Patents

Literature

274results about "Rail lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

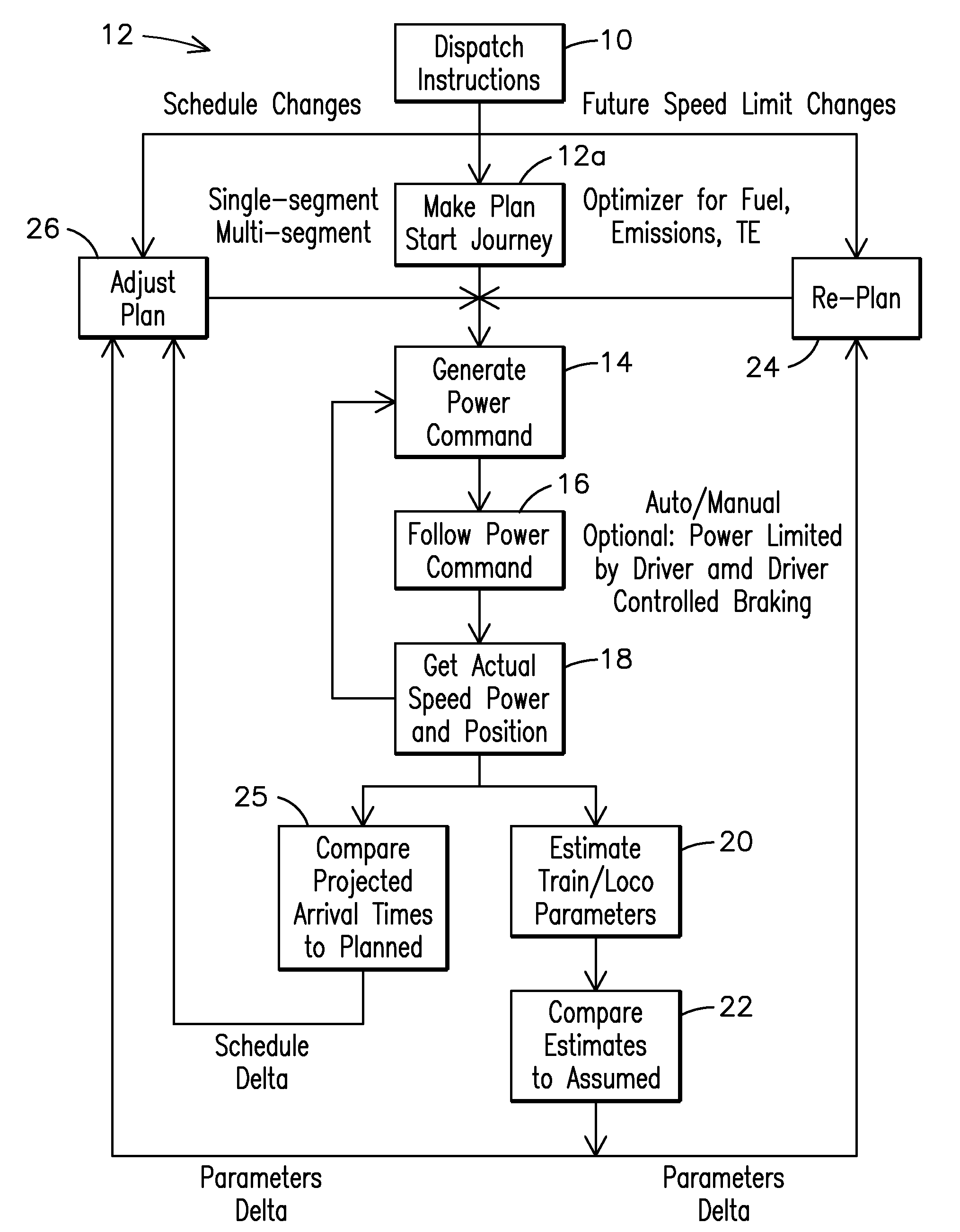

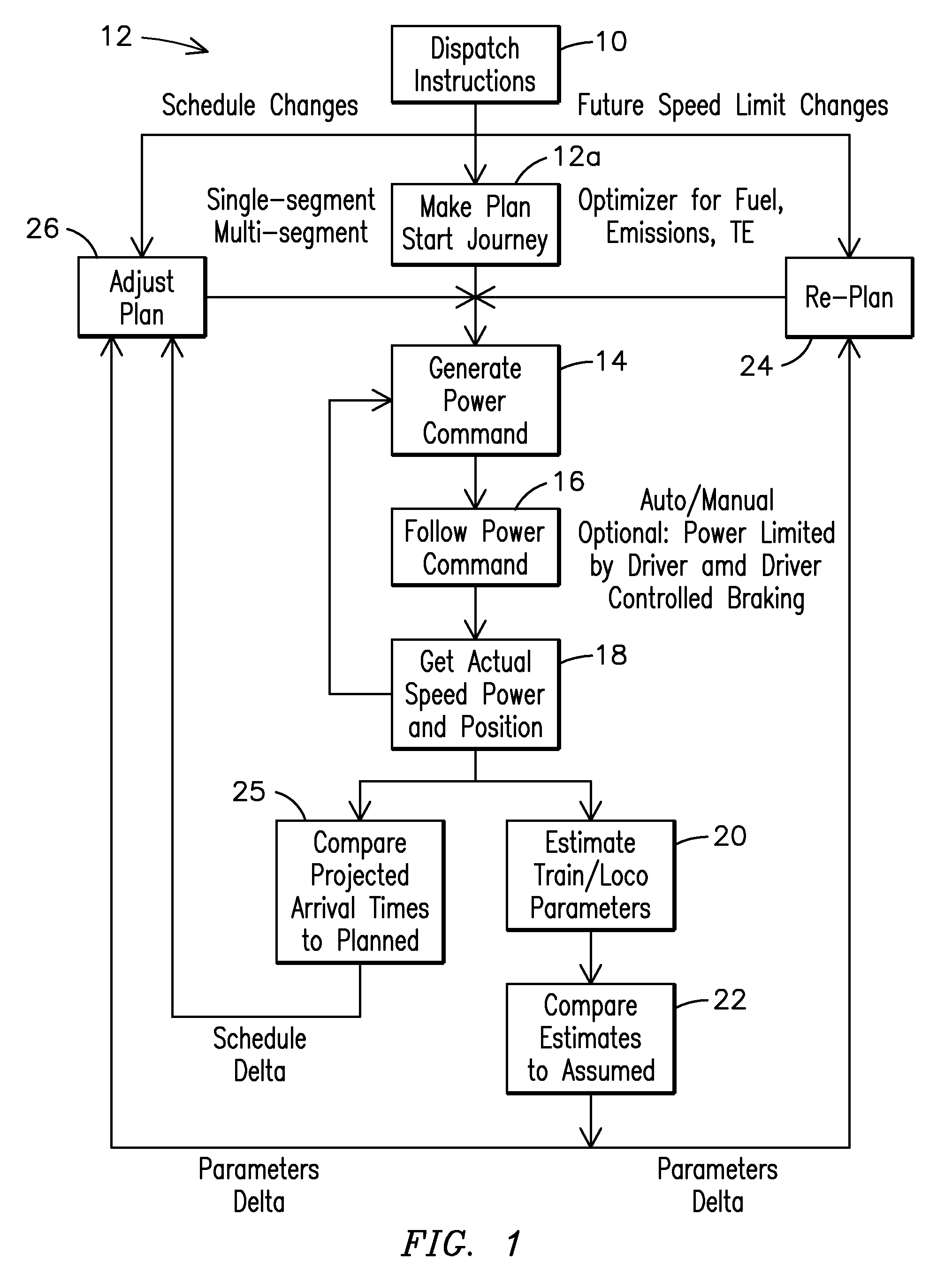

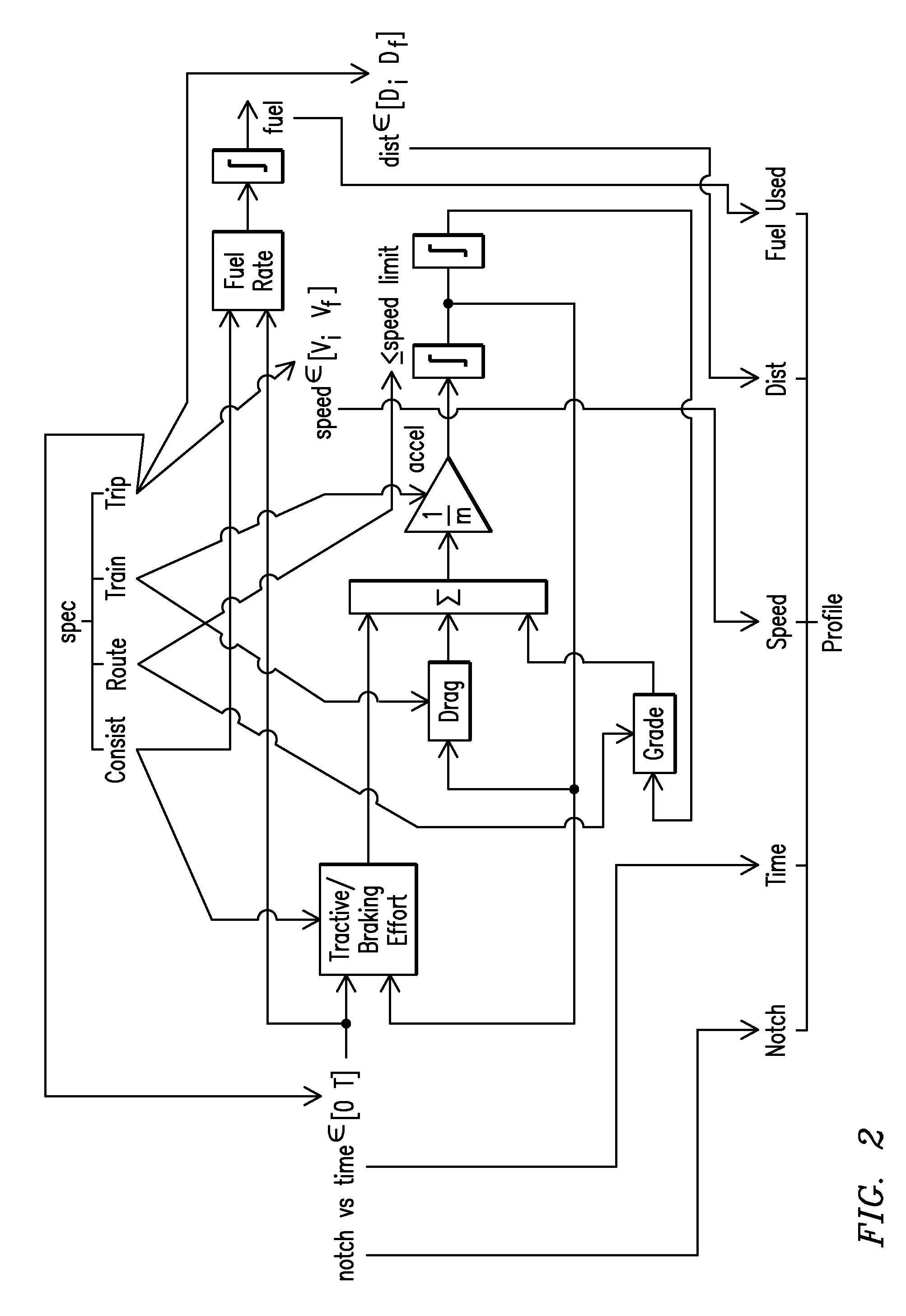

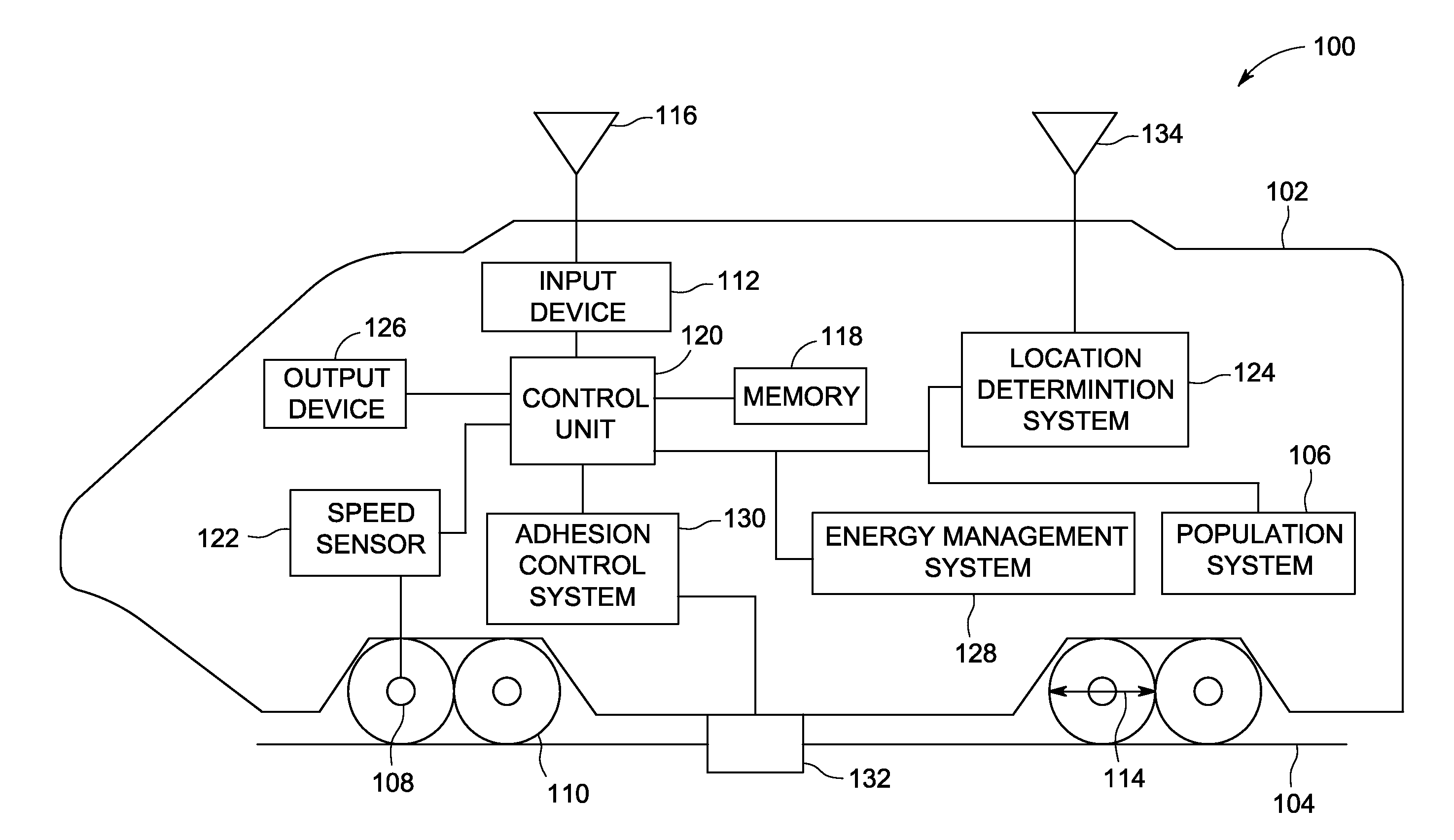

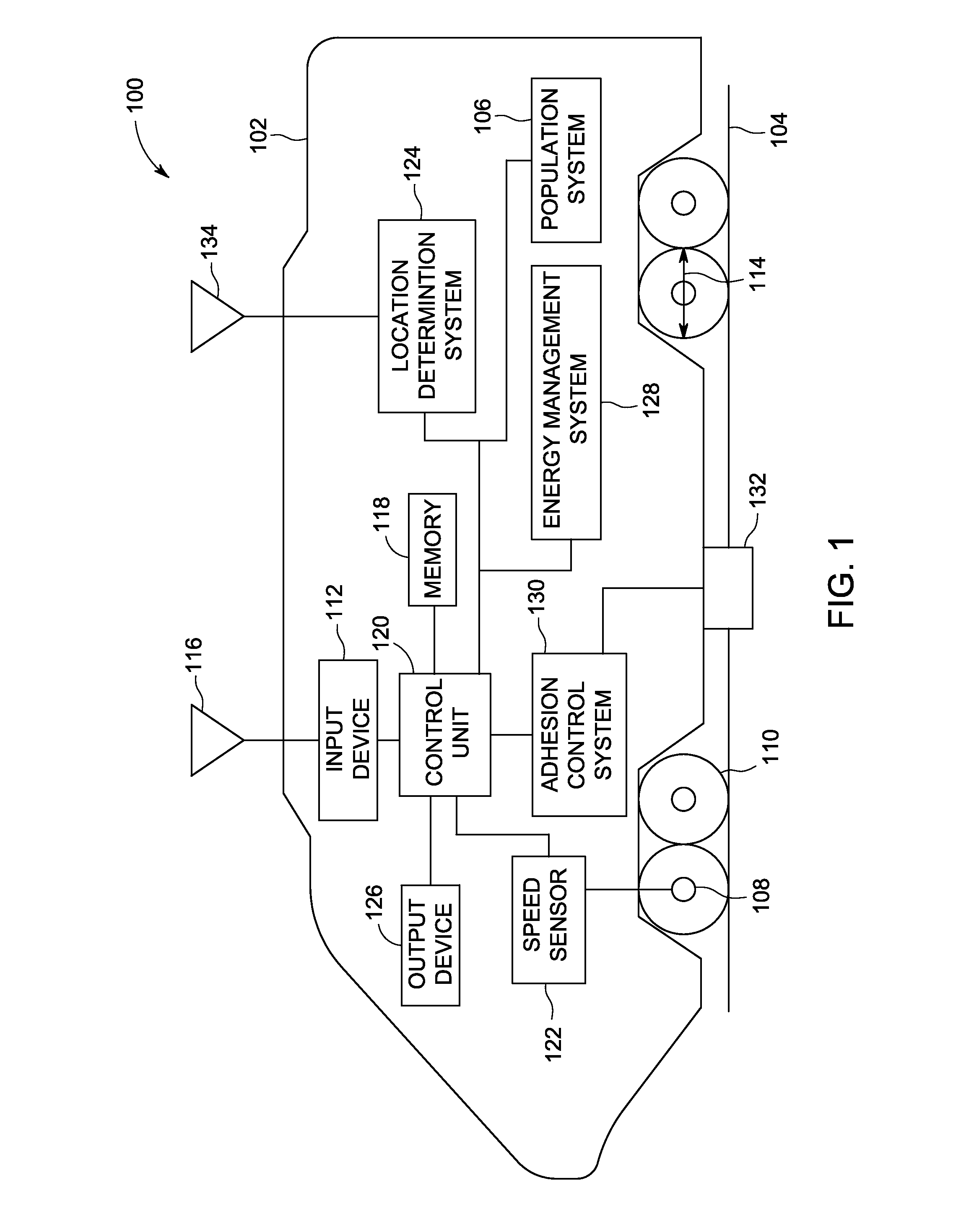

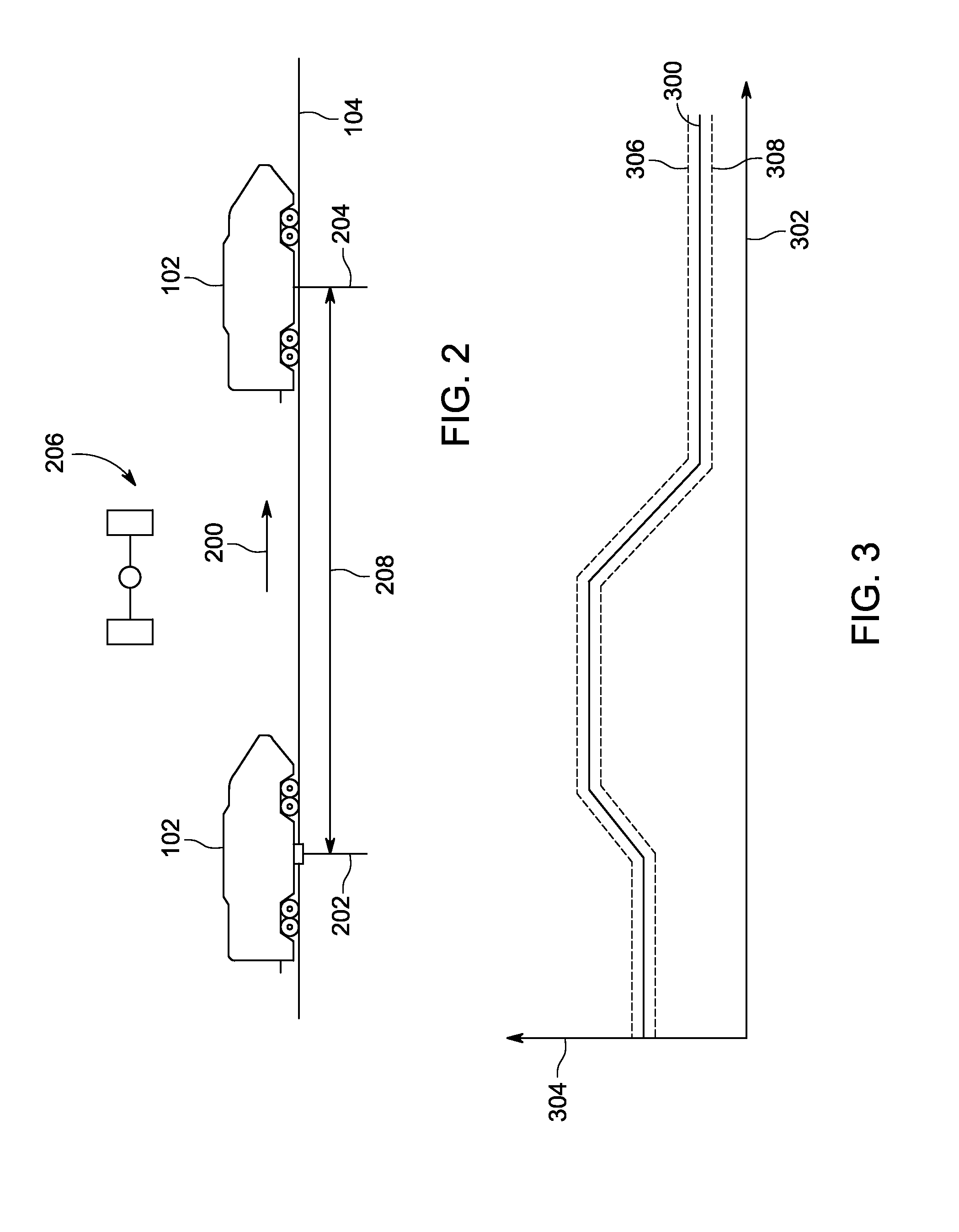

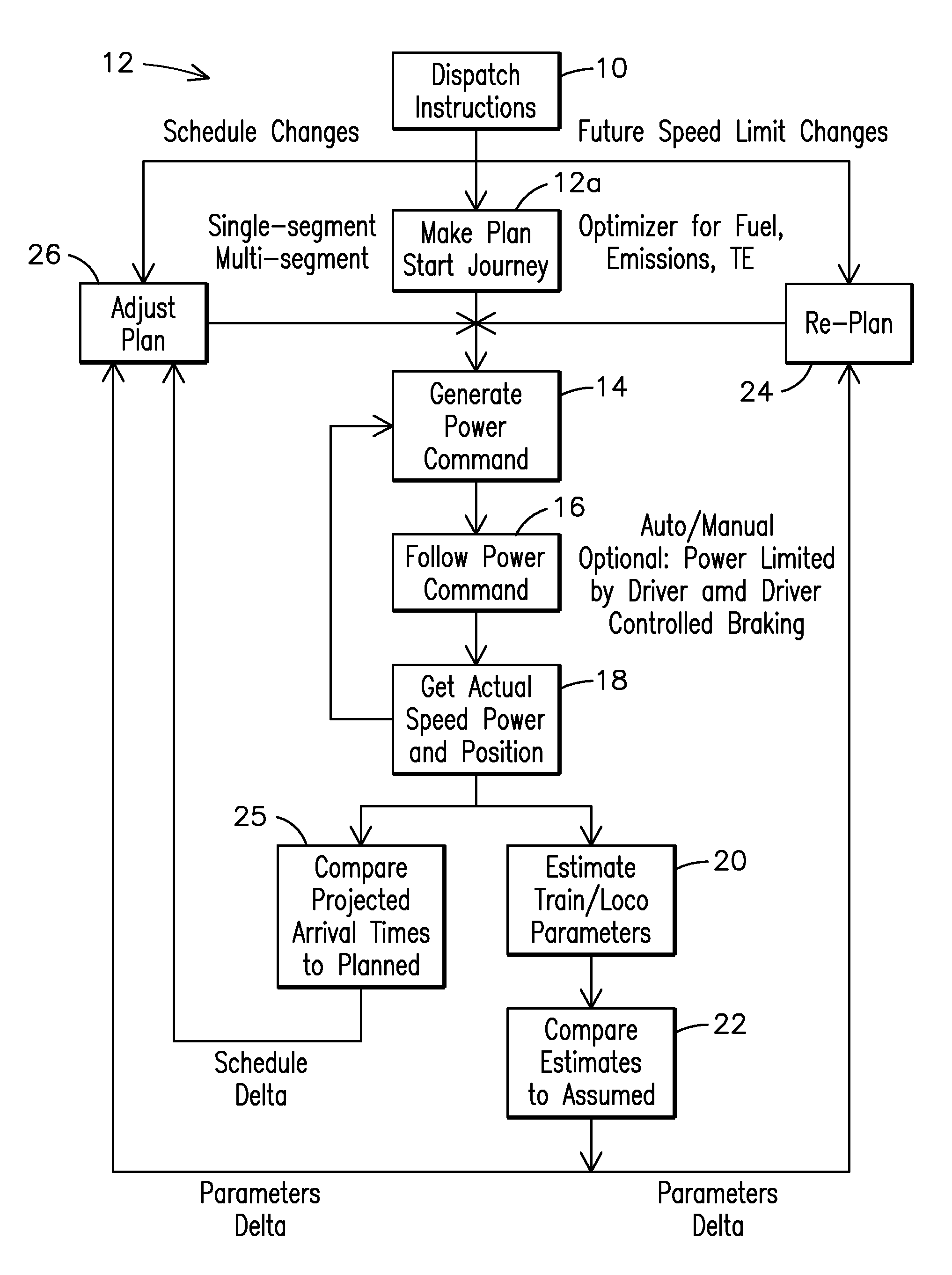

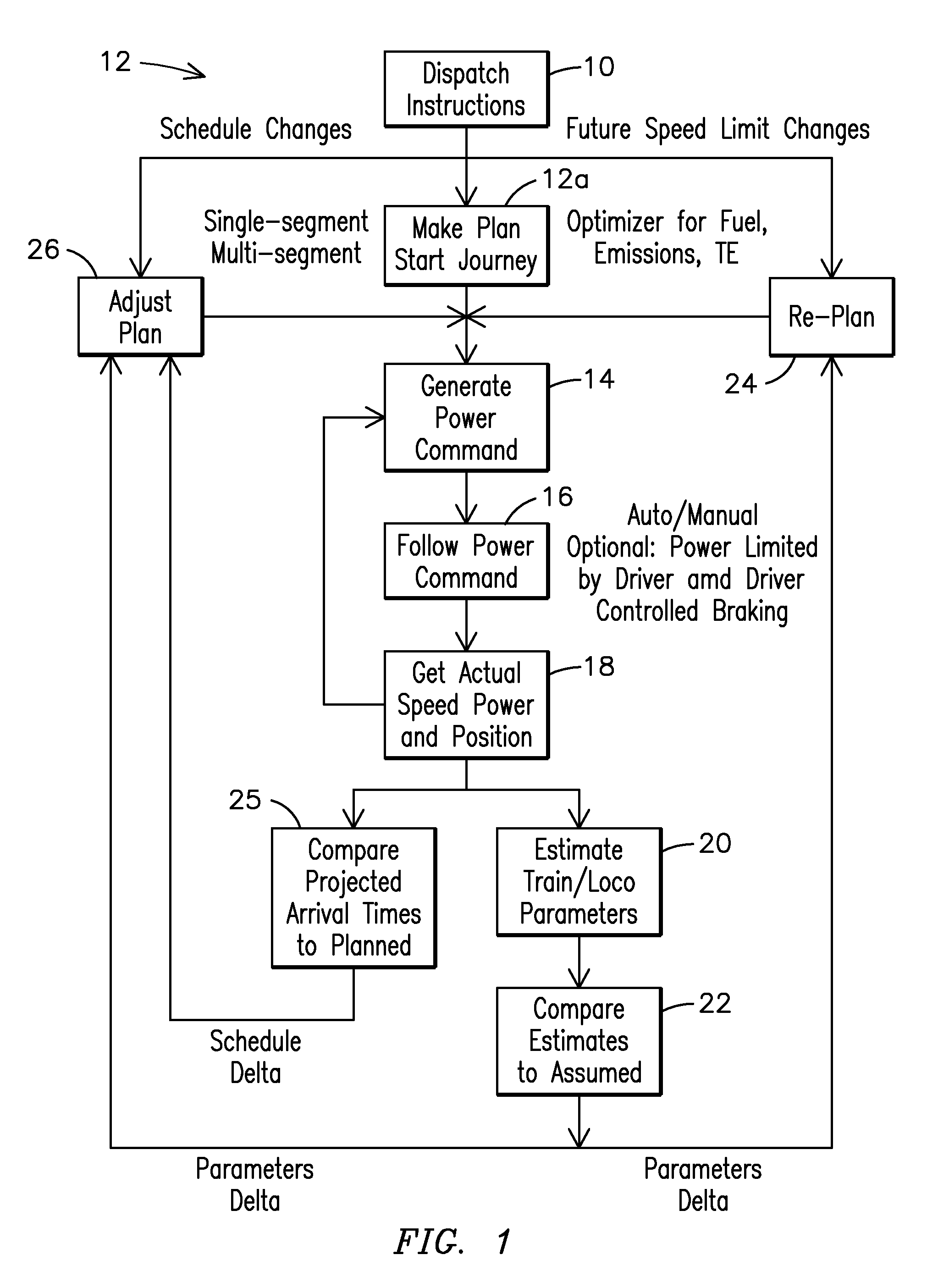

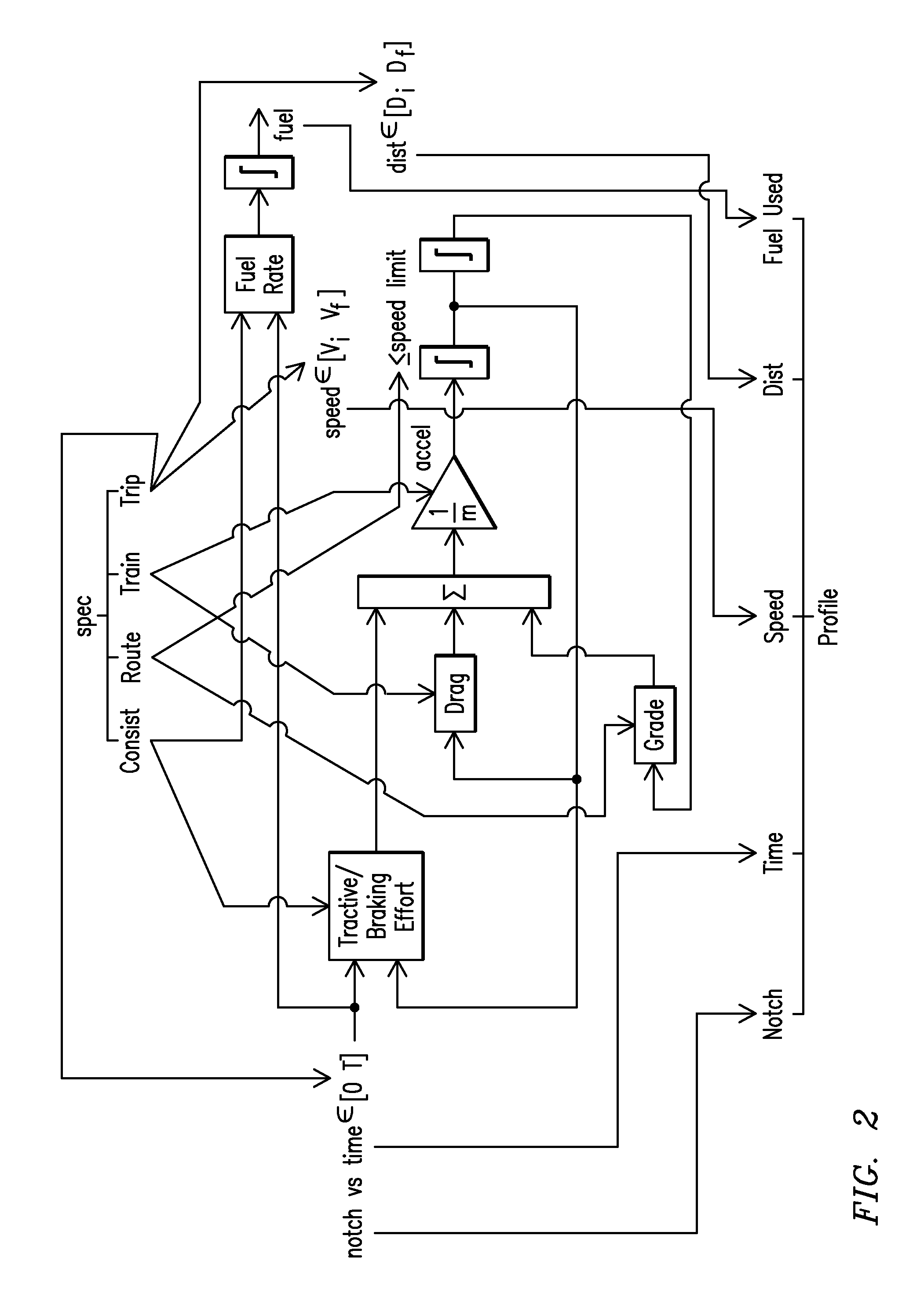

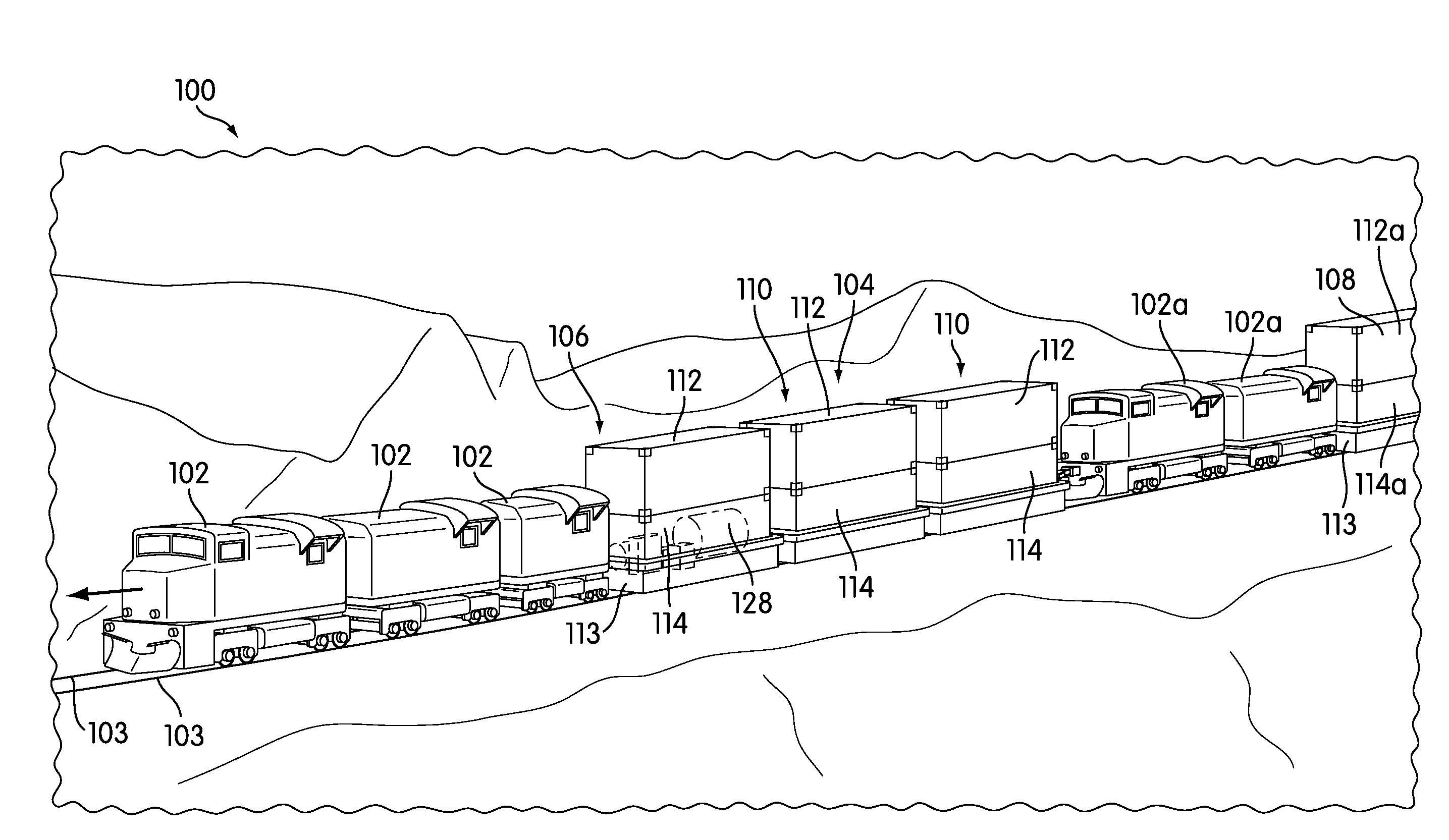

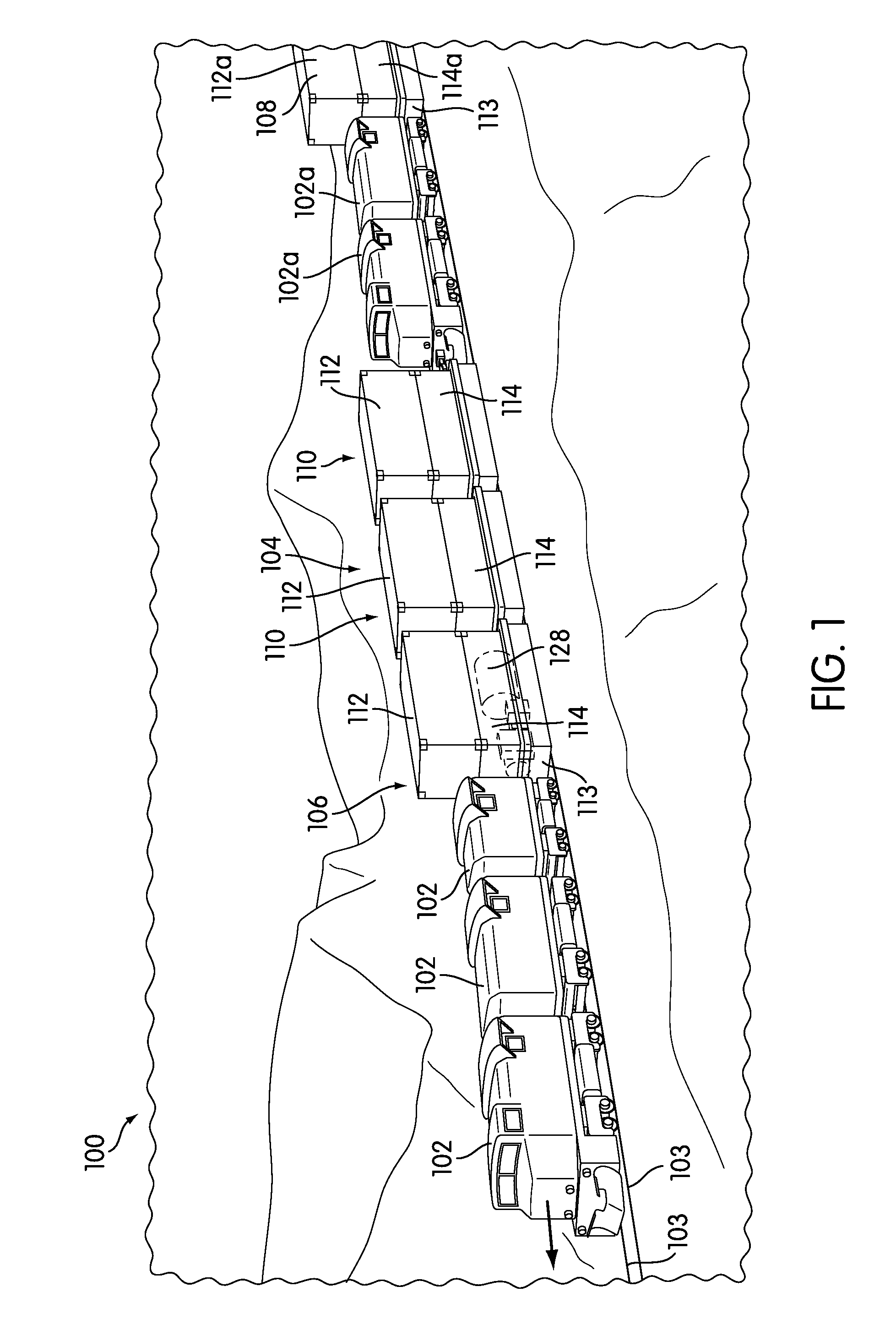

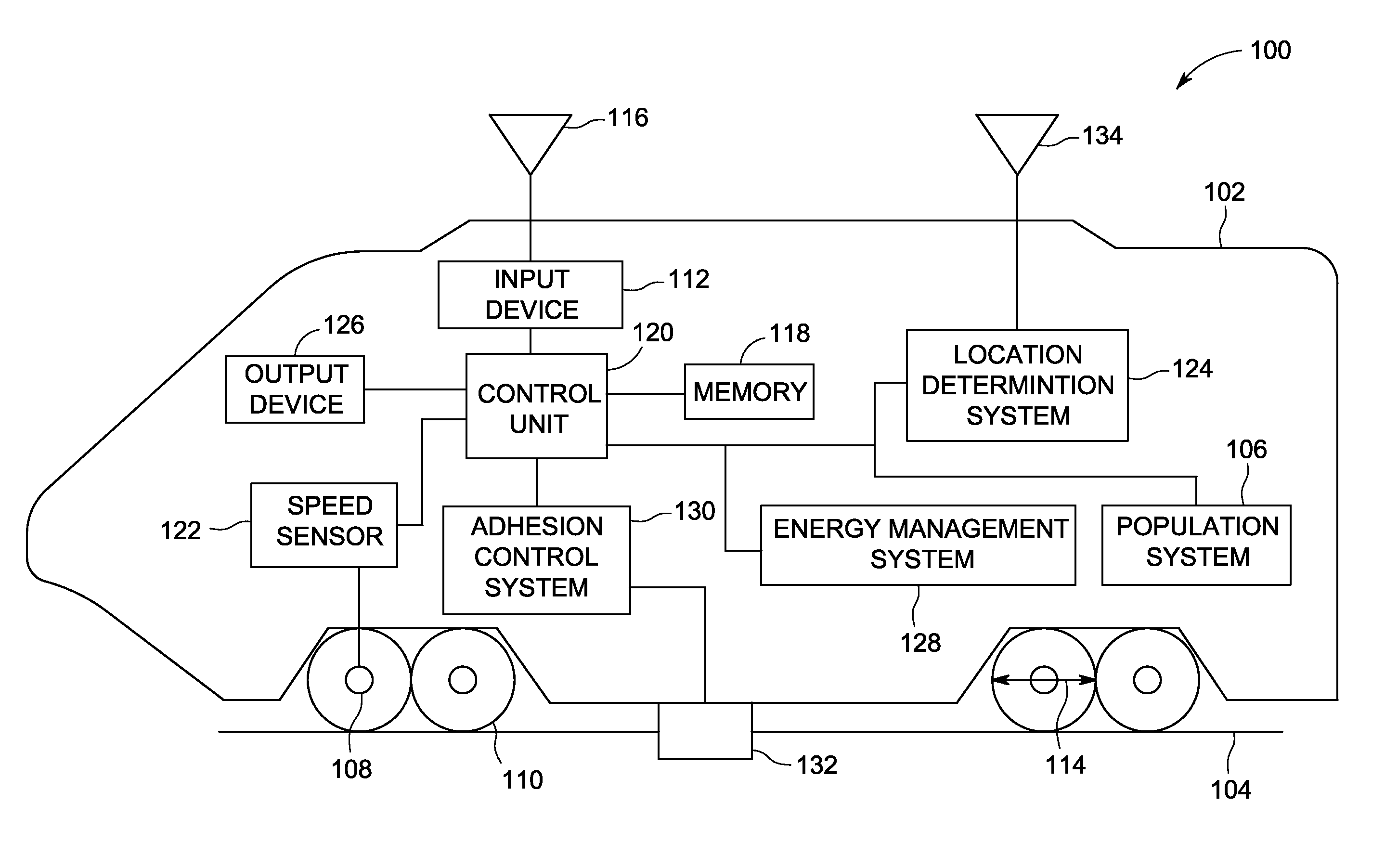

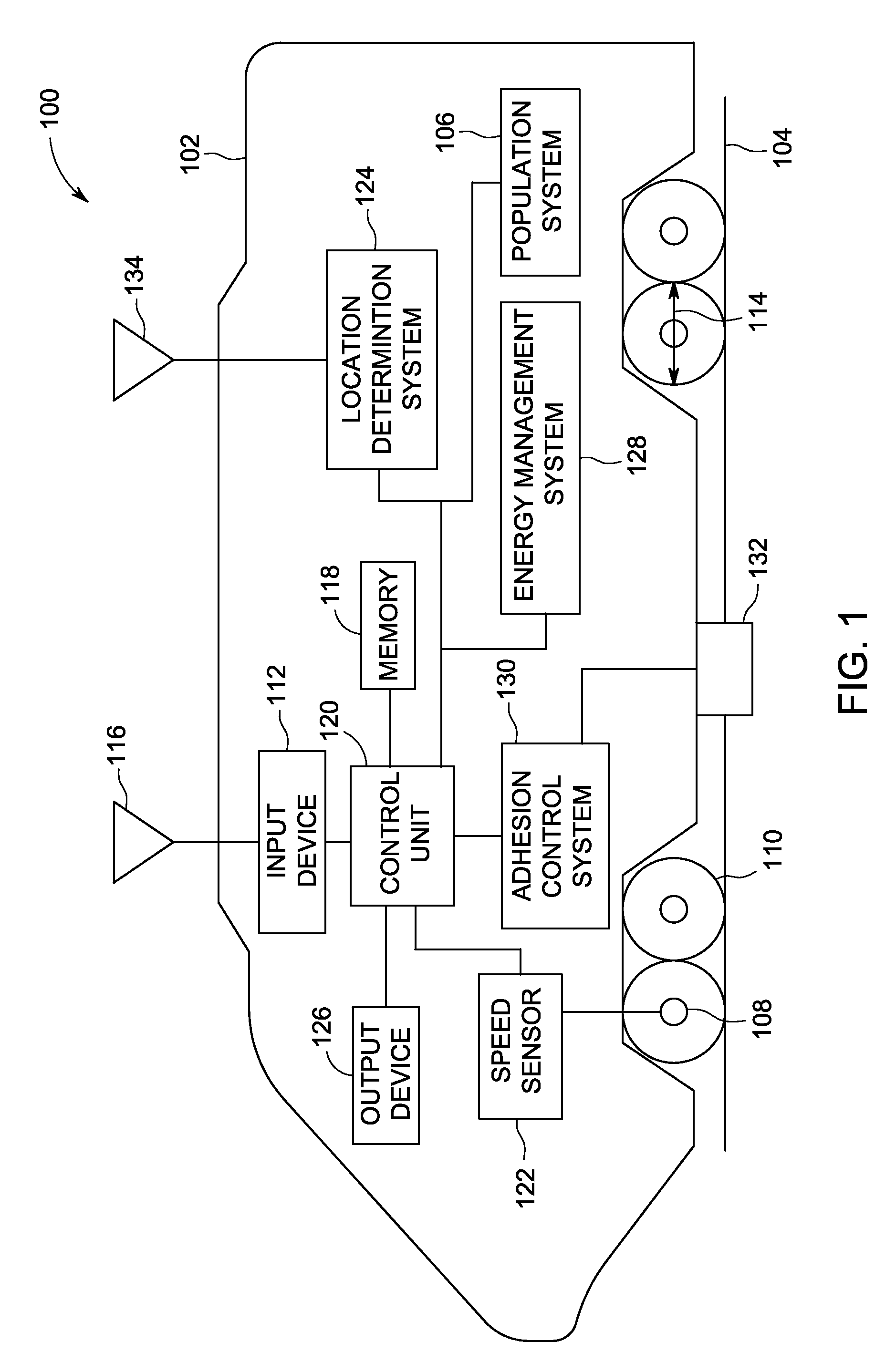

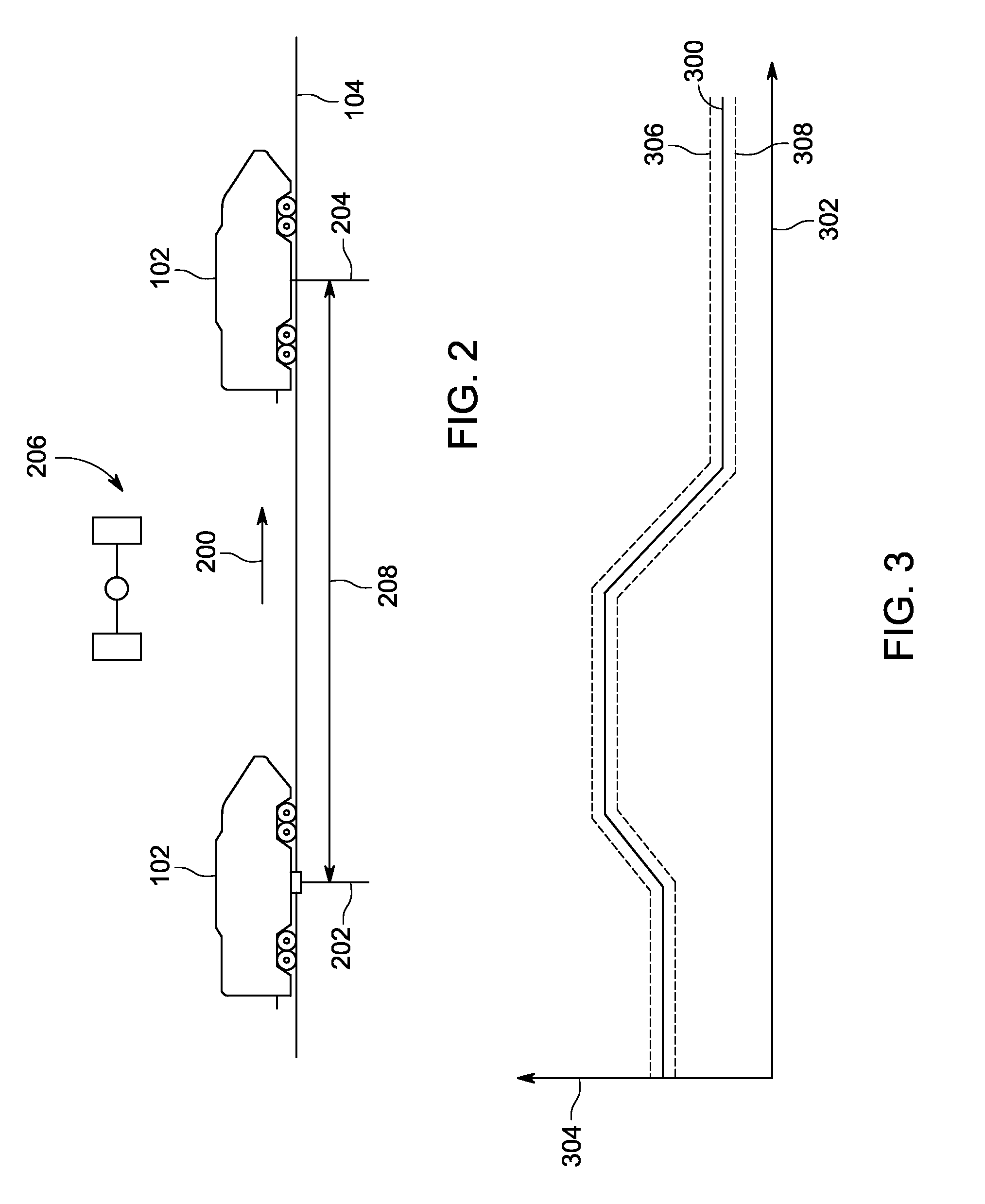

Trip optimizer method, system and computer software code for operating a railroad train to minimize wheel and track wear

ActiveUS20100023190A1Reduce the overall heightShorten speedDigital data processing detailsTrack side maintainanceWheel wearComputer software

A system for controlling a railroad train over a segment of track. The system comprises a first element for determining a location of the train on the segment of track; a second element for providing track characterization information for the segment of track; the track characterization information related to physical conditions of the segment of track; and a processor for controlling applied tractive forces and braking forces of the train responsive to the location of the train and the track characterization information to reduce at least one of wheel wear and / or track wear during operation of the train over the segment of track.

Owner:GE GLOBAL SOURCING LLC

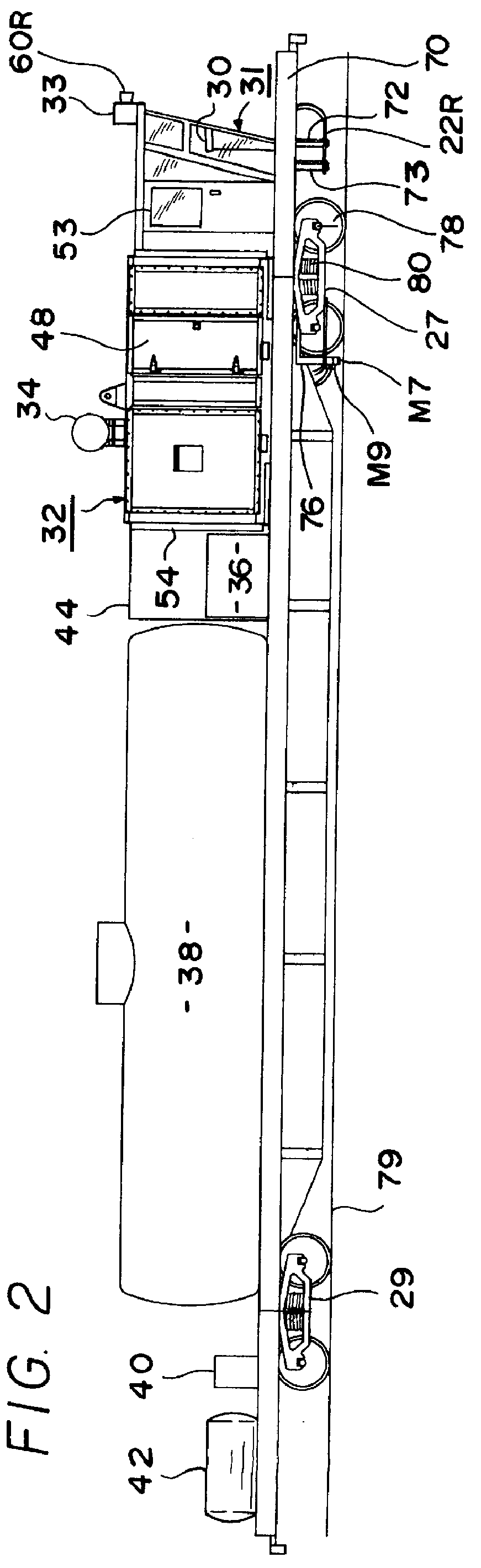

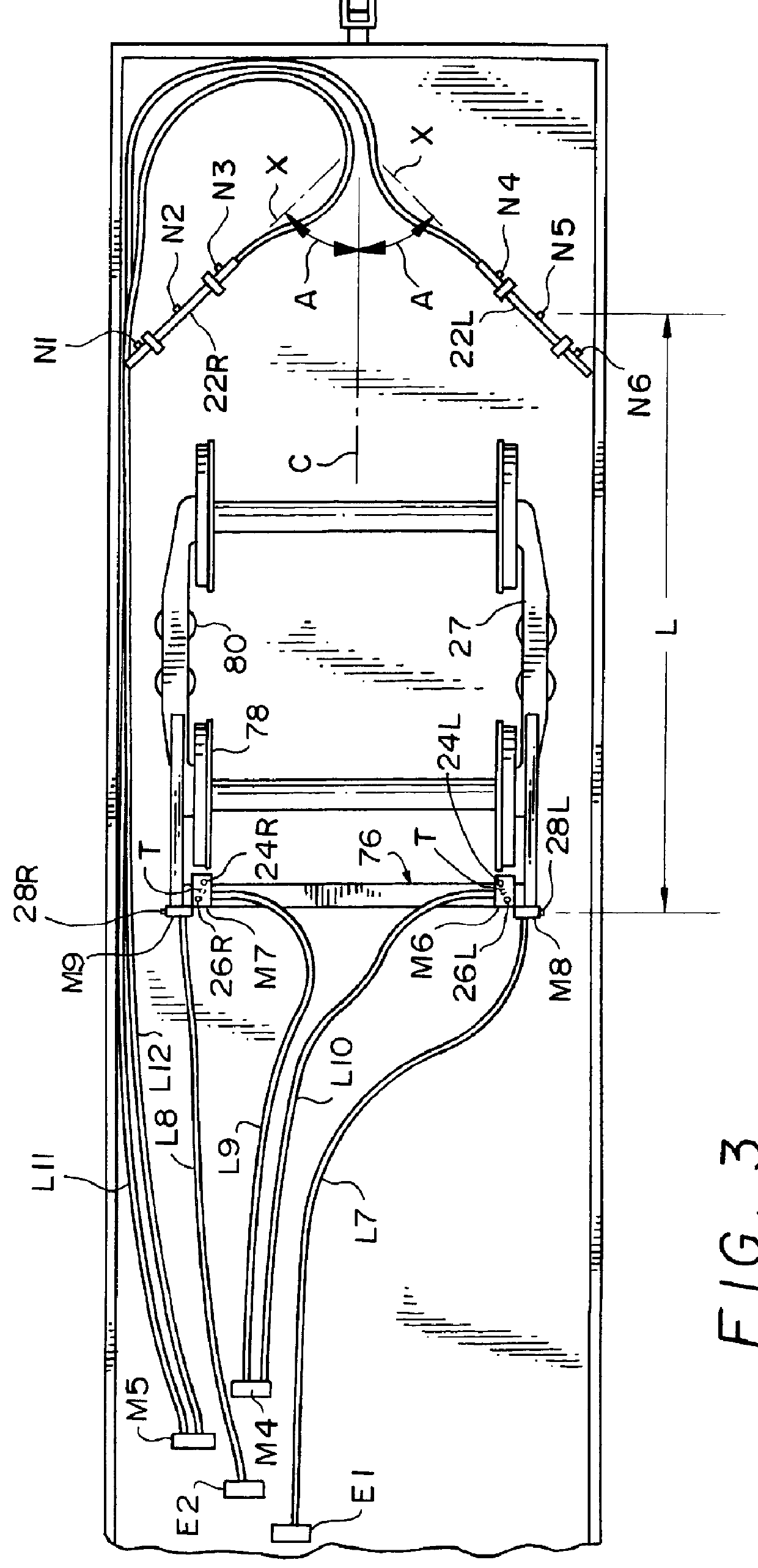

Railcar track cleaning system

InactiveUS6148732AWeaken energyEfficient and effectiveLiquid surface applicatorsSpray nozzlesLong axisSpray nozzle

