Patents

Literature

86 results about "Leucite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

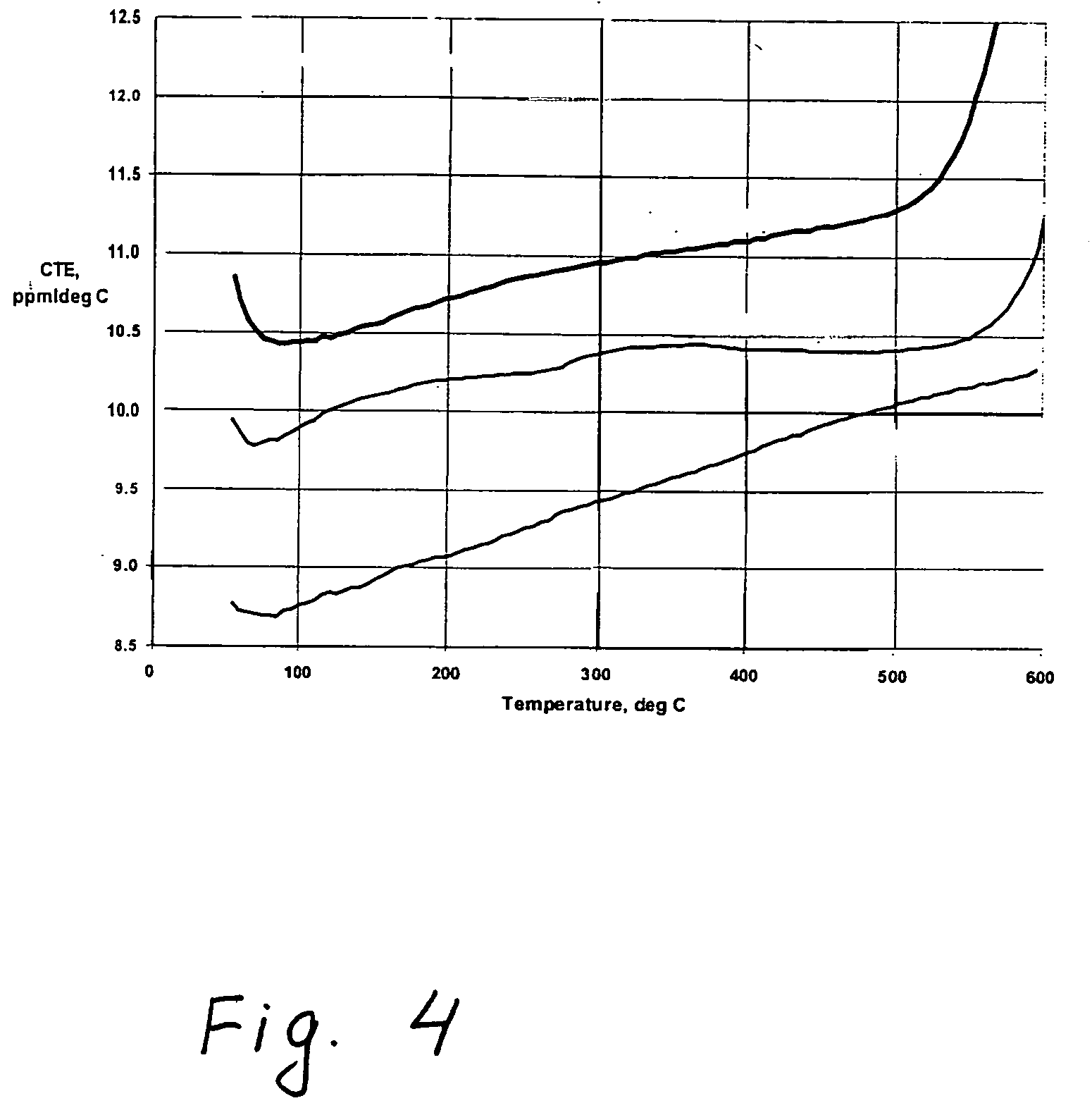

Leucite is a rock-forming mineral composed of potassium and aluminium tectosilicate K[AlSi₂O₆]. Crystals have the form of cubic icositetrahedra but, as first observed by Sir David Brewster in 1821, they are not optically isotropic, and are therefore pseudo-cubic. Goniometric measurements made by Gerhard vom Rath in 1873 led him to refer the crystals to the tetragonal system. Optical investigations have since proved the crystals to be still more complex in character, and to consist of several orthorhombic or monoclinic individuals, which are optically biaxial and repeatedly twinned, giving rise to twin-lamellae and to striations on the faces. When the crystals are raised to a temperature of about 500 °C they become optically isotropic and the twin-lamellae and striations disappear, although they reappear when the crystals are cooled again. This pseudo-cubic character of leucite is very similar to that of the mineral boracite.

Low alkali sealing frits, and seals and devices utilizing such frits

A solid oxide fuel cell device incorporates a sealing material resistant to hydrogen gas permeation at a sealing temperature in the intermediate temperature range of 600° C.–900° C., the seal having a CTE in the 100×10−7 / ° C. to 120×10−7 / ° C., wherein the sealing material comprises in weight %, of: (i) a 80 wt % to 100 wt % glass frit, the glass frit itself having a composition comprising in mole percent of: SiO2 15–65; Li2O 0–5; Na2O 0–5; K2O 0–10; MgO 0–5; CaO 0–32; Al2O3 0–10; B2O3 0–50; SrO 0 to 25, wherein the total amount of alkalis is less than 10 mole %; and(ii) zirconia or leucite addition 0 wt % to 30 wt.

Owner:CORNING INC

Ceramic dental restoration

A ceramic restoration based on a leucitic glass-ceramic, which is characterized in that the glass-ceramic includes by way of componentsin that it contains, as sole crystalline phase, leucite in a total proportion from 20 to 45 wt.-%, at least 80% of the theoretically producible quantity of leucite being present, and in that it exhibits a linear coefficient of thermal expansion alpha(20-500° C.) from 12.5.10-6 to 15.5.10-6 K-1. This glass-ceramic is particularly suitable for processing as pressed ceramic and can be advantageously faced with dental ceramic that exhibits a linear coefficient of thermal expansion alpha(20-500° C.) from 13.5.10-6 to 17.0.10-6 K-1.

Owner:DEGUSSA HULS AG

Low alkali sealing frits, and seals and devices utilizing such frits

A solid oxide fuel cell device incorporates a sealing material resistant to hydrogen gas permeation at a sealing temperature in the intermediate temperature range of 600° C.-900° C., the seal having a CTE in the 100×10−7 / ° C. to 120×10−7 / ° C., wherein the sealing material comprises in weight %, of: (i) a 80 wt % to 100 wt % glass frit, the glass frit itself having a composition comprising in mole percent of: SiO2 15-65; Li2O 0-5; Na2O 0-5; K2O 0-10; MgO 0-5; CaO 0-32; Al2O3 0-10; B2O3 0-50; SrO 0 to 25, wherein the total amount of alkalis is less than 10 mole %; and (ii) zirconia or leucite addition 0 wt % to 30 wt.

Owner:CORNING INC

Sealing materials and devices utilizing such materials

A solid oxide fuel cell device incorporates a sealing material resistant to hydrogen gas permeation at a sealing temperature in the intermediate temperature range of 600° C.-800° C., the seal having a CTE in the 100×10−7 / ° C. to 120×10−7 / ° C., wherein the sealing material comprises in weight %, of: (i) a 80 to 95 wt % of glass frit, the glass frit itself having a composition in mole percent of: SiO2 70-85%; Al2O3 0-5%; Na2O3 0-8%; K2O 10-25%; ZnO 0-10%; ZrO2 0-6%; MgO 0-7%; TiO2 0-2%; and (ii) and 5 wt % to 25 wt % of addition comprising at least one of: alumina, zirconia or leucite.

Owner:CORNING INC

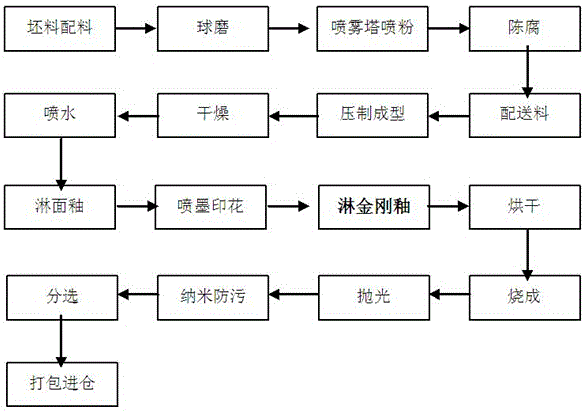

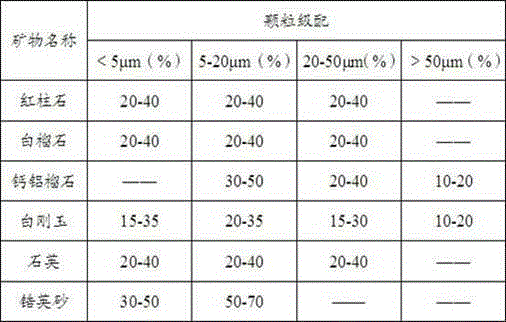

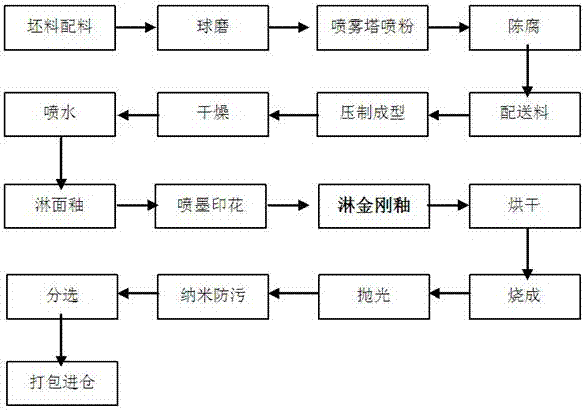

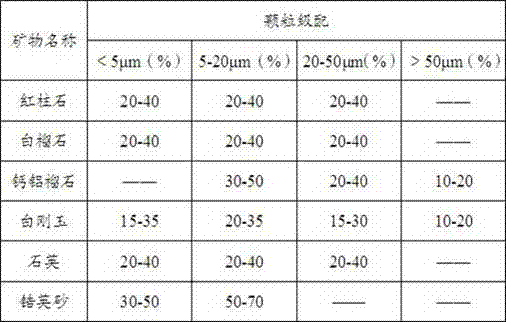

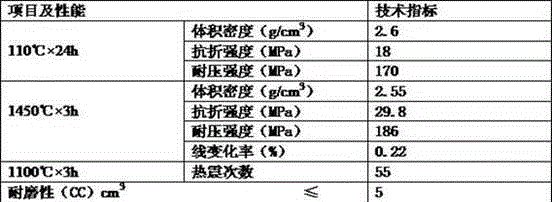

Wear resistant and high-hardness diamond glaze, preparation method and application

The invention discloses a wear resistant and high-hardness diamond glaze, a preparation method and application. The wear resistant and high-hardness diamond glaze is prepared from the following raw materials according to mass percent: 5 to 15% of kaolin, 5 to 10% of andalusite, 5 to 10% of orthoclase, 5 to 12% of leucite, 1 to 3% of essonite, 10 to 18% of nepheline, 5 to 15% of spodumene, 2 to 8% of wollastonite, 3 to 7% of quartz, 5 to 10% of zircon sand, 5 to 10% of white corundum, 1 to 3% of dolomite, 1 to 3% of calcined white talc, 0.1 to 0.5% of zinc oxide and 0.5 to 3% of additive. According to the wear resistant and high-hardness diamond glaze, the preparation method and the application, the selection of mineral raw materials of the glaze is optimized, firstly, the wear resistant and high-hardness mineral raw materials such as the andalusite (the hardness is 6.9 to 7.4), the white corundum (the hardness is 9.0), the leucite (the hardness is 5.5 to 6) and the essonite (the hardness is 7 to 7.5) are selected, the grain fineness and addition of the wear resistant and high-hardness mineral raw materials are controlled through reasonable grain composition, and by adopting the subsequent preparation process and application process, the wear resistance and hardness of the diamond glaze are greatly increased.

Owner:FOSHAN ZHONGCHENG SILICATE TECH CO LTD

Sealing materials and devices utilizing such materials

A solid oxide fuel cell device incorporates a sealing material resistant to hydrogen gas permeation at a sealing temperature in the intermediate temperature range of 600° C.–800° C., the seal having a CTE in the 100×10−7 / ° C. to 120×10−7 / ° C., wherein the sealing material comprises in weight %, of: (i) a 80 to 95 wt % of glass frit, the glass frit itself having a composition in mole percent of: SiO2 70–85%; Al2O3 0–5%; Na2O3 0–8%; K2O 10–25%; ZnO 0–10%; ZrO2 0–6%; MgO 0–7%; TiO2 0–2%; and (ii) and 5 wt % to 25 wt % of addition comprising at least one of: alumina, zirconia or leucite.

