Patents

Literature

30results about How to "Accurate horizontal position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

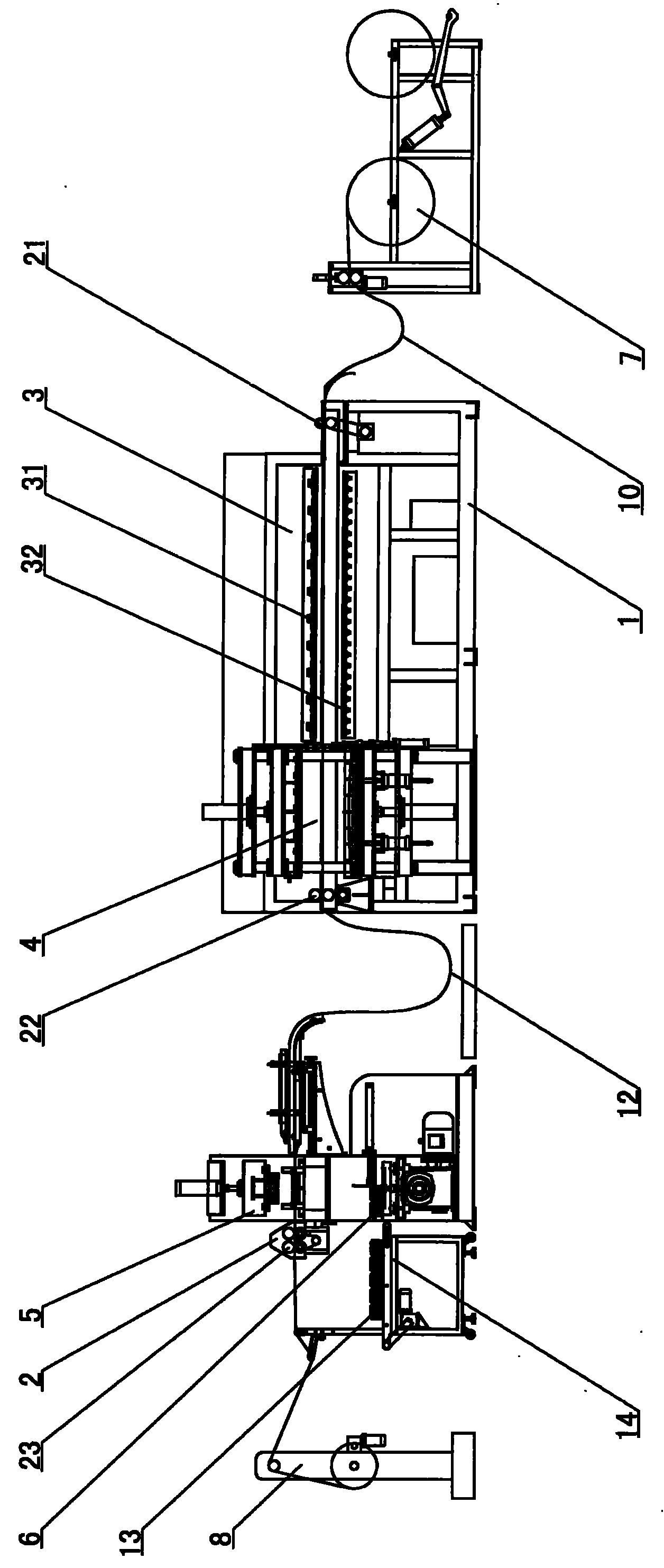

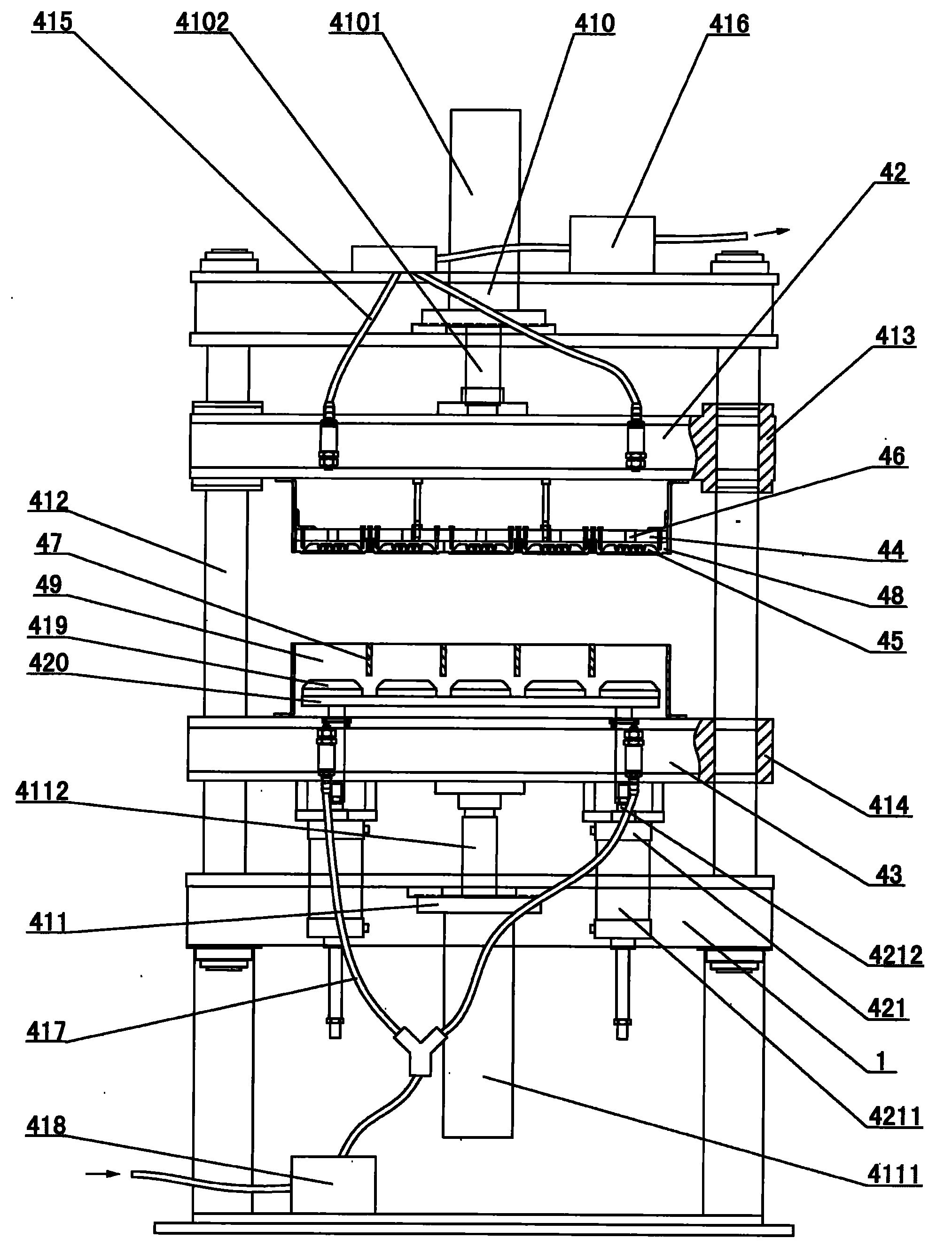

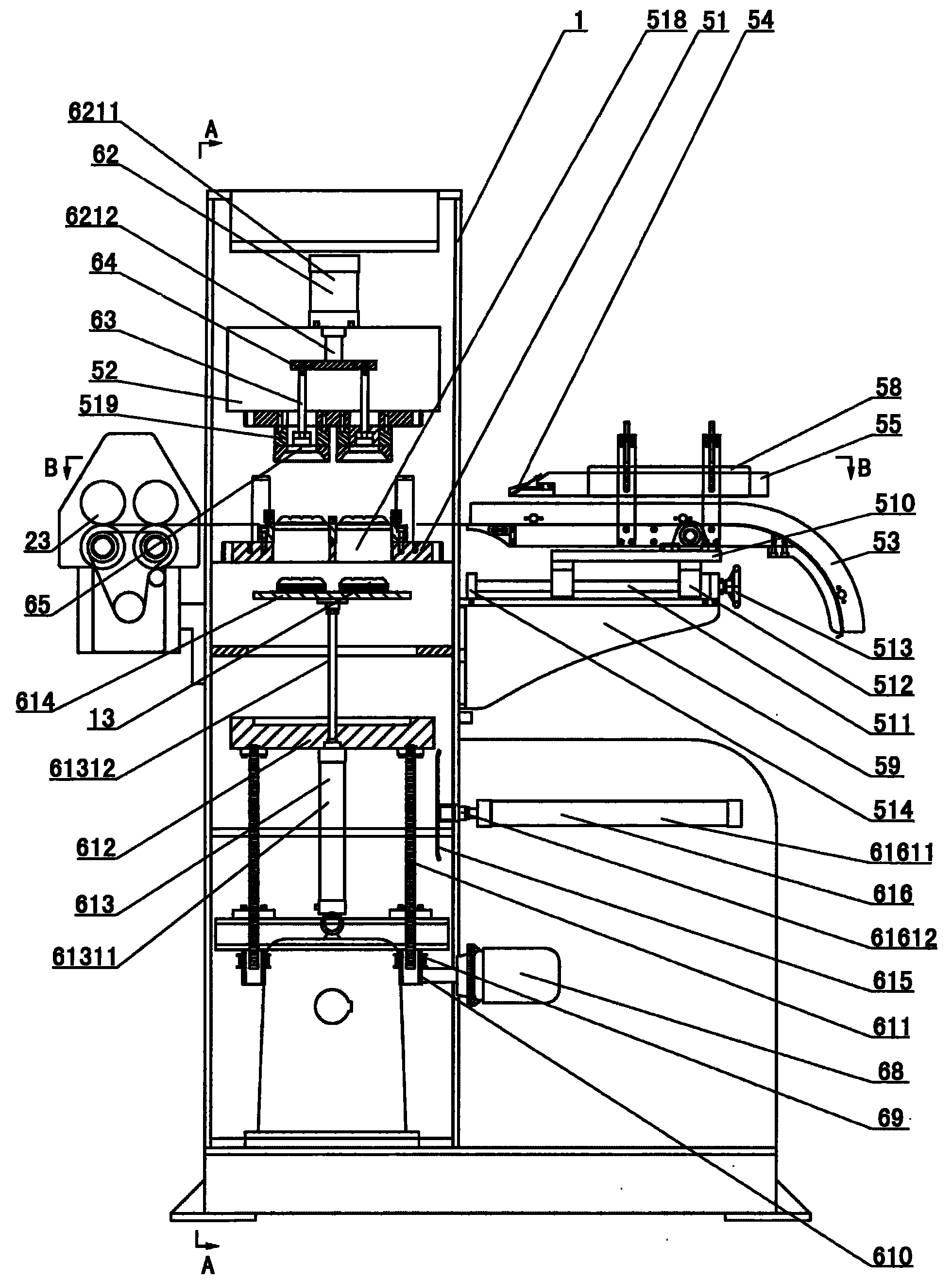

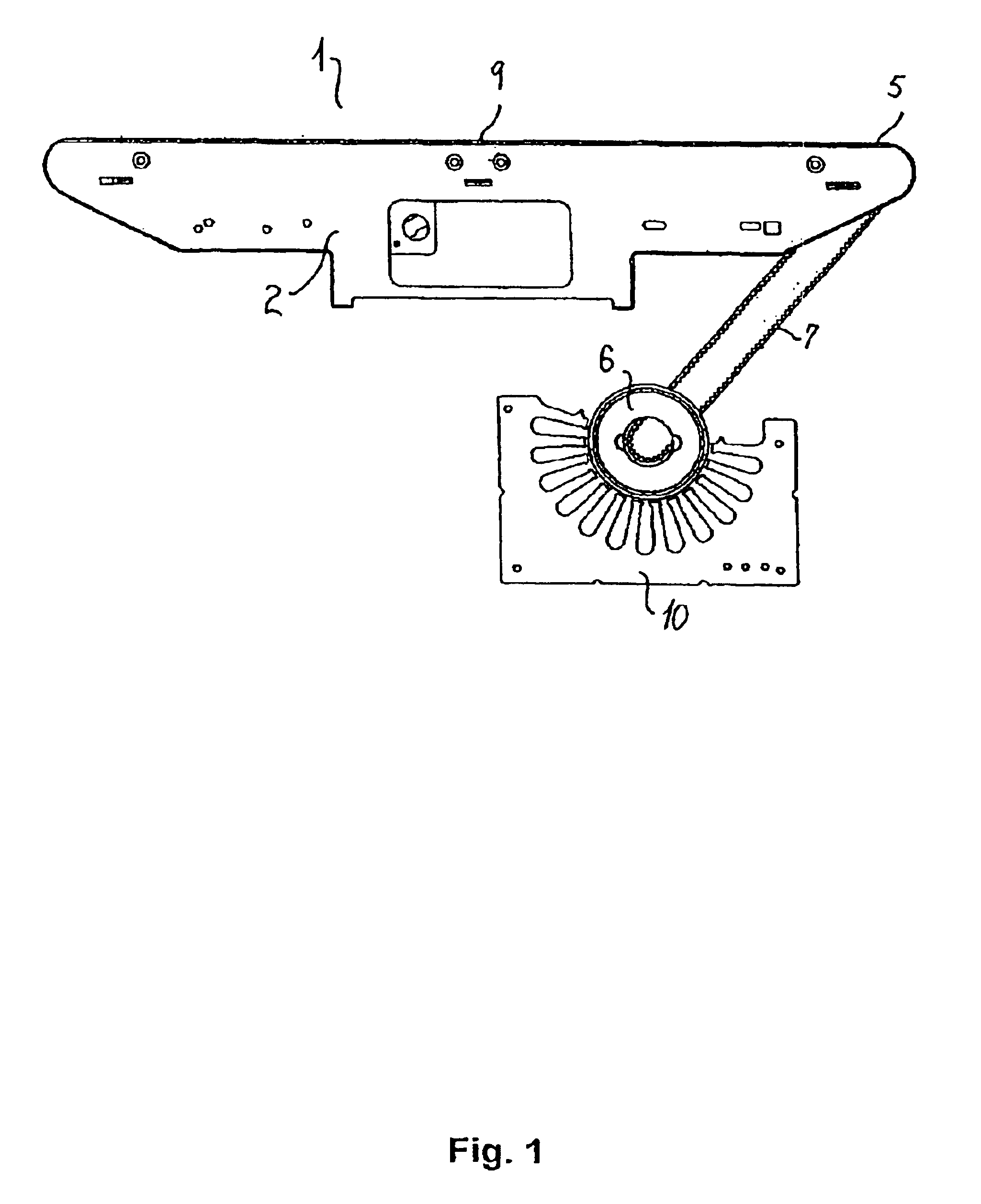

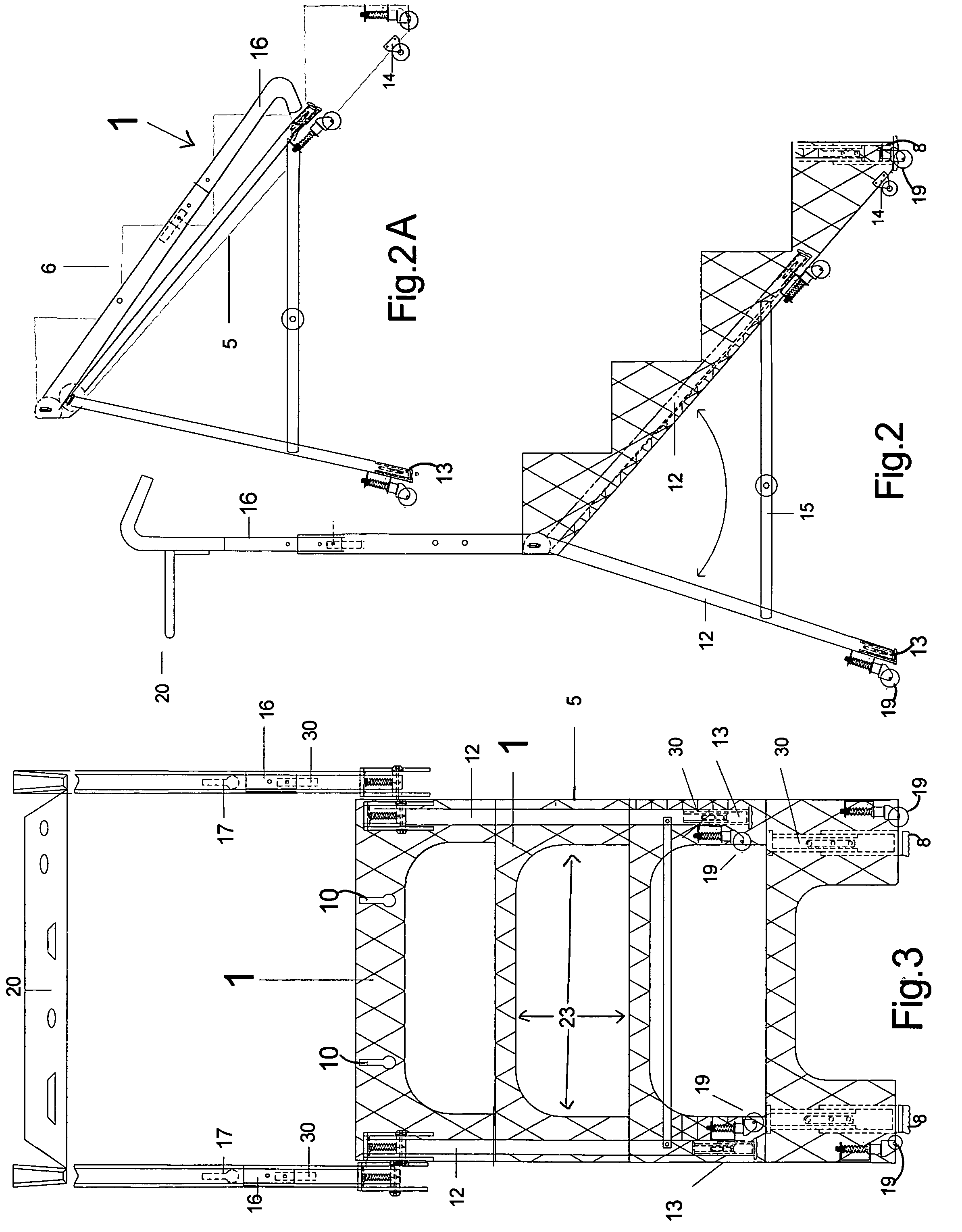

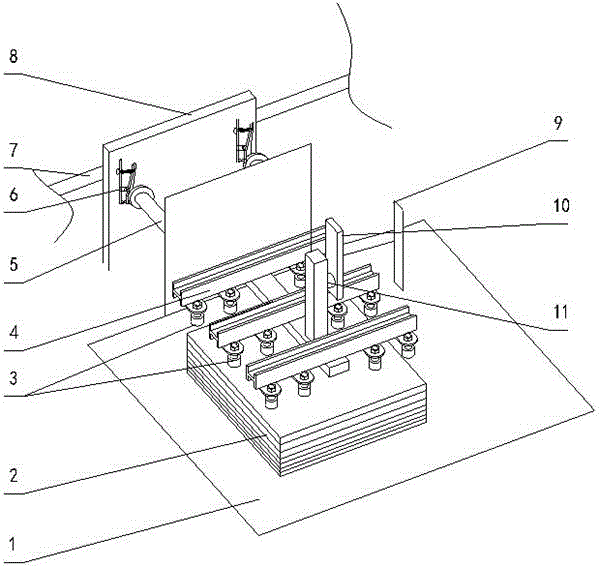

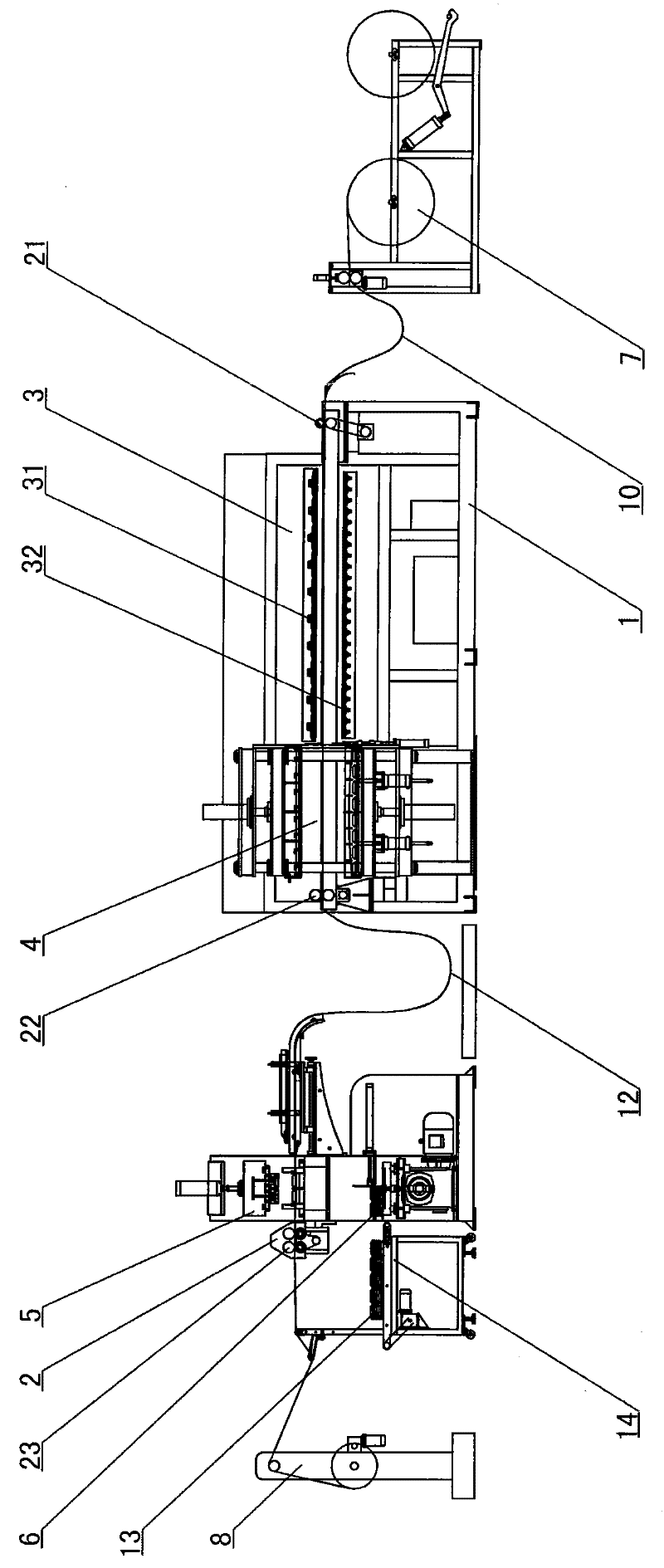

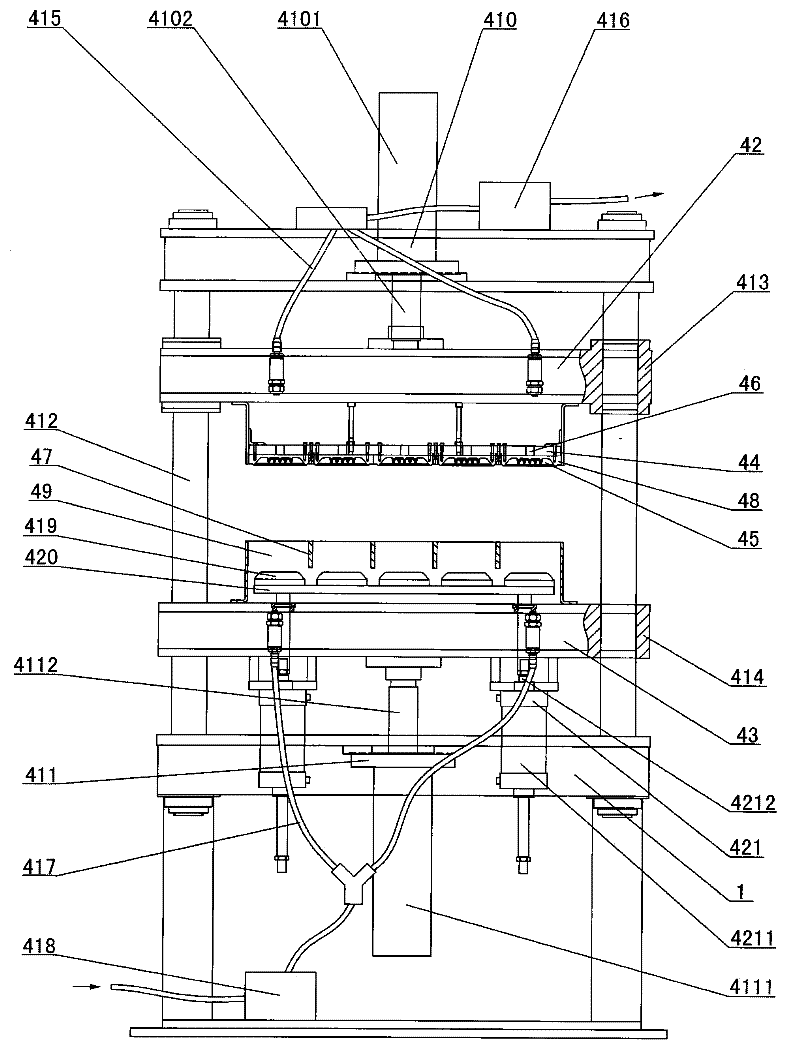

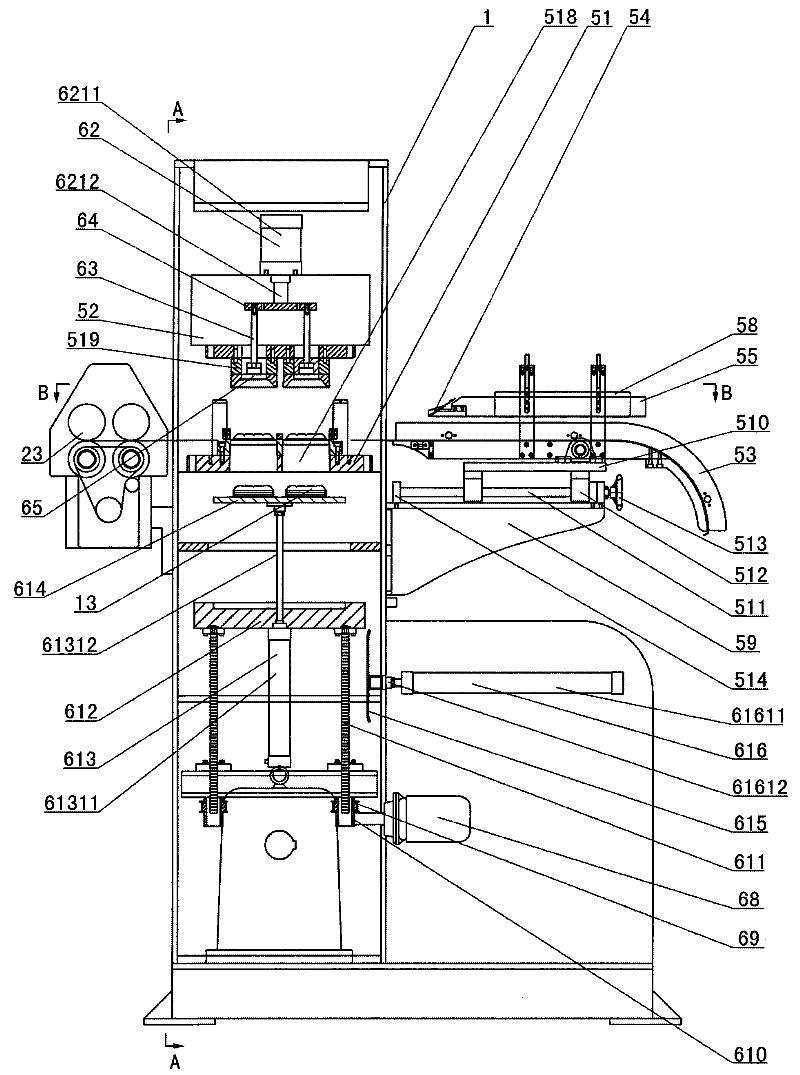

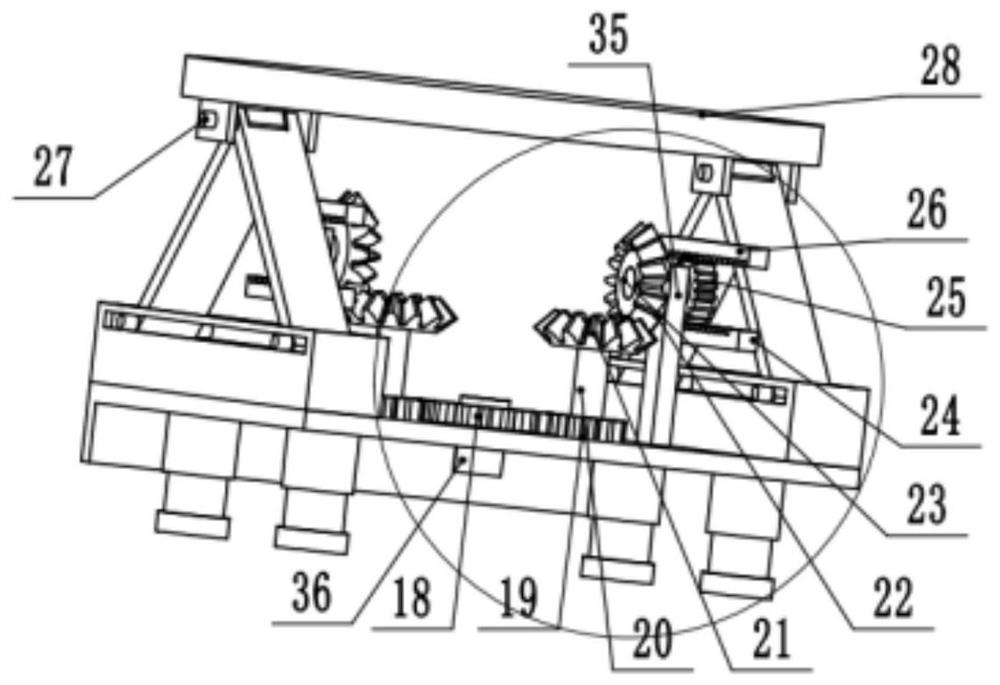

All-in-one machine for vacuum forming, molding and punching

InactiveCN101774273AAvoid lateral displacementAccurate horizontal positionMetal working apparatusTrappingPlastic film

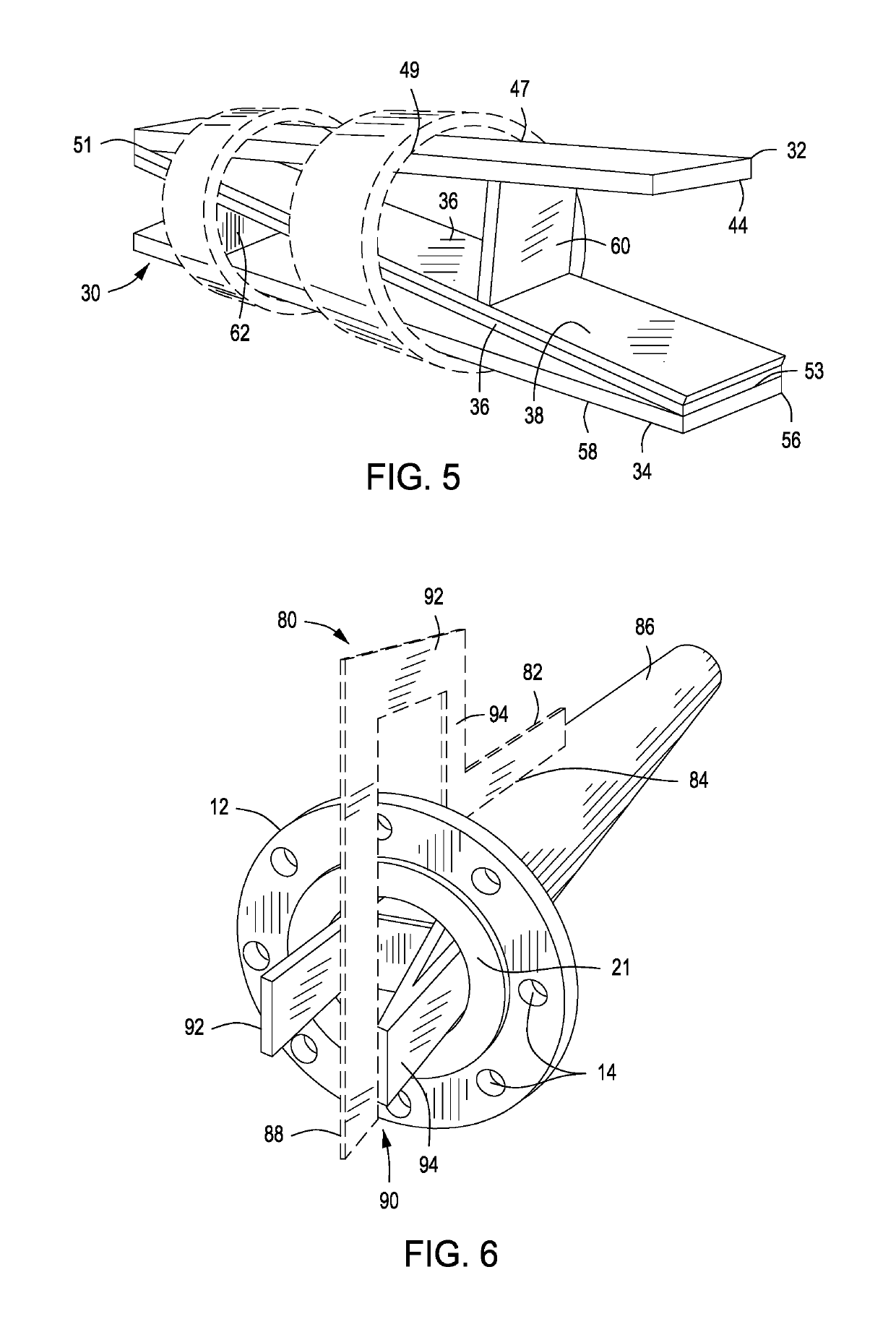

The invention relates to an all-in-one machine for vacuum forming, molding and punching, comprising a rack, a material traction device, a heating device, a forming unit, a punching device and a control device; wherein a top die platform and a bottom die platform of the forming device are provided with moulding moulds which are thereupon provided with a convex part or a concave part for forming a light trapping bump on plastic sheets; the punching device comprises a punching shear mechanism, a guide rail which moves frontwards and backwards and a photocell eye for detecting the light trapping bump; the guide rail is arranged in the front of the punching shear mechanism, the photocell eye is arranged in the front of the punching shear mechanism and is connected with a corresponding input terminal corresponding to the control device.In the invention, when forming is carried out, the light trap bump can be formed on the plastic sheet, the flaky plastic products can be prevented from transversely displacing by the guide of the guide rail, the photocell eye can be used to detect the light trap bump and the control device can be used to lead the material traction device to convey the flaky plastic products to preset distance, so that the longitudinal position of the plastic products is accurate when the plastic products enter the punching shear mechanism and the flaky plastic products can accurately arrive at the preset position of the punching mechanism.