A track cleaning system mounted on a railcar and comprising track rail cleaning nozzles, leaf removal nozzles and third rail cleaning nozzles. Each of the nozzles may provide a fan-shaped spray pattern diverging to either side of a central axis and having a major axis. For each track rail nozzle, the central axis may be perpendicular to a horizontal top rail surface and the major axis may be perpendicular to the rail surface centerline. For each leaf nozzle, the central axis may be directly downwardly from the horizontal and the major axis may be parallel to an elongated spray bar on which one or more leaf nozzles are mounted. For each third rail nozzle, the central axis may be directed downwardly from the horizontal and the major axis may be positioned vertically. The third rail nozzles may be mounted to the rear of the leaf nozzles to aid in leaf removal. Main water valves are remotely actuated by air to release high pressure water to corresponding sets of nozzles. A pressure control valve controls the pressure of water supplied to the main water valves from a positive displacement, high pressure water pump.

Owner:CAROLINA EQUIP & SUPPLY

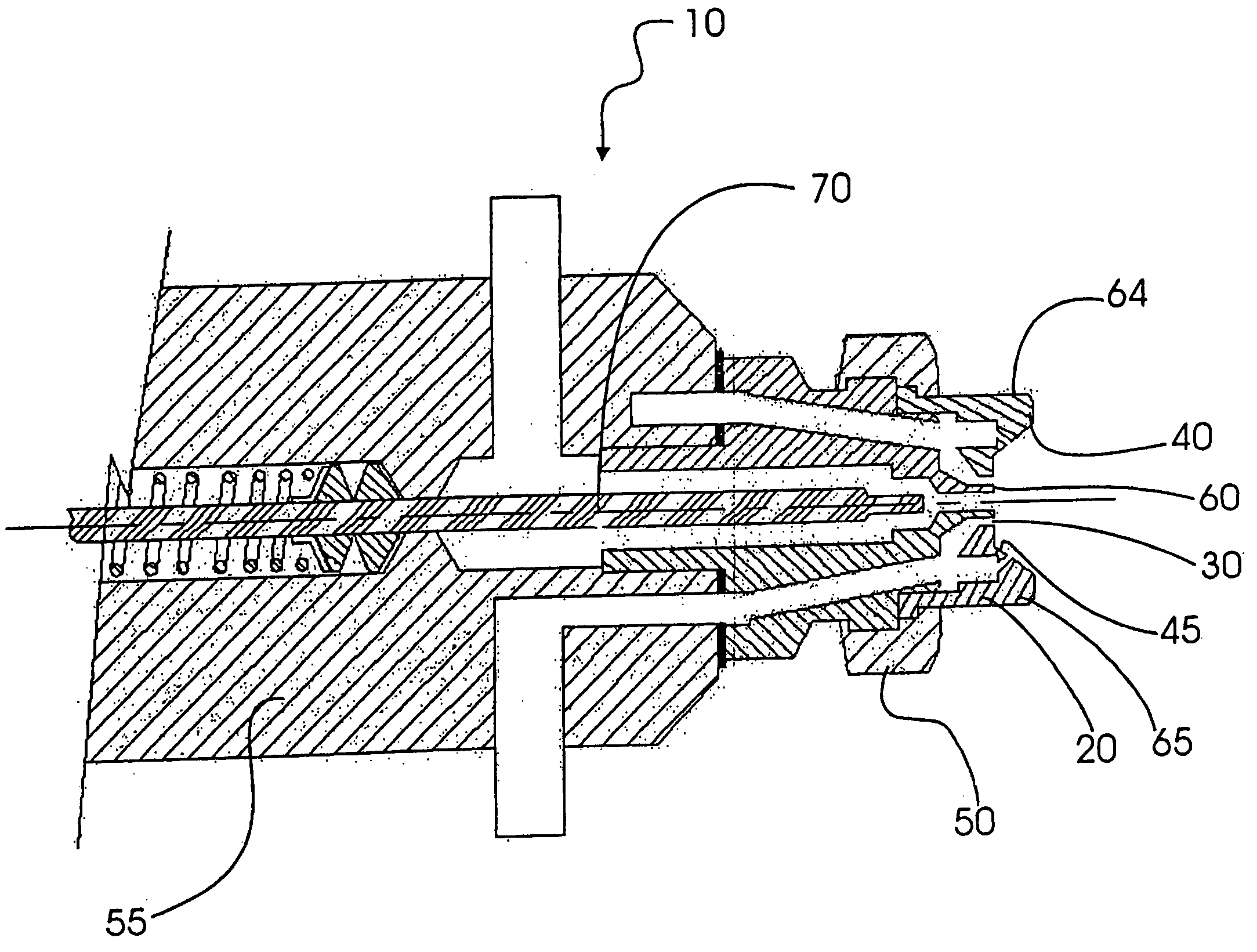

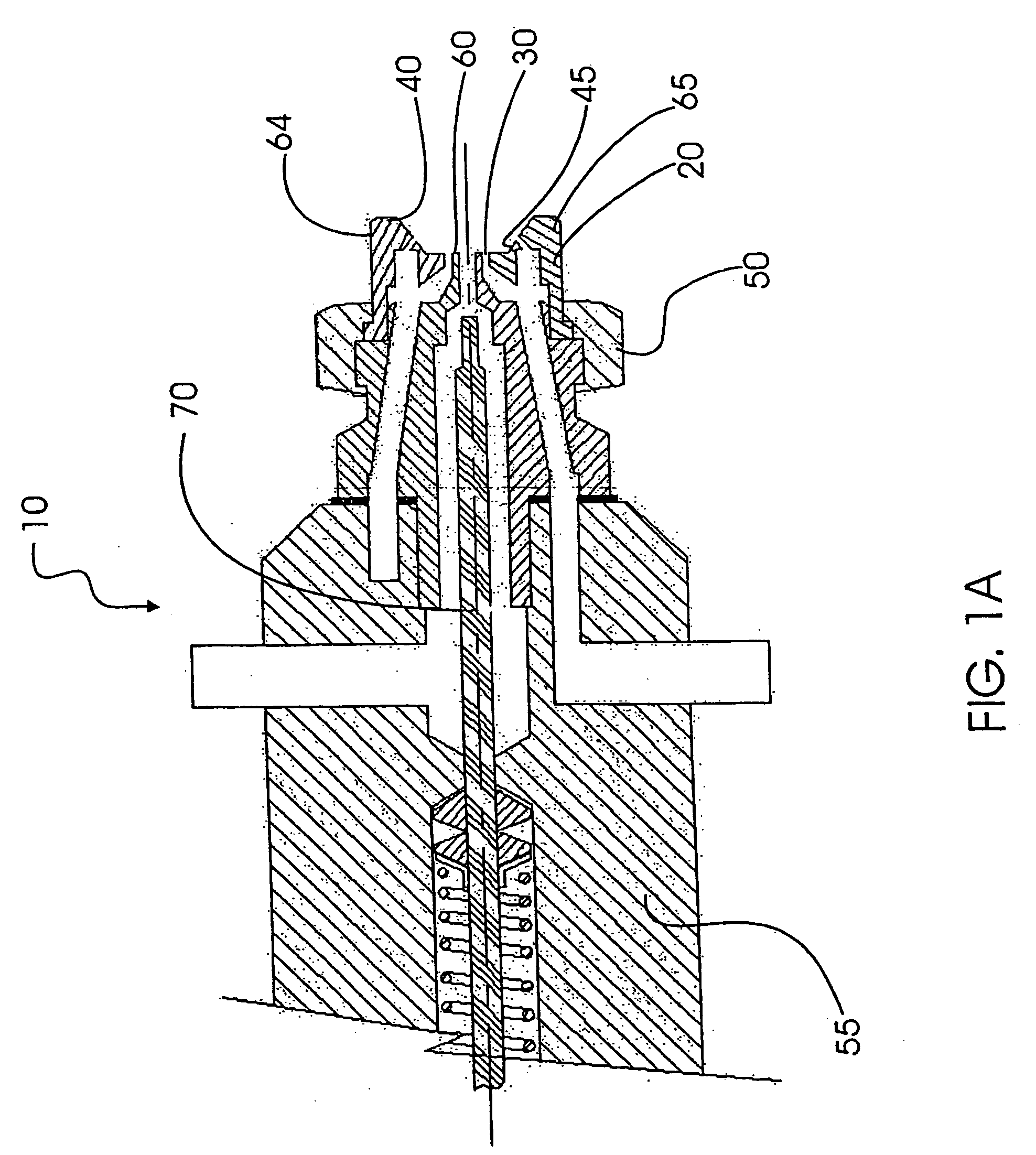

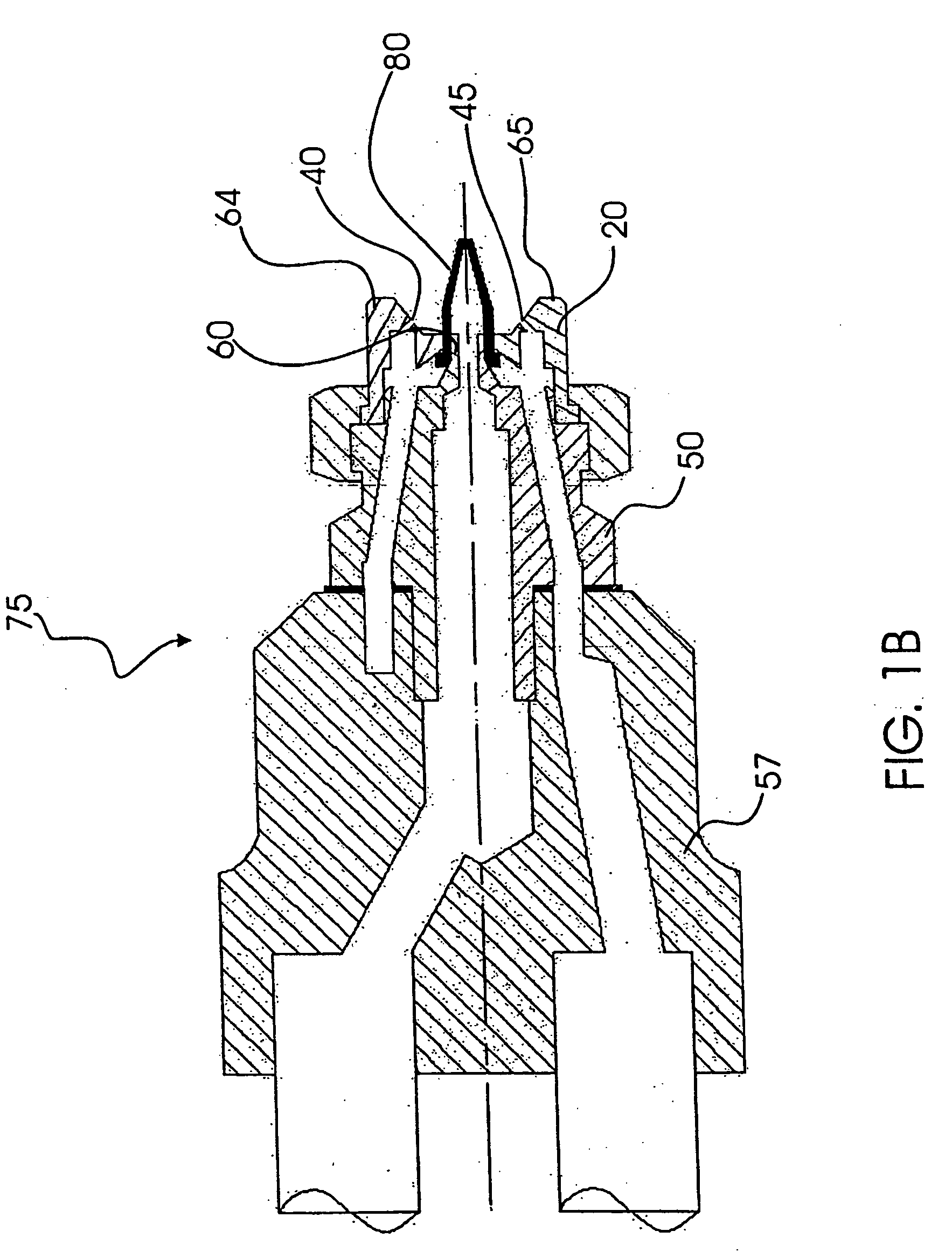

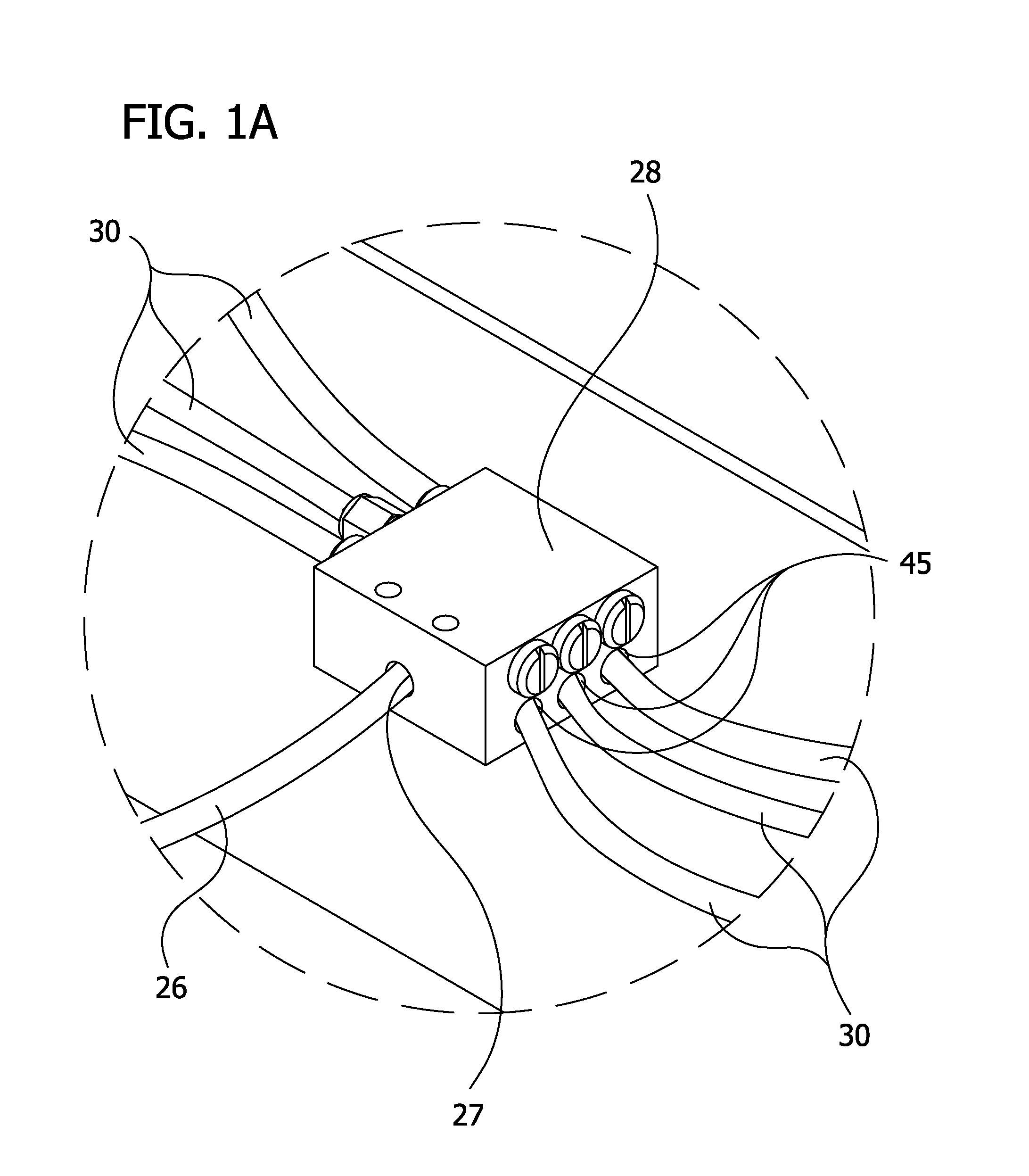

Spray nozzle assembly

InactiveUS20050173561A1Increase in sizeReduce amountSpray nozzlesFire rescueEngineeringMechanical engineering

A spray nozzle comprising a nozzle body (110) having an air channel in fluid communication with an air supply, and directing air to one or more air openings (160) at an end of the nozzle body, and a liquid channel in fluid communication with a liquid supply and directing a liquid to a liquid outlet (150) of the nozzle body. An air cap (120) is disposed at the end of the nozzle body and has an orifice in fluid communication with the one or more than one air openings, the orifice is disposed about the outside of the liquid outlet. The spray nozzle also comprises an extension (170) placed on the liquid outlet, outlet protrudes beyond the surface of the air cap. The spray nozzle is well suited for use under windy conditions in that fouling of the nozzle is reduced or eliminated.