Owner:CORNING INC

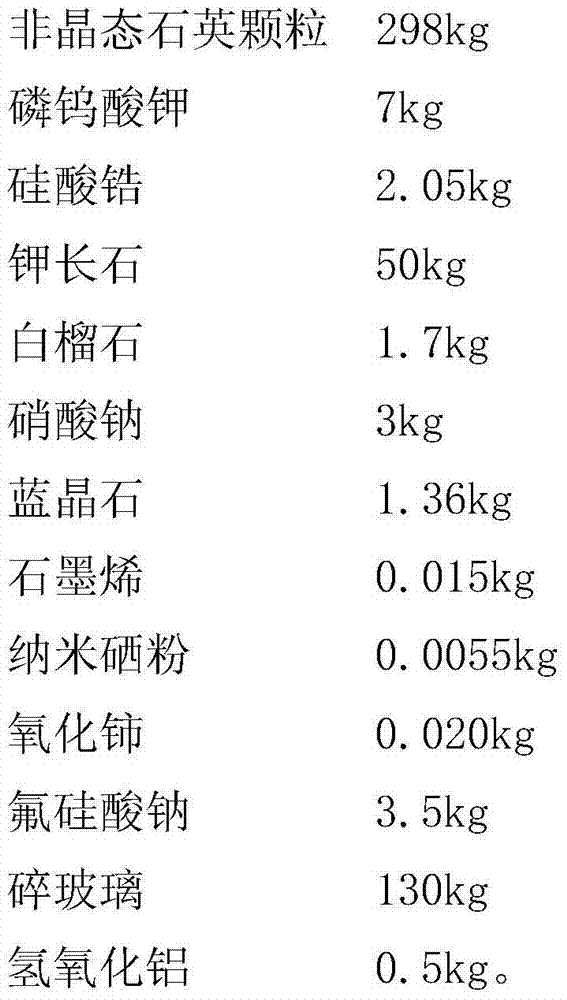

High-strength heatproof glassware

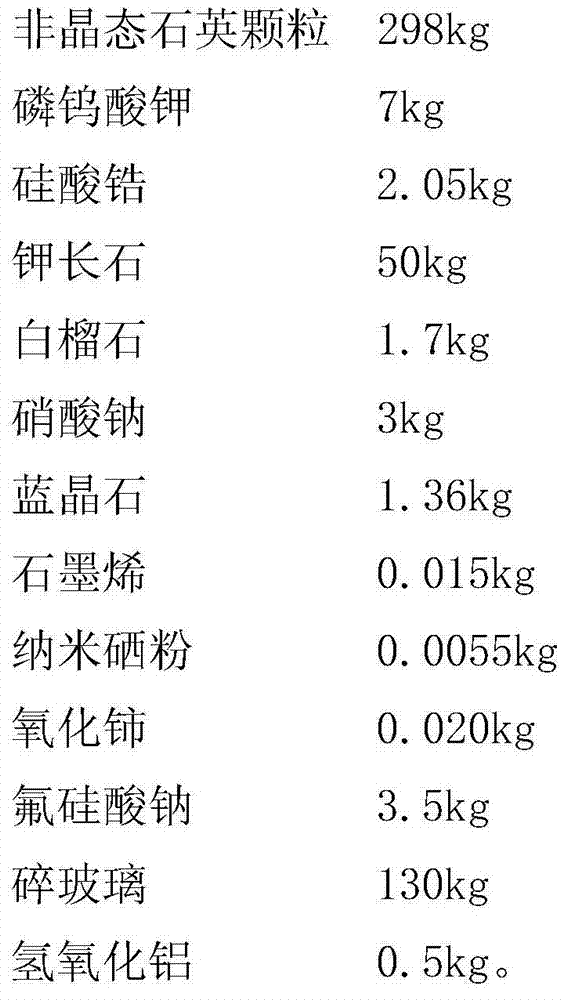

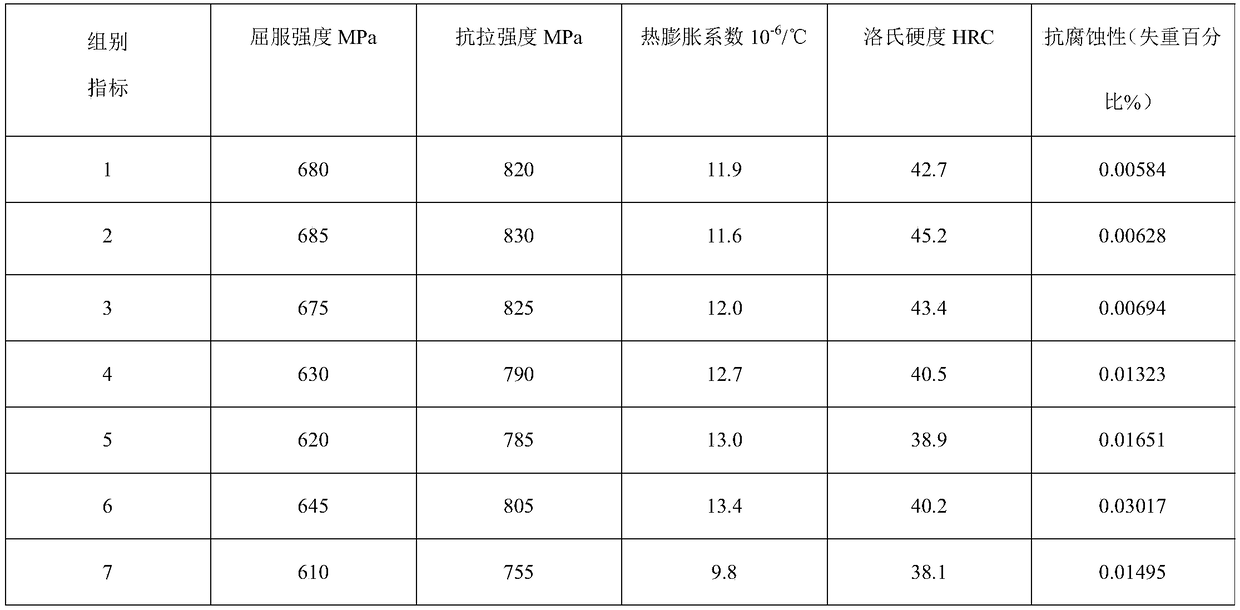

The invention relates to the technical field of glass and provides a high-strength heatproof glassware. The glassware comprises, by weight, 298 kg of an amorphous quartz granule, 7 kg of potassium phosphotungstate, 2.05 kg of zirconium silicate, 50 kg of potash feldspar, 1.7 kg of leucite, 3 kg of sodium nitrate, 1.36 kg of kyanite, 0.015 kg of graphene, 0.0055 kg of nanometer selenium powder, 0.020 kg of cerium oxide, 3.5 kg of sodium fluosilicate, 130 kg of cullet and 0.5 kg of aluminum hydroxide. According to the invention, since the amorphous quartz granule is used as a main material, a good molding effect and good glossiness are obtained; through addition of the component--graphene, electrochemical polarization among active substance particles is reduced, and the strength of the glassware is greatly improved due to structural strength and networking of graphene; a prepared glass is safe and reliable to use and has improved surface glossiness, an improved reflection effect and a beautiful color.

Owner:ANHUI FENGYANG HUAIHE GLASS

Tinct adjustable stomatic bioactive divitrified glass and its prepn

InactiveCN1349944AHigh strengthGood biocompatibilityArtificial teethLeuciteUltimate tensile strength

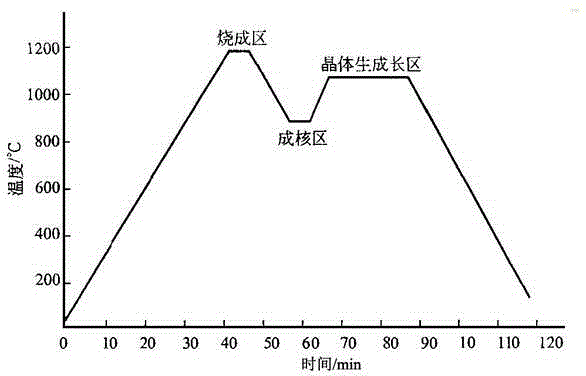

The invention relates to an oral cavity bio-active nucleated glass with adjustable colour and its rpeparation method. Its preparation method includes the following steps: firstly, uniformly mixing raw materials according to a certain mixing ratio, melting for 3 hr. at 1400-1550 deg.C, pouring the molten glass inti mould and forming to obtain blank, cooling to room temp., heating glass blank and heat-insulating to make glass nucleate, continuously heating and heat-insulating to make glass crystallize to obtain the bio-active nucteated glass using apatite and fluorophlogopite as main crystal phase. Said nucleated glass uses TiO2 / ZrO2 as crystal nucleus agent, and contains a certain crystal phase formed from leucite and calc-silicate stone to raise its strength, and said product possesses good bio-compatibility, machinability and beautifulness.

Owner:TSINGHUA UNIV

Machinable Porcelain Compositions and Mill Blanks Thereof

A porcelain blank comprising a porcelain composition for dental restorations comprising a leucite crystallite phase and a glass matrix phase, wherein the leucite crystallites possess diameters not exceeding about 10 micron. Preferably, the porcelain composition has a maturing temperature from about 750° C. to about 1050° C. and a coefficient of thermal expansion from about 9×10−6 / ° C. to about 17.5×10−6 / ° C., and comprises:SiO257-67 Al2O37-15K2O7-15Na2O6-15Li2O0.5-3.

Owner:ARDENT

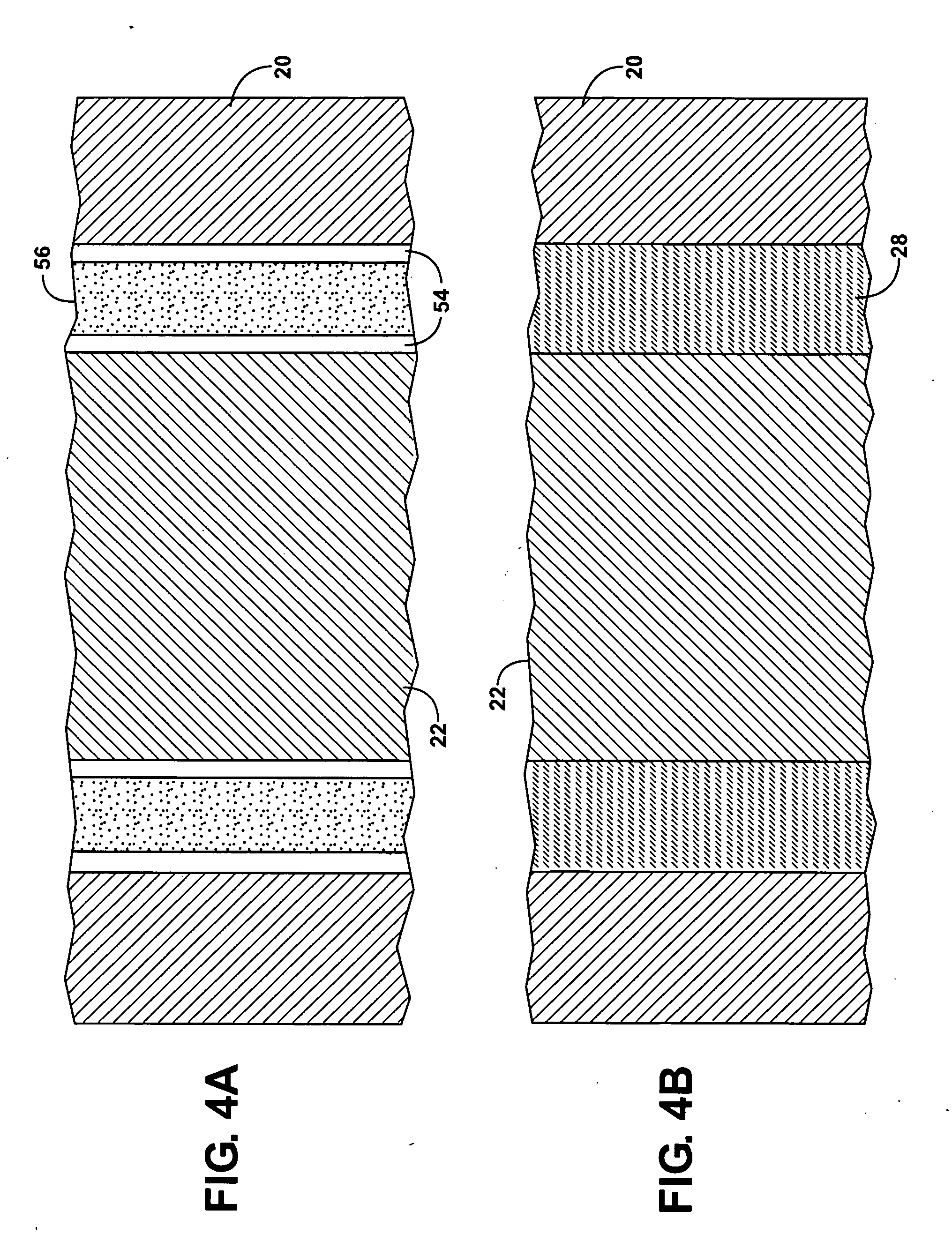

Nanometer porcelain denture and a manufacturing method thereof

ActiveCN108742904AImprove toughnessSuppress generationImpression capsArtificial teethLeuciteBiocompatibility Testing

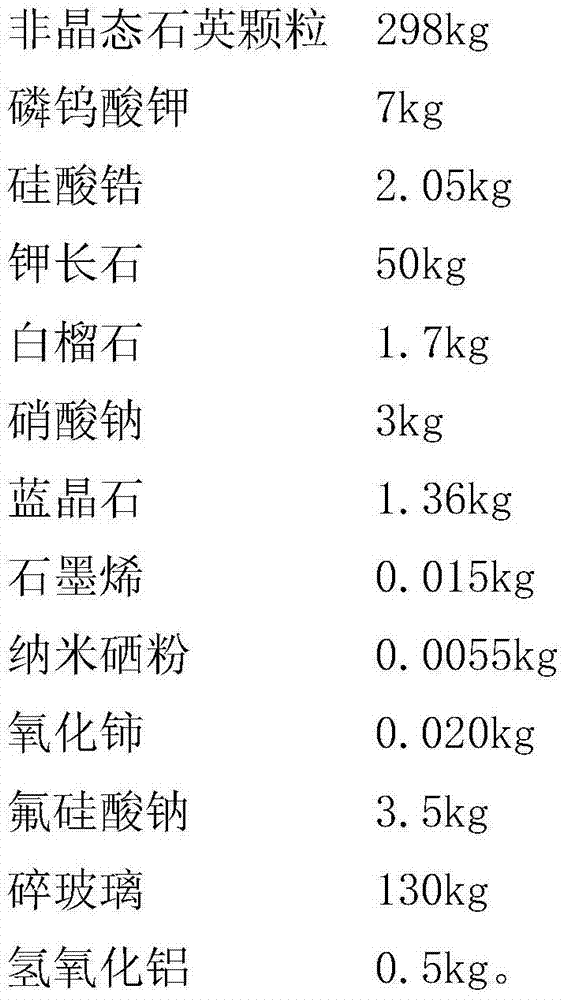

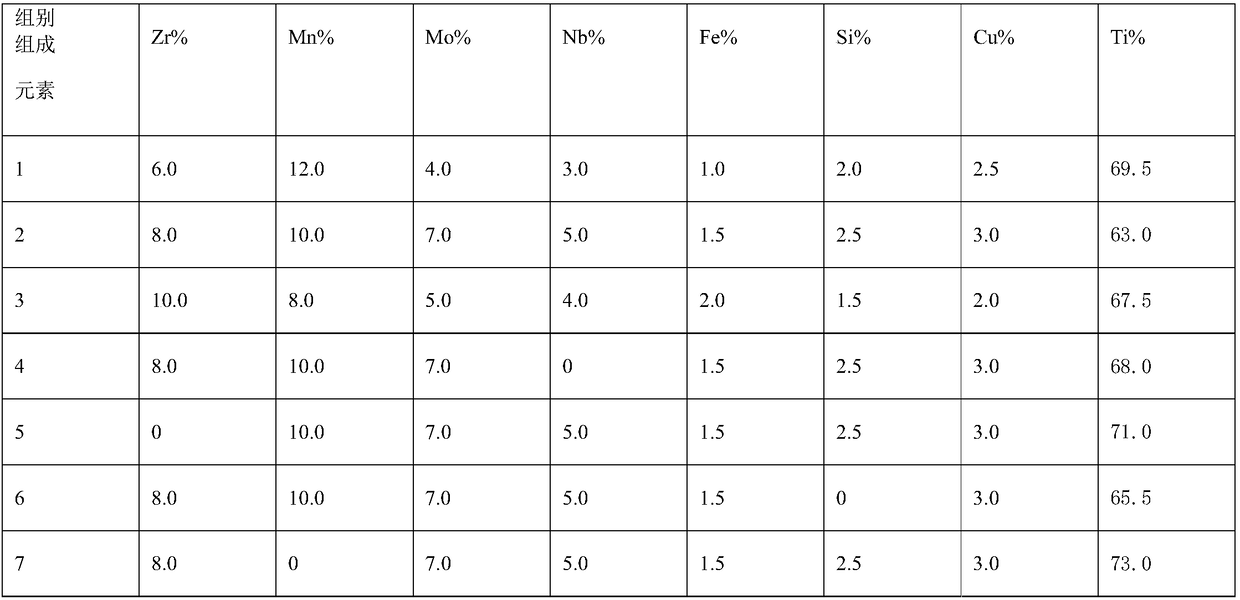

The invention belongs to the field of medical health, and particularly relates to a nanometer porcelain denture and a manufacturing method thereof, wherein the nanometer porcelain denture comprises ametal substrate and porcelain powder, the metal substrate comprises Zr, Mn, Mo, Nb, Fe, Si, Cu and Ti, and the porcelain powder comprises nanometer zirconia, nanometer titanium dioxide, nanometer hydroxyapatite, nanometer leucite and nanometer silica. According to the present invention, the process conditions of the manufacturing method are simple and easy to control, and the manufactured porcelain teeth have advantages of good stability, high safety and strong bonding force between gold and porcelain, and further integrate biocompatibility, mechanical compatibility and physical stability.

