Patents

Literature

107 results about "Borate glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Borate glasses have a more complex action of alkali ions than silicate glasses. Borate glasses also have major differences in their optical properties. The single largest use of boron compounds in the world (accounting for half of total global use) is the production of certain types of boron-treated glass fiber for insulating and structural fiberglass. In these uses the boron may be present as borax or boron oxide, and adds to the structural strength of the glass as borosilicate, or is added as a fluxing agent to decrease the melting temperature of pure silica, which is difficult to extrude as fibers and work with in pure form, due to the high temperatures involved.

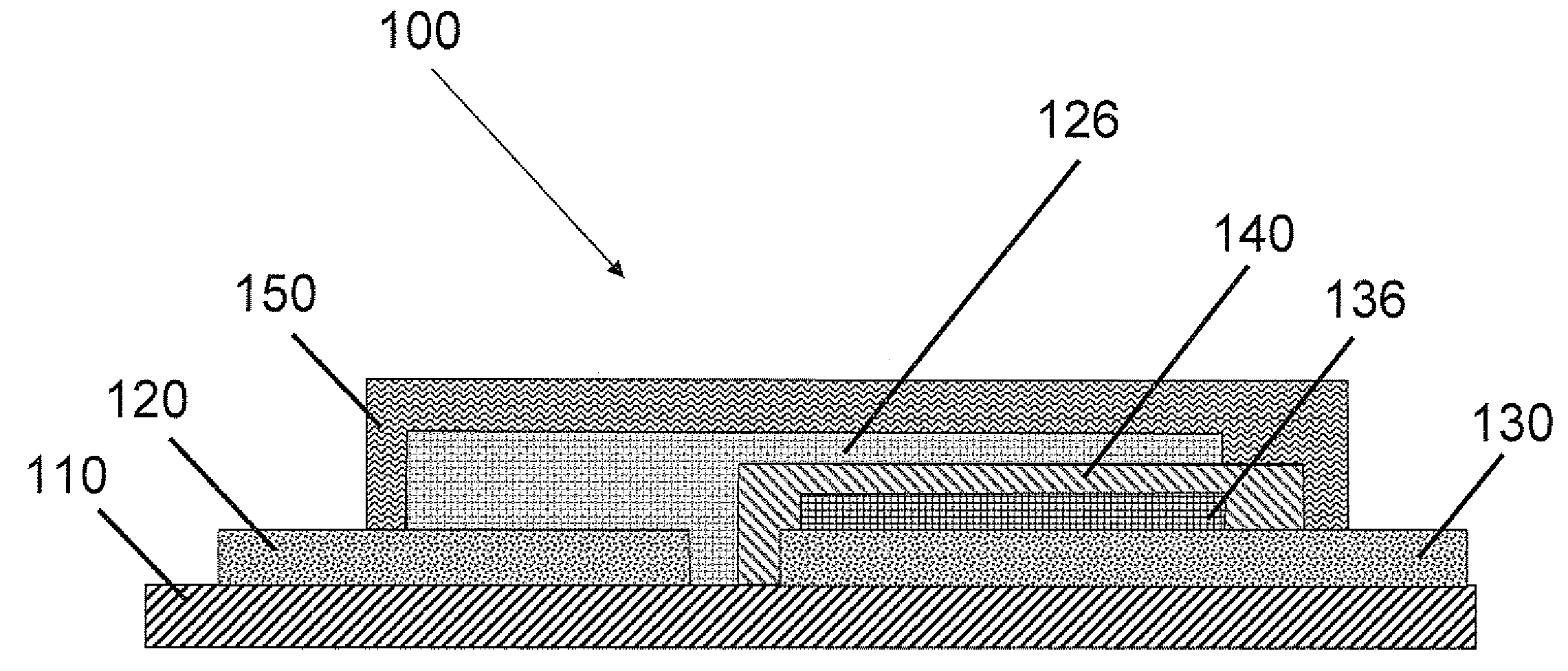

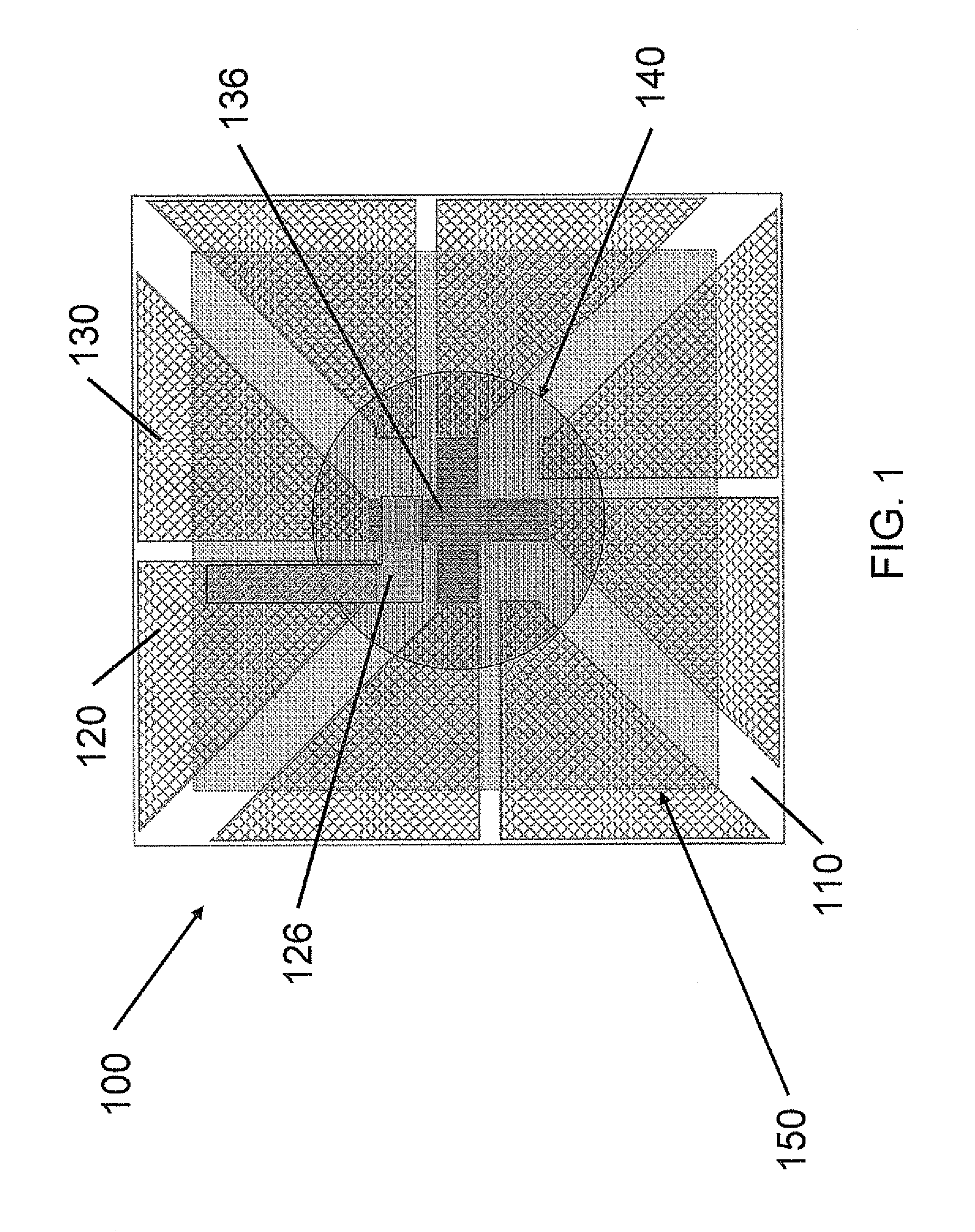

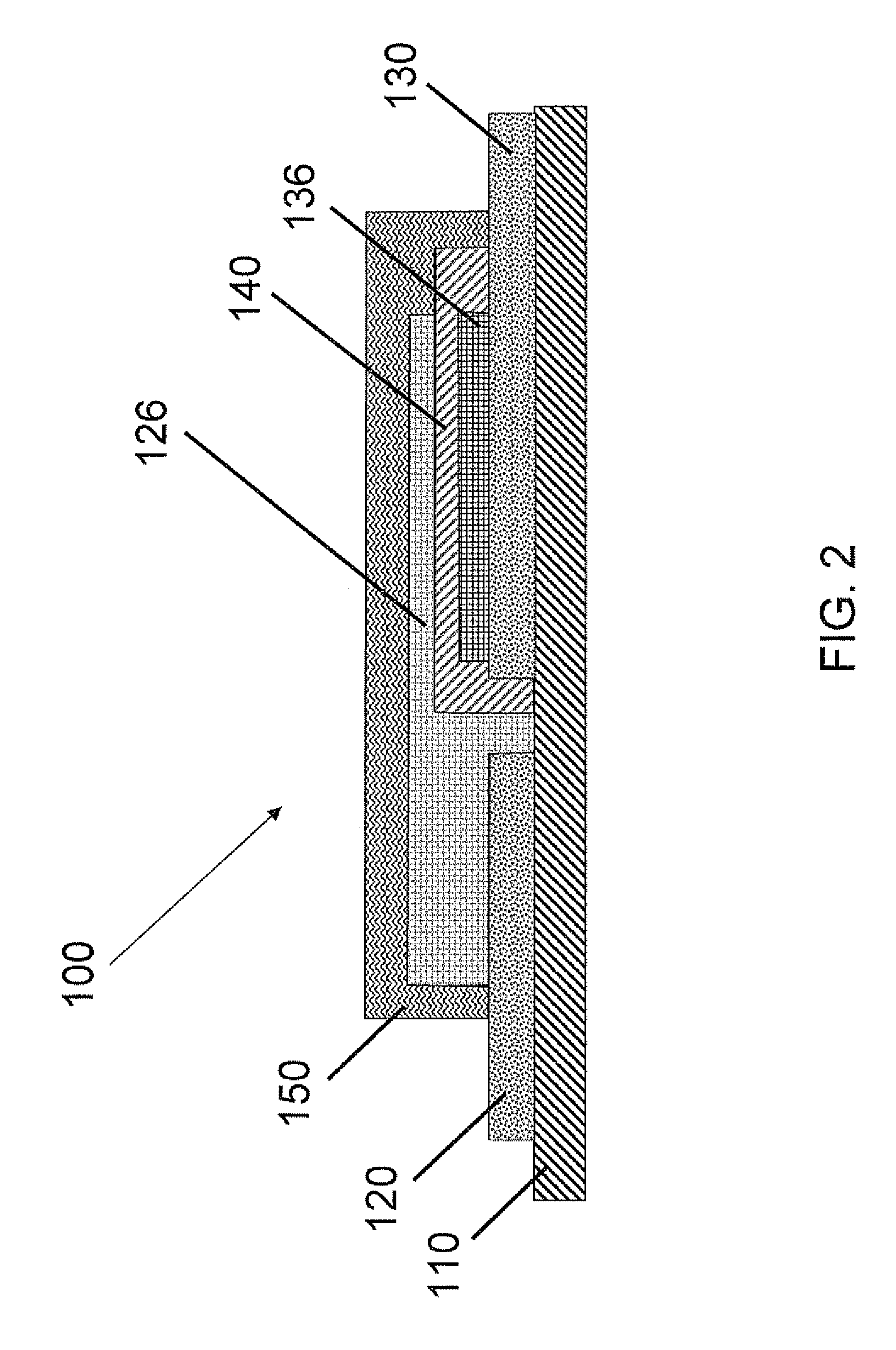

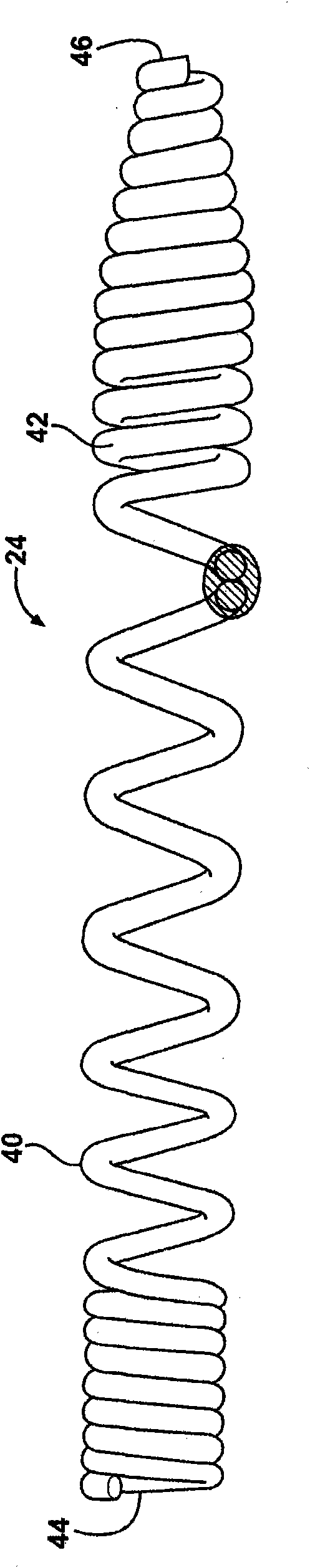

Barrier layer for thin film battery

InactiveUS20100190051A1Improve efficiencyExtend lifetime of battery packFinal product manufactureElectrode carriers/collectorsPhosphateChalcogenide glass

A thin film battery comprises a substrate, anode and cathode current collector layers formed over the substrate, anode and cathode layers formed over and in electrical contact with respective ones of the current collector layers, and an electrolyte layer formed between the anode and cathode layers. The thin film battery further comprises a barrier layer formed from a material such as tin oxide, tin phosphate, tin fluorophosphate, chalcogenide glass, tellurite glass or borate glass. The barrier layer is configured to encapsulate the thin film battery layers and substantially inhibit or prevent exposure of the thin film battery layers to air or moisture.

Owner:CORNING INC

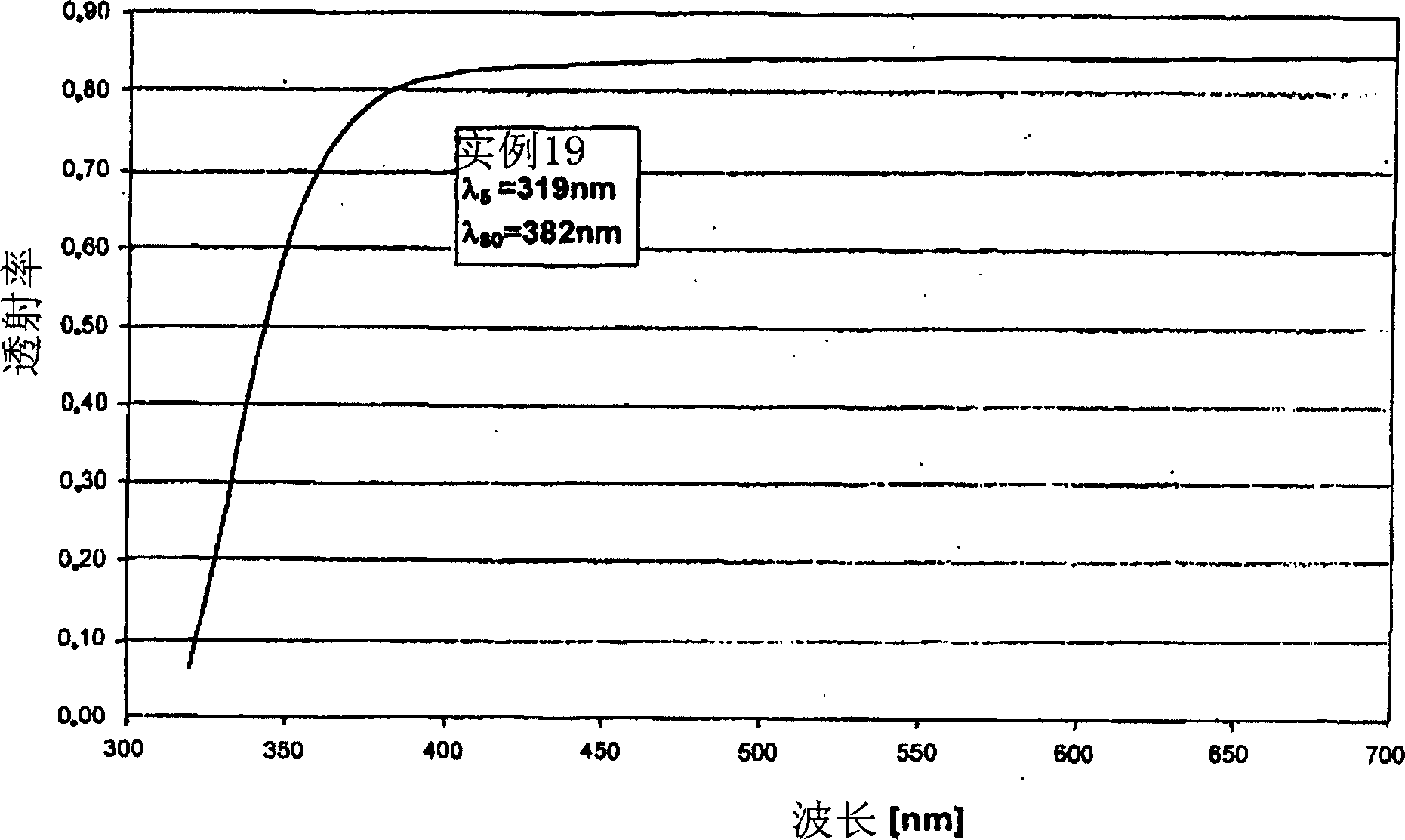

Lead and arsenic free optical lanthanum borate glass

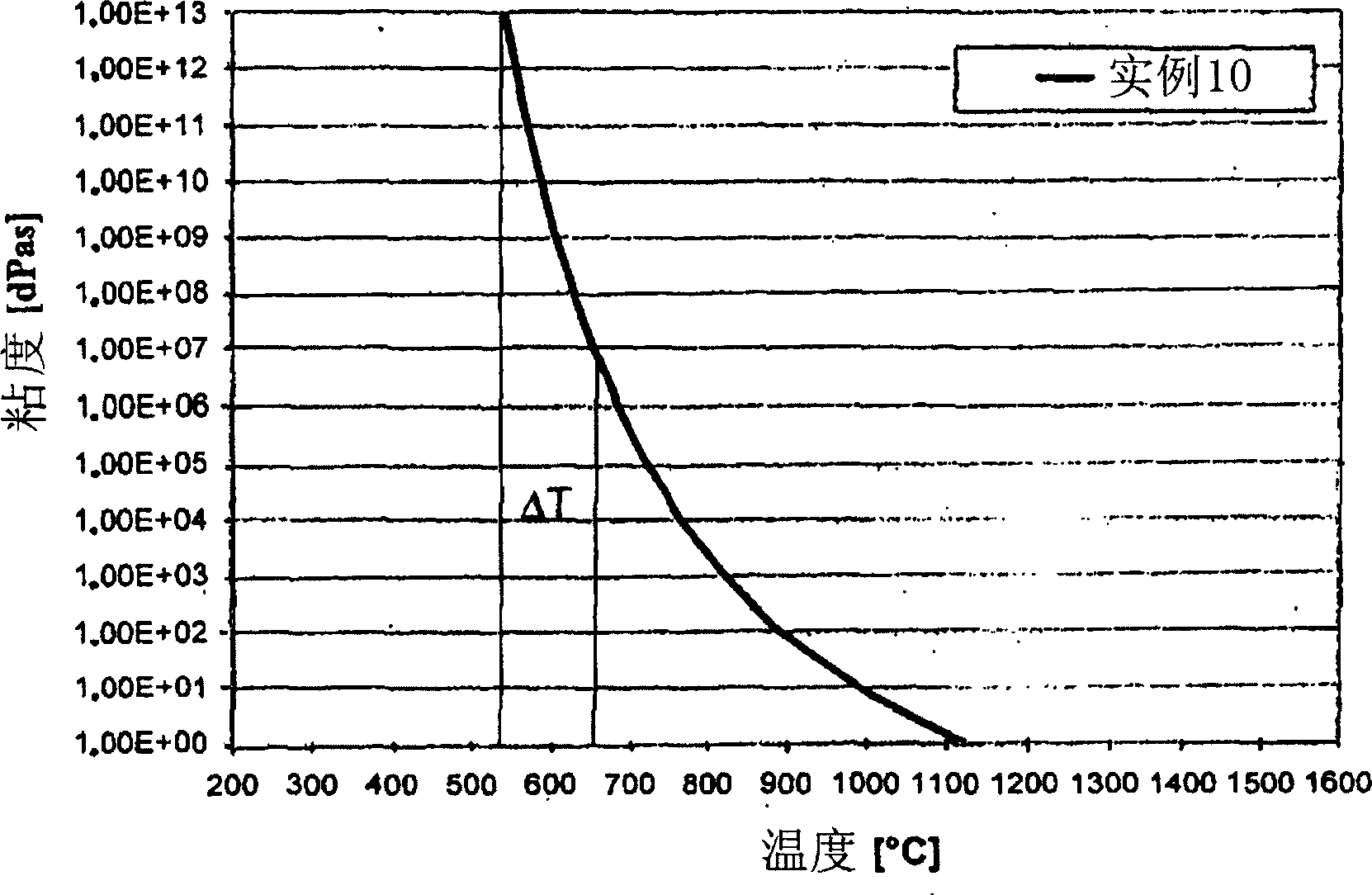

The present invention describes lead and arsenic free and preferably gadolinium and further preferably also fluorine free optical glasses for the application fields mapping, projection, telecommunication, optical communication engineering, mobile drive and / or laser technology with a refractive index of 1.75<=Nd<=1.85, an Abbe number of 34<=Vd<=44 and have a low transformation temperature, namely lower than or equal to 560 DEG C. and preferably lower than or equal to 550 DEG C., as well as good producability and processability and crystallisation stability. The glasses according to the present invention within the following composition range (based on oxide in % by weight) contain the following component B2O3, ZnO, La2O3, Ta2O5.

