Patents

Literature

527results about "Wheel-rims surveying/measuring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

On-line detection method and device for vehicle wheel set diameter

InactiveCN100999220ANo wear and tearEasy maintenanceImage analysisWheel-rims surveying/measuringEngineeringTread

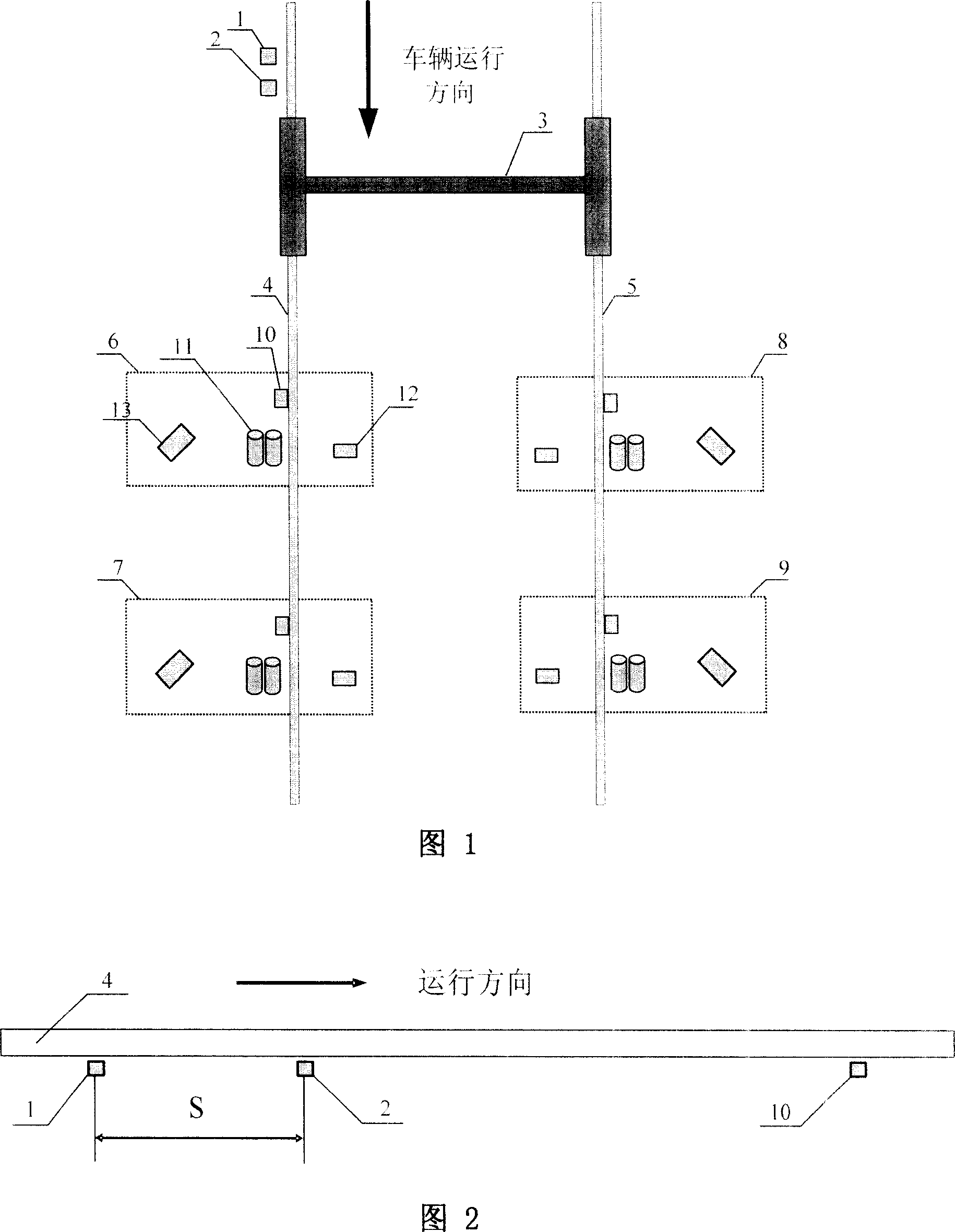

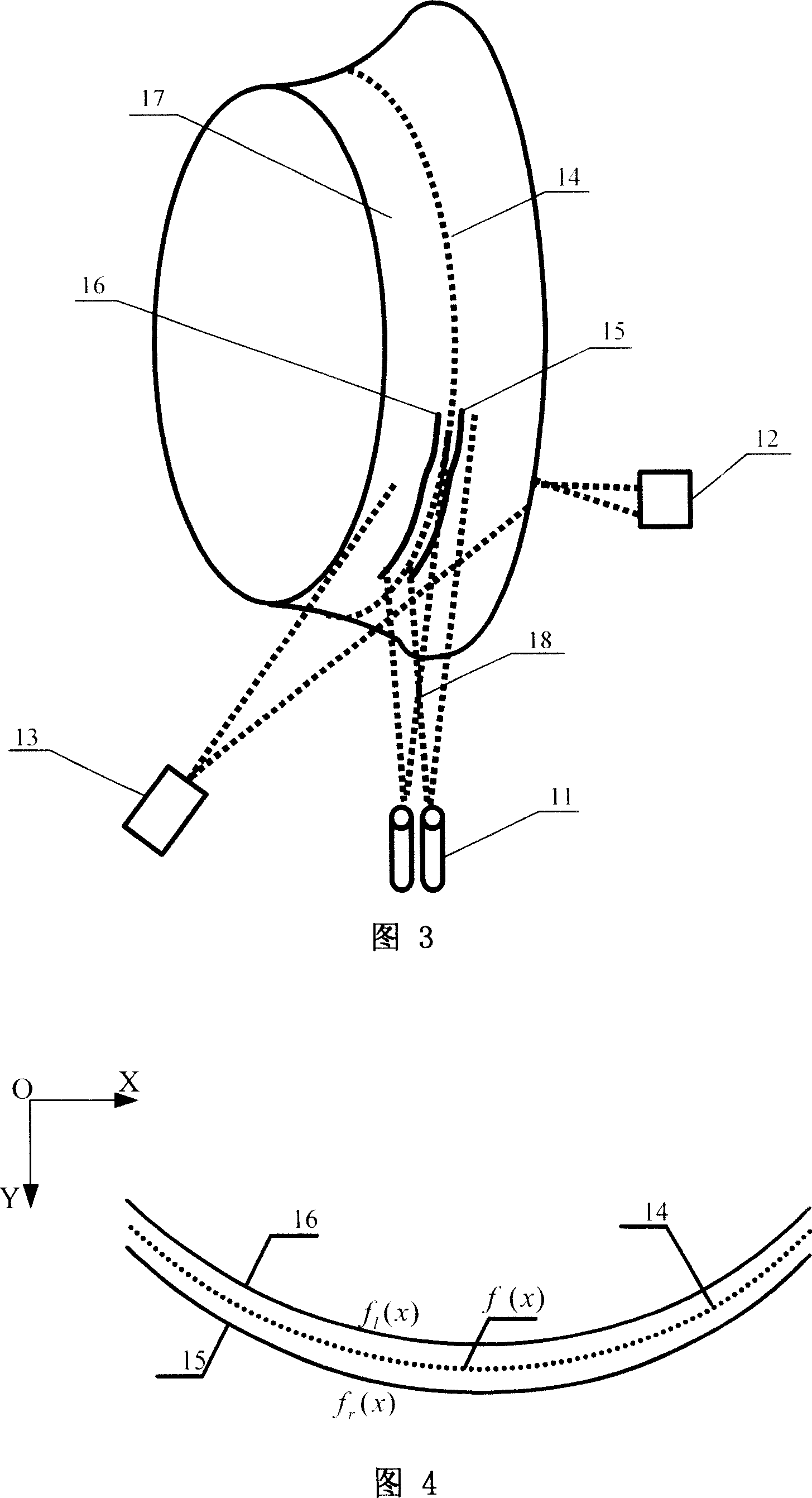

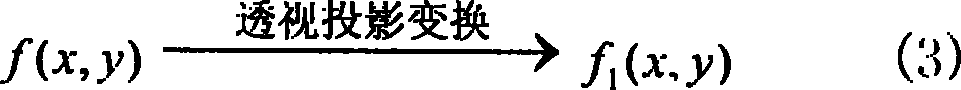

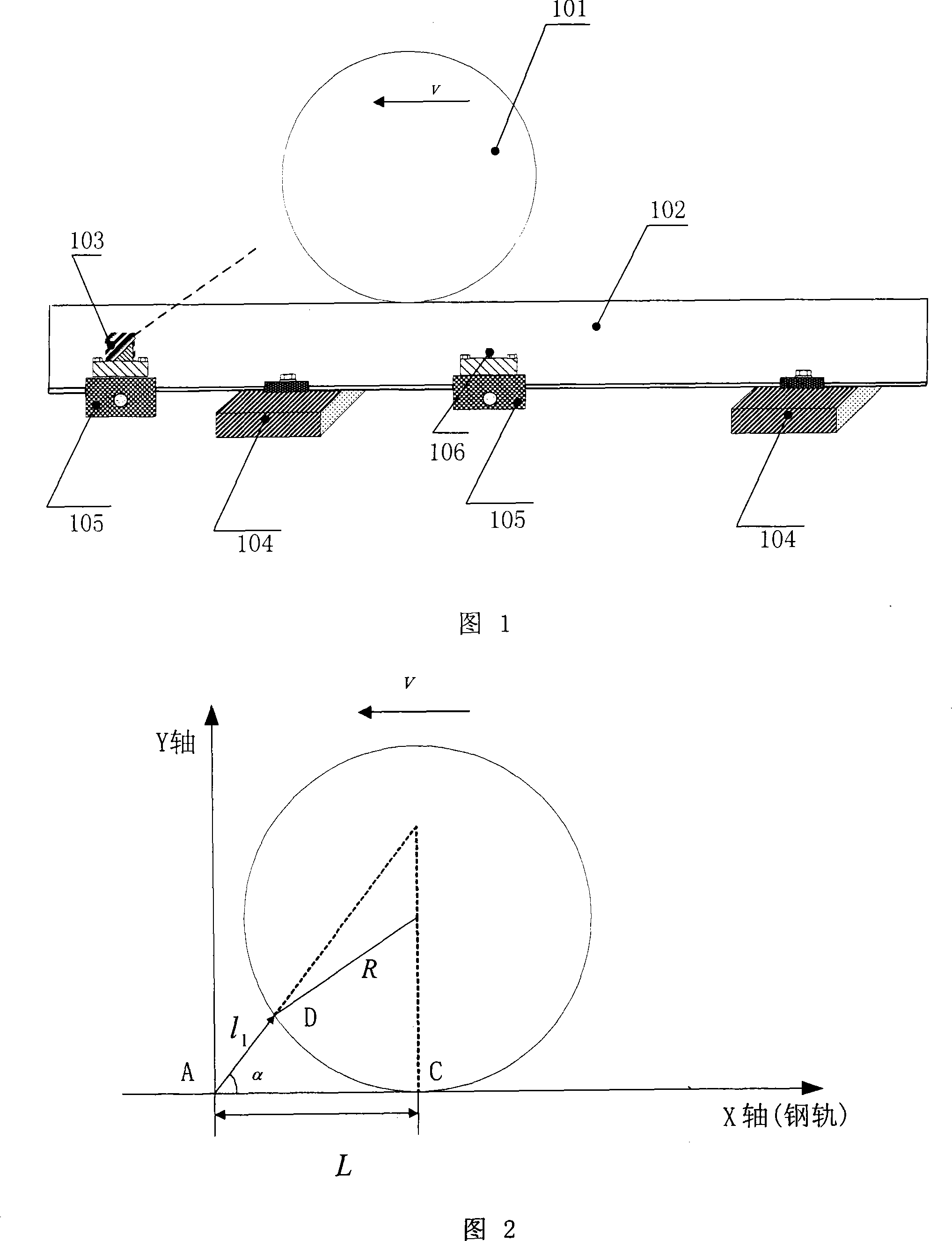

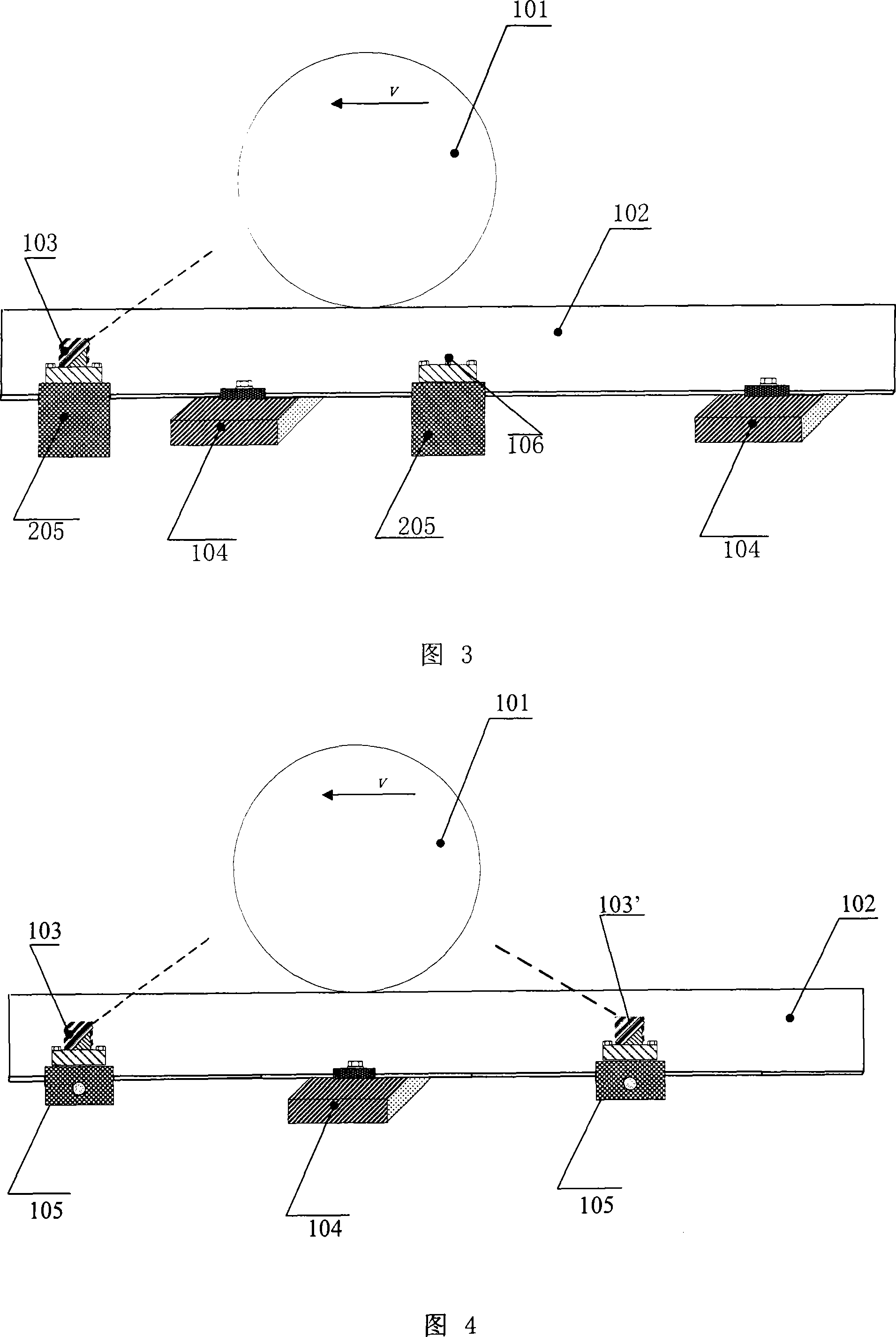

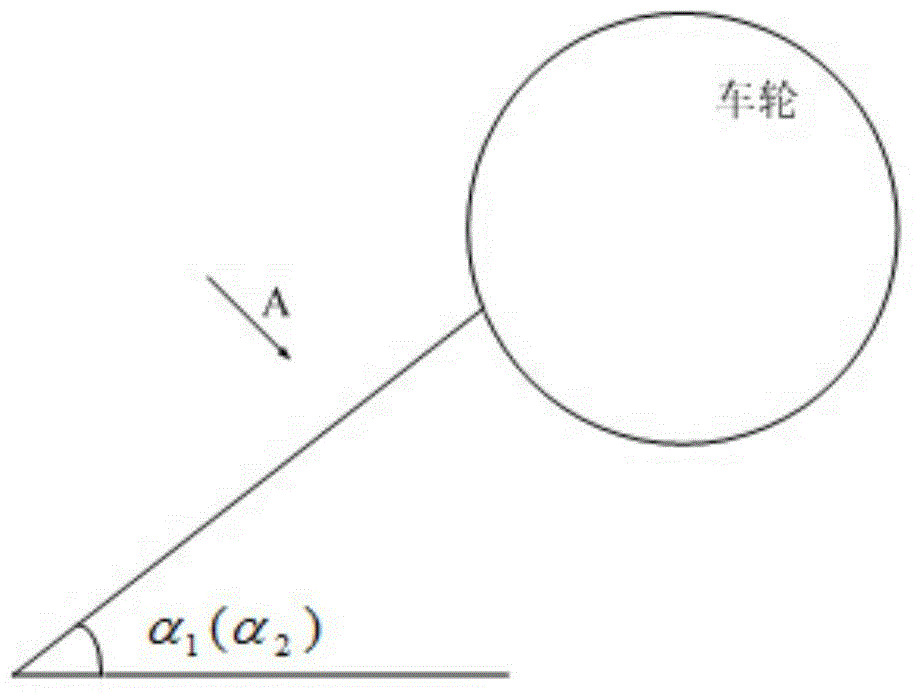

The present invention relates to a method for on-line detecting railway car wheel set diameter and its detection equipment. It is characterized by that it utilizes the projection information of light source of structure light on the wheel set tread and base point information detected by displacement sensor to detect wheel average diameter parameter and left-right wheels wheel-diameter difference parameter. Said method includes the following steps: speed detection, starting light source, starting inside surface detection and image collection, image treatment, fitting rolling circle and diameter parameter calculation.

Owner:HANGZHOU DIANZI UNIV

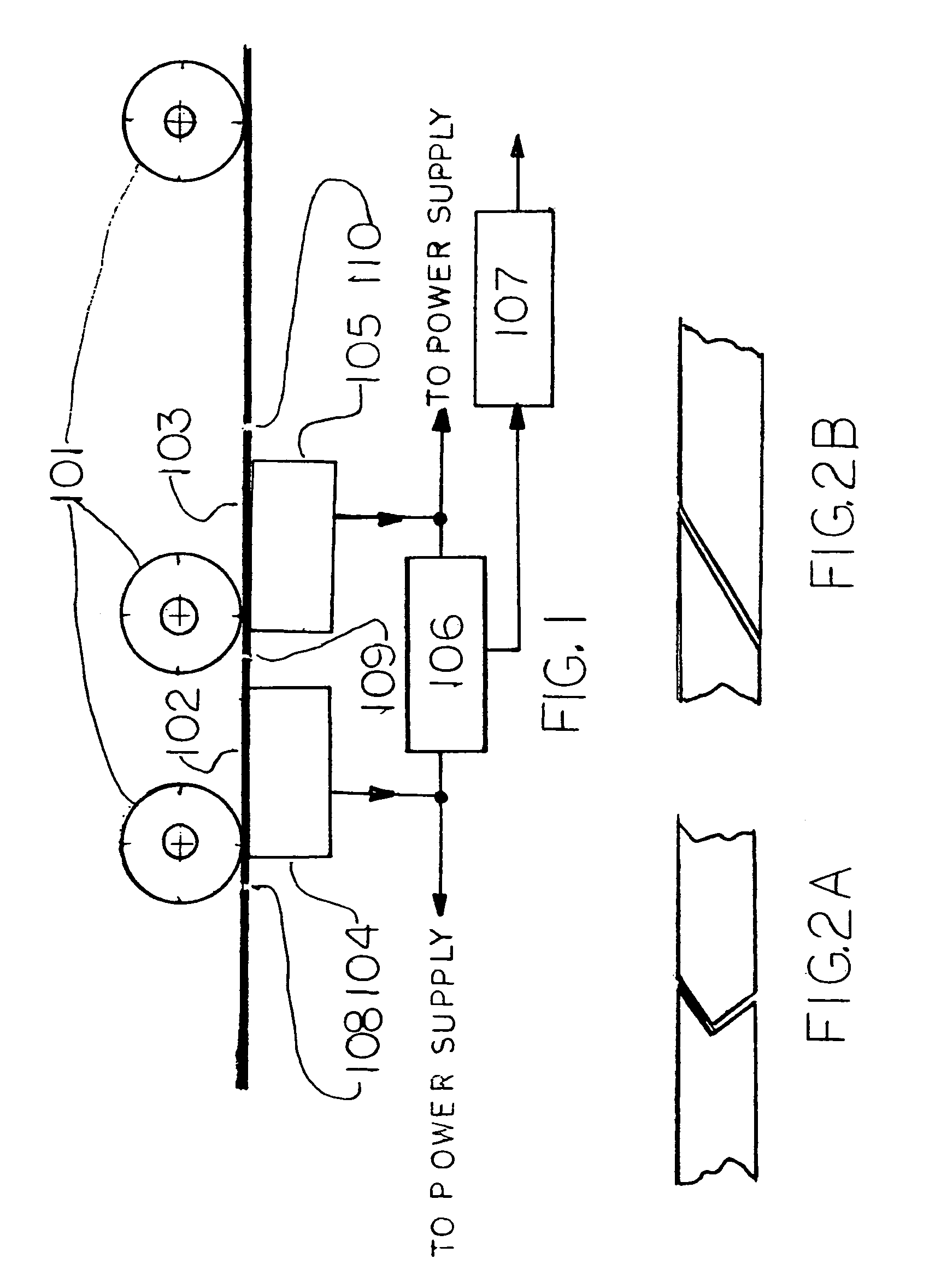

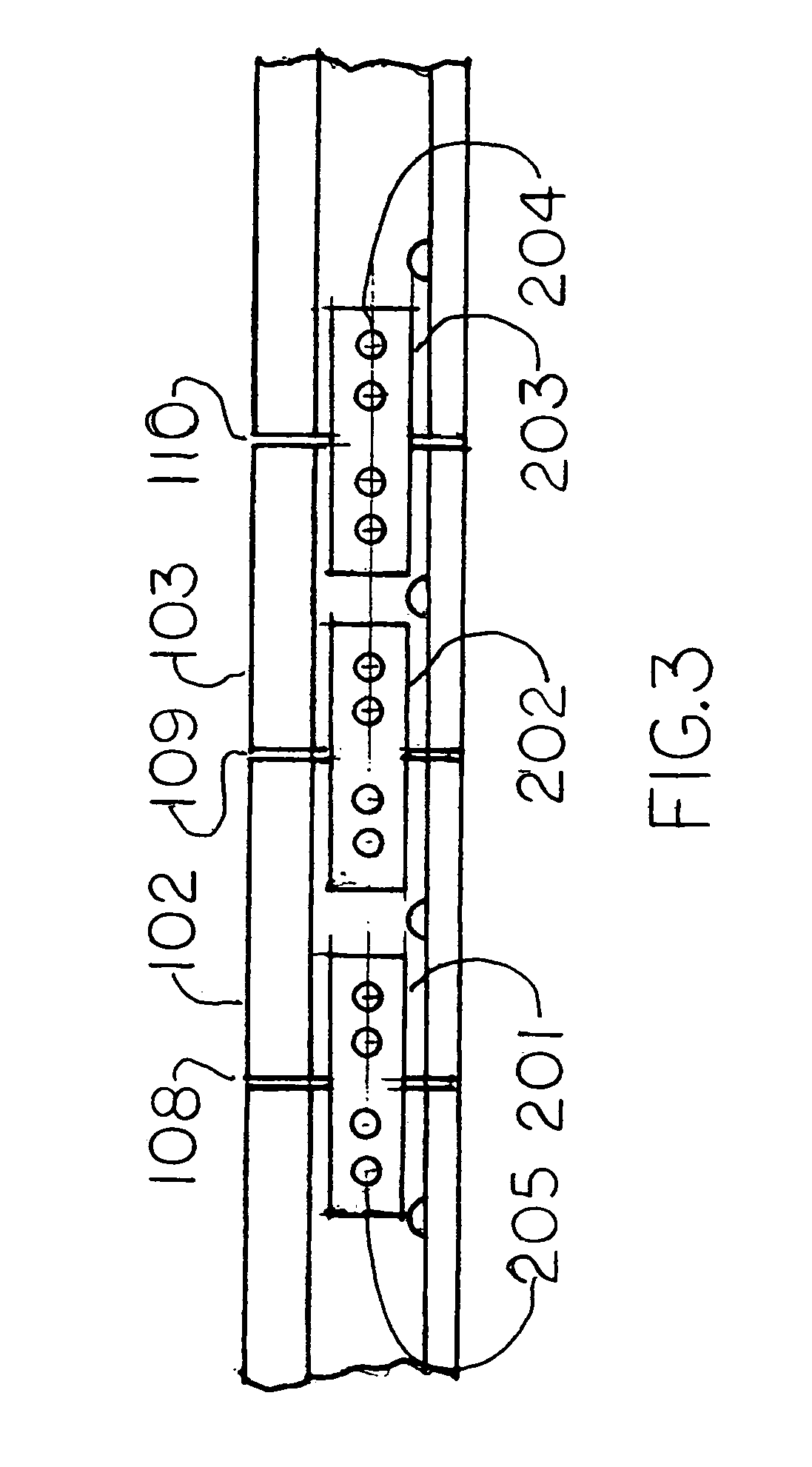

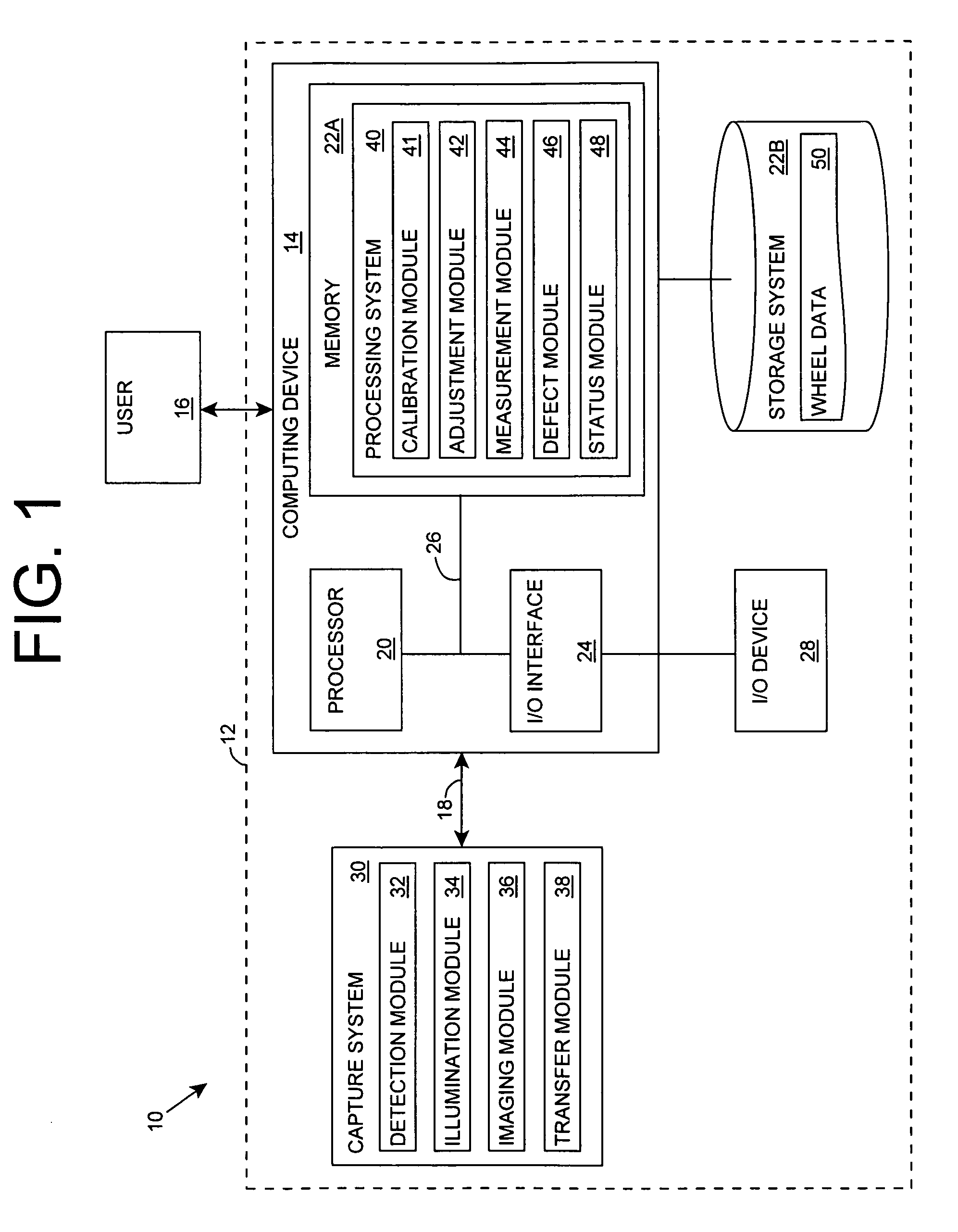

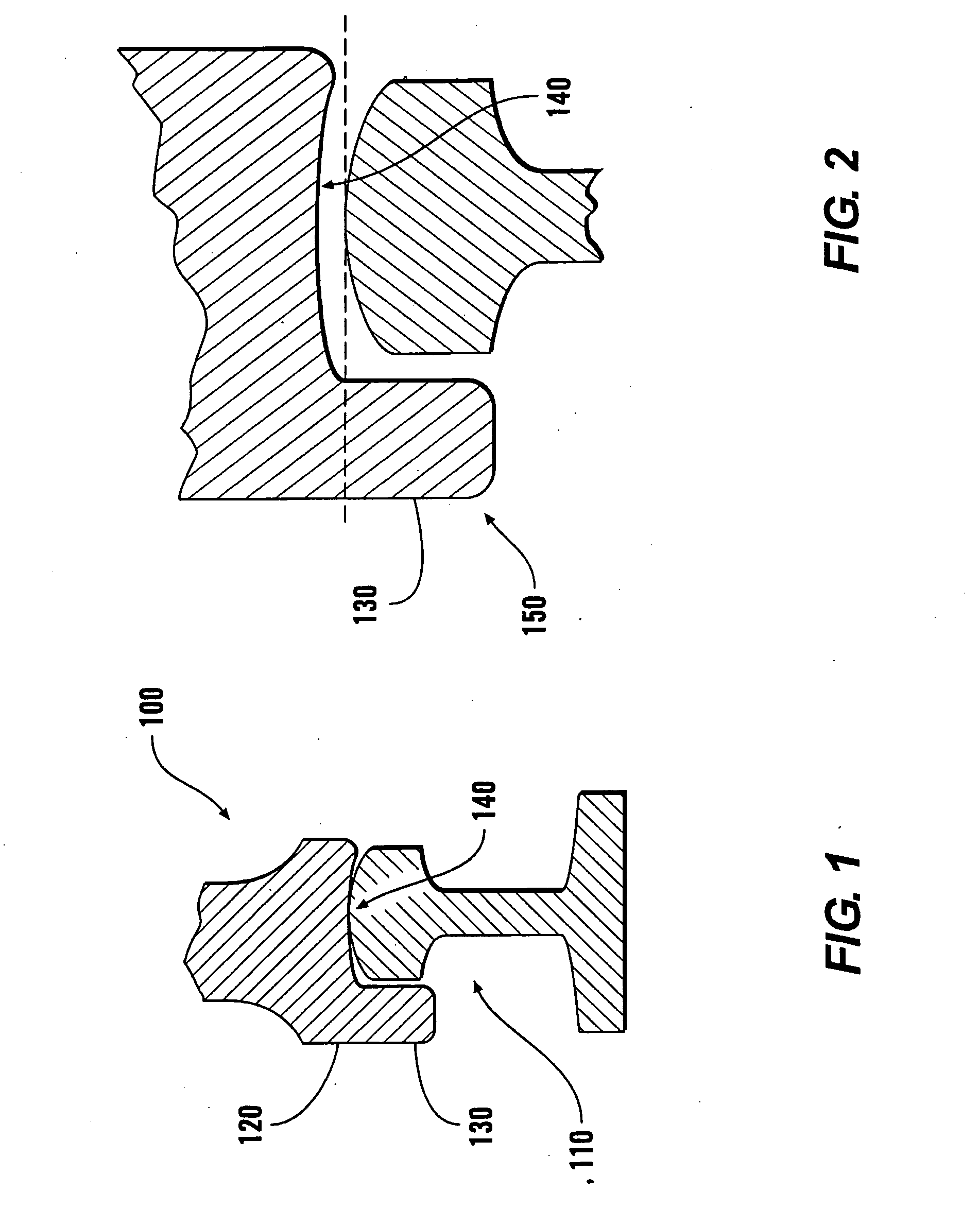

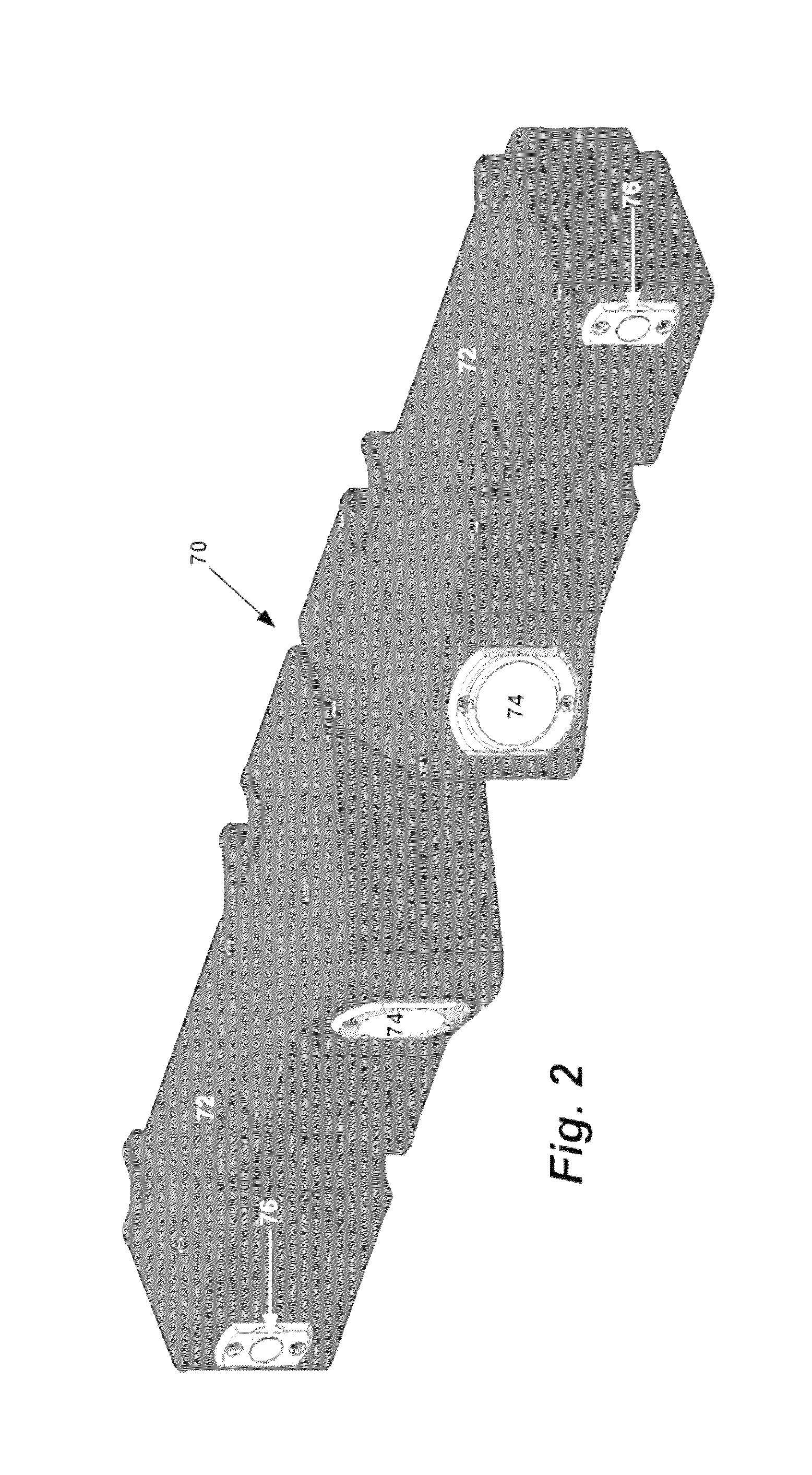

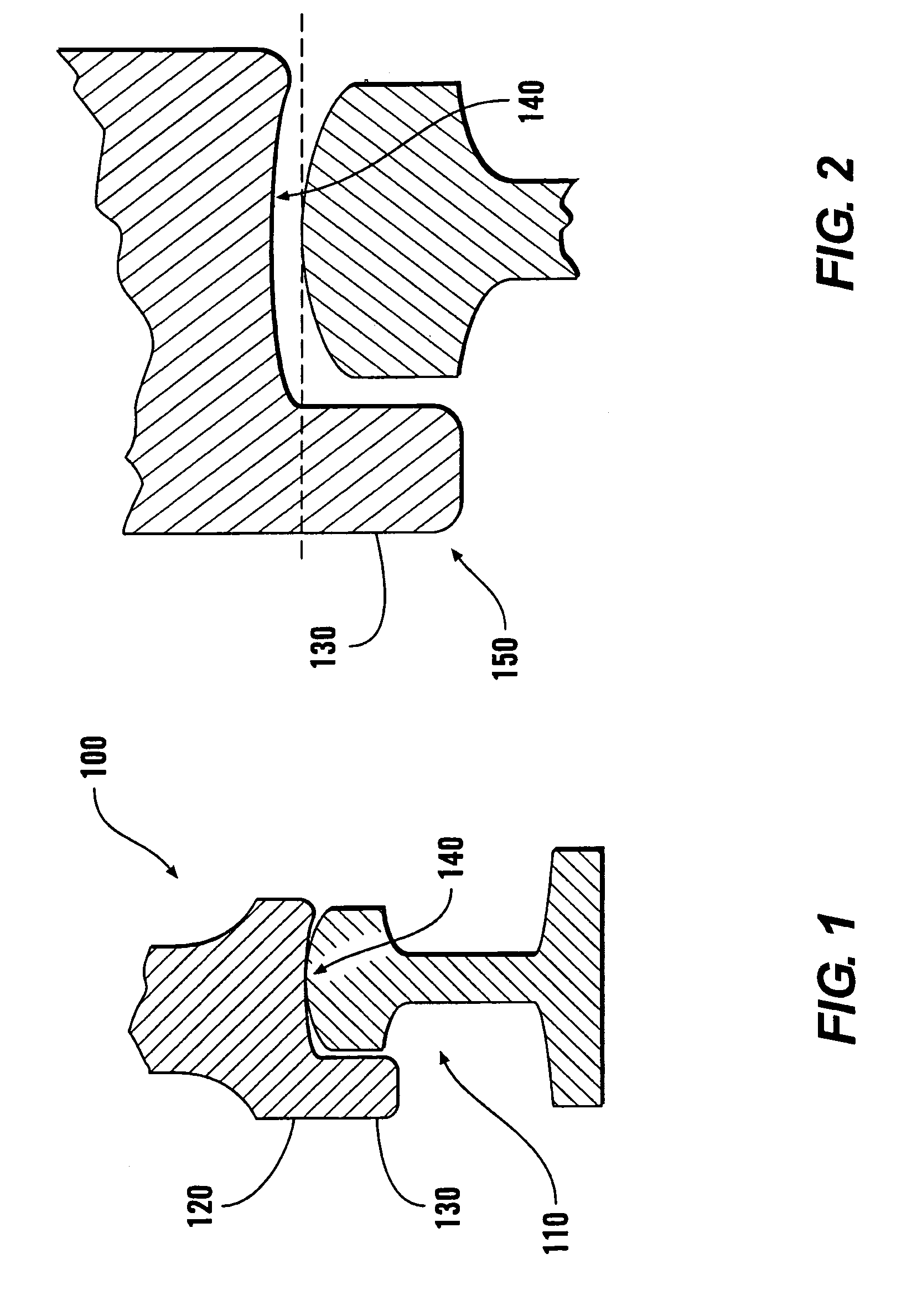

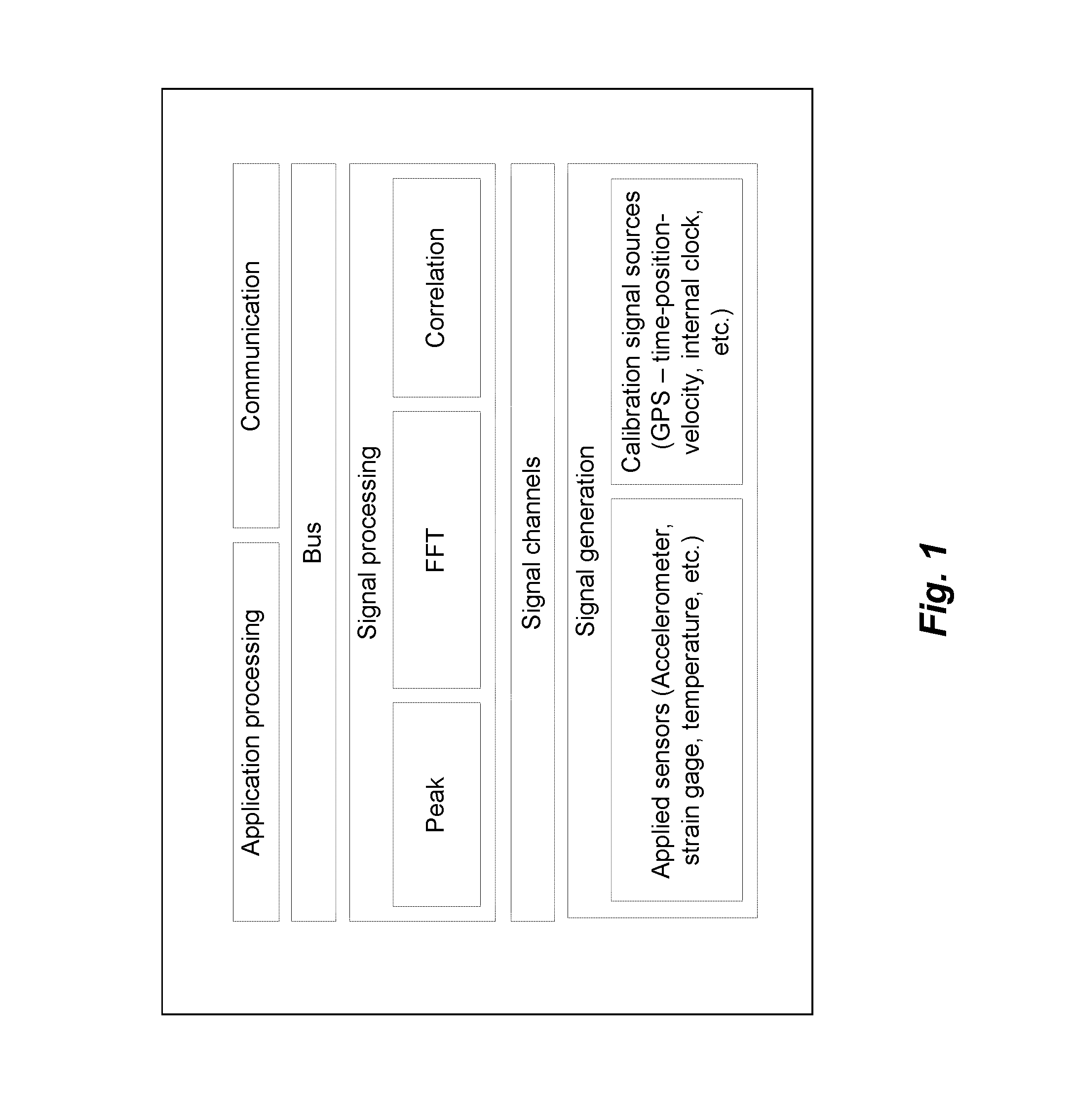

System for detection of defects in railroad car wheels

ActiveUS7213789B1Easy to modifyDefect locationWheel-rims surveying/measuringRailway vehicle testingFrequency spectrumSignal analyzer

