On-line detection method and device for thread defect of vehicle wheel set

A detection method and technology of detection device, which are applied in the direction of measurement device, rim measurement/measurement, radio wave measurement system, etc., can solve the problems of automatic defect detection method, difficulty in long-term tracking and recording of train wheel tread parameters, etc. maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

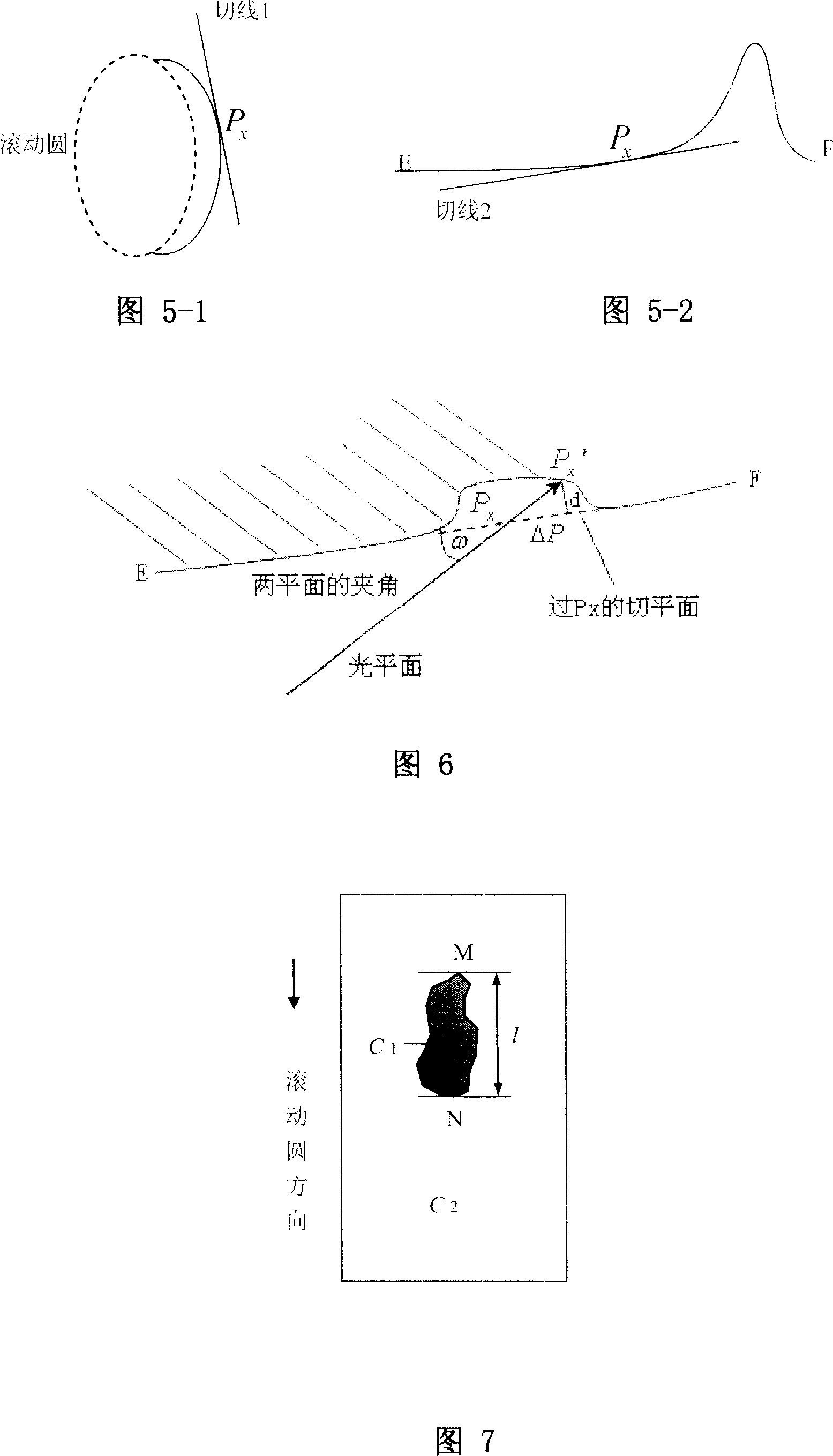

[0030] Before the tread defect detection system, the size profile parameters of the wheel set tread must be detected online in advance by another detection device, and the size parameters of each wheel set tread are used as known conditions for defect detection.

