Polyamide hot-melt adhesive

A polyamide hot-melt adhesive and polyamino ether technology, which is applied in adhesives, adhesive additives, polymer adhesive additives, etc., can solve problems such as poor toughness, low-temperature brittleness, low melt viscosity, etc., and achieve low-temperature Good flexibility and adhesion, good flexibility, and the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

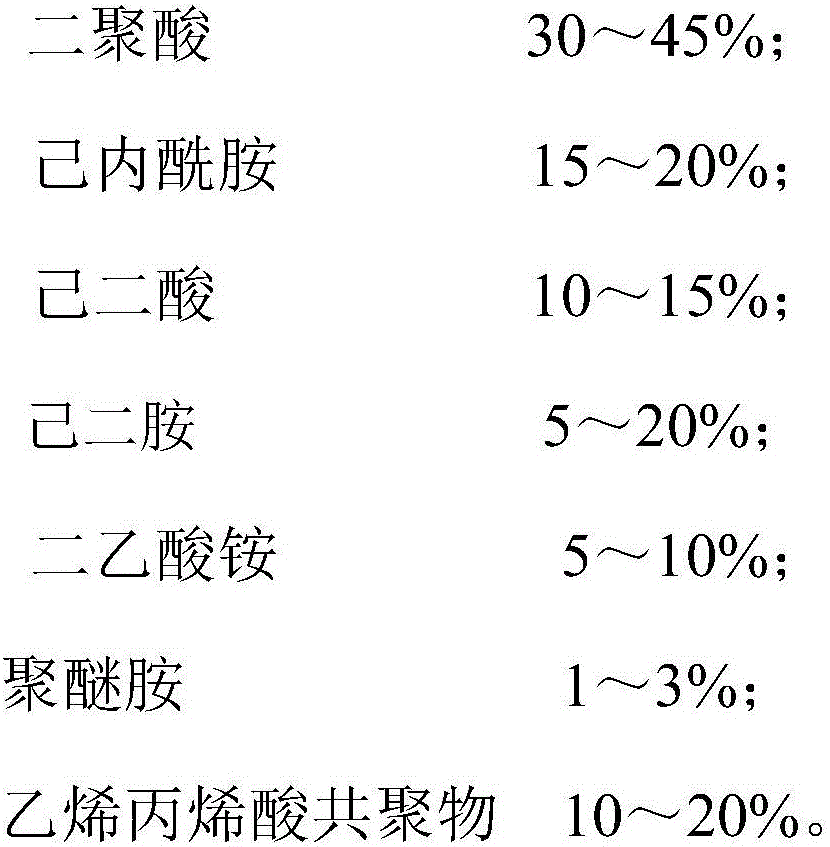

[0021] Polyamide hot melt adhesive, including the following components by weight percentage:

[0022]

[0023]

[0024] Preferably, the content of ethyl acrylate in the ethylene ethyl acrylate copolymer is 15 wt%, based on the weight of the ethylene ethyl acrylate copolymer.

[0025] Preferably, the weight average molecular weight of the ethylene ethyl acrylate copolymer is 8000-40000.

Embodiment 2

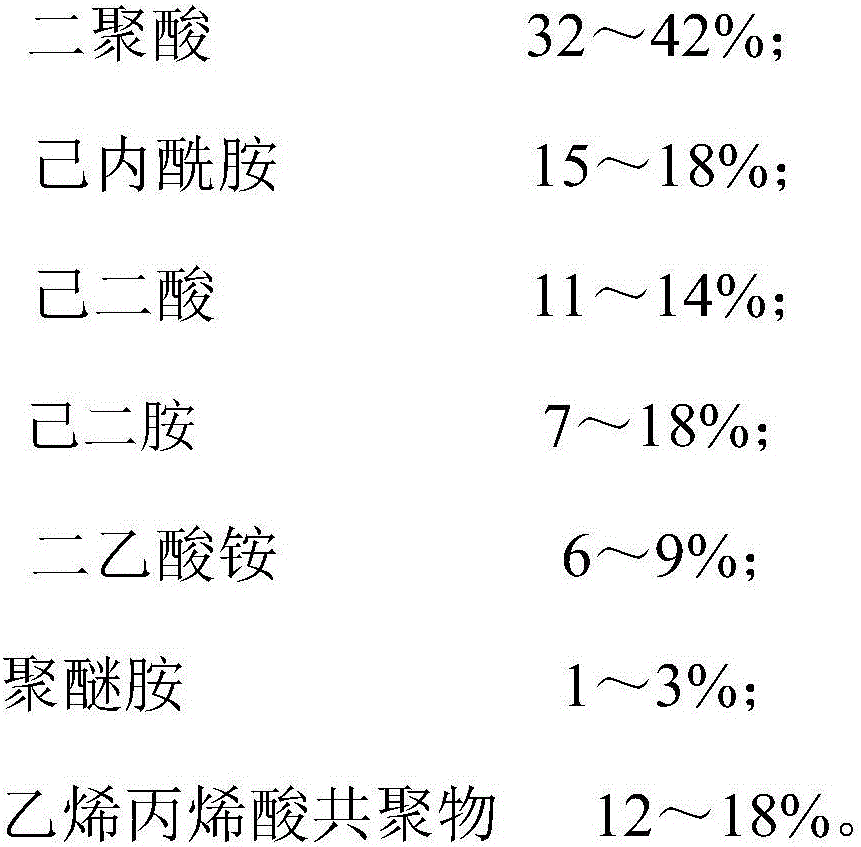

[0028] Polyamide hot melt adhesive, including the following components by weight percentage:

[0029]

[0030] Preferably, the content of ethyl acrylate in the ethylene ethyl acrylate copolymer is 18 wt%, based on the weight of the ethylene ethyl acrylate copolymer.

[0031] Preferably, the weight average molecular weight of the ethylene ethyl acrylate copolymer is 8000-40000.

Embodiment 3

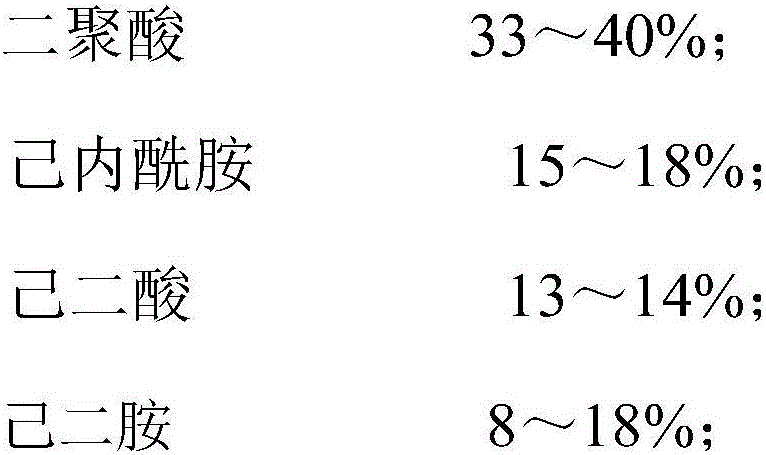

[0034] Polyamide hot melt adhesive, including the following components by weight percentage:

[0035]

[0036] Preferably, the content of ethyl acrylate in the ethylene ethyl acrylate copolymer is 17 wt%, based on the weight of the ethylene ethyl acrylate copolymer.

[0037] Preferably, the weight average molecular weight of the ethylene ethyl acrylate copolymer is 8000-40000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com