Owner:SCHOTT AG

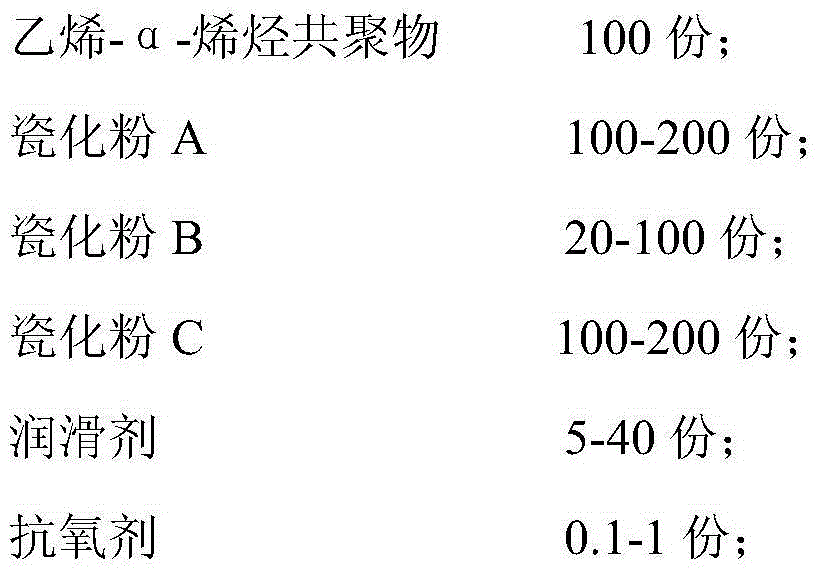

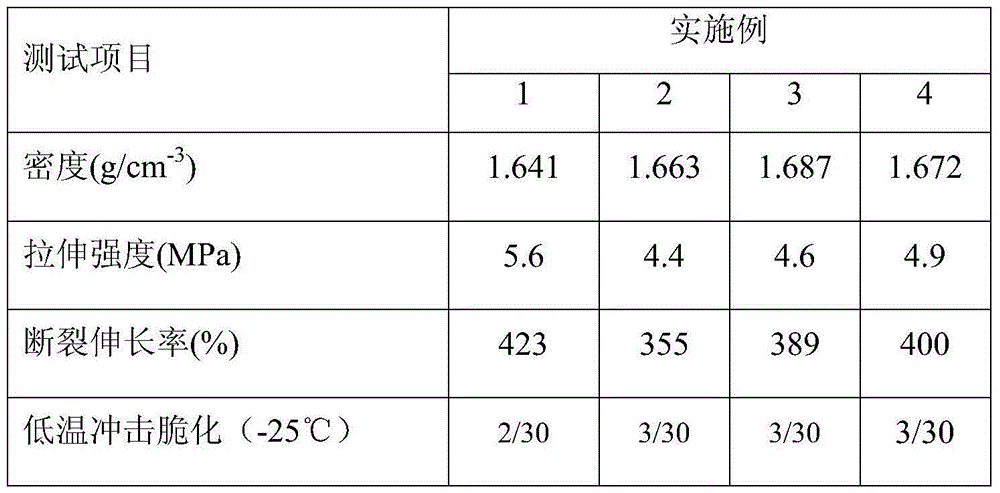

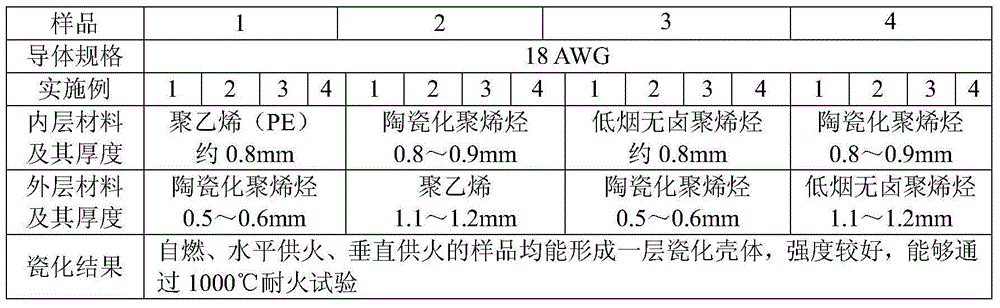

Ceramized polyolefin material and preparation method thereof

InactiveCN104558805AGood extrusion processing performanceGood porcelain performancePolyolefinAntioxidant

The invention discloses a ceramized polyolefin material and a preparation method thereof, belonging to the field of electric wire and cable materials. The ceramized polyolefin material comprises the following raw material components: 100 parts of an ethylene-alpha-olefin copolymer, 100-200 parts of ceramized powder A, 20-100 parts of ceramized powder B, 100-200 parts of ceramized powder C, 5-40 parts of a lubricating agent and 0.1-1 part of an antioxidant, wherein the ethylene-alpha-olefin copolymer is one or more selected from an ethylene and alpha-propylene copolymer, an ethylene and alpha-butylene copolymer, an ethylene and alpha-hexylene copolymer and an ethylene and alpha-octene copolymer; the ceramized powder A is one or a combination of more than one selected from layered inorganic powder, fibrous inorganic powder and needle-like inorganic powder; the ceramized powder B is at least one selected from borax, ammonium borate, a zinc borate and boron frit, phosphate glass powder with a low melting point, borate glass powder with a low melting point and silicate glass powder with a low melting point; the ceramized powder C is granular powder with excellent high-temperature insulativity; and the antioxidant is at least one selected from 1010, 1076, 168, 626, 300 and DSTDP.

Owner:JIANGSU ZHONGLI GRP CO LTD +2

Environment-friendly pouring box drying type vibrating material wedding agent

InactiveCN101293779AMeet the needs of smelting steel with low carbon contentNo irritating smellMagnesium saltPhosphate

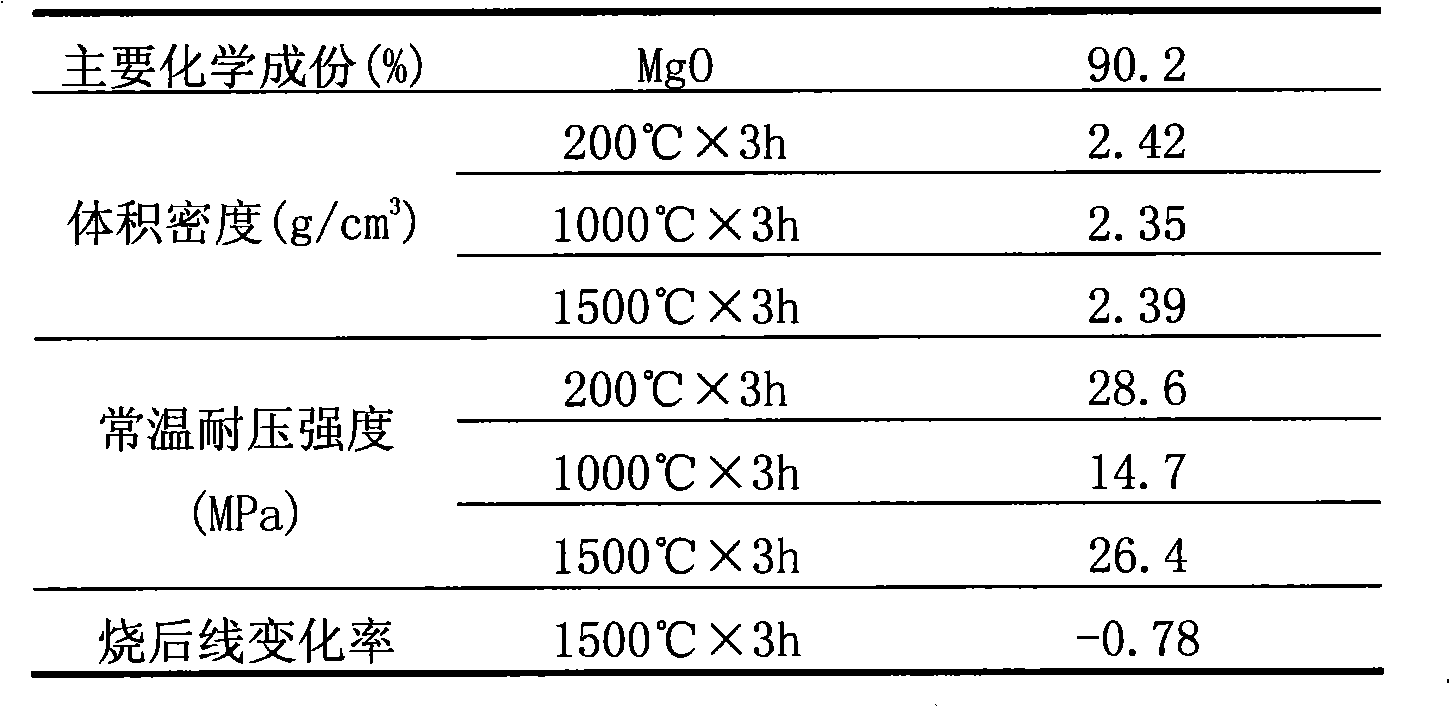

The invention relates to environment friendly binder for dry vibratory material for a tundish. The binder contains sodium-containing phosphate or borate glass 10-80 wt%, magnesium salt 15-85 wt%, and silicate or borate of alkali metal 0.01-5 wt%. The binder has the advantages that inorganic salts is used as the composite binder of carbon-free dry vibratory material and no carbon is introduced into molten steel to prevent carbon and hydrogen in molten steel from increasing, so requirement for smelting low-carbon steel can be satisfied; during a baking process, no pungent odor from formaldehyde, cresol, etc. is generated, and the binder is environment friendly; the bind has good erosion resistance, and is easily decomposed, and both the bonding strength and the moderate-temperature strength can satisfy requirements for demolding and application; and the service life of the tundish is prolonged, and the average service life of the dry material prepared from fused magnesite and sintered magnesite is 29 hours or longer.

Owner:HENAN GENGSHENG REFRACTORIES

Borate-glass biomaterials

ActiveUS20170274118A1Improving skin propertyCut skinCosmetic preparationsToilet preparationsBorate glassBiological materials

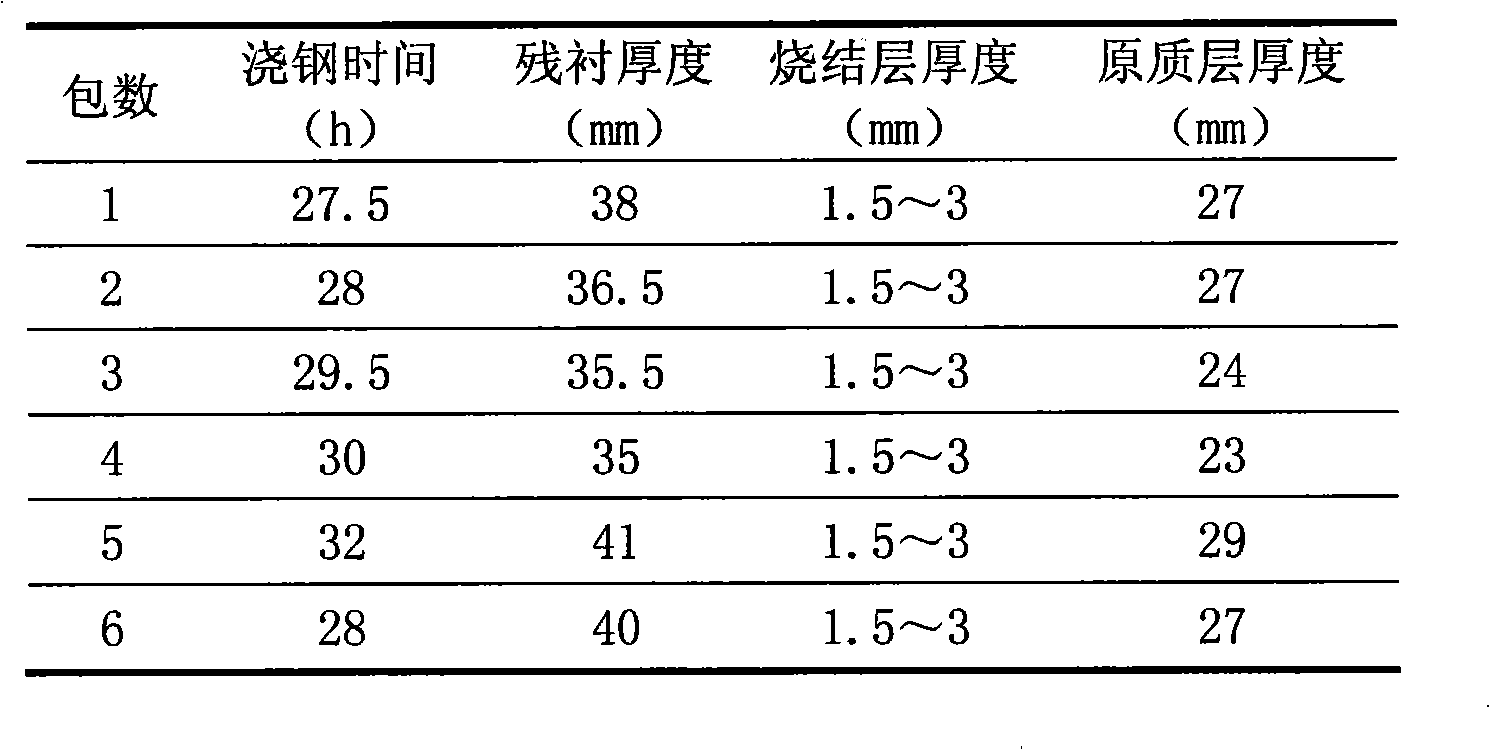

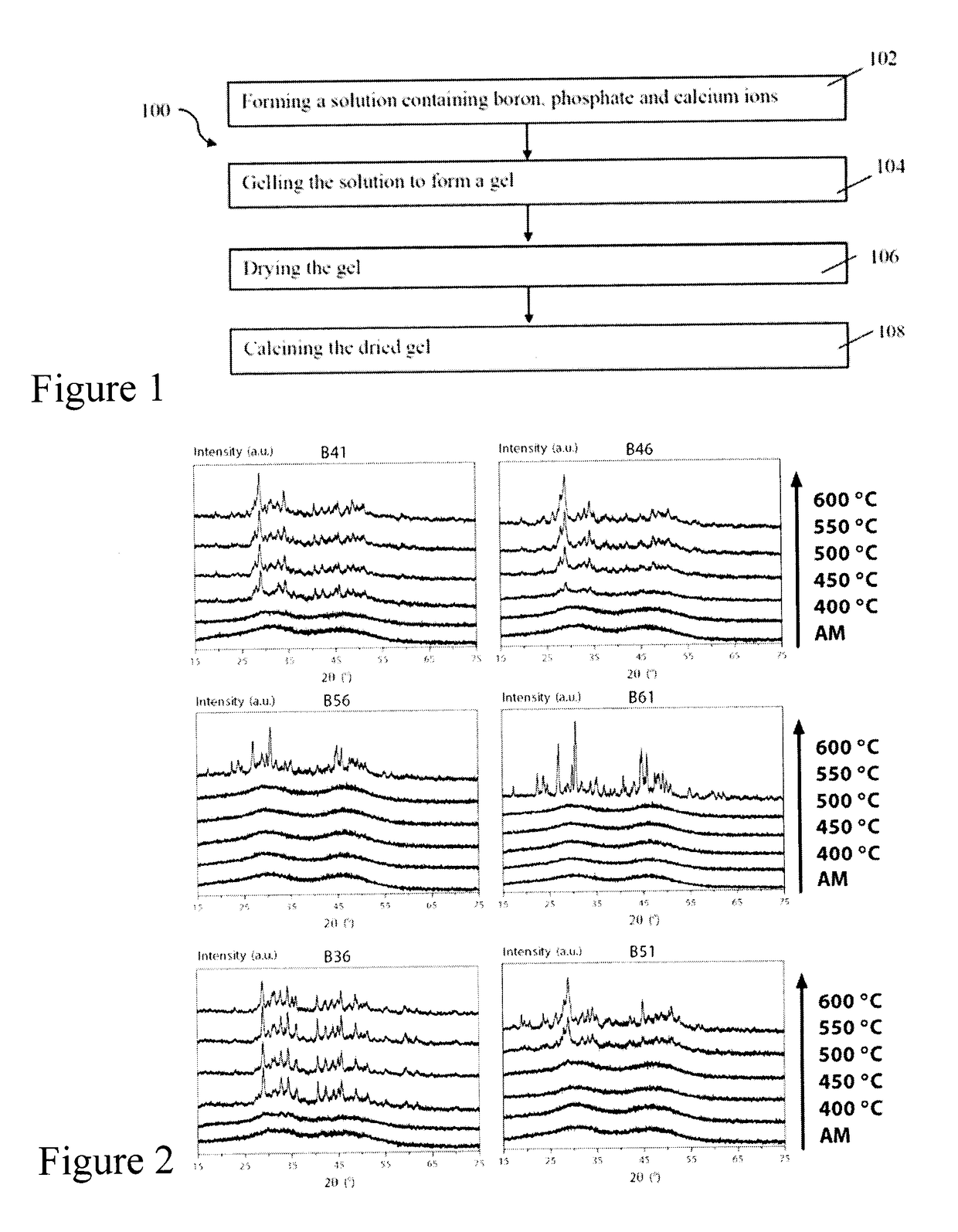

Borate-glass biomaterials comprising: aNa2O. bCaO. cP2O5. dB2O3 wherein a is from about 1-40 wt %, b is from about 10-40 wt %, c is from about 1-40 wt %, and d is from about 35-80 wt %; and wherein the biomaterial has a surface area per mass of more than about 5 m2 / g. Methods of making and uses of these biomaterials.

Owner:MCGILL UNIV

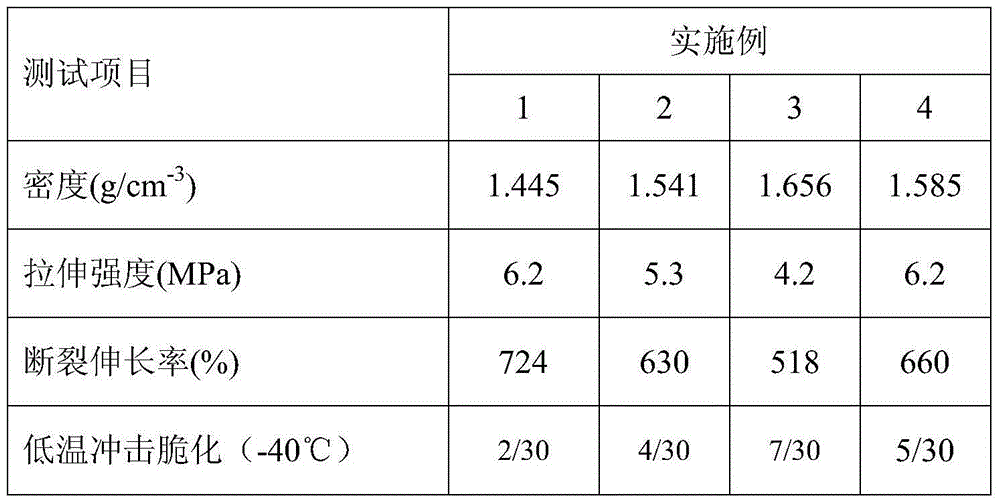

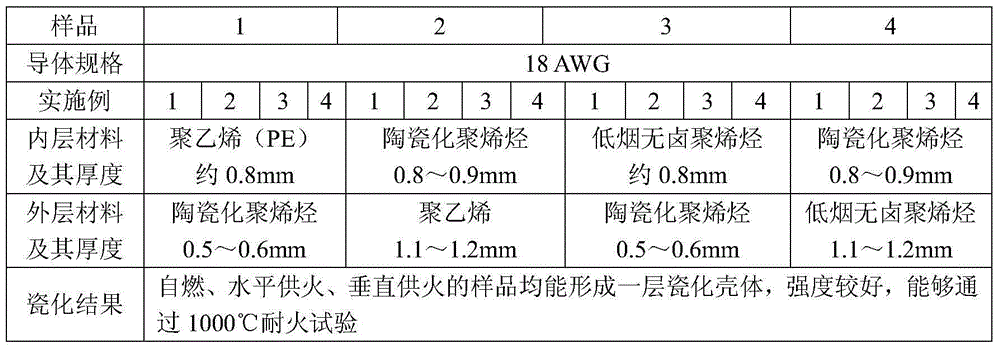

Ceramized polyolefin material and preparation method thereof

InactiveCN104558804AHigh strengthReduce the temperaturePlastic/resin/waxes insulatorsPolyolefinAntioxidant

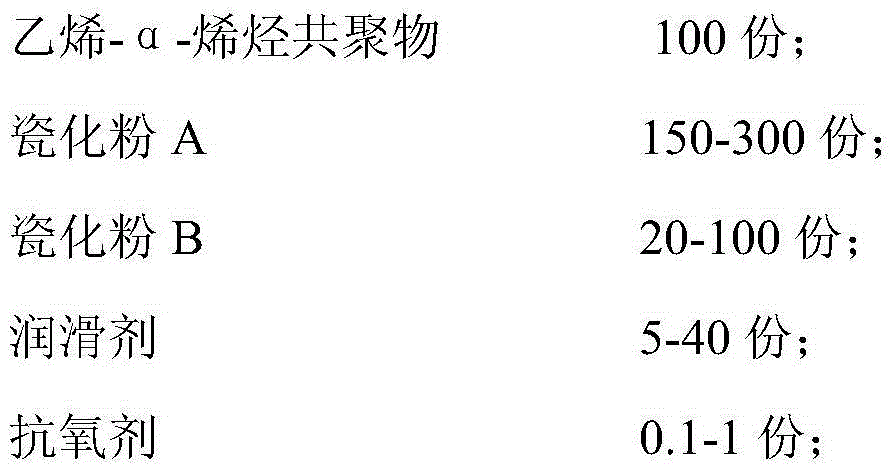

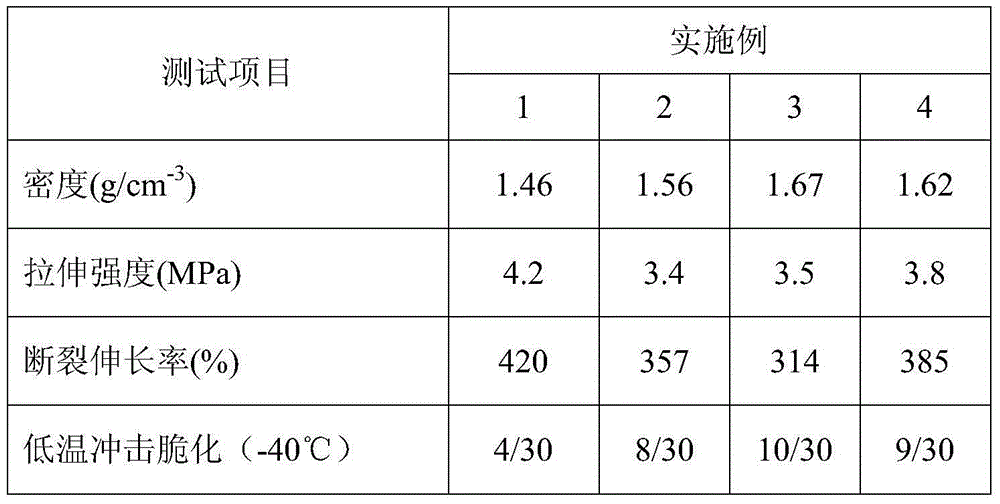

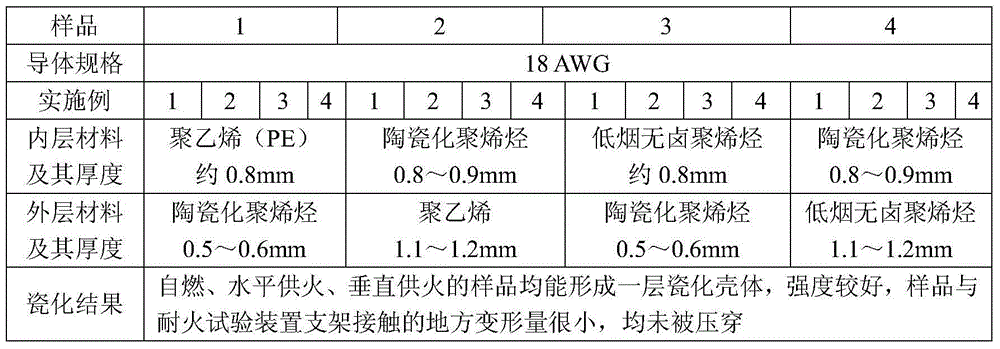

The invention discloses a ceramized polyolefin material and a preparation method thereof, belonging to the field of electric wire and cable materials. The ceramized polyolefin material comprises the following raw material components: 100 parts of an ethylene-alpha-olefin copolymer, 150-300 parts of ceramized powder A, 20-100 parts of ceramized powder B, 5-40 parts of a lubricating agent and 0.1-1 part of an antioxidant, wherein the ethylene-alpha-olefin copolymer is one or more selected from an ethylene and alpha-propylene copolymer, an ethylene and alpha-butylene copolymer, an ethylene and alpha-hexylene copolymer and an ethylene and alpha-octene copolymer; the ceramized powder A is one or a combination of more than one selected from layered inorganic powder, fibrous inorganic powder and needle-like inorganic powder; the ceramized powder B is at least one selected from borax, ammonium borate, a zinc borate and boron frit, phosphate glass powder with a low melting point, borate glass powder with a low melting point and silicate glass powder with a low melting point; and the antioxidant is at least one selected from 1010, 1076, 168, 626, 300 and DSTDP. The ceramized polyolefin material is reasonable in raw material and proportion, capable of ensuring normal operation of a route, good in flexibility, simple in process and low in cost.