Owner:广东金兴机械股份有限公司

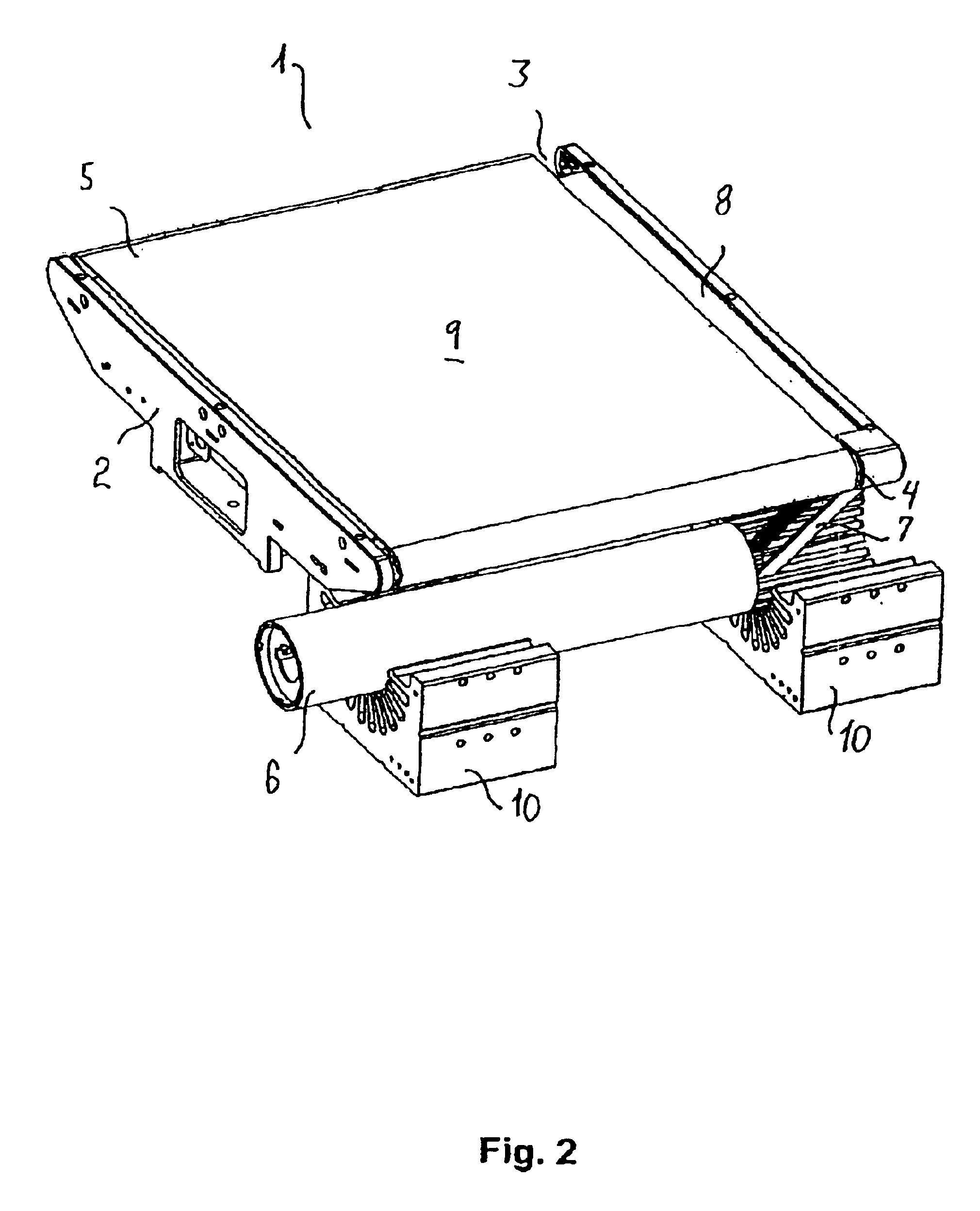

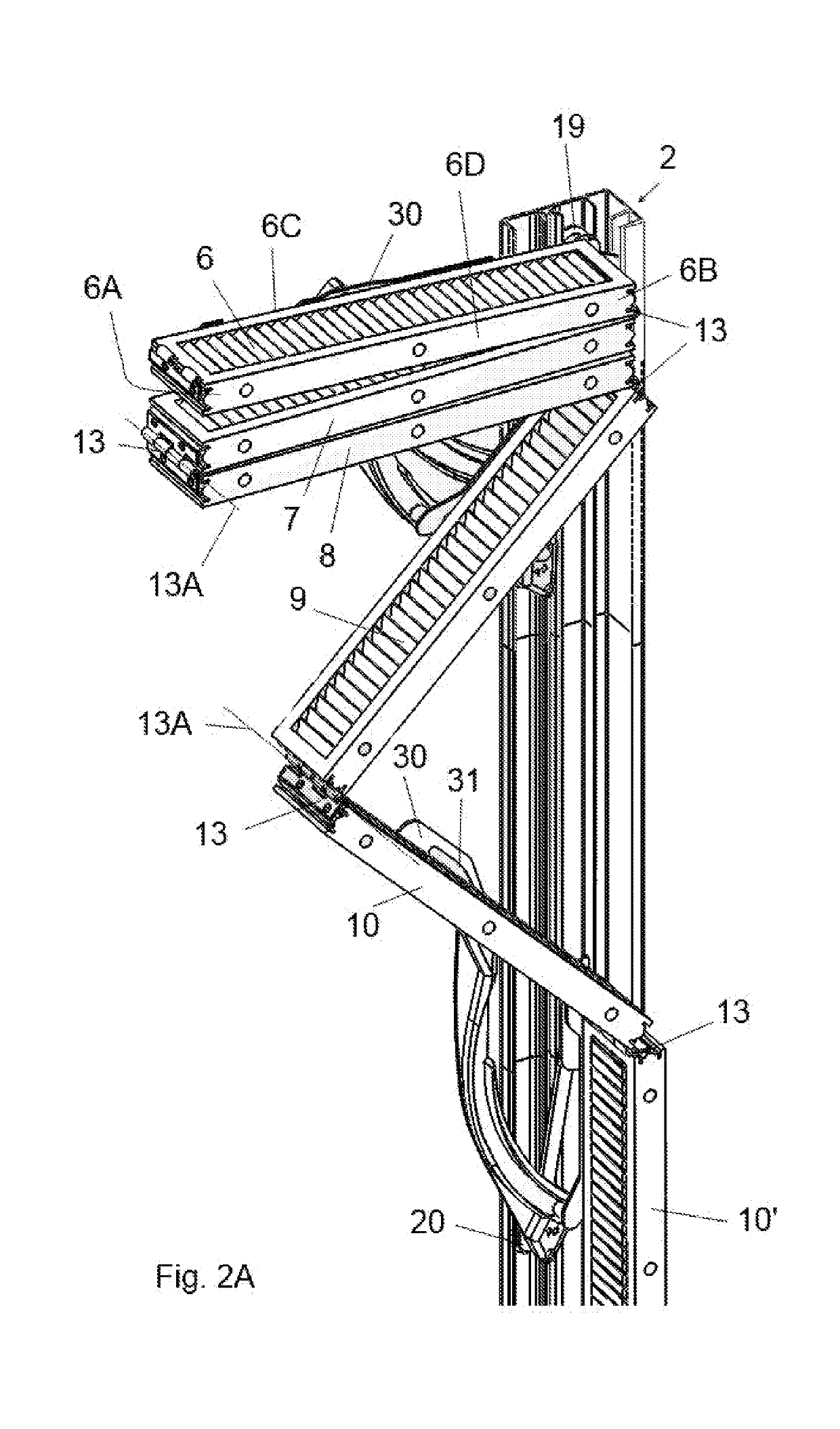

Sorter conveyor

InactiveUS6938750B2Increase delivery speedImprove efficiencyConveyorsPackagingElectric machineryLinear motor

A sorter conveyor having cross-belts for supporting and discharging article is disclosed, wherein the cross-belts are driven by interaction between a rotor moving with the cross-belts and stationary electric stator parts, wherein the rotor is arranged separate from the cross-belt and is connected to a drive roller with a transmission. Further is disclosed such sorter conveyors having tilt-trays driven by interaction between rotors moving with the tilt-trays and stationary electric stator parts, as well as such sorter conveyors which are driven along the stationary track by means of stationary linear motor stator parts interacting with the reaction means. Lastly, rotors and the manufacture of such rotors are disclosed.

Owner:CRISPLANT

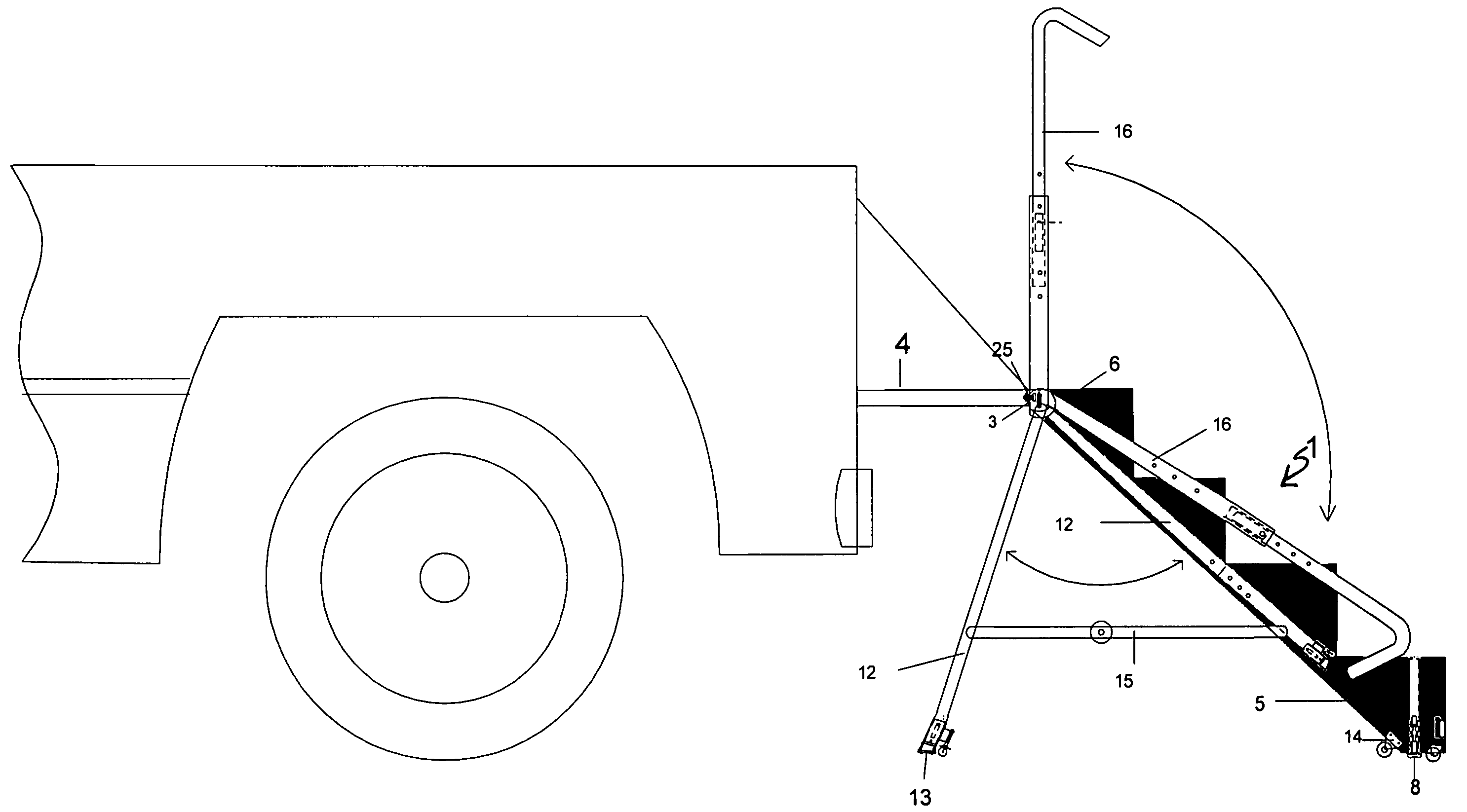

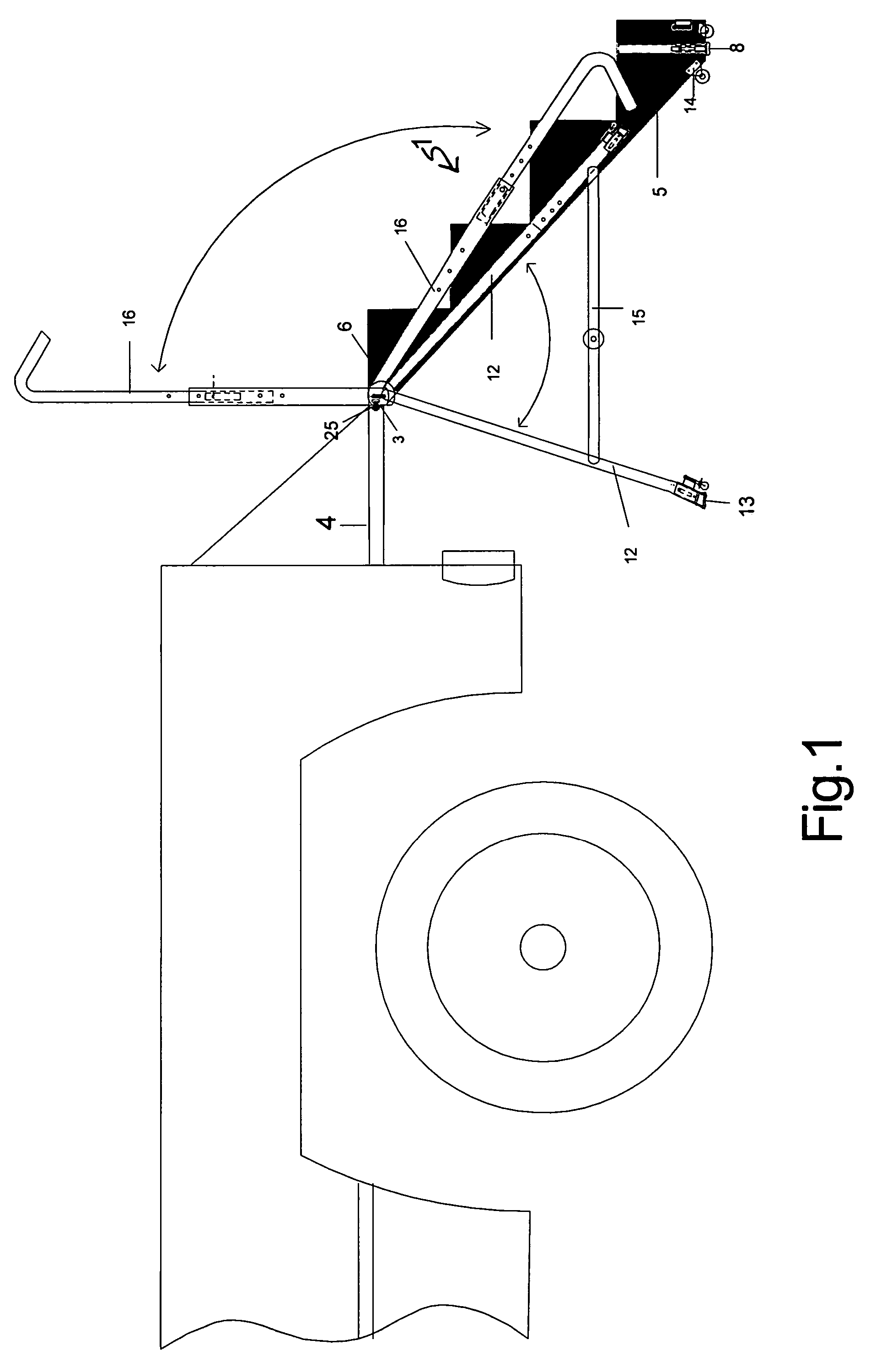

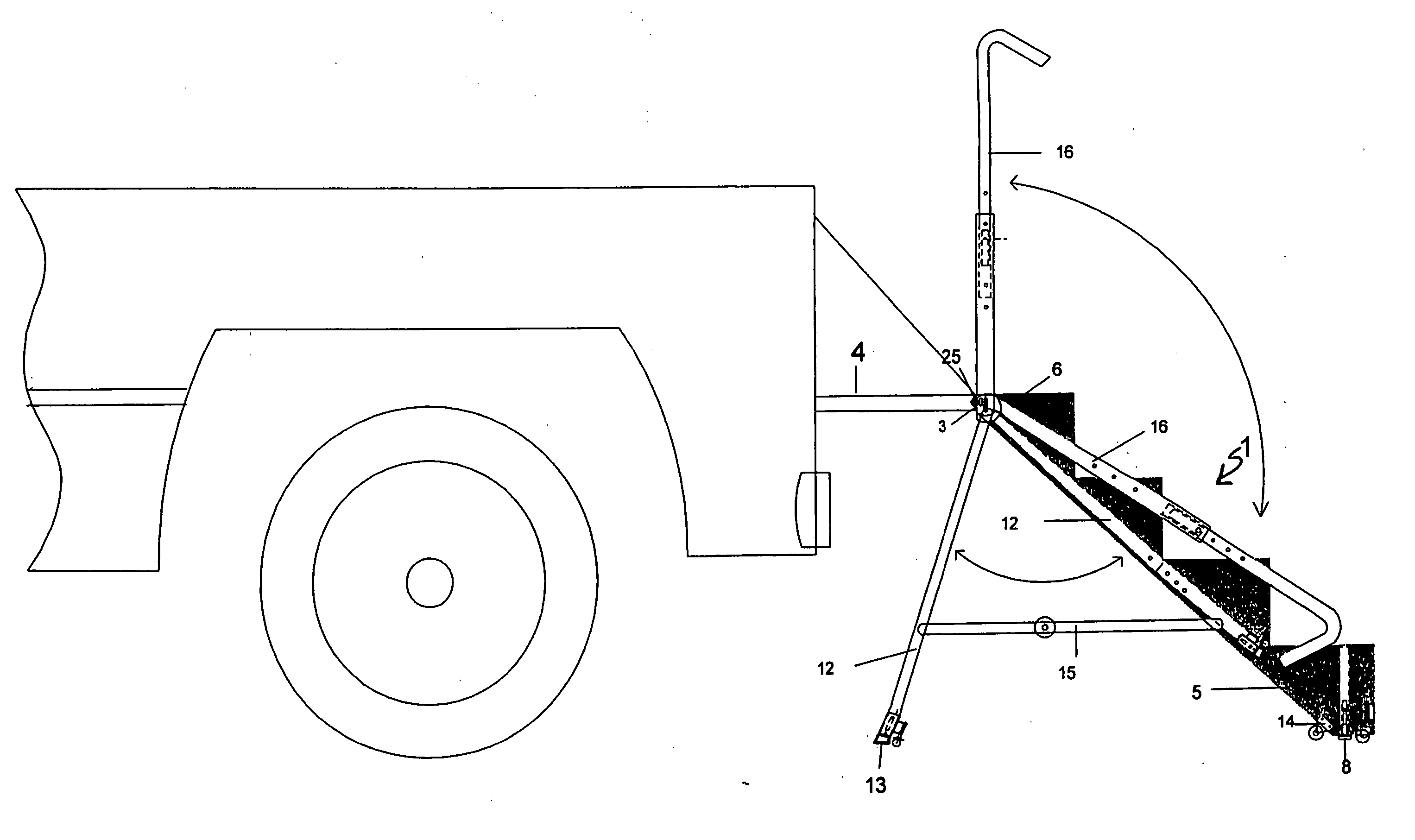

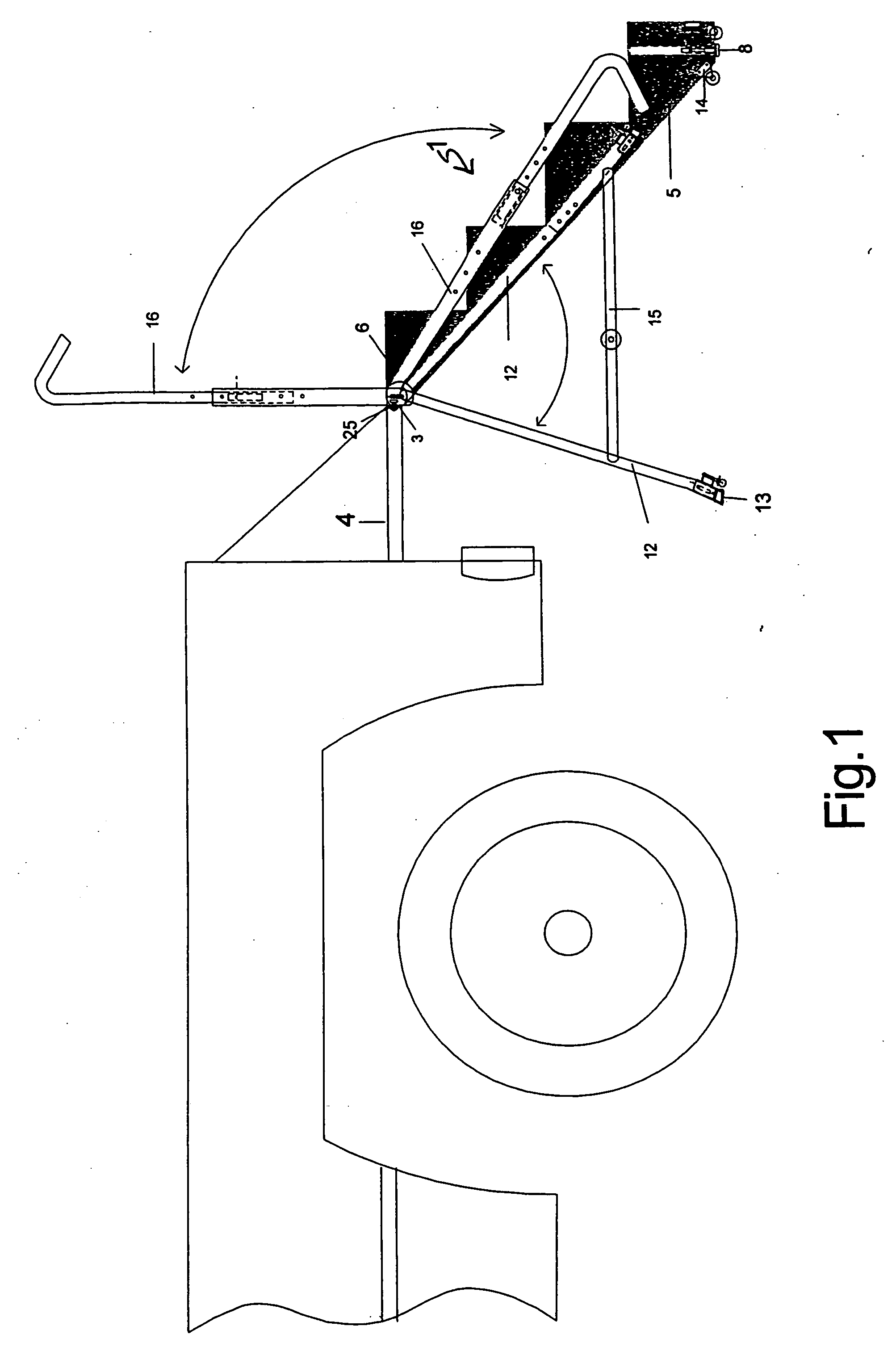

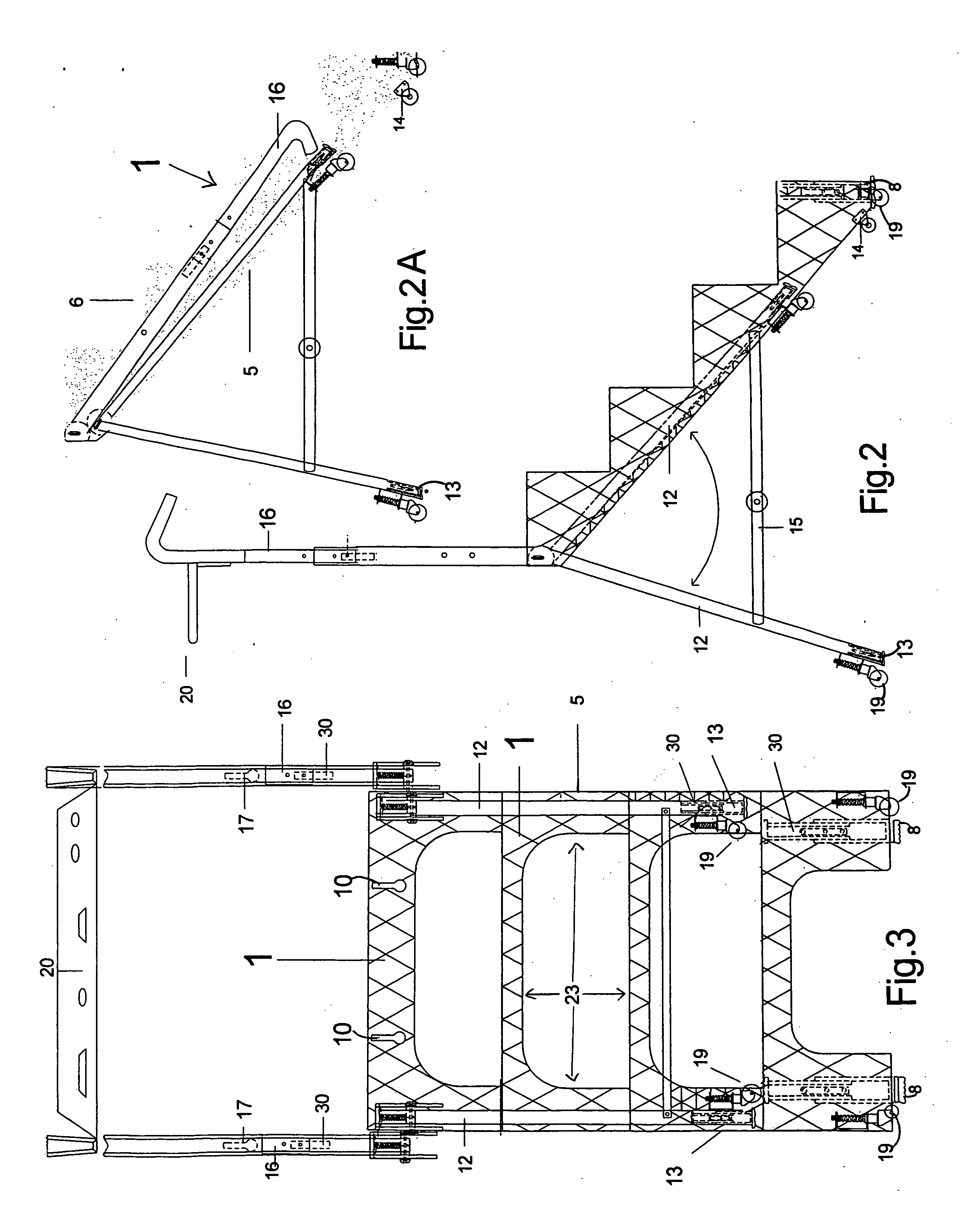

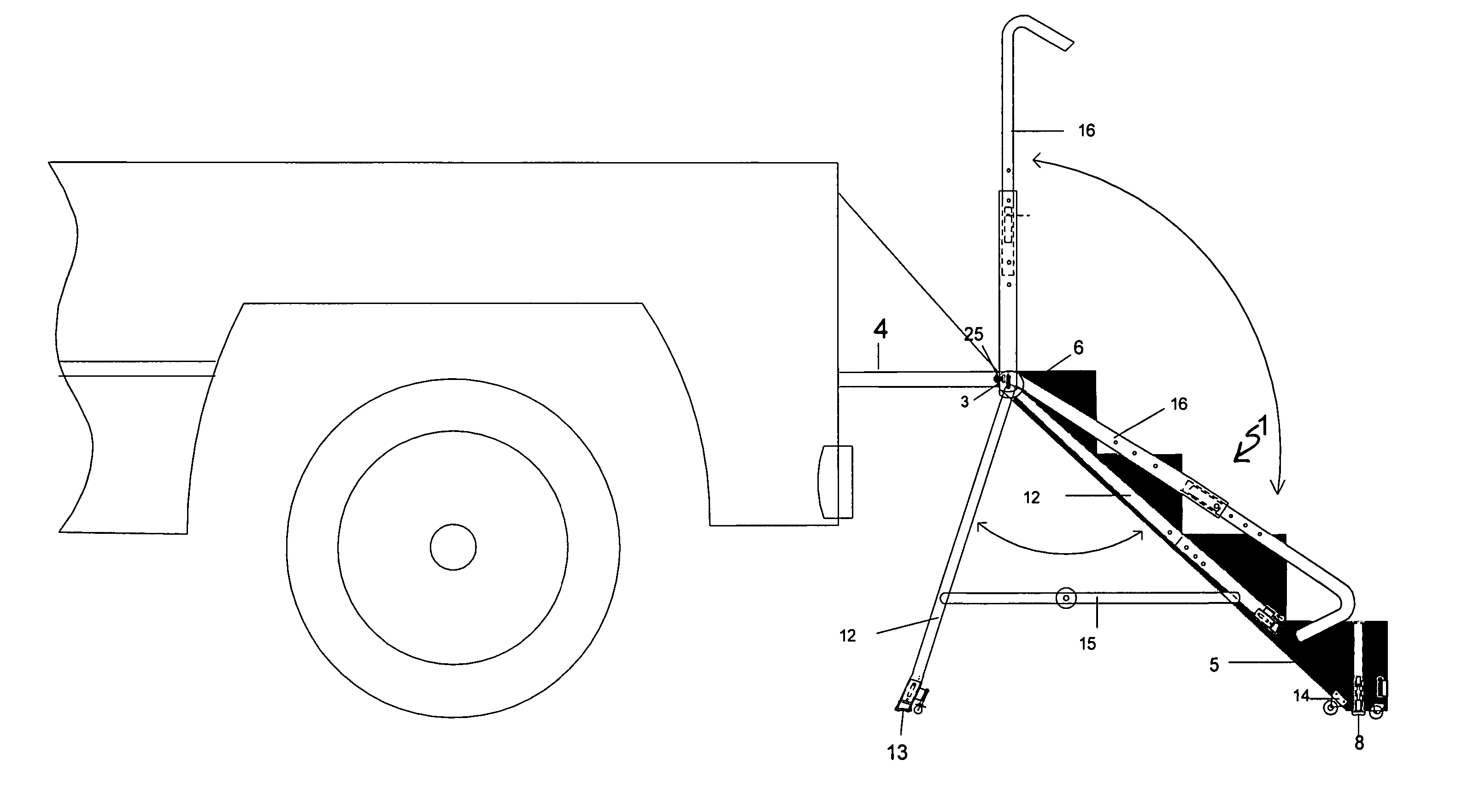

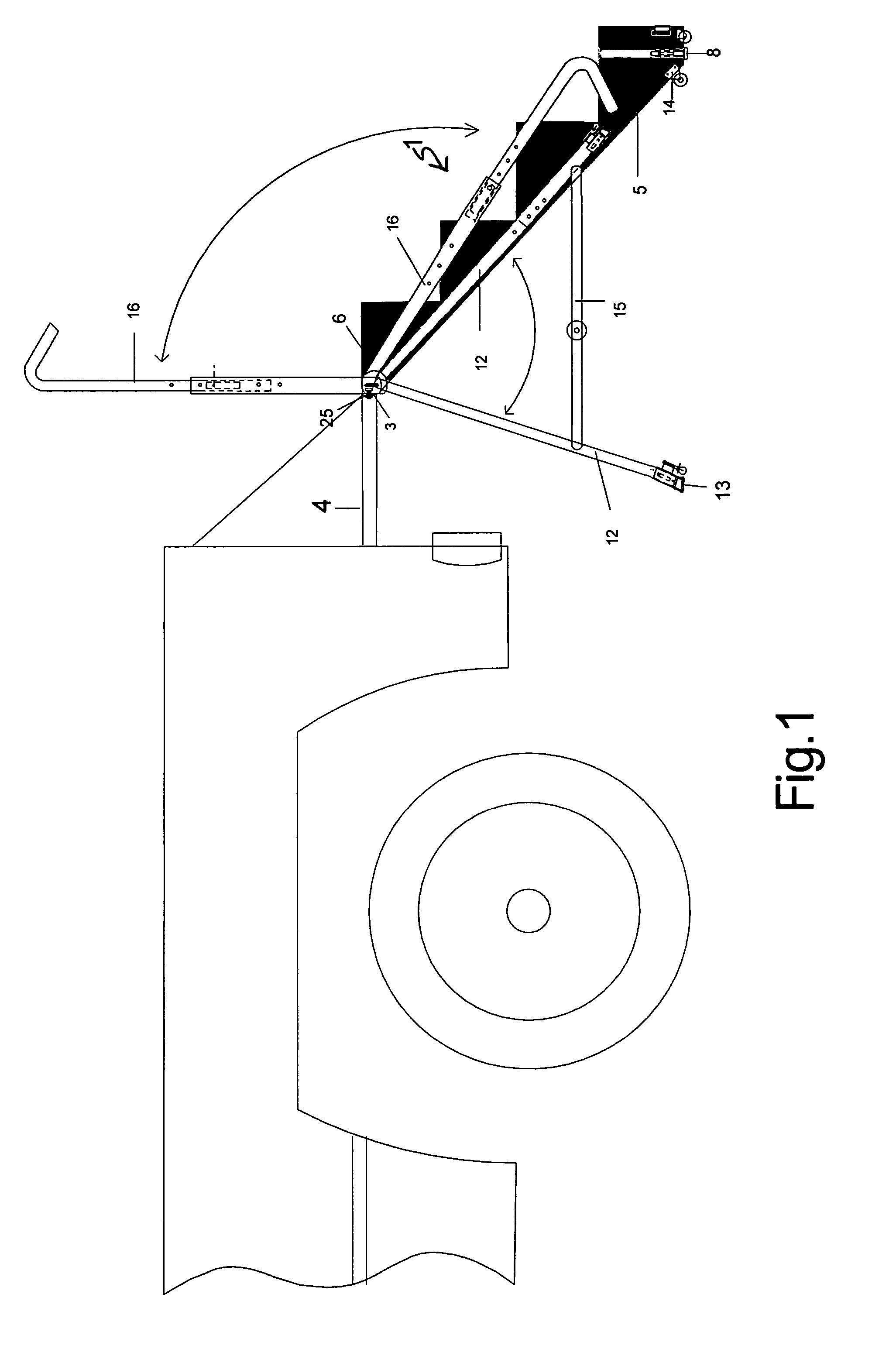

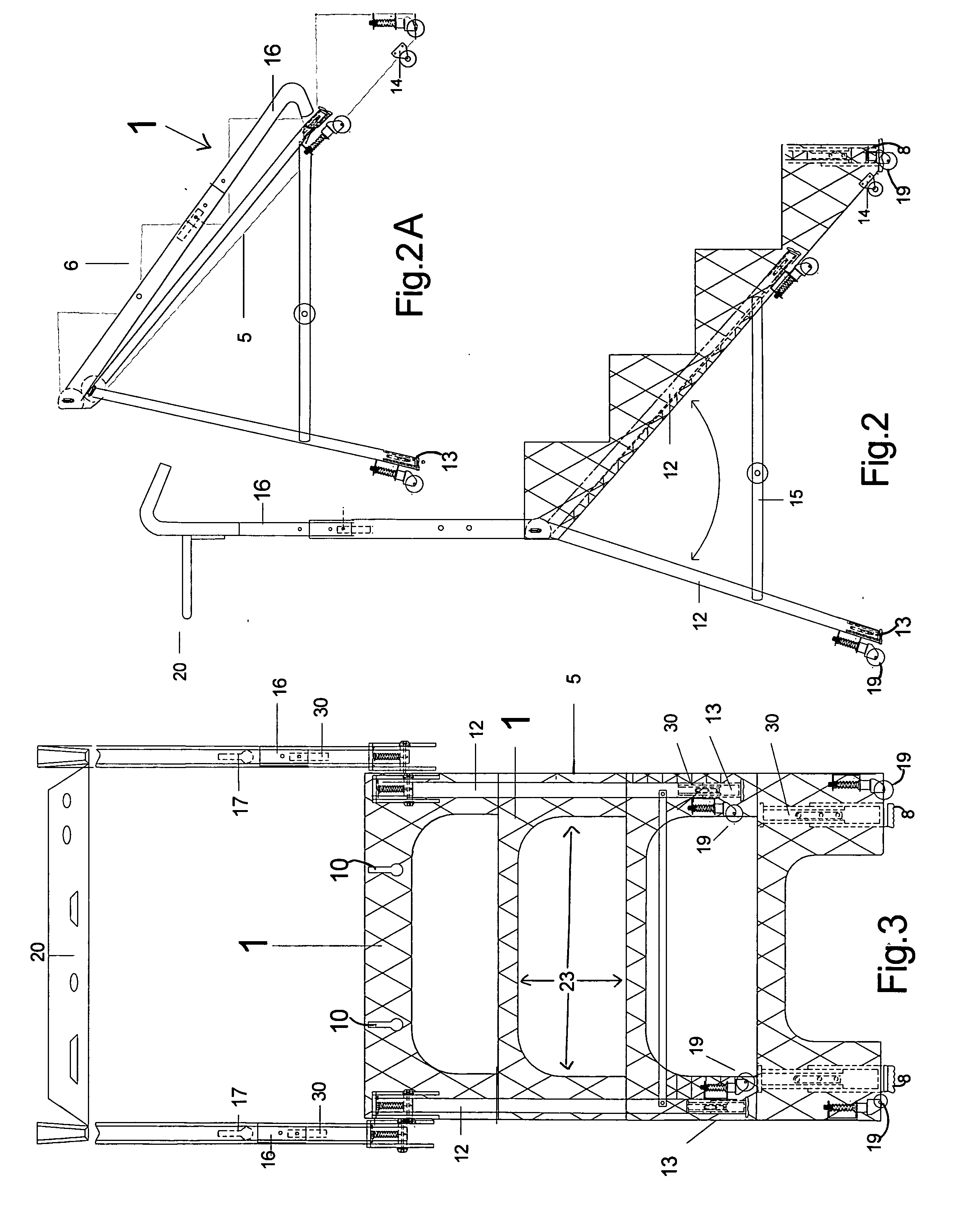

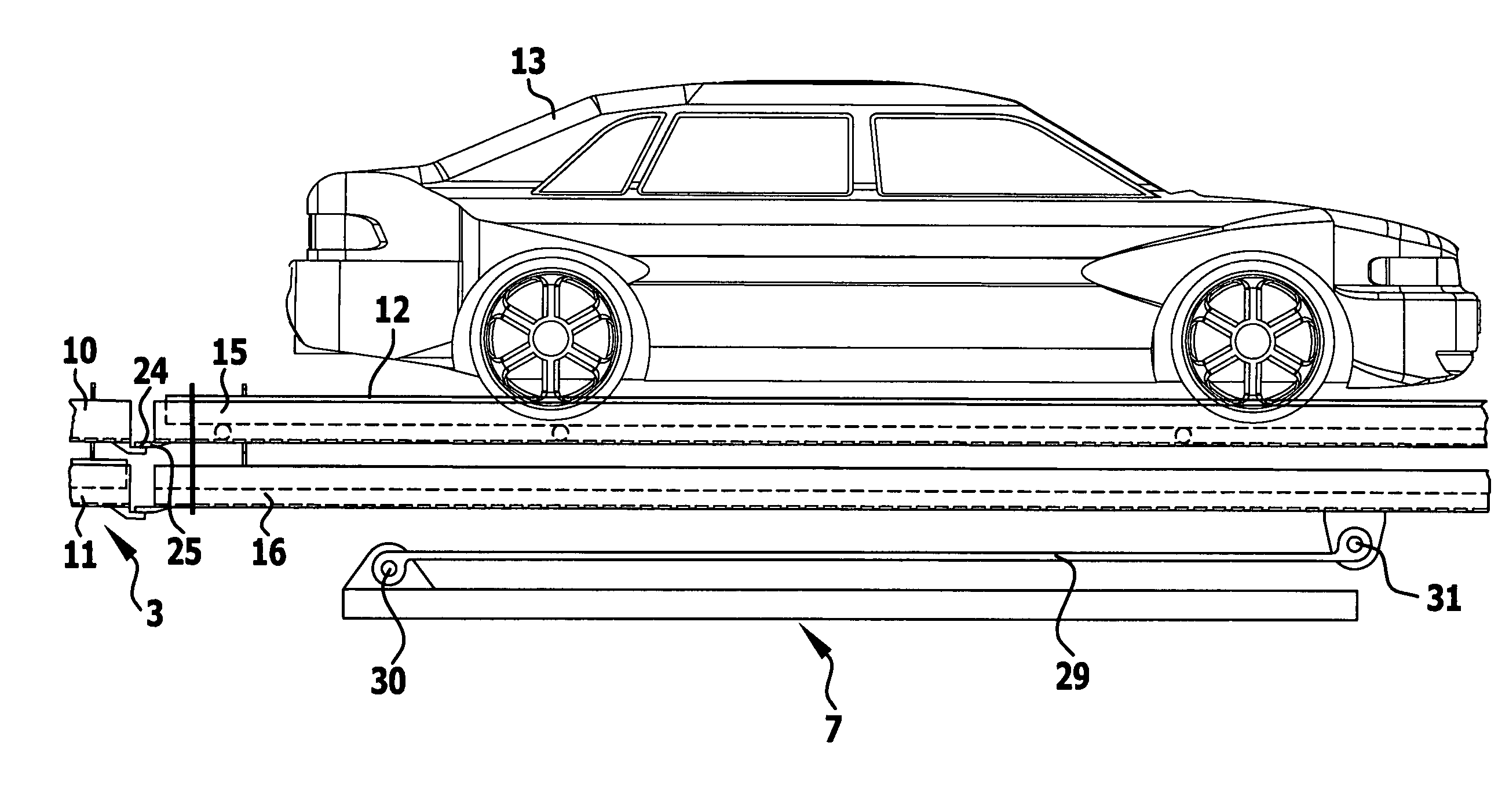

Compact truck tailgate and general purpose utility ladder

InactiveUS7240947B2Easy to disassembleAccurate horizontal positionSuperstructure subunitsSteps arrangementGeneral purposeCoupling

An exemplary embodiment sets forth an apparatus, including a non-collapsible single unit stair comprising: a pair of opposing side rails supporting at least a top step and a bottom step; a coupler adapted to couple the apparatus to an edge of a horizontal surface; and a height adjustable user-support arm, coupled to one of the side rails with a rotatable coupling, wherein the user-support arm is moveable between a support position and a storage position.