Owner:珠海新茂义齿科技有限公司

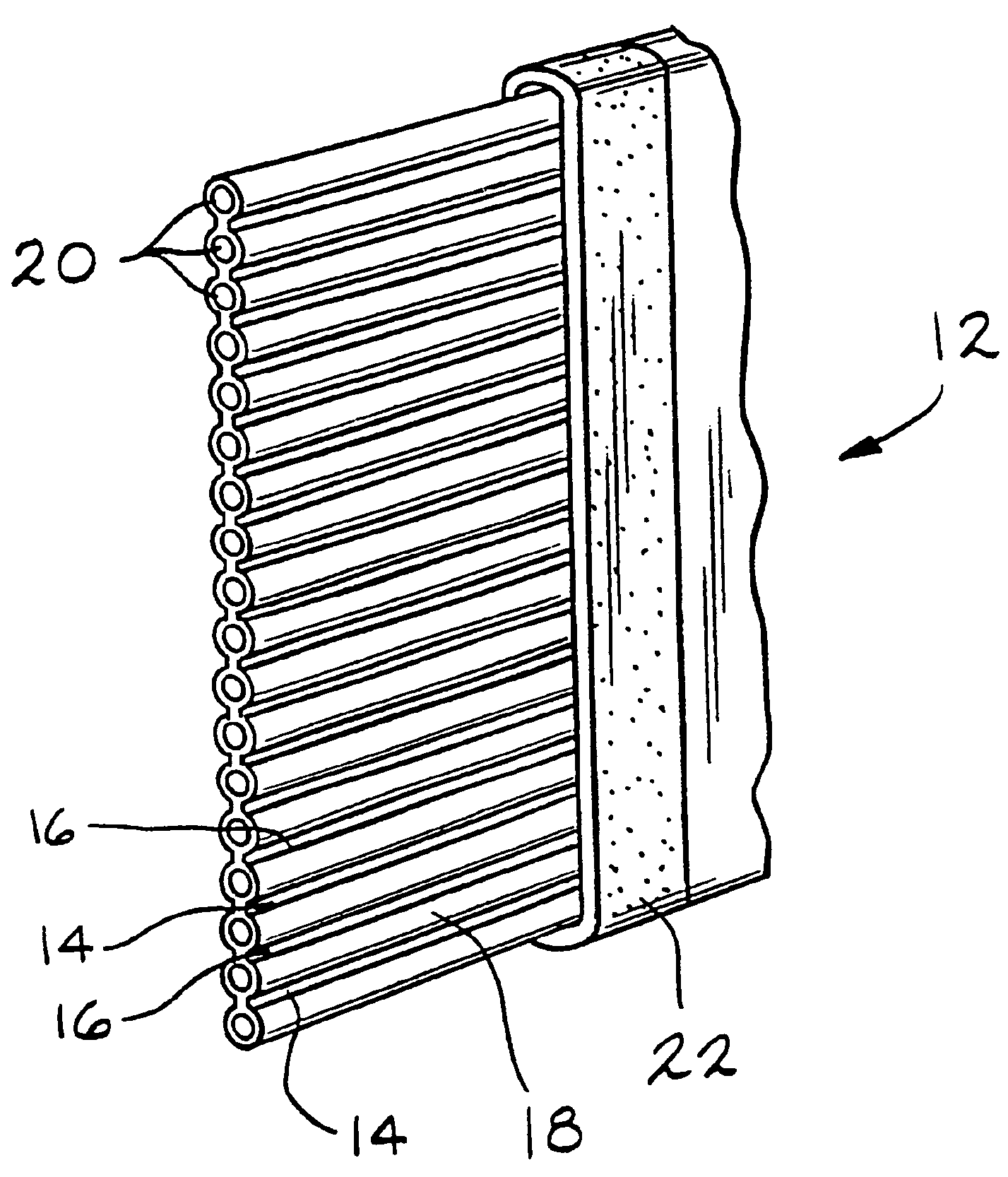

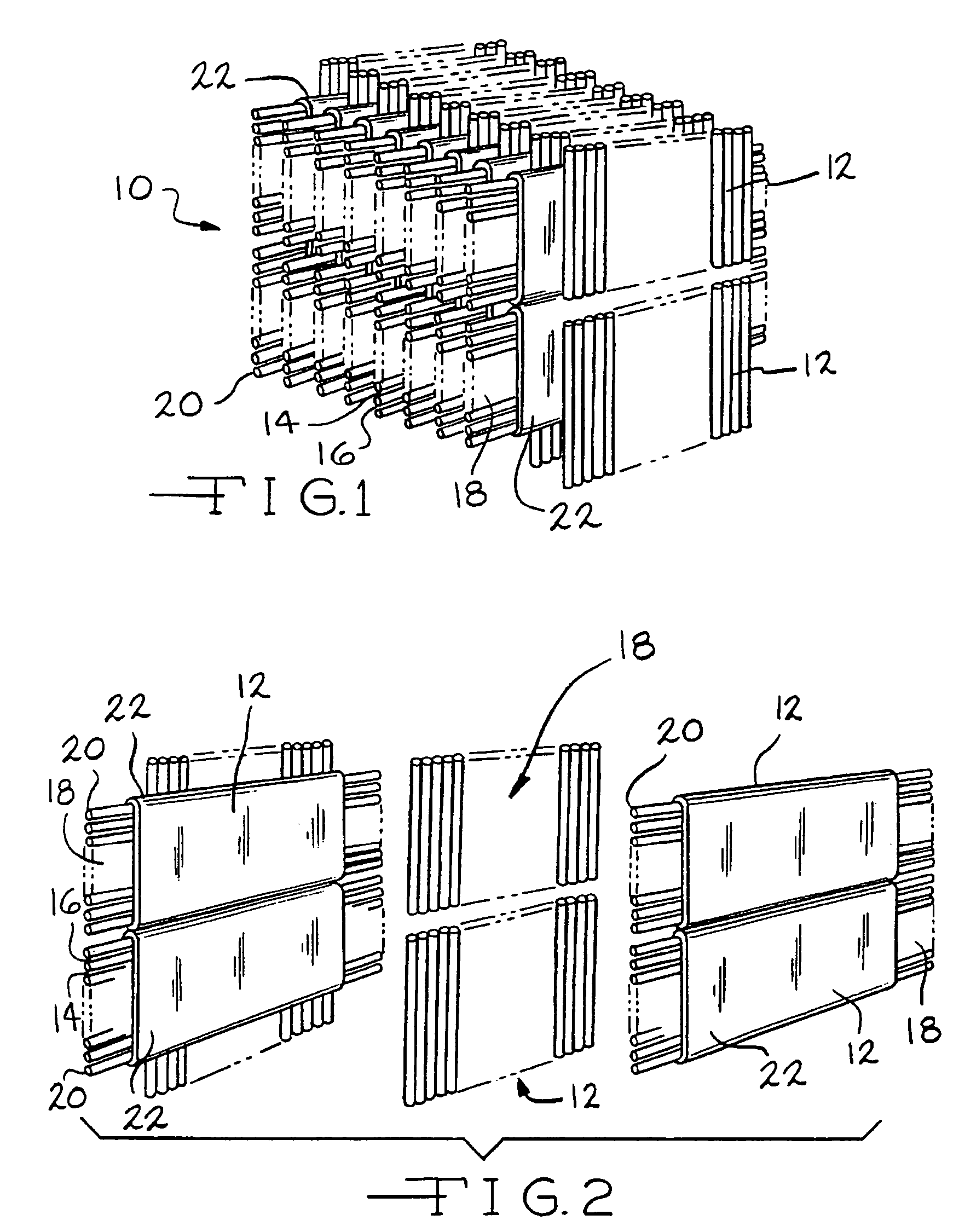

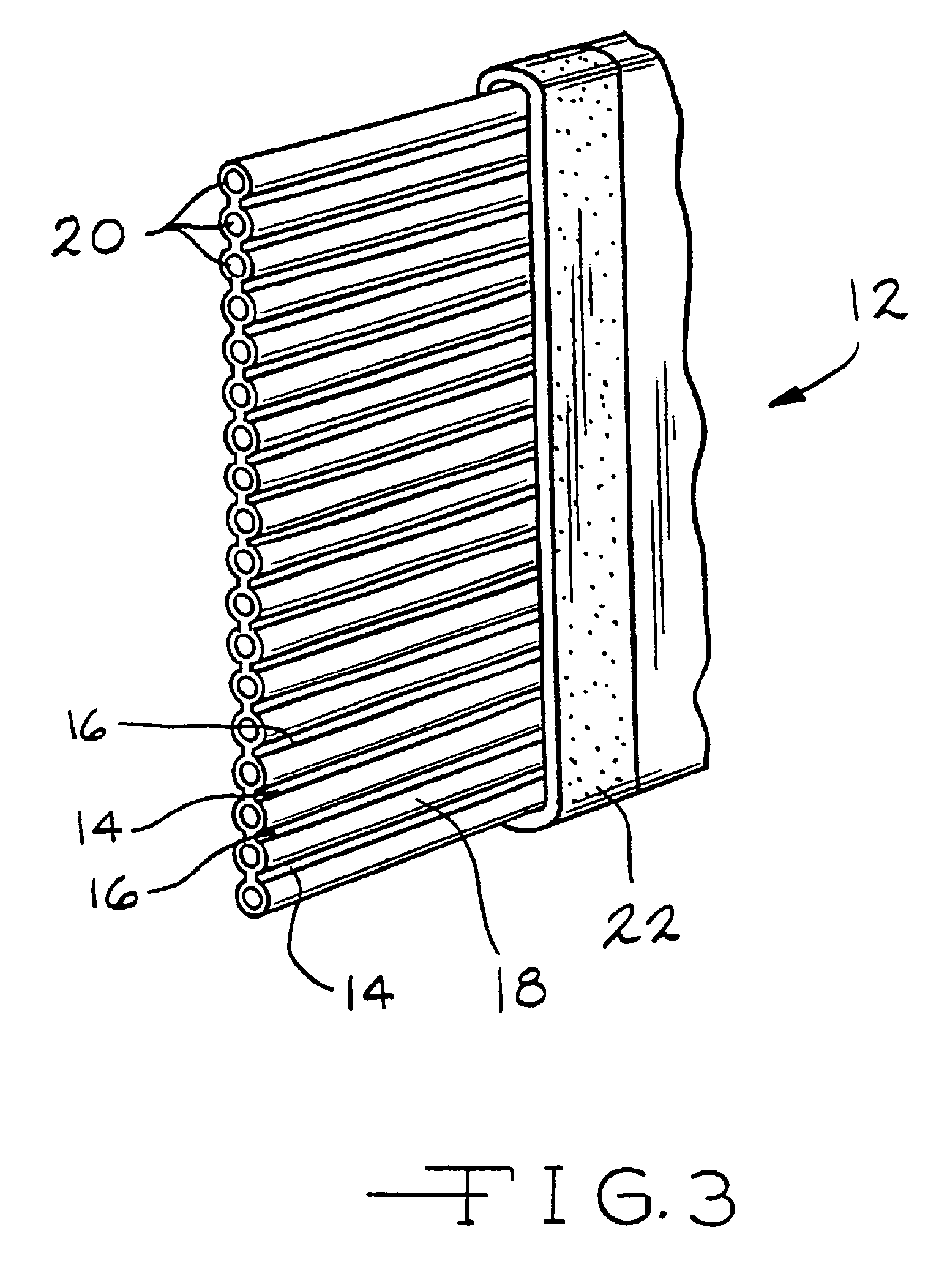

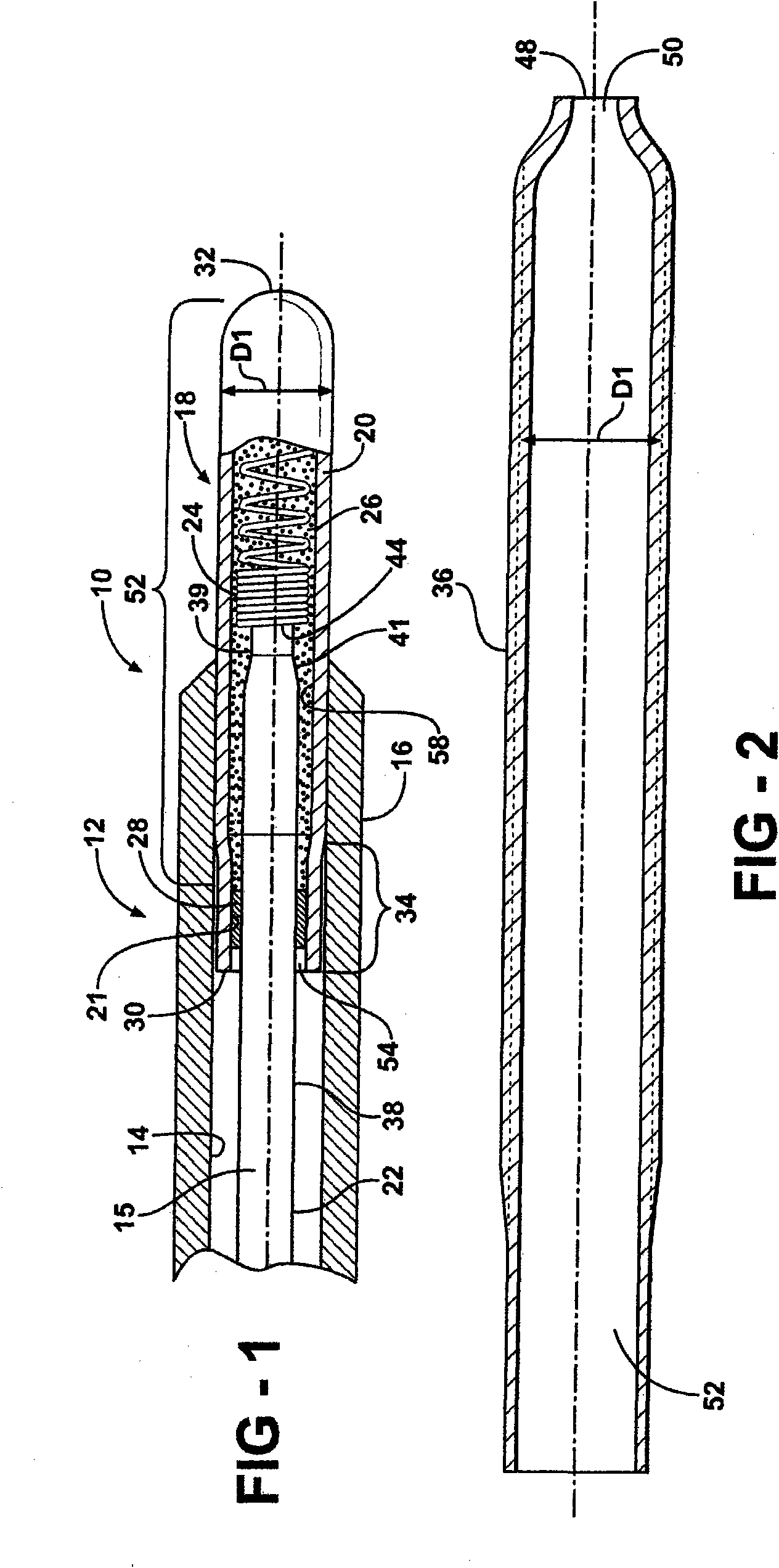

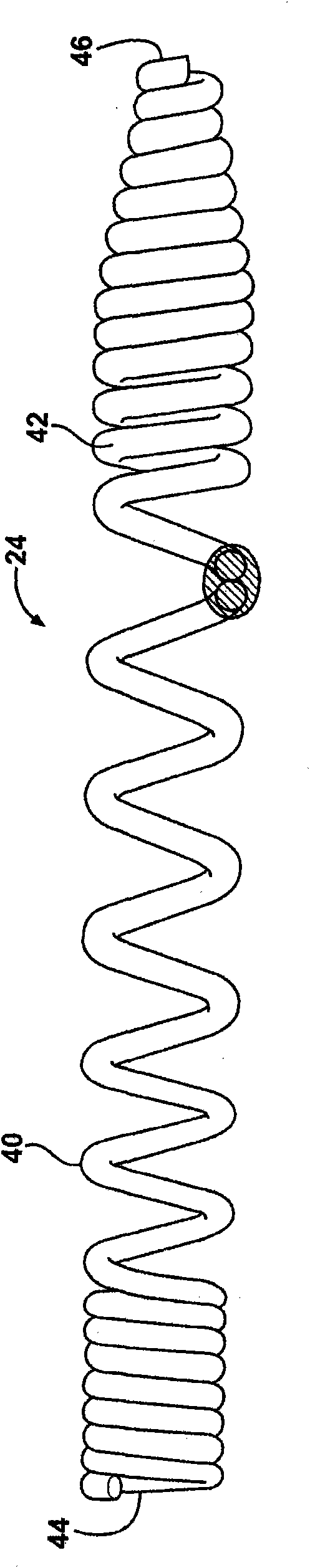

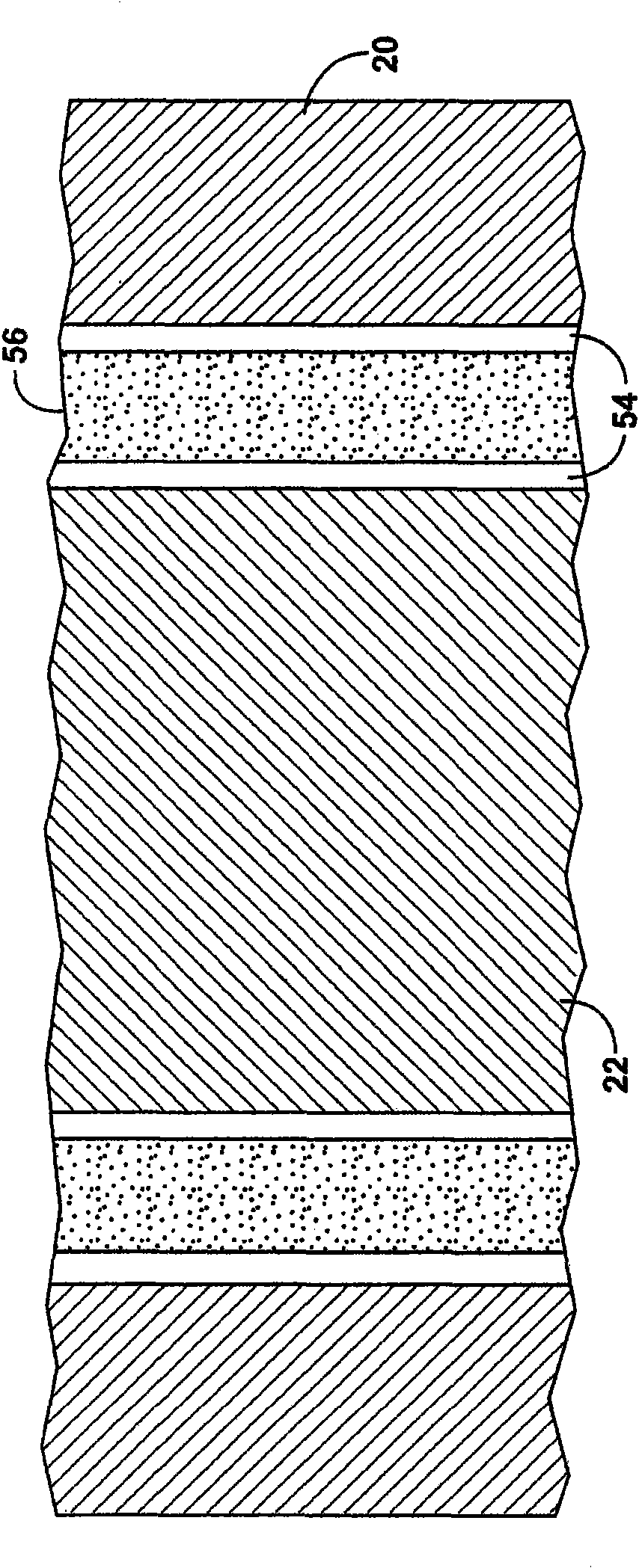

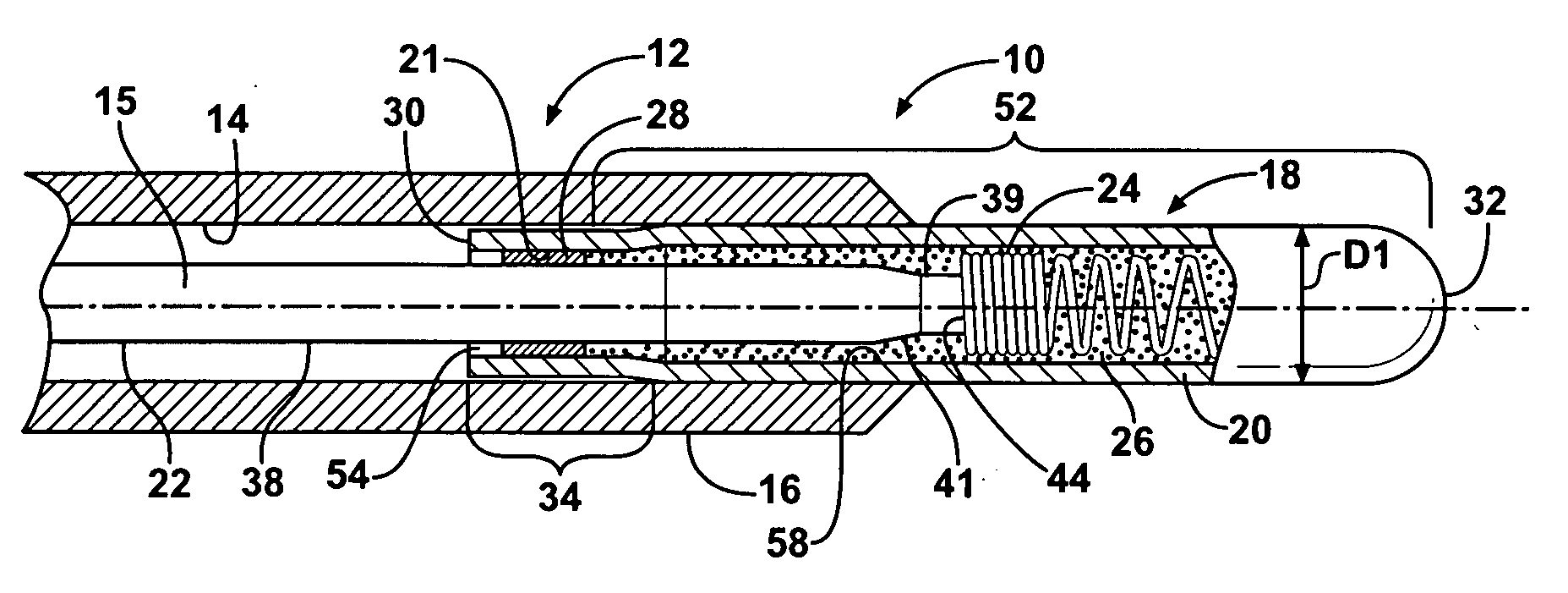

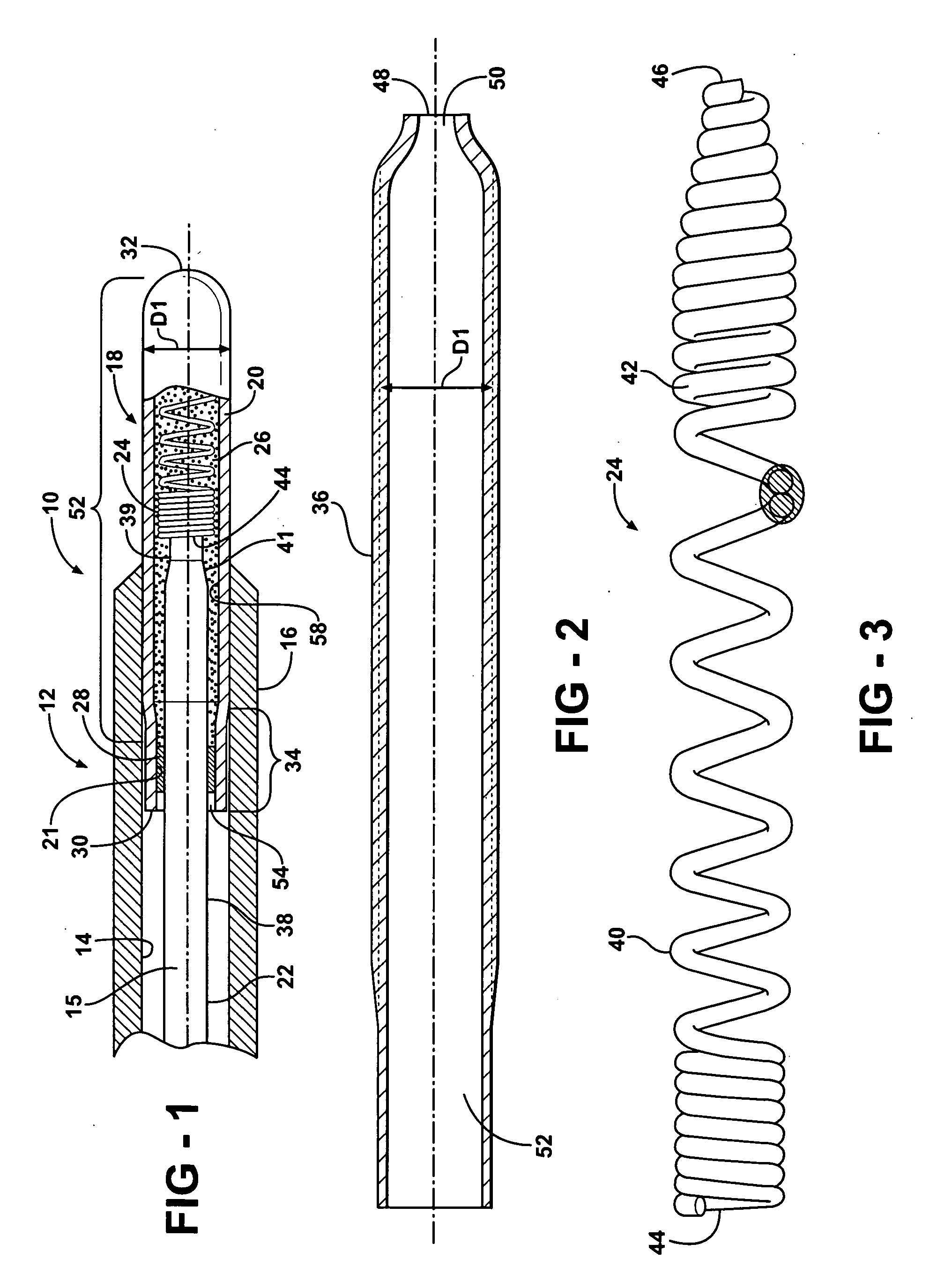

Sheathed glow plug

A glow plug which includes an annular metal shell, thermally conductive tubular sheath, central electrode; resistance heating element, and electrically insulating, thermally conductive powder includes a glass seal in sealing engagement with the sheath and the electrode to form a sealed cavity within the sheath. The glass seal may include silicate, borate and borosilicate glasses, and may include one or more transition metal oxides, such as oxides of chromium, cobalt, nickel, iron and copper. The glass may also include a filler, including a ceramic oxide, such as one selected from a group consisting of quartz, eucryptites, leucites, cordierites, beta-spodumene, glass-ceramics, low- expansion glass(CTE<5ppm / DEG C), mullite, zircon, zirconia and alumina. The sealed cavity may house a protective inert gas. The resistance heating element may be formed from a metal selected from a group consisting of tungsten, molybdenum, or alloys containing tungsten, molybdenum, nickel, iron, tantalum, niobium, titanium, vanadium, osmium and chromium.

Owner:FEDERAL MOGUL IGNITION

Ceramic product and ceramic member bonding method

ActiveUS20090214923A1Increased durabilityImprove heat resistanceCell electrodesFinal product manufactureLeuciteMetallurgy

The ceramic product provided by the present invention is provided with at least two ceramic members bonded to each other, and the bond parts between these ceramic members bonded to each other are formed from glass having leucite crystals precipitated within the glass matrix.

Owner:NORITAKE CO LTD

Sheathed glow plug

A glow plug which includes an annular metal shell, thermally conductive tubular sheath, central electrode; resistance heating element, and electrically insulating, thermally conductive powder includes a glass seal in sealing engagement with the sheath and the electrode to form a sealed cavity within the sheath. The glass seal may include silicate, borate and borosilicate glasses, and may include one or more transition metal oxides, such as oxides of chromium, cobalt, nickel, iron and copper. The glass may also include a filler, including a ceramic oxide, such as one selected from a group consisting of quartz, eucryptites, leucites, cordierites, beta-spodumene, glass-ceramics, low-expansion glass(CTE<5 ppm / ° C.), mullite, zircon, zirconia and alumina. The sealed cavity may house a protective inert gas. The resistance heating element may be formed from a metal selected from a group consisting of tungsten, molybdenum, or alloys containing tungsten, molybdenum, nickel, iron, tantalum, niobium, titanium, vanadium, osmium and chromium.

