Manufacturing method for steel inter-anticorrosion-mouth-repair-free elbow

A manufacturing method and internal anti-corrosion technology, applied in pipeline anti-corrosion/rust protection, elbows, siphon pipes, etc., can solve the problems of anti-corrosion repairing of the inner wall of pipe elbow welds, affecting the life of steel pipes, safety and environmental risks, etc. problems, to achieve the effect of solving the bottleneck of anti-corrosion technology in the welding joint of steel pipe elbows, reducing pipeline anti-corrosion and construction costs, and prolonging the life cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0026] The present invention includes the following contents:

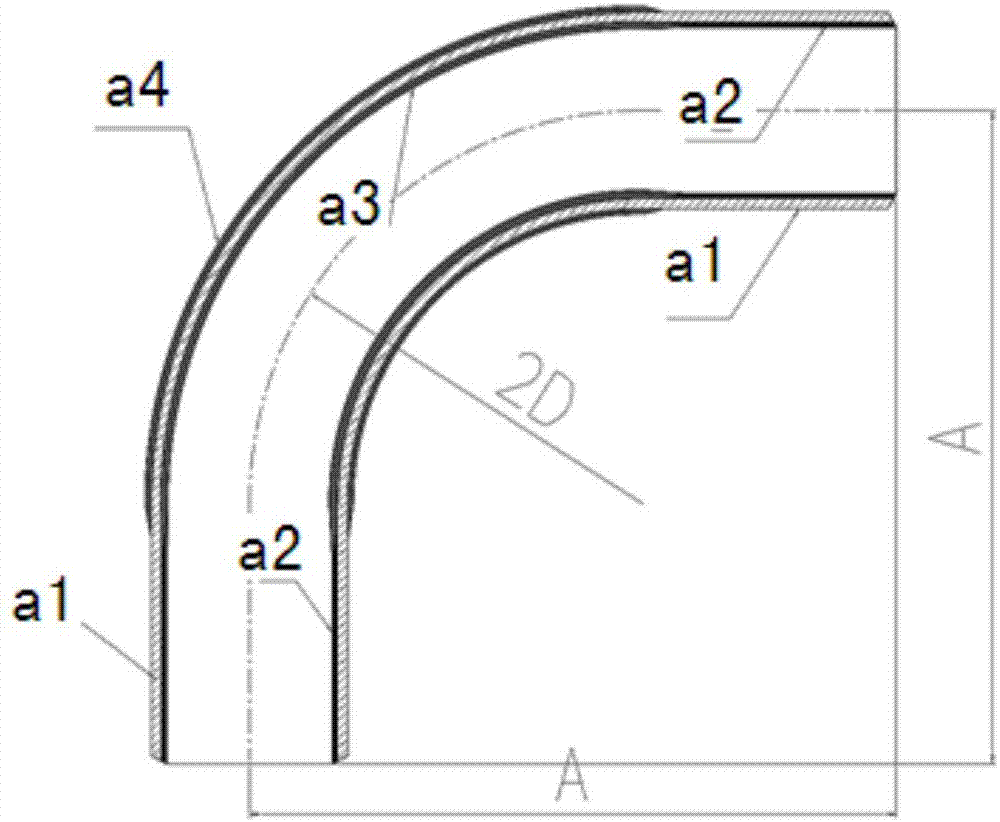