Owner:KUZNARIK JOHN +1

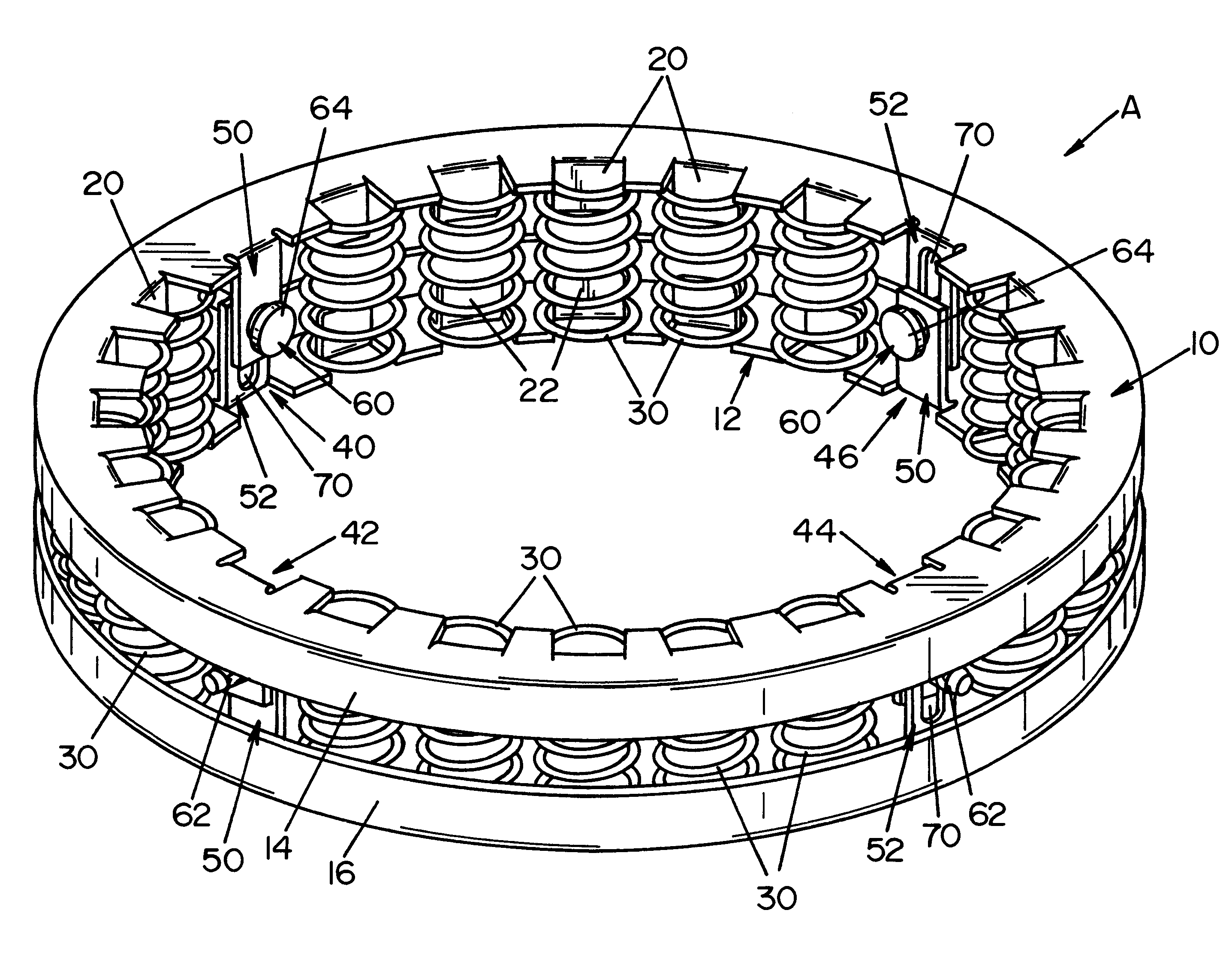

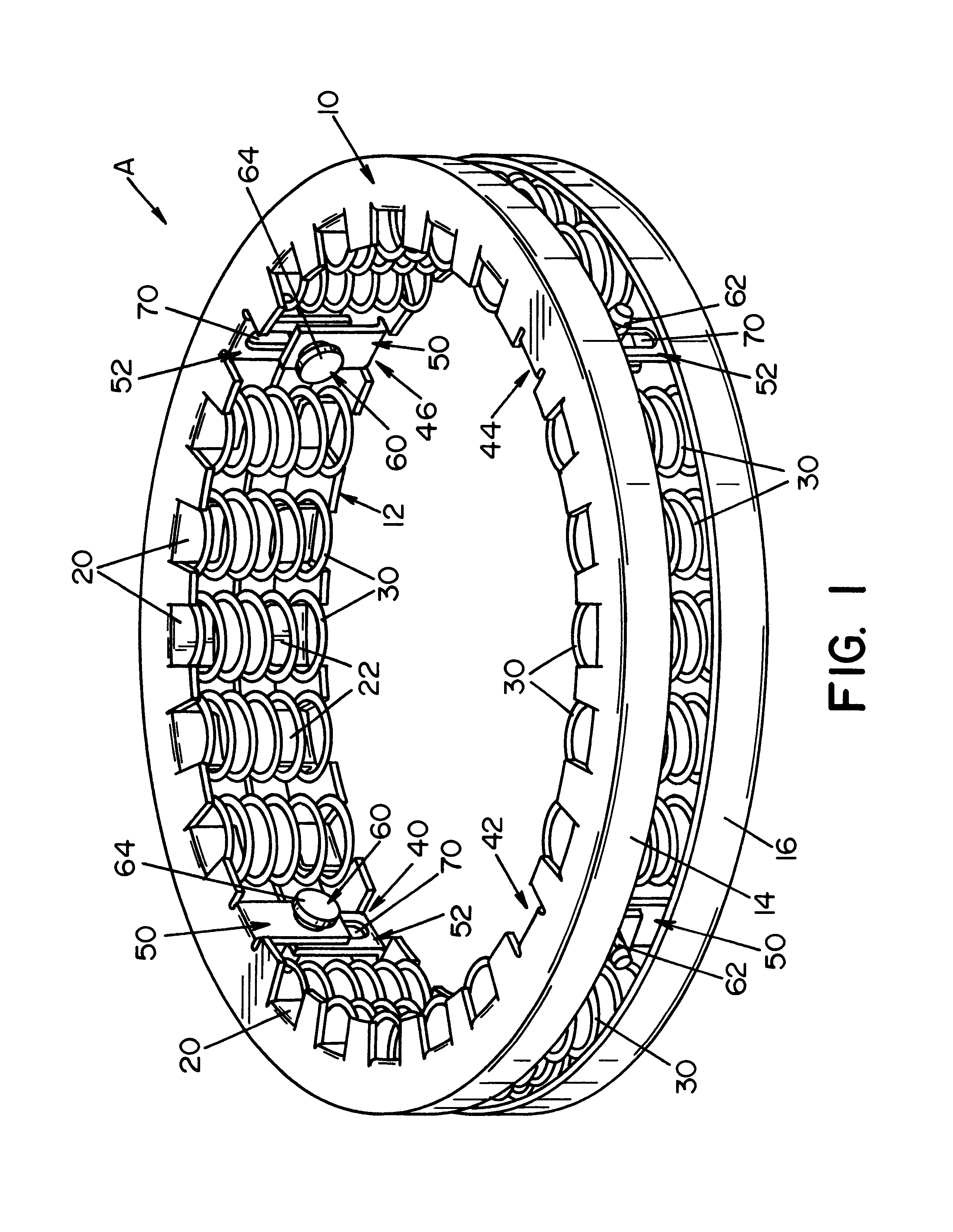

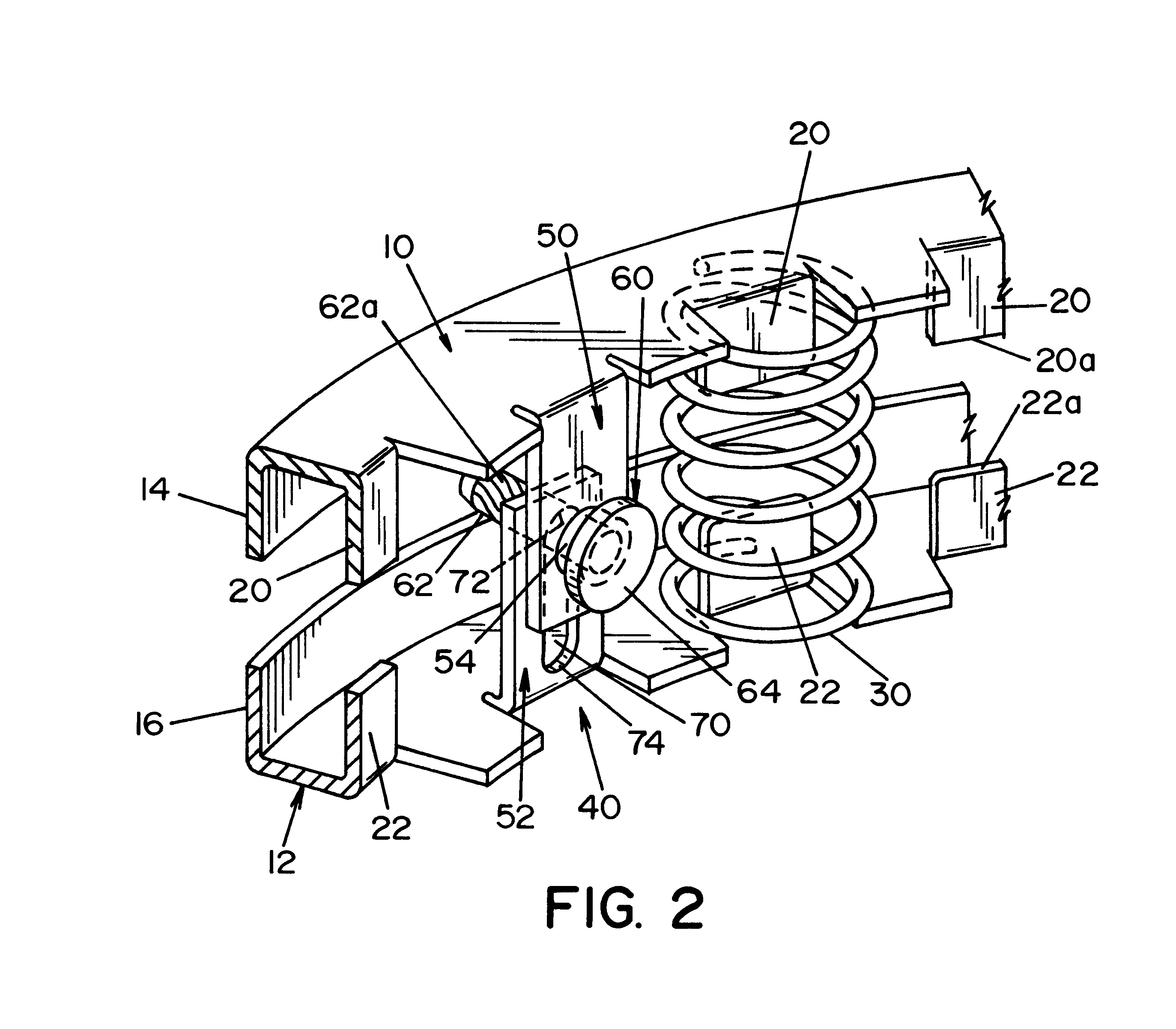

Ring shaped spring device

InactiveUS6575439B1Accurate horizontal positionWell formedMultiple spring combinationsSprings/dampers design characteristicsCoil springSliding contact

A spring device comprising a pair of spaced-apart first and second annular support plates defining a ring with a central axis; a plurality of circumferentially spaced, parallel oriented coil springs disposed between said annular plates; and, a plurality of guide assemblies located at circumferentially spaced positions around said ring, each of the guide assemblies including a first tab extending from one of the plates, a second top extending from the other of the plates to form a generally sliding contact between the first and second tabs as the plates move vertically to compress and / or release the coil springs wherein the first tab has a guide slot extending in a direction perpendicular to the plates and the second tab carries an assembled elongated guide member extending through the slot to guide vertical movement between the plates.

Owner:BARNES GROUP

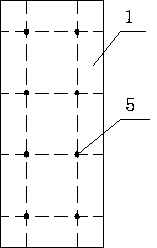

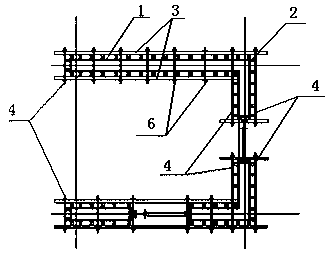

Formwork combination reinforcing and supporting structure used in short-leg shear wall construction and construction method thereof

InactiveCN103967271AImprove stabilityAccurate horizontal positionForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSupporting systemArchitectural engineering

The invention relates to a formwork combination reinforcing and supporting structure used in short-leg shear wall construction and a construction method thereof. The structure comprises formworks used for pouring a longitudinal short-leg shear wall and a transverse short-leg shear wall and split bolts between the formworks, and back supports of the formworks are composed of secondary edges and primary edges. The structure further comprises a plurality of horizontally arranged wall hoop bolts in the height direction of walls on the peripheries of the longitudinal shear wall formwork and the transverse shear wall formwork, wherein the wall hoop bolts are used for connecting and reinforcing a whole formwork enclosure system and the ends of the wall formworks in a tensioning mode. The lower portion of the formwork enclosure system is fixedly connected with short bolts pre-buried in last process, and tensile-connection bottom sealing is formed. For installation of the formworks of the short-leg shear walls, the structures of the formworks themselves are used in combination with the wall hoop bolts, therefore, the stability of a short-leg shear wall formwork supporting system is enhanced, the accuracy of the formworks in horizontal position and structure size is guaranteed, the effects on formwork supporting and reinforcement are achieved, and the purpose of lowering manufacturing cost is realized.

Owner:ANHUI HUALI CONSTR GRP

Compact truck tailgate and general purpose utility ladder

InactiveUS20060261623A1Easy to disassembleAccurate horizontal positionSuperstructure subunitsSteps arrangementGeneral purposeCoupling

An exemplary embodiment sets forth an apparatus, including a non-collapsible single unit stair comprising: a pair of opposing side rails supporting at least a top step and a bottom step; a coupler adapted to couple the apparatus to an edge of a horizontal surface; and a height adjustable user-support arm, coupled to one of the side rails with a rotatable coupling, wherein the user-support arm is moveable between a support position and a storage position.

Owner:KUZNARIK JOHN

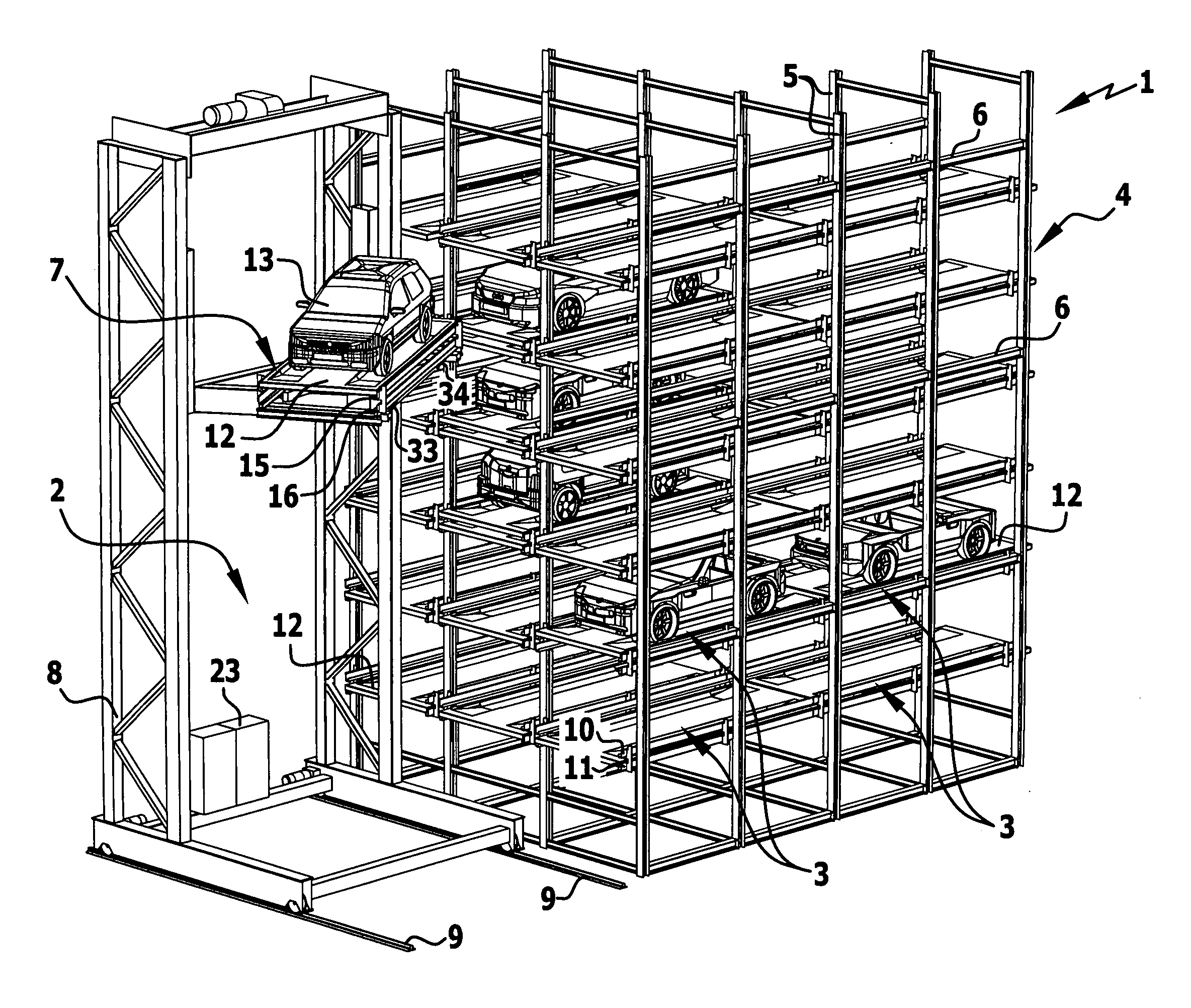

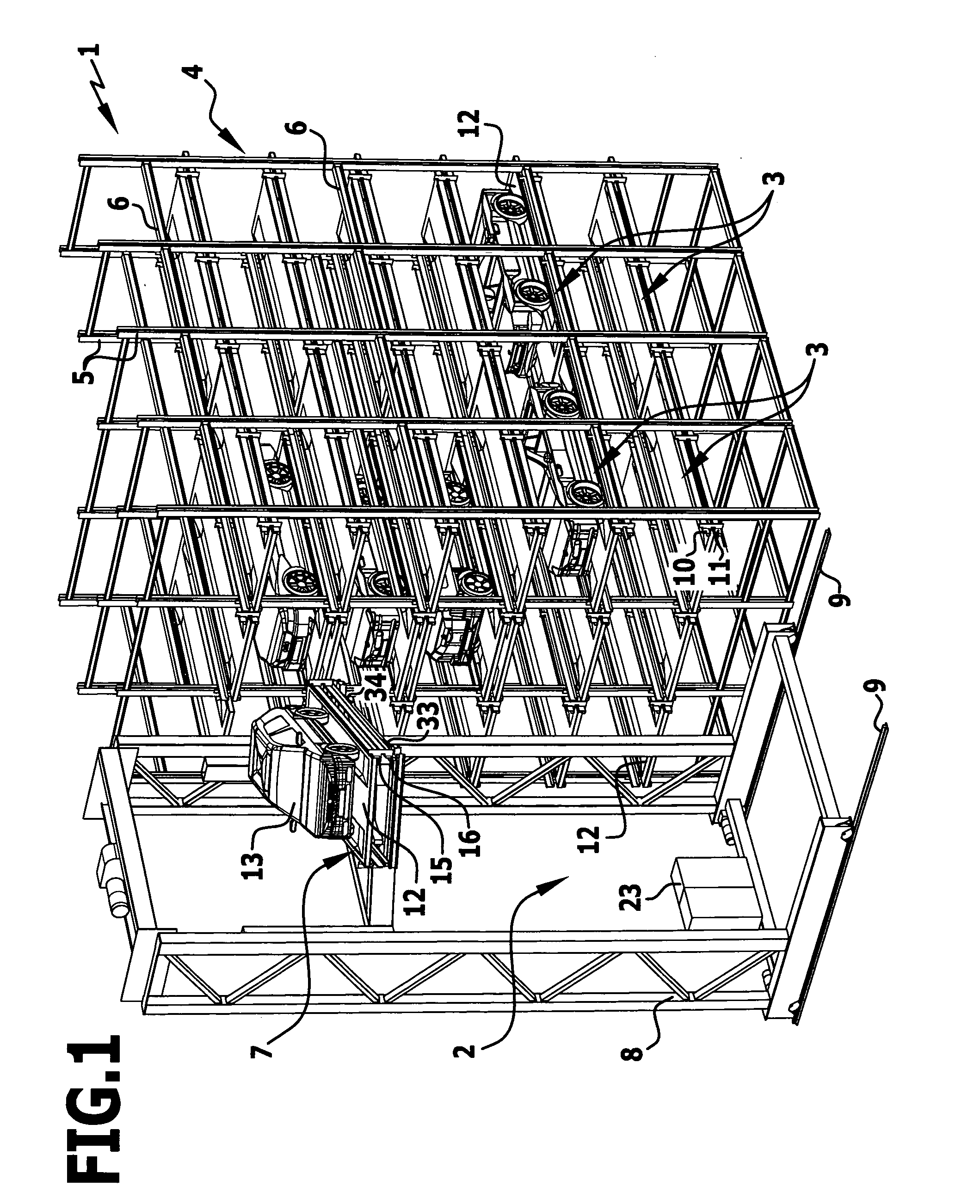

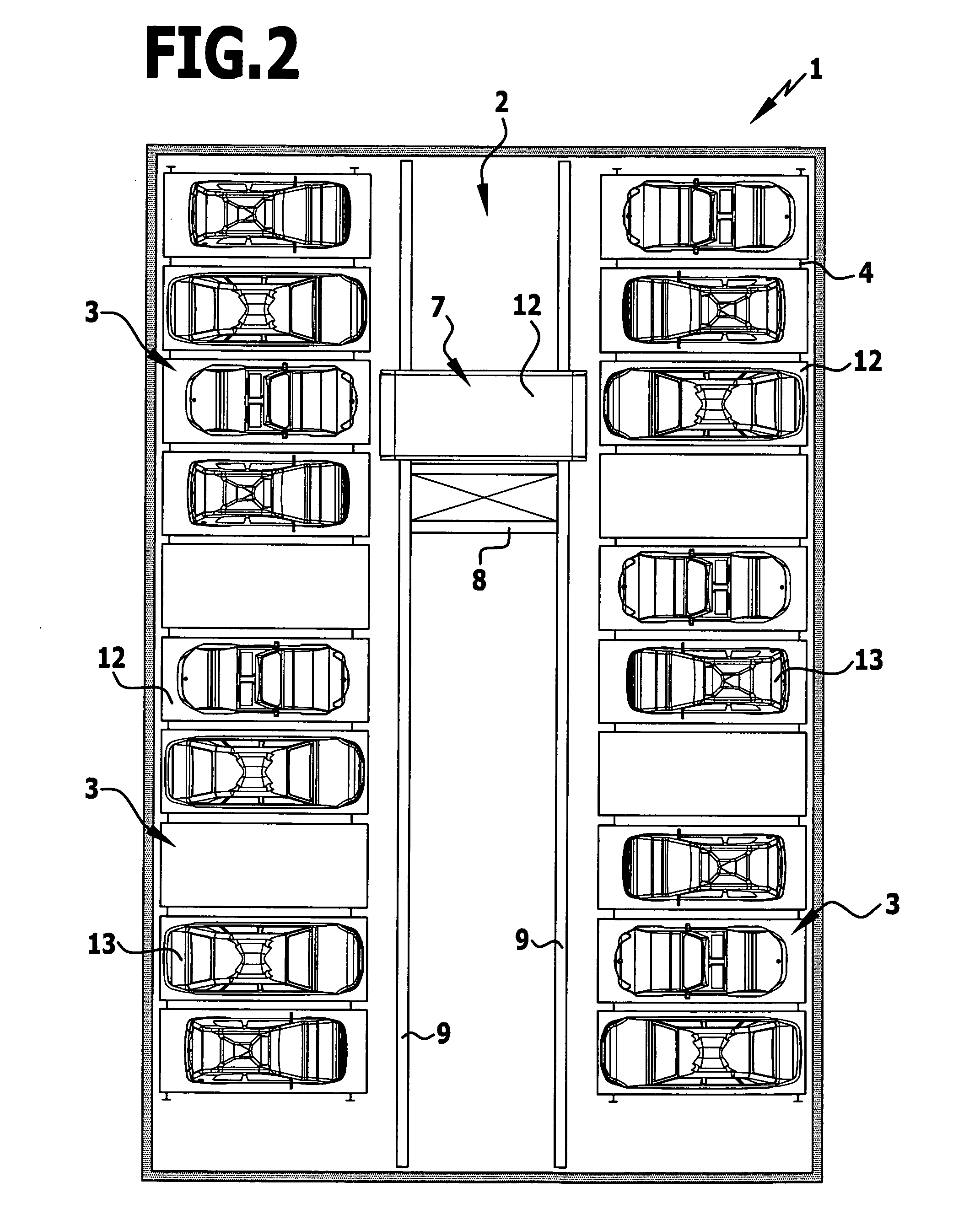

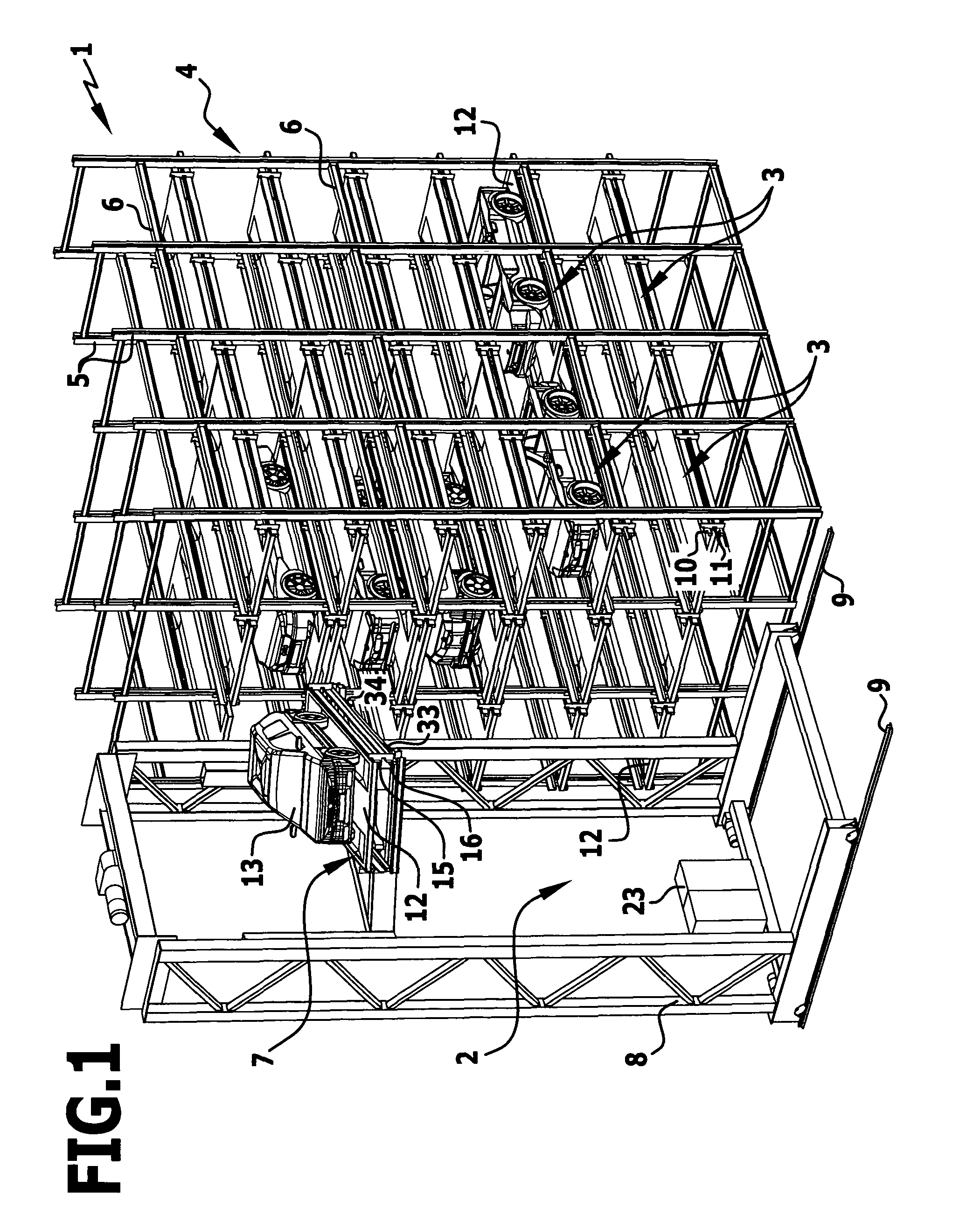

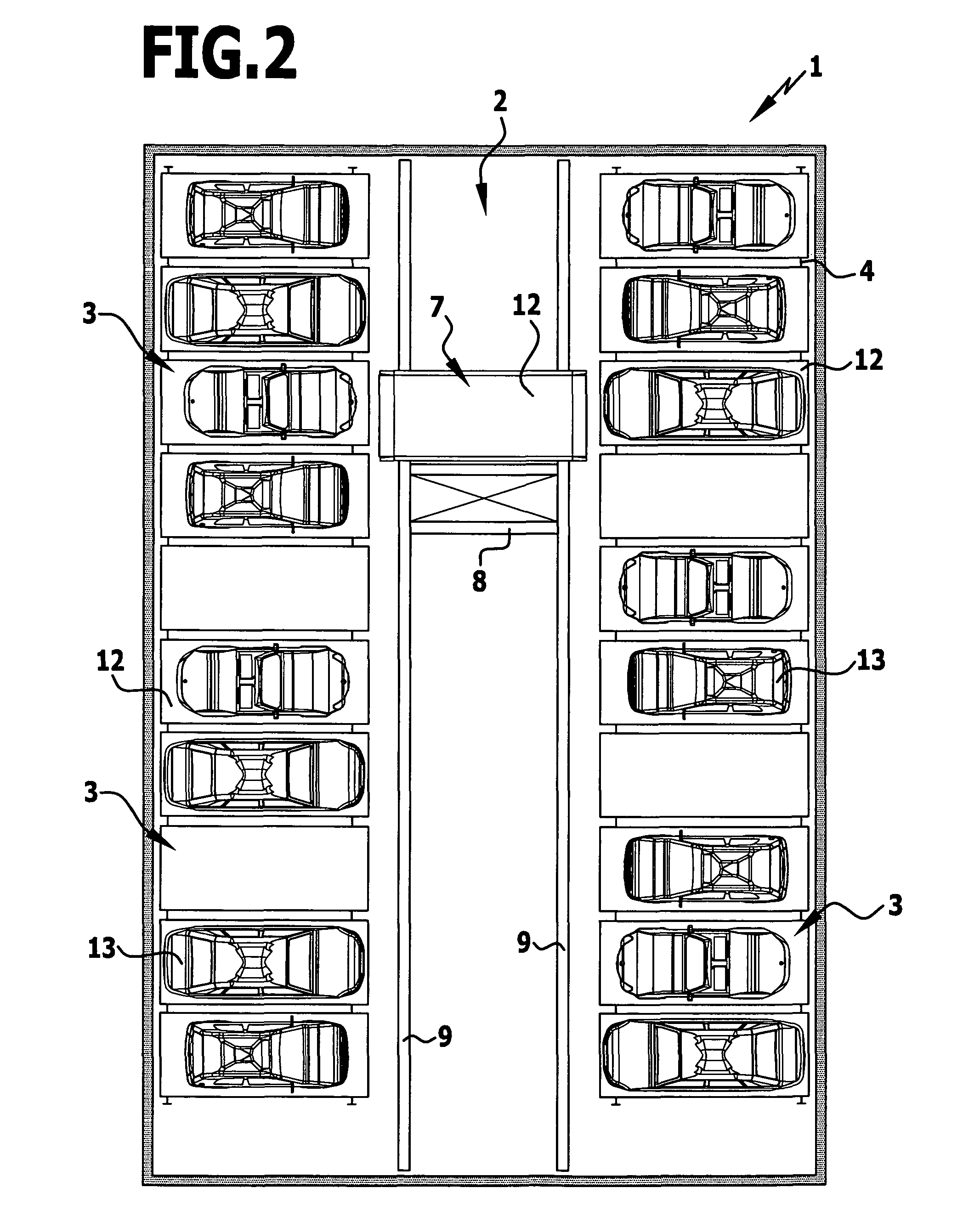

Parking facility for motor vehicles and method of operating same

ActiveUS20100017016A1Accurate horizontal positionDigital data processing detailsLifting devicesMobile vehicleParking space

In a method of operating a parking facility for motor vehicles that comprises fixed parking places arranged above each other and each having a guide for a pallet that is displaceable along the guide as well as a lift, which is disposed alongside the fixed parking places and also carries a guide for a pallet displaceable therein, in which method for displacement of a pallet between the guide of a fixed parking place and the guide of the lift the lift is stopped in such a way alongside a fixed parking place that the guides of the fixed parking place and of the lift are aligned with one another, wherein the guide of the lift at its end facing the fixed parking place is supported on a supporting surface connected to the fixed parking place, in order to improve the aligning of the guide in the lift with the guide in the parking place, it is proposed that the guide of the lift after being set down onto the supporting surface is pivoted about a horizontal parking-place-side pivotal axis, which extends transversely of the displacement direction and is defined by the support point of the guide of the lift on the supporting surface, until the guide of the lift is in a horizontal position.A parking facility that realizes this method is moreover described.

