Patents

Literature

50 results about "Mouth repair" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

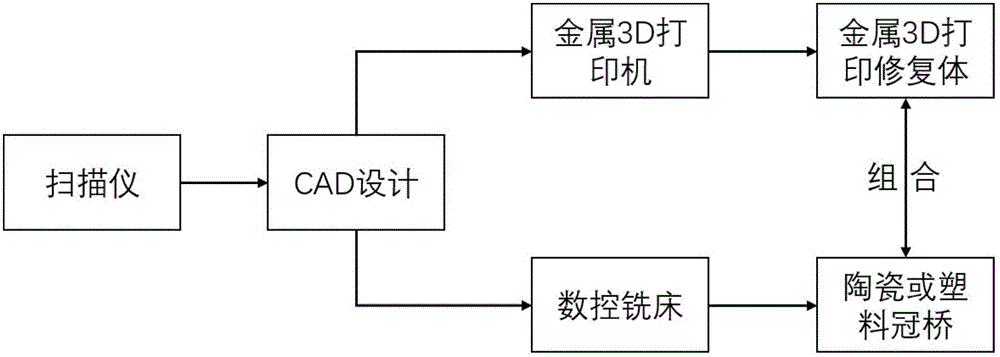

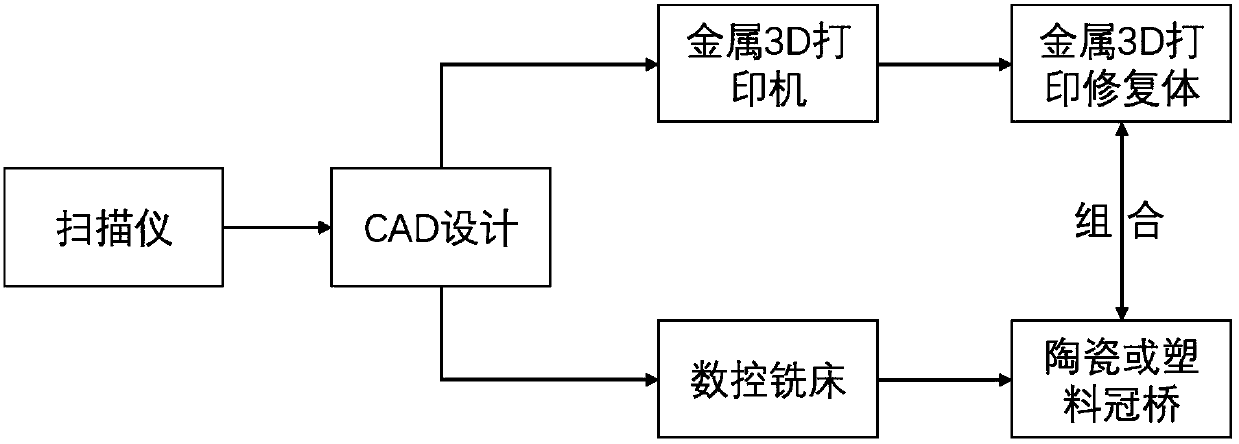

Dental prosthesis CAD/CAM/SLM-3D printing compound method

ActiveCN106264762AImprove product qualityImprove stabilityArtificial teeth3D printingNumerical controlMeasuring instrument

The invention discloses a novel dental prosthesis CAD / CAM / SLM-3D printing compound method. The method comprises the steps that a CAD / CAM / SLM-3D printing compound system which is composed of an optical scanning measuring instrument or a contact type scanning measuring instrument, computer-aided design software of a dental prosthesis, a miniaturized metal 3D printer and a numerical control milling machine is adopted to prepare a metal prosthesis, an existing dental CAD / CAM system is combined with a metal 3D printing technology, respective numerical control machining methods are organically combined, and the effect is extremely achieved. The automated production efficiency of the dental metal prosthesis, especially the complex dental metal prosthesis is greatly improved, traditional cumbersome processes for manually making a dental prosthesis are omitted, the making quality and stability of the prosthesis are improved, the purpose of rapid, accurate and personalized making is achieved, and the urgent needs of patients missing teeth are well met.

Owner:维视医疗信息科技山东有限公司

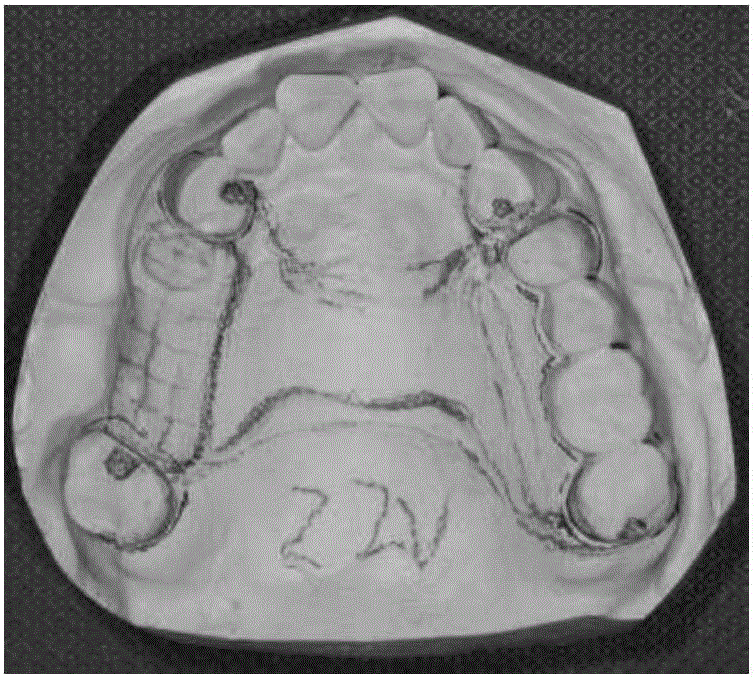

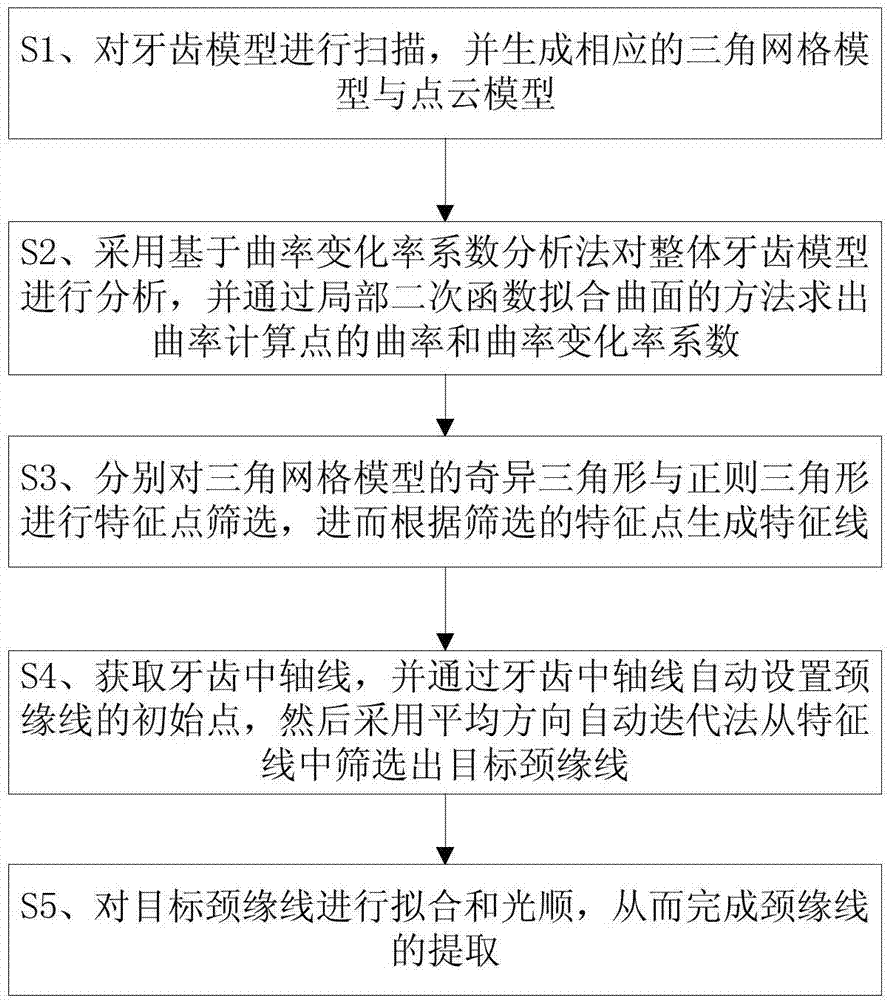

Neck-edge line extraction method based on simple crown prosthesis mesh model of false tooth

ActiveCN104504693AImprove extraction accuracySolve the problem that the neckline cannot be selected correctlyImage enhancementImage analysisLow noisePoint cloud

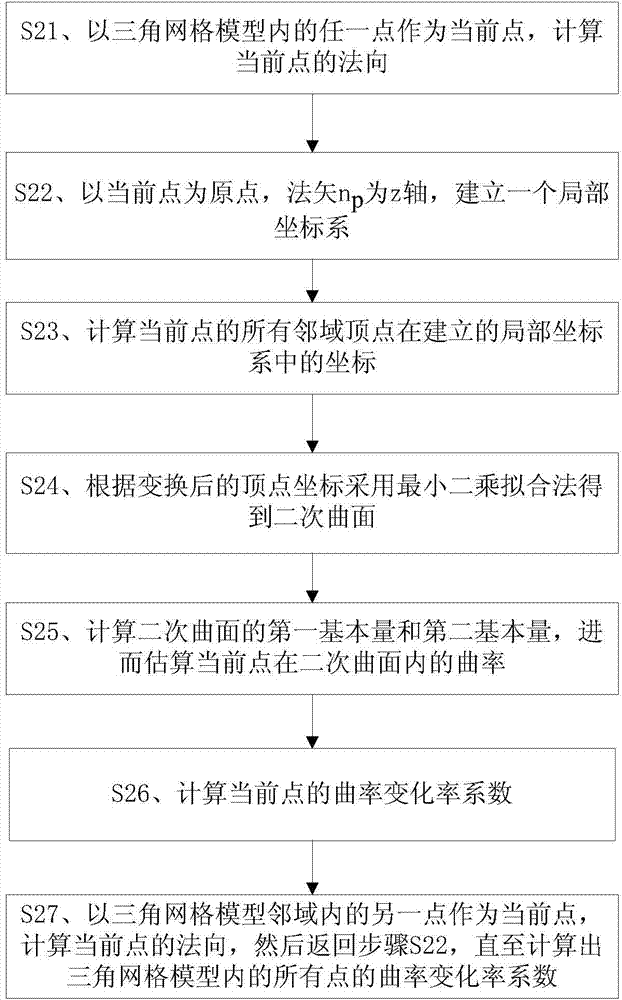

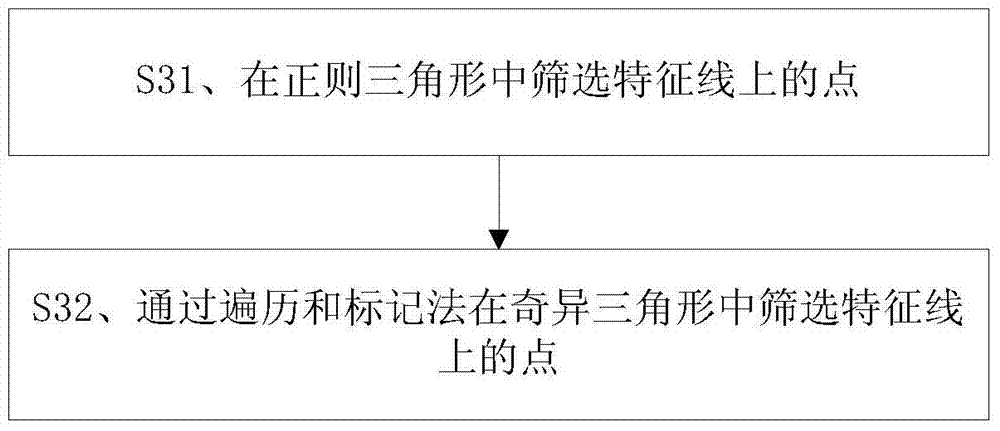

The invention discloses a neck-edge line extraction method based on a simple crown prosthesis mesh model of a false tooth. The neck-edge line extraction method comprises the following steps: scanning a tooth model, and generating a corresponding triangular mesh model and a corresponding point cloud model; analyzing the whole tooth model by adopting an analytical method based on curvature change rate coefficients, and determining the curvature of curvature calculation points and the curvature change rate coefficients through a local quadratic function fitting surface method; carrying out feature point screening on irregular-shaped triangles and regular triangles of the triangular mesh model respectively, and then generating feature lines according to the screened feature points; obtaining a tooth axle wire, automatically setting the initial points of neck-edge lines through the tooth axle wire, and then screening out a target neck-edge line from the feature lines by adopting an automatic iteration method in a mean direction; carrying out fitting and smoothening on the target neck-edge line so as to complete the extraction of the neck-edge line. The neck-edge line extraction method has the advantages of high extraction precision, reliability, high degree of intellectualization and low noise, and can be widely applied to the field of dental prosthesis.

Owner:FOSHAN NUOWEI TECH

Absorbable oral cavity restoration membrane and preparation method thereof

ActiveCN109513046AEffectively guide growthHave clinical valueNon-woven fabricsProsthesisTissue repairElectrospinning

The invention discloses an oral cavity restoration membrane and a preparation method thereof. The oral cavity restoration membrane uses gelatin and polycaprolactone as raw materials, which are subjected to a static spinning process respectively for obtaining a membrane formed by nanometer stage fiber; the lamination is performed in sequence of a gelatin layer, a polycaprolactone layer and a gelatin layer to obtain the three-layer structure oral cavity restoration membrane with the gradually changed fiber diameter. The preparation method of the oral cavity restoration membrane comprises the following steps of preparing a gelatin solution, preparing a gelatin membrane, drying the gelatin membrane, preparing a polycaprolactone solution, preparing a polycaprolactone membrane, drying the polycaprolactone membrane, laminating the gelatin fiber membrane and the polycaprolactone fiber membrane, and performing cutting, inner packaging, sterilization and outer packaging. The method has the advantages that the keratinized gum growth can be effectively guided; the restoration time is shortened; the membrane is applied to the oral cavity and maxillofacial soft tissue restoration in a wider range.

Owner:NEO MODULUS SUZHOU MEDICAL SCI TECH CO LTD

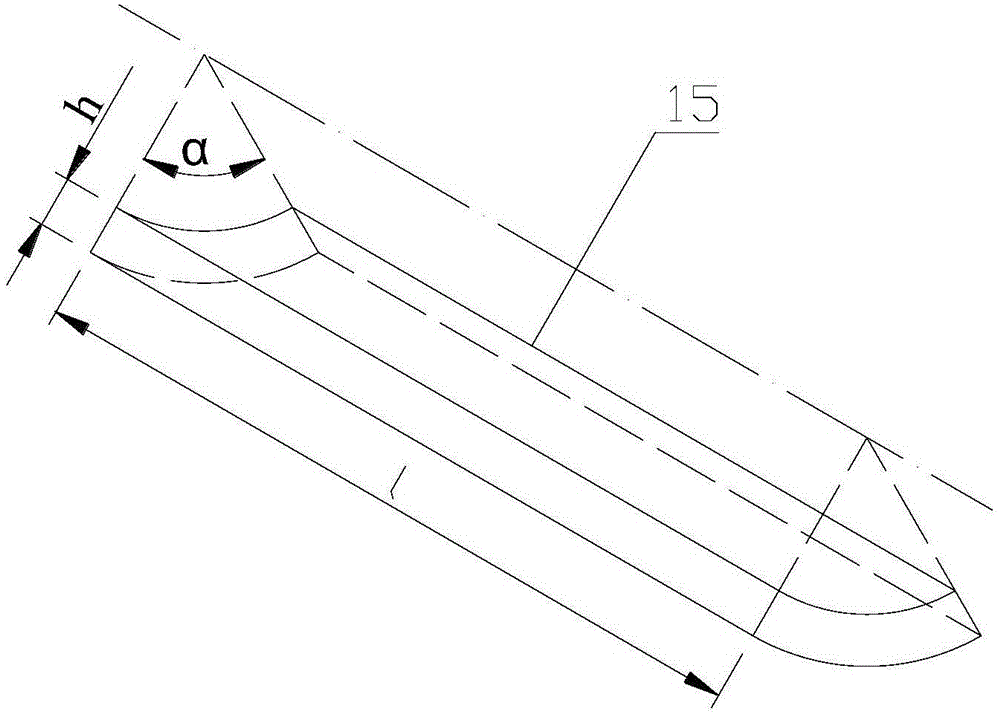

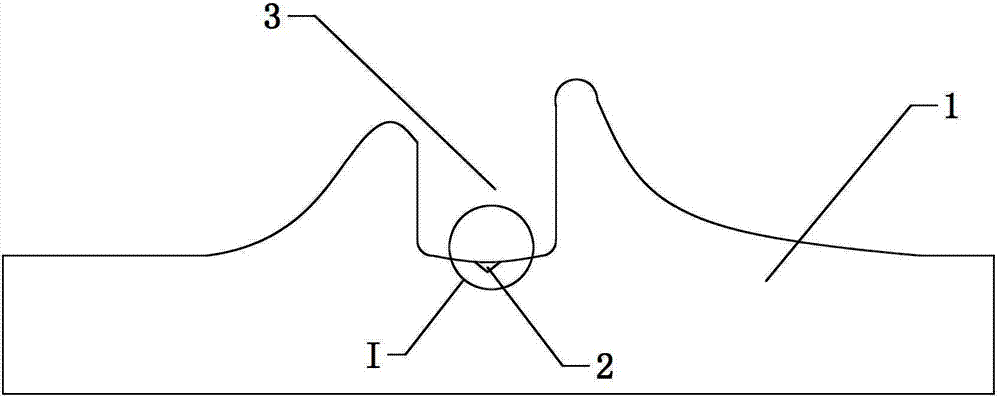

Construction method for enabling cable to pass through barrier

ActiveCN104332903AReduce tensionGuaranteed to be scientificApparatus for laying cablesPull forceRolling resistance

The invention relates to a construction method for enabling a cable to pass through a barrier. The construction method for enabling the cable to pass through the barrier sequentially includes following steps: firstly, confirming a pipe hole path so as to obtain the total length and the specification of a cable sleeve, prefabricating the cable sleeve by sections, threading a steel wire lead rope through the cable sleeve in advance, clearing the inner wall of the cable sleeve section by section, and performing anticorrosion and mouth repairing on the cable sleeve after a qualified pressure test on the cable sleeve is completed; then, performing a simulation experiment, obtaining a slide friction coefficient of the cable sleeve, figuring out the maximum slide traction resistance, judging whether the maximum slide traction resistance is larger than permissive pull force of the cable, and if yes, installing idler wheel hoops for a second experiment so as to obtain a rolling friction coefficient of the cable sleeve, figuring out the maximum rolling traction resistance during the cable passing process, and confirming specifications of traction facilities of a main steel wire rope and the like; finally, drilling pipe holes, enabling the cable to pass through the cable sleeve, using a winching to tow the cable, using an excavator to assist in cable feeding, feeding the cable in the cable sleeve for a section after installing each batch of the idler wheel hoops until the whole cable completely passes through the cable sleeve, and performing a performance test on the cable which passes through the cable sleeve after two end mouths of the cable sleeve are blocked. The construction method for enabling the cable to pass through the barrier can substantially reduce passing resistance of the cable, and is safe and reliable.

