Single-substrate fluorescent powder for ultraviolet excitation white-light LED (Light-Emitting Diode) as well as preparation and application methods thereof

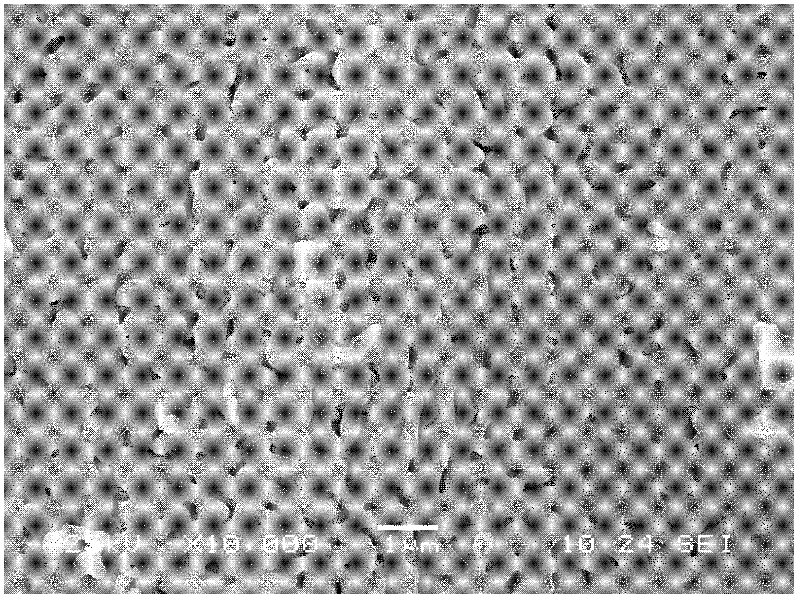

An application method and ultraviolet light technology, applied in the direction of chemical instruments and methods, luminescent materials, gas discharge lamps, etc., can solve problems such as poor stability, and achieve the effect of uniform particle size, high luminous intensity, and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

