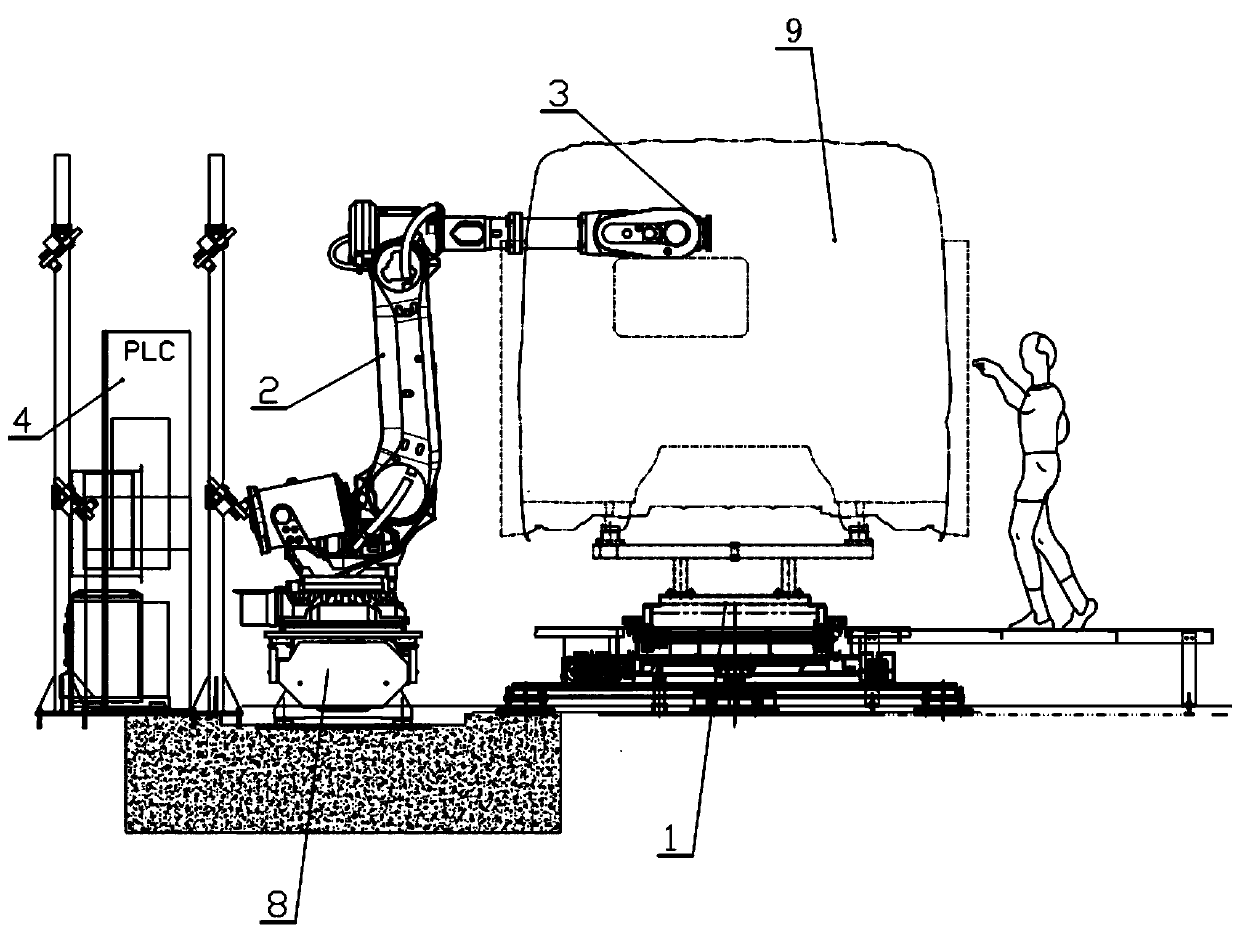

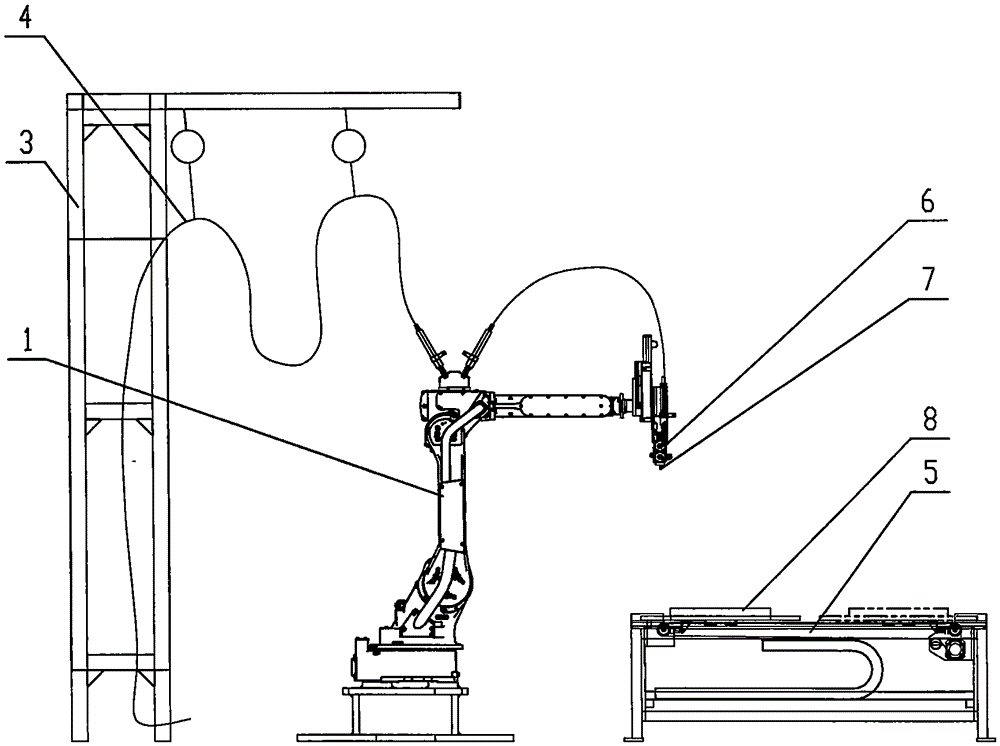

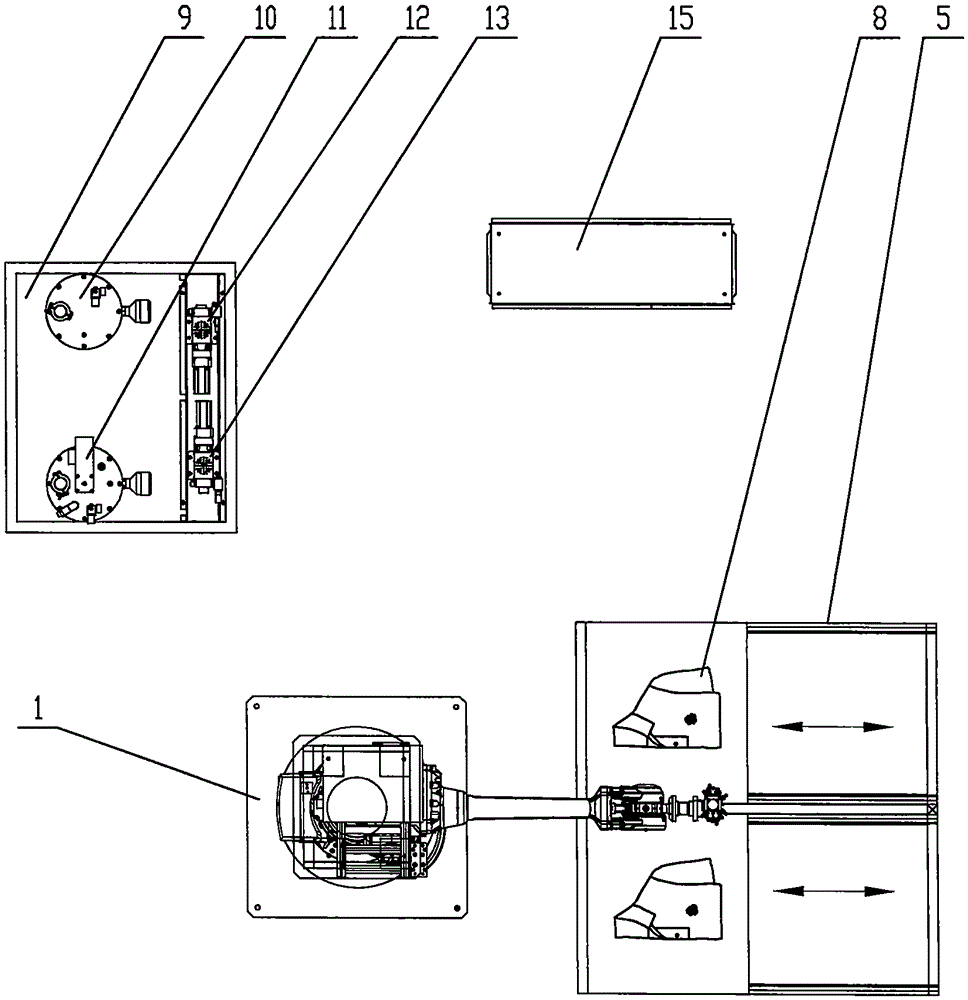

Truck whole vehicle automatic coating system and coating method

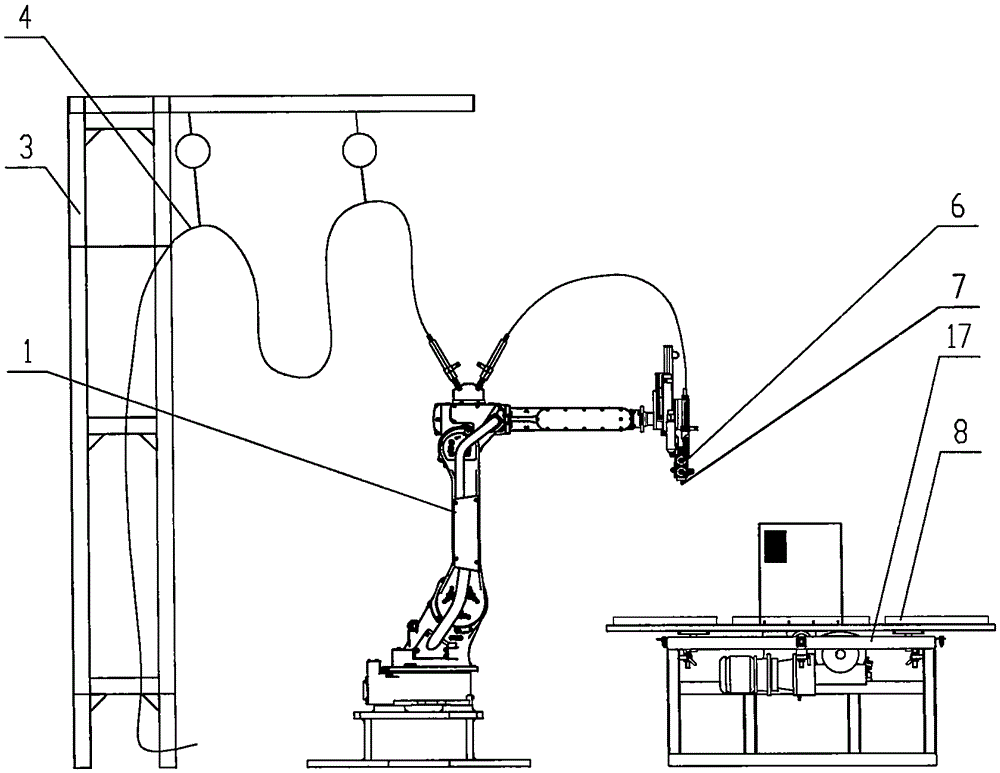

PendingCN110052349AReduce investmentReduce wasteLiquid surface applicatorsSpraying apparatusProduction lineCoating system

The invention discloses a truck whole vehicle automatic coating system and coating method. According to the system, a whole truck is carried by sliders to enter / leave the coating system. A code scanning gun, a rotatable rotary roll, a 3D visual system which is installed on the rotary roll and a spraying robot which is installed on a ground production line and in data transmission connection with the 3D visual system are included, a glue gun is installed on the spraying robot, the glue gun is provided with nozzles of different angles, and a PLC controlling system which controls all data signalsand a human-computer operation platform are included. The system has the advantages that the investment of labor force can be reduced, the waste of glue is reduced, the production efficiency is improved, and the demands of energy saving and emission reduction by existing enterprises are met; the advantages of high automation level, high repeating precision, stable technology and the like are achieved by adopting a robot coating technology, and the system and the method have higher using value on welding sealing glue coating working positions in truck industries.

Owner:济南希润自动化科技有限公司

Multi-proportion glue gun for soft packages

ActiveCN105499083ASimple structureEasy to installLiquid surface applicatorsCoatingsMechanical engineeringEngineering

Owner:常熟东南高新技术创业服务有限公司

Inner lining paper gluing and bonding mechanism of paper box machine

InactiveCN109501382ARealize automatic gluingBonding smoothlyBox making operationsPaper-makingCardboardEngineering

The invention discloses an inner lining paper gluing and bonding mechanism of a paper box machine. The inner lining paper gluing and bonding mechanism is characterized by comprising a paper storage rack and a paper suction board, wherein a glue storage box and a conveying belt are sequentially arranged on one side of the paper storage rack, a glue coating roller which is higher than the glue storage box is arranged in the glue storage box, the paper suction board is connected with a paper suction board driving mechanism, and the paper suction board is driven to horizontally move and be liftedamong the paper storage rack, the glue storage box and the conveying belt. The inner lining paper gluing and bonding mechanism is simple in structure and reasonable in design, automatic gluing and bonding of inner lining paper can be achieved, meanwhile, the side surface of the inner lining paper is guaranteed not to be glued, and then the inner lining paper can be ensured to be stably placed downwards and adhered to the bottom of a paper box.

Owner:WENZHOU ZHONGKE PACKAGING MACHINERY

Gluing scraper and gluing equipment

InactiveCN104475302AConsistent thicknessReduce labor intensityLiquid surface applicatorsCoatingsEngineeringMechanical engineering

Owner:SUZHOU TONGLI PHOTOELECTRIC CO LTD

Composite wood board gluing machine

ActiveCN108687893ARealize automatic gluingWasteful realizationAdhesive application devicesPulp and paper industryWood panel

The invention relates to a composite wood board gluing machine. The composite wood board gluing machine comprises a bottom plate, an installing frame, a stacking device and a gluing device; the installing frame is installed on the bottom plate, and provided with a slide groove; the gluing device is installed in the slide groove, and the stacking device is arranged at the lower end of the gluing device, and installed on the bottom plate; the stacking device comprises a linear guide rail, a limiting mechanism, a supporting mechanism and a feeding mechanism; the gluing device comprises a glue outflow mechanism and a uniform smearing mechanism; and the uniform smearing mechanism comprises a sliding block, a sliding rod, a cross plate, a telescopic uniform smearing frame, a fixed supporting plate, a length adjusting cylinder, a connection ring and a driving branched chain. The composite wood board gluing machine can solve the problems that in the existing composite wood board gluing process, wood boards are stacked in disorder, gluing is not uniform, glue waste can be caused easily, and adjustability is poor, the function of performing automatic gluing on composite wood boards can be achieved, and the beneficial effects that stacking is in order, gluing is uniform, glue waste is not likely to be caused, and adjusting is flexible are achieved.