Owner:WAP WOEHR AUTOMATIKPARKSYST

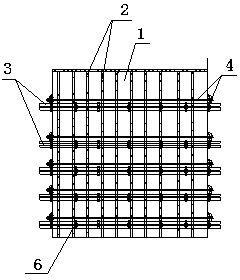

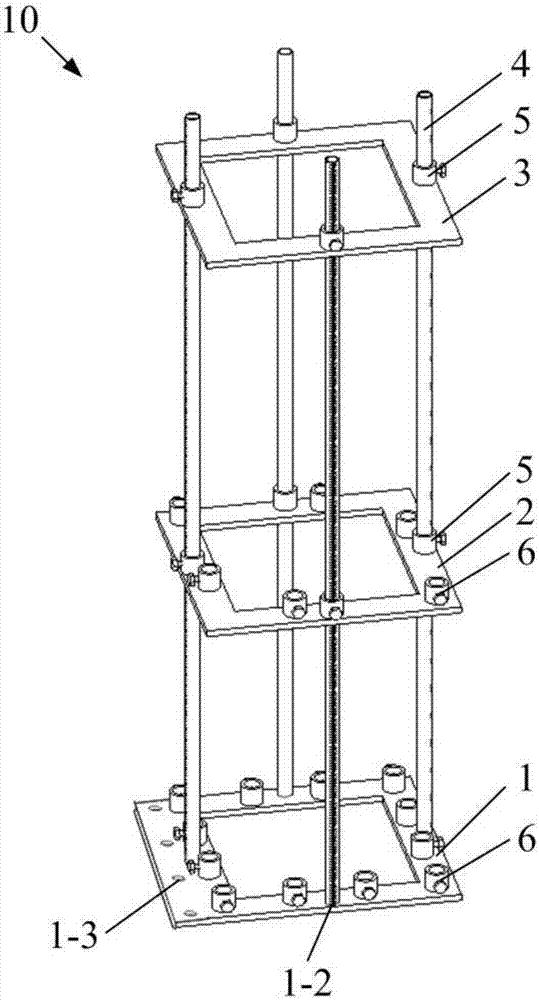

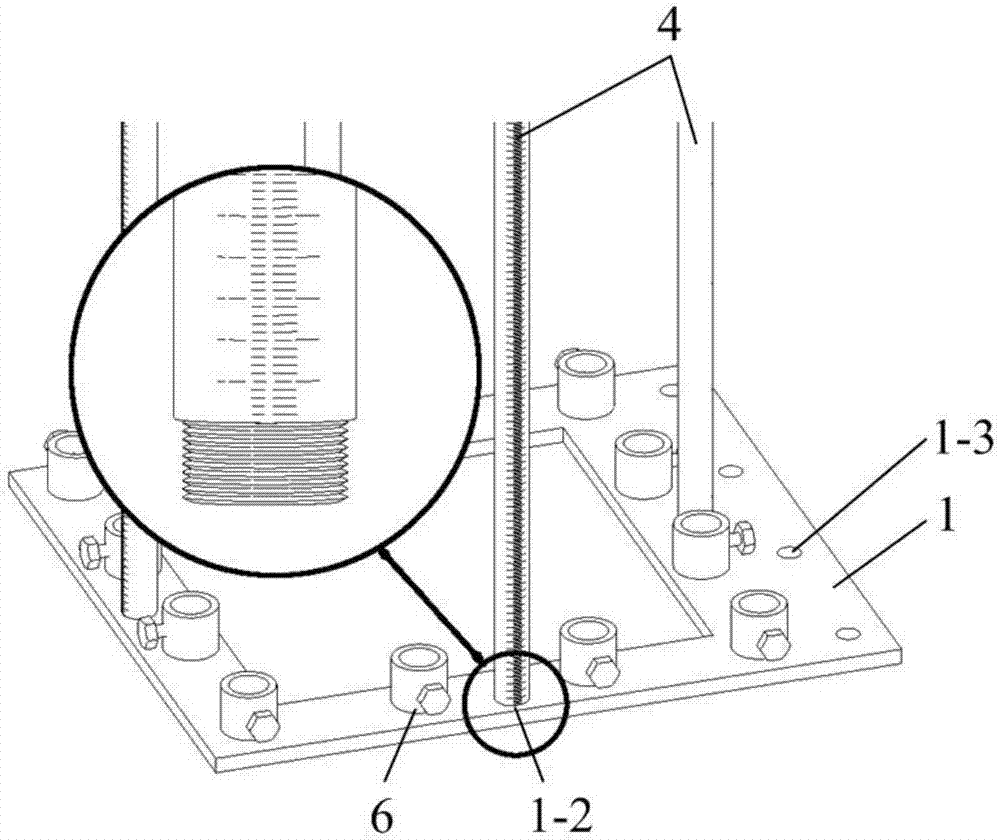

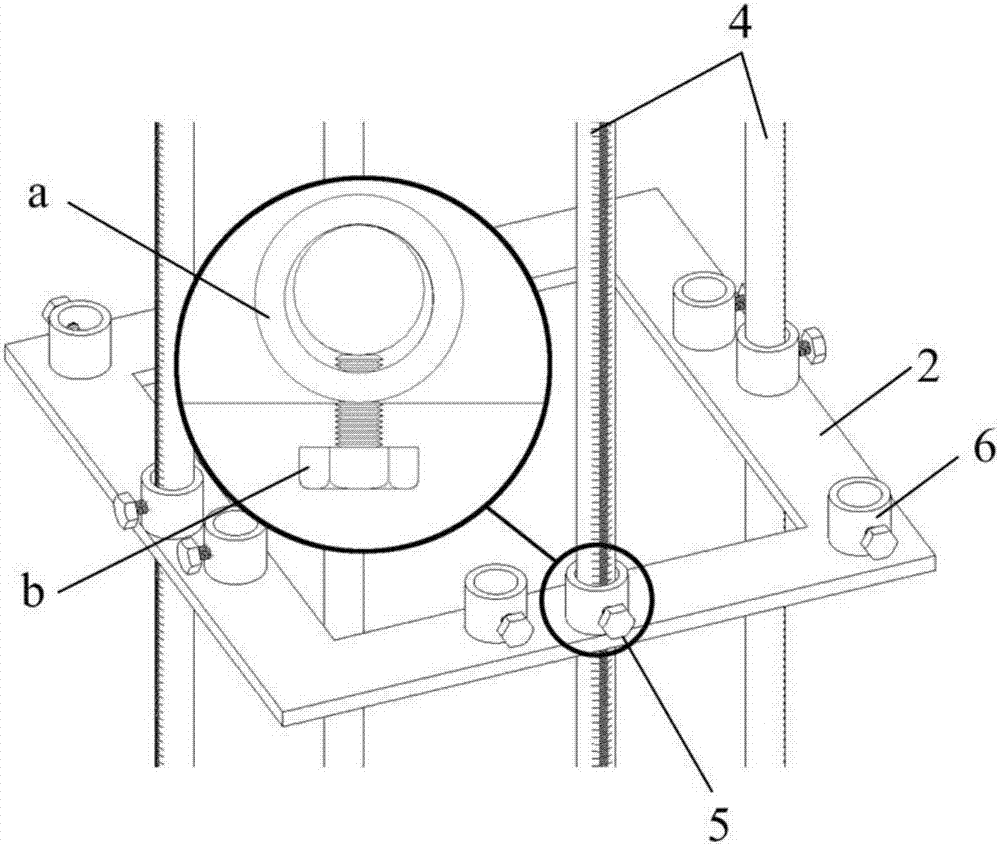

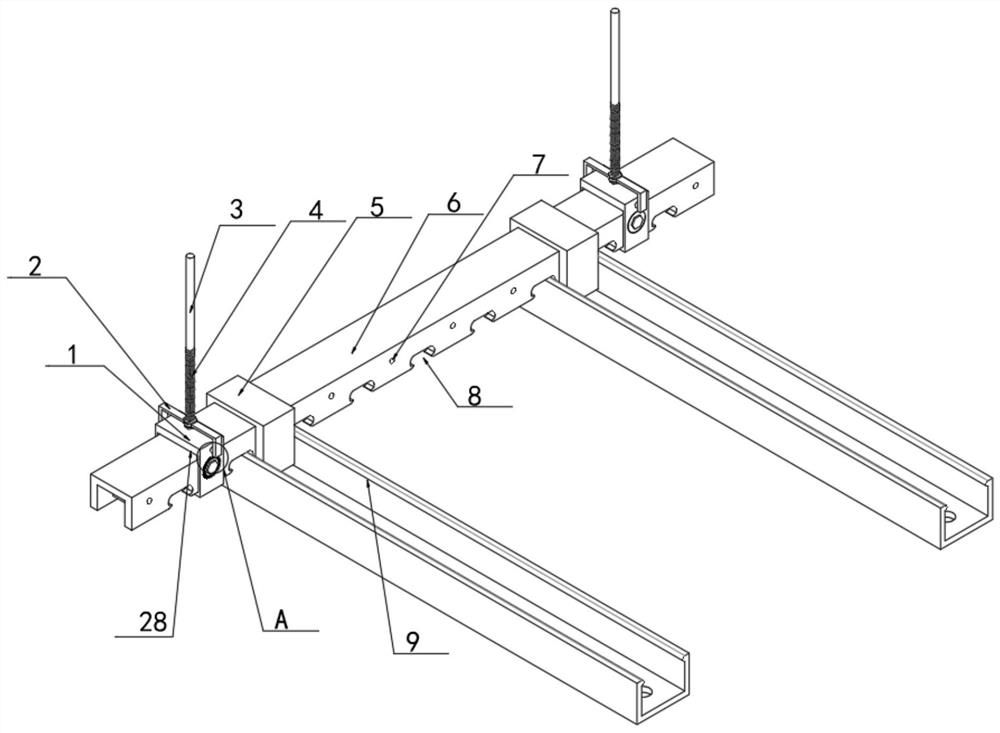

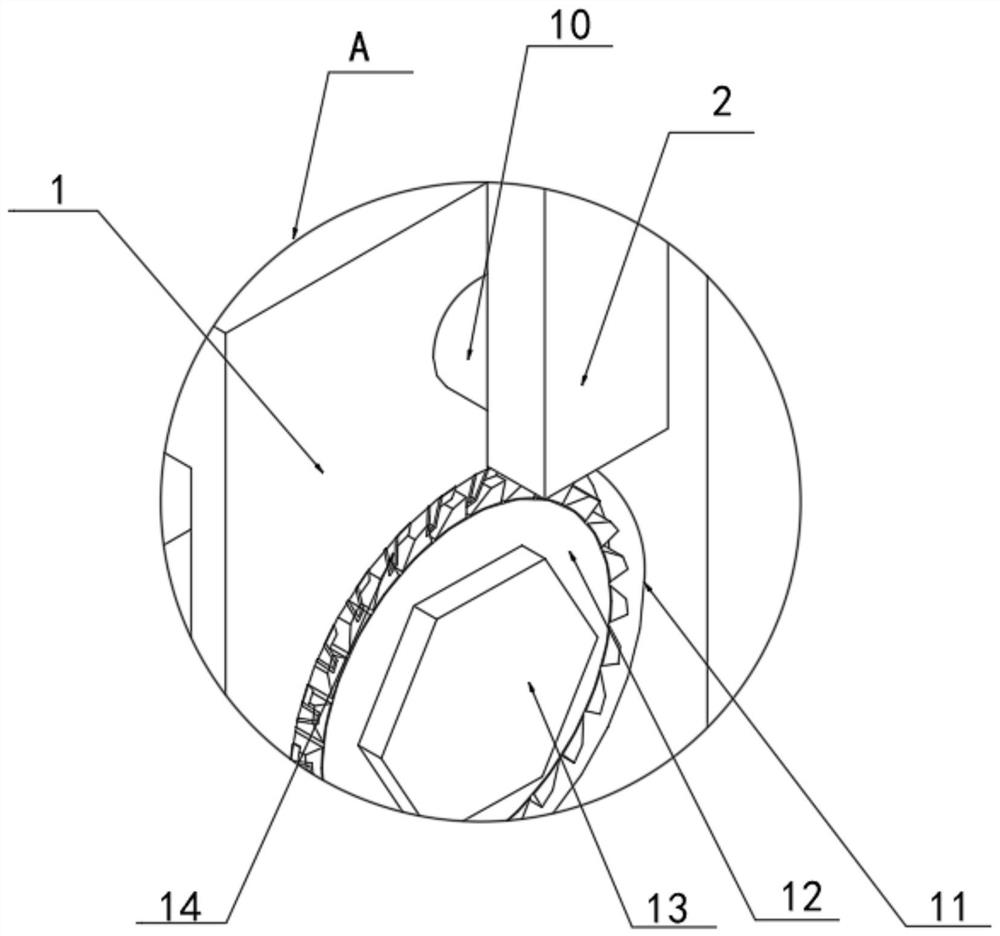

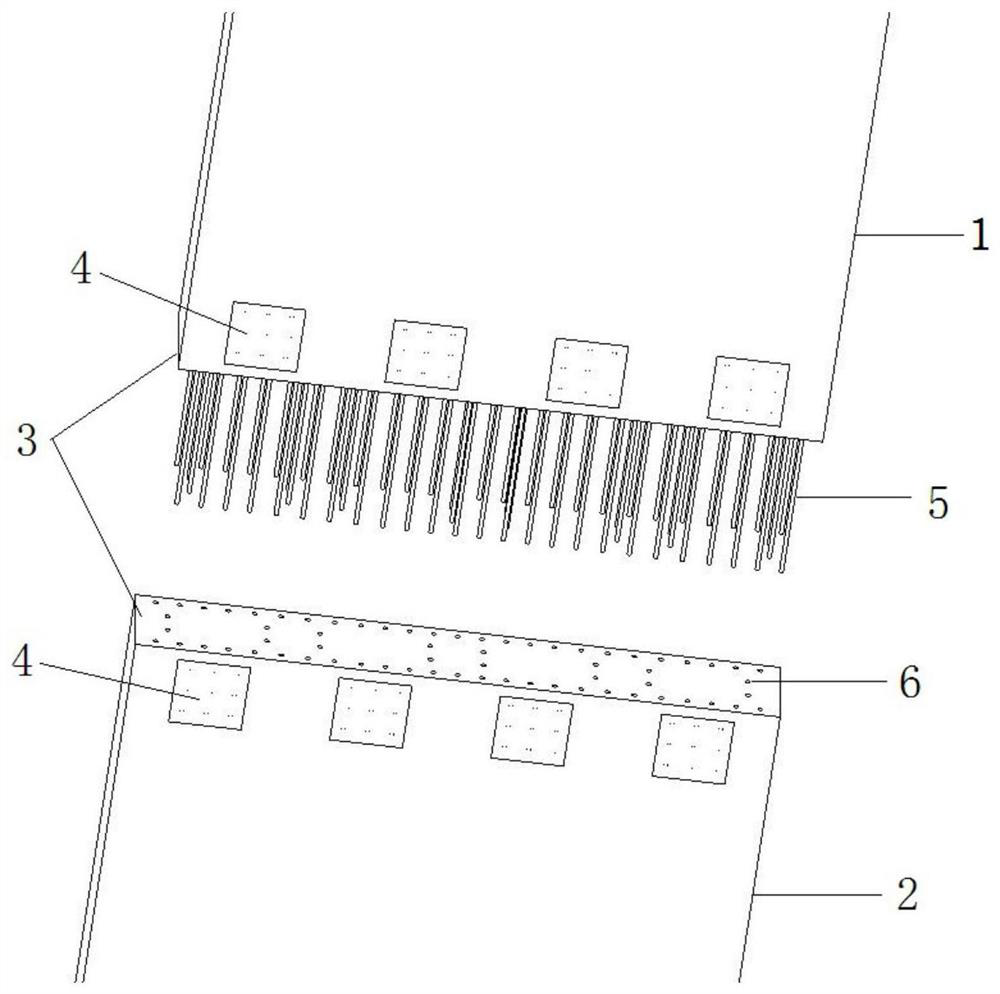

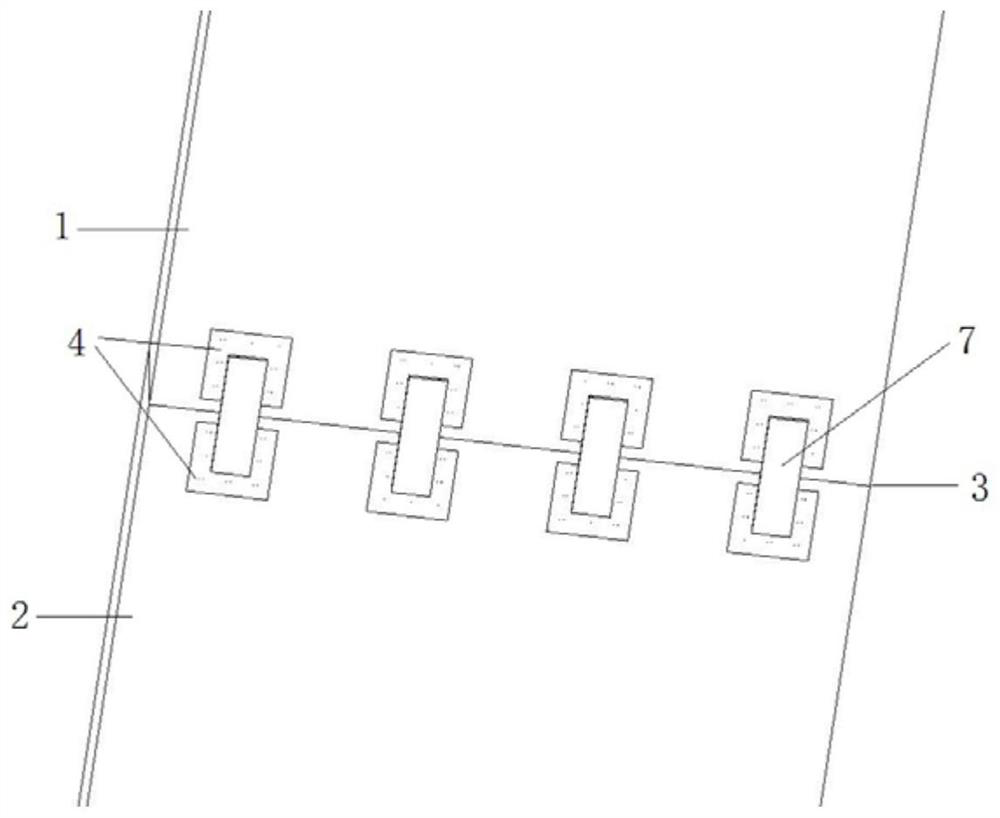

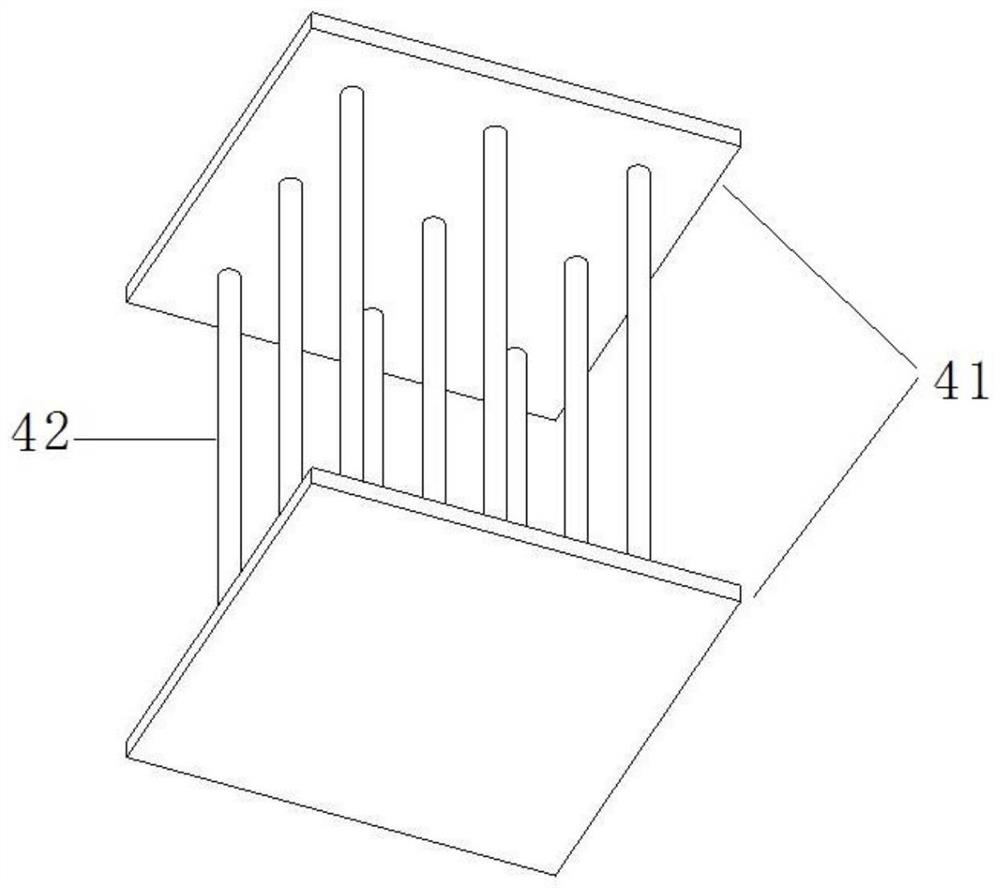

Positioning assembly, device and method for reserved joint bars in shear wall

PendingCN106884541AEasy to adjust and controlGuaranteed positioning accuracyBuilding material handlingRebarMechanical engineering

The invention discloses a positioning assembly, device and method for reserved joint bars in a shear wall, and relates to the technical field of constructional engineering. In order to solve the problems that according to an existing overall prefabricated reinforcing mesh building technology, reserved joint bar positioning is hard to control, precision is poor, and construction efficiency is low, the positioning assembly comprises a first limiting frame, a second limiting frame, a third limiting frame and a supporting rod, wherein the first, second and third limiting frames are arranged coaxially in a spaced mode, the supporting rod penetrates through supporting rod fixing pins of the second and third limiting frames and is movably connected with the first limiting frame, scale marks are arranged on the supporting rod, and a plurality of joint bar fixing pins are arranged on the first and second limiting frames. The positioning device comprises at least two positioning assemblies arranged in parallel. The positioning assemblies are connected through connecting frame bolts. The positioning method comprises the steps that the positioning device is installed on a constructed reinforcing mesh, reserved joint bars and middle joint bars are positioned and installed, and the positioning device is disassembled.

Owner:SHANGHAI NO 4 CONSTR

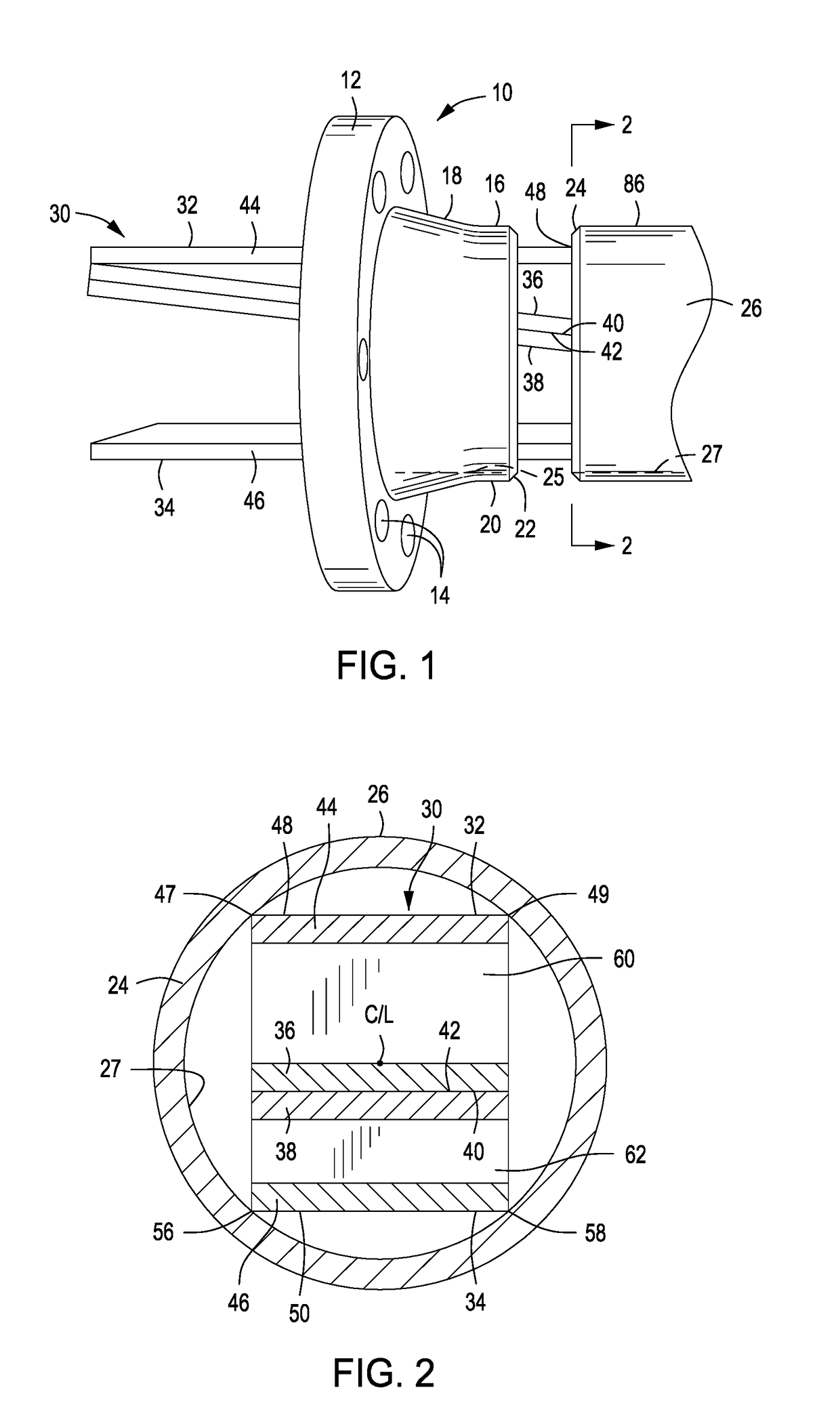

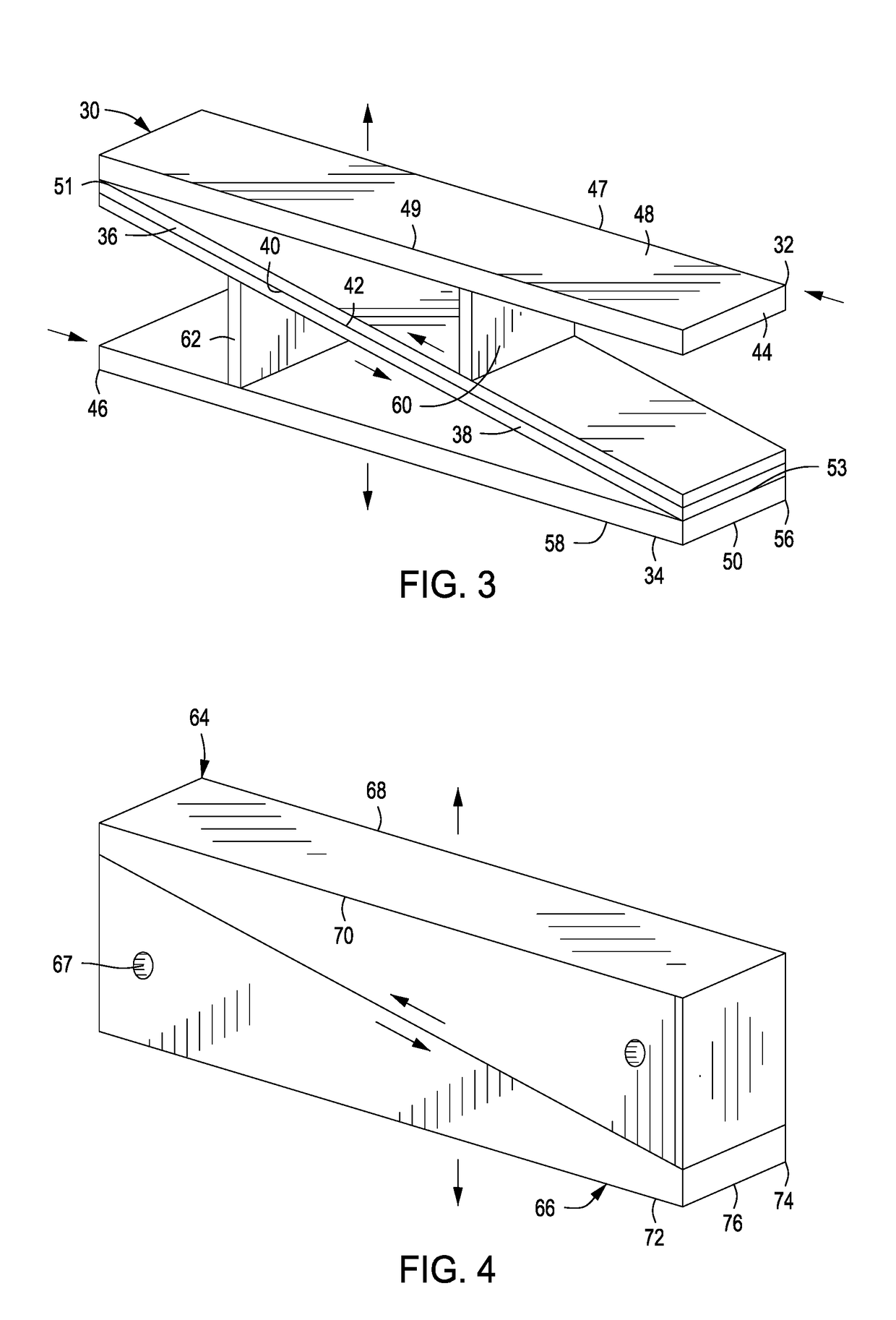

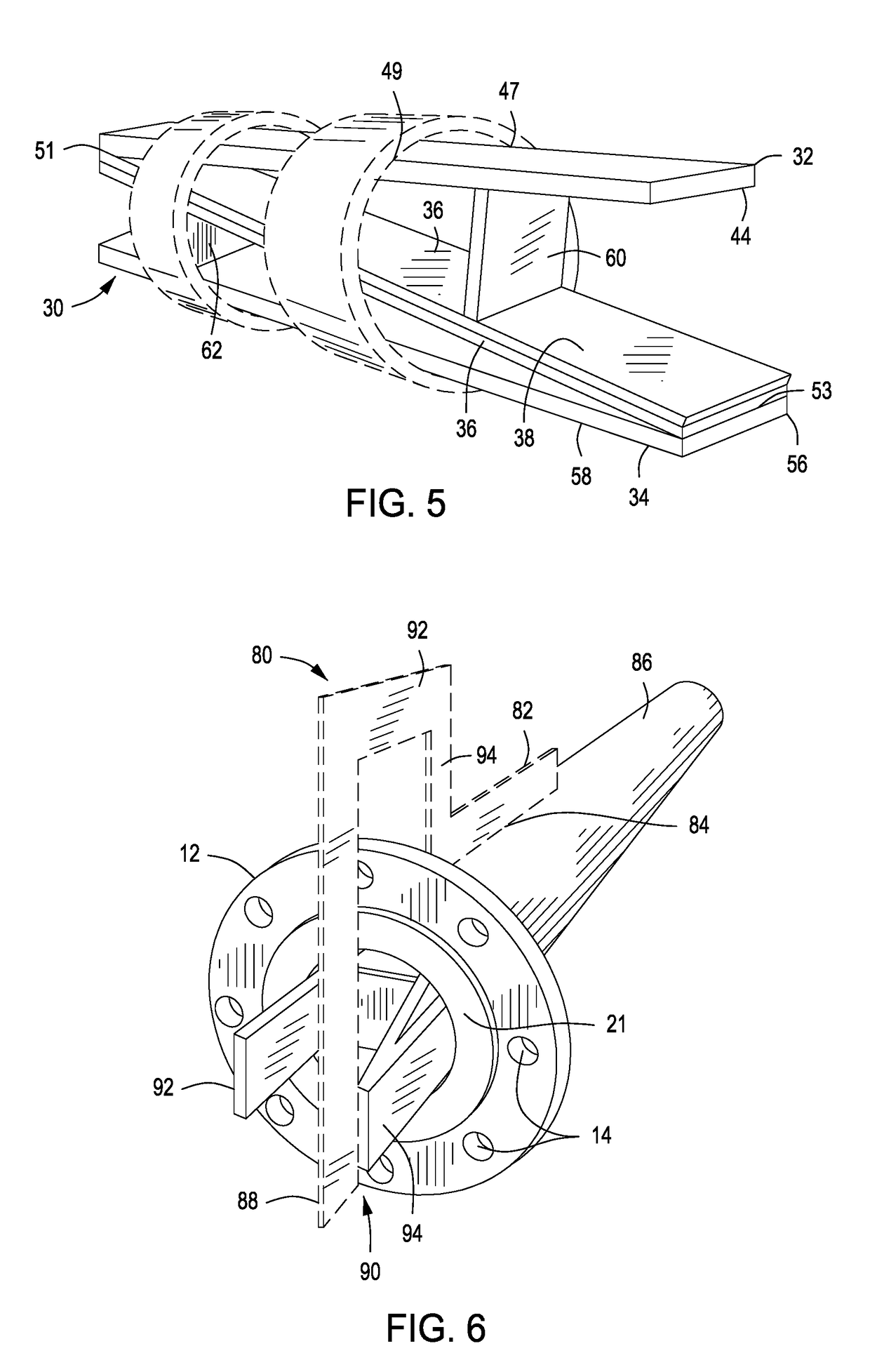

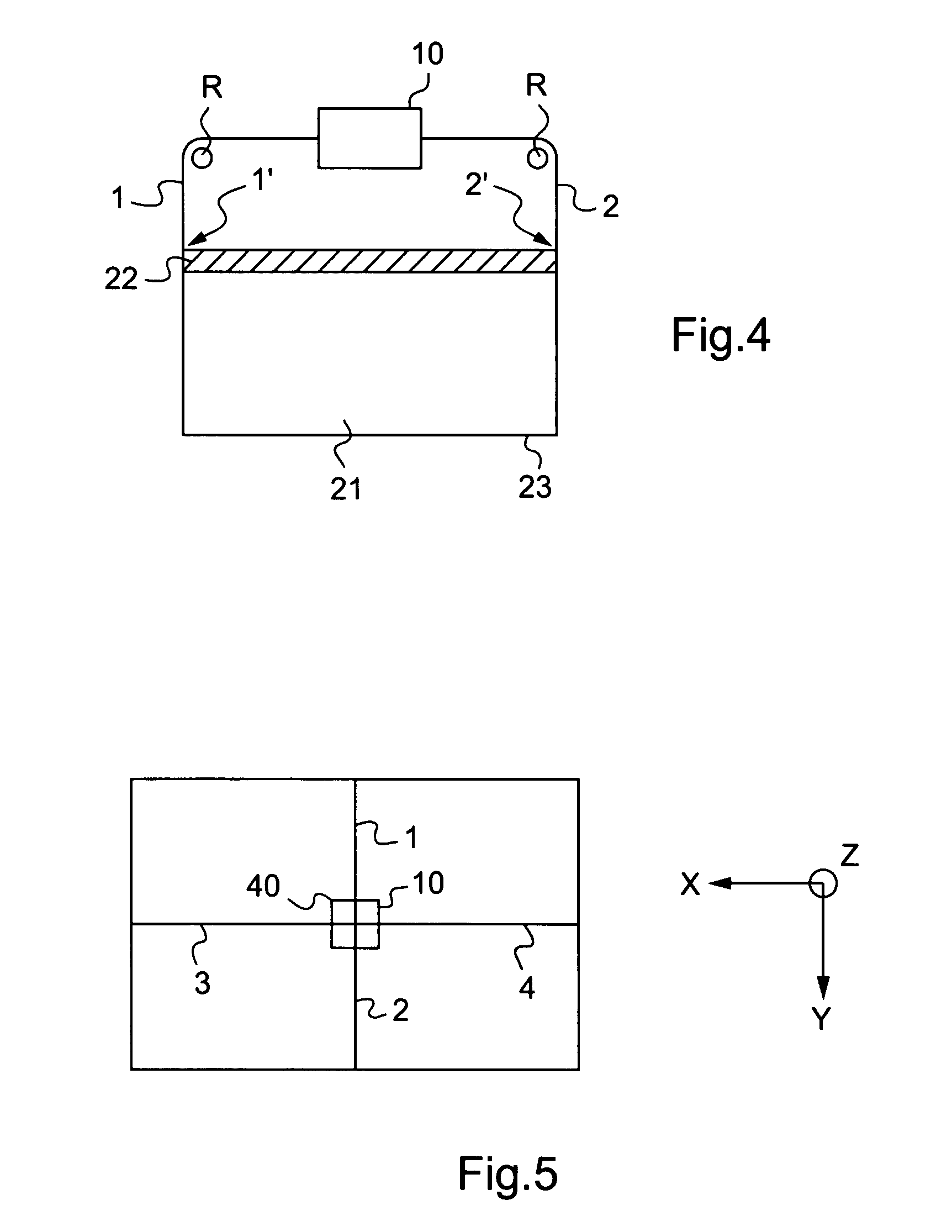

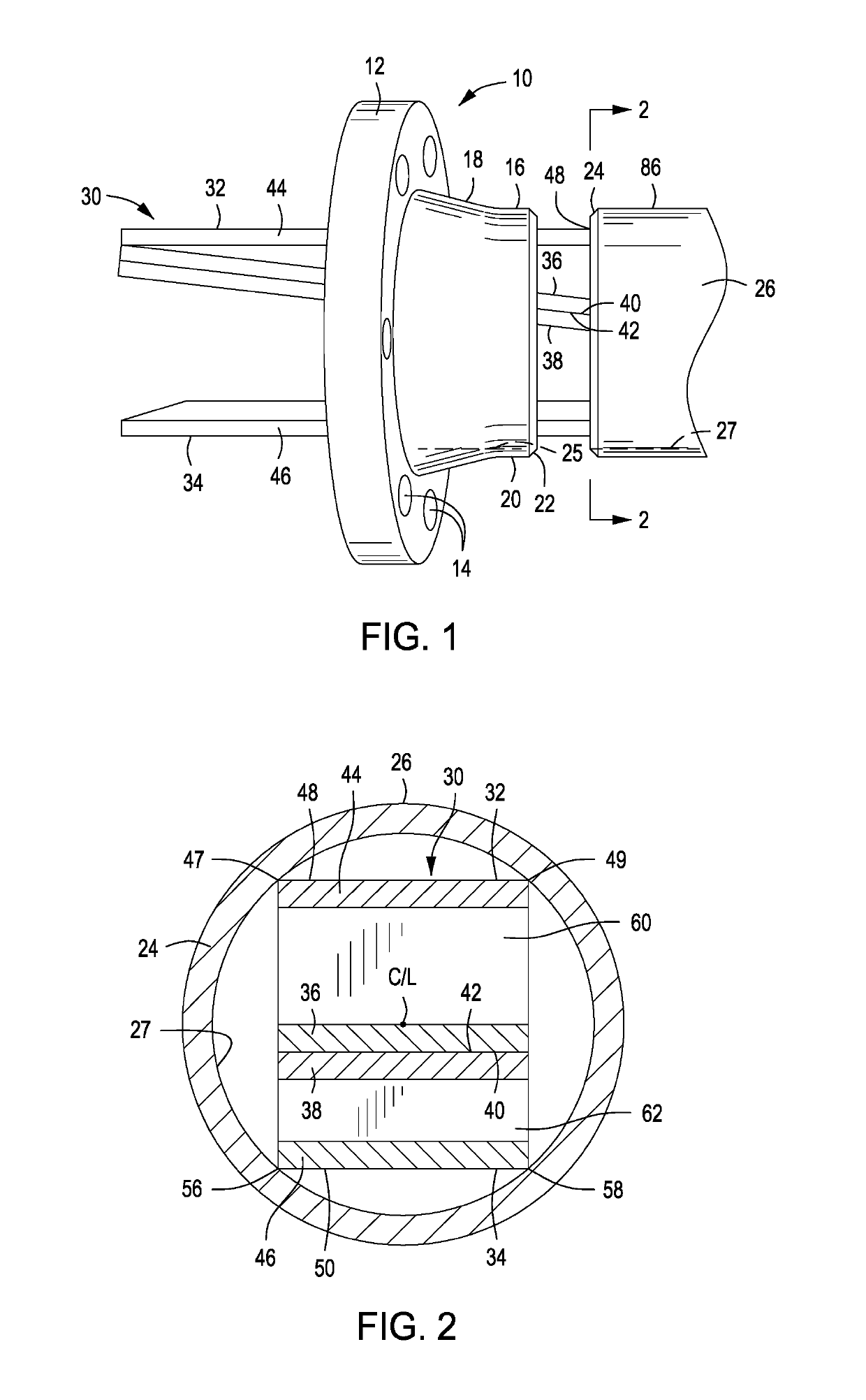

Method and apparatus for precision alignment and tack welding of weld-neck pipe fittings to pipe

