Method for preparing orientation arrangement Nb2O5 nanorod through single-reagent self reaction

A directional arrangement and self-reaction technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of poor orientation of nanorods, cumbersome nanorods, high energy consumption, etc., and achieve easy operation control, low cost, energy low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

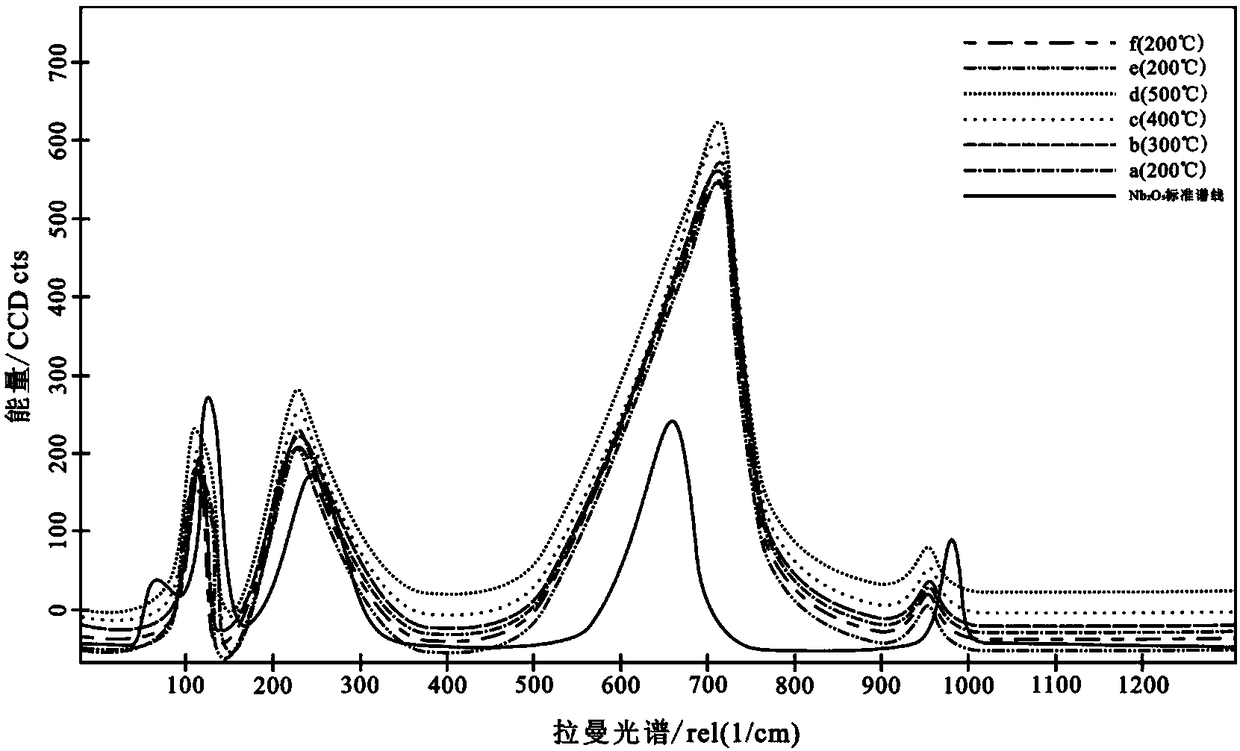

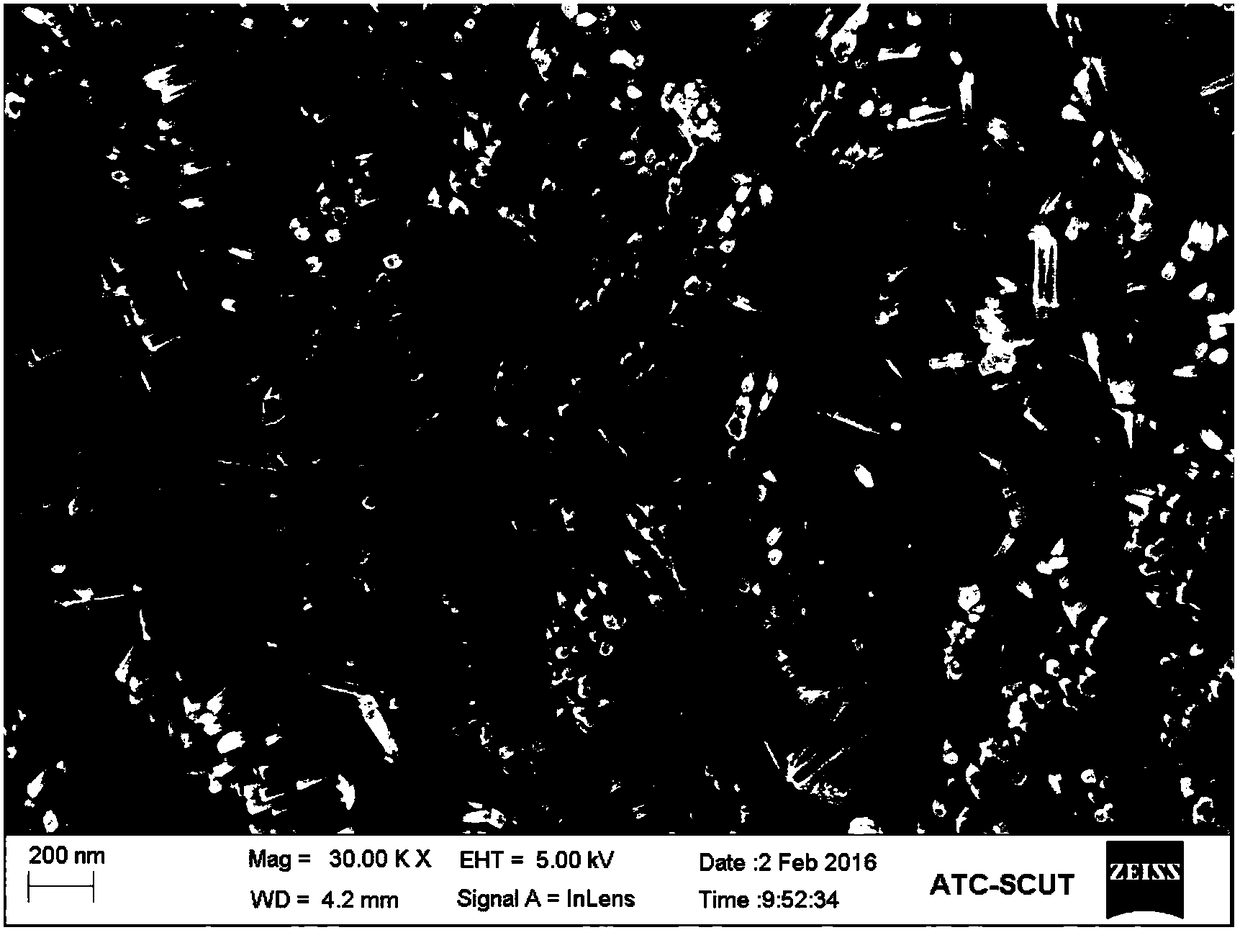

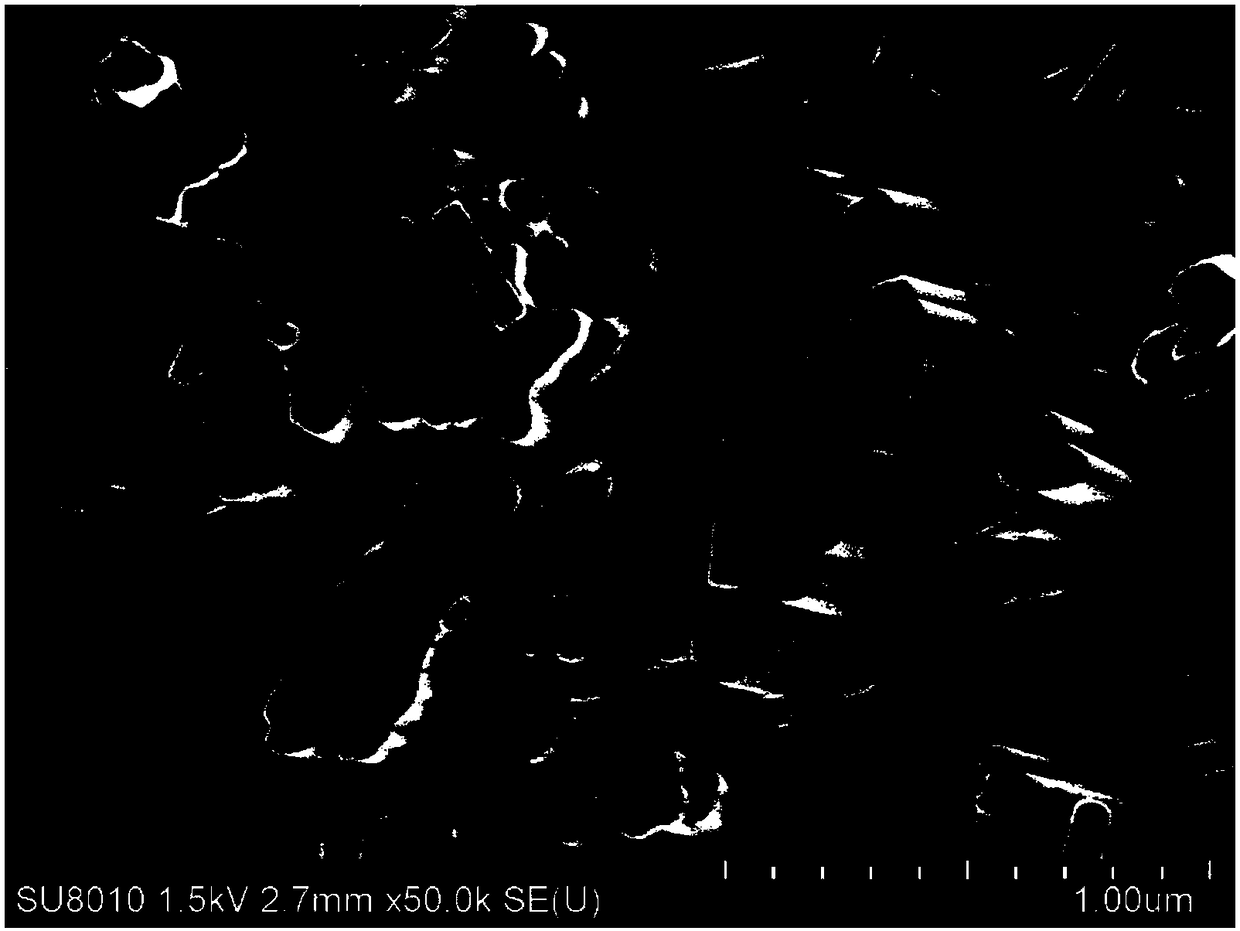

[0047] The alignment Nb provided by this embodiment 2 o 5 A method for preparing nanorods, comprising the following steps:

[0048] (1) A high-purity gold tube with a diameter of 3 to 5 mm is cut into 4 cm, placed in a beaker loaded with 0.01 mol / L dilute nitric acid solution, and placed on a heating plate at 80° C. for cooking for two hours; Ionized water washing, drying, and pre-sealing of one end and other pre-treatments ensure that there are no impurities and cracks in the gold tube;