Owner:KELSAN TECH

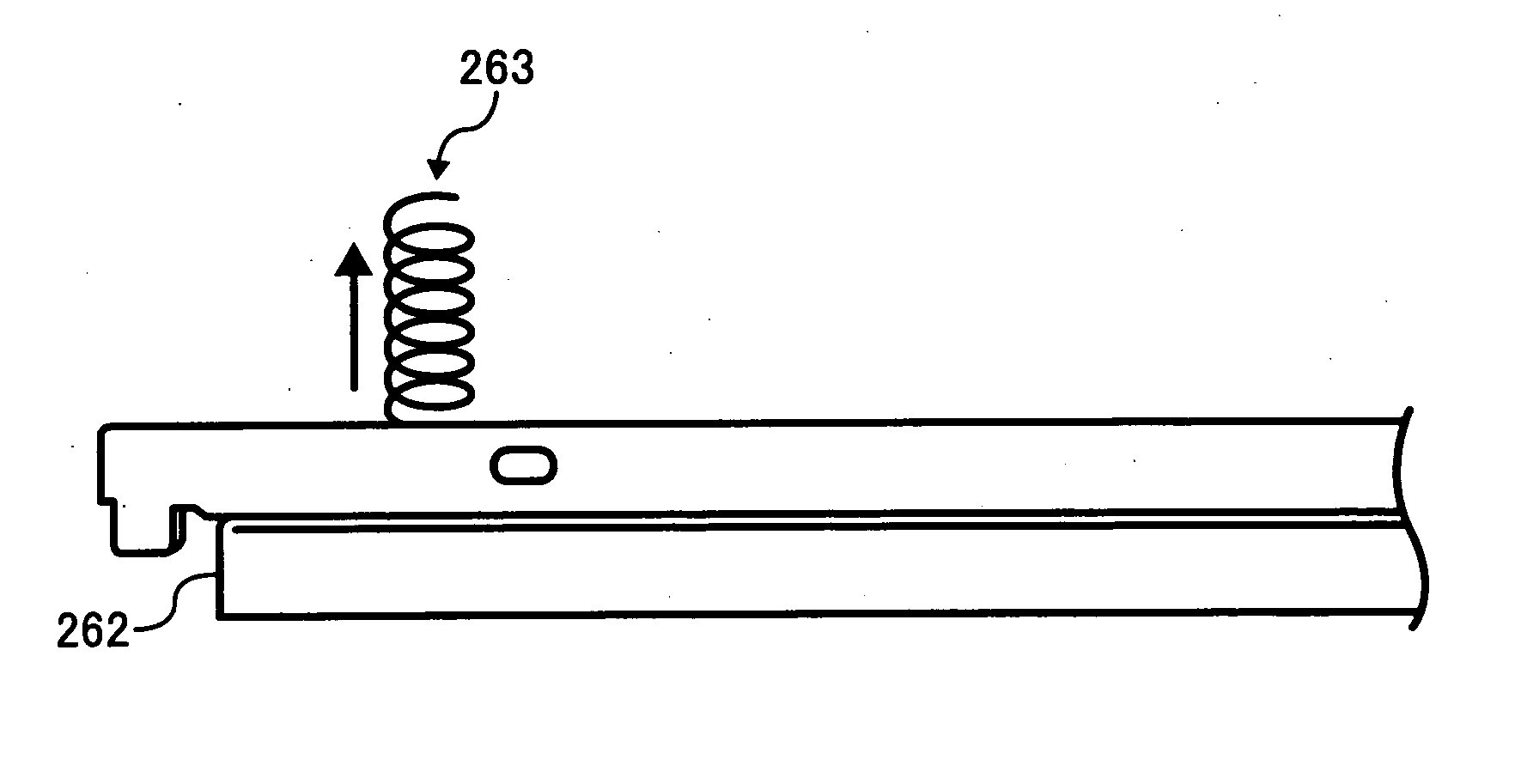

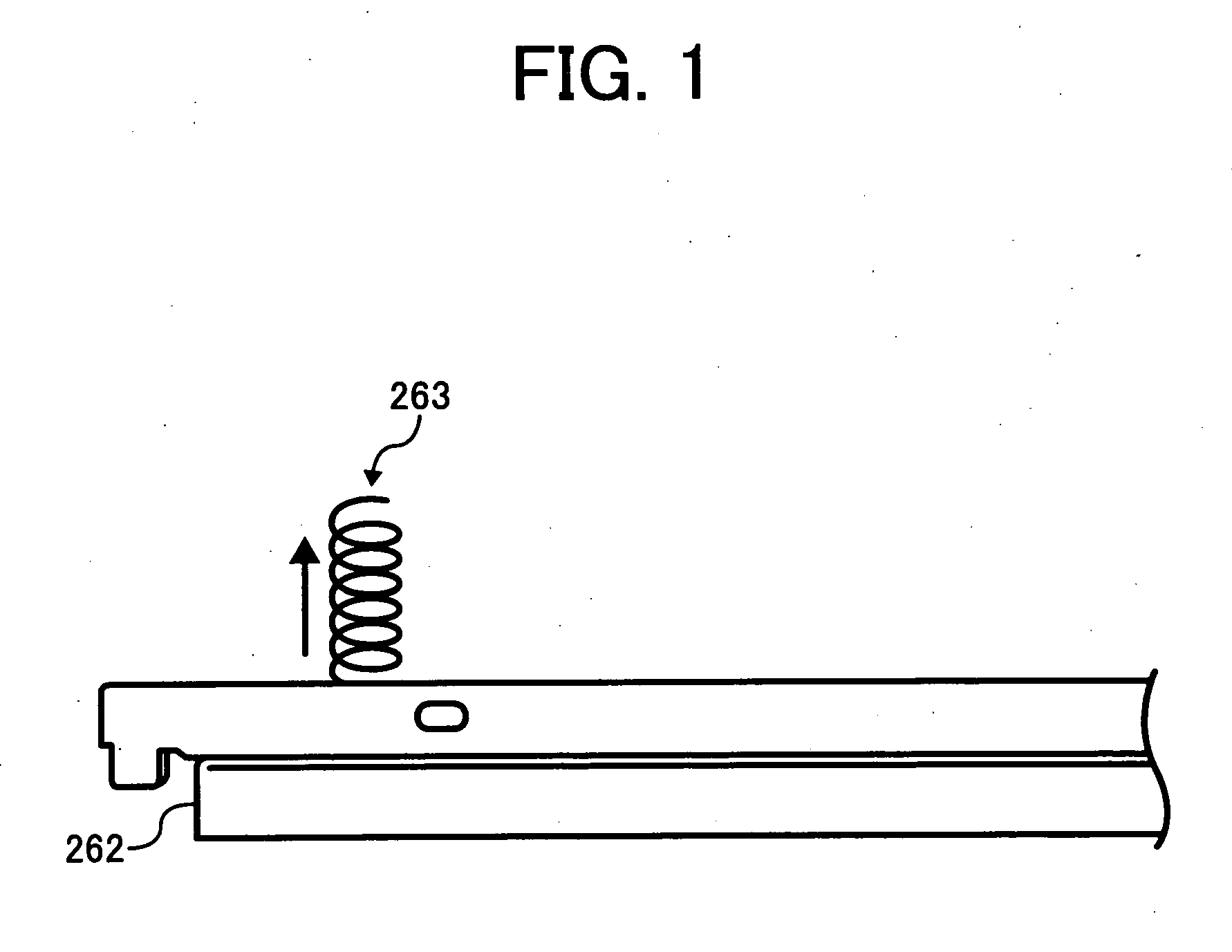

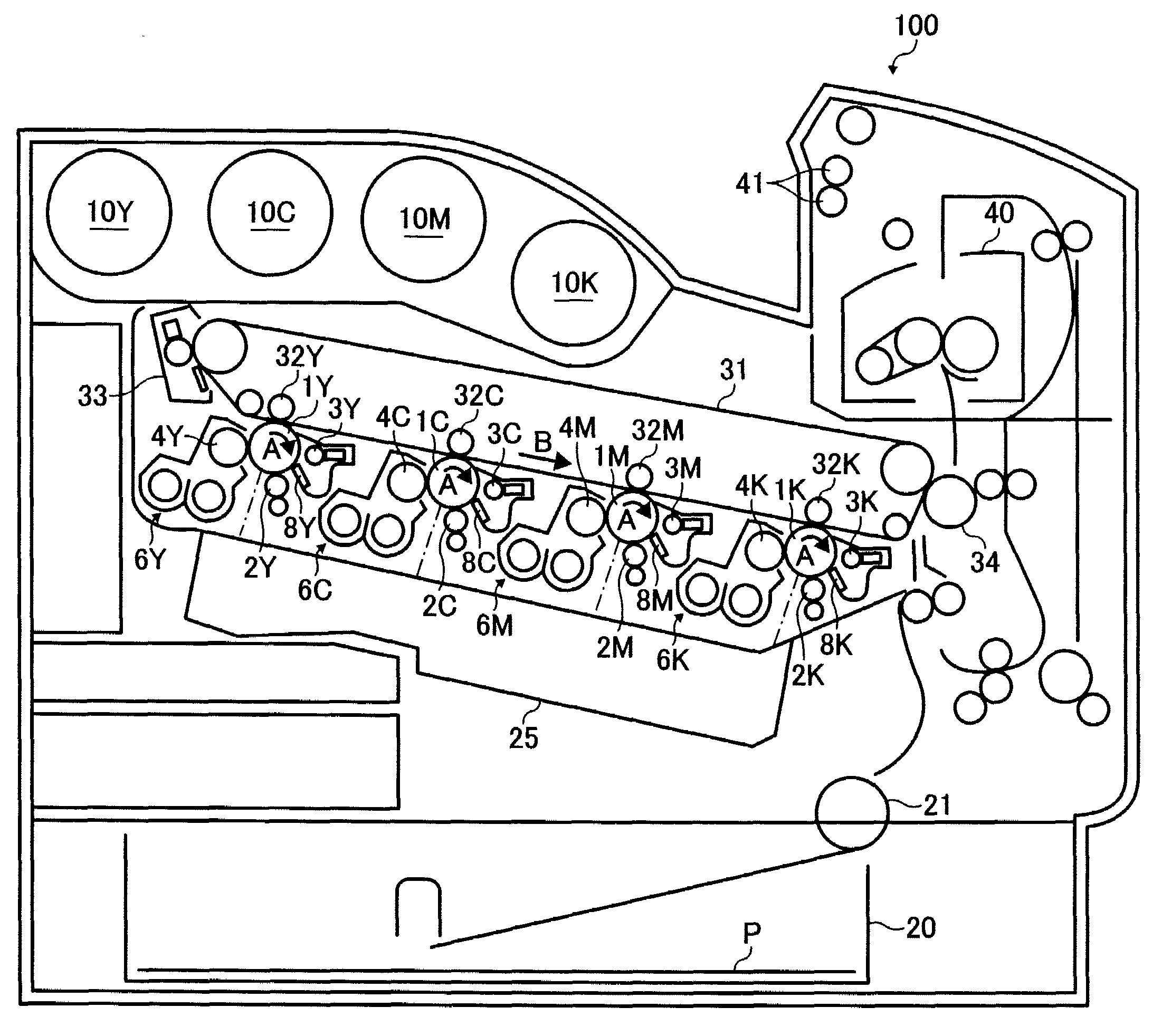

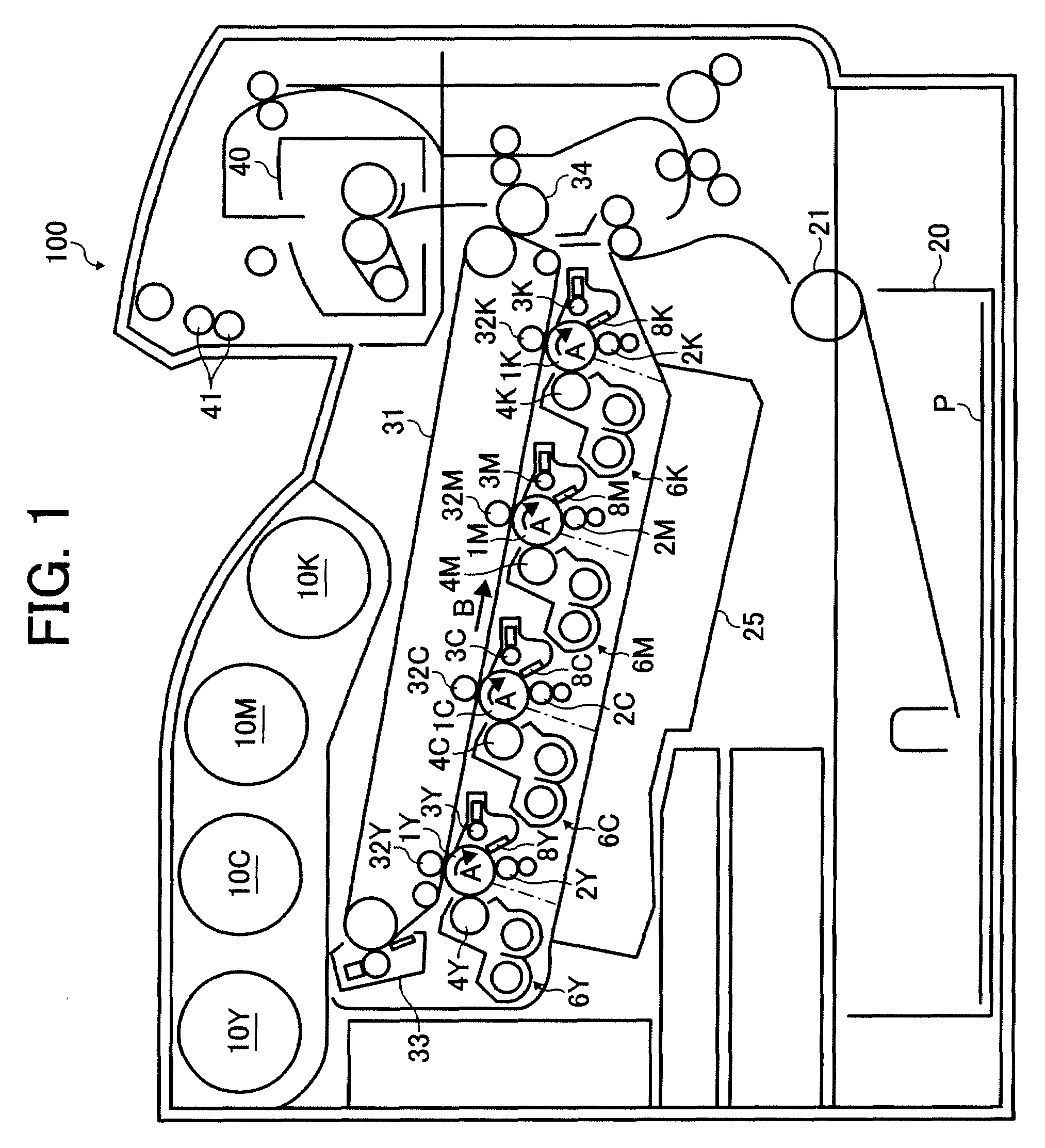

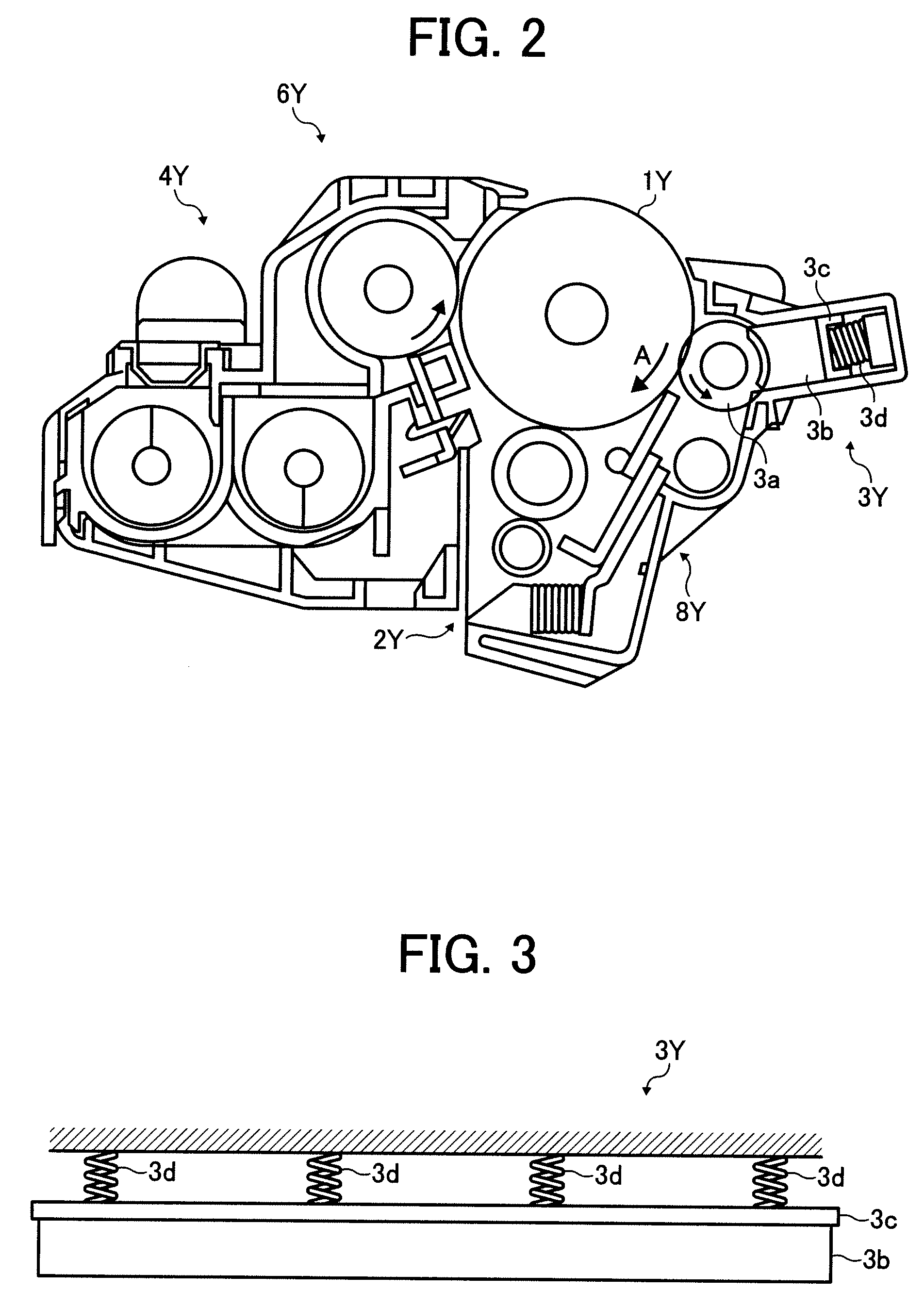

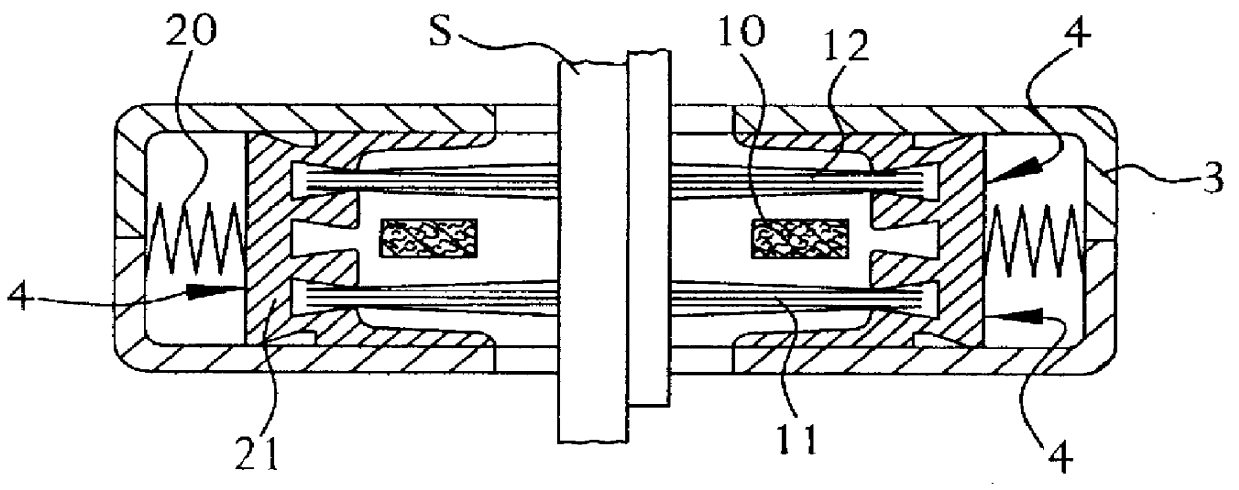

Lubricant supply device, image forming apparatus, and pressing device

ActiveUS20070068738A1Small amountSmall amount of changeElectrographic process apparatusRail lubricationEngineeringLubricant

A lubricant supply device includes a solid lubricant, a supply member contacting and rubbing the solid lubricant and thereby scraping a lubricant off the solid lubricant and supplying the lubricant to a lubricant supplying target, and a pressing mechanism pressing the solid lubricant against the supply member. The pressing mechanism includes a biasing device, and a plurality of pressing members receiving a biasing force of the biasing device and thereby pressing places of the solid lubricant at symmetrical positions with respect to a center of a contact part of the solid lubricant contacting the supply member, respectively.

Owner:RICOH KK

Top of rail applicator

Owner:PORTEC RAIL PRODS

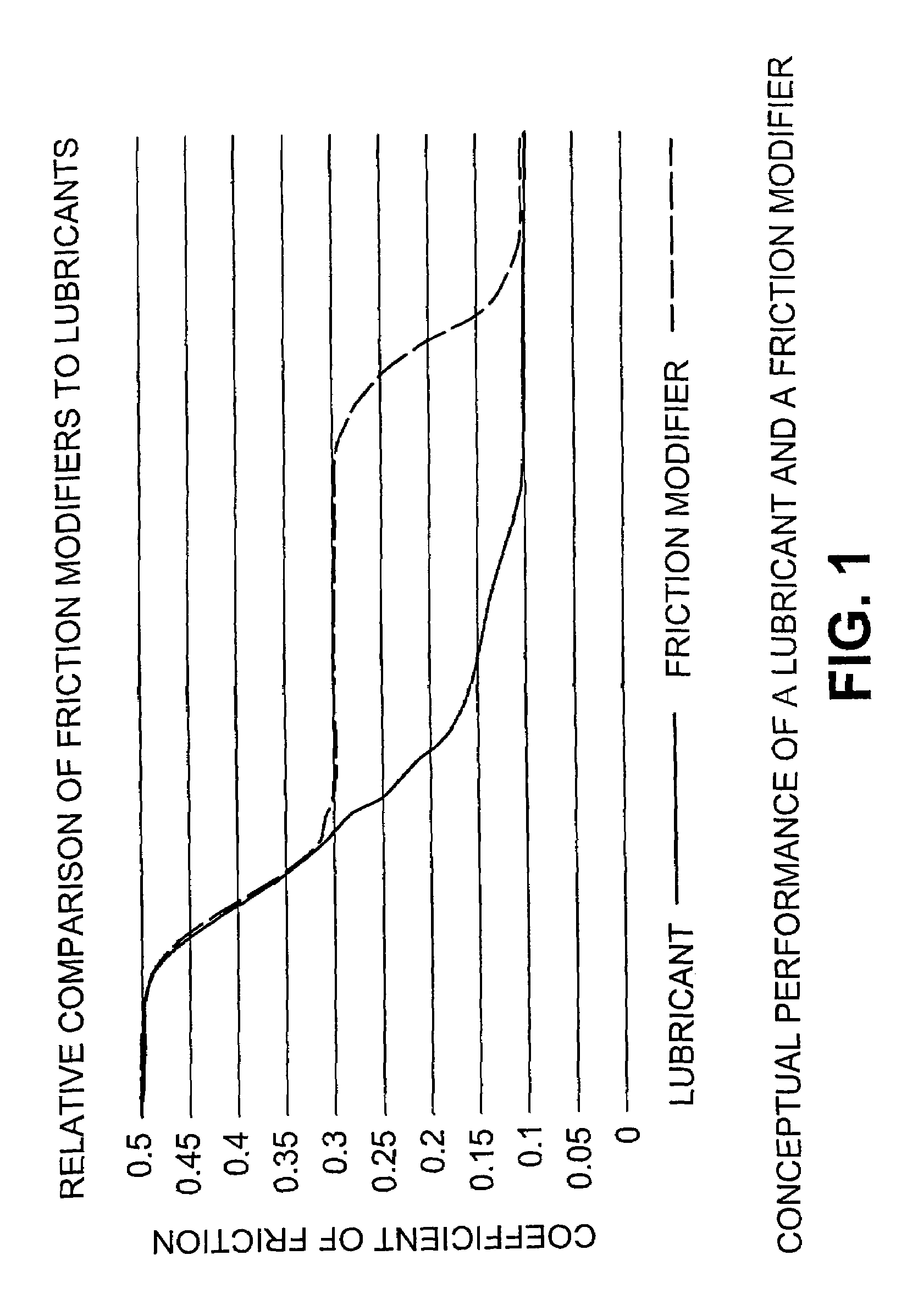

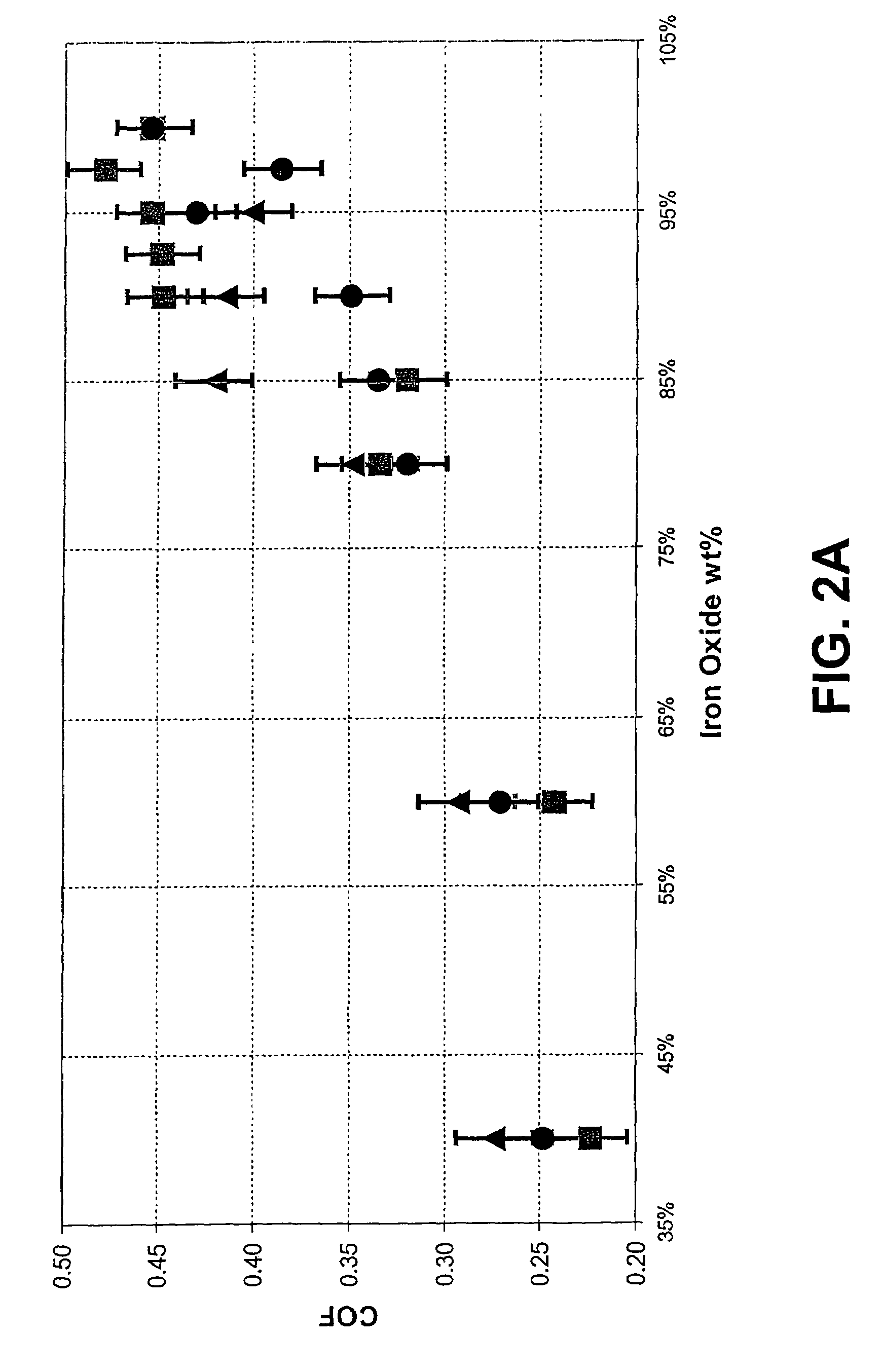

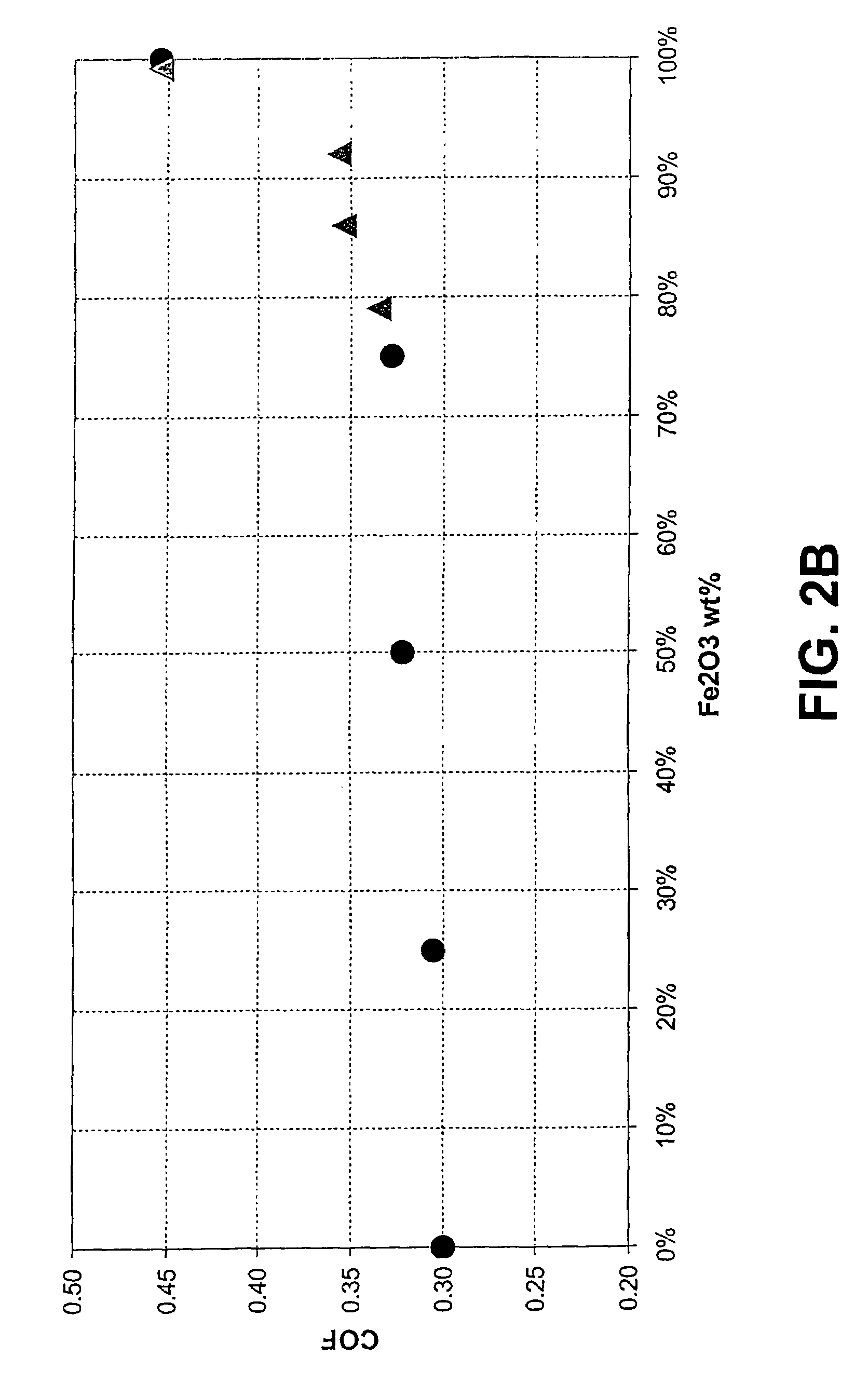

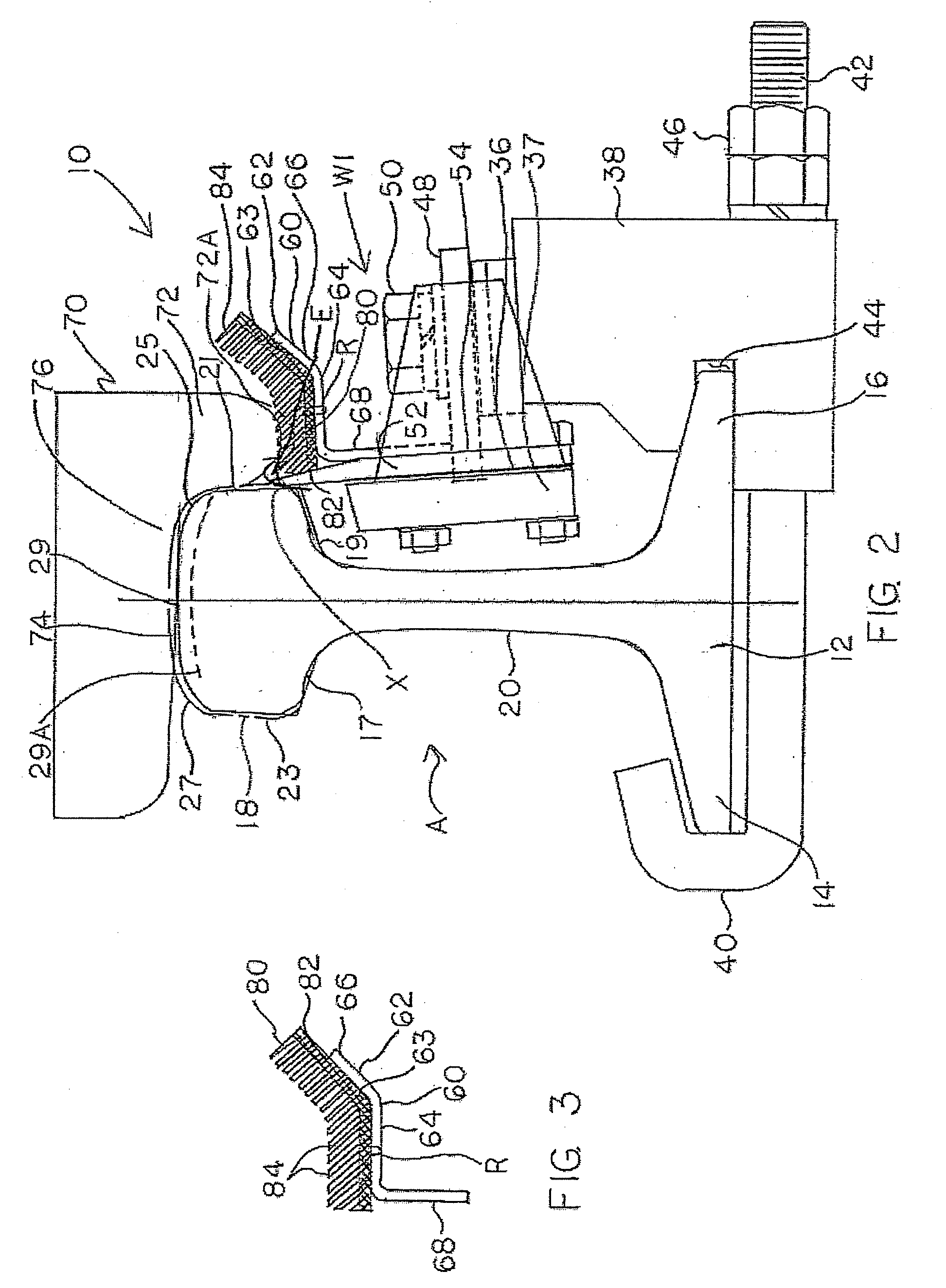

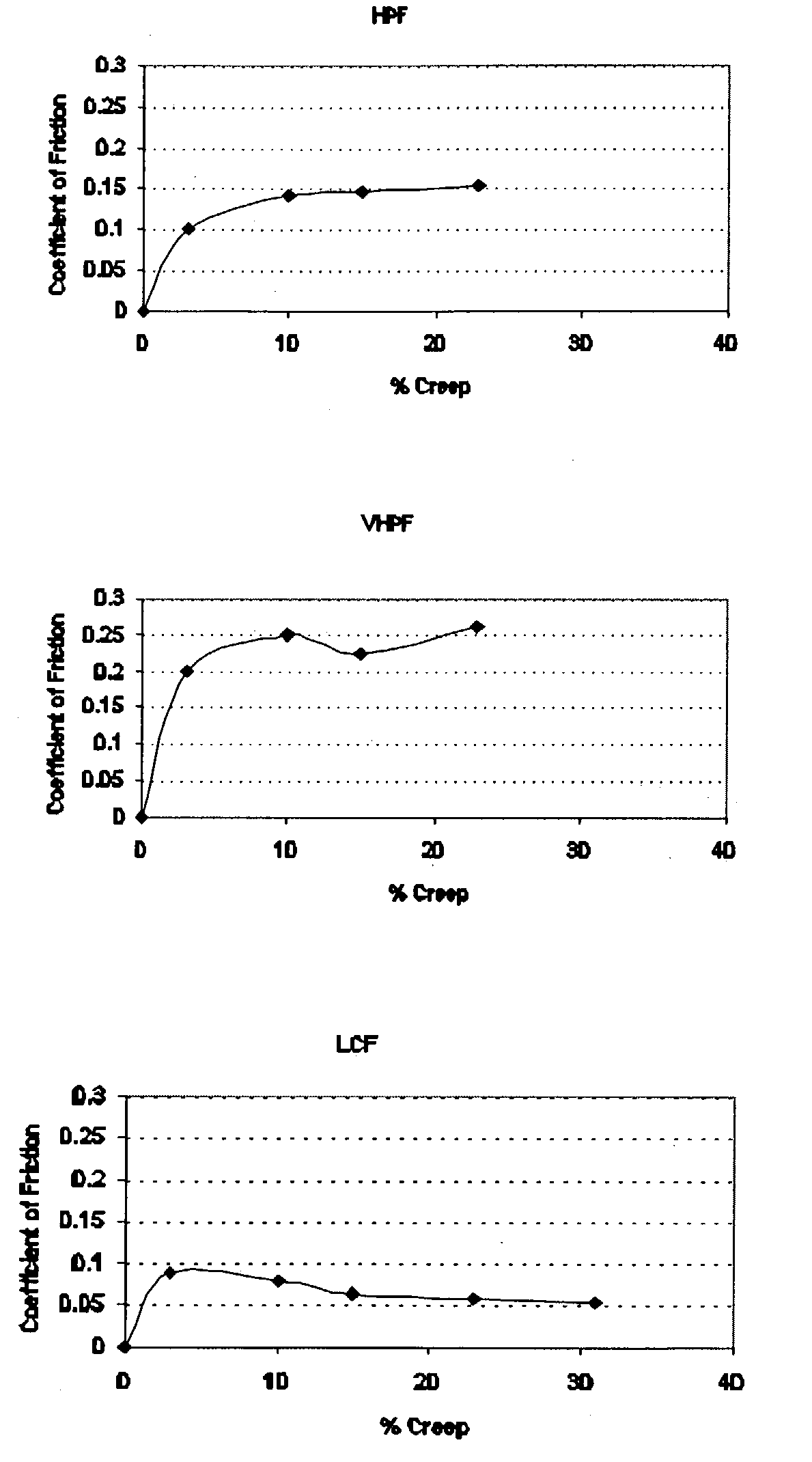

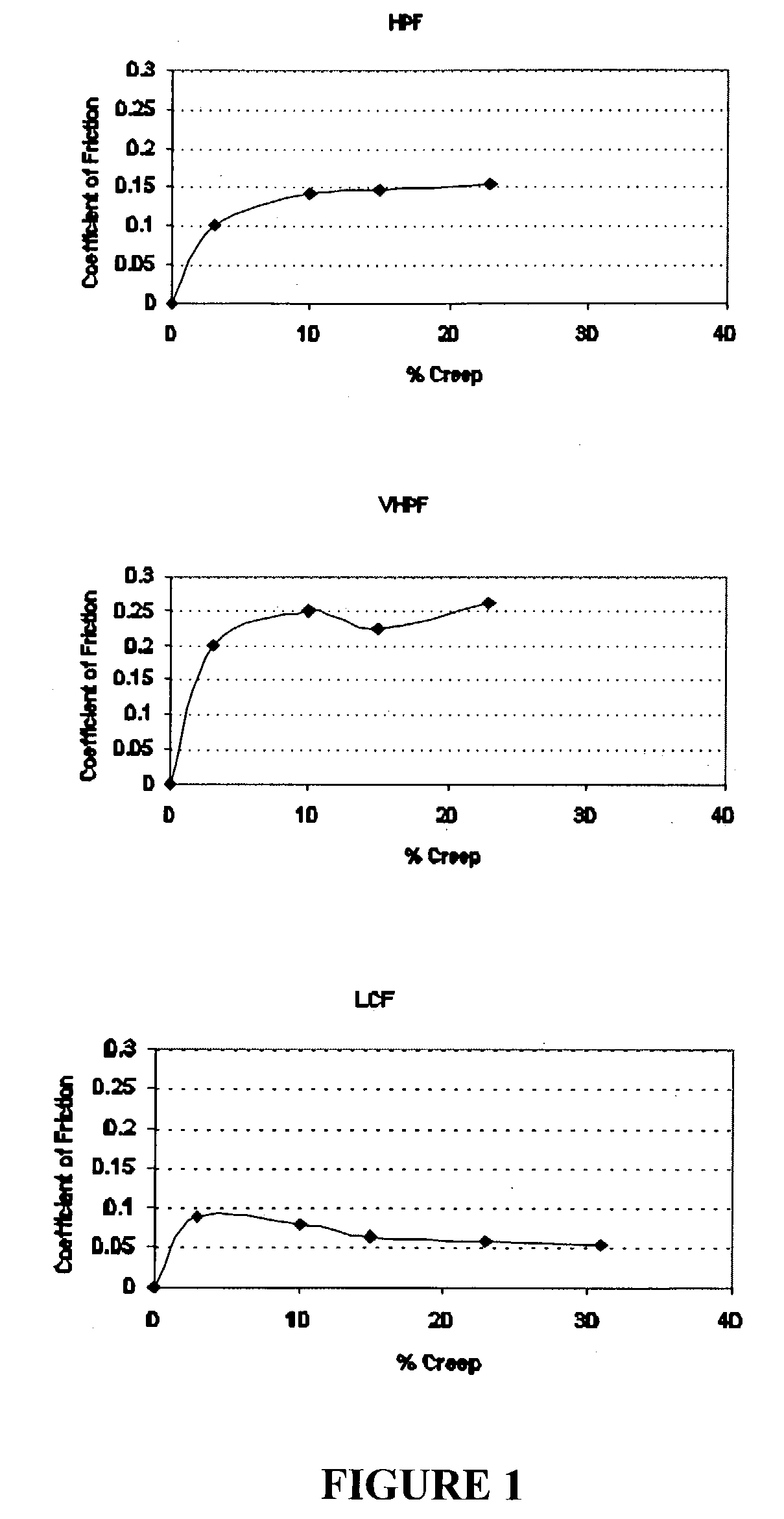

Modified friction control compositions

The present invention provides a friction control composition comprising a binder a rheological control agent, and optionally a lubricant. The liquid friction control composition may also comprise other components a wetting agent, a consistency modifier, and a preservative. The liquid friction control compositions may be used to modify the interfacial friction characteristics in sliding and rolling-sliding contact such as steel wheel-rail systems including mass transit and freight systems. A method of reducing lateral force, reducing energy consumption, or controlling friction between a metal surface and a second metal surface by applying the composition to metal surface, for example a top of rail or wheel, is also provided. The composition may be sprayed onto the rail surface.