Owner:JIANGSU ZHONGLI GRP CO LTD +2

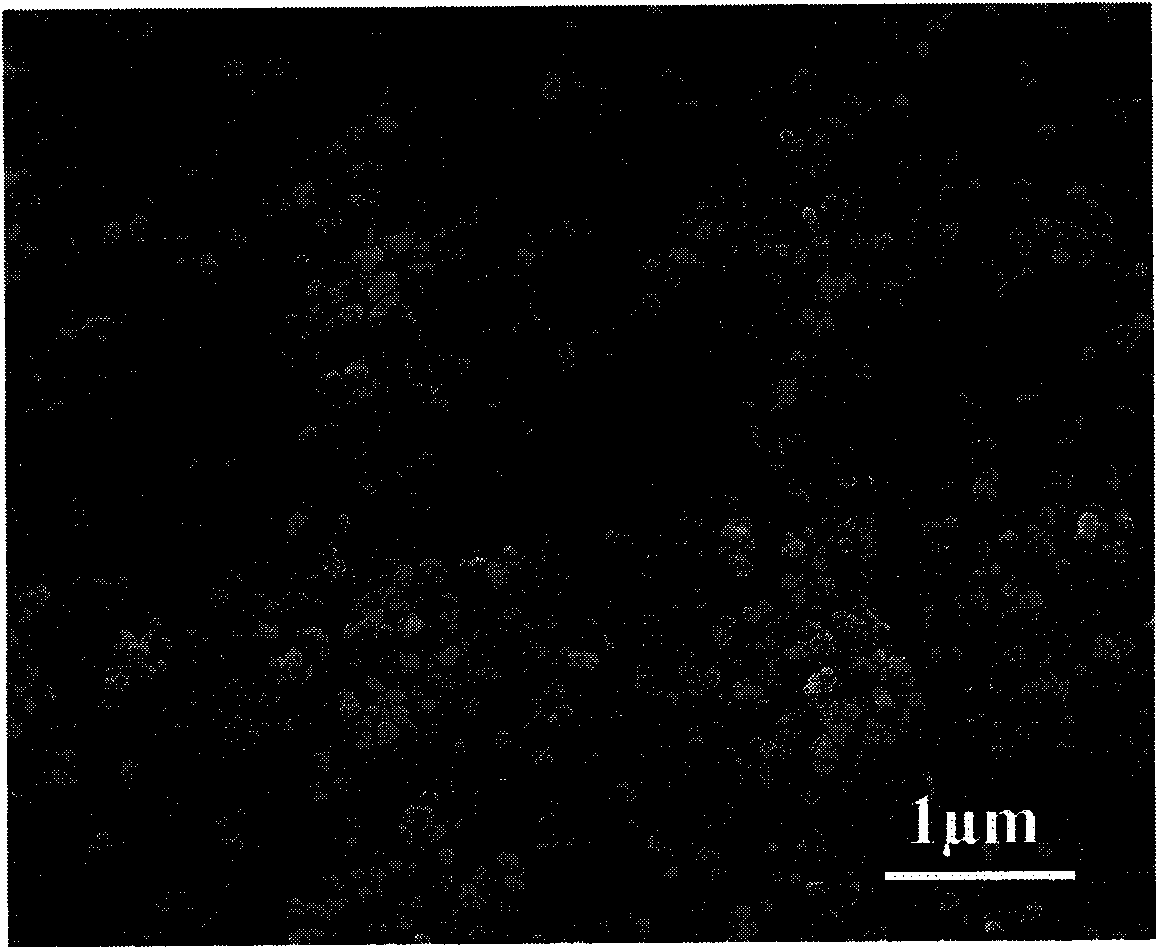

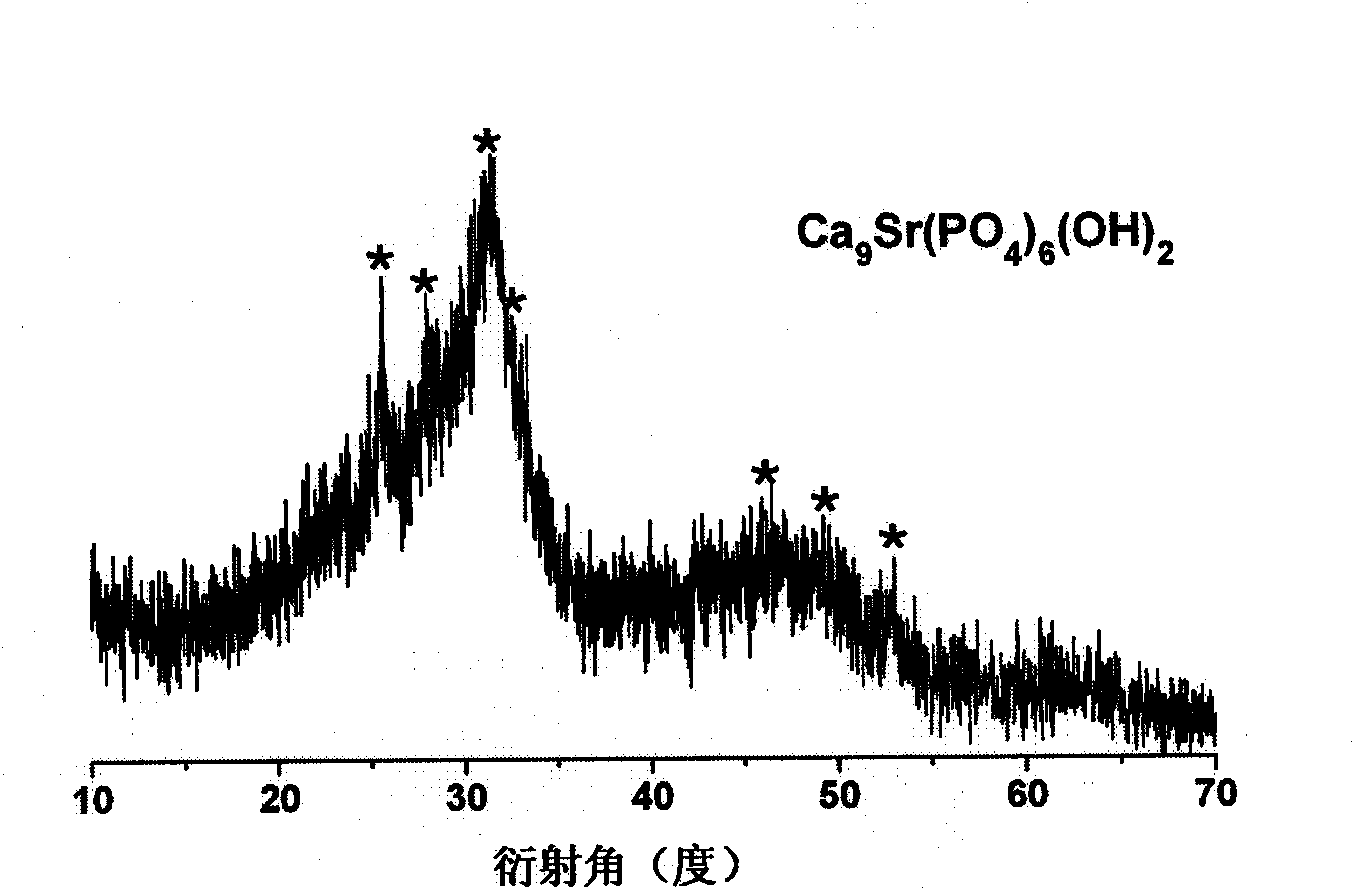

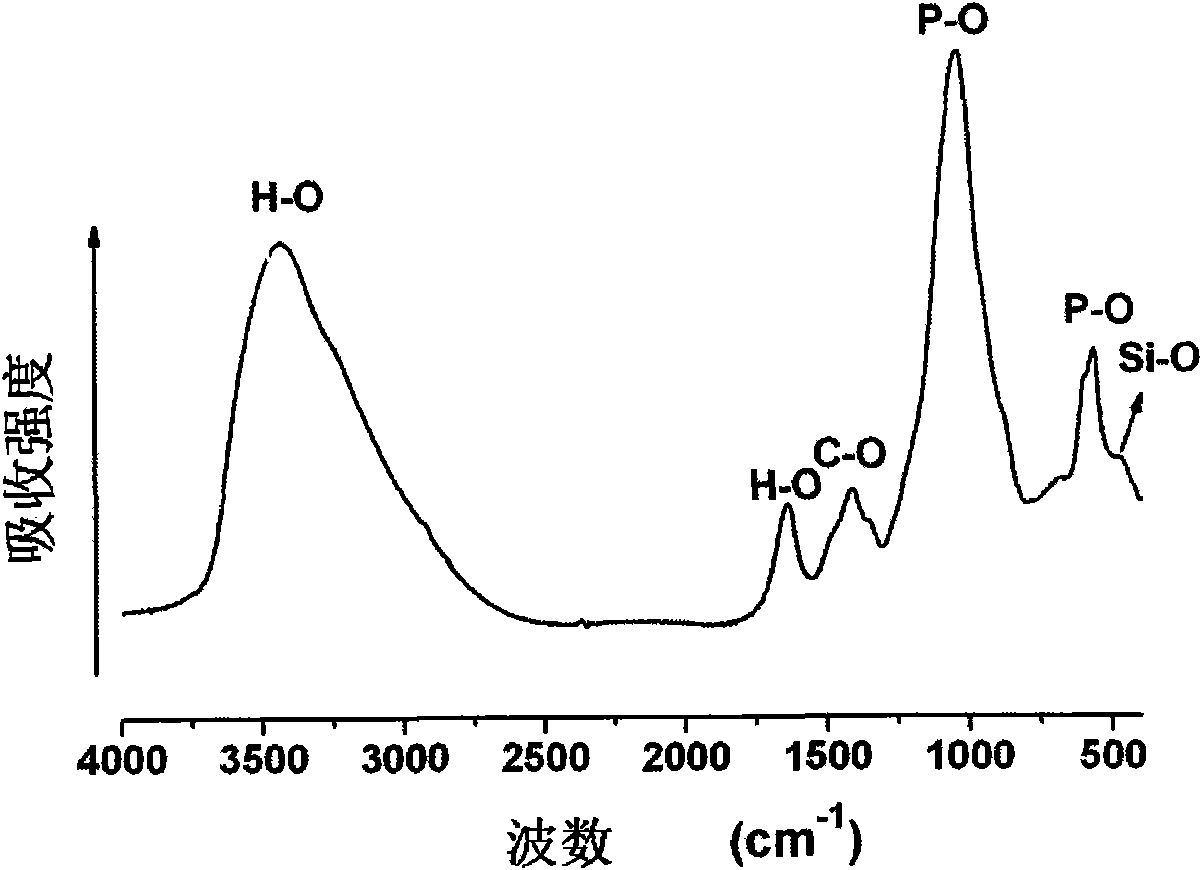

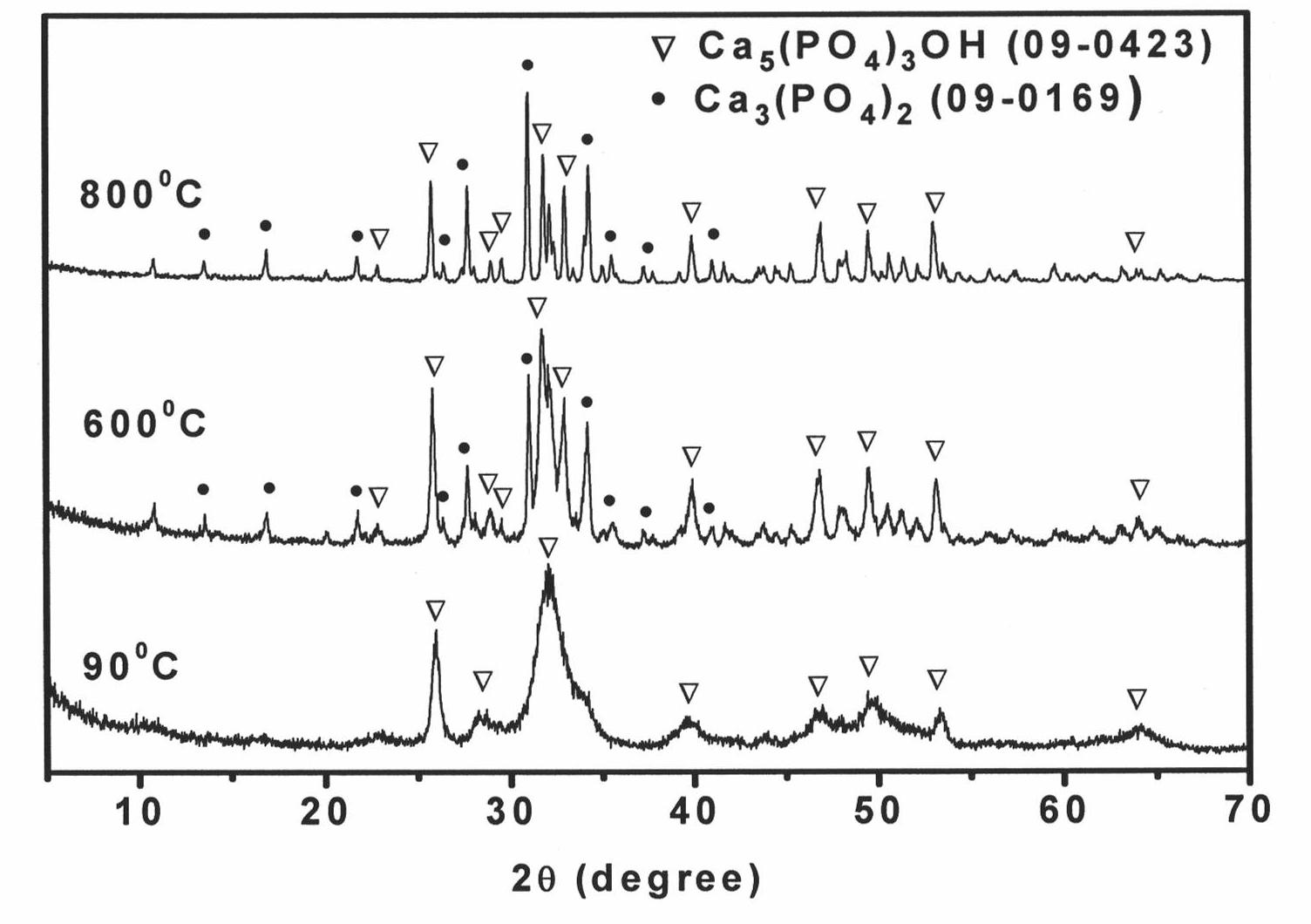

Preparation method and application of strontium-incorporated hydroxyapatite

InactiveCN101628124ABiocompatibleBiologically activeInorganic phosphorous active ingredientsSkeletal disorderProcess equipmentBorate glass

The invention belongs to the biomaterial technical field and particularly relates to a preparation method and an application of strontium-incorporated hydroxyapatite. The preparation method comprises the following steps: soaking borate glass or phosphate vitreum containing strontium and calcium with a certain shape in phosphate solution, adjusting the pH of the solution to more than 7, depositing nanoscale strontium-incorporated hydroxyapatite on the surface of glass at 20-250 DEG C under the pressure of 0.10-4.00MPa; and forming strontium-incorporated hydroxyapatite body with the same appearance and the size of glass in situ of the glass. The net formation oxide of the borate glass or phosphate glass is B2O3 or P2O5 or both or B2O3 and fewer SiO2 or P2O5 and fewer SiO2 or B2O3, P2O5 and fewer SiO2. The gap oxide of glass net contains one or more of other univalent, divalent, trivalent and tetravalent metal oxides beside CaO and SrO so as to adjust the dissolution velocity of glass. The method has simple device, easy operation and low cost. By adopting different glass compositions or different reaction conditions, strontium-incorporated hydroxyapatites with various sizes or nanoscale strontium-incorporated hydroxyapatites with various shapes can be obtained. The strontium-incorporated hydroxyapatite with a certain shape and properties can be used as the bone filler or bone tissue engineering scaffold for repairing bones or curing osteoporosis.

Owner:TONGJI UNIV

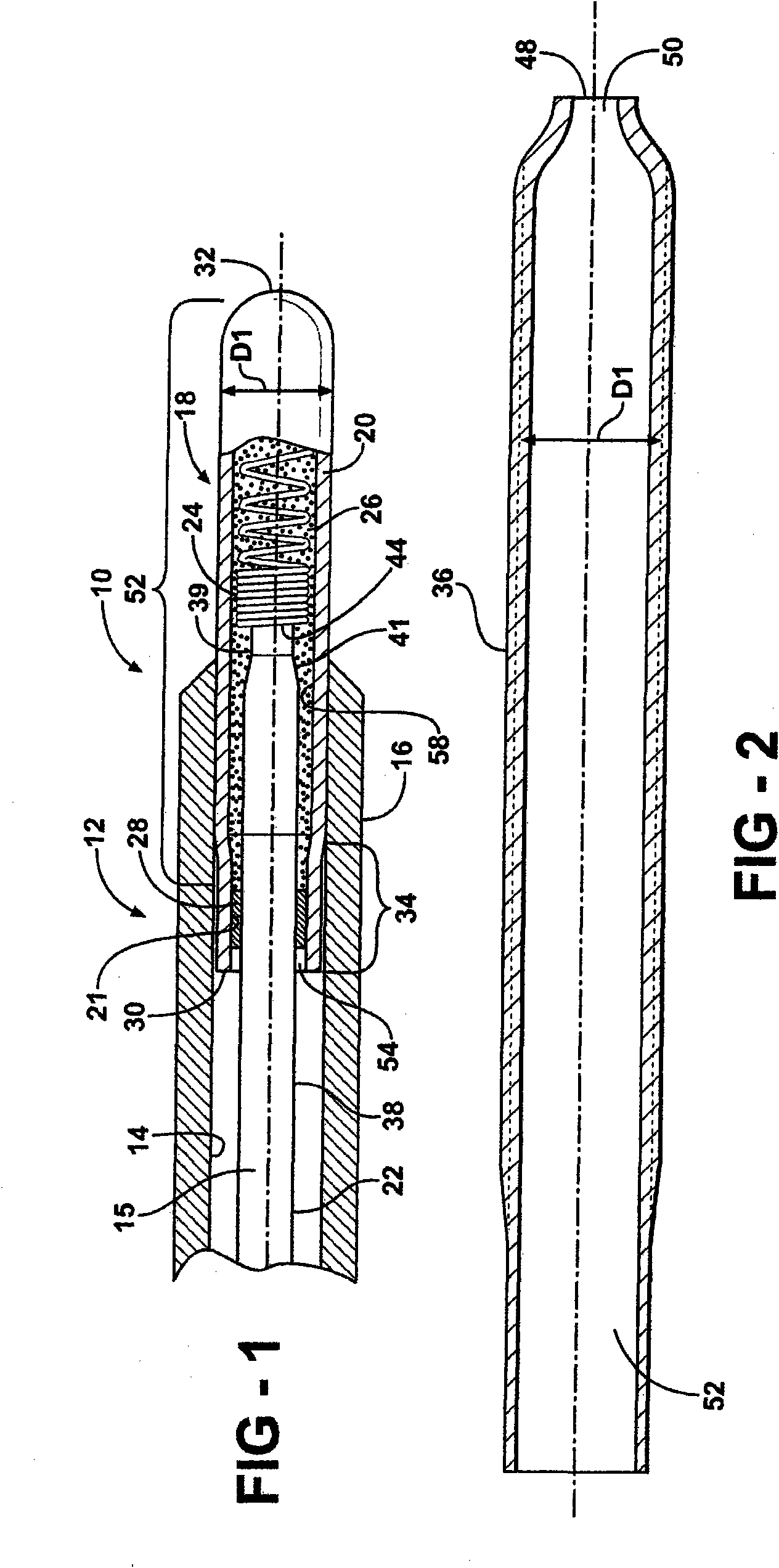

Sheathed glow plug

A glow plug which includes an annular metal shell, thermally conductive tubular sheath, central electrode; resistance heating element, and electrically insulating, thermally conductive powder includes a glass seal in sealing engagement with the sheath and the electrode to form a sealed cavity within the sheath. The glass seal may include silicate, borate and borosilicate glasses, and may include one or more transition metal oxides, such as oxides of chromium, cobalt, nickel, iron and copper. The glass may also include a filler, including a ceramic oxide, such as one selected from a group consisting of quartz, eucryptites, leucites, cordierites, beta-spodumene, glass-ceramics, low- expansion glass(CTE<5ppm / DEG C), mullite, zircon, zirconia and alumina. The sealed cavity may house a protective inert gas. The resistance heating element may be formed from a metal selected from a group consisting of tungsten, molybdenum, or alloys containing tungsten, molybdenum, nickel, iron, tantalum, niobium, titanium, vanadium, osmium and chromium.

Owner:FEDERAL MOGUL IGNITION

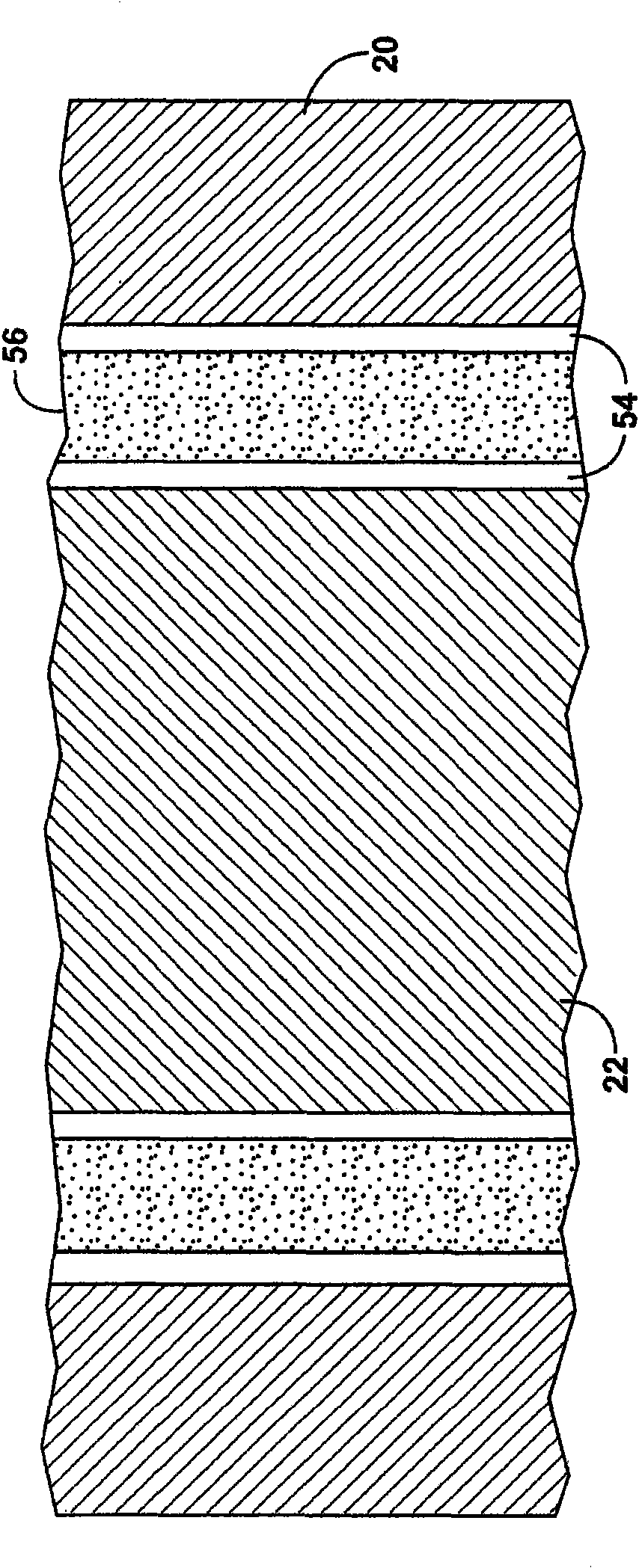

Highly-heat-resistant liquid silicate water-based heat-insulating coating material and preparation method thereof

InactiveCN103275531AImprove water resistanceImprove heat resistanceAlkali metal silicate coatingsCelluloseWater based

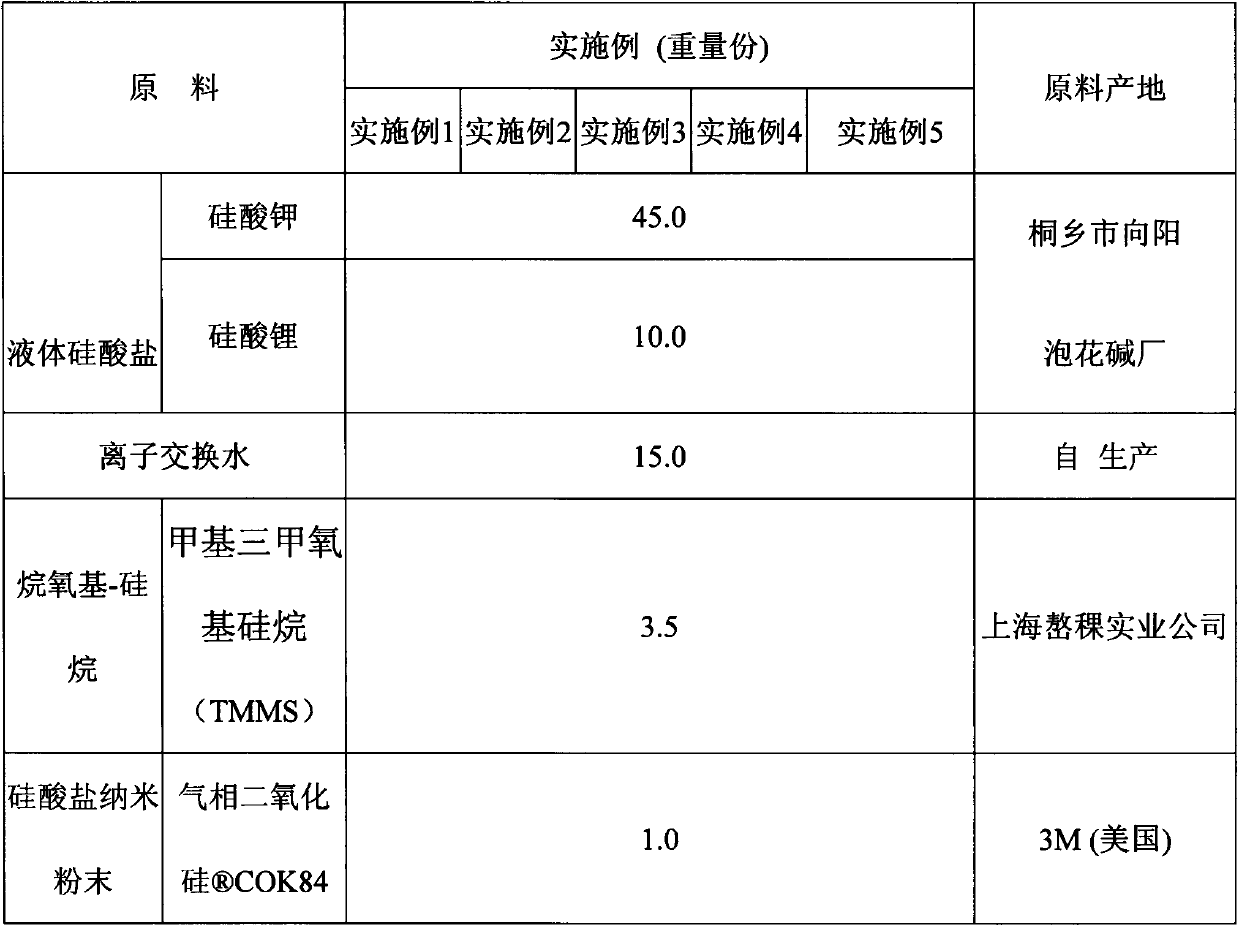

The invention relates to a highly-heat-resistant liquid silicate water-based heat-insulating coating material and a preparation method thereof. The coating material comprises the following components by weight percent: 45% to 60% of liquid silicate, 11% to 16% of ion exchange water, 3% to 5% of alkoxy silane, 0.5% to 1.5% of silicate nanopowder, 1% to 2.7% of wetting agent, 1% to 3% of mineral cellulose, 5% to 10% of ludox, 1.5% to 3.5% of ultrafine silica nanoparticle powder, 5% to 9% of sodium borate glass hollow spheres, 0.3% to 1.0% of phosphoric acid aqueous solution and 5% to 10% of inorganic filler. The preparation method comprises the following steps of: evenly mixing the liquid silicate with the ion exchange water; sequentially adding the alkoxy silane and the silicate nanopowder; sequentially adding the wetting agent, the mineral cellulose and the inorganic filler; adding the ludox and the ultrafine silica nanoparticle powder; adding the sodium borate glass hollow spheres; and finally, slowly adding the phosphoric acid aqueous solution, thereby obtaining a target product. The coating material provided by the invention is excellent in water resistance, heat resistance and heat insulation as well as simple in preparation process, broad in raw material source and low in cost, thereby being suitable for large-scale industrial production.

