Preparation method of leucite

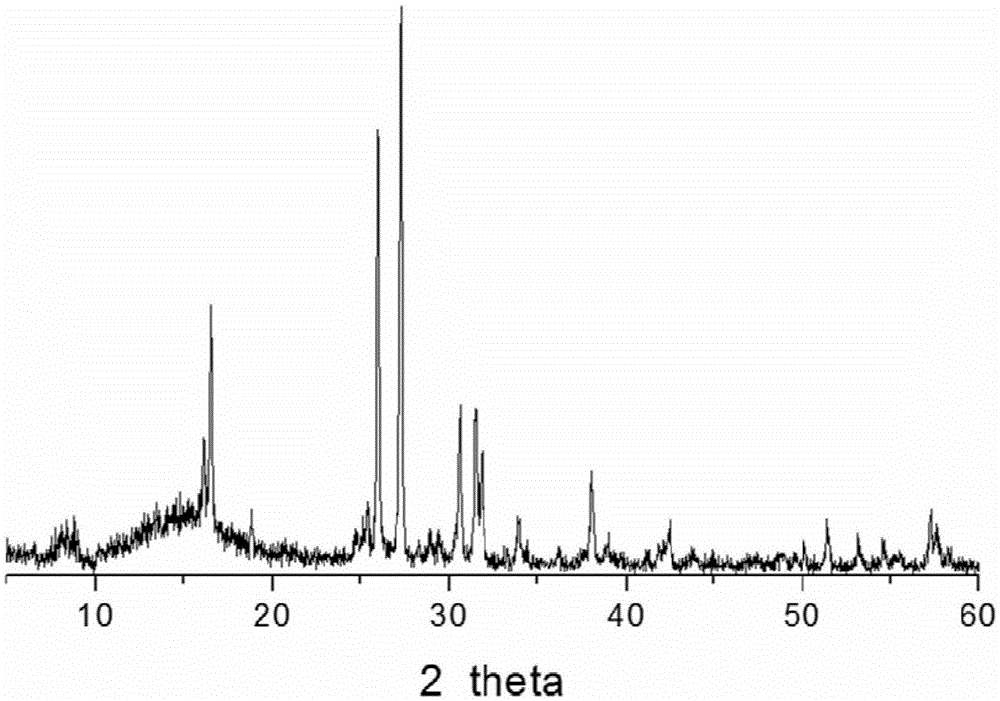

A technology of leucite and analcite, applied in the field of dental materials, can solve the problems of uneven particle size distribution of leucite powder, high energy consumption, difficult particle size control, etc., and is suitable for large-scale popularization and application. Low consumption and adjustable particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

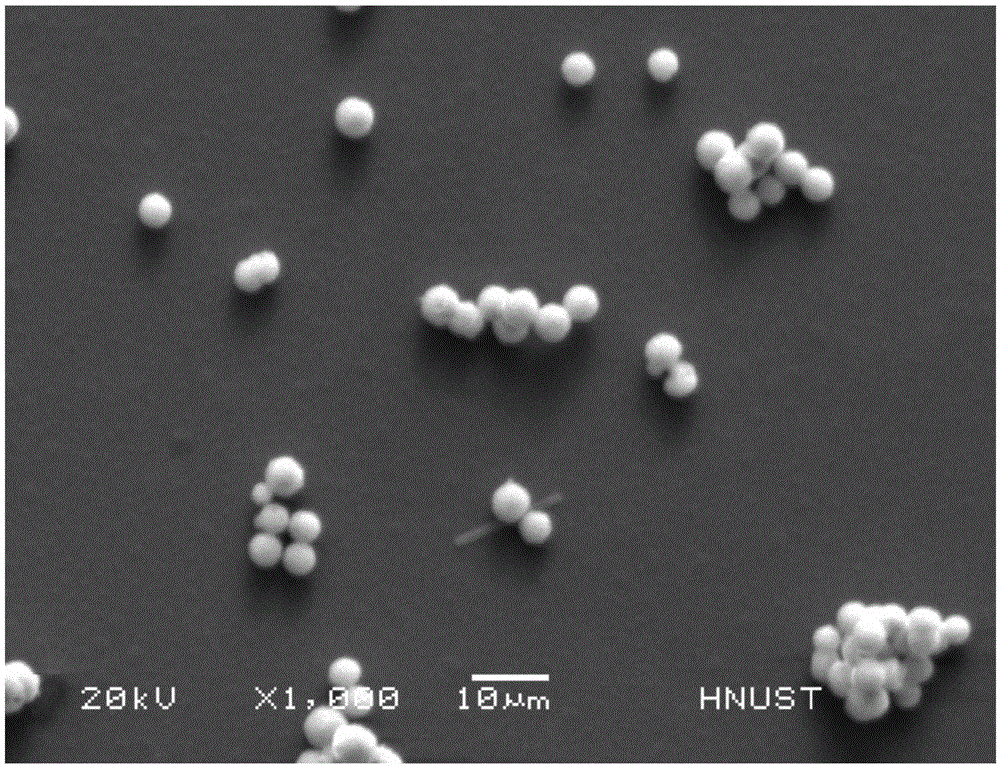

Embodiment 1

[0028] The preparation method of the leucite of the present embodiment may further comprise the steps:

[0029] 1) Add 30 mL of 10 mol / L sodium hydroxide solution into a single-necked flask, add 24 g of aluminum hydroxide powder under stirring conditions (the molar ratio of sodium hydroxide to aluminum hydroxide is 1.0), heat and reflux for 7 hours, and then put The obtained suspension solution was subjected to suction filtration, washed with water for 3 times, and the filtrate was collected to obtain a sodium metaaluminate solution, which was diluted to 1.5 mol / L;

[0030] 2) At a stirring speed of 200r / min, add the sodium metaaluminate solution obtained in step 1) dropwise to the mixed solution of sodium silicate solution and PVP, and then stir and react for 10 minutes after the dropwise addition to form a milky white gel Mixture; wherein, the concentration of sodium silicate solution is 1.5mol / L, every 1.5mol sodium silicate is added PVP12g, and the molar ratio of sodium si...

Embodiment 2

[0034] The preparation method of the leucite of the present embodiment may further comprise the steps:

[0035] 1) Add 30 mL of 10 mol / L sodium hydroxide solution into a single-necked flask, add 26 g of aluminum hydroxide powder under stirring conditions (the molar ratio of sodium hydroxide to aluminum hydroxide is 1.1), heat and reflux for 9 hours, and then put The obtained suspension solution was subjected to suction filtration, washed with water for 3 times, and the filtrate was collected to obtain a sodium metaaluminate solution, which was diluted to 1.5 mol / L;

[0036] 2) At a stirring speed of 250r / min, add the sodium metaaluminate solution obtained in step 1) dropwise to the mixed solution of sodium silicate solution and PVP, and then stir and react for 10 minutes after the dropwise addition to form a milky white gel Mixture; wherein, the concentration of sodium silicate solution is 2.0mol / L, every 2.0mol sodium silicate is added PVP20g, and the molar ratio of sodium si...

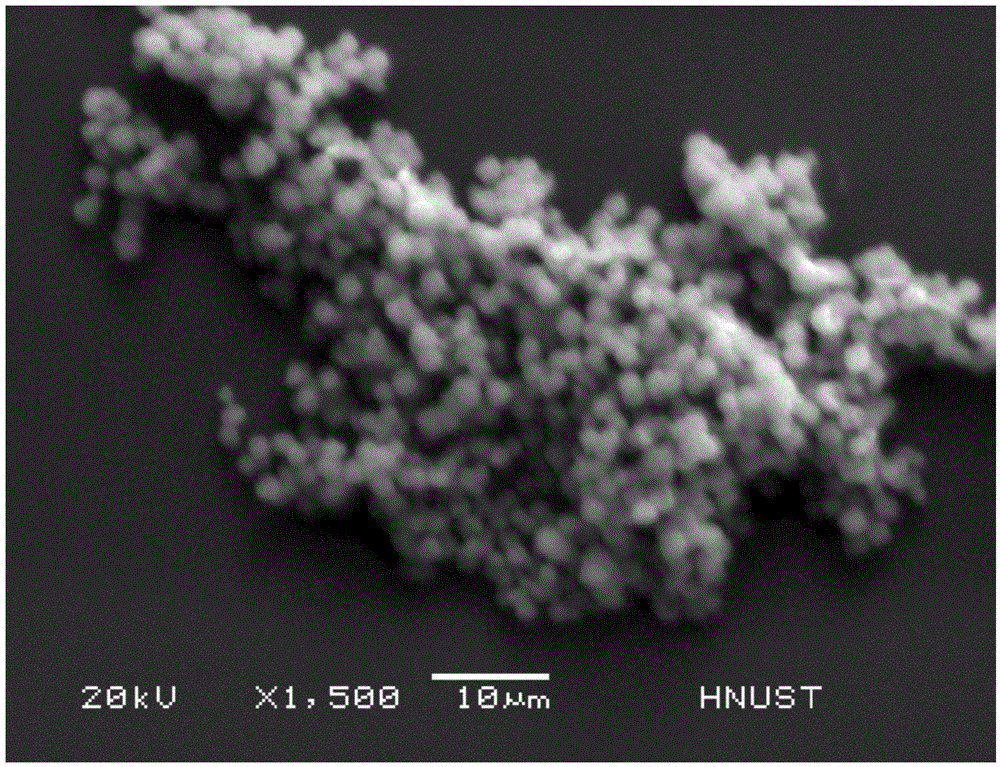

Embodiment 3

[0040] The preparation method of the leucite of the present embodiment may further comprise the steps:

[0041] 1) Add 30 mL of sodium hydroxide solution with a concentration of 10 mol / L into a single-necked flask, add 26 g of aluminum hydroxide powder under stirring (the molar ratio of sodium hydroxide to aluminum hydroxide is 1.1), heat and reflux for 5 hours, and then put The obtained suspension solution was subjected to suction filtration, washed with water for 3 times, and the filtrate was collected to obtain a sodium metaaluminate solution, which was diluted to 3mol / L;

[0042]2) At a stirring speed of 300r / min, add the sodium metaaluminate solution obtained in step 1) dropwise to the mixed solution of sodium silicate solution and PVP, and then stir and react for 12 minutes after the dropwise addition to form a milky white gel Mixture; wherein, the concentration of sodium silicate solution is 3.0mol / L, every 3.0mol sodium silicate is added PVP20g, and the molar ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com