Owner:FEDERAL MOGUL IGNITION

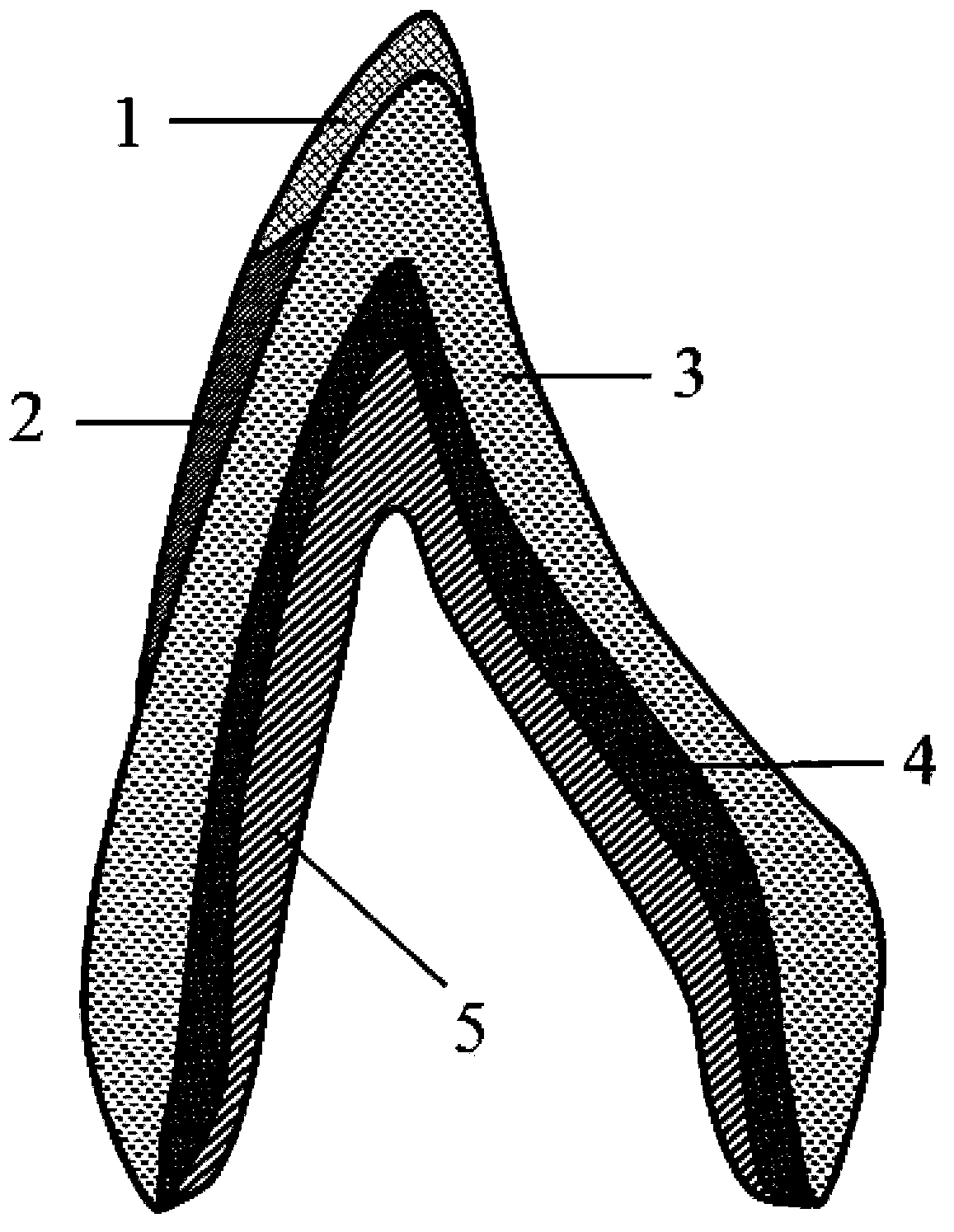

Glass used as dental veneering porcelain, preparation method and application thereof

ActiveCN103910489APorcelain low temperaturePorcelain temperature loweredGlass productionDental Veneer MaterialLeucite

The invention relates to a glass used as a dental veneering porcelain. The glass comprises, by mass, 50%-70% of SiO2, 6%-17% of B2O3, 6%-25% of Al2O3, 1%-10% of Na2O, and 17%-30% of K2O. The glass undergoes heat treatment at 700DEG C-1100DEG C, and leucite microcrystalline glass with different thermal expansion coefficients can be obtained. The microcrystalline glass only contains tetragonal phase leucite crystals, the size of which is less than 4 micrometers. The leucite microcrystalline glass has very good thermal stability, after experiencing a porcelain fusing program 10 times, the thermal expansion coefficient change of the leucite microcrystalline glass is less than 2%, and in a 120min process of heat preservation at a porcelain fusing temperature of 850DEG C, the size and number of the leucite crystals do not have obvious change. The leucite microcrystalline glass can be used as a transparent porcelain and incisal porcelain in the veneering porcelain, and also can be used as a body porcelain if a pigment is added.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Ceramic material

The invention discloses a ceramic material. According to the raw material formula, the ceramic material comprises, by weight, 50-100 parts of iron oxide, 50-100 parts of magnesium oxide, 50-80 parts of silicon dioxide, 50-80 parts of manganese, 30-50 parts of calcium oxide, 10-30 parts of molybdenum, 10-30 parts of aluminum, 10-30 parts of zinc, 10-30 parts of calcium, 20-30 parts of MgO-MnO-Al2O3-SiO2 system inclusion, 5-10 parts of pyrolusite, 100-150 parts of kaolinite and 100-150 parts of leucite. The ceramic material comprises aluminum oxide, magnesium oxide and other raw materials high in specific stiffness, and the aluminum oxide, the magnesium oxide and other raw materials high in rate serve as main components. The ceramic material meets the requirements for a low reflectivity and semi-conduction without greatly decreasing the rate of the aluminum oxide, the magnesium oxide and other raw materials.