Owner:KELSAN TECH

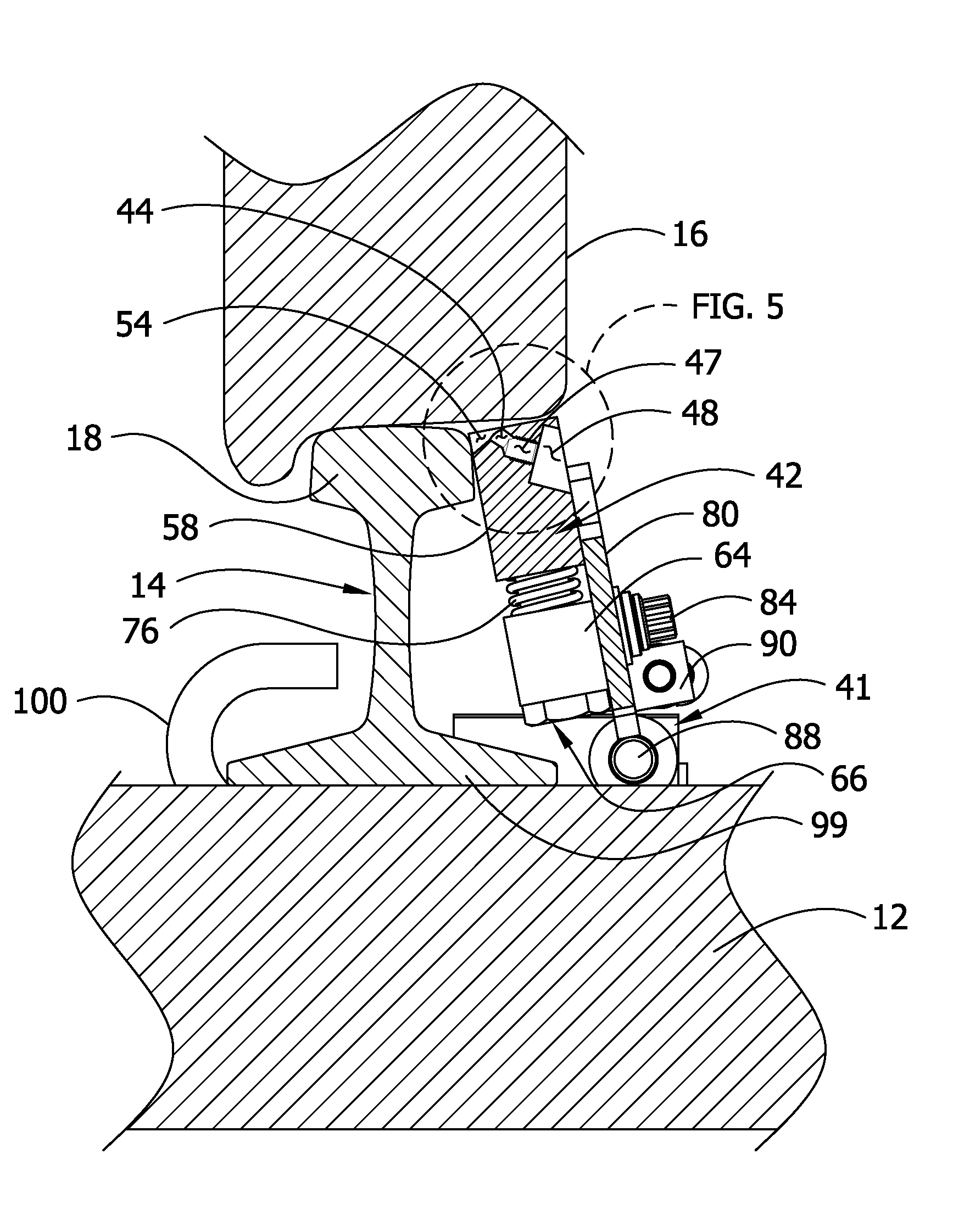

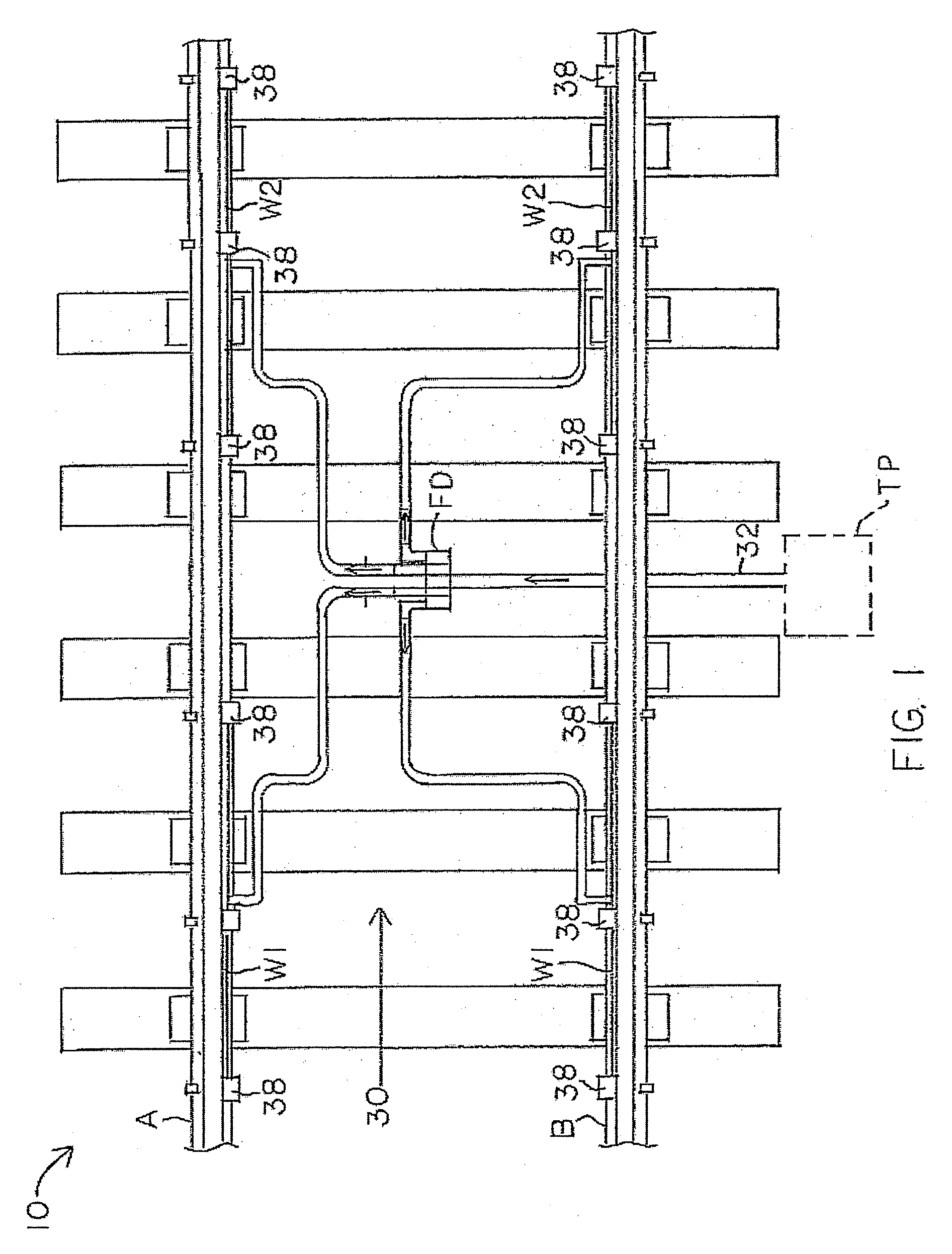

Apparatus for Applying a Pumpable Material to a Rail Head

An applicator assembly for delivery of a pumpable material to a top surface of a rail head of rail includes an applicator body having an orifice for delivery of the pumpable material to the top surface of the rail. The body is resiliently yieldable to permit the applicator body to move from a raised position, in which the orifice is positioned for delivering the pumpable material to the top surface of the rail head, to a depressed position in the event the applicator is contacted by a train wheel. The applicator body thereafter is adapted to return to the raised position.

Owner:LINCOLN INDUSTRIES CORP

Method and system for identifying an erroneous speed of a vehicle

InactiveUS20130268172A1Analogue computers for vehiclesAnalogue computers for trafficSize determinationEngineering

A method includes receiving an input size of a wheel of a vehicle, determining a derived speed of the vehicle that is based on the input size of the wheel, determining a reference speed of the vehicle as the vehicle moves, comparing the derived speed with the reference speed of the vehicle, and identifying an error in the input size of the wheel based on a difference between the derived speed and the reference speed. A system includes a control unit configured to determine a derived speed of a vehicle that is based on an input size of the wheel and a reference speed of the vehicle as the vehicle moves. The control unit compares the derived speed with the reference speed of the vehicle in order to identify an error in the input size of the wheel.

Owner:GE GLOBAL SOURCING LLC

Grease Guide

A trough for use on wiping bar assembly of a rail lubrication system, wherein the wiping bar assembly includes a manifold body and a flow passageway having an exit end at least partially defined in the manifold body. The trough includes a body having a first section and a second section extending away from the first section, wherein the first section of the body is positioned adjacent the exit end, and wherein a mat is provided within the trough.

Owner:PORTEC RAIL PRODS

Method for reducing wear of steel elements in sliding-rolling contact

InactiveUS7244695B2Quantity minimizationConvenient amountOrganic chemistryWork treatment devicesAntioxidantMetallurgy

According to the invention there is provided a method of reducing wear of one or both of two steel elements having surfaces in sliding or sliding-rolling contact. The method involves applying an HPF friction control composition to one, or more than one contacting surface of one or both of the two steel elements. In a particular example, the HPF friction control composition comprises a rheological control agent, a lubricant, a friction modifier, and one, or more than one of a retentivity agent, an antioxidant, a consistency modifier, and a freezing point depressant.

Owner:KELSAN TECH

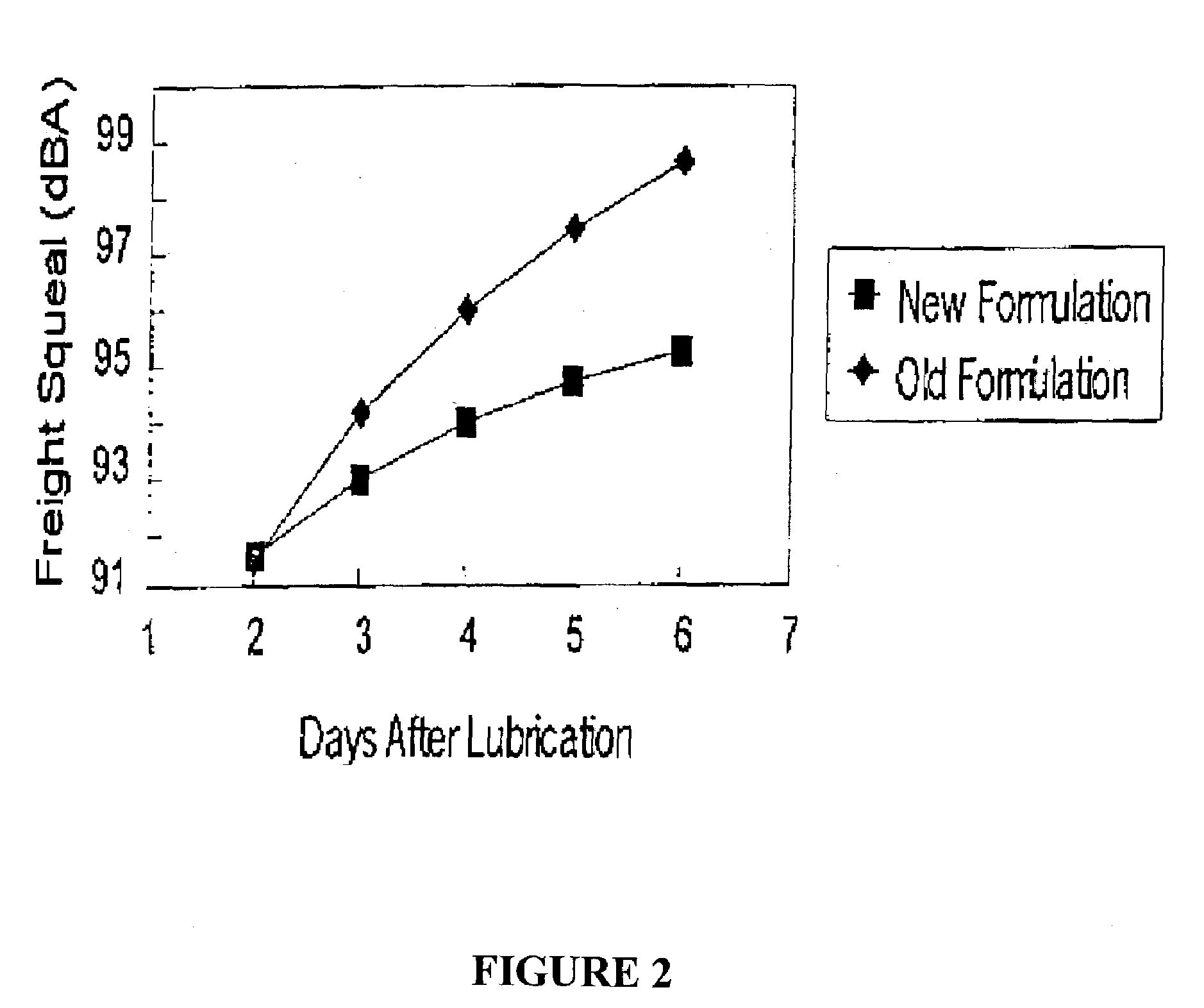

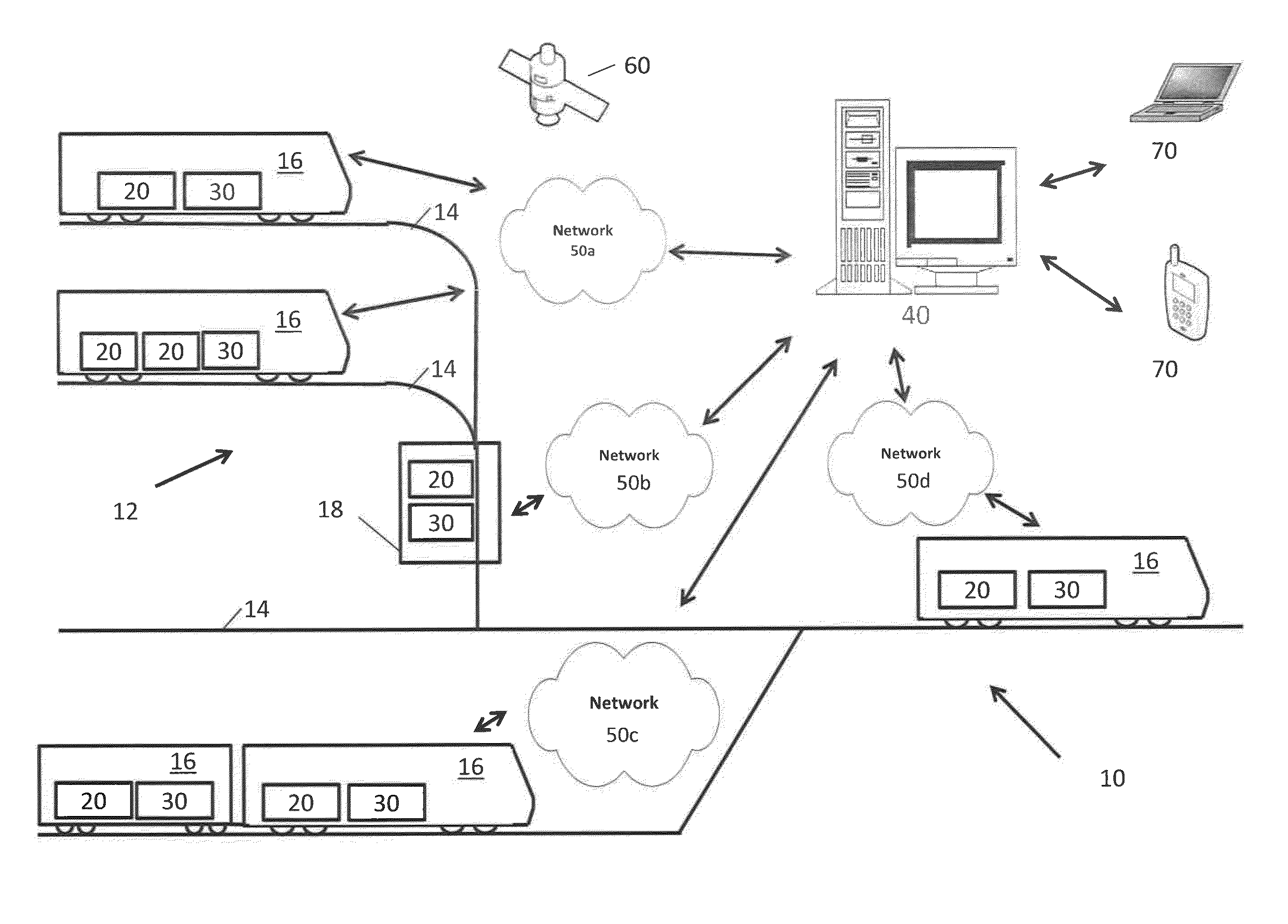

System and method for fleet wheel-rail lubrication and noise management

InactiveUS20140142791A1Wheel-rims surveying/measuringDigital data processing detailsFleet managementLubrication

The present invention is a system and method for the control of applying lubrication to the wheels of a fleet of railed-based vehicles and the rails on which the railed-based vehicles travel. In an aspect, the wheel-rail lubrication fleet management system is configured to analyze and optimize the application of wheel / rail lubrication within a whole fleet to the best possible efficiency. In an additional aspect, the wheel-rail lubrication fleet management system is further configured to manage the noise created by the interaction between the wheels and rails of the whole fleet. In such aspects, the wheel-rail lubrication fleet management system can monitor the real results of the application of lubricant of rail-wheel systems that utilize the lubrication fleet management system.