Owner:苏州绿科环保新材料有限公司

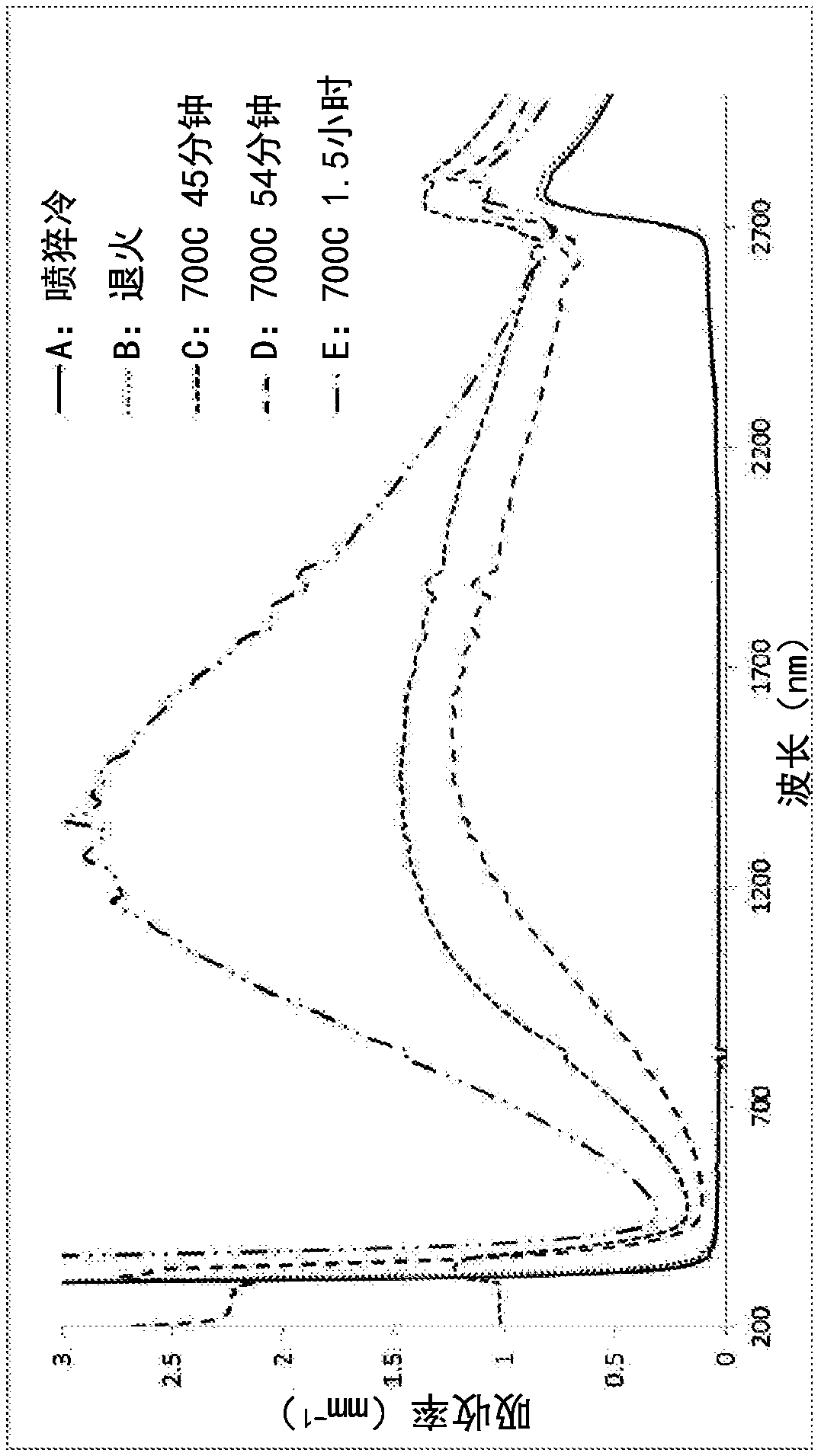

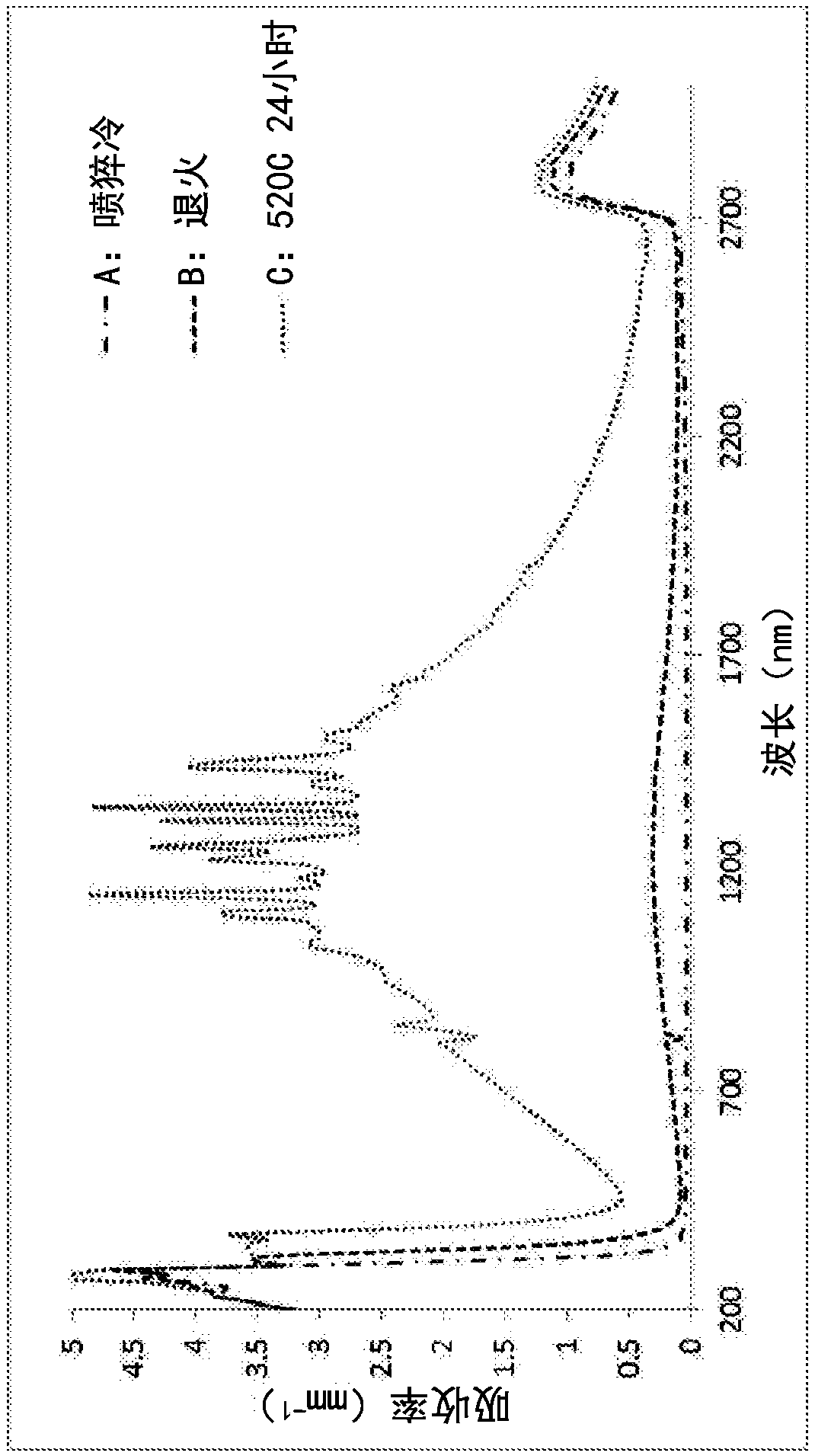

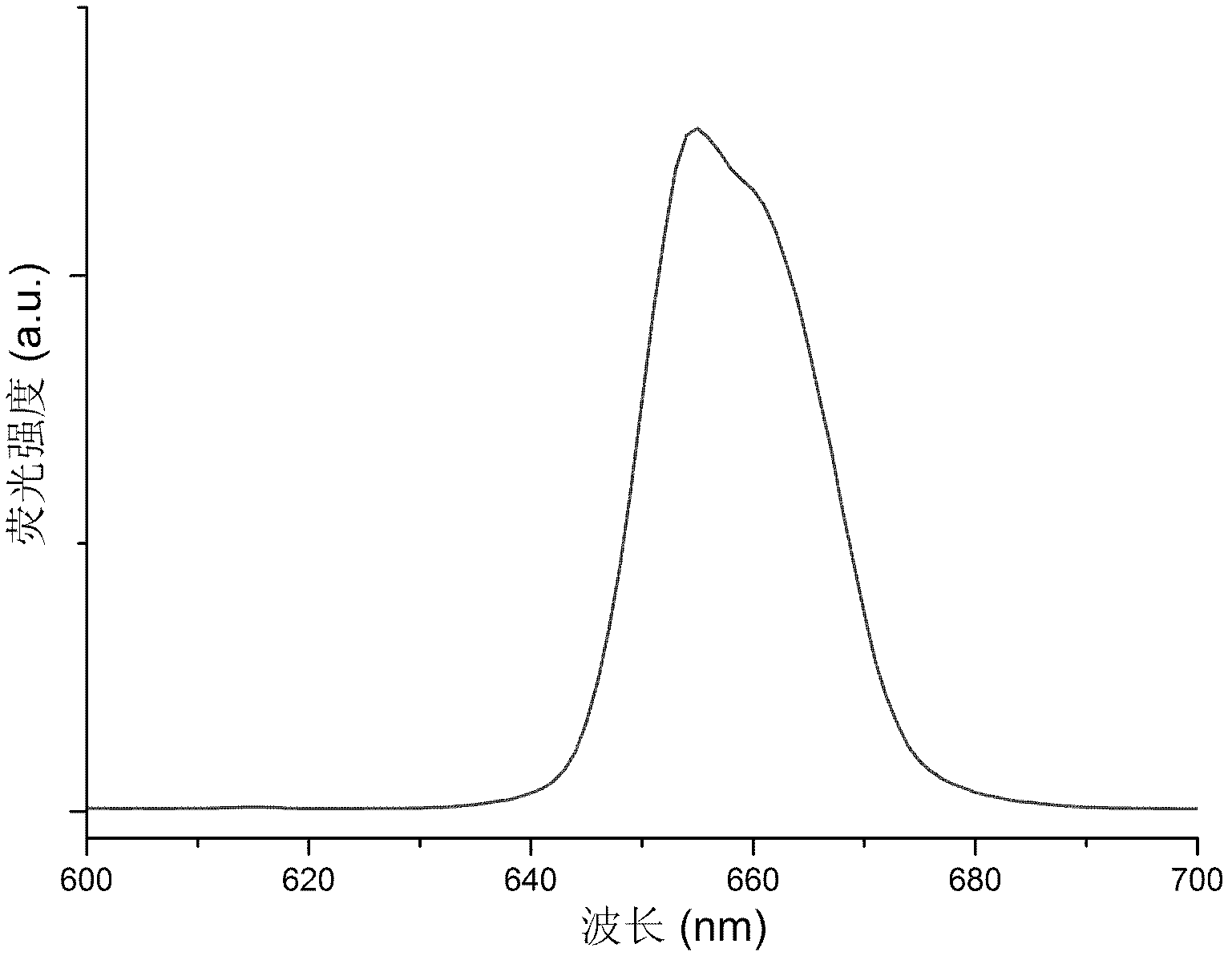

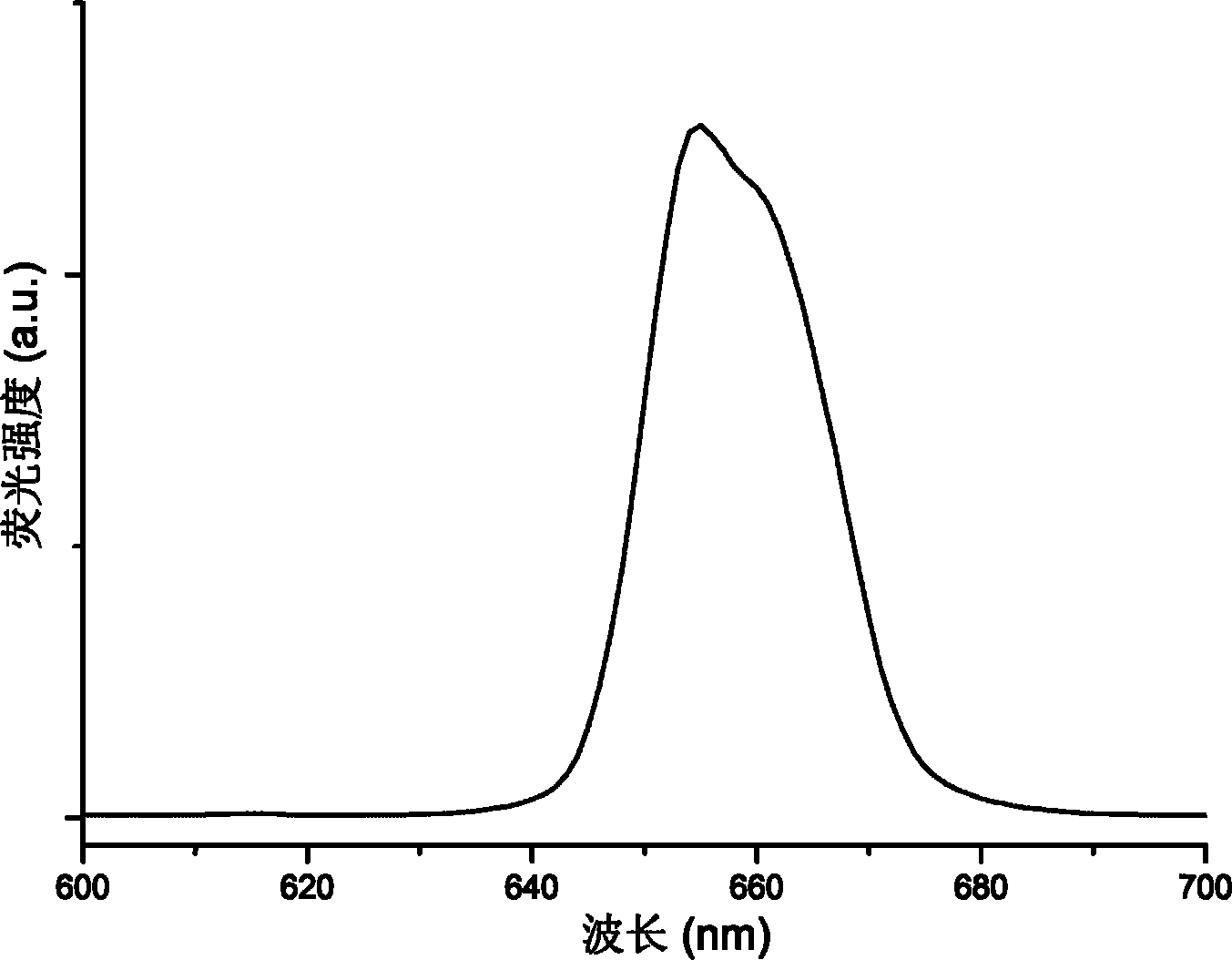

Luminescent borate glass and preparation method therof

InactiveUS20120126172A1High luminous intensityEasy to packGlass drawing apparatusGlass forming apparatusLuminous intensityBorate glass