Owner:李兆源

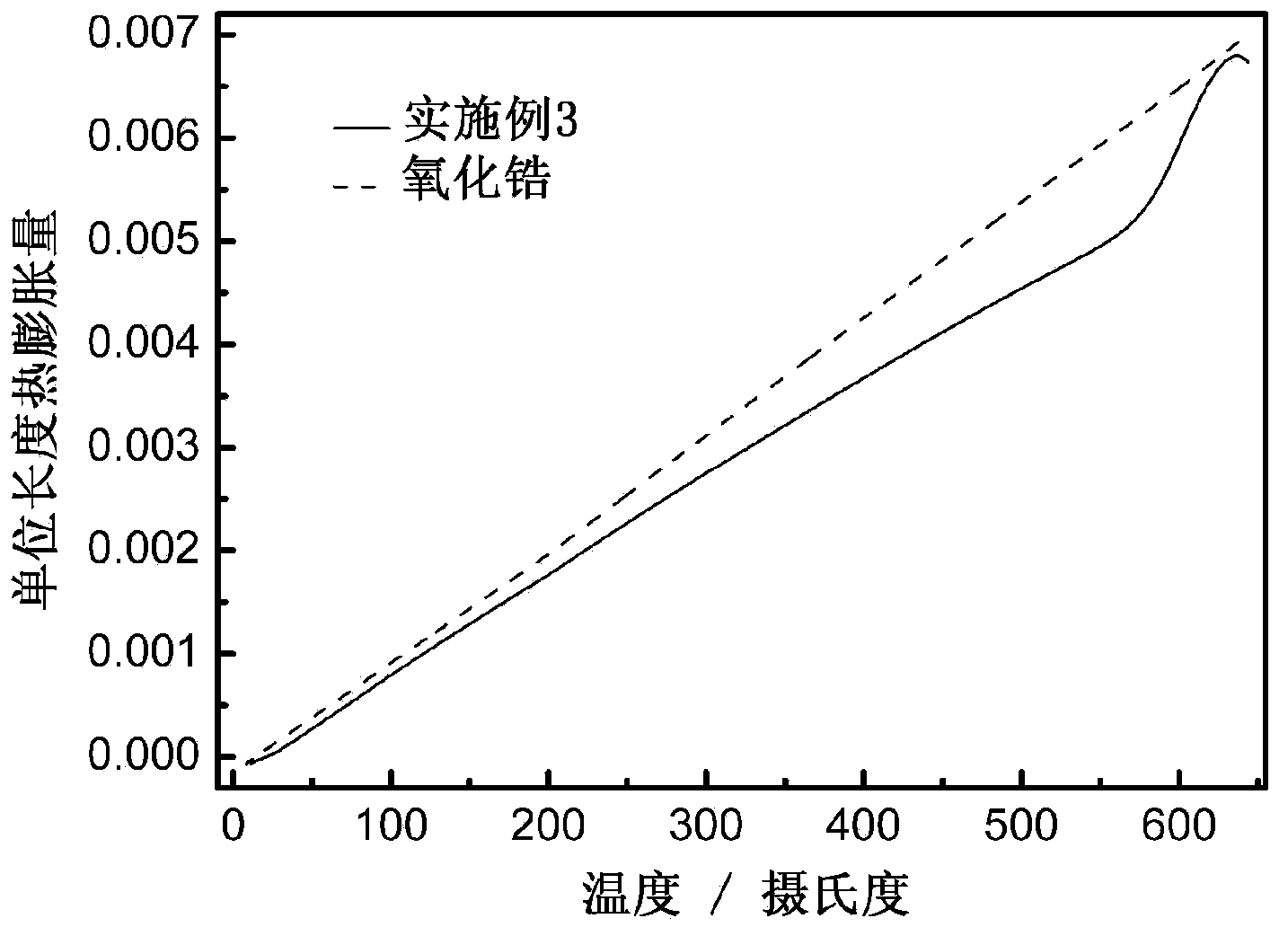

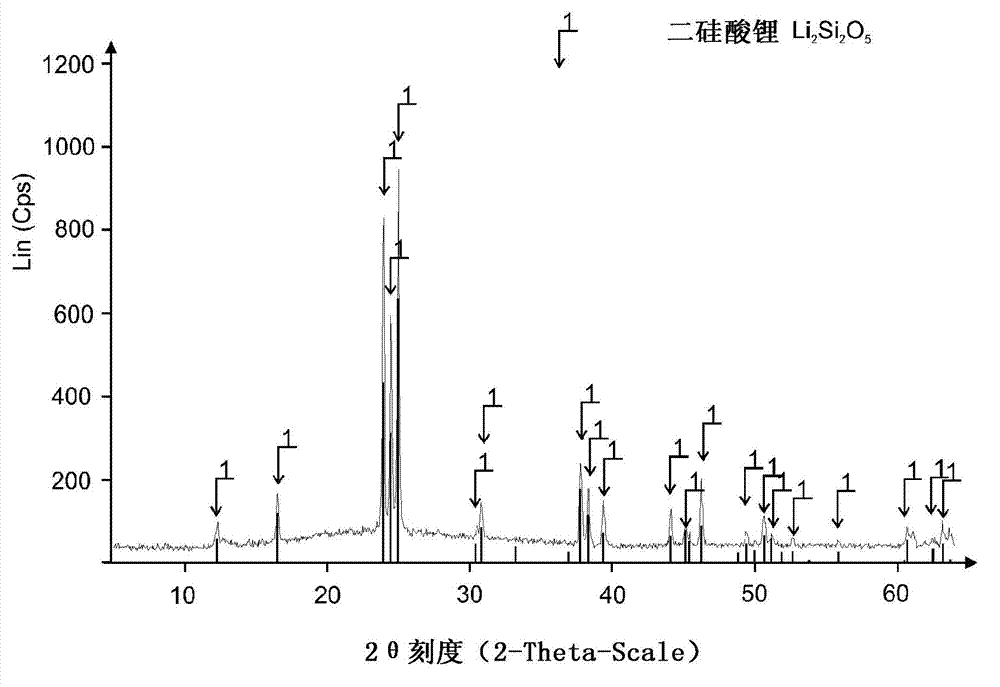

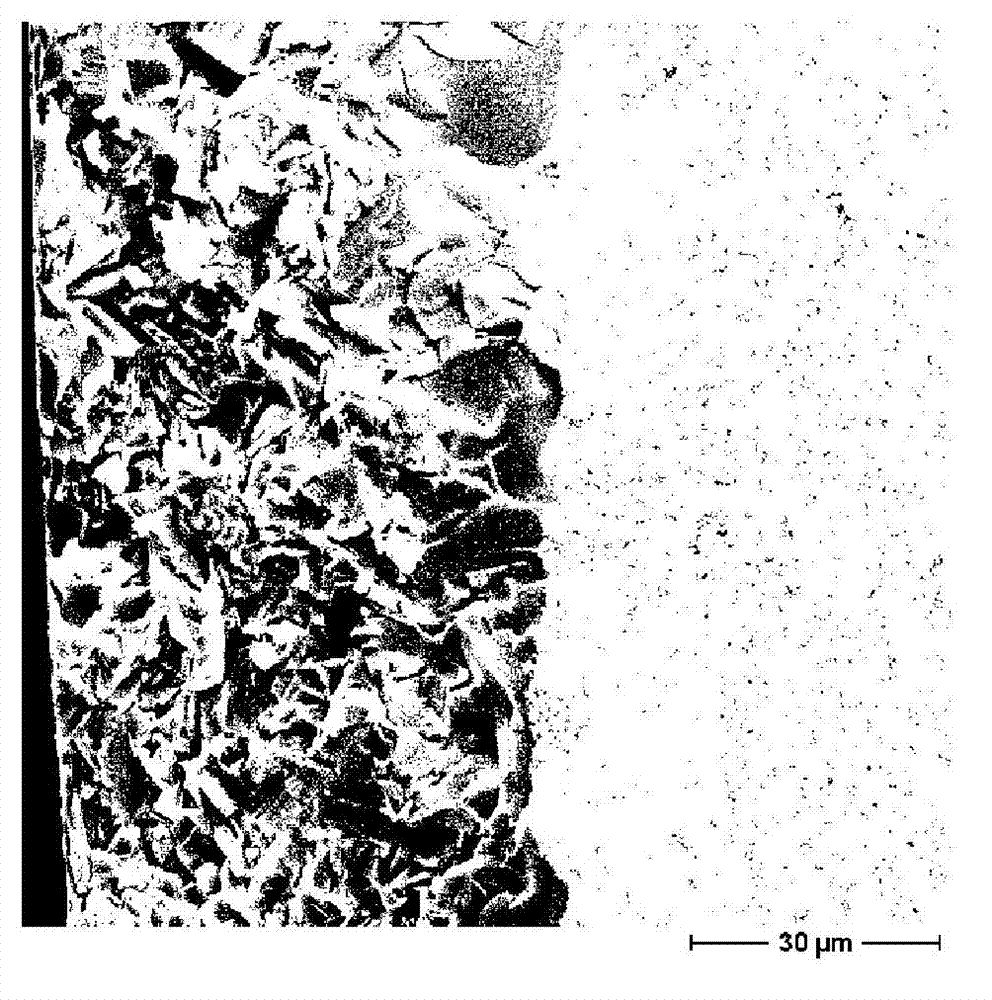

Veneering ceramic for dental restorations made of yttrium-stabilized zirconium dioxide and method for applying said veneering ceramic

The invention relates to veneering ceramics for dental restorations, wherein the framework ceramic is made of yttrium-stabilized zirconium dioxide. The aim of the invention is to develop a translucent veneering ceramic based on lithium disilicate and a method for applying the veneering ceramic for dental restorations made of yttrium-stabilized zirconium dioxide. Said veneering ceramic should not contain any leucite, lithium metasilicate, or ss-spodumene and should have very good chemical resistance, high adhesive strength with respect to zirconium dioxide, and good surface quality. According to the invention, said aim is achieved for a veneering ceramic on yttrium-stabilized zirconium dioxide in that the veneering ceramic is produced from the following components: a) SiO2 55.0 - 72.5 mass percent; b) Nb2O5 6.0 - 19.8 mass percent; c) B2O3 1.0 - 9.0 mass percent; d) Al2O3 1.2 - 6.0 mass percent; e) Li2O 5.0 - 16.5 mass percent; f) Na2O 1.4 - 11.0 mass percent; and g) ZrO2 0.5 - 4.0 mass percent, and is provided with a thin glass layer formed during the crystallization on the surface of the veneering ceramic.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Dentistry zirconia and leucite compound porcelain powder and preparing method thereof

InactiveCN101229100AReduce synthesis process proceduresUniform crystal phase distributionImpression capsDentistry preparationsHigh fractureLeucite

The invention relates to a tooth zirconia / leucite composite porcelain powder and a preparation method thereof. The material includes the following components: 50 to 60 percent of Sio2, 10 to 20 percent of Al2O3, 16 to 30 percent of K2O, 2 to 5 percent of Na2O and 2 to 15 percent of ZrO2. The preparation method of the material relates to: selecting a mineral potassium feldspar powder of the first grade, adding a certain amount of potash, nanometer tetragonal zirconia powder body and ethanol to uniformly mix in a globe mill and acquiring a raw material powder after drying; placing the raw material powder into a corundum crucible to calcine under a temperature of 1000 to 3000 DEG C for 30 to 90 minutes, cooling naturally and acquiring the zirconia / leucite composite porcelain powder with a grain diameter of 10 to 30Mum after crushing the raw material through ball milling. The crystalling phases of the zirconia and the leucite in the porcelain powder are distributed uniformly. The heat expansion coefficient of the powder is (12 to 16) multiplied by 10<-6>K and the anti-bending intensity of the powder is 90 to 130MPa. The invention is also characterized by good color masking property and high fracture toughness property, etc., and lays a foundation for the clinic application of mouth porcelain repairing.

Owner:SICHUAN UNIV

High-elasticity vibration-resistant expanded polyethylene plate and method for manufacturing same

The invention discloses a high-elasticity vibration-resistant expanded polyethylene plate and a method for manufacturing the same. The high-elasticity vibration-resistant expanded polyethylene plate comprises, by weight, 120-140 parts of polyethylene, 20-30 parts of ethylene-vinyl acetate copolymers, 10-14 parts of p-toluenesulfonhydrazide, 5-8 parts of dichlorotetrafluoroethane, 3-5 parts of dicumyl peroxide, 7-9 parts of zinc oxide, 40-50 parts of titanate-modified calcium carbonate, 8-10 parts of leucite powder, 5-7 parts of dynasylan ibteo, 6-9 parts of magnesium stearate, 4-6 parts of butyl stearate, 4-5 parts of hexamethylenetetramine, 3-5 parts of polycarbonate, 10-14 parts of aluminum hydroxide, 7-9 parts of titanium nitride whiskers, 6-8 parts of dioctyl adipate, 3-5 parts of 2-aminoethanol, 8-9 parts of dicyclohexyl phthalate, 7-9 parts of magnesium diboride and 4-6 parts of jade powder. The high-elasticity vibration-resistant expanded polyethylene plate and the method have the advantages that the polyethylene plate manufactured by the aid of the method not only is excellent in vibration-resistant and buffer performance, but also is high in mechanical strength and good in ageing resistant, and good flame-retardant effects can be realized.

Owner:周诗慧

Cutable bioactive devitrified glass and its prepn

The invention relates to a machinable bio-active nucleated glass and its preparation method. Said preparation method includes the following steps: firstly, uniformly mixing raw materials according toa certain proportion, melting them at 1400-1550 deg.C for 2-4 hr., pouring the molten glass liquor into mould and forming to make blank, cooling to room temp., heating and heat-insulating to make glass nucleate, continuously heating and heat-insulating to make gas crystallize to obtain biological nucleated glass using apatite and fluorophlogopite as main crystal phase. Said product also contains a certain reinforced phase formed fronm leucite and wollastonite, and possesses good biological compatibility, machinability and beautifulness.