Owner:桃江县万众木业股份有限公司

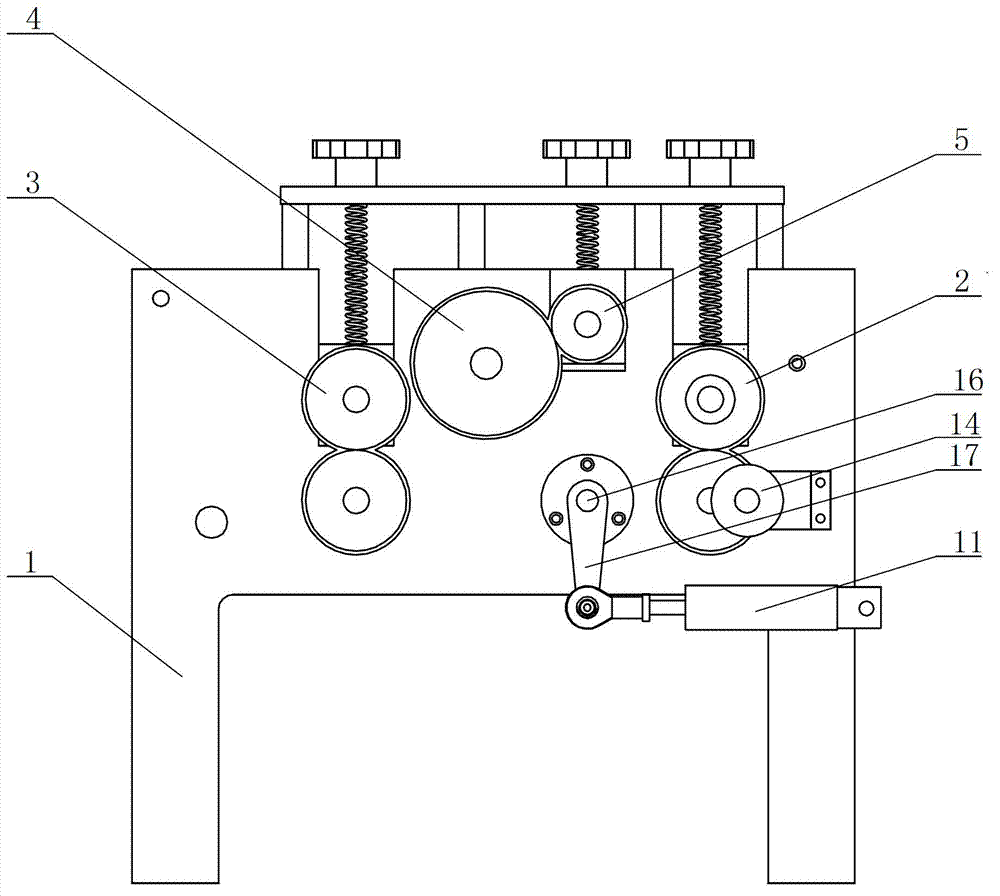

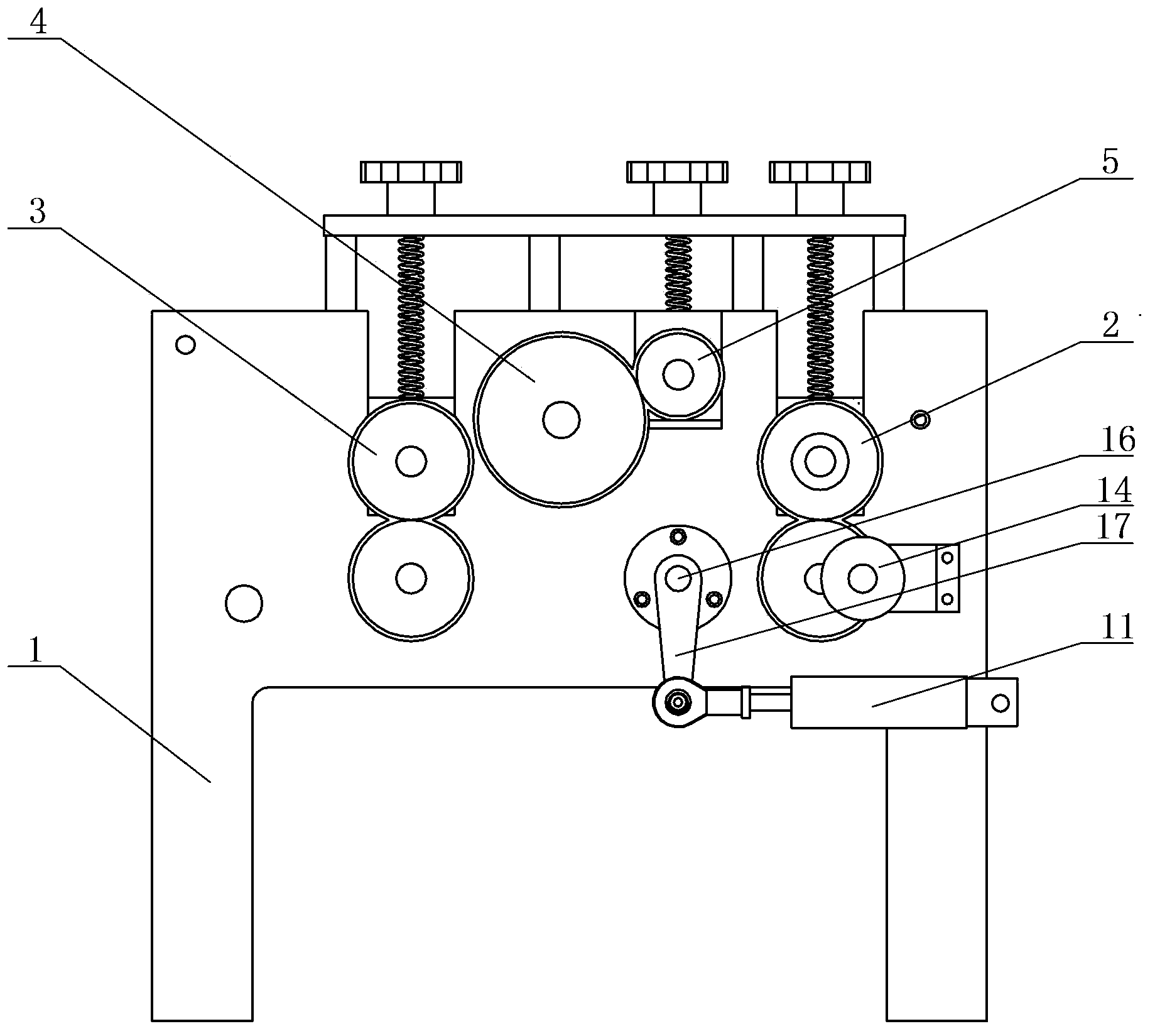

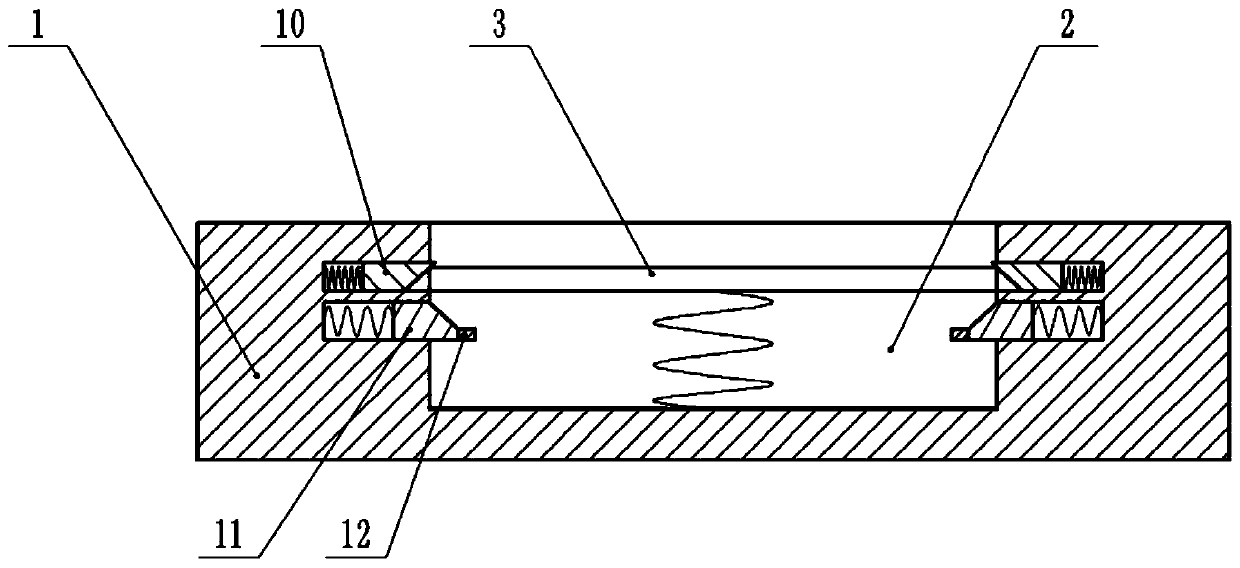

Spacing-adjustable gluing mechanism capable of keeping gluing face upwards

InactiveCN102862320ARealize automatic gluingHigh energy saving and environmental protectionBox making operationsPaper-makingEngineeringMicrocomputer

A spacing-adjustable gluing mechanism capable of keeping a gluing face upwards mainly solves problems of time and labor waste, low processing efficiency and high processing cost in gluing for transverse edges of paperboards in the prior art. The spacing-adjustable gluing mechanism capable of keeping the gluing face upwards is characterized in that a gluing roll (4) is mounted on a frame (1) between an input press roll group (2) and an output press roll group (3), a middle gluing press roll group (9) is mounted on the frame (1), blade gluing press rolls (10) are respectively mounted on sliding support plates (20) on two sides of the frame (1), the middle gluing press roll group (9) and the blade gluing press rolls (10) are respectively driven by a first air cylinder (11) and a second air cylinder (12), and a photoelectric sensor (13) for detecting the paperboards is mounted on the output side of the input press roll group (2), and is connected with an encoder (14) for detecting running length of the paperboards and a microcomputer controller sequentially. By the spacing-adjustable gluing mechanism capable of keeping the gluing face upwards, two transverse edges of each paperboard can be glued automatically, and accordingly, time, labor and energy are saved, environmental protection is achieved, and processing efficiency is high.

