Lead and arsenic free optical lanthanum borate glass

A glass, B2O3 technology, applied in the field of preforms of optical components, can solve problems such as damage to the internal transmittance of glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

[0095] Tables 2 to 5 in Example 2 contain examples of implementation within preferred composition ranges. The glasses described in the examples were prepared as in Example 1:

example 1

[0097] Weigh the raw material for oxide, add one or more clarifiers (for example, Sb 2 o 3 ), followed by thorough mixing. The glass mixture was melted at about 1150°C into a continuous molten aggregate, followed by clarification (1200°C) and homogenization. At a casting temperature of about 1180°C, the glass can be cast and processed to the desired dimensions. Experience has shown that in large volume continuous aggregates, the casting temperature can be lowered by at least about 100K and the material can be processed to the final geometry by pressing methods.

[0098] Oxide

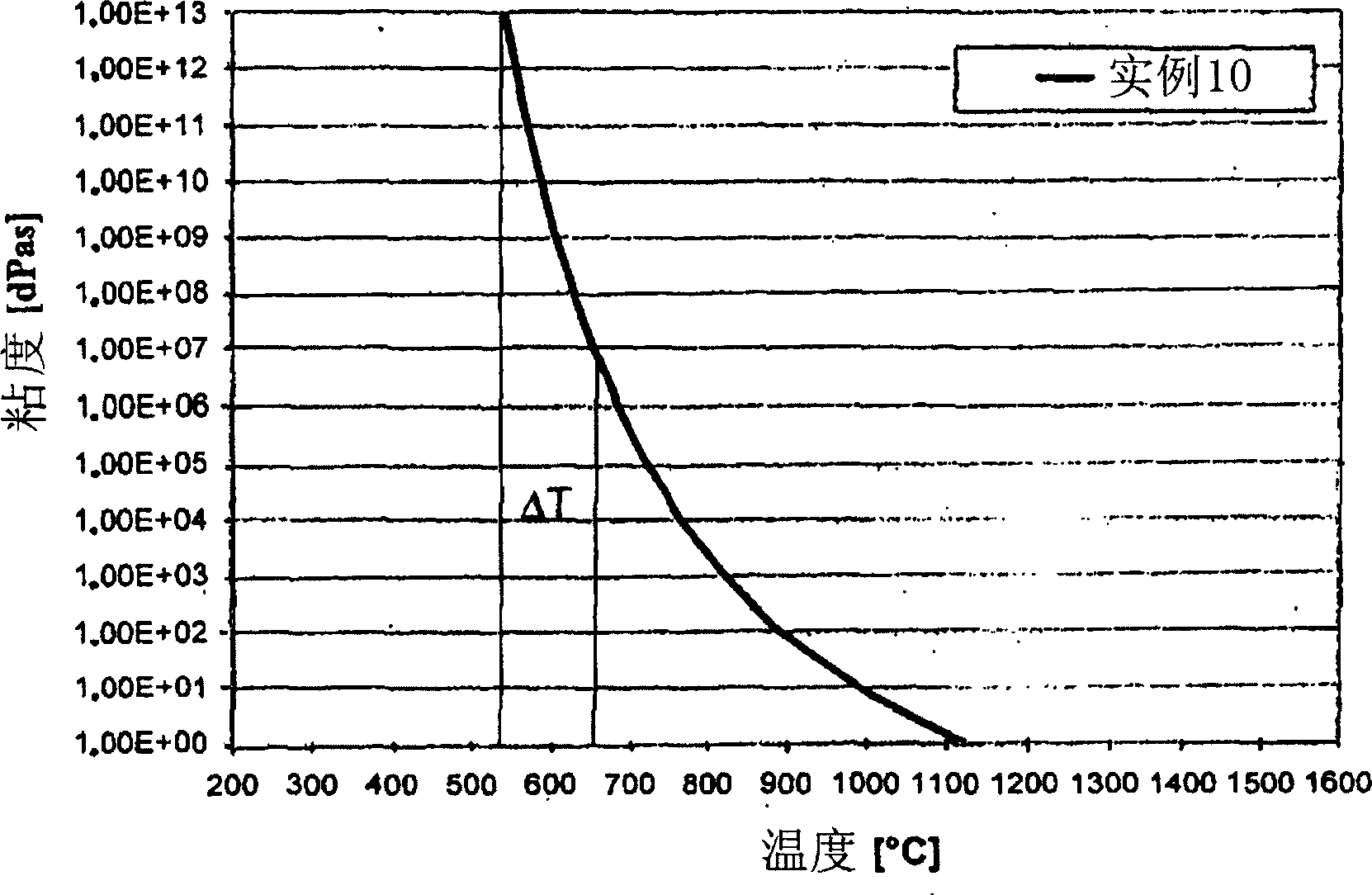

[0099] The properties of the glass thus obtained are given in Table 3 of Example 10.