A system for automatic detection of defects in railroad wheels, a system that is stationary and is installed in extended intervals in the rails uses stationary acoustical / vibration sensors installed at intervals in the rails. Rail segments associated with the detectors are acoustically isolated. The sensors acquire the sounds and vibrations generated by the wheels rolling over the rails. Signal analyzers identify rail defects from intensity vs., frequency distributions of acoustical spectra. Such spectra reflect the condition of the wheels and change their intensity vs. frequency distributions when the wheels pass the sensors installed in the rails. The acquired information on the condition of the wheels is transmitted to a central location. Any defective wheel is identified and marked for repair or replacement.

Owner:MATZAN EUGENE

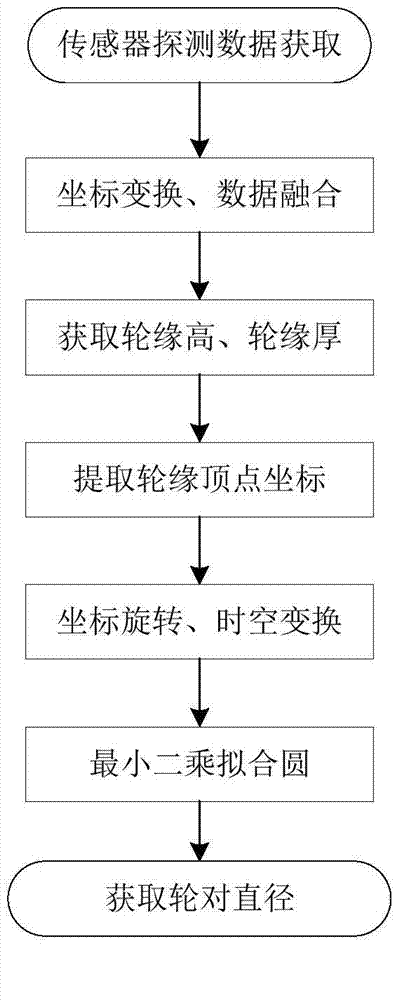

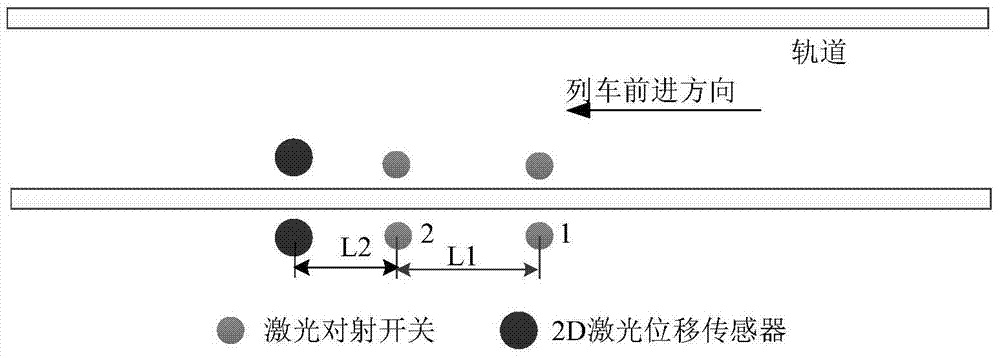

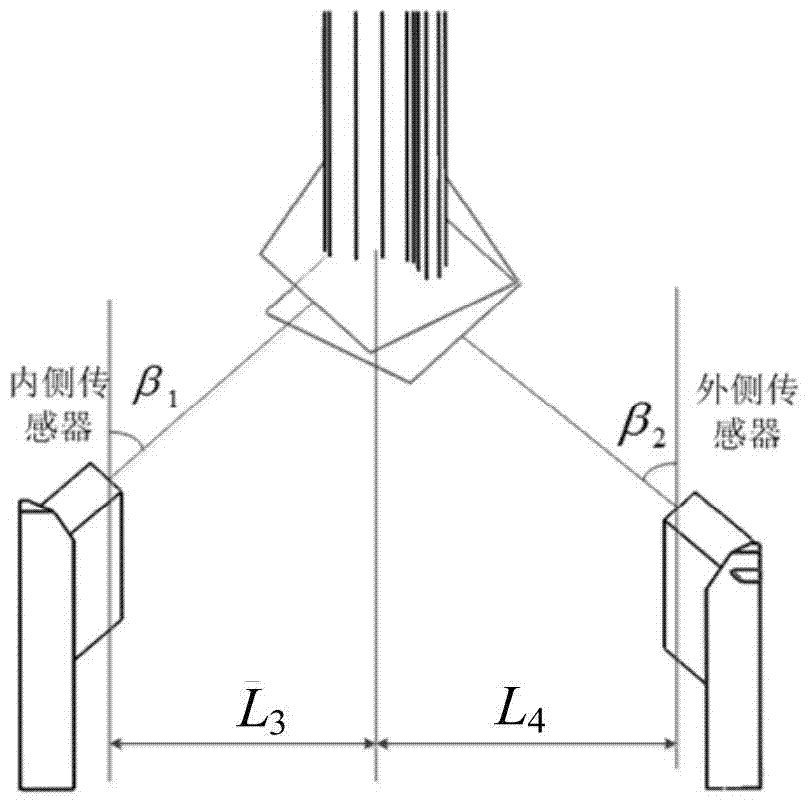

Method and device for online detection of size of city rail train wheel set

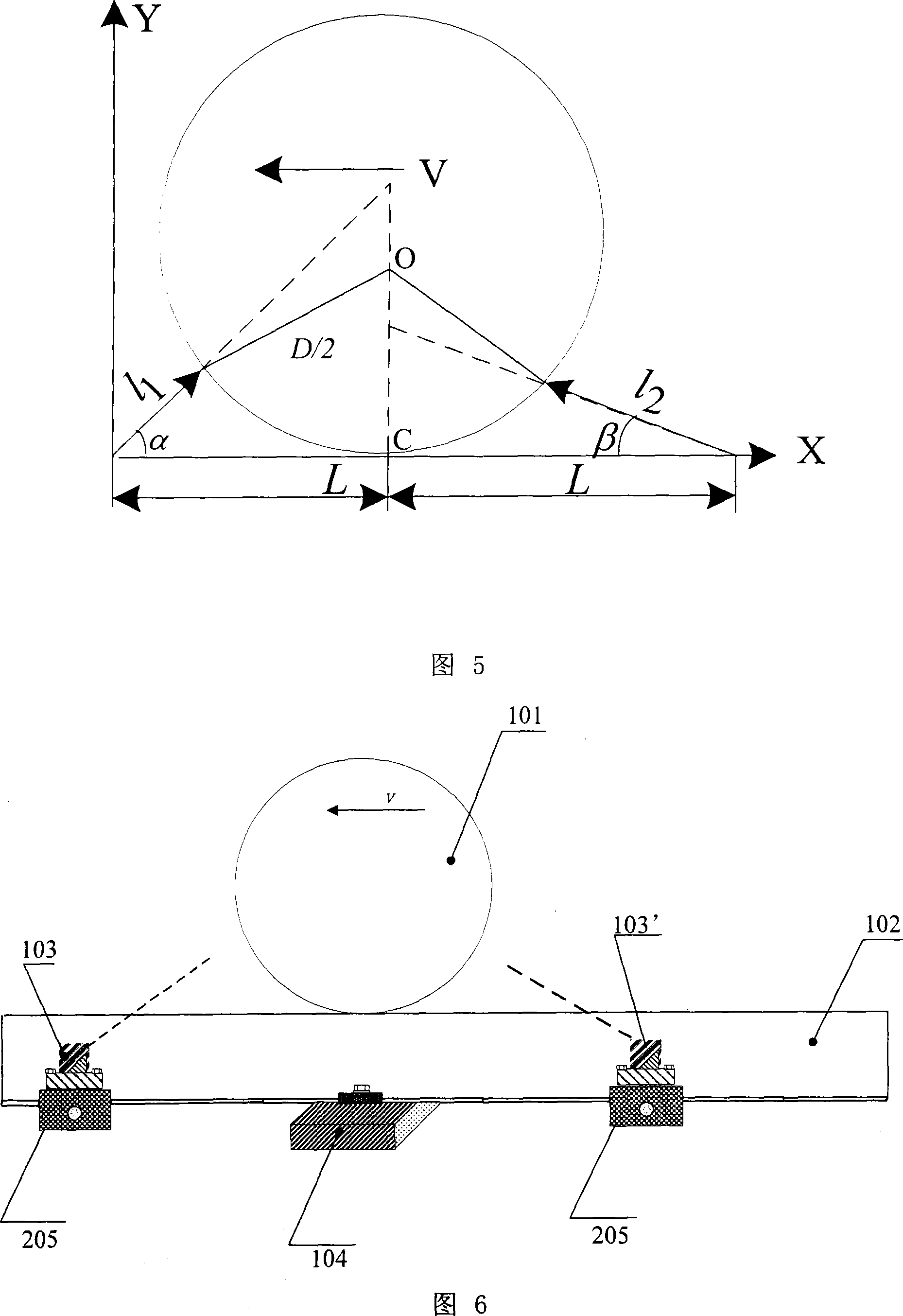

ActiveCN104228875ALow costEasy to operateWheel-rims surveying/measuringGeometric relationsContact type

The invention discloses a method and device for online detection of the size of a city rail train wheel set. A system is mainly comprises two 2D laser displacement sensors arranged along a train rail in a mirror symmetric mode, and two laser bijection switches arranged on the two sides of the same rail in a certain geometrical relation. The 2D laser displacement sensors detect and obtain tread contour lines, and the two laser bijection switches detect the wheel passing speed. The rim height and the rim thickness are worked out by extracting the tread contour lines of wheels passing through a detection system according to the geometrical relation. The coordinates of the lowest rim points of the detected tread contour lines of the wheels at different moments are extracted, the coordinates at the different moments are restored to coordinate values at the same moment on the condition that the speed is given, so that the circle where the top points of the rims of the wheels are located is fitted out, the two times of the height of the rims is subtracted from the diameter of the circle of the top points of the rims, and thus the diameters of the wheels are obtained. The method and device for online detection of the size of the city rail train wheel set are low in cost, simple in operation and high in non-contact type measurement precision.

Owner:NANJING UNIV OF SCI & TECH +1

Optical wheel evaluation

ActiveUS20070064244A1Enhanced image dataIncrease contrastWheel-rims surveying/measuringInvestigating moving sheetsImage basedEngineering

Owner:INT ELECTRONICS MACHINES

Optical wheel evaluation

ActiveUS7564569B2Increase contrastData augmentationWheel-rims surveying/measuringInvestigating moving sheetsMechanical engineeringImaging data

Owner:INT ELECTRONICS MACHINES

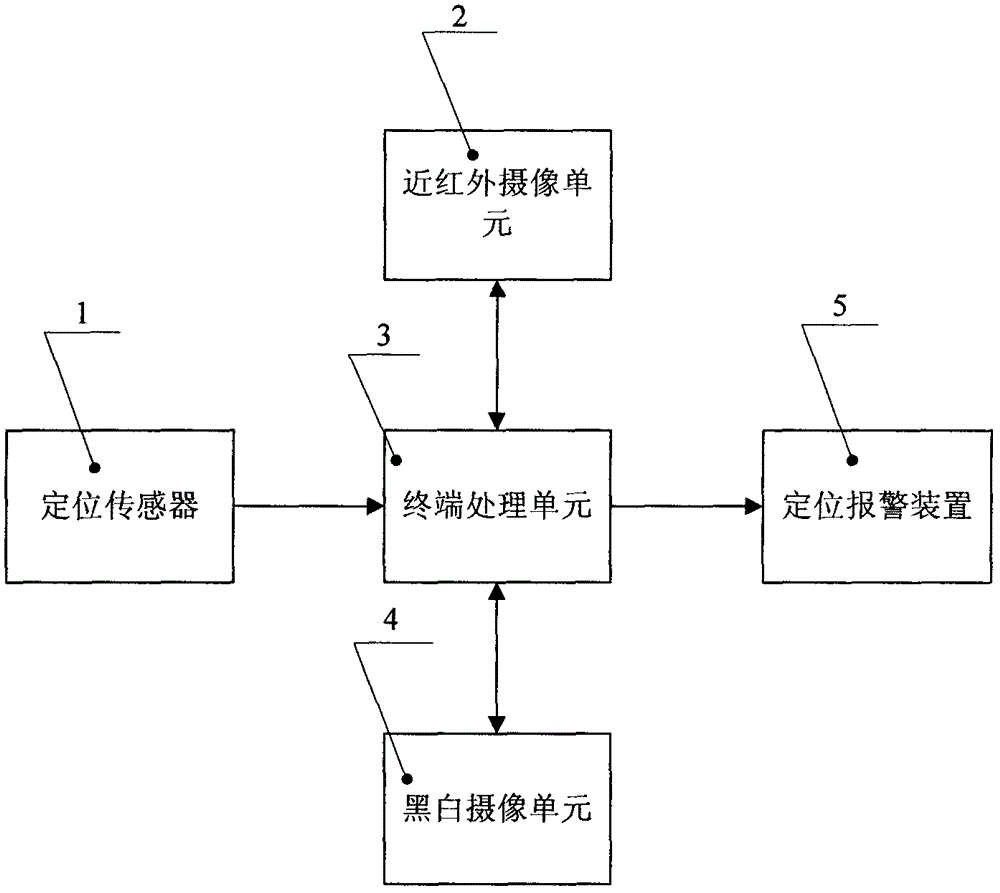

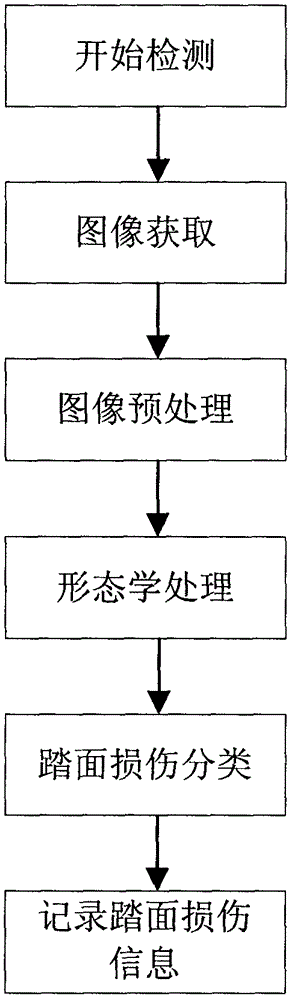

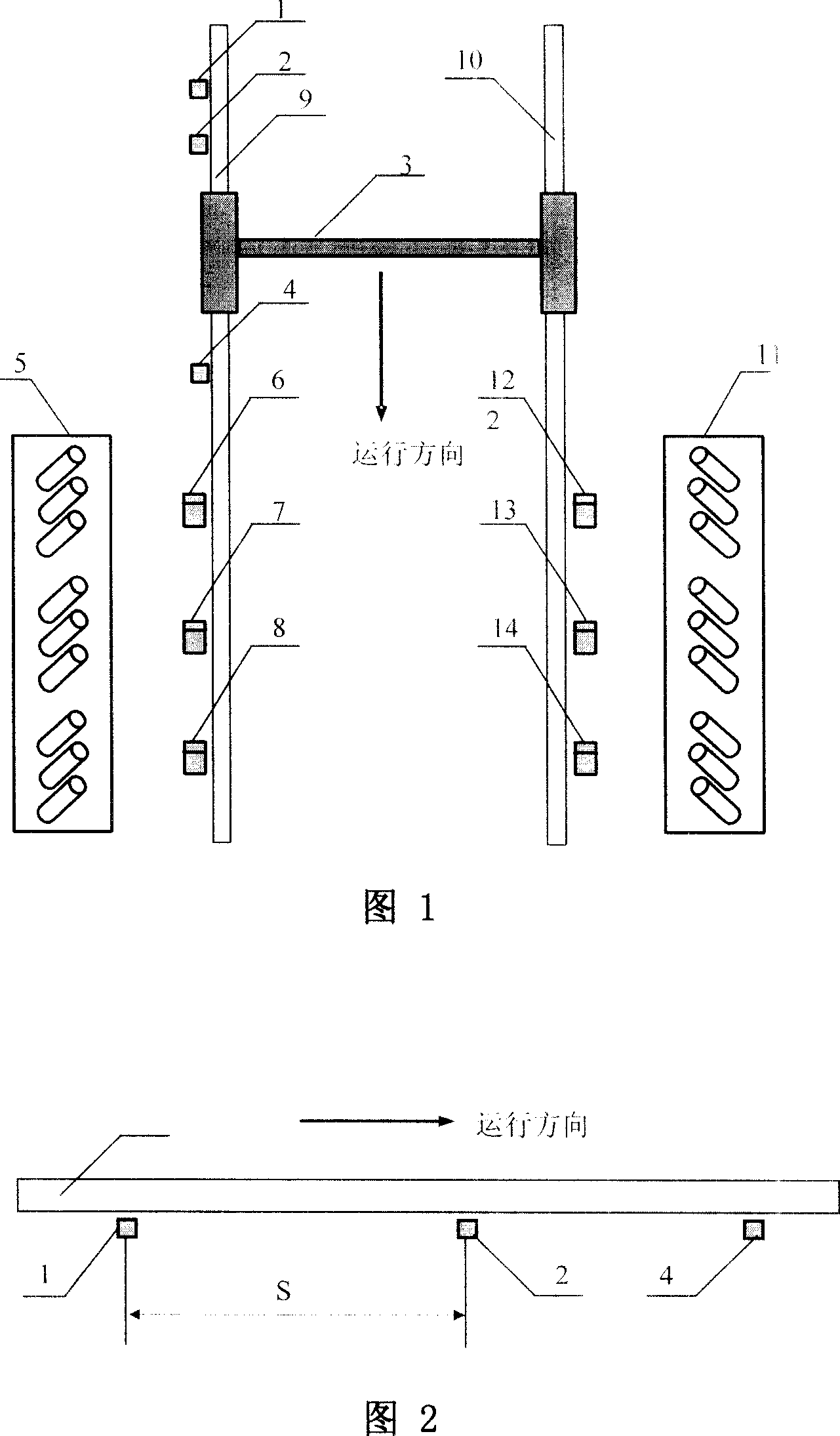

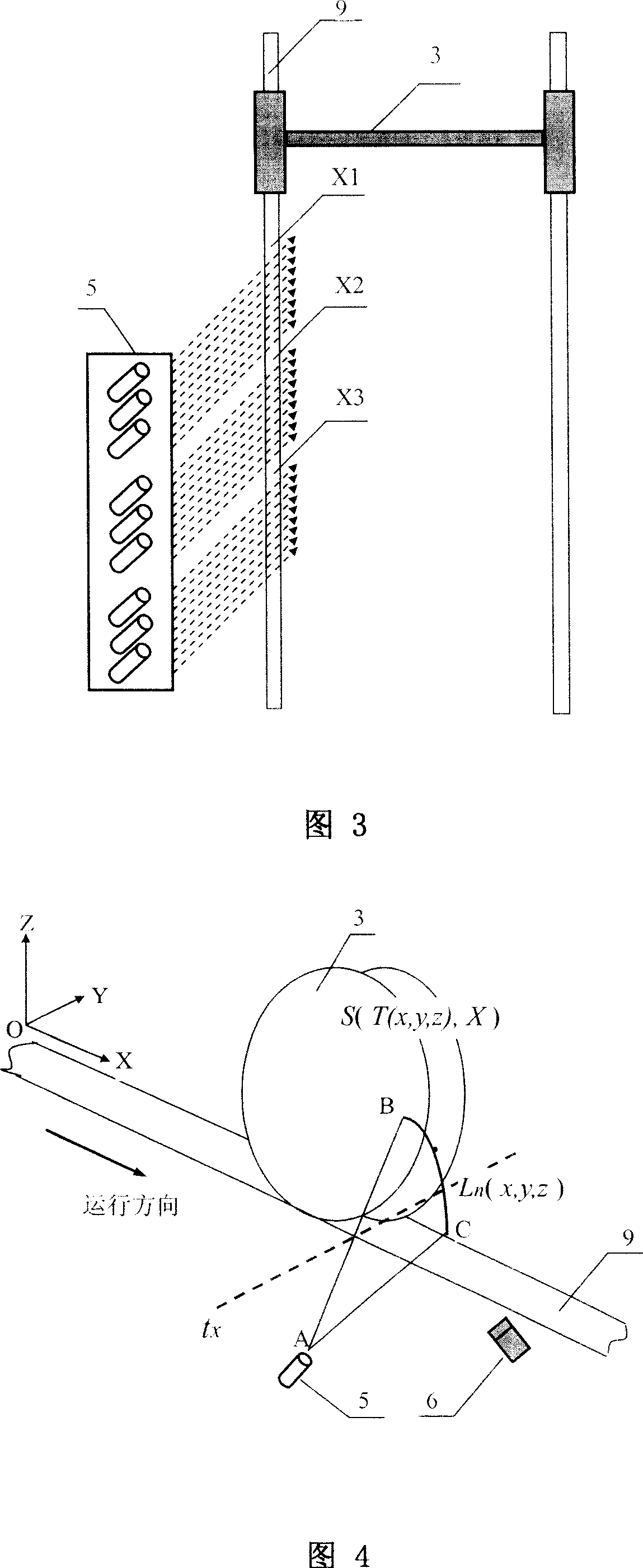

Information fusion technology based train wheel set tread damage online detection and recognition method

InactiveCN104608799AConvenient re-examinationShorten the timeImage enhancementImage analysisPattern recognitionInformation integration

An information fusion technology based train wheel set tread damage online detection and recognition method comprises the steps of 1 image acquisition, 2 image pre-processing, 3 preliminary damage detection, 4 accurate damage positioning and 5 damage judgment, wherein the step 4 is that an infrared image processing result and a gray image processing result are subjected to data fusion, a tread image is marked and positioned, damaged texture and area are obtained through morphological processing, morphological processing is conducted on tread cracks to obtain the length of the cracks, and the step 5 is that features of a tread damage region are extracted and selected, a BP neural network is designed and trained, the defects of the BP neural network are classified, and reference is provided for operation situation analysis of wheels, locomotives and lines according to train wheel set tread damage information recorded by a terminal processing unit. The information fusion technology based train wheel set tread damage online detection and recognition method has the advantages of being comprehensive in detection, high in automatic degree, high in detection speed and detection accuracy and the like.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

On-line detection method and device for thread defect of vehicle wheel set

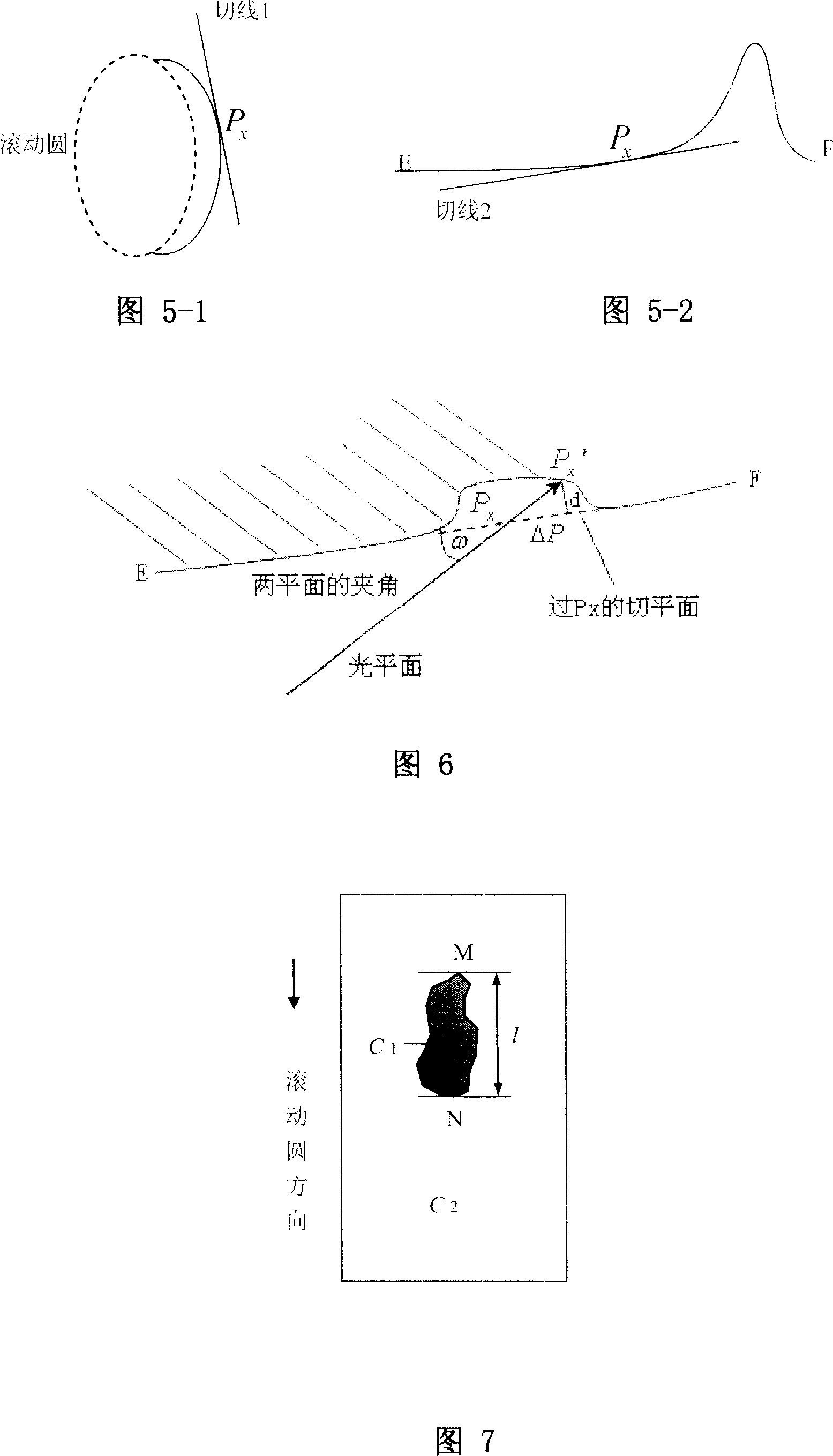

InactiveCN100999219ANo wear and tearEasy maintenanceWheel-rims surveying/measuringMaterial analysis by optical meansProjection imageEngineering

The present invention discloses a method for online detecting railway car wheel set tread defect and its on-line detecting equipment. It is characterized by that the light sent out by light source of structure light can be irradiated on the wheel set tread, on the tread a projection image is formed. When the wheel set is run to the set position, the third position sensor can give out a triggering signal to start image sensor to shoot a series of tread projection images. By utilizing analysis and calculation a deviation image of actual shot image and defectless image can be obtained, it can further judge that in the deviation image the defect is existed or not, and can calculate tread defect parameter.

Owner:HANGZHOU DIANZI UNIV

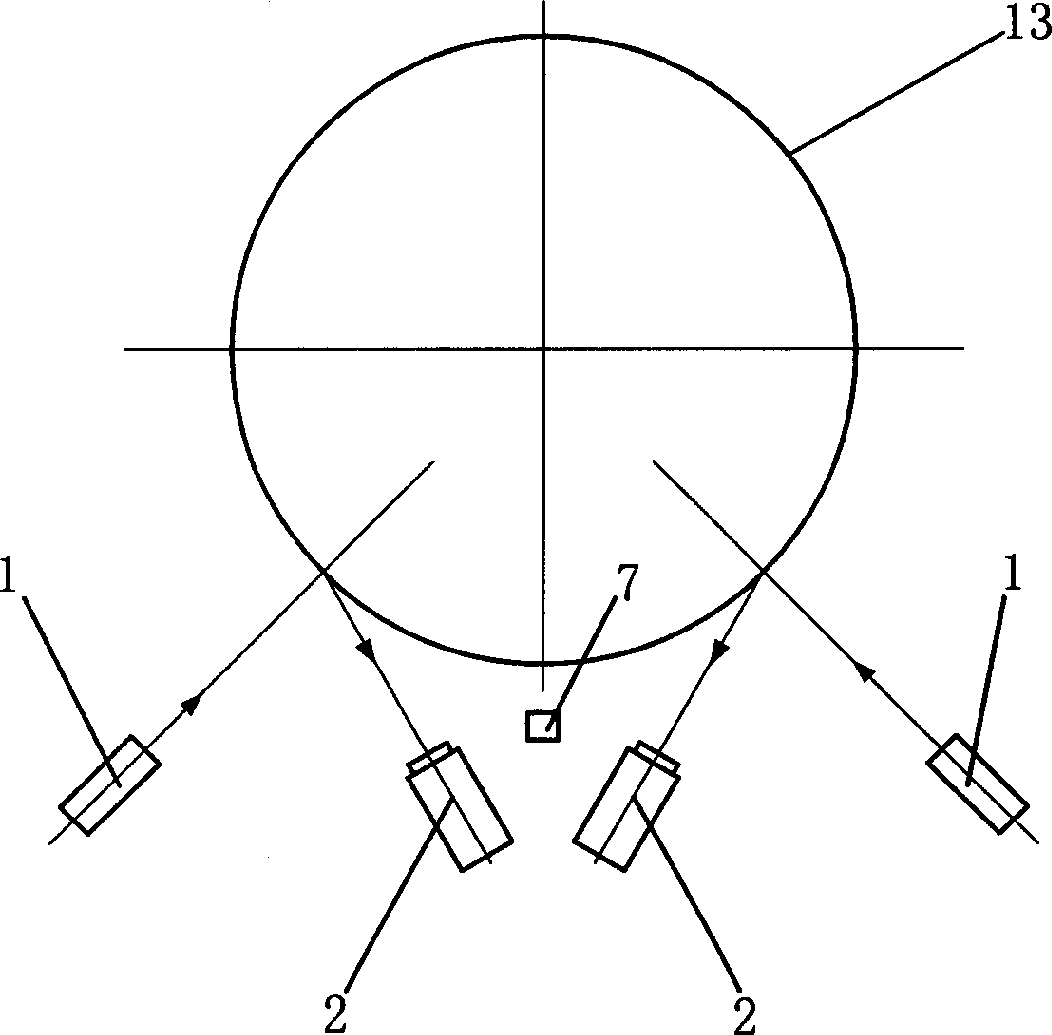

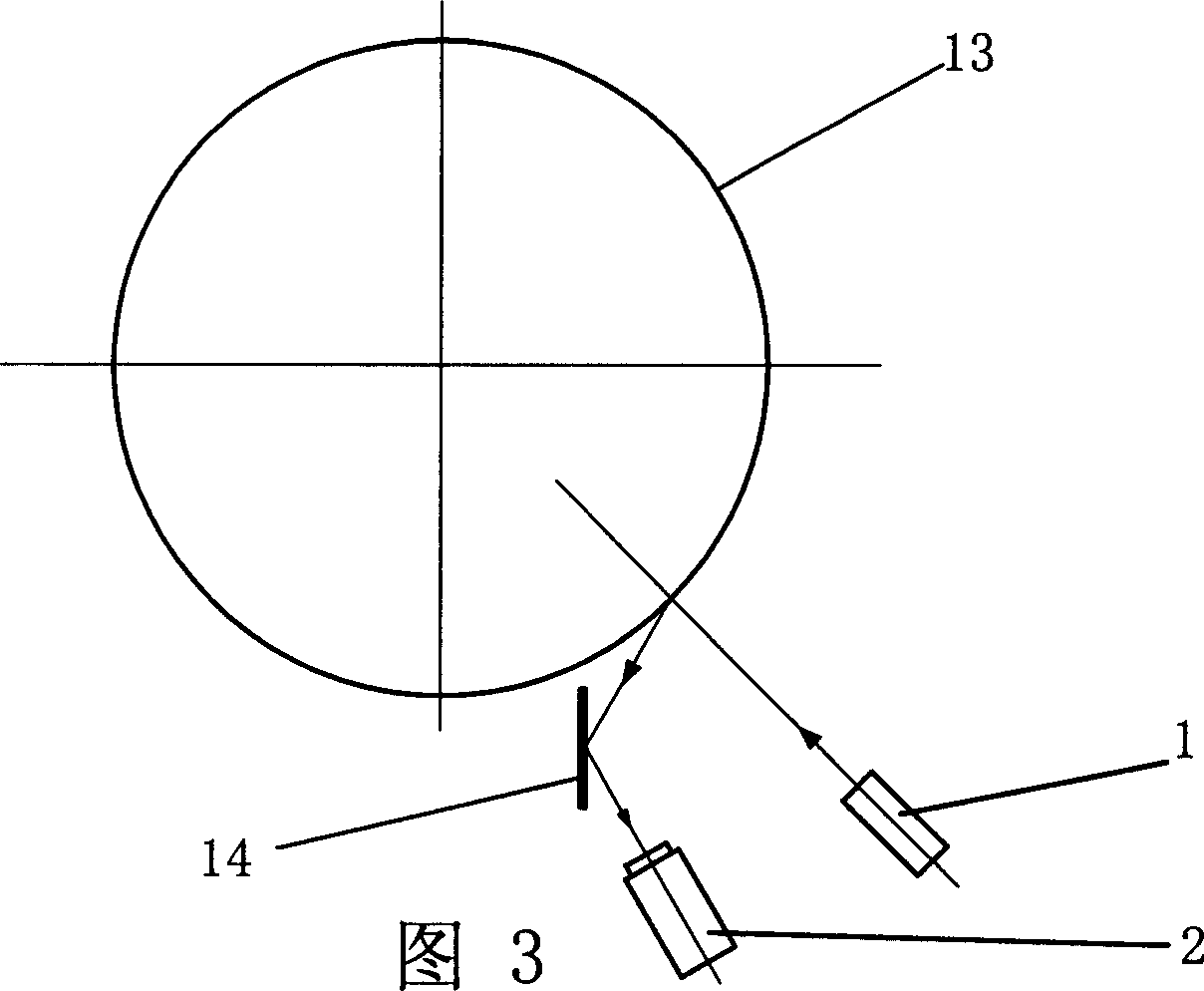

Non-contact type dynamic measuring device and method for wheel diameter based on laser and method thereof

ActiveCN101219672ASimple measuring principlePractical measurement principleWheel-rims surveying/measuringMeasurement deviceOptoelectronics

The invention discloses a non-contact dynamic measuring device for a wheel diameter based on laser and a method thereof. The measuring device consists of a laser displacement sensor, a wheel positioning sensor or two laser displacement sensors; the two sensors are arranged along the direction of a steel rail. When the two laser displacement sensors are applied, light spots of irradiation laser can directly irradiate onto two opposite surfaces of the measured wheel; the two laser displacement sensors respectively and continuously measure the distance between each sensor and corresponding point on a tread of the wheel; the reading data of distance in each laser displacement sensor is recorded when the sum of the distance measured by the two laser displacement sensors is basically unchanged, to calculate the diameter of the train wheel. The invention requires two sensors at most, and measurement principle is simple and practical.