Owner:IGRALUB NORTH AMERICA

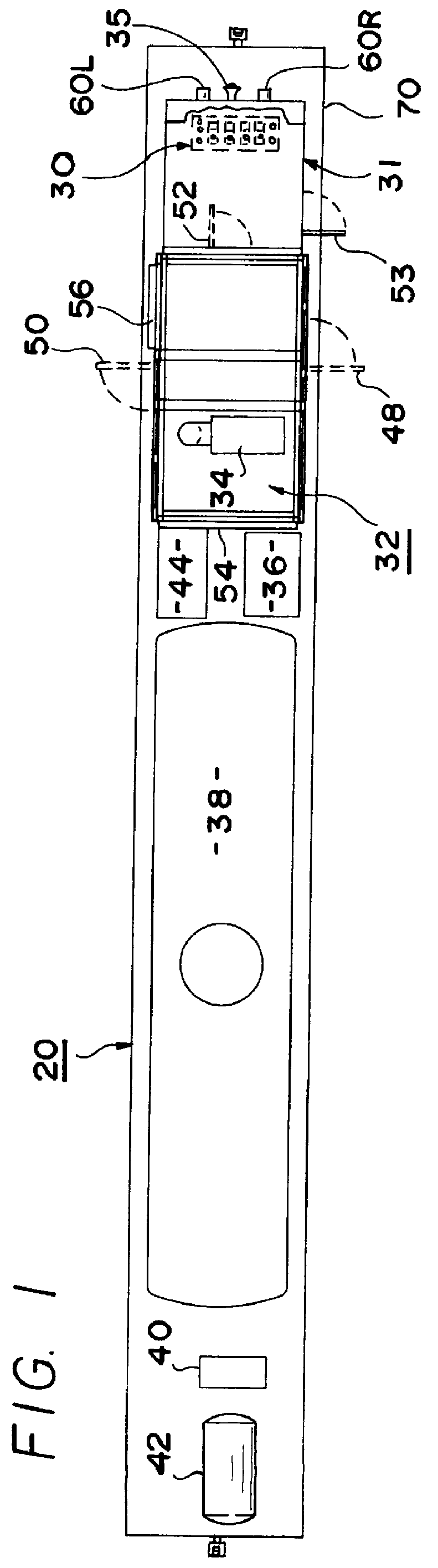

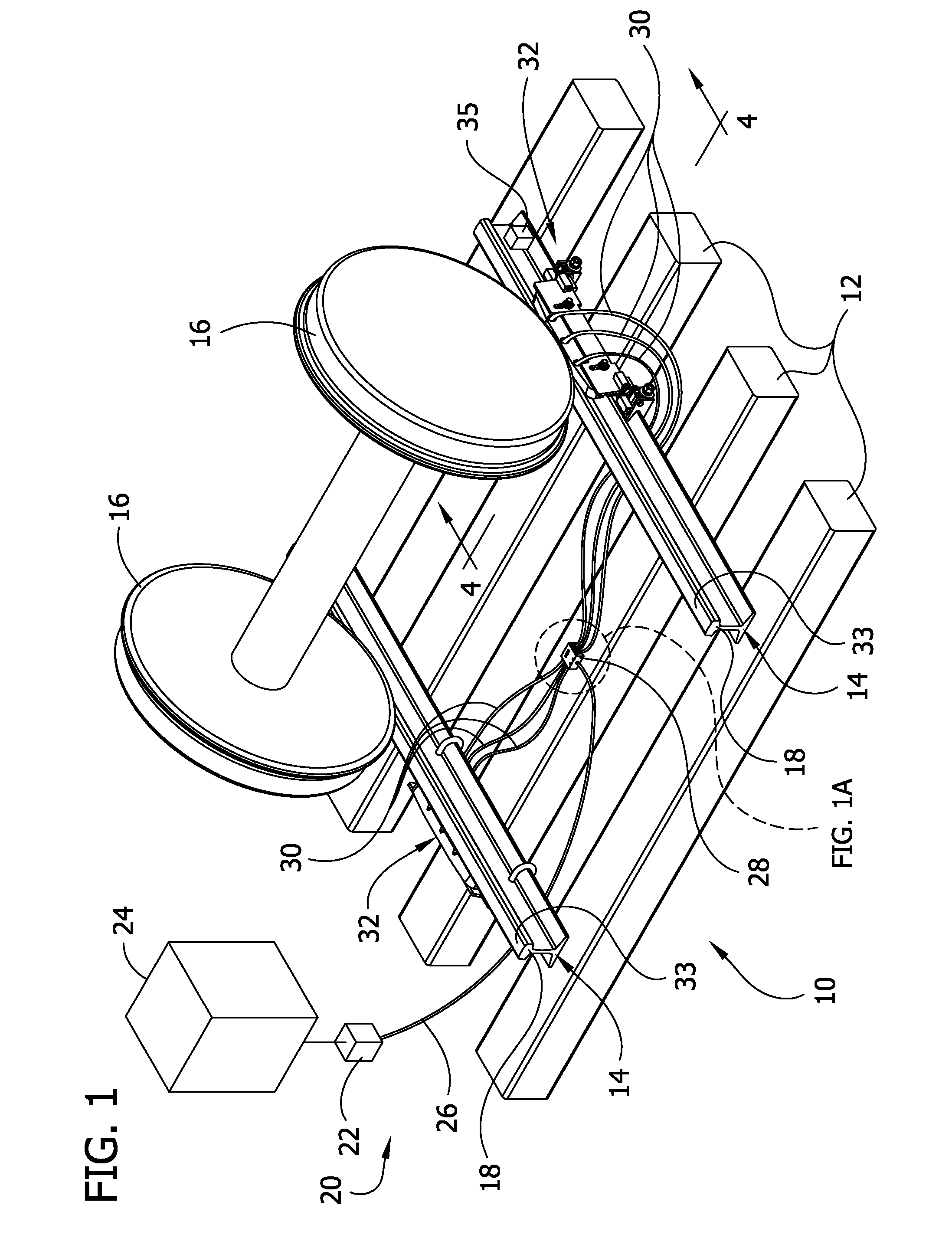

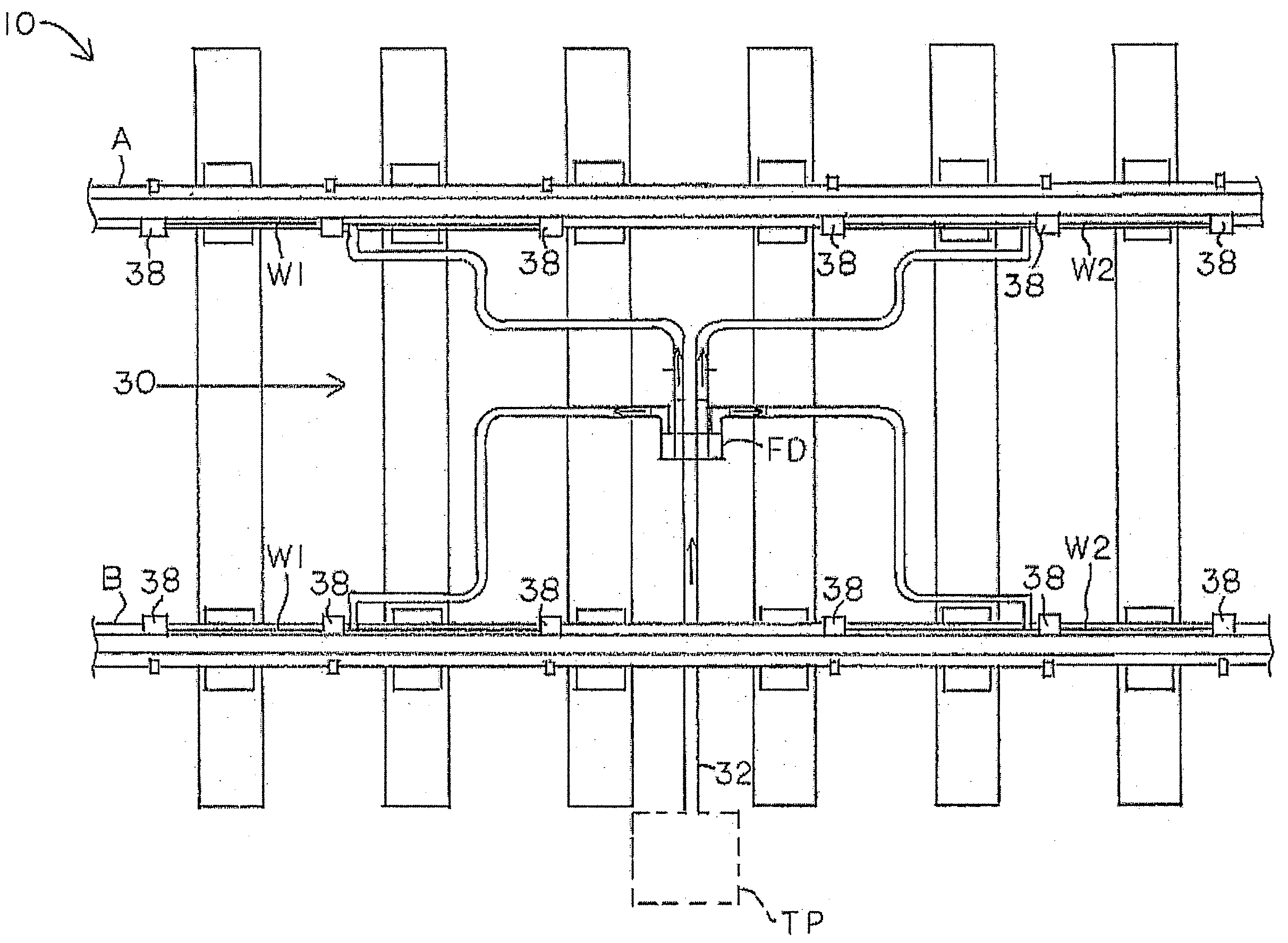

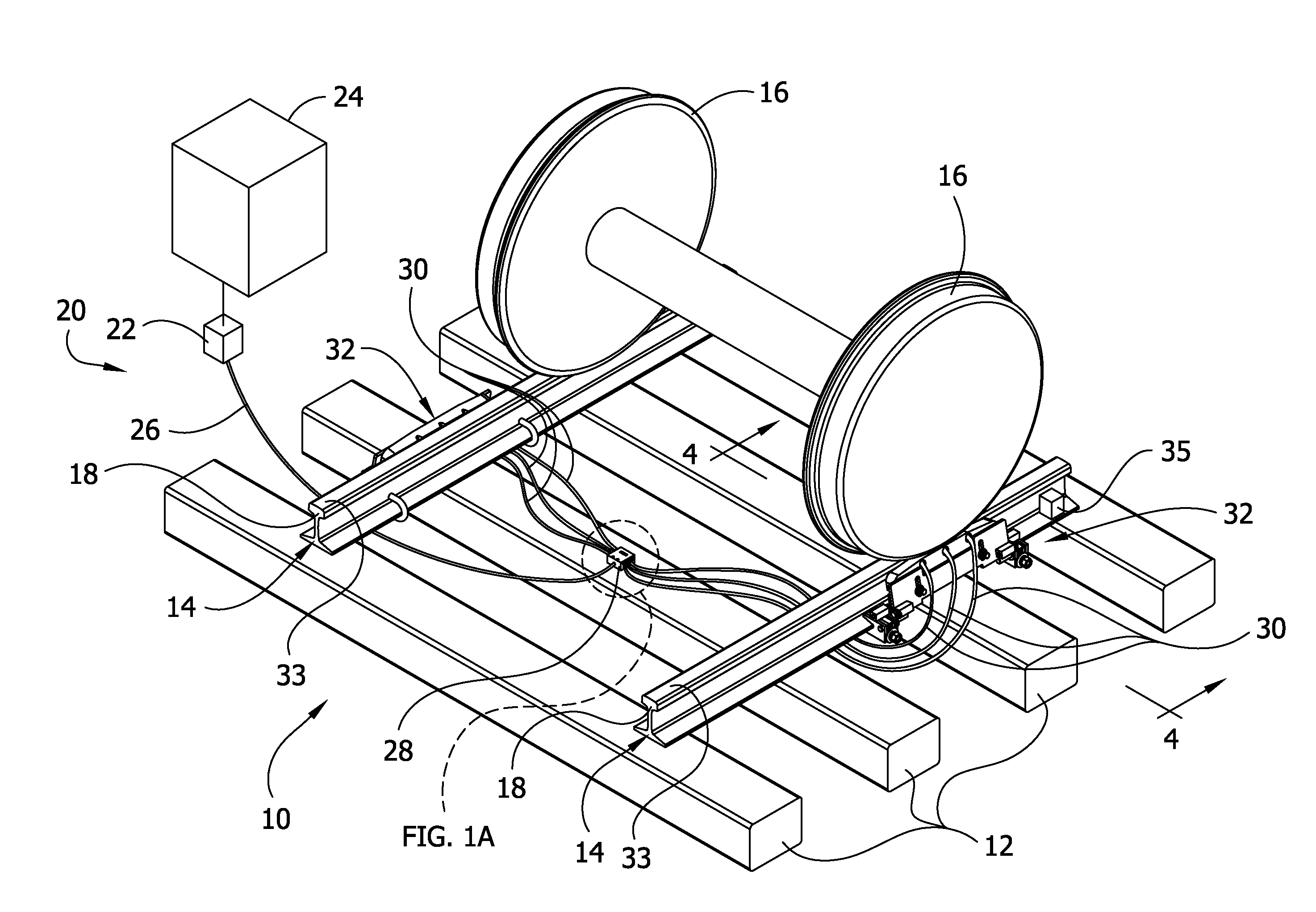

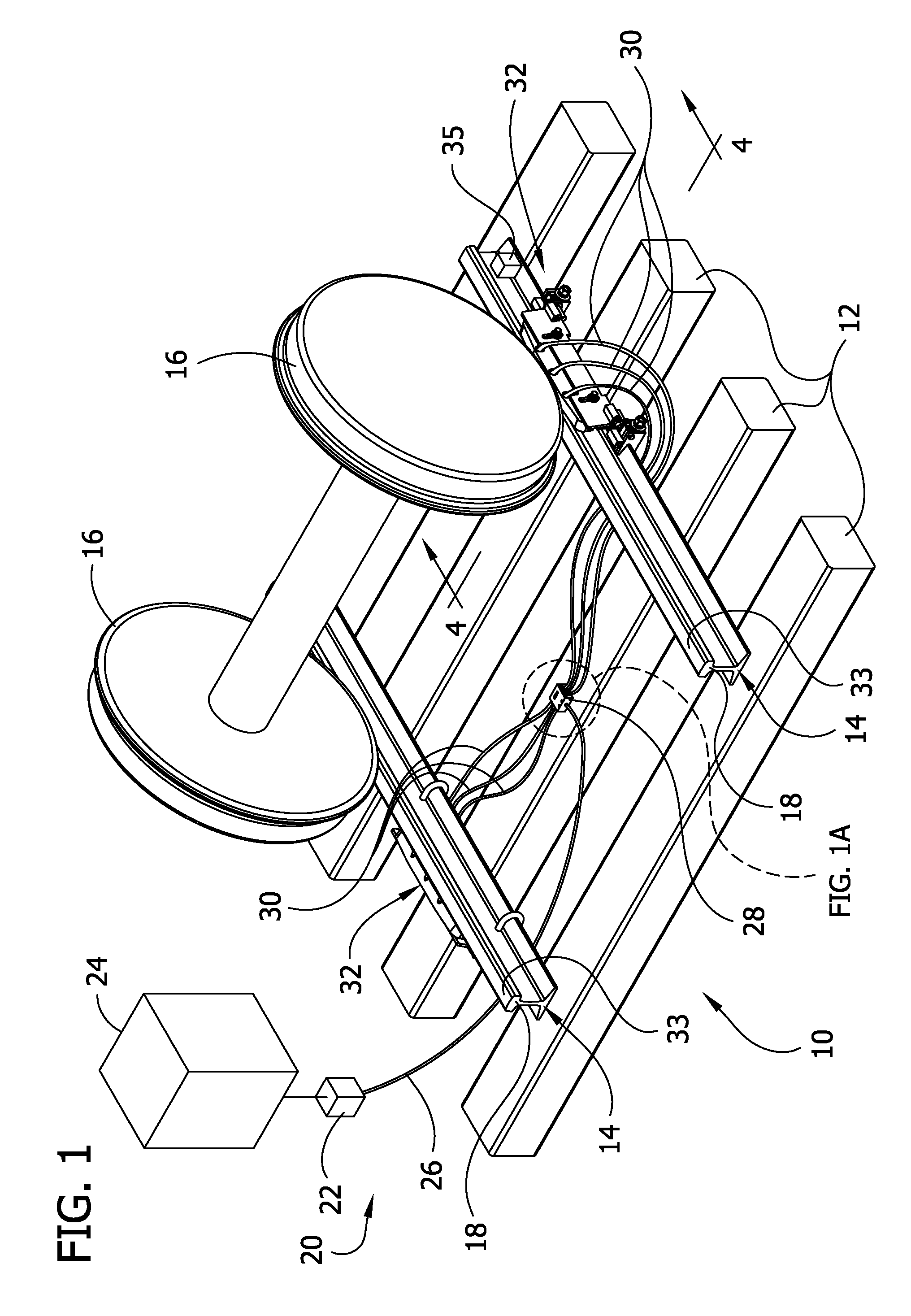

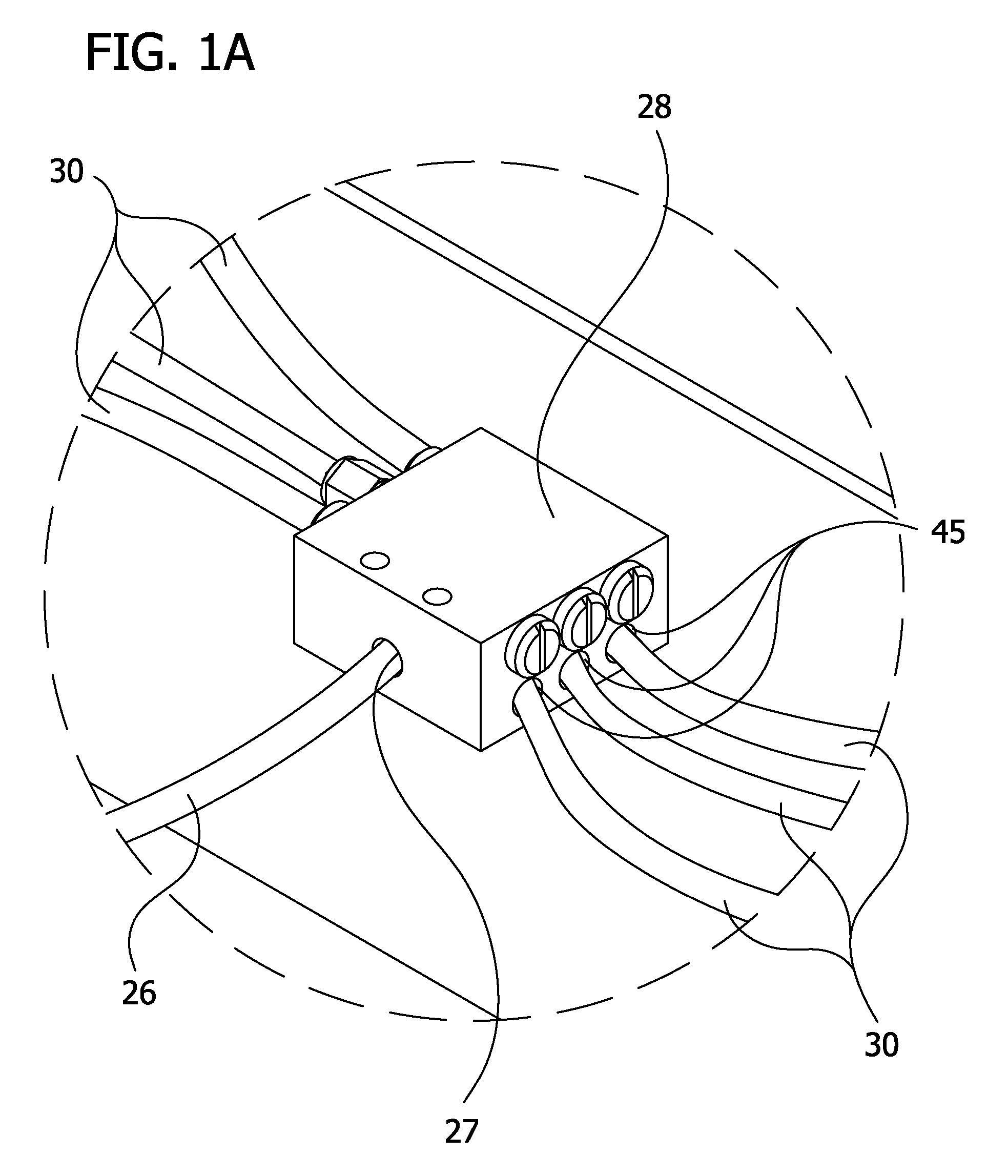

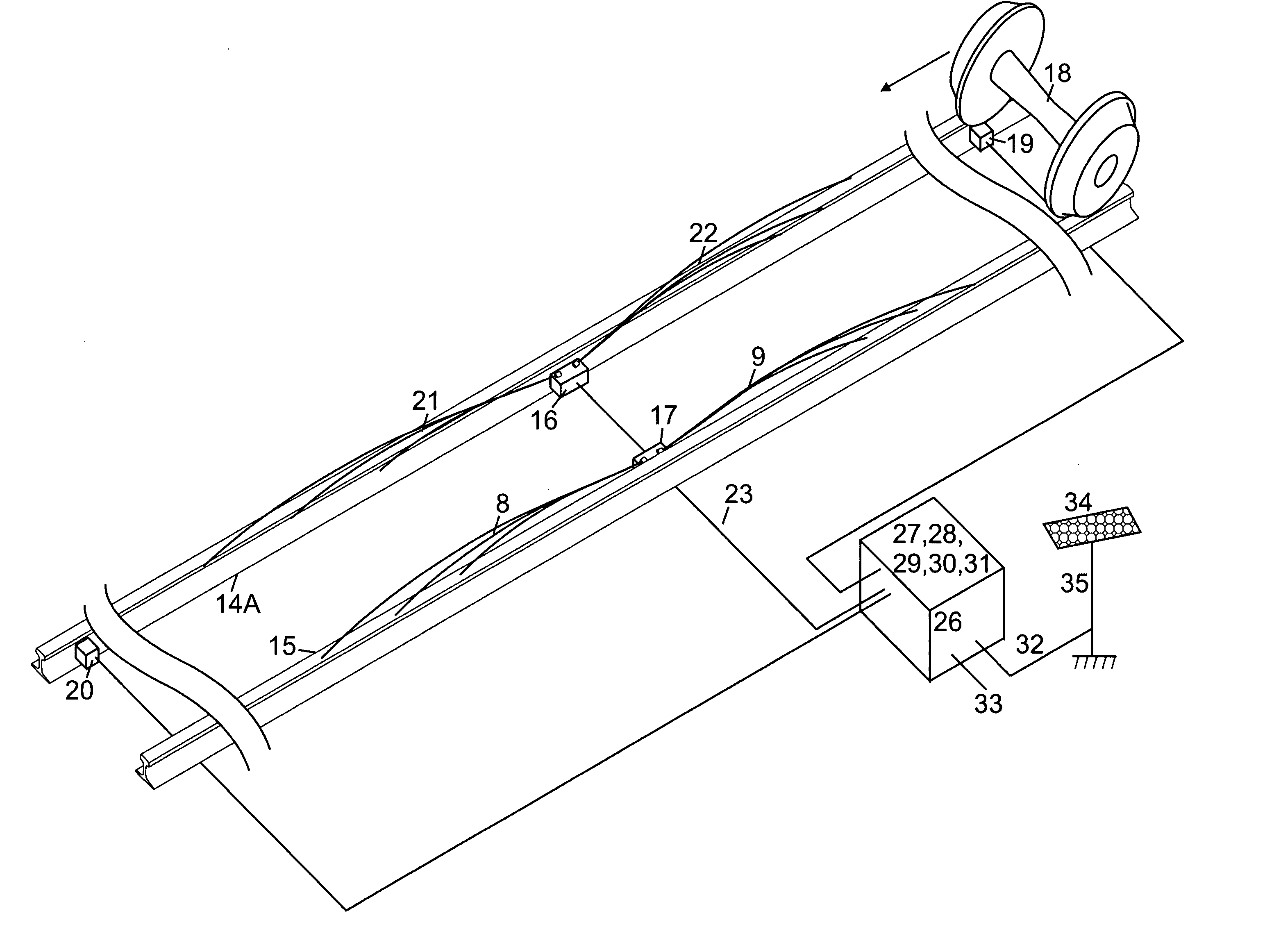

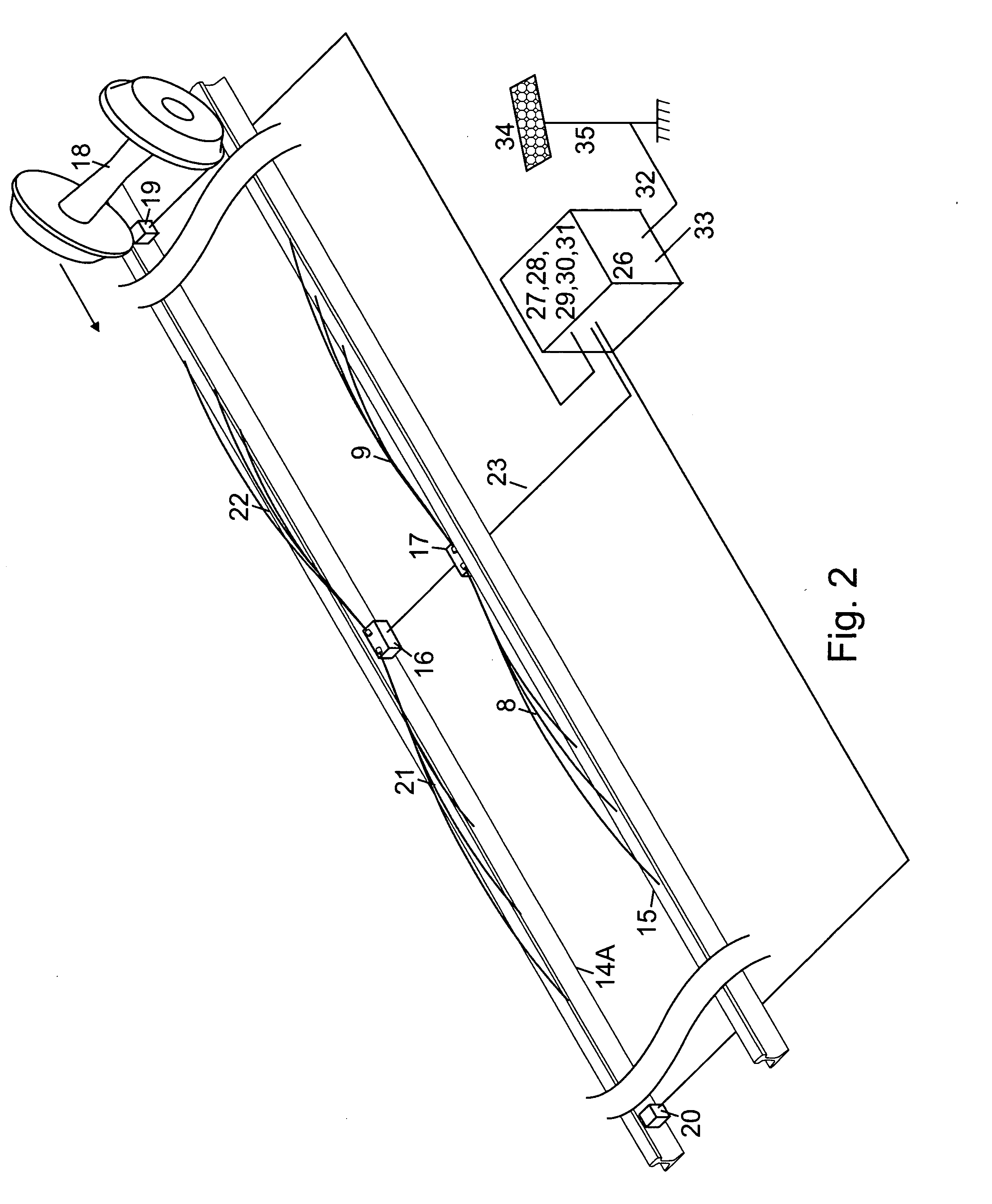

Method And Apparatus For Applying Liquid Compositions In Rail Systems

ActiveUS20070272486A1Increase capacityRail lubricationRail wetting/lubricationEngineeringLiquid composition

A method for applying a liquid composition to a rail surface is provided. This method involves supplying a liquid composition in one or more reservoirs on a rail car (revenue generating car), and applying the liquid composition from the one or more reservoirs to the rail surface. A liquid composition application system is also provided. The liquid composition application system includes a reservoir(s) for holding a liquid composition mounted on a rail car. A pipe is connected to the reservoir(s), and a pump, for moving the liquid composition from the reservoir(s) to a dispensing nozzle(s), is provided. A controller processes topological information, data from the liquid composition application system, or both. The application of the liquid composition may be monitored and controlled from a remote site separate from the rail car.

Owner:L B FOSTER RAIL TECH INC

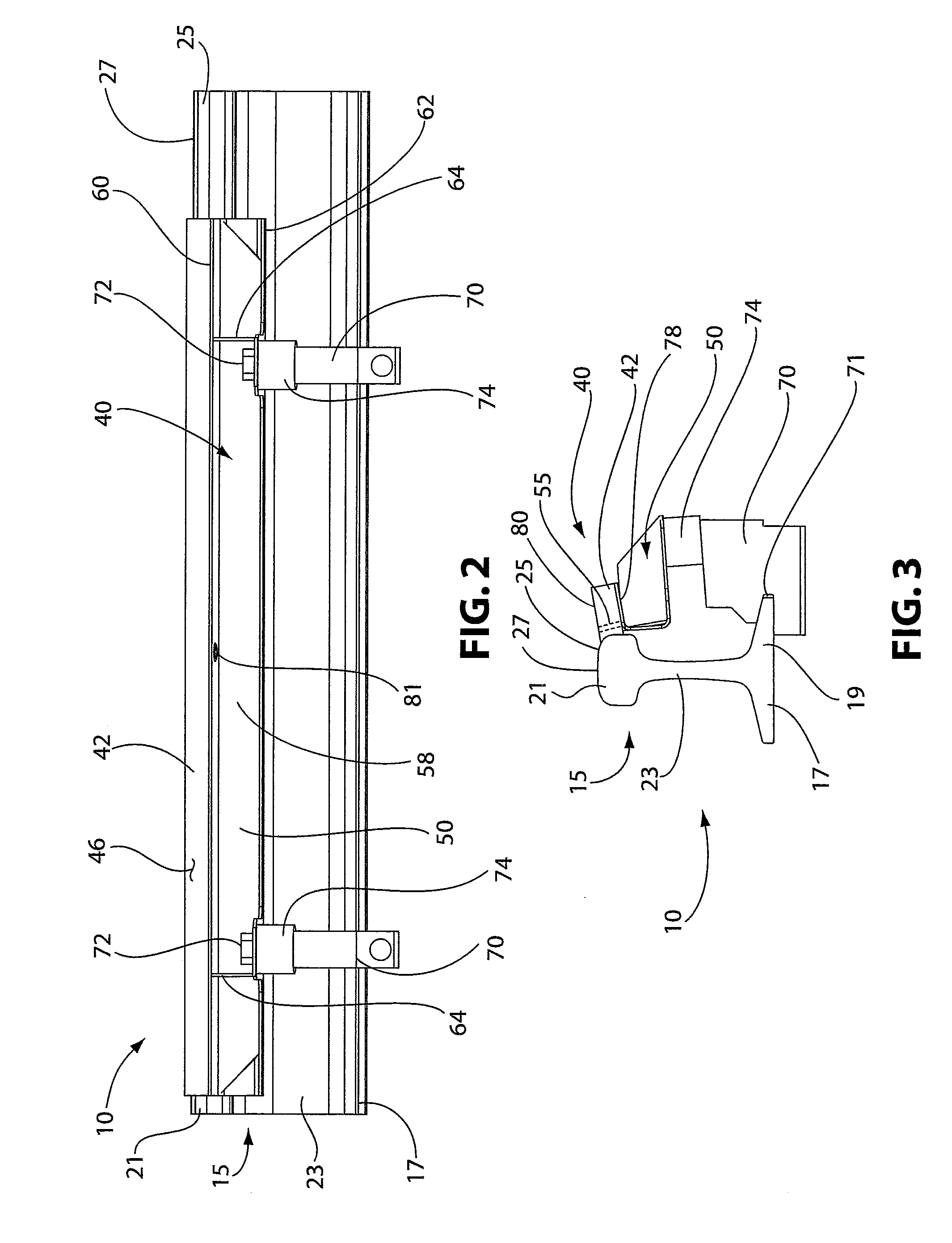

Top of Rail Foam Bar

A rail applicator assembly includes a rail having a head portion, a base portion, and a web portion extending between the head portion and the base portion. The head portion defines an outer surface. An applicator for applying a friction modifying material to the surface of the rail includes a foam body and an applicator support. The foam body is secured to the applicator support and defines a flow passageway that extends through the foam body for friction modifying material to flow through.