Owner:张银国

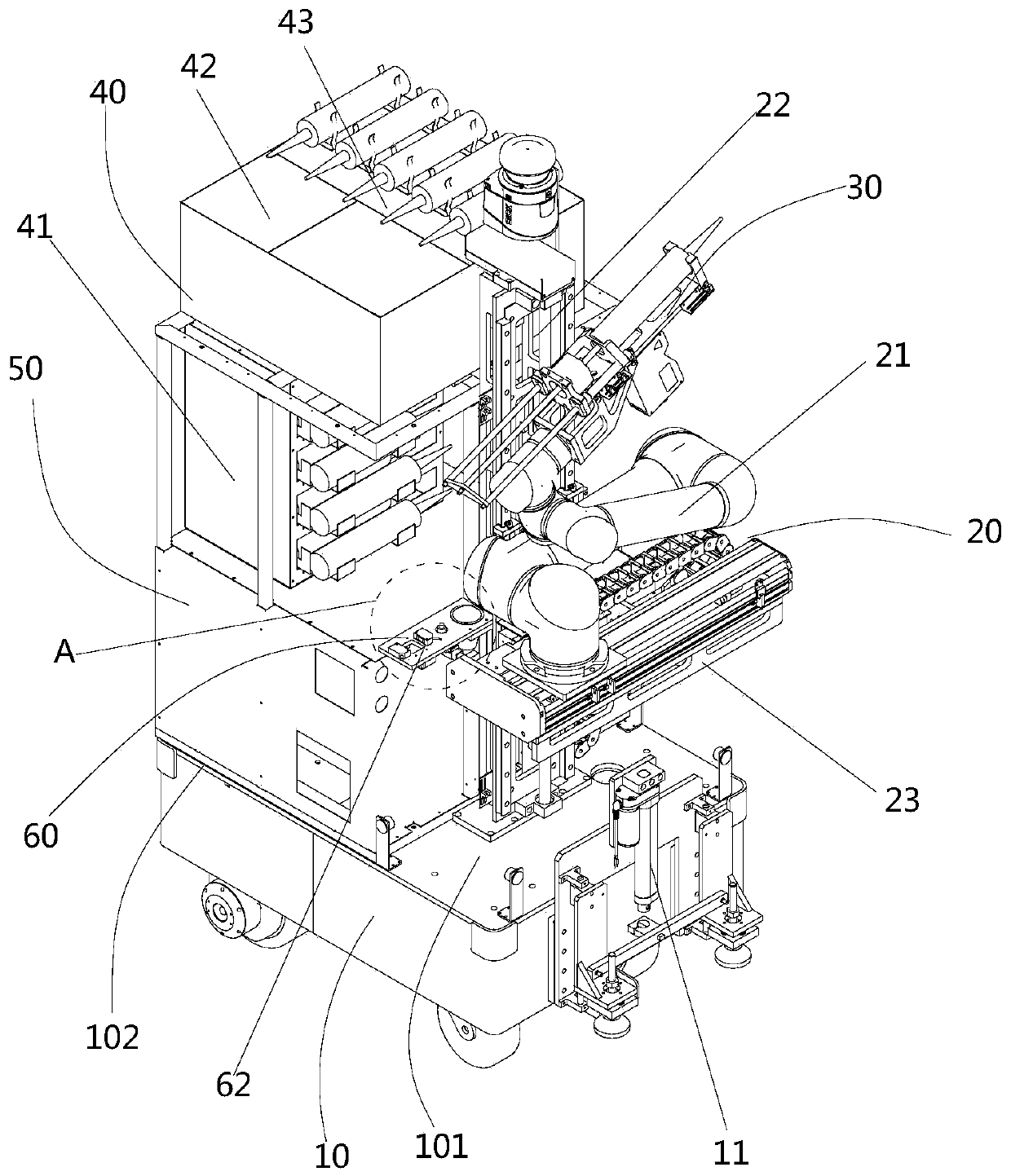

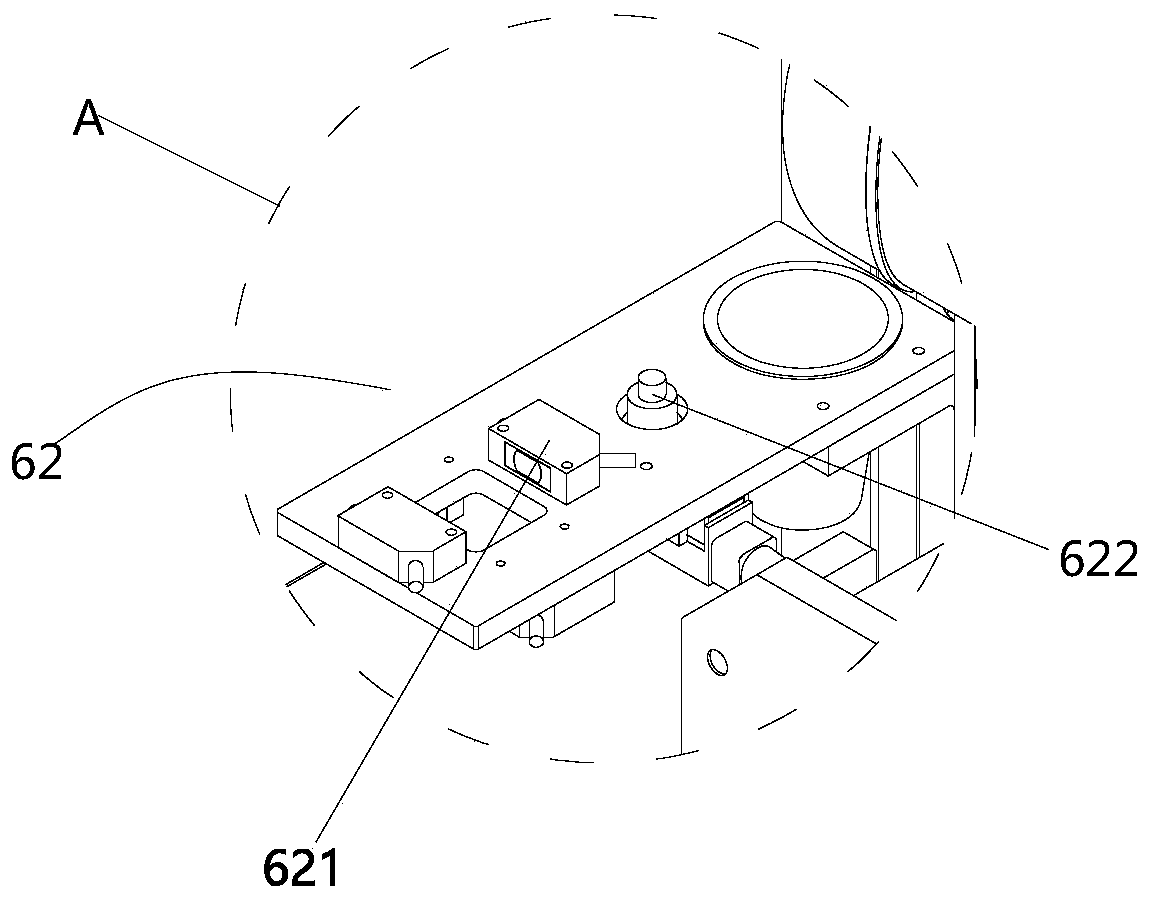

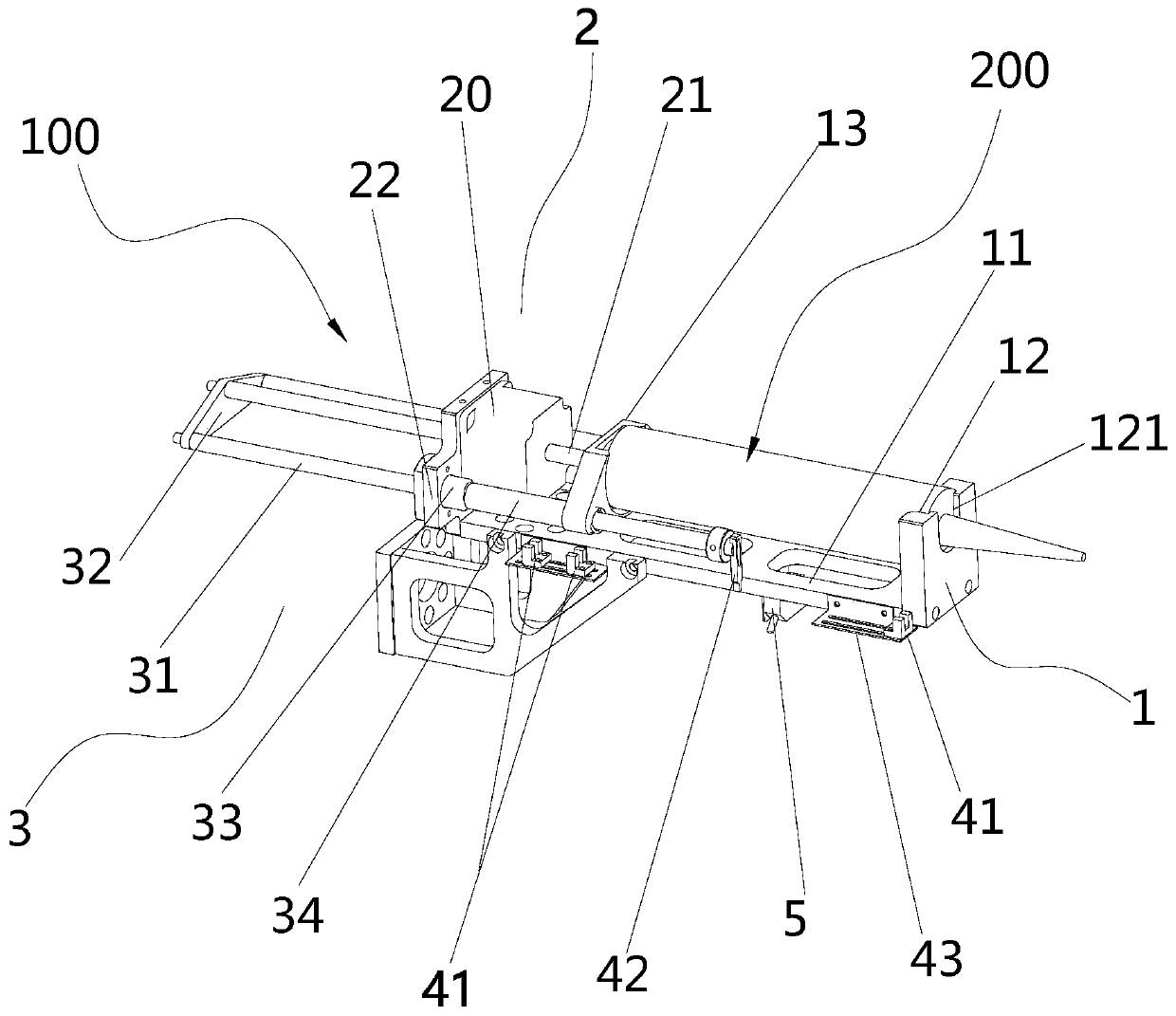

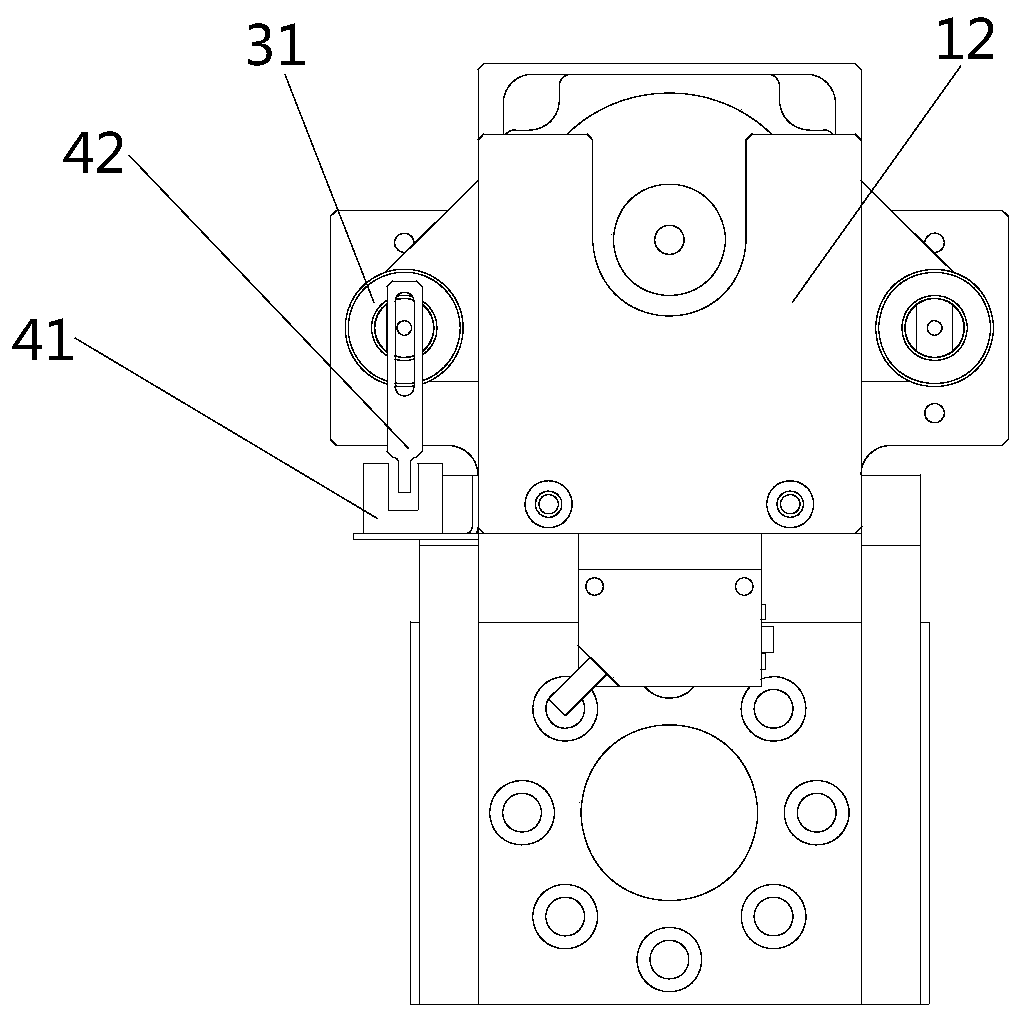

Gluing robot and glue applying device thereof

ActiveCN110961314ARealize automatic replacement functionReduce participationLiquid surface applicatorsCoatingsEngineeringElectric drive

The invention provides a gluing robot and a glue applying device thereof. The glue applying device comprises a glue cylinder clamping mechanism and a gluing mechanism. The glue cylinder clamping mechanism comprises a bottom plate, a front end plate fixedly arranged on the bottom plate and used for supporting the front end of the glue cylinder, and a tail end plate capable of being driven to be close to or away from the front end plate to act on the tail end of the glue cylinder. The gluing mechanism comprises a push rod, and the push rod is connected to the tail end plate and can be driven toact on an inner cover in the glue cylinder so as to extrude glue liquid. The front end plate of the glue cylinder clamping mechanism is fixed with the bottom plate, the tail end plate can be driven tomove relative to the front end plate, so that the glue cylinder can be clamped or loosened; the push rod is electrically driven to push glue, the glue applying device can automatically glue and replace the glue cylinder, personnel participation can be reduced in the construction process of the gluing robot, the labor cost is reduced, and the gluing quality is improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