InactiveUS20190015938A1Simple and efficient positioningSufficient forceFlanged jointsWelding/cutting auxillary devicesLinear motionPipe fitting

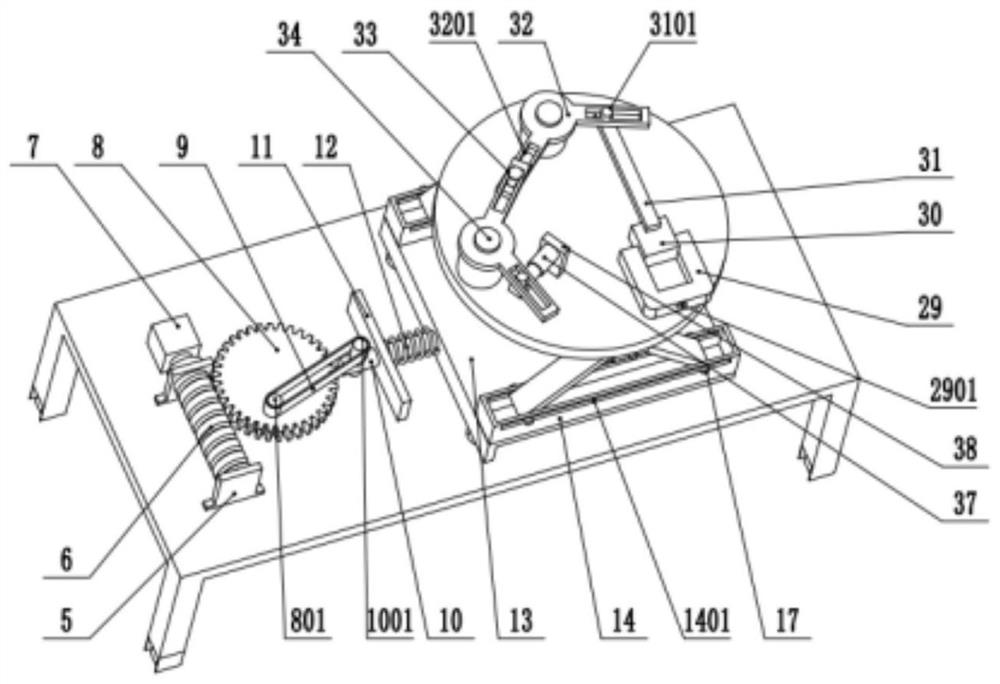

Internal clamping of a weld-neck fitting to a pipe in preparation for precision tack welding of the fitting to the pipe is established by a pair of alignment and clamping wedge members, each having alignment and gripping members and angulated reaction surfaces which are positioned within the pipe and weld-neck fitting with the angulated reaction surfaces in relatively moveable engagement. One of the alignment and clamping wedge members is moved linearly, causing the angulated reaction surfaces to translate the linear movement to lateral movement, forcing the alignment and gripping members laterally against the internal surfaces of the pipe and fitting and supporting the fitting in precision aligned relation with the pipe to facilitate tack welding. A gauge member confirms precision alignment of the fitting with the pipe before and after applying the tack welds, then the alignment and clamping apparatus is loosened by opposite linear movement of the wedge members which are removed to permit final weld connection of the fitting to the pipe.

Owner:BRANTLEY RICHARD

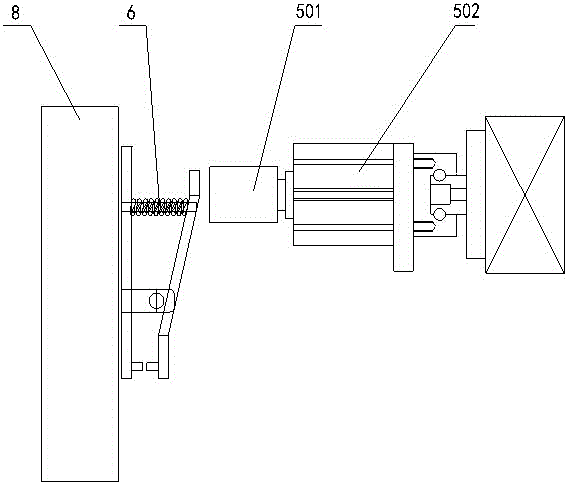

Feed mechanism of VCP (vertical continuous plating) plating line

InactiveCN104962980AImprove work efficiencyAccurate horizontal positionElectrolysis componentsHorizontal transmissionProduction line

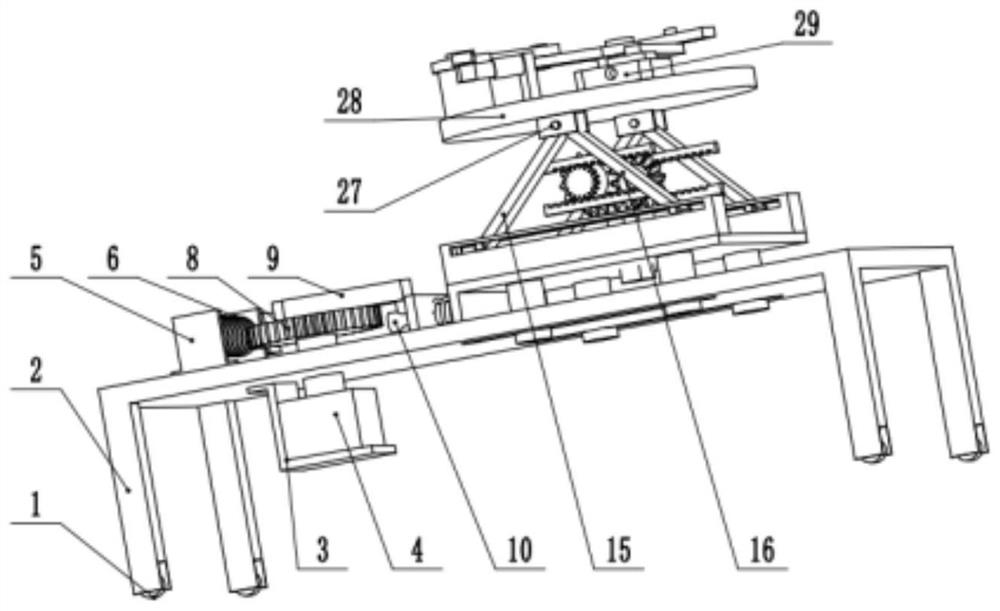

The invention discloses a feed mechanism of a VCP (vertical continuous plating) production line, which comprises a machine frame, a controller, a plate storage platform fixed on the machine frame, and a horizontal transmission device, wherein the upper part of the plate storage platform is provided with a sucker device corresponding to the stored plate; the sucker device is connected with an elevating mechanism through a rotating motor; the horizontal transmission device is distributed with a plurality of conductive bars; the side surface of the conductive bars is provided with a normally closed clamp which is butted with the sucker device and used for clamping the plate; the side surface of the machine frame is provided with a push rod device corresponding to the clamp; the feed position of the machine frame is provided with an inductive switch corresponding to the conductive bars; and the inductive switch, rotating motor, elevating mechanism and push rod device are connected with the controller. The feed mechanism disclosed by the invention can complete automatic feed of the plates, enhances the operating efficiency, can ensure the accuracy of the feed position, and is beneficial to subsequent processing.

Owner:SHENZHEN JIAZHIHONG ELECTRONICS

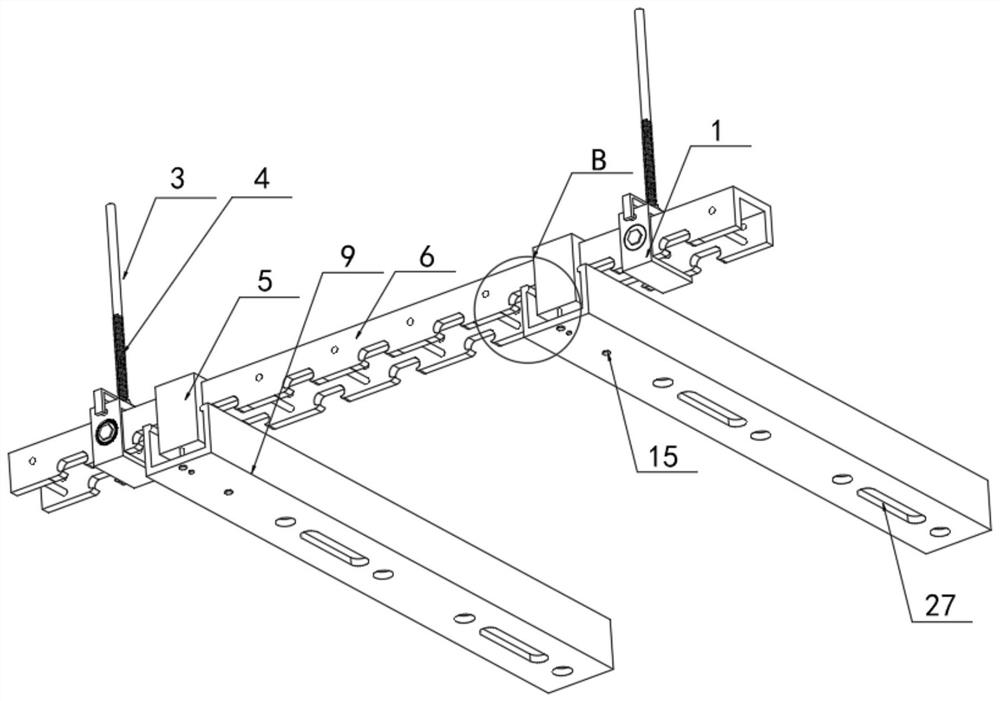

Keel mounting structure of fabricated integrated ceiling

The invention provides a keel mounting structure of a fabricated integrated ceiling, and relates to the technical field of ceiling keel mounting. The keel mounting structure of the fabricated integrated ceiling comprises a main keel, an auxiliary keel is arranged at the bottom of the main keel, the two ends of the outer side of the main keel are sleeved with first hanging brackets correspondingly,and adjusting mechanisms are arranged in the first hanging brackets; and each adjusting mechanism comprises a first ratchet wheel, the first ratchet wheels are arranged on the outer sides of the first hanging brackets, and first locking bolts are arranged in the first ratchet wheels. According to the keel mounting structure of the fabricated integrated ceiling, the first hanging brackets drive first pawls to rotate, so that the two first hanging brackets rotate to a proper angle to solve the problem of inclination of the main keel, then threaded columns and second locking bolts are driven tomove upwards, thus the horizontal position of the auxiliary keel can be finely adjusted, and therefore, the accurate horizontal position can be achieved during mounting in cooperation with the operation of the adjusting mechanisms.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

Compact truck tailgate and general purpose utility ladder

InactiveUS20060261622A1Easy to disassembleAccurate horizontal positionSuperstructure subunitsSteps arrangementGeneral purposeCoupling

An exemplary embodiment sets forth an apparatus, including a non-collapsible single unit stair comprising: a pair of opposing side rails supporting at least a top step and a bottom step; a coupler adapted to couple the apparatus to an edge of a horizontal surface; and a height adjustable user-support arm, coupled to one of the side rails with a rotatable coupling, wherein the user-support arm is moveable between a support position and a storage position.

Owner:KUZNARIK JOHN +1

Parking facility for motor vehicles and method of operating same

ActiveUS8033773B2Accurate horizontal positionStorage devicesLoading/unloadingParking spaceEngineering

A parking facility for motor vehicles having fixed parking places arranged above each other and each having a guide for a pallet that is displaceable along the guide as well as a lift, which is disposed alongside the fixed parking places and which also carries a guide for the pallet is provided. For displacement of the pallet between the respective guides of a parking place and the lift, the lift is stopped alongside a parking place such that the respective guides are aligned with one another. The guide of the lift at its end facing the parking place is supported on a supporting surface connected to the parking place. The guide of the lift after being set down onto the supporting surface is pivoted about a horizontal pivotal axis until the guide of the lift is in a horizontal position.

Owner:WAP WOEHR AUTOMATIKPARKSYST

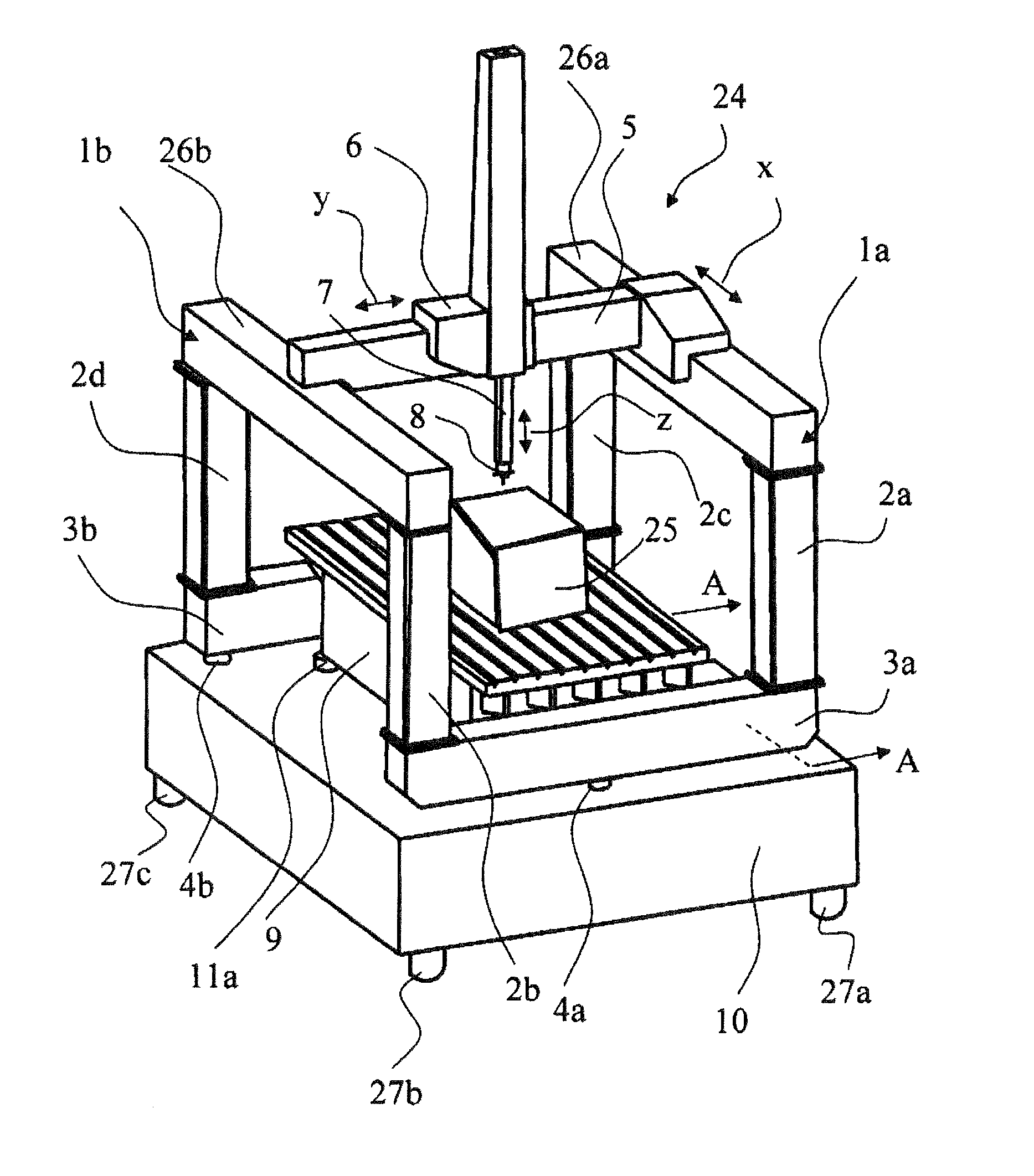

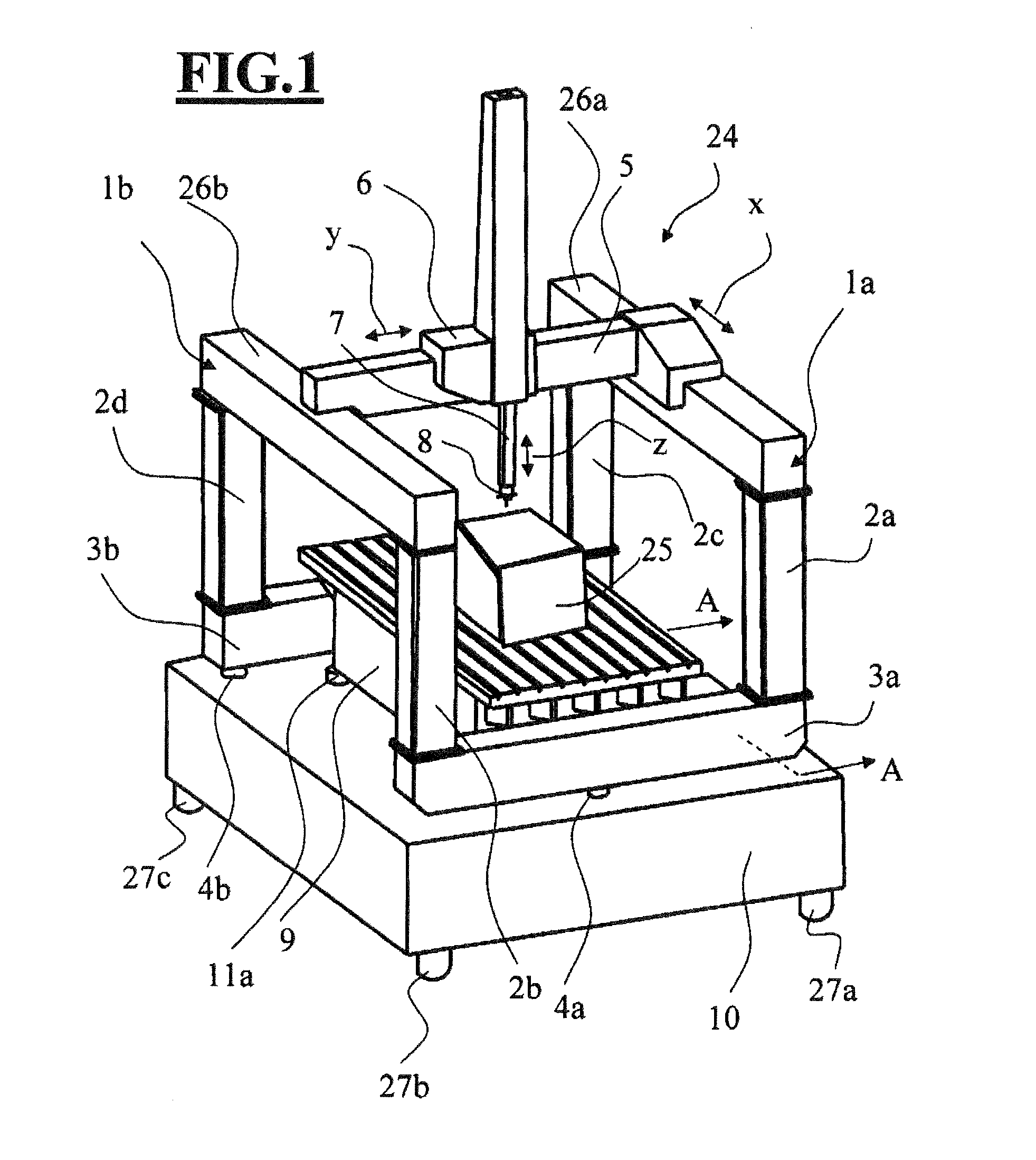

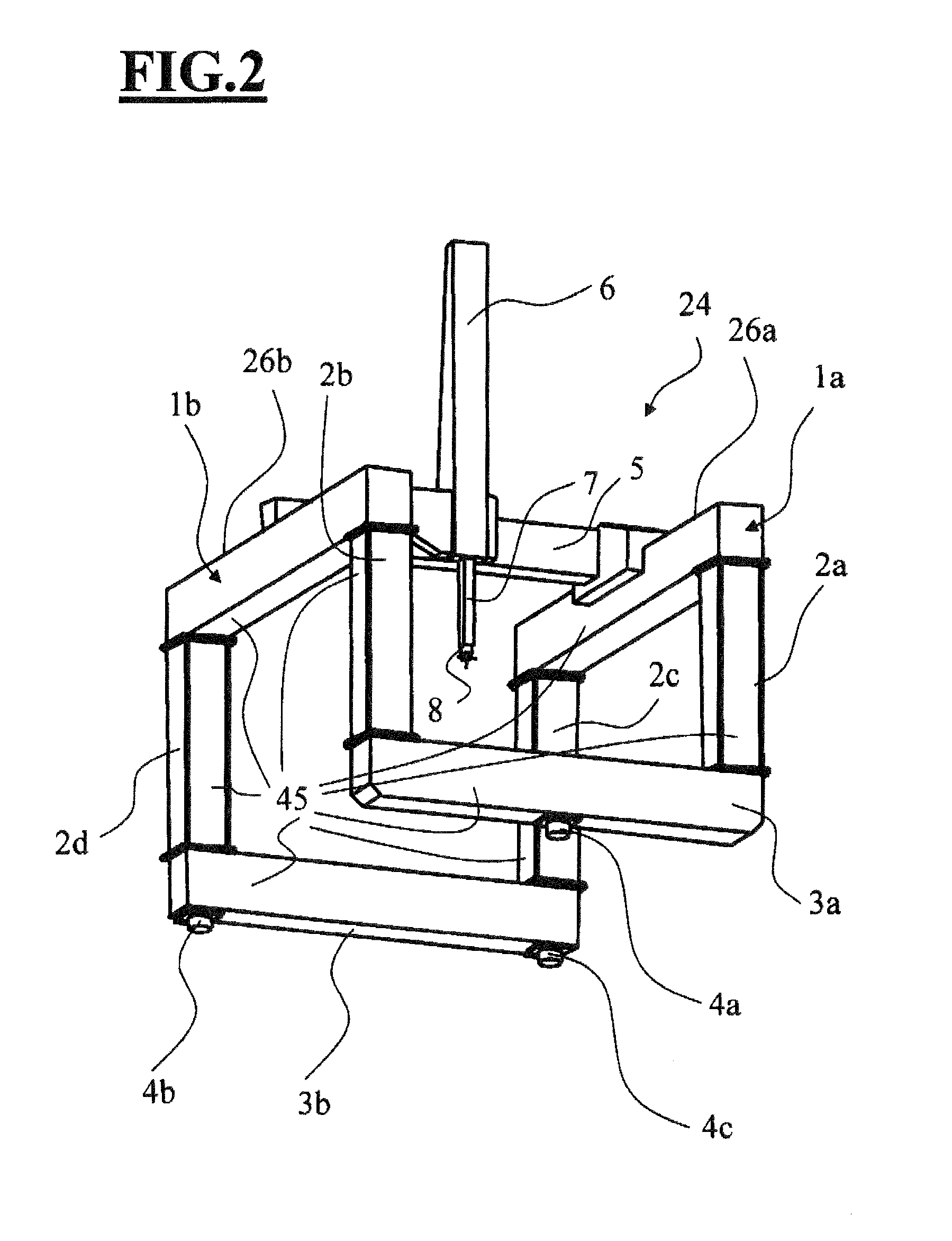

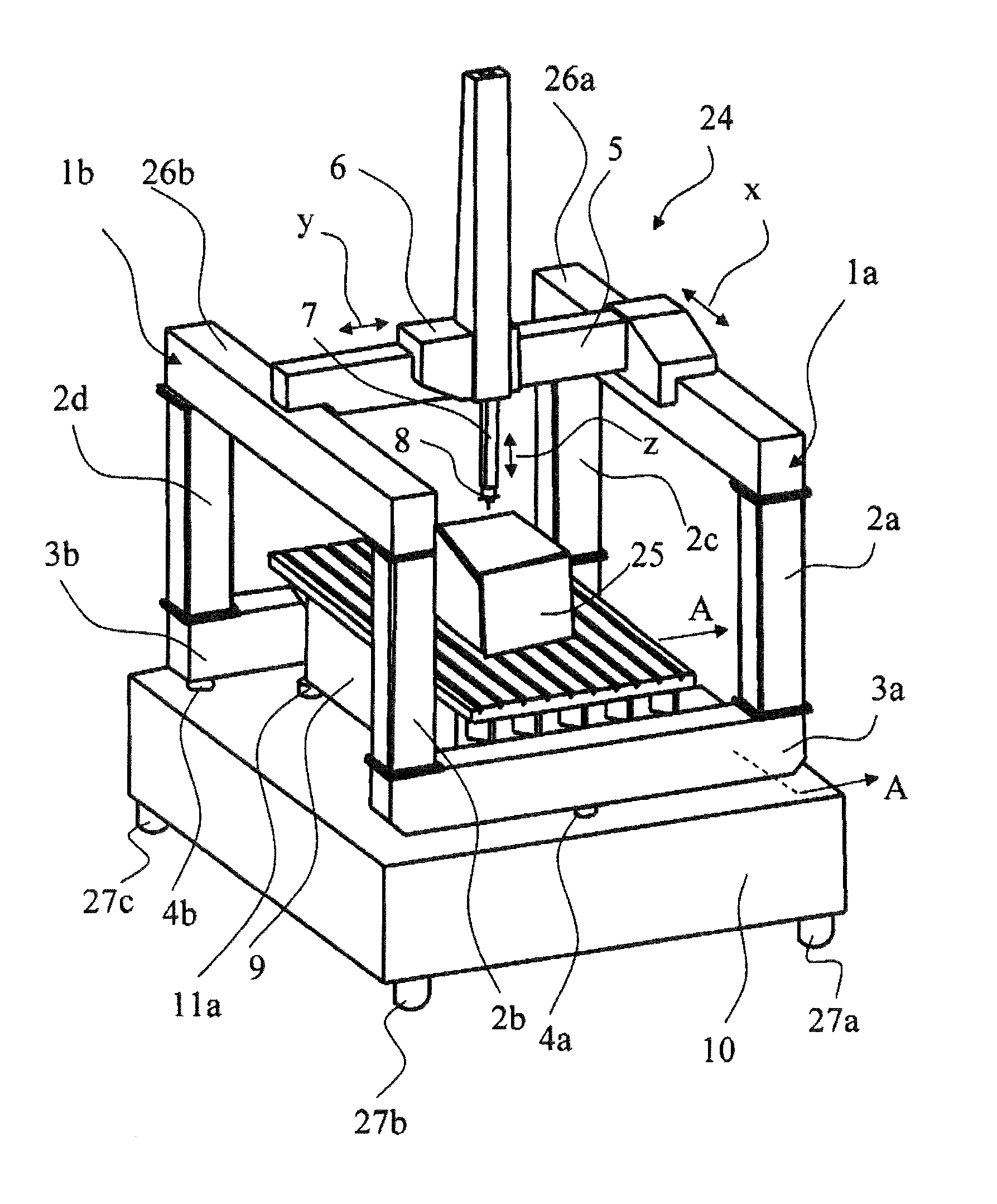

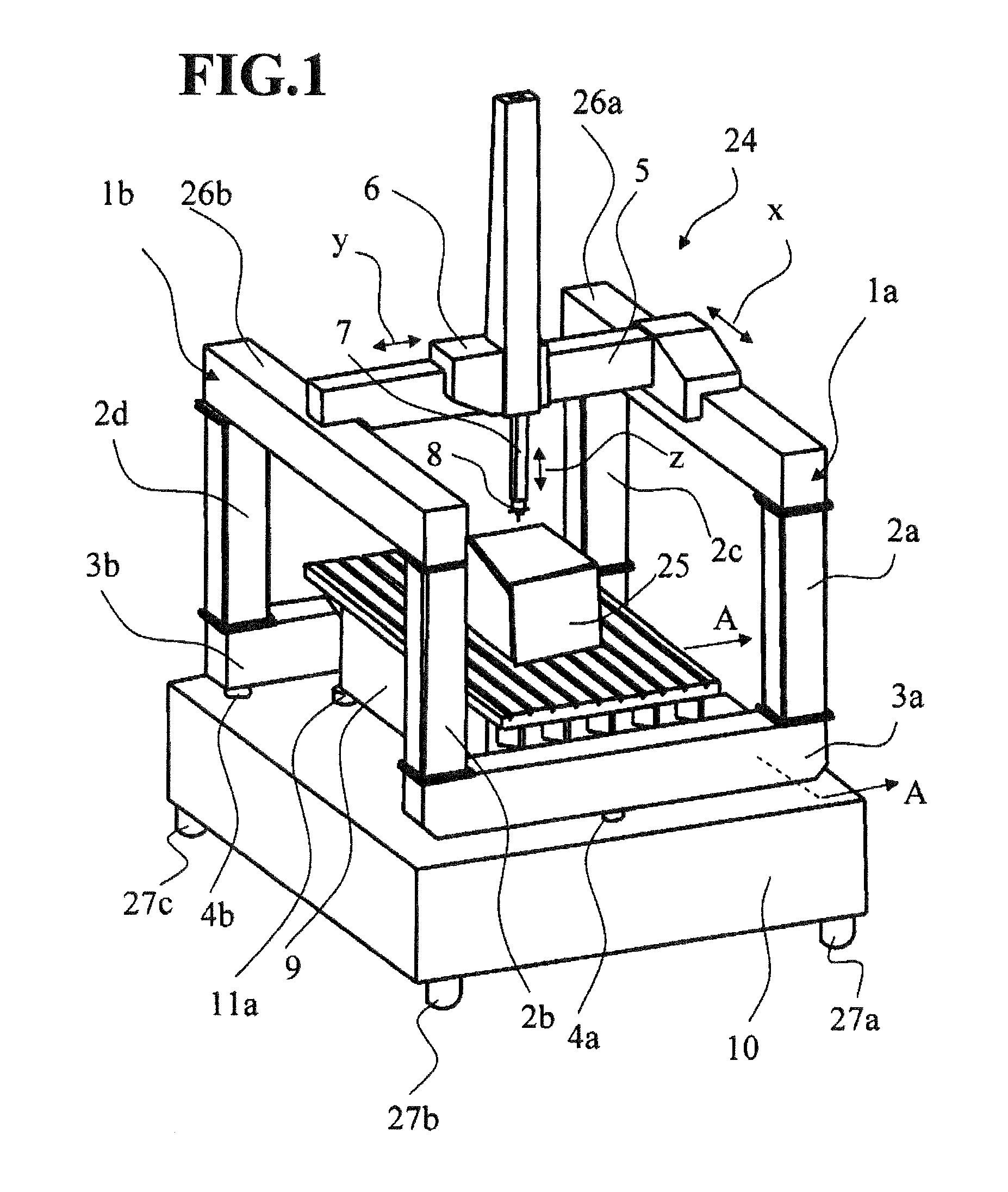

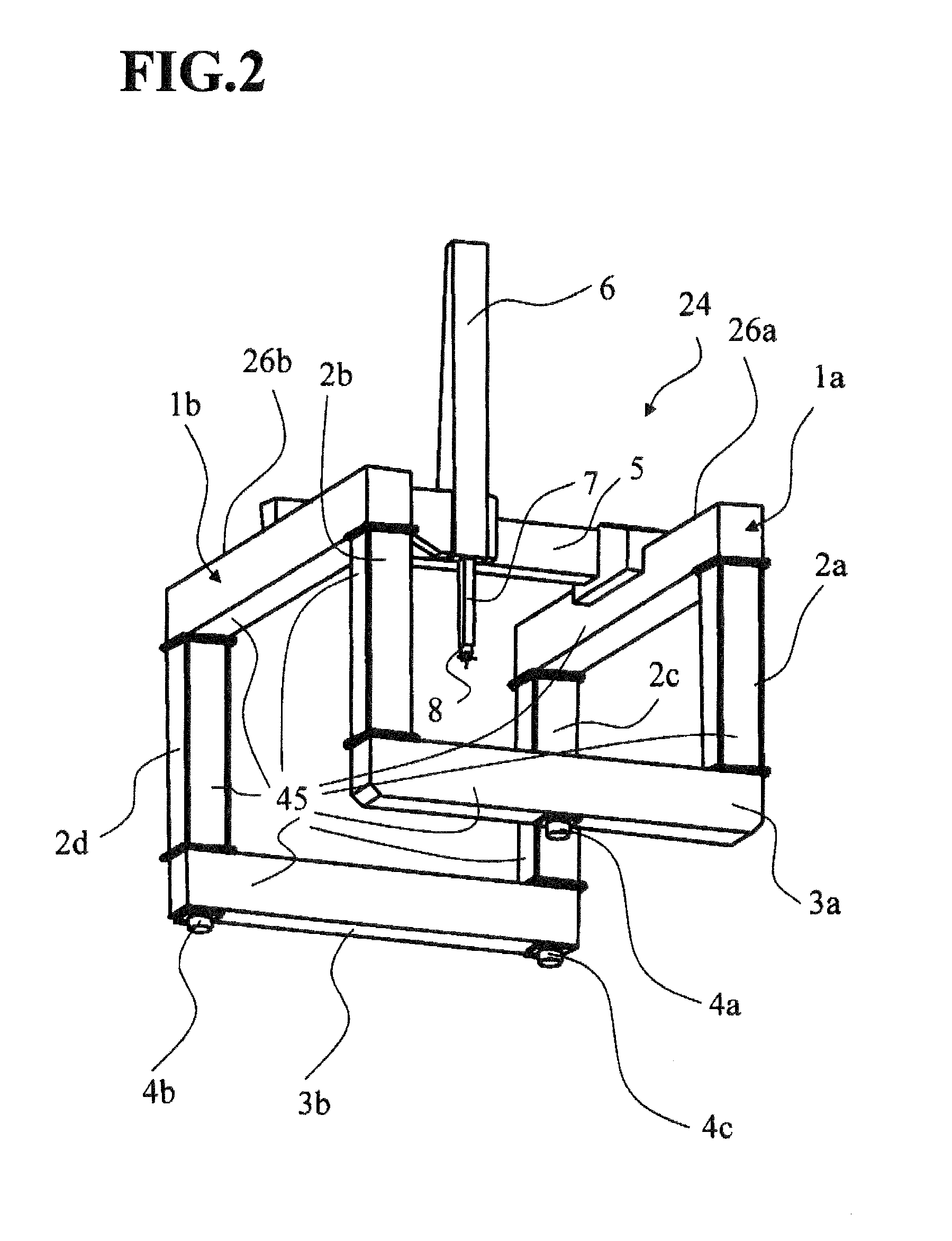

Coordinate measuring apparatus for measuring a workpiece

ActiveUS20140144032A1Made preciselyHighly space-savingError compensation/eliminationEngineeringMechanical engineering

A coordinate measuring apparatus for measuring a workpiece having a workpiece surface includes a sensor to capture the workpiece surface and a mechanism to move the sensor in coordinate directions (x, y, z) relative to the workpiece. The mechanism includes a rigid frame, a mount and measuring skids. The rigid frame includes mutually parallel horizontal longitudinal members having respective horizontal guides. The rigid frame includes vertical supports having respective upper and lower ends. The horizontal longitudinal members are rigidly connected to the upper ends of the vertical supports. The rigid frame includes transverse members oriented transverse to the longitudinal members and being rigidly connected to the lower end of the vertical supports. The transverse members are supported via the mount and a first one of the measuring skids is configured to move the sensor in the coordinate direction (x) along the first and second horizontal guides.