Owner:CHINA PETROLEUM & CHEM CORP +1

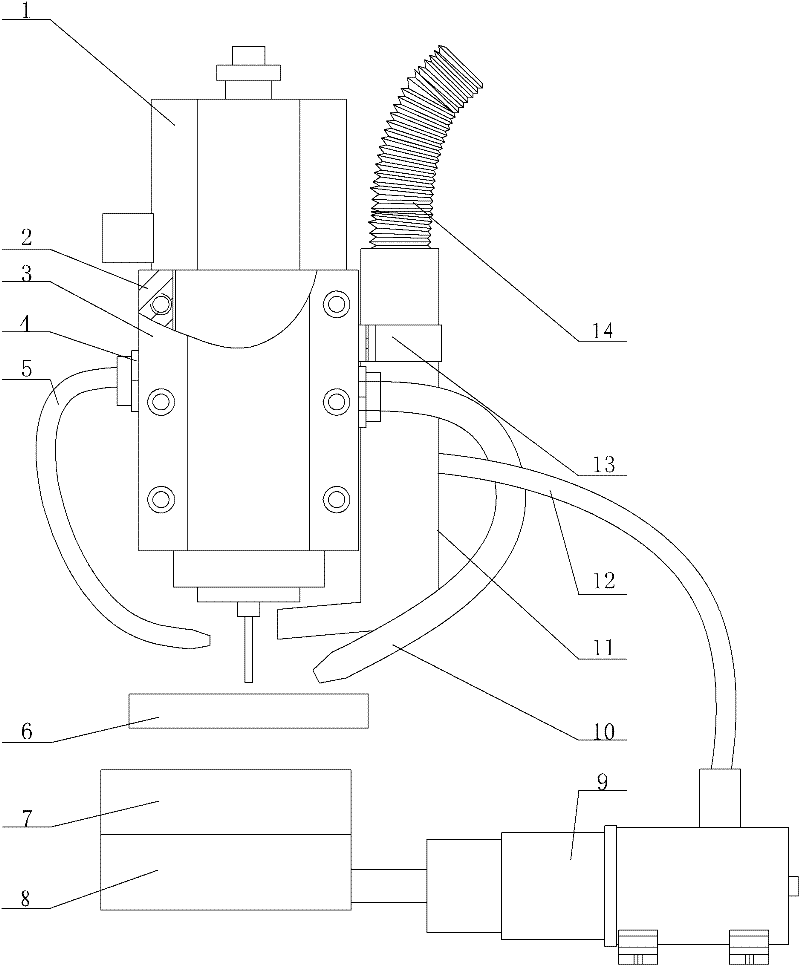

Double-cooking device of full-automatic artificial tooth engraving and milling machine

The invention belongs to the technical field of the artificial tooth processing of the dental restoration industry, and particularly relates to a double-cooking device of full-automatic artificial tooth engraving and milling machine, which comprises an electric spindle, and an inner clamping sleeve and an outer clamping sleeve which are used for fixing the electric spindle, wherein a joint and a support are respectively arranged on the side wall of the inner clamping sleeve, the joint is respectively connected with an air blowpipe and a cooling water pipe, a dust suction pipe is installed on the support, an air pipe is arranged at the top end of the dust suction pipe, a filter screen is arranged below the electric spindle, a water tank is arranged at the bottom of the filter screen, and is connected with a water circulating pump, a water pipe is arranged on the water circulating pump, the rear end of the water pipe is connected with the cooling water pipe. The invention has the beneficial effects that: the double-cooking device has a simple structure, is convenient to use, and can select the appropriate cooling mode according to different processing materials, and the working quality and efficiency are improved.

Owner:SHINVA MEDICAL INSTR CO LTD

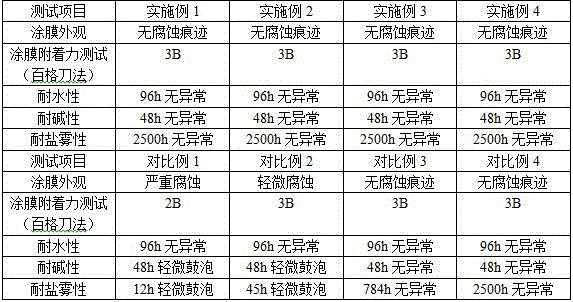

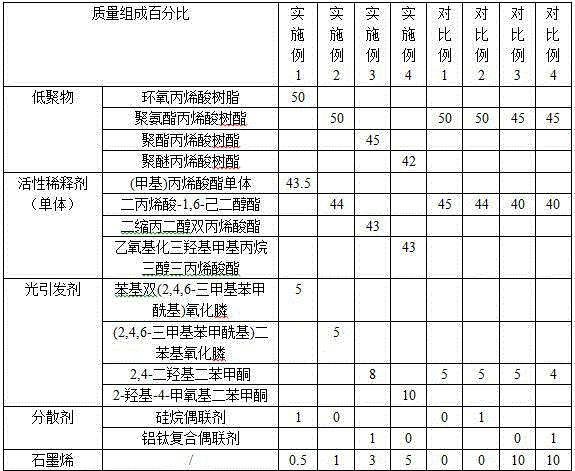

Photocuring joint coating provided with graphene filler and preparing method thereof

ActiveCN105176326AFast curingIncrease productivityAnti-corrosive paintsPolyurea/polyurethane coatingsMouth repairReactive diluent

The invention relates to an anti-corrosive coating for metal, in particular to a photocuring joint coating provided with graphene filler and a preparing method thereof. The photocuring pipeline joint coating is composed of a low polymer, a reactive diluents (monomer), a photoinitiator, a dispersing agent and graphene, wherein graphene is evenly dispersed in the photocuring joint coating and accounts for 0.5-5% of the total mass of the composite coating. The photocuring joint coating has the advantages of being high in curing speed, high in production efficiency, free of volatile solvent, safe, free of pollution, low in energy consumption, high in tenacity, high in adhesive force, high in water resistance, high in hardness, excellent in corrosion resistance and the like and can be used for mouth repairing and mending during pipeline site operation, corrosion resistance of oil gas conveying pipelines and the like.

Owner:泉州职业技术大学

Ceramic material used for mouth rehabilitation and preparation method thereof

InactiveCN105906334AImprove the lack of brittleness and brittlenessImprove clinical successImpression capsDentistry preparationsNano al2o3Rare earth

The invention discloses a ceramic material used for mouth rehabilitation. The ceramic material is prepared from the following components in parts by weight: zirconia, nanometer aluminum oxide, niobium pentoxide, rare earth oxide, rectorite, molybdenum boride, aluminium borate, calcium-magnesium silicate whisker and fluorapatite. The invention also discloses a preparation method of the ceramic material used for the mouth rehabilitation. The Vickers hardness of the ceramic material used for the mouth rehabilitation exceeds 21.4GPa, the bending strength of the ceramic material exceeds 963.2MPa, and the breaking tenacity of the ceramic material is higher than 16.3MPa.m1 / 2. The defect of the traditional ceramic material that the traditional ceramic material is likely to be subjected to brittle failure since the traditional ceramic material is crisp is eliminated, a clinic success rate is improved, and the ceramic material can be used as a mouth rehabilitation material and has a wide application prospect.

Owner:王泽陆

Prosthodontic material based on nanometer zirconia and alumina composite ceramic

InactiveCN110194659AAccelerated anisotropyImprove toughnessImpression capsPharmaceutical delivery mechanismMicrometerAlumina composite

The invention relates to a prosthodontic material based on a nanometer zirconia and alumina composite ceramic, wherein the prosthodontic material is prepared from the following components by weight: 10-40 parts of alumina having a particle size of less than or equal to micrometer, 6-12 parts of alumina having a particle size of more than or equal to nanometer, 20-50 parts of zirconia having a particle size of more than or equal to nanometer, and 31-52 parts of a ceramic glass having a micro-pore size of more than or equal to nanometer. The preparation method comprises: mixing the components according to a certain ratio in the presence of a certain amount of a solvent or in the absence of a solvent, carrying out mixing ball milling or sand milling on the obtained mixture, carrying out centrifugal infiltration grouting to form a billet, and sintering the dried billet at a high temperature under a high pressure to obtain the prosthodontic material based on the nanometer zirconia and alumina composite ceramic.