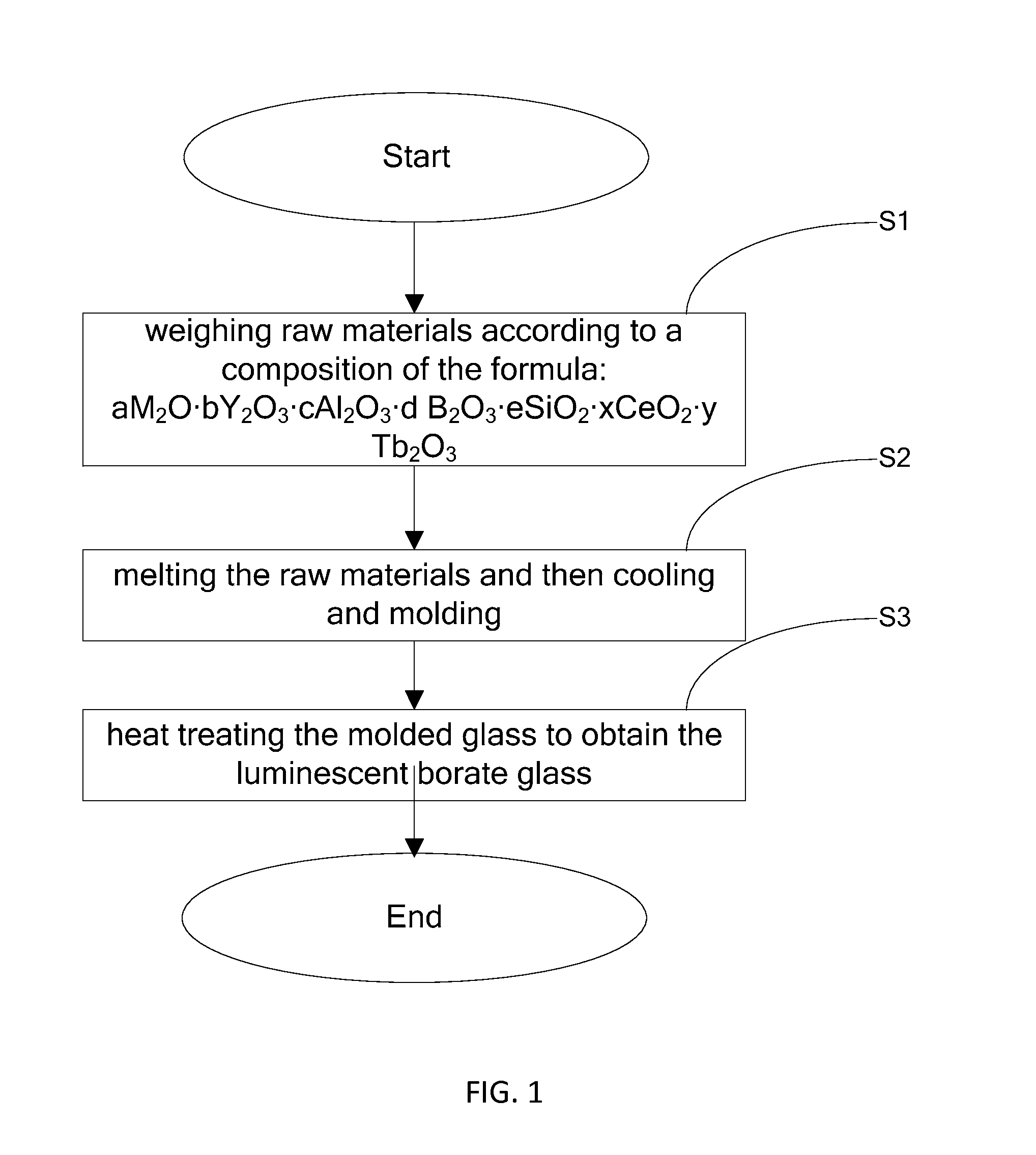

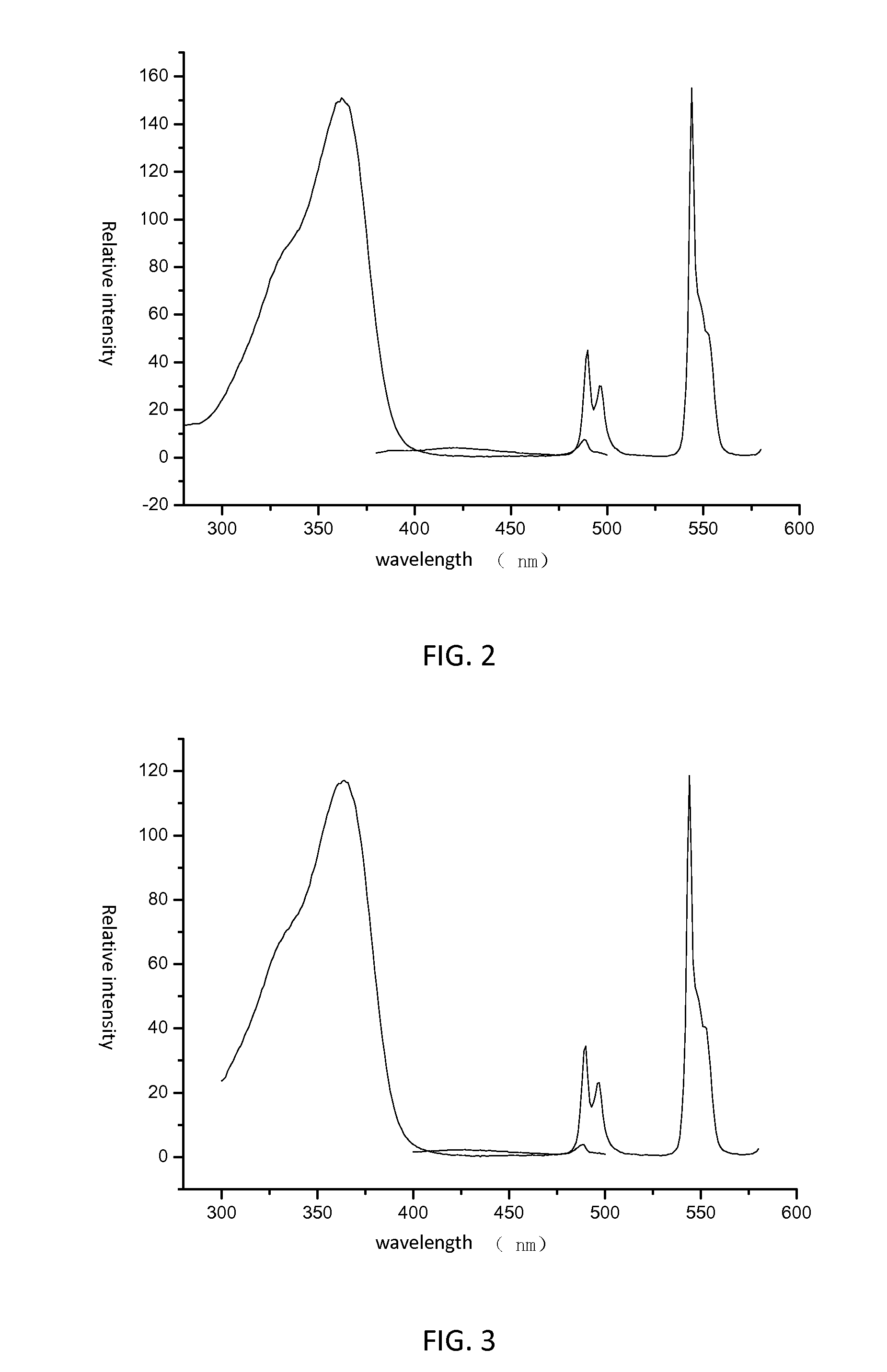

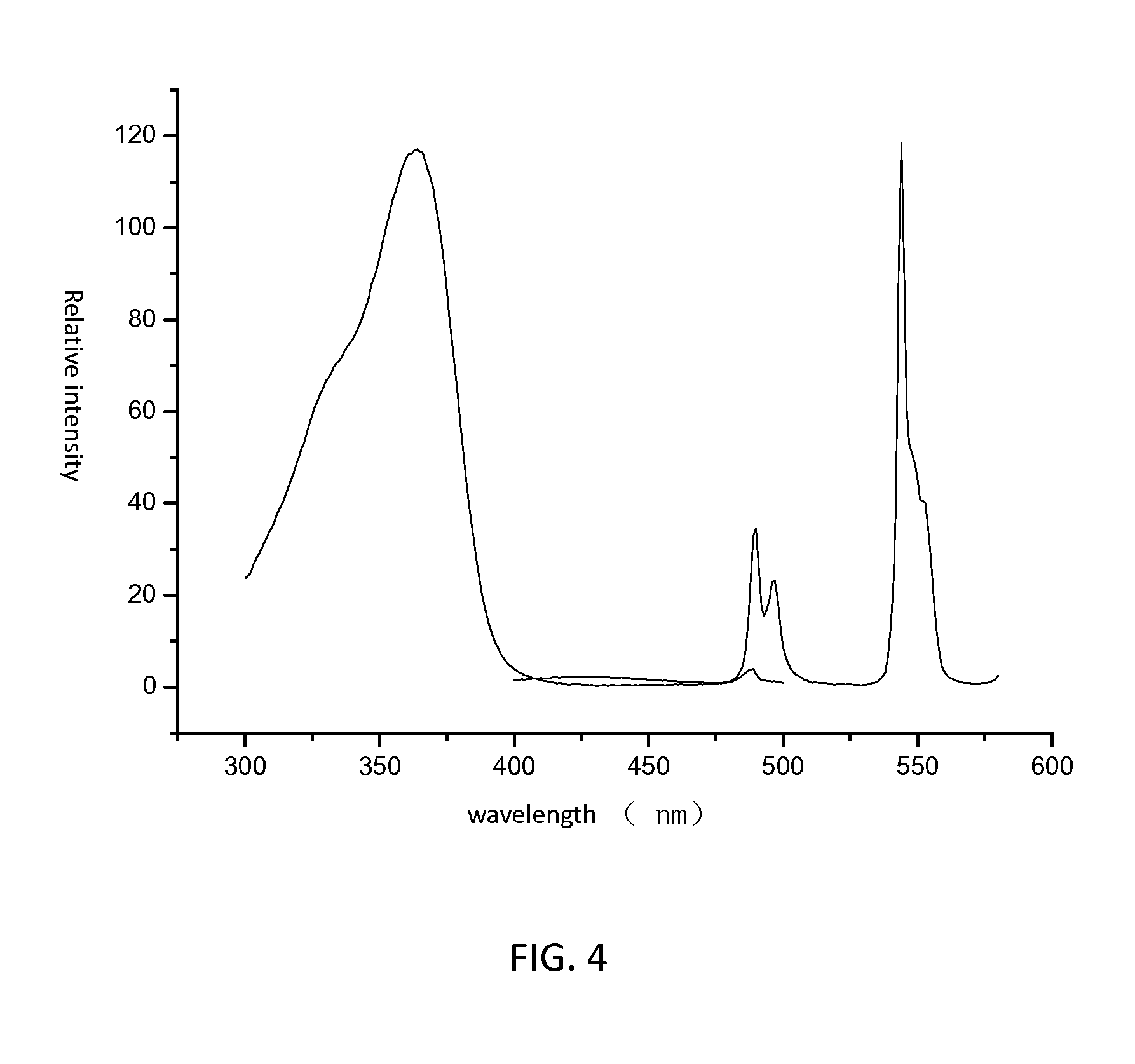

A luminescent borate glass and a preparation method thereof are disclosed. The preparation method includes: weighing raw materials according to a composition of the formula: aM2O.bY2O3.cAl2O3.d B2O3.eSiO2.xCeO2.y Tb2O3, wherein M represents at least one selected element from the group consisting of Na, K, and Li; a, b, c, d, e, x, and y are, by mole parts, 0˜20, 7˜15, 20˜40, 40˜60, 0˜15, 0.1˜1.5, 0.1˜3, respectively; melting the raw materials and then cooling and molding; and heat treating the molded glass to obtain the luminescent borate glass. The luminescent borate glass prepared according to the method has some advantages such as high luminous intensity, uniformity and stability.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

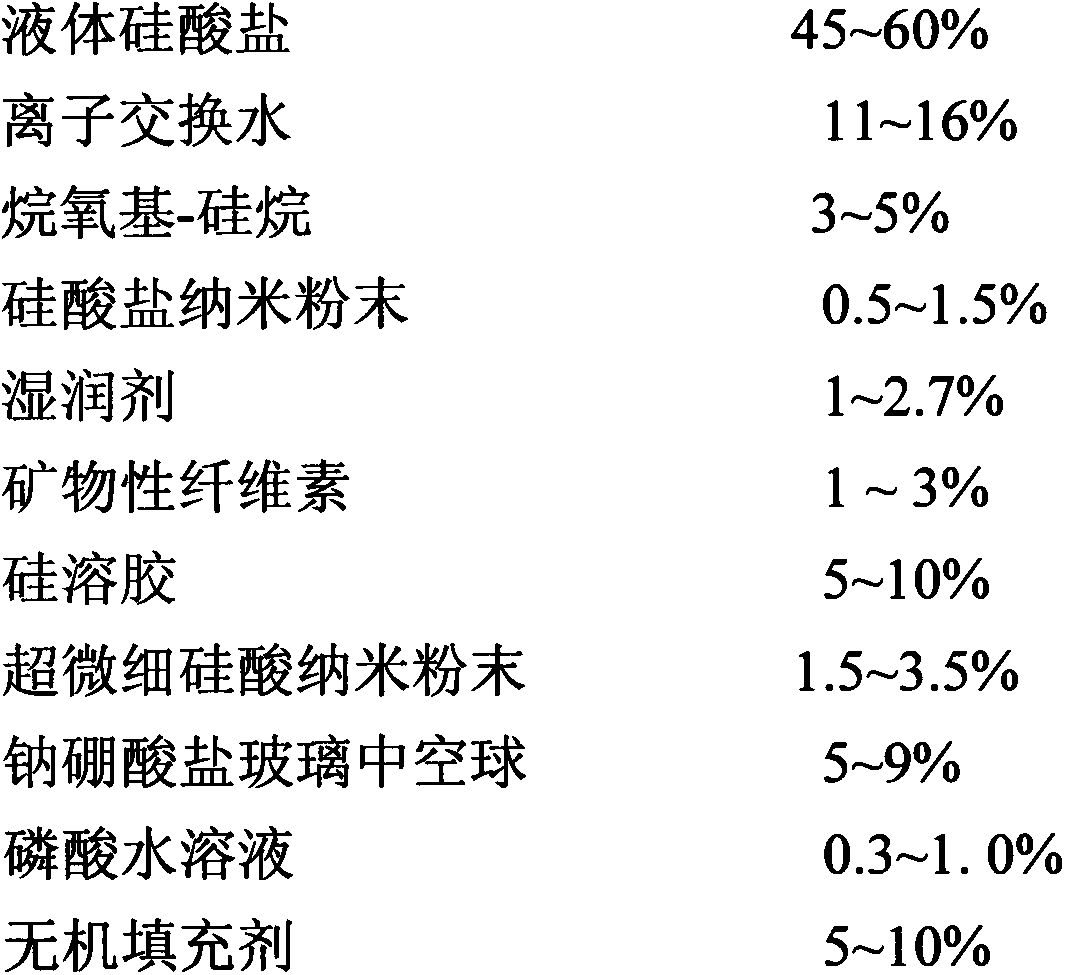

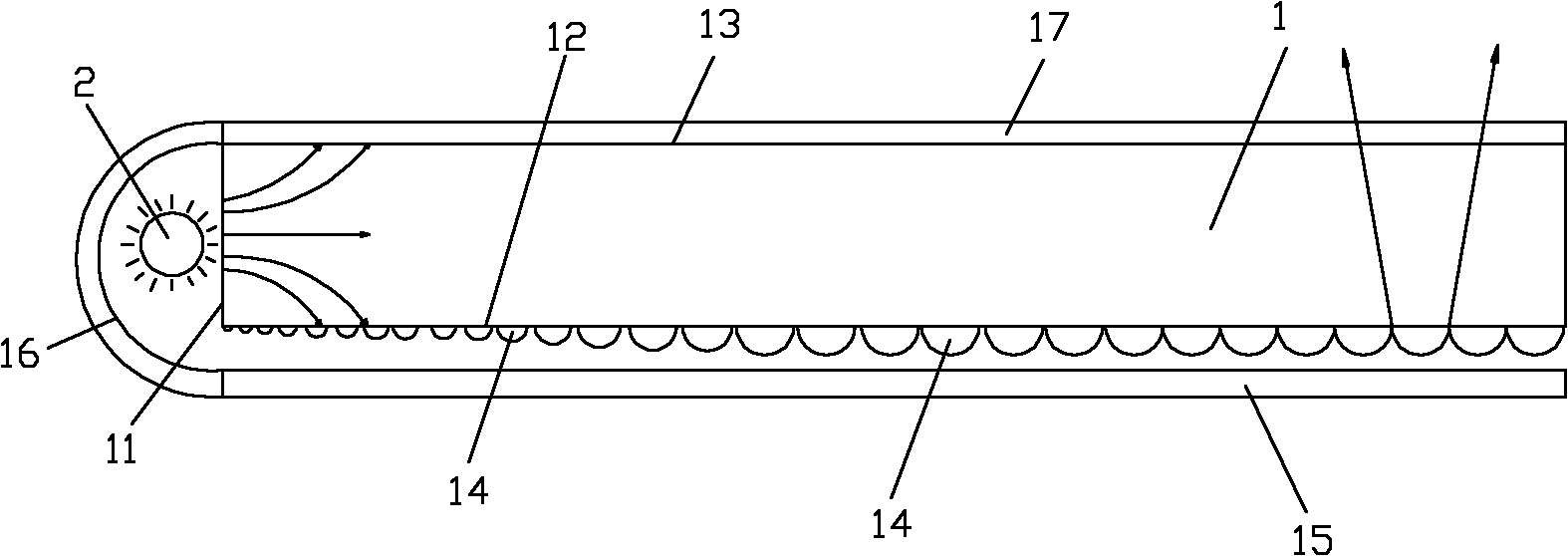

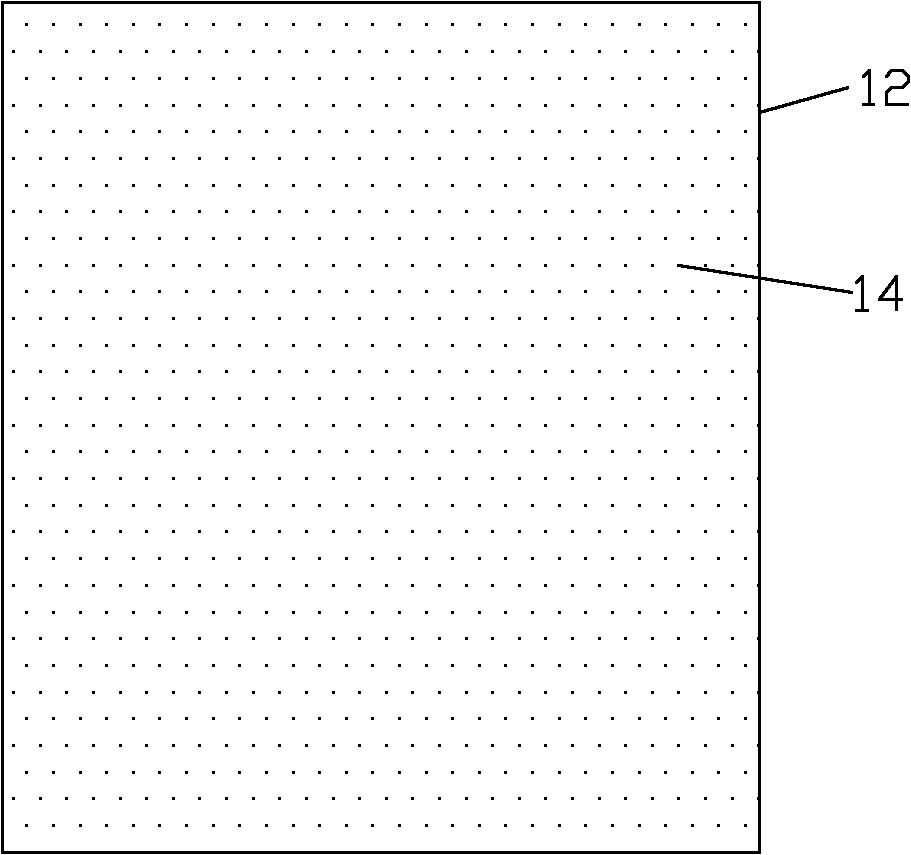

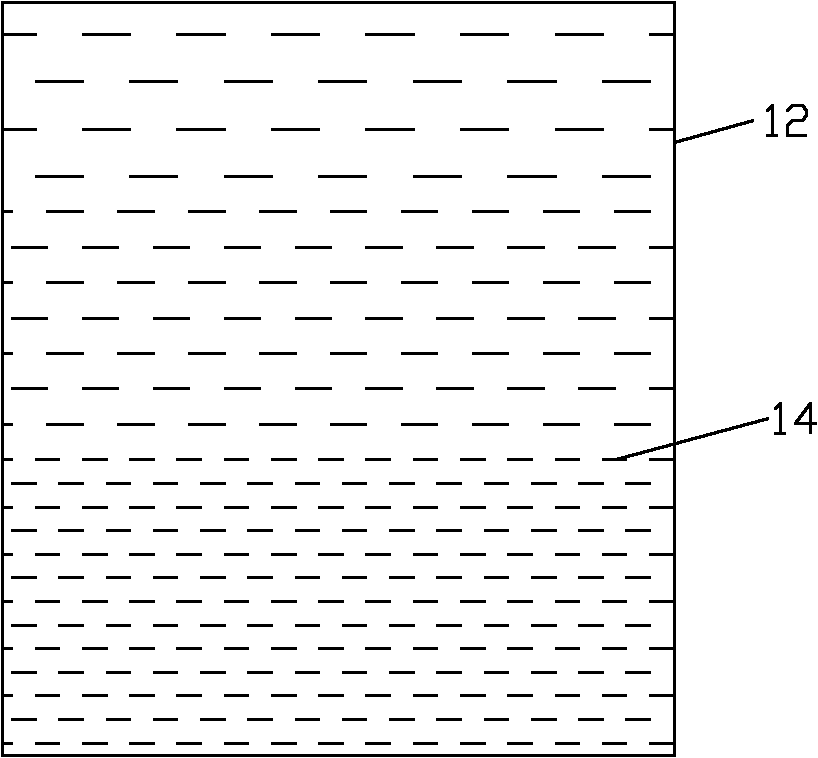

Light guide plate, backlight source and illuminating device

InactiveCN102374493AImprove uniformityEvenly distributedMechanical apparatusLight guides for lighting systemsRough surfaceLight guide

The invention is suitable for the field of illumination, and provides a light guide plate, a backlight source and an illuminating device. The light guide plate is made of ultra-white glass and is provided with at least one light incident surface for receiving light beams, a bottom surface connected with the light incident surface and a light-emitting surface opposite to the bottom surface, wherein the light-emitting surface is used for guiding light in the light guide plate out; in the ultra-white glass, oxide glass of silicate glass, phosphate glass or borate glass or non-oxide glass of chalcogenide glass and halide glass is used as a matrix; the light-emitting surface of the light guide plate is a mirror surface or a rough surface; and pits or bulges are etched, carved or printed on the bottom surface of the light guide plate. In the invention, the ultra-white glass is used as the light guide plate, the light-emitting surface of the light guide plate is used as the mirror surface or the rough surface, and a plurality of pits or bulges are formed on the bottom surface, so that the light emitted from the light-emitting surface of the light guide plate is distributed uniformly, and the light-emitting uniformity of the light guide plate is improved greatly.

Owner:SHENZHEN DIQUANG ELECTRONICS CO LTD

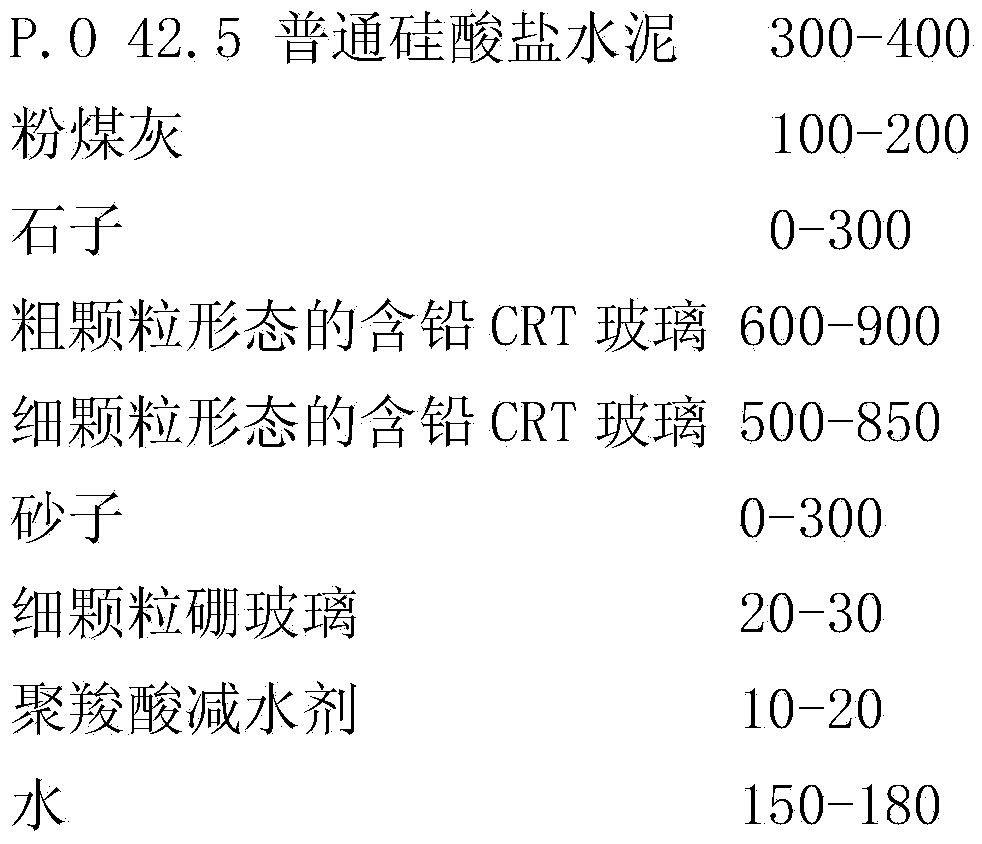

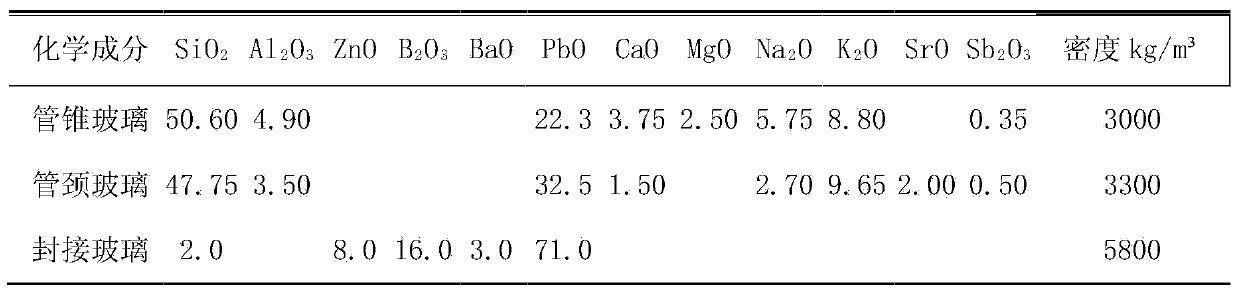

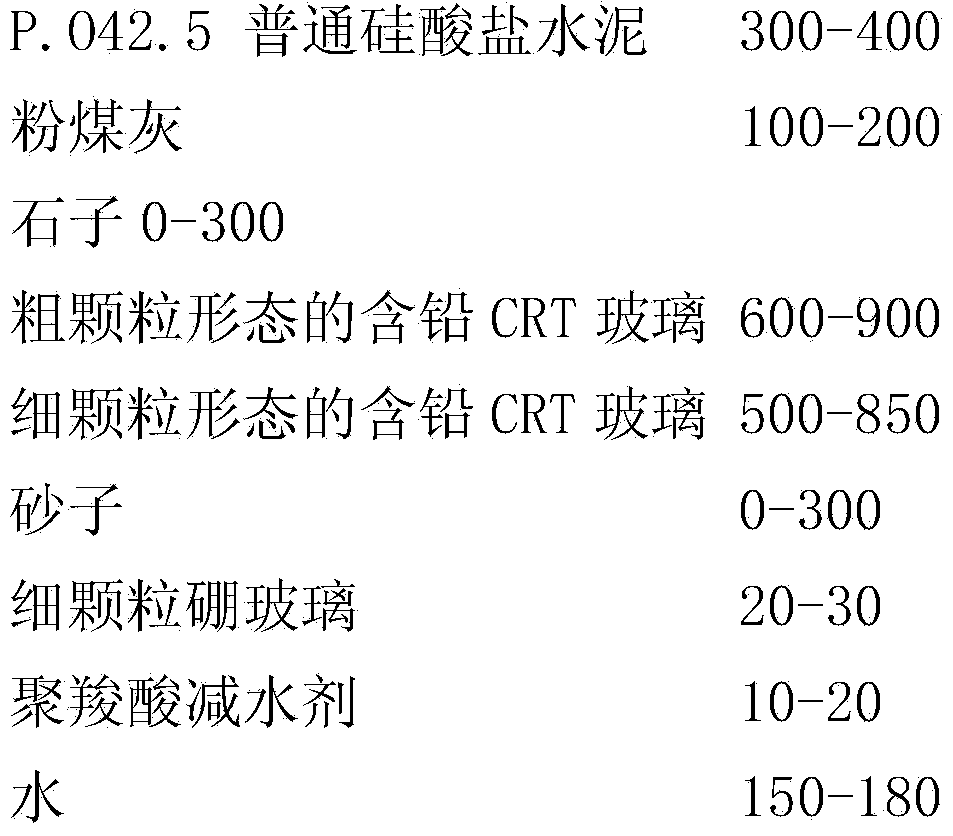

Method for preparing radiation-resistant concrete from lead-containing CRT (cathode ray tube) glass

InactiveCN104177024AImprove protectionHigh mechanical strengthSolid waste managementNuclear powerBorate glass

The invention relates to a method for preparing radiation-resistant concrete from lead-containing CRT (cathode ray tube) glass. The radiation-resistant concrete can be as a shielding material for absorbing and shielding nuclear power station rays, and is beneficial to resource circulation and environmental protection. The substitution of CRT display products with TFT-LCD (thin film transistor-liquid crystal display) electronic display products results in mass rejection of the CRT display products; and CRT glass is the main component for CRT display, and the lead-containing CRT glass has potential environmental pollution and belongs to hazard solid wastes. According to the invention, the lead-containing CRT glass is prepared into the radiation-resistant concrete to satisfy the use of nuclear island construction for nuclear power stations. The radiation-resistant concrete is prepared from 300-400kg of P.O 42.5 ordinary Portland cement, 100-200kg of fly ash, 0-300kg of gravel, 600-900kg of coarse-particle lead-containing CRT glass, 500-850kg of fine-particle lead-containing CRT glass, 0-300kg of sand, 20-30kg of fine-particle borate glass, 10-20kg of polycarboxylic acid water reducer and 150-180kg of water.

