Method for preparing antibacterial borate glass bracket

A technology of antibacterial glass and borate, applied in the field of biomedical materials, can solve the problems of bacterial drug resistance and low drug efficacy, and achieve the effects of low cost, easy operation and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of silver-doped 0.05% salt antibacterial glass stent

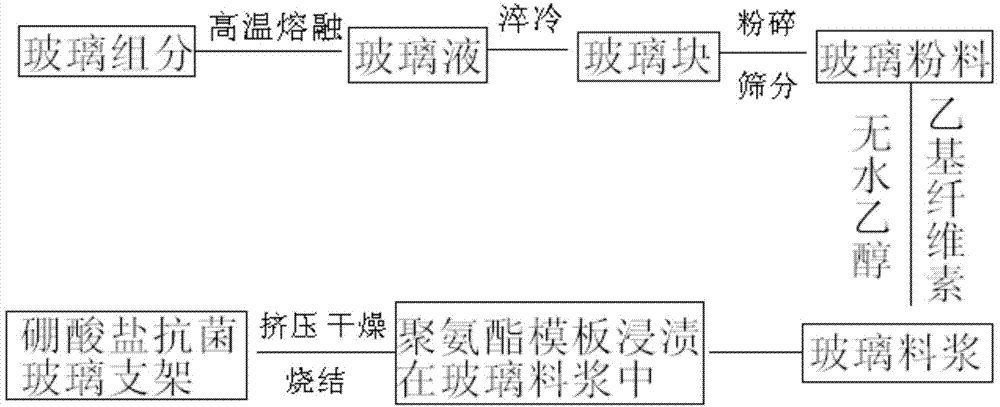

[0041] like figure 1 as shown, figure 1 It is the preparation method flowchart of borate antibacterial glass support shown in embodiment 1.

[0042] (1) Preparation of glass powder

[0043] According to the composition of the borate bioglass in Table 1, the oxides, chlorides, carbonates, sulfates and phosphates corresponding to the metal oxides are weighed as glass batch materials, and the purity of the raw materials is analytically pure. After mixing evenly, Put the original ingredients in a platinum crucible at 1150°C and melt for 1 hour. Then quenching to obtain a glass block; the obtained glass block is coarsely crushed by a horizontal ball mill, finely crushed by a jet mill, and sieved to obtain a glass powder with a final particle size of 0.05-50 μm.

[0044] Table 1

[0045]

[0046] (2) Preparation of glass slurry

[0047] Mix the glass powder obtained in step (1) with ethyl cellulose an...

Embodiment 2

[0052] Preparation of silver-doped 1% antibacterial and degradable borate bioactive glass scaffolds

[0053] (1) Preparation of glass powder

[0054] According to the composition of the borate bioglass in Table 2, the oxides, chlorides, carbonates, sulfates and phosphates corresponding to the metal oxides are weighed as glass batch materials, the purity of the raw materials is analytically pure, after mixing evenly, Put the original ingredients in a platinum crucible and melt at 1300°C for 1.5h. Then quenching to obtain a glass block; the obtained glass block is coarsely crushed by a horizontal ball mill, finely crushed by a jet mill, and sieved to obtain a glass powder with a final particle size of 0.05-50 μm.

[0055] Table 2

[0056]

[0057] (2) Preparation of glass slurry

[0058] Mix the glass powder obtained in step (1) with ethyl cellulose and absolute ethanol at a mass ratio of 3:0.12:2.5. Use a ball mill to mix absolute ethanol and ethyl cellulose for 30 minut...

Embodiment 3

[0063] Preparation of silver-doped 0.5% borate antibacterial glass stent

[0064] (1) Preparation of glass powder

[0065] According to the composition of the borate bioglass in Table 3, the oxides, chlorides, carbonates, sulfates and phosphates corresponding to the metal oxides are weighed as glass batch materials. The purity of the raw materials is analytically pure. After mixing evenly, Put the original ingredients in a platinum crucible at 1200°C and melt for 1.5h. Then quenching to obtain a glass block; the obtained glass block is coarsely crushed by a horizontal ball mill, finely crushed by a jet mill, and sieved to obtain a glass powder with a final particle size of 0.05-50 μm.

[0066] table 3

[0067]

[0068] (2) Preparation of glass slurry

[0069] Mix the glass powder obtained in step (1) with ethyl cellulose and absolute ethanol at a mass ratio of 3:0.12:2.5. Use a ball mill to mix absolute ethanol and ethyl cellulose for 30 minutes, then put in glass powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com