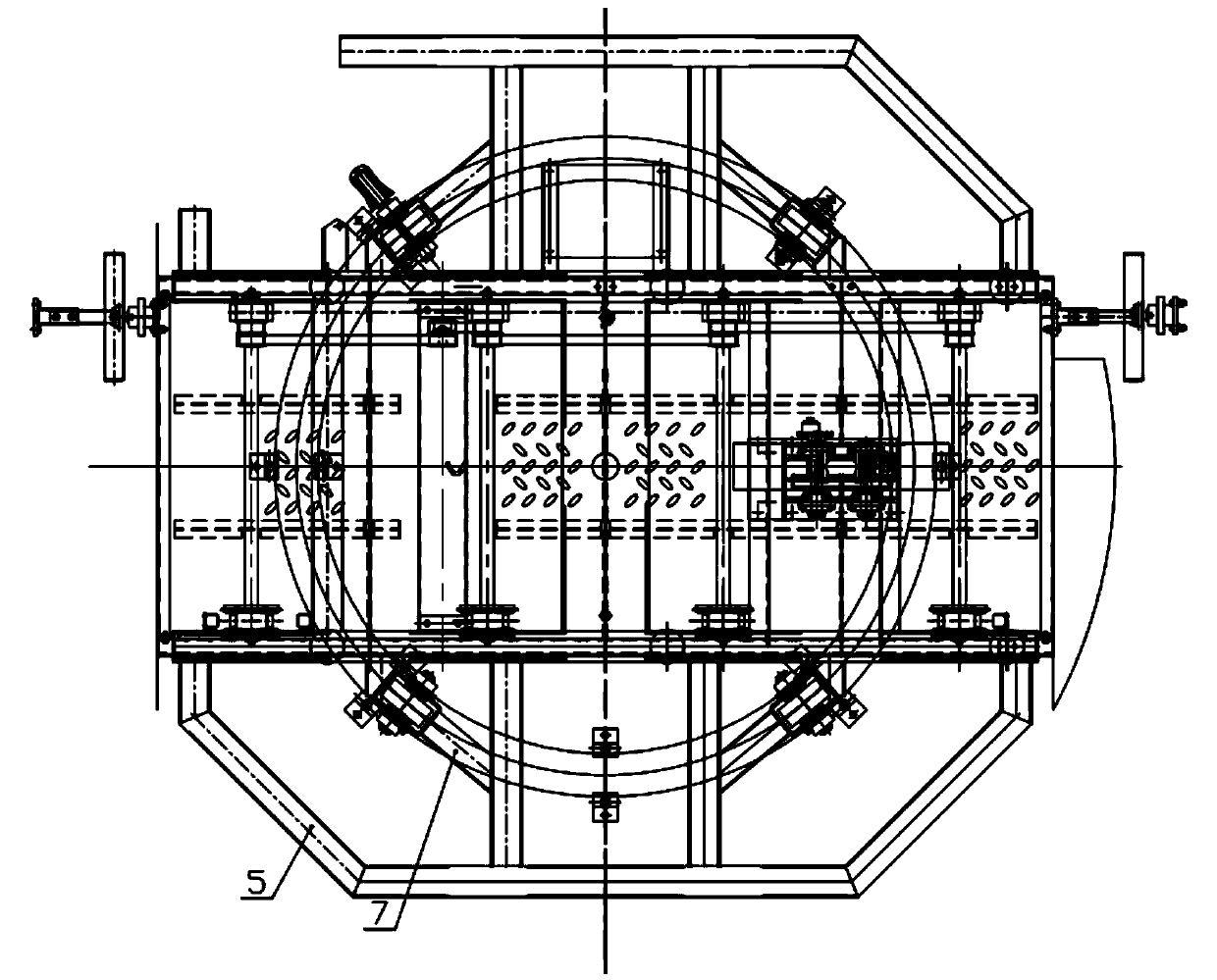

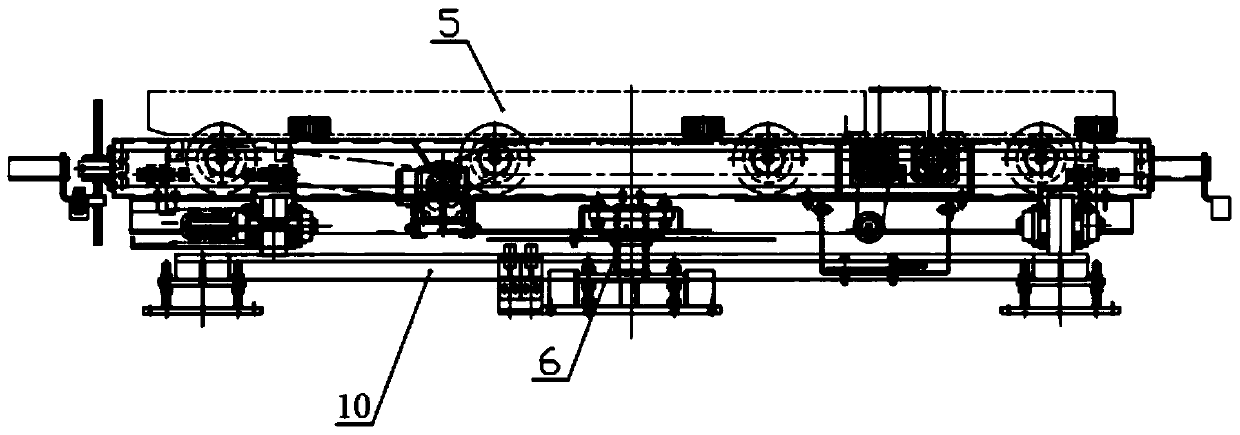

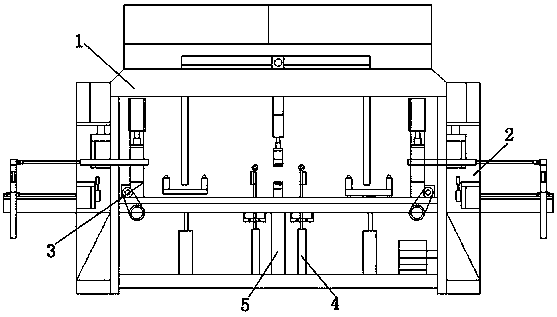

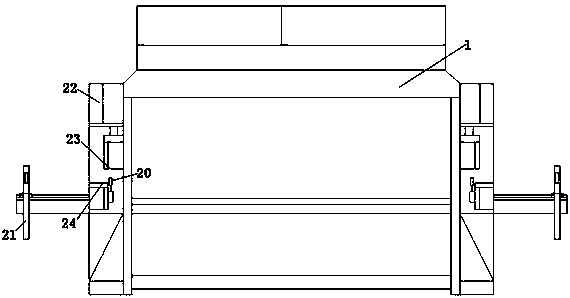

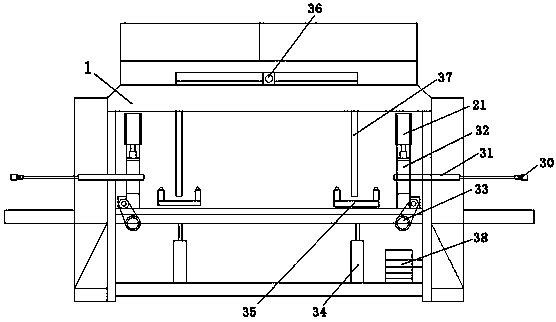

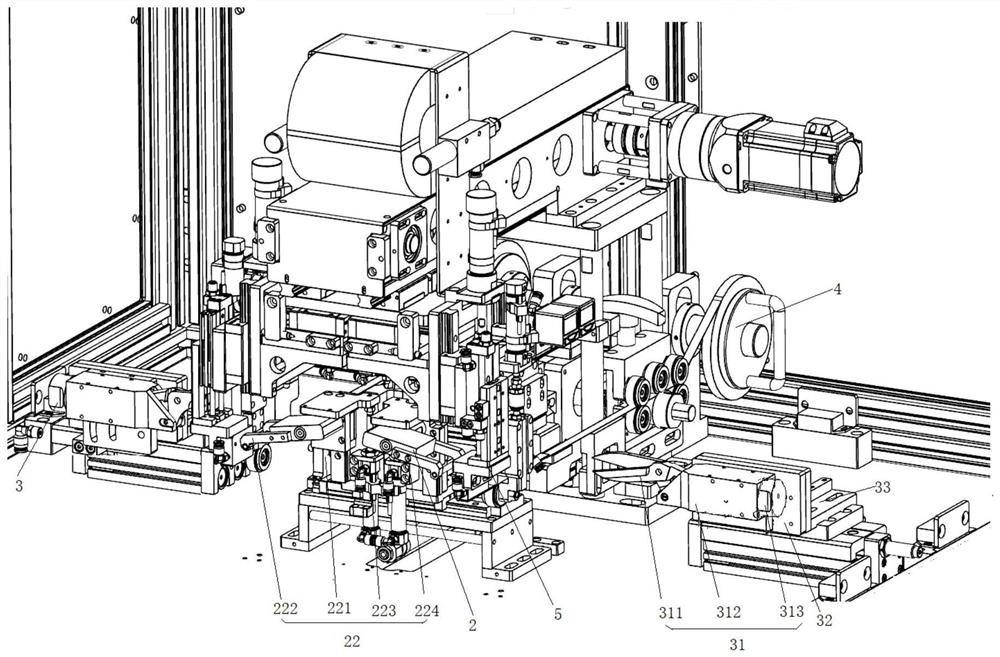

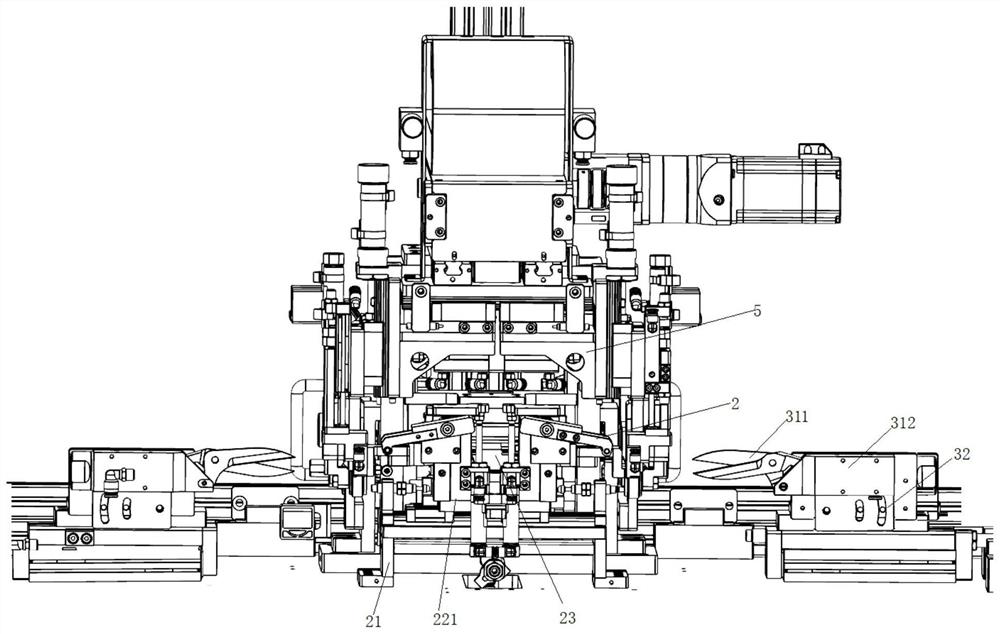

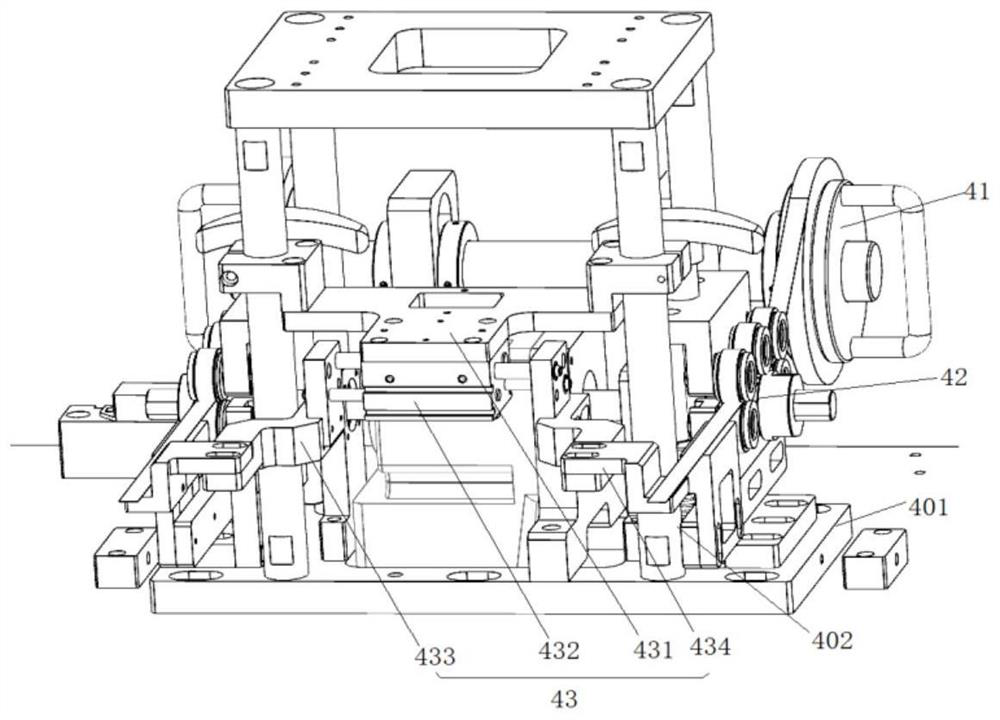

Middle plate tooth joint machine

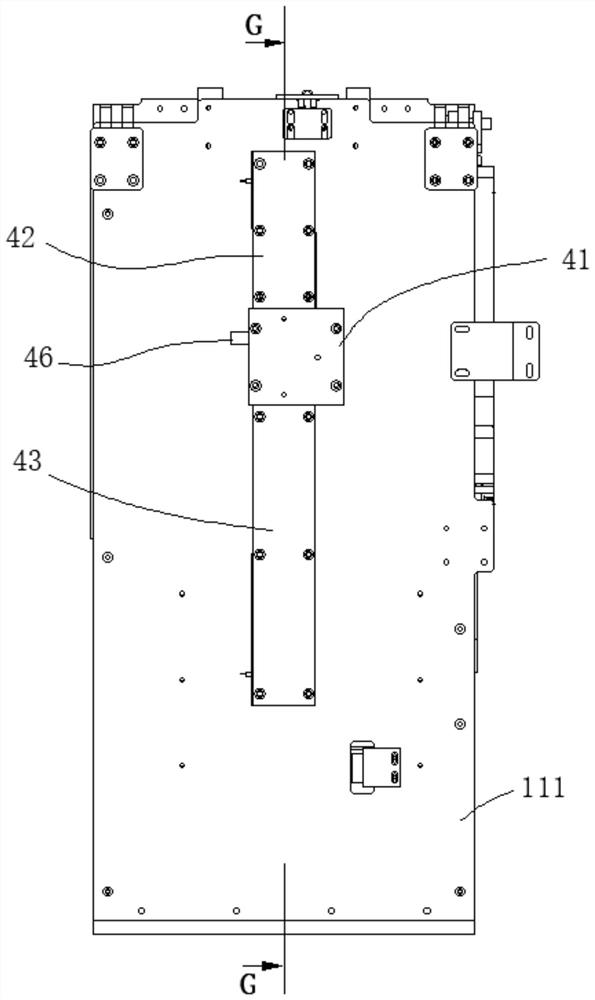

PendingCN107718189AImprove efficiencyQuality improvementWood veneer joiningGlue vesselsArcuate shapeGear cutting

The invention discloses a middle plate tooth joint machine. The middle plate tooth joint machine comprises a main frame, tooth cutting machines, a conveying device, a gluing device and a tooth joint device and is characterized in that the tooth cutting machines are arranged on the two sides of the main frame, the tooth joint device is arranged in the middle, the gluing device is arranged between the tooth cutting machines and the tooth joint device, and the conveying device is arranged on the main frame. Through action joint between mechanisms, two middle plates can be subject to tooth joint,the wood tooth joint efficiency and quality can be improved, and workloads of a worker can be reduced. A tooth knife with the circular-arc-shaped tooth tip is adopted, circula-arc teeth can be cut out, gluing and tooth joint are facilitated, and toughness of the tooth-joint wood can be improved. A gluing bar is added, and through gluing teeth, automatic gluing of the wood teeth can be achieved; electric heating pipes are arranged in the gluing bar and a glue groove, it is ensured that hot melt adhesive is in the liquid shape, the wood teeth can be glued conveniently, the wood tooth joint quality is improved, a cooling bar is added, and solidification of glue between wood can be quickened.

Owner:广州市俊金机械有限公司 +1

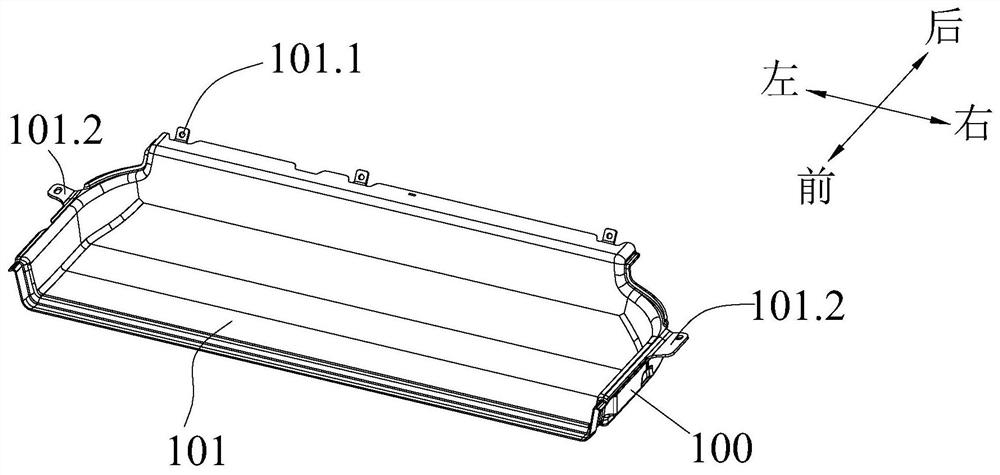

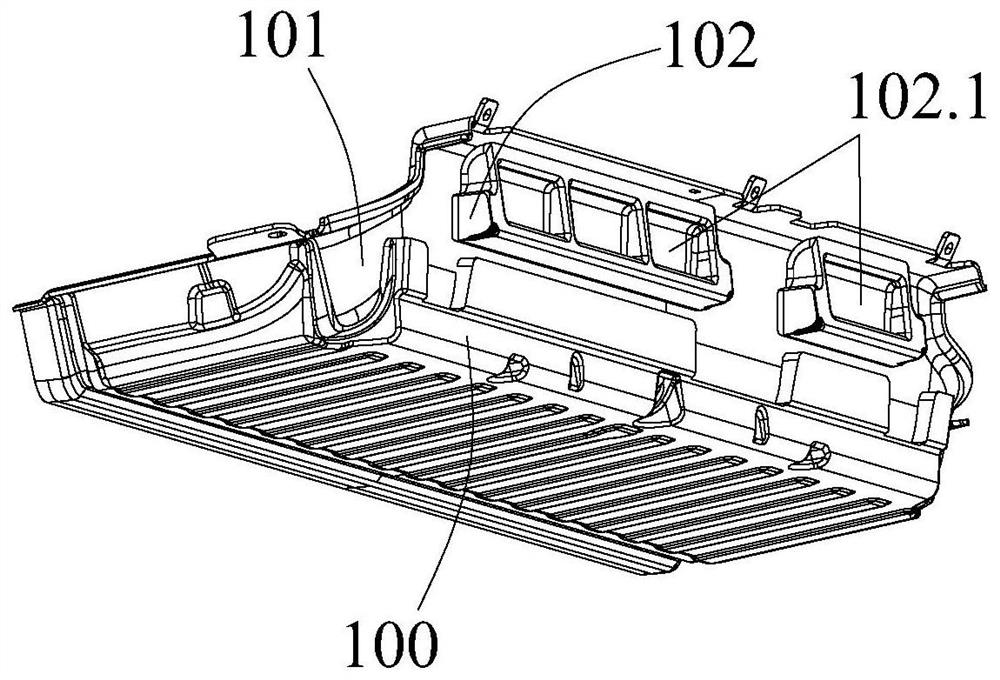

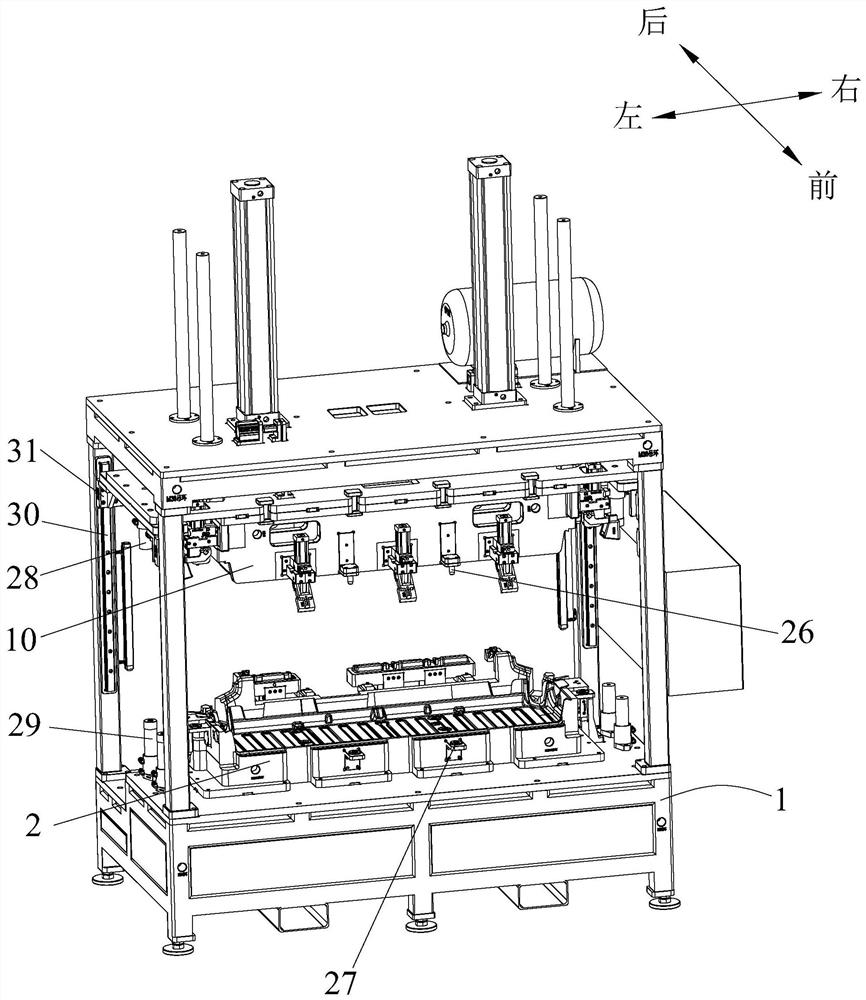

Automobile passenger compartment rear carpet assembly pressing device

ActiveCN113021914AGuaranteed accuracyAccurate horizontal positionDomestic articlesAutomotive engineeringManufacturing engineering

The invention discloses an automobile passenger compartment rear carpet assembly pressing device which comprises a rack. A positioning base, a third positioning assembly and a driving assembly are arranged on the rack. A first positioning assembly and a second positioning assembly are arranged on the positioning base. A press-fitting mechanism capable of ascending and descending in the vertical direction is further arranged on the rack, and a clamping mechanism is arranged on the press-fitting mechanism. After PU cotton and a carpet are sequentially placed on the positioning base from bottom to top and positioned, the press-fitting mechanism moves downwards to enable the clamping mechanism to clamp the carpet and then reset upwards, a gluing robot glues the binding face, and the press-fitting mechanism moves downwards again to enable the carpet and the PU cotton to be in press fit. The driving assembly drives the third positioning assembly to move towards the rear side of the carpet so that a foam plastic piece can be pressed and bonded to the rear side wall of the carpet. According to the automobile passenger compartment rear carpet assembly pressing device, the structure is simple, automatic pressing and bonding of the PU cotton, the carpet and the foam plastic piece can be achieved, the bonding position is accurate, and the working efficiency is high.