Owner:BEIJING JIAOTONG UNIV

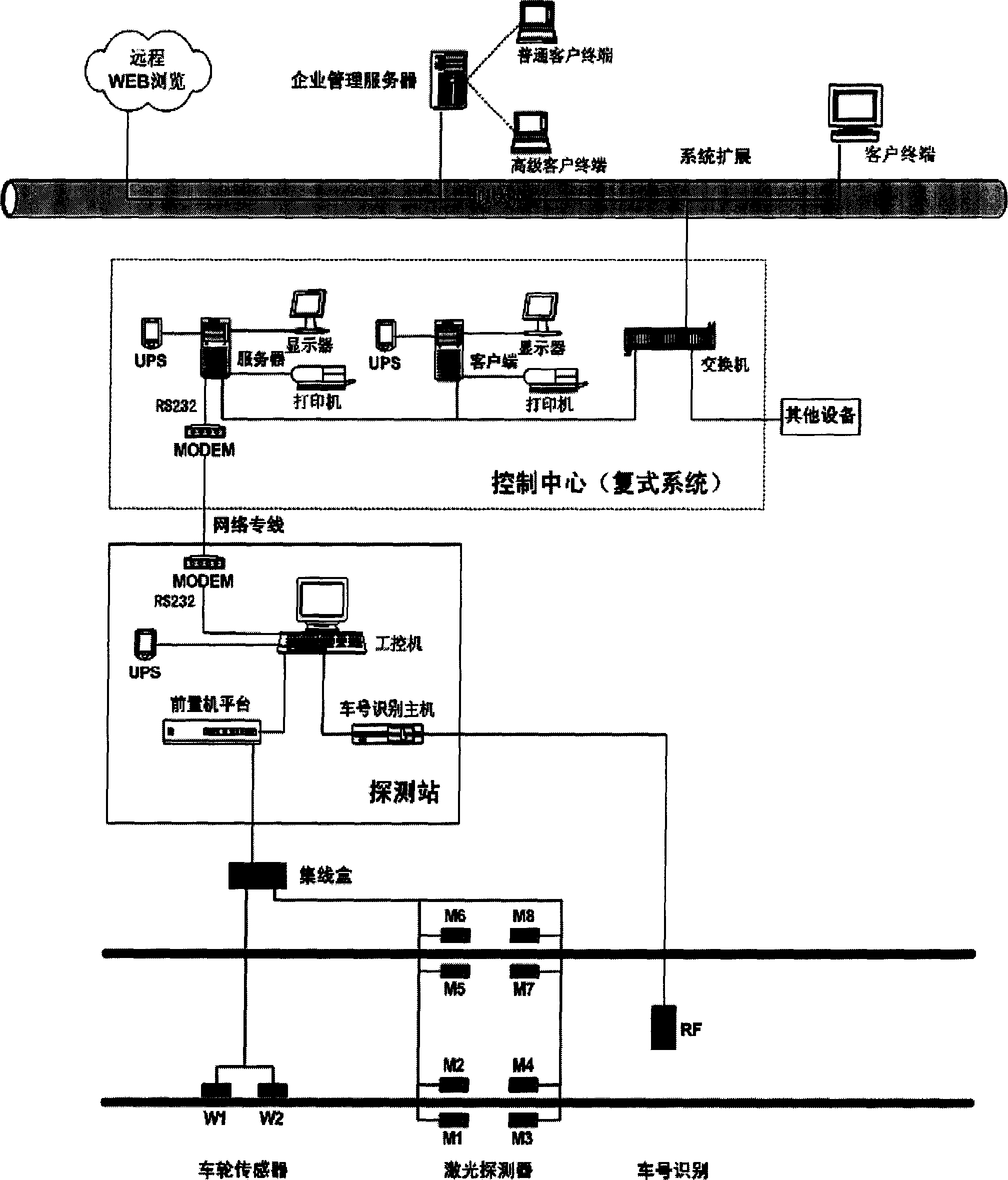

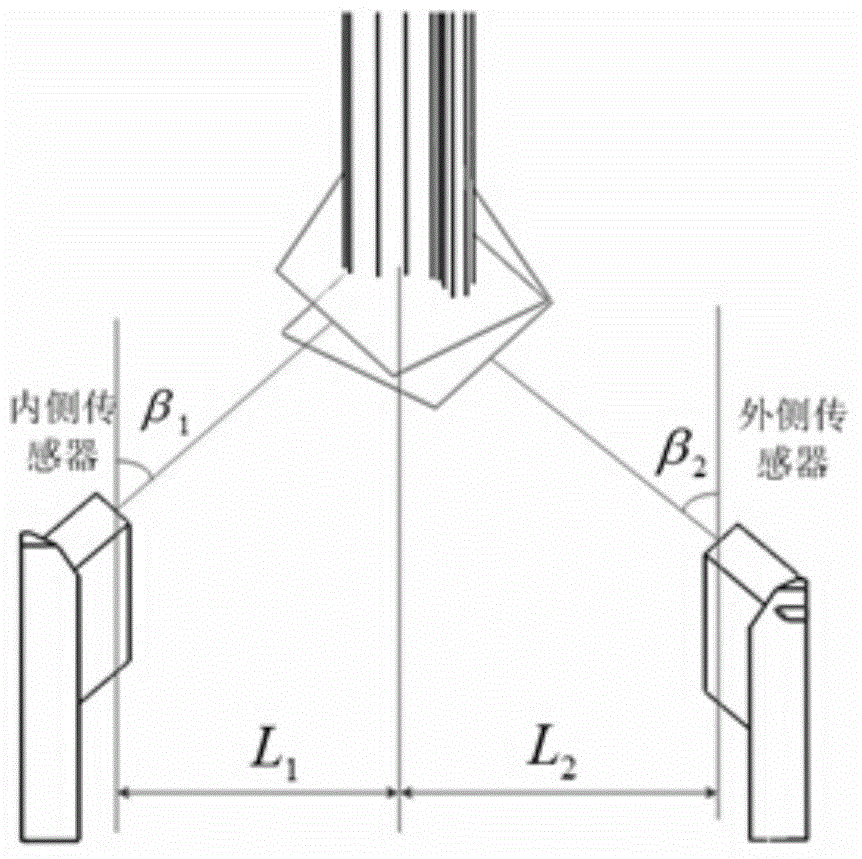

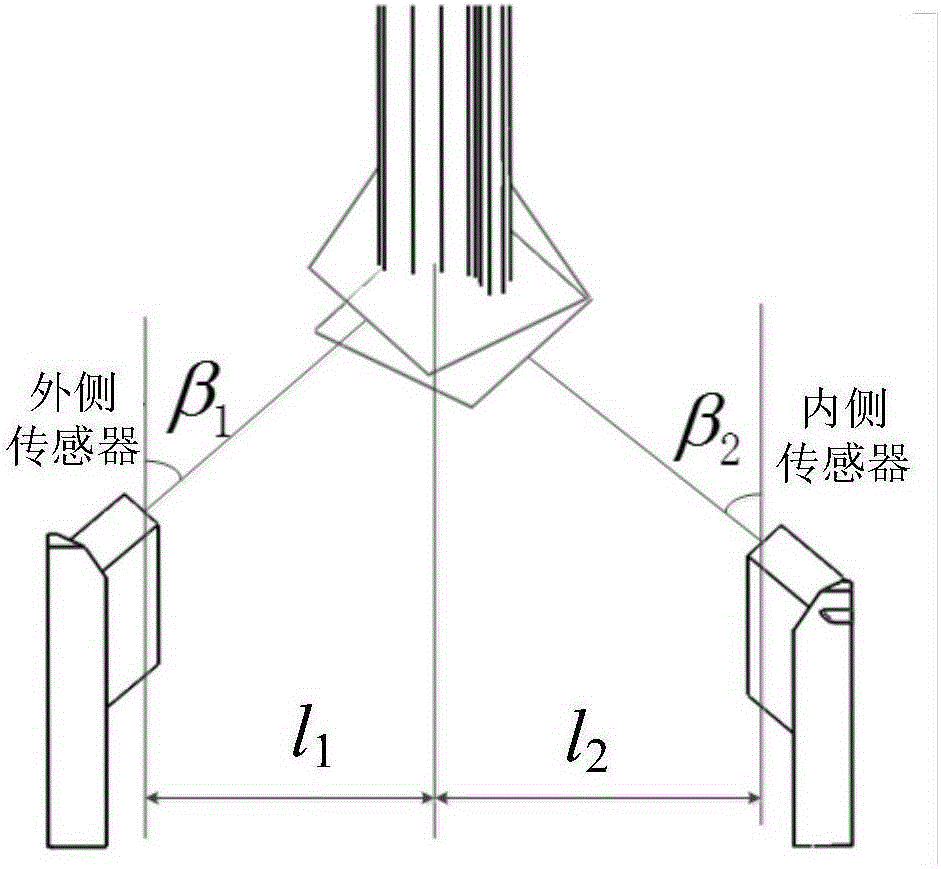

Online detection mthod and device for train wheel pair size

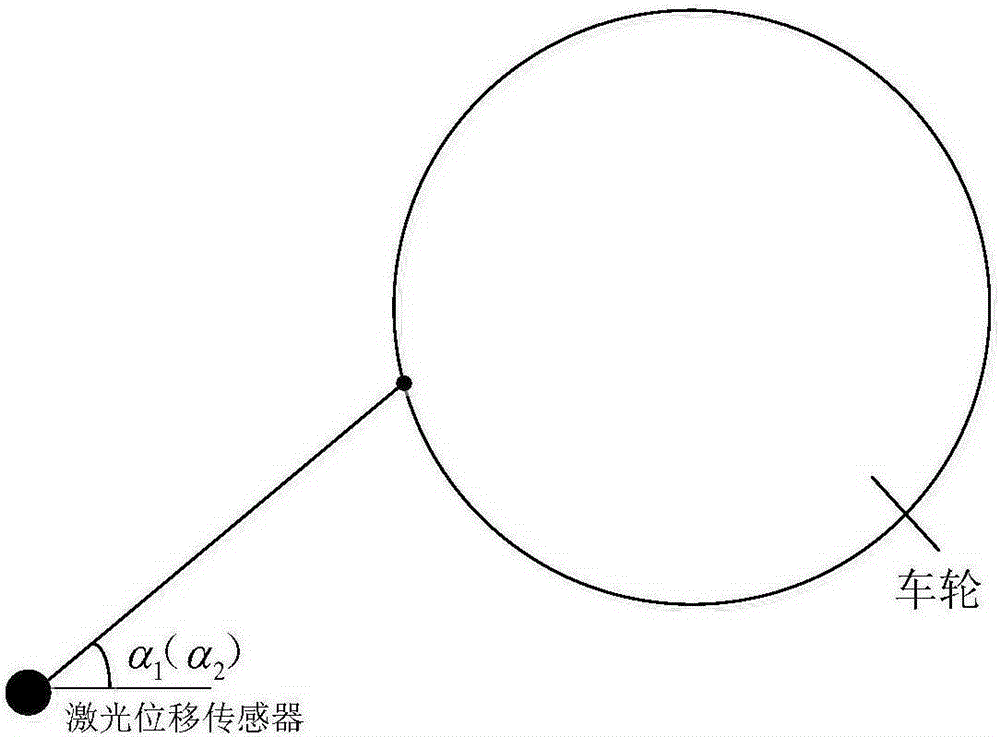

InactiveCN1899904AEasy to controlRealize high-precision detectionWheel-rims surveying/measuringUsing optical meansData acquisitionEngineering

The present invention discloses on-line detection method and device for train wheel pair size. There are two pairs or four coaxial laser displacement detectors set on two sides of two tracks to send laser beams projected obliquely to the wheel pair for detecting the distances between each wheel end place to the laser detector, one high speed data acquisition and treat circuit, and one industrial control computer for recording, analysis and displaying. Based on PSD laser position measurement, the present invention can measure the flange thickness, flange height, wheel diameter and distance between backs of wheel flanges of high speed train in high precision.

Owner:GUANGZHOU AUTO TRANSPORT MEASURE & CONTROL TECH

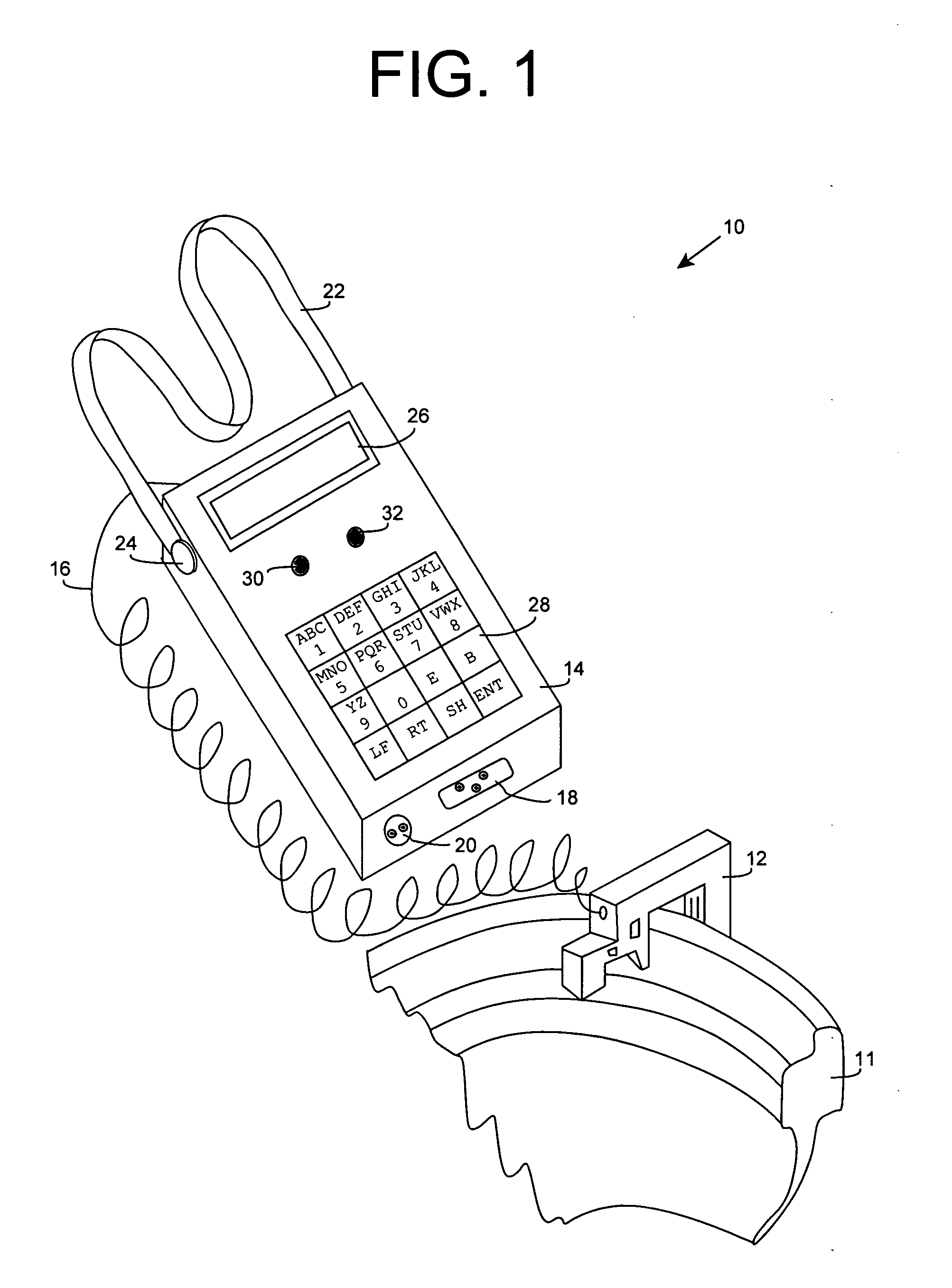

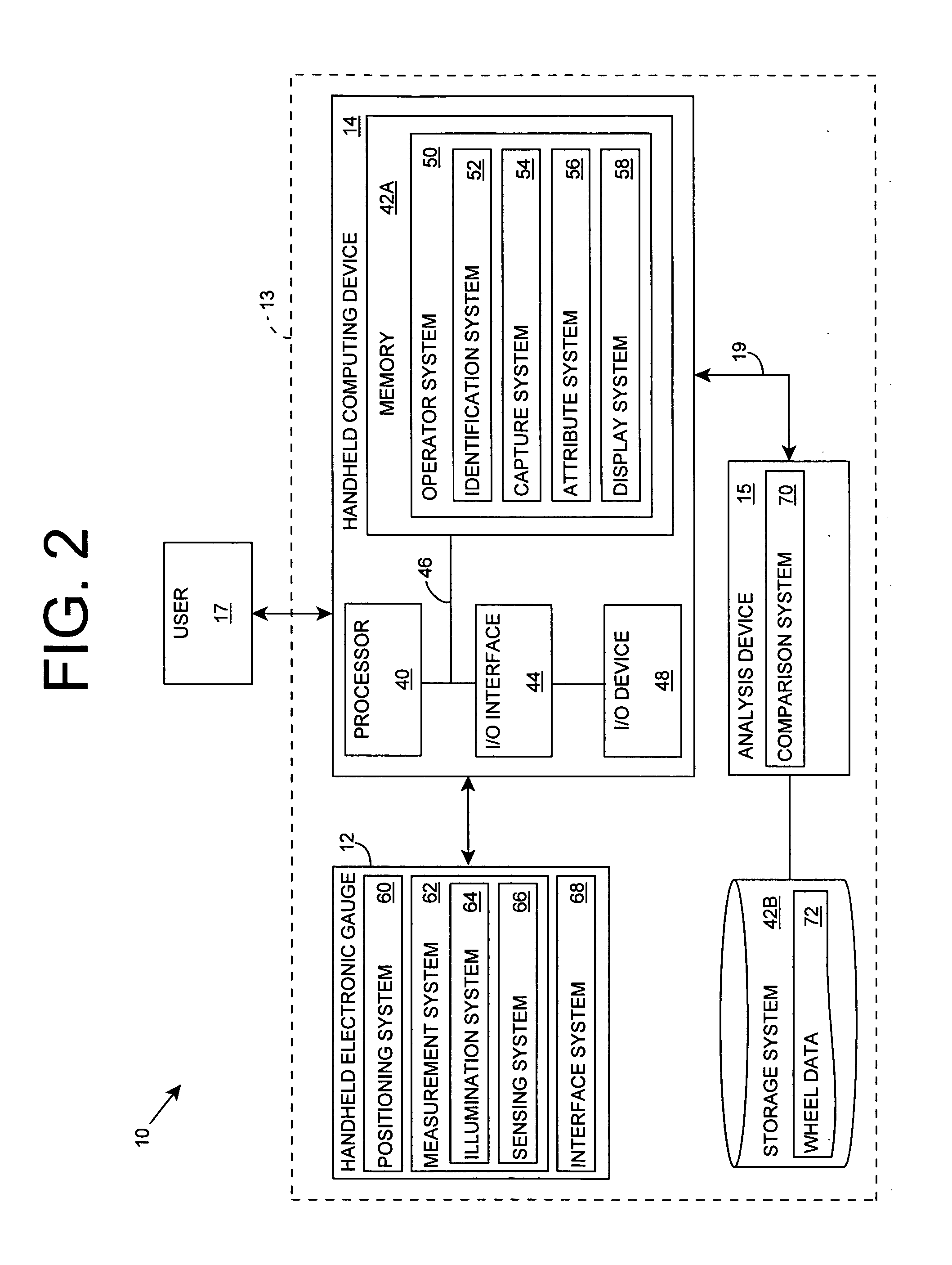

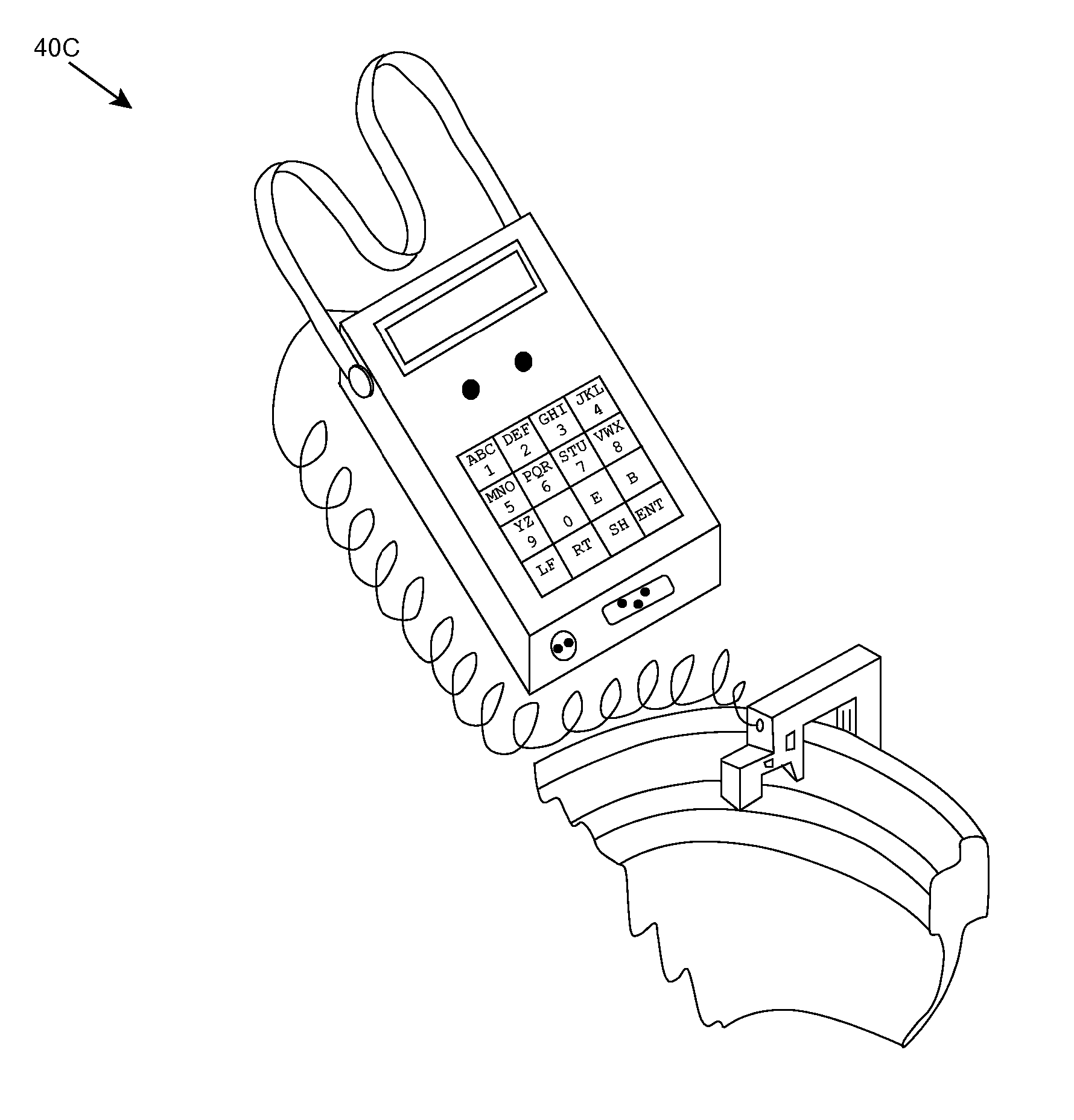

Portable electronic measurement

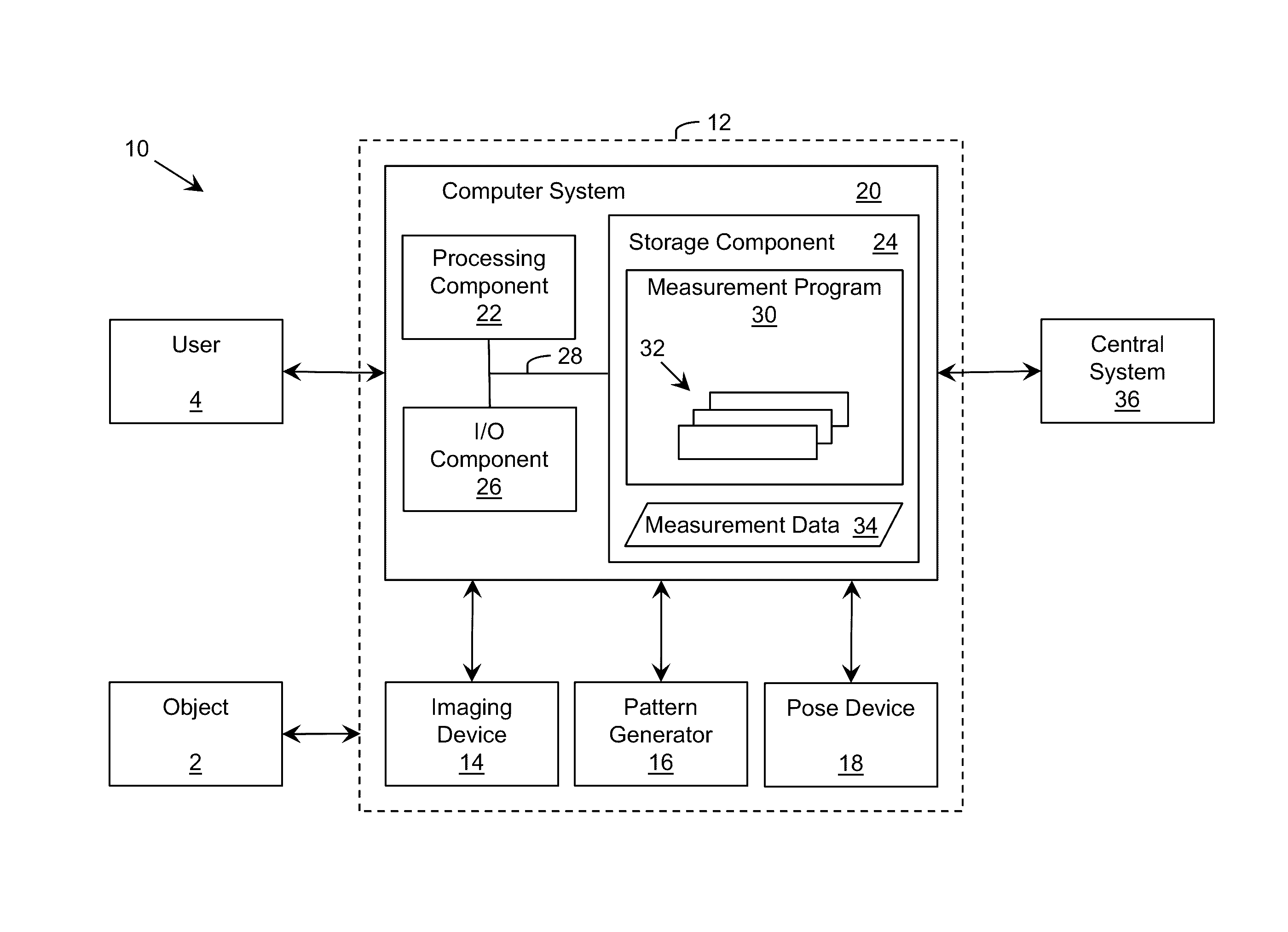

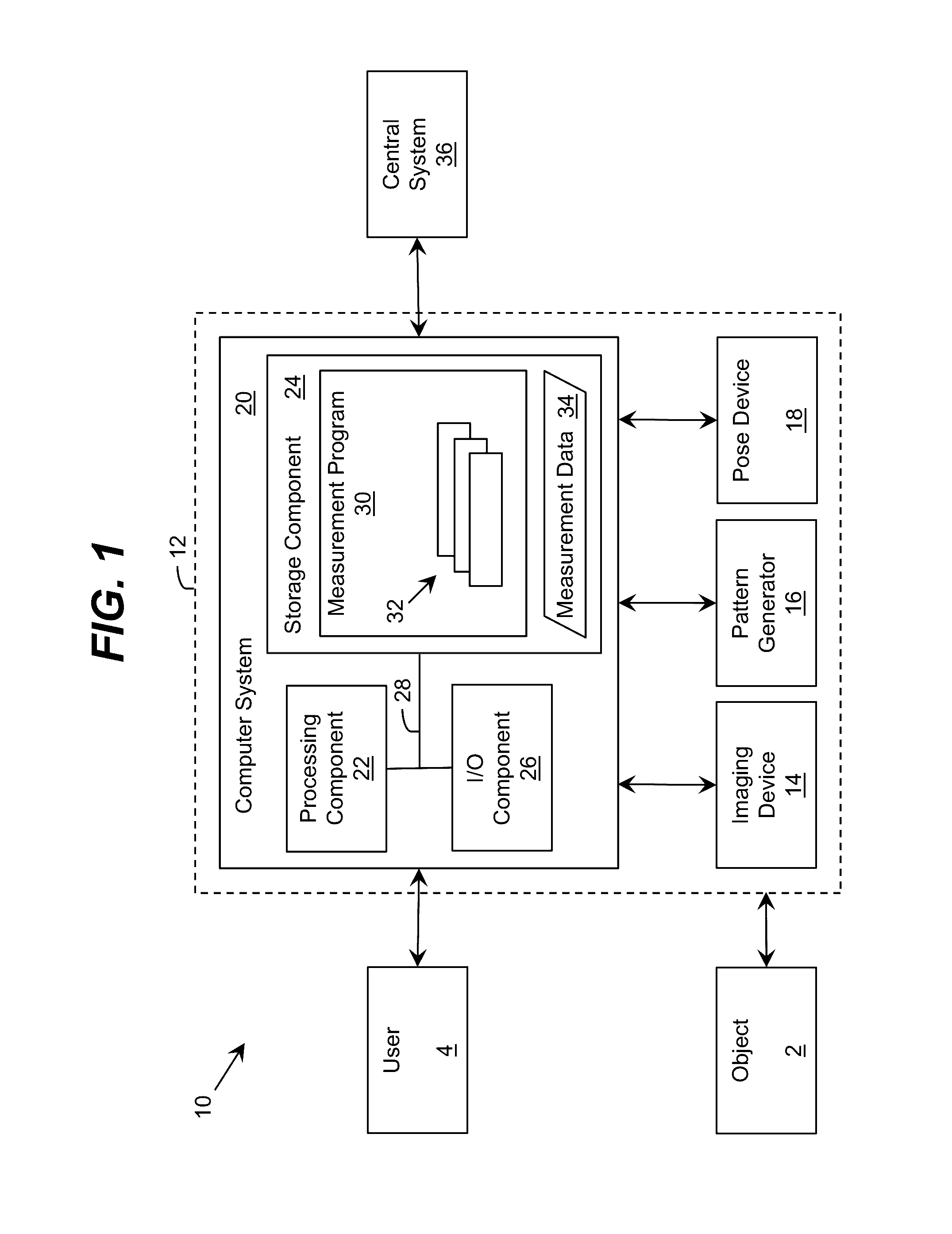

ActiveUS20050259273A1Angles/taper measurementsWheel-rims surveying/measuringHand heldComputer science

The invention provides a handheld electronic gauge that is configured to obtain measurement data for an object, such as a wheel, rail, axle, or the like. The gauge includes one or more position sensors that automatically determine when the gauge is in a measurement position. The invention also provides a handheld computing device that can automatically determine when a gauge is in the measurement position and automatically obtain measurement data using the gauge. As a result, the invention provides a solution for measuring an object, such as a railway wheel, that is portable and capable of repeatedly providing various desired measurements, irrespective of the operator.