Owner:CARL ZEISS IND MESSTECHN GMBH

Coordinate measuring apparatus for measuring a workpiece

ActiveUS9476688B2Accurate horizontal positionMade preciselyError compensation/eliminationEngineeringMechanical engineering

A coordinate measuring apparatus for measuring a workpiece having a workpiece surface includes a sensor to capture the workpiece surface and a mechanism to move the sensor in coordinate directions (x, y, z) relative to the workpiece. The mechanism includes a rigid frame, a mount and measuring skids. The rigid frame includes mutually parallel horizontal longitudinal members having respective horizontal guides. The rigid frame includes vertical supports having respective upper and lower ends. The horizontal longitudinal members are rigidly connected to the upper ends of the vertical supports. The rigid frame includes transverse members oriented transverse to the longitudinal members and being rigidly connected to the lower end of the vertical supports. The transverse members are supported via the mount and a first one of the measuring skids is configured to move the sensor in the coordinate direction (x) along the first and second horizontal guides.

Owner:CARL ZEISS IND MESSTECHN GMBH

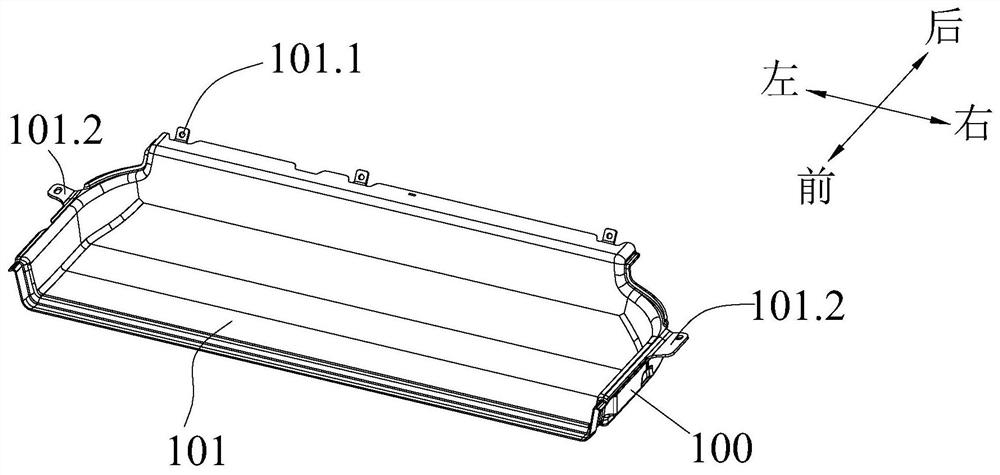

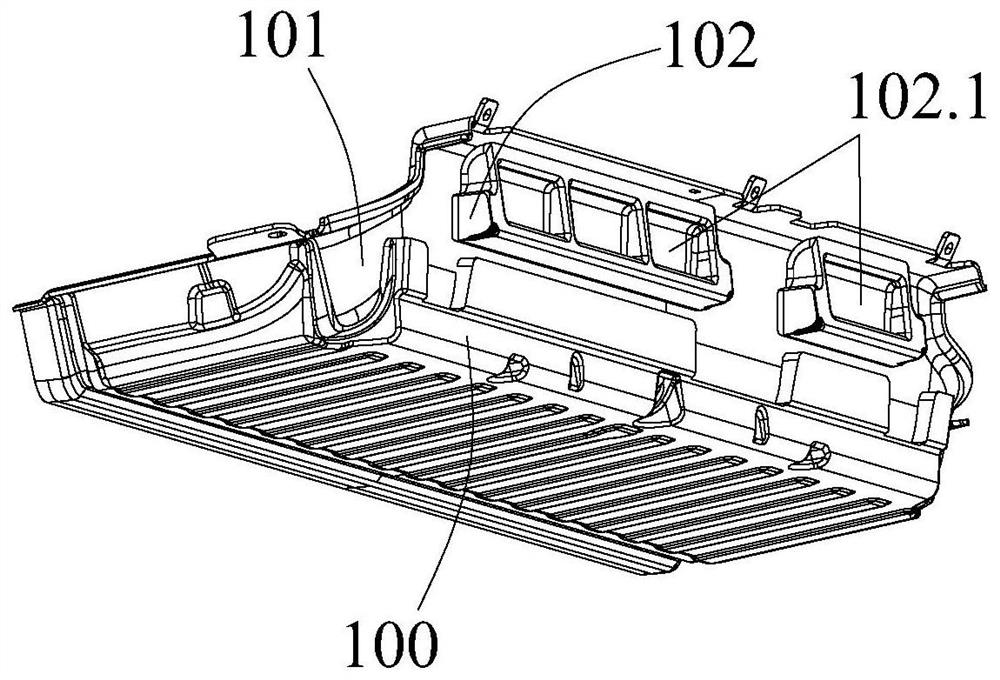

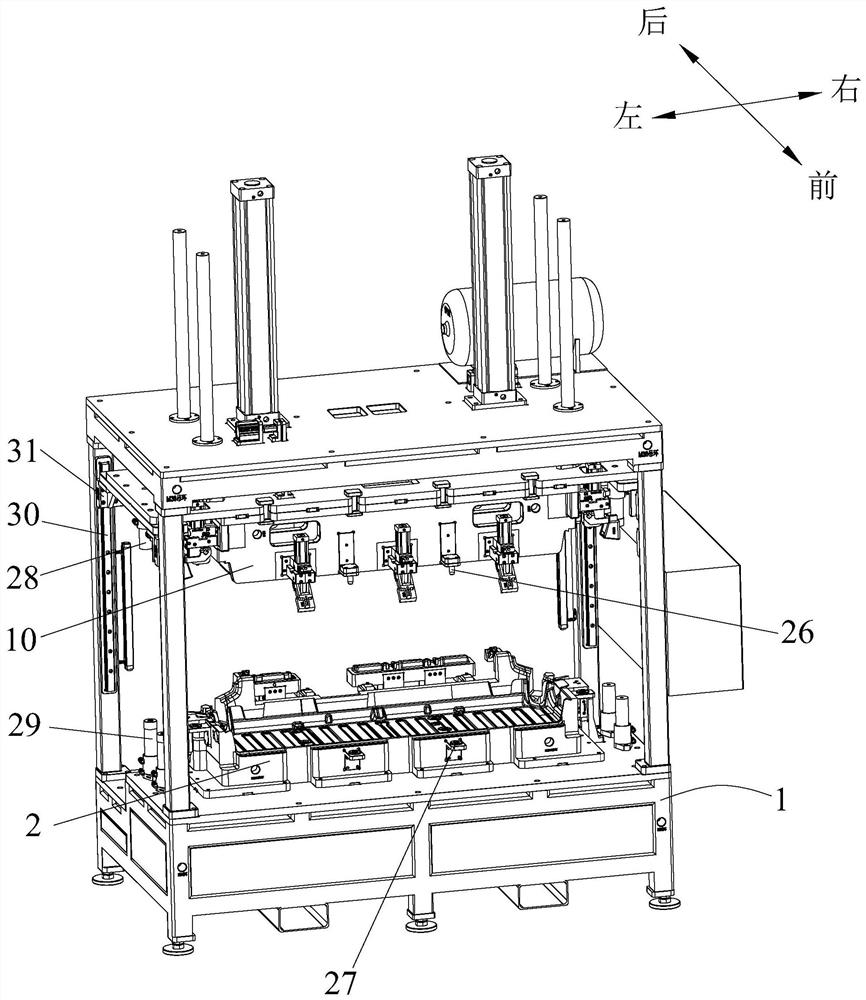

Automobile passenger compartment rear carpet assembly pressing device

ActiveCN113021914AGuaranteed accuracyAccurate horizontal positionDomestic articlesAutomotive engineeringManufacturing engineering

The invention discloses an automobile passenger compartment rear carpet assembly pressing device which comprises a rack. A positioning base, a third positioning assembly and a driving assembly are arranged on the rack. A first positioning assembly and a second positioning assembly are arranged on the positioning base. A press-fitting mechanism capable of ascending and descending in the vertical direction is further arranged on the rack, and a clamping mechanism is arranged on the press-fitting mechanism. After PU cotton and a carpet are sequentially placed on the positioning base from bottom to top and positioned, the press-fitting mechanism moves downwards to enable the clamping mechanism to clamp the carpet and then reset upwards, a gluing robot glues the binding face, and the press-fitting mechanism moves downwards again to enable the carpet and the PU cotton to be in press fit. The driving assembly drives the third positioning assembly to move towards the rear side of the carpet so that a foam plastic piece can be pressed and bonded to the rear side wall of the carpet. According to the automobile passenger compartment rear carpet assembly pressing device, the structure is simple, automatic pressing and bonding of the PU cotton, the carpet and the foam plastic piece can be achieved, the bonding position is accurate, and the working efficiency is high.

Owner:NINGBO TUOPU GROUP CO LTD

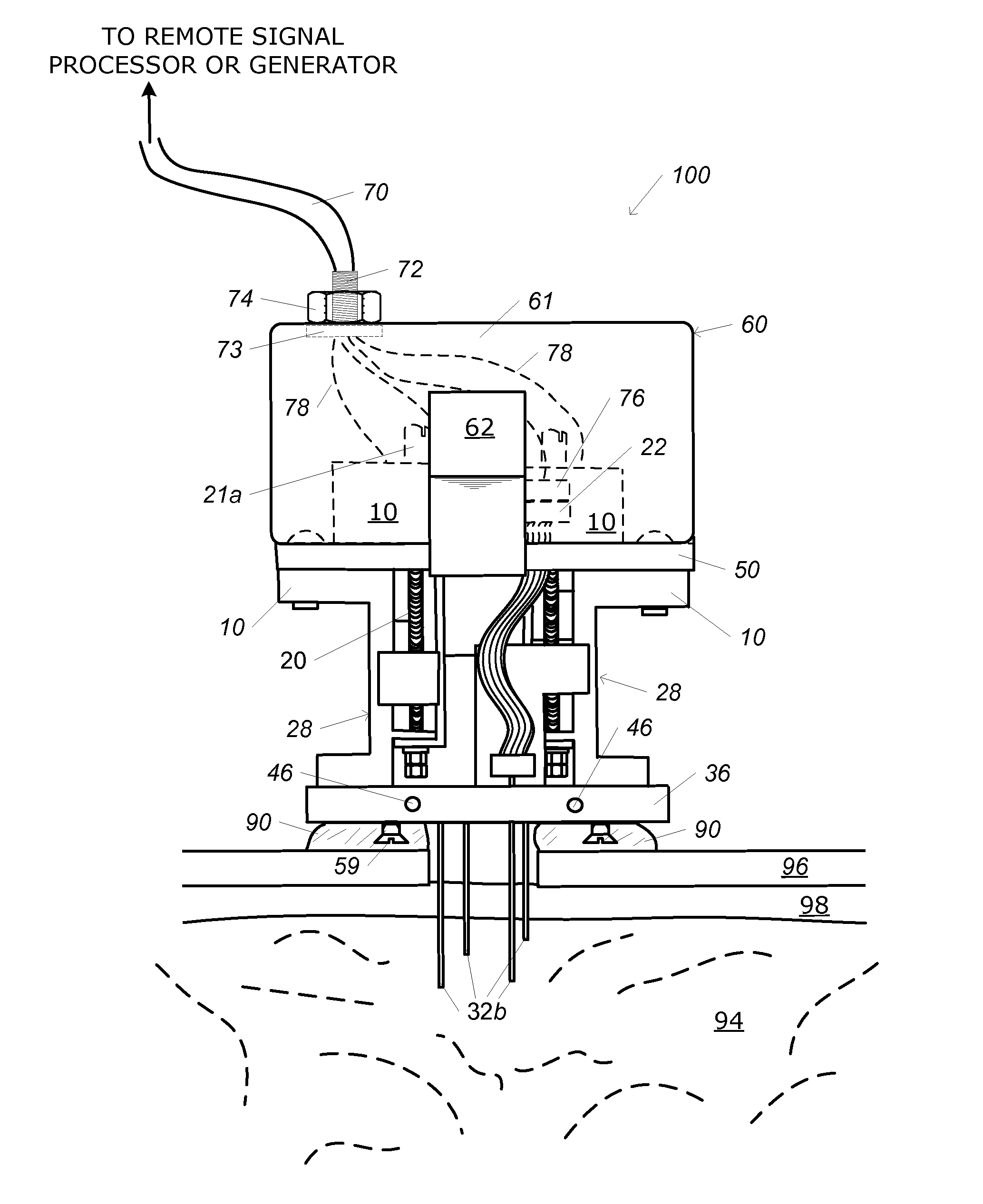

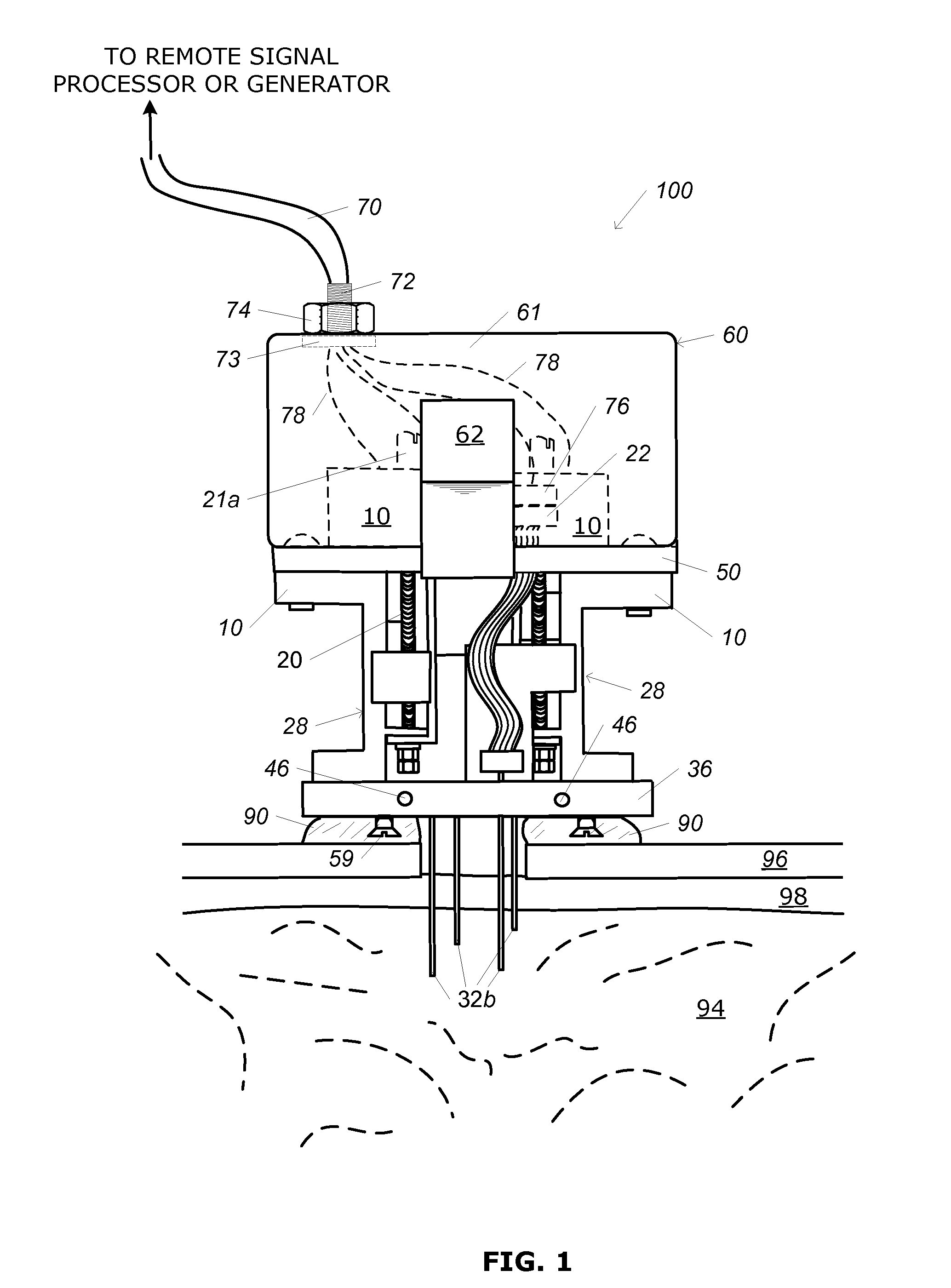

Microdrive and Modular Microdrive Assembly for Positioning Instruments in Animal Bodies

InactiveUS20100211081A1Accurate horizontal positionAccurate vertical positionDiagnosticsSurgical manipulatorsHeadframeModularity

Microdrive and modular microdrive assembly for positioning the tips of substantially rigid medical and scientific instruments, such as electrodes, mechanical probes and needles, that are chronically implanted in animals, especially conscious and freely-moving animals, without passing the substantially rigid instruments through tubular guides or using immobilizing stereotactic surgical guide systems, such as arcuate rails mounted on relatively large and unwieldy external surgical headframes. Embodiments of the invention comprise a bottom plate adapted to be surgically attached to the animal and fixedly secured to a frame so that a void in the bottom plate is fixedly disposed over the implantation site. A carriage having a platform for mounting the substantially rigid instrument is alternately lowered and raised by rotating a drive rod connecting the carriage to the frame, enabling precise movement of the tip of the substantially rigid instrument into and out of the animal's body tissue.

Owner:MERCK SHARP & DOHME CORP

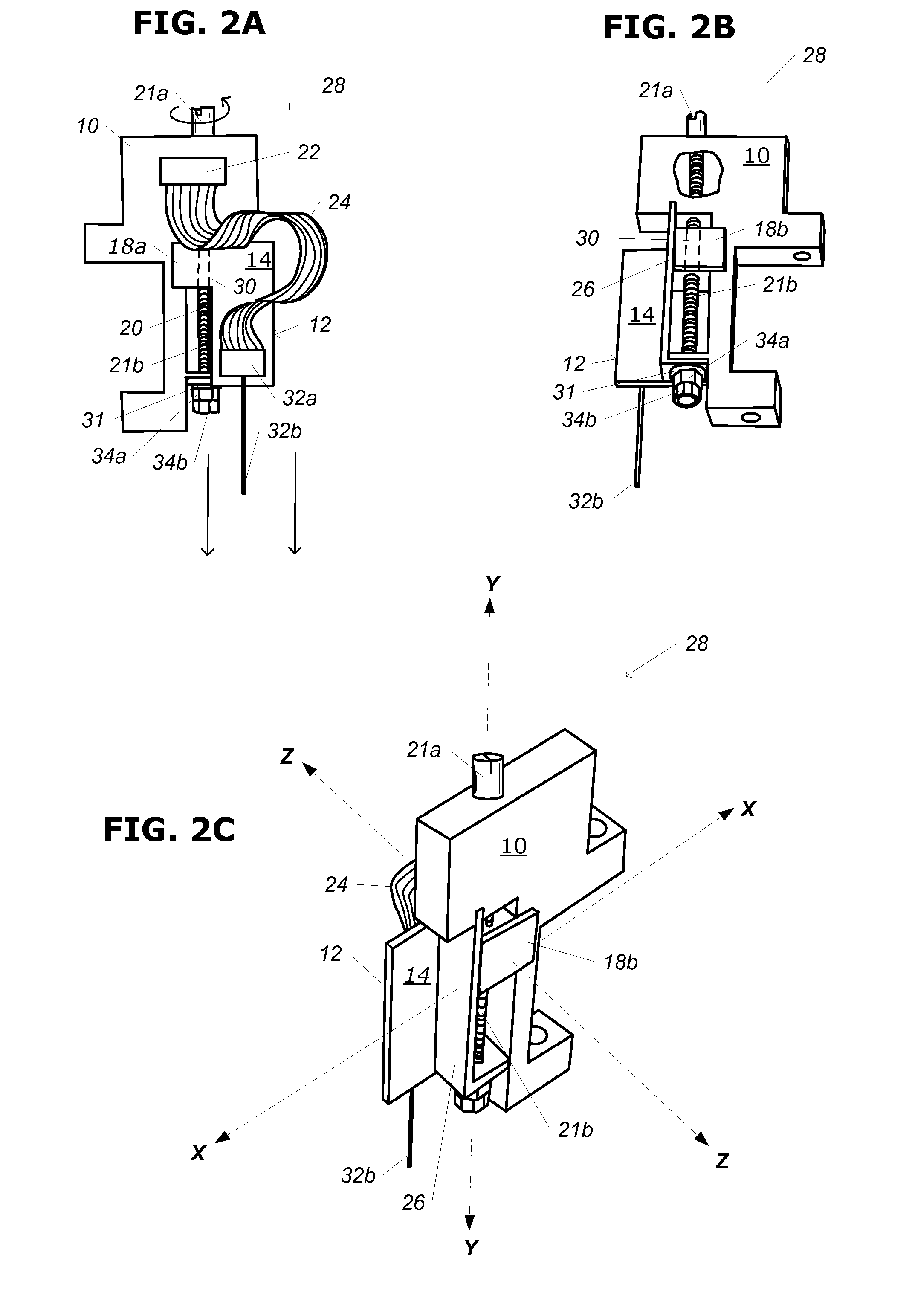

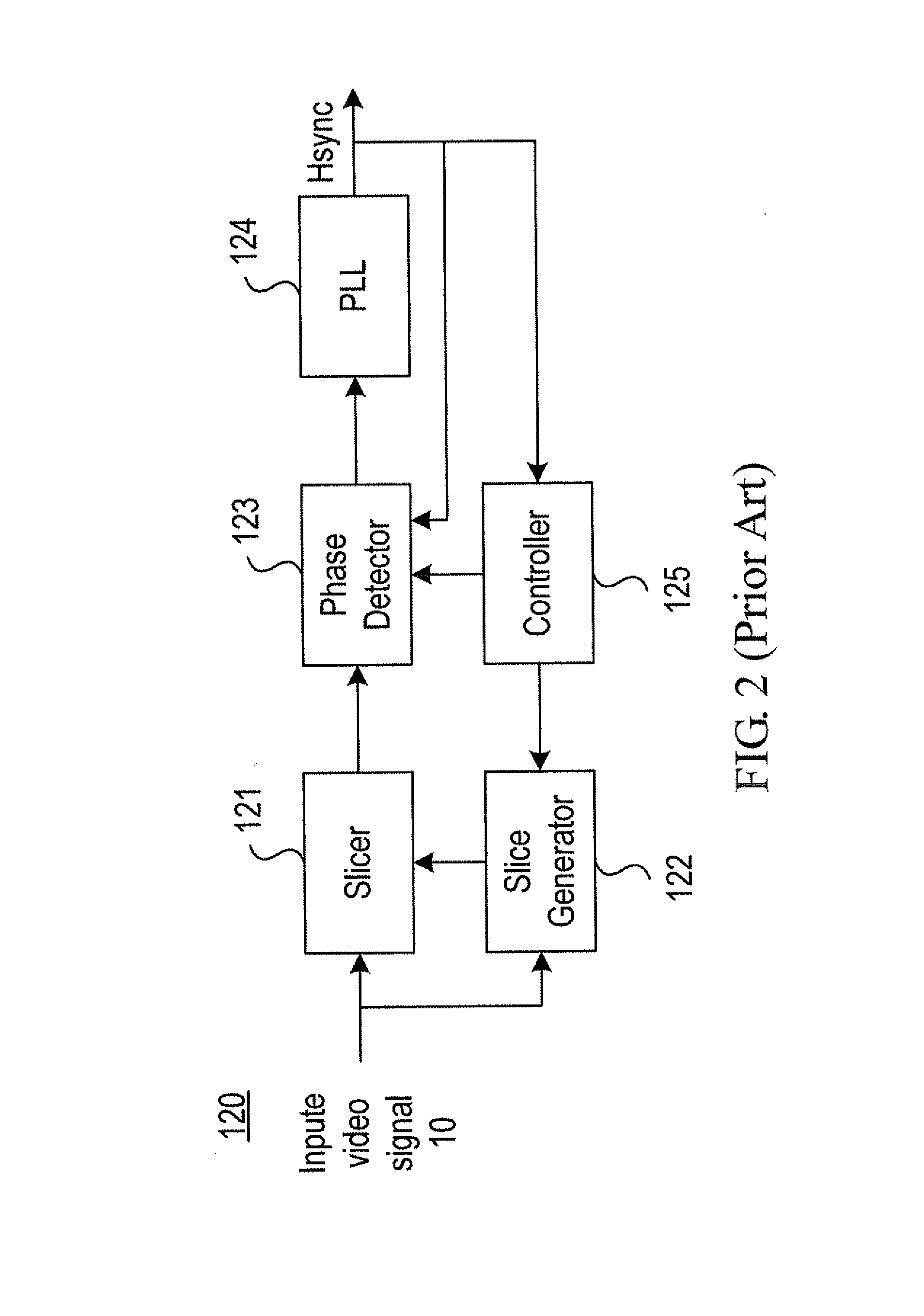

Horizontal synchronization signal detection system and method

InactiveUS8564722B2Accurate horizontal positionTelevision system detailsPulse automatic controlComputer scienceFine-tuning

A horizontal synchronization signal detection system includes a coarse period estimator and a fine period time estimator. The coarse period estimator estimates a minimum value and corresponding position of each period of a CVBS signal to calculate a coarse period of a horizontal synchronization signal. The fine period time estimator divides the horizontal synchronization signal into a first part and a second part so as to generate a first sum and a second sum by adding signals of the first part and the second part, and detects a middle point of the horizontal synchronization signal when the first sum equals the second sum. The steps of fine-tuning the coarse period to generate a fine-tuned coarse period, extracting the horizontal synchronization signal according to the fine-tuned coarse period, and determining whether the first sum is equal to the second sum are repeatedly executed until the first sum equals the second sum.

Owner:SUNPLUS TECH CO LTD

Transverse socket and spigot joint suitable for prefabricated underground diaphragm wall

PendingCN112030945AMeet the carrying capacity requirementsAchieve waterproof functionBulkheads/pilesSlurry wallButt joint

The invention discloses a transverse socket and spigot joint suitable for a prefabricated underground diaphragm wall. The transverse socket and spigot joint comprises a first fixing device and a second fixing device, wherein the first fixing device is arranged on the side surface of the wider side of a splicing surface and used for transversely fixing an upper section and a lower section, the first fixing device comprises counter-pull embedded parts and connecting steel plates arranged on the surfaces of the counter-pull embedded parts at the opposite positions of the upper section and the lower section, the second fixing device is arranged on the splicing surface and is used for longitudinally fixing the upper section and the lower section, and the second fixing device comprises connecting pieces arranged on the splicing surface of the upper section and holes formed in the splicing surface of the lower section and used for allowing the connecting pieces to be placed. The transverse socket and spigot joint is simple in structure, the construction quality and the component strength can be effectively controlled, the construction process is simple, the construction efficiency is high, the horizontal position is effectively ensured to be accurate after the upper section and the lower section of the wall are in butt joint, and the waterproof function of wall joints is achieved.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