Owner:NINGBO TUOPU GROUP CO LTD

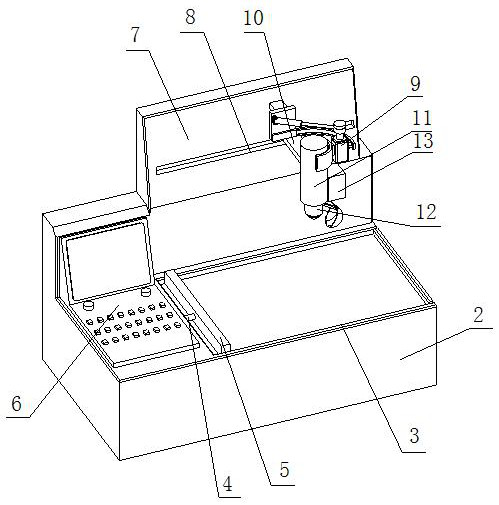

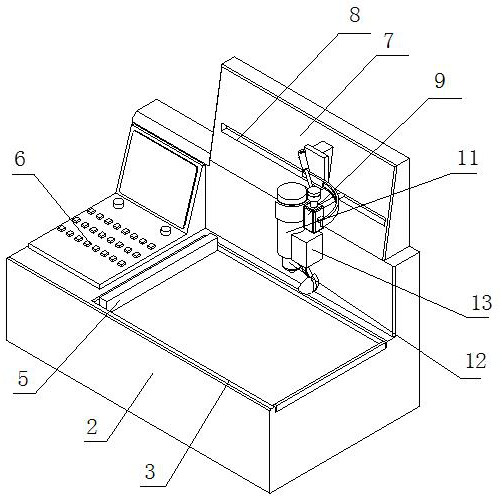

Equipment and method for coating surfaces of clothing or ornaments with three-dimensional patterns

InactiveCN105562312AStrong three-dimensional senseGood continuous coatingPretreated surfacesCoatingsTrademarkEngineering

The invention discloses equipment and a method for coating surfaces of clothing or ornaments with three-dimensional patterns, belongs to the industry of gluing equipment and is used for coating the clothing or the ornaments or objects with polyurethane patterns or cartoons or trademarks. The equipment comprises three-axis gluing equipment or robot gluing equipment, a double-station workbench or a multi-station rotating workbench, a gluing head and a glue supply device, wherein the gluing head is fixed on the gluing equipment, glue A and glue B in the glue supply device are measured and supplied respectively, after the glue A and the glue B are mixed in the gluing head, a nozzle of the gluing head moves along tracks of the patterns or the cartoons or the trademarks, mixed two-component polyurethane flows out of the nozzle, and the surfaces of the clothing or the ornaments are coated with the two-component polyurethane uniformly, quickly and efficiently. Pretreatment is not required, the continuous gluing property is good, drawing is avoided, foamed or unfoamed patterns are highly three-dimensional, colors are convenient to adjust, the bonding strength is high, the adhesion is good, automatic gluing can be realized, and the production efficiency can be improved.

Owner:DALIAN HUAGONG INNOVATION TECH

Polyamide hot-melt adhesive

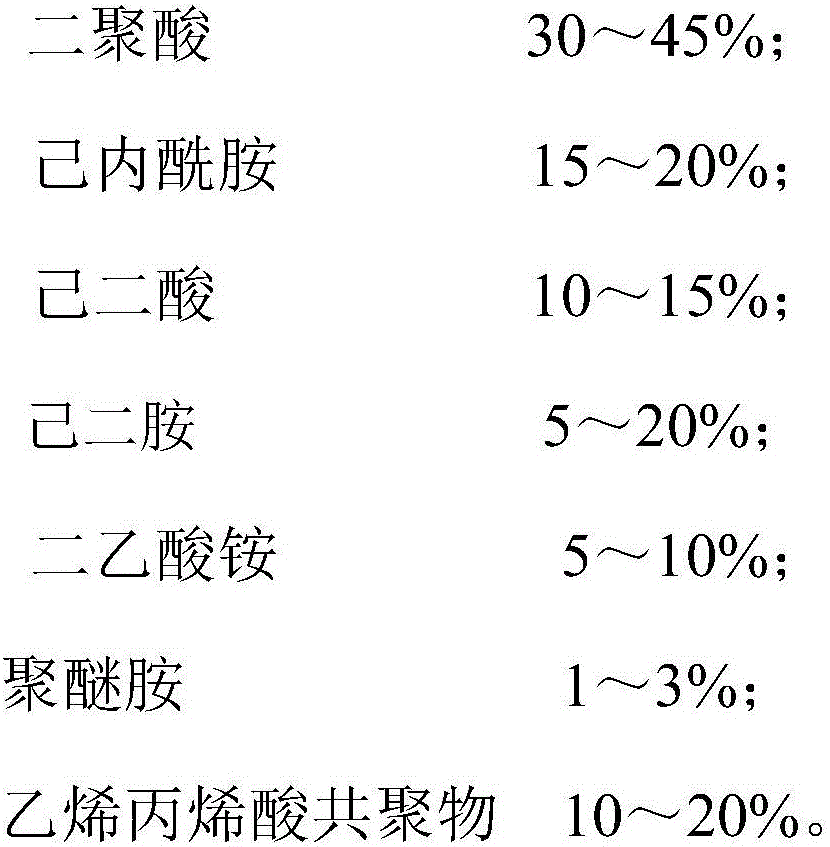

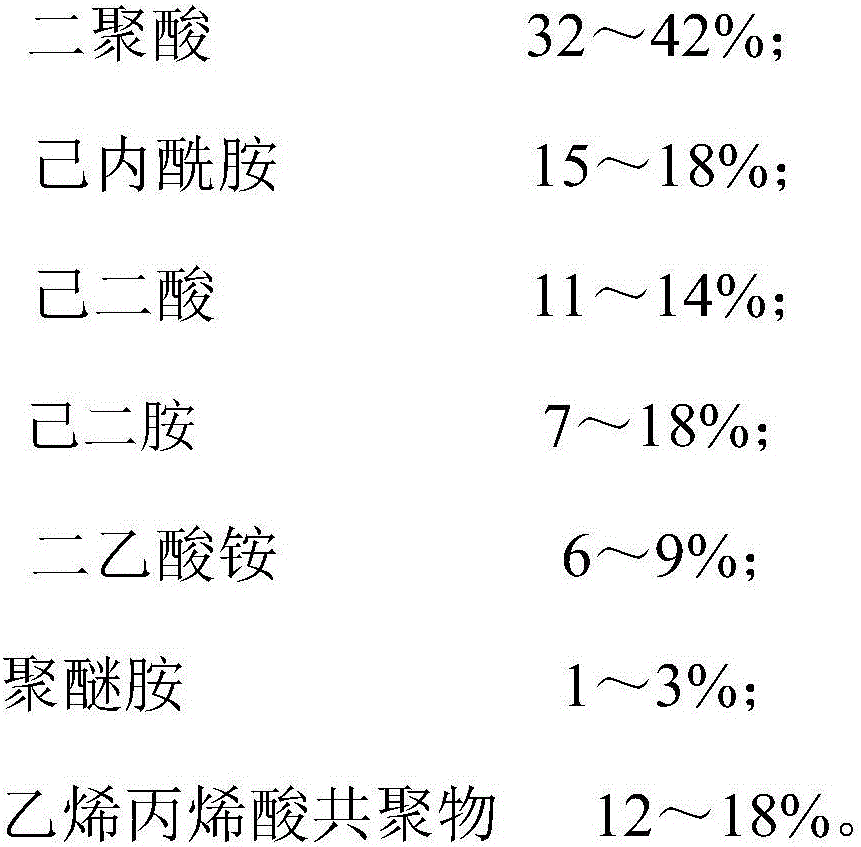

InactiveCN106433550APlay a toughening roleReduce processing costsMacromolecular adhesive additivesHexamethylenediamineAdipic acid

The invention relates to the technical field of hot-melt adhesives, particularly a polyamide hot-melt adhesive. The polyamide hot-melt adhesive comprises the following components in percentage by weight: 30-45% of dimer acid, 15-20% of caprolactam, 10-15% of adipic acid, 5-20% of hexamethylenediamine, 5-10% of ammonium diacetate, 1-3% of polyetheramine and 10-20% of ethylene-acrylic acid copolymer. Compared with the prior art, the polyamide hot-melt adhesive is prepared by the following steps: carrying out polymerization reaction on the acids and amines to form amides, granulating to form granules, adding the high-melt-index ethylene-acrylic acid copolymer, extruding to obtain a strip, and rolling to obtain the finished product. The ethylene-acrylic acid copolymer performs the toughening function. The product has favorable flexibility, heat stability and processibility; the Shore hardness is 75, the softening point is 185 DEG C, the low temperature resistance is -45 DEG C, the peel strength reaches 6.5 N / mm, and the elongation percentage is up to 620%; and the product has favorable low-temperature flexibility and adhesion, is especially suitable for various lasting adhesive applicators to implement automatic adhesive application, has favorable processability, and greatly lowers the processing cost of shoes.