Owner:南京赛诺特斯材料科技有限公司

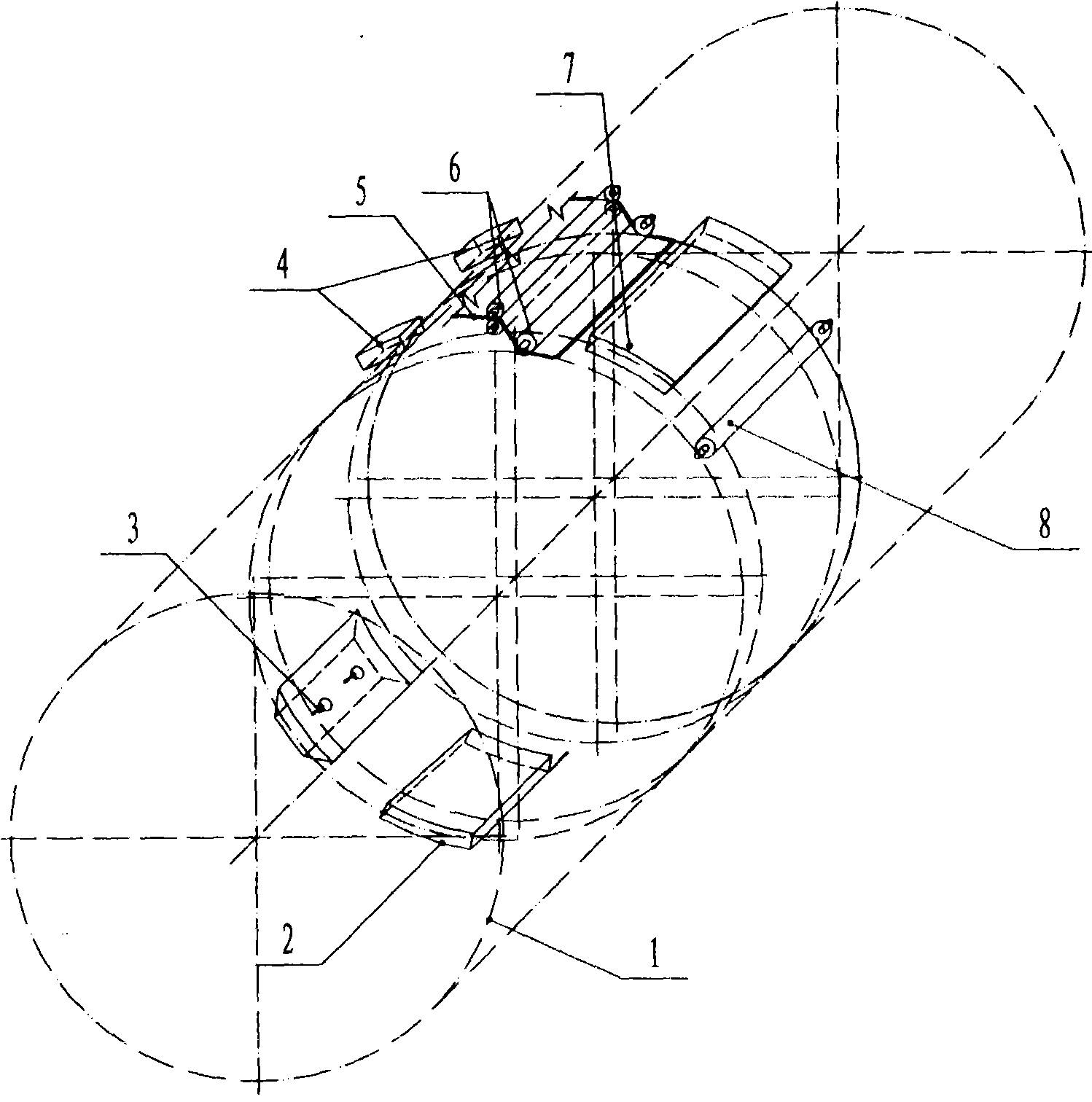

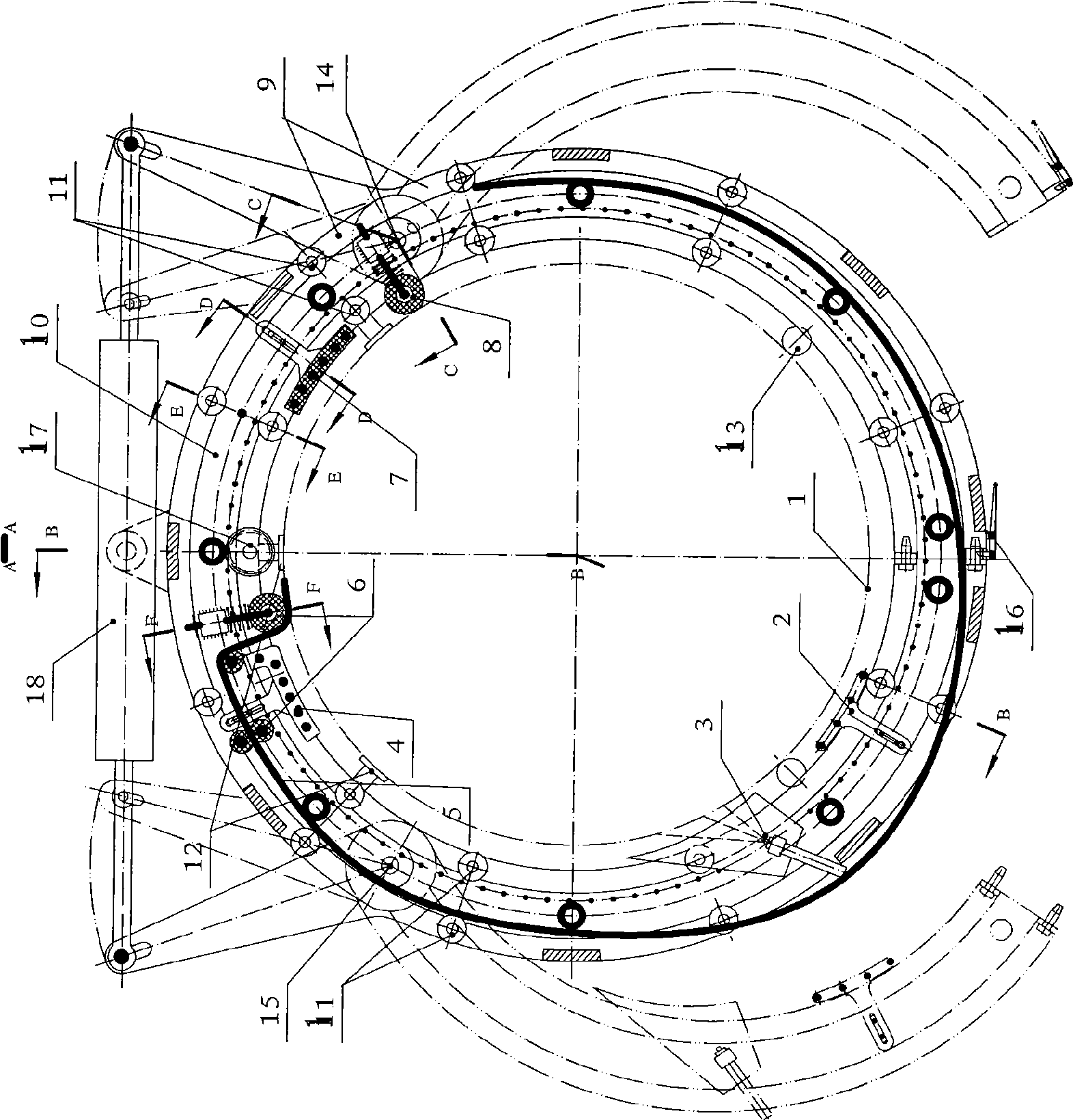

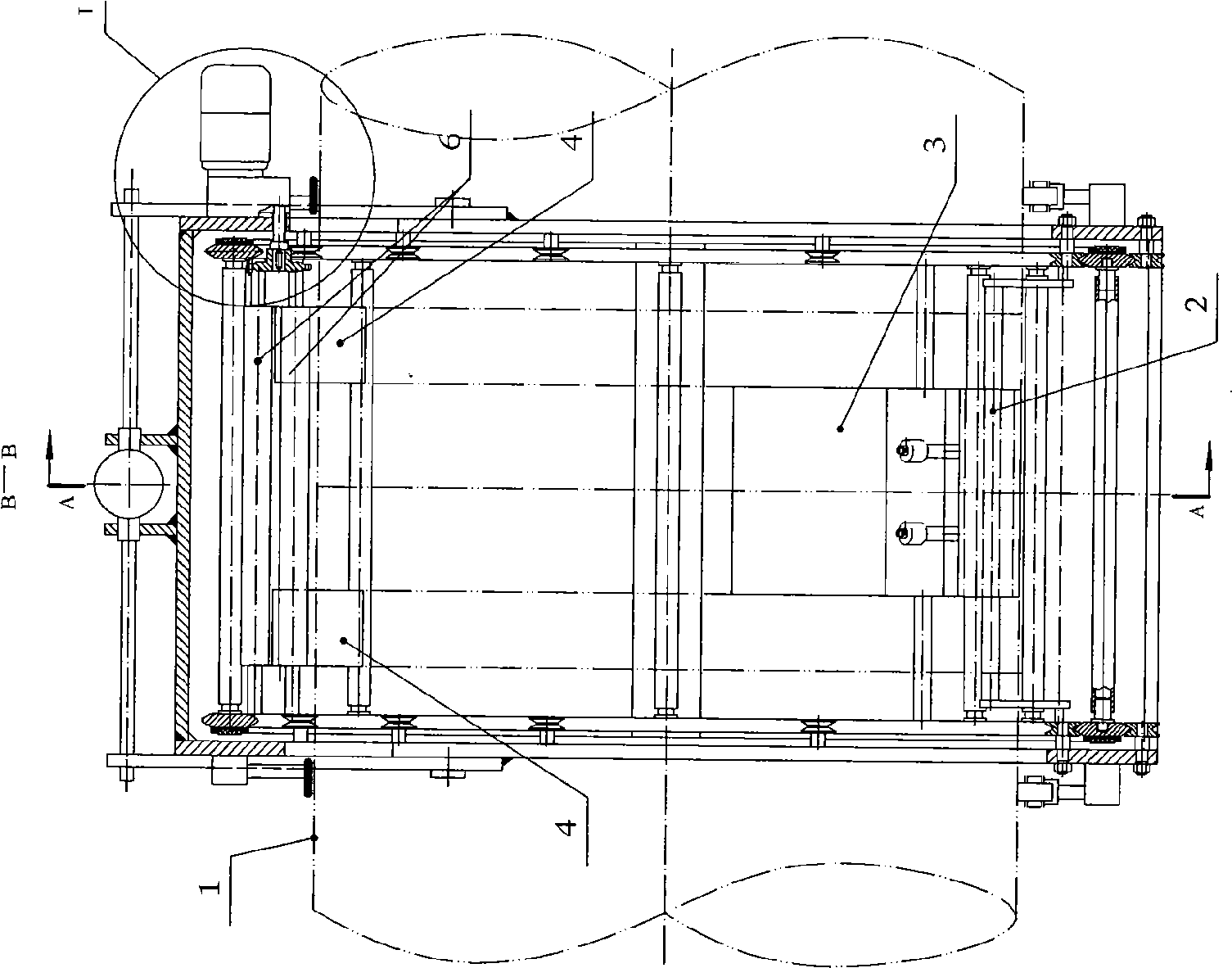

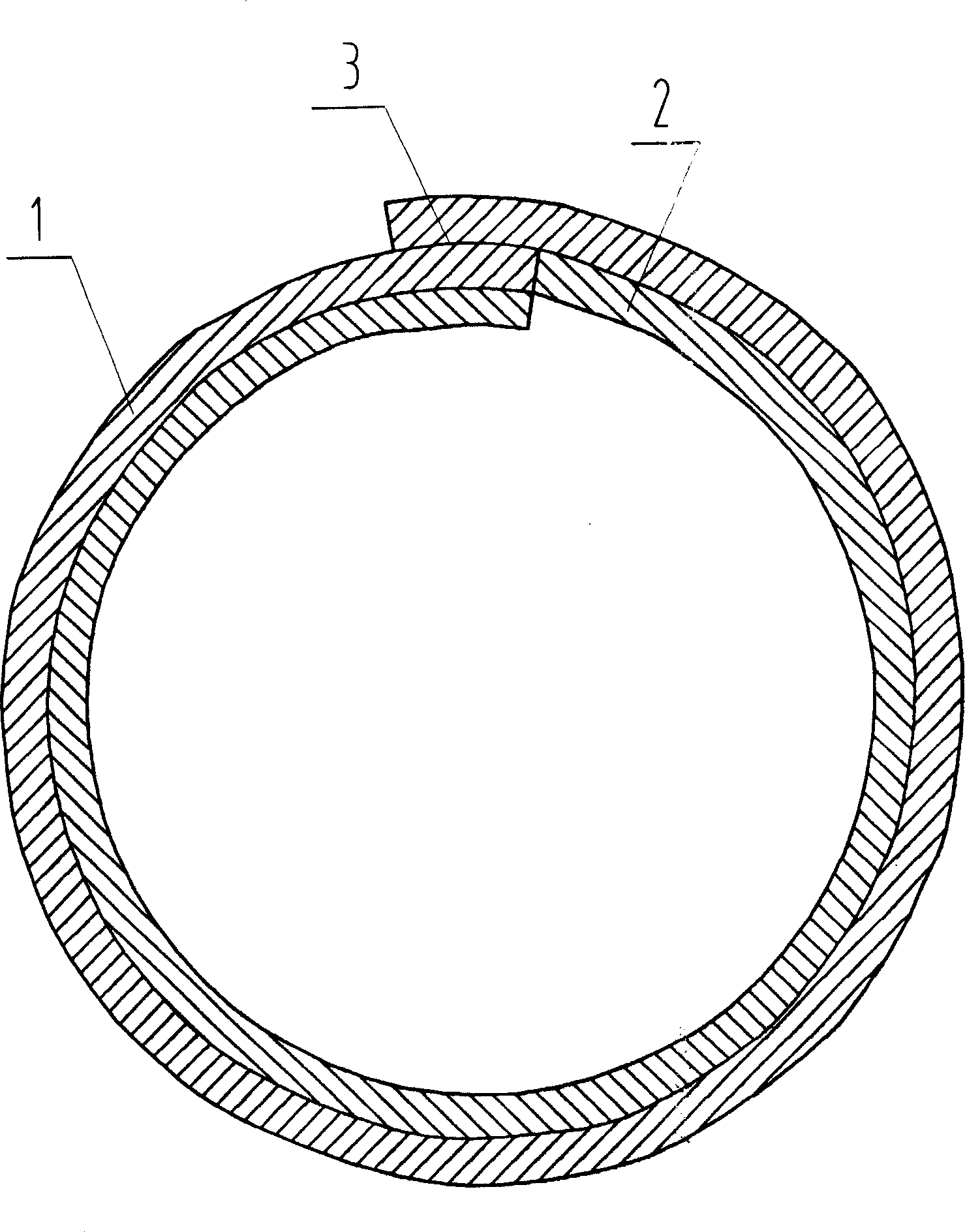

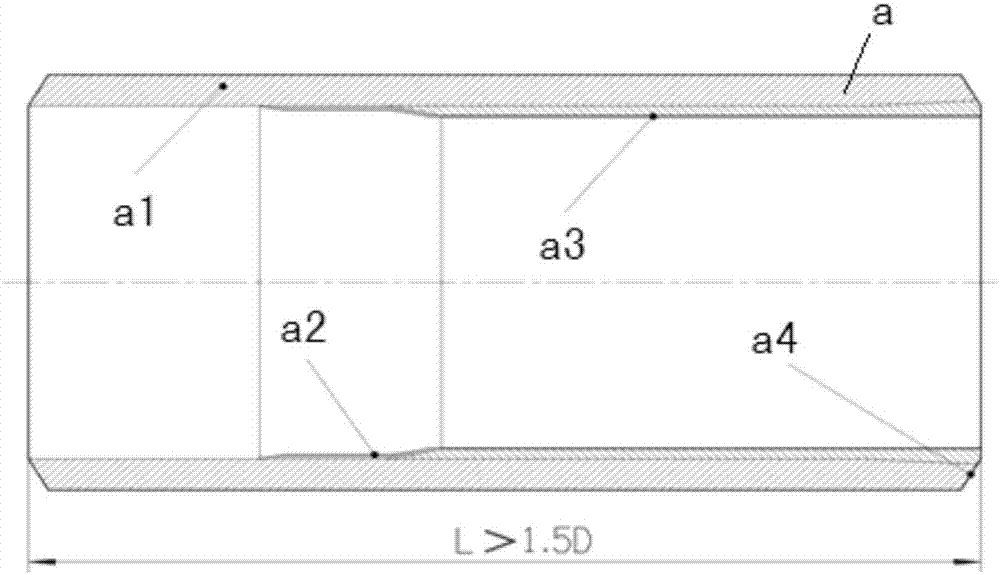

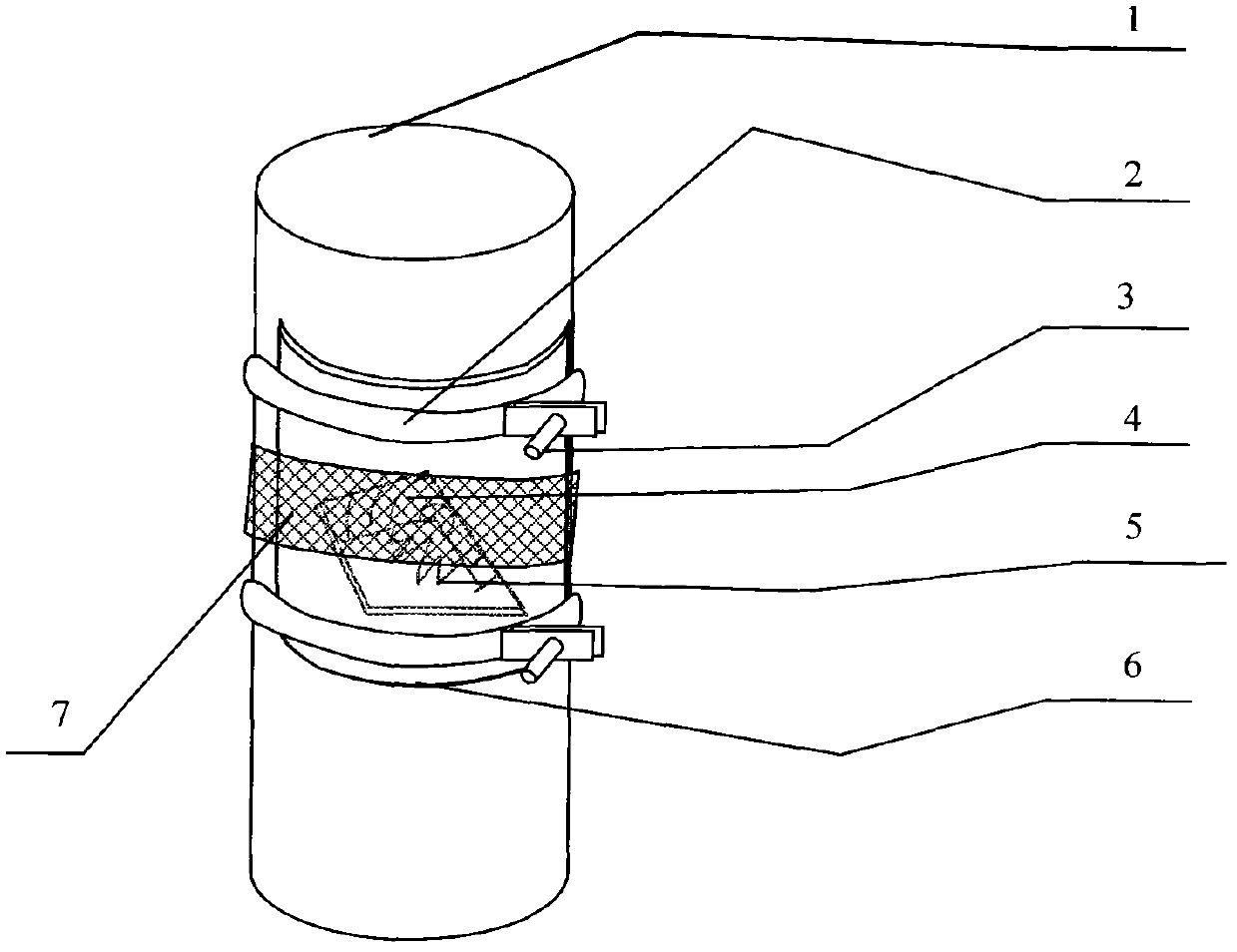

Mouth compensating method for pipeline corrosion protection layer and integrated mouth compensating machine

