Grease Guide

a technology of grease guide and lubricant, which is applied in the direction of rail wetting/lubrication, rail lubrication, rail components, etc., can solve the problems of reducing the efficiency of lubricant transfer to the train wheels, reducing the effectiveness of the trough, and reducing the efficiency of the trough transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

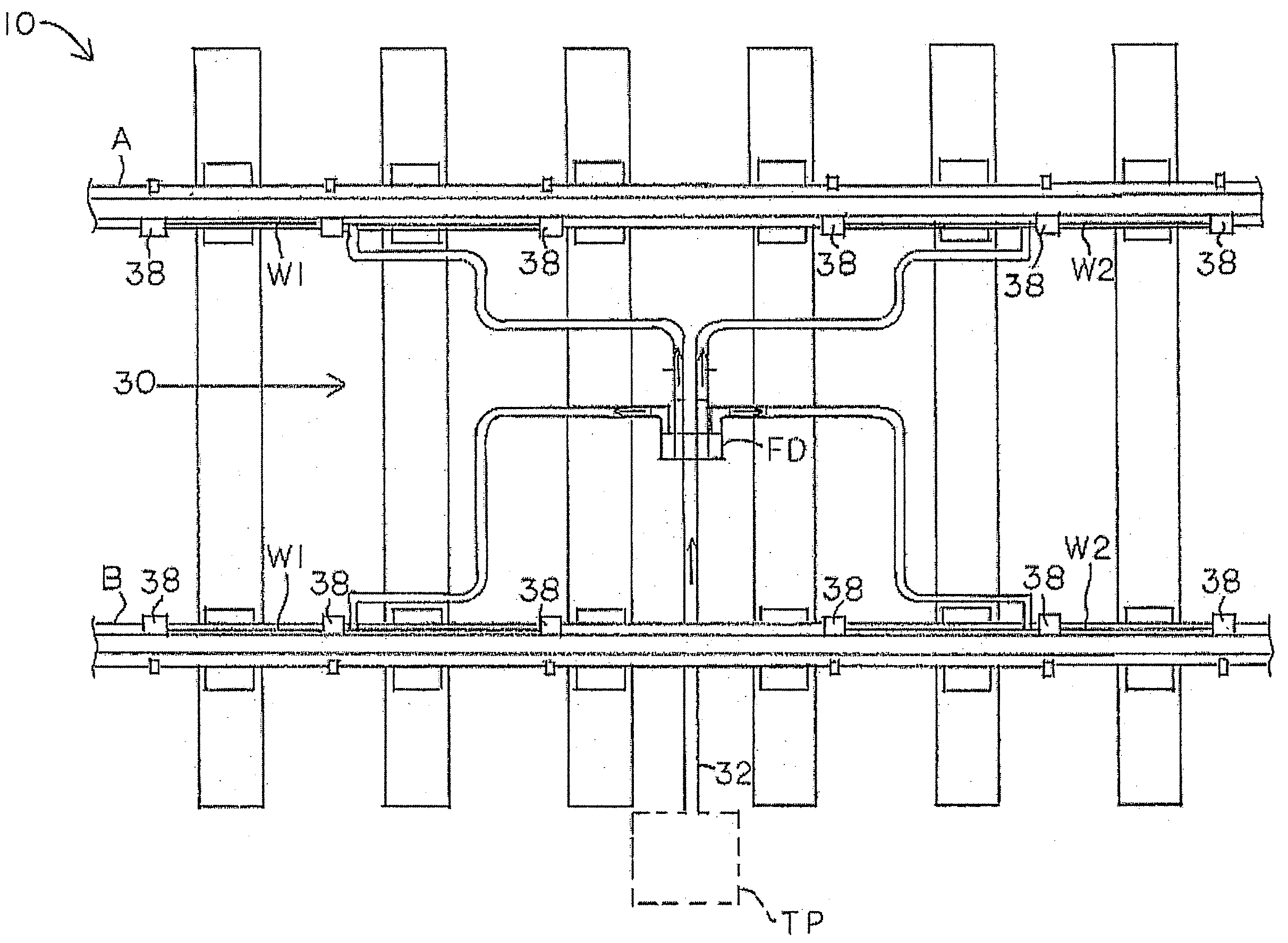

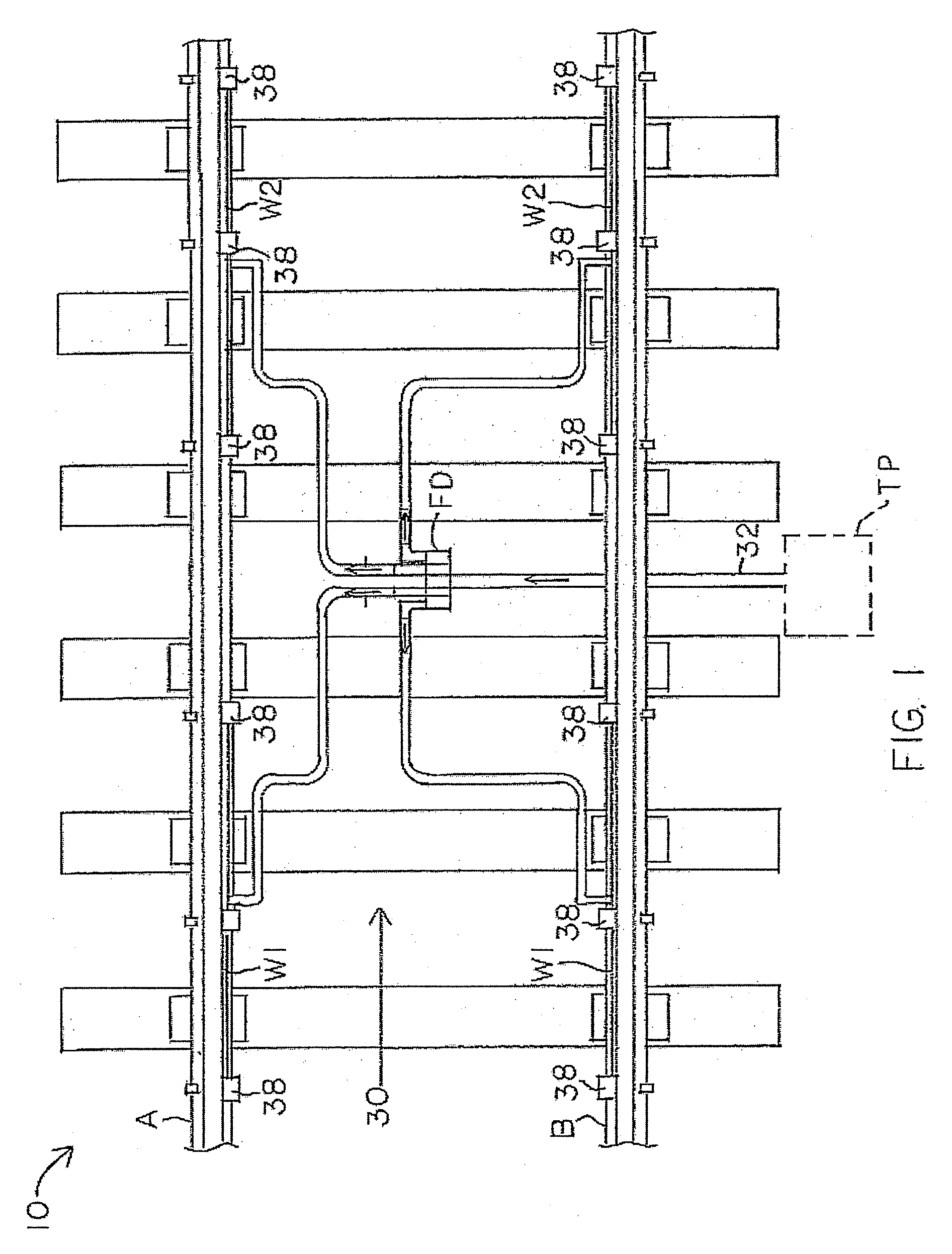

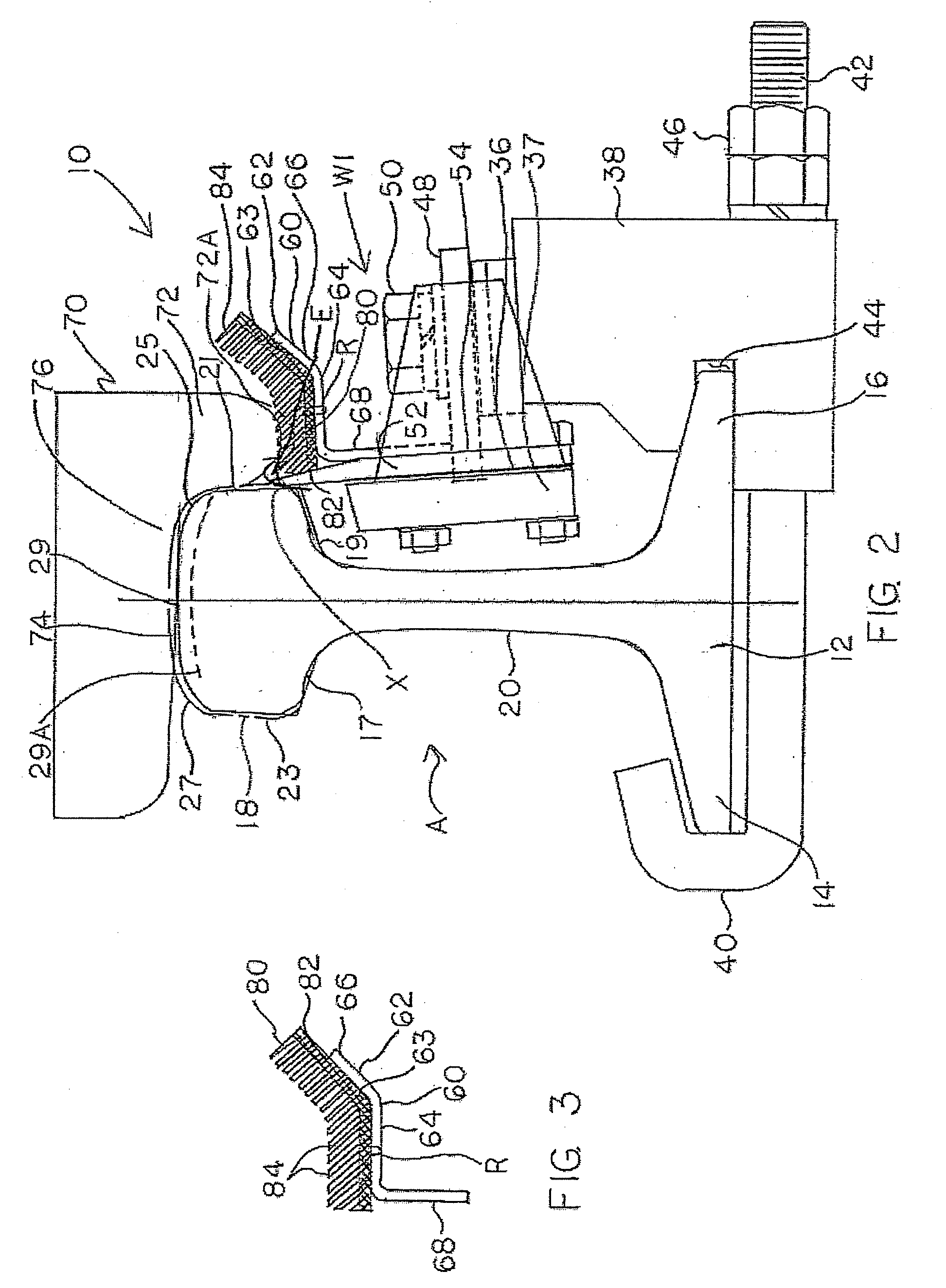

[0020]Referring to FIG. 1, the present invention provides for a rail lubrication system 10 that includes railroad rails A and B and wiping bar assemblies W1 and W2 secured thereto for applying friction modifying material to the railroad rails, Rail A and Rail B. The system 10 also includes a flow divider arrangement 30 in fluid communication with a lubricant tank containing a lubricant, such as grease, and a pump, via an inlet line 32. Such pump and tank arrangements are well known in the art and are designated as TP shown in phantom in FIG. 1. Referring to FIG. 2, Rail A, which is identical to Rail B, is a steel rail of usual cross-section and includes a base 12 having opposing flanges 14 and 16 extending therefrom. Rail A also includes a head 18 and a web 20 which secures the head 18 to the base 12. The head 18 has downwardly facing surfaces 17 and 19 on opposite sides of the web 20, generally vertical side surfaces or faces 21 and 23 (wherein side surface 21 is referred to as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com