Owner:BEIJING UNIV OF TECH +2

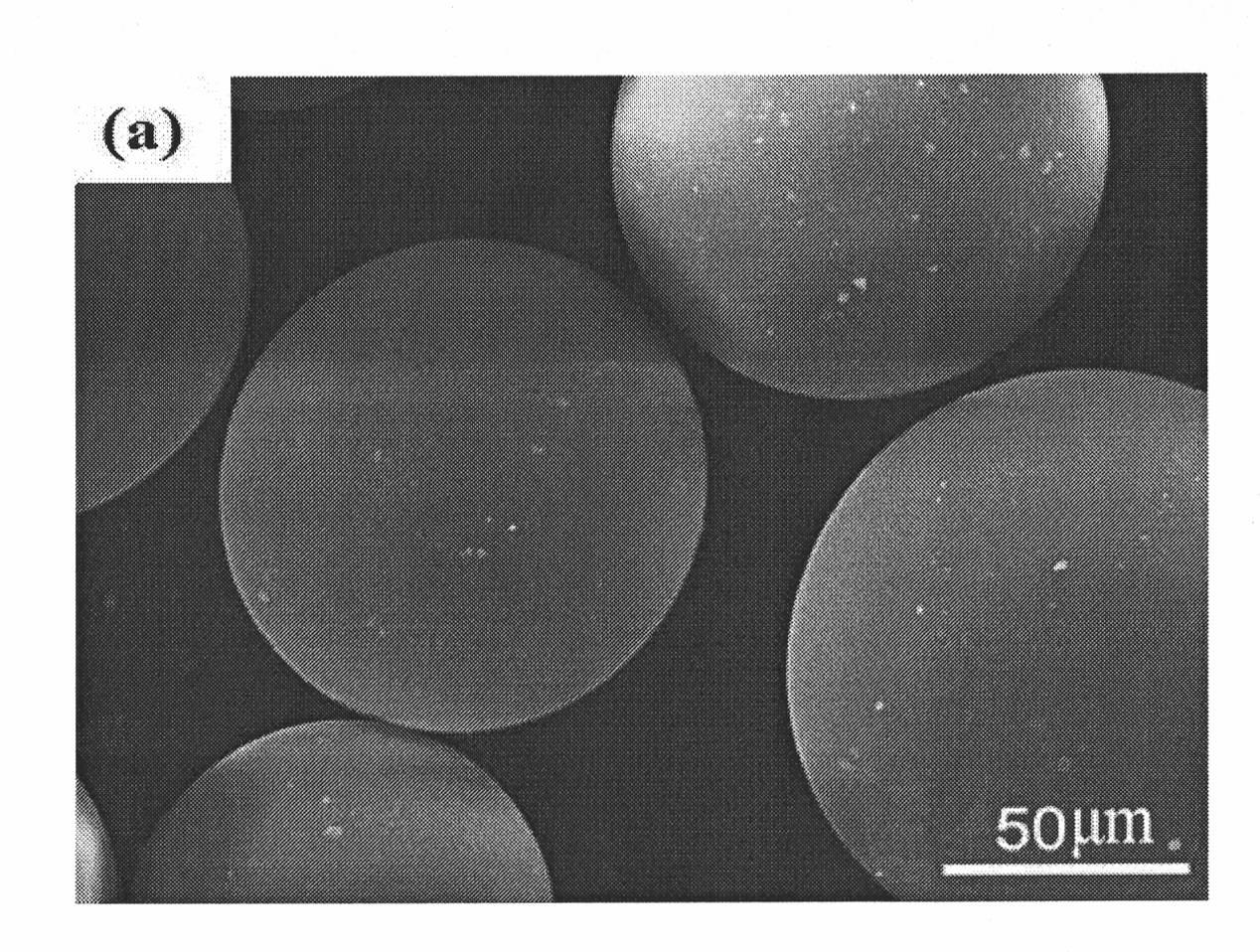

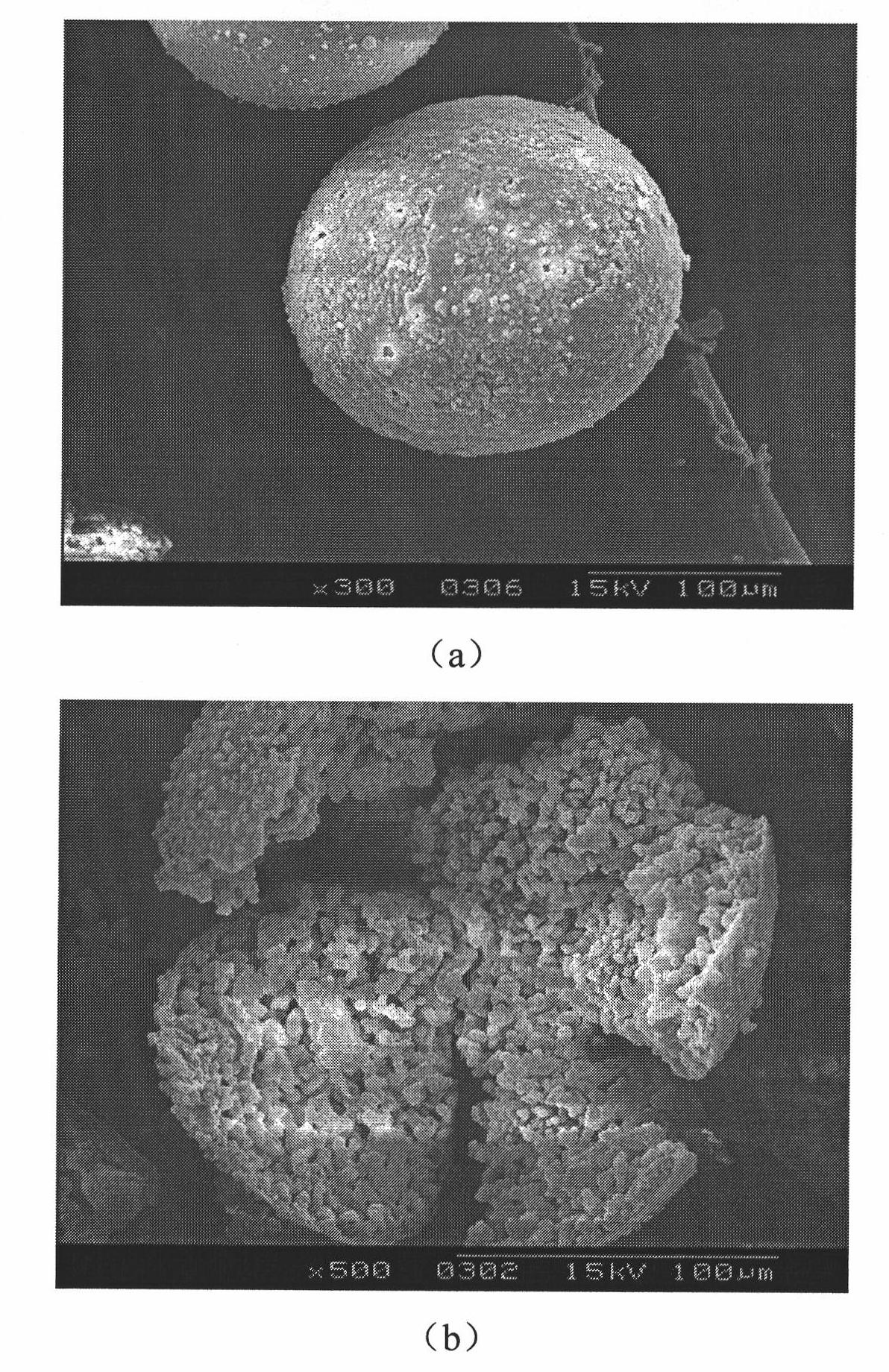

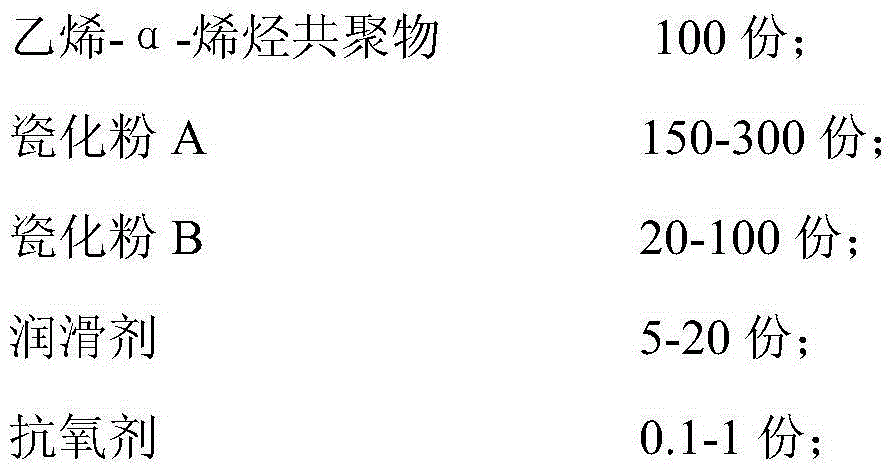

Porous calcium phosphate microsphere with medicinal controlled release function, preparation method and application thereof

InactiveCN101804206AUniform size distributionPromote repairInorganic non-active ingredientsProsthesisMicrosphereBorate glass

The invention belongs to the field of biological medical materials, in particular relates to a porous calcium phosphate microsphere with a medicinal controlled release function, a preparation method and an application thereof. The main component of the microsphere is tricalcium phosphate, and the microsphere contains little hydroxyapatite at the same time. Mass pores exist on the surface of the microsphere and inside the microsphere, so that both load and controlled release of medicament is favored, the growth of new bone tissues can be promoted, and dual efficacies of medicament treatment and bone defect repairing can be realized. The preparation method is a borateglass in-situ conversion method, and comprises the step of immersing the glass microspheres of Li2O-CaO-B2O3 in different proportions in phosphate solution to prepare the porous calcium phosphate microsphere at low temperature (less than 100 DEG C). The adopted method is simple and feasible, haw low preparation temperature, and cannot affect the appearance and performance of the microsphere in the preparing process.

Owner:TONGJI UNIV

Ceramic polyolefin cable material and preparation method thereof

InactiveCN104558806AHigh strengthReduce the temperaturePlastic/resin/waxes insulatorsPolyolefinAntioxidant

The invention discloses a ceramic polyolefin cable material and a preparation method thereof, and belongs to the technical field of a wire / cable material. The ceramic polyolefin cable material consists of the following raw material components in parts by weight: 100 parts of an ethylene-alpha-olefine copolymer, 150-300 parts of ceramic powder A, 20-100 parts of ceramic powder B, 5-20 parts of a lubricant and 0.1-1 part of an antioxidant, wherein the ethylene-alpha-olefine copolymer is a mixture of ethylene and any one or more of alpha-propylene, alpha-butylene, alpha-hexylene and alpha-octylene copolymers according to any proportions by weight; the ceramic powder A is any one or any combinations of lamellar inorganic powder, fibrous inorganic powder and acicular inorganic powder; the ceramic powder B is at least one of borax, ammonium borate, zinc borate, boron frit, low-melting-point phosphate glass powder, low-melting-point borate glass powder and low-melting-point silicate glass powder; and the antioxidant is at least one of 1010, 1076, 168, 626, 300 and DSTDP.

Owner:JIANGSU ZHONGLI GRP CO LTD +2

Bioactive borophosphate glass and preparation method thereof

ActiveCN108164135AControl degradation rateGood biocompatibilityAbsorbent padsProsthesisBiological bodyPhosphate

The invention discloses bioactive borophosphate glass and a preparation method of the bioactive borophosphate glass. The method comprises the steps of preparing boron glass by a fusion and cooling method, and then steeping in a solution containing phosphorus ions to form the double-layer bioactive glass taking porous phosphate as a shell and borate as a kernel, wherein the boron glass comprises the following raw materials: B2O3, MgO, CaO, Na2O, K2O and SrO at a mass ratio of (45-60):(2-10):(15-25):(3-10):(10-15):(1-8). A degradation rate of a borate glass structure in an organism can be controlled, and the biocompatibility of a biological material can be improved by the porous shell; and therefore, the repairing speed of an injured body surface tissue is significantly increased.

Owner:FUZHOU RUIKE BULANG MEDICAL TECH CO LTD

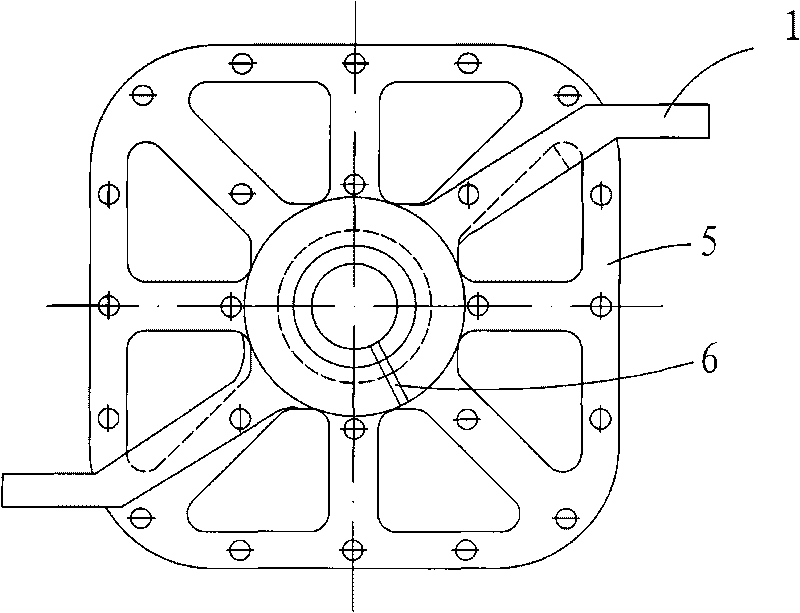

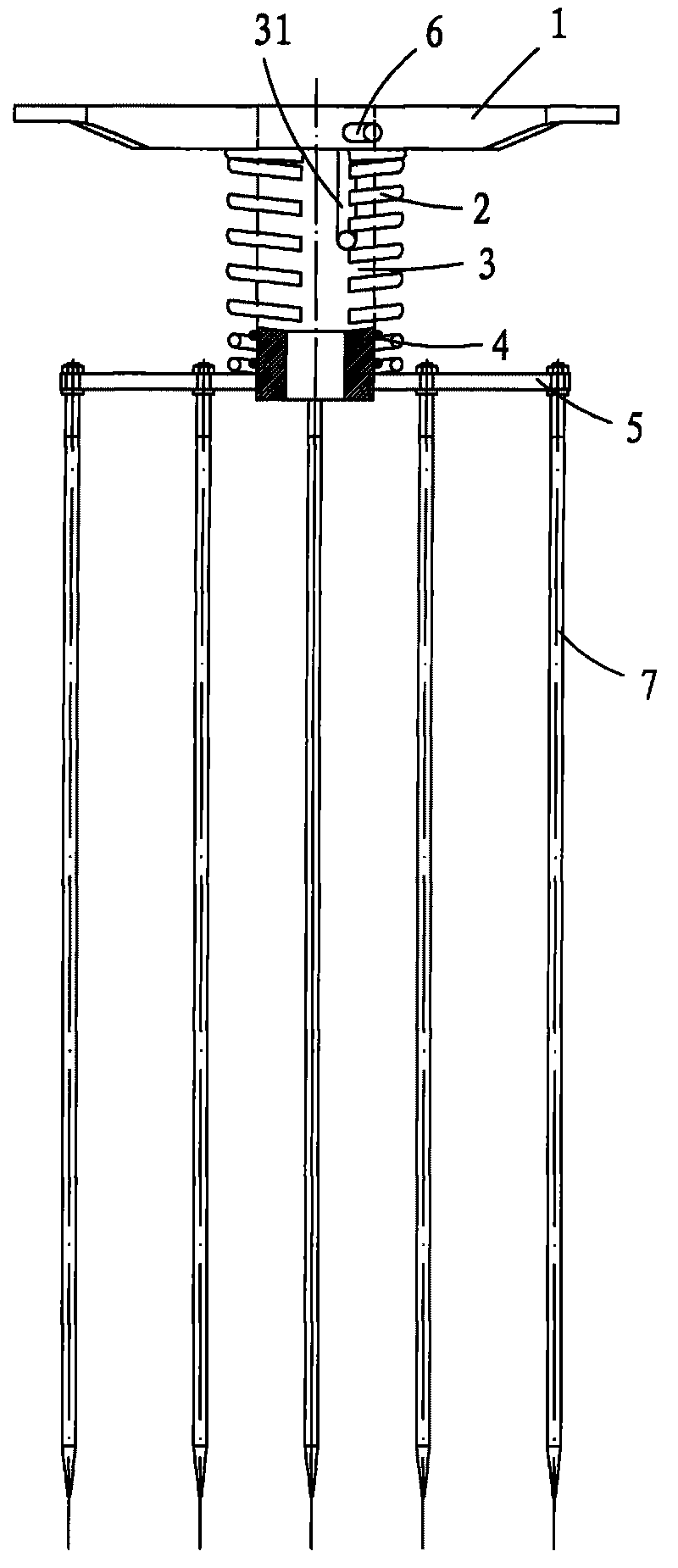

Processing method of burnable poison bar of nuclear power station and suspension frame for burnable poison bar

InactiveCN101710496AFor long-term storageReduce occupancyRadioactive decontaminationNuclear powerBorate glass

The invention provides a processing method for a burnable poison bar of a nuclear power station, which comprises the following steps: arranging the burnable poison bar on a suspension frame; then cutting and disintegrating the burnable poison bar by a cutting machine in a spent fuel canning tank; collecting and putting the cut burnable poison bar into a packing container; and finally, putting the packing container on a spent fuel grillage for storing. The suspension frame provided by the invention comprises a connecting plate and a yoke plate, wherein the connecting plate is connected with the yoke plate through a guide cylinder; and a plurality of connecting holes which can be connected with the burnable poison bar are uniformly distributed on the connecting plate. In the invention, the burnable poison bar is arranged on the suspension frame, then cut and disintegrated by the cutting machine in the spent fuel canning tank, put into the special packing container and stored in the spent fuel grillage, thus the disposition volume of the radioactive waste can be maximumly reduced, the fuel grillages occupied by the burnable poison bar can be greatly reduced, the container can be stored for a long time, and at the same time, when the burnable poison bar is cut, no crushed borate glass falls into a water tank.

Owner:CHINA GENERAL NUCLEAR POWER CORP +1

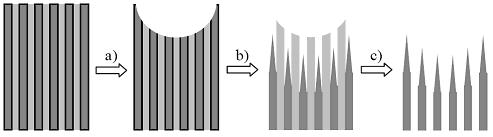

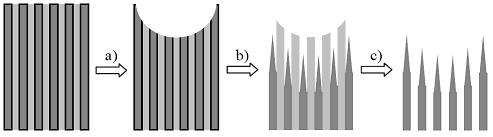

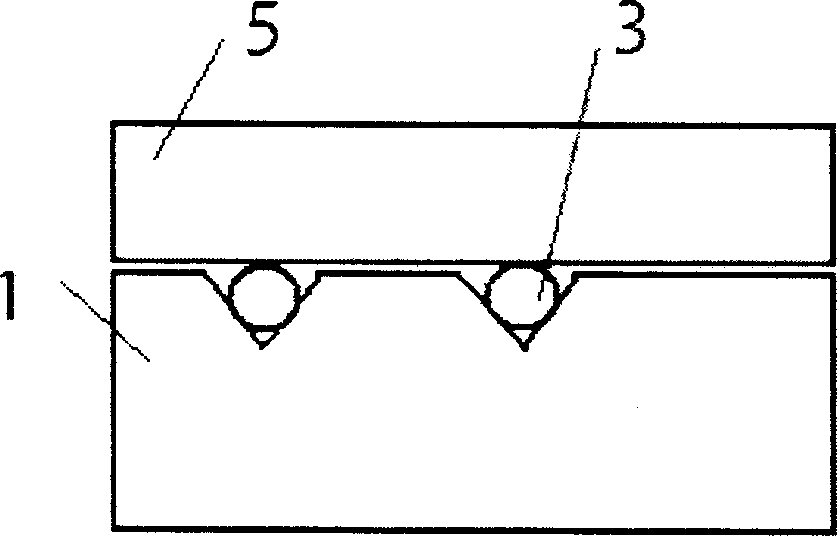

Nonplanar micron/submicron microneedle array and method for producing same

InactiveCN102502474ALow costThe process is simple and reliableSemi-permeable membranesPrecision positioning equipmentFiberMicrometer

The invention discloses a nonplanar micron / submicron microneedle array and a method for producing the same. The nonplanar micron / submicron microneedle array comprises parallel microneedles 200 nanometers to 1000 micrometers in diameter. Tips of the microneedle array form a convex face, a concave face, grooves and holes, or any combination of these, and the microneedles are made of quartz glass, soda-lime-silica glass, borate glass and the like. The method for preparation includes: firstly, obtaining a fiber and polymer composite structure by a method provided by a patent ZL200710134575.2, and cutting the structure into short posts; secondly, the end face of each short post is machined into the convex face, the concave face, the grooved face and the holed face, or any combination of these; thirdly, placing the sample into HF (hydrofluoric) acid etchant solution for 10 seconds to 72 hours to form a needle array structure; and fourthly, removing filled polymer and obtaining the nonplanar micron / submicron microneedle array. The nonplanar micron / submicron microneedle array is novel in structure and applicable to the fields of detection, sensing, optics, biomedicine and the like.