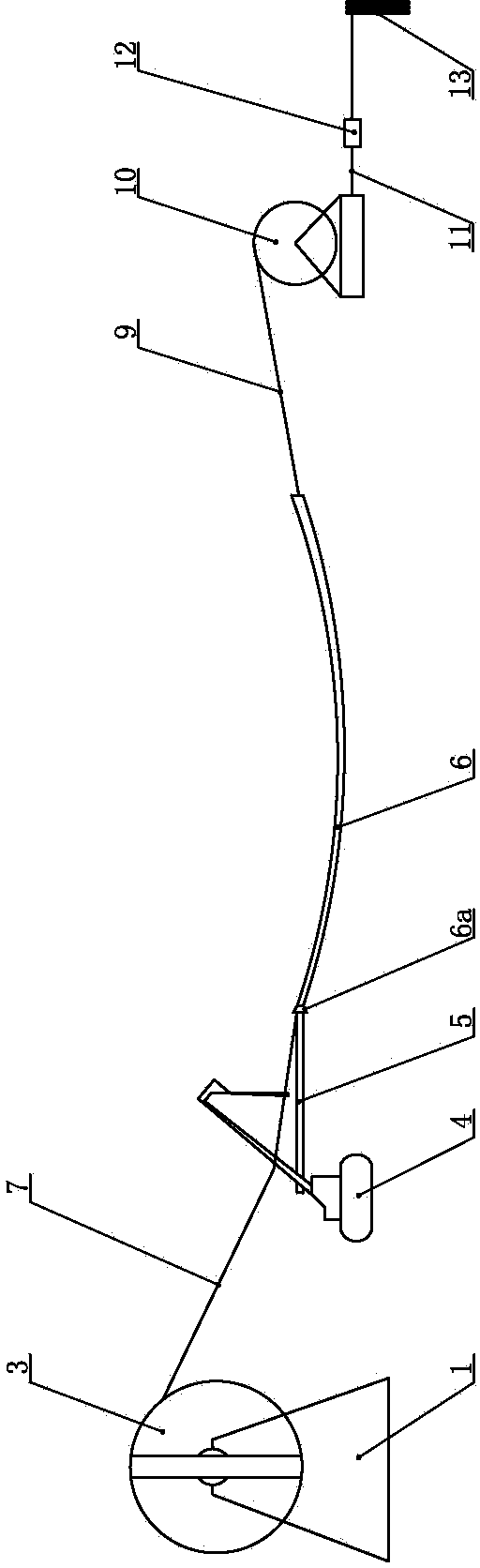

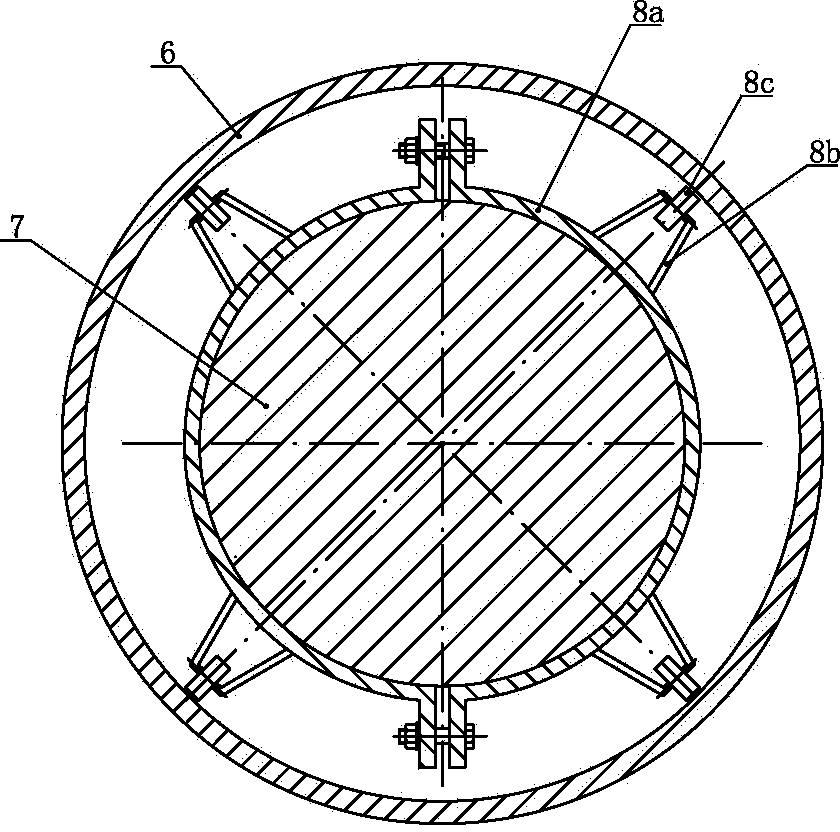

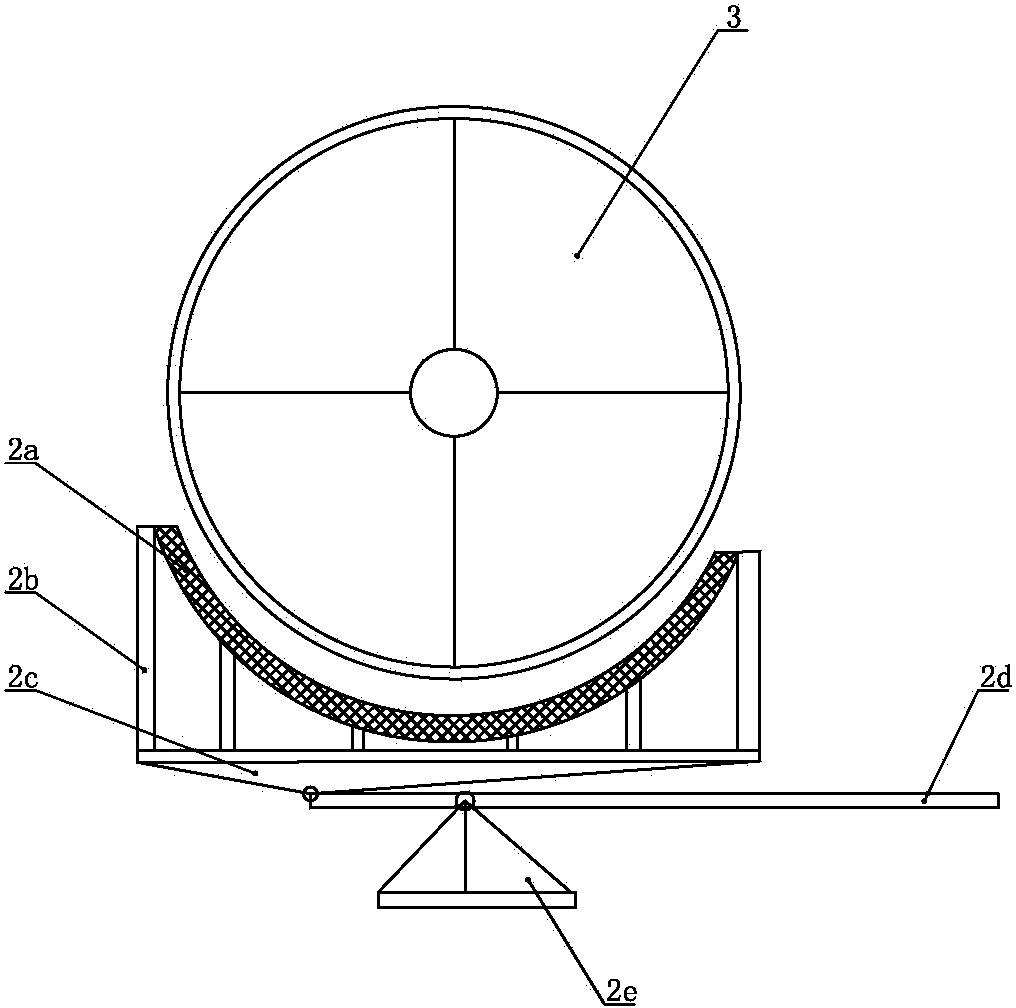

The invention relates to a mouth repairing method for continuously molding three PE repaired mouth anticorrosion layers of a pipeline and an integrated mouth repairing machine. The mouth repairing method comprises the following steps that: the outer circumference of a steel tube section along a repaired mouth is subjected to heating of a steel tube, heating of a lap, coating of primer, winding and rolling of an anticorrosion belt, heating of the repaired mouth anticorrosion layer, the rolling of the repaired mouth anticorrosion layer and other working procedures and is provided with corresponding working procedure parts thereof, so that each working procedure part continuously operates to form the three PE repaired mouth anticorrosion layers according to the sequence of the working procedures when each working procedure part rotates along the outer circumference of the steel tube. The integrated mouth repairing machine has a cirque tubular structure which can be sleeved on a pipeline and can be opened and closed; a fixed ring rack of the machine is supported and fixed on the outer circumference of the repaired mouth pipe section; a rotary ring frame rack and the fixed ring rack are in circumferential guiding connection through a circumferential guiding mechanism; working procedure parts are arranged on the circumference of the rotary ring rack according to the sequence of the working procedures; and the rotary ring rack is driven by power to rotate along the pipeline to drive each working procedure part to perform continuous rotating operation along the outer circumferenceof the pipeline.

Owner:JIANGSU JINSHENGYUAN SPECIAL VALVE

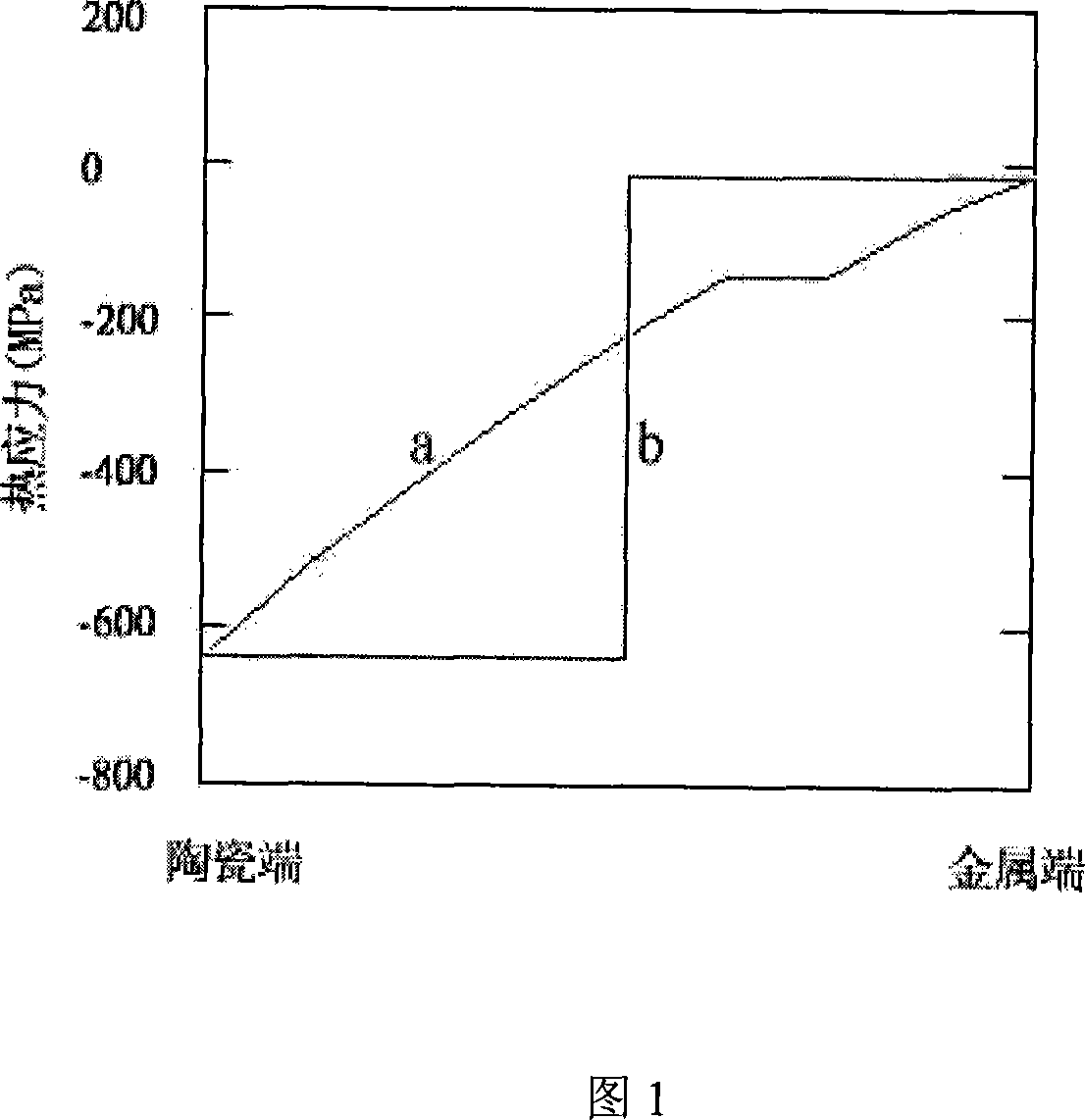

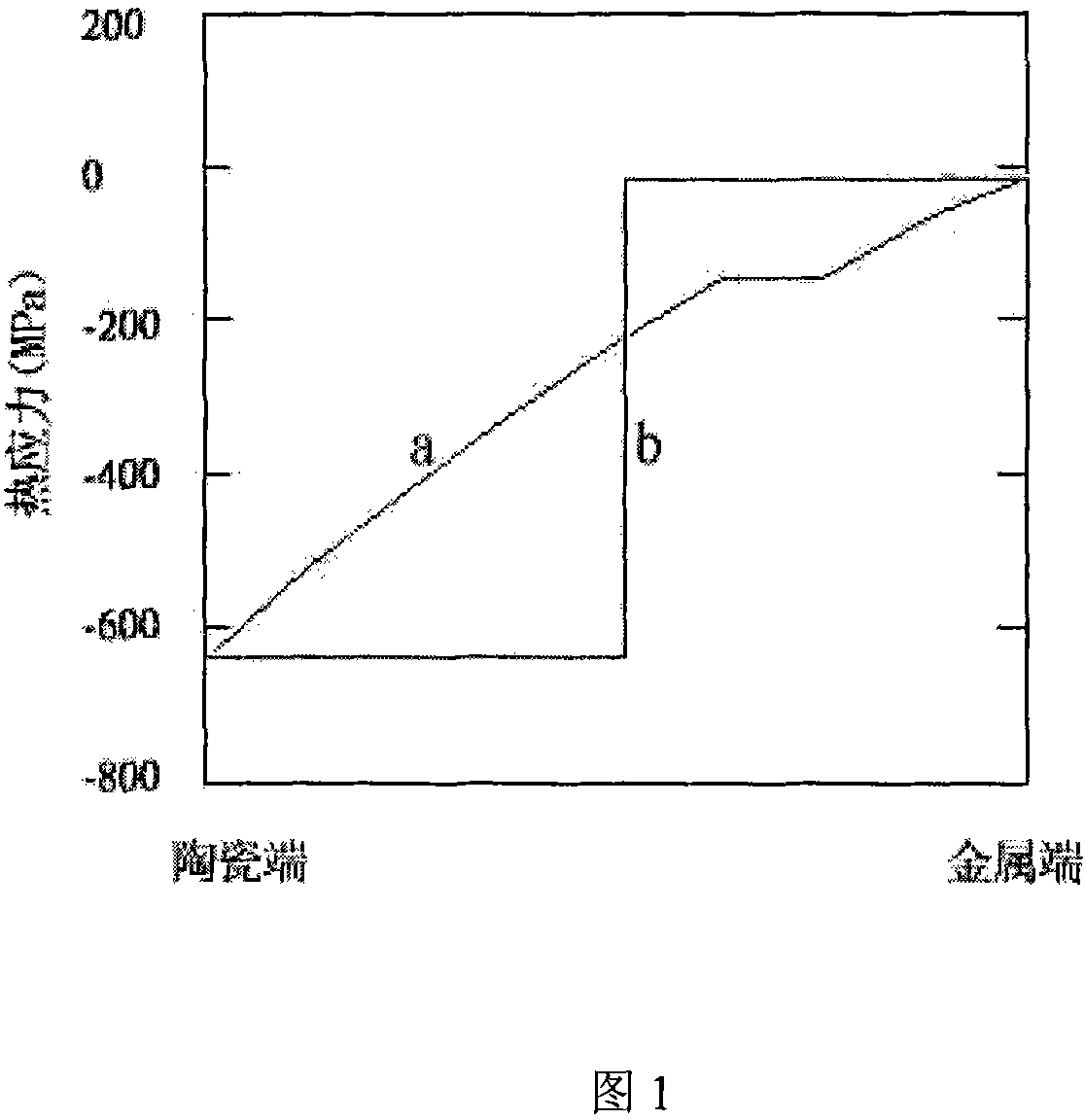

Dentistry gradient slope structure metal porcelain stuff and preparing method thereof

InactiveCN101229101AImprove performanceRelieve heat stressImpression capsDentistry preparationsLeuciteMouth repair

The invention belongs to a field of preparation and application technology of porcelain materials in mouth repairing field, in particular to a preparation method for a grads porcelain material with nickel chrome as a metal floor. A porcelain powder which takes leucite as a main crystalling phase is synthesized and the weight percentage for the components of the powder relates to 66.67 percent of SiO2, 16.57 percent of Al2O3, 12.81 percent of K2, 2.64 percent of Na2, and 0.89 percent of others. Grads adjusting components are added in the porcelain powder and the weight percentage of the components relates to 30 to 40 percent of Ni, 10 to 20 percent of Cr, 0 to 10 percent of NiO and 40 to 50 percent of Cr2O3. The porcelain powder added with the grads adjusting components is molded with a layer accumulation method and is agglomerated. The prepared component grads porcelain material is characterized by easing the heat stress between gold and porcelain and improving the intensity, and lays a foundation for the clinic application of mouth porcelain repairing.

Owner:SICHUAN UNIV

Anticorrosive heat shrink sleeve for mouth-repairing for welding engineering pipeline

InactiveCN1664431AIncrease productivityHigh degree of mechanizationCorrosion preventionPipe protection against corrosion/incrustationCrack resistanceUltrasonic welding

The invention relates to a joint engineer pipeline patch antisepsis heat-shrinking sleeve that includes outside of the base material and heat shrinking belt sheet material made up of the inner layer of hot-melt adhesive covered on the outside of the base material. The feature is that the head and the end of the heat-shrinking sleeve are connected together to form a circle, and welding the connecting place to heat shrinking sleeve by ultrasonic welding machine. By using the invention, the manufacturing efficiency, mechanization degree, and cracking resistance would be improved.

Owner:四川久远科技股份有限公司

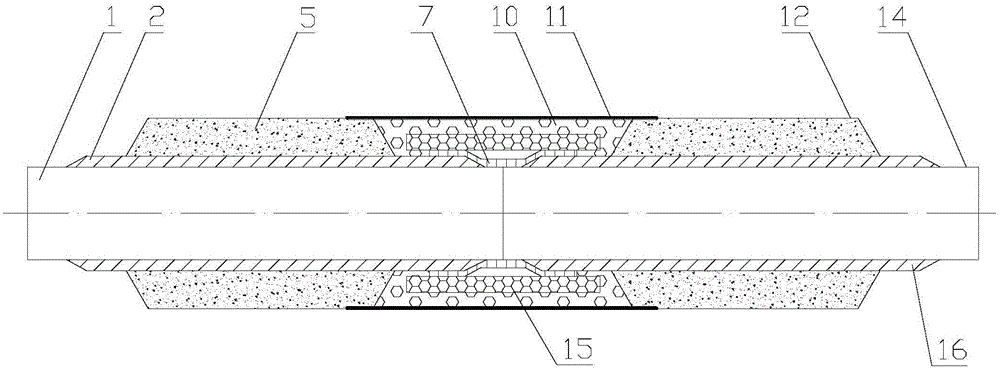

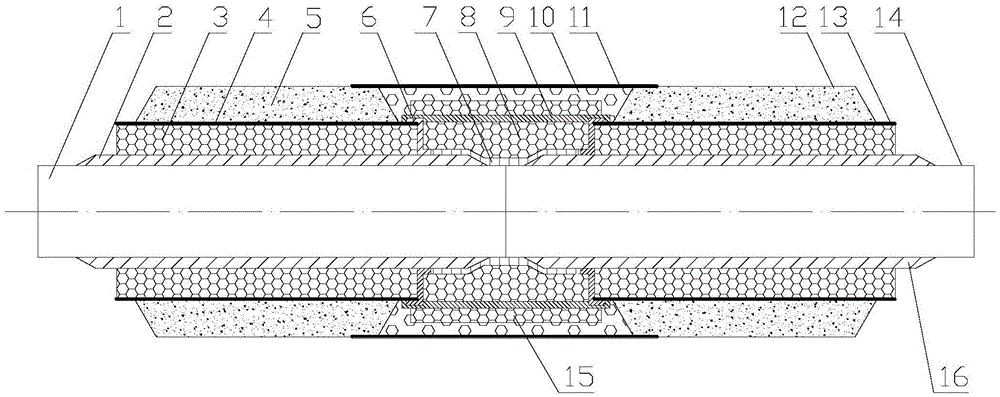

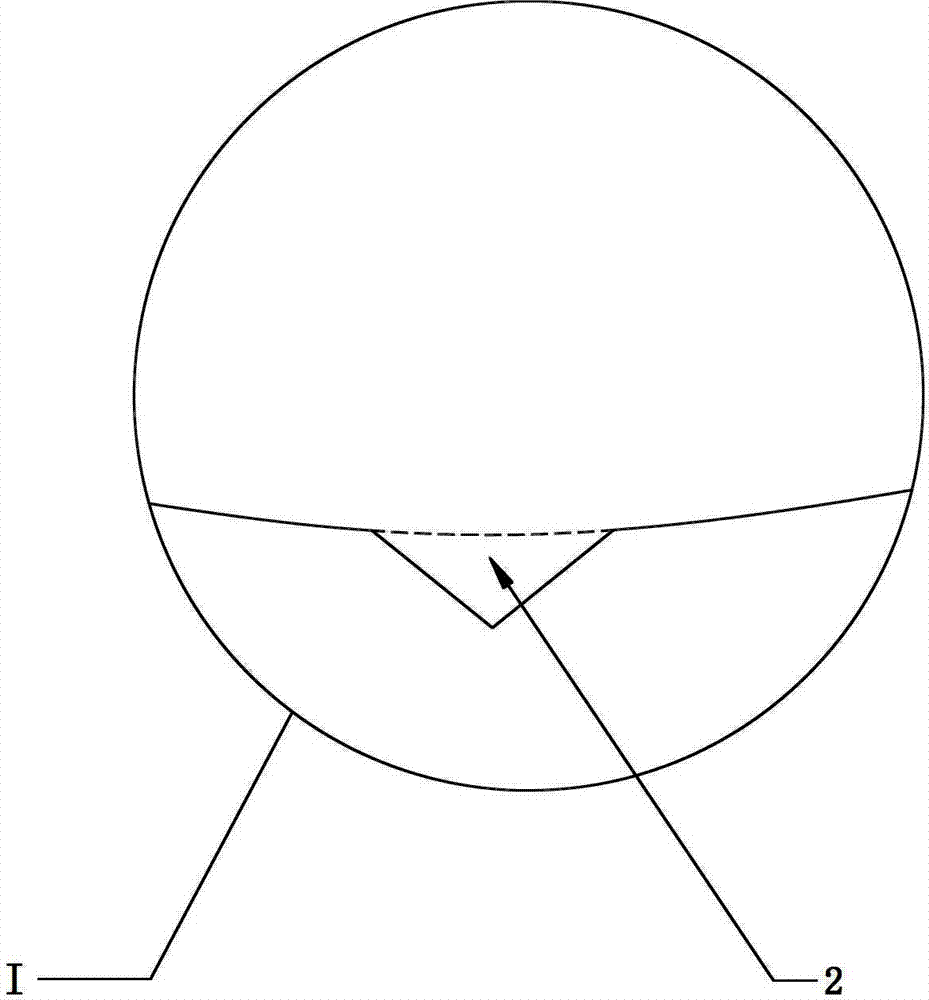

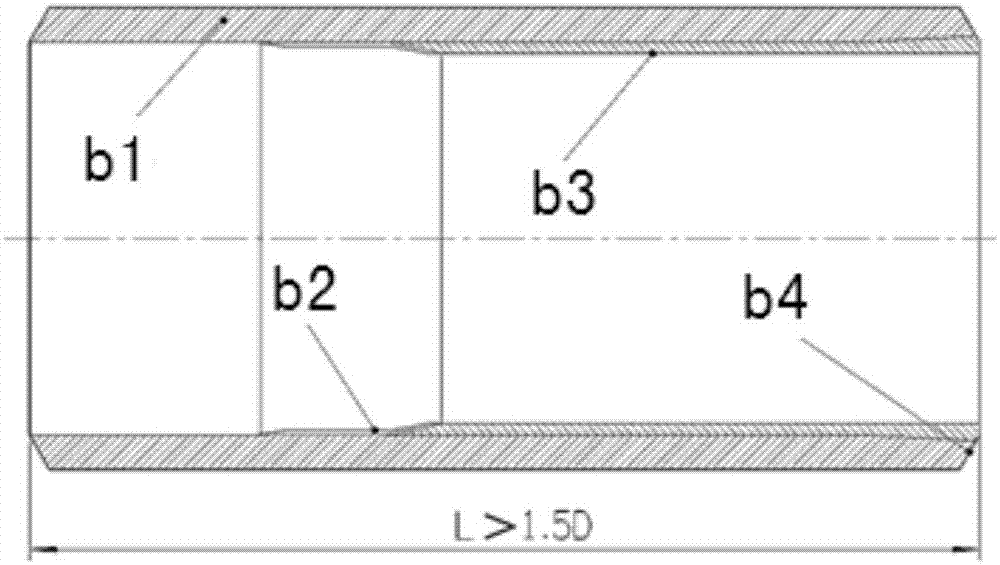

Composite mouth-repairing structure for counterweight layer of large-caliber submarine pipeline