Owner:东莞市舜天实业有限公司

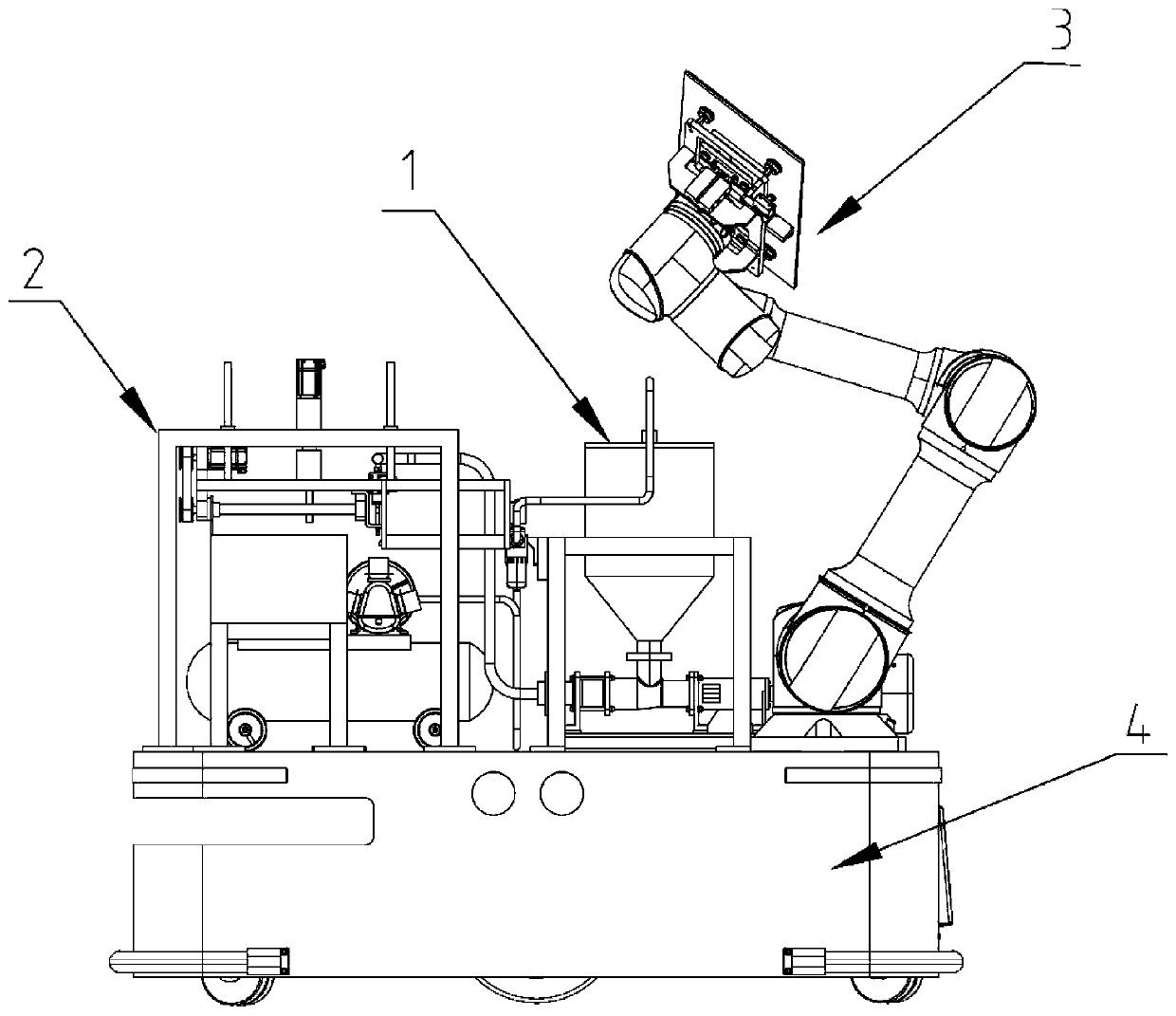

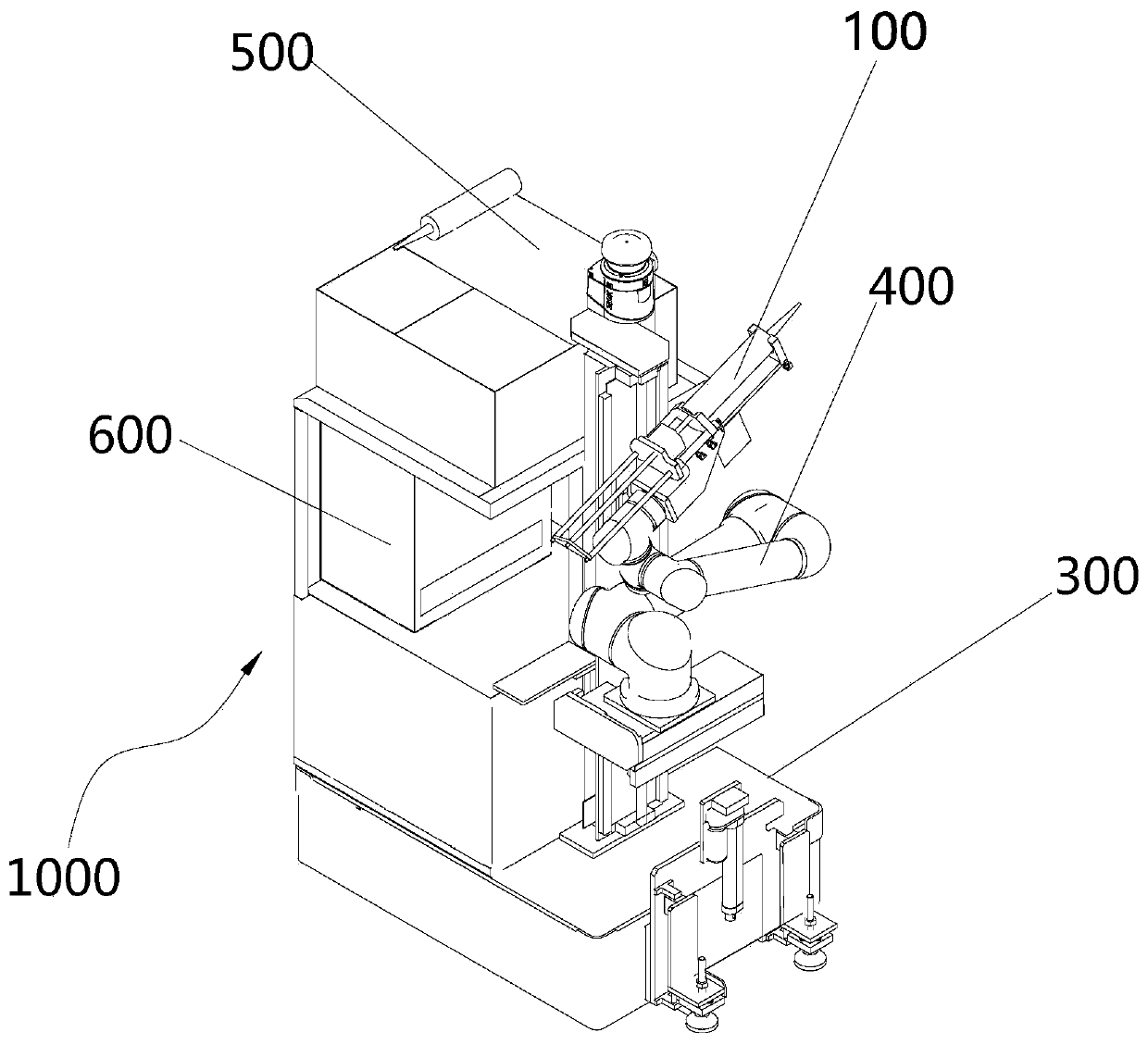

Transfer gluing equipment and application method thereof

PendingCN109107821ARealize automatic gluingAvoid the shortage of manual double-sided adhesive bondingLiquid surface applicatorsCoatingsResource savingEngineering

The invention provides transfer gluing equipment and an application method thereof, and relates to the technical field of packaging equipment. The transfer gluing equipment comprises a machine body, amechanical arm, a gluing device, a detection device and a glue smelting device, wherein a conveying belt conveyor is arranged on the machine body and is used for conveying a product; the mechanical arm is arranged at a feeding side of the machine body and is used for placing the product on the conveying belt conveyor; the gluing device is arranged on the machine body, can move relative to the conveying belt conveyor to get far away from or close to the conveying belt conveyor and is used for gluing the product placed on the conveying belt conveyor; the detection device is arranged on the machine body and can move relative to the conveying belt conveyor to get far away from or close to the conveying belt conveyor; the glue smelting device is arranged at one side of the machine body and isused for smelting glue and supplying glue to the gluing device. The transfer gluing equipment has the beneficial effects that automatic gluing can be realized and the equipment has the advantages of high production efficiency, low production cost, manpower resource saving and good environment protection effect.

Owner:余碧茵

Glue robot

ActiveCN110962144BImprove stabilityConvenient glue workLiquid surface applicatorsCoatingsSpinningGelatin

The invention provides a gluing robot, which includes a movable chassis, a gluing mobile device, a gluing device and a silo; Cylinder supply area; the gluing device and the gluing moving device are both arranged in the gluing implementation area, and the gluing moving device is connected to the movable chassis, and the gluing device is arranged in the gluing implementation area. The glue moving device is used to automatically clamp the rubber cartridge for glue application or loosen the glue cartridge for replacement of the glue cartridge; the silo is located in the glue cartridge supply area. By setting the movable chassis, gluing device, gluing mobile device and silo, and setting the silo at the rear end of the movable chassis, the gluing device and the gluing mobile device at the front end of the movable chassis, it can be used reasonably The space above the chassis facilitates the completion of a larger range of gluing work, and makes the weights of the gluing implementation area and the rubber cartridge supply area match each other, improving the stability of the gluing robot.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

AC and DC dual-purpose small automatic glue coating machine

InactiveCN103586163BAvoid stickingReduce cumbersome operationsLiquid surface applicatorsCoatingsElectric machineryPush pull

AC and DC dual-purpose small automatic glue applicator. It belongs to the field of office supplies. It solves the problems of slow manual glue application, uneven coating and easy adhesion. A rack (4) is fixed in the cavity (3) of the bottom plate (1) of the gluing machine, a gear meshing with the rack (4) is fixed on the cross bar of the door frame (2), and the first motor (6 ) is fixed with one end of the crossbar; the lead screw (7) between the two columns (5) is covered with a slider (8), and the second motor (9) is fixed with one end of the lead screw (7); the lower part of the slider (8) A push-pull electromagnet (10) is fixed, and a rubber bottle (12) is fixed at the lower end of the push-pull electromagnet (10). The glue port is closed by a cylindrical pressure head (18); the lower end of the threaded rod (15) is fixed with a pressure piece (19). The invention has the advantages of fast glue application speed, uniform glue application, time saving and labor saving, and convenient movement and portability.

Owner:NORTHEAST GASOLINEEUM UNIV

Hot melt adhesive powder

InactiveCN106318306AReduce processing costsImprove adhesionNon-macromolecular adhesive additivesAntioxidantProcessing cost

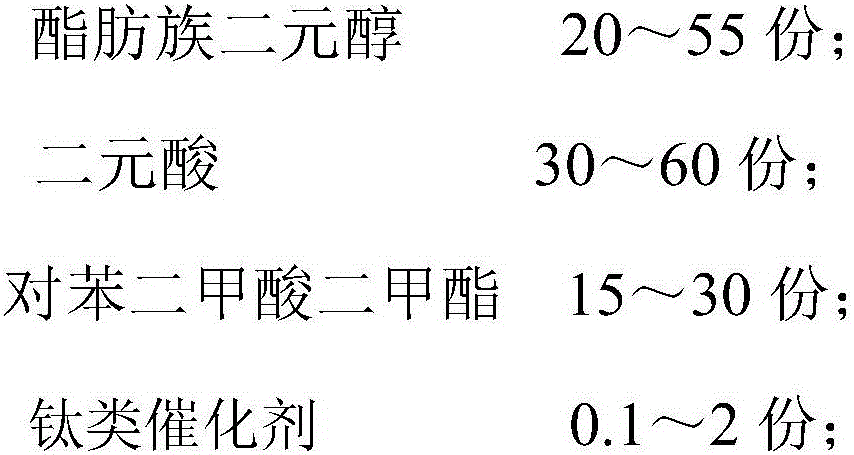

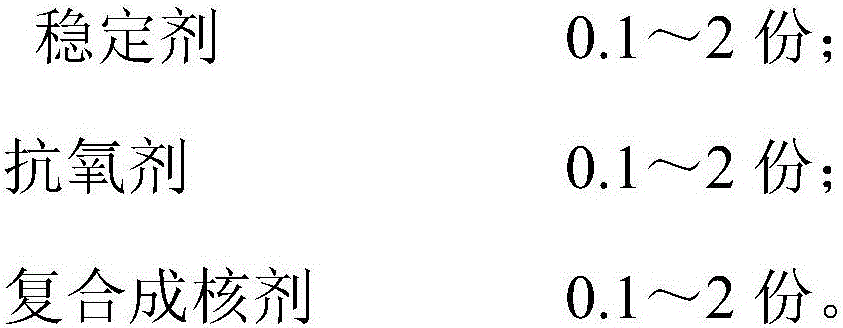

The invention relates to the technical field of hot melt adhesives, in particular to hot melt adhesive powder, which is prepared from the following components in parts by weight: 20 to 55 parts of aliphatic seriesdihydric alcohol, 30 to 60 parts of binary acid, 15 to 30 parts of dimethyl terephthalate, 0.1 to 2 parts of titanium catalyst, 0.1 to 2 parts of stabilizer, 0.1 to 2 parts of antioxidant,and 0.1 to 2 parts of composite nucleating agent. Compared with the prior art, the hot melt adhesive powder provided by the invention adopts the aliphatic seriesdihydric alcohol, the binary acid and the dimethyl terephthalate as a synthesis system, a composite additive is added, and the polyester is modified, so that the hot melt adhesive powder has a good adhesion force; particularly, after the composite nucleating agent is added, the hot melt adhesive powder is fast in curing speed, has the shore hardness being 70, the softening point being 175 DEG C, the resistance to low temperature of minus 45 DEG C, the peeling strength being 6.8N / mm, and the elongation being 620 percent, has good low temperature flexibility and adhesion, is particularly suitable for various sizing machines for lasting, realizes automatic sizing, is good in processing performance and low in cost, and is beneficial to greatly reducing the processing cost of shoes.