Owner:TSINGHUA UNIV

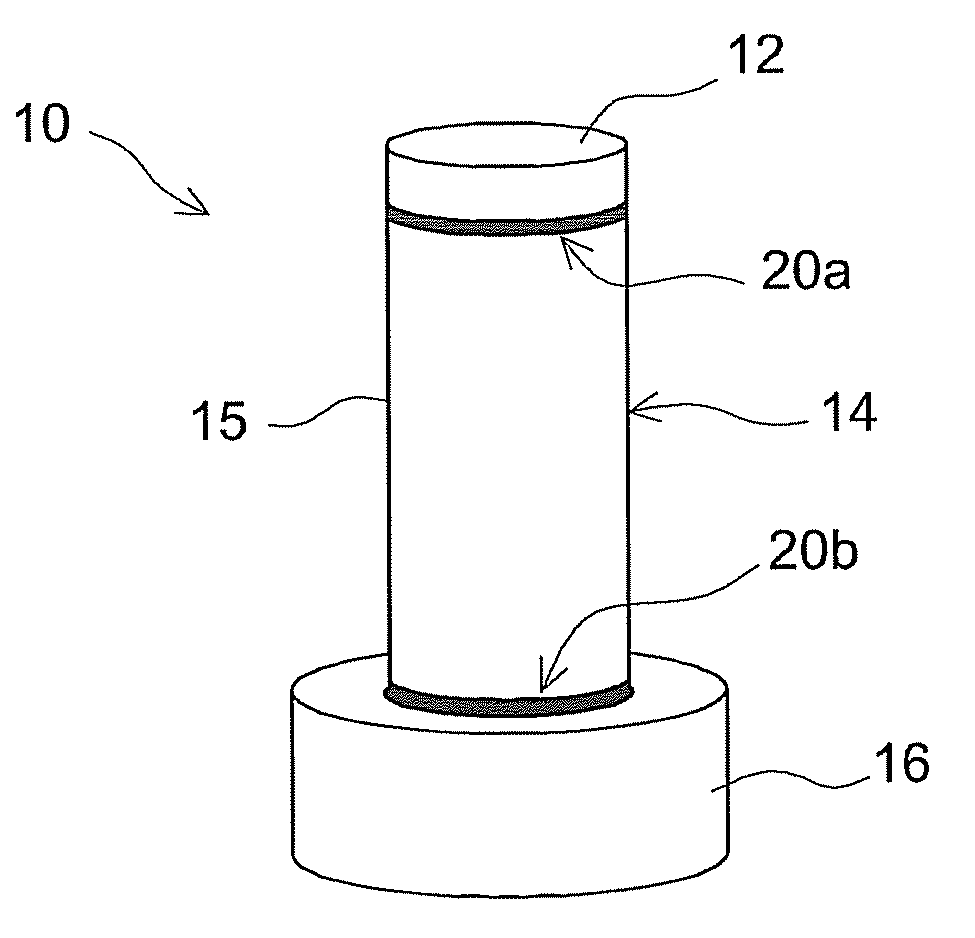

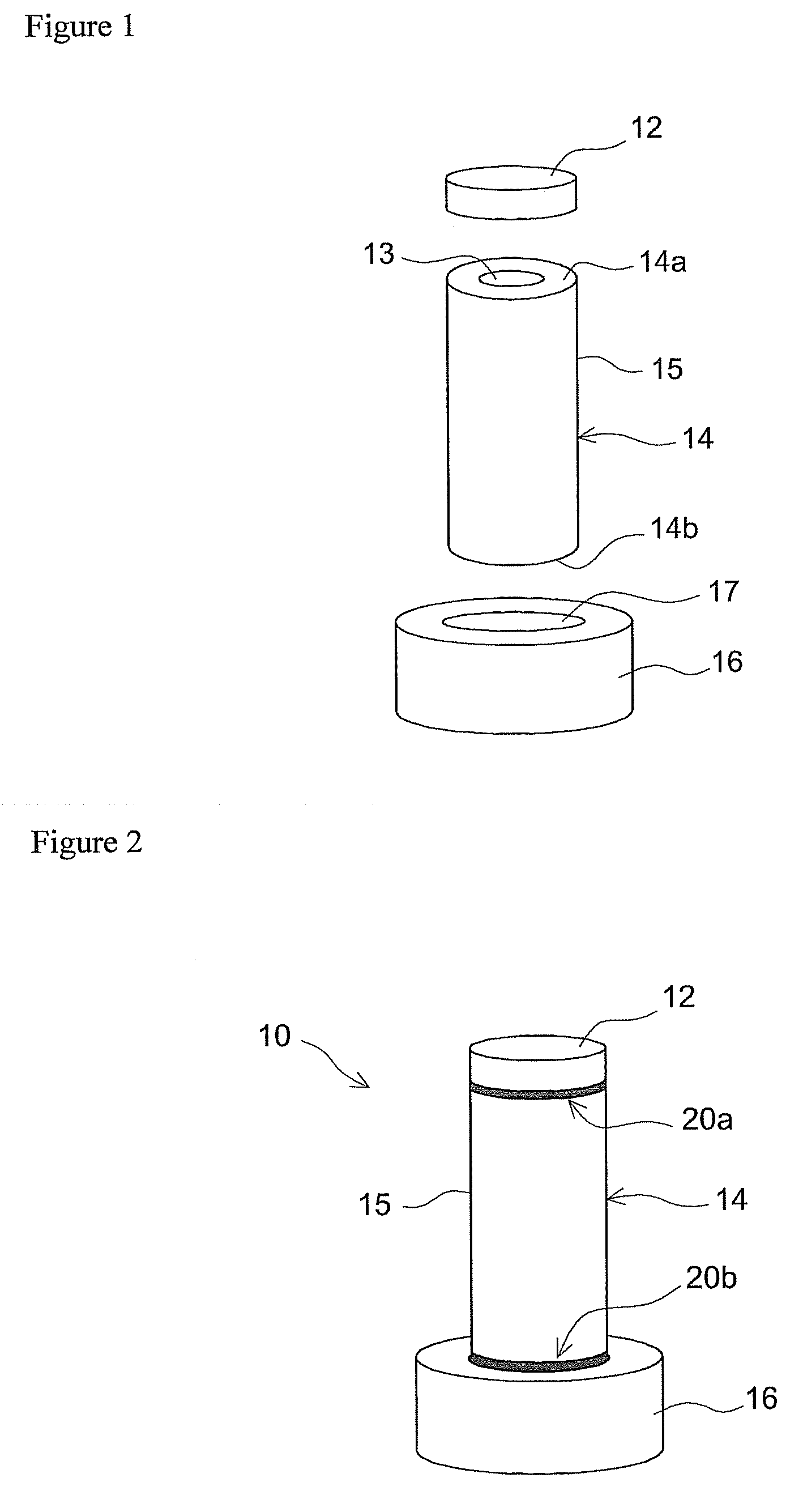

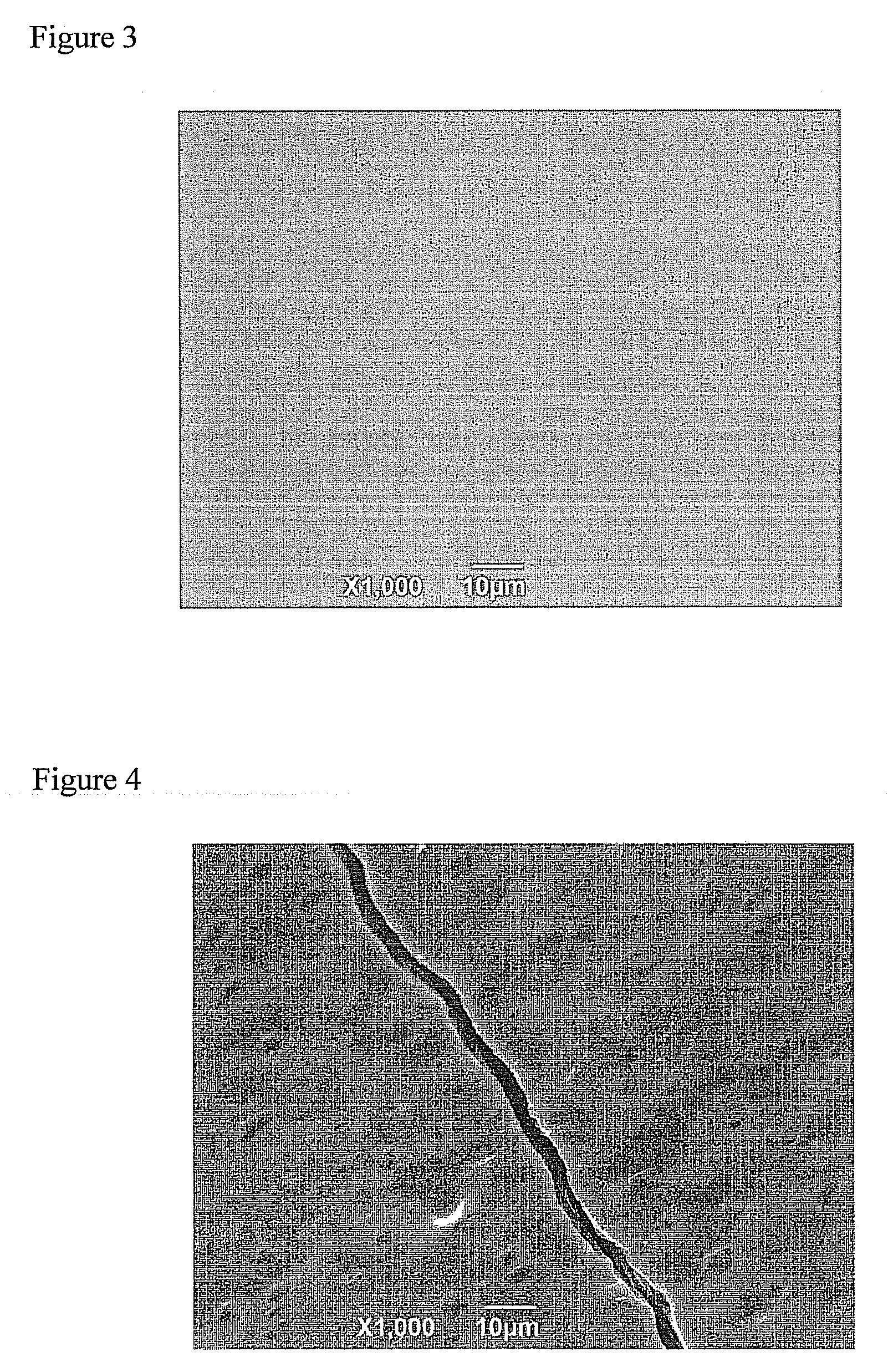

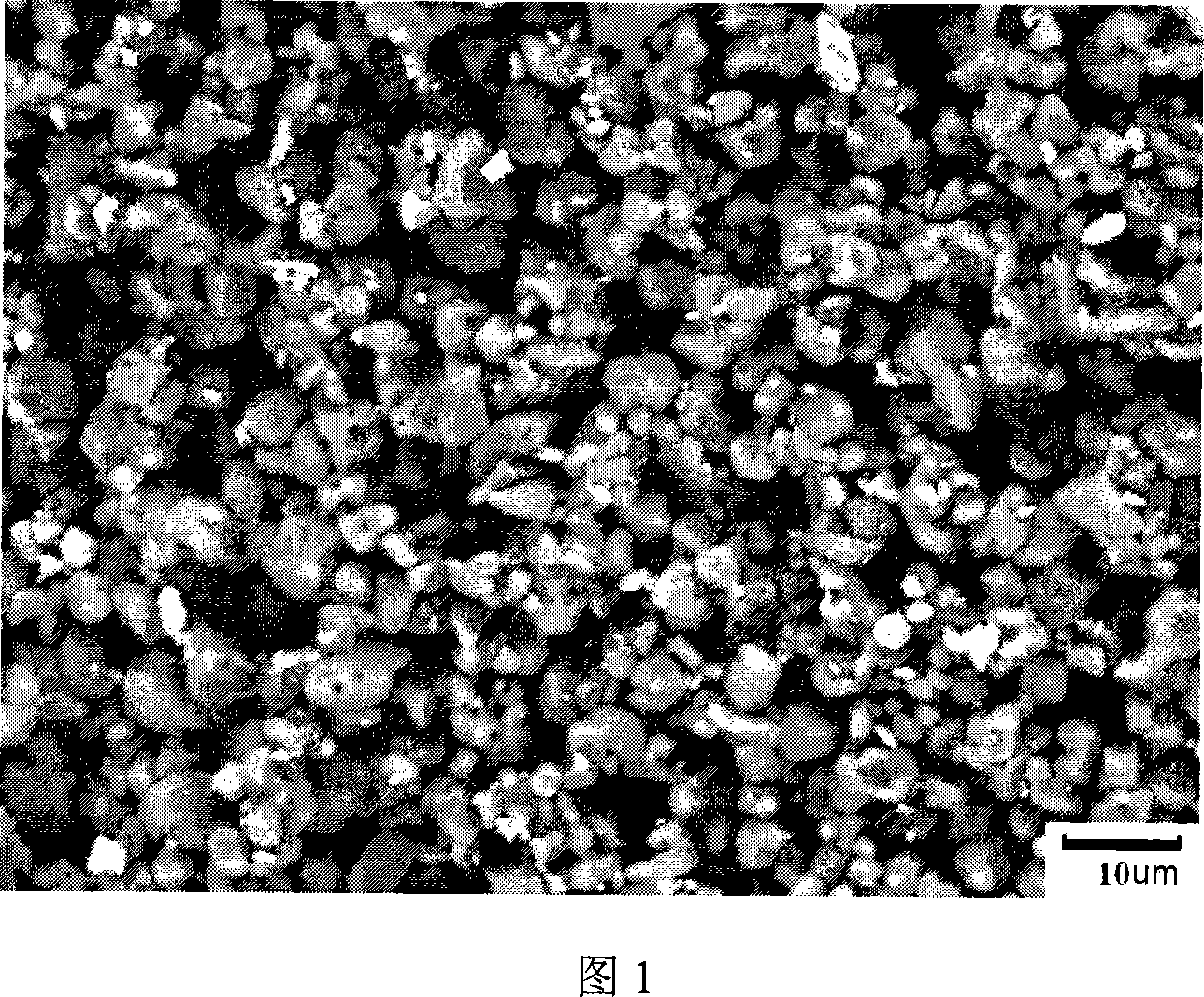

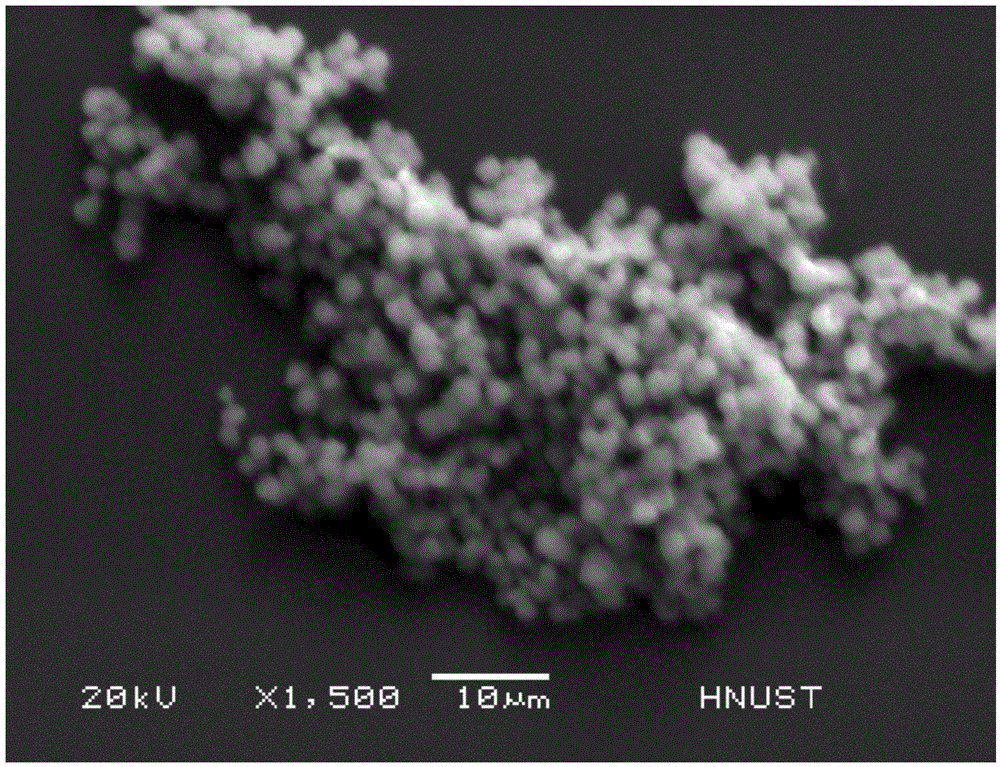

Graphene/leucite nano-composite ceramic material generated in high-temperature in-situ mode and preparation method thereof

The invention relates to a ceramic material and a preparation method of the ceramic material, in particular to a graphene / leucite nano-composite ceramic material generated in a high-temperature in-situ mode and a preparation method of the graphene / leucite nano-composite ceramic material. The graphene / leucite nano-composite ceramic material and the preparation method aim to solve the problem that because graphene added into ceramic is poor in dispersity, the ceramic is poor in performance. The graphene / leucite nano-composite ceramic material generated in the high-temperature in-situ mode is prepared from a graphene oxide suspension, an alkali-activated solution and metakaolin powder. The preparation method comprises the steps of preparing the graphene oxide suspension, preparing the alkali-activated solution, preparing graphene oxide / alkali-activated mixed liquor, preparing graphene / aluminosilicate polymer precursor slurry, carrying out curing forming of a precursor, and carrying out high-temperature treatment. The preparation method can be used for preparing the graphene / leucite nano-composite ceramic material generated in the high-temperature in-situ mode.

Owner:HARBIN INST OF TECH

Method for producing glass from granite scrap

The invention discloses a method for producing glass from purified granite scrap. The method comprises the following steps: weighing the following raw materials in parts by weight: 20-45 parts of high-whiteness potash feldspar and soda feldspar powder, 10-35 parts of spodumene, 20-45 parts of leucite, 15-45 parts of kieselguhr, 10-40 parts of magnesite, 5-25 parts of plant ash, 3-20 parts of graphene, 1-12 parts of potassium acetate, 5-25 parts of zinc oxide, 1-20 parts of calcium sulfide and 1-20 parts of mirabilite; uniformly mixing the high-whiteness potash feldspar and soda feldspar powder, the spodumene, the kieselguhr and the leucite, performing microwave roasting, adding water to prepare a suspension, performing high-speed grinding, and performing spray drying to obtain powder particles; uniformly mixing the powder particles with the magnesite, the plant ash and the graphene, and heating until all the materials are molten; and adding the remaining raw materials, stirring, blanking, performing water quenching, drying, smelting, and molding through a mold to obtain the glass. The glass produced by the invention has excellent chemical corrosion resistance, is especially tolerant to strongly-acidic and strongly-basic environments, has long service life and high refractivity, can meet the corrosion resistance requirements of different reflecting films, and has a wide application range.