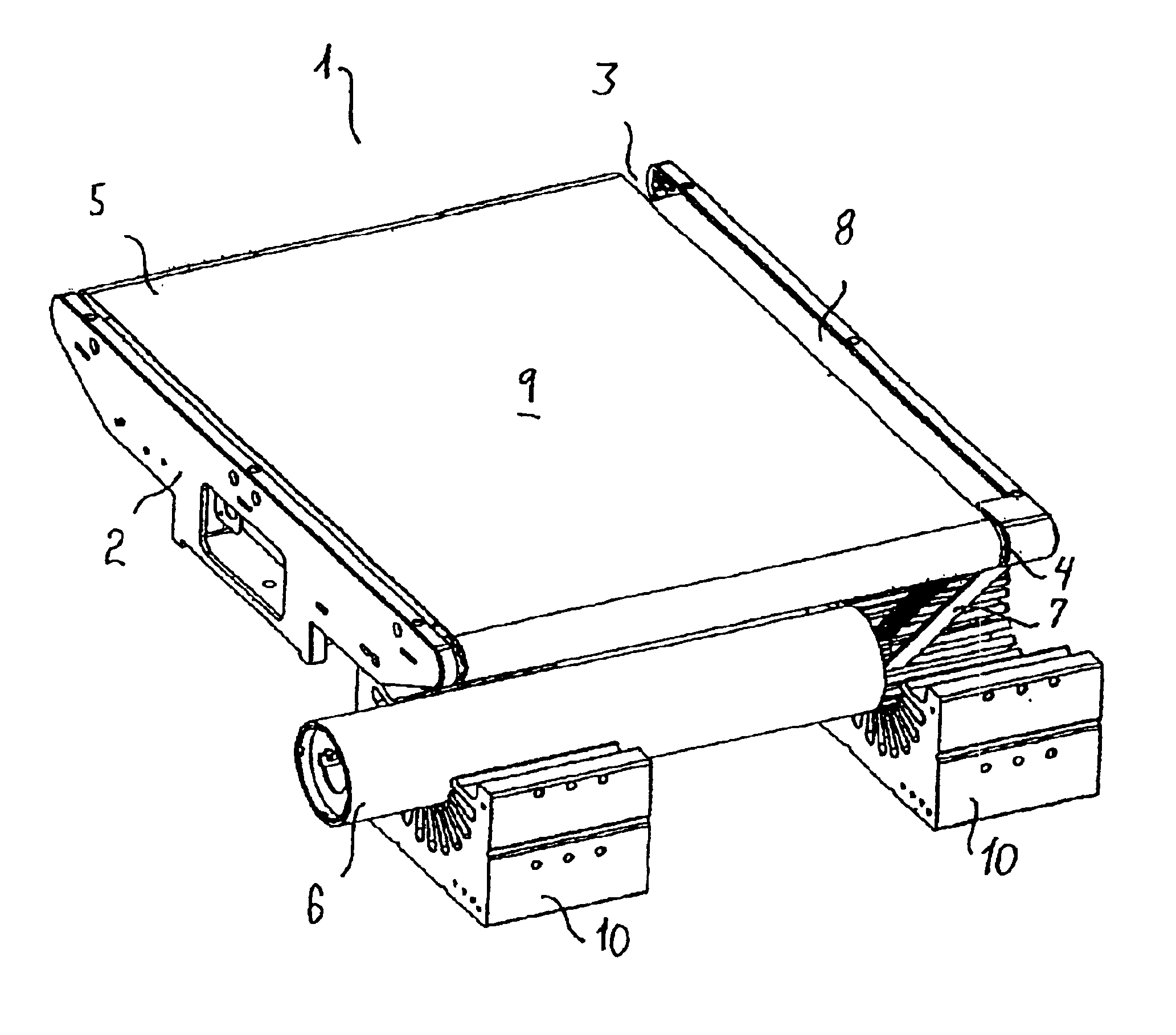

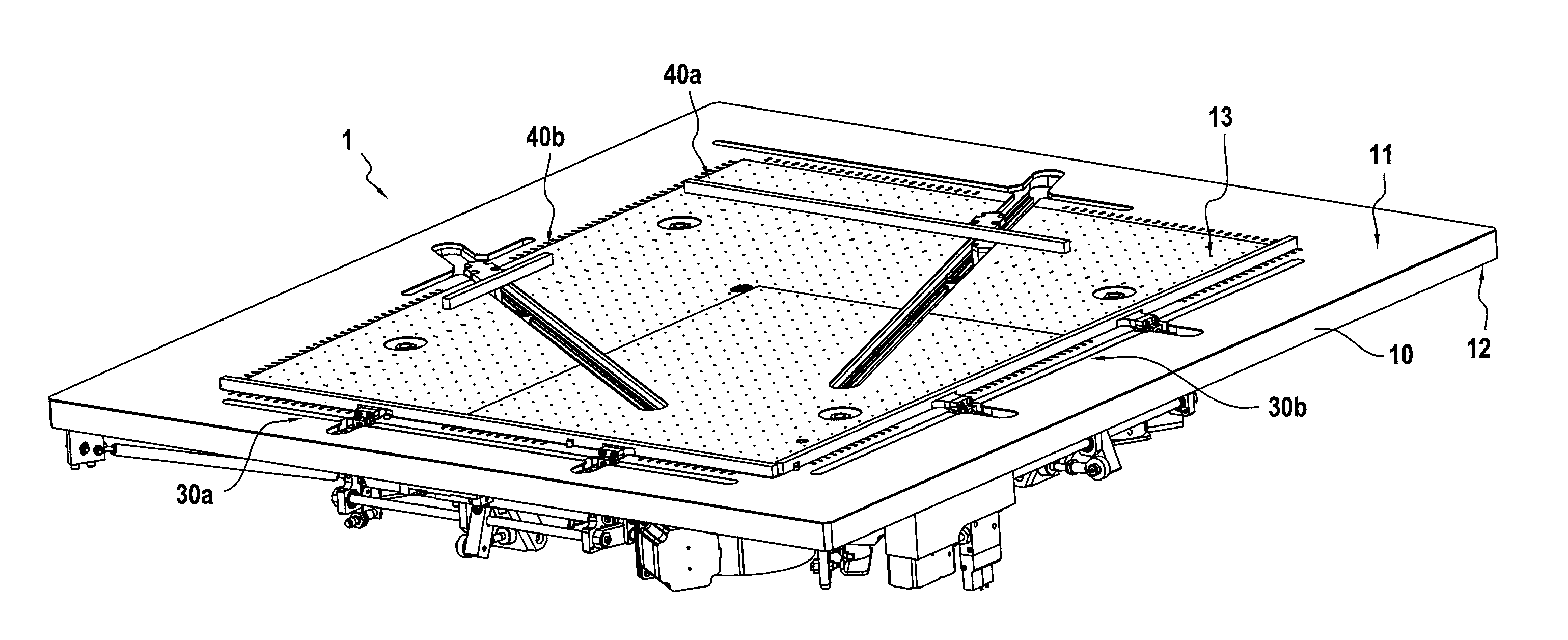

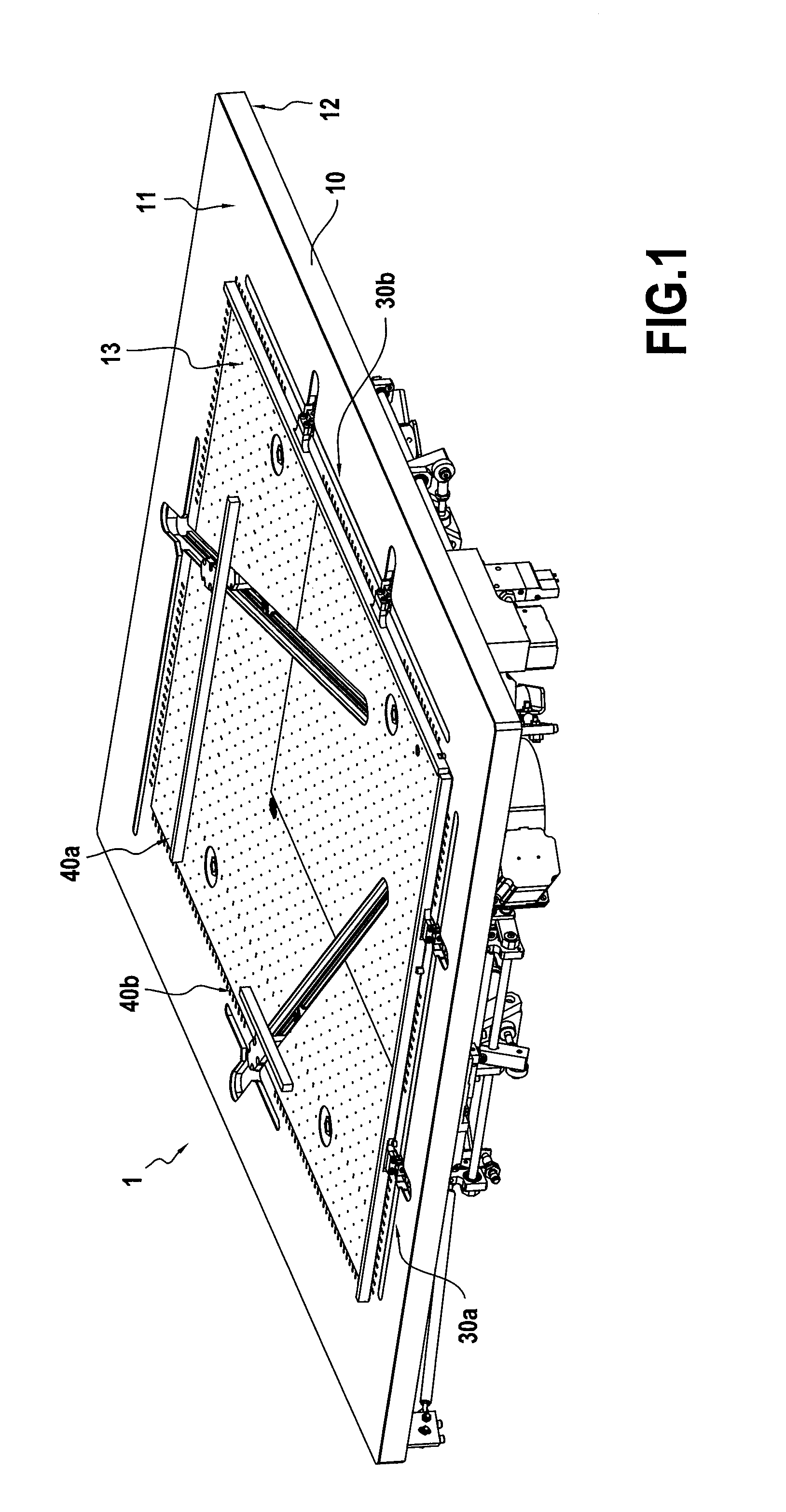

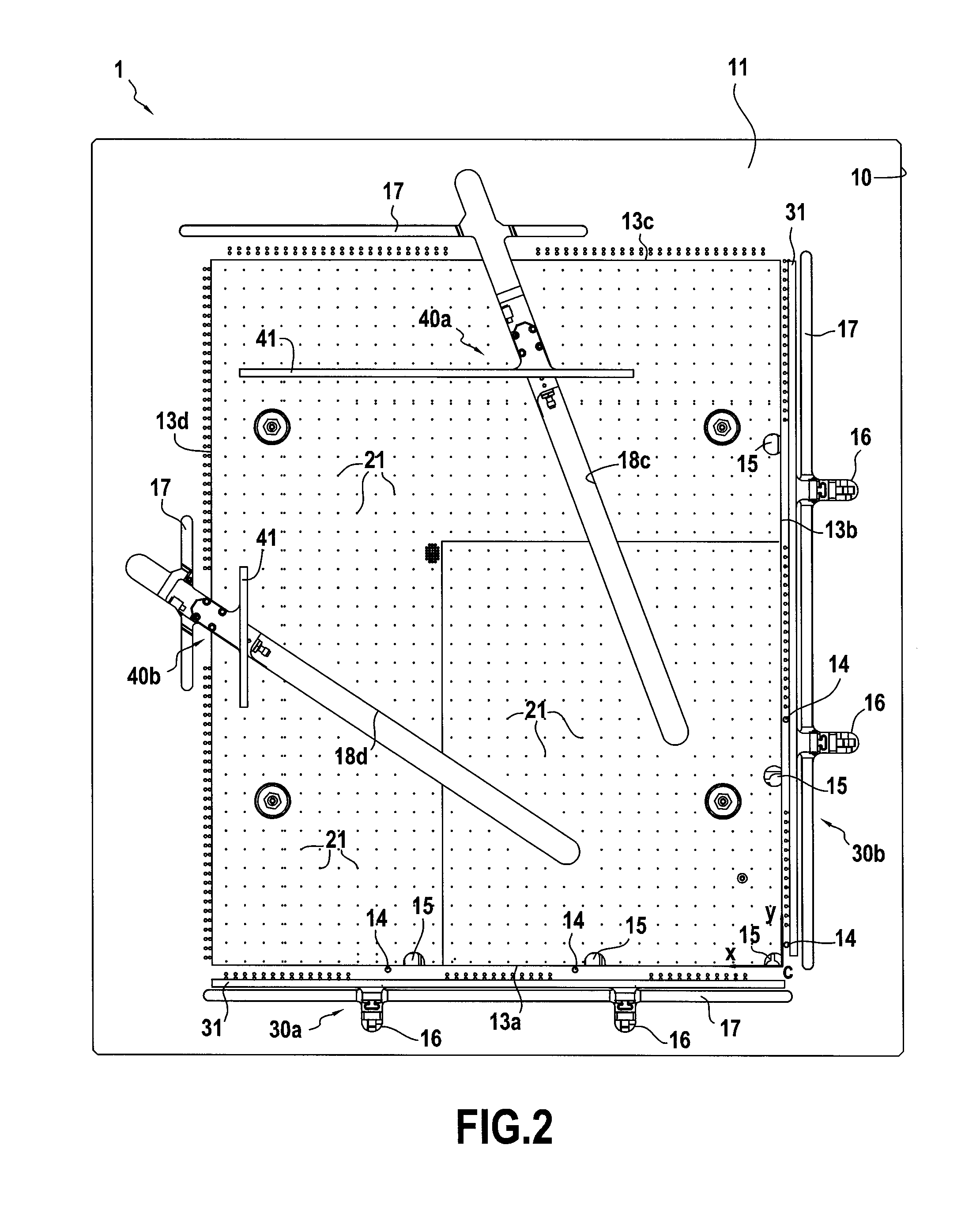

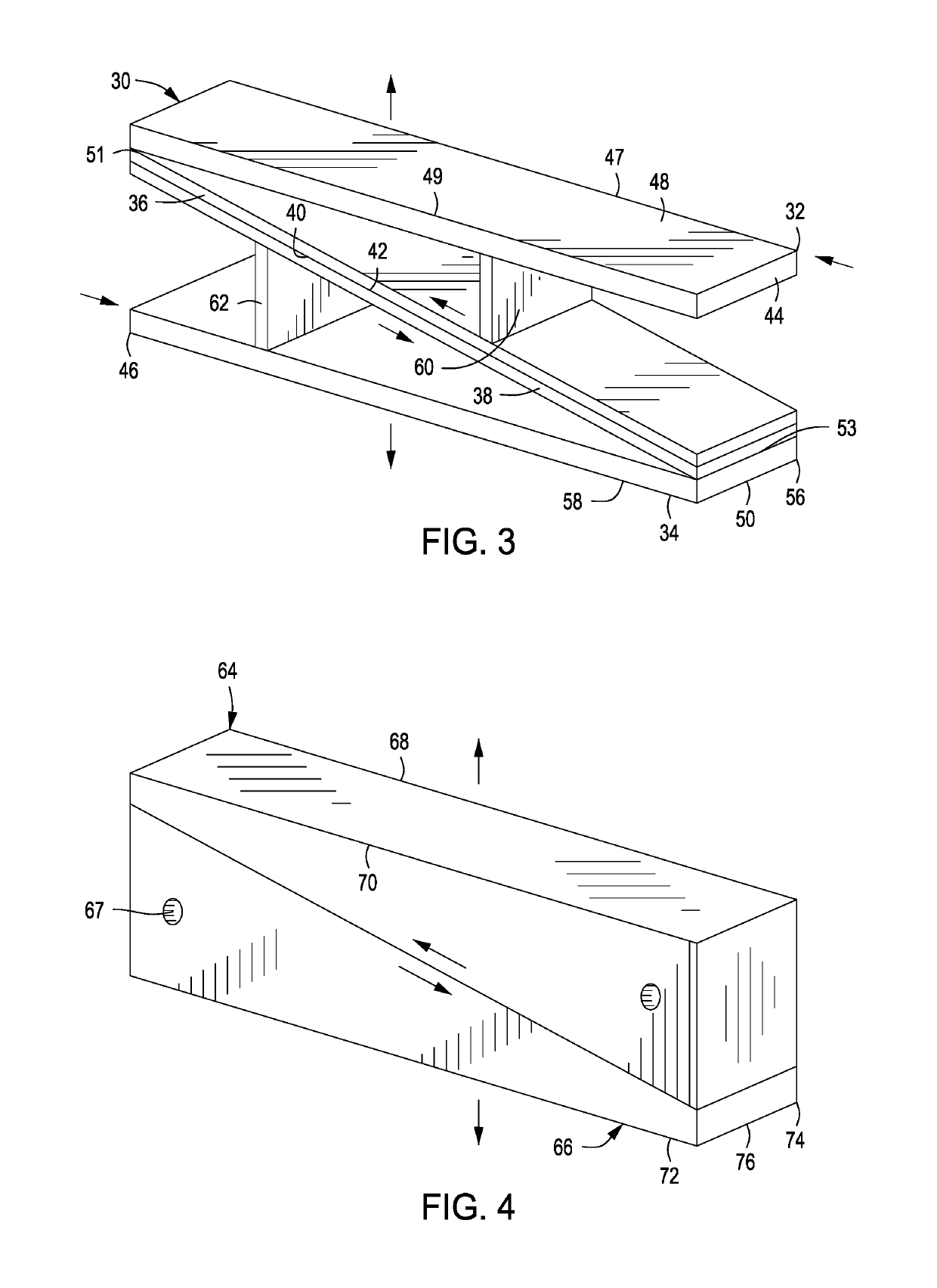

Tray for an exposure machine

ActiveUS20150124235A1Efficient pressingAccurate horizontal positionSemiconductor/solid-state device manufacturingCircuit board tools positioningEngineeringFixed position

A tray for a panel exposure machine, and also such a machine, enabling a panel to be retained and pressed down so as to be presented facing an exposure device. The tray comprises a work surface (13) adapted to receive panels of different sizes, said work surface (13) being substantially plane and possessing first and second adjacent edges (13a, 13b) extending along substantially orthogonal first and second directions (X, Y) defining a reference corner (C); and first and second holder devices (30a, 30b) of a first type and at least a first holder device (40a) of a second type, each holder device being actuatable between a holding, first state in which it exerts pressure directed towards the work surface (13), thereby defining a holding position, and a rest, second state in which said pressure is released; a positioning device (14) arranged along at least a portion of the first edge (13a) and along at least a portion of the second edge (13b); the holder devices (30a, 30b) of the first type extend along at least a portion of the first and second edges (13a, 13b) respectively, their holding positions being fixed in a plane parallel to the work surface; the holder device (40a) of the second type is movable in a plane parallel to the work surface (13) in order to adapt its holding position as a function of the size of the panel in use.

Owner:ALTIX

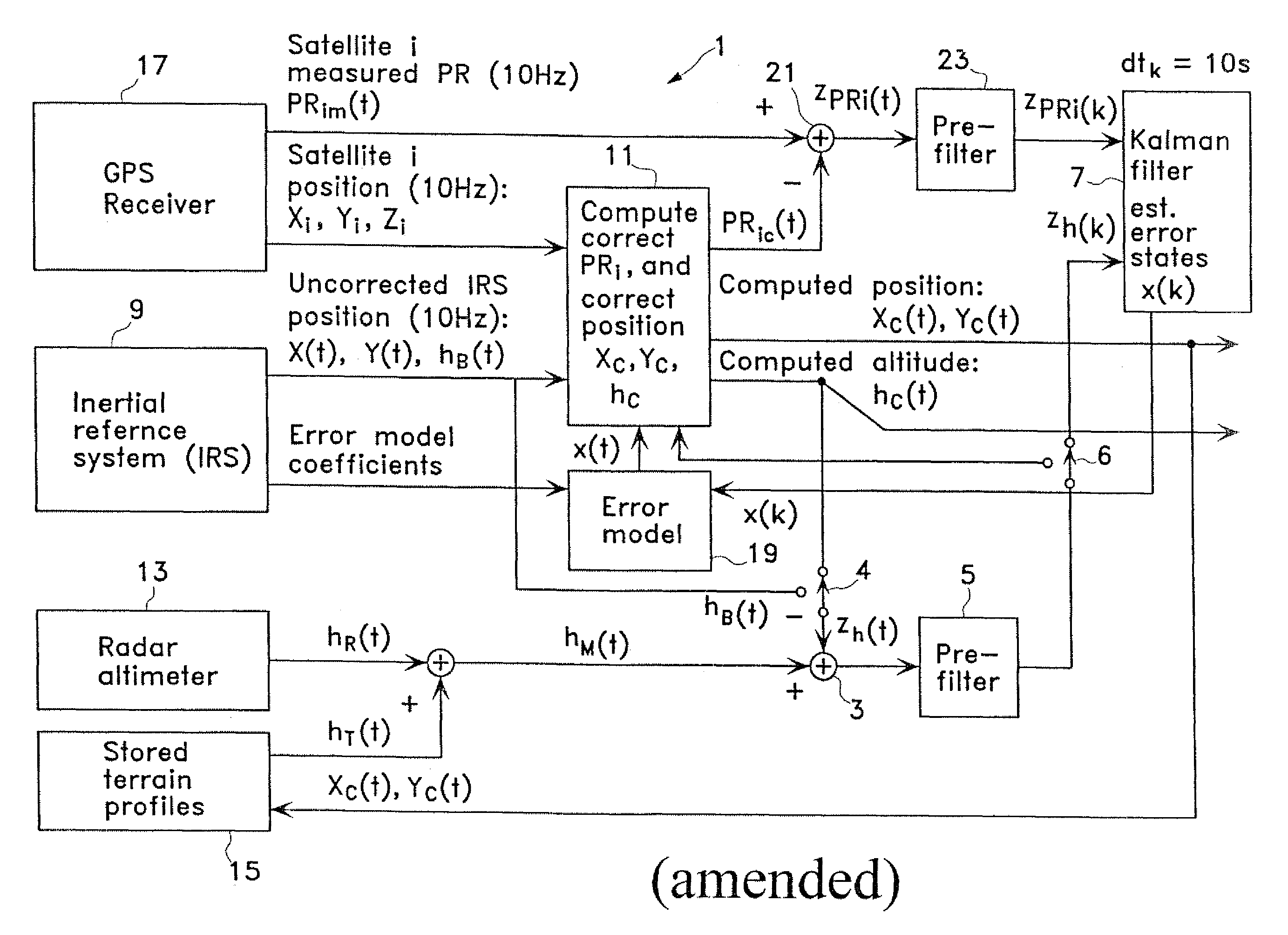

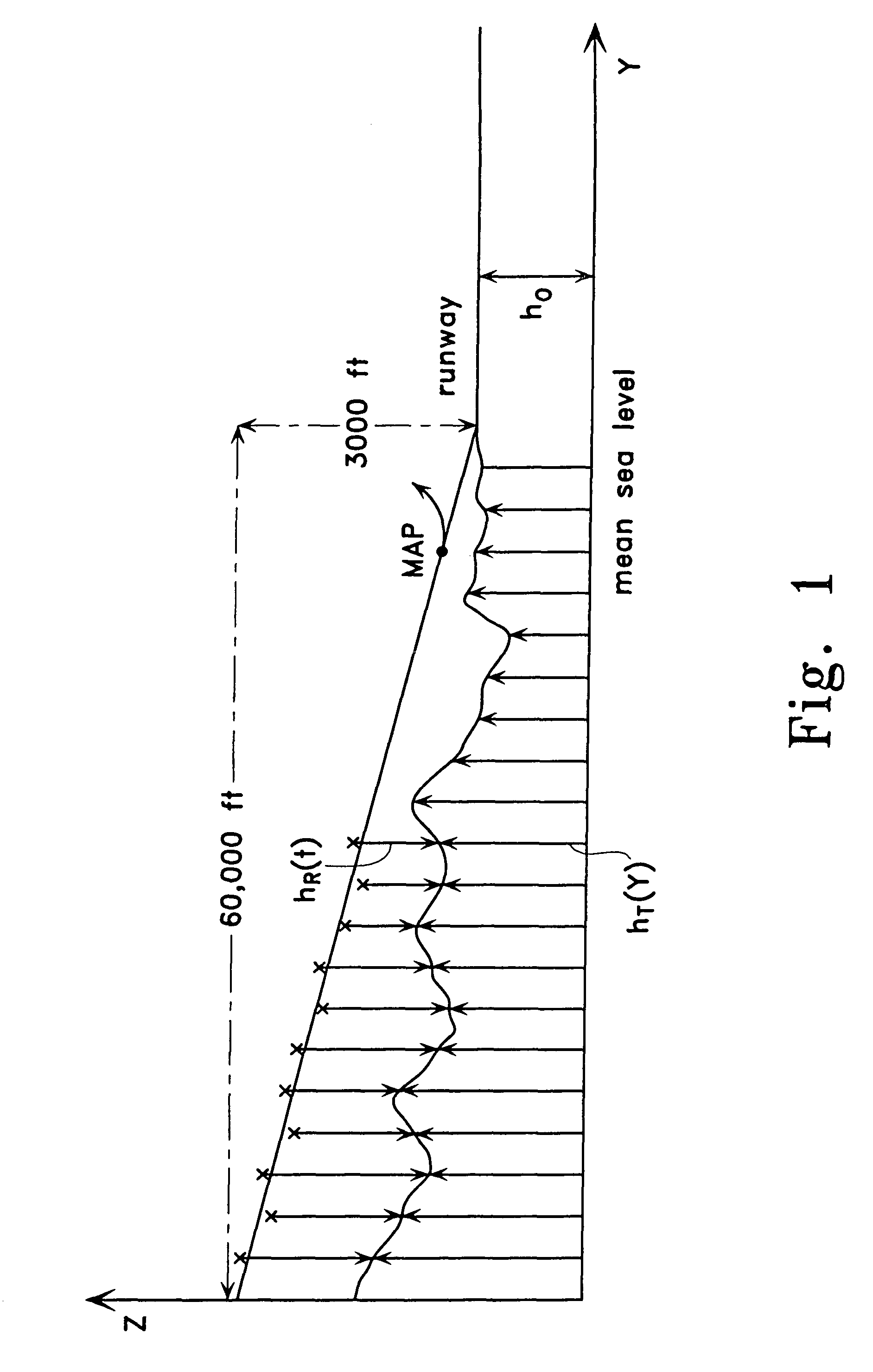

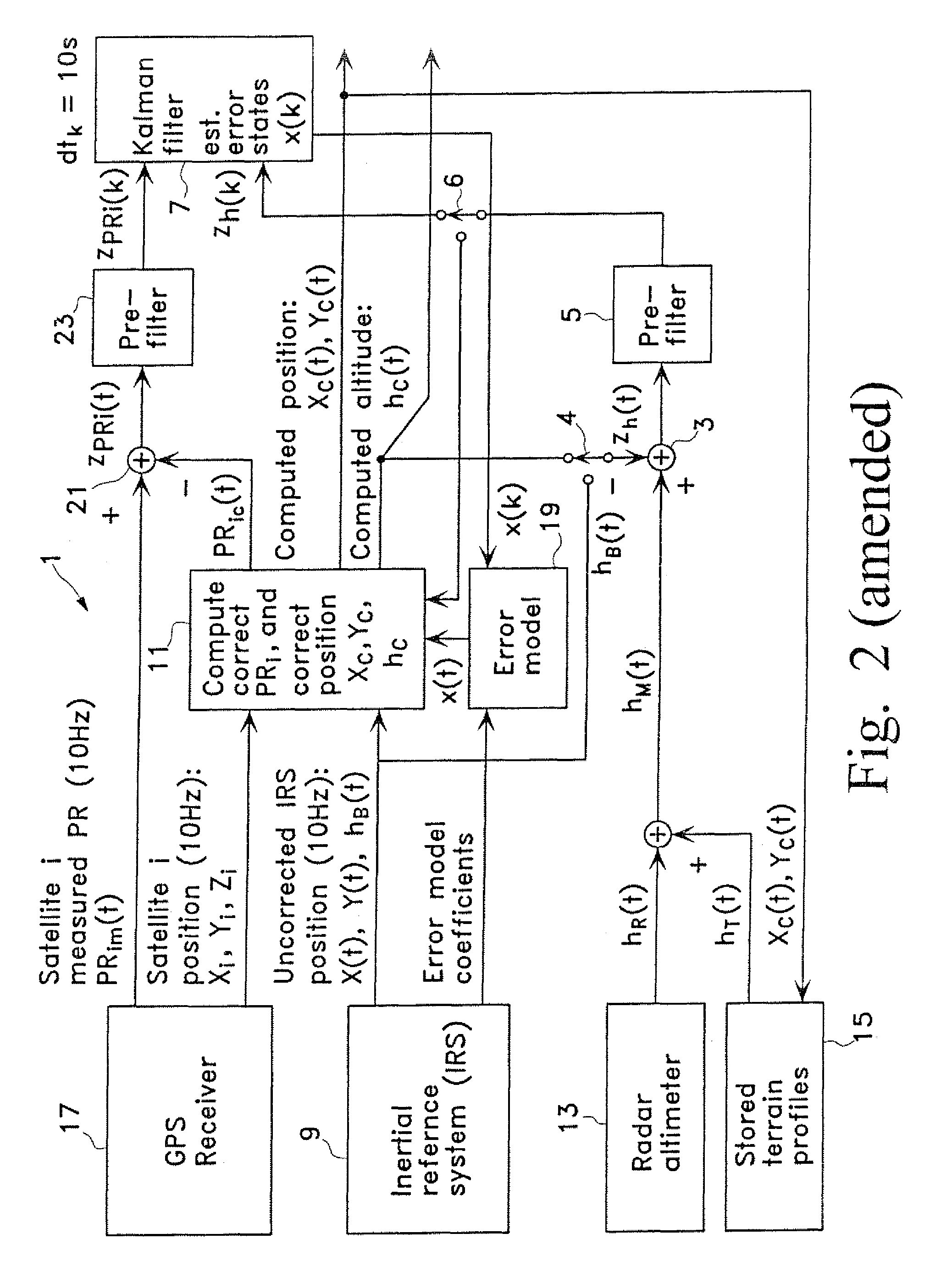

3D AIME™ aircraft navigation

InactiveUSRE42891E1Accurate horizontal positionImprove integrityInstruments for road network navigationCosmonautic vehiclesTerrainKaiman filter

The apparatus of the present invention uses radar altimeter measurements and stored terrain altitude profiles to provide pre-filtered observations to a Kalman filter for estimating barometric offset at the airport runway, and barometric scale factor for offsets above the runway. These offsets are used with the smoothed baro-inertial output from an inertial reference system to provide 3 dimensional constant rate of descent approach procedures to replace non-precision approach procedures based on constant barometric altitude step approaches. The horizontal positions used as reference for the stored terrain altitude profiles are obtained from a prior art navigation apparatus. The integrity of all measurements is assured by using long term averages of the Kalman filter residuals to detect failures. In addition, the estimated baro offset at the runway is compared for consistency with the baro offset obtained by the pilot from the airport by radio.