[0049] (2) 0.76g potassium fluoroniobate (K 2 NbF 7 , commercially available product, the same below) powder is dissolved in 250mL deionized water, fully dissolved to obtain a concentration of 0.01mol / L K 2 NbF 7 solution, put about 0.2mL of the prepared reaction solution into a gold tube, control the filling degree to about 40% to 70%, and seal it by welding. 110°C drying oven for more than 2 hours, and then weigh again to ensure that the weight error before and after weighing is less...

Embodiment 2

[0056] The alignment Nb provided by this embodiment 2 o 5 A method for preparing nanorods, comprising the following steps:

[0057] (1) the pretreatment of platinum tube is the same as embodiment 1;

[0058] (2) Potassium fluoroniobate (K 2 NbF 7 ) powder was dissolved in 250mL deionized water, fully dissolved to obtain 0.005mol / L K 2 NbF 7 solution, put about 0.2mL of the prepared reaction solution into a platinum tube, the filling degree is controlled at about 40% to 70%, and seal it by welding. Put it into a 110°C drying oven for more than 2 hours, and then weigh again to ensure that the weight error before and after weighing is less than 0.001g, indicating that the gold tube is well sealed;

[0059] (3) Put the platinum tube, which is confirmed to be well sealed and contains the solution sample, into the high-temperature and high-pressure reactor. After tightening the reactor, check the tightness of the reactor. After confirming that it is correct, inject deionized w...

Embodiment 3

[0065] The alignment Nb provided by this embodiment 2 o 5 A method for preparing nanorods, comprising the following steps:

[0066] (1) the pretreatment of gold-palladium tube is the same as embodiment 1;

[0067] (2) 0.76g potassium fluoroniobate (K 2 NbF 7 ) powder was dissolved in 250mL deionized water, fully dissolved to obtain 0.01mol / L K 2 NbF 7 solution, put about 0.2mL of the prepared reaction solution into a gold-palladium tube, control the filling degree to about 40% to 70%, and seal it by welding. Put the tube in a 110°C drying oven for more than 2 hours, and then weigh it again to ensure that the weight error before and after weighing is less than 0.001g, indicating that the gold-palladium tube is well sealed;

[0068] (3) Put the gold-palladium tube that is confirmed to be well sealed and contains the solution sample into the high-temperature and high-pressure reaction kettle. After tightening the reaction kettle, check the tightness of the reaction kettle. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com