Owner:吴海屏

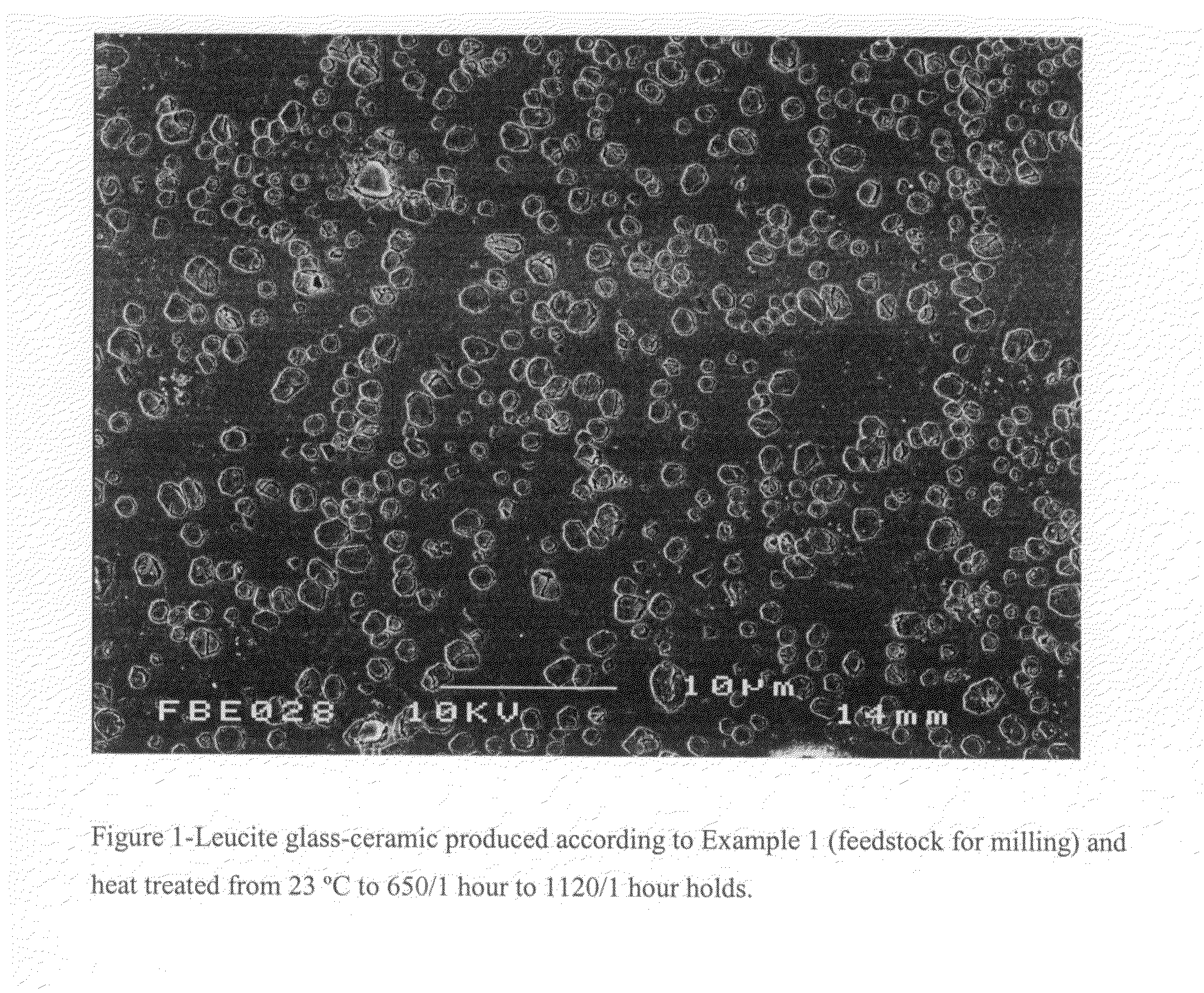

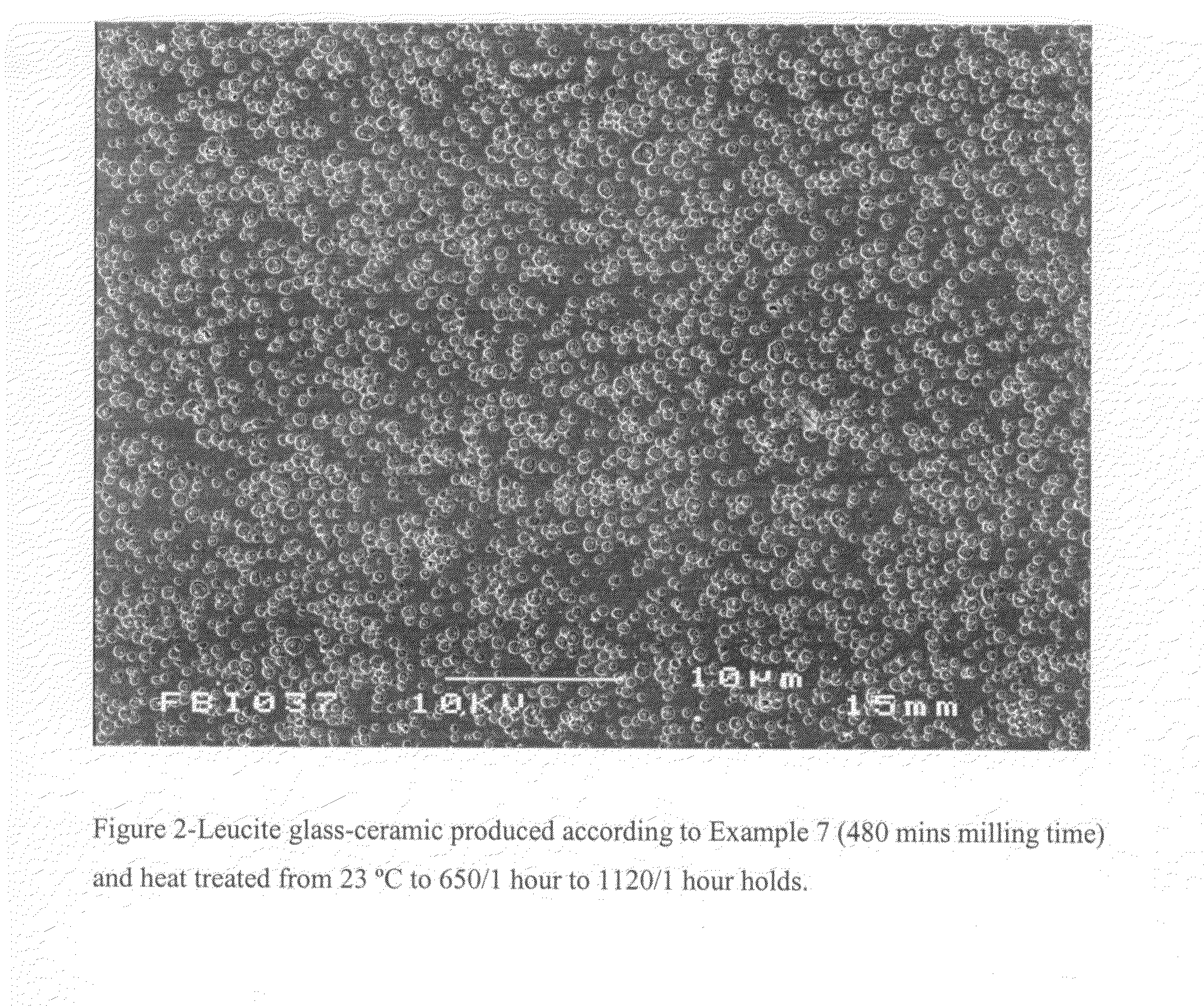

Control of ceramic microstructure

The present invention provides for the production of a single frit, dental porcelain, glass-ceramic containing small, uniformly dispersed, single leucite crystals of ellipsoidal habit and very uniform size.

Owner:DEN MAT HLDG

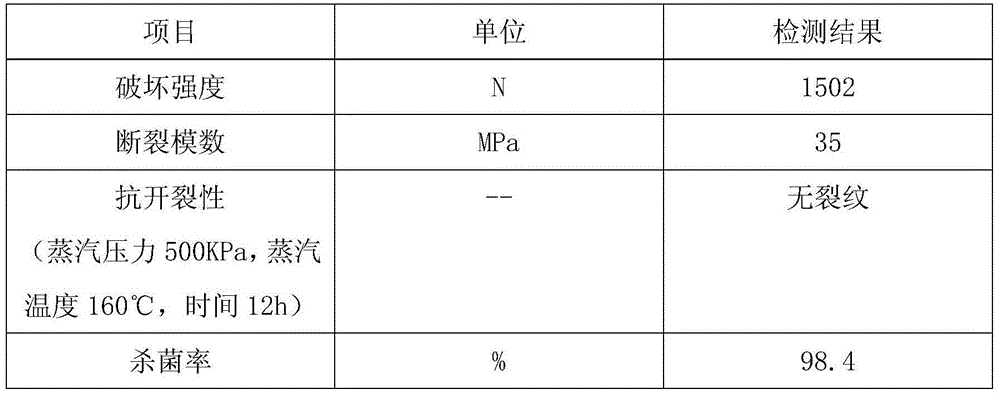

Customized fixed partial denture porcelain veneer

InactiveCN106116547AGood compatibilityStable chemical propertiesImpression capsTeeth fillingNatural toothLeucite

The invention discloses a customized fixed partial denture porcelain veneer. Porcelain powder with leucite as the main ingredient is directly used for paste-on-paste decoration of tooth repair form. The porcelain veneer comprises SiO2, Al2O3, K2O, Na2O, Li2O, BaO, B2O3, CaO, Sb2O3, ZrO2, SnO2, CeO2, F and TiO2. A method for preparing the porcelain veneer comprises the steps of making a high-temperature resistant tooth die, conducting pretreatment and soaking on the die so that porcelain coating and sintering can be conducted, coating combination porcelain, dentin porcelain and cutting porcelain in sequence, conducting sintering in a sintering furnace at different temperatures every time porcelain coating is conducted, conducting form polishing and finishing after sintering, then conducting glazing, conducting sintering in the furnace again, removing the die material, and taking off the veneer with overall thickness of 0.5-0.7 mm. The veneer has high tissue compatibility, stable chemical performance and high breaking strength, the color of the veneer can be adjusted to be matched with natural teeth, and a basis is laid for clinical application of porcelain repair of oral cavity.

Owner:SHANXI MEIYUAN PHARMA TECH

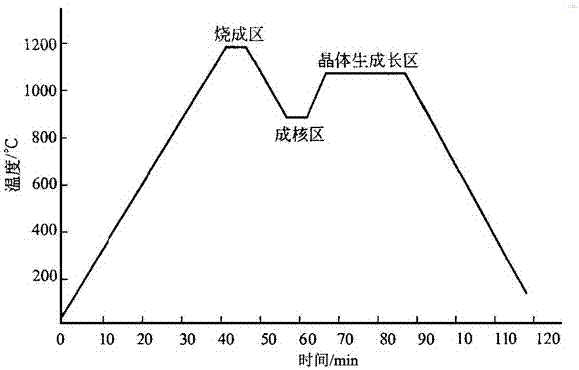

A wear-resistant high-hardness diamond glaze, preparation method and application

The invention discloses a wear-resistant and high-hardness diamond glaze, a preparation method and an application thereof. According to the mass percentage, the glaze formula comprises: 5-15% of kaolin, 5-10% of andalusite, 5-10% of potassium feldspar, Leucite 5‑12%, Grossartite 1‑3%, Nepheline 10‑18%, Spodumene 5‑15%, Wollastonite 2‑8%, Quartz 3‑7%, Zircon Sand 5 ‑10%, white corundum 5‑10%, dolomite 1‑3%, calcined white talc 1‑3%, zinc oxide 0.1‑0.5%, additive 0.5‑3%. The present invention optimizes the selection of glaze mineral raw materials, and firstly selects mineral raw materials with high hardness and wear resistance, such as andalusite (hardness 6.9‑7.4), white corundum (hardness 9.0), leucite (5.5‑6), Gross garnet (hardness 7‑7.5); and through reasonable particle gradation, the particle fineness and addition amount of high hardness and wear-resistant mineral raw materials are controlled; and the subsequent preparation process and application process have greatly improved the diamond enamel. abrasion resistance and hardness.

Owner:FOSHAN ZHONGCHENG SILICATE TECH CO LTD

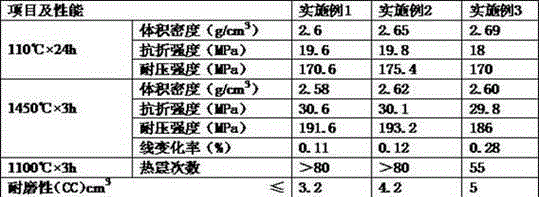

12000 T/D kiln outlet special-use castable

The invention discloses a 12000 T / D kiln outlet special-use castable and belongs to the field of fireproofing materials. The castable inclues the components, by weight, 15-25% of mullite, 10-20% of sillimanite, 25-30% of tabular corundum, 5-10% of strontium titanate powder, 5-8% of zirconium dioxide powder, 1-3% of zinc-aluminium spinel powder, 3-5% of boron nitride, 5-10% of aluminum oxide micro powder, 4-6% of pure calcium aluminate cement, 0.2% of polylactic acid fibers, 0.1% of sodium hexametaphosphate, 0.1% of leucite and 0.1% of C12H14N4O5S2. The castable is improved in thermal shock resistance, high-temperature resistance, volume stability and wear resistance, is high in strength, is improved in the defects that a kiln outlet is not wear-resistant and is poor in thermal shock resistance, and can prolong the service life of a kiln outlet of a cement kiln from about 10 months to 2 years and more.

Owner:徐梅子

Ageing cracking resistant ceramic bowl and preparation method thereof

The invention discloses an ageing cracking resistant ceramic bowl and its preparation method. The ceramic bowl is prepared from the following raw materials, by weight, 33-47 parts of meerschaum, 25-35 parts of leucite, 22-33 parts of barite, 18-26 parts of nacrite, 15-25 parts of glass flake, 4-8 parts of tea dust, 3-6 parts of calcium hexaboride, 9-16 parts of konjaku flour, 4-7 parts of soya lecithin, 2-4 parts of disodium ethylene diamine tetraacetate, 3-5 parts of poly-aluminum ferric silicate sulfate, 2-3 parts of CITREM, 4-6 parts of alkali lignin and 8-10 parts of antimicrobial powder. With addition of glass flake, tea dust and calcium hexaboride, chemical corrosion resistance and ageing resistance of ceramic tiles can be enhanced. In addition, with addition of konjaku flour, soya lecithin, poly-aluminum ferric silicate sulfate and the like, adhesive stress among mineral particles can be raised, and ageing cracking of ceramic tiles can be prevented effectively. The prepared ceramic bowl has excellent heat resistance, corrosion resistance and ageing resistance, is not easy to crack or break and has long service life.

Owner:安徽省含山瓷业股份有限公司

Wear-proof and anti-seismic tile and preparation method thereof

InactiveCN106082957AImprove wear resistanceGood weather resistanceCeramic materials productionClaywaresLeuciteSlag

The invention discloses a wear-proof and anti-seismic tile and a preparation method thereof. The tile is prepared from raw materials in parts by weight as follows: 25-35 parts of waste clay bricks, 22-33 parts of marine dredged mud, 19-31 parts of yellow phosphorus slag, 14-26 parts of indianite, 18-30 parts of Huanglong mountain green mud, 23-34 parts of leucite, 16-28 parts of vesuvianite, 24-36 parts of metallurgy waste residues, 27-39 parts of periclase, 17-29 parts of brown fused alumina residues, 8-16 parts of aluminum diboride, 15-25 parts of dihydrate gypsum and 18-26 parts of diamond grinding wheel wastes. The added diamond grinding wheel wastes, waste clay bricks and other raw materials can improve the wear resistance and the weather resistance of the tile, the added brown fused alumina residues, aluminum diboride and other raw materials can improve the anti-seismic property and the heat stability of the tile. The prepared tile has the advantages of being high in mechanical strength, wear-proof, anti-seismic, resistant to high temperature, weather-resistant, ageing-resistant and the like and is long in service life and good in environmental suitability.

