Automatic feeding and extrusion forming machine

A technology of automatic feeding and extrusion molding, which is applied in the field of extrusion molding machines, can solve the problems that it is difficult to realize this structure, and the convex ring perpendicular to the main axis of the alloy profile bar is pressed, so as to improve efficiency, avoid low processing accuracy, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be further described in detail below in conjunction with specific embodiments.

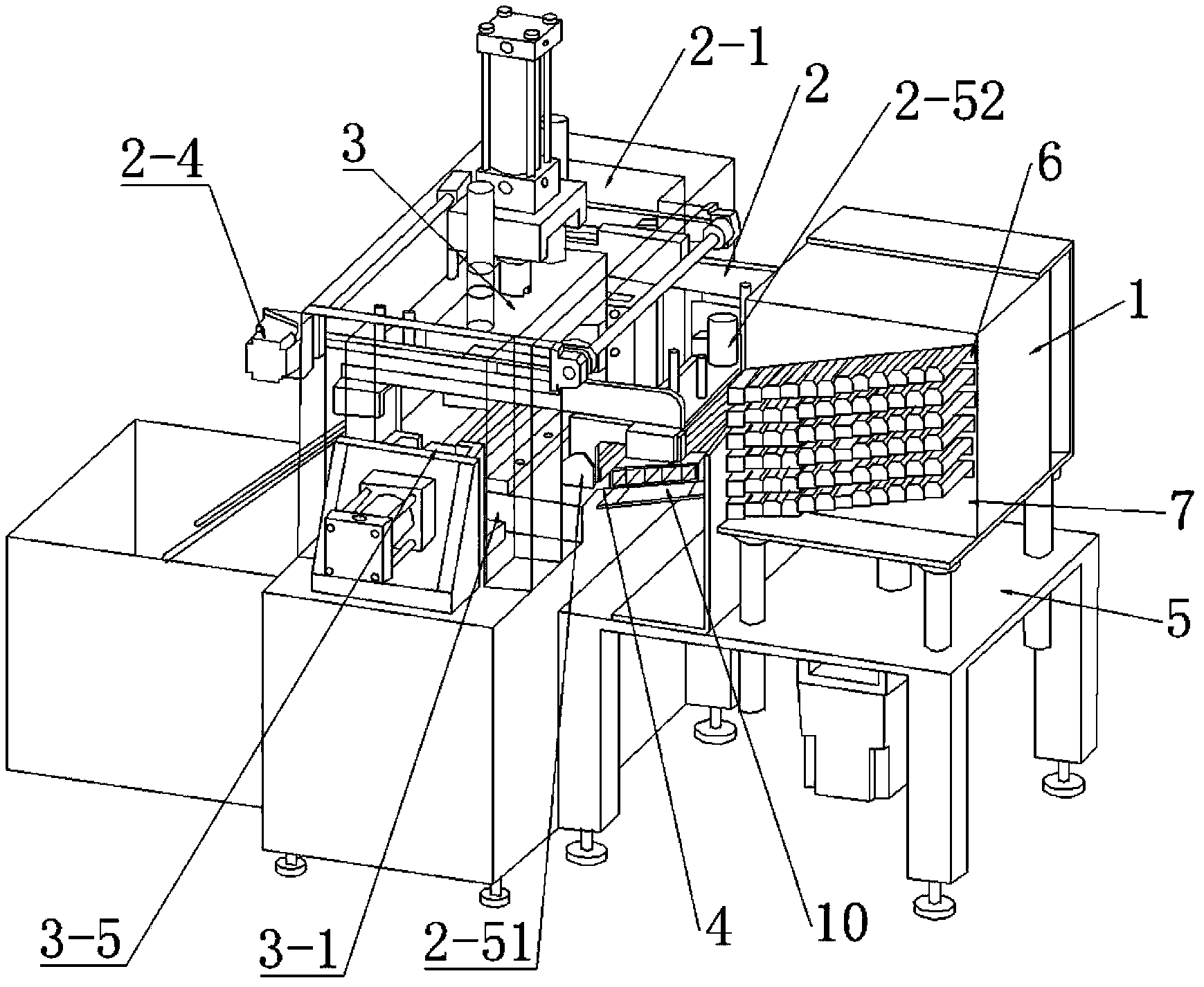

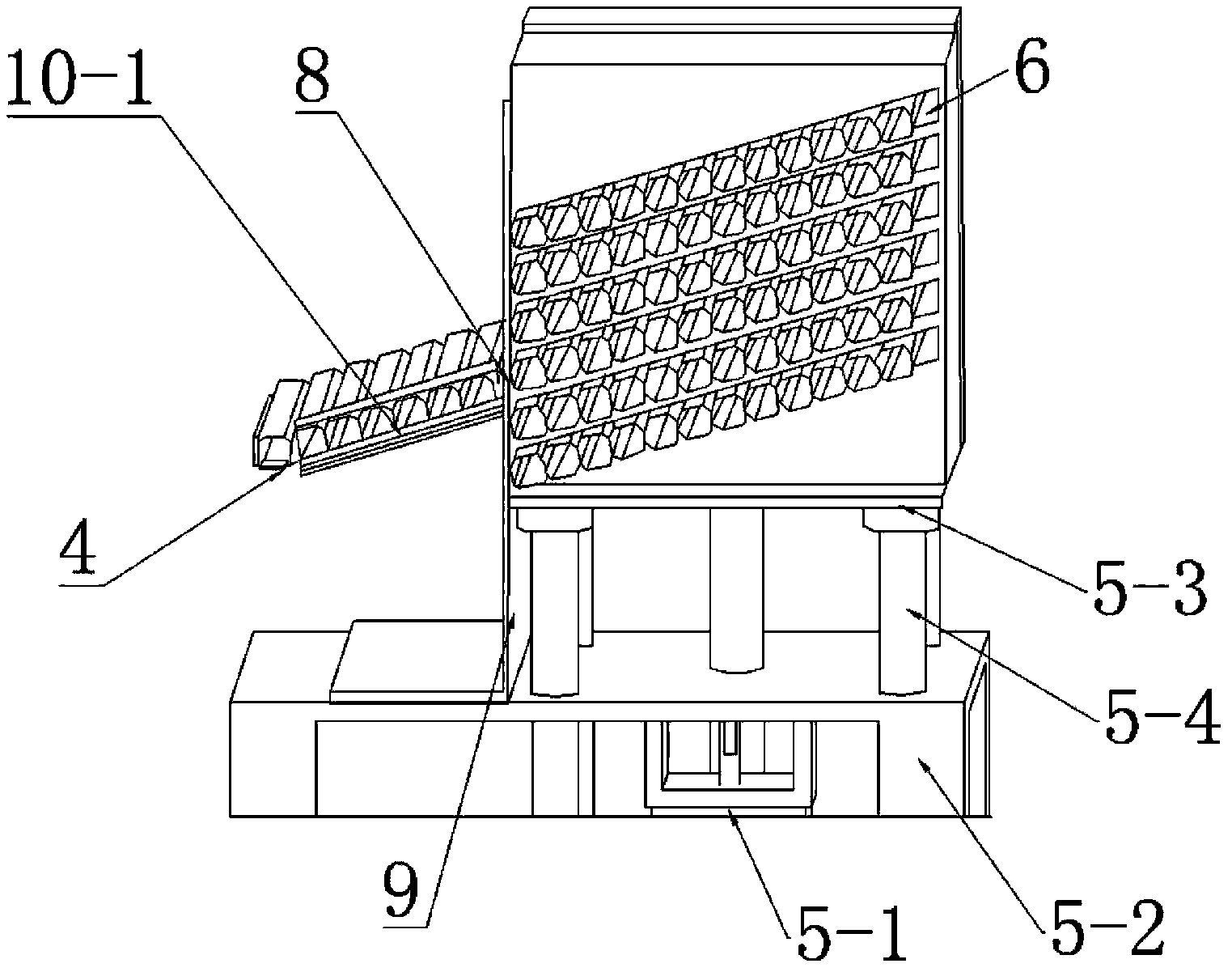

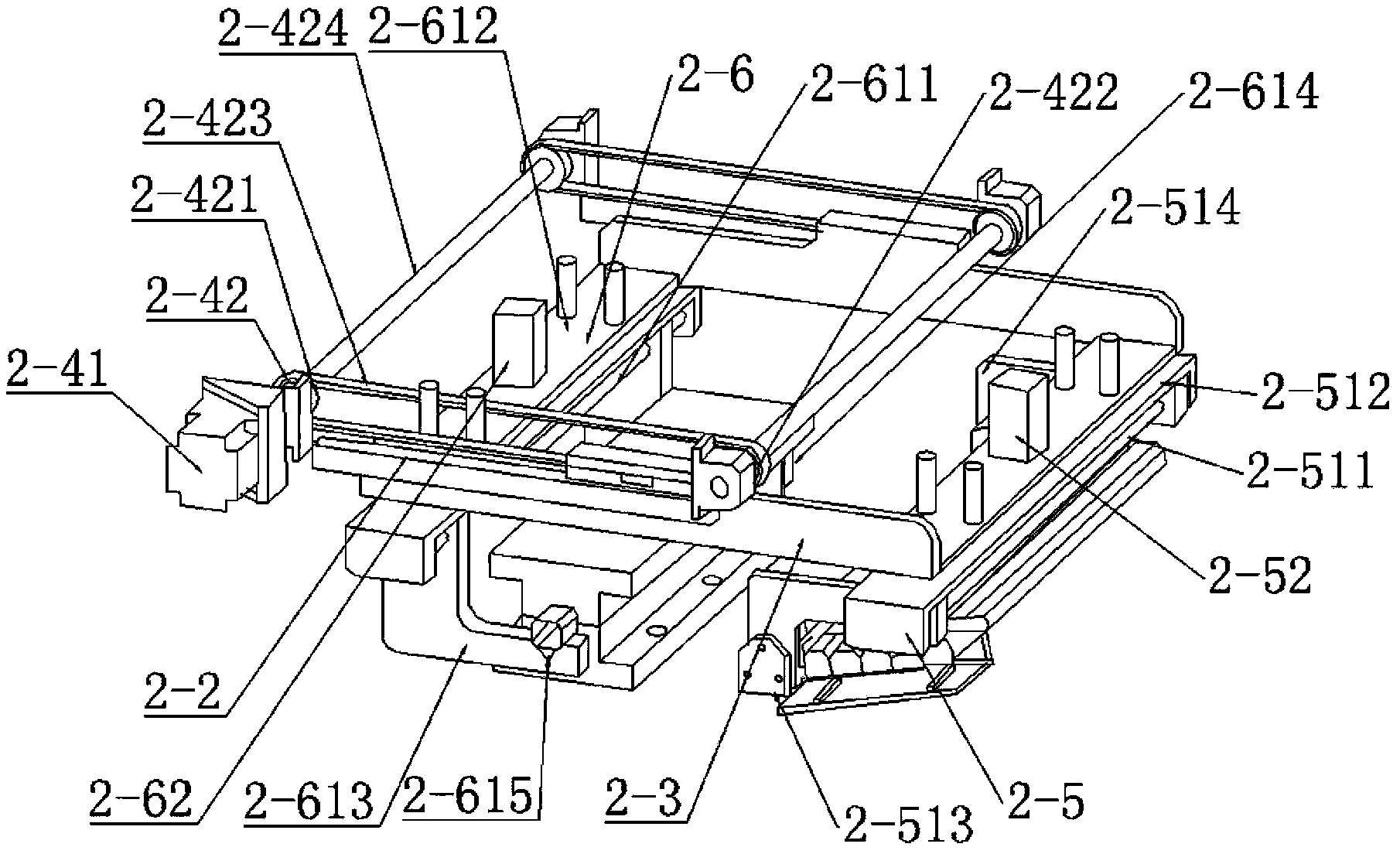

[0024] Such as Figure 1-Figure 4 As shown, a kind of automatic feeding extrusion molding machine of the present invention, it comprises charging box 1, automatic feeding mechanism 2, extrusion molding mechanism 3 and control system, automatic feeding mechanism 2 and extrusion molding mechanism 3 are connected with control system respectively , the feeding and extrusion process is uniformly controlled by the control system; the automatic feeding mechanism 2 is set between the charging box 1 and the extrusion molding mechanism 3, including the feeding bracket 2-1 and the guide rail 2-2 set on the feeding bracket 2-1 And the sliding seat 2-3 installed on the guide rail, the power unit 2-4 that drives the sliding seat 2-3 to move along the guide rail, and the loading manipulator 2-5 and the unloading manipulator 2-6, the loading box 1 There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com