Owner:INT ELECTRONICS MACHINES

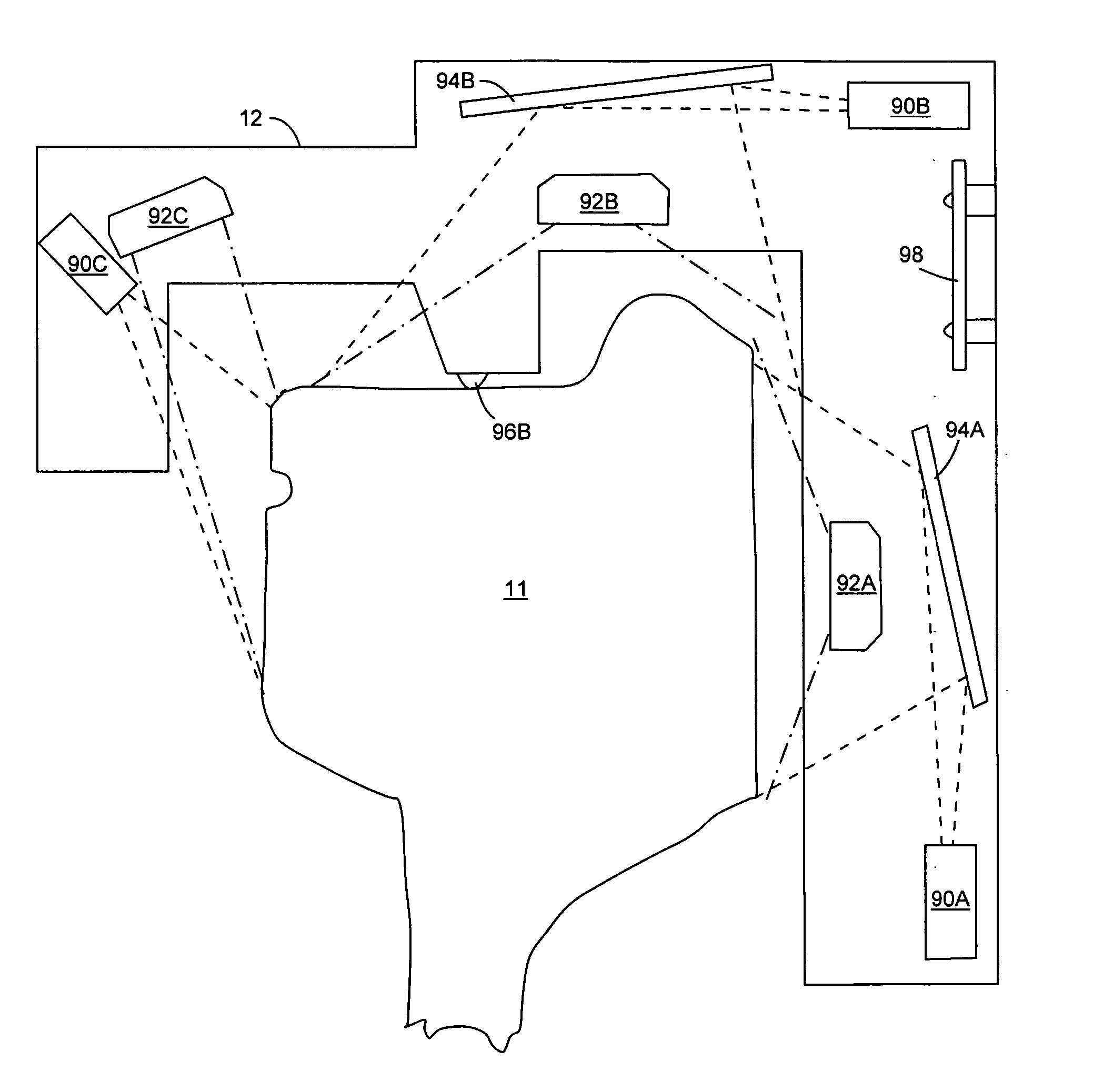

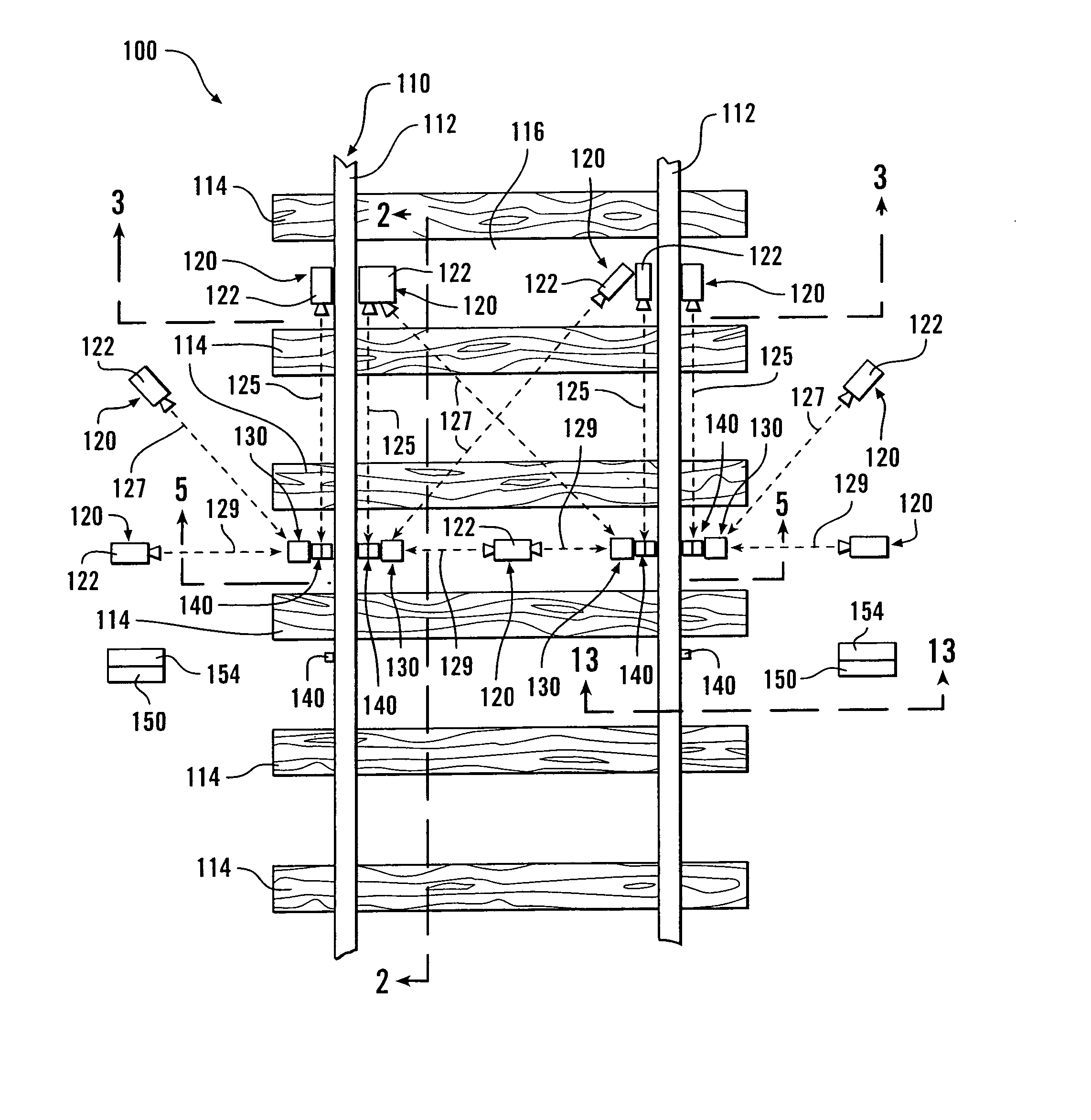

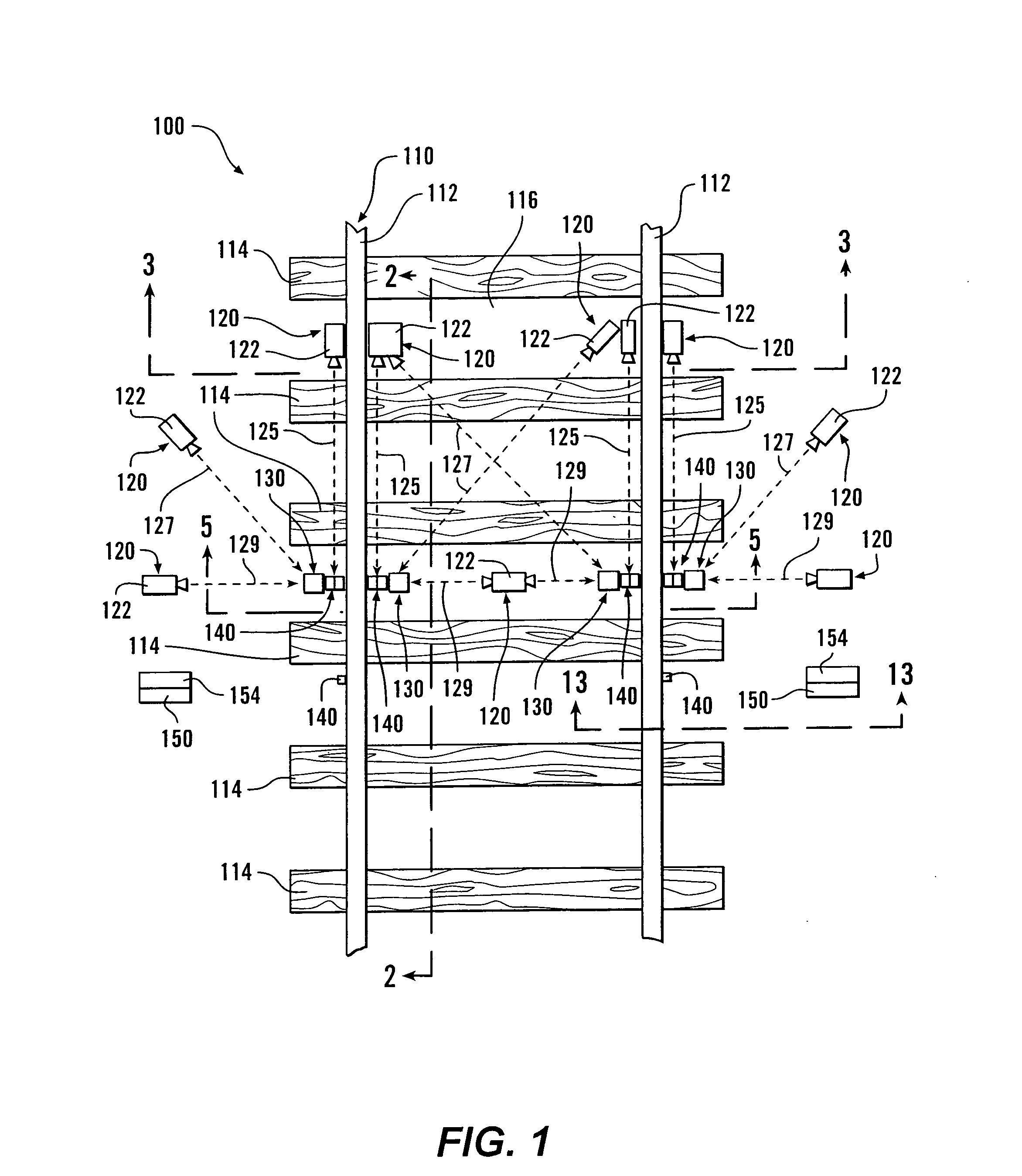

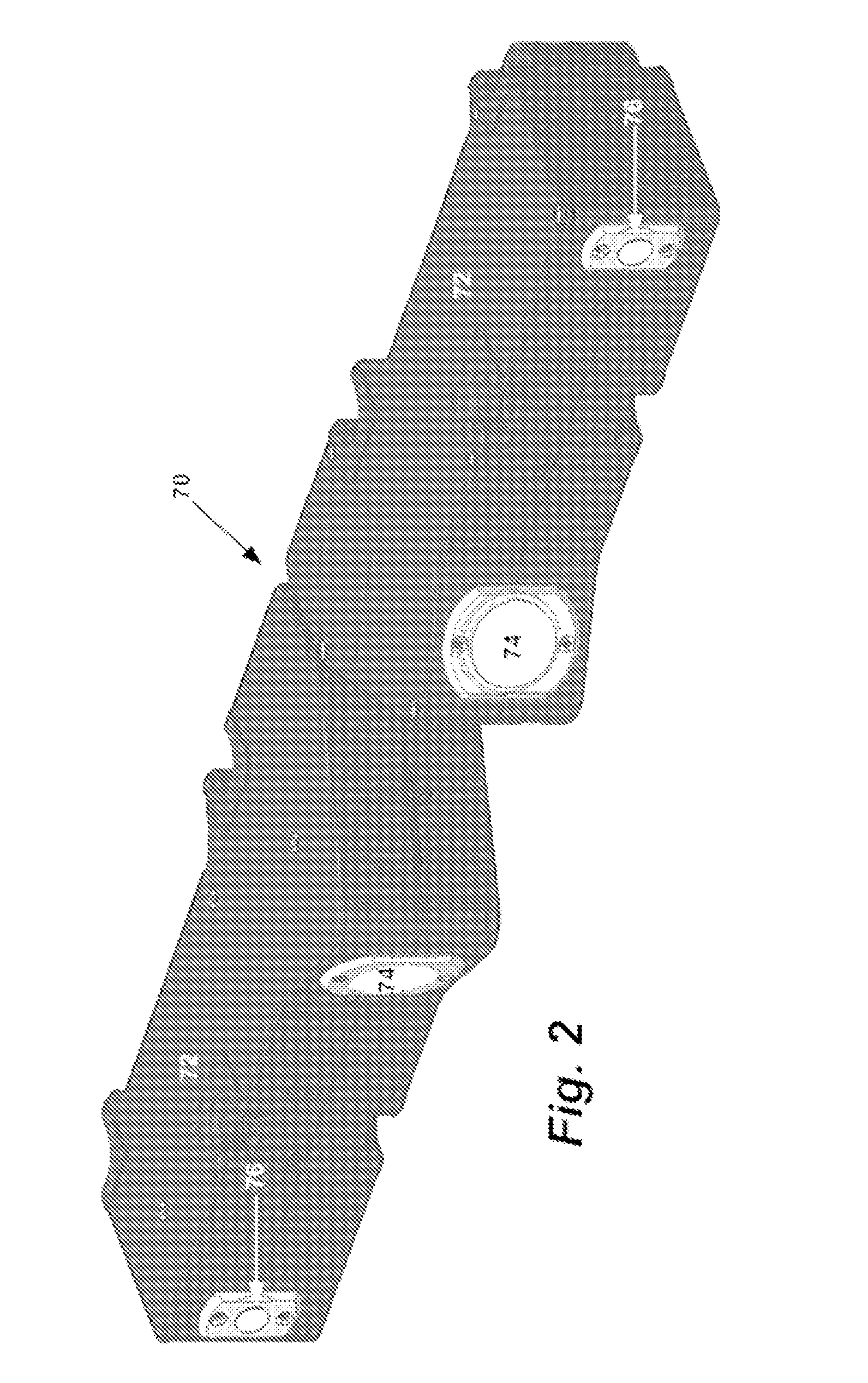

Systems and methods for obtaining improved accuracy measurements of moving rolling stock components

ActiveUS20070211145A1Low costGood delayWheel-rims surveying/measuringMaterial analysis by optical meansDynamic motionEngineering

Reference markers are attached to rails and / or other dynamically moving components of railroad tracks, and / or located at fixed and stationary positions adjacent to the track. When images of railway rolling stock are obtained, the reference marker(s) appear in the image. Accordingly, measurements of various aspects and parameters of various components of the railway rolling stock can be obtained at high precision and / or accuracy relative to the railroad track component to which the reference marker is attached and / or relative to the stationary position. The reference markers allow one or more images, obtained at some intervening time interval, to be accurately and precisely aligned relative to the reference marker(s) regardless of the dynamic motion of the railroad track component(s) and / or of the rolling stock that occurred as the images were captured. The reference markers can include optical, thermal or other indicia. The indicia have known dimensions and / or known distances from an image capture device.