ActiveCN105156831AAvoid the problem of incomplete mold fillingShorten the ripening timePipe elementsOcean bottomHigh density

The invention discloses a composite mouth-repairing structure for a counterweight layer of a large-caliber submarine pipeline. The composite mouth-repairing structure comprises a mouth-repairing anticorrosive coating, a mould layer, ring-direction high-density polyurethane foam tiles and high-density polyurethane foams, wherein the mouth-repairing anticorrosive coating is arranged on outer surfaces of steel tube reserved welding sections and tube body anticorrosive coating mouth-repairing sections of two counterweight tubes, and is connected with tube body anticorrosive coatings on the end surfaces of the mouth-repairing sections of the two counterweight tubes; the two ends of the mould layer are respectively arranged on the outer surfaces of concrete counterweight layer mouth-repairing sections of the two counterweight tubes; the ring-direction high-density polyurethane foam tiles are arranged at the periphery of the mouth-repairing anticorrosive coating; the thicknesses of the ring-direction high-density polyurethane foam tiles are smaller than those of the concrete counterweight layers by 30-50mm; and the high-density polyurethane foams are filled between the ring-direction high-density polyurethane foam tiles and the mould layer in a site casting mode, and are integrated with the ring-direction high-density polyurethane foam tiles and the mould layer to coat the outer side of the mouth-repairing anticorrosive coating. According to the technical scheme disclosed by the invention, the technical problems that open-cell polyurethane foams are cured prematurely, mould filling is incomplete and time for reaching strength required by laying is long during filling construction of the counterweight layer of the large-caliber submarine pipeline in the prior art are solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

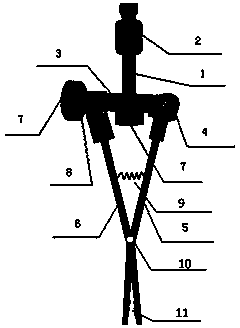

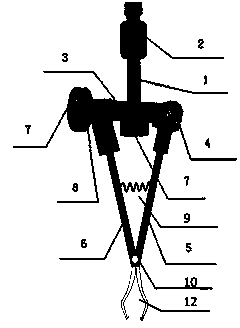

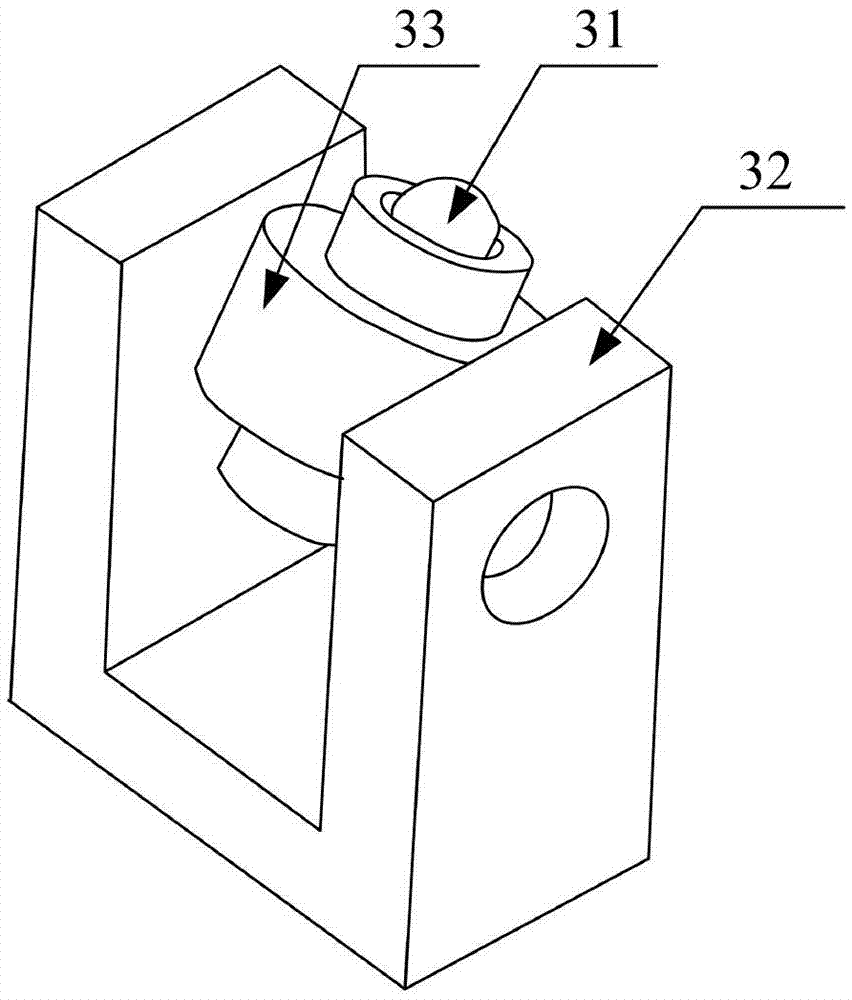

Mouth rehabilitation metal dowel pin removal device

The invention provides a mouth rehabilitation metal dowel pin removal device, and belongs to the field of mouth rehabilitation medical devices and instruments. The mouth rehabilitation metal dowel pin removal device includes a slider, a slide hammer, a parallel rod, a movable joint, a male piece, a female piece, nuts and a screw rod, wherein one end of the slider is fixedly connected with the slide hammer, the slider and the slide hammer form an impact device, the other end of the slider is movably connected with the parallel rod, the tail end of the slider passes through the parallel rod, the tail end of the slider is mounted with the nut, the male piece is connected with the parallel rod through the movable joint, one end of the female piece is movably sleeved on the thread of a screw rod, the other end of the female piece is movably connected with the male piece in a cross manner, the male piece and the female piece form a clamping mechanism, one end of the screw rod is fixedly connected with the parallel rod, the other end of the screw rod is provided with the nut, and the parallel rod, the nut and the screw rod constitute a force-applying device. The removal device is simple in structure, convenient to operate, low in cost, and suitable for dental clinical application. The removal device has good market prospects and facilitates good application in the field of medical devices.

Owner:中国人民解放军第二〇八医院四六一临床部

Epoxy glass fiber reinforced pipeline mouth repairing method

ActiveCN103807564AExtended service lifeOvercoming Inherent Technical DeficienciesCorrosion preventionPipe elementsGlass fiberEpoxy

The invention discloses an epoxy glass fiber reinforced pipeline mouth repairing method, wherein the technological process comprises the steps of sand blasting treatment for the surface of a repaired mouth, gas treatment for the surface of the repaired mouth, corrosion resistance treatment for the surface of the repaired mouth, a PE material in a repaired mouth area is polarized by using a gas treating agent, the treatment process is simple, and the surface is uniformly treated; a corrosion resistance structure and a pipe body effectively form a whole, the corrosion resistance structure is stable in long-term performance and long in service life, a solventless coating with high temperature resistance property and a high-strength glass fiber are chosen to meet the application of the high temperature environment, and the hardness and the wear resistance property of the repaired mouth are enhanced while the intrinsic technical defects of a traditional heat shrinking sleeve (band) are overcome. The epoxy glass fiber reinforced pipeline mouth repairing method is simple in process, convenient in operation, strong in adhesive force, high in corrosion resistance performance, wide in scope of applicable temperatures, and convenient in popularization and application.

Owner:北京双元油通工程技术有限公司 +1

Mouth-repairing modified polyurea coating in petroleum pipeline

The invention provides a mouth-repairing modified polyurea coating in a petroleum pipeline which realizes mouth-repairing construction at the low temperature, and fills up the domestic blanks. The mouth-repairing modified polyurea coating in the petroleum pipeline is characterized in that the modified polyurea coating is prepared from a component A and a component B, wherein the component A is prepared from the following ingredients in parts by mass: 25-35 parts of carbodiimide modified MDI, 20-30 parts of modified polymer, 40-50 parts of hydroxy polyether and 5-10 parts of a functional assistant, and the component B is prepared from 25-35 parts of D-2000, 10-20 parts of T-5000, 2-8 parts of D-230, 10-20 parts of DETDA, 10-20 parts of DMTDA and 1-5 parts of functional filler. The mouth-repairing modified polyurea coating in the petroleum pipeline is long in service life, environmentally friendly and free of pollution, and can adapt to outdoor low temperature environments, in particularto mouth-repairing construction at the low temperature (-20 DEG C).

Owner:大连美宸特环保节能产品有限公司

Air-jet loom profiled steel reed defect mouth repairing process

InactiveCN102886723AImprove weaving efficiencyLow costBelt grinding machinesAir-jet loomStructural engineering

The invention discloses an air-jet loom profiled steel reed defect mouth repairing process which comprises the following steps of: (1) checking the two ends of a profiled steel reed airflow groove, and determining the defect mouth position of the profiled steel reed airflow groove; (2) adopting a grinding tool to grind the defect mouth position of the profiled steel reed airflow groove to and forth along the profiled steel reed length direction until the two edges of the defect mouth are in smooth transition; (3) rubbing a ground surface (which is caused by grinding) to and fro by using a honing stick so as to remove defective wools of the ground surface; (4) using an abrasive belt to penetrate through a gap between profiled steel reed sheets within a ground surface range, and utilizing the friction of the abrasive belt and the side walls of the profiled steel reed sheets to remove residual defective wools; and (5) polishing the ground surface of a profiled steel reed on an air sand blaster, and ensuring the ground surface to be smooth and fine. With the adoption of the repairing process, the profiled steel reed can be repaired, and the repaired profiled steel reed can satisfy the normal use of an air-jet loom.

Owner:ZHANGJIAGANG JINGRUI REED GRINDING TECH CO LTD

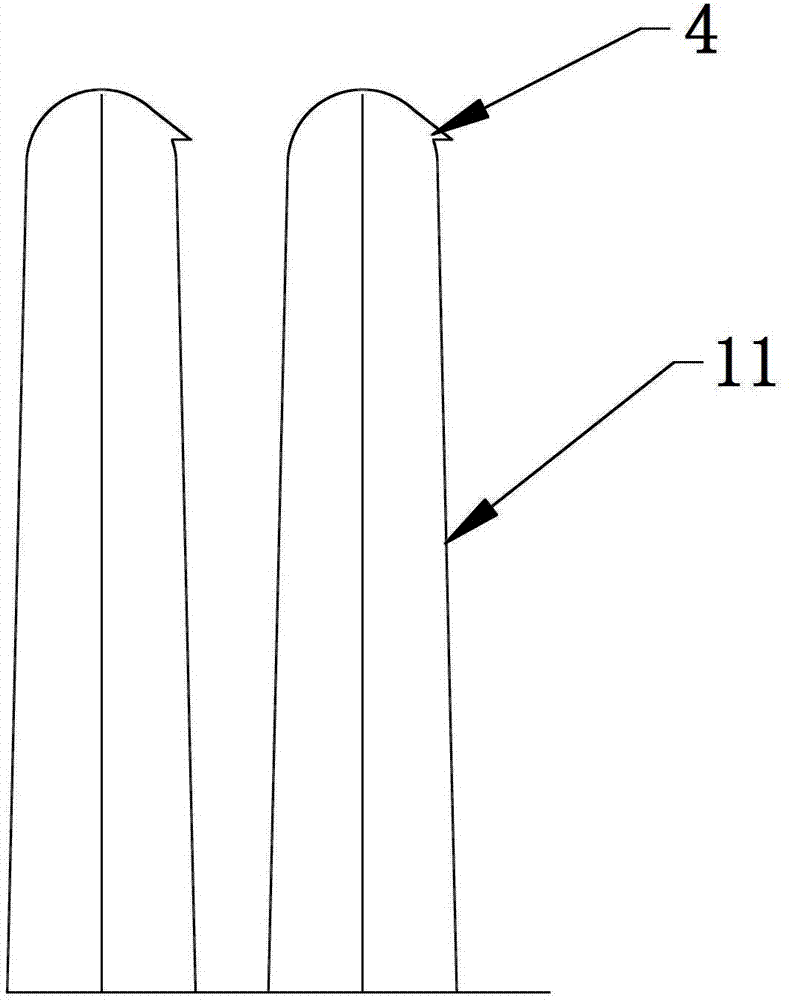

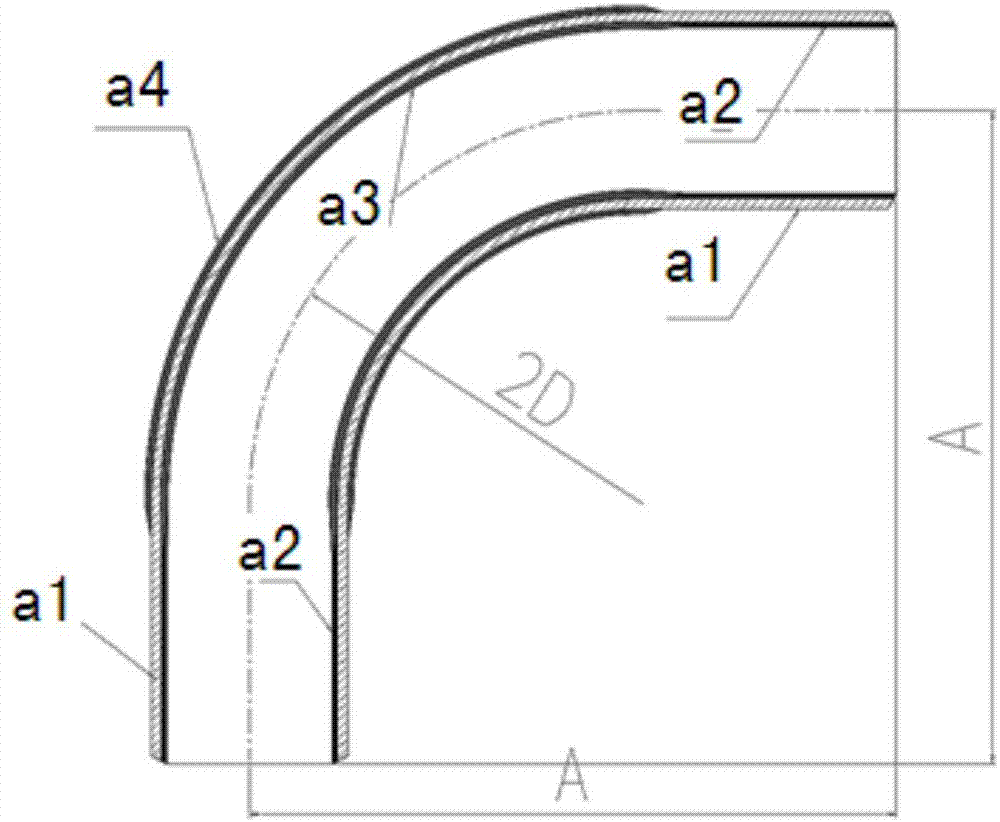

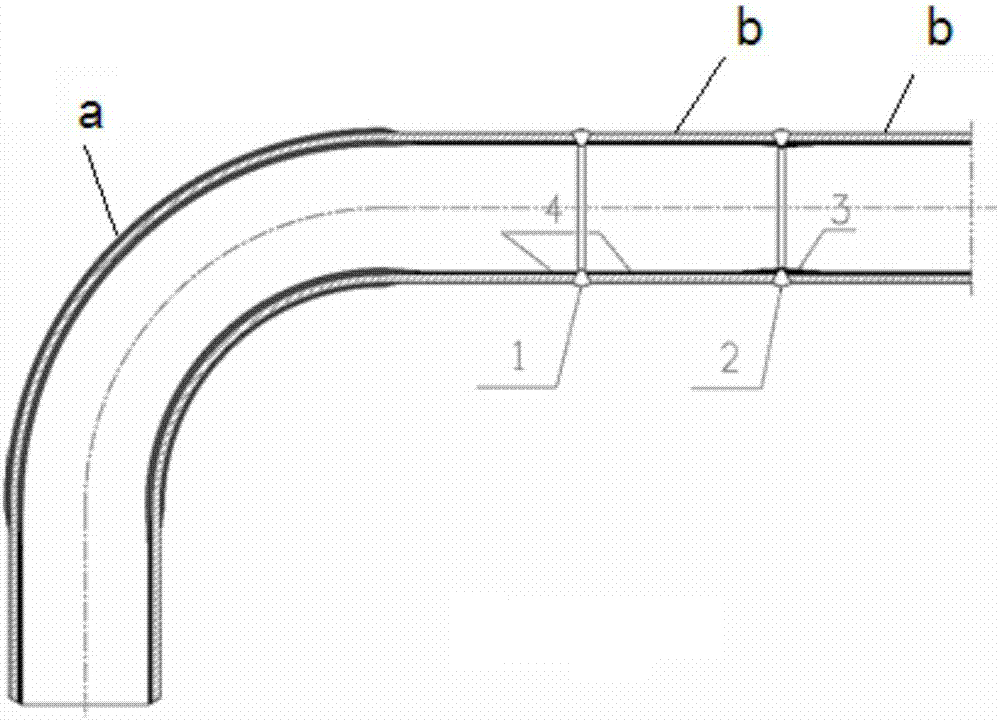

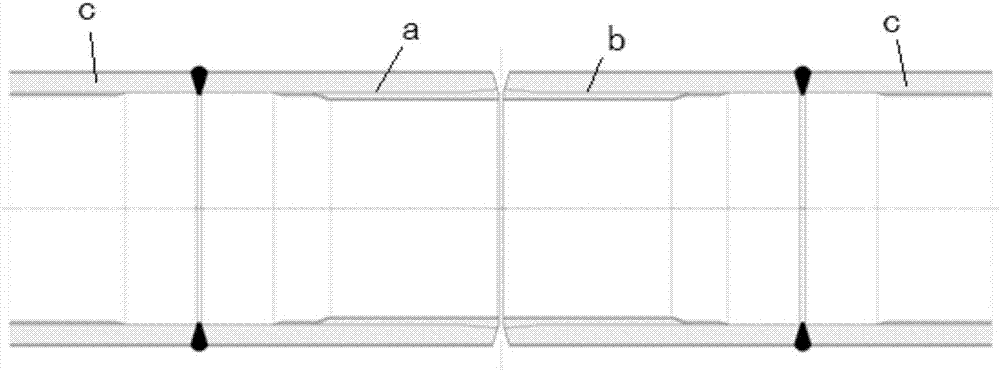

Manufacturing method for steel inter-anticorrosion-mouth-repair-free elbow

InactiveCN107191729AImprove continuityAvoid destructionCorrosion preventionPipe protection against corrosion/incrustationWeld seamAlloy