Owner:东莞市舜天实业有限公司

Side binding device of binding machine

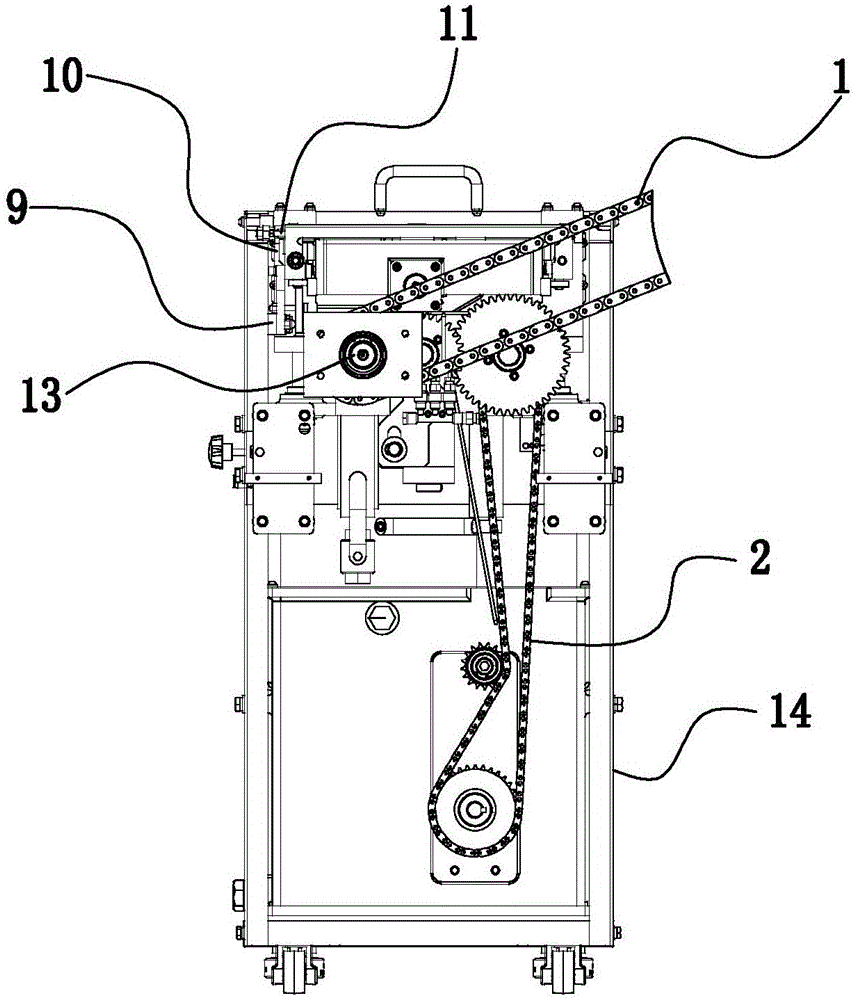

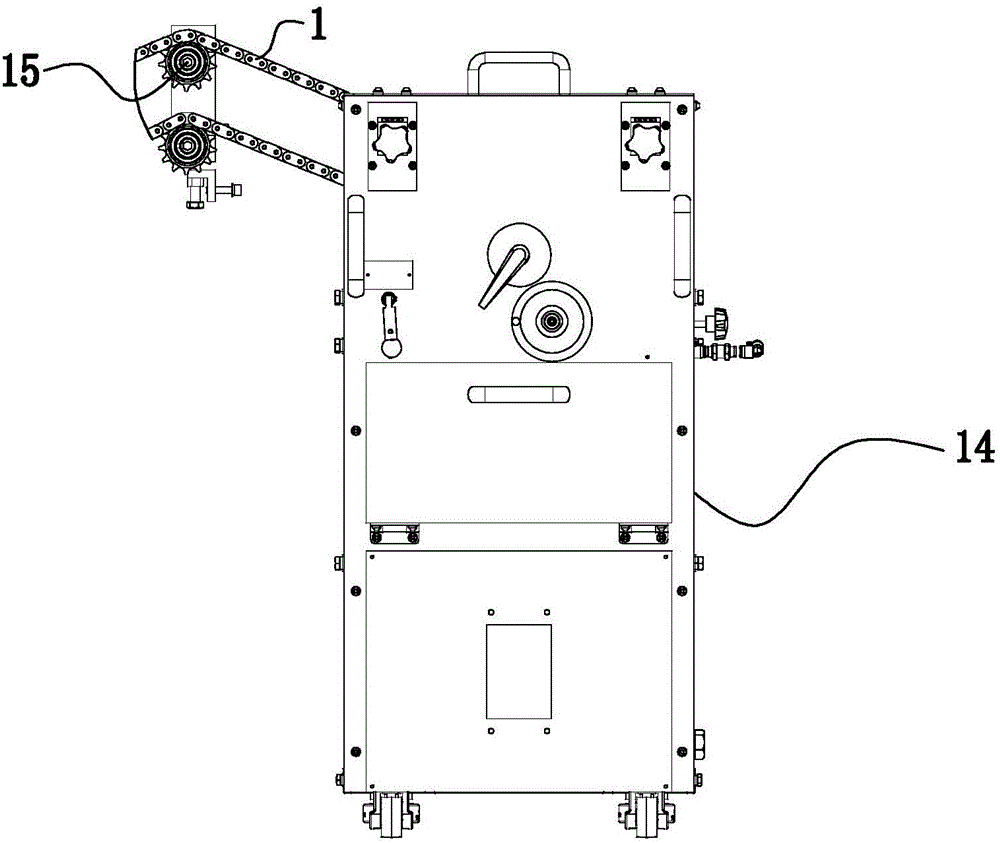

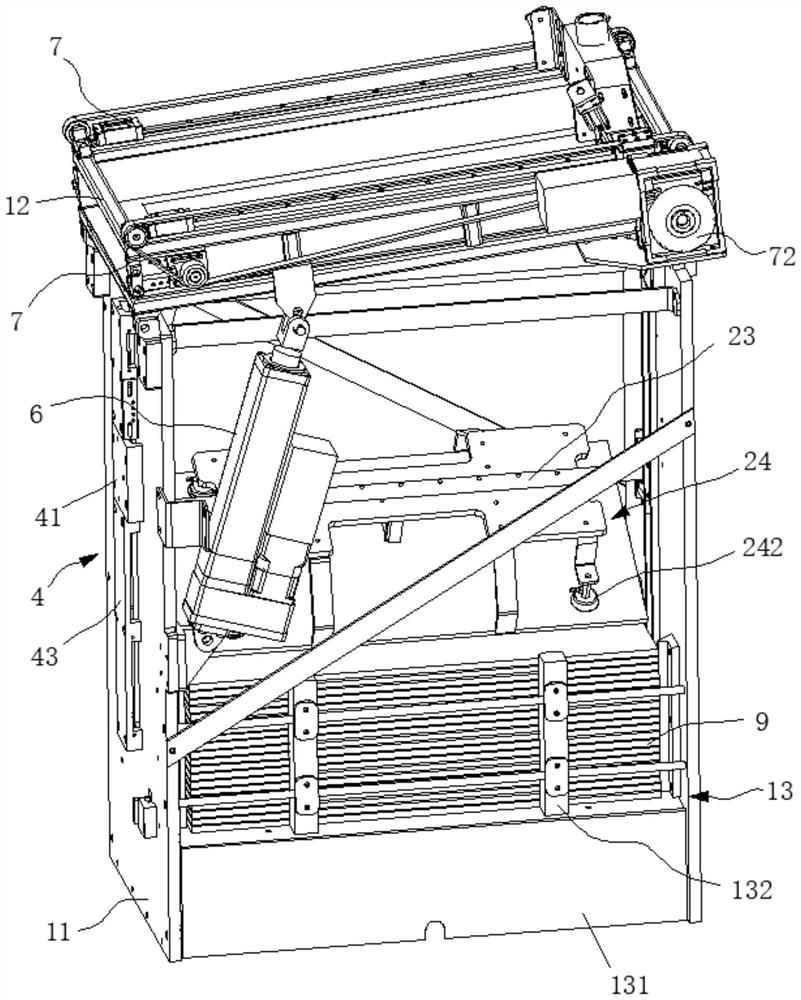

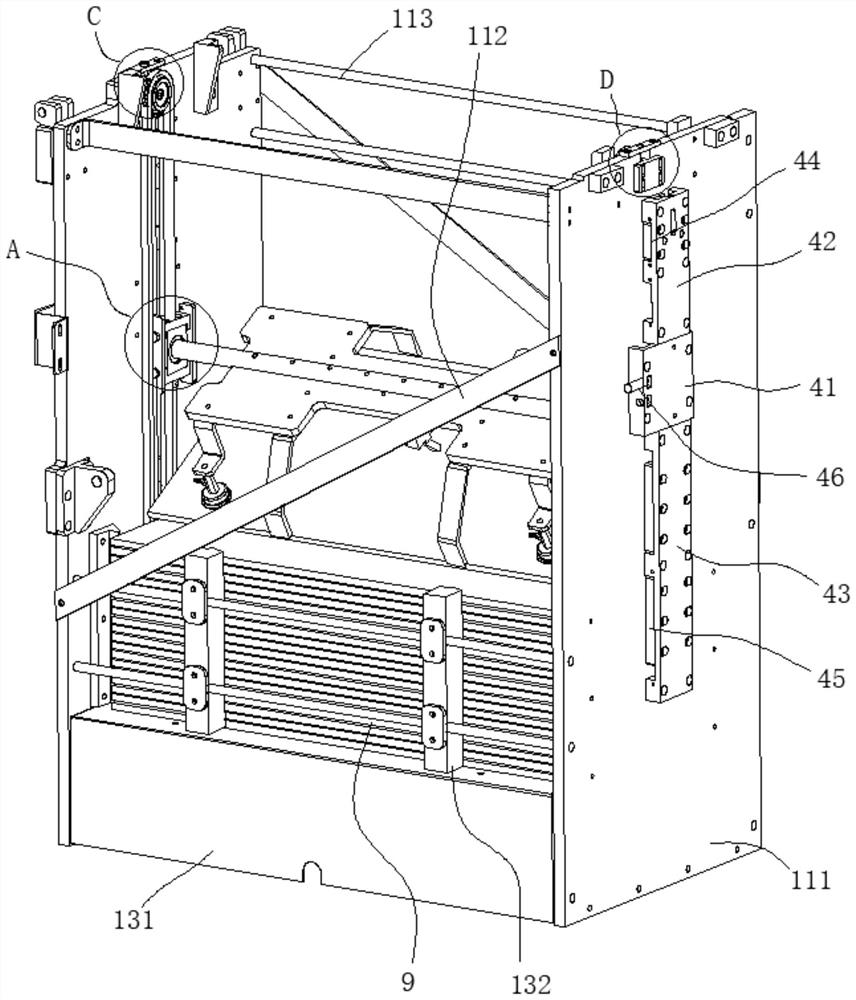

InactiveCN105882191AReasonable structural designRealize automatic gluingBookbinding adhesiveSprocketEngineering

The invention relates to a side binding device of a binding machine. The side binding device of the binding machine comprises a side binding device body and a gear shaft installed at the upper end of the side binding device body, wherein a chain wheel is installed in the position, at the outer end of the side binding device body, of the gear shaft and used for driving the gear shaft to rotate; the chain wheel is rotatably connected with the gear shaft through a first chain; a plurality of drive gear components are arranged at the lower end of the gear shaft; the first chain drives a second chain to be in rotatable connection with the first chain through the drive gear components; a gear pump is arranged at the bottom of the side binding device body; the second chain is in rotatable connection with the gear pump and drives the gear pump to rotate; a glue pot is arranged on the upper portion of the side binding device body; and the glue pot is connected with the gear pump through a corrugated pipe. The side binding device of the binding machine is reasonable in structural design and capable of implementing automatic glue feeding in a reciprocating mode; and meanwhile, a glue scraping piece is designed to be in contact with a glue wheel, redundant glue can be scraped into the glue pot, and the wiredrawing phenomenon is reduced to the greatest extent when book blocks pass.

Owner:PINGHU BIND EX MACHINERY

A gluing device and a tile laying robot

ActiveCN111058597BMiniaturizationRealize automatic gluingBuilding constructionsBrickStructural engineering

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

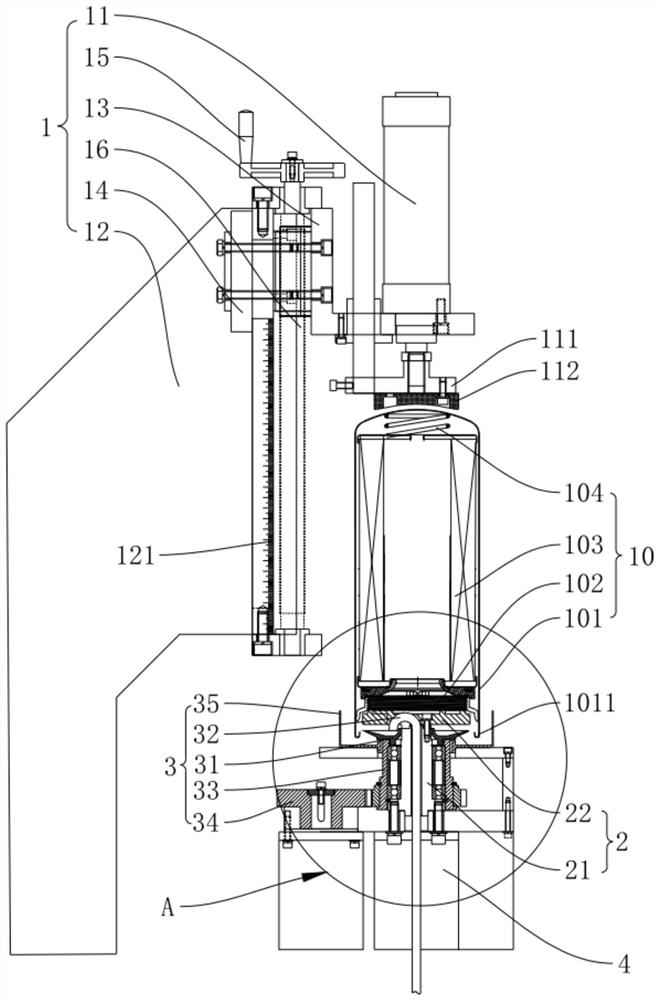

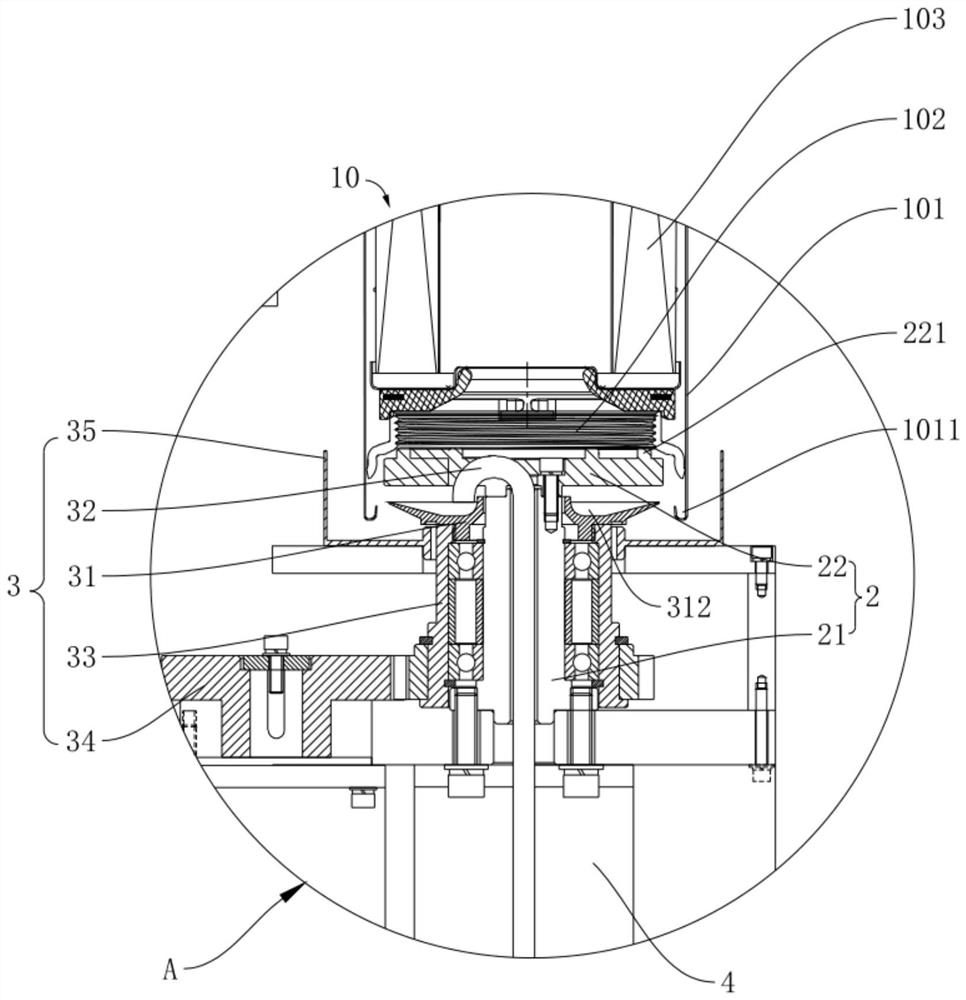

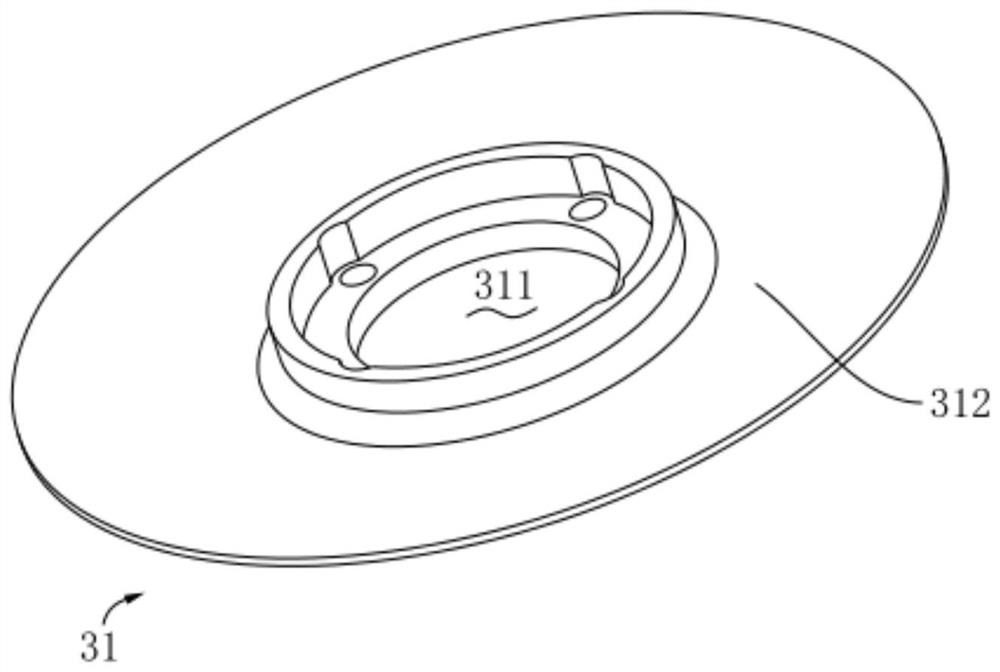

Glue throwing device and glue throwing method

ActiveCN112974064ARealize automatic gluingQuality improvementMaterial gluingSpraying apparatusEngineeringMechanical engineering

The invention relates to the technical field of filters, and discloses a glue throwing device and a glue throwing method. The glue throwing device comprises a pressing assembly, a bearing assembly and a glue throwing assembly, and the pressing assembly is arranged above a filter and is configured to press a shell of the filter; the bearing assembly is arranged at the bottom of the filter, and a threaded cover plate of the filter is arranged on the bearing assembly; the glue throwing assembly comprises a glue throwing disc and a glue outlet pipe, the glue throwing disc is rotatably arranged below the filter, and the glue outlet pipe can convey glue to the glue throwing disc; and when the pressing assembly presses the shell downwards, the shell overcomes the elastic force of a spring of the filter to move downwards relative to the threaded cover plate, the shell covers the glue throwing disc, the glue throwing disc rotates so that the glue can be thrown to the inner side wall of the shell, and the glue flows into a J-shaped seam of the shell under the action of gravity. According to the glue throwing device, automatic gluing of the filter is achieved, the labor cost is saved, the production efficiency is improved, gluing is uniform, the quality of the filter is improved, and the service life of the filter is prolonged.

Owner:SHANGHAI FLEETGUARD FILTER

Sheet-by-step automatic feeding, marking and gluing integrated equipment

ActiveCN104708689BFast processingSpread evenlyOther plywood/veneer working apparatusAdhesive application devicesProduction lineMaterial scattering

The invention discloses layer-by-layer automatic feeding, marking and gluing integrated equipment for sheet materials. The layer-by-layer automatic feeding, marking and gluing integrated equipment for the sheet materials comprises a marking device and a gluing device; the gluing device is arranged on one side of the marking device and a layer-by-layer automatic feeding device is arranged on the other side of the marking device; the layer-by-layer automatic feeding device comprises a pushing mechanism, a hoisting mechanism and a sliding mechanism in sequence; and the gluing device comprises a supporting framework, a stirring mechanism arranged at the upper end of the supporting framework, a material scattering mechanism arranged at the bottom of a transverse beam of the supporting framework, and a compression roller gluing mechanism arranged under the supporting framework. According to the layer-by-layer automatic feeding, marking and gluing integrated equipment, marking and gluing are integrated, transmission and interruption of machines are reduced in the process and the consistency of a production line is improved; and the machining time of the whole sheet material is shortened, materials can be automatically fed layer by layer, the transmission is buffered, the gluing can be automatically realized and the gluing is uniform.