Owner:WABTEC CONTROL SYST PTY LTD

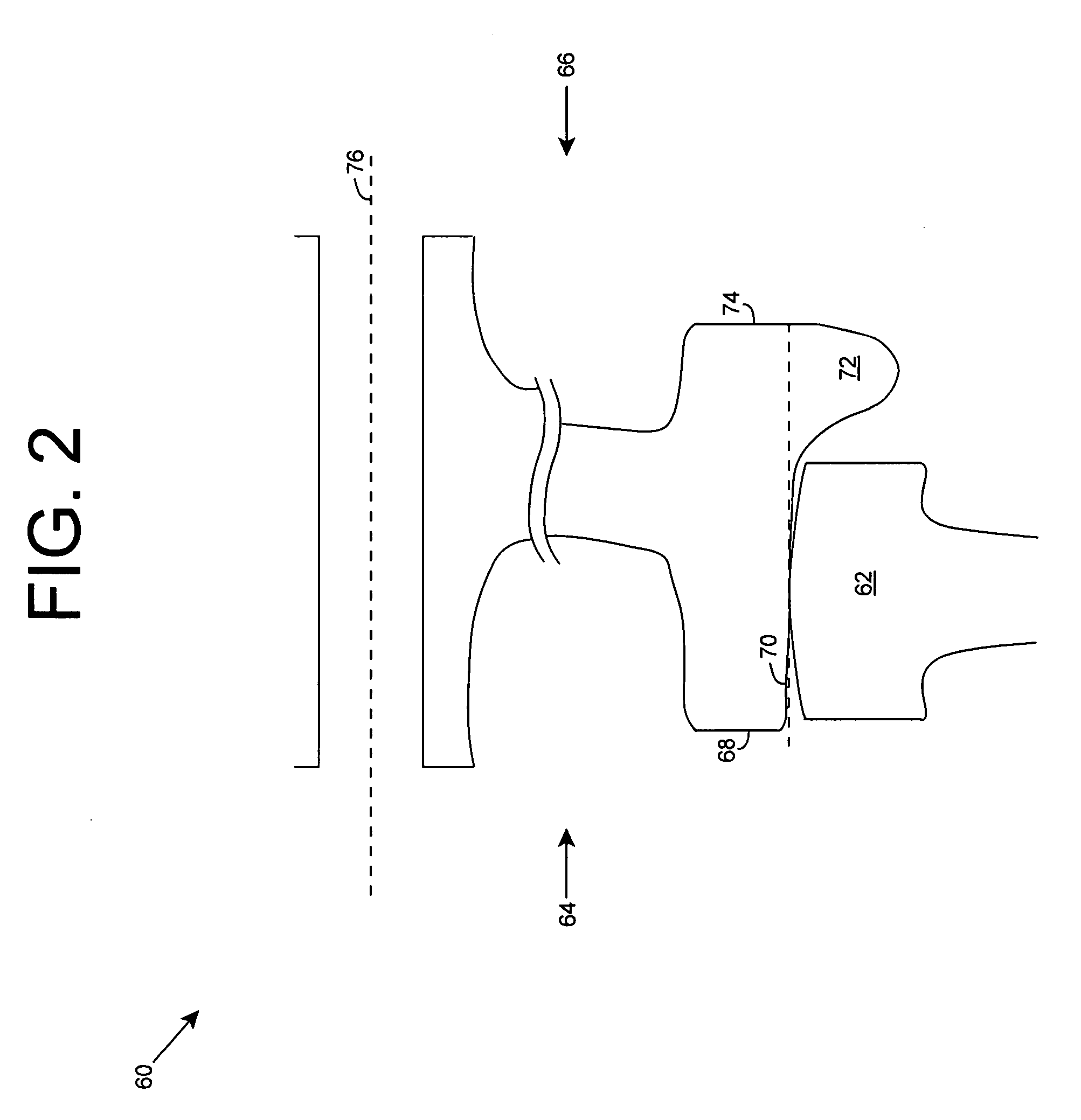

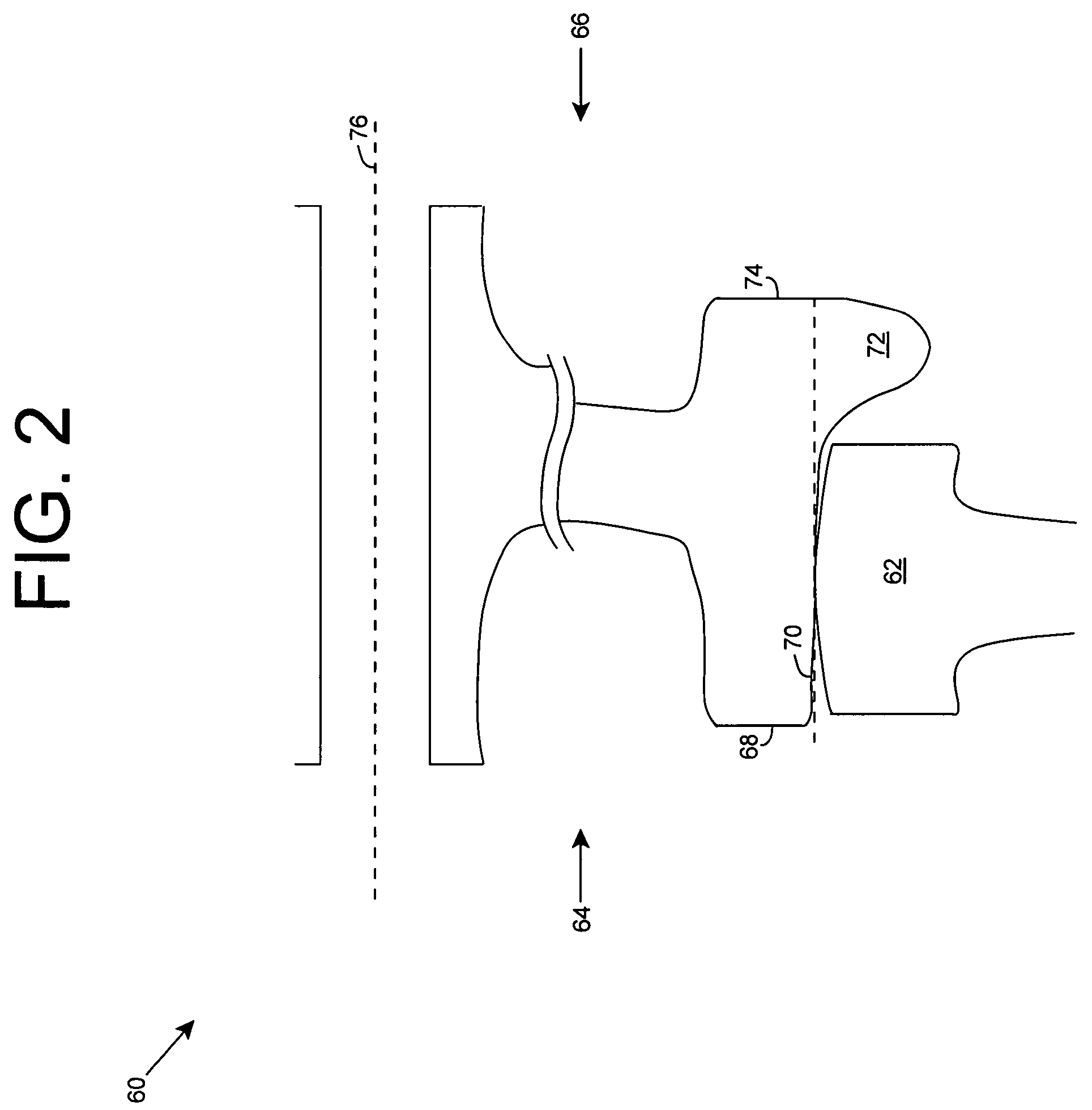

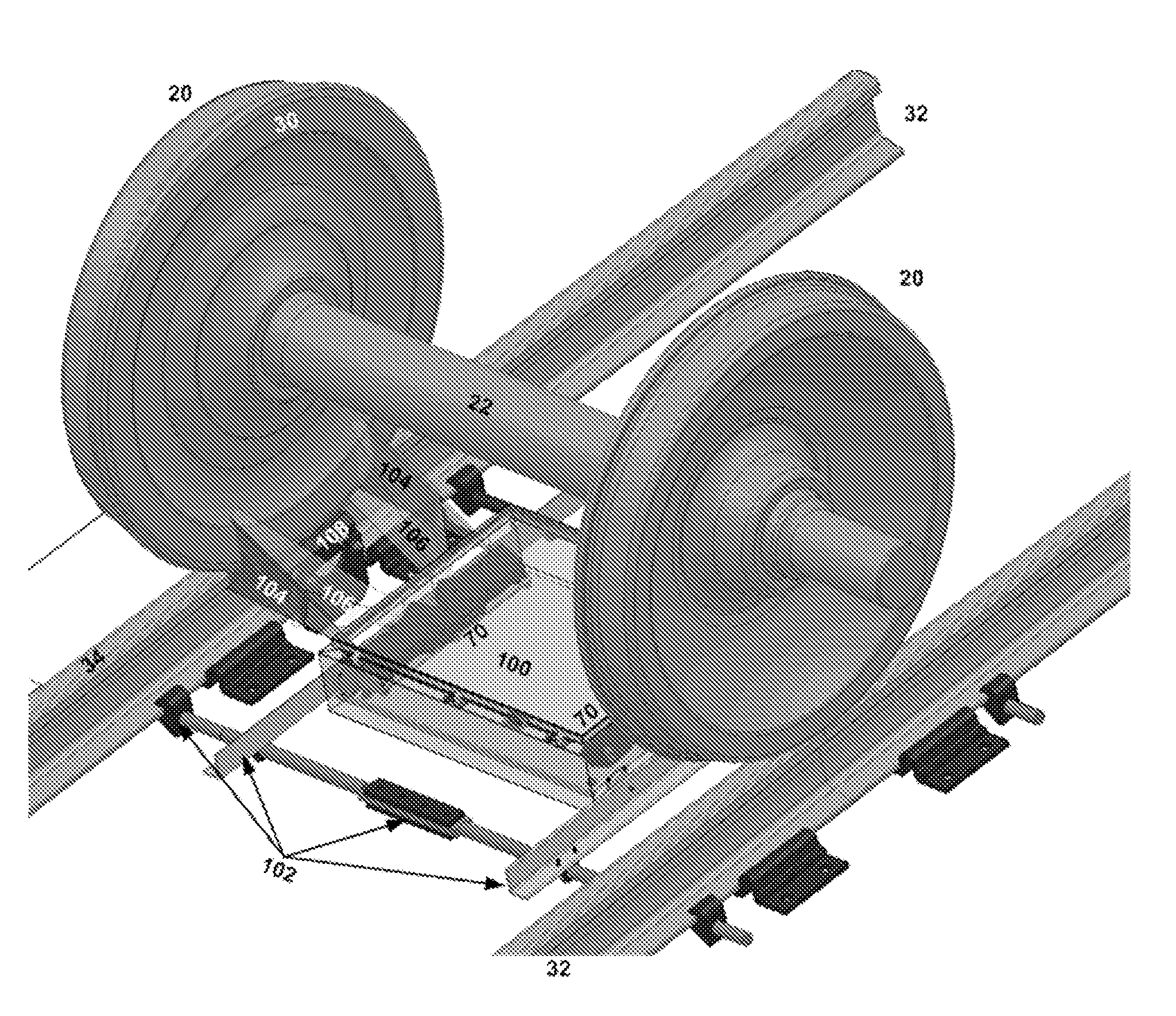

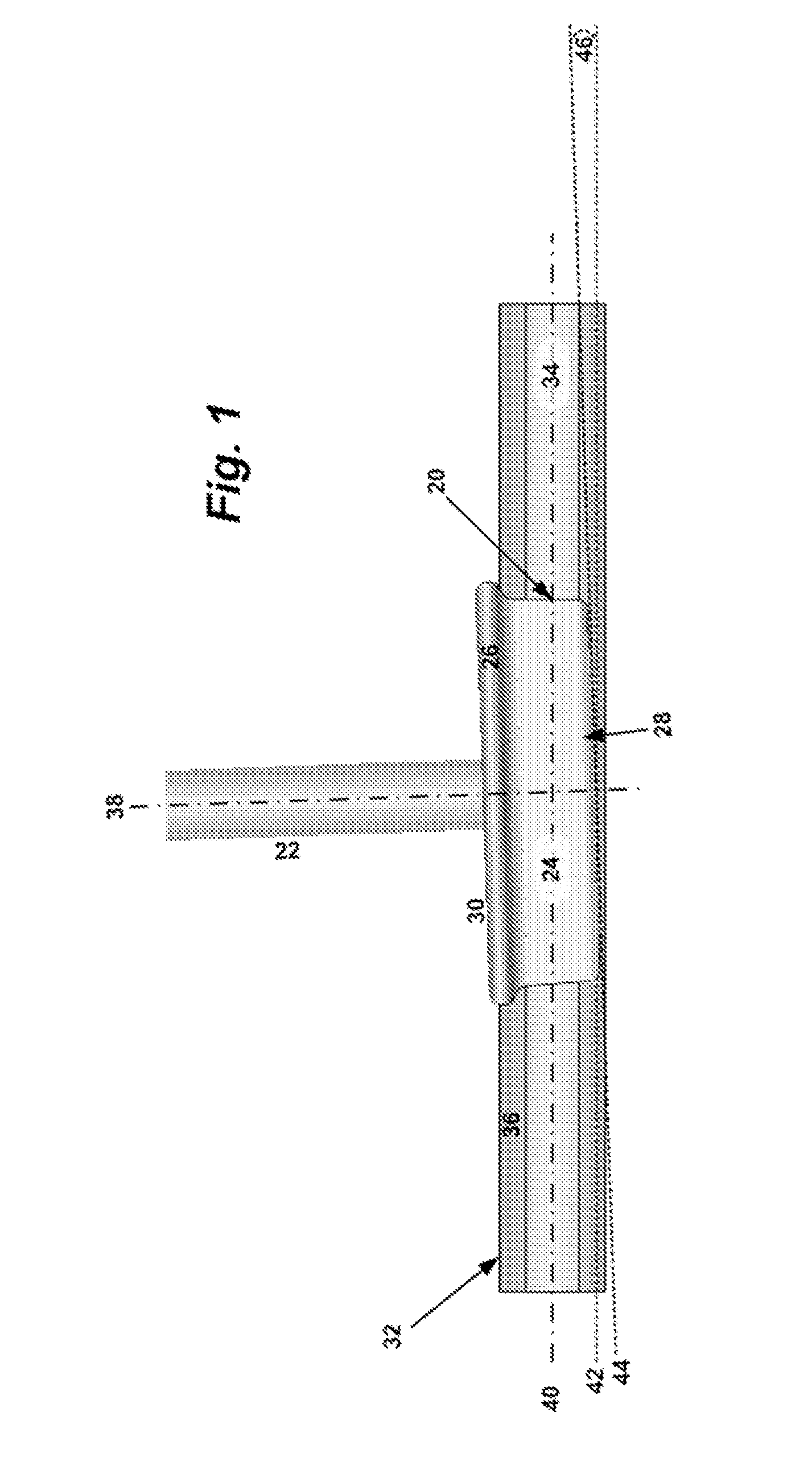

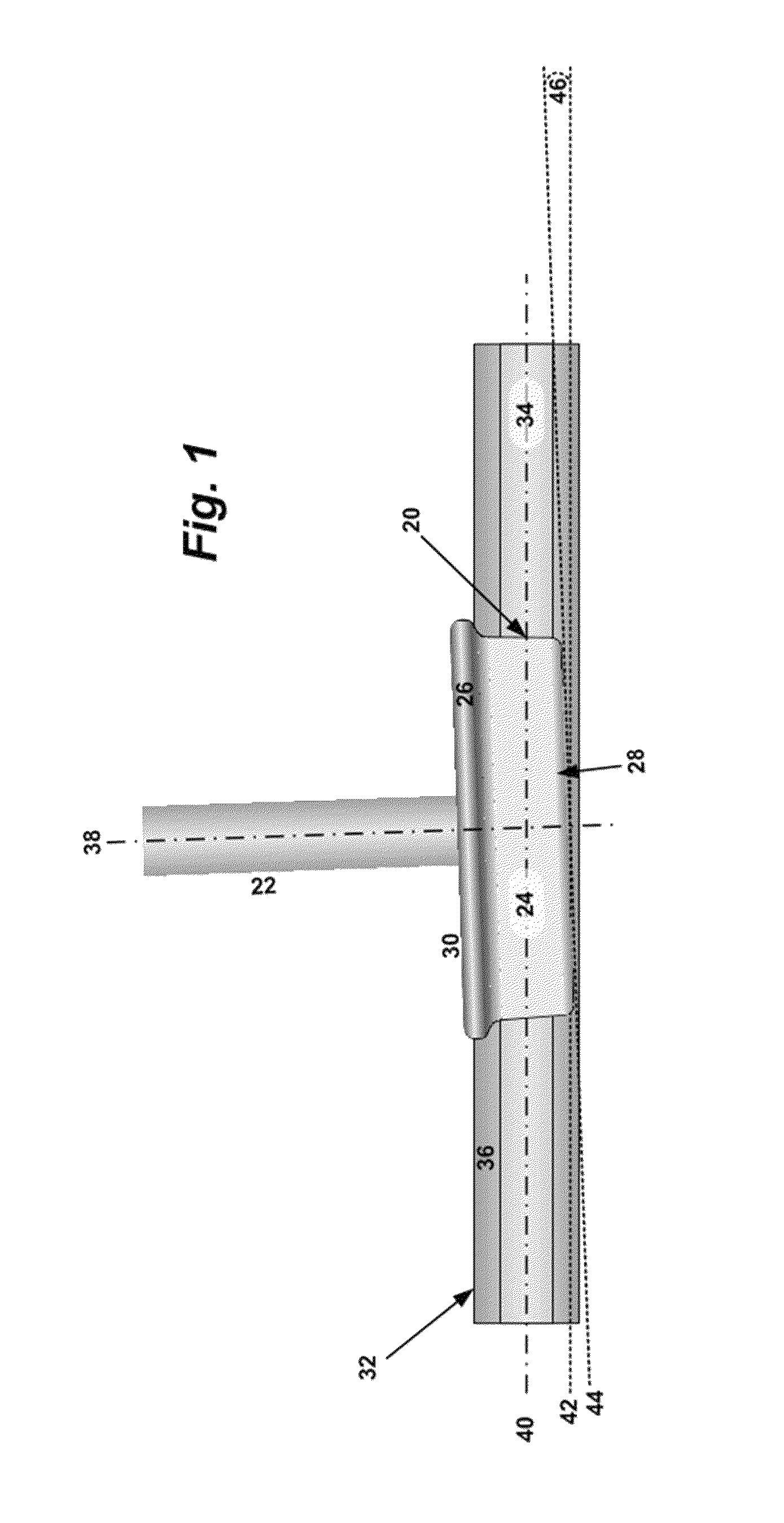

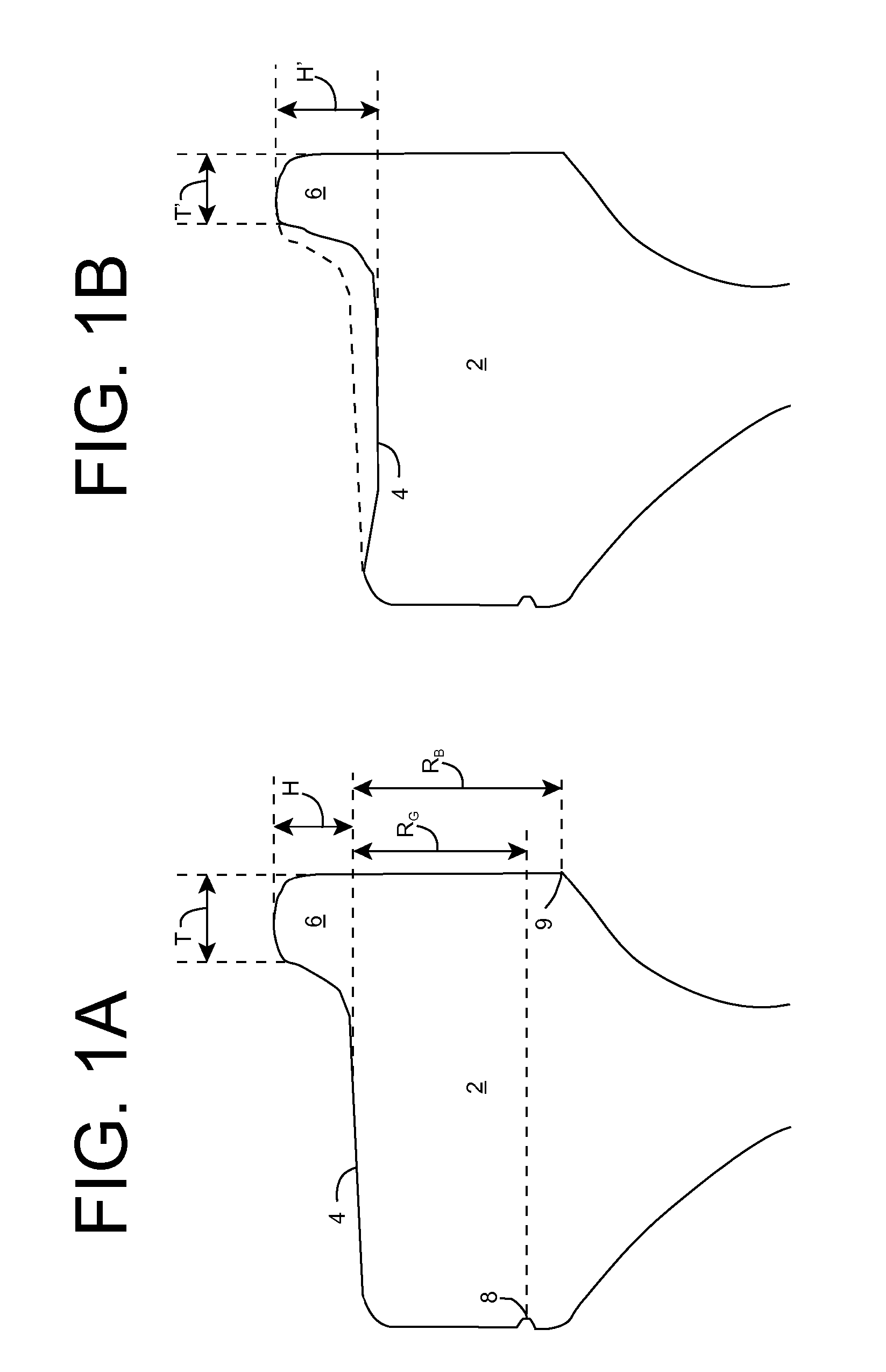

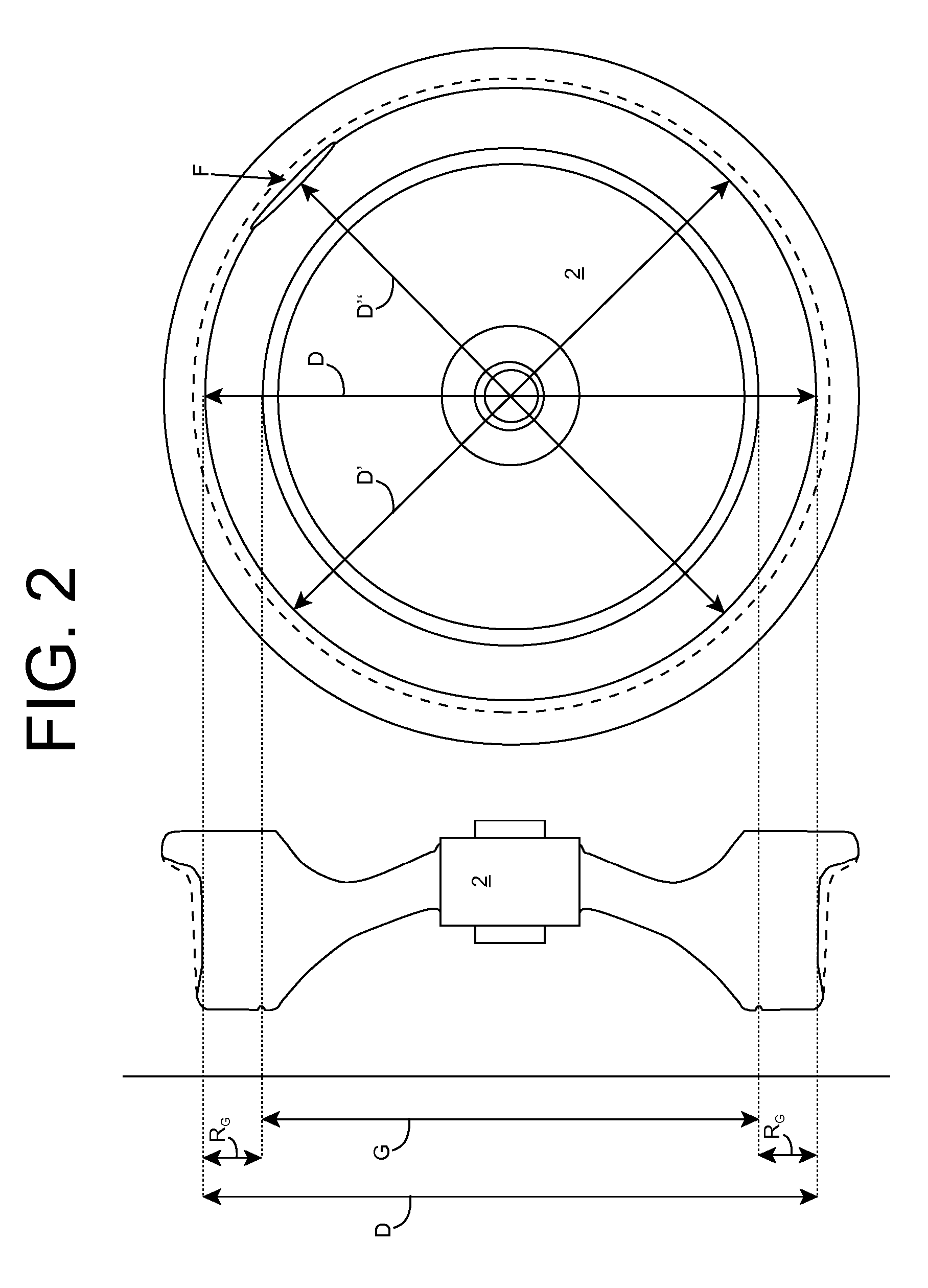

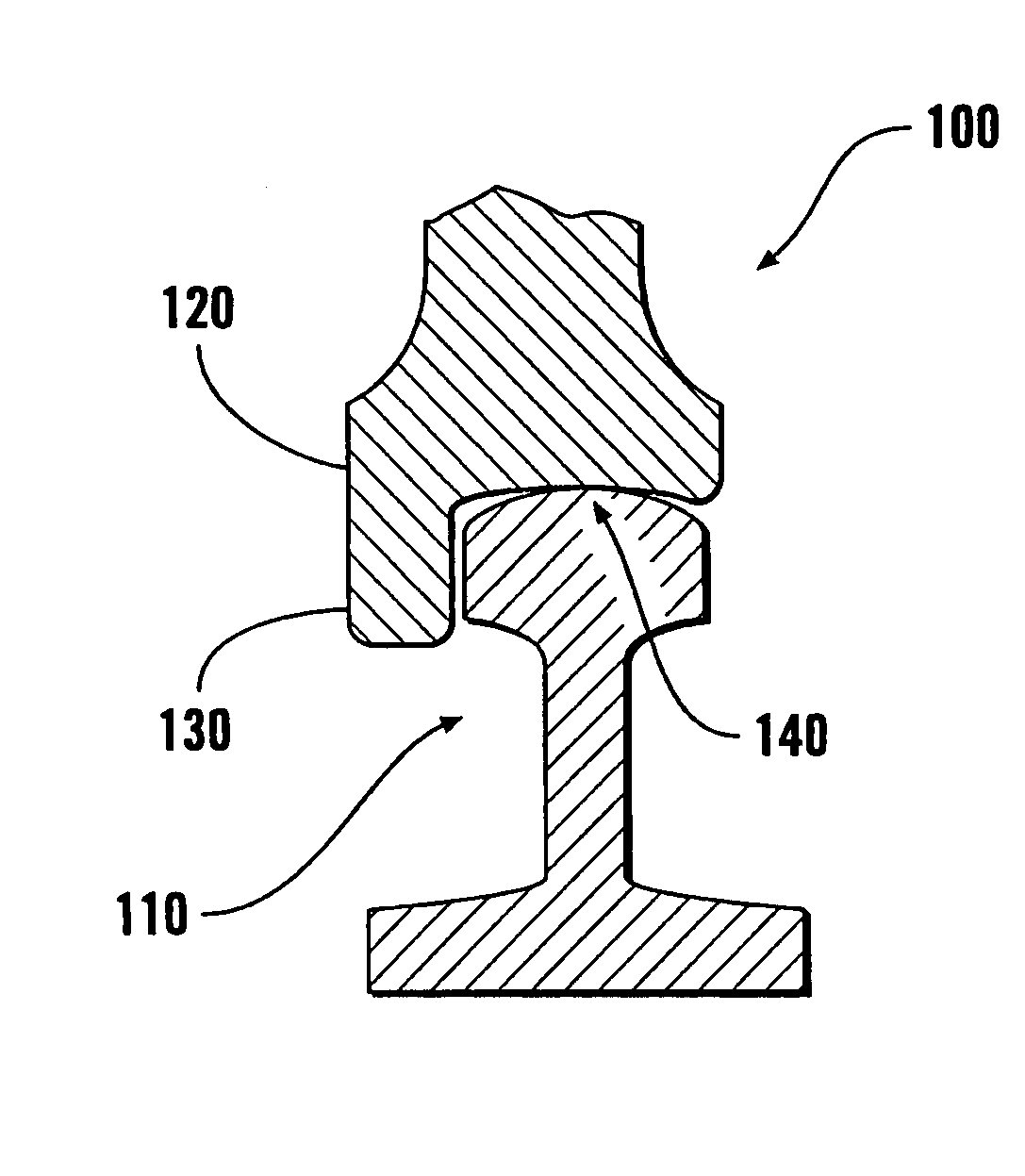

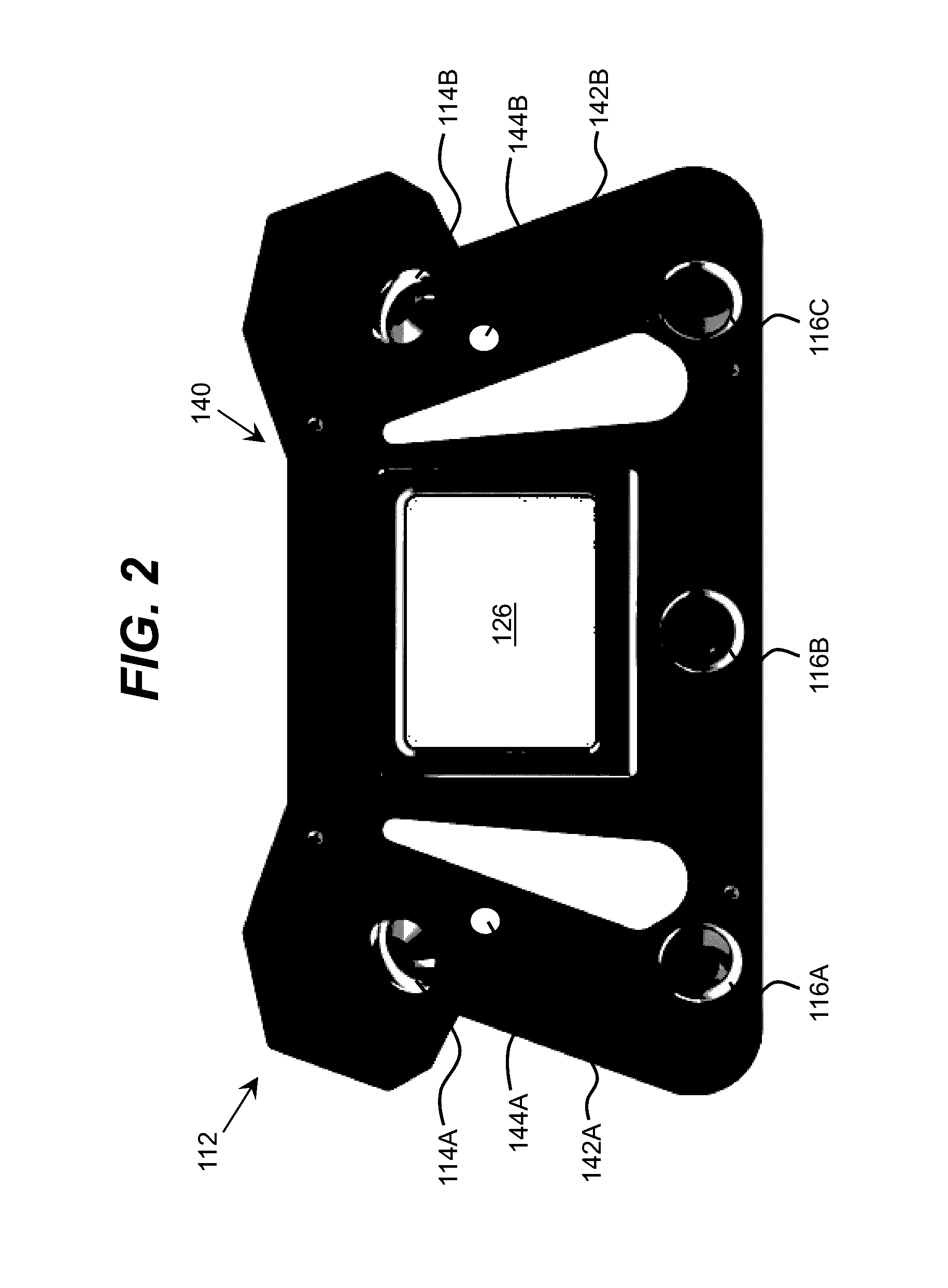

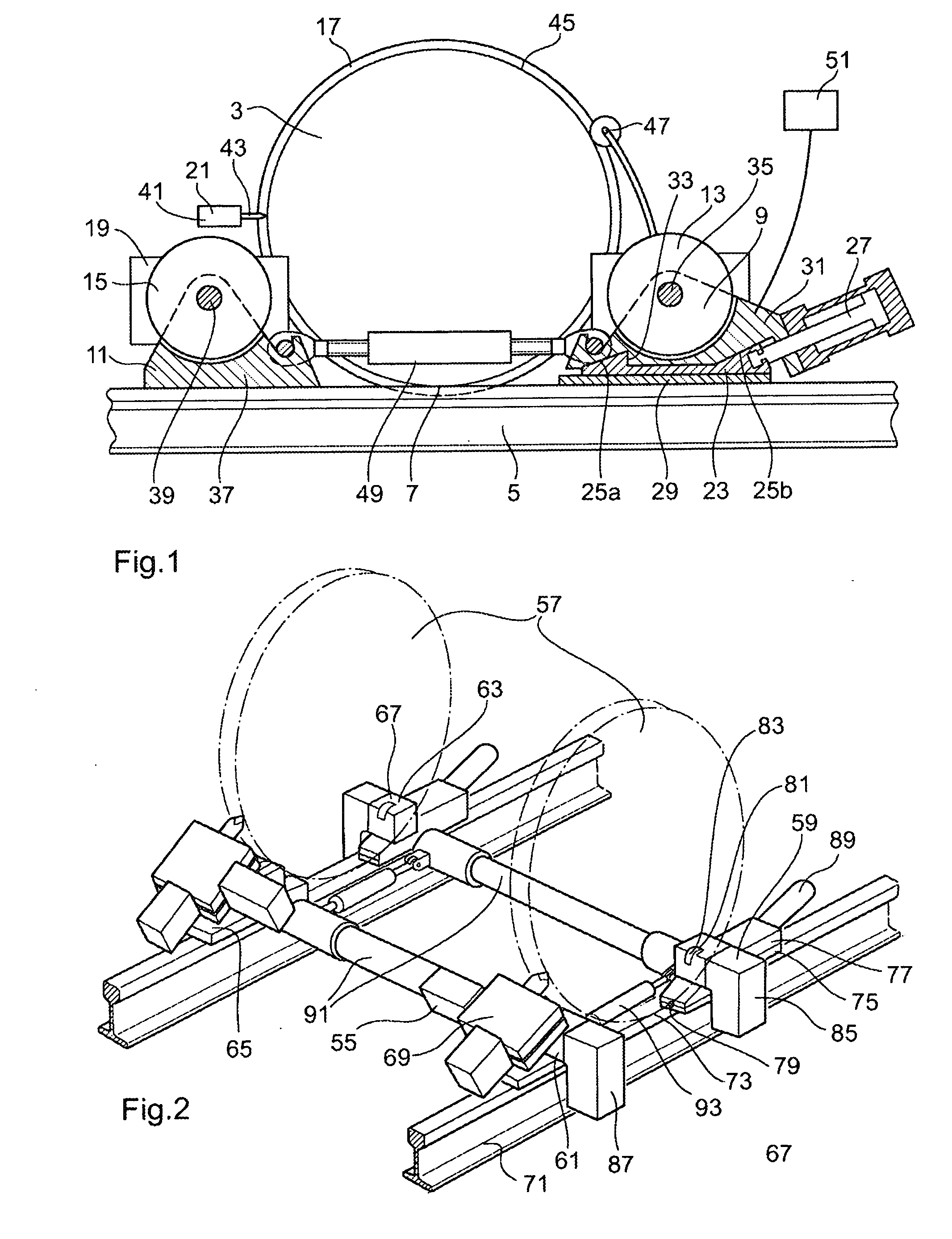

Wayside Measurement of Railcar Wheel to Rail Geometry

ActiveUS20130313372A1Eliminate errorsReduce needWheel-rims surveying/measuringRailway profile gaugesTriangulationTrackway

Considerable damage to rails, wheels, and trucks can result from geometric anomalies in the wheelsets, rails, and truck hardware. A solution for identifying and quantifying geometric anomalies known to influence the service life of the rolling stock or the ride comfort for the case of passenger service is described. The solution comprises an optical system, which can be configured to accurately perform measurements at mainline speeds (e.g., greater than 100 mph). The optical system includes laser line projectors and imaging cameras and can utilize structured light triangulation.

Owner:INT ELECTRONICS MACHINES

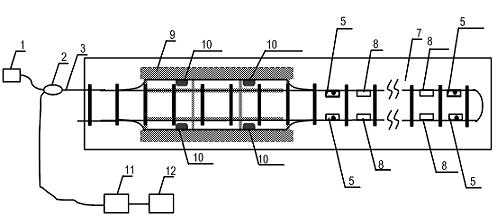

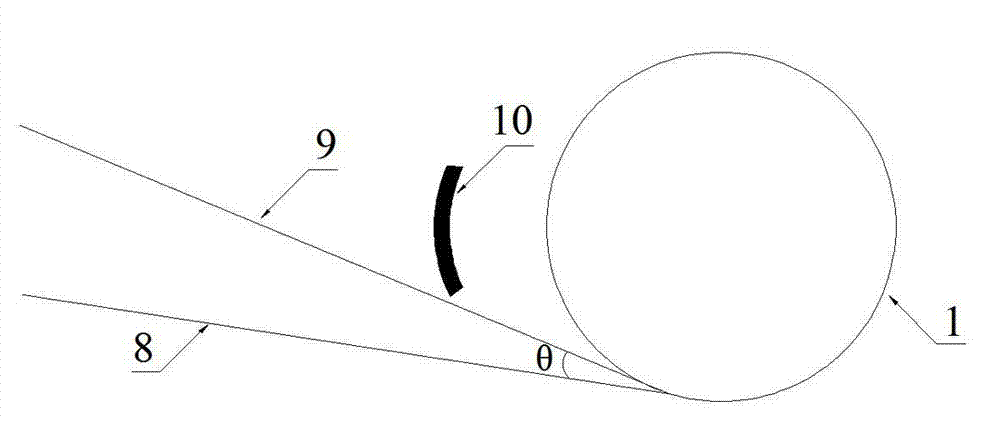

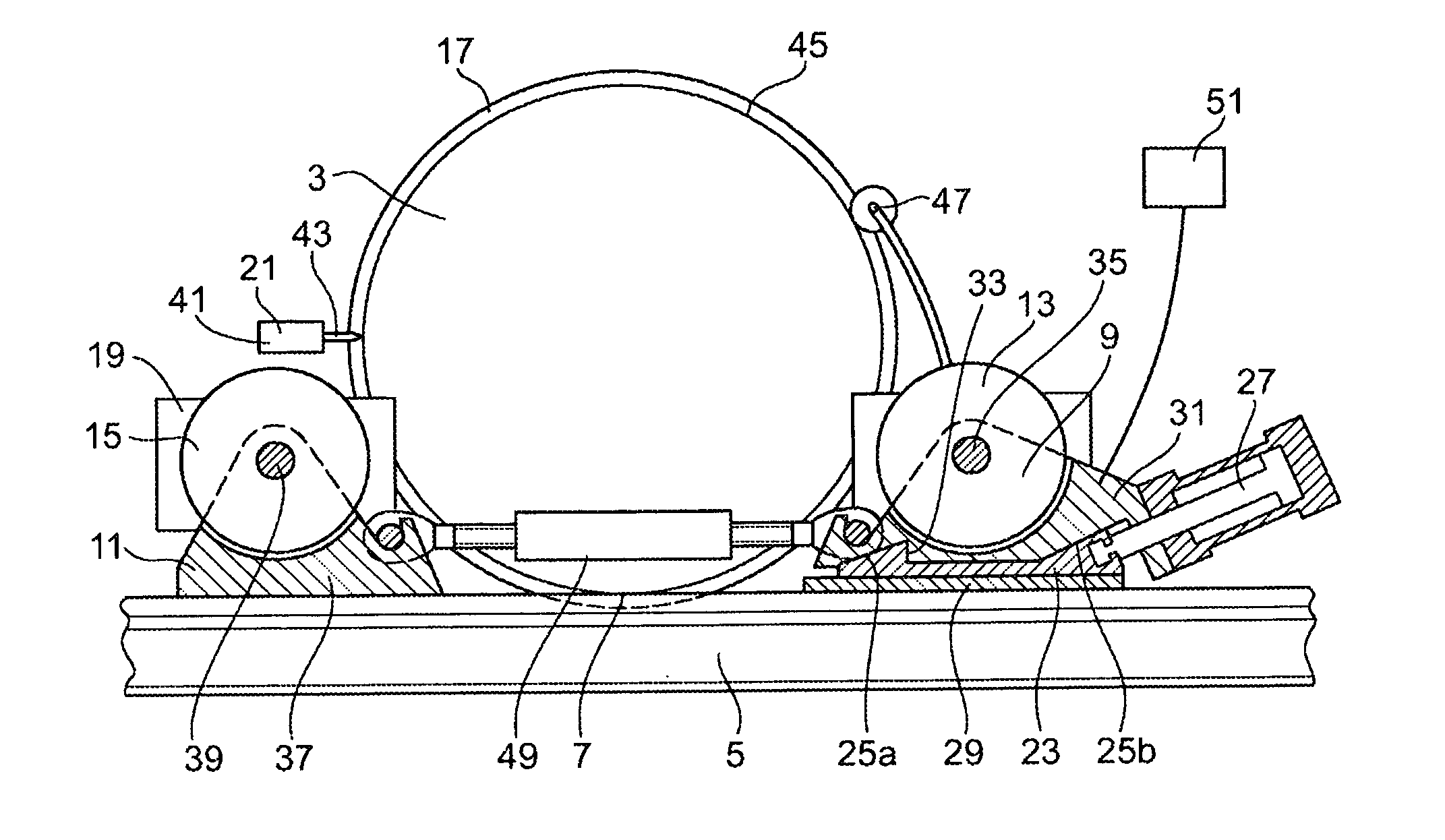

System and method for inspecting the geometric parameters of the wheels of railway vehicles

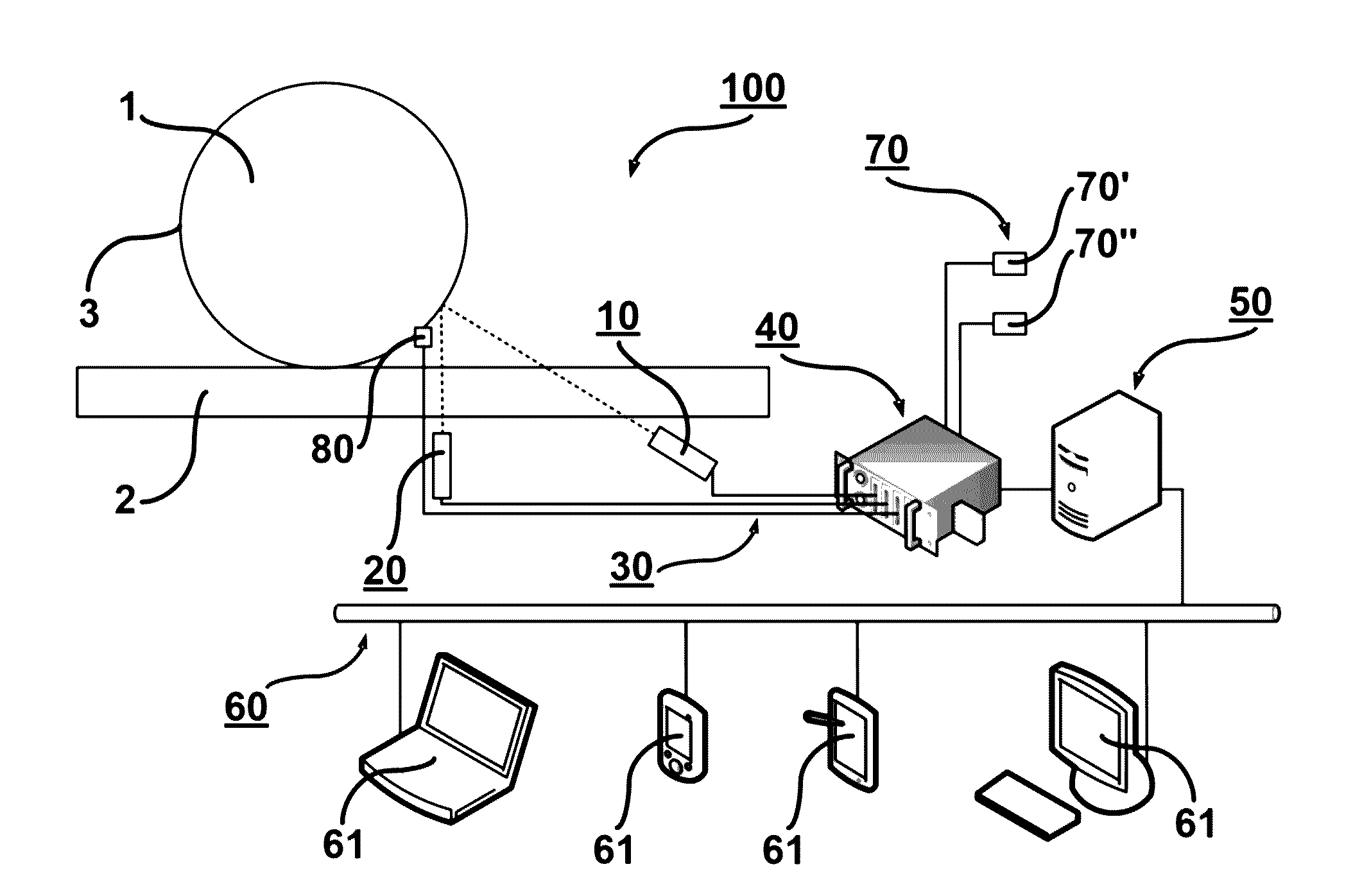

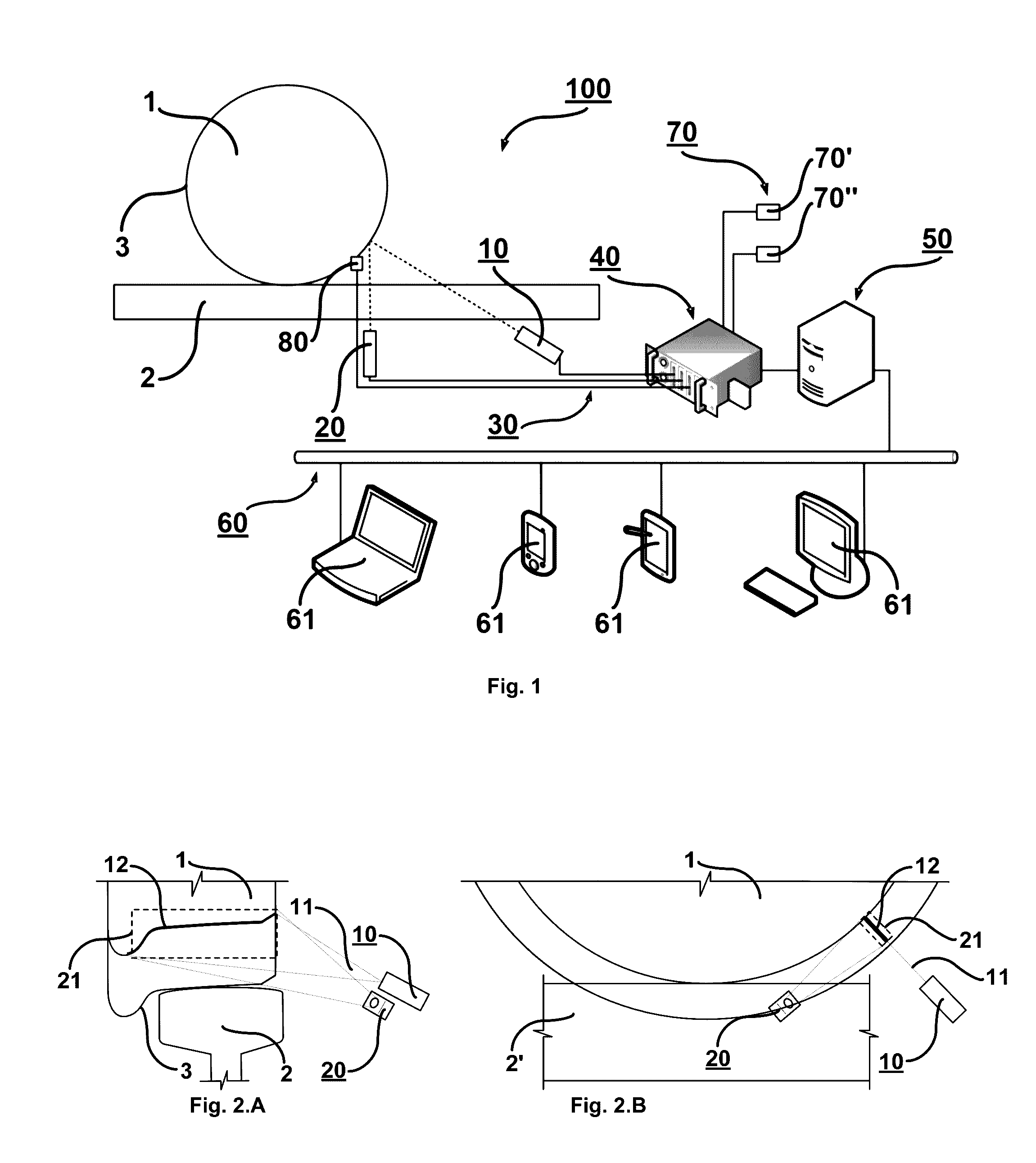

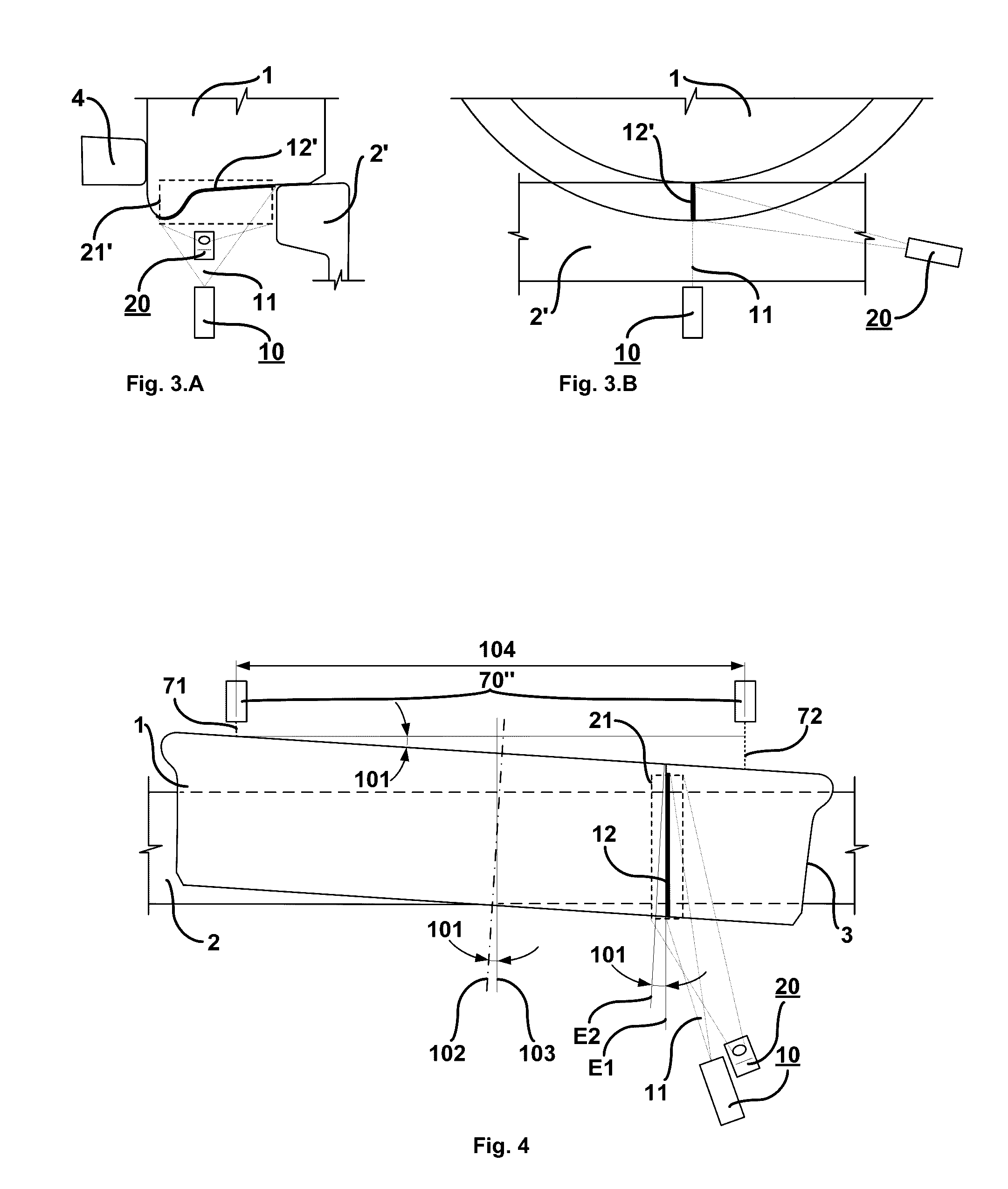

The present invention relates to a system and method for the automated inspection of geometric parameters of railway wheels rolling on a track by artificial vision techniques. The present invention uses a structured light source (10) that illuminates a line of light (12) upon a fraction of the surface of revolution (3) of a wheel (1), a CCD camera (20), which captures an image (21) of the illuminated area, and a data processing system that records, digitalizes, geometrically corrects and reconstructs information of the surface of revolution (3) that is not recorded in the image (21), in order to obtain a numeric description of the complete transverse section of the wheel (1) represented by a reconstructed profilogram (500) for calculating the geometric parameters of the wheel (1).

