Apparatus for Applying a Pumpable Material to a Rail Head

a technology of friction modification material and rail head, which is applied in the direction of rail lubrication, rail wetting/lubrication, rail components, etc., can solve the problems of less than satisfactory prior art devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

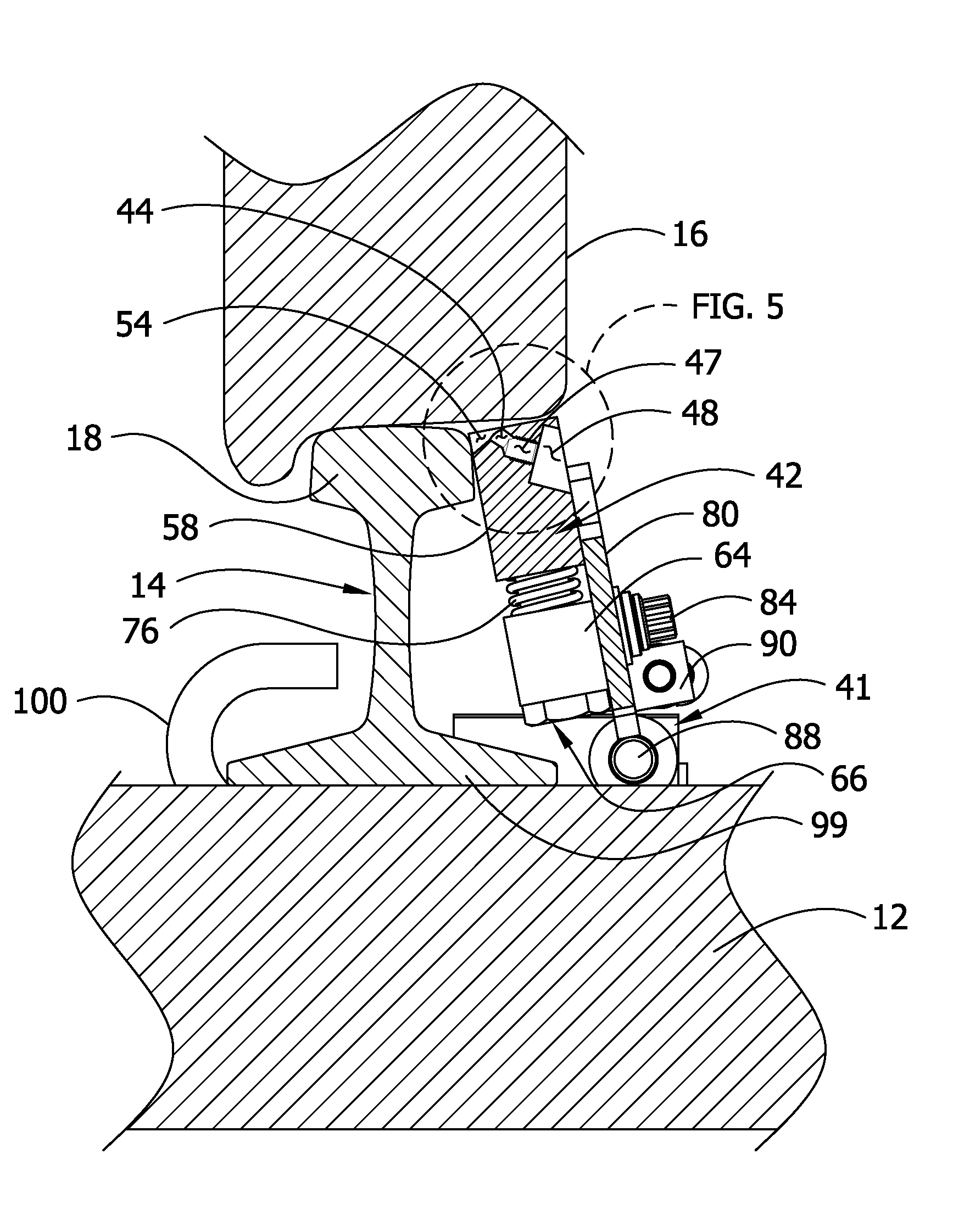

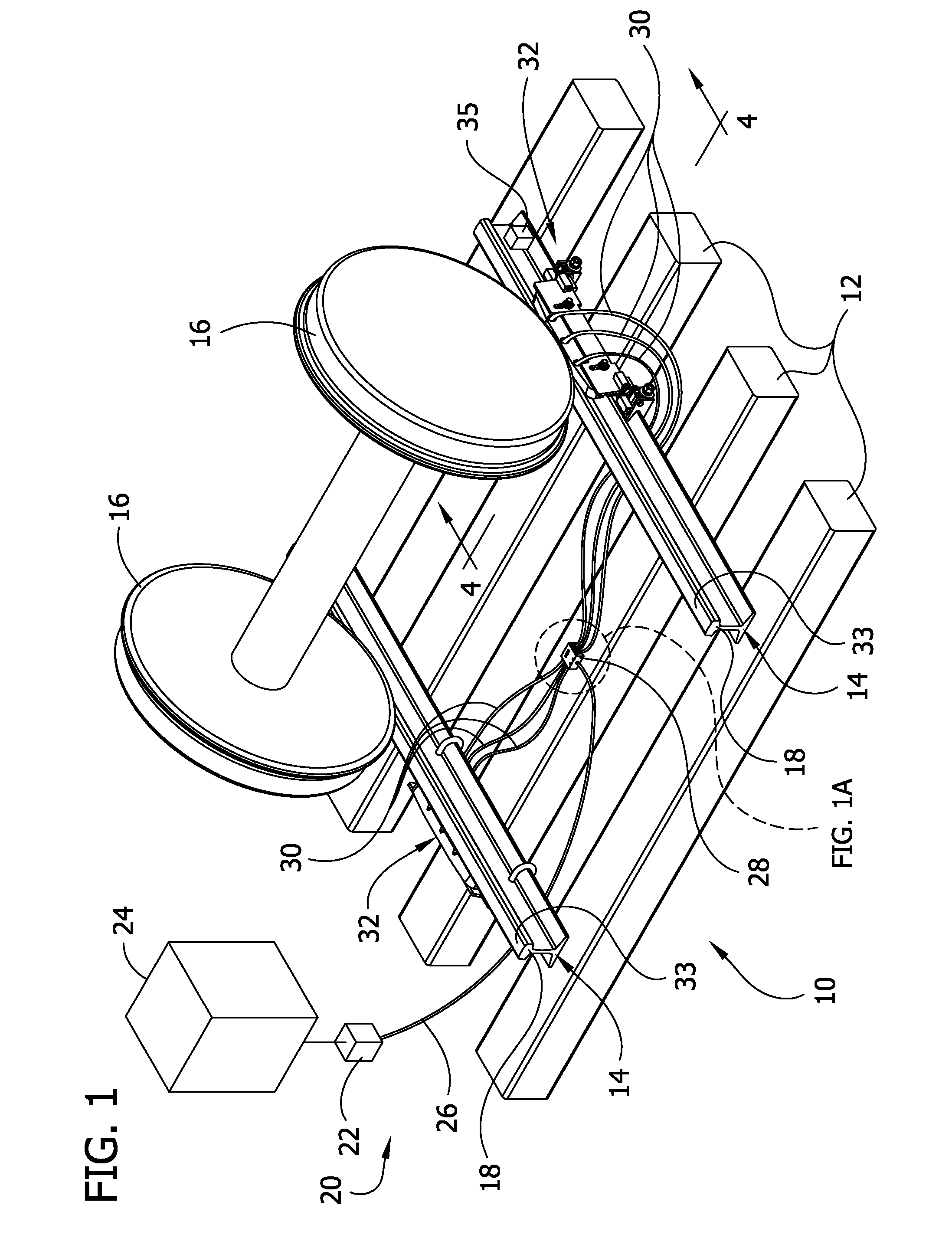

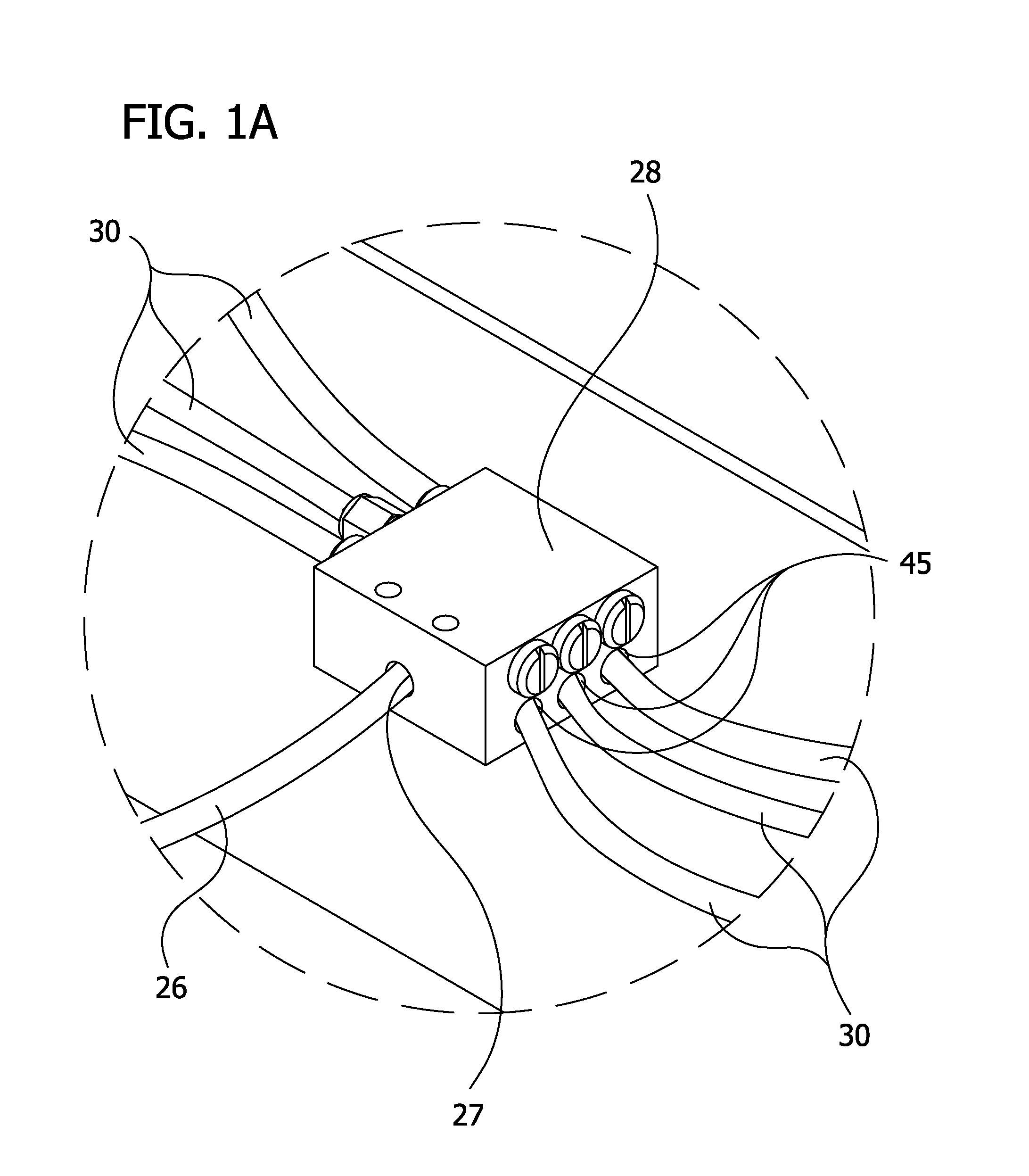

[0021]Referring to FIG. 1, a conventional railroad track, generally indicated at 10, is shown as comprising a series of rail ties 12 and a pair of parallel rails, each generally indicated at 14. Train wheels 16 rolling on the rails 14 are also shown. A system of this invention for applying a pumpable material to a rail head 18 of each rail 14 is indicated generally at 20. The system is particularly adapted for applying a friction modifying material to the rail head 18, and even more particularly adapted for applying a material that controls the friction between the rail 14 and the wheels 16 of a train. A suitable pump 22 delivers the pumpable material under pressure from a reservoir 24 through a main conduit 26 to the inlet 27 of a divider or distribution valve 28. For example, the pump may be a 24 VDC electric Flowmaster® pump, and the distribution valve may be a SSV Metering Device with cycle switch, both of which are manufactured and sold by Lincoln Industrial Corp., St. Louis, M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com