Power cable conductor temperature automatic following and control method

A conductor temperature and automatic tracking technology, which is applied in the direction of temperature control using electric methods, can solve the problems of cumbersome process, large influence on temperature control accuracy, difficulty in ensuring dynamic stability of conductor temperature, etc., to avoid poor control accuracy, Avoid cumbersome process and control the effect well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples, but the following examples should not be construed as limiting the present invention.

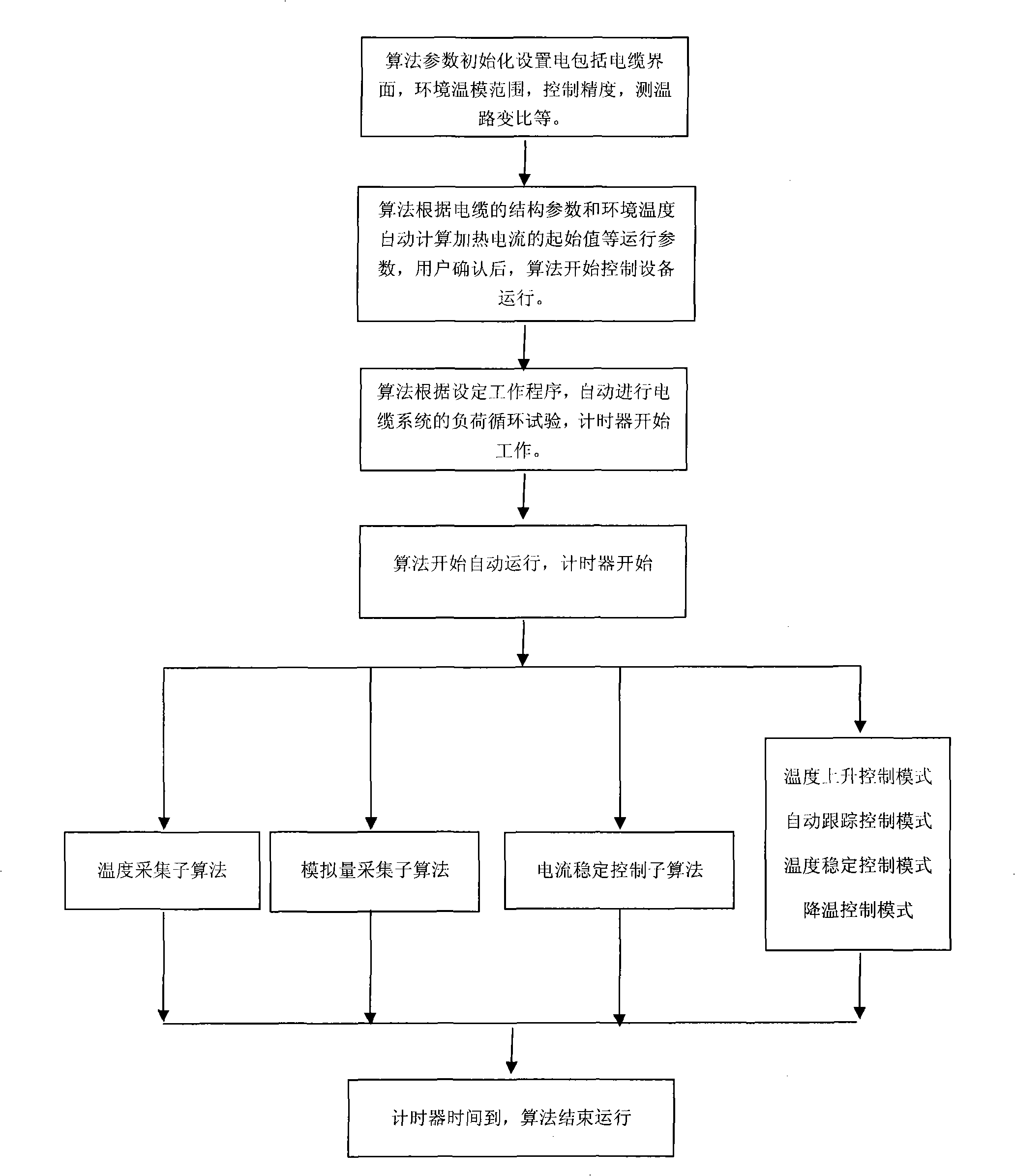

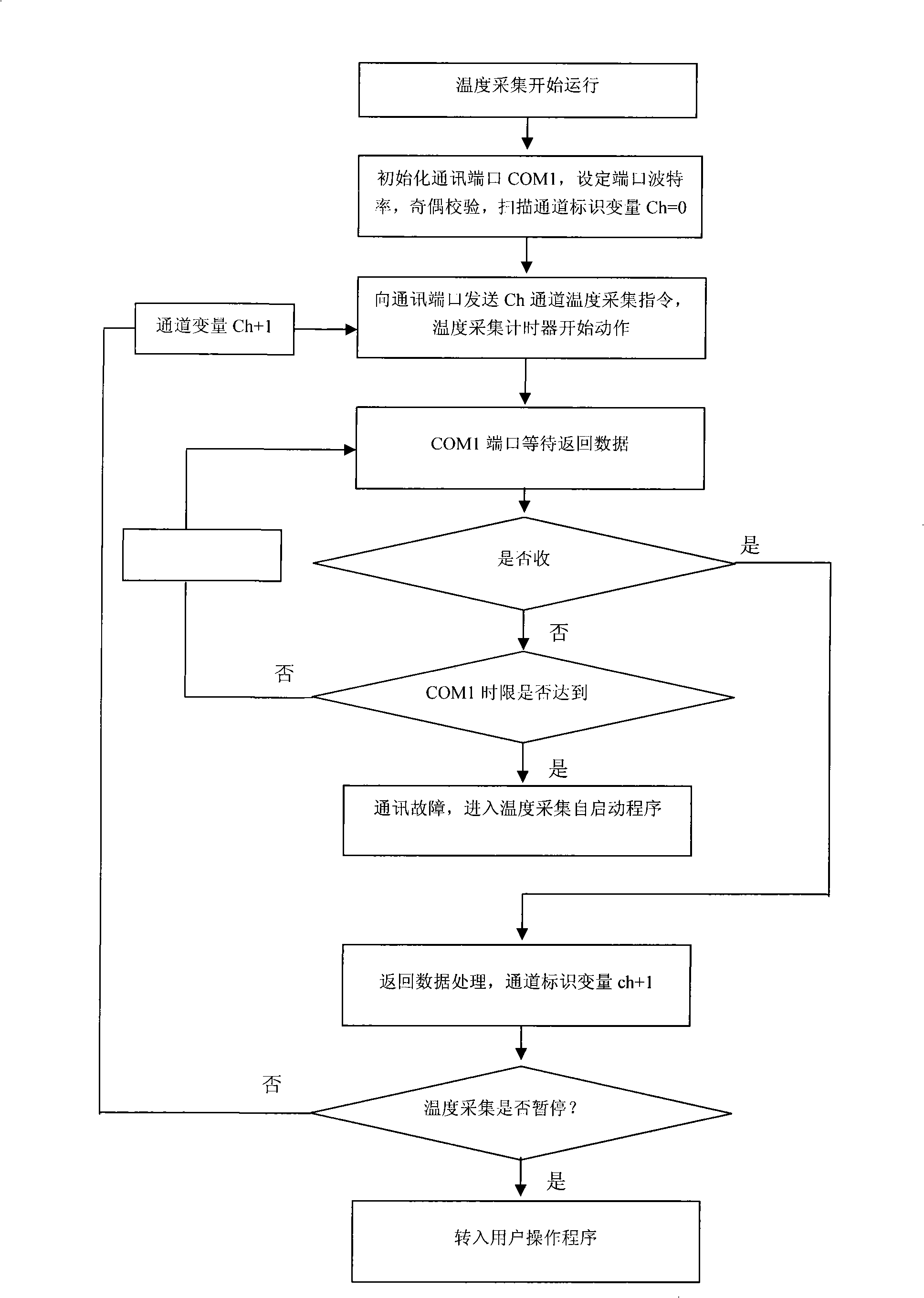

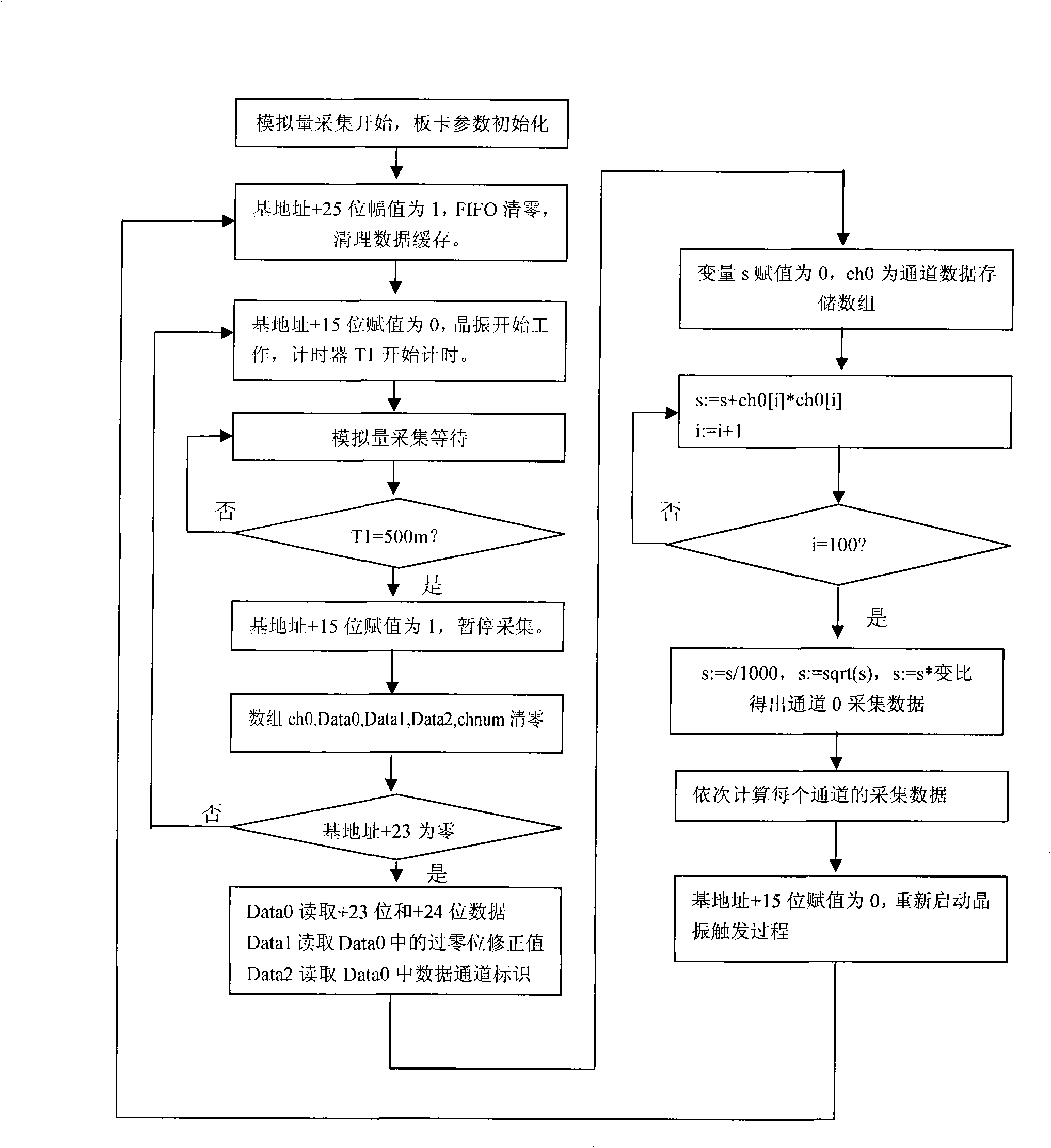

[0020] Before the automatic control of the present invention, the cable circuit for testing should be installed at first, and the special current generator, current transformer and related measurement and control circuit should be installed. After the basic structural parameters of the cable test product are input, the heating process of the cable will It starts automatically, and through real-time monitoring of the heating current of the cable and the current value and change trend of the conductor temperature, the fully automatic tracking and control of the conductor temperature is realized by a special algorithm, and the temperature data and history of temperature control are analyzed by the expert software system. The records are automatically saved to comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com