Owner:EMPRESA DE TRANSPORTE MASIVO DEL VALLE DE ABURRA LTDA METRO DE MEDELLIN LTDA

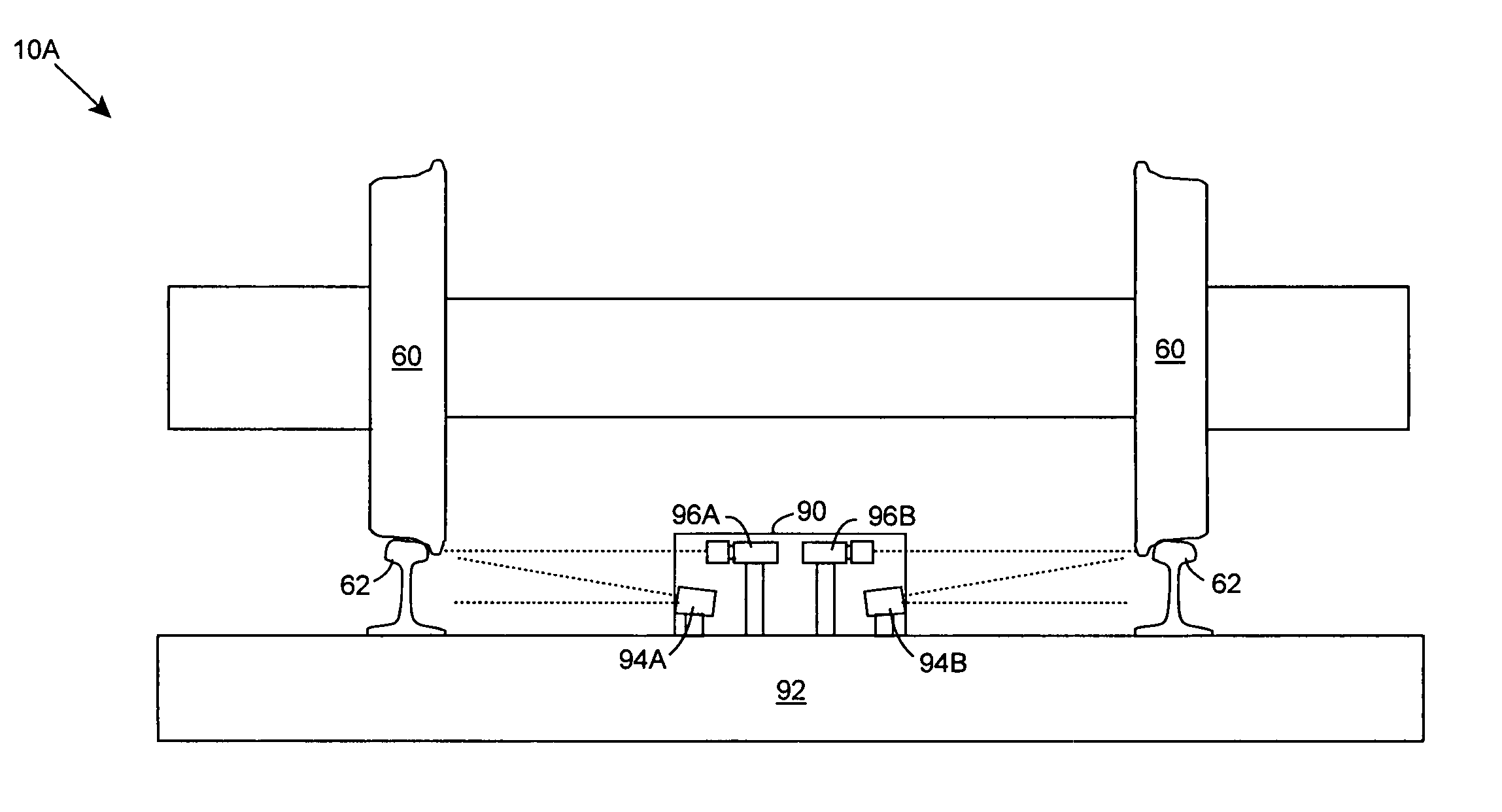

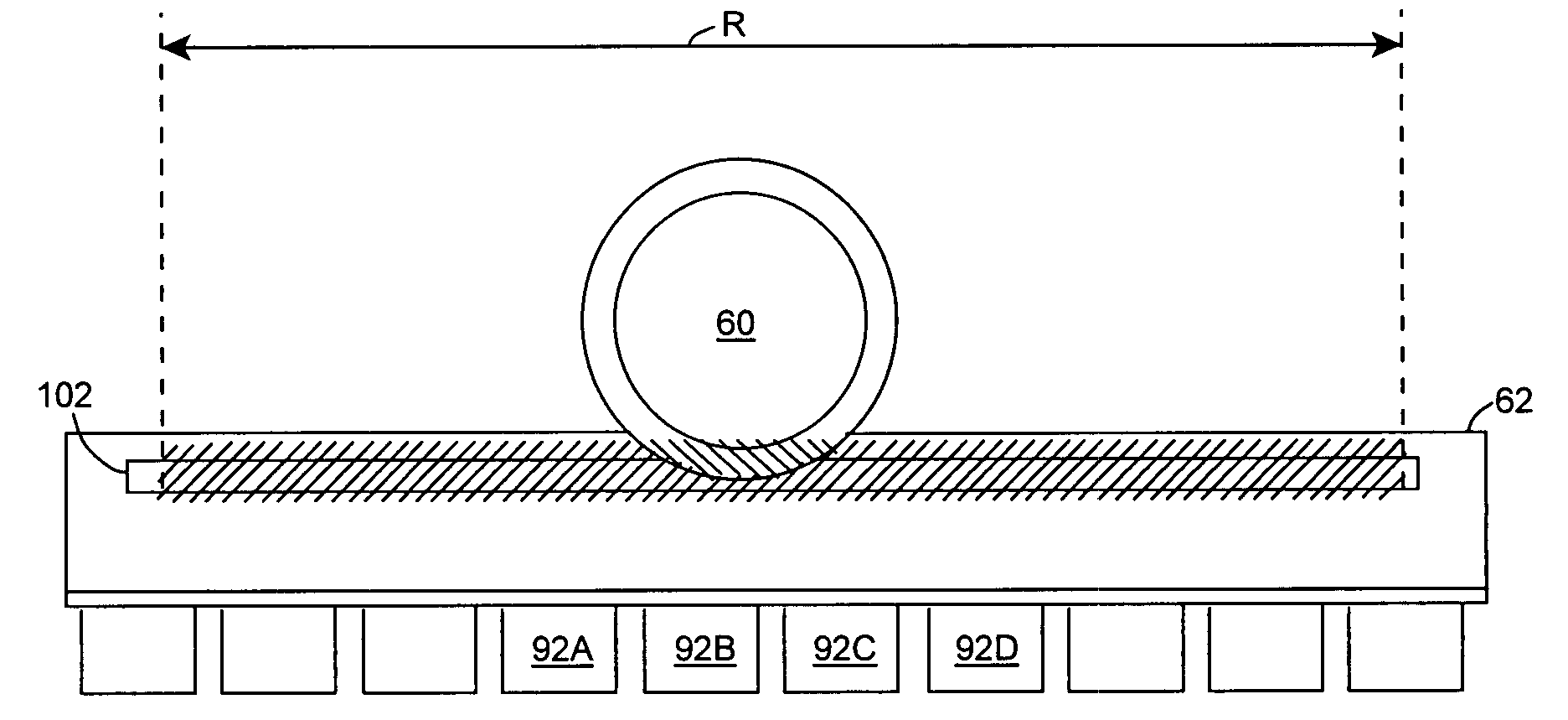

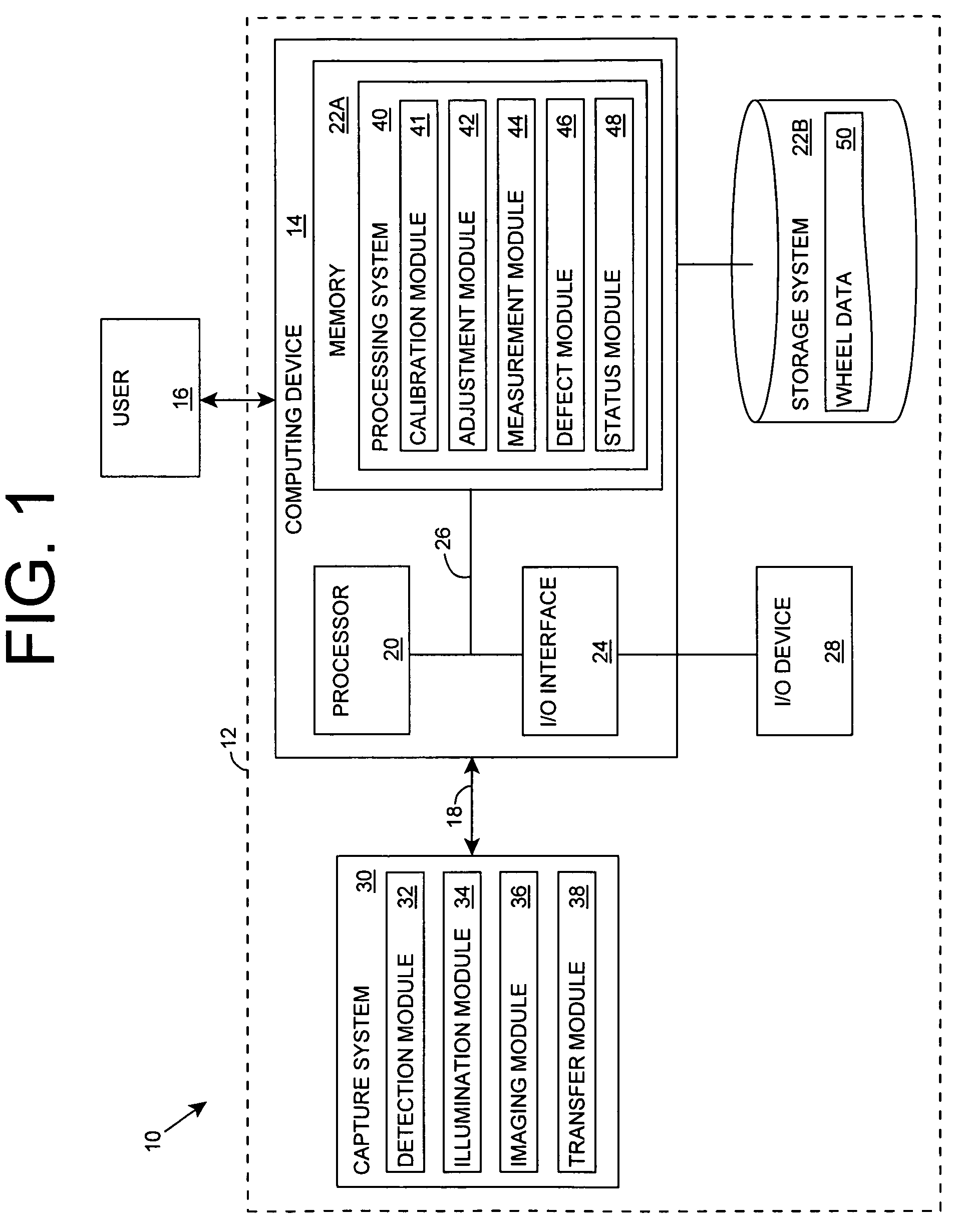

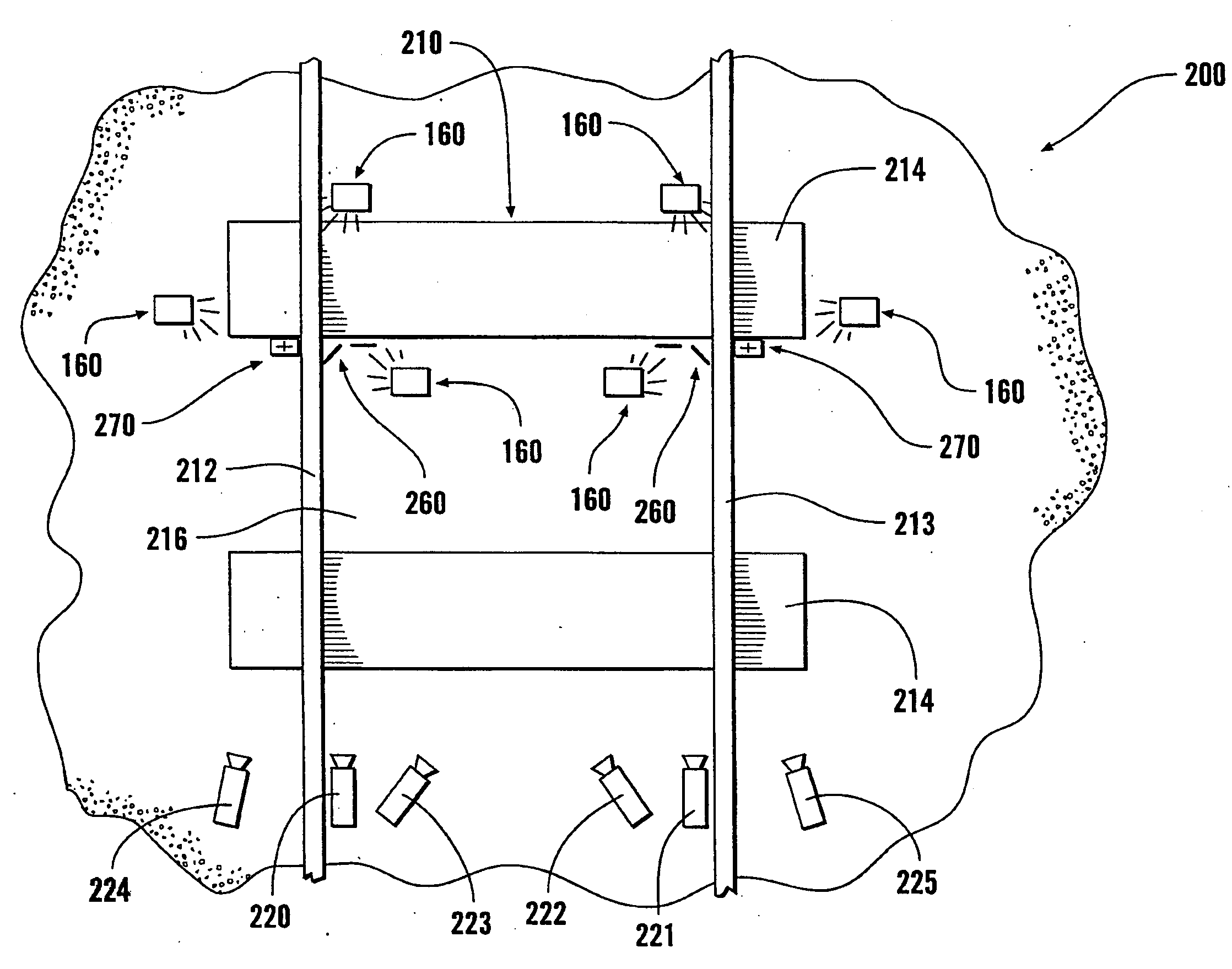

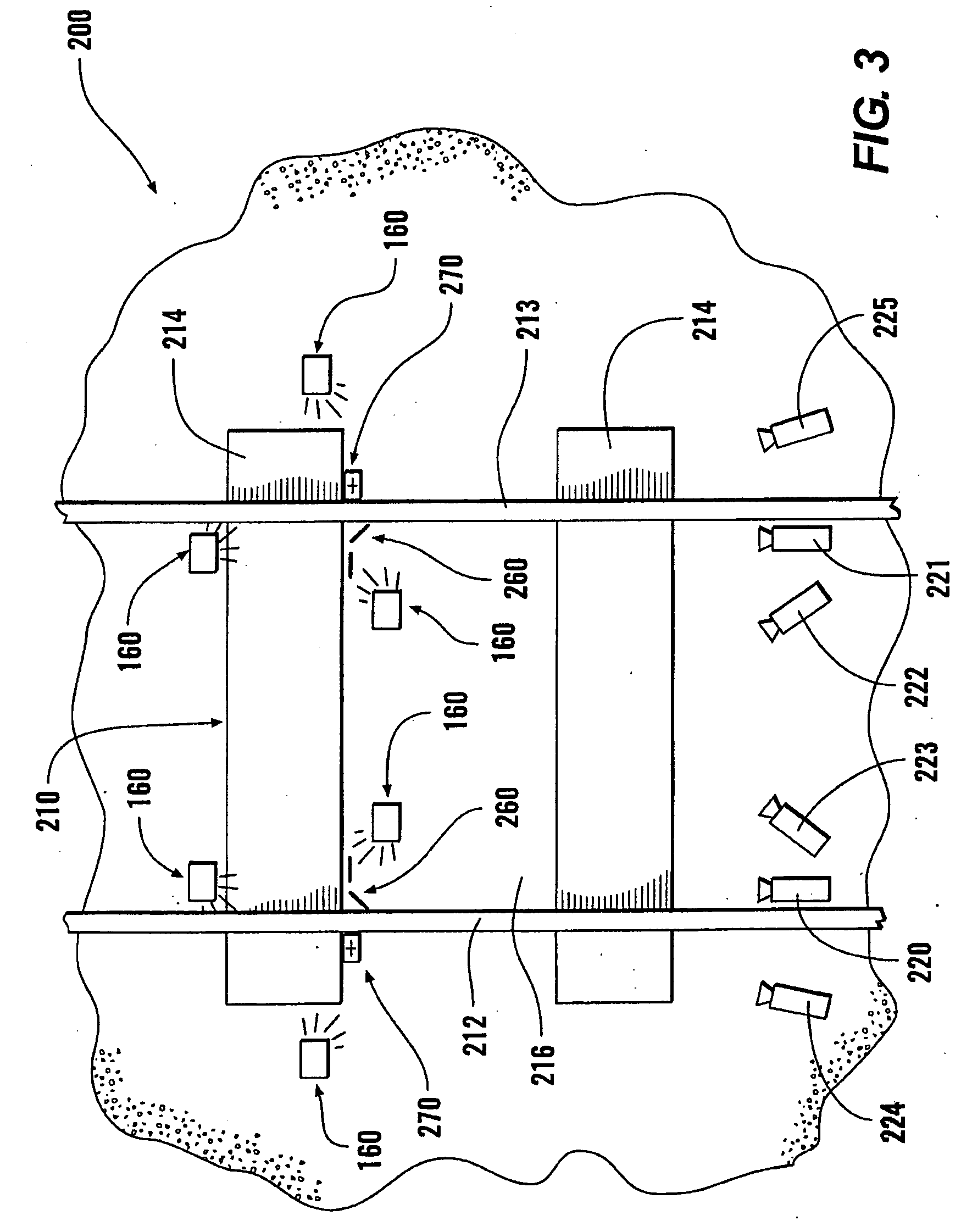

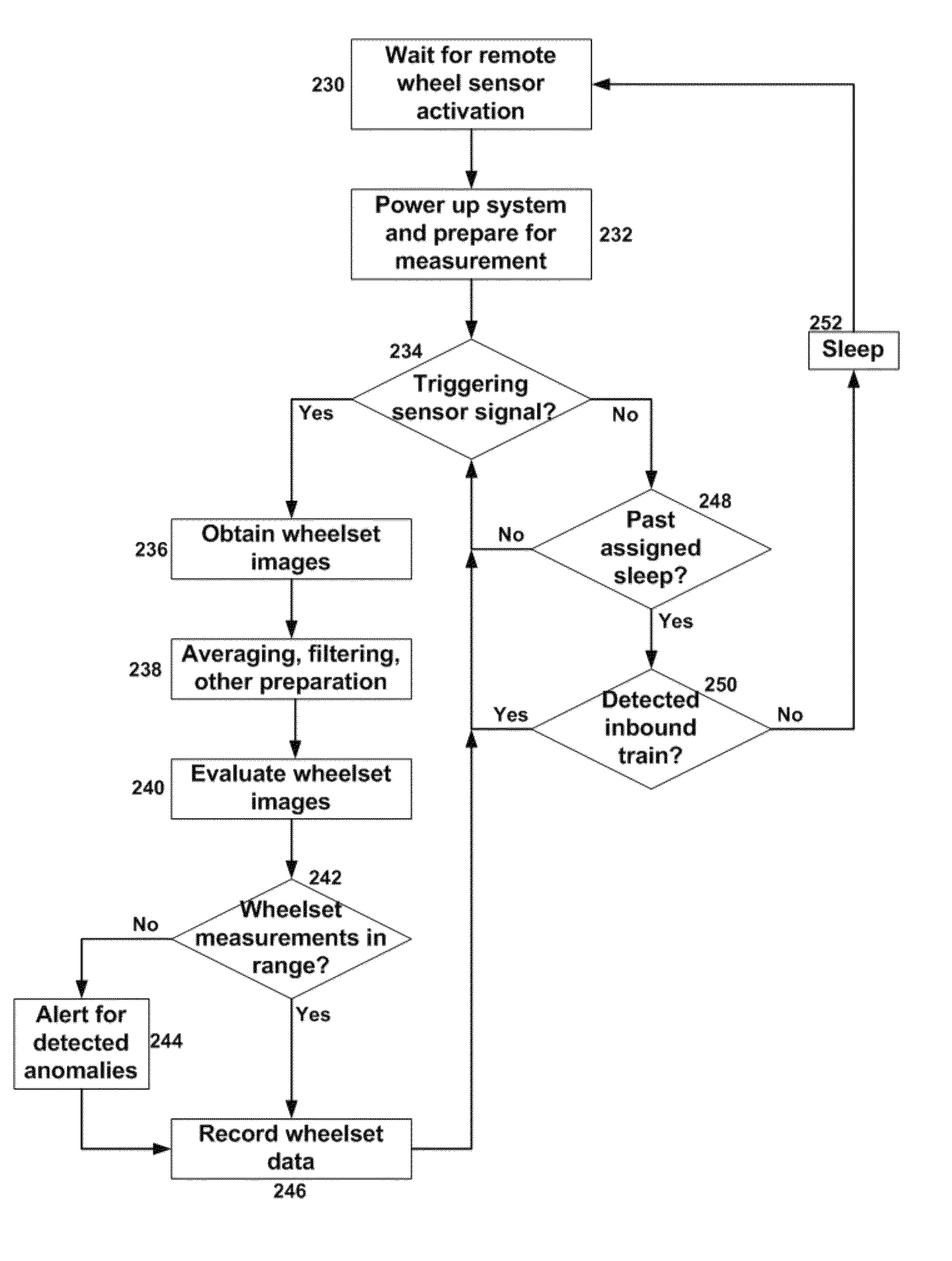

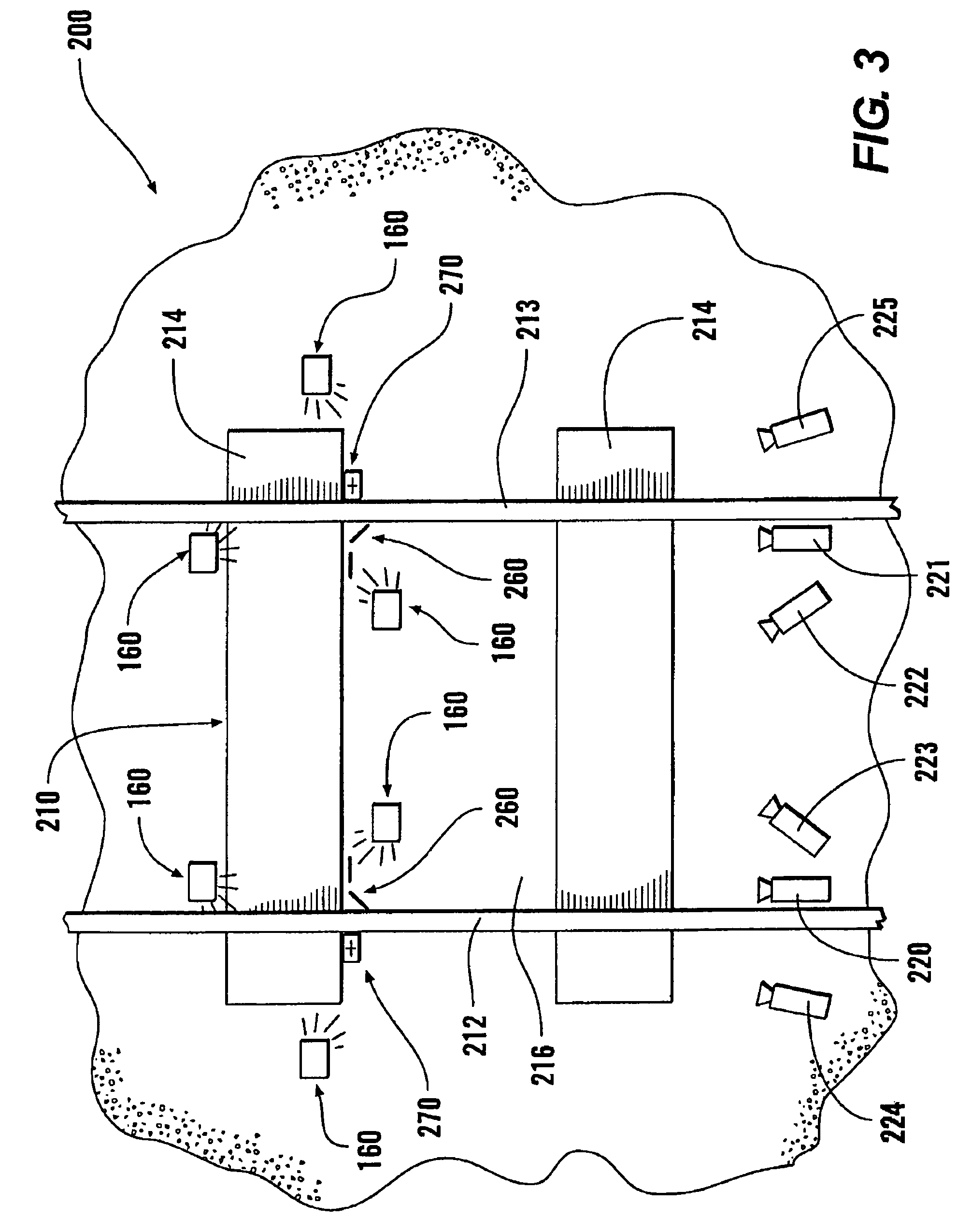

System and method for analyzing rolling stock wheels

An exemplary system and method for analyzing rolling stock wheels helps allow a wheel to be analyzed at speed, reducing any need for manual inspections or other related delays. An exemplary system may include one or more strobe lights and one or more high-speed cameras to capture images of the rolling stock wheel(s) at speed. The images may include one or more markers to assist in analyzing various parameters of the rolling stock wheel. The exemplary system may include one or more backface illumination plates to assist in illuminating the rolling stock wheel(s) and / or the one or more marker(s).

Owner:WABTEC CONTROL SYST PTY LTD

Wayside measurement of railcar wheel to rail geometry

ActiveUS8925873B2Reduce needReduce impactOptical rangefindersWheel-rims surveying/measuringTriangulationTrackway

Owner:INT ELECTRONICS MACHINES

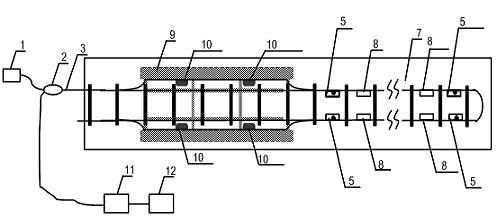

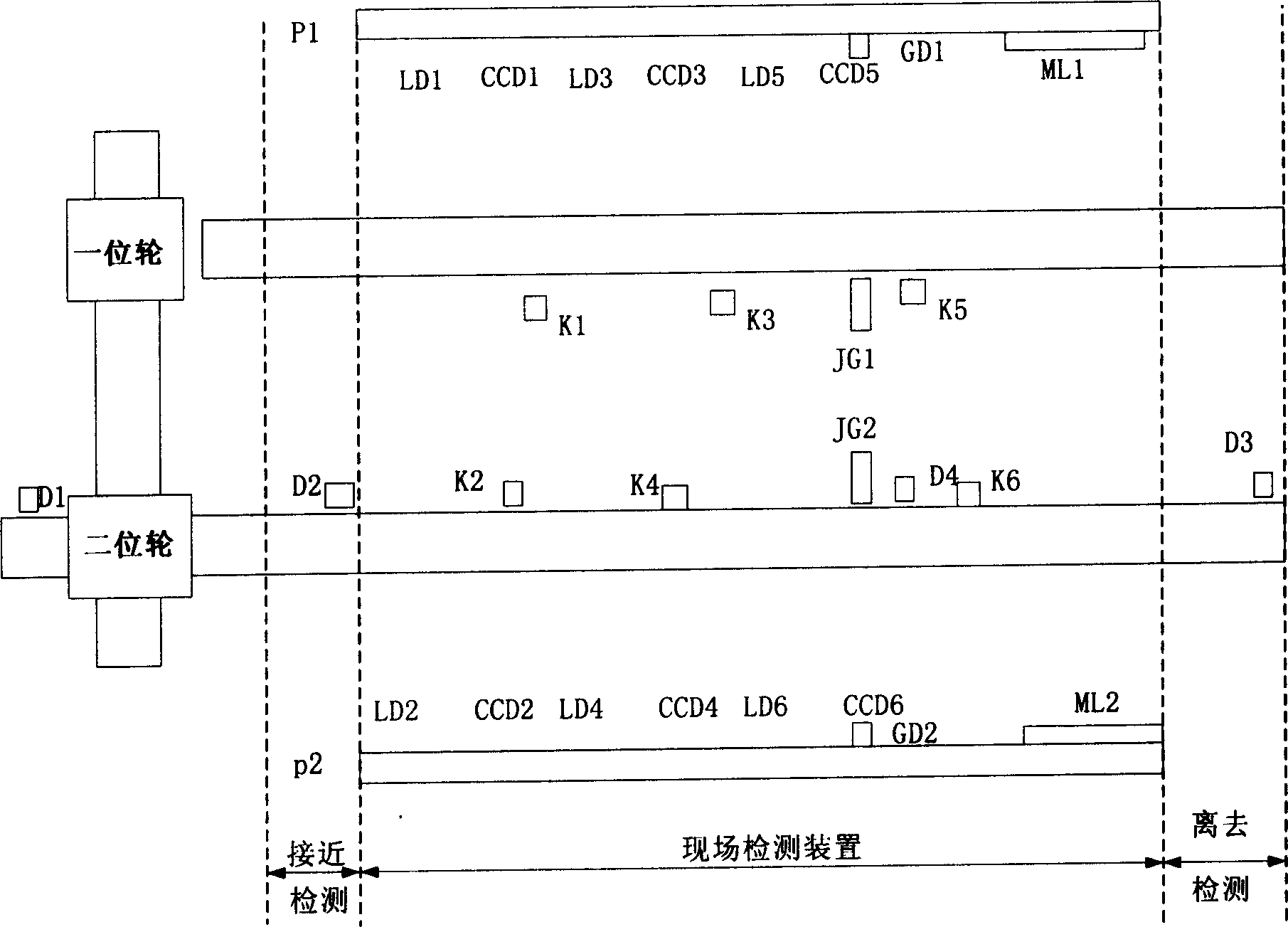

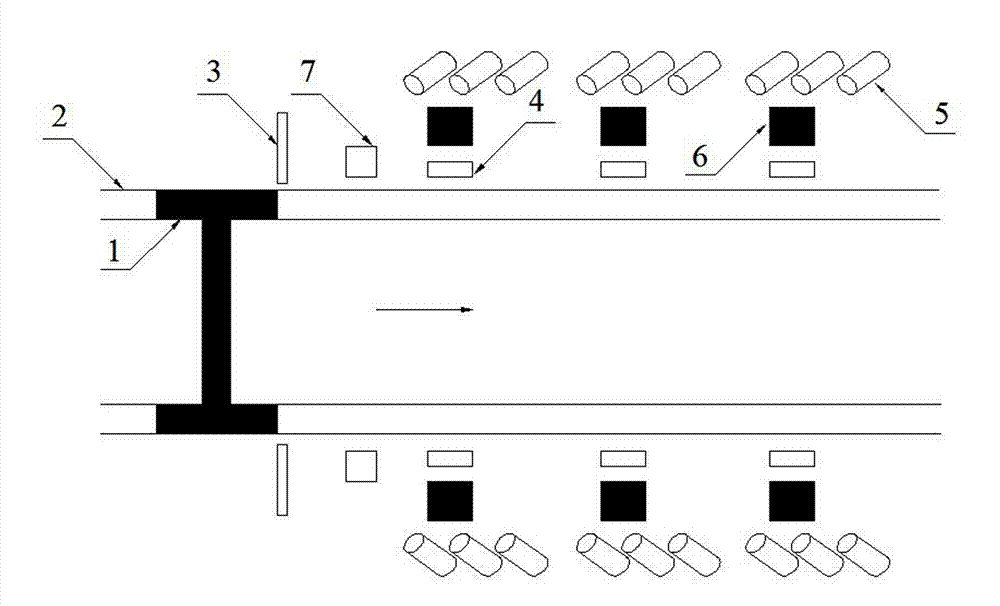

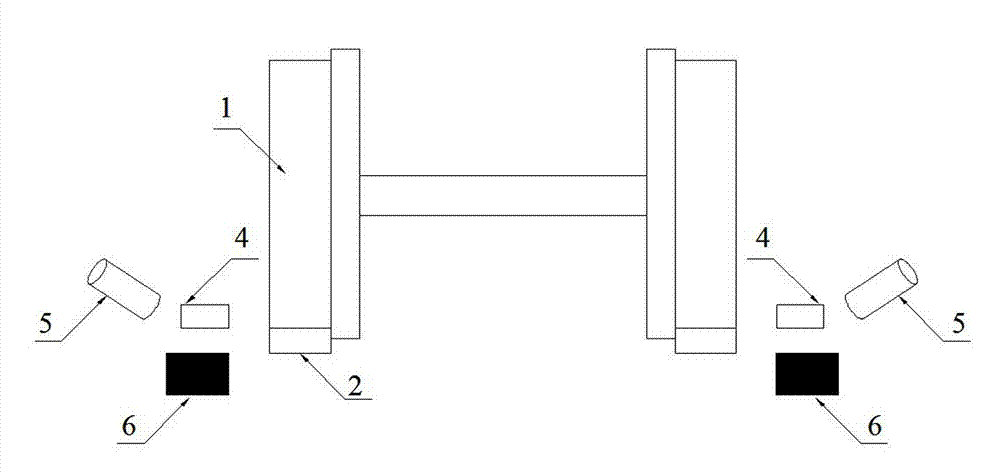

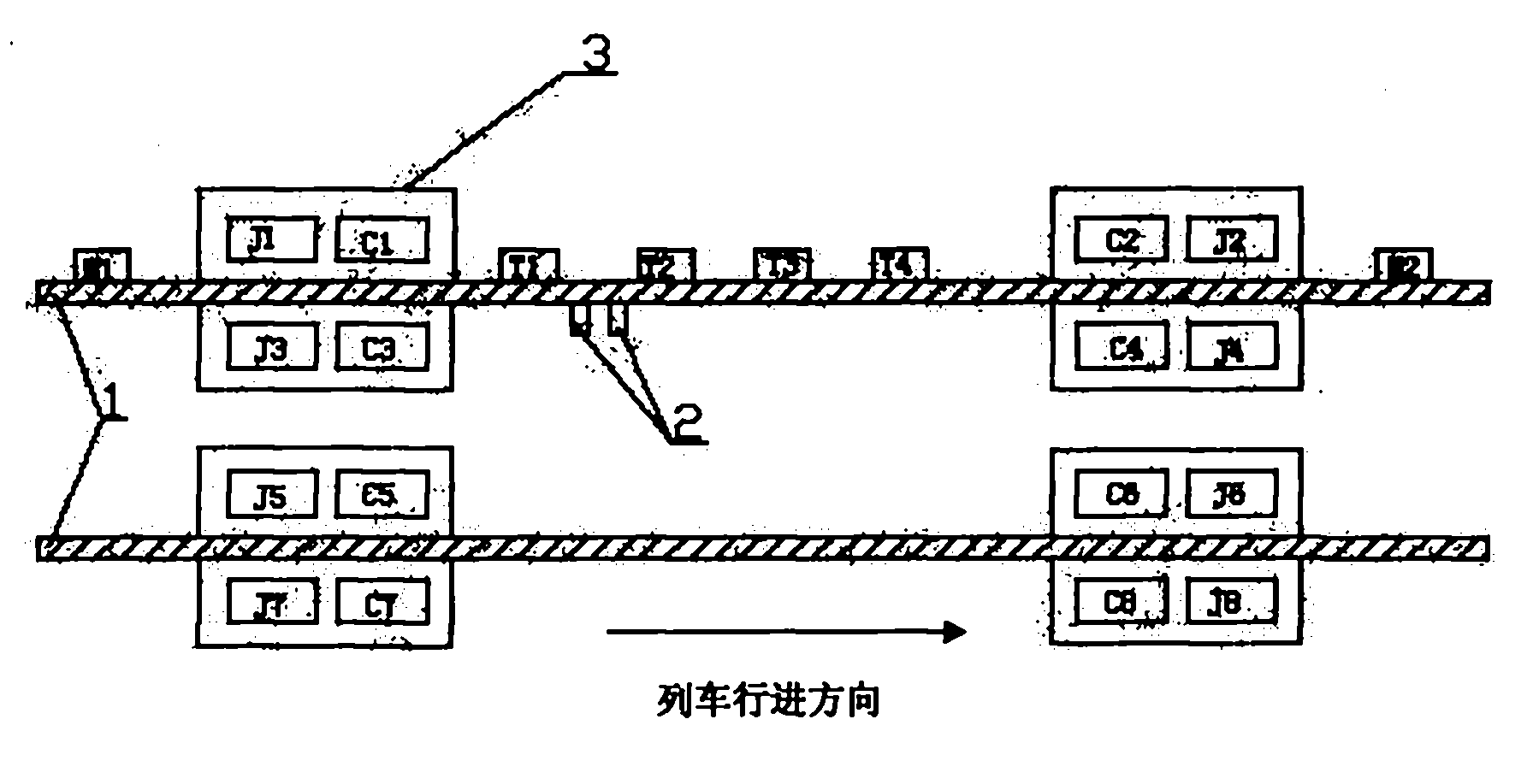

On-line dynamic detecting device of locomotive wheel lset exterior size

ActiveCN1868793ASmall speed limitHigh measurement accuracyWheel-rims surveying/measuringProximity sensorEngineering

An in-line dynamic detecting apparatus for the profile size of wheel pair on rolling stock is composed of the camera units installed at inside and outside of each rail, wheel detector close to the camera unit at inside of rail, proximity sensor before camera unit, go-off sensor behind camera unit, and data processing and control unit.

