Construction method for enabling cable to pass through barrier

A construction method and obstacle technology, applied in cable laying equipment and other directions, can solve the problems of reducing insulation, waterproof performance, cable plastic deformation, and breaking, and save construction time, reduce friction resistance, and prevent excessive resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

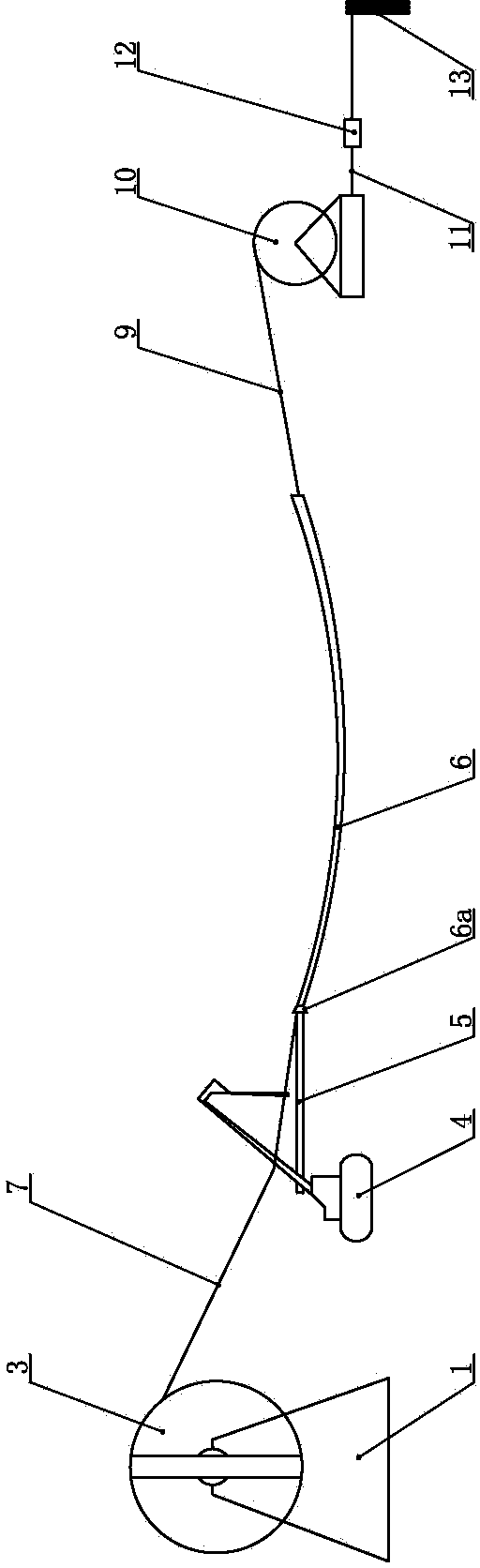

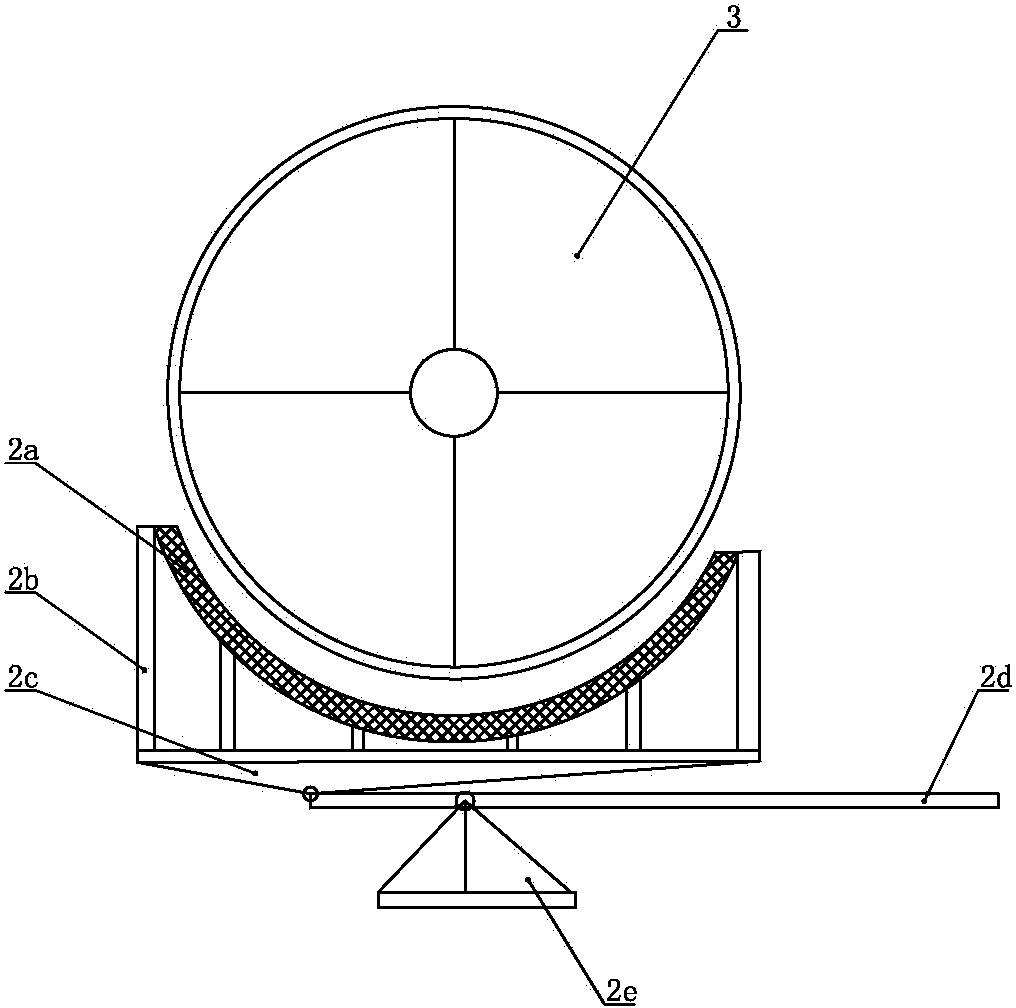

[0027] The construction method of cable crossing obstacle of the present invention, comprises the following steps successively:

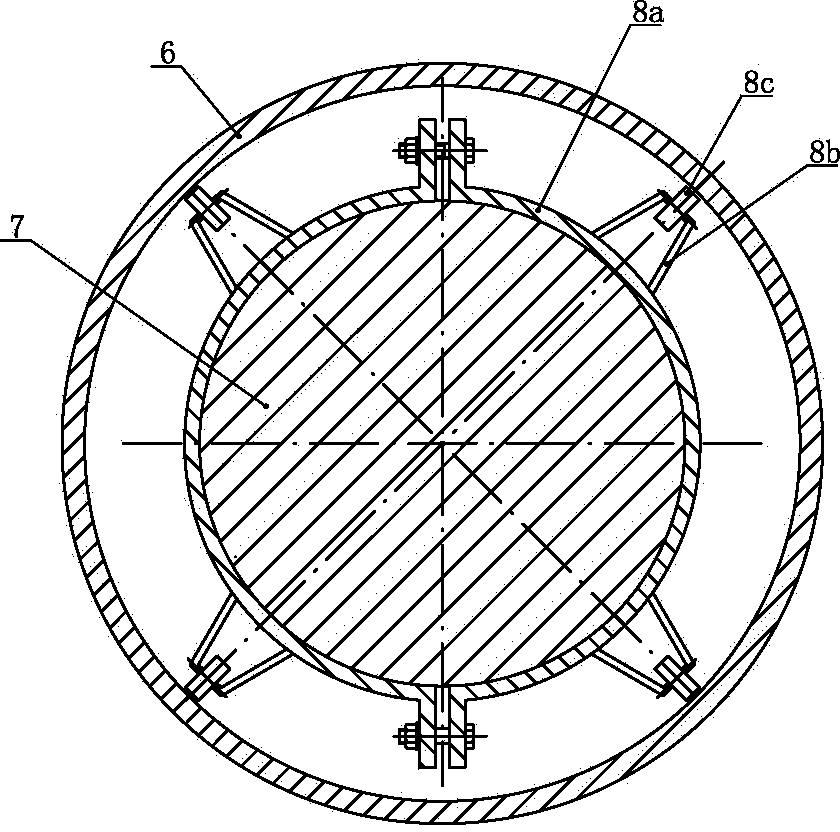

[0028] (1) Determine the coordinates of the entry point and exit point of the cable through the pipe hole and the entry and exit angle α to obtain the total length of the cable sleeve 6. The inner diameter of the cable sleeve 6 is 1.5 to 2 times the outer diameter of the cable.

[0029] ⑵ Prefabricated cable casings in sections, the casing group is pre-pierced into steel wire guide ropes during welding, and the inner wall of the casing is cleaned one by one during the prefabrication process of cable casings.

[0030] Step ⑵The cleaning of the inner wall of the casing is carried out as follows: multiple steel discs with a thickness of 8mm are used, and the centers of each steel disc are respectively connected to Φ10mm round steel at the same intervals. The outer diameter of the steel discs is less than The inner diameter of the cable sleeve 6 is 5 mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com