The invention relates to a manufacturing method for a steel inter-anticorrosion-mouth-repair-free elbow. The manufacturing method comprises the following steps that the elbow is prepared; four short pipes with the same length are cut, and two of the short pipes are used as the short pipes for field connection; a stainless steel welding wire is used as a surfacing material, a stainless steel layer is arranged on the inner wall of one end of each short pipe in a surfacing manner, and anticorrosion alloy pre-mouth-repair layers are formed; and grooves and surfacing transition regions are machined; the non-surfacing ends of the two connecting short pipes are welded to the two ends of the elbow, and the straight pipe ends are formed; and during the field elbow connection, the other two short pipes are correspondingly welded to the straight pipe ends of the two ends of the elbow, anticorrosion coating is conducted on the inner walls of welding seams, and continuous anticorrosion layers are formed. The manufacturing method has the beneficial effects that the bottleneck problem of the steel pipeline elbow welding seam inner anticorrosion technology is solved, the internal anticorrosion factorization of the elbow welding seams is achieved, and the pipeline construction efficiency is improved; the pipeline corrosion prevention and construction cost is lowered, and the service life of the pipeline is prolonged; and the environment protection and safety risks caused by the corrosion leakage of the pipeline elbow welding seams are lowered.

Owner:山东胜利长龙管道科技有限公司 +2

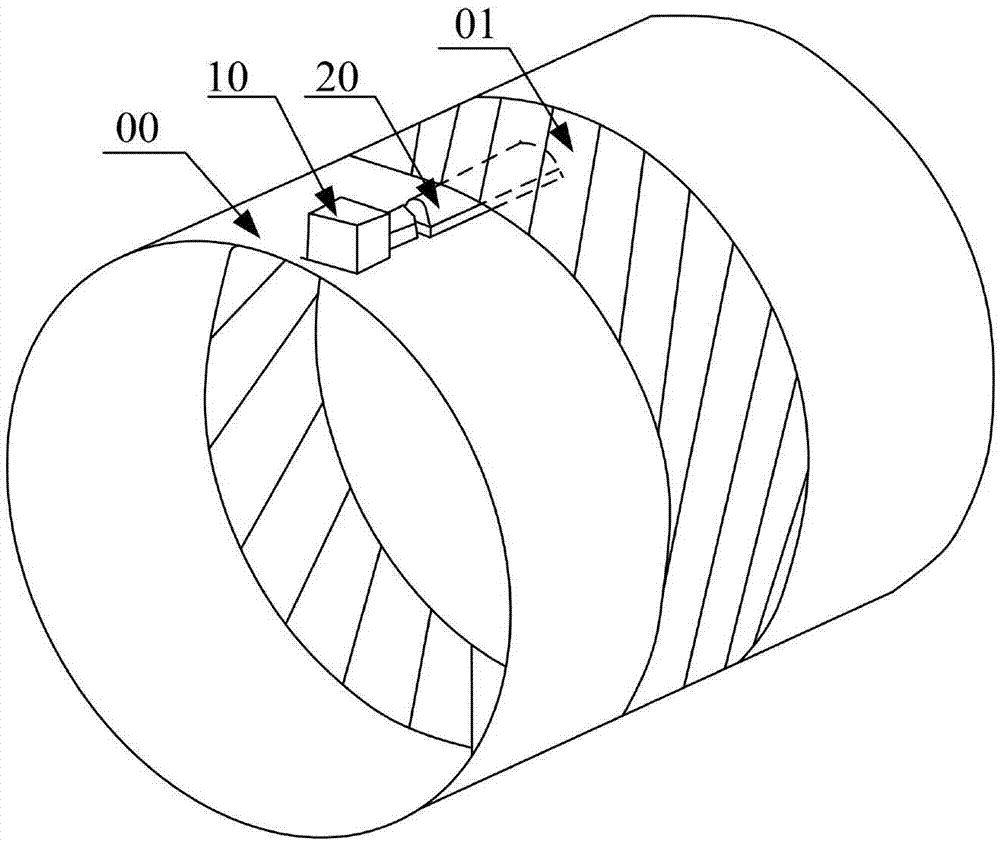

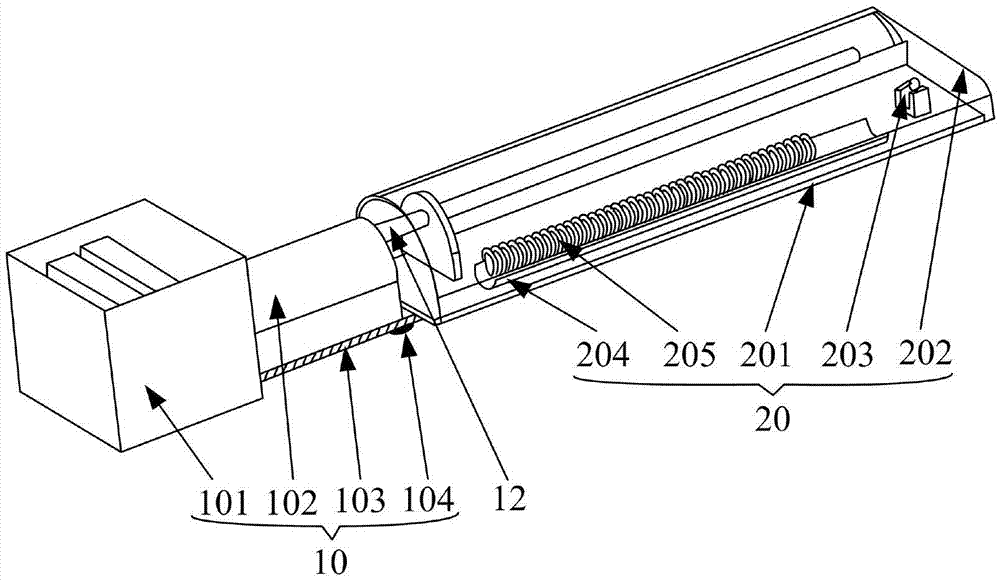

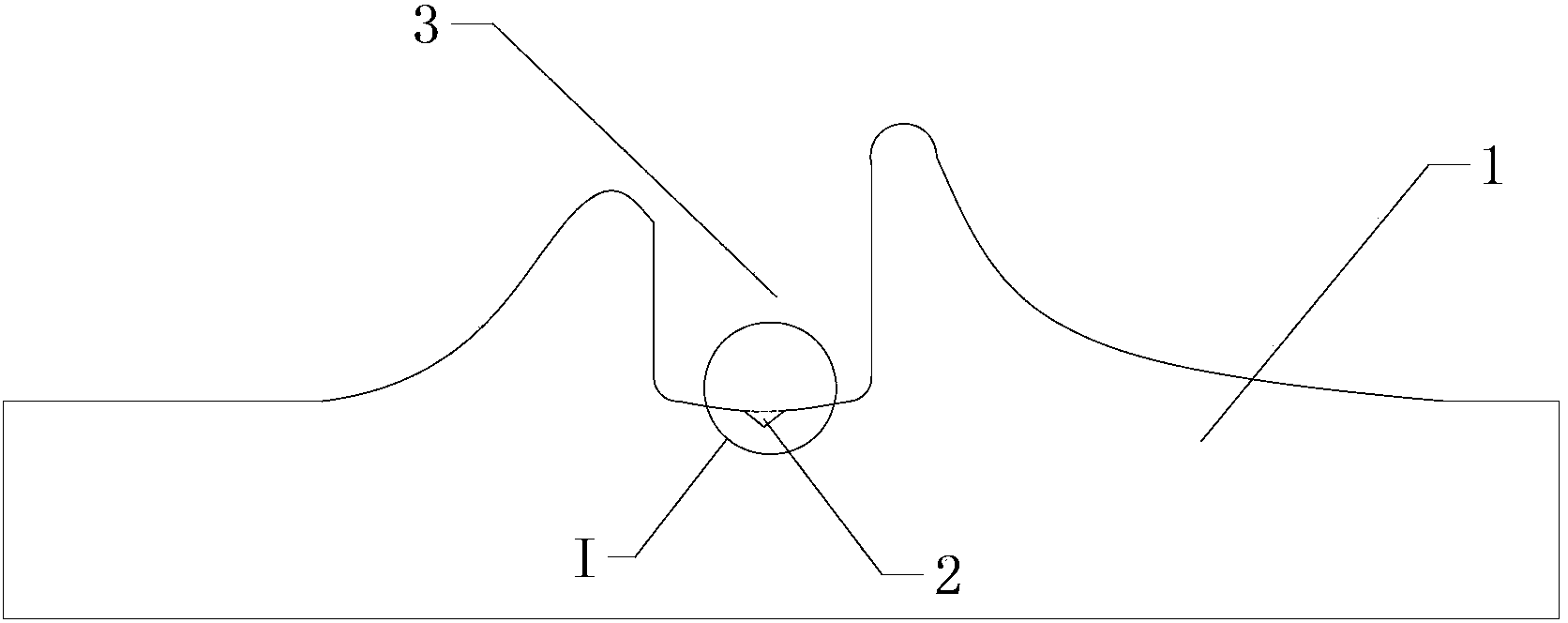

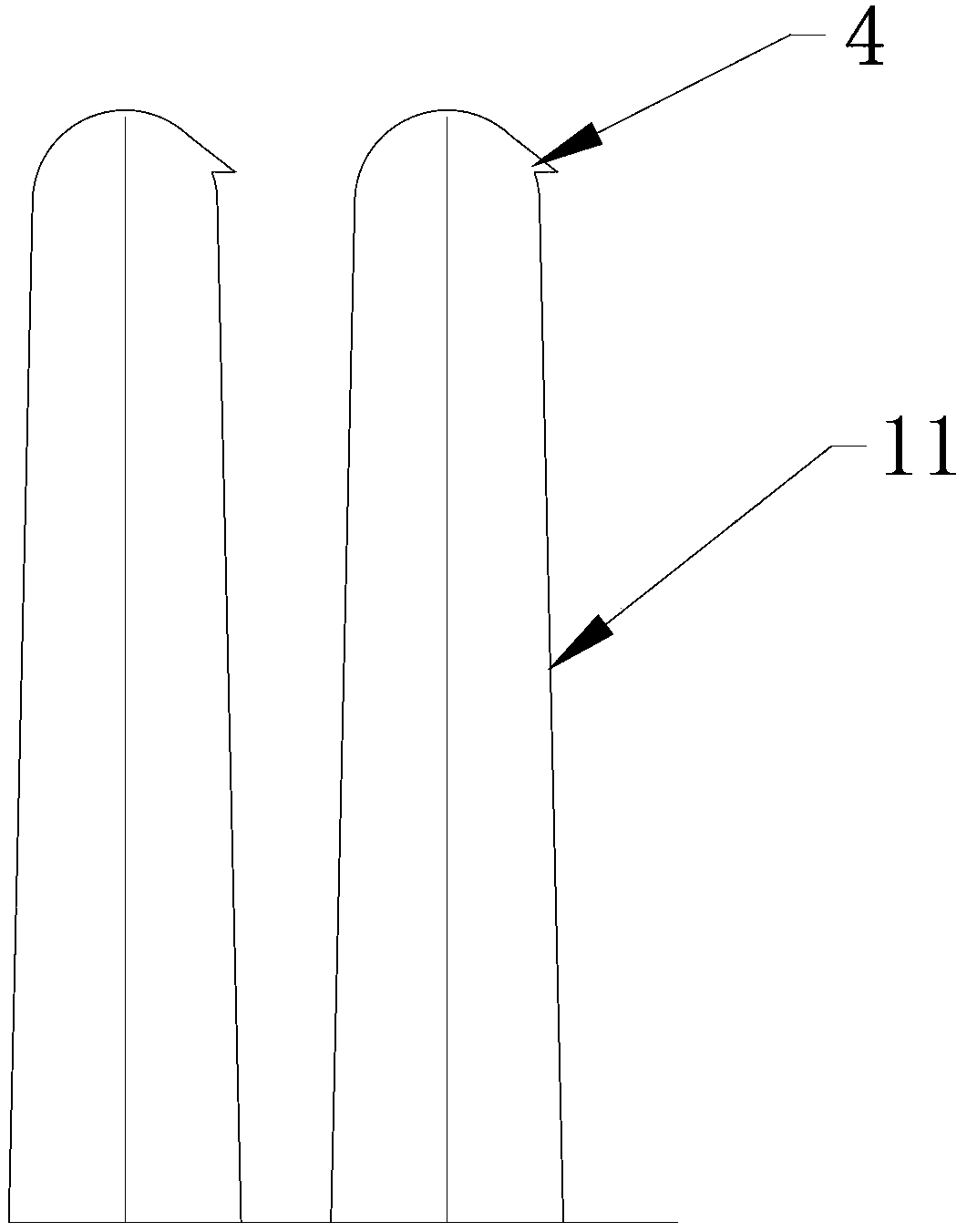

Support device of pipe repaired mouth heat shrinkage sleeve

The invention discloses a support device of a pipe repaired mouth heat shrinkage sleeve, and belongs to the field of oil and gas storage and transportation. The device comprises a control module, and a slide module slidingly connected with the control module; the control module and the slide module are absorbed on the outer wall of a pipe through fixed pieces; the slide module is positioned between the outer wall of the pipe and the heat shrinkage sleeve, and is used for supporting the heat shrinkage sleeve; and the control module is positioned out of an area covered by the heat shrinkage sleeve, and is used for controlling the slide module to slide in a direction near the control module until the slide module slides out of the heat shrinkage sleeve in the shrinkage process of the heat shrinkage sleeve. The support device of the pipe repaired mouth heat shrinkage sleeve improves the pipe mouth repair efficiency, solves the problems of low pipe mouth repair efficiency and weak mouth repair effect in related technologies, and is applied to pipe mouth repair.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

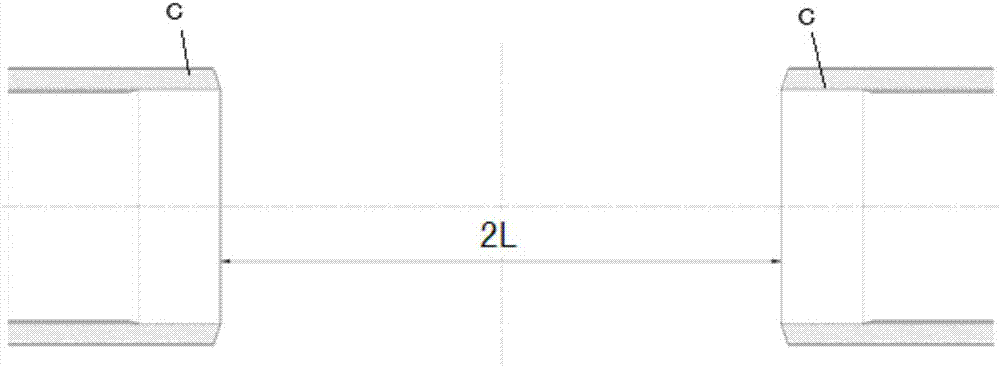

Two-section type inter-anticorrosion-mouth-repair-free dead-mouth tie-in method for steel pipelines

InactiveCN107191743AAvoid burnsExtended service lifeCorrosion preventionPipe elementsMouth repairAlloy

The invention relates to a two-stage method for connecting dead ends of steel pipelines without internal anti-corrosion. It includes the following steps: (1) Processing steps of connecting short pipes: (1) Cut two sections of short steel pipes according to the steel pipe specifications specified in the design; (2) Use a surfacing machine to circumferentially surfacing stainless steel materials on the inner wall of the pipe end; (3) Lathe Process the corrosion-resistant alloy pre-joining layer and the grooves at both ends of the short pipe; (2) On-site pipe dead end connection steps: Weld the unsurfacing end of the short pipe to the pipes at both ends; perform internal welding on the inner wall of the welding joint. After the anti-corrosion patching treatment, the same welding material as the pre-patching surfacing is used to weld the dead seam. The beneficial effects are: the present invention can eliminate the need for anti-corrosion patching within the dead end of the steel pipeline through two sections of pre-patched surfacing short pipes, solves the technical bottleneck of anti-corrosion patching within the dead end weld of the pipeline, and simplifies the connection of the dead end of the internal anti-corrosion pipeline. The first step of the process reduces the construction cost of dead-end joints of internal anti-corrosion steel pipes.