Owner:WUXI IMPRINT NANO TECH

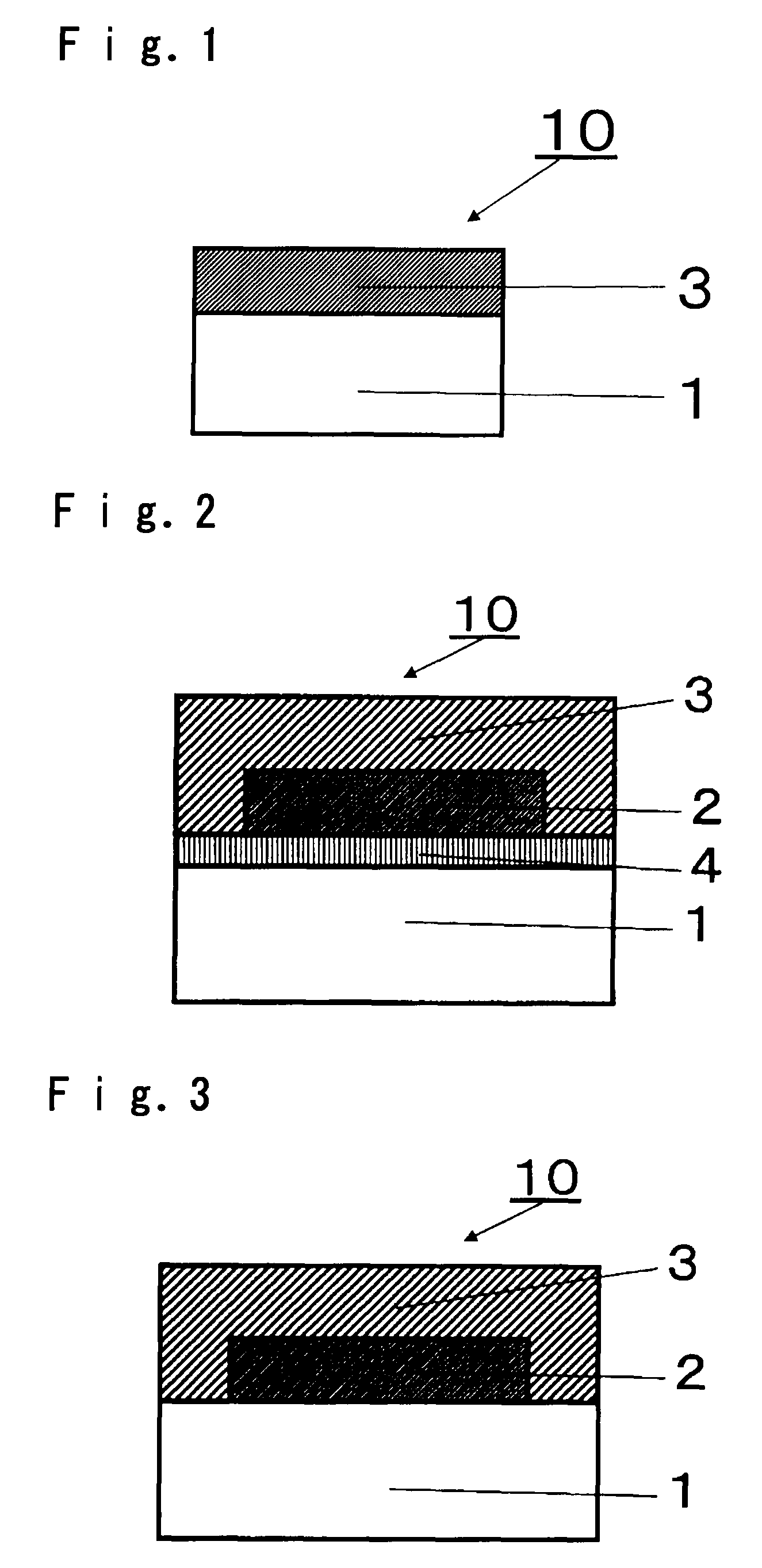

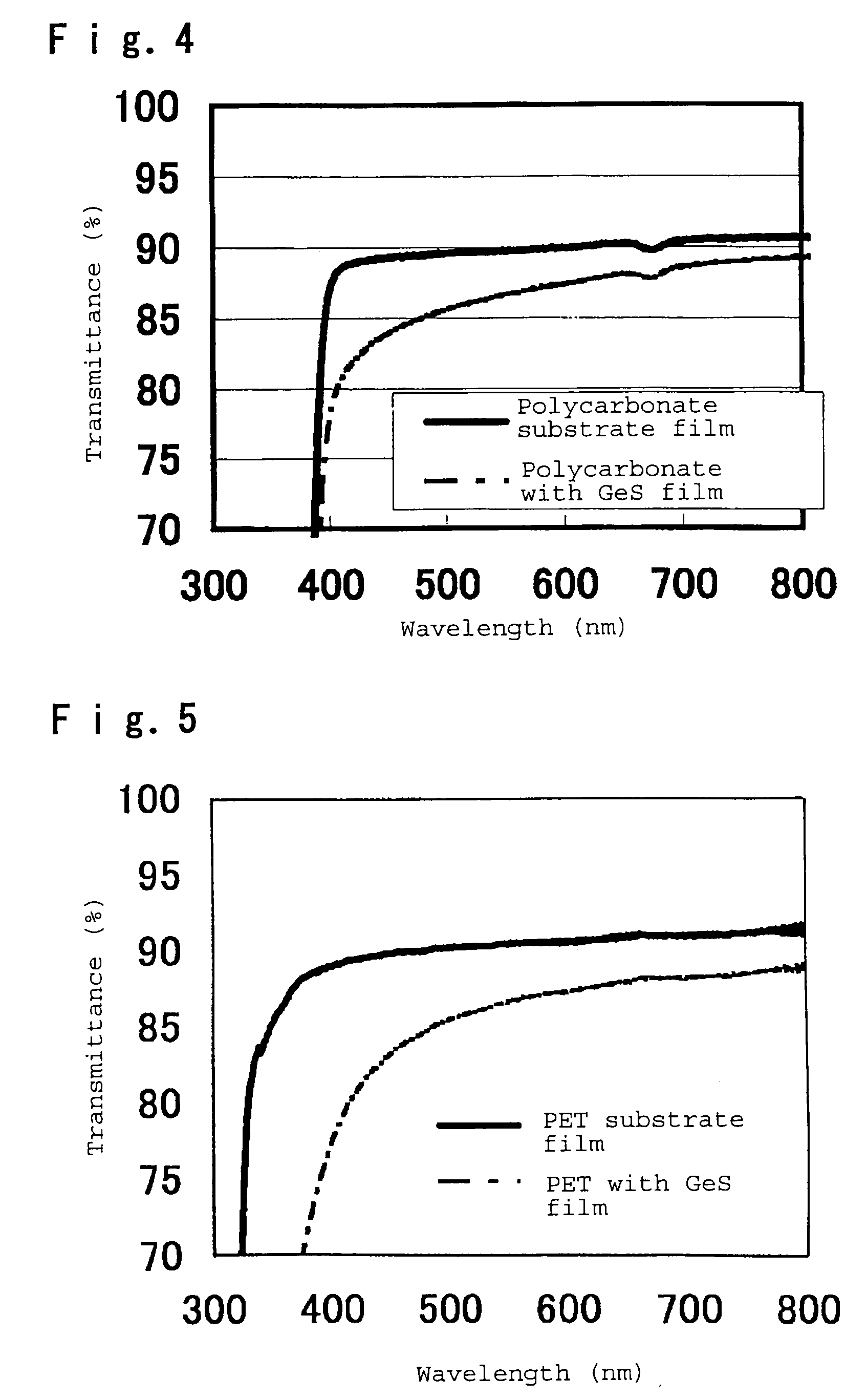

Substrate with film and glass for formation film

ActiveUS7923115B2High light transmittanceExcellent gas barrier performanceVacuum evaporation coatingSolid-state devicesProduction rateSulfur

Owner:AGC INC

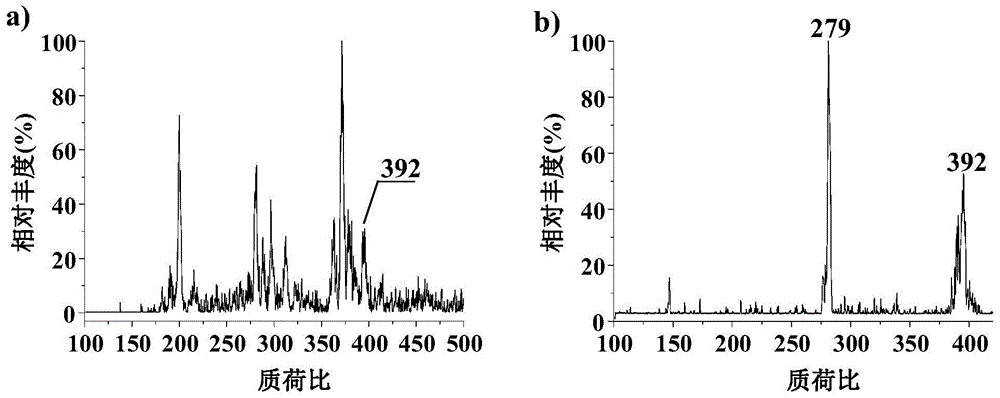

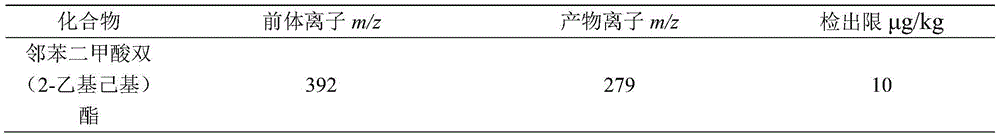

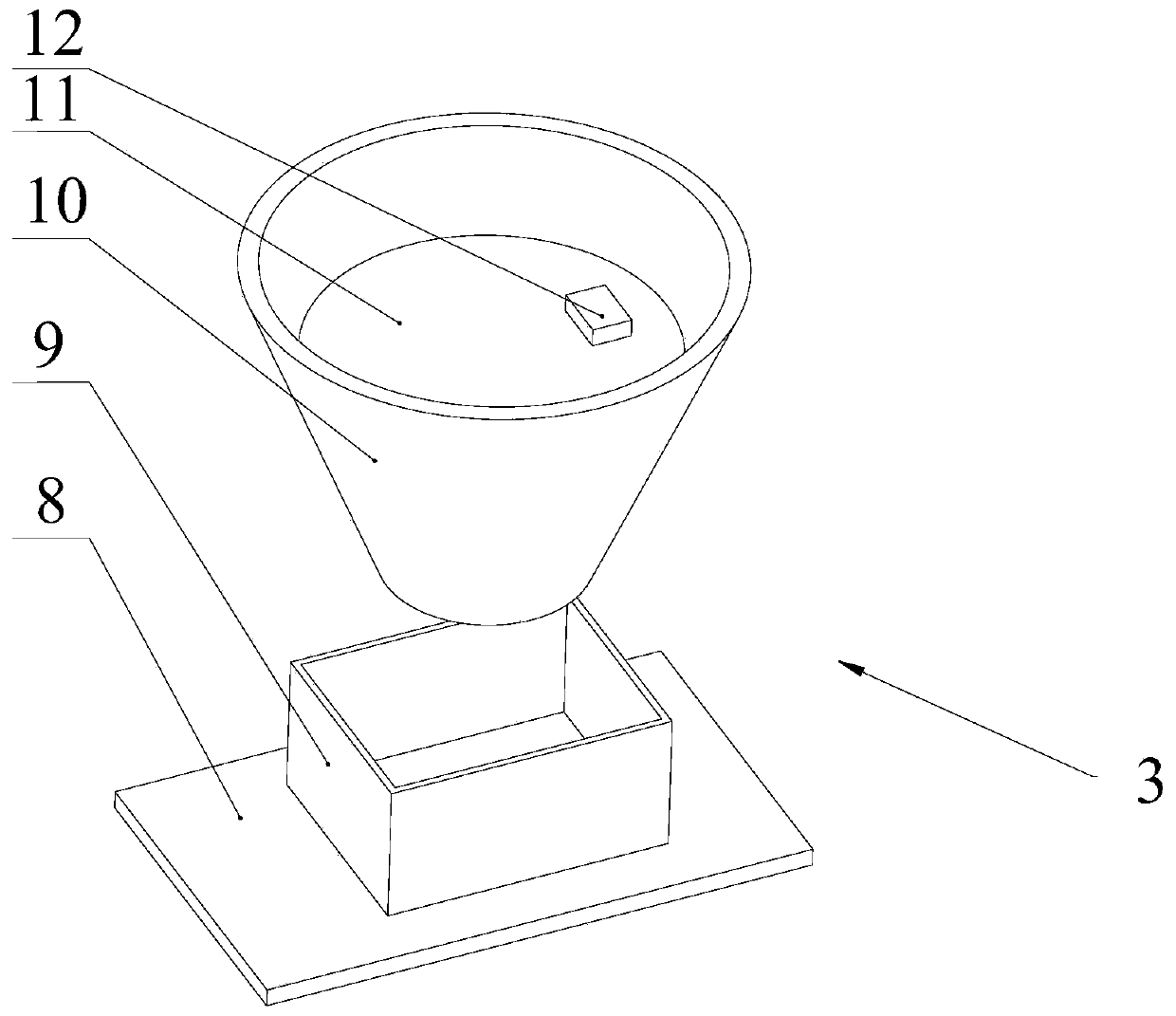

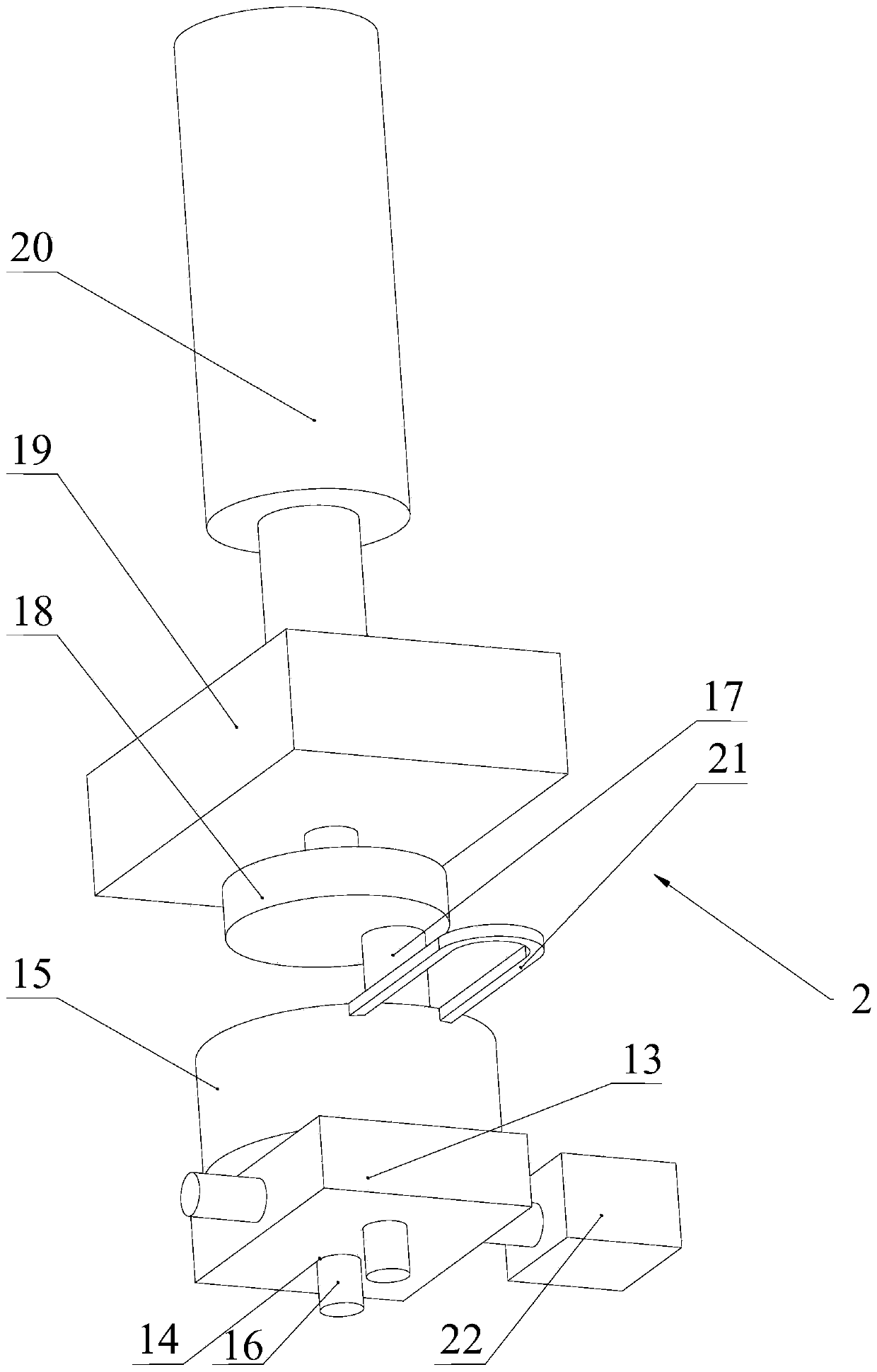

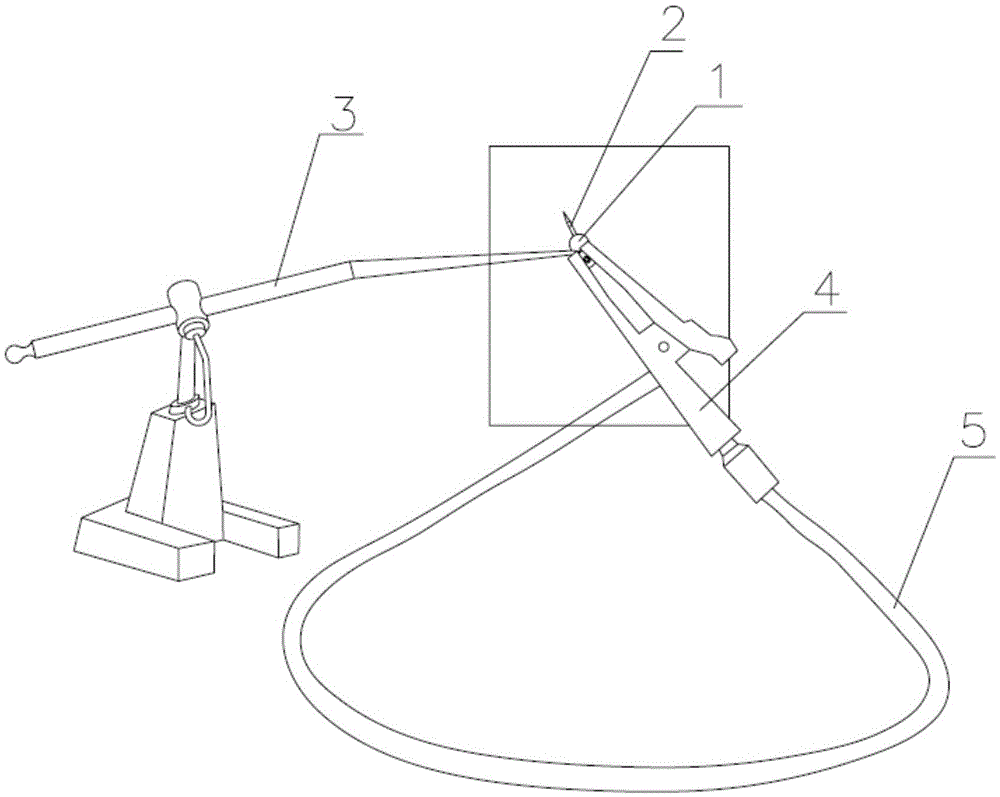

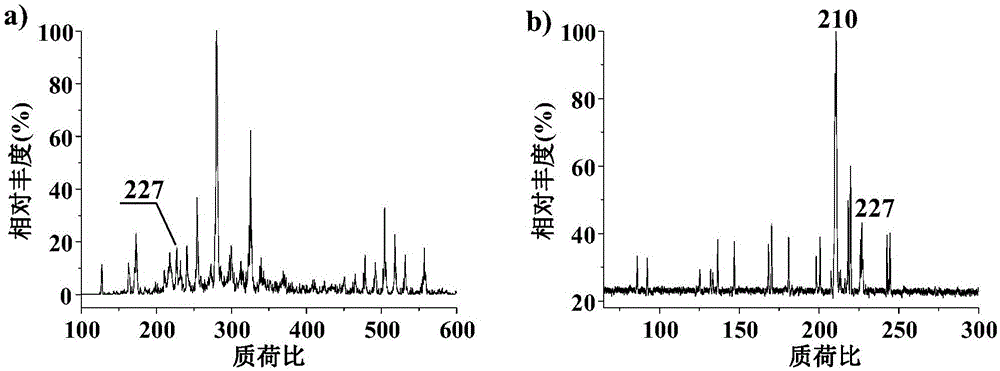

Quick detection method of di(2-ethylhexyl) phthalate in beverages

InactiveCN105606689ALow costSimple structureMaterial analysis by electric/magnetic meansSpectroscopyBorate glass

The invention discloses a quick detection method of di(2-ethylhexyl) phthalate in beverages. The quick detection method includes following steps: making an atomizing ionization device: drawing a borosilicate glass capillary and assembling the spraying ionization device; detecting: sequentially injecting ethyl acetate and a beverage sample into the borosilicate glass capillary, after fully mixing, extracting and mutually layering, inserting a metal microelectrode (1) into an ethyl acetate layer solution from the rear end of the borosilicate glass capillary, applying high voltage on a metal clamp from a high-voltage power source, conducting to the ethyl acetate layer solution in the borosilicate glass capillary (2) from the metal microelectrode (1), generating electric spray for mass spectroscopy, setting parameters of an ion trap mass spectrometer, and performing positive ion mode detection. The quick detection method is low in cost, simple and convenient to operate and supportive of quick and accurate detection of the beverage sample.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

Manufacturing method of optical fiber connector

ActiveCN1794027AHigh precisionSimple preparation processCoupling light guidesChemical treatmentAdhesive

A method for preparing optical fiber connector includes applying process of femtosecond laser shining and chemical processing to treat base plate surface of quarts glass, borate glass and micro crystal glass to work out V form micro channel or U form micro channel, then placing optical fiber in micro channel and using adhesive to fix a press - plate cover over on base plate.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

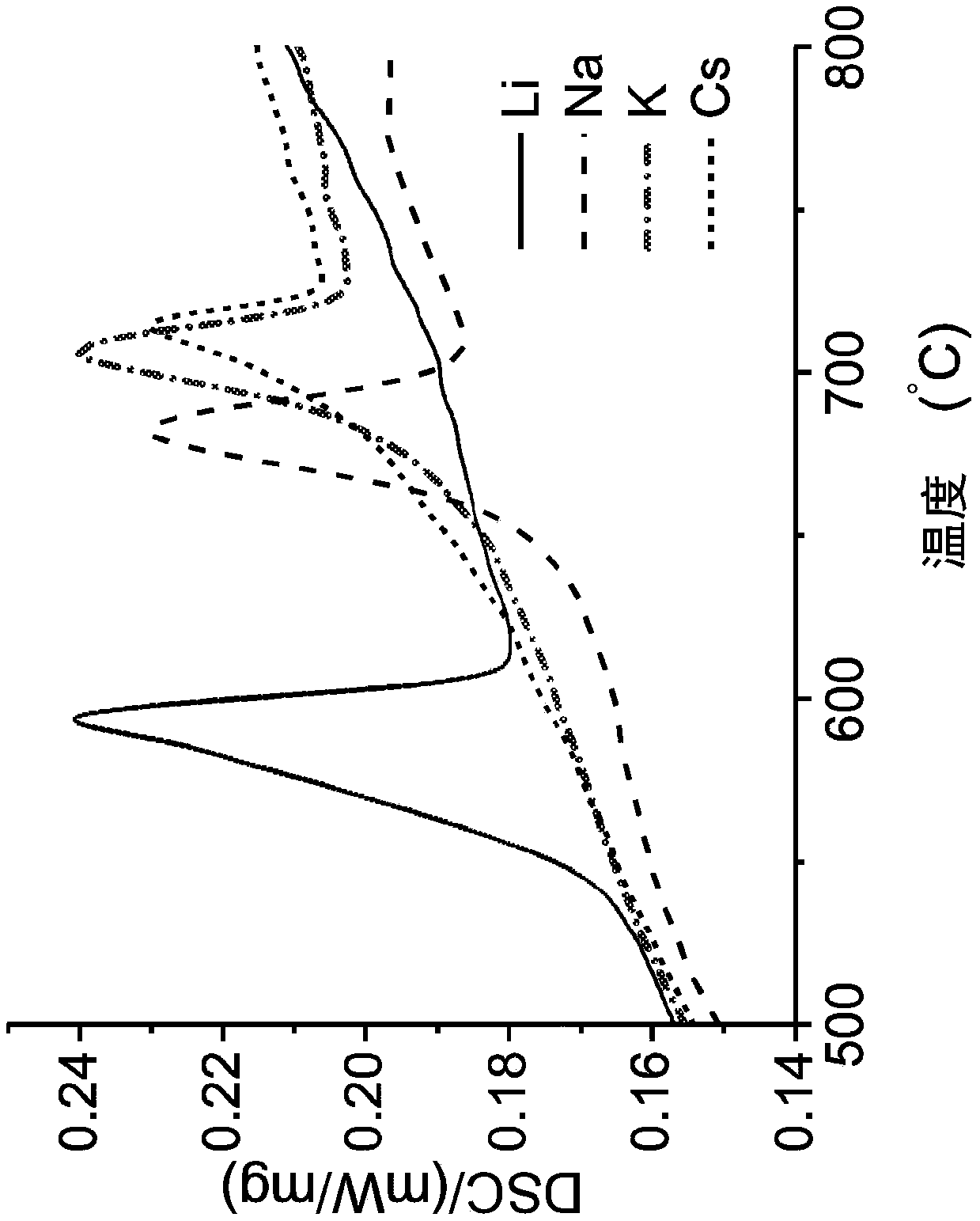

Transparent, near infrared-shielding glass ceramic

Optically transparent glass ceramic materials comprising a glass phase and a crystalline tungsten bronze phase comprising nanoparticles and having the formula MxWO3, where M includes at least one H, Li, Na, K, Rb, Cs, Ca, Sr, Ba, Zn, Cu, Ag, Sn, Cd, In, Tl, Pb, Bi, Th, La, Pr, Nd, Sm, Eu, Gd, Dy, Ho, Er, Tm, Yb, Lu, and U, and where 0 < x < 1. Aluminosilicate and zinc-bismuth-borate glasses comprising at least one of Sm2O3, Pr2O3, and Er2 O3 are also provided.

