Feed mechanism of VCP (vertical continuous plating) plating line

A material feeding and sheet material technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of high labor intensity, low efficiency, affecting processing, etc., and achieve the effect of improving work efficiency, facilitating subsequent processing, and accurate feeding position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

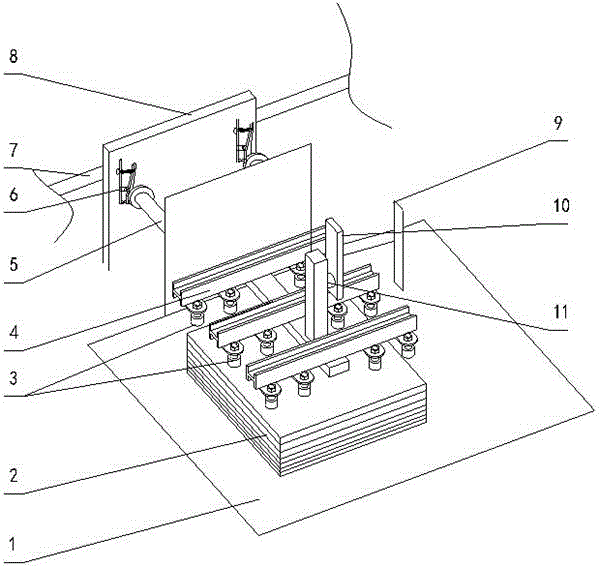

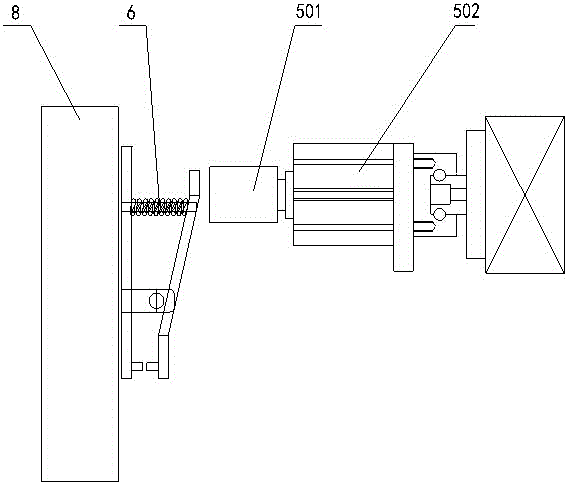

[0012] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] Such as Figure 1 to Figure 2 As shown, the feeding mechanism of the VCP production line disclosed by the present invention includes a frame, a controller, a sheet material storage platform 1 fixed on the frame, and a horizontal transfer device 7, and the upper part of the sheet material storage platform 1 is provided with The suction cup device 4 corresponding to the sheet material 2 stored therein, for example, in a specific implementation, a plurality of suction nozzles 3 corresponding to the stored sheet material 2 are evenly distributed on the lower part of the suction cup device 4, and the suction nozzles 3 pass through the trachea (not shown in the figure) is connected with the air pump, the suction cup device 4 absorbs the sheet material 2 piece by piece through the suction nozzle 3, and the suction cup device 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com