[0031] The wheel tread is the contact part between the left and right wheels and the rail. Tread defects include two parameters of tread scuffing and tread peeling, which are measured by scratch depth and peeling length along the rolling circle direction of the wheel respectively.

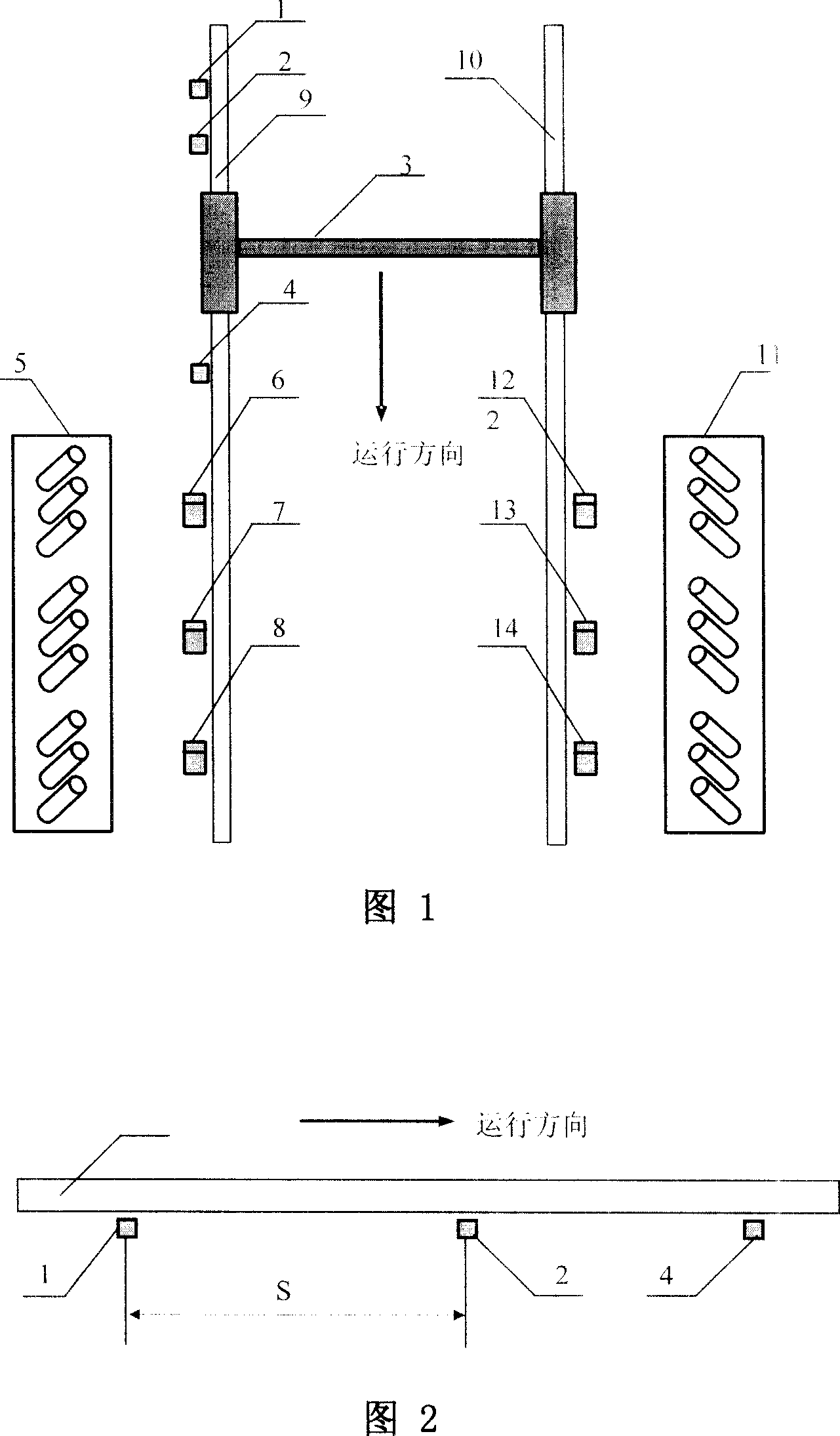

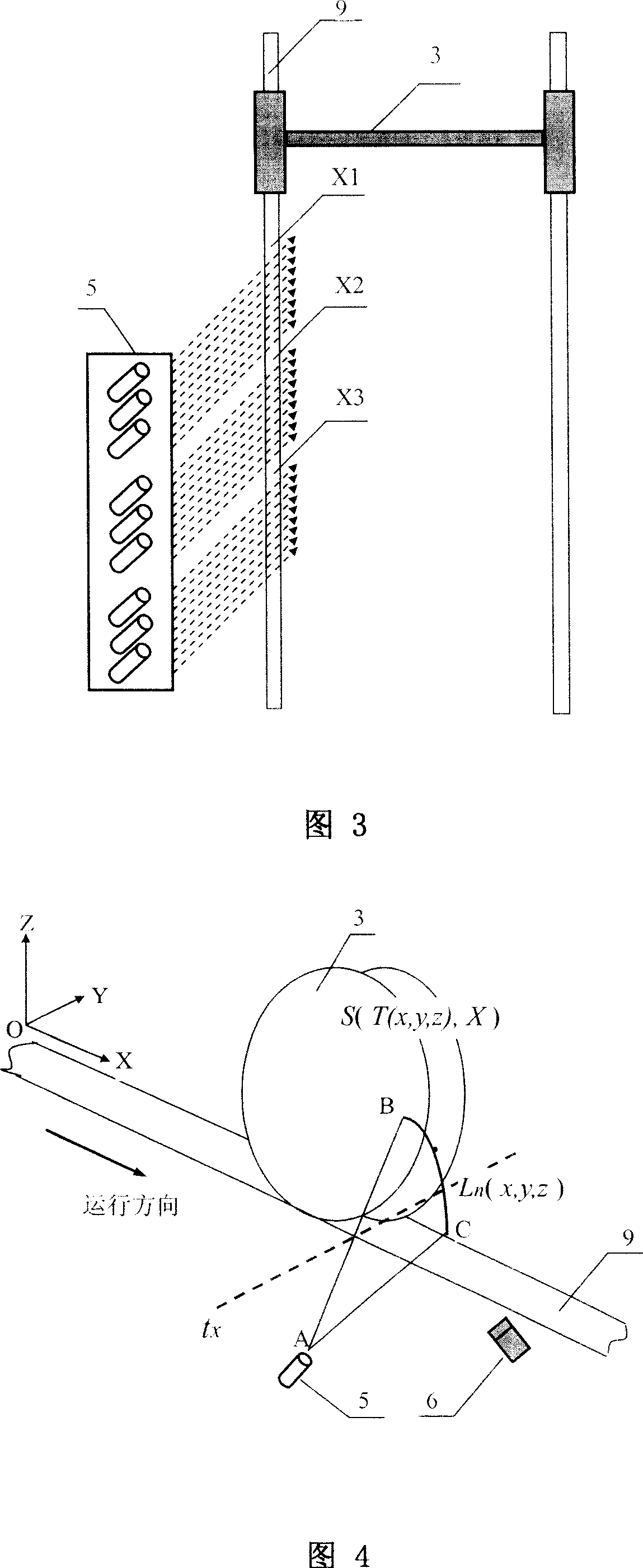

[0032] Figure 1 is a schematic diagram of the overall configuration of the detection device. Two speed measuring position sensors 1 and 2 are arranged in sequence along one side of the track close to the position of the track, and one trigger position sensor 4 . The structured light source 5 and the line array cameras 6, 7 and 8 form a set of image acquisition devices, which are distributed on the outside of the straight track 9 . The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com