Dental prosthesis CAD/CAM/SLM-3D printing compound method

A technology of oral prosthesis and 3D printer, which is applied in 3D printing, dental prosthesis, manufacturing tools, etc., can solve the problems of material waste, single type of prosthesis, and inability to cut and process prosthesis, so as to get rid of cumbersome procedures and improve production Quality and stability, the effect of personalized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

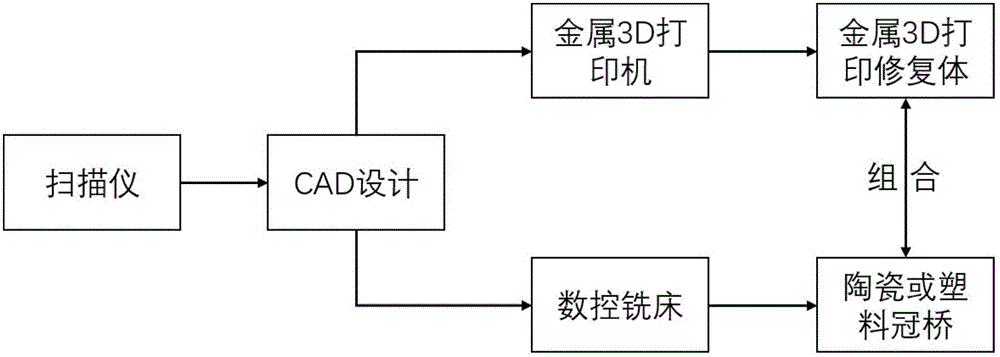

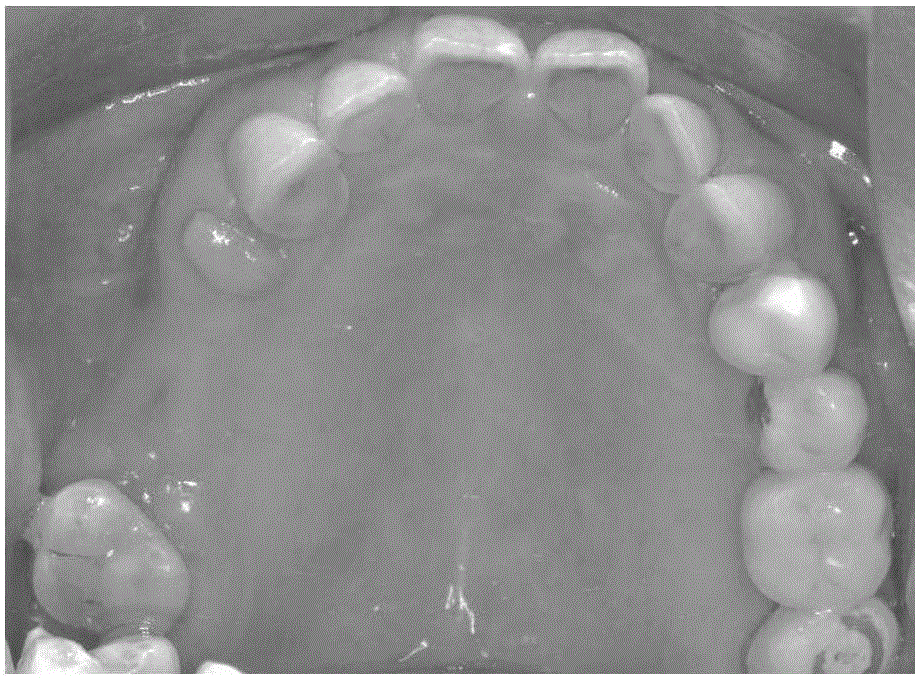

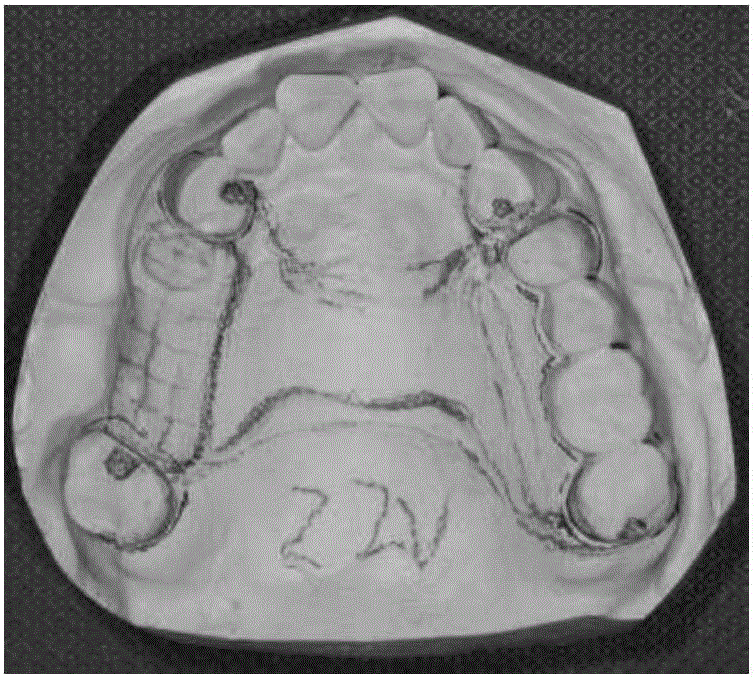

[0055] In the following examples, the applicant adopts a CAD / CAM / SLM-3D printing composite composed of an optical scanning measuring instrument or a contact scanning measuring instrument, a computer-aided design software for dental restorations, a miniaturized metal 3D printer, and a CNC milling machine. The system consists of three parts. The first is an optical scanning measuring instrument or a contact scanning measuring instrument, which completes the collection of oral digital models by scanning plaster models, impressions made in the mouth, and directly scanning soft and hard tissues in the mouth. ; The second is the computer-aided design software for oral restorations, which completes the computer-aided design of oral restoration configurations. The third is the miniaturized metal 3D printer and CNC milling machine. The 3D printer prints the designed metal base or bracket CAD data with metal powder, and the metal powder meets the national medical license standard. CNC c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com