[0100] Example 2:

[0101] Tables 2 to 5 contain Examples 1 to 26 according to the invention.

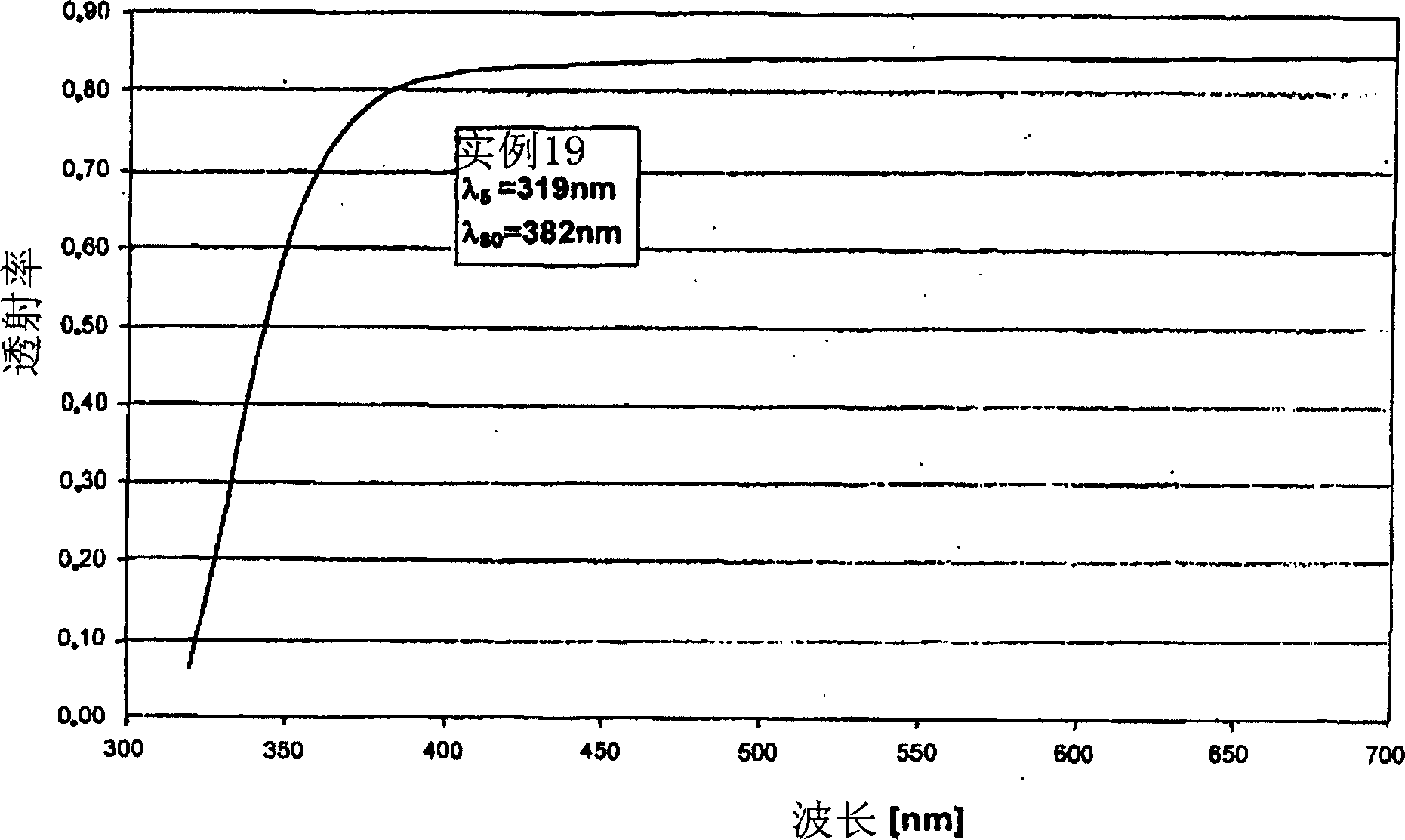

[0102] The glasses according to the invention all have a Tg lower than or equal to 560° C., have very good alkali resistance and can be processed well. The glass according to the invention has a color code v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Abbe number | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com