Owner:JIANGSU KENTIER WOOD

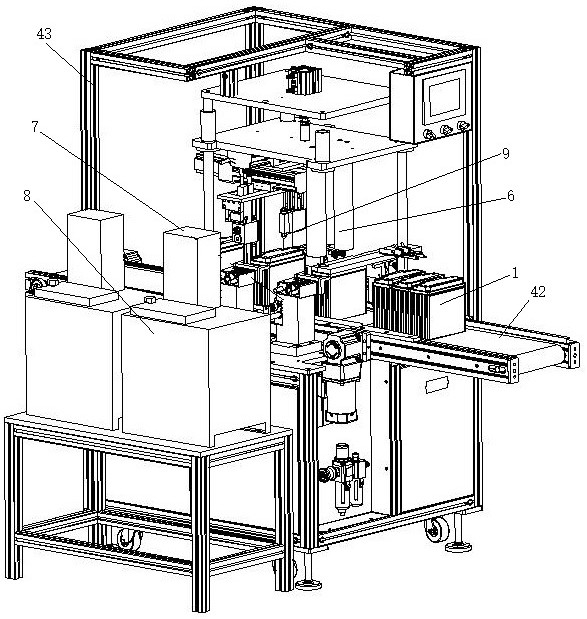

A processing device and processing technology for in-line light-emitting diodes

ActiveCN112547434BRealize automatic gluingAvoid pollutionLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses an in-line light-emitting diode processing device and its processing technology, comprising a diode body, a package case is arranged inside the diode body, an LED chip is arranged inside the package case, and one side outer wall of the package case is fixedly connected with a Lead legs. By placing the LED chip under the glue head, start the stretching part to stretch and move the glue head, so that the glue can be placed on the top of the LED chip, through the setting of the protective device, after gluing, start the stretching part to drive The glue head moves upwards, the vertical rod and the pull rod rotate at the same time, the vertical block moves downward when the driving part is activated, one side of the wedge-shaped groove fits the inner wall of the through block, the inner wall of the groove in the outer wall of the sliding column slides, and the sliding column moves away from the inner wall. One side of the groove is attached to the through block, the vertical block and the through block move at the same time, the pull rod drives the protective shell to rotate, and stops when it rotates to the bottom of the glue outlet, the protective shell can effectively prevent excess glue from falling on the top of the console and causing pollution , the use effect is better, and the protection range is comprehensive.

Owner:安徽明万兴电子有限公司

Spacing-adjustable gluing mechanism capable of keeping gluing face upwards

InactiveCN102862320BRealize automatic gluingImprove processing efficiencyPaper-makingBox making operationsMicrocomputerPaperboard

Owner:张银国

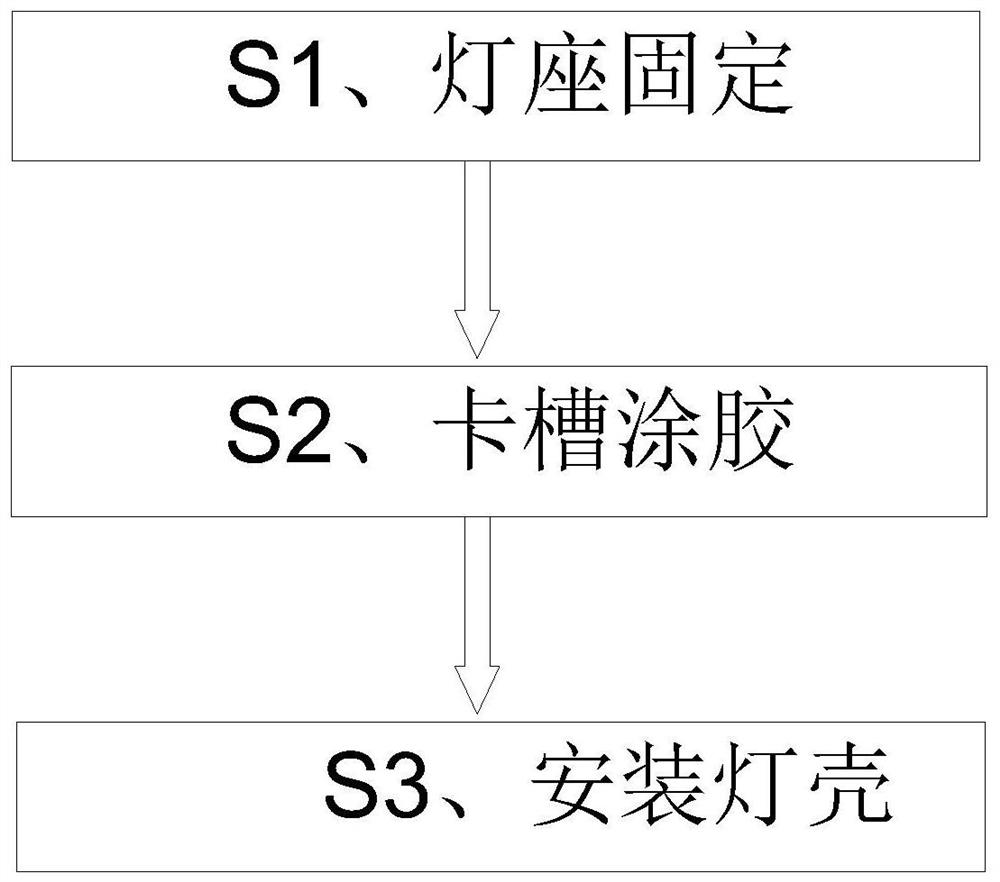

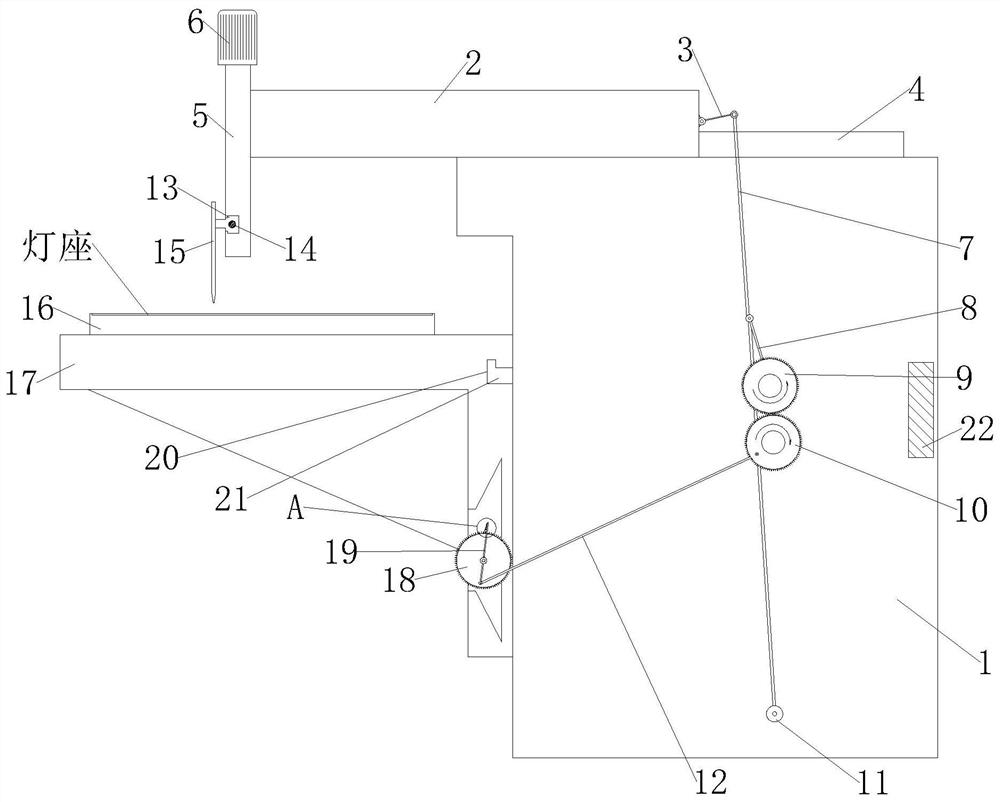

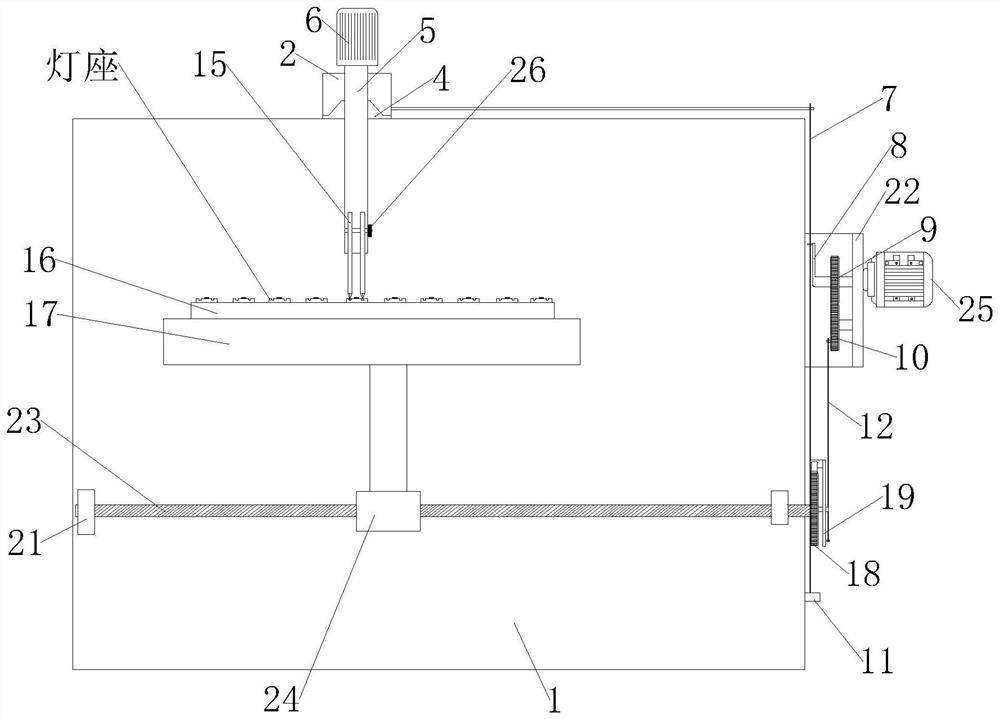

A production and sealing process of led bulbs

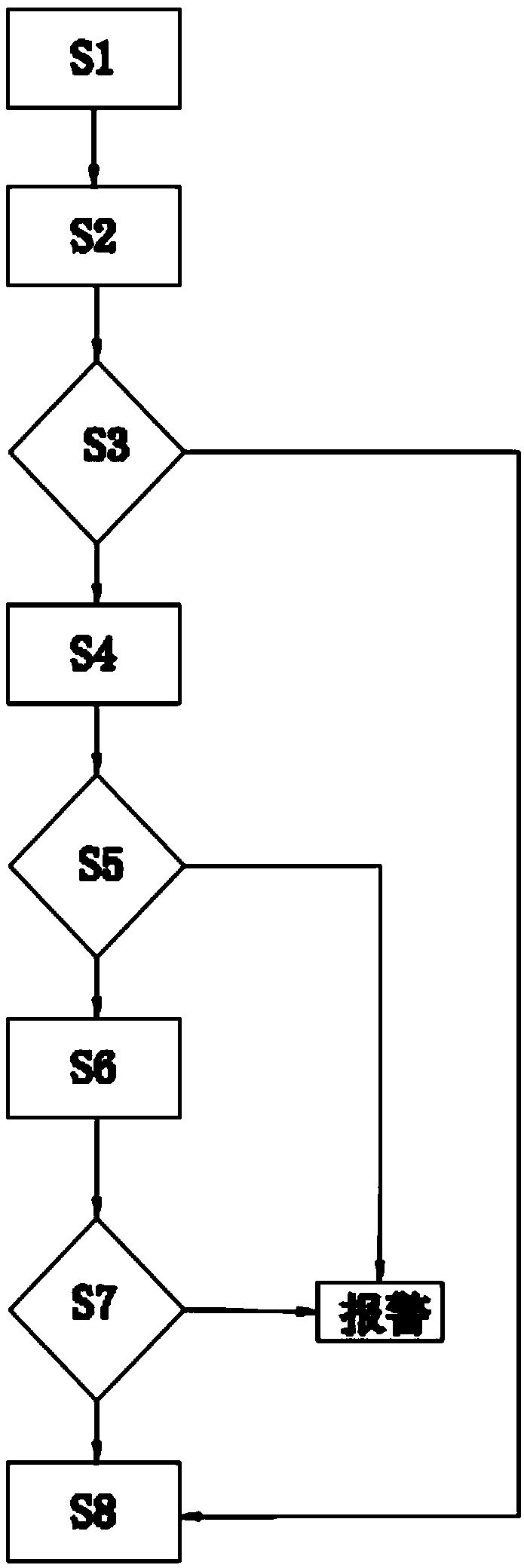

ActiveCN112555700BImprove uniformityPrecise applicationLiquid surface applicatorsCoatingsEngineeringLamp shell

The invention provides a LED bulb production and sealing process, which relates to the technical field of LED bulb production and processing, and specifically includes the following steps: S1. Fixing the lamp holder: installing the strip-shaped lamp holders equipped with LED lamps at equal intervals, and The two ends of two adjacent lamp holders are fixed in parallel; S2, card groove glue application: apply sealing glue to the top of each lamp holder fixed in parallel at equal intervals in step S1, and apply the sealing glue to the two ends of the top of each lamp holder. and the same amount of sealing glue applied in the two slots at the top of each lamp holder; S3, install the lamp housing: install the lamp housing on the top of the lamp holder coated with sealing glue in the slot in step S2, The lamp housing is fixed in the draw-in groove at the top of the lamp holder; the LED bulb production sealing device of the present invention is fixedly installed with downward vertical gluing pens on at least two sliders, so that each time the gluing pen frame moves to the left , Apply sealing glue to the multiple slots on the top of the lamp holder to improve the application efficiency.

Owner:江苏利宏光电科技有限公司

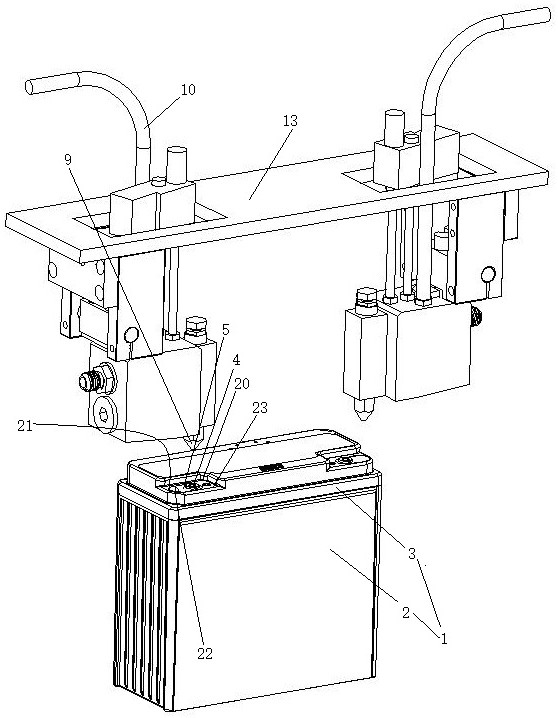

Battery pole gluing method and battery pole gluing mechanism

ActiveCN111211359BAvoid oxidation and blackeningPrecise positioningLiquid surface applicatorsFinal product manufactureConveyor beltHot-melt adhesive

Owner:JIANGXI XINWEI POWER ENERGY TECH

Sole gluing device for training shoes

Owner:CHONGQING HUIMEI IND CO LTD

Busbar glue winding device integrating glue feeding and glue winding and working method of busbar glue winding device

The invention discloses a busbar adhesive tape winding device integrating adhesive tape conveying and adhesive tape winding, which comprises an adhesive tape conveying device and an automatic adhesive tape winding device, the adhesive tape conveying device and the automatic adhesive tape winding device are both arranged on a working table, the lower part of one end of the automatic adhesive tape winding device is connected with the working table through a group of upright posts, and the upright posts are arranged on the working table. And the automatic adhesive tape winding device is arranged above the adhesive tape conveying device. According to the busbar adhesive tape winding device integrating adhesive tape feeding and adhesive tape winding, adhesive tape feeding and adhesive tape winding are integrated through cooperation of the adhesive tape conveying device and the automatic adhesive tape winding device, automatic adhesive tape feeding is achieved, adhesive tape feeding and continuous adhesive tape supply are achieved, the adhesive tape feeding and winding efficiency is greatly improved, and the workload of workers is reduced; and the production requirements can be better met.

Owner:苏州科伦特电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com