Owner:CORNING INC

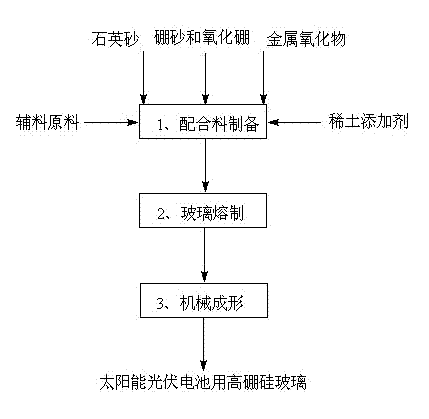

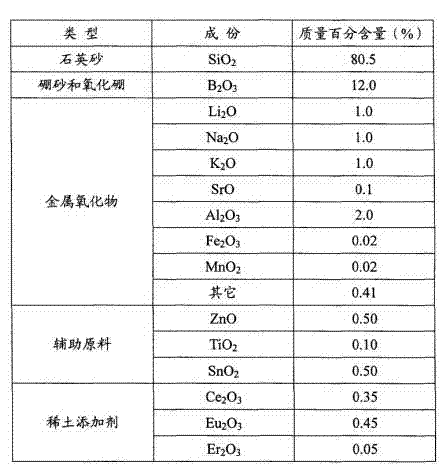

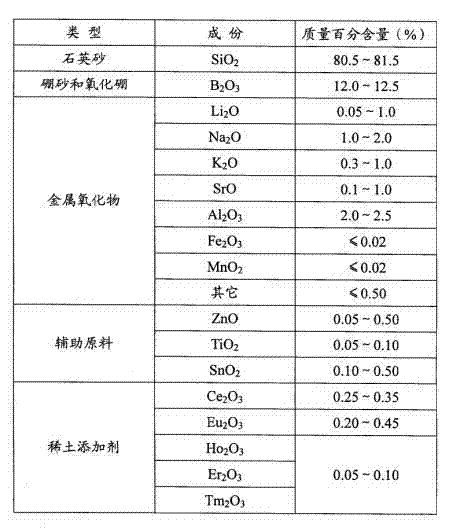

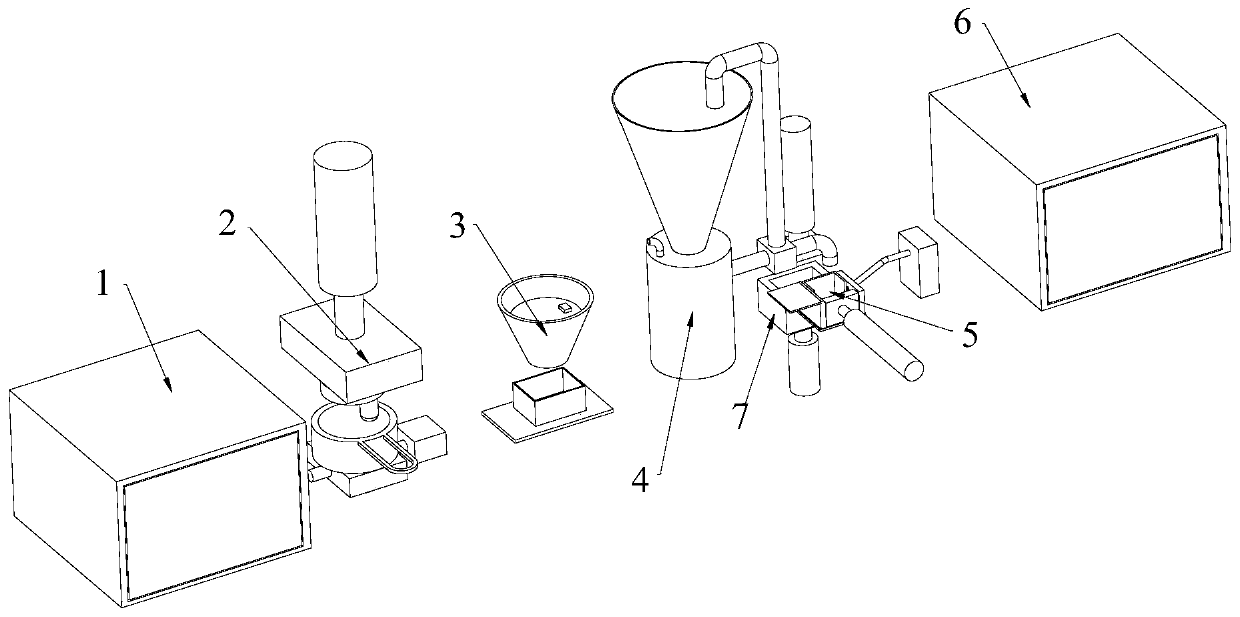

Preparation method of high borosilicate glass for solar photovoltaic batteries

The invention especially relates to a preparation method of high borosilicate glass for solar photovoltaic batteries. The method comprises the following steps: 1, batch preparation: adding a rare earth element additive to present high borosilicate glass, wherein visible light is formed through converting infrared light and ultraviolet light by a conversion luminescence effect through applying an up-conversion luminescence principle, and illuminates; the rare earth additive is simultaneously used as a clarificant, a color complementation agent and a conversion luminescence couplant to improve the visible light transmittance of glass; and rare earth element borate glass has a high refractive index and a low chromatic dispersion, and is novel optical glass; 2, glass melting: carrying out high temperature melting of the glass batch in an electric melting furnace to form molten glass, carrying out clarification homogenizing, and cooling to form liquid glass; and 3, mechanical shaping: processing the liquid glass through adopting a float process production technology to form flat glass. The glass prepared through the method provided by the invention has a high visible light transmittance, and can be used as a glass matrix material and a packaging material for the solar photovoltaic batteries.

Owner:YANGZHOU TONGHE GLASS

Material for surface composite modification of magnesium alloy made by lost foam casting (LFC) and preparation method thereof

The invention discloses a material for surface composite modification of magnesium alloy. The material comprises the following compositions in percentage by mass: 30 to 50 percent of glass dust (with the melting point between 350 and 500 DEG C), 10 to 15 percent of metal powder, 0.4 to 0.6 percent of defoaming agent, 2.0 to 4.0 percent of caking agent, and the balance of water, wherein the glass dust is one of borate glass, phosphate glass and lead-zinc glass; the metal powder is at least one of aluminum powder and zinc powder; the defoaming agent is one of polydimethylsiloxane, polyoxyethylene polyoxypropylene ether and polyoxypropylene glycerol ether; and the caking agent is one of polyvinyl alcohol and sodium carboxymethyl cellulose. The prepared material is coated on a foamy surface to form an alloying layer and a ceramic layer synchronously during magnesium alloy casting; moreover, the compositions of the surface layer of a cast product is in ladderlike distribution from the outside to the inside to form a composite layer, thereby providing double protection for a matrix and increasing the corrosion resistance and abrasion resistance of the magnesium alloy. The material has the advantages of low cost, simple operation, easily controlled parameters, and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Borate glass ceramic low-temperature solidification method of silver-coated silica gel

ActiveCN109748509AHigh bulk densityLow nuclide leaching rateGlass furnace apparatusBorate glassIodine

The invention discloses a borate glass ceramic low-temperature solidification method of silver-coated silica gel. The borate glass ceramic low-temperature solidification method of silver-coated silicagel comprises the following steps: mixing silver-coated silica gel granules containing radioactive iodine and a borate glass ceramic powder, adding deionized water and grinding to obtain a humid mixture, wherein the borate glass ceramic consists of boron oxide, bismuth oxide and zinc oxide; dryin the humid mixture to obtain a dried mixture; and putting the dried mixture into a sintering device, sintering and cooling after sintering to obtain a glass ceramic sintering body. The glass ceramic sintering body provided by the invention contains silver-coated silica gel containing radioactive iodine; and the glass ceramic sintering body has the advantages of high volume density, low nuclide leaching rate and the like and can inhibit migration of the radioactive iodine in the natural world well.In addition, the low-temperature solidification method has the characteristics of simple technological process, energy conservation, environmental friendliness, safety, reliability and the like, andhas a good industrial application prospect.

Owner:SOUTHWEAT UNIV OF SCI & TECH

High-durability ceramic grinding tool

The invention discloses a high-durability ceramic grinding tool which is characterized by comprising the following components in parts by weight: 11-27 parts of zirconite, 31-50 parts of calcite, 3-14 parts of ethylene copolymer elastomer, 1-9 parts of closed-cell perlite, 15-45 parts of borate glass, 5-17 parts of solid paraffin, 11-25 parts of tourmaline concentrate micropowder, 3-4 parts of molybdenum disilicide, 34-61 parts of spodumene, 11-31 parts of mica, 3-5 parts of zinc oxide, 5-12 parts of ferric sodium pyrophosphate, 1-3 parts of calcium hydrogen phosphate and 5-9 parts of cryolite. The high-durability ceramic grinding tool has the advantages of sharp grinding grains, low trimming frequency, favorable sharpness, low grinding temperature, favorable toughness, low abrasion, high durability and long service life, and can be used for high depth, roughing feed, heavy load and high efficiency grinding.

Owner:QINGDAO XIANGHAI ELECTRONICS

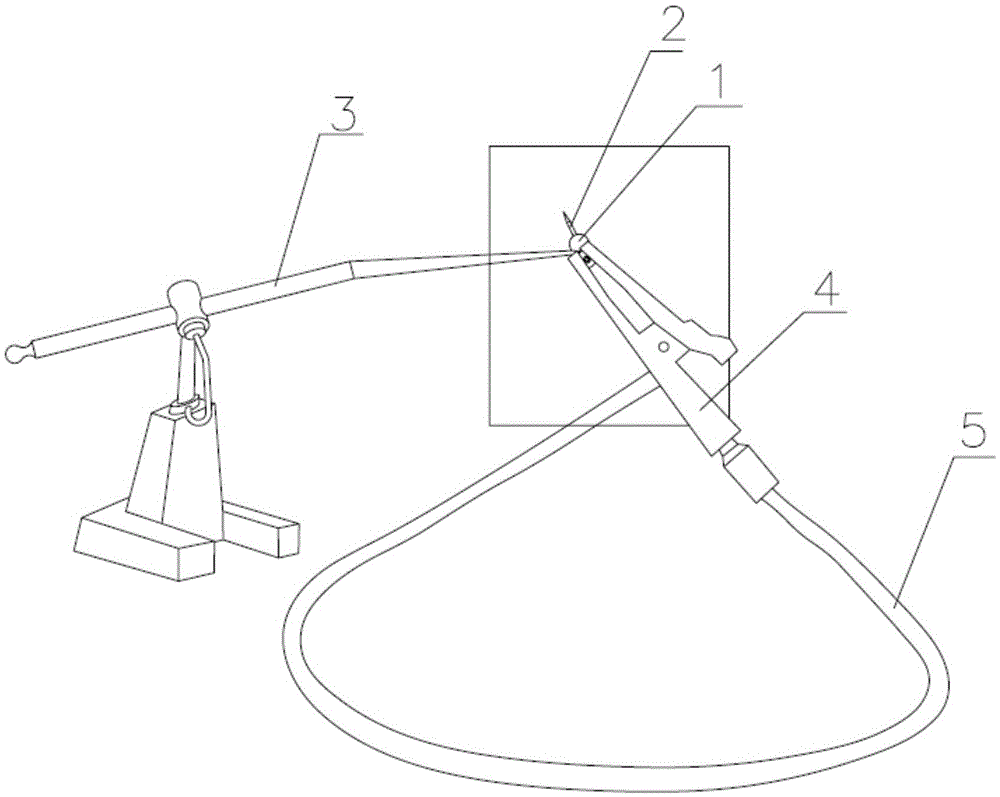

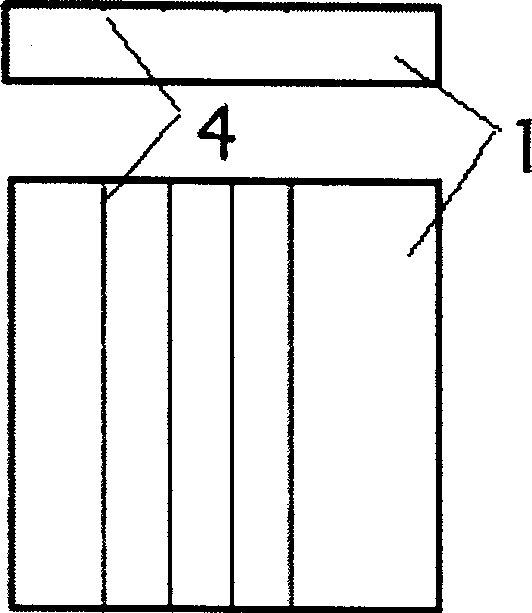

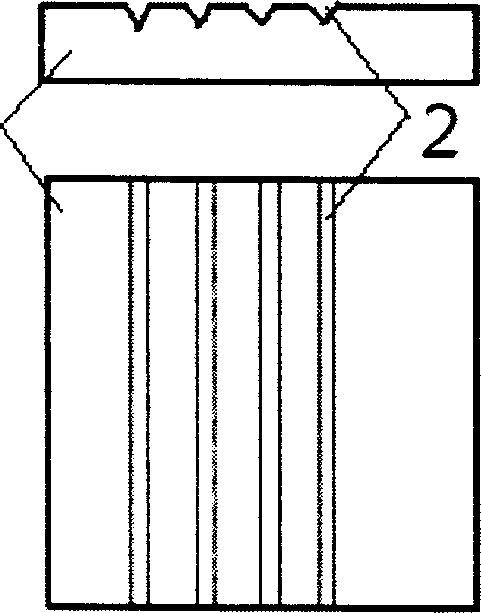

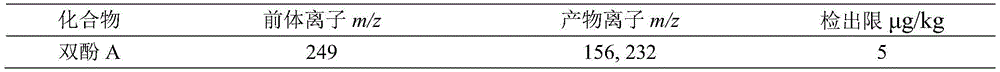

Rapid detection method of bisphenol A in liquid milk

InactiveCN105675707AHigh-precision detectionLow costPreparing sample for investigationMaterial analysis by electric/magnetic meansBorate glassLiquid milk

The invention discloses a rapid detection method of bisphenol A in liquid milk. The method comprises the following steps: a spray ionization device is manufactured: drawing of a borosilicate glass capillary and assembling of the spray ionization device are included; an ion trap mass spectrometer is adopted for detection: ethyl acetate and a liquid milk sample are successively injected into the borosilicate glass capillary (2) from its real end, a metal microelectrode (1) is inserted into the ethyl acetate layer solution from the rear end of the borosilicate glass capillary after fully mixing, extraction and layering, a high voltage power supply applies 2.5kV voltage across a metal clip (4) so as to conduct into the ethyl acetate layer solution in the borosilicate glass capillary (2) from the metal microelectrode (1), generating electrospray ionization and carrying out mass spectrometry, setting parameters of the ion trap mass spectrometer, and carrying out negative ion mode detection. The rapid detection method of bisphenol A in liquid milk is low-cost, is simple to operate and can realize rapid and accurate detection of a liquid milk sample.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

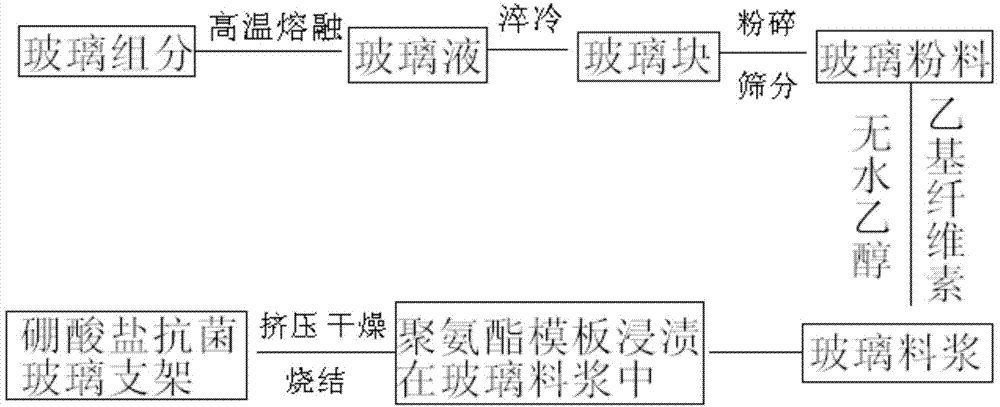

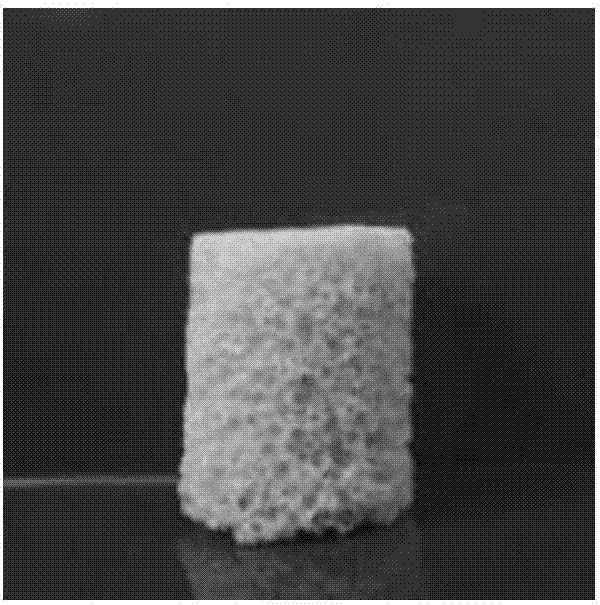

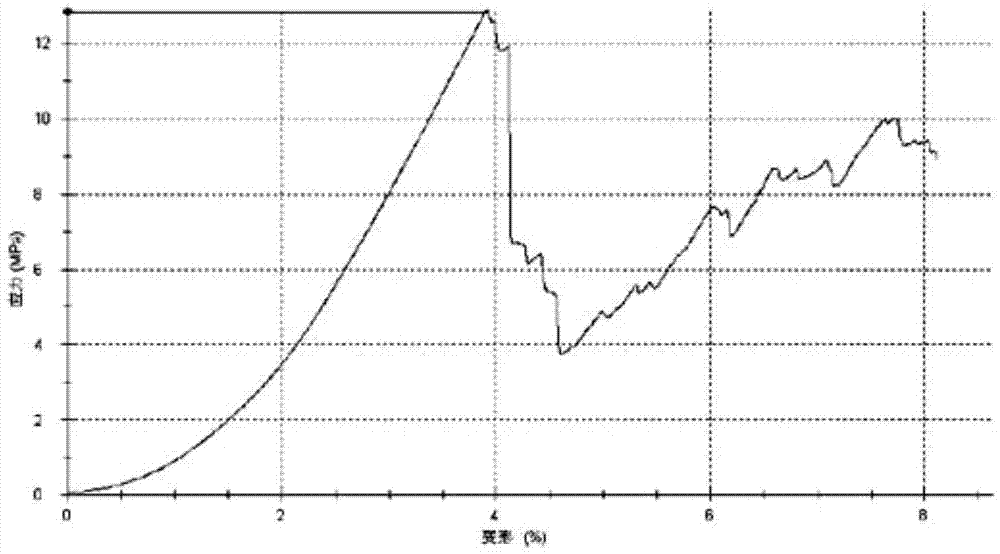

Method for preparing antibacterial borate glass bracket

The invention discloses a method for preparing an antibacterial borate glass bracket. The method comprises the following steps: uniformly mixing glass components composed of an outer network body with molar percentage of 44% and a network forming body with molar percentage of 56%; fusing at a temperature of 1000-1400 DEG C, and performing heat preservation for 0.5-1.5 hours to obtain glass liquid; quenching the glass liquid to obtain a glass block; carrying out coarse crushing, fine crushing and sieving on the obtained glass block in sequence to obtain glass powder; mixing the obtained glass powder with ethyl cellulose and absolute ethyl alcohol according to a mass ratio of 3:0.12:2.5; firstly flat-grinding and mixing absolute ethyl alcohol with ethyl cellulose, and putting the mixture in the glass powder to obtain glass slurry; mixing the prepared glass slurry with a polyurethane template, then extruding the excessive slurry to prepare a grouting glass bracket, drying, sintering and cooling to obtain the antibacterial borate glass bracket. The antibacterial borate glass bracket prepared by the method disclosed by the invention has an excellent antibacterial effect, has no biological resistance, and has long-term sustained release antibacterial property, and high-temperature stable and acid-base stable antibacterial property.

Owner:TONGJI UNIV

Main grid positive silver paste suitable for step-by-step screen printing

ActiveCN110648781AImprove the ability to collect electronsImprove conductivityNon-conductive material with dispersed conductive materialSemiconductor devicesScreen printingSilver paste

The invention discloses main grid positive silver paste suitable for step-by-step screen printing. The slurry comprises the following components in percentage by weight: 78-89 wt% of silver powder, 5-15 wt% of an organic carrier, 1.2-3.0 wt% of glass powder, 2.0-15 wt% of a diluting agent and 0.2-5.0 wt% of an auxiliary. The glass powder comprises at least one of silicate glass, borate glass, phosphate glass and heavy metal oxide glass. The auxiliary comprises an adhesion promoter. By optimizing the formula composition, the prepared paste has the advantages of low solid content, low cost, goodconductivity and high adhesive force, and is suitable for step-by-step screen printing of a main grid part.

Owner:GUANGZHOU RUXING TECH DEV +1

Up-conversion luminescence transparent glass ceramics and preparation method thereof

ActiveCN102503139ASimple processReduce manufacturing costUpconversion luminescenceLuminous intensity

The invention provides a method for preparing up-conversion luminescence transparent glass ceramics. The method comprises the following steps of: dispersing up-conversion luminescence doping gadolinium oxide nanocrystals in borate glass uniformly, batching, melting, forming, annealing and the like. The prepared up-conversion luminescence transparent glass ceramics have a simple process, and are low in production cost and high in luminous intensity.

Owner:FUJIAN CAS CERAMIC OPTOELECTRONICS TECH CO LTD

Preparation method for front-surface electrode of solar cell

InactiveCN102800755AHigh silver contentImprove conductivityFinal product manufactureSemiconductor devicesSilver pasteBorate glass

The invention provides a preparation method for the front-surface electrode of a solar cell. The preparation method comprises the following steps of: texturizing, diffusing, etching, depositing a silicon nitride film, printing a silver paste, and sintering, and further comprising a step of removing the silicon nitride film at the position of a preformed front-surface gate line after depositing the silicon nitride film on a silicon slice. In the preparation method provided by the invention, because the silicon nitride film at the position of the preformed front-surface gate line is removed before printing the silver paste, lead-containing borate glass powder has no need to be doped in the silver paste to corrode the silicon nitride film, and a high-temperature sintering process has no need to be adopted in the subsequent steps. Because the glass powder is not contained in the silver paste, the content of silver in the silver paste can be increased, and then the conducting performance of the silver paste can be improved; simultaneously, lead is not contained in the silver paste, so that environmental friendliness is contributed; and a low-temperature sintering process is adopted in the subsequent steps, so that the electric energy consumed by equipment can be effectively saved.

Owner:YINGLI ENERGY CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com