Owner:山东胜利长龙管道科技有限公司 +2

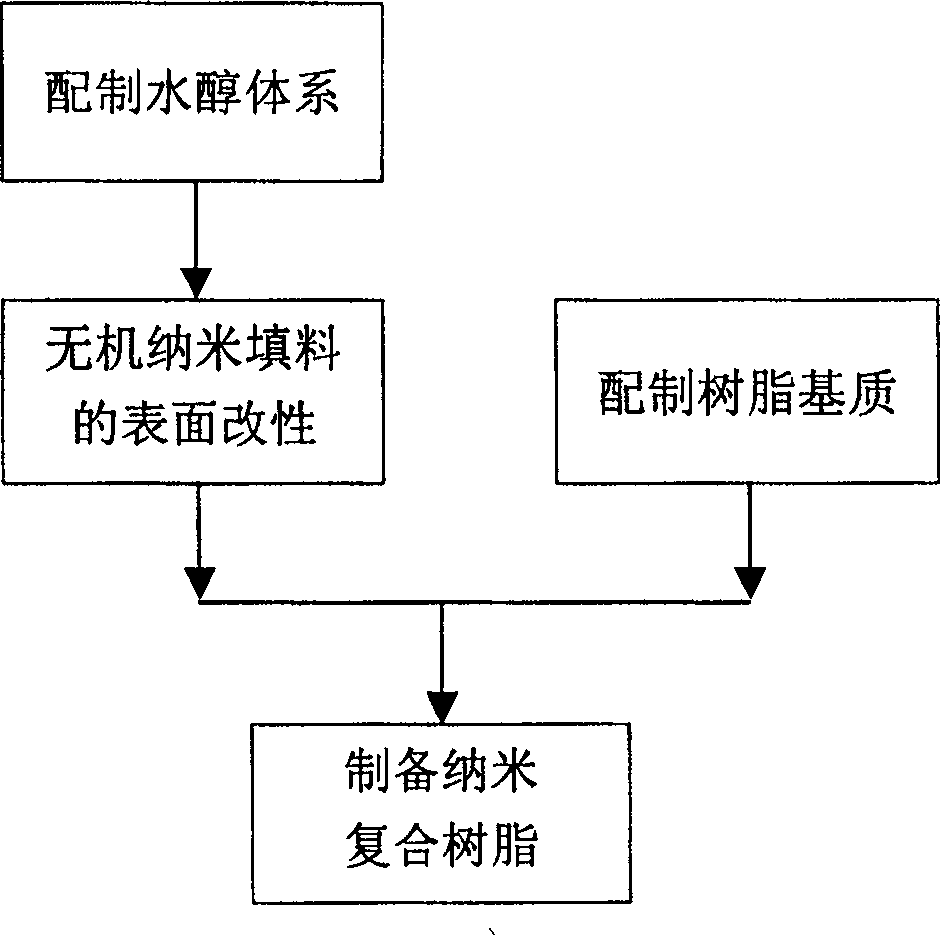

A method for preparing nano compound resin prosthetics material

InactiveCN100467008CIncrease the areaGood compatibilityImpression capsDentistry preparationsAcetic acidAlcohol

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Preparation method of zirconia biological ceramic for oral cavity repair

InactiveCN109836151AImprove mechanical propertiesImprove fracture toughnessImpression capsDentistry preparationsBiocompatibility TestingSodium titanate

The invention belongs to the field of materials, and particularly relates to a preparation method of a zirconia biological ceramic for oral cavity repair, wherein the raw materials comprise, by weight, 20-30 parts of zirconia, 10-15 parts of nanometer alumina, 10-15 parts of nanometer magnesium oxide, 10-15 parts of nanometer titanium oxide, 5-10 parts of nanometer zinc oxide, 5-10 parts of boronoxide, 5-10 parts of sodium titanate, and 5-10 parts of hydroxyapatite. According to the present invention, the prepared zirconia biological ceramic as the novel fine ceramic has advantages of good mechanical properties (fracture toughness, strength, hardness and the like), good biocompatibility, good stability, good aesthetic property, good thermal conductivity and good formability, can well solve the problem of insufficient strength and insufficient toughness of conventional all-ceramic crown materials, has mechanical properties comparable to metals, and can completely bear the chewing forceof posterior teeth.

Owner:沈阳益泰科信息技术有限公司

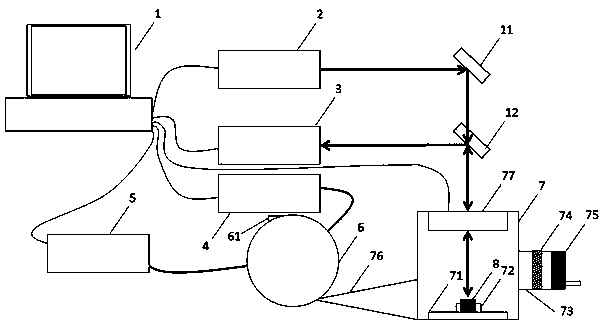

Oral restoration and correction auxiliary device

InactiveCN110000163AReal time monitoringThe test result is accurateBracketsCleaning processes and apparatusIntegratorAdhesive

The invention relates to an oral restoration and correction auxiliary device and provides a novel orthodontic bracket adhesive removing mode. Laser is adopted for ablating the surface of an orthodontic bracket, plasma is formed, and adhesive is removed; meanwhile, the plasma produced when the adhesive is removed is utilized for performing laser breakdown spectroscopy analysis, removed components are obtained, and the removing process can be monitored in real time; and a novel gas detecting method is designed by the invention when the adhesive is removed, gas is introduced into a spherical integrator, light absorption detection is performed in the integrator, and detection results are made more accurate.

Owner:王娟

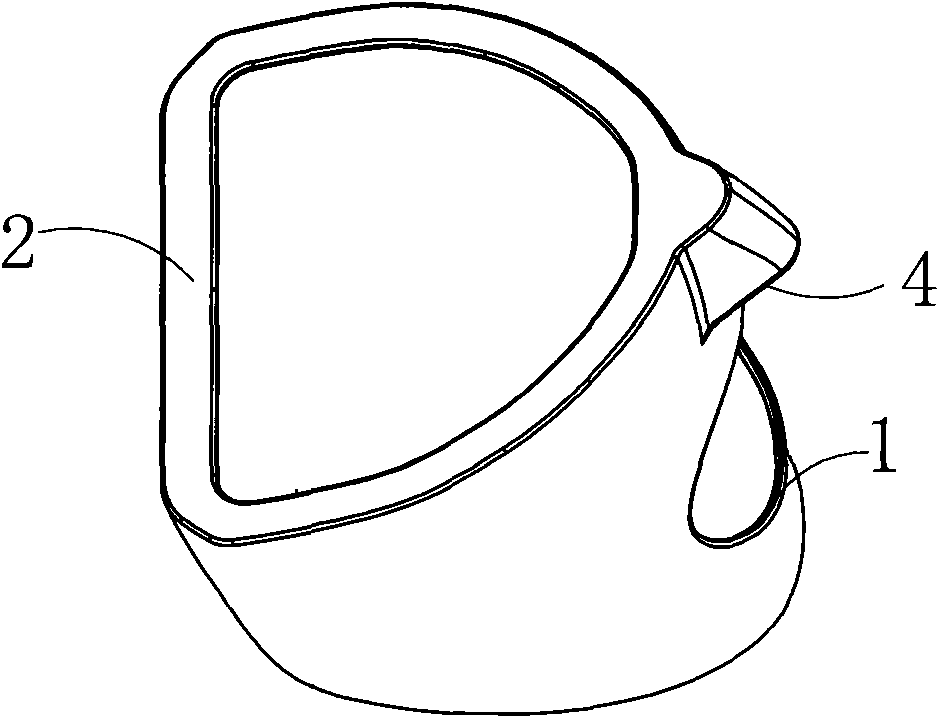

Mask of head-imitating mold for oral teaching

The invention discloses a mask of a head-imitating mold for oral teaching. The mask is characterized in that the mask is sleeved outside the head-imitating mold and is provided with a cavity; an occluder and a tooth model are contained in the cavity; the mask is provided with an open mouth; and the tooth model is exposed in the open mouth. The mask has the following beneficial effects: as the mask is sleeved outside the head-imitating mold and is made of materials similar to the human face skin texture, the head-imitating mold is more lifelike; the open mouth of the mask is enlarged, and the edges of the mouth are reinforced, so that the mouth is more durable; the upper edge of the mask ensures that the water for treatment can not overflow when the head-imitating mold imitates flat lying treatment; a human Frankfort plane corresponding to the upper edge of the mask and a human ala-tragus plane corresponding to the ala of the mask serve as reference planes for oral restorative treatment; the jaw of the mask is provided with a drain cavity and a drain hole for draining the water for treatment; and in conclusion, the mask of the head-imitating mold for oral teaching enables the head-imitating mold used for oral medicine teaching practice to be more lifelike and be convenient for practice operation.

Owner:NISSIN EDUCATION PROD KUNSHAN CO LTD

Dentistry gradient structure metal porcelain stuff and preparing method thereof

InactiveCN101229101BImprove performanceRelieve heat stressImpression capsDentistry preparationsLeuciteMouth repair

The invention belongs to a field of preparation and application technology of porcelain materials in mouth repairing field, in particular to a preparation method for a grads porcelain material with nickel chrome as a metal floor. A porcelain powder which takes leucite as a main crystalline phase is synthesized and the weight percentage for the components of the powder relates to 66.67 percent of SiO2, 16.57 percent of Al2O3, 12.81 percent of K2O, 2.64 percent of Na2O, and 0.89 percent of others. Grads adjusting components are added in the porcelain powder and the weight percentage of the components relates to 30 to 40 percent of Ni, 10 to 20 percent of Cr, 0 to 10 percent of NiO and 40 to 50 percent of Cr2O3. The porcelain powder added with the grads adjusting components is molded with a layer accumulation method and is agglomerated. The prepared component grads porcelain material is characterized by easing the heat stress between gold and porcelain and improving the intensity, and lays a foundation for the clinic application of mouth porcelain repairing.

Owner:SICHUAN UNIV

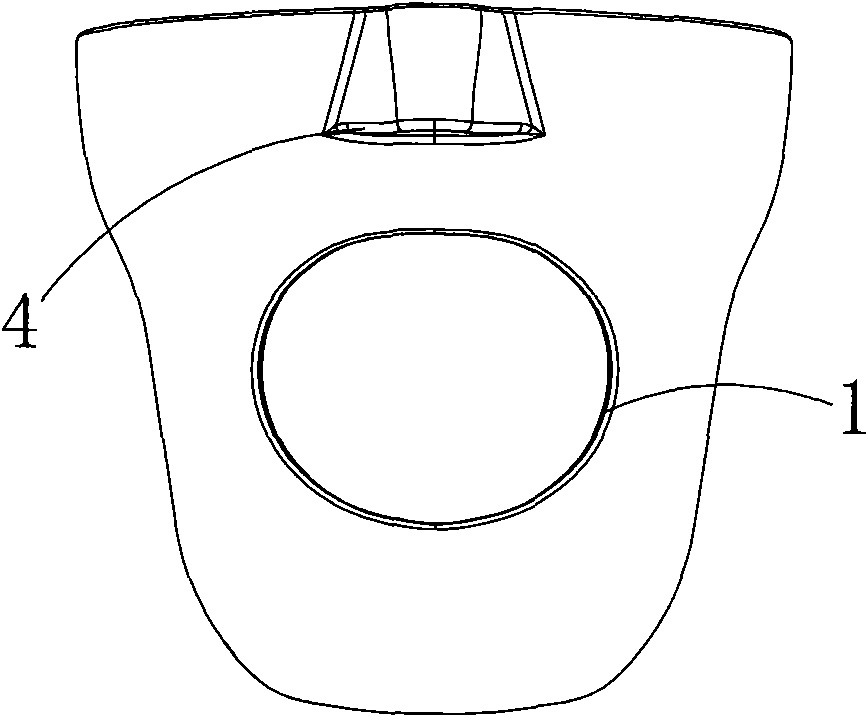

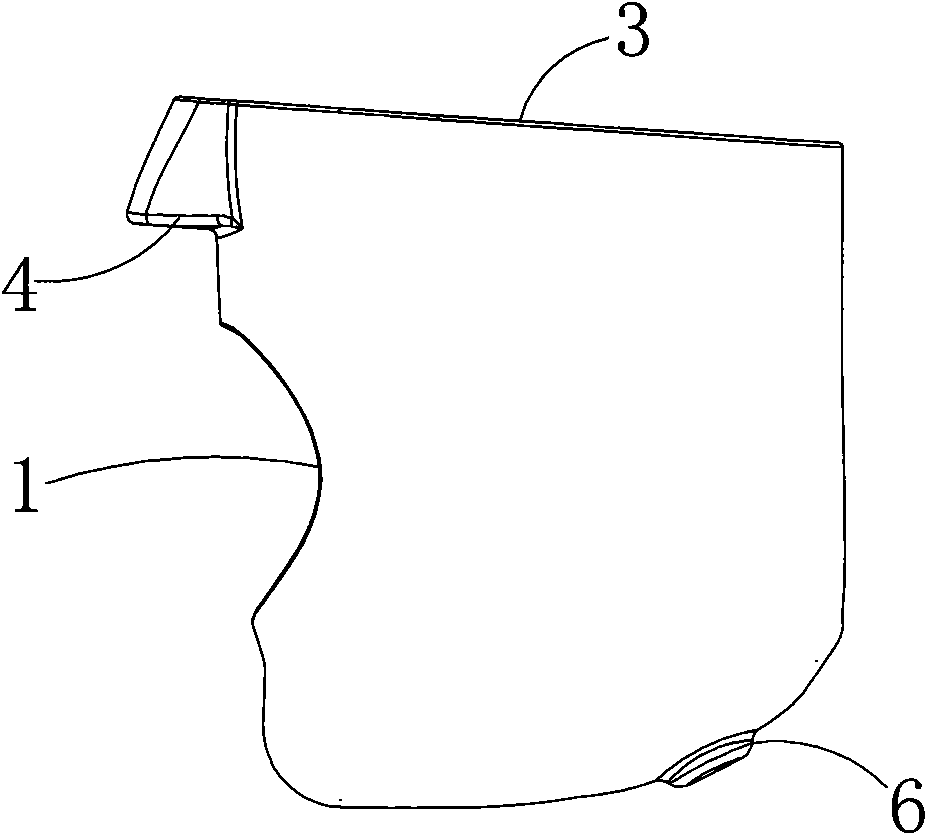

Dental restoration cad/cam/slm-3d printing composite method

ActiveCN106264762BImprove product qualityImprove stabilityArtificial teethPersonalizationOral Prosthesis

Disclosed is a CAD / CAM / SLM-3D combined printing method for dental restorations. A CAD / CAM / SLM-3D combined printing system, constituted by an optical scanning measurement instrument or a contact scanning measurement instrument, computer-aided design software for dental restorations, a miniaturized metal 3D printer, and a numerically controlled milling machine, is used to prepare a metal restoration, combining the existing dental CAD / CAM system with a metal 3D printing technique to combine the respective numerically controlled processing methods thereof so as to maximize the effects. The method can improve the automatic production efficiency of metal dental restorations, especially complex metal dental restorations, and eliminate the cumbersome procedures in the traditional manual manufacture for dental restorations. Thus the method improves the manufacturing quality and stability of restorations, achieving the purpose of rapid, accurate and personalized manufacturing, and better satisfying the urgent requirements of patients with tooth loss.

Owner:维视医疗信息科技山东有限公司

Rapid plugging method for fiberglass pipeline with water and pressure

Owner:NO 1 CONSTR ENG CO LTD OF GUIZHOU CONSTR & ENG GRP

Air-jet loom profiled steel reed defect mouth repairing process

InactiveCN102886723BImprove weaving efficiencyLow costBelt grinding machinesAir-jet loomMouth repair

The invention discloses an air-jet loom profiled steel reed defect mouth repairing process which comprises the following steps of: (1) checking the two ends of a profiled steel reed airflow groove, and determining the defect mouth position of the profiled steel reed airflow groove; (2) adopting a grinding tool to grind the defect mouth position of the profiled steel reed airflow groove to and forth along the profiled steel reed length direction until the two edges of the defect mouth are in smooth transition; (3) rubbing a ground surface (which is caused by grinding) to and fro by using a honing stick so as to remove defective wools of the ground surface; (4) using an abrasive belt to penetrate through a gap between profiled steel reed sheets within a ground surface range, and utilizing the friction of the abrasive belt and the side walls of the profiled steel reed sheets to remove residual defective wools; and (5) polishing the ground surface of a profiled steel reed on an air sand blaster, and ensuring the ground surface to be smooth and fine. With the adoption of the repairing process, the profiled steel reed can be repaired, and the repaired profiled steel reed can satisfy the normal use of an air-jet loom.