Owner:王黎 +4

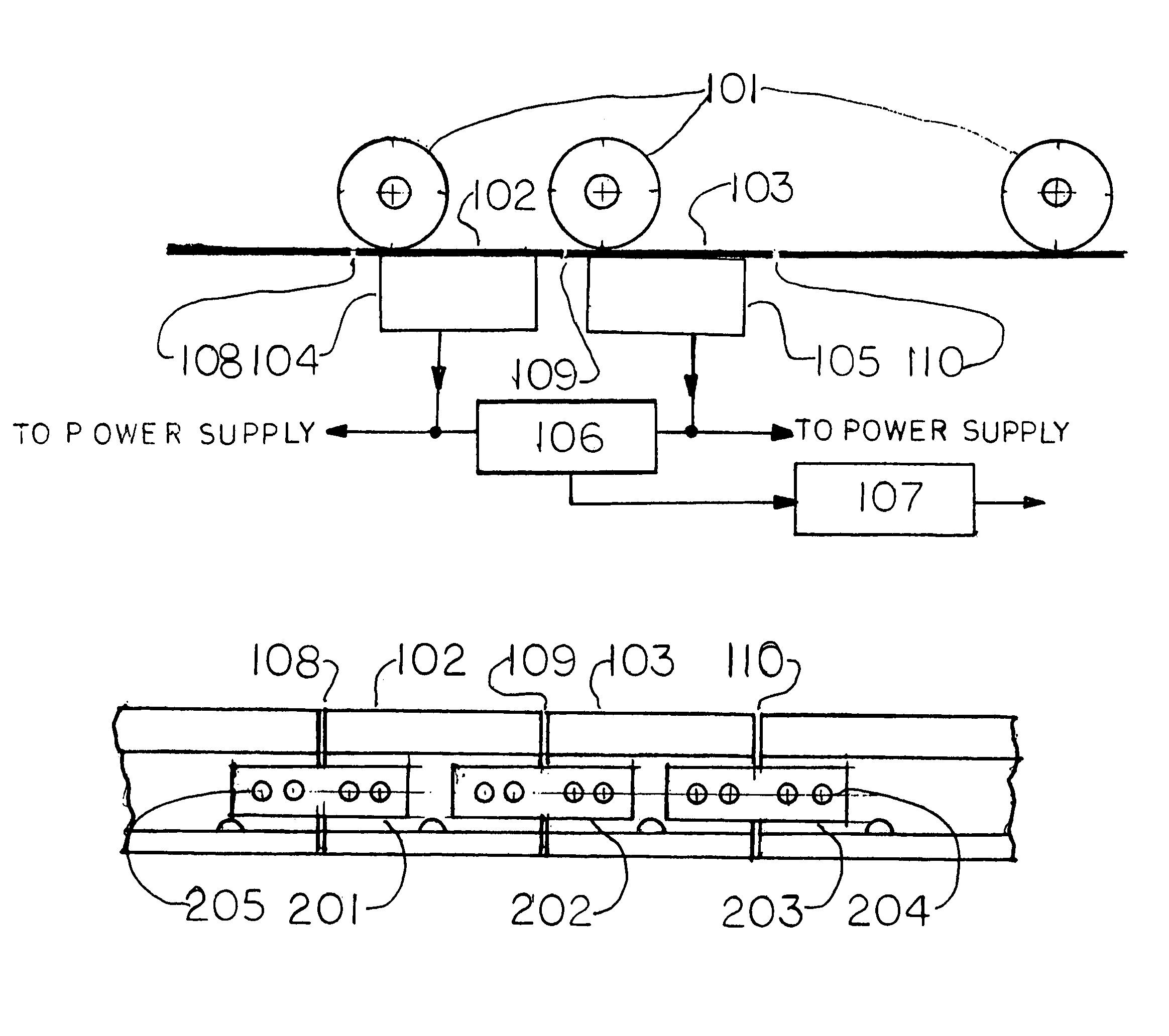

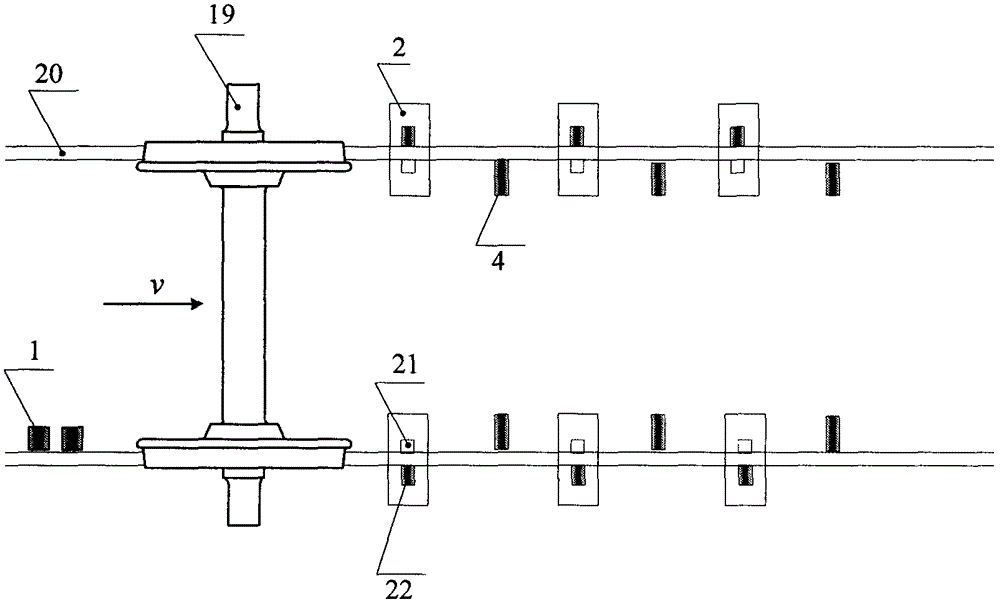

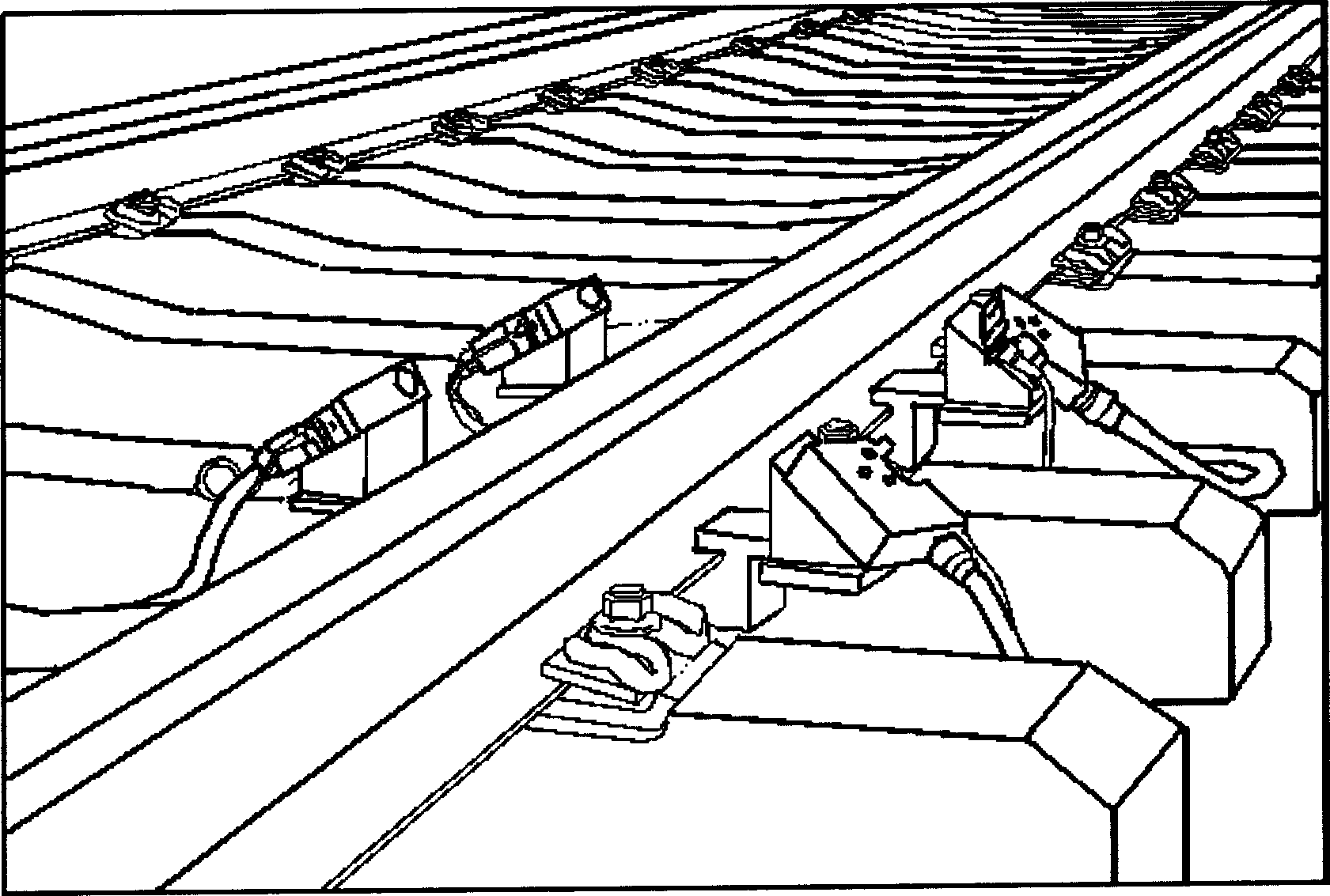

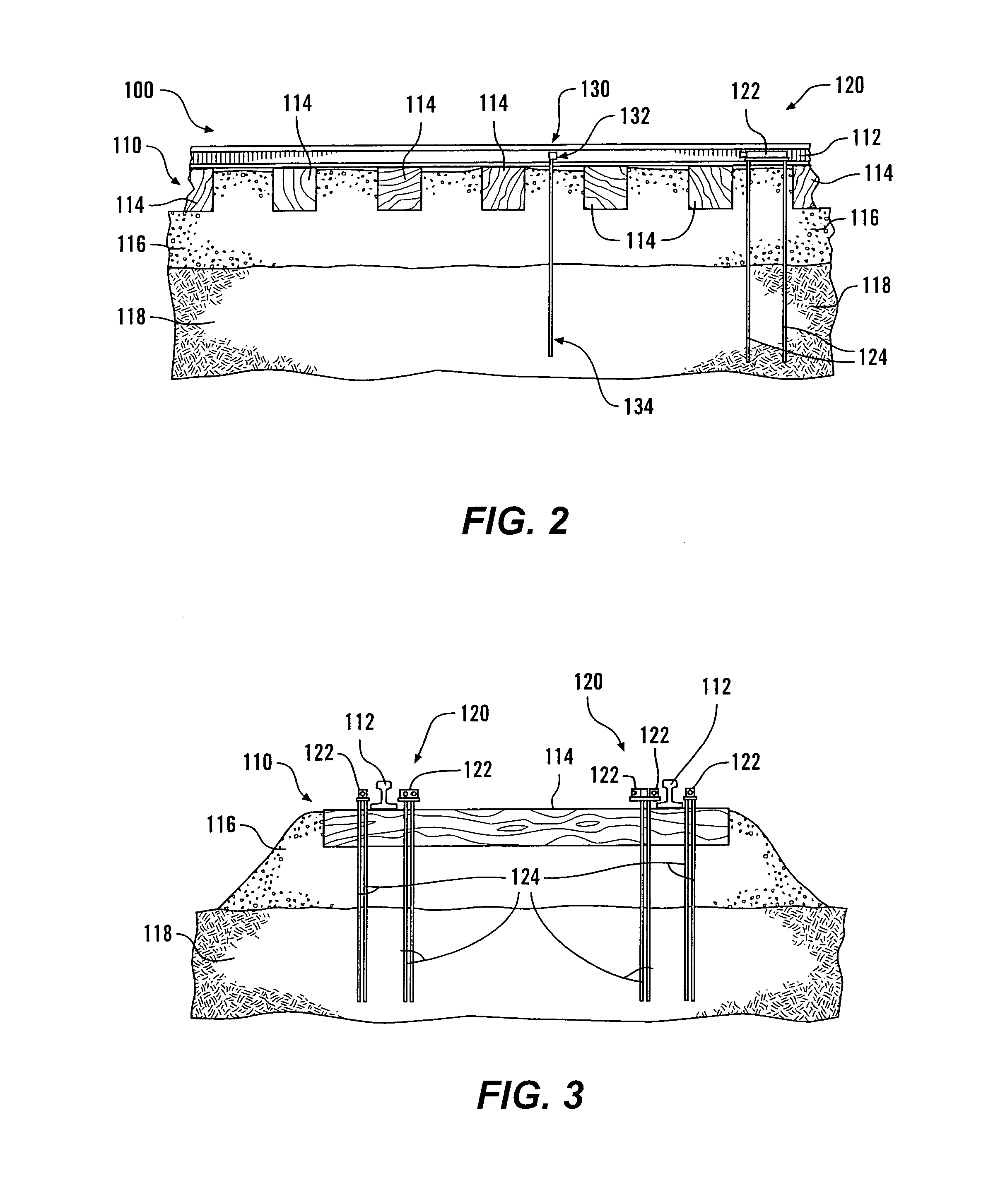

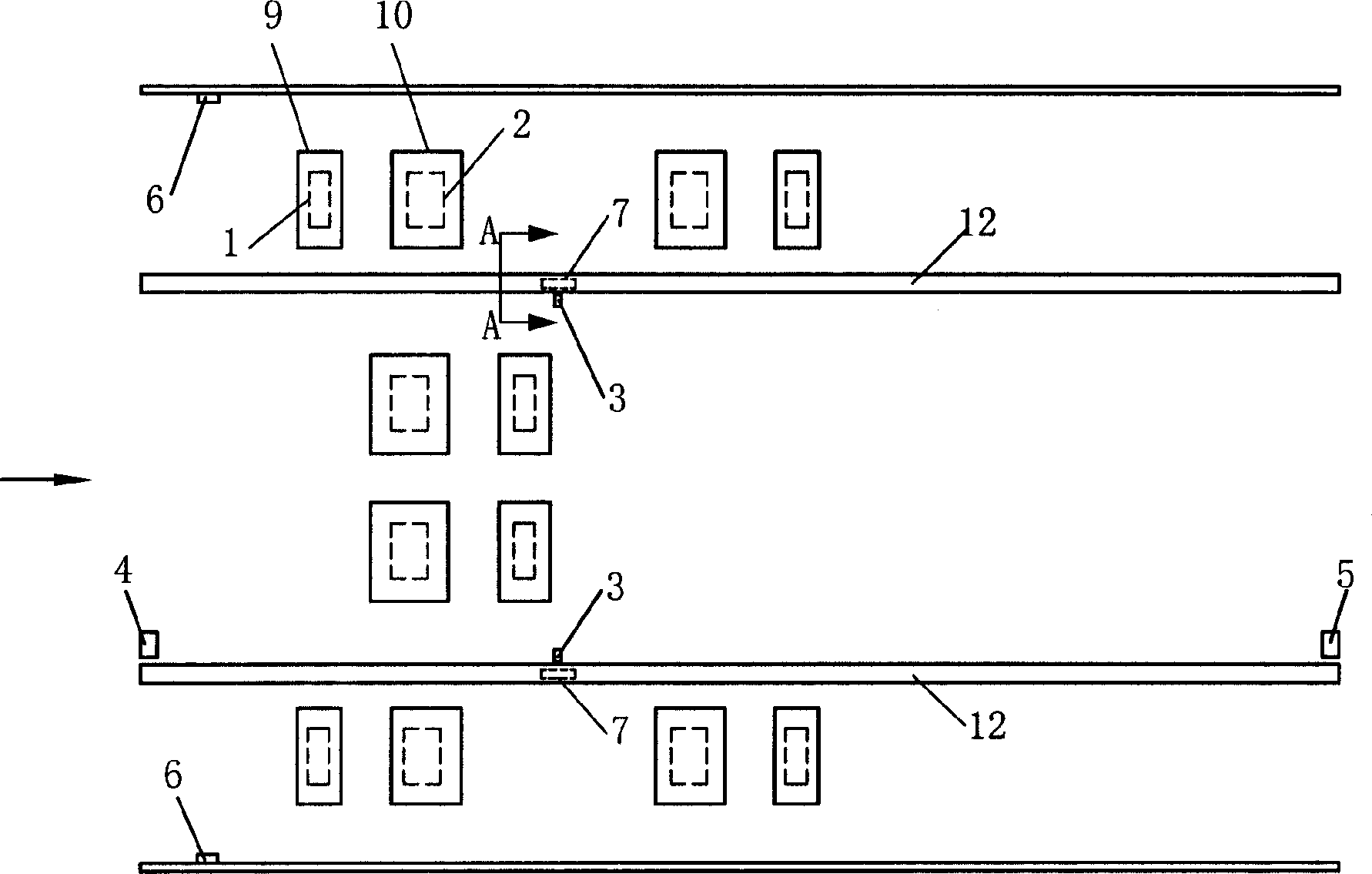

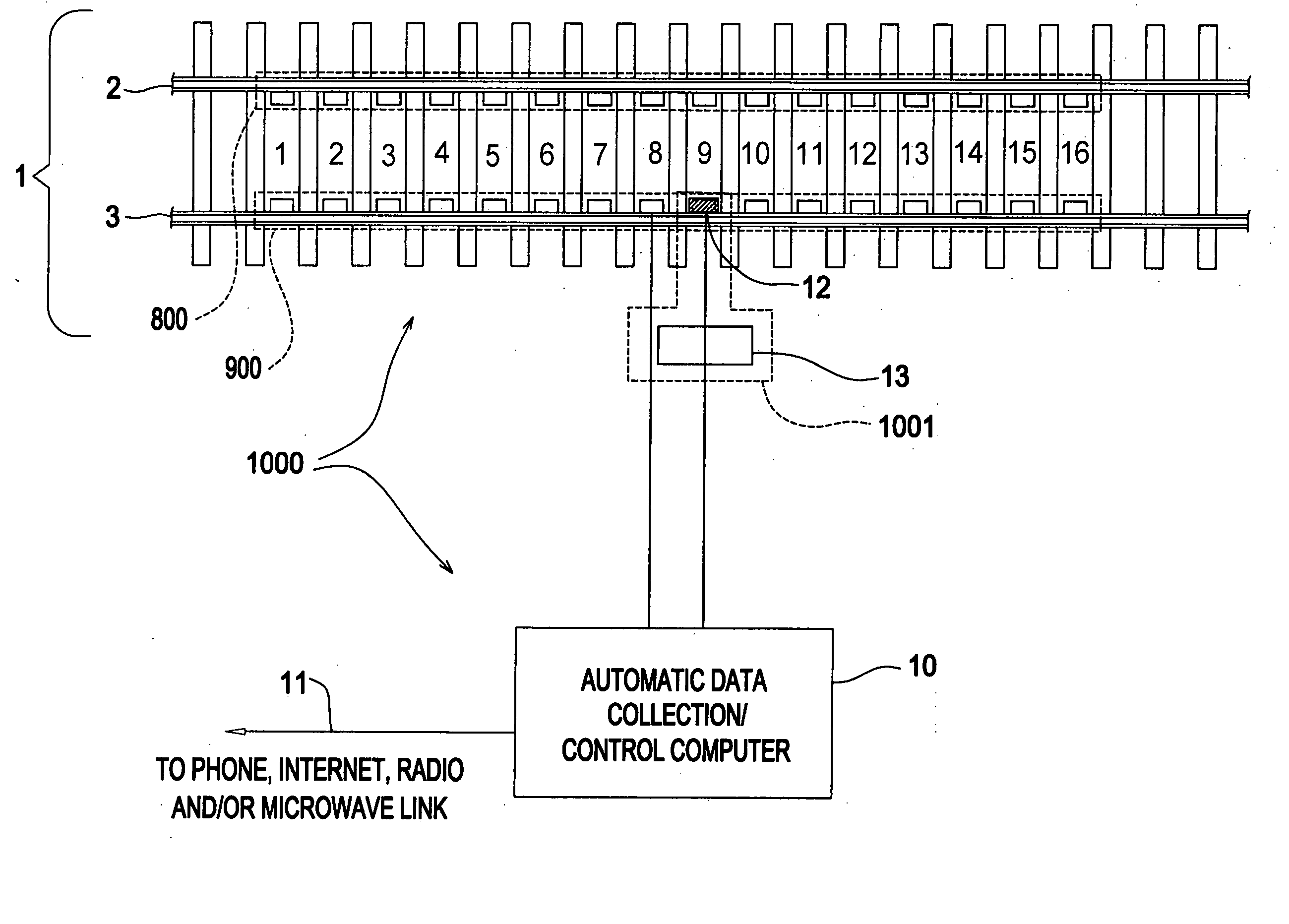

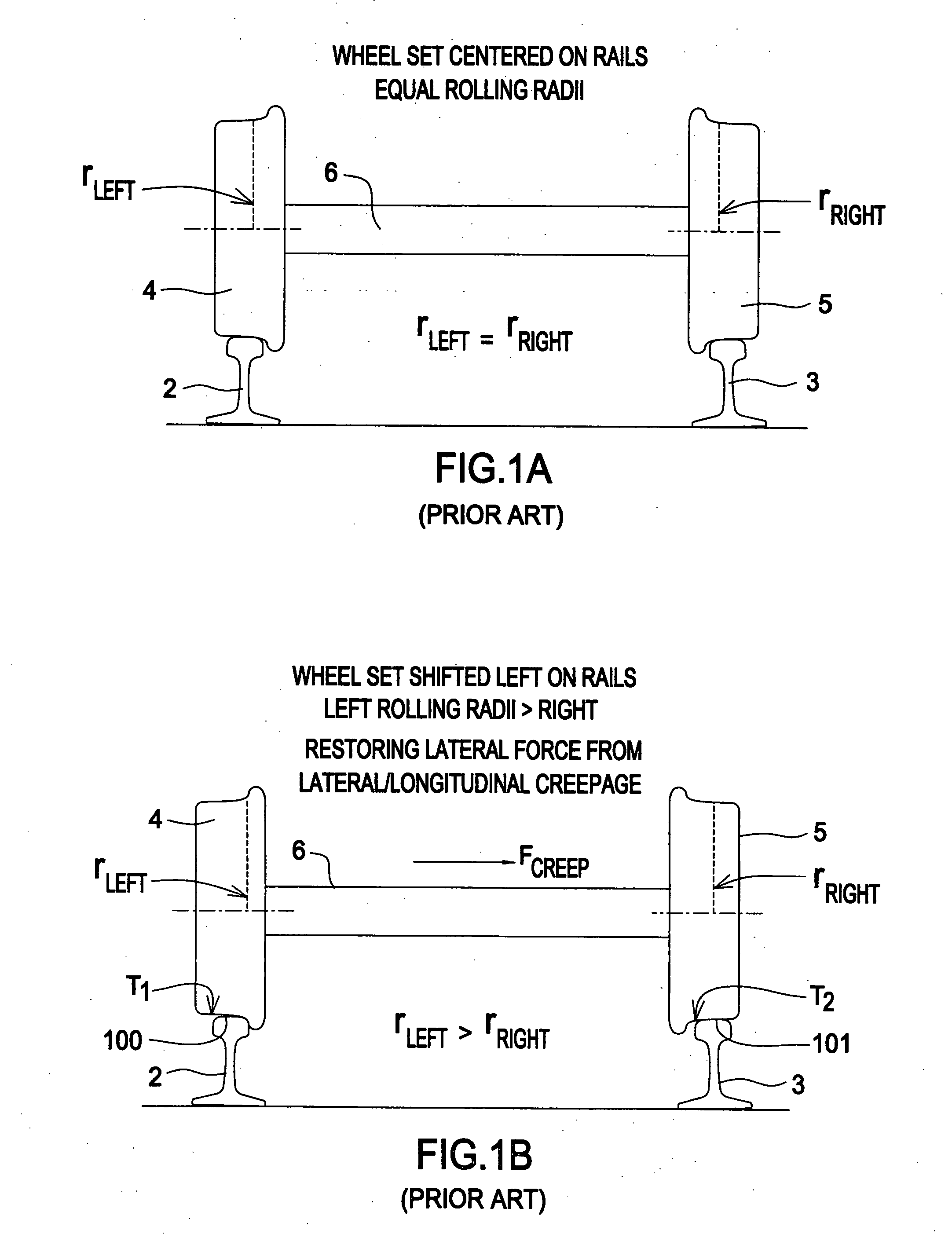

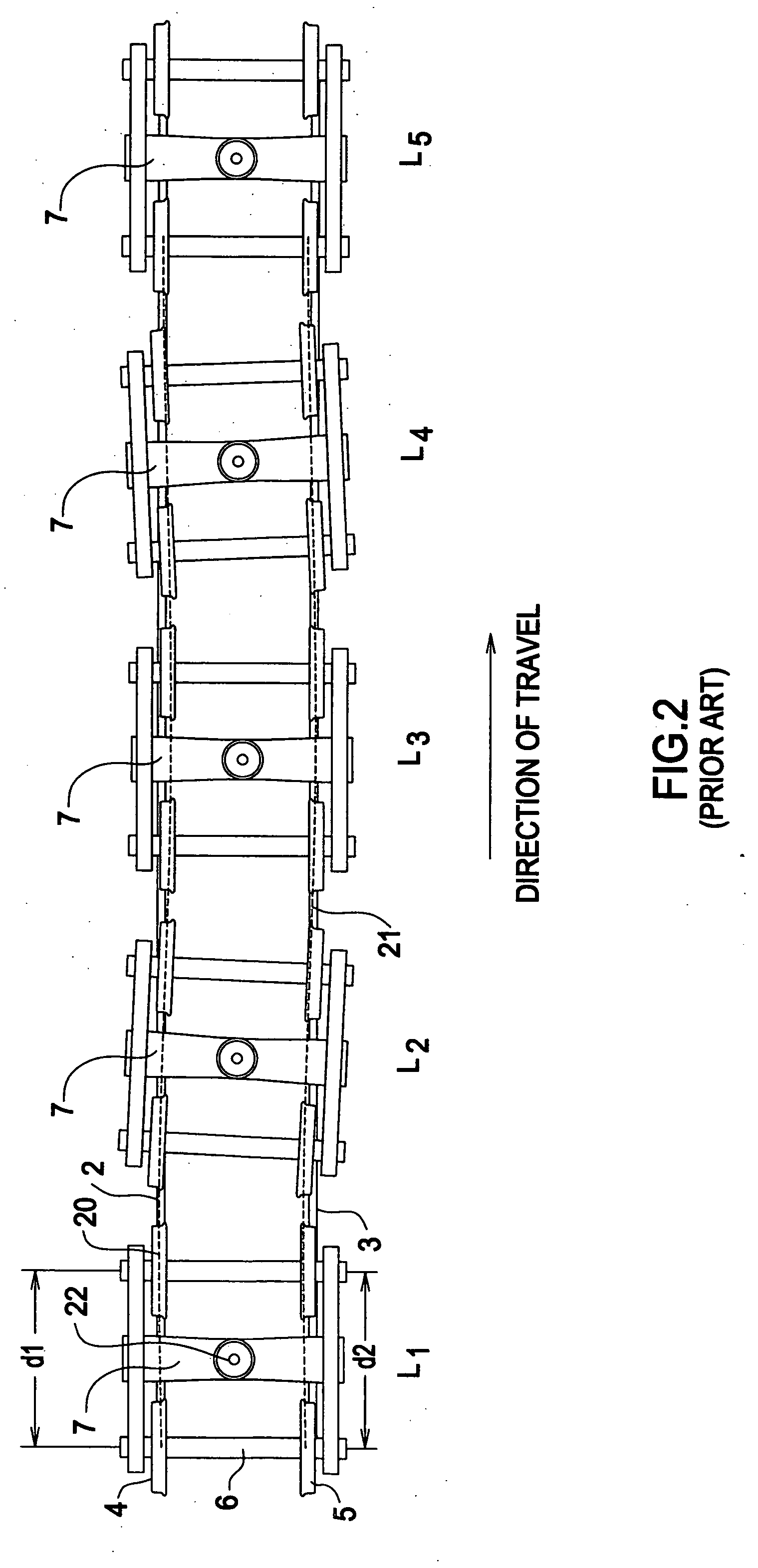

Railroad car lateral instability and tracking error detector

InactiveUS20060261218A1Wheel-rims surveying/measuringRail derailment preventionProximity sensorRailroad wheel

The current invention is intended to be installed in revenue service railroad tracks to detect railroad cars exhibiting wheel set lateral instability. The invention utilizes an array of inductive proximity sensors mounted at regular intervals in a section of railroad track. Each proximity sensor is oriented to sense the lateral position of railroad car wheel sets. The invention employs a computer algorithm to extrapolate the trajectory from the set of proximity sensor signals for each wheel set. A second algorithm evaluates the shape of the trajectory to detect oscillating lateral motion of the wheel set. A third algorithm assesses the severity of any wheel set lateral oscillations that are detected. An additional function of the invention is to detect railroad car trucks that exhibit “tracking errors”.

Owner:PROGRESSIVE RAIL TECH

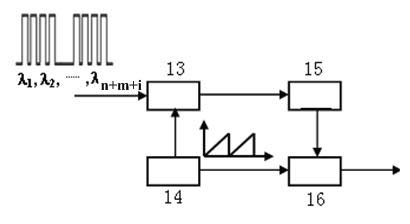

Safe and real-time detection system and method of heavy haulage lines based on optical fiber sensor network

InactiveCN101830237AHigh precisionAchieving Corrosion ResistanceWheel-rims surveying/measuringVehicle route interaction devicesGratingThermal expansion

The invention provides a safe and real-time detection system and a method of heavy haulage lines based on an optical fiber sensor network, relating to the technical field of optical fiber sensor networks and solving the problems of low precision, high cost and inconvenient real-time on-line detection of the existing heavy haulage rail haulage line safety monitoring technology. A rail fiber bragg grating strain sensor, a rail fiber bragg grating strain and acceleration combined sensor and a bridge fiber bragg grating strain and temperature combined temperature sensor are connected in series to form a monitoring area via transfer optical fibers; light emitted by a light source is incident in the monitoring area by a coupler; and when a heaving haul train passes through the rails in the monitoring areas, the running state among rails can lead the reflective wavelength of the fiber bragg grating to change, a computer judges the fracture condition at a rail seamless welding part, the damage conditions of train wheels, rails and roadbeds, inner strain condition caused by expansion and contraction of rails due to temperature and bridge structure safe state according to the change condition of the reflective wavelength. The invention is applicable to on-line monitoring of the heavy haulage lines.

Owner:HEILONGJIANG UNIV

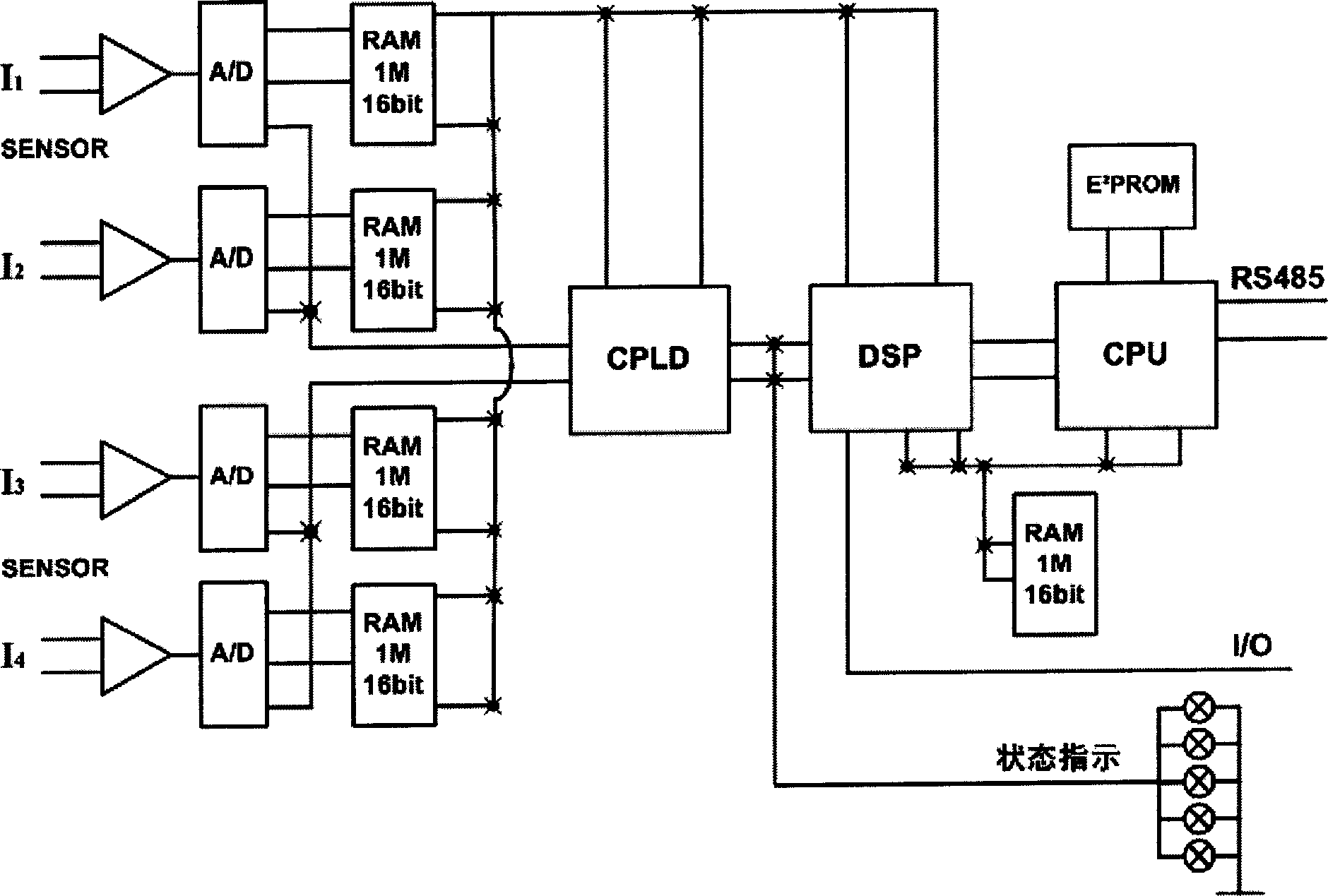

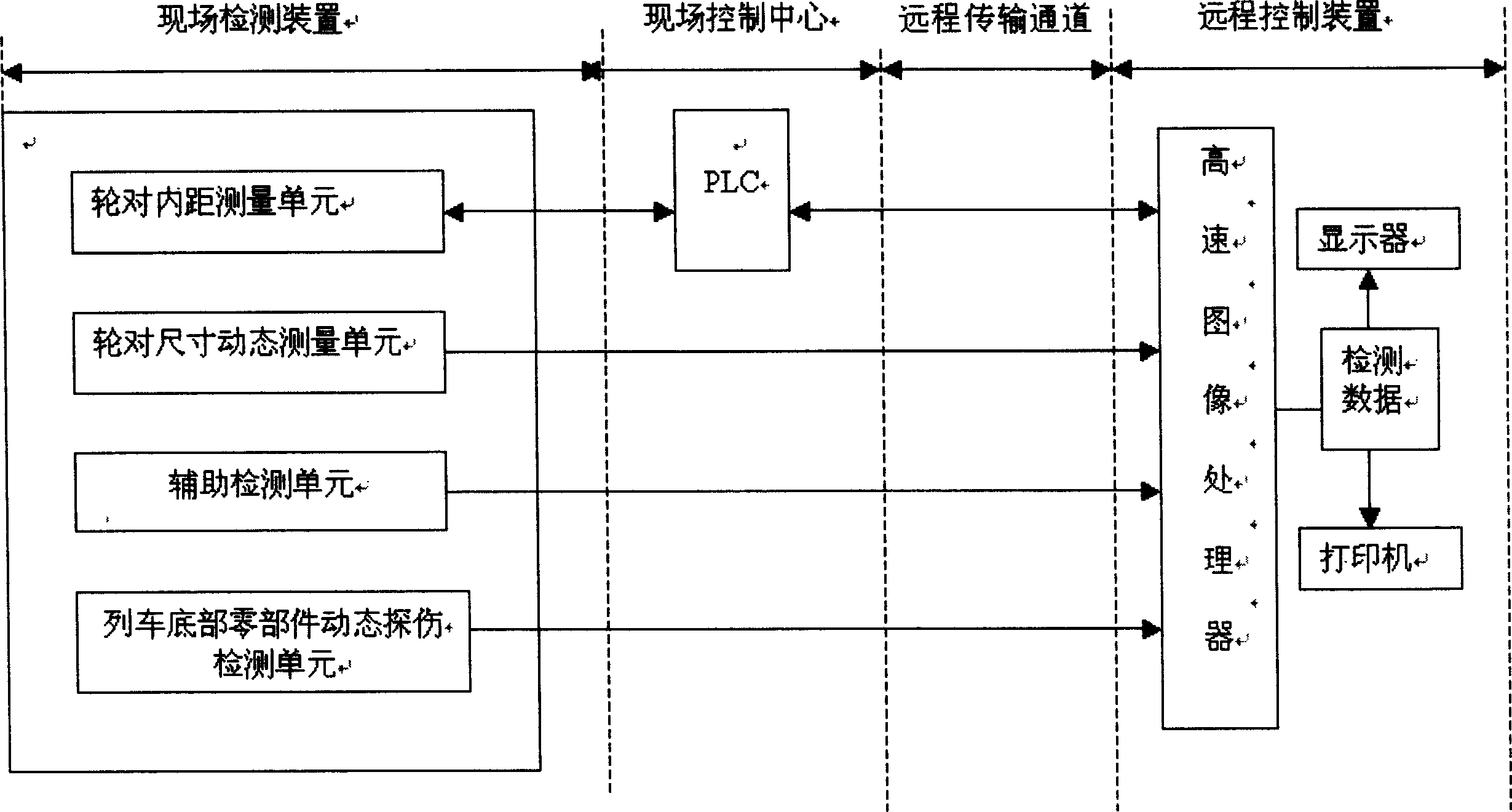

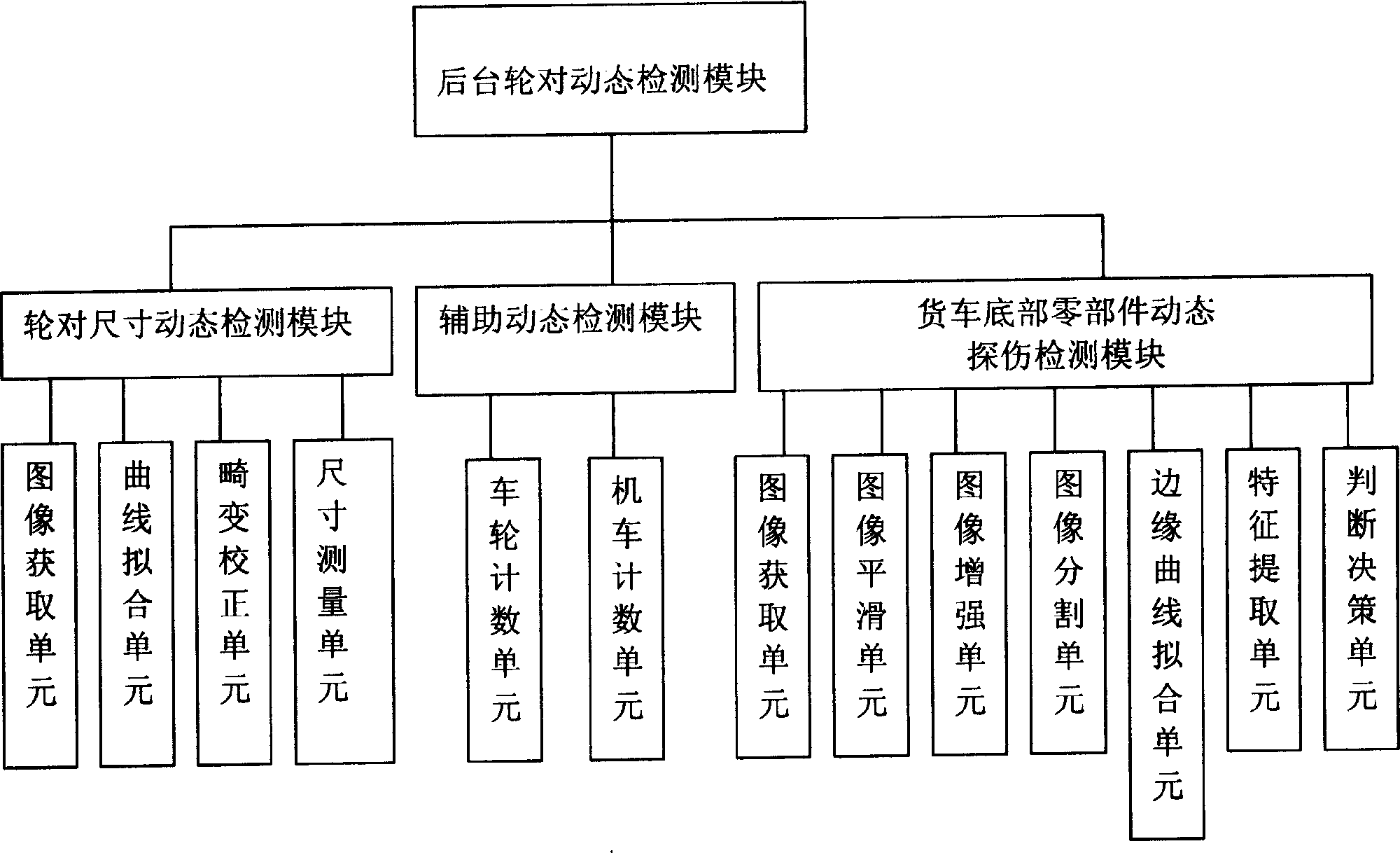

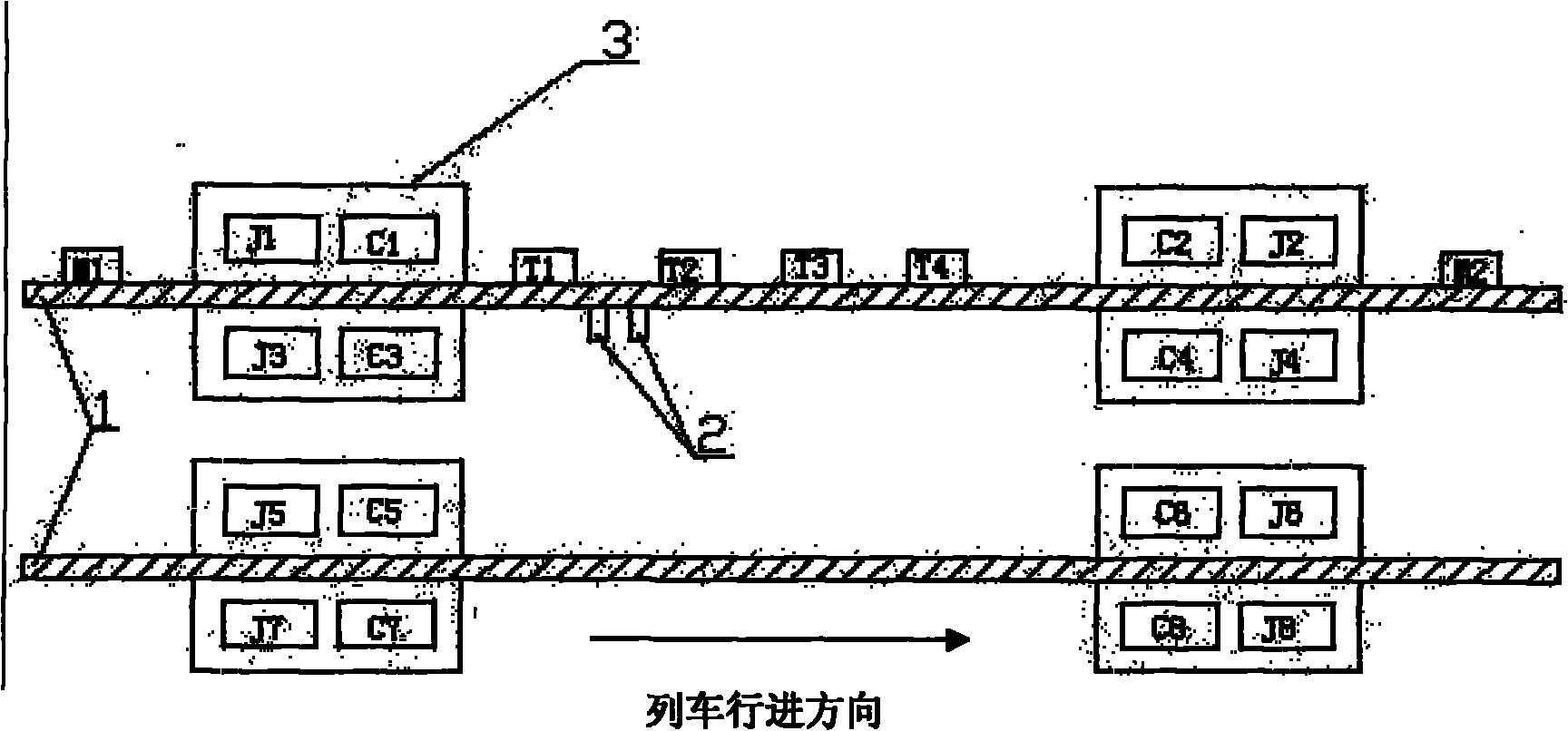

Dynamic detection system of train wheel pair and detection method thereof

InactiveCN1843822ADoes not account for running timeComprehensive detection functionWheel-rims surveying/measuringPhase detectorControl system

The invention discloses a dynamic detector of train wheels and relative detecting method, which can improve the driving safety. Said detector comprises a on-site controller, a remote-controller, and a on-site detector, wherein, the on-site detector is controlled by the on-site controller to output the detecting result, which via the remote transmission channel is transmitted to the remote controller to be processed; the remote-controller comprises a background wheel dynamic detecting software, to control the open, detecting, image picking, automatic wheel size detecting, accident recognize, automatic storage, displaying, and printing; the on-site controller controls the on-site detector to detect and keep communication with the remote-controller. The invention can avoid contact train, with high automation and detecting accuracy, while it can realize unattended management.

