High-strength heatproof glassware

A heat-resistant glass, high-strength technology, applied in the field of glass, can solve the problems of being unable to keep up with and satisfy, powerless, poor processing quality and processing efficiency, etc., and achieve the effect of beautiful color, improved strength, increased appearance gloss and reflective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

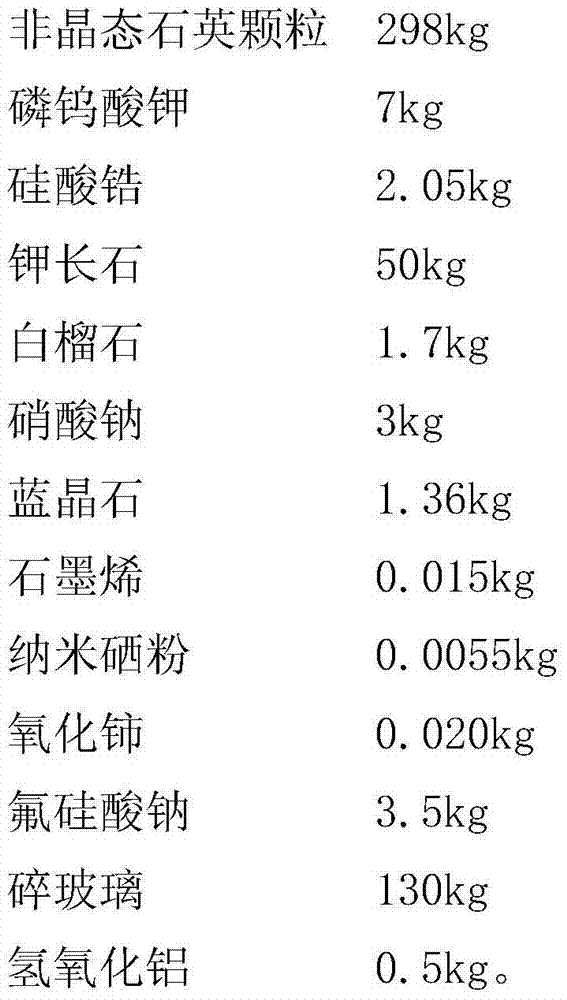

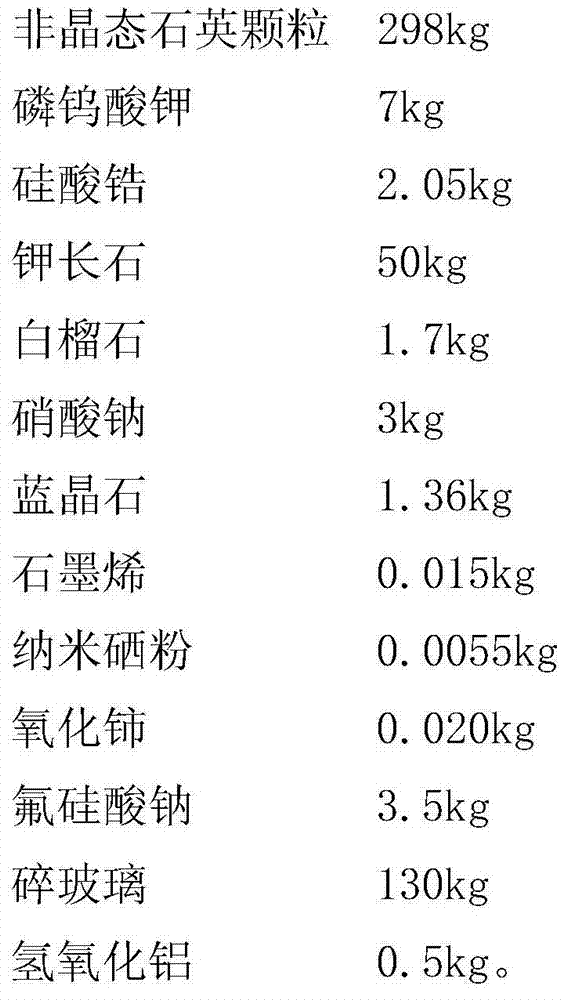

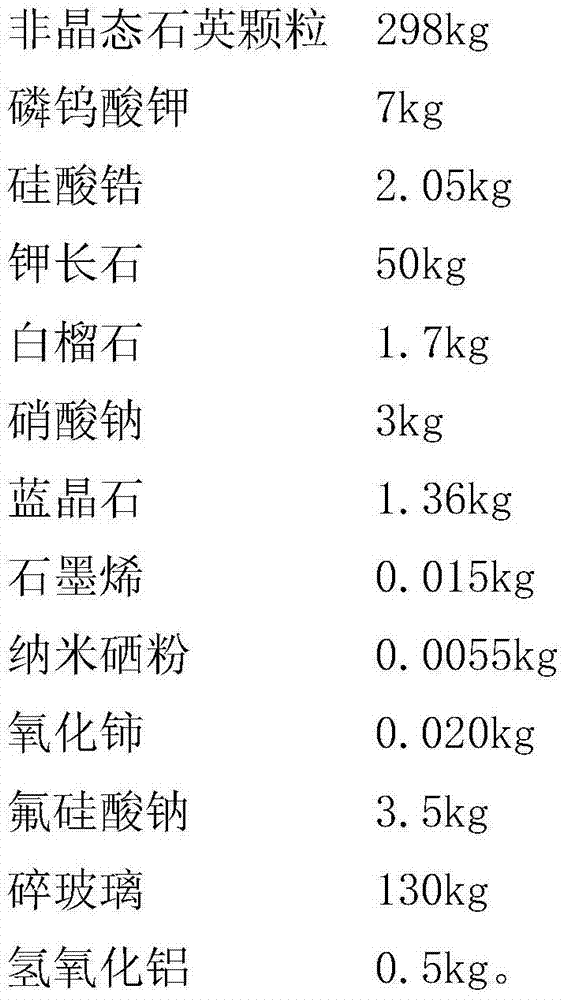

[0019] A high-strength heat-resistant glass vessel consisting of components by weight of,

[0020]

[0021] The preparation method is as follows:

[0022] 1) Weigh each raw material according to the weight ratio, send it to a mixer to mix evenly, and then send it to an ultrasonic disperser for ultrasonic dispersion for 1 hour to obtain a mixture for use;

[0023] 2) Put the ultrasonically dispersed mixture into a ball mill, use agate balls as grinding balls, the mass ratio of balls to materials is 6:1, and continuously mill in the ball mill for 2 hours at a speed of 150 rpm to obtain Powder ready for use;

[0024] 3) Put the powder in step 2) into the furnace, seal it and heat it, so that the temperature of the mixture reaches 1720-1760°C, and keep this temperature for 12-14 hours, so that the mixture reaches a molten state, and a glass melt is obtained ;

[0025] 4) Send the molten glass into the molding machine to make glasses of different sizes, cool the glass to 400°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com