Owner:NORTHROP GRUMMAN SYST CORP

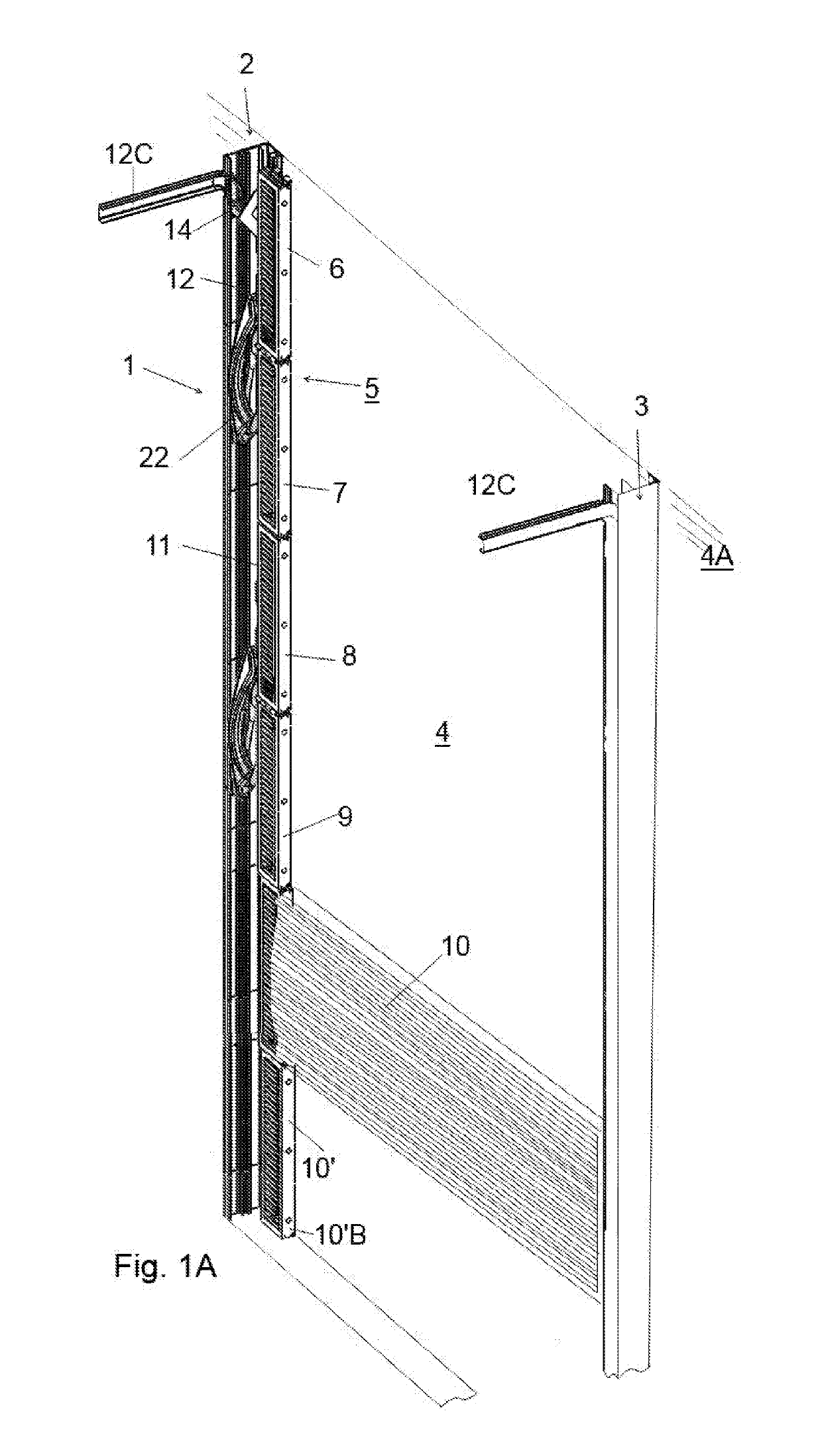

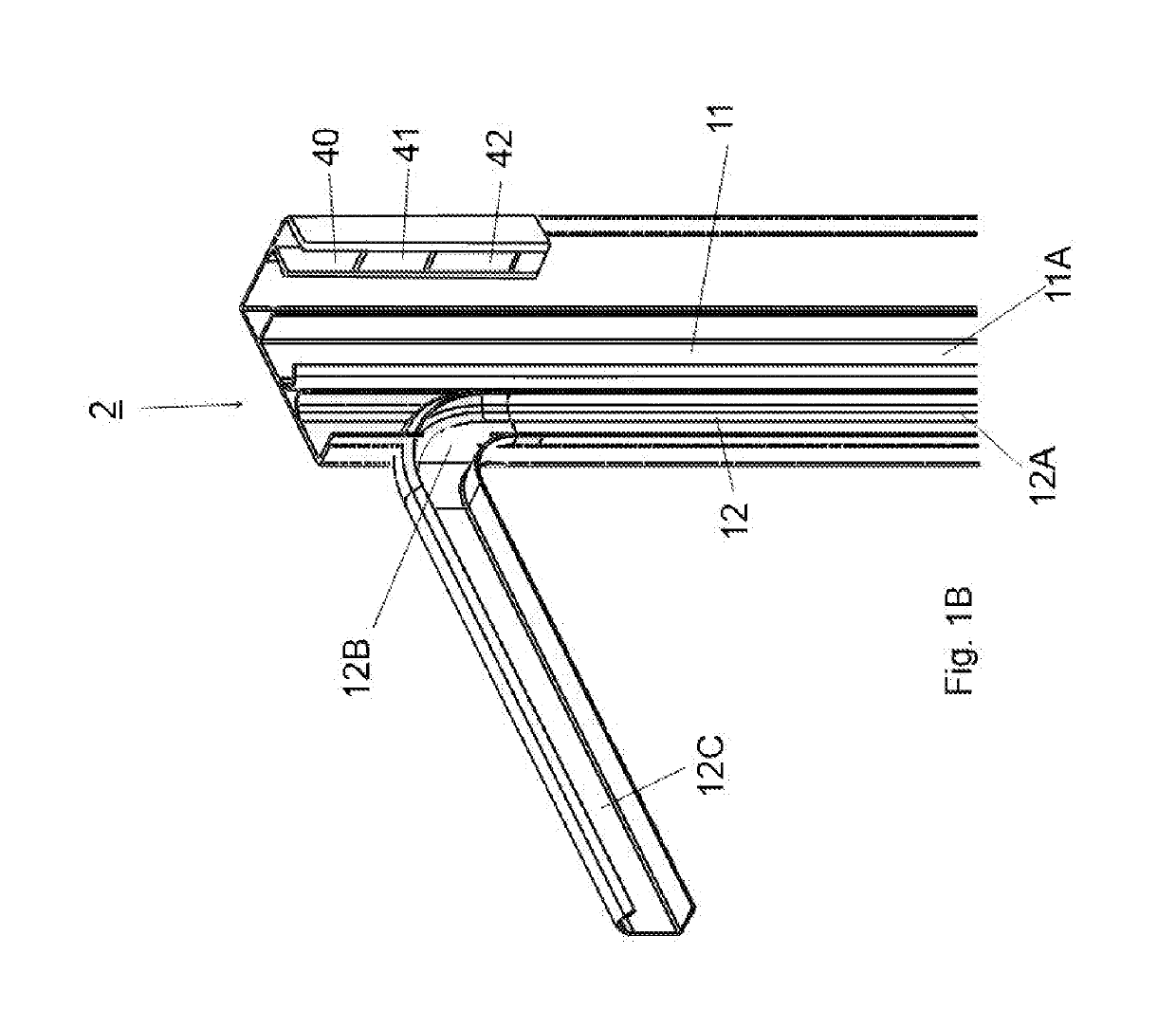

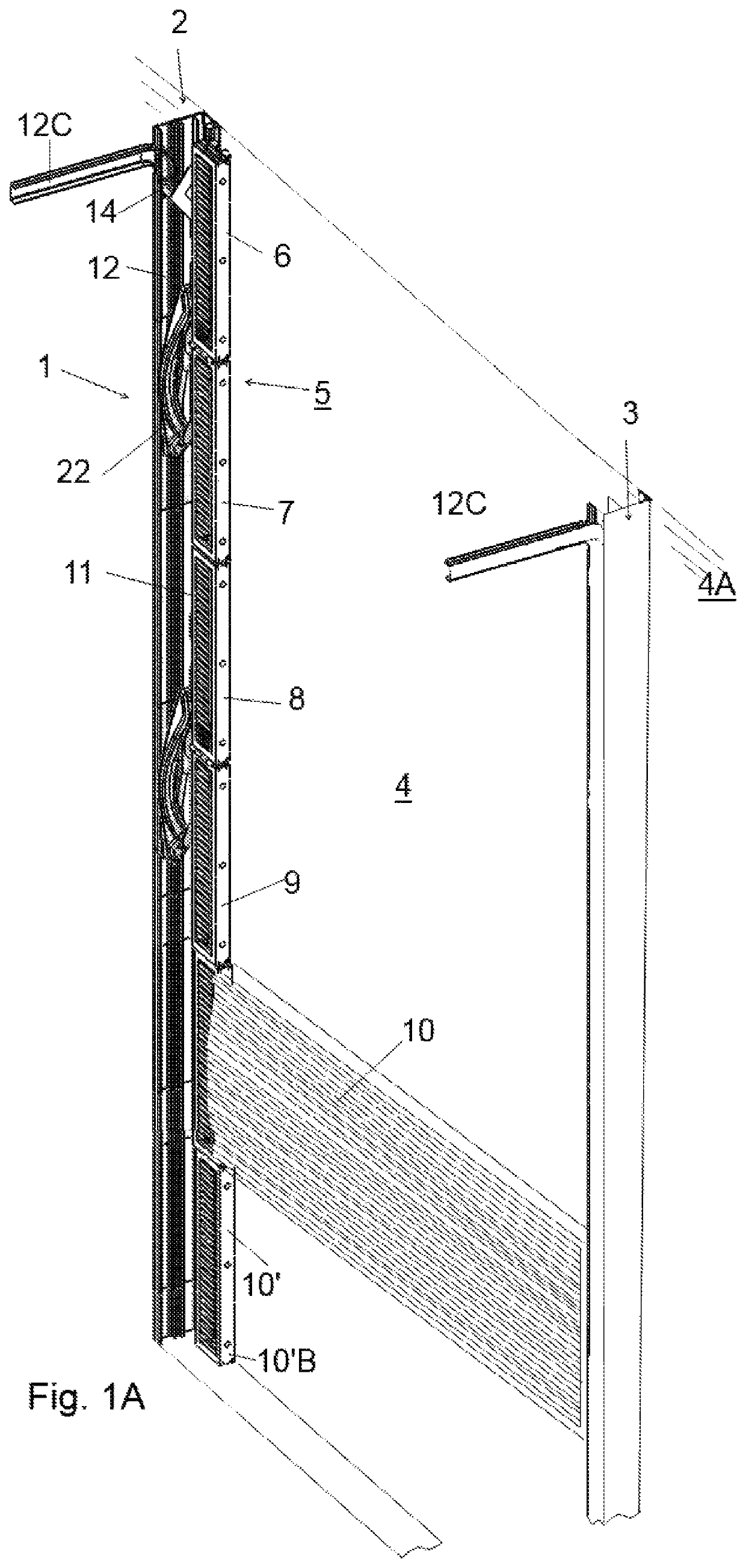

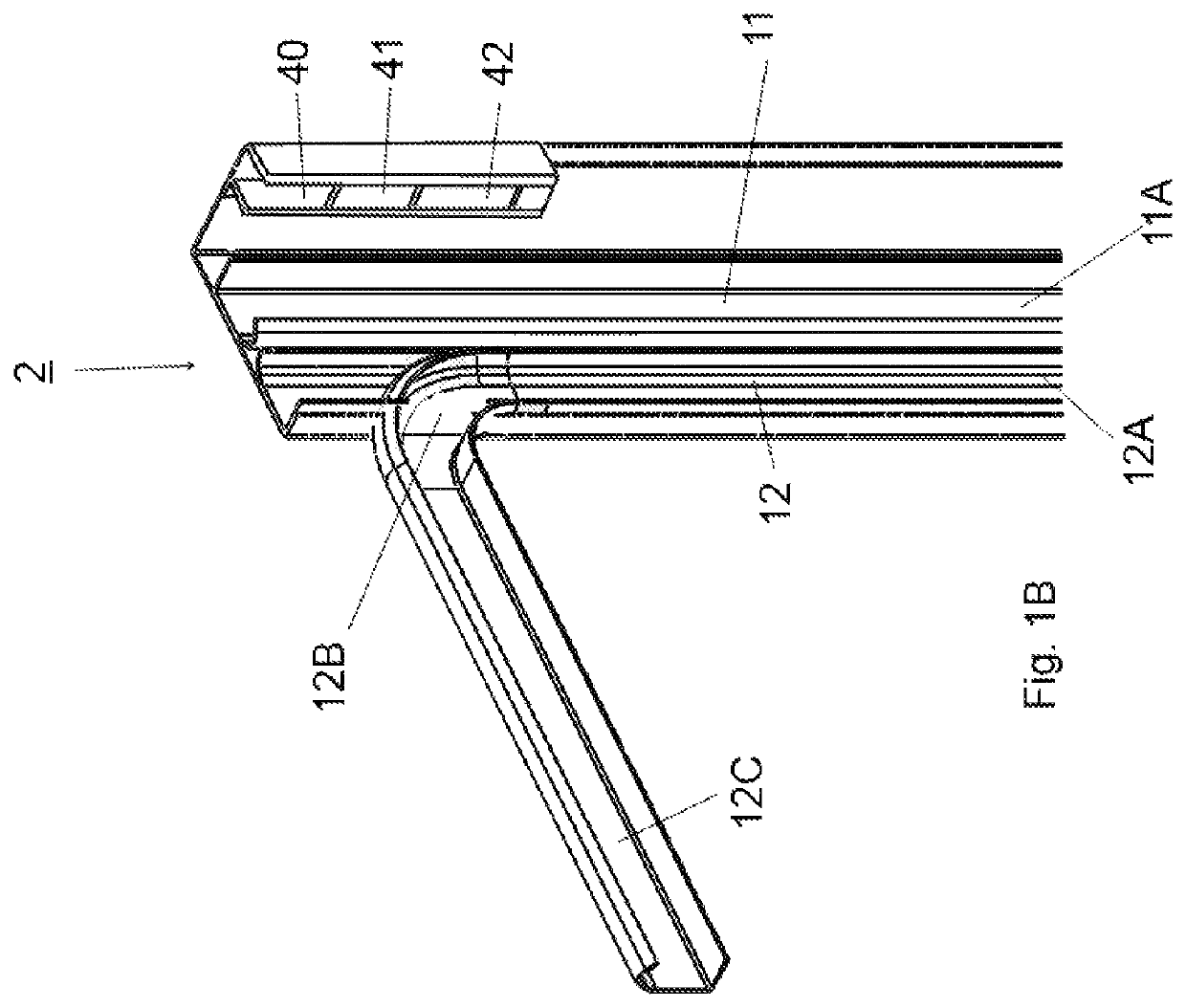

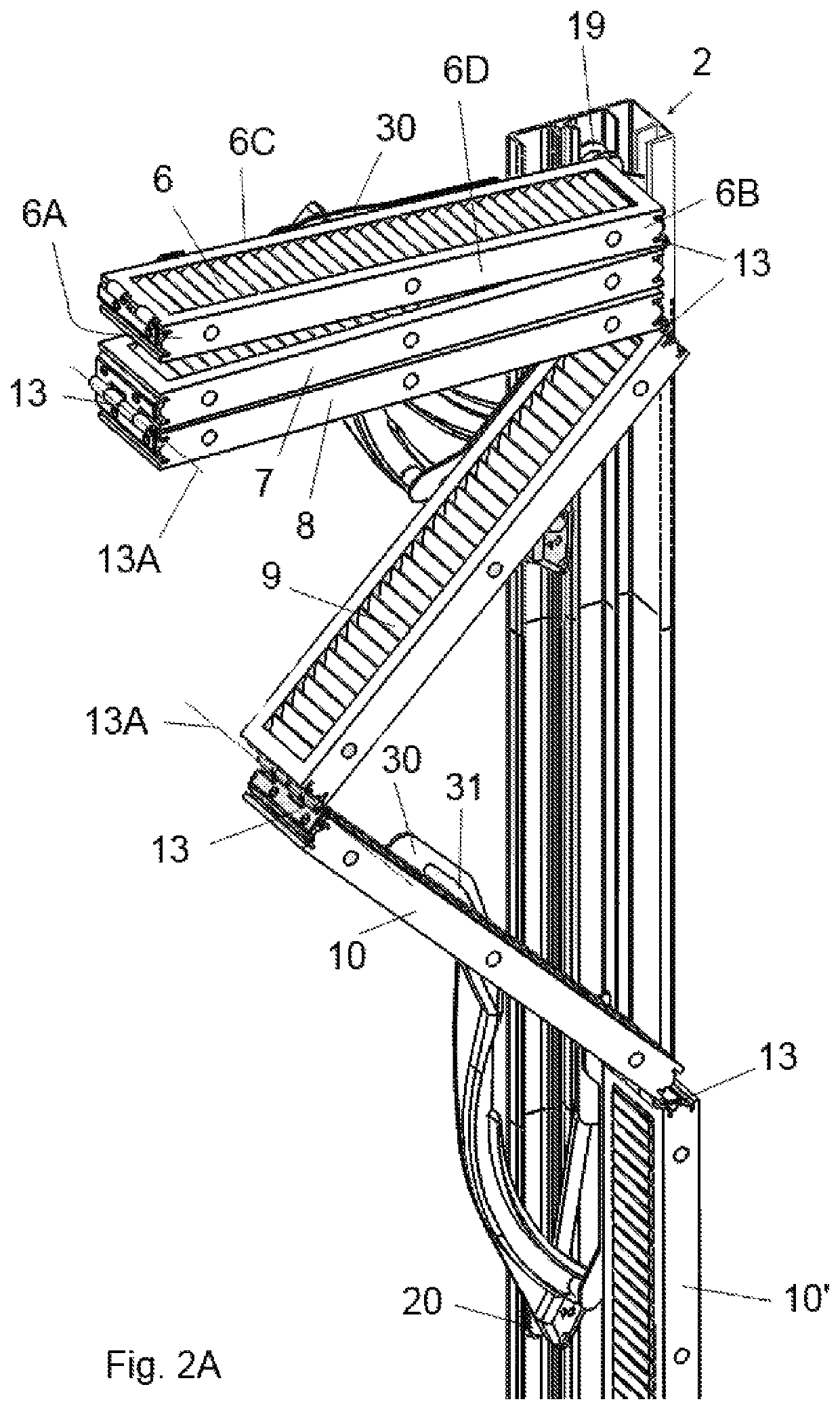

Sectional folding overhead door assembly

ActiveUS20190330913A1Reduce in quantityHeavyShutters/ movable grillesWing arrangementsEngineeringMovement control

A sectional folding overhead door assembly comprising a pair of opposite, vertically disposed side support and guide means defining a door opening between them, each guide means including a first channel and a second channel disposed side-by-side, a door component comprising a first, second, third and fourth rectangular panel adapted for folding vertical movement along said support and guide means, the door component further comprises at each side of the first and second panel a folding movement controlling member, each folding movement controlling member having an folding movement controlling member upper end hingeably connected to a respective side edge of the first and third panel, respectively, and a folding movement controlling member lower end hingeably connected to the respective guide plate lower end around a folding movement controlling member hinge axis, each folding movement controlling member further including a folding movement guiding channel into which folding movement guiding channel a respective side plate guiding pin of a side plate attached to the second panel extends.

Owner:ROLFLEX EXPL BV

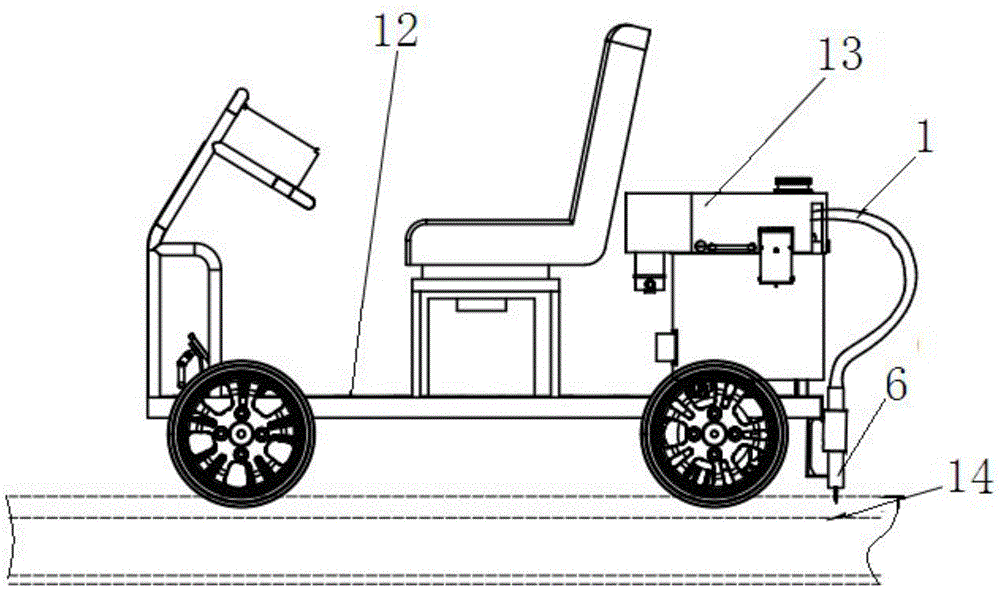

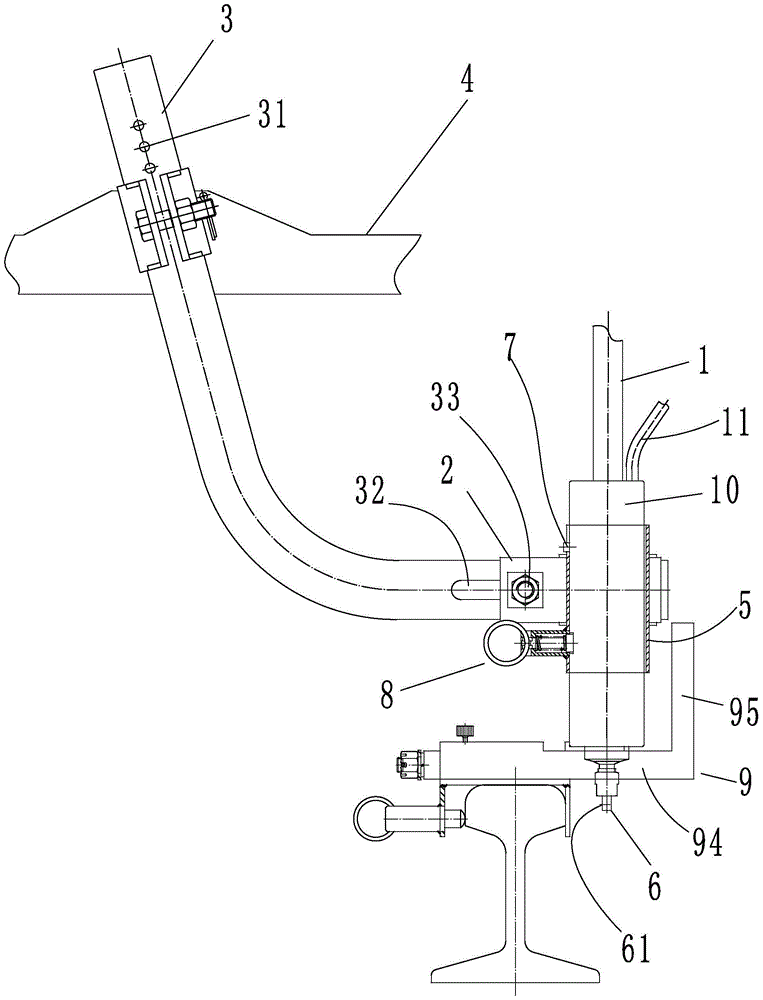

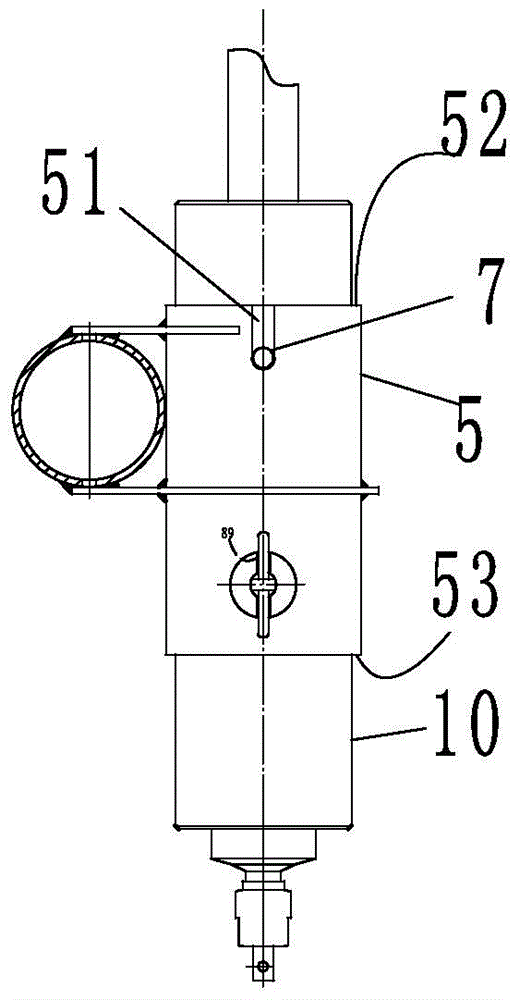

Electric curved rail lubricant coating vehicle

ActiveCN105416339BEasy to assemble and disassembleEasy to get offRail lubricationRail wetting/lubricationSpray nozzleEngineering

The invention discloses an electric curve steel rail lubricating agent coating vehicle which comprises a rail vehicle and a coating device. The coating device comprises a control structure, a lubricating agent container, a lubricating oil pump and a lubricating agent spraying structure. The control structure controls the start action of the lubricating oil pump. The rail vehicle comprises a front axle with a front moving wheel and a rear axle with a rear moving wheel. The front axle is connected with the rear axle through a vehicle body. The front moving wheel and the rear moving wheel are matched with a rail. The rail vehicle and the lubricating oil pump are powered by a direct current power source. The control structure, the lubricating agent container and the lubricating oil pump are arranged above the rear portion of the rail vehicle. The lubricating agent spraying structure is arranged below the rear portion of the rail vehicle. The lubricating agent spraying structure is connected with a shaft box of the rail vehicle and is connected with the lubricating oil pump through an oil spraying pipe. A side spraying nozzle of the lubricating agent spraying structure corresponds to a curve steel rail outer gauge corner. By the adoption of the electric curve steel rail lubricating agent coating vehicle, assembly and disassembly are convenient, rail entering is convenient, coating efficiency is high, and the problem that manual coating is low in efficiency and poor in effect is solved.

Owner:济南三新铁路润滑材料有限公司

All-in-one machine for vacuum forming, molding and punching

InactiveCN101774273BAvoid lateral displacementAccurate horizontal positionMetal working apparatusTrappingEngineering

The invention relates to an all-in-one machine for vacuum forming, molding and punching, comprising a rack, a material traction device, a heating device, a forming unit, a punching device and a control device; wherein a top die platform and a bottom die platform of the forming device are provided with moulding moulds which are thereupon provided with a convex part or a concave part for forming a light trapping bump on plastic sheets; the punching device comprises a punching shear mechanism, a guide rail which moves frontwards and backwards and a photocell eye for detecting the light trapping bump; the guide rail is arranged in the front of the punching shear mechanism, the photocell eye is arranged in the front of the punching shear mechanism and is connected with a corresponding input terminal corresponding to the control device.In the invention, when forming is carried out, the light trap bump can be formed on the plastic sheet, the flaky plastic products can be prevented from transversely displacing by the guide of the guide rail, the photocell eye can be used to detect the light trap bump and the control device can be used to lead the material traction device to convey the flaky plastic products to preset distance, so that the longitudinal position of the plastic products is accurate when the plastic products enter the punching shear mechanism and the flaky plastic products can accurately arrive at the preset position of the punching mechanism.

Owner:广东金兴机械股份有限公司

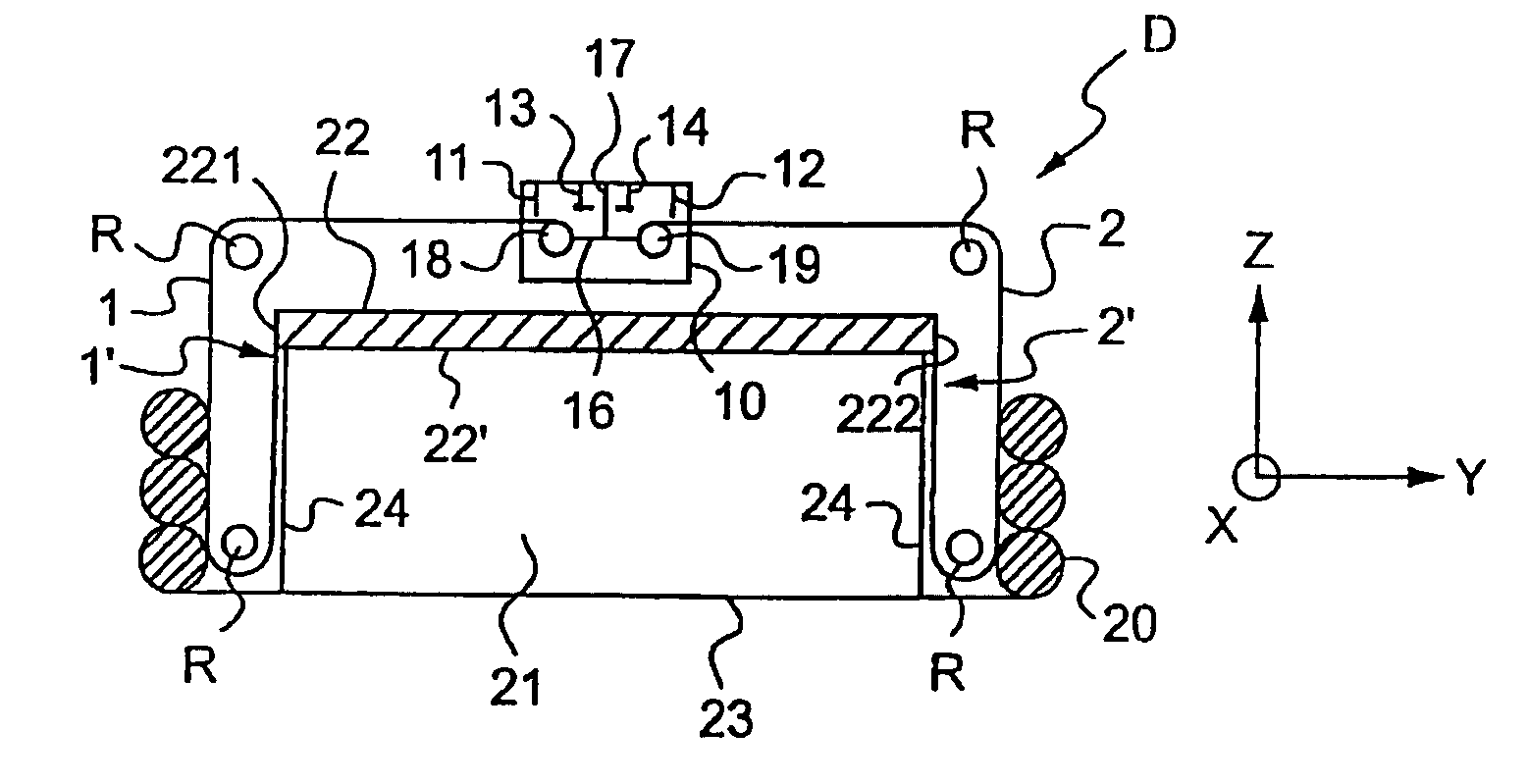

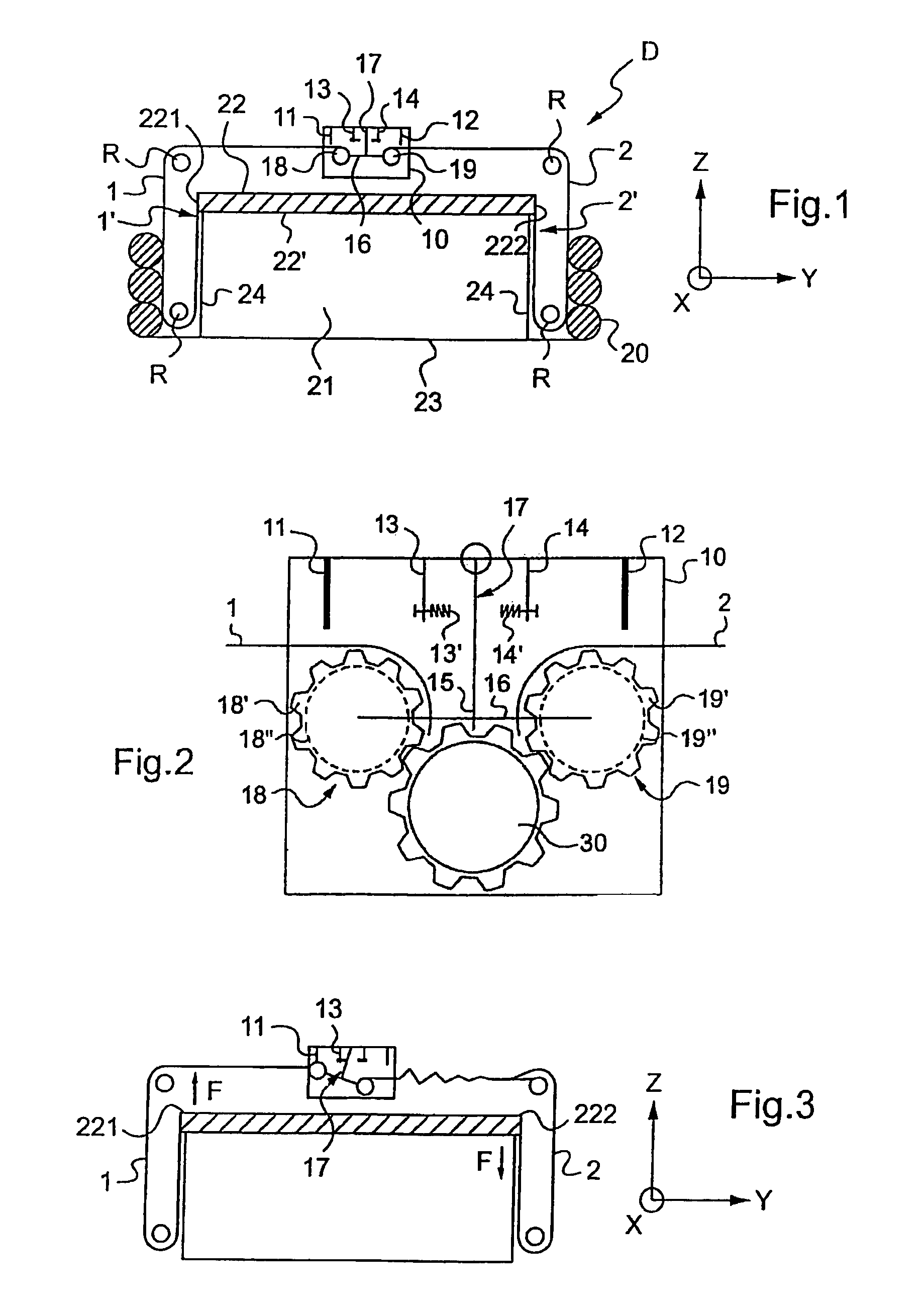

Device for opposing sloshing in a flexible tank

ActiveUS8136764B2Inhibition effectAccurate horizontal positionCosmonautic vehiclesPower plant fuel tanksEngineeringFlexible tanks

A device (D) for opposing sloshing in a flexible tank (21) provided with a top cushion (22) and having a bottom (23) and a plurality of sides (24), the device includes at least first and second ties (1 and 2). The first and second ties (1 and 2) are secured respectively to first and second edges (221 and 222) of the cushion, with the first edge (221) being opposite from the second edge (222). The device is remarkable in that it includes main distributor elements (10) for blocking only one of the ties when the tension exerted on that tie is greater than the tension exerted on the other tie, the first and second ties (1 and 2) also being secured to the main distributor unit (10).

Owner:EUROCOPTER

Method and apparatus for precision alignment and tack welding of weld-neck pipe fittings to pipe

InactiveUS10300566B2Simple and efficient positioningSufficient forceFlanged jointsWelding/cutting auxillary devicesLinear motionPipe fitting

Internal clamping of a weld-neck fitting to a pipe in preparation for precision tack welding of the fitting to the pipe is established by a pair of alignment and clamping wedge members, each having alignment and gripping members and angulated reaction surfaces which are positioned within the pipe and weld-neck fitting with the angulated reaction surfaces in relatively moveable engagement. One of the alignment and clamping wedge members is moved linearly, causing the angulated reaction surfaces to translate the linear movement to lateral movement, forcing the alignment and gripping members laterally against the internal surfaces of the pipe and fitting and supporting the fitting in precision aligned relation with the pipe to facilitate tack welding. A gauge member confirms precision alignment of the fitting with the pipe before and after applying the tack welds, then the alignment and clamping apparatus is loosened by opposite linear movement of the wedge members which are removed to permit final weld connection of the fitting to the pipe.

Owner:BRANTLEY RICHARD

Tool assembly for machining inner spherical surfaces

InactiveCN104511603ASimple structureEasy to operateAutomatic conveying/guiding stockTurning toolsEngineeringMachining process

The invention relates to a tool assembly for machining inner spherical surfaces. The tool assembly is characterized in that a supporting seat is fixed on a central supporting plate in the front of a lathe square tool post, and a guide rod is fixed in an inner hole of the supporting seat. A tool sleeve is fixed at the front end of the guide rod through a hinge pin I and is connected with a sliding threaded sleeve through a connection rod, and the connection rod is connected with the tool sleeve through a hinge pin II. A tool body is fixed in the tool sleeve through a screw, a threaded rod is screwed in the sliding threaded sleeve, and a handle is connected with the end of the threaded rod. The tool assembly has the advantages of being accurate in spherical center location, suitable for being produced in batch, simple in structure, easy to operate and capable of not affecting other machining processes.

Owner:李旭

A brain contrast medium injection device

ActiveCN112316249BControl doseAccurate horizontal positionAutomatic syringesIntravenous devicesHuman bodyPhysical medicine and rehabilitation

The invention discloses a cerebral cistern contrast medium injection device, which comprises a left and right moving mechanism, a lifting mechanism and an injection mechanism. The horizontal movement of the left and right moving mechanism enables the entire operating table to be adjusted in the horizontal direction through the cooperative movement of the worm gear. The lifting mechanism realizes the adjustment of the position of the console in the vertical direction through the cooperative movement of two sets of bevel gears and the rack and pinion. The injection mechanism injects the to-be-injected agent into the human body through the swing of the link mechanism and the sliding of the slider mechanism, and completes the human body injection of the contrast medium in the brain cisterns.

Owner:THE PEOPLES HOSPITAL SHAANXI PROV

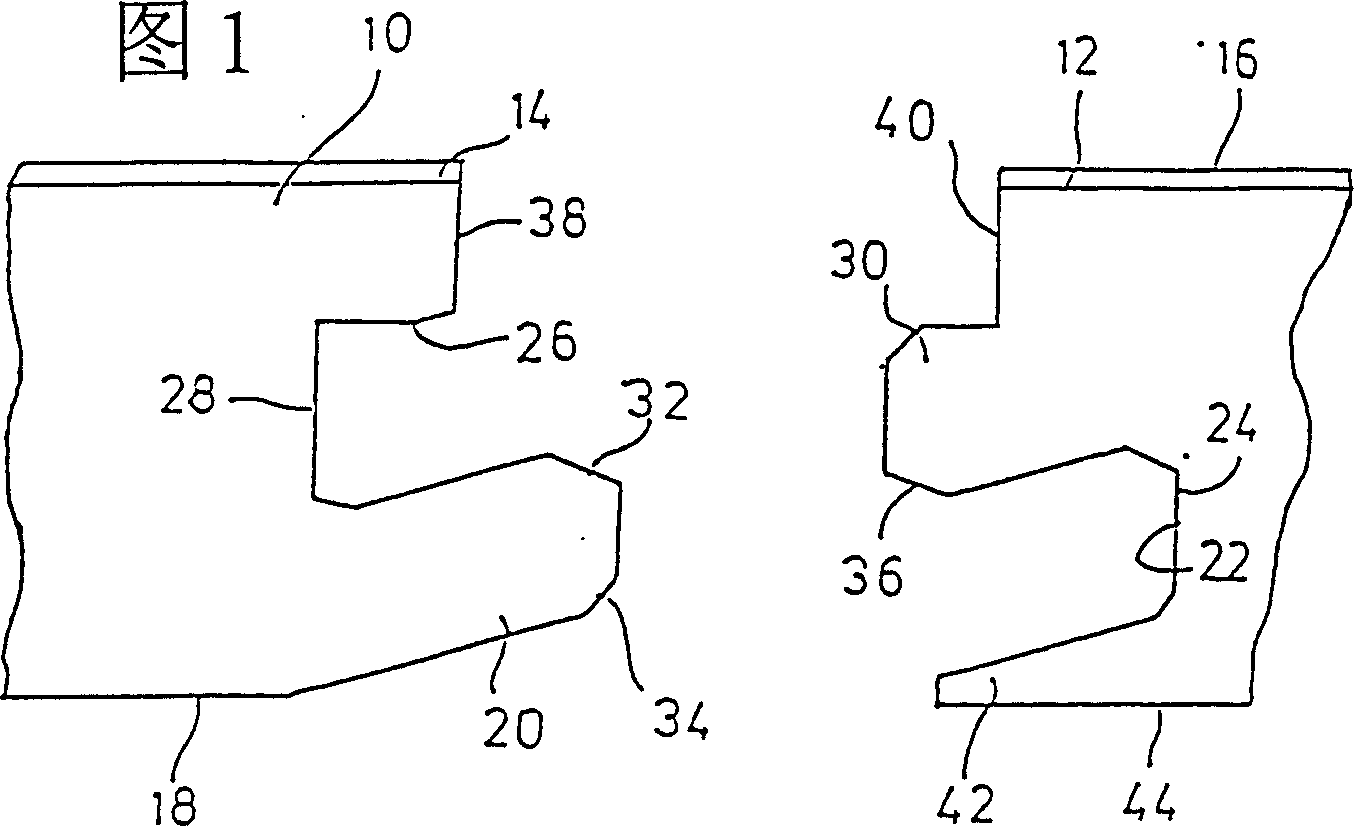

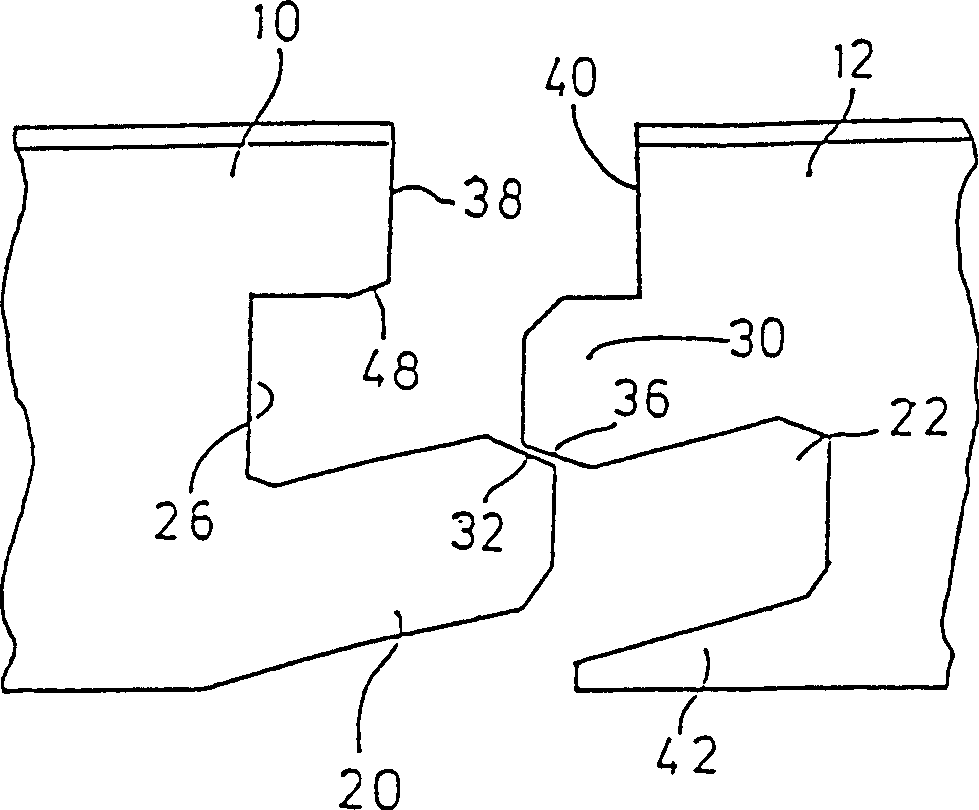

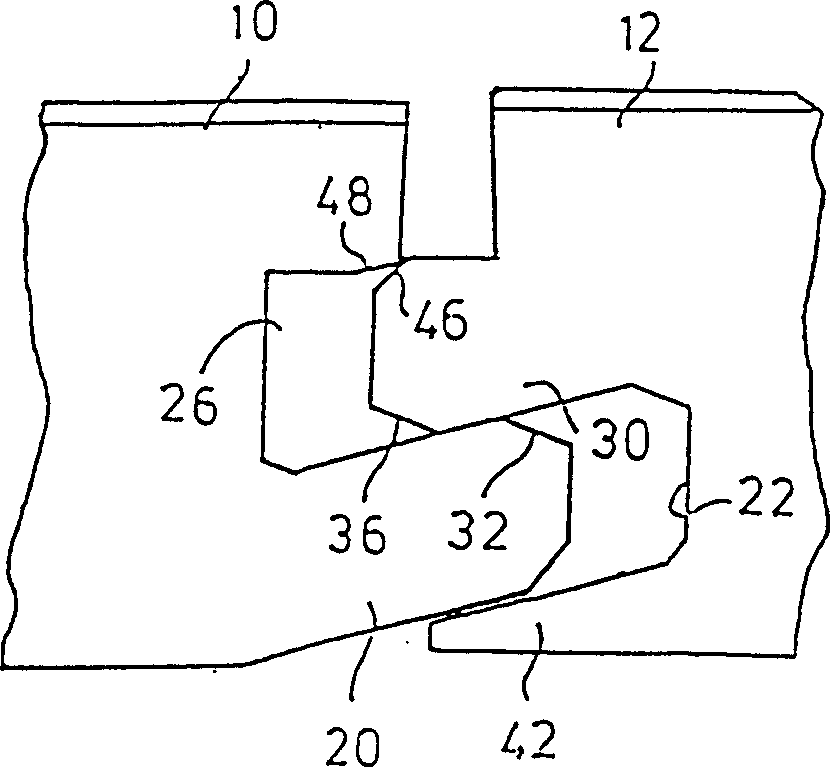

Floor covering plate

InactiveCN1211550CAccurate horizontal positionAvoid warpingFlooringConnectionsEngineeringFloor covering

The invention relates to a floor covering plate, especially a laminated panel, wooden flooring element or the like, comprising an edge profile section on at least two opposite-lying edges in the form of a modified groove and tongue assembly which is used to connect adjacent plates, a further arrangement respectively consisting of a groove (22, 122, 26, 126) and a tongue (20, 120, 30, 130) on the at least two edges, whereby the tongue on one edge of the first plate ascends at a slanted angle and the groove on an associated edge of a second plate ascends at a slanted angle from the lower part of the plate. The edge profile sections are directly incorporated into the support material of the floor covering plate, the groove (26, 126) of the first plate being located directly above the tongue associated therewith (20, 120) and the lower wall of the groove descending towards the bottom of the groove (28, 128) as the tongue (20, 120) of the first plate ascends. The upper wall of the groove (26, 126) of the first plate (10, 110) extends in a substantially parallel manner in relation to the plane of the plate and the tongue (30, 130) of the second plate (12, 112) is provided with an upper surface lying substantially parallel to the plane of the plate, whereby a lower surface extends downwards as far as the end of the tongue (30, 130), corresponding to the shape of the groove (26, 126).

Owner:WINDMOLLER FLOORING PROD

Sectional folding overhead door assembly

ActiveUS11156029B2Reduce in quantityPanel is often heavyShutters/ movable grillesWing arrangementsEngineeringStructural engineering

A sectional folding overhead door assembly that includes a pair of opposite, vertically disposed side supports and guides defining a door opening between them, each of the supports and guides including a first channel and a second channel disposed side-by-side, a door component having a first, second, third and fourth rectangular panel adapted for folding vertical movement along the supports and guides, a folding movement controlling member, each folding movement controlling member having a folding movement controlling member upper end hingeably connected to a respective side edge of the first and third panels, respectively, and a folding movement controlling member lower end hingeably connected to the respective guide plate lower end around a folding movement controlling member hinge axis, and a folding movement guiding channel into which a respective side plate guiding pin of a side plate attached to the second panel extends.

Owner:ROLFLEX EXPL BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com