On-line closed loop optimally-adjusting-and-controlling method for mine ventilation system

A mine ventilation system and mine ventilation technology, applied in mine/tunnel ventilation, mining equipment, earthwork drilling and mining, etc., can solve the problem of uneconomical, unsuitable real-time pressure equalization requirements, and failure to meet mine normal and catastrophic periods Air supply needs and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] The present invention will be described in detail below in conjunction with the drawings:

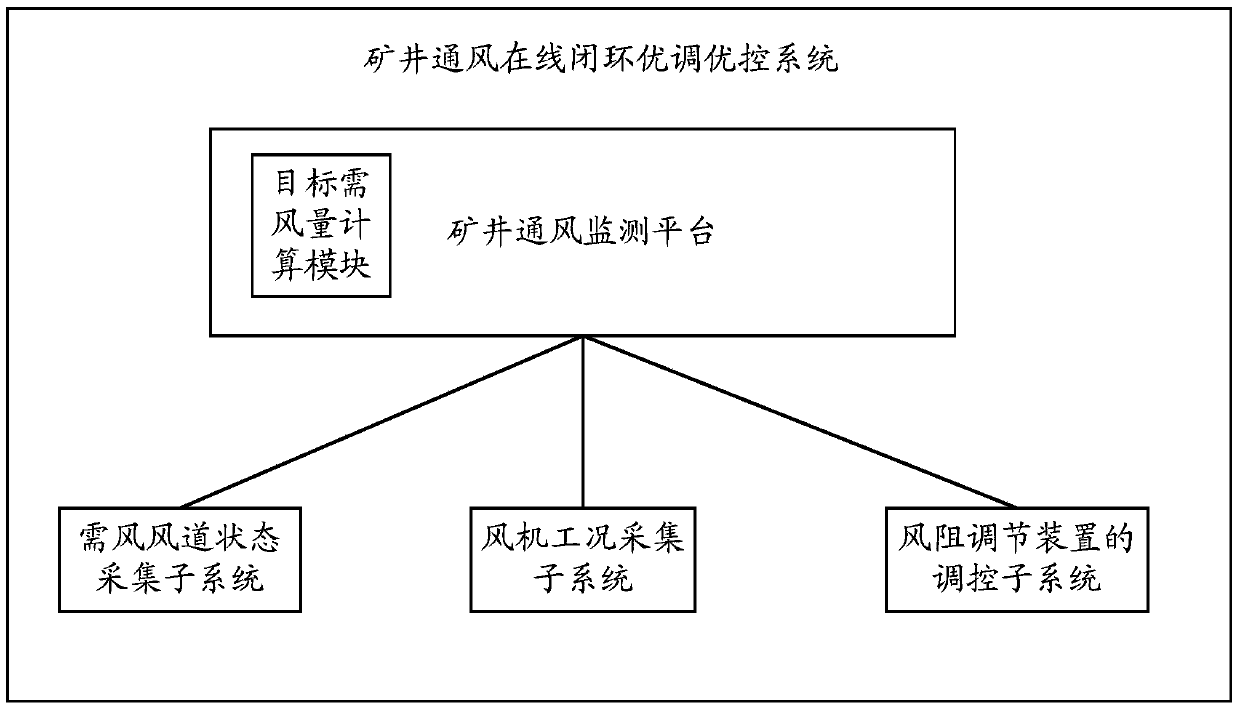

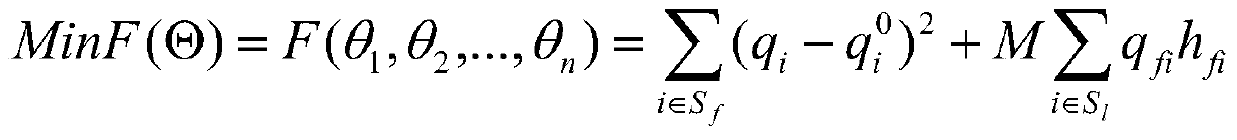

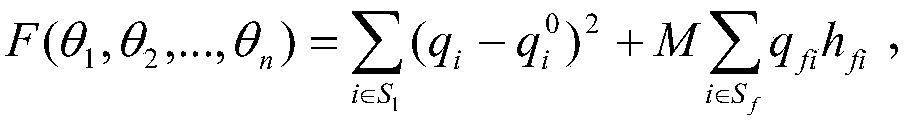

[0103] The present invention provides an online closed-loop optimization and control method of mine ventilation system to solve the problem of online optimization, optimization and control of the mine ventilation system in the normal period and catastrophic period of the mine. The core idea of the present invention is: establishing an online closed-loop optimization of the mine ventilation system Tuning and controlling mathematical model. The model takes the sum of squares of the difference between the measured air supply volume of each air demand point and its target air demand and the minimum power consumption of the fan as the objective function, and uses the adjustment parameters of each air resistance adjustment device as the control variable to control the variable The adjustable range of is a constraint; according to the target air volume required for each adjustment, the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com