System and method for fleet wheel-rail lubrication and noise management

a technology of fleet wheel-rail lubrication and noise management, which is applied in the direction of rail lubrication, process and machine control, instruments, etc., can solve the problems of increasing the chance of a rail vehicle derailing event, undesirable nuisance of curves, and common wear and tear of rails and wheels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]In the following detailed description of the preferred embodiments, reference is made to the accompanying drawings, which form a part hereof, and within which are shown by way of illustration specific embodiments by which the invention may be practiced. It is to be understood that other embodiments may be utilized and structural changes may be made without departing from the scope of the invention.

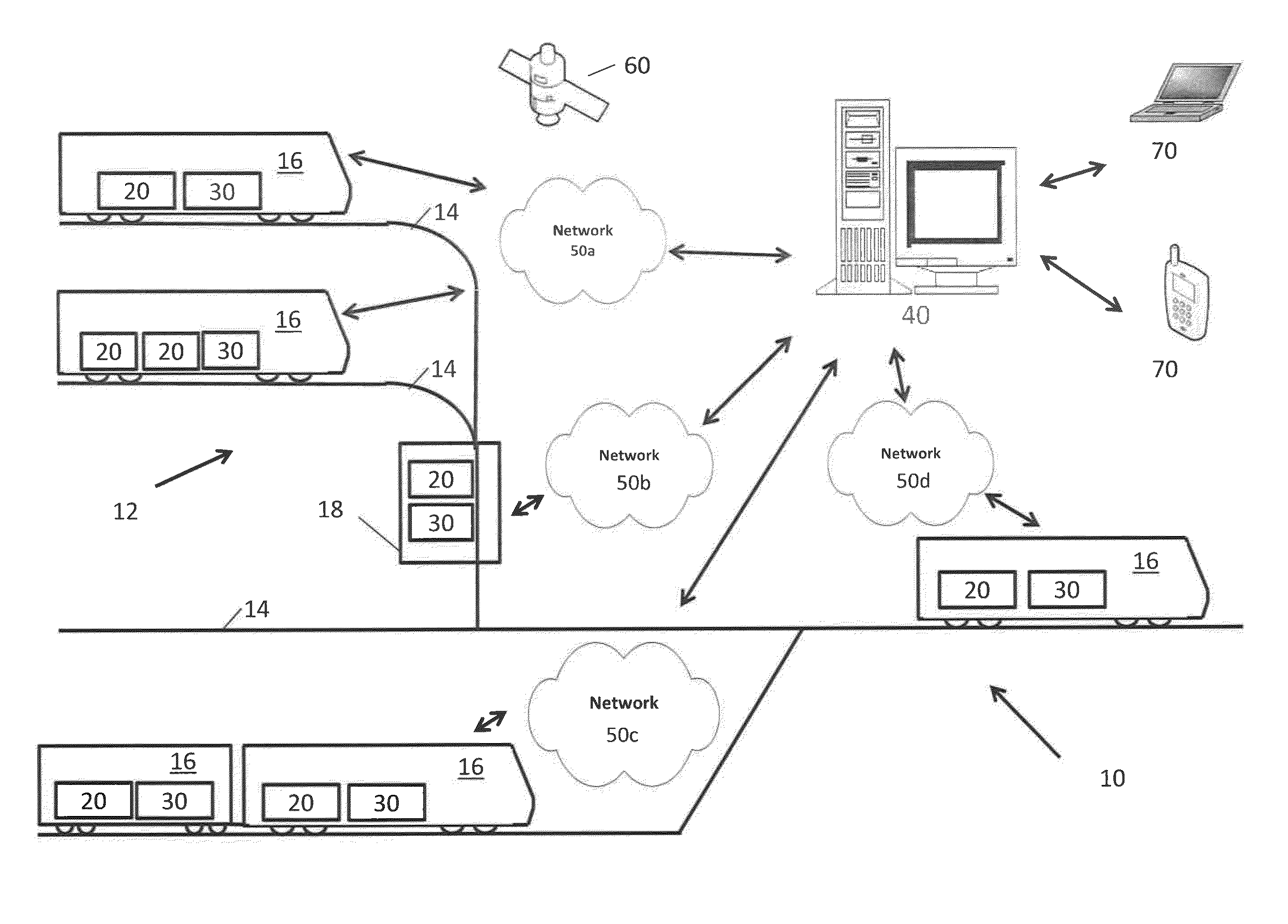

[0049]Referring to FIG. 4, the present invention is directed to a wheel-rail lubrication and noise fleet management system 10. The wheel-rail lubrication and noise fleet management system 10 assists in the application of lubricants to components of rail-wheel systems 12. In an aspect, the components of rail-wheel systems 12 can include rails / tracks 14, rail-based vehicles 16, and stationary waysides 18. The wheel-rail lubrication and noise fleet management system 10 includes lubrication systems 20. The lubrication systems 20 can be found at locations along the rails 14, on rail-based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com