Sheathed glow plug

A technology for glow plugs and sheaths, applied in lighting and heating equipment, combustion methods, incandescent ignition, etc., can solve the problems of reducing and limiting the working life of glow plugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

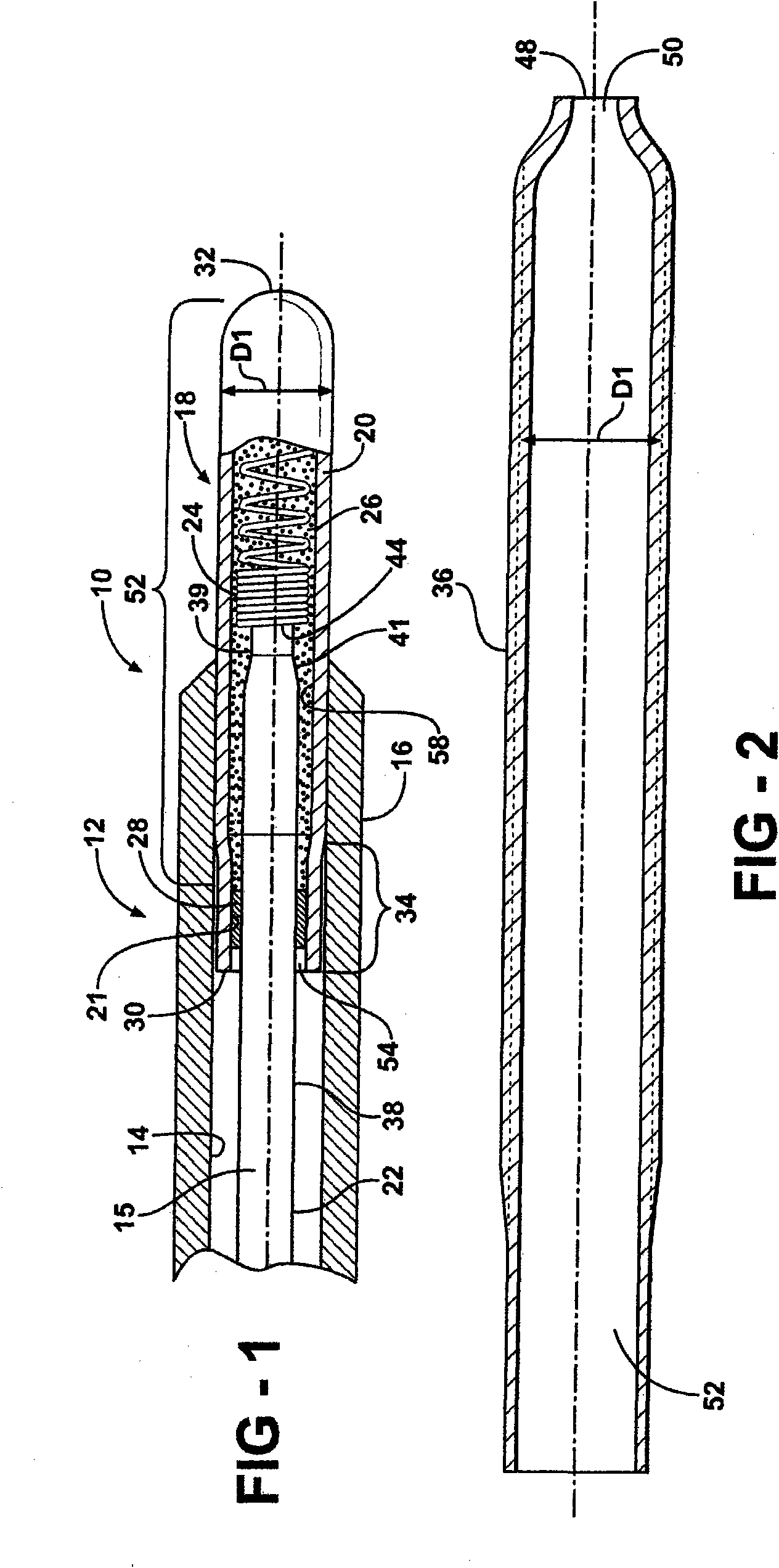

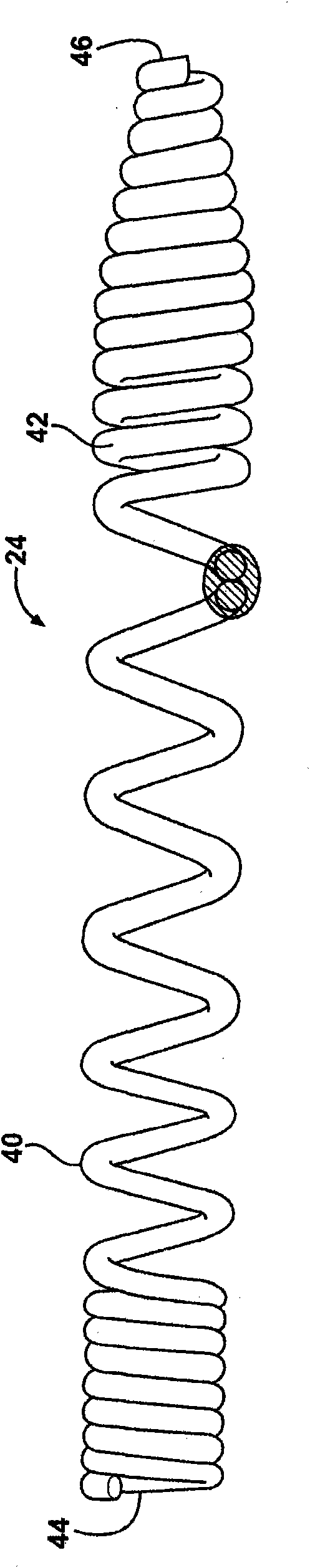

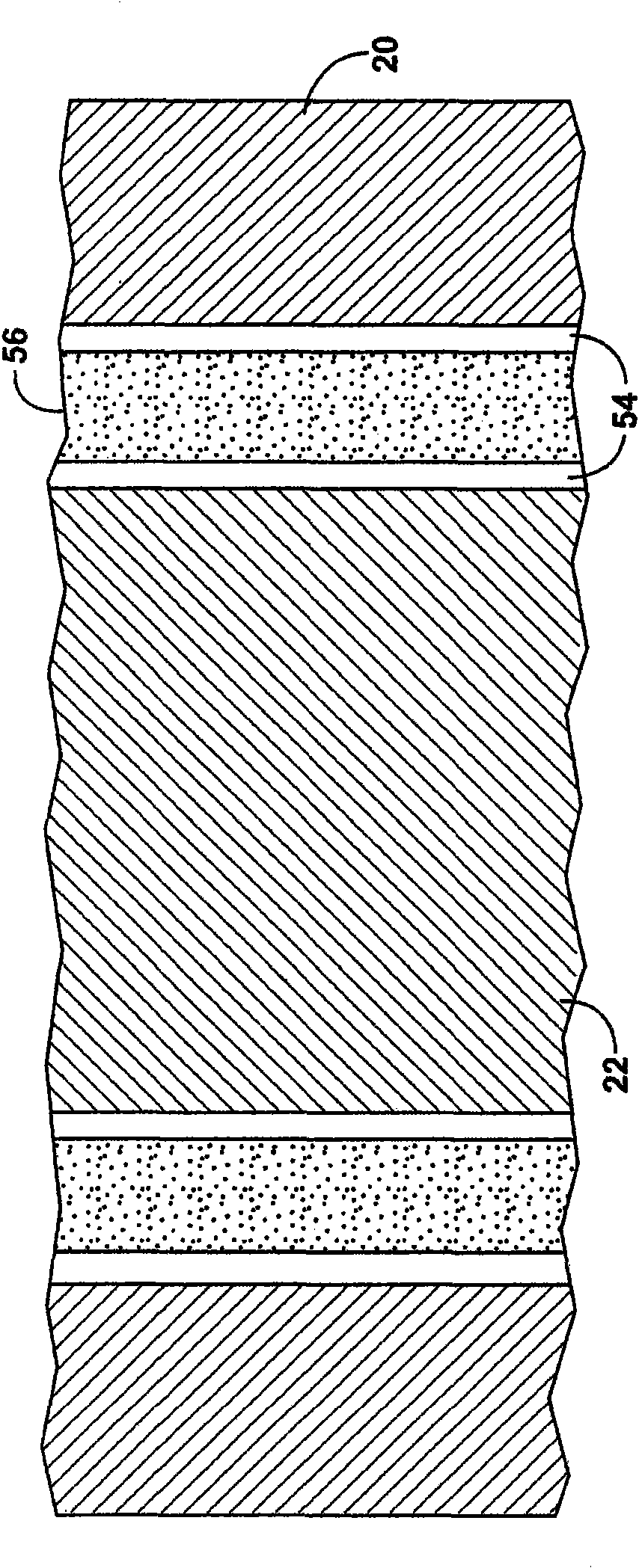

[0033] The present invention provides glow plugs with improved sealing and heating element assemblies that reduce the exposure of thermally conductive, electrically insulating powders and the helical wire heating elements embedded in the powders to oxygen and water vapor, thereby eliminating or substantially reducing the aforementioned the deterioration process. In the glow plug of the invention, the components are treated such that oxygen and water vapor within the powder layer are removed or substantially reduced during the mounting seal. Once installed, the seal eliminates or greatly reduces the ability of the surrounding atmosphere, including oxygen and water vapor, to penetrate the insulating powder and reach the resistance wire heating element, thereby inhibiting the potential for degradation of the resistance wire heating element as described above.

[0034] The glow plugs and glow plug heater assemblies of the present invention use glass or glass-ceramic seals instead ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com