Owner:安徽省亚欧陶瓷有限责任公司

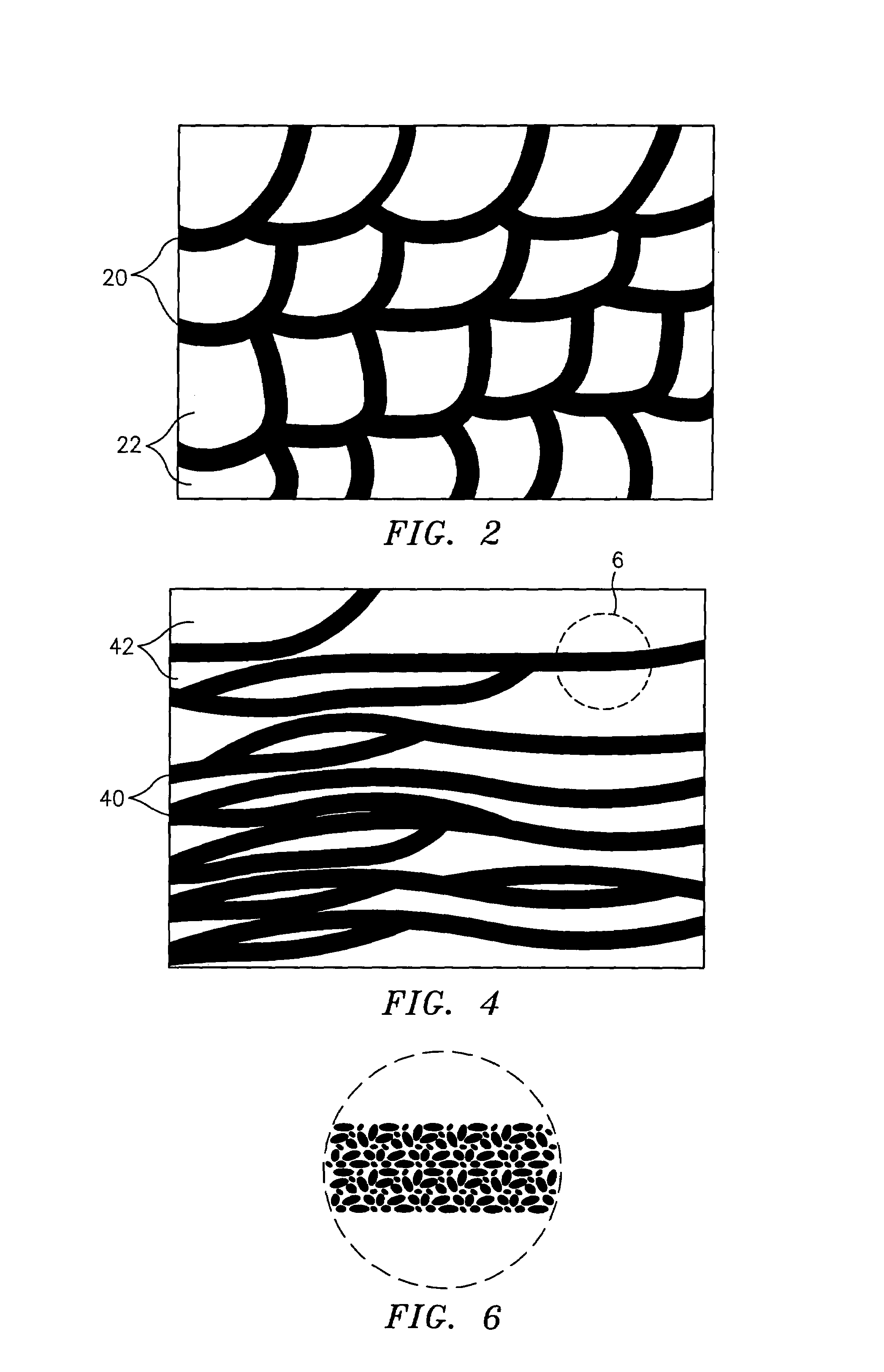

Pressable glass-ceramics with textured microstructure

A pressable dental ceramic comprising a mixture of glass and glass-ceramic frits. A refractory filler is also combined with the frits. The dental ceramic contains an amount of leucite less than about 35 percent by weight. Other additives may be included such as pigments, opacifying agents and fluorescing agents. The dental ceramic comprises a cellular-like microstructure comprised of glassy regions surrounded by clusters of leucite crystals distributed around those glassy regions forming a cellular three-dimensional network.

Owner:ARDENT

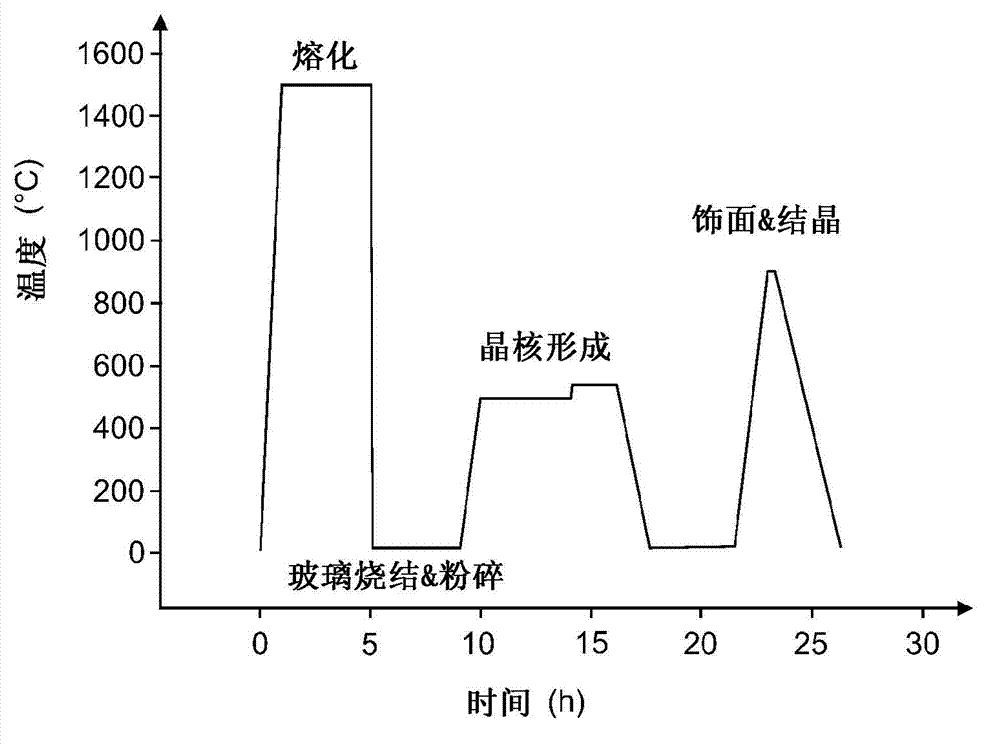

A preparing method of a dental ceramic composite material

The invention relates to a preparing method of a dental ceramic composite material. The method includes mixing 15.00-25.00% by mass of K2O, 20.00-30.00% by mass of Al2O3, 48.00-60.00% by mass of SiO2, 1.50-7.00% by mass of CaO, 0.05-1.00% by mass of MgO, 0.01-0.10% by mass of Fe2O3 and 0.01-0.10% by mass of TiO2, adding 75-95% by mass of ethanol, grinding with the granularity of ground powder being controlled to be lower than 4 mu, drying, melting for form glass, smashing and grinding the cooled glass with the granularity of ground powder being controlled to be 4 mu or below, covering microcrystalline alumina ceramic with the ground powder with the thickness being 0.3-3 mm, pressing and performing isostatic cool pressing through a former, nucleating and performing crystallization heat treatment to obtain the dental ceramic composite material. Mechanical performances of the prepared dental ceramic composite material are better than those of leucite-enhanced dental microcrystalline glass at present, and physical and chemical performances of the prepared dental ceramic composite material are better than those of microcrystalline alumina ceramic at present, so that the dental ceramic composite material can be used as restorations for repairing tooth defects. The method is easily available in raw materials and simple in production process and has good development and application prospects.

Owner:WUHAN UNIV

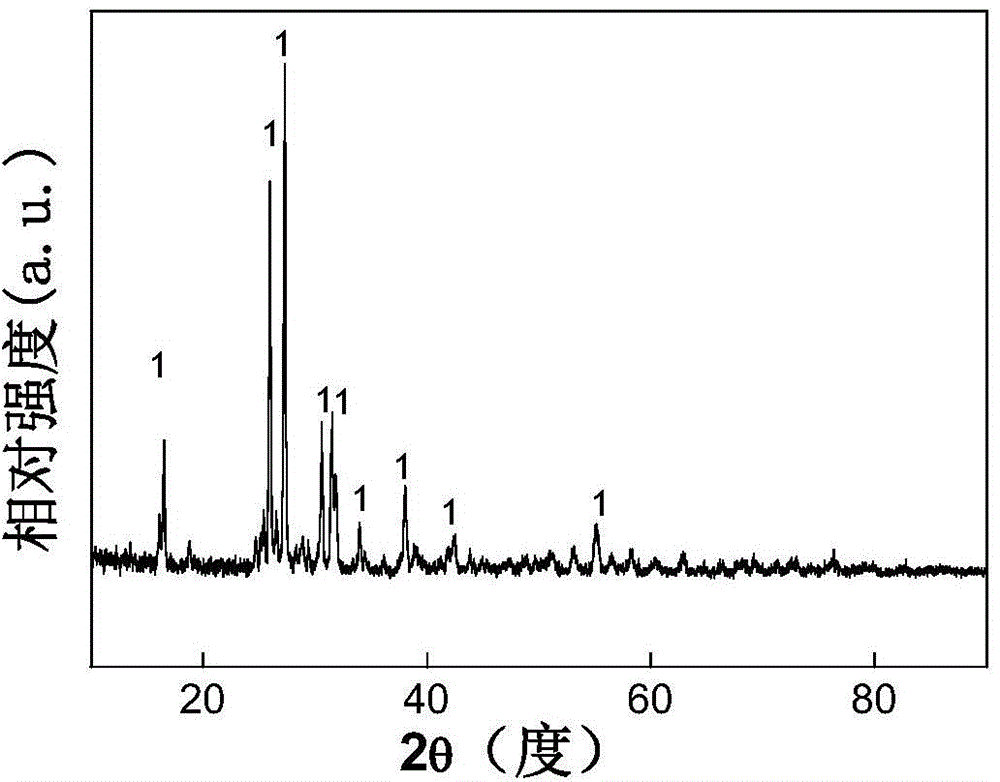

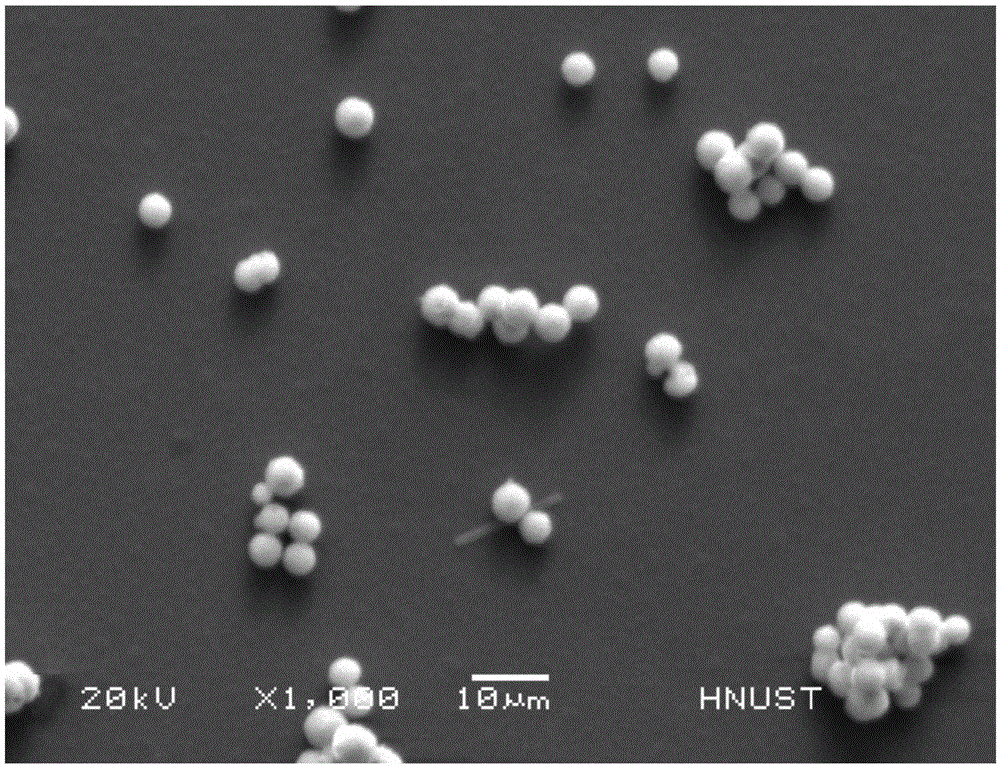

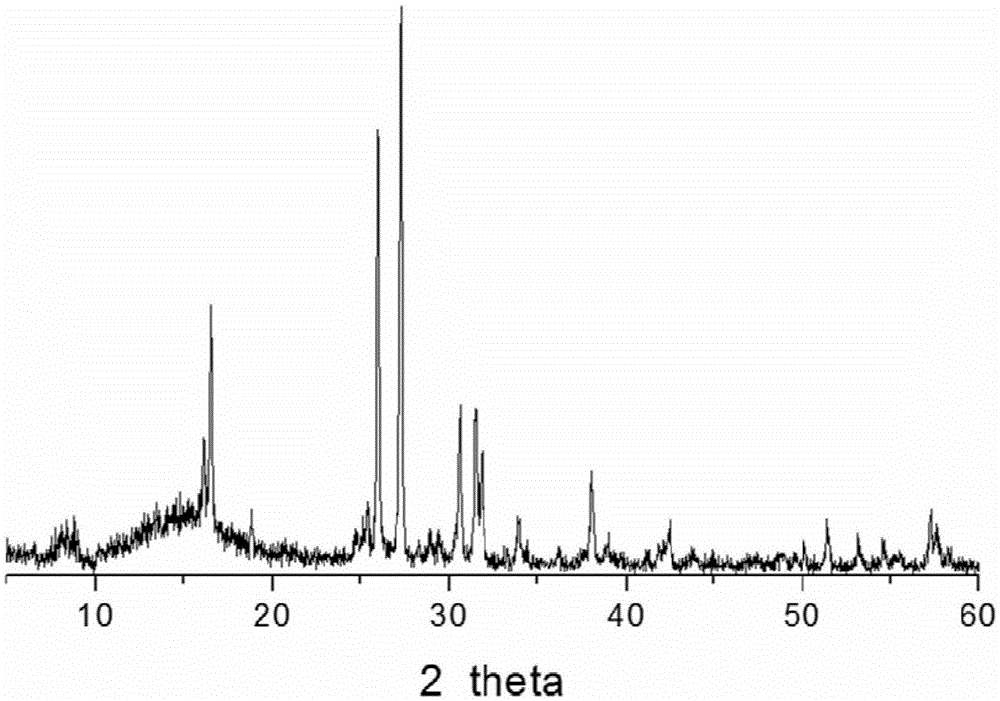

Preparation method of leucite

The application discloses a preparation method of leucite. The method comprises the following steps: 1) adding aluminium hydroxide into a sodium hydroxide solution, carrying out a heating reflux reaction, filtering, washing, and collecting a filtrate to obtain a sodium metaaluminate solution; 2) adding the sodium metaaluminate solution into a mixed solution of a sodium silicate solution and polyvinylpyrrolidone, stirring and reacting to obtain a mixture; 3) carrying out a hydrothermal reaction on the mixture at 150-220 DEG C for 3-6 h, filtering, washing, and drying to obtain analcite; and 4) adding analcite into a potassium nitrate solution and carrying out a hydrothermal reaction at 150-250 DEG C for 3-6 h, filtering, washing and drying so as to obtain leucite. According to the method, leucite is prepared by combination of a hydrothermal method and an ion exchange method. The method has characteristics of low reaction temperature, easy operation, low energy consumption and no pollution. Particle size of leucite powder is controllable and small, and particle size distribution is narrow.

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com