Owner:XIAN YINGZHUO ELECTRONICS EQUIP

On-line high-speed detection system of train wheel set tread and wheel rim and detection method thereof

InactiveCN102788803AResolve detectionAddress the sphere of influenceWheel-rims surveying/measuringOptically investigating flaws/contaminationImaging processingSand blasting

The invention discloses an on-line high-speed detection system of train wheel set treads and wheel rims and a detection method thereof. The detection system comprises a target detection unit, a speed measurement unit, a location determination unit and an image acquisition unit which are arranged at the outside of tracks in order, and an image processing unit and a control unit, wherein the image acquisition unit comprises multi-group line structure-light sources and a high-speed planar array camera, an intersecting line formed by intersecting the light plane with the wheel set is arranged between a train sand blasting pipe / braking unit and the track, and the imaging filed of the planar array camera covers and is slightly larger than the intersecting area. The detection method comprises: 1, judging whether the wheel set is defective by canny edge detection; 2, calculating the depth of the defects to obtain the size of the defects; and 3, splicing the light band portion of each image in order into an image. According to the invention, the influence of the train sand blasting pipe and braking unit on the detection is avoided, and the detection speed is fast; the system is suitable for 20-300km / h train on-line detection, the precision is high, the detection of the defects which are less than 1mm can be realized; the detection result is displayed in an image, thus the observation is convenient.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

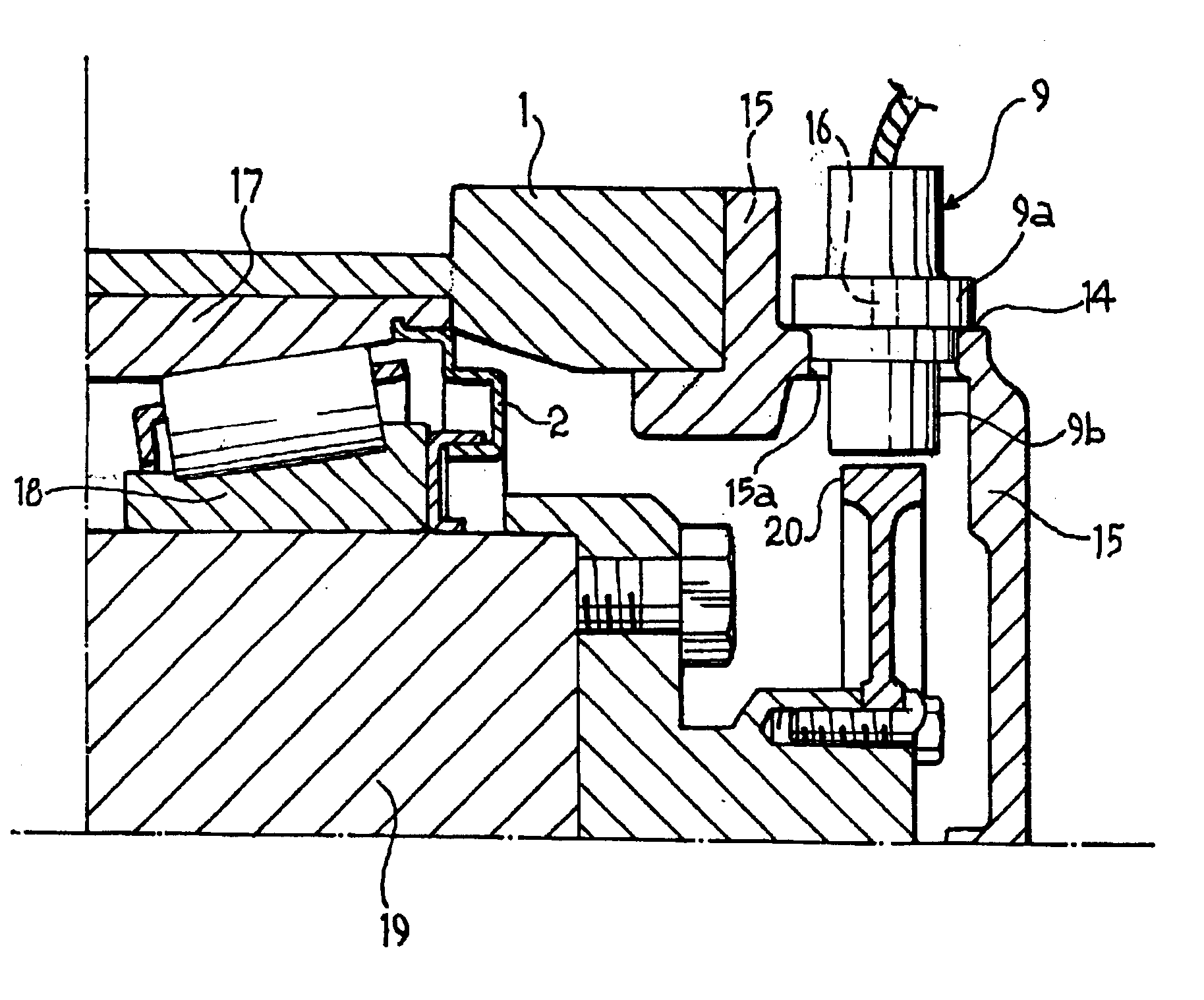

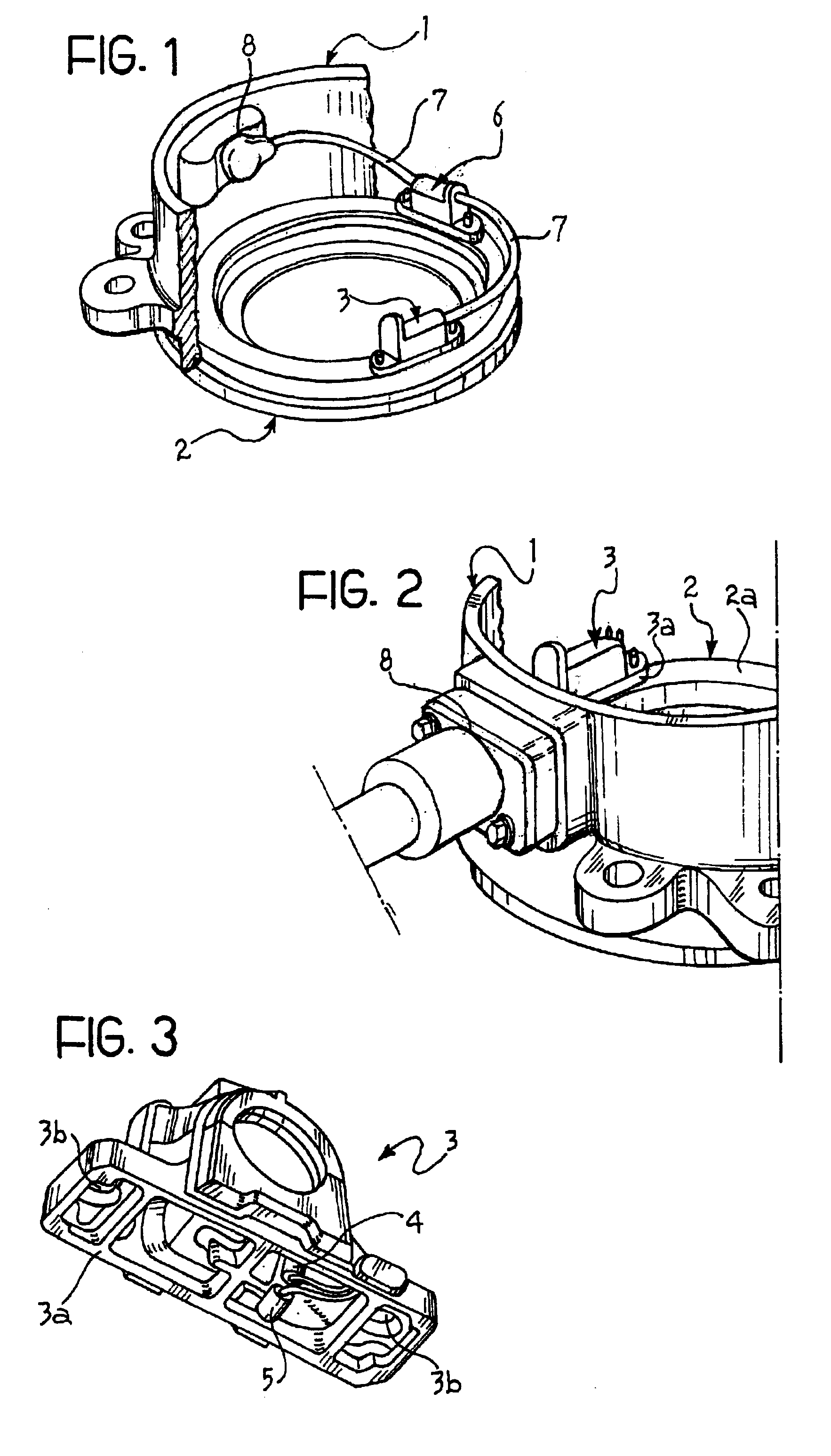

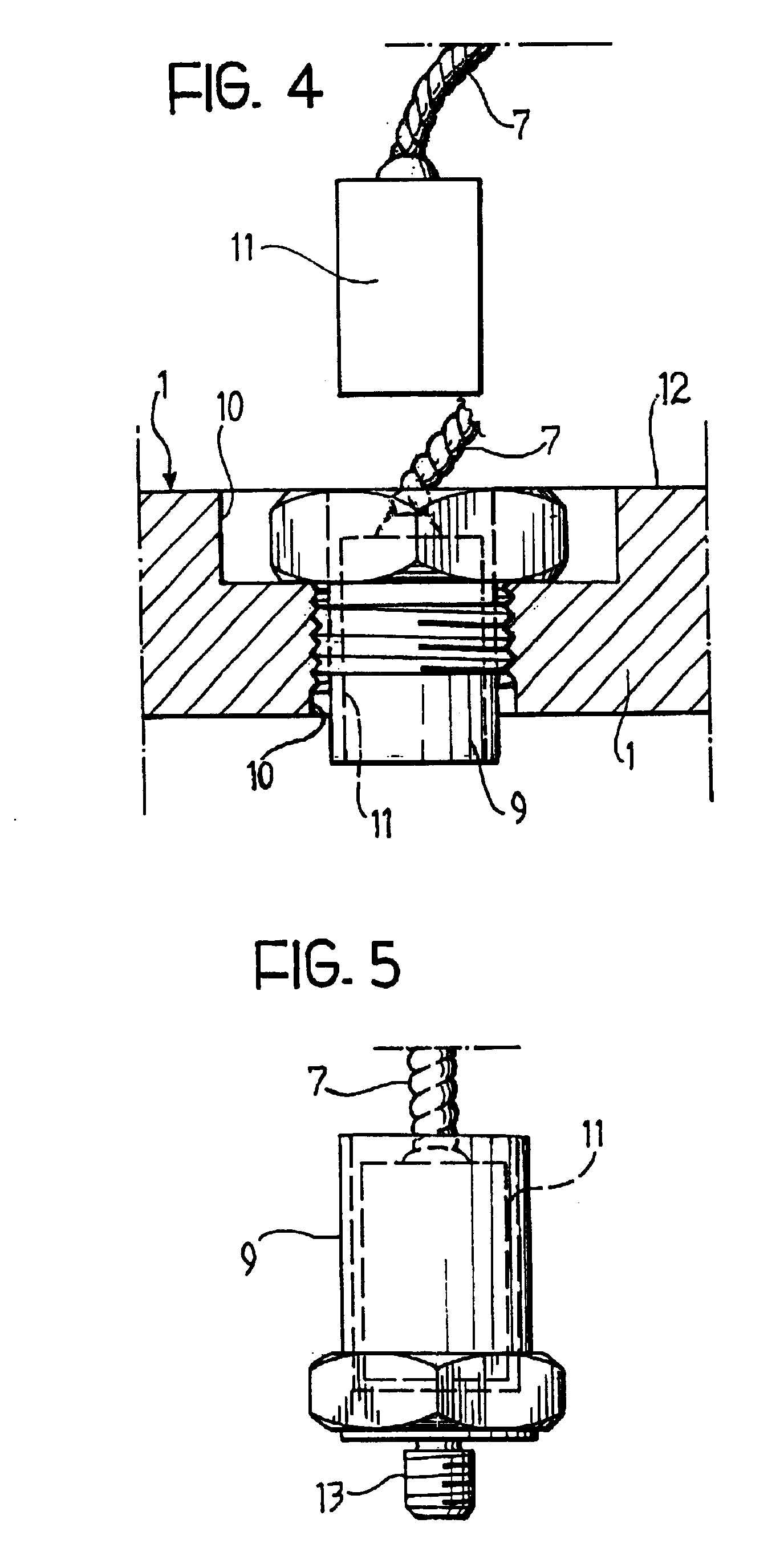

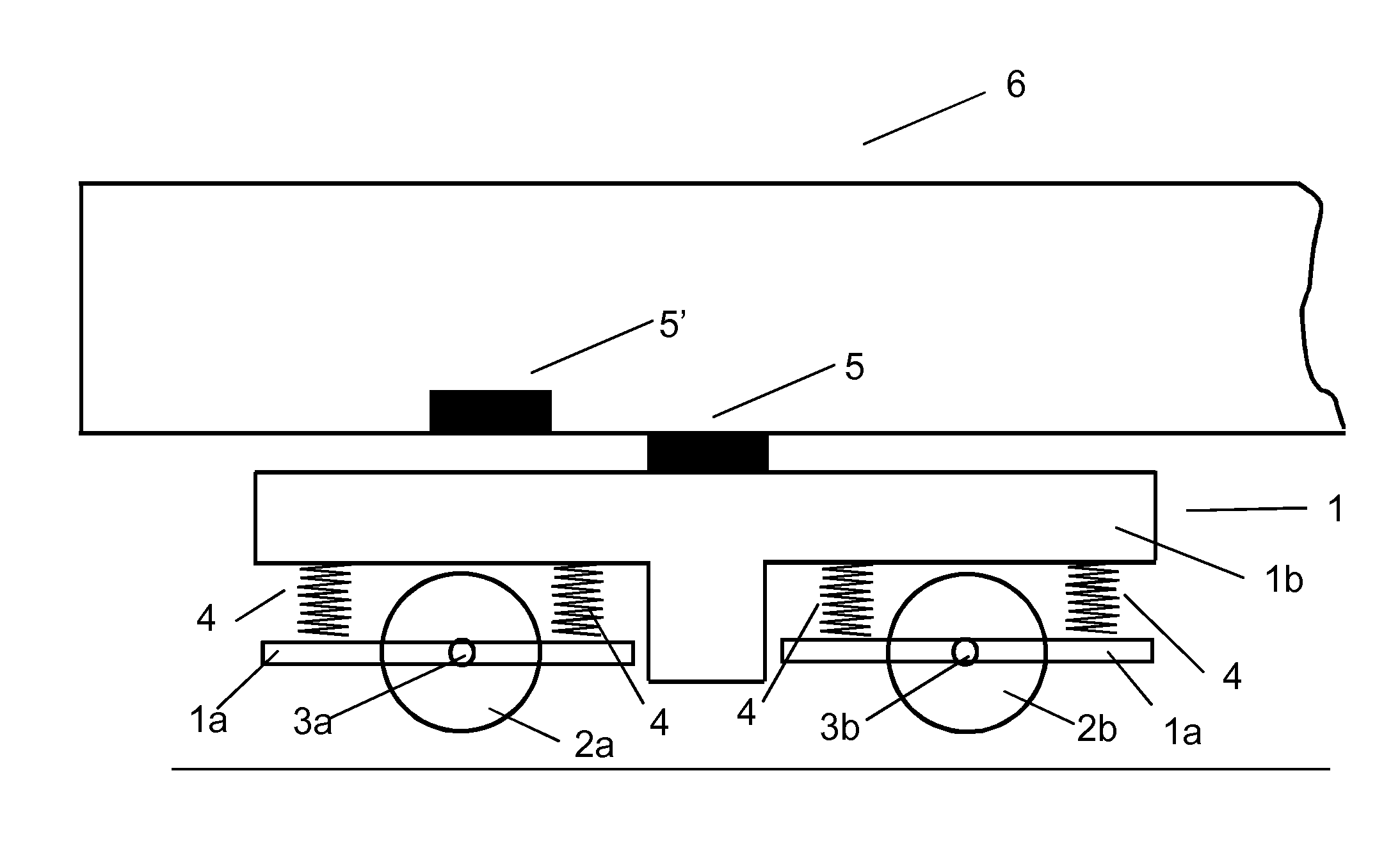

Railway axle hub unit

InactiveUS6672681B1Vibration measurement in solidsMachine part testingOn boardAutomotive engineering

A railway axle hub unit of the type including an axle box housing (1) for supporting a bearing, is provided with a sensor body (3, 9) containing sensors (4, 5) for detecting vibration in the vertical direction and the horizontal axial direction. The sensor body is mounted onto a stationary support element (2, 1, 15) rigidly secured to the bearing, preferably an annular sealing insert. The sensors perform monitoring of the operation condition of the hub unit by generating and transmitting signals indicative of the detected level of vibration to an electronic processing unit mounted on board of the railway vehicle or the train. The processing unit is capable of signalling in real time an impending failure and / or a damaged condition associated with the monitored hub unit.

Owner:SKF IND SPA

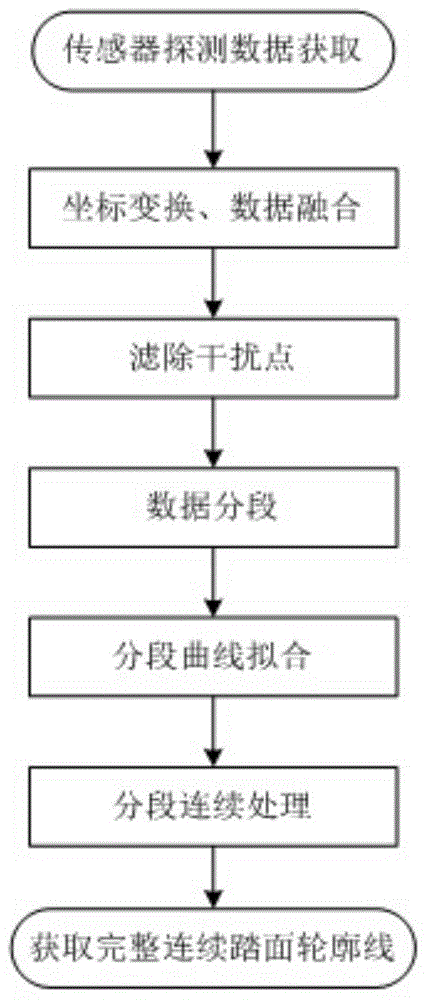

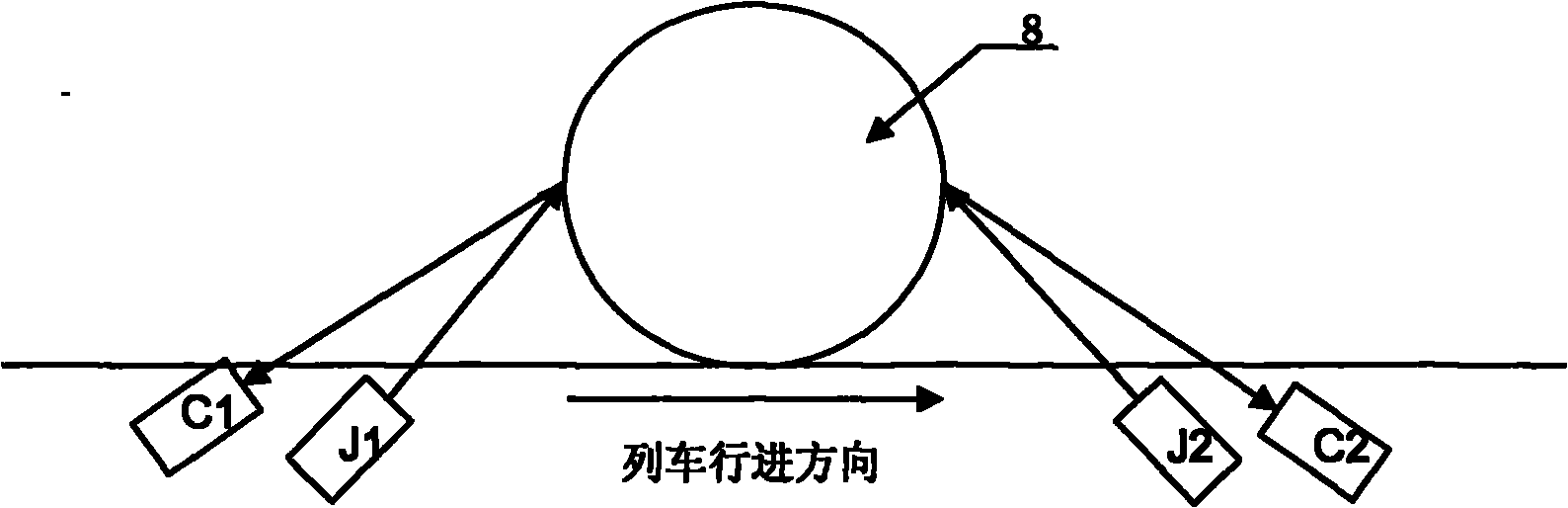

Method and device for obtaining wheel set tread contour line of urban rail train

ActiveCN104163188ARelatively small errorWith online non-contact measurementWheel-rims surveying/measuringContact typeEngineering

The invention discloses a method and device for obtaining a wheel set tread contour line of an urban rail train. The device comprises two sets of 2D laser displacement sensors installed on the two sides of a rail in a mirror symmetry mode. The laser detection faces of the two sets of sensors are located on the same plane, and the integral device is lower than the rail surface. The method comprises the steps that after the sensors detect wheels at the same time to obtain detection point coordinates, the output points of the two sets of sensors are combined to a same coordinate system through coordinate transformation and coordinate translation; the x-coordinate value of the right end face of a tread is obtained, and a filtering window is established based on the x-coordinate value to remove interference points of measuring data; the x-coordinate value of the right end face of the tread is obtained, and measured data points are divided into K number sets according to the actual situations; least squares curve fitting is carried out on the data points of each number set; coordinate values of segment points are obtained, and each segment curve is smoothened into an integral tread contour line according to the lagrange multiplier method. The method and device have the advantages of being high in speed and precision, easy to operate, capable of carrying out online non-contact type measurement, and the like.

Owner:NANJING UNIV OF SCI & TECH

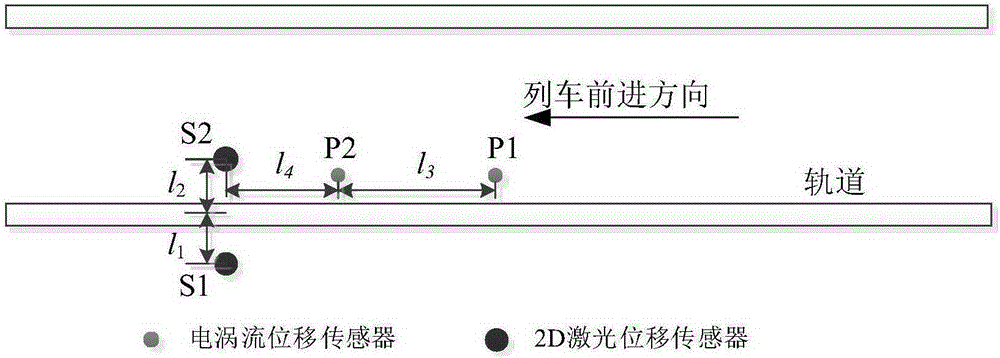

Non-contact wheel set dimension online detection method and device based on various sensors

InactiveCN105292180ALow costSimple measuring principleWheel-rims surveying/measuringUsing optical meansGeometric relationsEddy current

The invention discloses a non-contact wheel set dimension online detection method and device based on various sensors. The device comprises the two laser displacement sensors symmetrically arranged on the inner side and the outer side of a track, and the two eddy current displacement sensors arranged on the inner side of the tract. The method comprises the steps that the two laser displacement sensors detect and obtain tread contour lines, and the rim height and the rim thickness are calculated through the extracted tread contour lines according to the geometric relation; the two eddy current displacement sensors are used for detecting the distances to the vertexes of the rims in the vertical direction, measurement data of the three sensors on the inner side of the track are extracted at the moment when wheels pass through the effective measurement range of the eddy current displacement sensors and the laser displacement sensors on the inner side of the rack simultaneously, the diameters of the vertex circles of the rims are calculated according to the measurement data and the geometric relation, and then the diameters of the wheels are calculated according to the wheel rim height. The non-contact wheel set dimension online detection method and device based on various sensors have the advantages that the measurement principle is simple and practical, cost is low, and precision is high; non-contact and real-time measurement can be achieved.

Owner:NANJING UNIV OF SCI & TECH

Online dynamic detection device of all-periphery contour dimension of locomotive wheel pair

InactiveCN102060037APrecise control over acquisition timeDetect wearWheel-rims surveying/measuringUsing optical meansProximity sensorAcquisition time

The invention discloses an online dynamic detection device of an all-periphery contour dimension of locomotive wheel pair, which comprises a proximity sensor, a leaving sensor, pickup units, a train speed detection unit and a data processing control device, and also comprises a time reference unit, wherein the time reference unit comprises a plurality of time reference sensors, the time reference sensors are arranged outside a rail along the length direction of the rail, the time reference sensors are connected with the data processing control device; and the pickup unit comprises a surface array laser generator arranged near the rail and a surface array CCD (Charge Coupled Device) image sensor. The surface array laser generator and the surface array CCD image sensor form the pickup units to ensure that the acquired image is more accurate; the time reference unit is arranged between the front pickup unit and the rear pickup unit, the image acquisition time can be accurately controlled, the all-periphery contour dimension key parameters of the measured wheel are obtained by analyzing an image sequence, and more detailed and accurate measurement is provided for the conditions of wheel deformation, abrasion, loss and defects.

Owner:安徽科富光电装备有限公司

Wheel measurement systems and methods

ActiveUS20070075192A1Improve efficiencyImprove reliabilityElectric devicesWheel-rims surveying/measuringGraphicsMeasurement device

An improved maintenance, inspection, and / or measurement solution is provided. An embodiment of the invention includes a handheld measurement device for measuring an object, such as a railway wheel on a train. The handheld measurement device can comprise a single unit to provide one handed operation and can include various features, such as onboard evaluation, a graphical user interface, and / or a self-health monitor. Additionally, aspects of the invention provide an inspection environment that incorporates preliminary measurement data, wireless communications, and / or historical data into the measurement and evaluation process.

Owner:INT ELECTRONICS MACHINES

System and method for analyzing rolling stock wheels

An exemplary system and method for analyzing rolling stock wheels helps allow a wheel to be analyzed at speed, reducing any need for manual inspections or other related delays. An exemplary system may include one or more strobe lights and one or more high-speed cameras to capture images of the rolling stock wheel(s) at speed. The images may include one or more markers to assist in analyzing various parameters of the rolling stock wheel. The exemplary system may include one or more backface illumination plates to assist in illuminating the rolling stock wheel(s) and / or the one or more marker(s).

Owner:WABTEC CONTROL SYST PTY LTD

Method and system for detection and analysis of railway bogie operational problems

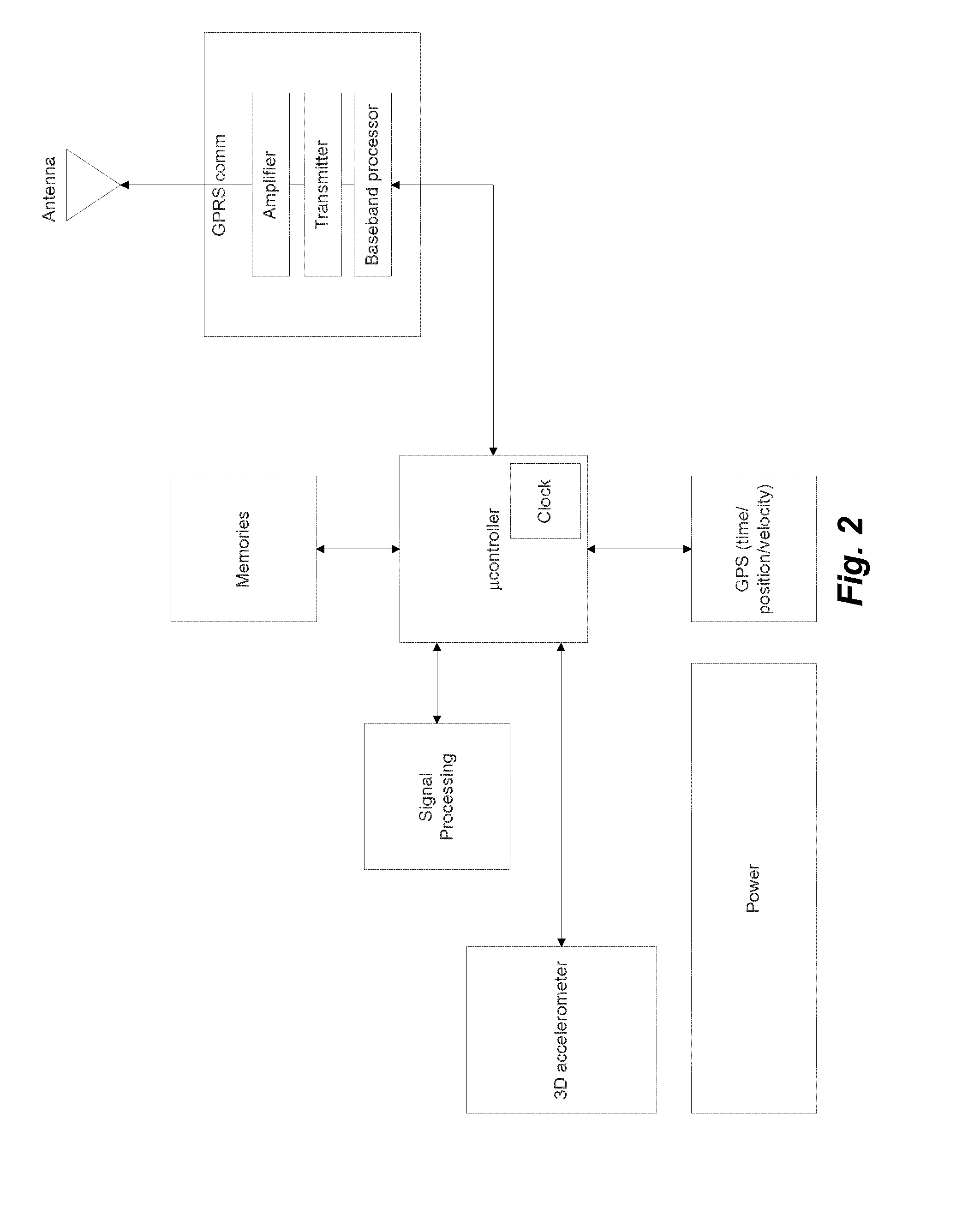

ActiveUS20150051792A1Easy to installWheel-rims surveying/measuringRegistering/indicating working of vehiclesBogieOperational Problem

A method and system for detecting defects to railway wagon wheels and to the rail. A method for detecting a wheel flat, or an event that may cause a wheel flat to develop on a railway wagon, including the steps of a) monitoring at least the longitudinal and vertical acceleration of said railway wagon, and b) concluding that a wheel flat has developed, or that there is a risk of developing a wheel flat, if a specific acceleration pattern is monitored, said pattern comprising a longitudinal acceleration above a first threshold followed by a vertical acceleration above a second threshold. A system for detecting a wheel flat of at least one wheel of a railway wagon and the use of an acceleration sensor mounted on the sprung part of a railway wagon for estimating the wheel flat size of a wheel of the railway wagon.

Owner:RAILWAY METRICS & DYNAMICS SWEDEN

Noncontact measuring device

Owner:INT ELECTRONICS MACHINES

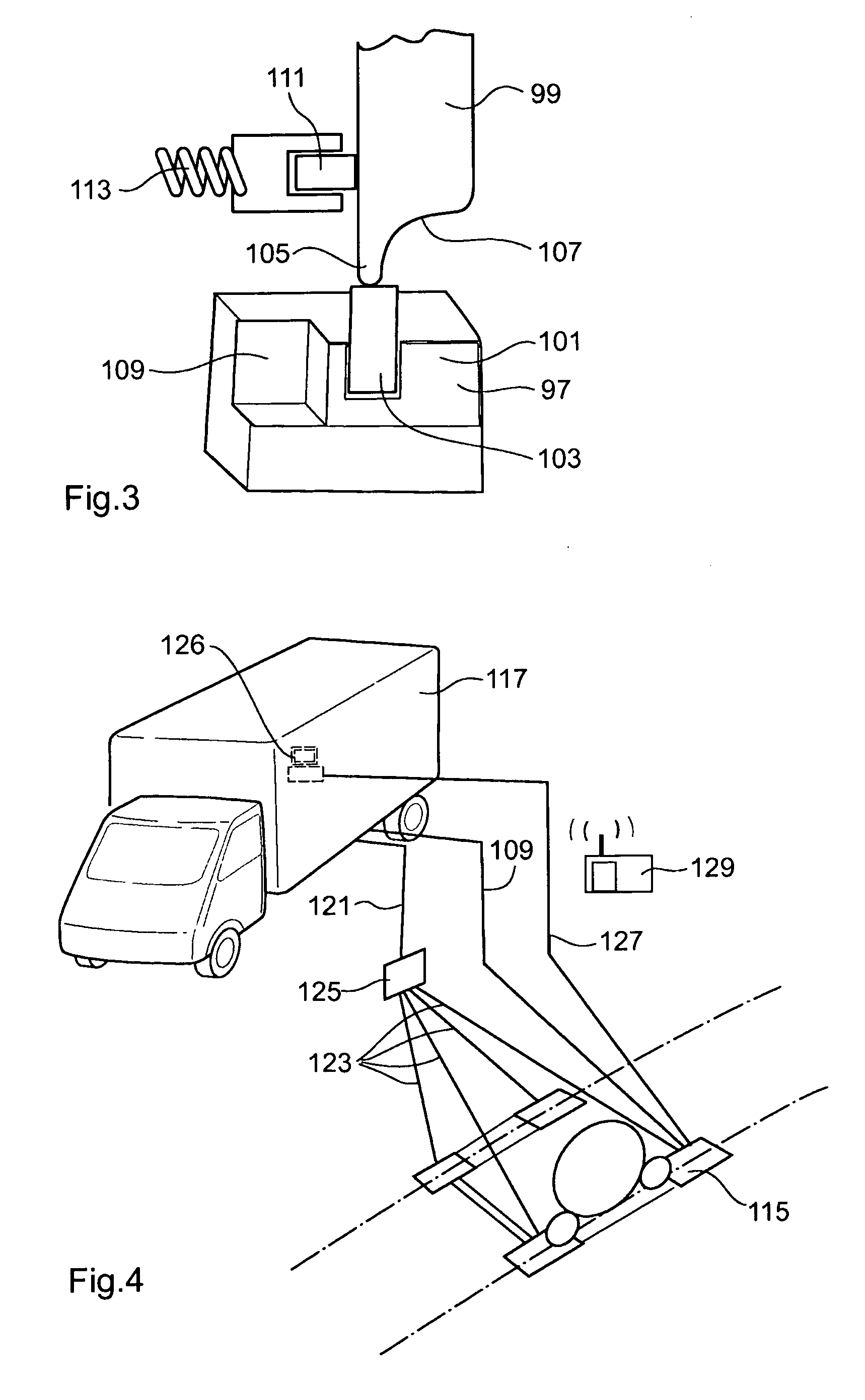

Device for lifting at least one wheel of a railbound vehicle

InactiveUS20100154606A1Raise the possibilityAvailable spaceLathesWheel-rims surveying/measuringMechanical engineering

Owner:EUROMAINT AB

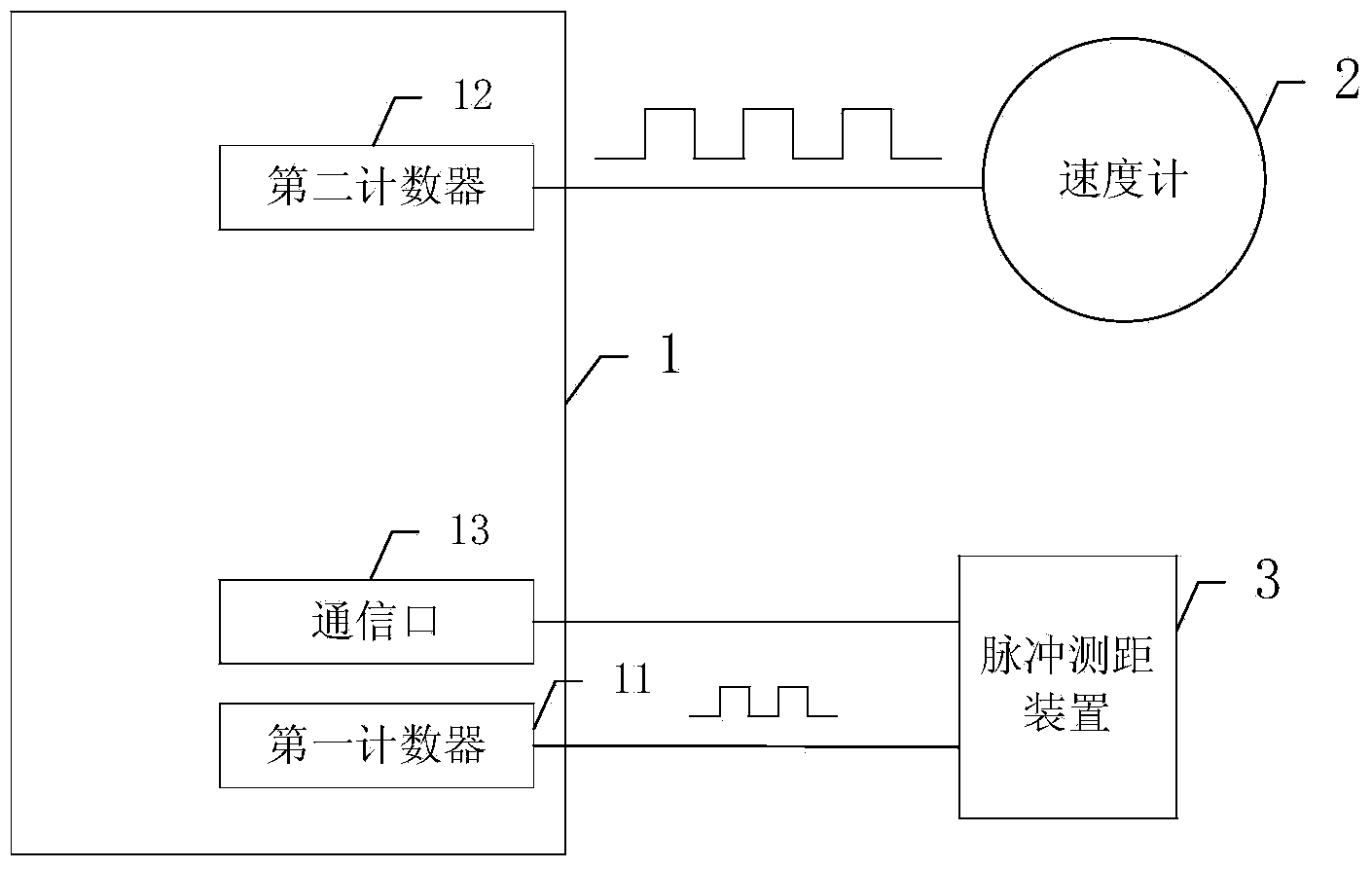

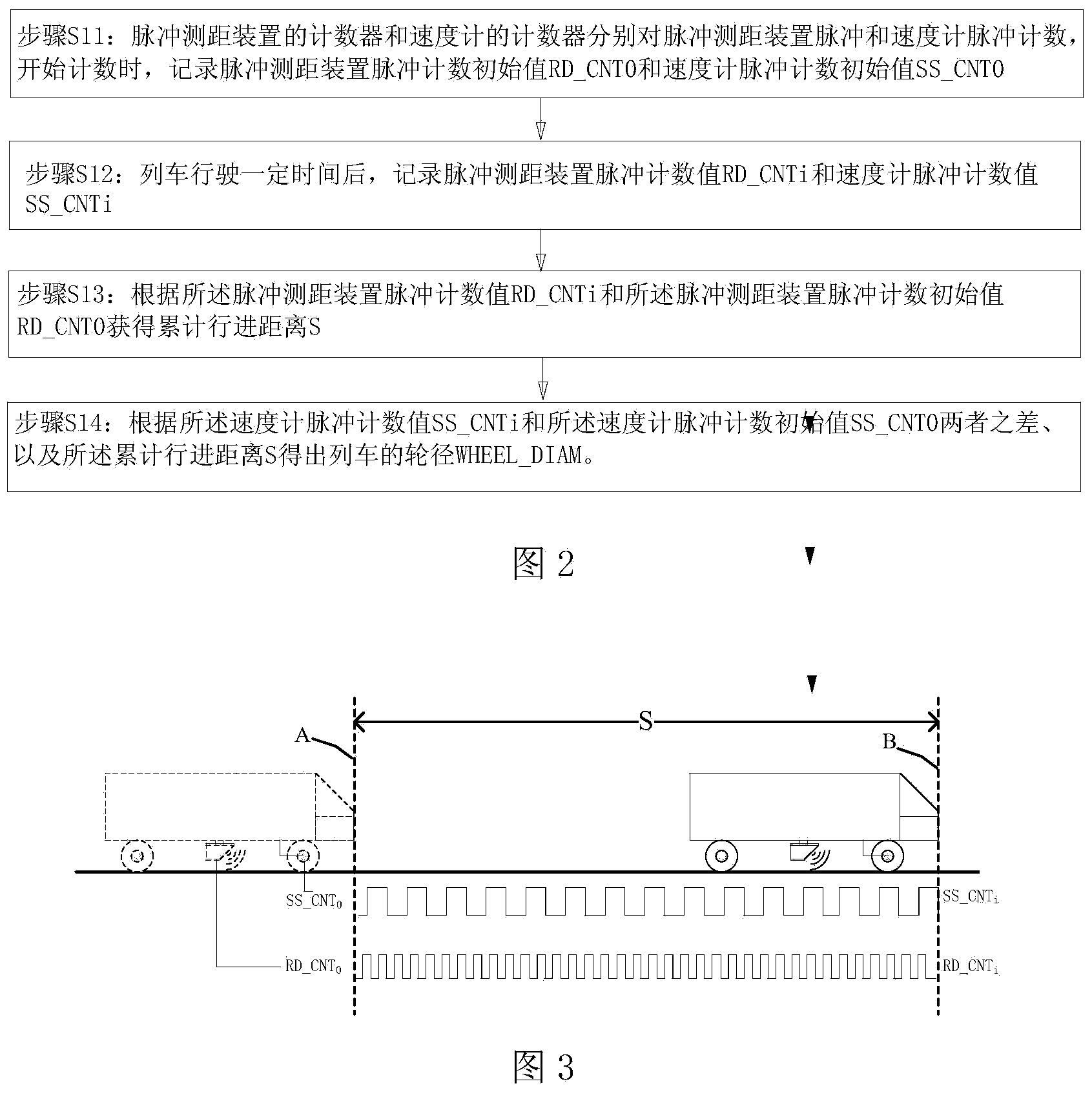

Method and system for calibrating train wheel diameter

ActiveCN103754236AOvercoming difficult and costly problemsIncrease flexibilityWheel-rims surveying/measuringWheel sizingPulse counting

The invention discloses a method and system for calibrating the train wheel diameter. The method comprises the following steps that firstly, a counter of a pulse distance measuring device and a counter of a speedometer are used for counting pulses of the pulse distance measuring device and pulses of the speedometer respectively, and when the counting is started, the pulse counting initial value of the pulse distance measuring device and the pulse counting initial value of the speedometer are recorded at the same time; secondly, after a train is driven for certain time, the pulse counting value of the pulse distance measuring device and the pulse counting value of the speedometer are recorded at the same time; thirdly, the train accumulation advancing distance is obtained according to the pulse counting value of the pulse distance measuring device and the pulse counting initial value of the speedometer; fourthly, the wheel diameter of the train is obtained according to the difference between the pulse counting value of the speedometer and the pulse counting initial value of the speedometer and the train accumulation advancing distance. Wheel diameter calibration can be carried out at any time in the driving process of the train, and the precision of wheel diameter calibration is improved.

Owner:浙江众合科技股份有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com