Two-section type inter-anticorrosion-mouth-repair-free dead-mouth tie-in method for steel pipelines

An internal anti-corrosion, two-stage technology, applied in pipeline anti-corrosion/rust protection, pipeline protection, pipes/pipe joints/fittings, etc., can solve the problems of reducing construction efficiency and increasing construction costs of joints, so as to improve service life , reduce safety and environmental risks, and ensure the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

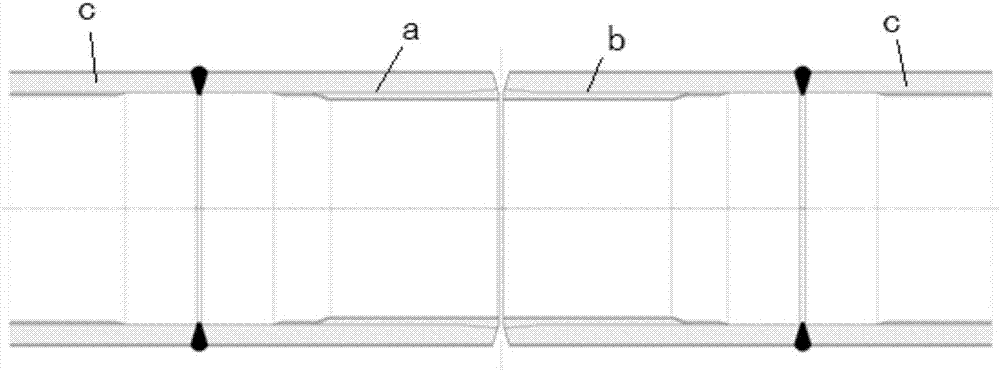

[0029] The present invention relates to a two-stage steel pipeline-free internal anti-corrosion mending method for jointing dead joints, comprising the following steps:

[0030] (1) Processing steps of connecting short pipe:

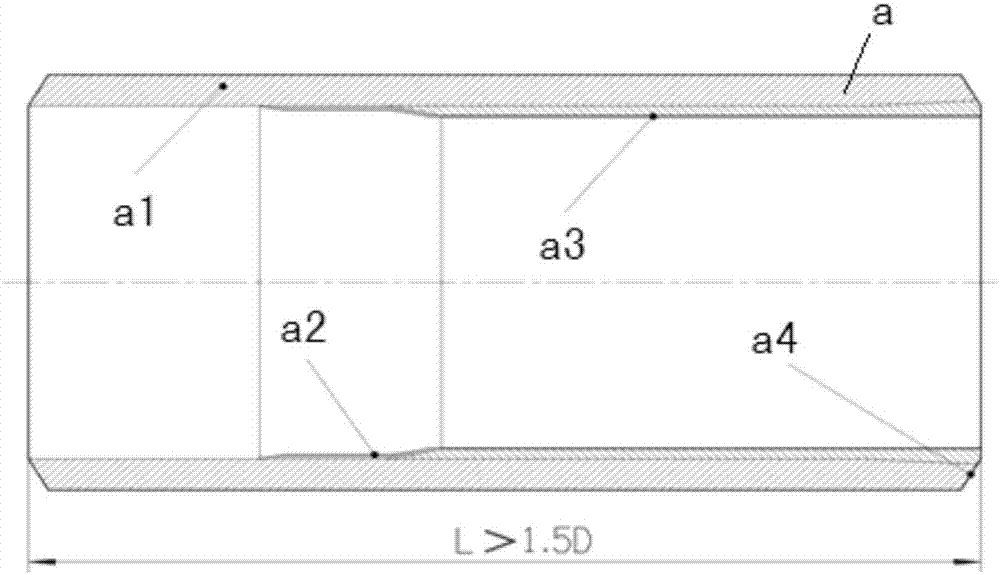

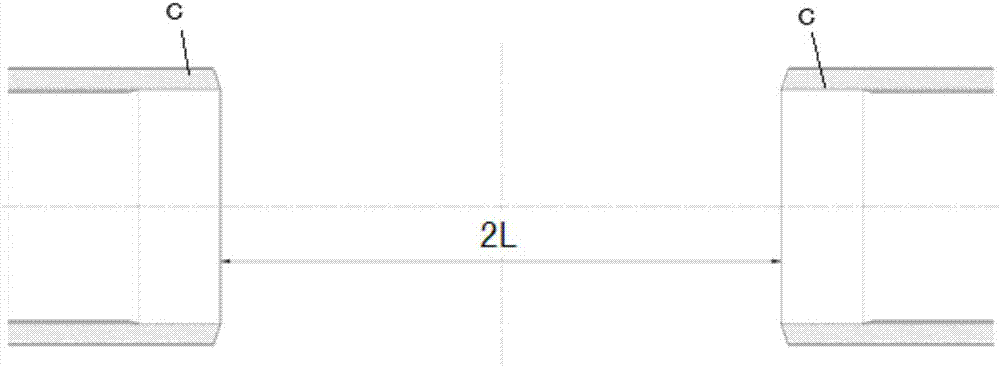

[0031] (1) According to the steel pipe specifications specified in the design, two sections of steel pipe short pipes are intercepted as the first joint short pipe a and the second joint short pipe b, and the length of the short pipes is greater than 1.5D;

[0032] (2) Use TIG steel pipe internal surfacing welding machine to surfacing stainless steel materials on the inner wall circumference of the first short pipe a and the second short pipe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com