Owner:L B FOSTER RAIL TECH INC

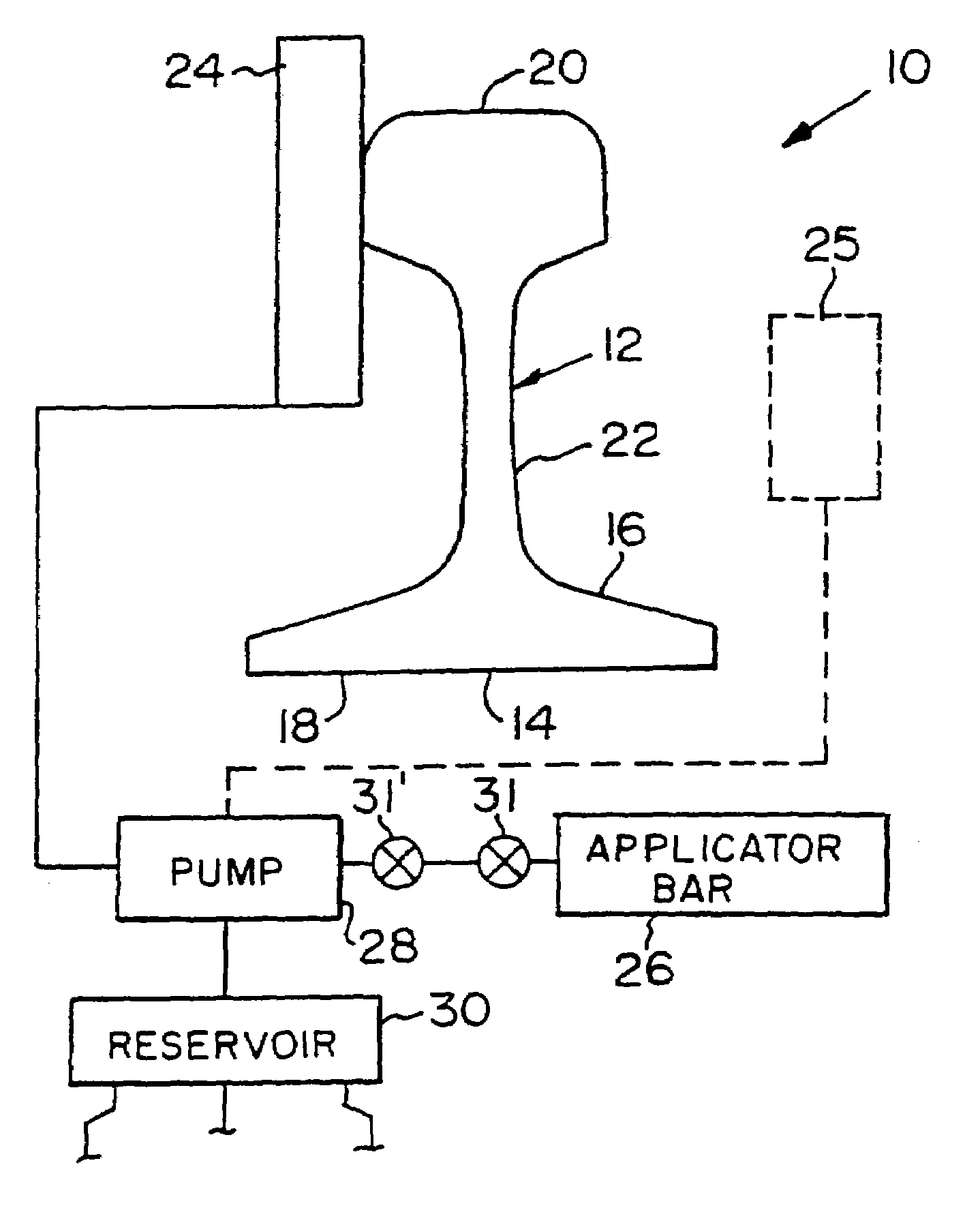

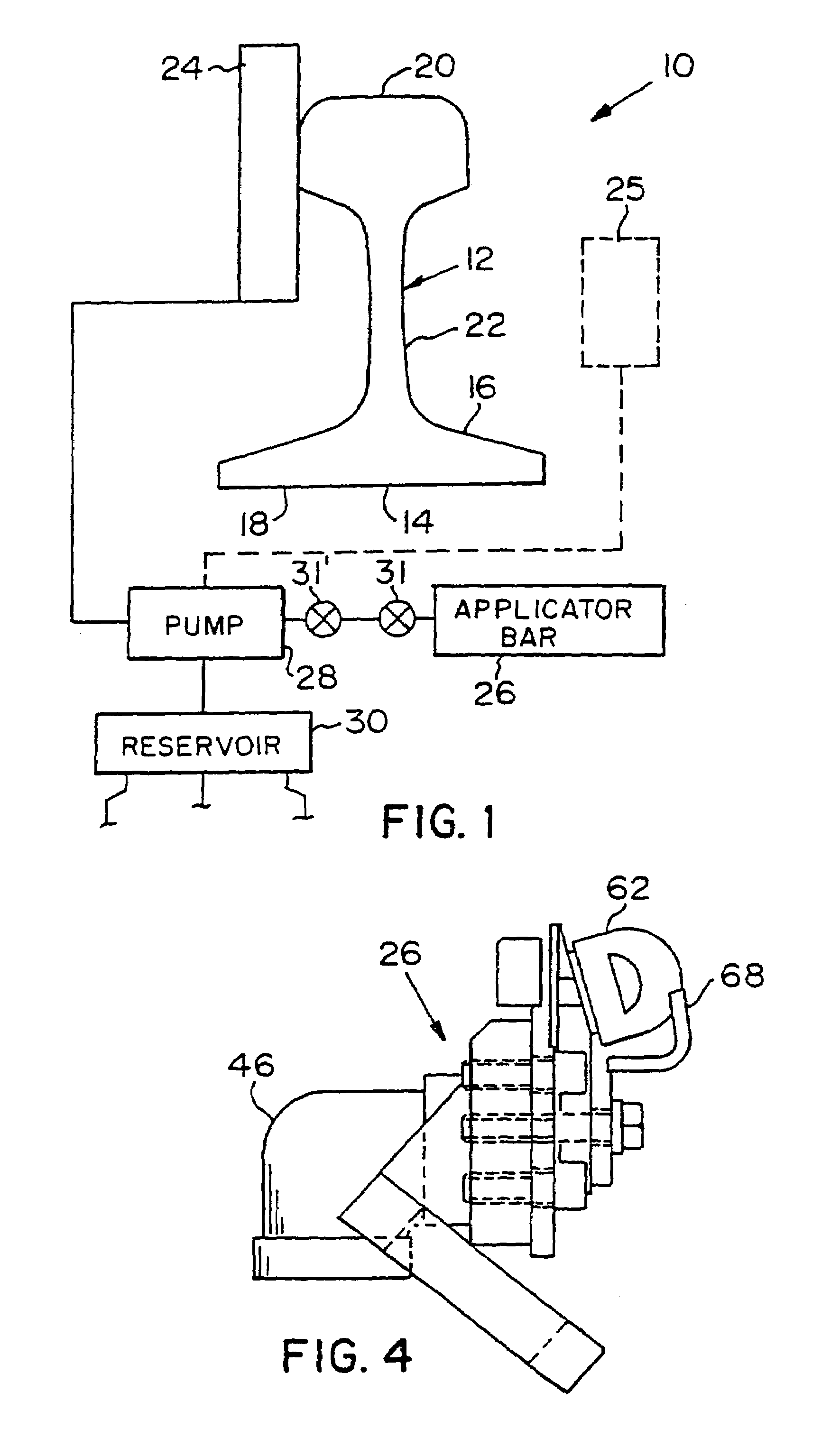

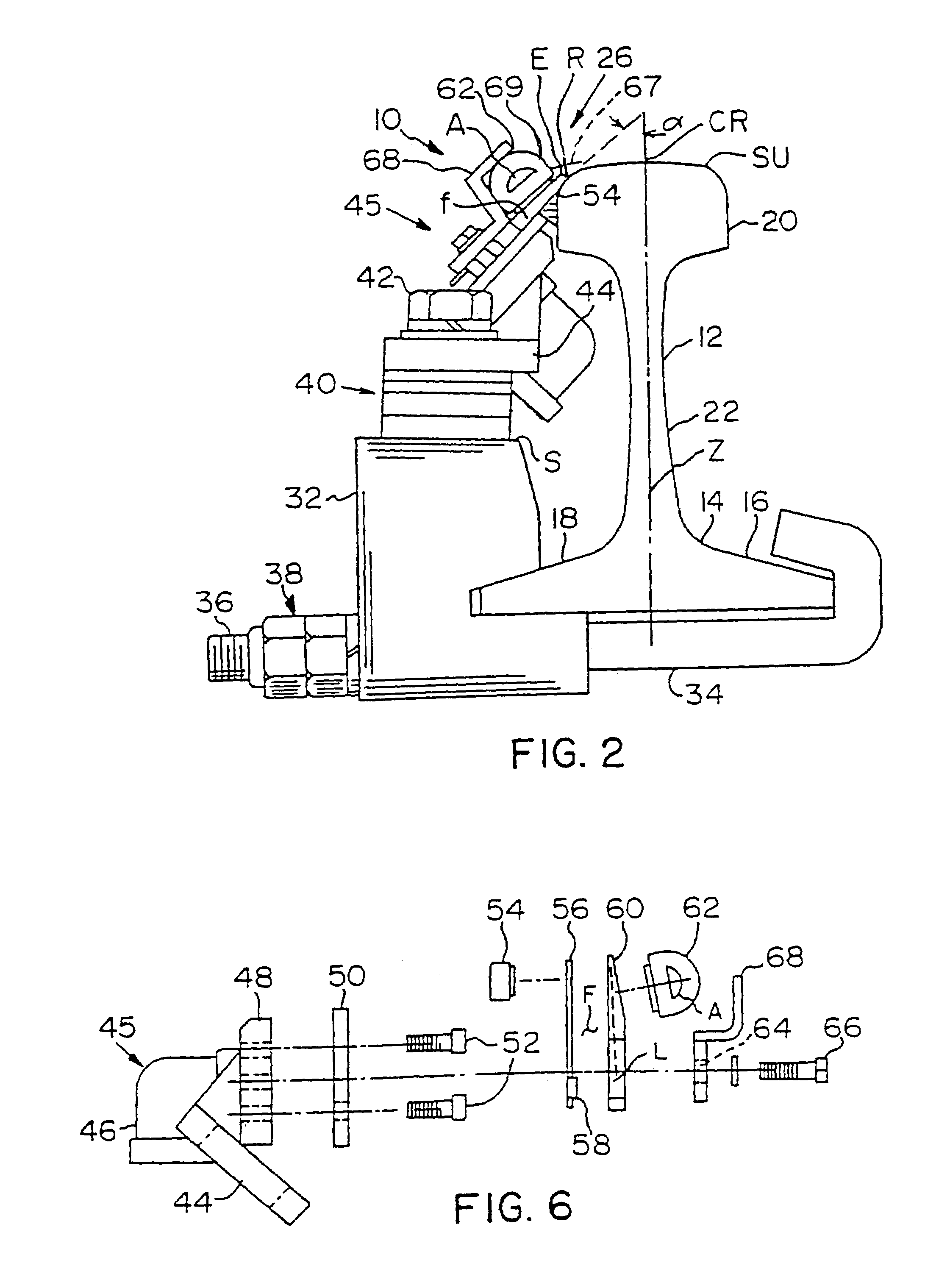

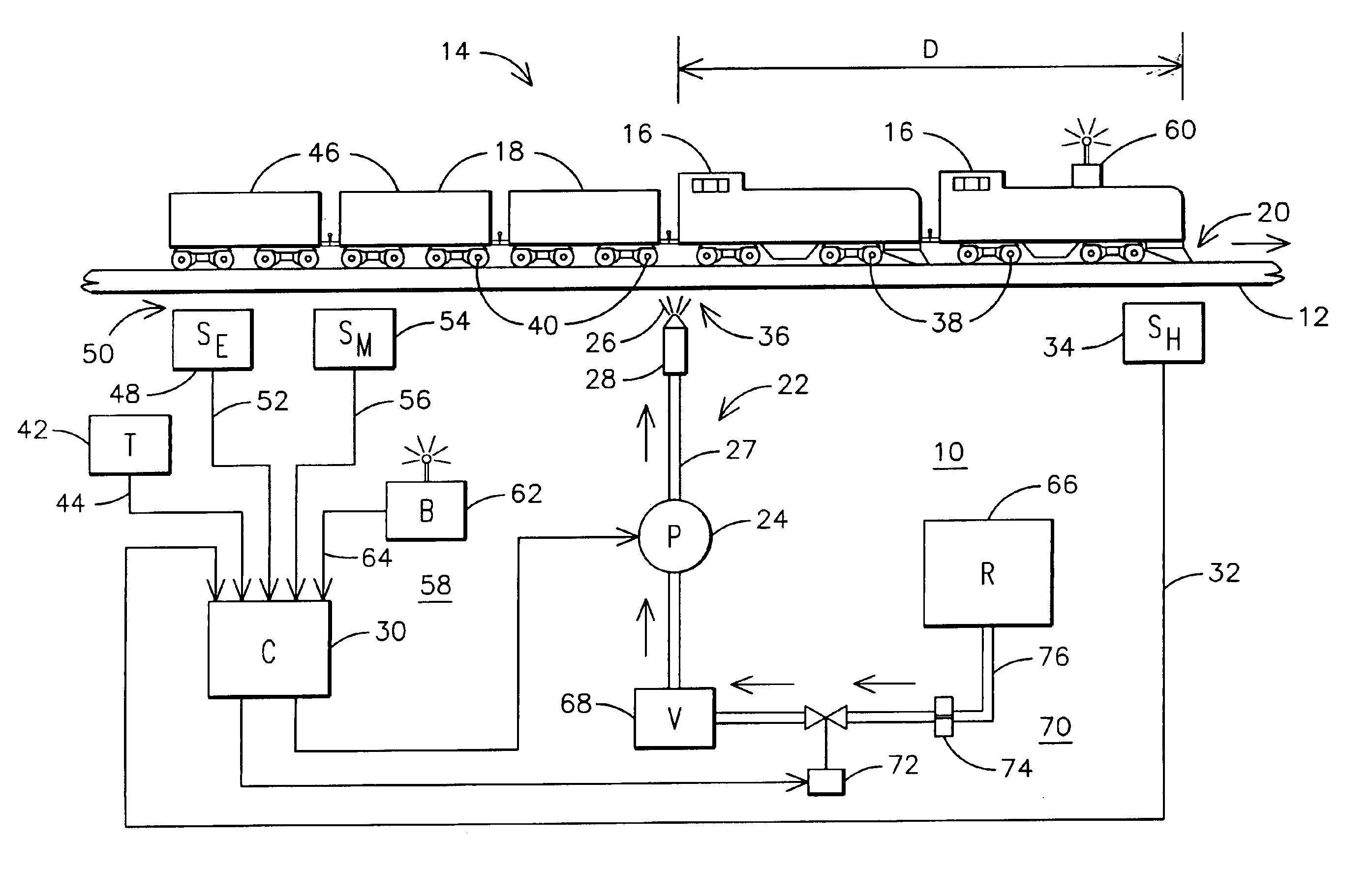

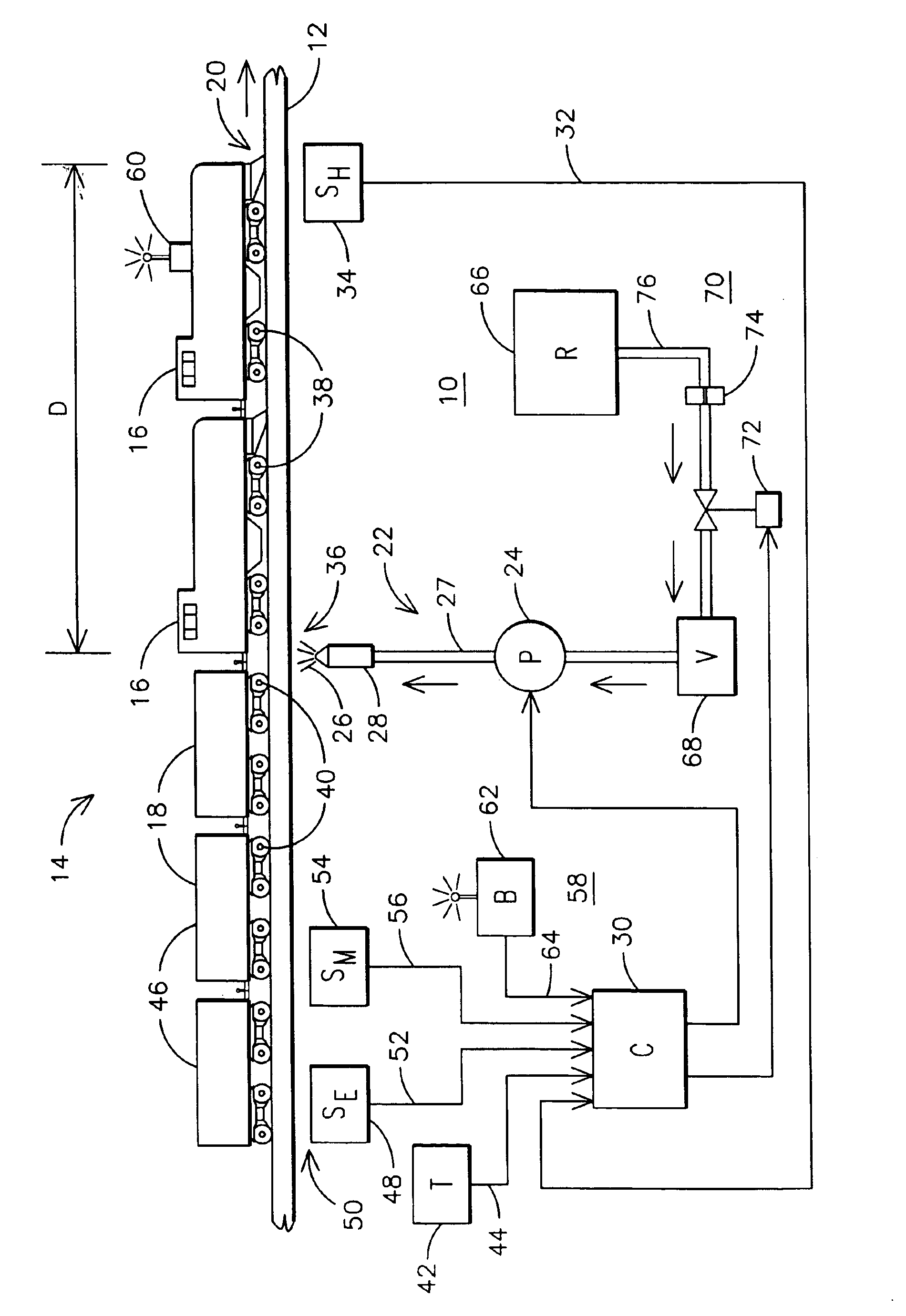

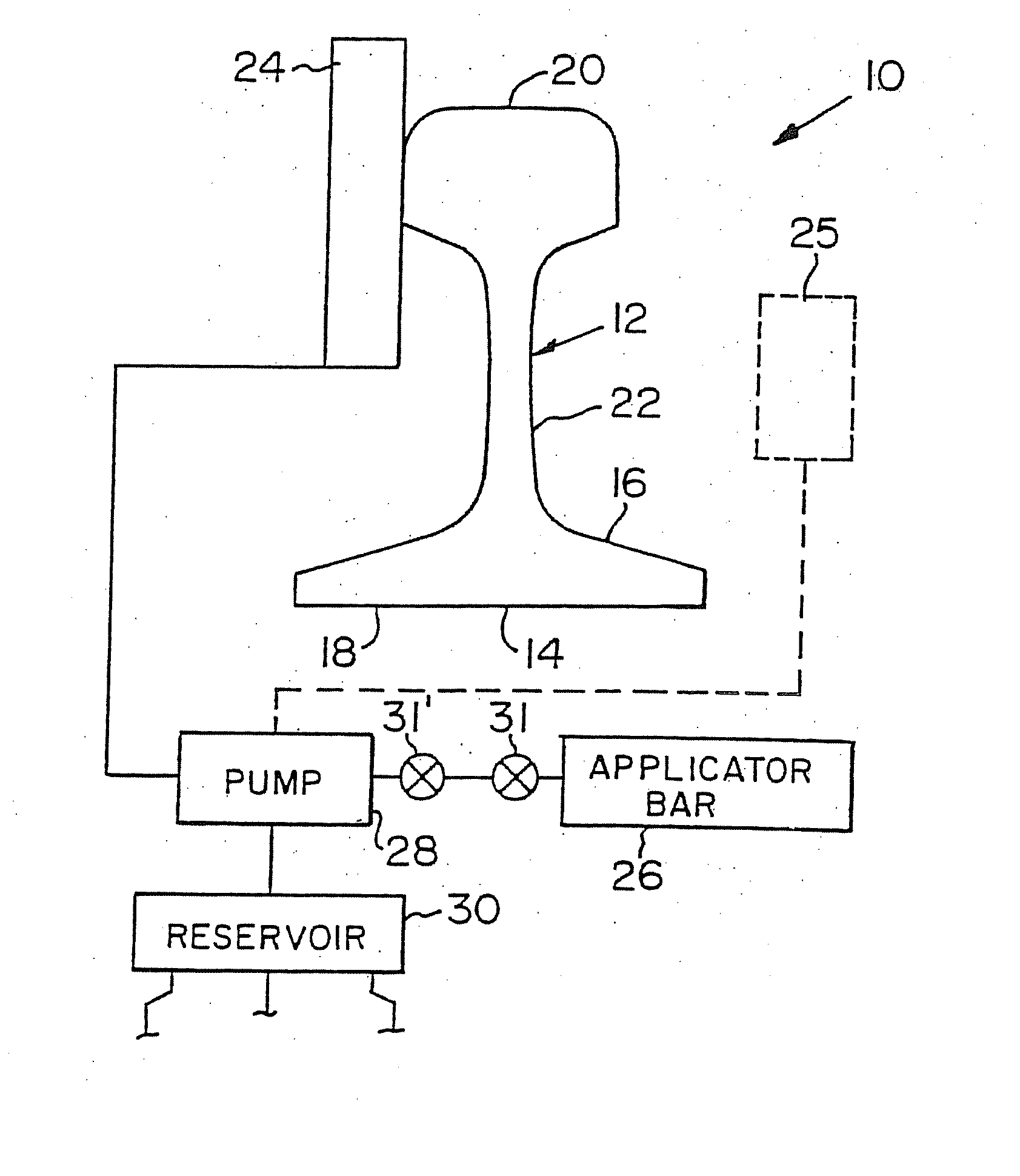

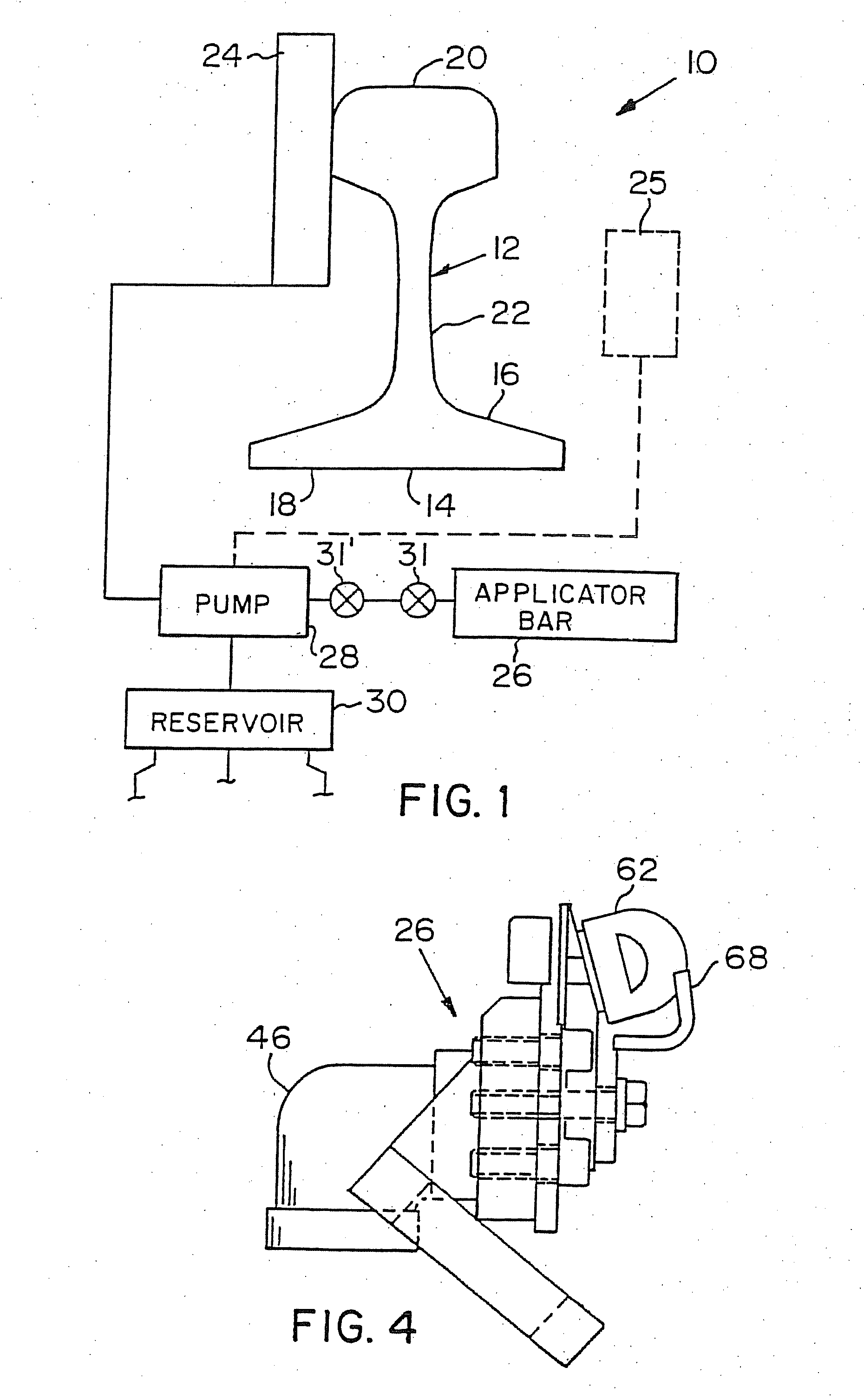

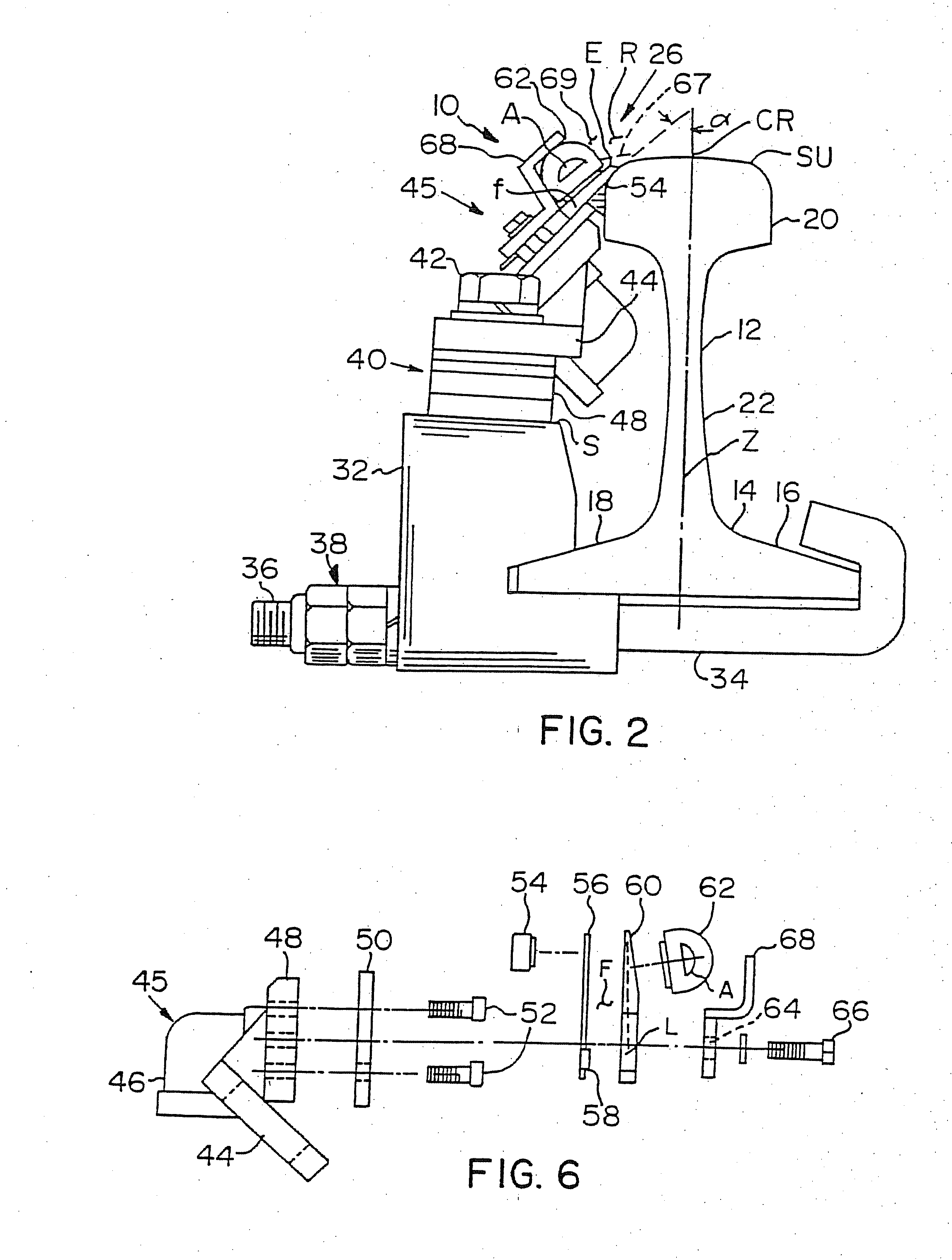

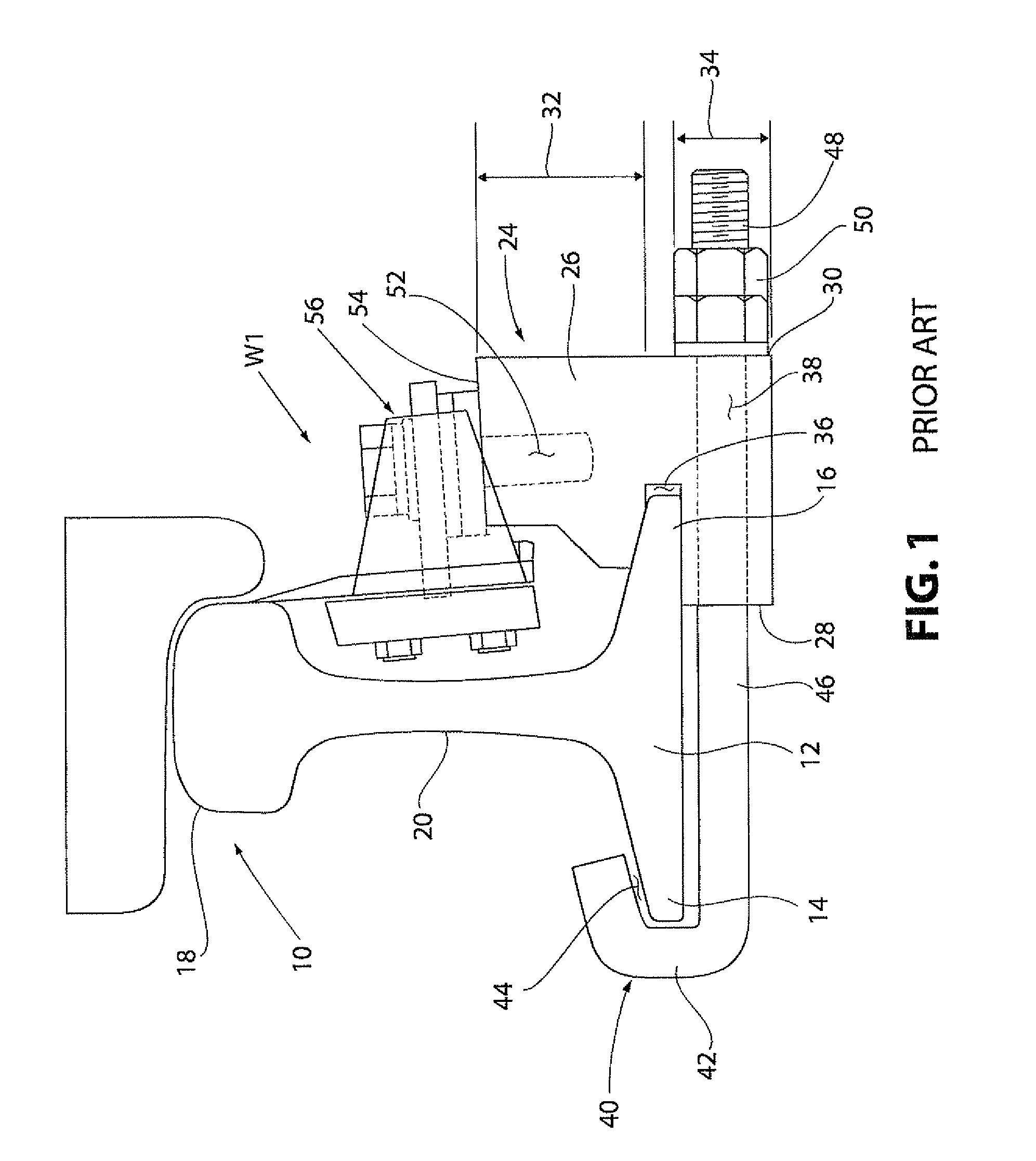

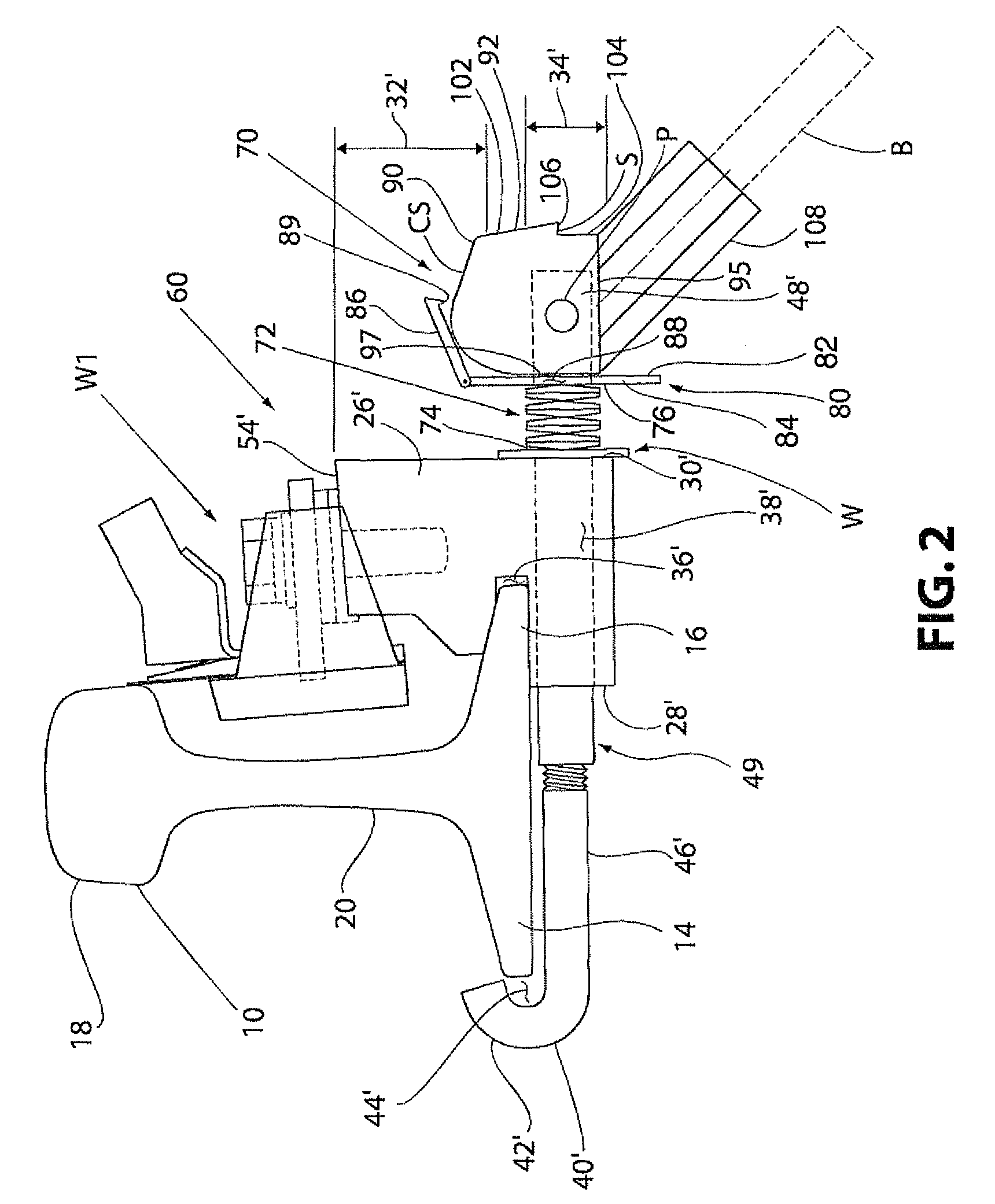

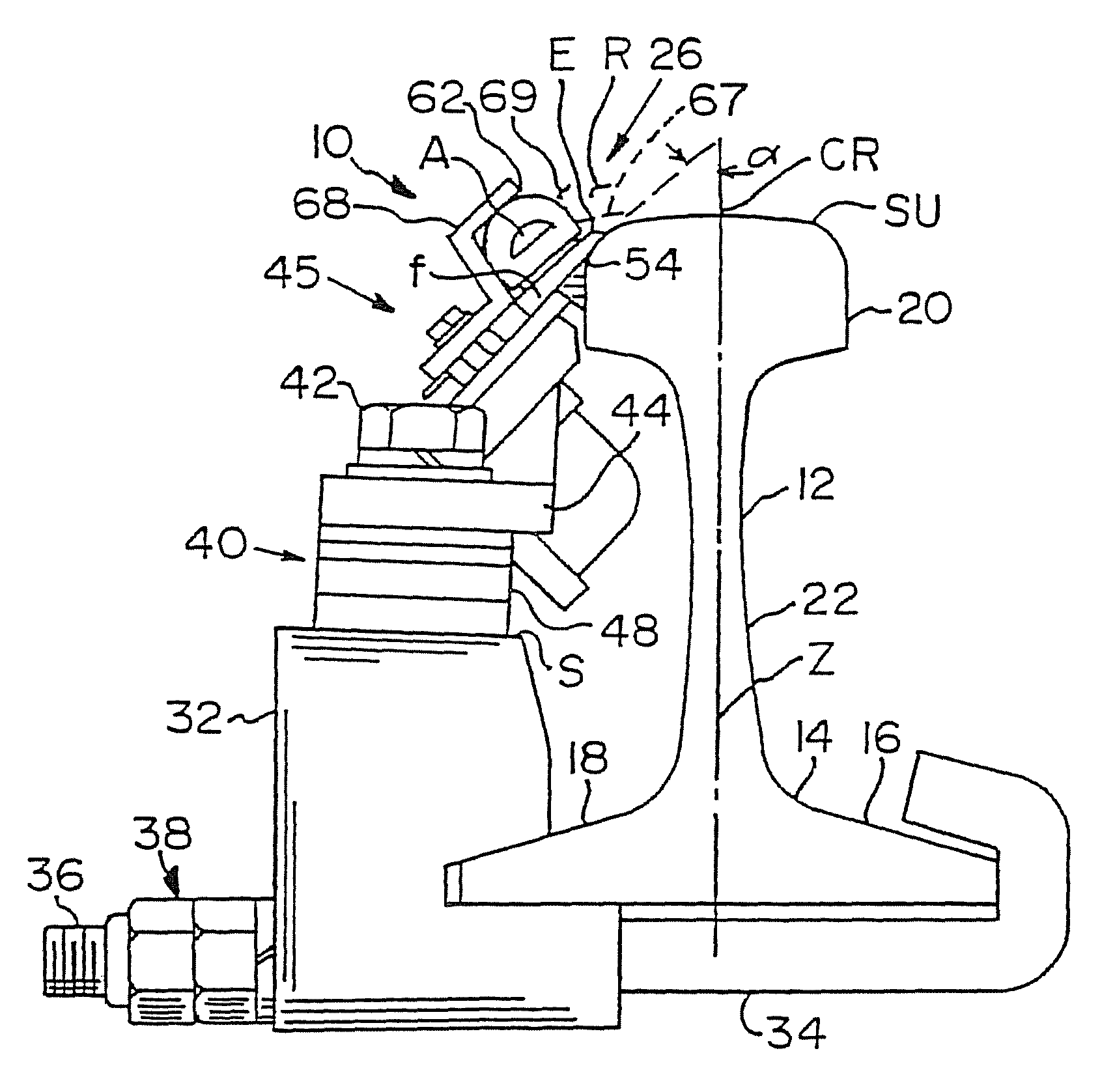

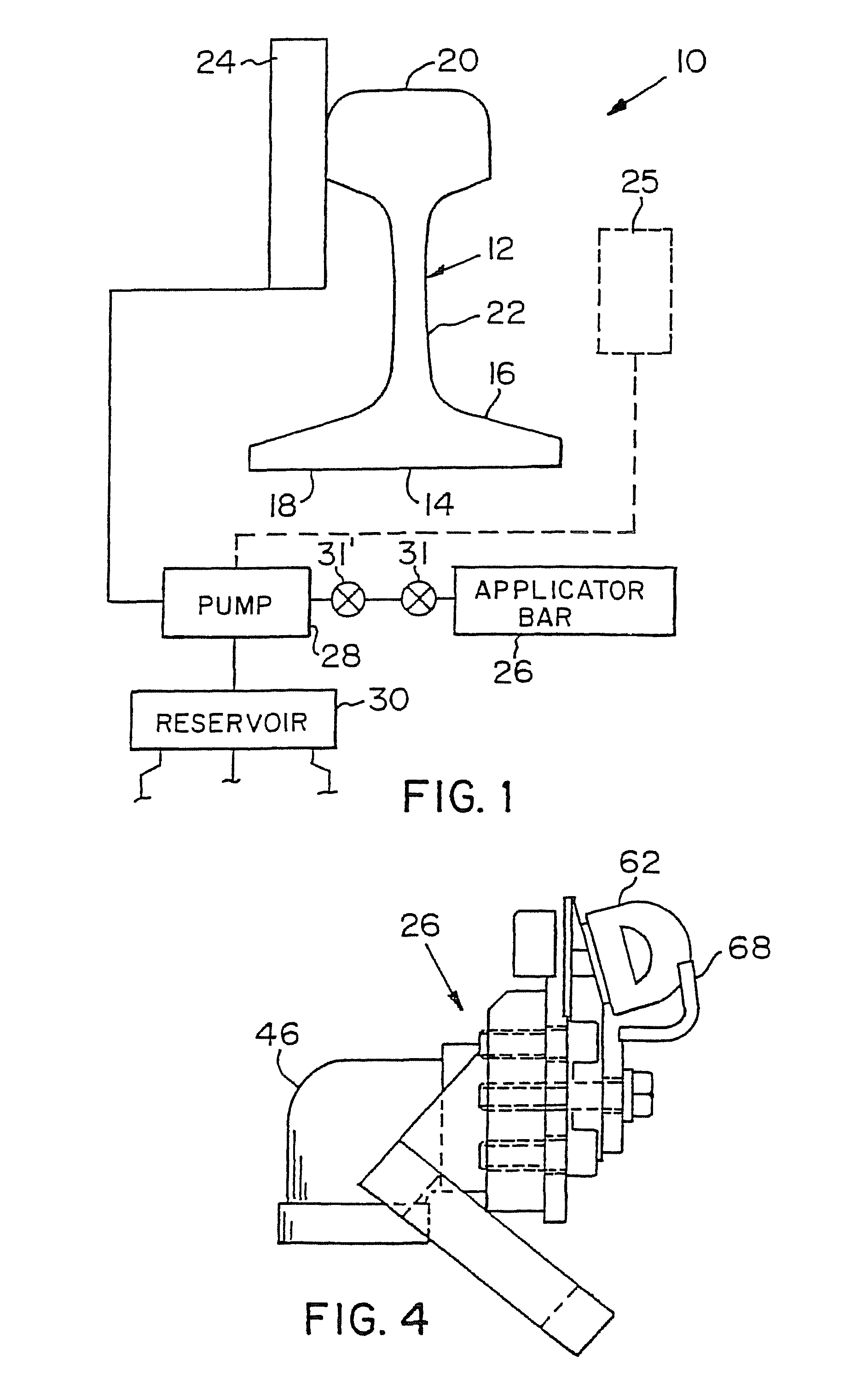

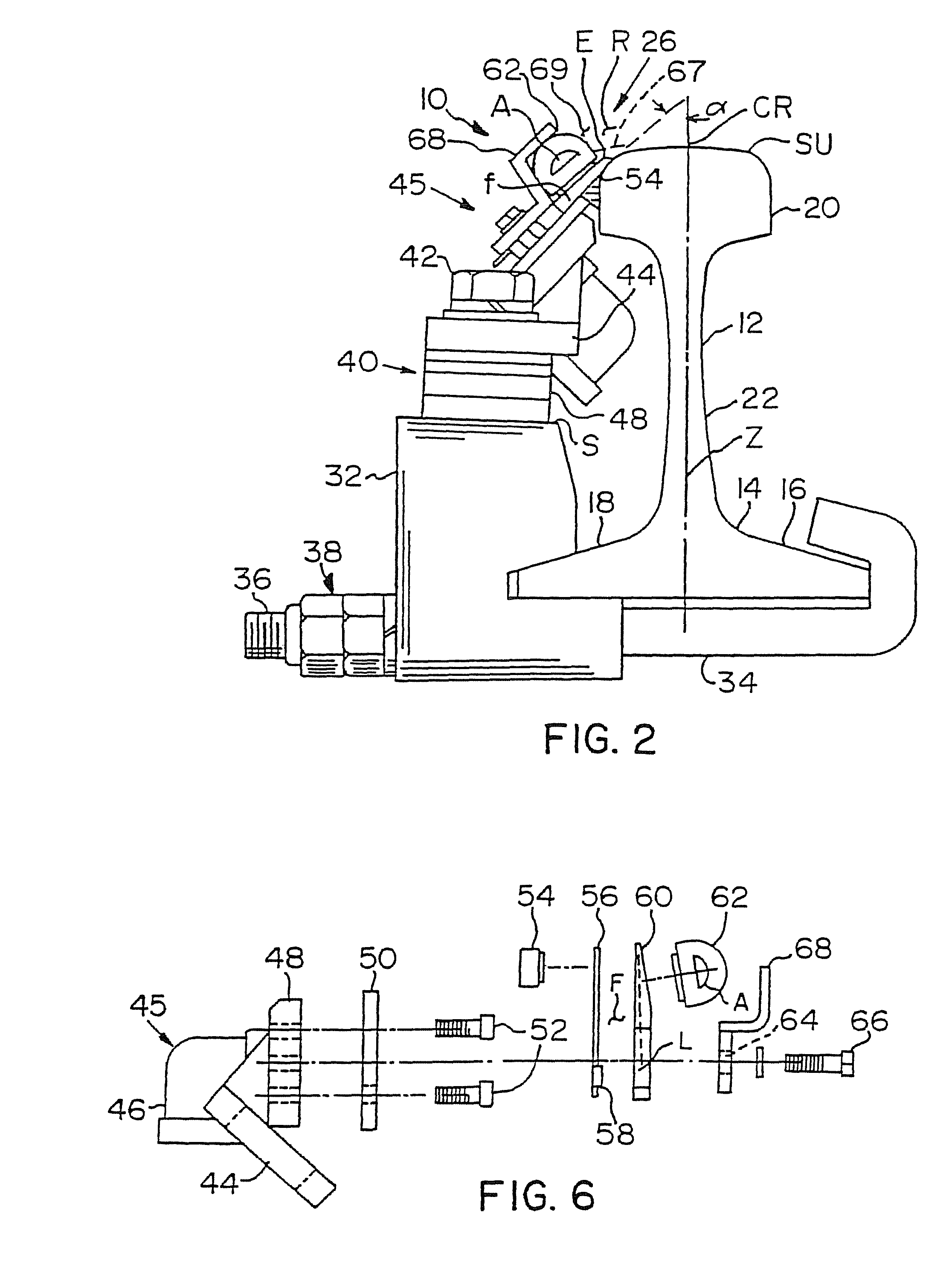

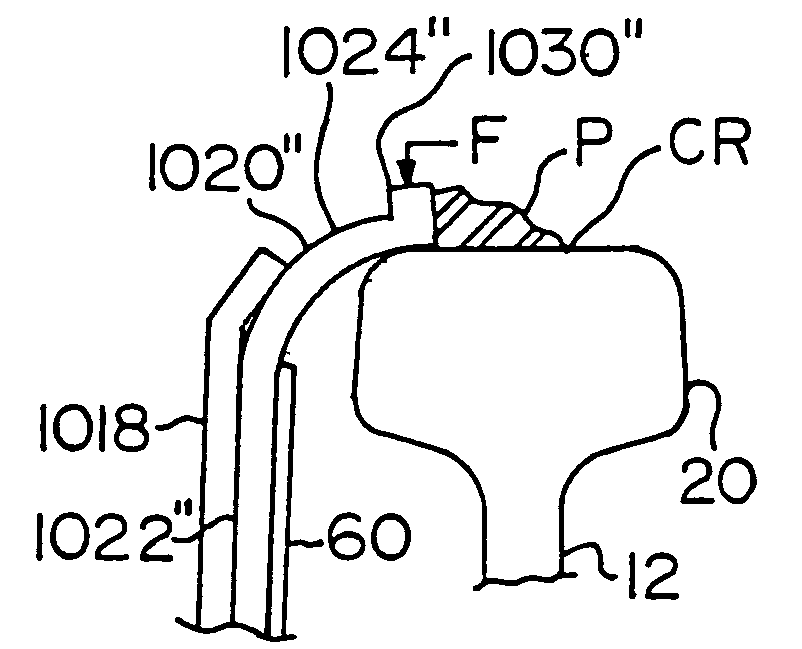

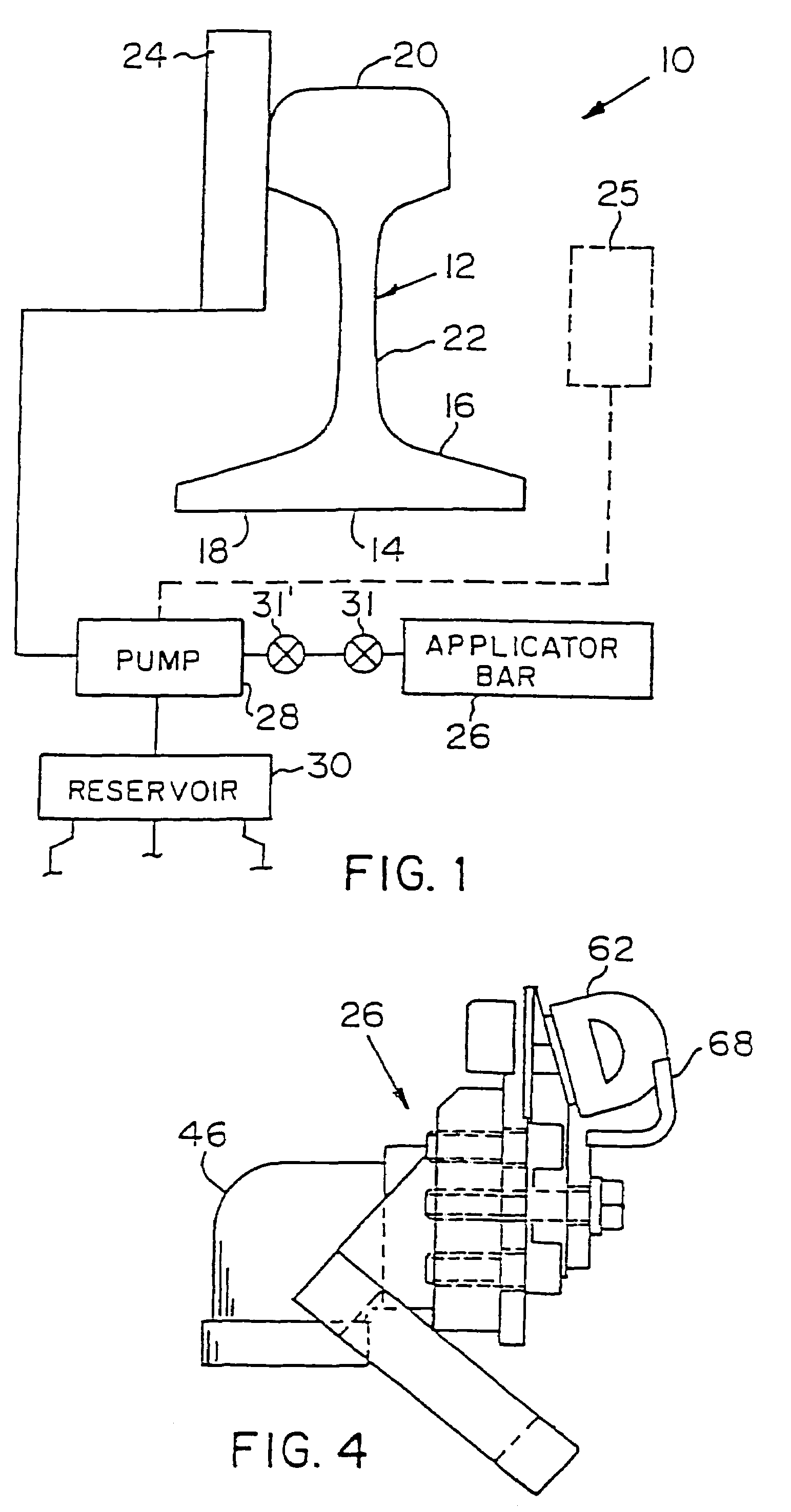

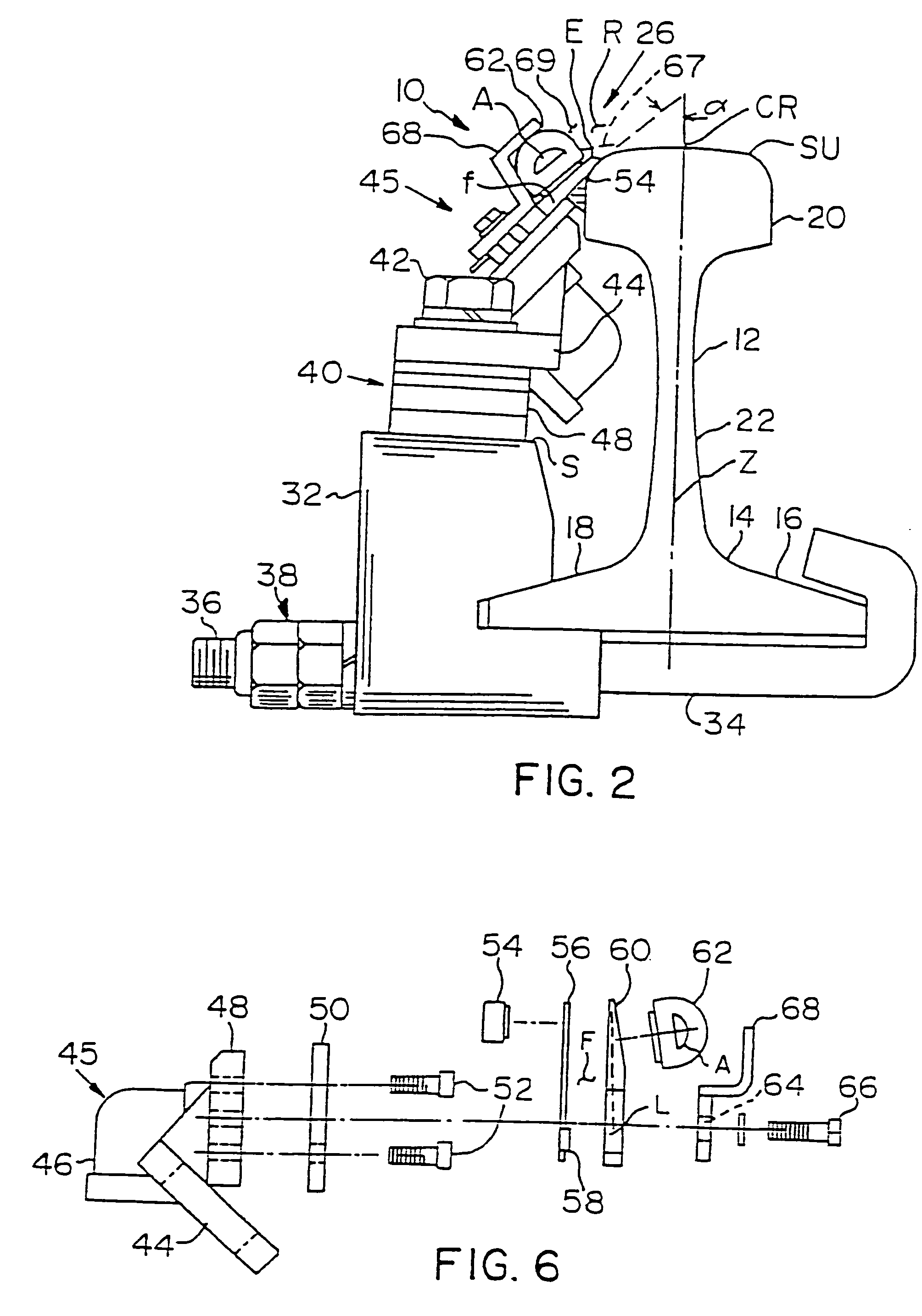

Wayside rail lubrication apparatus and method

A wayside lubrication apparatus (10) for applying a lubricant (26) to a second position (36) of a rail (12) in response to the head of a train (14) being proximate a first position (20) of the rail. The distance (D) between the two positions prevents the lubricant from reducing the traction capability of the drive wheels (38) of the locomotives (16). The application of the lubricant is terminated before a number of rear load cars (46) passes the lubricant applicator (28) so that the residual lubricant remaining on the rail after the train has passed is reduced. Operation of the lubricant dispensing apparatus (22) may be bypassed by an operator-controlled bypass device (60) or in response to a signal (56) indicating moisture on the rail. To avoid excessive lubricant on the rail, a timer (42) is used to prevent repeated applications of lubricant within a predetermined time period, and / or a lubricant container (68) is refilled at a controlled rate to proportion the amount of lubricant applied in response to a second consecutive train.

Owner:GENERAL ELECTRIC CO

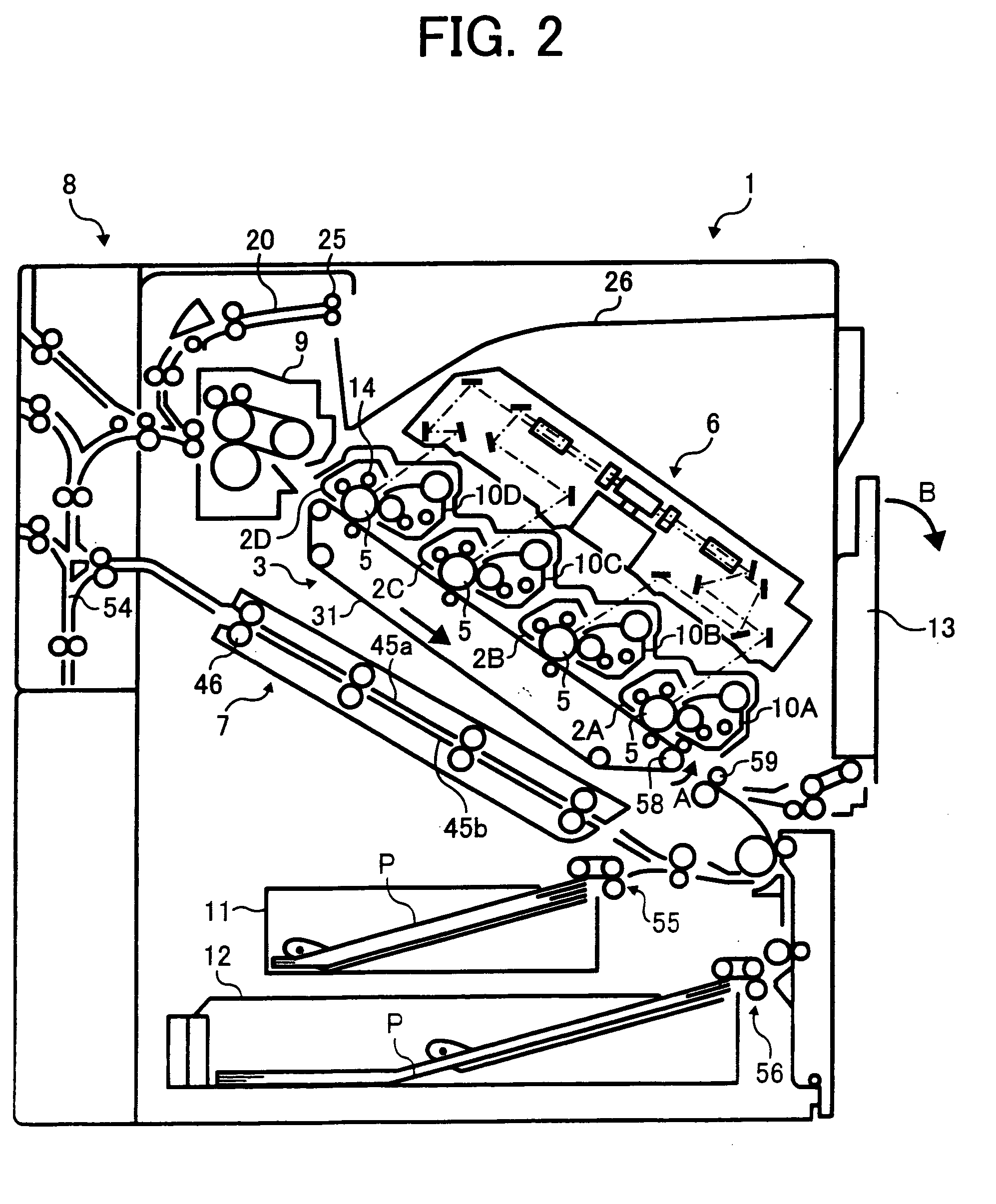

Image forming apparatus, process cartridge, and lubricant applicator

An image forming apparatus includes a photoconductor and a lubricant applicator. The photoconductor carries a toner image formed by developing an electrostatic latent image with a toner. The lubricant applicator applies a solid lubricant to a surface of the photoconductor, and includes a brush roller, a holder, a pressing member, and a protrusion. The holder holds the solid lubricant. The brush roller scrapes off the solid lubricant from the holder and applies the scraped solid lubricant to the surface of the photoconductor. The pressing member has an ellipse shape and presses the solid lubricant toward the brush roller via the holder. The protrusion is disposed on the holder and contacts an inner circumferential surface of the pressing member at two positions provided in both end portions of the pressing member in a direction of a minor axis of the ellipse formed by the pressing member to support the pressing member.

Owner:RICOH KK

Top of rail applicator

Owner:PORTEC RAIL PRODS

Trip optimizer method, system and computer software code for operating a railroad train to minimize wheel and track wear

ActiveUS9233696B2Reduce problemsReduce wearDigital data processing detailsTrack side maintainanceWheel wearComputer software

A system for controlling a railroad train over a segment of track. The system comprises a first element for determining a location of the train on the segment of track; a second element for providing track characterization information for the segment of track; the track characterization information related to physical conditions of the segment of track; and a processor for controlling applied tractive forces and braking forces of the train responsive to the location of the train and the track characterization information to reduce at least one of wheel wear and / or track wear during operation of the train over the segment of track.