Owner:ZHANGJIAGANG JINGRUI REED GRINDING TECH CO LTD

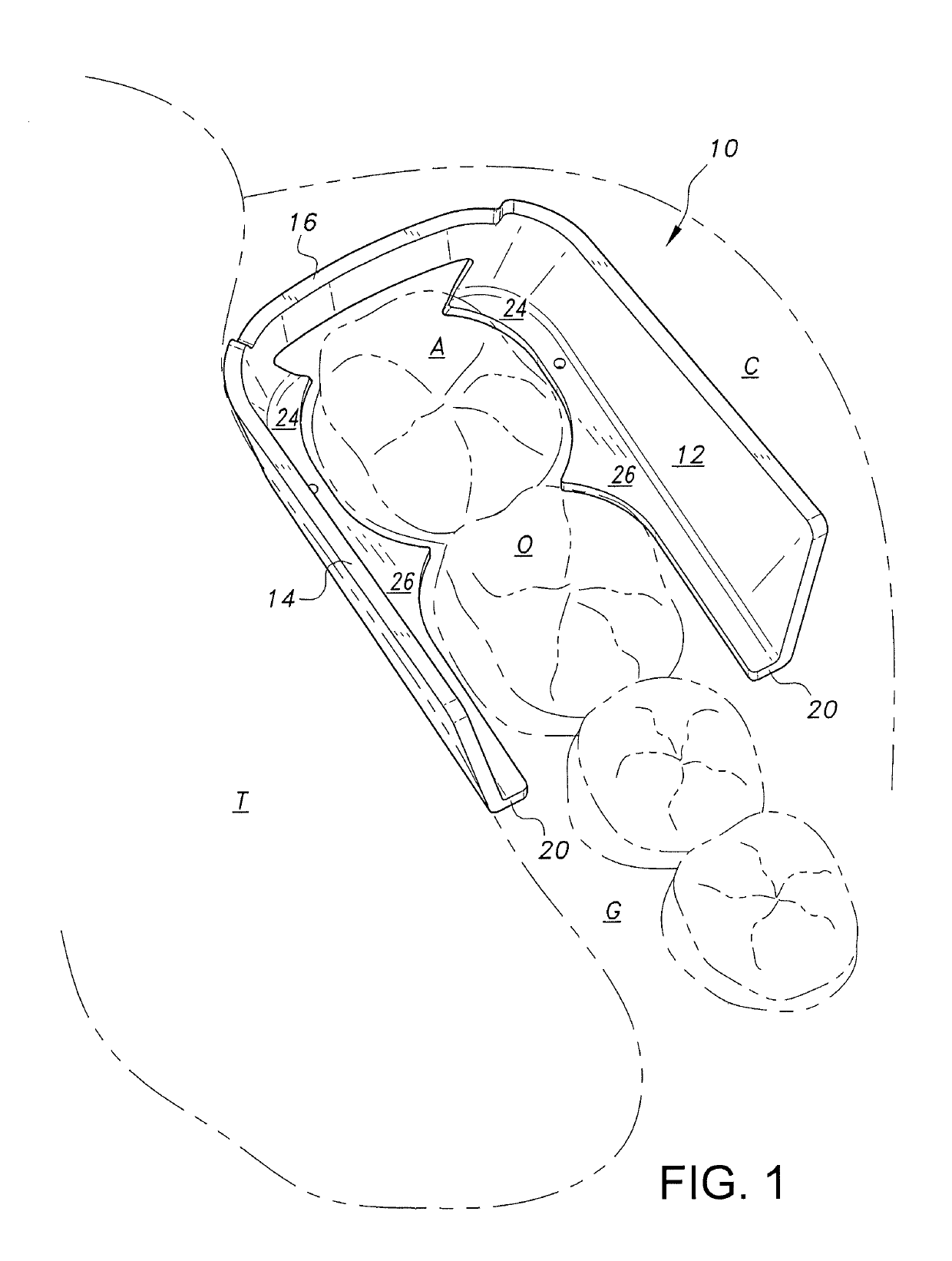

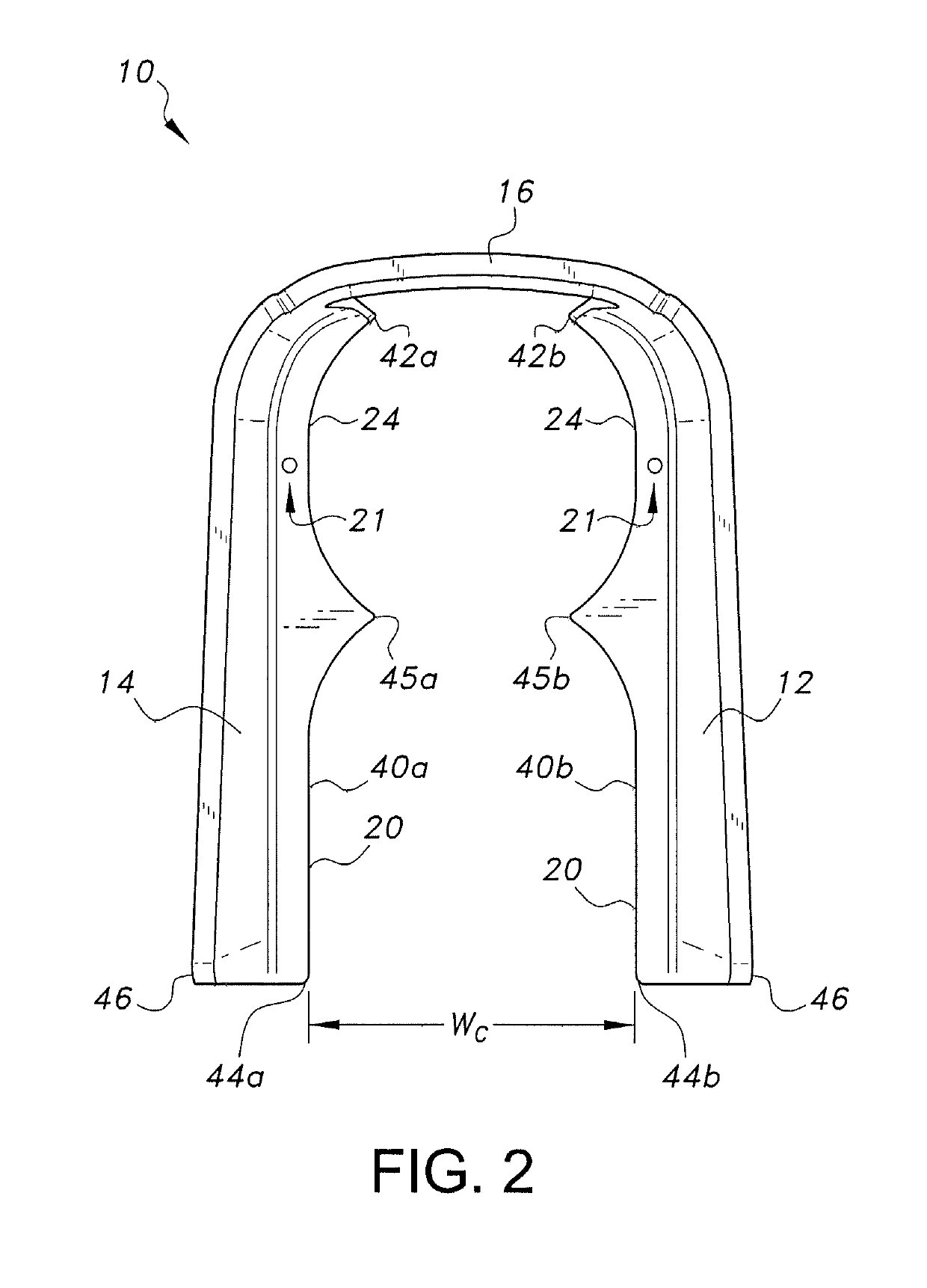

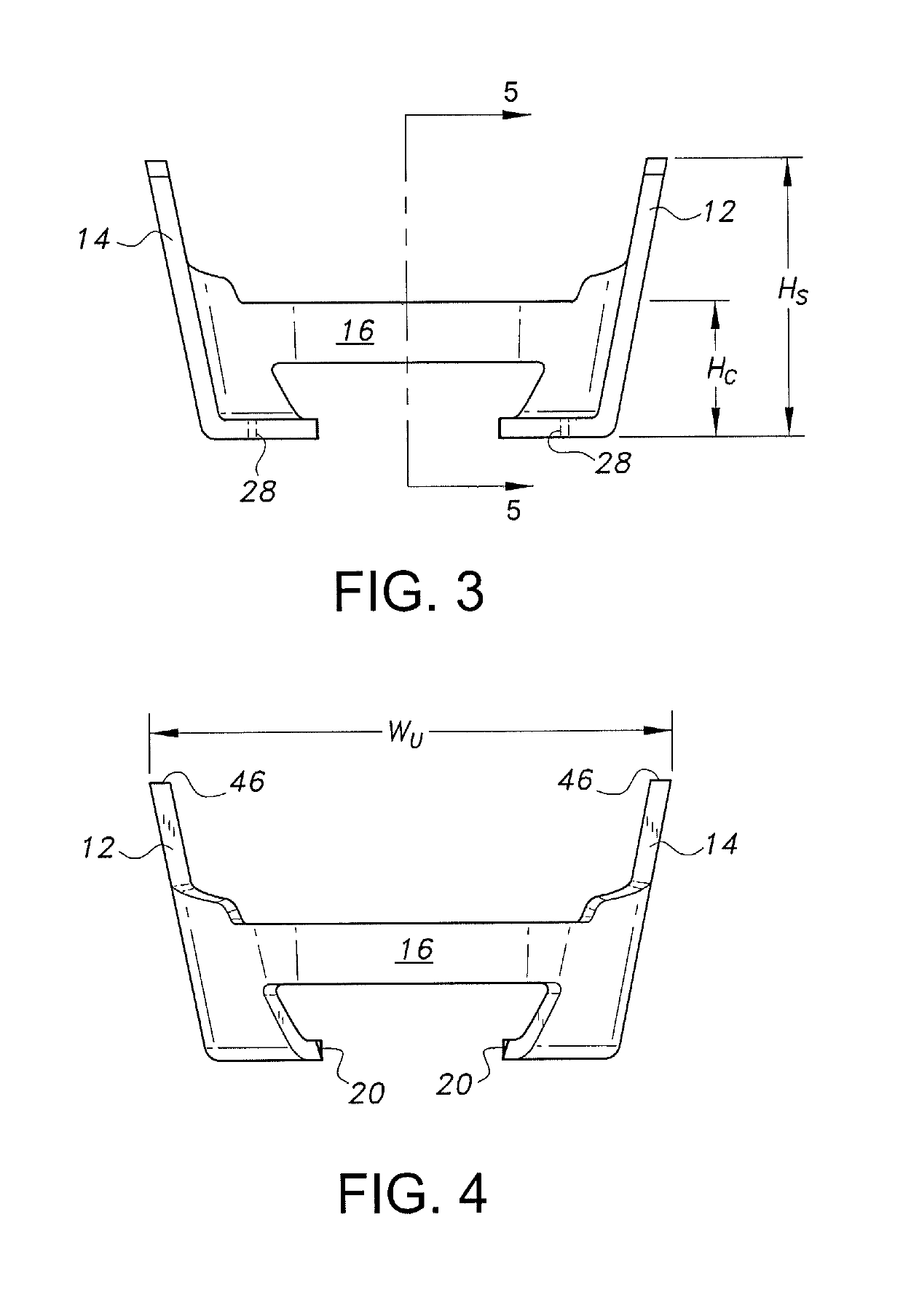

Cheek and tongue retractor

The retractor is a generally U-shaped device for protecting the cheek and tongue from instruments used during dental and prosthodontic procedures. The retractor has a planar base defined by two spaced arms, a pair of upright shields extending from the arms, and a posterior connector connecting the shields. The base is contoured to grip the tooth adjacent to the tooth to be treated, and thereby, secure the retractor within the patient's mouth.

Owner:KING SAUD UNIVERSITY

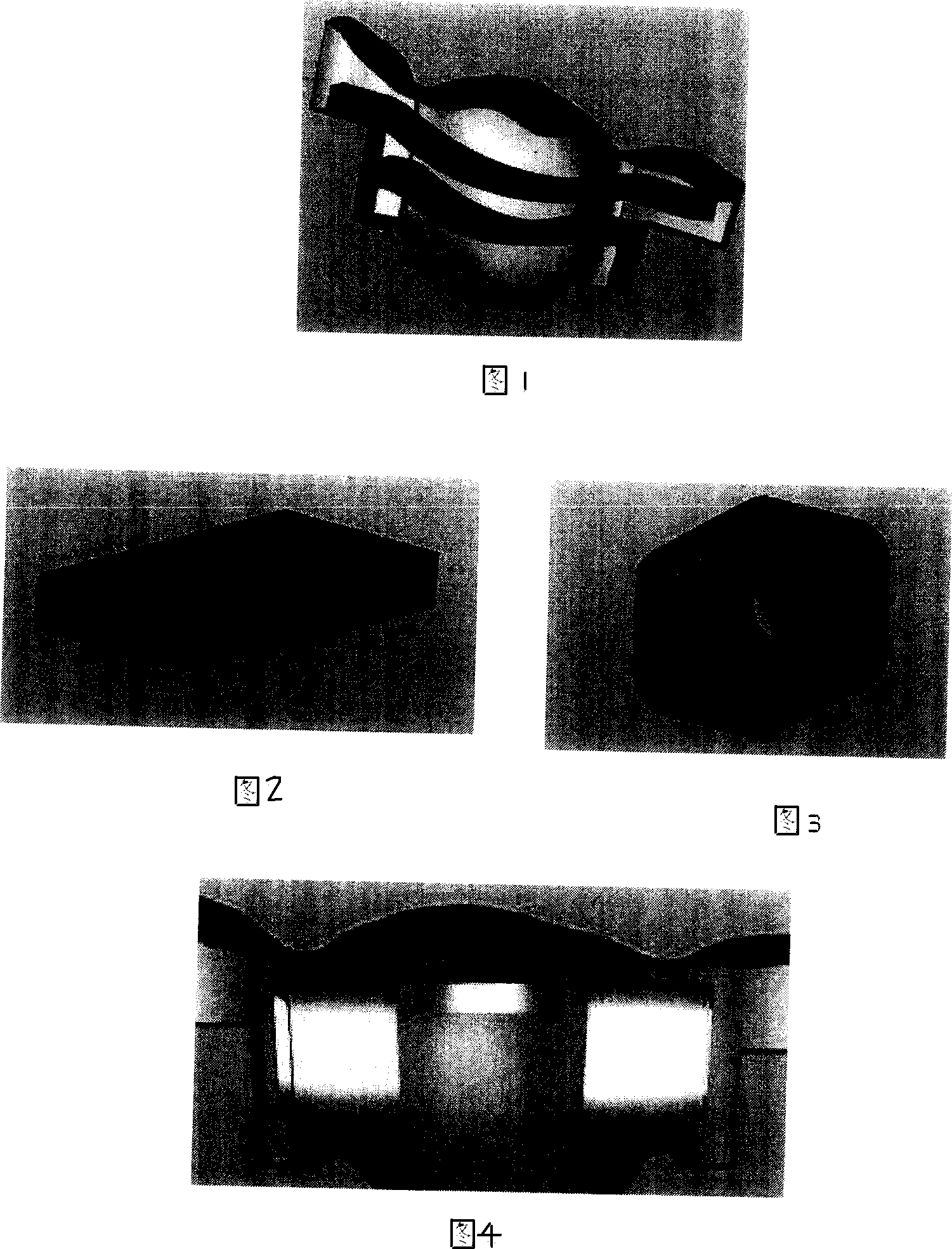

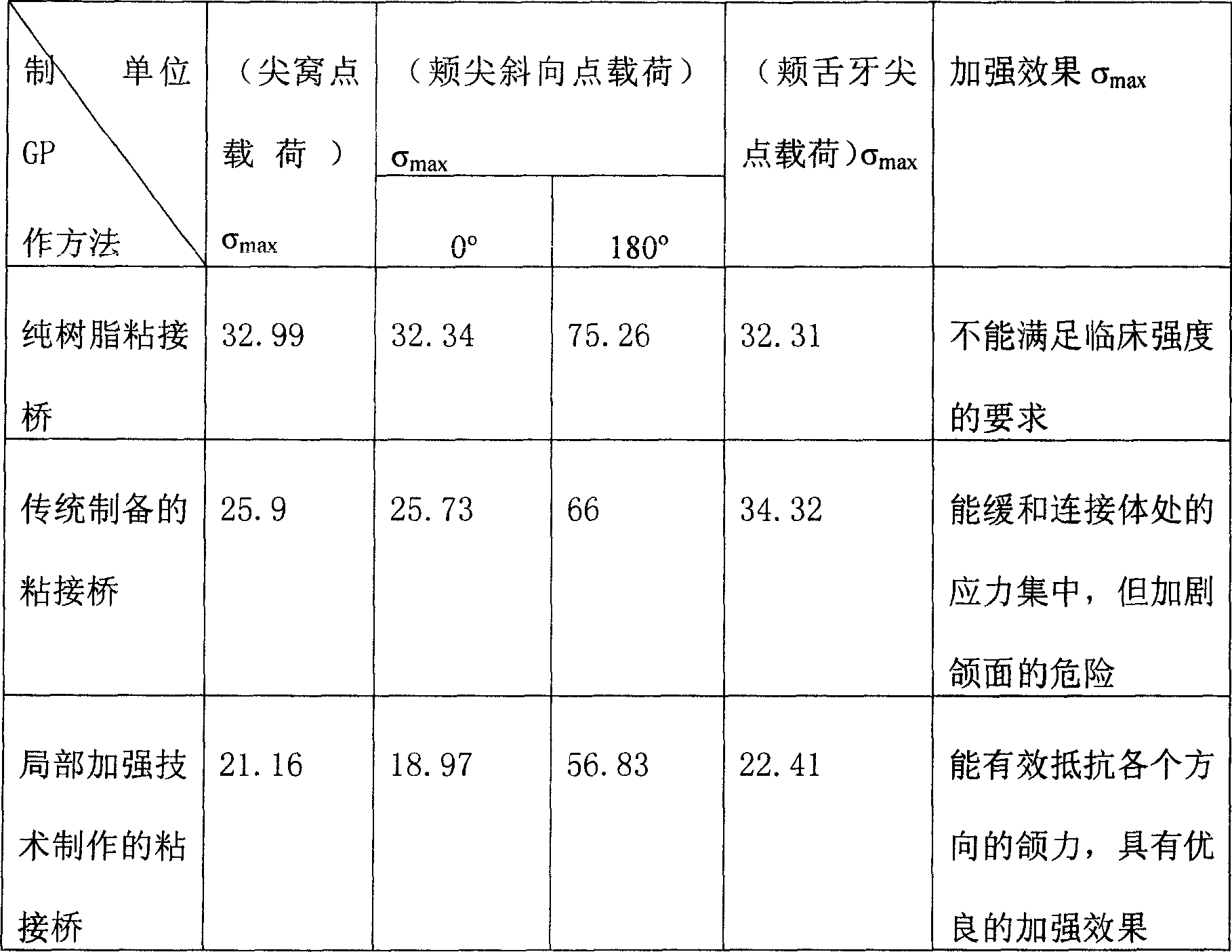

Glass fiber reinforced compoite resin adhesive bridge

InactiveCN1331442CGood for healthPerfect repair formDental implantsTeeth fillingStress concentrationGlass fiber

A glass fibre reinforced composite resin adhesive bridge for repairing the back teeth deficiency in oral cavity features that a rectangular supporting frame is additionally arranged at the proper position in occlusal region and a rectangular hollow supporter is additionally arranged at the proper position in the connection region. Its advantages are high strength and high load-bearing power.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com