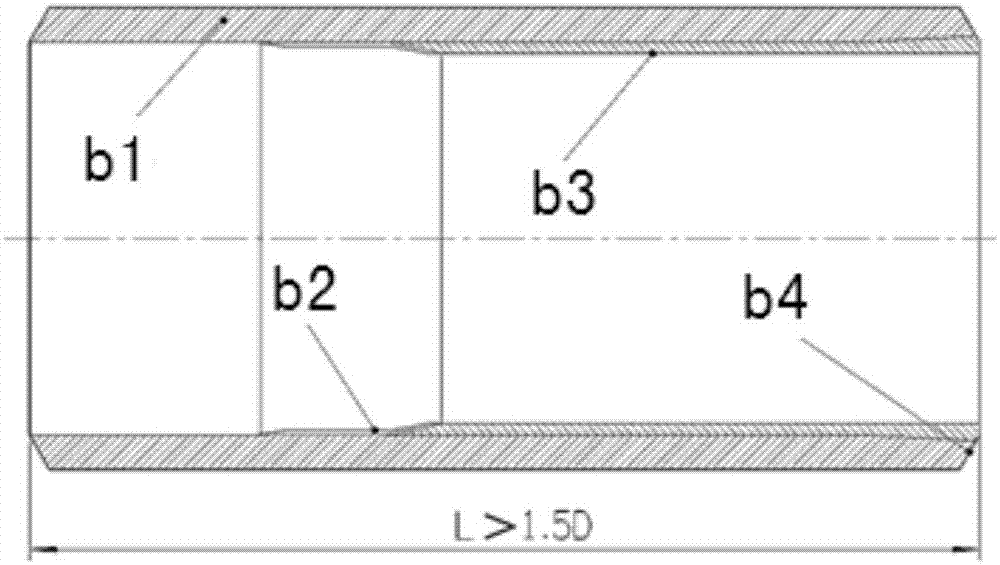

[0027] (1) A pre-welded elbow welded at both ends of the elbow, with a stainless steel short pipe pre-surfacing on the inner wall of the pipe end, and a steel anti-corrosion-free repaired elbow coated with an anti-corrosion coating on the inner and outer walls of the elbow The manufacturing method of the tube; its structure is as ( figure 1 ), the bend radius is equal to 2D;

[0028] (2) The specifications of elbows with different outer diameters are specified in the table below:

[0029]

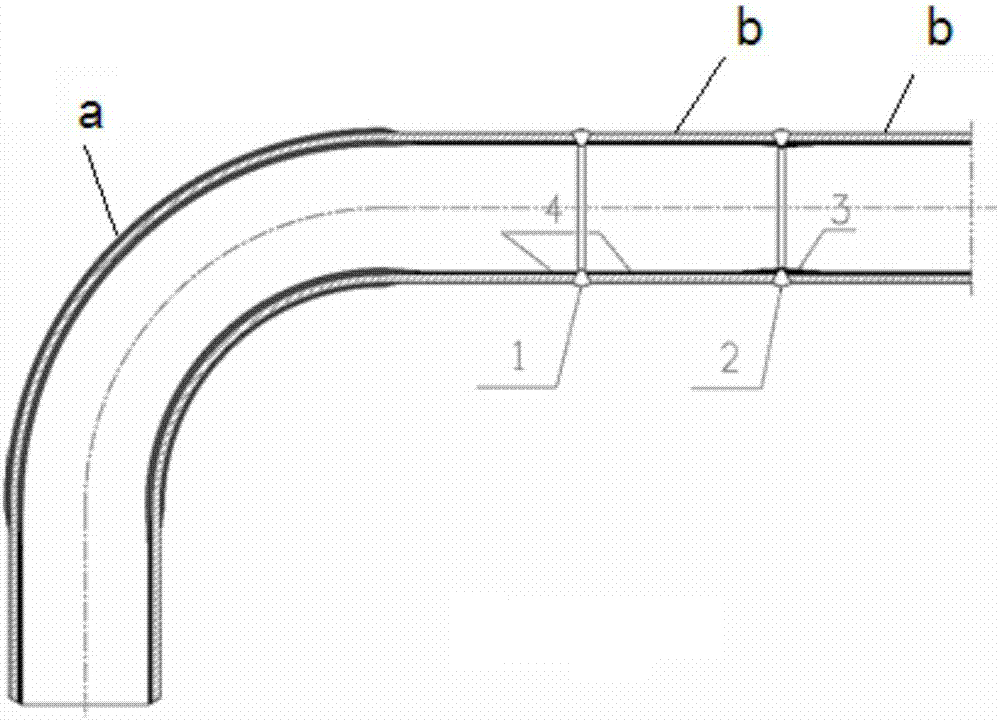

[0030] (3) Provides on-site connection methods;

[0031] Its specific implementation steps are as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com