Owner:GE GLOBAL SOURCING LLC

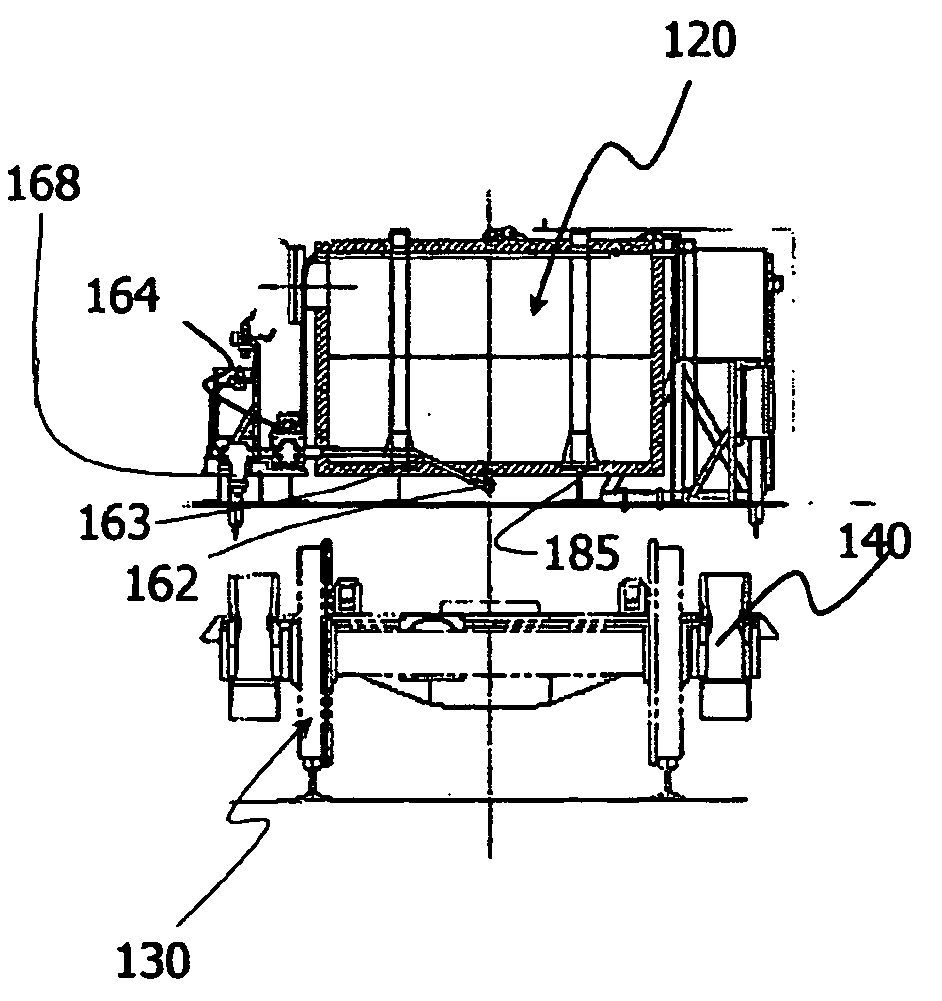

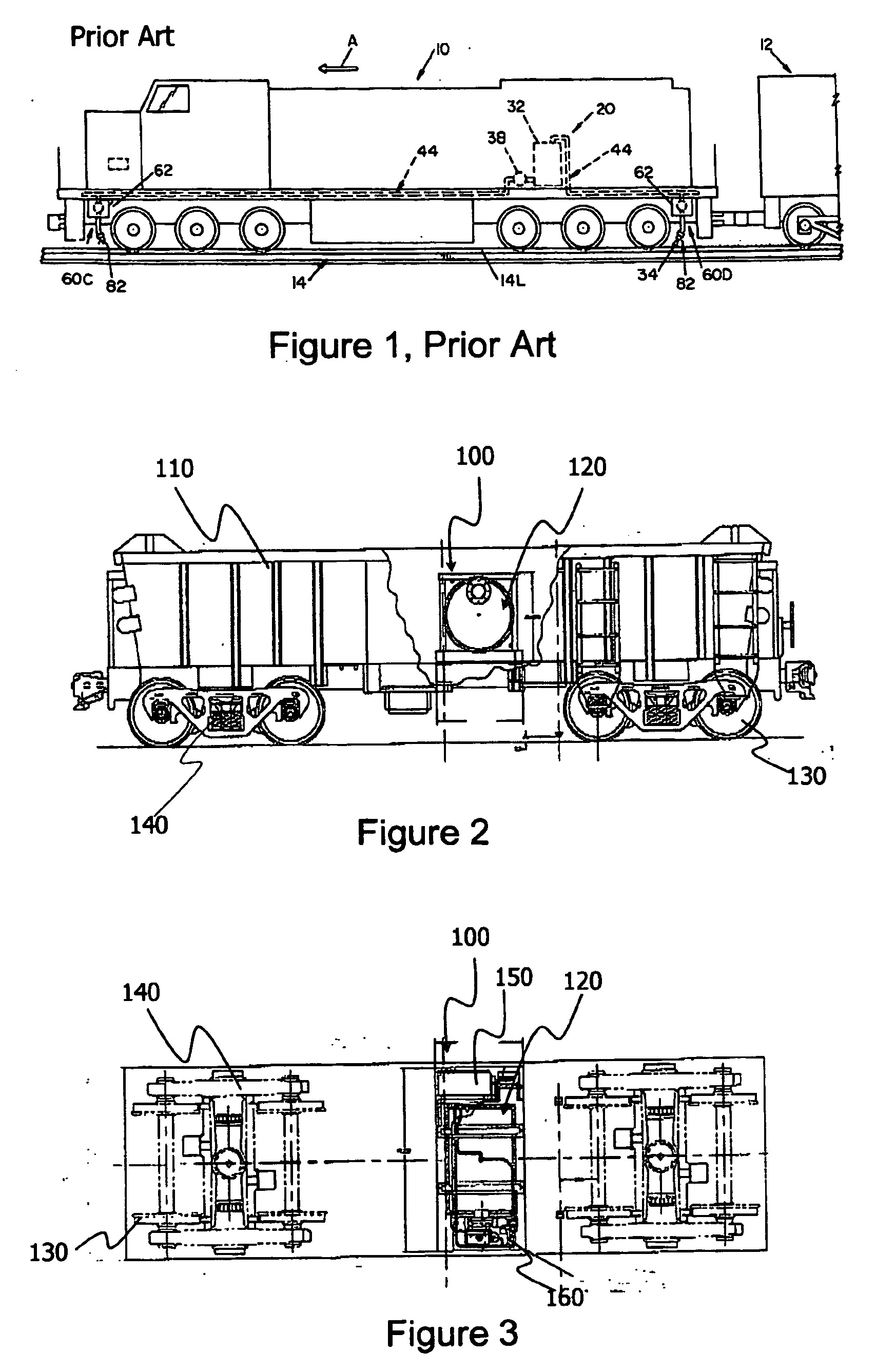

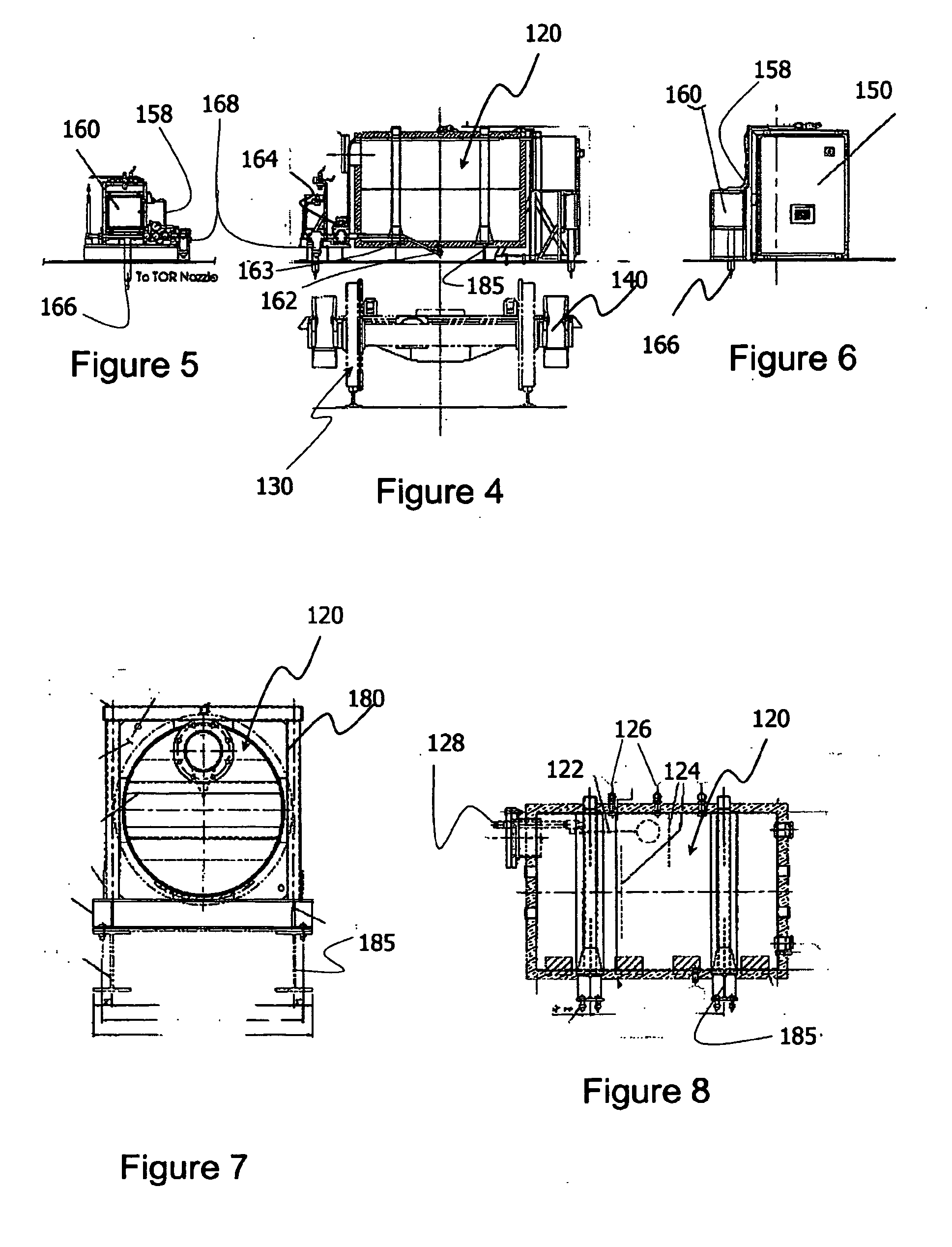

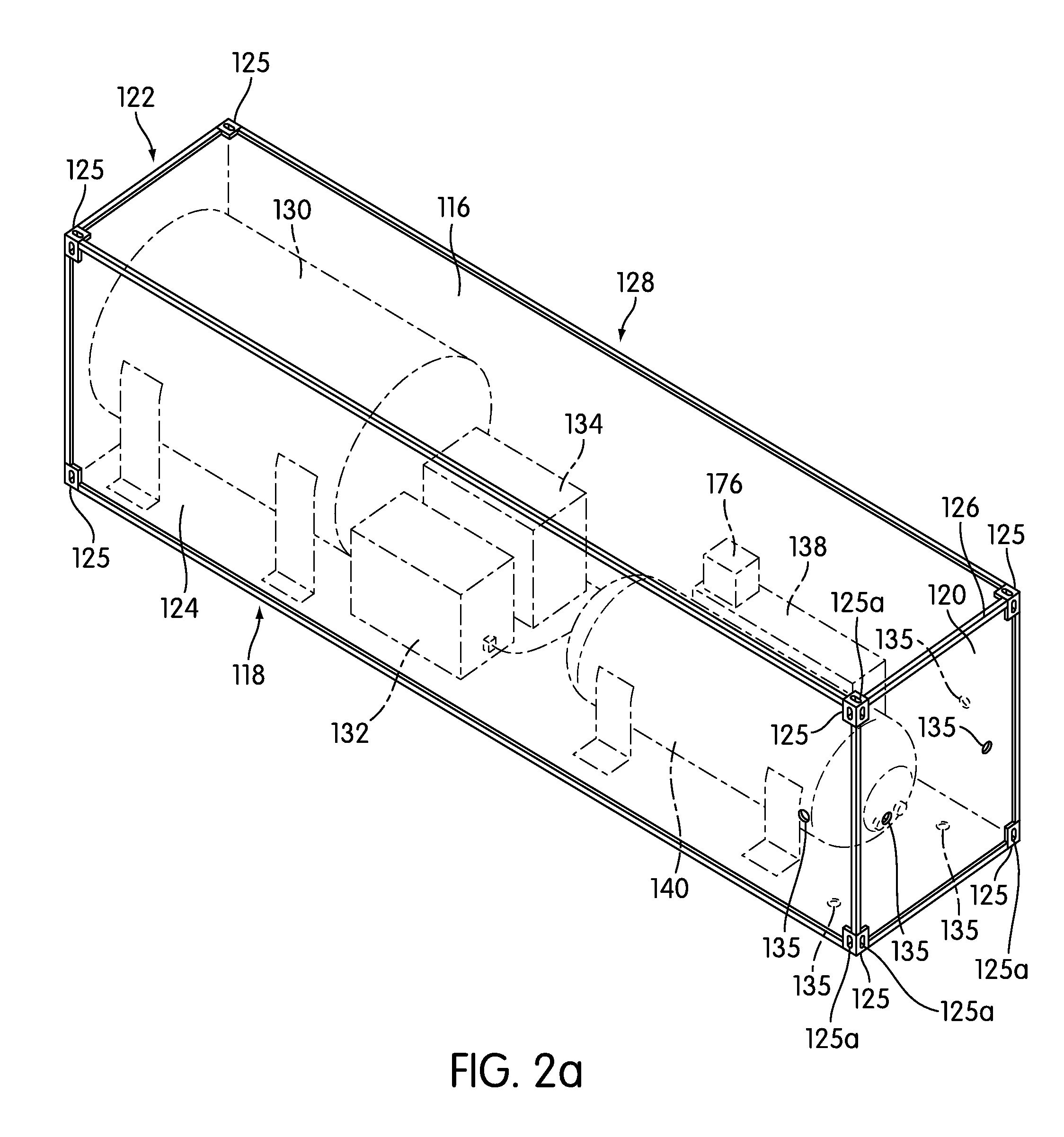

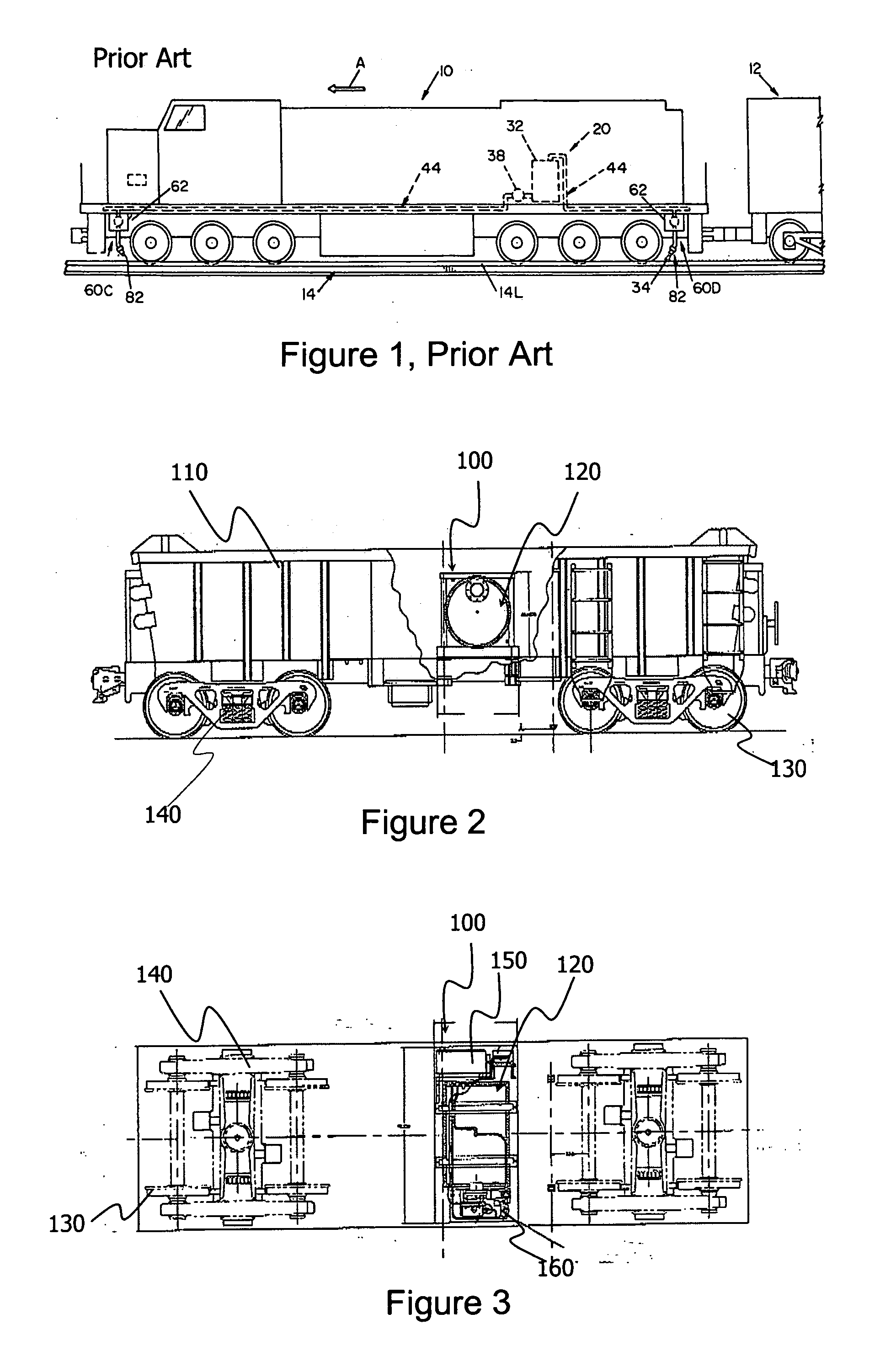

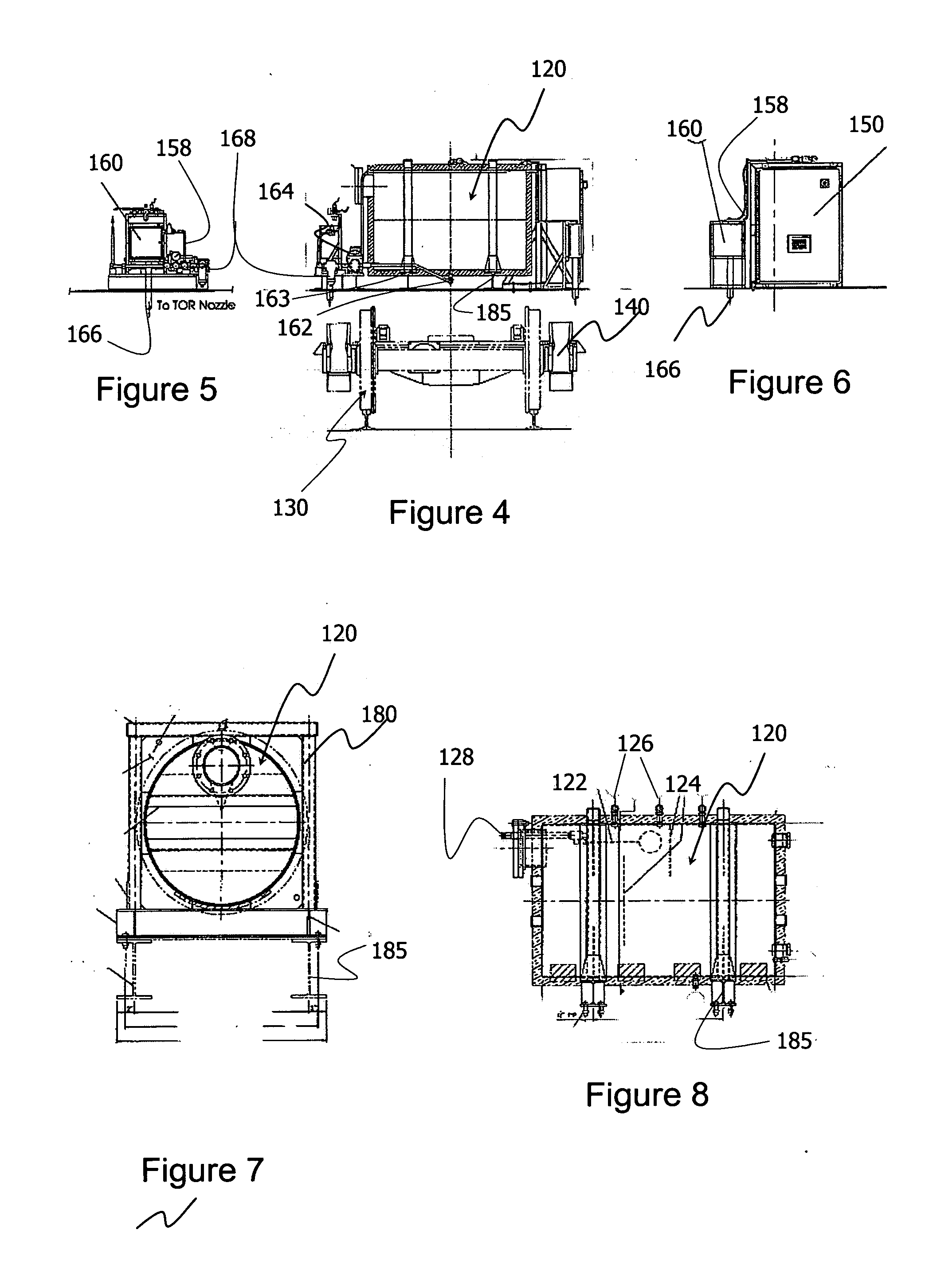

Rail lubrication and/or friction modification system within a non-freight carrying intermodal container

A lubrication system is contained within the body of a non-freight carrying intermodal container for lubricating a pair of rails of a train track. The lubrication system includes at least a lubricant holding tank for holding lubricant, a lubricant dispensing pump, and one or more hoses connected to the lubricant holding tank for directing a flow of the lubricant to one or more nozzles. The nozzles are positioned to distribute lubricant to at least a top of the pair of rails. The nozzles may be mounted with respect to a car body, floor, or axle trucks. The container is easily moved and repaired via its corner fittings, for example.

Owner:UNION PACIFIC RAILROAD

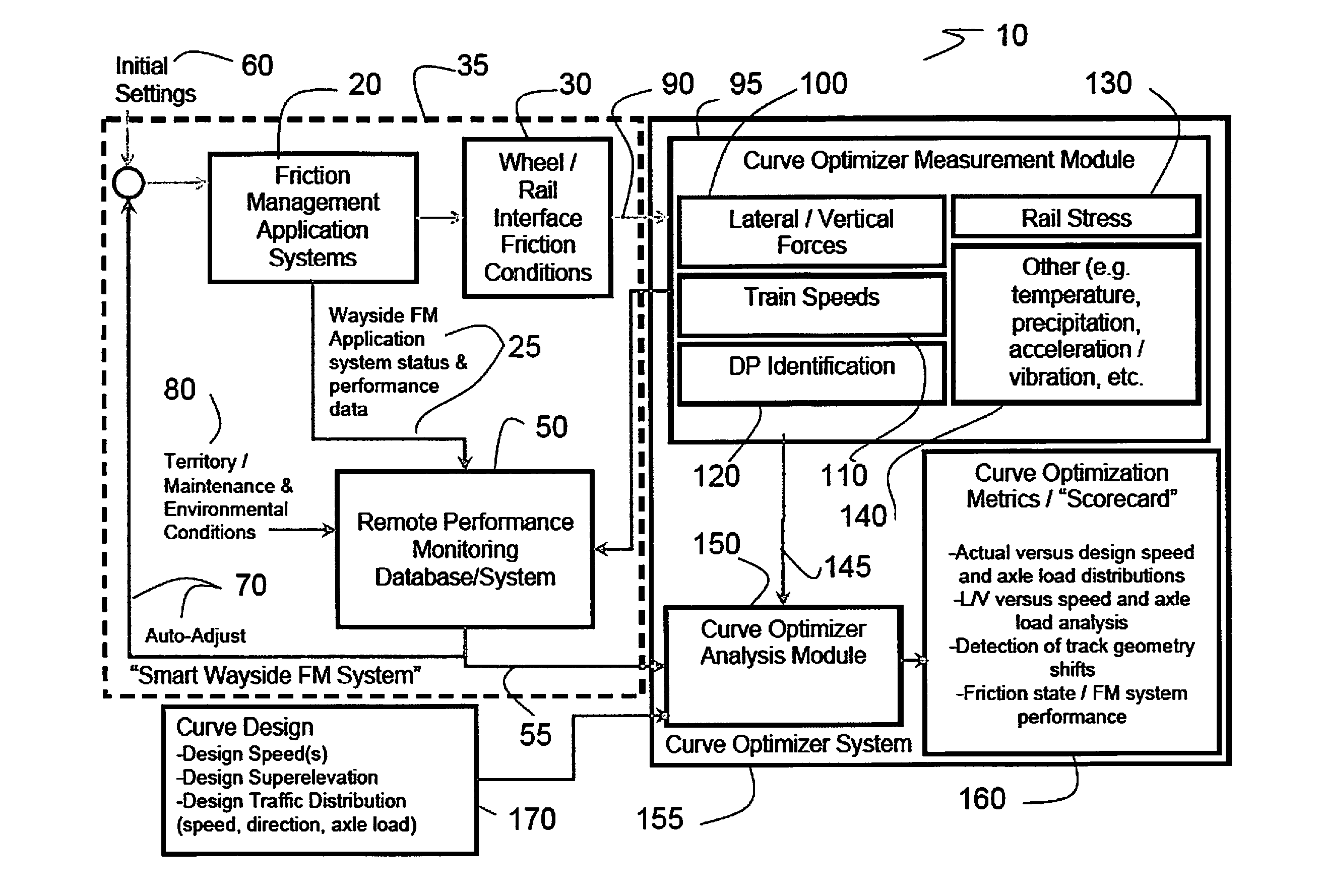

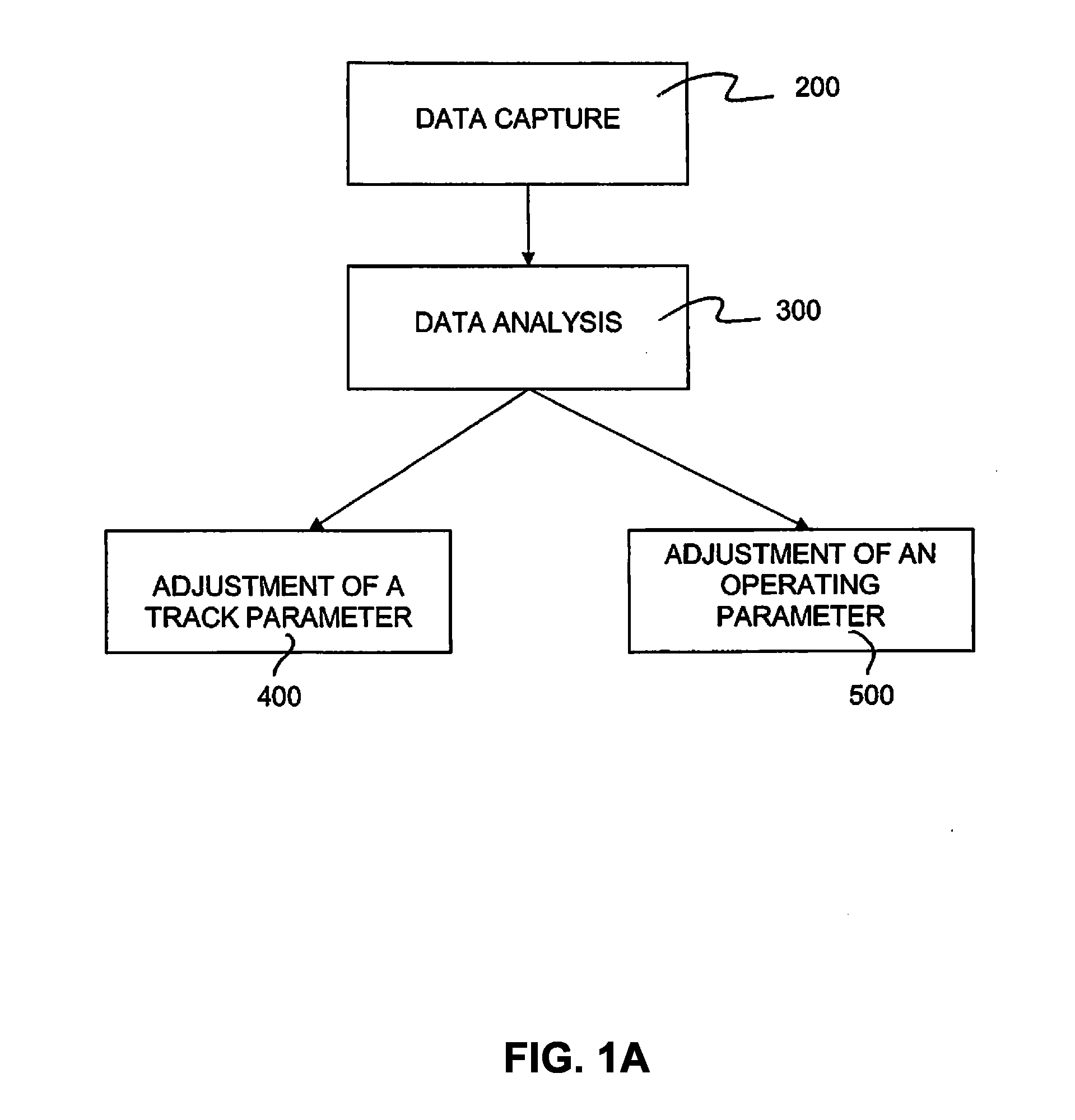

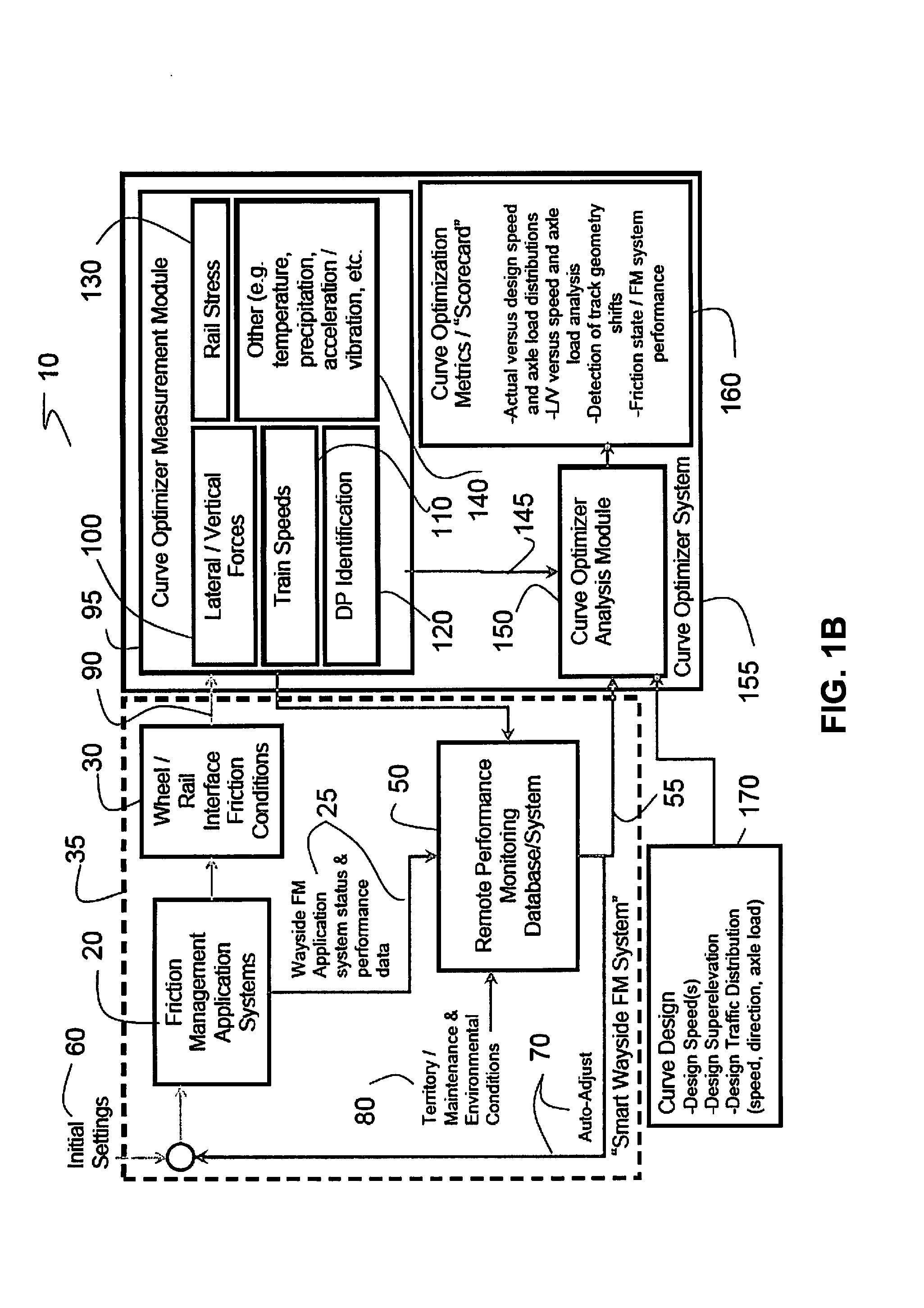

Optimizing Rail Track Performance

ActiveUS20120150370A1Prolong lifeMinimize curving forceDigital data processing detailsRail lubricationEngineeringMeasurement site

A method for optimizing track performance comprising: is provided. The method involves measuring one or more track status data at one or more measurement sites of the track during a train pass though the one or more measurement sites. Followed by analyzing the one or more track status data against one or more baseline reference values to obtain a track status profile, and adjusting an operating parameter, a track parameter, or both the operating and track parameters, based on the track status profile, to optimize the track's performance.

Owner:L B FOSTER RAIL TECH CANADA

Method and system for identifying an erroneous speed of a vehicle

InactiveUS8874345B2Analogue computers for vehiclesInstruments for road network navigationSize determinationControl theory

A method includes receiving an input size of a wheel of a vehicle, determining a derived speed of the vehicle that is based on the input size of the wheel, determining a reference speed of the vehicle as the vehicle moves, comparing the derived speed with the reference speed of the vehicle, and identifying an error in the input size of the wheel based on a difference between the derived speed and the reference speed. A system includes a control unit configured to determine a derived speed of a vehicle that is based on an input size of the wheel and a reference speed of the vehicle as the vehicle moves. The control unit compares the derived speed with the reference speed of the vehicle in order to identify an error in the input size of the wheel.

Owner:GE GLOBAL SOURCING LLC

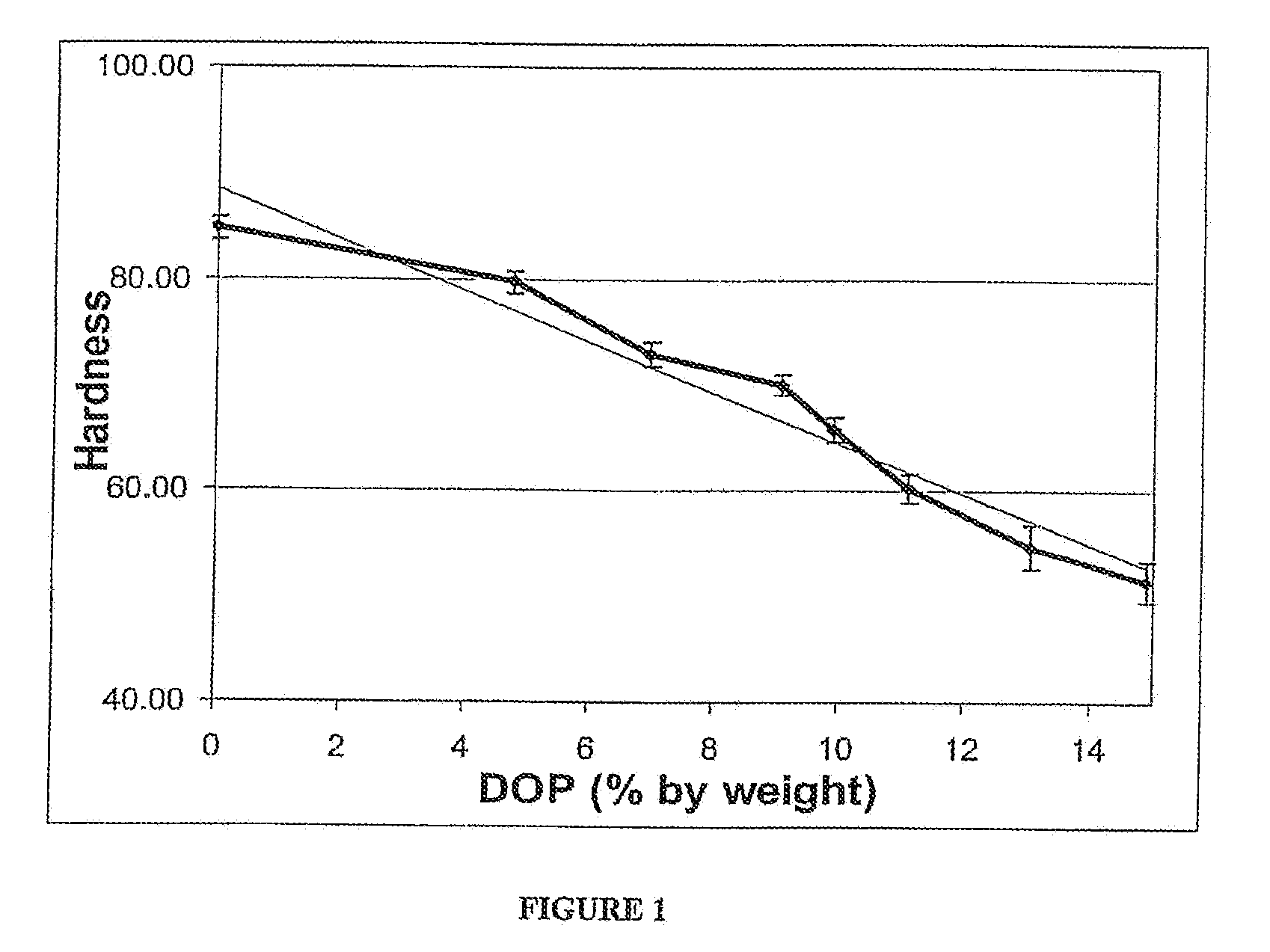

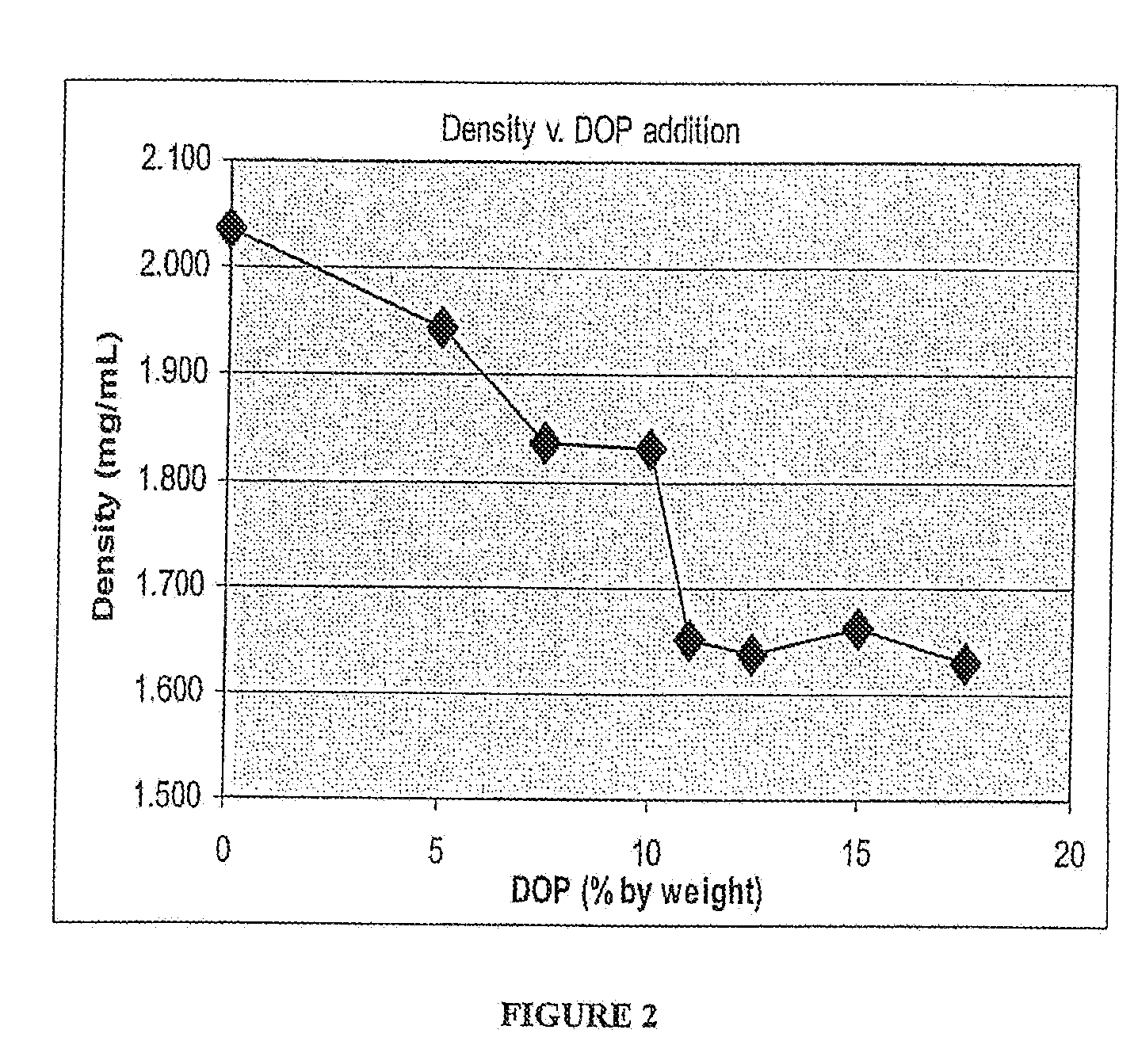

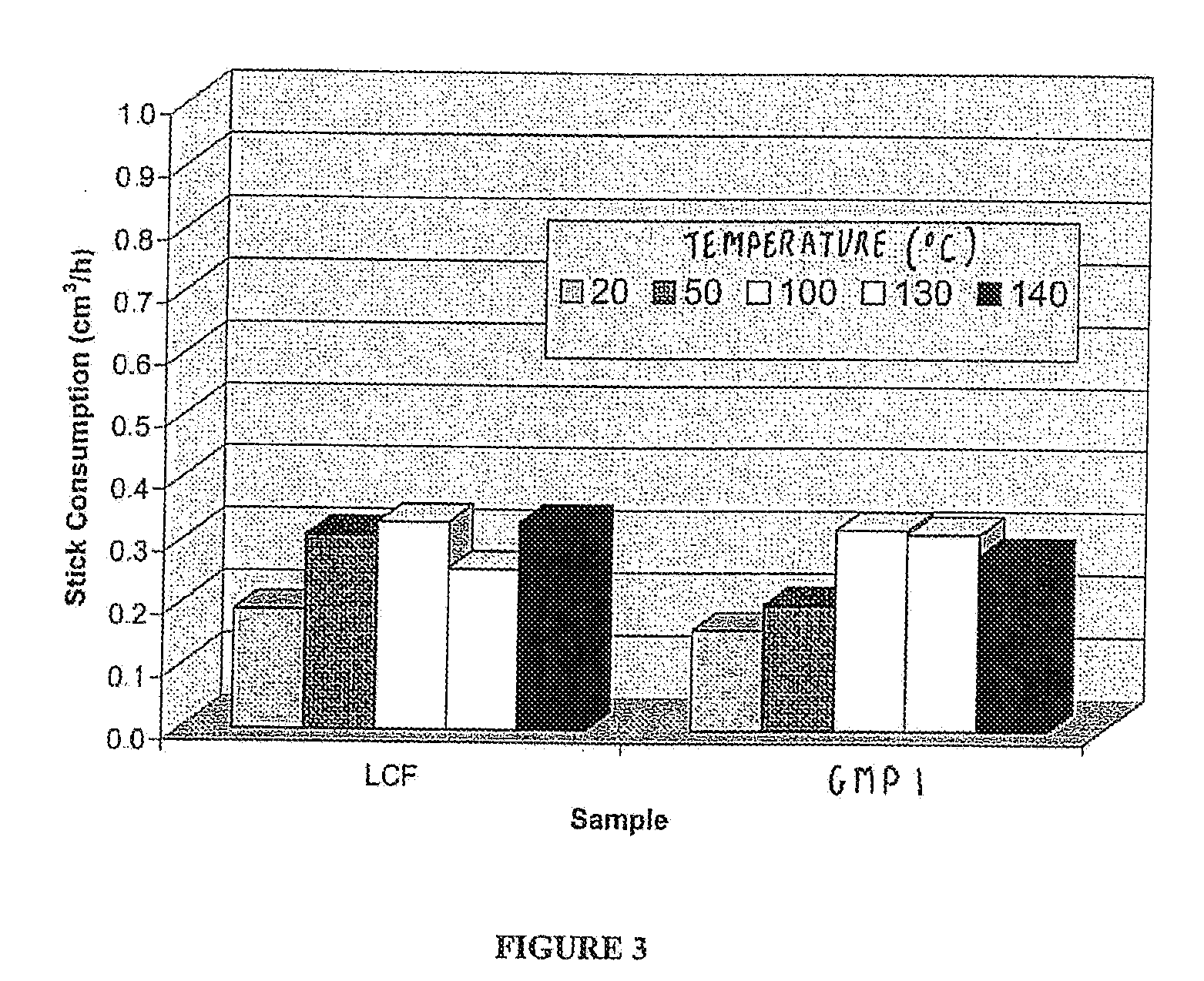

Solid stick grease compositions

InactiveUS20070010405A1Reduce consumptionReduce wearBearing componentsLiquid carbonaceous fuelsOil and greaseRolling sliding

The present invention provides a solid stick composition comprising a thermosetting resin and a grease. Optionally, the solid stick composition may comprise a lubricant, a friction modifier, a thermoplastic placticizer or a combination thereof. The solid stick compositions may be used for application between two metal surfaces in sliding and rolling-sliding contact such as steel wheel-rail systems including mass transit and freight systems. A method of reducing energy consumption, or controlling friction between a metal surface and a second metal surface by applying the solid stick composition to one or more than one of the metal surfaces, is also provided.