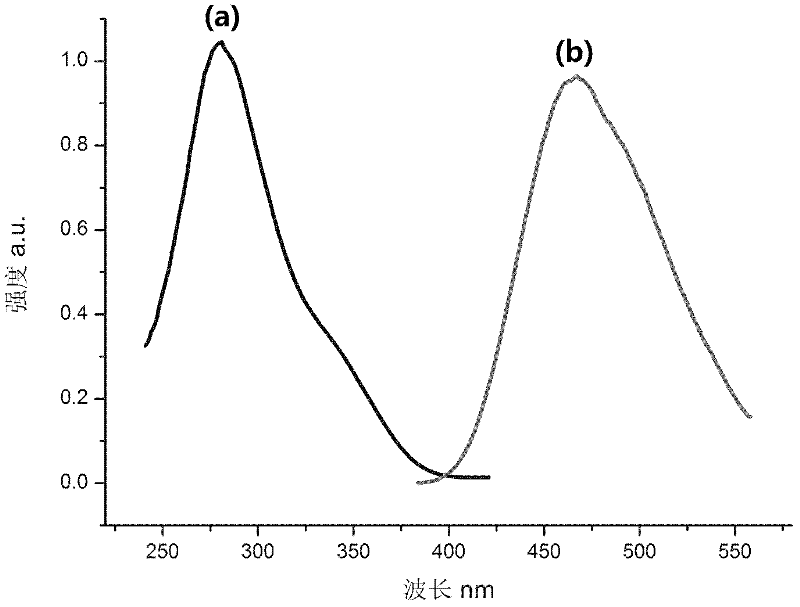

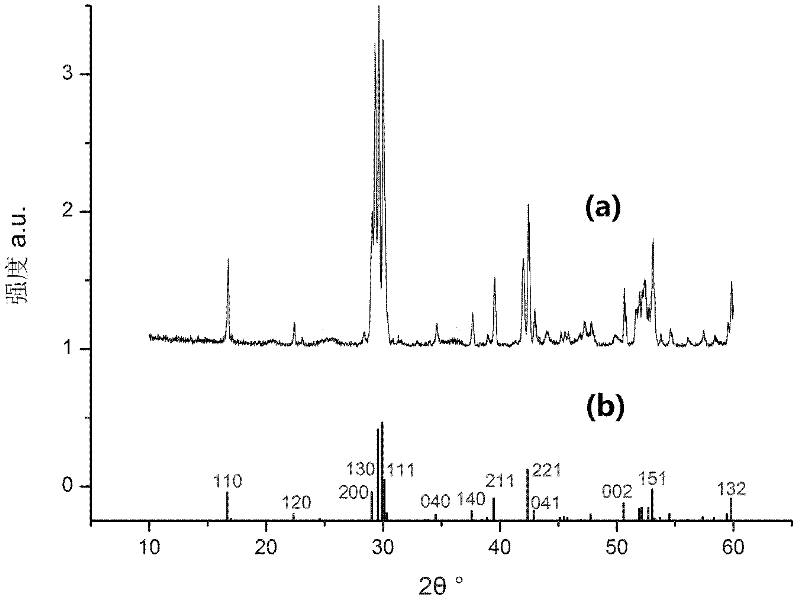

[0022] Weigh Sr(NO 3 ) 2 and Ce(NO 3 ) 3 As the matrix raw material, take the nitrate of Sm ions with a molar percentage of 0 mol% as an activator, and weigh the nitrate of Li ions with a molar percentage of 0 mol% as a charge compensator, and configure a molar concentration of 0.5 mol / L ammonium oxalate solution as a precipitant for hydrothermal reaction. Matrix raw materials, activators, and charge compensators were mixed with deionized water to form a solution with a total concentration of 0.5mol / L. After stirring for 30 minutes in ultrasonic waves, a precipitant was added, and stirring was continued for 30 minutes to obtain a white precipitate. After filtering, wash with water for 3 The second time, transfer to the hydrothermal reaction kettle for hydrothermal reaction. The hydrothermal reaction temperature is 240°C, the reaction time is 12h, and the filling ratio is 75%. After natural cooling, the precipitate is filtered and washed 3 times, dried at 120°C for 12h, an...

Embodiment 2

[0024] Weigh Sr(NO 3 ) 2 and Ce(NO 3 ) 3 As the matrix raw material, take the nitrate of Sm ion with a molar percentage of 0.125mol% as an activator, and weigh the nitrate of a Li ion with a molar percentage of 0.125mol% as a charge compensator, and configure a molar concentration of 0.5 mol / L ammonium oxalate solution was used as precipitant for hydrothermal reaction. Matrix raw materials, activators, and charge compensators were mixed with deionized water to form a solution with a total concentration of 0.5mol / L. After stirring for 30 minutes in ultrasonic waves, a precipitant was added, and stirring was continued for 30 minutes to obtain a white precipitate. After filtering, wash with water for 3 The second time, transfer to the hydrothermal reaction kettle for hydrothermal reaction. The hydrothermal reaction temperature is 240°C, the reaction time is 12h, and the filling ratio is 75%. After natural cooling, the precipitate is filtered and washed 3 times, dried at 120°C...

Embodiment 3

[0026] Weigh Sr(NO 3 ) 2 and Ce(NO3 ) 3 As the matrix raw material, take the nitrate of Sm ion with a molar percentage of 0.25 mol% as an activator, and weigh the nitrate of a Li ion with a molar percentage of 0.25 mol% as a charge compensator, and configure a molar concentration of 0.5 mol / L ammonium oxalate solution was used as precipitant for hydrothermal reaction. Matrix raw materials, activators, and charge compensators were mixed with deionized water to form a solution with a total concentration of 0.5mol / L. After stirring for 30 minutes in ultrasonic waves, a precipitant was added, and stirring was continued for 30 minutes to obtain a white precipitate. After filtering, wash with water for 3 The second time, transfer to the hydrothermal reaction kettle for hydrothermal reaction. The hydrothermal reaction temperature is 240°C, the reaction time is 12h, and the filling ratio is 75%. After natural cooling, the precipitate is filtered and washed 3 times, dried at 120°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com