Owner:KELSAN TECH

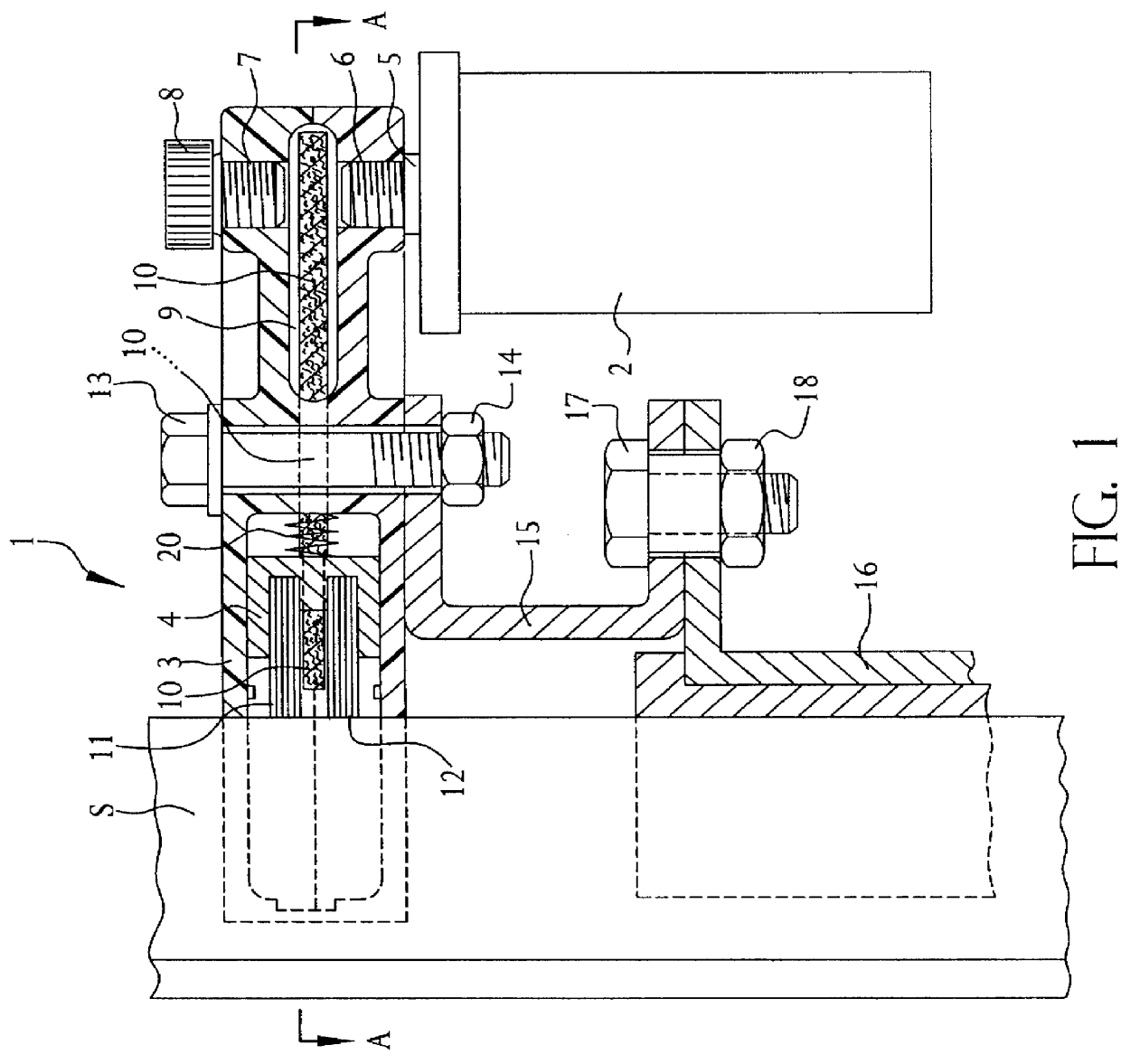

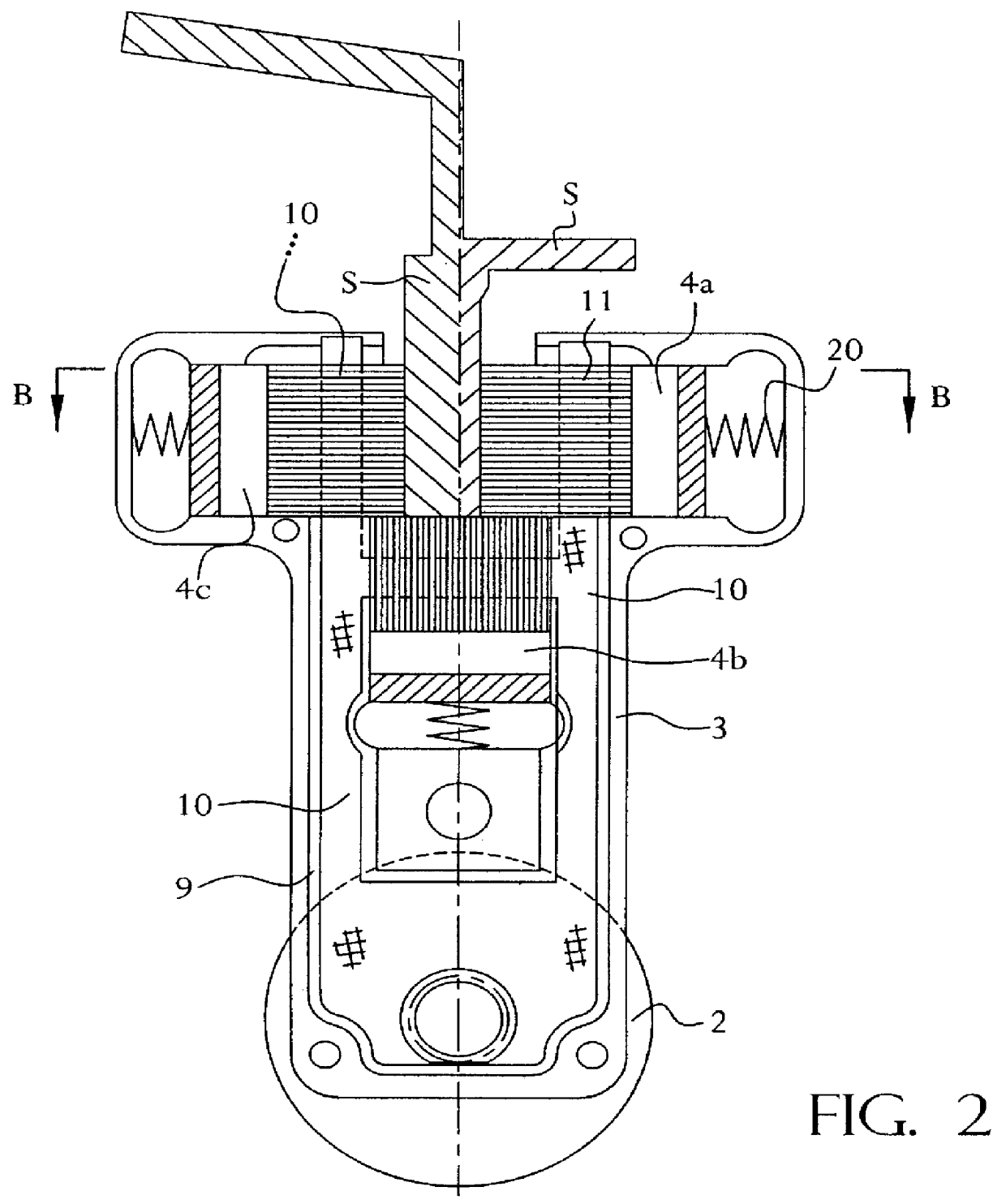

Brushing device for lubricating and cleaning guide and/or drive elements

A brushing device (1) for lubricating and cleaning guide and drive elements has a lubricant dispenser (2), a brush element (4) for applying the lubricant to the machine element, a delivery line device (3) connected to the lubricant dispenser for feeding lubricant to the brush element (4), where the delivery line device (3) is provided with a delivery line path (10) composed of an absorbent pad of a felt-like or fleece-like material.

Owner:WYSSMANN MAX

Apparatus for applying a pumpable material to a rail head

An applicator assembly for delivery of a pumpable material to a top surface of a rail head of rail includes an applicator body having an orifice for delivery of the pumpable material to the top surface of the rail. The body is resiliently yieldable to permit the applicator body to move from a raised position, in which the orifice is positioned for delivering the pumpable material to the top surface of the rail head, to a depressed position in the event the applicator is contacted by a train wheel. The applicator body thereafter returns to the raised position. The applicator body is mounted for movement between a working position in which the applicator body is closely adjacent the rail head and a rail-service position in which the applicator body is remote from the rail head. When the applicator body is in its working position, a metal portion of the applicator body contacts the rail head to form a metal-on-metal hard seal extending lengthwise of the rail head for inhibiting leakage of the pumpable material from the top of the rail head. The applicator assembly is free of any non-metal seals for sealing against such leakage.

Owner:LINCOLN INDUSTRIES CORP

Method and apparatus for applying liquid compositions in rail systems

ActiveUS20050285408A1Reservoir capacity can be increasedIncrease capacityWheel adhesionRail lubricationEngineeringLiquid composition

A method for applying a liquid composition to a rail surface is provided. This method involves supplying a liquid composition in one or more reservoirs on a rail car (revenue generating car), and applying the liquid composition from the one or more reservoirs to the rail surface.

Owner:KELSAN TECH

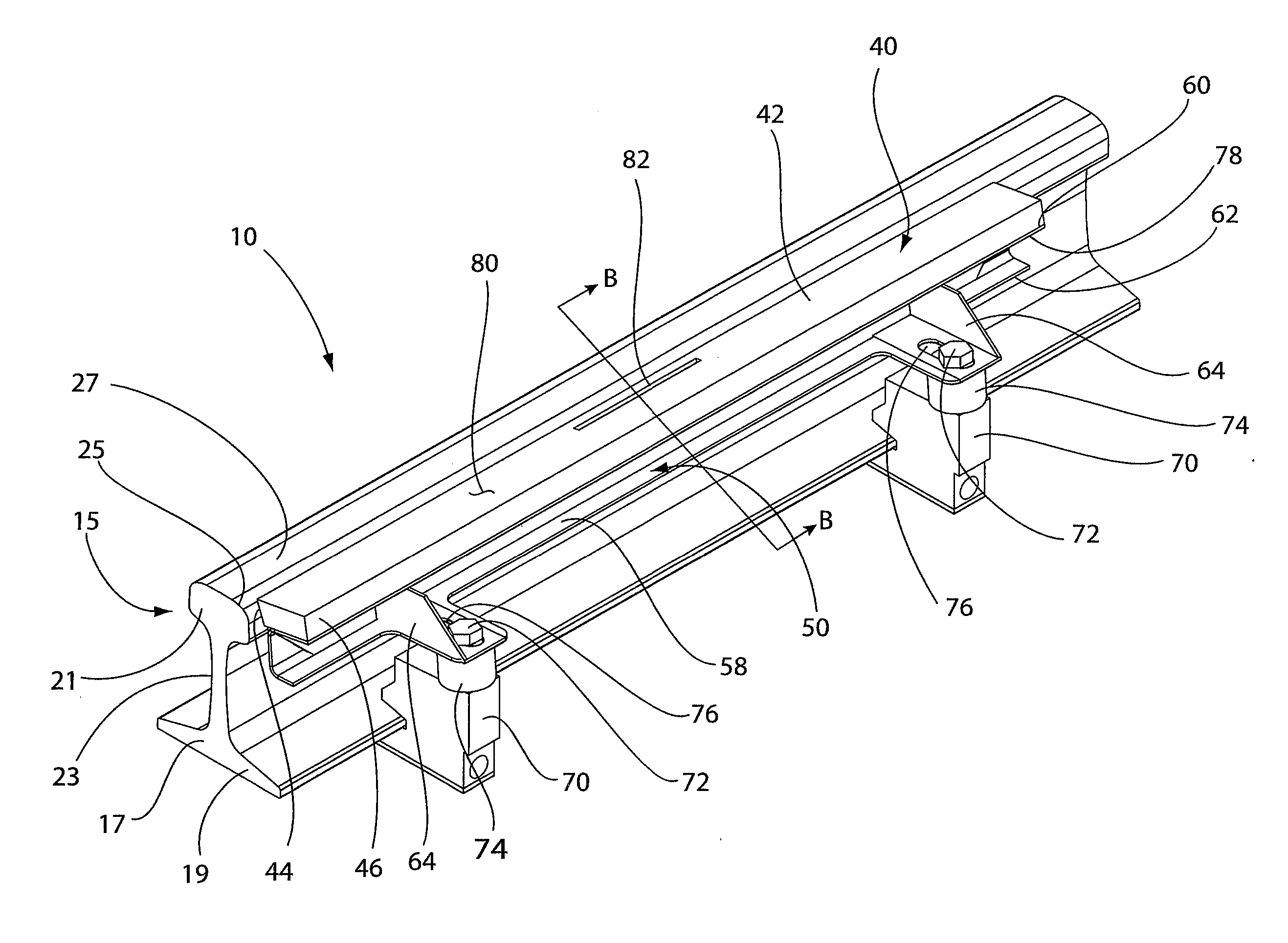

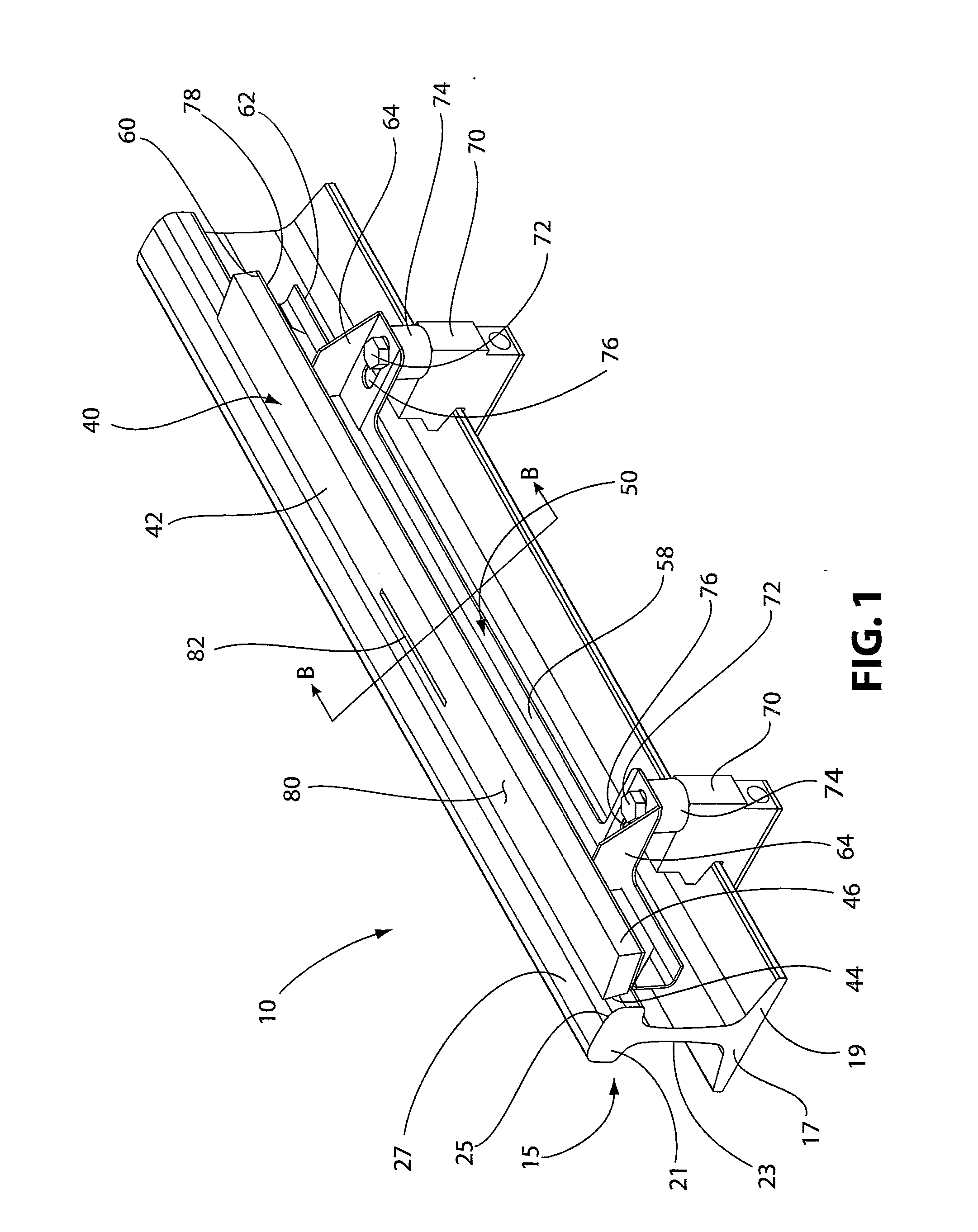

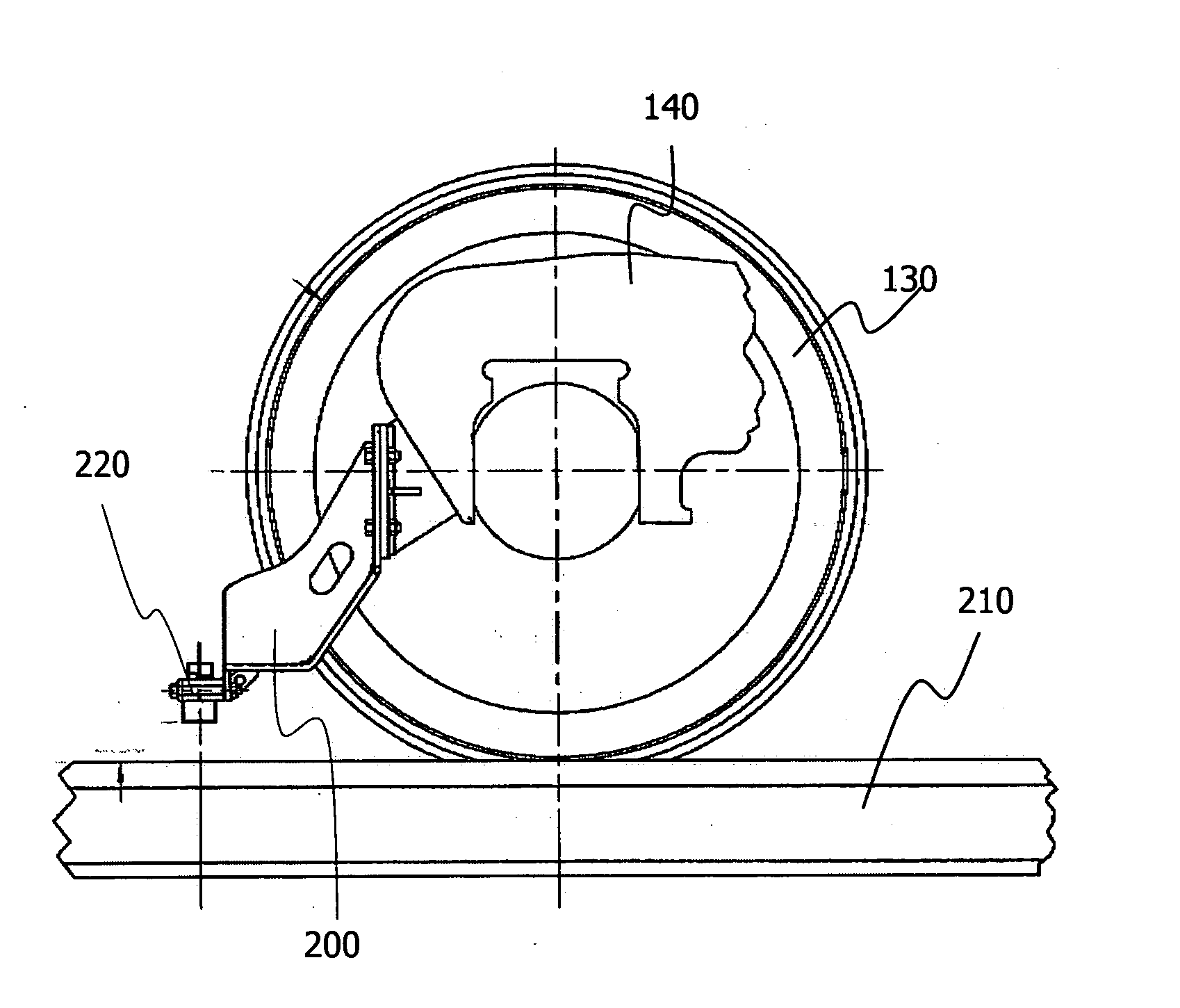

Wiping bar quick clamp

A clamp device for mounting a rail device onto a railroad rail includes a clamp body having an upper section and a lower section. The clamp body defines a recess portion between the upper and lower sections and a bore extending through the lower section of the clamp body. A bolt having a first end and a second end extends through the bore of the clamp body. The clamp device also includes a quick release mechanism having a lever arm and a cam member pivotally connected to the second end of the bolt. The lever arm is connected to the cam member and has a clamped position and a released position whereby pivoting the lever arm from the released position to the clamped position draws the first end of the bolt and the clamp body together.

Owner:L B FOSTER RAIL TECH INC

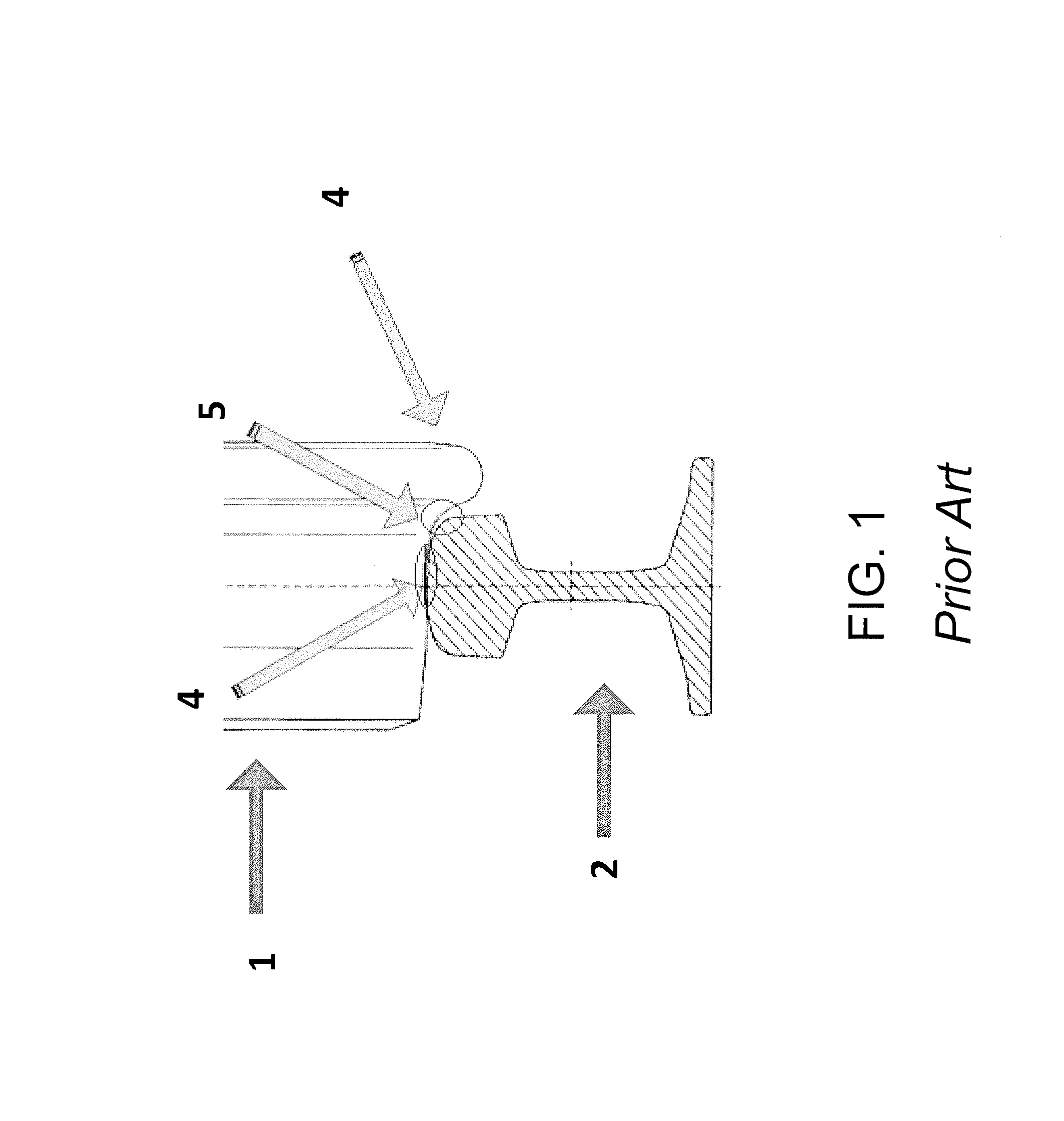

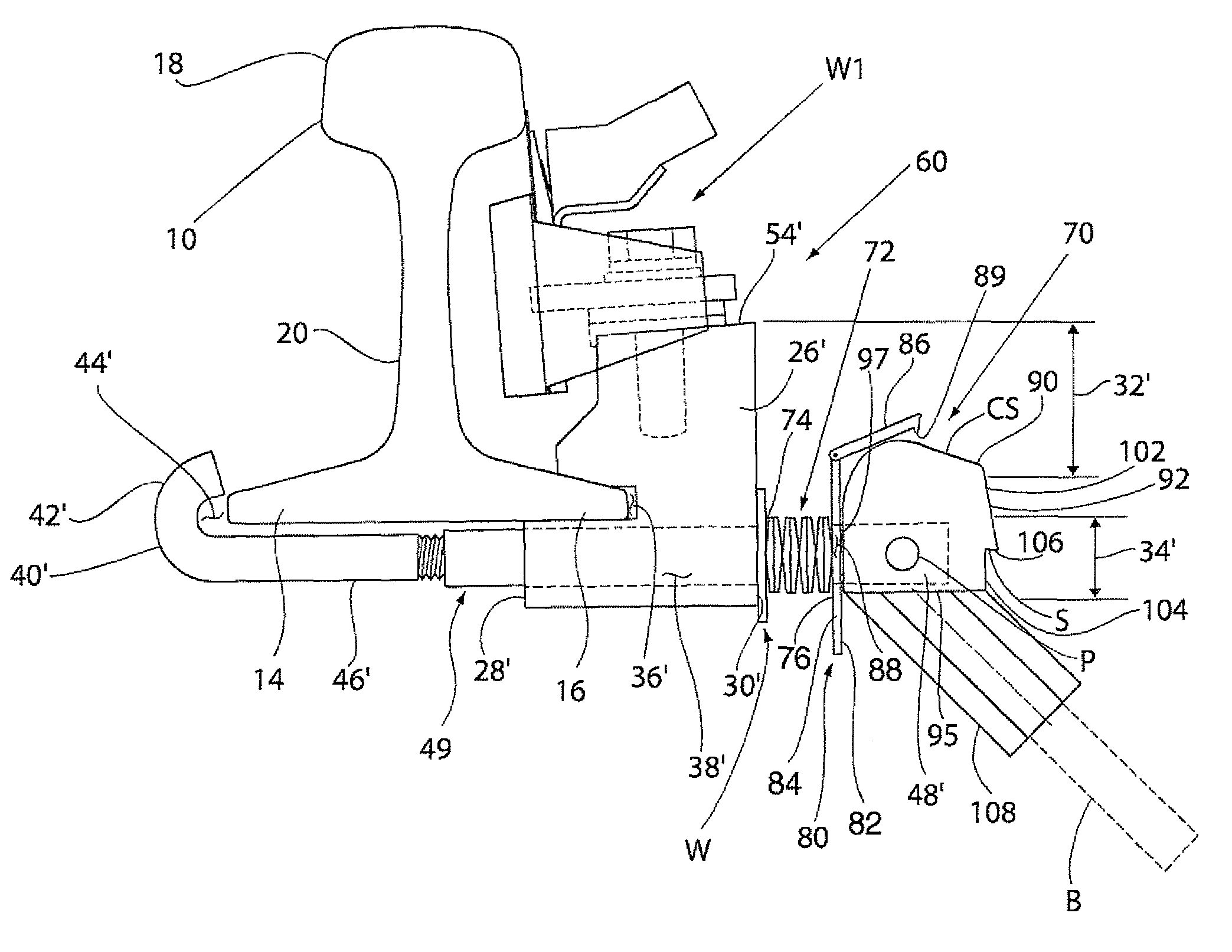

Gage side or field side top-of-real plus gage corner lubrication system

A rail lubricator for a railroad rail has a nozzle adjacent to the rail and attached thereto. The nozzle has a discharge orifice disposed beneath the top surface of the rail. The orifice is aimed generally longitudinally of the rail with the aiming including an upward component and a lateral component toward the centerline of the rail. Jets of lubricant project upwardly from the nozzle, arch above the top surface of the rail, and then fall onto the top surface and gage corner of the rail. This lubricates the top of a rail using an optimum amount of lubricant on the optimum area of the railhead. The lubricant is applied when the nozzles are spanned by a car.

Owner:TRANERGY CORP

Top of rail applicator

Owner:PORTEC RAIL PRODS

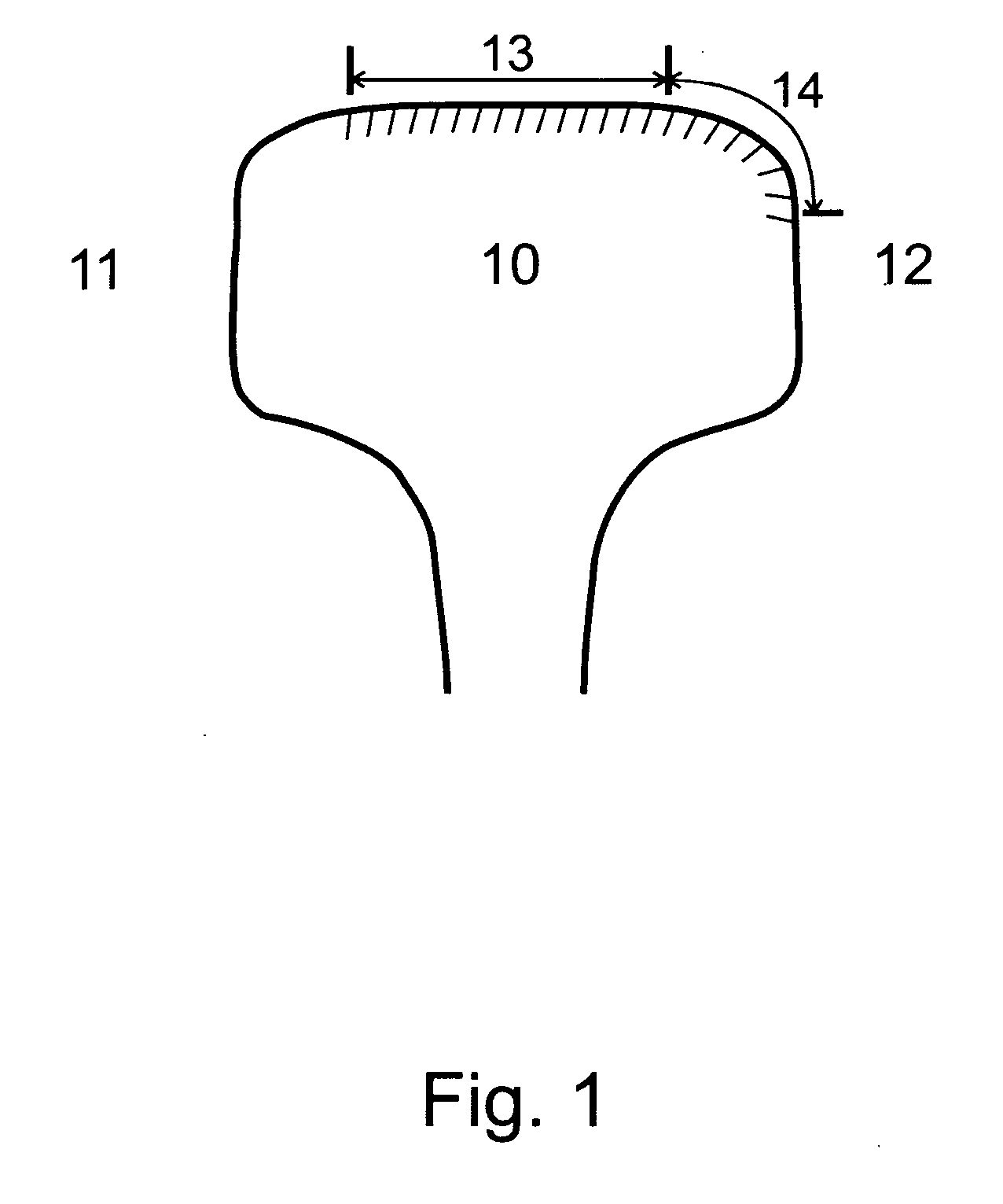

Wheel-rail solid lubrication block and preparation method thereof

InactiveCN104927991AReduce coefficient of frictionImprove wear resistanceRail lubricationRail wetting/lubricationFriction effectLubrication

The invention discloses a wheel-rail solid lubrication block and a preparation method thereof. The lubrication block is prepared from the following materials in parts by weight: 30-70 parts of polytetrafluoroethylene powder, 30-70 parts of graphite powder and 2-10 parts of paraffin. The preparation method comprises the following steps: conducting extrusion formation on polytetrafluoroethylene powder and graphite powder; heating by the stepped heating method; then cooling to the room temperature by the stepped cooling-down method; enabling paraffin to permeate to obtain the wheel-rail solid lubrication block. The polytetrafluoroethylene material is low in friction coefficient and better in anti-friction effect, thereby prolonging the life cycles of both wheels and rails; as no molybdenum disulfide, lead or other rare and heavy metal is added, environmental protection is more facilitated; friction between the wheels and the rails is effectively reduced, so that the engine traction efficiency is improved, and energy conservation and emission reduction are further realized.

Owner:吕卫东 +2

Skirt for top of rail applicator

Owner:PORTEC RAIL PRODS

Liquid lubricating antifriction repairing agent for wheel/rail, preparing method and application

ActiveCN102643707AIn-situ friction reduction repairedGreat tractionRail lubricationRail wetting/lubricationEngineeringLubrication

A liquid lubricating antifriction repairing agent for a wheel / rail having the effects of lubrication, friction prevention and in-situ repair comprises 50-60 parts of resin, 40-50 parts of curing agent, 5-10 parts of grease, 6-15 parts of sub-nanometer scale silicate powder, 4-10 parts of lubricant and 0.05-0.2 part of coupling agent. A method for preparing the liquid lubricating antifriction repairing agent for the wheel / rail is further provided, and the method comprises the following steps of: (1) preparing the resin, the curing agent, the grease, the sub-nanometer scale silicate powder, the lubricant and the coupling agent in accordance with proportions according to claim 1; (2) covering the sub-nanometer scale silicate powder with the coupling agent at a covering temperature ranging from 80 to 90 DEG C; (3) mixing the curing agent with the grease; (4) mixing the substance obtained in the step (2) with the mixture obtained in the step (3); (5) mixing the lubricant with the mixture; (6) mixing the resin with the mixture, wherein the time of mixing the resin is controlled within 15-20 minutes; and (7) pouring the mixture in a die for curing and formation. The repairing agent can be coated on the rim of the wheel through a filler.

Owner:北京天捷优越科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com